Page 1

Magnetically Coded

Non Contact Switch (MC2)

Installation Instructions

Certifications

IMPORTANT:

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE

Note: Refer to Technical Specifications for Certification information and ratings.

440N-Z21W1PA 3 Metre Cable

440N-Z21W1PB 10 Metre Cable

440N-Z21W1PH 8-Pin micro (M12) Pigtail

Page 2

Table of Contents

Installation Instructions 3

Warnings 3

Technical Specification 3

Safety Ratings 3

Operating Characteristics 3

Physical Characteristics 3

Outputs 3

Response Time 3

Environmental 3

Protection 4

Dimensions 4

Mode of Operation 4

Status Indicators 4

Mounting Information 4

Nut Torque Specification 4

Minimum Distance Between Sensors 5

Misalignment Curve 5

Diagnostics 6

Troubleshooting 6

Wiring Diagram 7

Recommended Mating Cable 7

Power Supply Requirements 8

Approved Relays 8

Application Wiring Examples 9

Maintenance 12

Repair 12

Declaration of Conformity 12

72697 Issue 4 EO: 28485

2 Magnetically Coded Non Contact Switch Installation Instructions

ENGLISH:

This instruction sheet is available in multiple languages at www.rockwellautomation.com/literature.

Select publication language and type "SensaGuard" in the search field.

GERMAN: Dieses Instruktionsblatt kann in mehreren Sprachen unter www.rockwellautomation.com/literature gelesen werden.

Bitte Ihre Sprache anwählen und "SensaGuard" im Suchfeld eintippen.

FRENCH: Ces instructions sont disponibles dans différentes langues à l'adresse suivante www.rockwellautomation.com/literature.

Sélectionner la langue puis taper “SensaGuard” dans le champ de recherche.

ITALIAN:

La presente scheda d'istruzione è disponibile in varie lingue sul sito www.rockwellautomation.com/literature.

Selezionare la lingua desiderata e digitare "SensaGuard" nel campo di ricerca.

SPANISH:

Puede encontrar esta hoja de instrucciones en varios idiomas en www.rockwellautomation.com/literature.

Seleccione el idioma de publicación y escriba "SensaGuard" en el campo de búsqueda.

PORTUGUESE:

Esta folha de instruções está disponível em várias línguas em www.rockwellautomation.com/literature.

Seleccione a língua de publicação e entre com "SensaGuard" no espaço de busca.

POLISH:

Ta kartka z instrukcjami jest dostepna w wielu jezykach na stronie: www.rockwellautomation.com/literature

Wybierz jezyk publikacji i wpisz w polu poszukiwania "SensaGuard".

Page 3

1. Installation Instructions

Installation must be in accordance with the following steps and stated specifications and should be carried out by suitable competent personnel. The unit is not to be used as a mechanical stop. Guard stops and guides must be fitted.

Adherence to the recommended maintenance instructions forms part of the warranty.

This device is intended to be part of the safety related control system of a machine. Before installation, a risk assessment should be performed to determine whether the specifications of this device are suitable for all foreseeable operational and environmental characteristics of the machine to which it is to be fitted. Refer to Technical Specifications for

Certification information and ratings.

ATTENTION: The presence of spare actuators compromise the integrity of the safety systems. Personal

injury or death, property damage or economic loss can result. Appropriate management controls, working procedures and alternative protective measures should be introduced to control

their use and availability.

WARNING: Do not defeat, tamper, remove or bypass this unit. Severe injury to personnel could result.

2. Technical Specification

2.1

Safety Ratings

Standards EN1088,ISO14119, IEC/EN60947-5-3

Safety Classification Dual contacts suitable for Cat.3 or 4 systems

Functional Safety Data B10d: > 2 x 10

6

operations at min.

