Page 1

GuardShield™ PAC Type 4

(Perimeter Access Control)

Safety Light Curtain

User Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this publication, those responsible for the

application and use of this control equipment must satisfy themselves that all necessary steps have been

taken to assure that each application and use meets all performance and safety requirements, including

any applicable laws, regulations, codes and standards.

Reproduction of the contents of this copyrighted publication, in whole or part, without written permission

of Rockwell Automation, is prohibited.

Throughout this manual we use notes to make you aware of safety considerations:

The illustrations, charts, sample programs and layout examples shown in the guide are intended solely for

purposes of example. Since there are many variables and requirements associated with any particular

installation, Rockwell Automation does not assume responsibility or liability (to include intellectual property

liability) for actual use based upon the examples shown in this publication.

Rockwell Automation publication SGI-1.1, Safety Guidelines for the Application, Installation and

Maintenance of Solid-State Control (available from your local Rockwell Automation sales oce), describes

some important dierences between solid-state equipment and electromechanical devices that should be

taken into consideration when applying products such as those described in this publication.

It is recommended that you save this user manual for future use.

Identifies information about practices or circumstances that can cause an explosion in

a hazardous environment, which may lead to personal injury or death, property

damage, or economic loss.

Identifies information that is critical for successful application and understanding of

the product.

Identifies information about practices or circumstances that can lead to personal

injury or death, property damage, or economic loss. Attentions help you identify a

hazard, avoid a hazard, and recognize the consequences.

SHOCK HAZARD

Labels may be on or inside the equipment (for example, drive or motor) to alert people

that dangerous voltage may be present.

BURN HAZARD

Labels may be on or inside the equipment (for example, drive or motor) to alert people

that surfaces may reach dangerous temperatures.

WARNING

IMPORTANT

ATTENTION

Page 3

GuardShield™ PAC Safety Light Curtain Installation Instructions

ATTENTION

Failure to read and follow these instructions can lead to misapplication or misuse of the

GuardShield safety light curtains, resulting in injury and damage to equipment.

Conditions required for proper use of the

GuardShield PAC Safety Light Curtain

Please make sure you read and understand these requirements before you select and install the

GuardShield PAC safety light curtain. GuardShield PAC safety light curtains are perimeter access

safeguarding devices. These safety light curtains are intended to be used to provide perimeter access

safeguarding of personnel around a variety of machinery.

The GuardShield PAC family of safety light curtains are general purpose presence sensing devices

which are designed to protect personnel working on or near machinery.

The installation of the GuardShield PAC safety light curtains must comply with all applicable federal,

state, and local rules, regulations, and codes.

It is the responsibility of the employer to properly install, operate and maintain the product as well as

the machinery on which the GuardShield PAC presence sensing device is installed.

GuardShield PAC safety light curtains must be properly installed by qualified personnel.

GuardShield PAC safety light curtains are presence sensing devices and will not protect personnel

from heat, chemicals, or flying parts. They are intended to signal a stop of hazardous machine motion

when the sensing field is broken.

GuardShield PAC safety light curtains can only be used on or around machinery which can be

stopped anywhere in its stroke or cycle.

GuardShield PAC safety light curtains should never be used for guarding full revolution clutched

machinery.

The effectiveness of the GuardShield PAC safety light curtains depend upon the integrity of the

machine control circuit. The machinery that the GuardShield PAC presence sensing device is installed

on should have control circuitry that is fail safe in design.

All stopping mechanisms for the machinery should be inspected regularly to ensure proper

operation. The protected machinery must have a consistent reliable and repeatable stopping time.

Original instructions

1

Page 4

GuardShield™ PAC Safety Light Curtain Installation Instructions

Generally recognized technical regulations and quality

assurance system ISO 9000 are carefully applied during the

development and production of Allen-Bradley/Guardmaster

products.

This technical description must be followed when installing

and commissioning the GuardShield PAC. Inspection and

commissioning must be carried out by a qualified person.