Usable for ISO 13849-1:2006 and IEC 62061. Data other PFH

D

: > 3 x 10

7

than B10d is based on: Usage rate of 10p/10mins., MTTFd: > 385 years

24 hrs/day, 360 days/year, representing 51840 operations Dual channel interlock may be suitable for performance

per year. levels PLe or PLd (according to ISO 13849-1:2006) and for

use in SIL2 or SIL3 systems (according to IEC 62061)

Note:

For up-to-date information, visit www.ab.com depending on application characteristics.

Certifications CE marked for all applicable directives, cULus, and TUV

2.2

Operating Characteristics (at rated temperature range)

Make, minimum Break, maximum

Sensing distance horizontal plane of operation 10mm 25mm

Sensing distance vertical plane of operation 6mm 20mm

Typical misalignment ±4mm (see Misalignment Graphs)

Operational Current ≤ 30mA + 1 Aux

Maximum # of switches, connected in series Monitoring Relay Unit dependent (see Section 10)

Operating Voltage 24V dc +10% / -15% (see Section 9)

2.3

Physical Characteristics

Case Material ULTRADUR

Actuator Material ULTRADUR

Colour Red

2.4

Outputs

Safety Output (Solid State Relay) 2 x N.C. 50mA

Auxiliary 1 x PNP N.O. 200mA

2.5

Response Time

Switch response time 5ms

Series response time 5ms

Maximum Frequency of Operation 1Hz

2.6

Environmental

Operating Temperature -10…+55°C (+14…+131°F)

Operating Humidity 5% -95% relative

Washdown rating / Enclosure type rating NEMA 3, 4X, 12,13, IP67, 68 & 69K

Shock & Vibration IEC680068-2-27 30 g, 11ms

IEC680068-2-6 10…55Hz

E.M.C. EN 61000-6-2, EN 60947-5-3

2.7

Protection

Safety Output Short-Circuit Protection Provided by the approved safety Relays (See section 10)