Table of Contents

GuardShield PAC Safety Light Curtain . . . . . . .3

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Principles of Safe Use and Symbols Used. . . . . . . . . . . . . . . . . . . . 4

Specialist Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Range of Uses of the Device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Proper Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

General Protective Notes and Protective Measures . . . . . . . . . . 4

Product Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Special Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Light Curtain Principle of Operation . . . . . . . . . . . . . . . . . . . . . . . . 5

Examples of Range of Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Safety Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation and Mounting. . . . . . . . . . . . . . . . . . . . . . . . . 11

Response Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Determining the Safety Distance. . . . . . . . . . . . . . . . . . . . 9

US Safety Distance Formula . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

OSHA Safety Distance Calculation Formula . . . . . . . . . . . . . . . . . 9

The ANSI Safety Distance Formula . . . . . . . . . . . . . . . . . . . . . . . . . 10

European Safety Distance Formula . . . . . . . . . . . . . . . . . . . . . . . . 10

Multiple GuardShield PACs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Mounting Brackets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Safety Instructions—Maintenance . . . . . . . . . . . . . . . . . 22

Daily Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Six-month Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Model Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

IMPORTANT: Save these instructions for

use at a future time.

Rockwell Automation reserves the right to make changes or

revisions to the material contained in this publication and cannot

be held liable for incidental or consequential damages resulting

from the furnishing, performance or use of this material.

Electrical Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

System Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Teach Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

This manual covers the operation and installation of the:

• Standard GuardShield PAC light curtain

• GuardShield PAC with Integrated Laser Alignment system

• GuardShield PAC with Integrated Laser Alignment and

ArmorBlock Guard I/O connectivity

2

Original instructions

Page 5

GuardShield™ PAC Safety Light Curtain Installation Instructions

IMPORTANT

These installation instructions are designed

to address the technical personnel of the

machine manufacturer and or the installer of

the safety system regarding the proper

mounting, configuration, electrical

installation, commissioning, operation and

maintenance of the GuardShield safety light

curtain.

These installation instructions do not provide

instruction for the operation of machinery to

which the GuardShield safety light curtain is,

or will be, integrated. Only qualified

personnel should install this equipment.

Additional measures may be necessary to

ensure that the ESPE does not fail to danger

when other forms of light radiation are

present in a particular application (i.e., use of

cableless control devices on cranes, radiation

from weld spatter or effects from strobe

lights).

GuardShield PAC Safety Light Curtain

Introduction

The GuardShield PAC safety light curtain is a multiple beam,

presence sensing device designed for perimeter or access

detection around hazardous machinery or equipment The

GuardShield PAC is a Type 4 AOPD per IEC 61496. It is a self

contained, optically synchronized, two box (transmitter and

receiver) safety light curtain with dip switch selectable operating

modes.

The GuardShield PAC safety light curtain consists of a nonmatched pair of optic units, i.e., transmitter and receiver. The

transmitter and receiver operate on +24V DC. The maximum

distance between transmitter and receiver is referred to as the

protective field width or range. The protective field height is the

distance between the first and last beam in the device.

The transmitter emits sequential pulses of infrared light which are

received and processed by the GuardShield PAC receiver. The

synchronization of the timing of the emission and reception of

infrared light pulses is accomplished optically by the first beam

adjacent to the GuardShield PAC status LEDs. This beam is

referred to as the synchronization beam. Because the

GuardShield PAC transmitter and receiver are optically

synchronized, no electrical connection is required between the

transmitter and receiver.

The GuardShield PAC receiver has two safety outputs, Output

Signal Switching Devices (OSSDs) and one nonsafety auxiliary

output. When the GuardShield PAC transmitter and receiver are

properly powered and aligned, all OSSDs are current sourcing

+24V DC with a switching capacity of 500mA. The two safety

OSSDs are cross monitored and short-circuit protected.

Interruption of the sensing field causes the receiver to switch the

sourced current OFF (0V DC).

Restoring the GuardShield PAC sensing field, (in Guard only

configuration) causes all outputs (OSSDs) to switch to the active

high state (resume current sourcing +24V DC with a switching

capacity of 500mA).

The GuardShield PAC is offered in a number of configurations

based on a standard Type 4 safety light curtain platform.

In addition to the standard GuardShield PAC, the GuardShield PAC

is offered with an integrated laser alignment system or with an

integrated laser alignment system with connectivity to

ArmorBlock Guard I/O. The ArmorBlock Guard I/O optim allows

network connectivity providing OSSDs over a DeviceNet™ or

DeviceNet safety network. The ArmorBlock™ Guard I/O option is

only available in GuardShield PACs with integrated laser

alignment systems.

Selectable functions of the GuardShield PAC and GuardShield PAC

with integrated laser alignment are:

•Beam coding

• EDM (External Device Monitoring)

•Start interlock

•Restart interlock

Original instructions

Selectable functions of GuardShield PAC with ArmorBlock Guard

I/O connectivity:

•Beam coding

Range of Uses of the Device

The GuardShield PAC safety light curtain is classified as electrosensitive protective equipment (ESPE). The maximum protective

field width is 16m (52.5ft) for the GuardShield PAC.

The device is a Type 4 ESPE as defined by IEC 61496-1 and CLC/TS

61496-2 and is therefore allowed for use with controls in safety

category Type 4 in compliance with EN ISO 13849, SIL CL3 in

accordance with EN 62061 or up to PLe in accordance with ENISO

13849. The device is suitable for:

• Hazardous area protection

• Access protection

Access to the hazardous point must be allowed only through the

protective field. The machine/system is not allowed to start as

long as personnel are within the hazardous area. Refer to the

“Examples of Range of Use” on page 6 for an illustration of the

protection modes.

The GuardShield PAC is intended as a perimeter or access

protection device for a whole body detection and can not be used

in horizontial detection applications as it may be possible for

personnel to step between the beams and access the hazard

without being detected.

Depending on the application, mechanical protection devices

may be required in addition to the safety light curtain.

IMPORTANT

GuardShield PAC Laser Alignment

The laser light source in the integrated laser alignment system of

the GuardShield PAC light curtains is a Class 1, eye safe laser diode

with a wavelength of 670 nm.

3

Page 6

GuardShield™ PAC Safety Light Curtain Installation Instructions

ATTENTION

Use of controls or adjustments or

performance of procedures other than those

specified herein, may result in hazardous

radiation exposure.

ATTENTION

ATTENTION

Potentially hazardous situation, which, if not

prevented, might lead to serious or deadly

injury.

Failure to observe may result in dangerous

operation.

ATTENTION

be maintained at all times.

Additional mechanical protective devices have to be

installed in a way that hazardous machine elements cannot

be reached without passing through the protective field.

The GuardShield has to be installed in a way that operators

can only operate within the sensing area.

Improper installation can result in serious injury.

Never connect the outputs to +24V DC. If the outputs are

connected to +24V DC, they are in ON-state and cannot stop

hazardous spots at the machine/application.

Never expose the GuardShield to flammable or explosive

gases.

Regular safety inspections are imperative (see maintenance).

Do not repair or modify the GuardShield. The GuardShield

safety light curtain is not field repairable and can only be

repaired at the factory. Removal of either of the GuardShield

endcaps will void the warranty terms of this product.

The GuardShield PAC must not be used with

machines that cannot be stopped electrically

in an emergency.

The safety distance between the GuardShield

and a dangerous machine movement has to

Safety Notes

Please observe the following items in order to

ensure the proper and safe use of the

GuardShield safety light curtain.

This Class 1, eye safe laser is switched from a low output power

state to a high output power state (and back again) by means of

control circuitry which detects reflected laser light from a

temporary blockage of the emitted laser light. This is most

commonly accomplished by a person’s finger placed over the

laser overlay window. There is also an automatic shutdown

feature that switches the laser diode from the high power state to

the low power state, if there is no finger or other interruption

detected for a period of five minutes.

During the high output mode of operation, the laser is pulsed at a

rate of approximately 2 Hz in order to facilitate finger detection in

high ambient light conditions.

Safety Precautions

Principles for Safe Use and Symbols Used

The following instructions are preventive warnings to ensure the

safe and proper operation of the GuardShield PAC. These

instructions are an essential part of the safety precautions and

therefore have to be observed at any time.