Auxiliary Overload Protection Internal Resettable Fuse

24V Supply Reverse Polarity Protection Incorporated

Electrical Life 1 x 10

6

cycles

72697 Issue 4 EO: 28485

Magnetically Coded Non Contact Switch Installation Instructions 3

Page 4

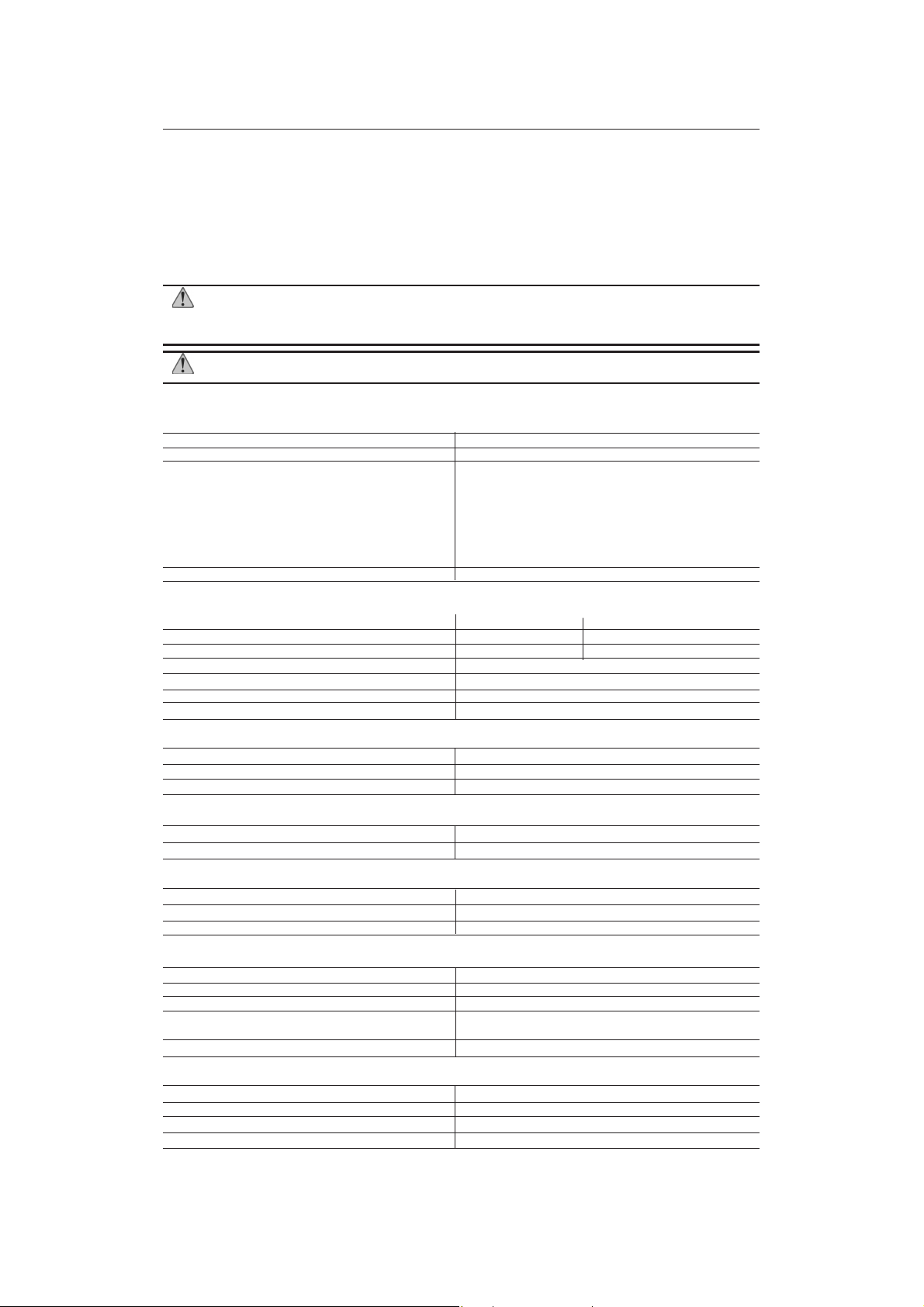

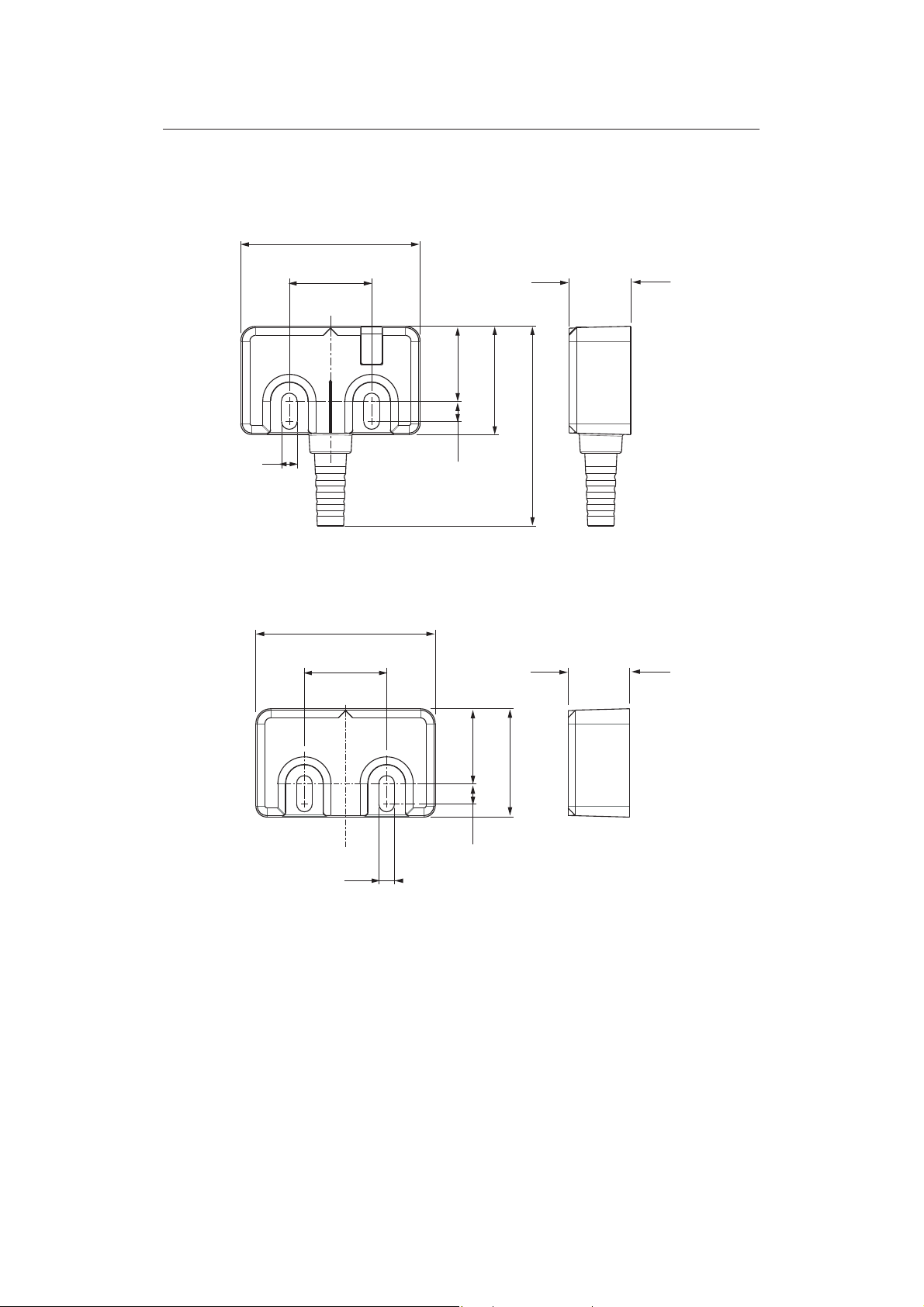

3. Physical Dimensions - mm (inches)

4. Mounting Information

Use non-removable screws, bolts, or nuts to mount the switch and actuator. Do not over torque the

mounting hardware. It is recommended to use M3 screws and washers throughout.

Position the switch and actuator so they are aligned with each other.

4.1

Mounting for Maximum Misalignment

Mount the Sensor to the fixed part of the guard and the Actuator to the movable section. Keep the

Sensor and Actuator within the sensing range detailed in section 4.4.

72697 Issue 4 EO: 28485

4 Magnetically Coded Non Contact Switch Installation Instructions

Note: Refer to Technical Specifications for Certification information and ratings.

48.0

(1.89)

16.5

(0.65)

(2.1)

Ø4.2

(0.17)

22.0

(0.87)

20.0

5.5

(0.79)

(0.22)

29.0

(1.14)

53

48.0

(1.89)

16.5

(0.65)

(0.87)

Ø4.2

(0.17)

22.0

20.0

5.5

(0.79)

(0.22)

29.0

(1.14)

Page 5

4.2

Maximum Torque Specification

- 1 N•M (8.86 in•lbs), use non-magnetic fixing hardware.

4.3

Minimum Distance Between Sensors

- 50mm

4.4

Misalignment Curve

4.5.

Direction of Approach

72697 Issue 4 EO: 28485

Magnetically Coded Non Contact Switch Installation Instructions 5

Note: Refer to Technical Specifications for Certification information and ratings.

Note: To prevent damage to the MC2 it is recommended to leave a 2mm gap between the Sensor and Actuator.

The maximum switching distance and misalignment tolerance will be obtained when the MC2 is mounted on non-ferrous material. Mounting the MC2 on ferrous/magnetic material will reduce the switching distances and tolerance to

misalignment.