Throughout this manual we use the labels AT T E NT I O N and

IMPORTANT to alert you to the following:

Failure to observe may result in dangerous

operation

ATTENTION: Identifies information about practices of

circumstances that can lead to personal injury or death, property

damage, or economic loss.

AT TE N T IO N helps you

• Identify a hazard

•Avoid a hazard

• Recognize the consequences

IMPORTANT: Identifies information that is especially important

for successful application and understanding of the product.

4

Specialist Personnel

The GuardShield PAC safety light curtain must be installed,

commissioned and serviced only by a qualified person. A qualified

person is defined as a person who:

• Has undergone the appropriate technical training

and

• Who has been instructed by the responsible machine

operator in the operation of the machine and the currently

valid safety guidelines

and

• Who has read and has ongoing access to these installation

instructions

Proper Use

The GuardShield PAC safety light curtain must be used only as

defined in the “Range of Uses of the Device.” It must be used only

by qualified personnel and only on the machine where it has been

installed and initialized by qualified personnel.

If the device is used for any other purposes or modified in any

way, warranty claims against Allen-Bradley Guardmaster shall

become null and void.

General Protective Notes and

Protective Measures

IMPORTANT

Original instructions

Page 7

GuardShield™ PAC Safety Light Curtain Installation Instructions

Transmitter Receiver

• The national/international rules and regulations apply to

the installation, use and periodic technical inspections of

the safety light curtain, in particular:

♦ Machine Directive 98/37/EEC

♦ Equipment Usage Directive 89/655/EEC

♦ The work safety regulations/safety rules

♦ Other relevant health and safety regulations

Manufacturers and users of the machine with which the

safety light curtain is used are responsible for obtaining and

observing all applicable safety regulations and rules.

• The notices, in particular the test regulations of these

installation instructions (e.g. on use, mounting, installation

or integration into the existing machine controller) must be

observed.

• The tests must be carried out by specialist personnel or

specially qualified and authorized personnel and must be

recorded and documented to ensure that the tests can be

reconstructed and retraced at any time.

• The installation instructions must be made available to the

user of the machine where the GuardShield PAC safety light

curtain is installed. The machine operator is to be instructed

in the use of the device by specialist personnel and must be

instructed to read the installation instructions.

Product Description

This section provides information on the special features and

properties of the safety light curtain. It describes the structure

and functions of the unit, in particular the different operating

modes.

® Please read this section before mounting, installing and

commissioning the unit.

Special Features

•Start interlock

•Restart interlock

• External Device Monitoring (EDM)

•Machine test signal

•Beam coding

GuardShield Light Curtain

Principle of Operation

The GuardShield PAC safety light curtain consists of a

nonmatched pair of optic units, i.e. transmitter and receiver with

the same number of beams and spacings. The transmitter and

receiver operate on +24V DC. The maximum distance between

the transmitter and receiver is referred to as the protective field

width or range. The protective field height is the distance

between the first beam and the last beam in the device.

The transmitter emits sequential pulses of infrared light, which

are received and processed by the GuardShield PAC receiver. The

synchronization of the timing of the emission and reception of

infrared light pulses is accomplished optically by the first beam

adjacent to the GuardShield PAC’s status LEDs. This beam is

referred to as the synchronization beam. Because the GuardShield

PAC’s transmitter and receiver are optically synchronized, no

electrical connection is required between the transmitter and

receiver.

The GuardShield PAC’s receiver has two safety outputs, OSSDs

(Output Signal Switching Devices) and one nonsafety auxiliary

output. When the GuardShield PAC’s transmitter and receiver are

properly powered and aligned, all OSSDs are current sourcing

+24V DC with a switching capacity of 500mA. The two safety

OSSDs are cross monitored and short-circuit protected.

Interruption of the sensing field causes the Receiver to switch the

sourced current Off (0V DC).

Restoring the GuardShield PAC’s sensing field, (in Guard only

configuration) causes all outputs (OSSDs) to switch to the active

high state (resume current sourcing +24V DC with a switching

capacity of 500mA).

The GuardShield PAC Light Curtain

The GuardShield PAC safety light curtain consists of a transmitter

and a receiver.