To obtain maximum switching

distance center switches +/- 4mm

To prevent damage it is recommended

Actuator

that a 2mm gap be maintained

between the actuator and sensor

Sensor Sensor

distance 8 - 14 mm

For more detailed misalignment characteristics refer to the misalignment curves

24

20

16

12

8

4

2mm Gap

0

-4 -8 -12 -16 -2048-24121620

0

0

2mm Gap

0

24

20

16

12

8

4

-4 -8 -12 -16 -2048-24121620

SensorActuator

To prevent damage it is recommended that a 2mm gap

be maintained between the actuator and sensor

Actuator

To obtain maximum switching

distance 8 - 14 mm

16

12

8

0

0

2mm Gap 2mm Gap

0

2mm Gap

0

4

-4 -8 -12 -16 -2048-24121620

20

16

12

8

4

-4 -8 -12 -16 -2048-24121620

Page 6

5. LED Operation and Diagnostic

Unit Indicators (per IEC 60073)

State Status Troubleshooting

Off Not Powered Check supply, check wiring to controller A

Device Output Off Overload Check AUX connections

LED Red Actuator not present If actuator present check misalignment.

Green Actuator Present NA

Green Actuator Present Check wiring to controller

flashing Actuation not present on other Check actuators on other switches

switches or wiring fault

6. Troubleshooting

72697 Issue 4 EO: 28485

6 Magnetically Coded Non Contact Switch Installation Instructions

Note: Refer to Technical Specifications for Certification information and ratings.

S11

S21

Safety A

Safety B

24V

Aux

Safety A

Safety B

24V

Aux

Safety A

Safety B

24V

Aux

Safety A

Safety B

24V

Aux

Safety A

Safety B

24V

Aux

S12

S22

LED - Flashing

Green

LED - Red

Aux - ON

LED - Red

Aux - ON

LED - Green

Aux - OFF

Aux - OFF

LED - Flashing

Green

Aux - OFF

AuxAuxAuxAuxAux

6.1

Series Circuit - 2 Guards Open

6.2

Series Circuit - Open circuit on channel A

The auxiliary contacts close at the same time as the first safety contact opens

The auxiliary contacts close at the same time as the first safety contact opens

Open Circuit between two MC2s

S11

S21

Safety A

Safety B

24V

LED - Green

Aux - OFF

Aux

Safety A

Safety B

24V

LED - Green

Aux - OFF

Aux

Safety A

Safety B

24V

LED - Flashing

Green

Aux - OFF

Aux

Safety A

Safety B

24V

LED - Flashing

Green

Aux - OFF

Aux

Safety A

Safety B

24V

Aux

LED - Flashing

Green

Aux - OFF

S12

S22

AuxAuxAuxAuxAux

Page 7

7. Connection Information

7.3

Connection Table

MSR100 family MSR200/300

Red/Safety A S11 S11

Grey/Safety A S12 S12 or S42

Yellow/Safety B S21 S21

Pink/Safety B S22 S22 or S52

Brown / +24V A1 / +24V A1 / +24V

Blue / 0V A2 / 0V A2 / 0V

Note: When the MC2 is used with any MSR100 series Relay for the diagnostic function to operate

correctly the Red and Grey wires (Safety A) must be connected to S11 and S12.

72697 Issue 4 EO: 28485

Magnetically Coded Non Contact Switch Installation Instructions 7

Note: Refer to Technical Specifications for Certification information and ratings.

7.1

Wiring Diagram

Pin # Wire Colour Signal

1 White PNP Aux

2 Brown +24V

3 Green Not connected

4 Yellow Safety B

5 Grey Safety A

6 Pink Safety B

7 Blue 0V

8 Red Safety A

7.2

Recommended Mating Cable

For 8-Pin micro (M12) option. 889D-F8AB-*. Lengths are available up to 30m (98.4 ft)

Not

connected

Safety A

Safety B

2

3

476

1

8

5

+24V

Aux

Gnd

Safety B

Safety A

Page 8

8. Power Supply Requirements

24V dc +10%/-15% has to be supplied by a power supply that complies with IEC / EN 60204 and IEC / EN 61558-1.

Such a power supply meets the electrical safety requirements and maintains the minimum power of

20.4V dc during 20ms even in the event of voltage dips.

When using an approved Relay with an MC2 and the same power supply is utilised for all devices the

Relay will provide surge protection for the MC2. If a separate power supply is used for the MC2 then

extra protection will be required.

9. Approved Monitoring Relay Units

1. MC2 can only be used with the approved Relays, use of other devices not

listed is at the users own risk.

2. Only 24Vdc MSR Relays or MSR Relays configured for 24Vdc operation are

compatible with MC2.

9.1

Approved Monitoring Relay Unit List and maximum number

of series MC2s

Monitoring Relay Series Catalogue Part No. Maximum number of

MC2 units in series

24Vdc Supply Voltage

MSR Series -5% -10% -15%

MSR30RT/RTP 440R-N23197/440R-N23198 10 10 10

MSR 100 Series

MSR121RT 440R-J23102 8 - MSR123RT 440R-J23106 8 - MSR124RT 440R-G23110/440R-G23108/440R-G23107 10 10 10

MSR126T/R 440R-N23117/440R-N23123 10 10 10

MSR126.1T/.1R 440R-N23114/440R-N23120 10 10 10

MSR127T/TP 440R-N23126/440R-N23132 10 10 10

MSR127R/RP 440R-N23129/440R-N23135 10 10 10

MSR131RTP 440R-C23139 10 10 10

MSR138DP 440R-M23151 10 10 10

MSR138.1DP 440R-M23084 10 10 10

MSR142RTP 440R-G23216 10 8 MSR144RTP 440R-C23205 10 10 10

MSR178DP 440R-M23227 10 10 10

MSR 200 Series

MSR210P 440R-H23176 10 10 10

MSR220P 440R-H23177 10 10 10

MSR300 Series

MSR320P connected to a 440R-W23218 10 10 10

MSR310 or MSR312

Note:

For up-to-date information, visit www.ab.com

9.2

Safety Ratings

1. An MC2 can achieve up to Cat 4/PLe, SIL CL3 when individually monitored by an approved

Monitoring Relay Unit (see 9.1) that itself achieves Cat 4/PLe, SIL CL3.

2.. Two or more MC2 Sensors connected in series with an approved Relay achieves up to

CAT3/PLd/SIL CL2.

72697 Issue 4 EO: 28485

8 Magnetically Coded Non Contact Switch Installation Instructions

Note: Refer to Technical Specifications for Certification information and ratings.

Page 9

10. Application Wiring Examples

10.1

Single Switch, Automatic Reset, Monitored Outputs MSR127TP

72697 Issue 4 EO: 28485

Magnetically Coded Non Contact Switch Installation Instructions 9

Note: Refer to Technical Specifications for Certification information and ratings.

MC2

Connected

Not

Aux

Safety B-

Safety B+

Safety A-

Safety A+

0v

+24v

Green (3)

White (1)

Pink (6)

Yellow (4)

Grey (5)

Red (8)

Blue (7)

Brown (2)

L2 L3

L1

3313A1 S11 S12 23

K1

K2

34 42

Grey

Red

S52 41

MSR127RP

S34 14A2 S21 S22 24

Pink

Yellow

+24V

diagnostic operation the

red wire (QD pin 8) must

be connected to S11.

Note: To maintain correct

0V

Page 10

10.2

Multiple Switches, Automatic Reset, Monitored Output MSR127TP

72697 Issue 4 EO: 28485

10 Magnetically Coded Non Contact Switch Installation Instructions

Connected

Green (3)

Not

Aux

White (1)

Safety B-

Pink (6)

Safety B+

Yellow (4)

Safety A-

Safety A+

0v

+24v

Connected

Not

Aux

Safety B-

Safety B+

Safety A-

Safety A+

0v

+24v

Connected

Not

Aux

Safety B-

Safety B+

Safety A-

Safety A+

0v

+24v

Connected

Not

Aux

Safety B-

Safety B+

Safety A-

Safety A+

0v

+24v

Connected

Not

Aux

Safety B-

Safety B+

Safety A-

Safety A+

0v

+24v

Grey (5)

Red (8)

Blue (7)

Brown (2)

Green (3)

White (1)

Pink (6)

Yellow (4)

Grey (5)

Red (8)

Blue (7)

Brown (2)

Green (3)

White (1)

Pink (6)

Yellow (4)

Grey (5)

Red (8)

Blue (7)

Brown (2)

Green (3)

White (1)

Pink (6)

Yellow (4)

Grey (5)

Red (8)

Blue (7)

Brown (2)

Green (3)

White (1)

Pink (6)

Yellow (4)

Grey (5)

Red (8)

Blue (7)

Brown (2)

Red

Grey

Red

Grey

Red

Grey

Grey Red

Yellow

Pink

Yellow

Pink

Yellow

Pink

Yellow

Pink

L1 L2 L3

Fuses

Grey

Red

the Red (QD pin 8) wire from the

Note: To maintain diagnostic function

K1

K2

24 24

24 24

S34 14A2 S21 S22 24

S52 13A1 S11 S12 23

MSR127TP

Pink

Yellow

S5

S4

Actuator in place Flashing LED Green Actuator in place Flashing LED Green

S3

Actuator NOT in place LED Red

MC2 MC2 MC2

S1 S2

Actuator in place LED Green Actuator in place LED Green

MC2 MC2

first switch (S1 in this example)

must be connected to S11

+24V

0V

Page 11

10.3

Multiple Switches, Manual Reset, Monitored Output MSR210P

72697 Issue 4 EO: 28485

Magnetically Coded Non Contact Switch Installation Instructions 11

MC2

Connected

Not

Aux

Safety B

Safety B

Safety A

Safety A

0v

+24v

Green (3)

White (1)

Pink (6)

Yellow (4)

Grey (5)

Red (8)

Blue (7)

Brown (2)

L1 L2 L3

Fuses

31

13A1

K1

K2

Expansion Cable

Termination or

32

14 24

RESET

S34A2 S21

MC2

Connected

Not

Aux

Safety B

Safety B

Safety A

Safety A

0v

+24v

Green (3)

White (1)

Pink (6)

Yellow (4)

Grey (5)

Red (8)

Blue (7)

Brown (2)

+24V

S12 23

S22

S41 S32 S51 Y31 Y40 Y41 Y42

Expansion Cable

Termination or

S62

S52 Y30 Y32 Y2Y1Y33

S42

S11

0V

Page 12

11. Maintenance

Every six months

Check the correct operation of the switching circuit. Also check for signs of abuse or tampering.

Inspect the switch casing for damage.

12. Repair

If there is any malfunction or damage, no attempts at repair should be made. The unit should be

replaced before machine operation is allowed.

13. Declaration of Conformity

This is to declare that the products shown on this document conforms with the Essential Health and

Safety Requirements (EHSRs) of the European Machinery Directive (98/37/EC Machinery Directive,

2004/108/EC EMC Directive). These products also conform to EN 60947-5-3, EN 1088, EN ISO

12100 parts 1 & 2, EN 60204-1 and have Third Party Approval.

For a comprehensive certificate please visit:

www.ab.com

72697 Issue 4 EO: 28485

12 Magnetically Coded Non Contact Switch Installation Instructions

R

Copyright © 2012 Rockwell Automation, Inc. All Rights Reserved.

Check the machine is

isolated and stopped

whenever the interlocked

guard door is open.

IMPORTANT: After

installation and

commissioning, the

actuator, switch and hardware

should be coated with

tamper evident varnish or

similar compound.

Loading...

Loading...