Figure 1: Components of the GuardShield PAC

The individual beams of the GuardShield PAC are identified by

markings on the housings.

The width of the protective field is derived from the length of the

light path between sender and receiver and must not exceed the

maximum rated width of the protective field 16m (52.5ft).

The GuardShield PAC is also offered with an integrated laser

alignment system which has a constantly powered Class 1, eye

safe laser located in the top of the GuardShield PAC transmitter

and in the bottom of the GuardShield PAC receiver. Each Class 1,

eye safe laser emits a low level of visible light. Simply blocking this

light below the finger symbol causes the light to be reflected back

to a photo sensor which changes the condition of the laser light. If

this light is at a low level, interrupting it will cause the laser to emit

a highly visible level of light. Interrupting the visible light in the

same location will cause the laser to switch to a low level of

emission. The emission of visible light will also change to a low

level after five minutes of activation.

Across from each laser is a target used to help with the alignment

of the GuardShield PAC pair. Positioning the visible light in the

center of the top and bottom targets will position the

GuardShield PAC pair for optimal alignment.

Original instructions

5

Page 8

GuardShield™ PAC Safety Light Curtain Installation Instructions

The protective system must be tested for

proper operation after each and every

change to the configuration.

Start interlock is not available in GuardShield

PAC light curtains with ArmorBlock Guard I/O

connectivity.

It is not possible to have both “Start Interlock”

and “Restart Interlock” configured at the

same time in the GuardShield PAC.

Configuring “Restart Interlock” behaves the

same as “Start Interlock” at power up, i.e., a

reset of the system is required at power up.

Restart interlock should always be configured

for the GuardShield PAC light curtains. The

reset switch should be located outside of the

work cell and positioned so that a clear view

of the work cell is possible.

Restart interlock is not available in

GuardShield PAC light curtains with

ArmorBlock Guard I/O connectivity. this

functionality must be configured and

through the safety PLC.

EDM is not available in GuardShield PAC light

curtains with ArmorBlock Guard

I/O connectivity.

Examples of Range of Use

The GuardShield PAC safety light curtain operates as a proper

protective device only if the following conditions are met:

• The control of the machine must be electrical.

• The controlled machine must be able to be stopped any

where in the machines stroke or cycle.

• The transmitter and receiver must be mounted such that

access to the hazard is only through the light curtain’s

protective field.

• The restart button must be located outside the hazardous

area such that it cannot be operated by a person working

inside the hazardous area.

• The statutory and local rules and regulations must be

observed when installing and using the device.

Safety Functions

The GuardShield PAC safety light curtain offers a variety of

functions, which are integral to the system.

Operating modes, functions and features of the GuardShield PAC

system are activated through dip switch settings.

IMPORTANT

Guard Only

When in the guard only mode of operation, the light curtain

operates as an on/off device, meaning the OSSD outputs switch

off/on according to an obstruction or clearing of the detection

field. The GuardShield PAC is shipped from the factory in the

guard only mode.

Start Interlock

The start interlock prevents the OSSD outputs from switching to

ON state after power up of the system with the protective field

unobstructed. A manual reset of the system is required for the

GuardShield PAC to enter the ON state.

This can be accomplished by one of two methods.

• Actuation of a momentary N.O. push button

• Interruption and restoration of the protective field within

one second.

Activation of this mode of operation and selection of the resetting

method is through dip-switch settings. Indication of this mode of

operation is through illumination of a yellow LED on the

GuardShield PAC’s receiver.

IMPORTANT

Restart Interlock

The restart interlock mode of operation prevents the OSSD

outputs from switching to ON after interruption and clearance of

the protective field. A manual reset of the GuardShield PAC

6

Original instructions

system is required. Resetting of the system is accomplished

through a momentary N.O. push button or key switch.

Configuration and activation of this mode of operation is through

dip-switch settings. The Restart Interlock mode is indicated by the

illumination of a yellow LED on the GuardShield PAC’s receiver.

IMPORTANT

External Device Monitoring (EDM) or Machine

Primary Control Element (MPCE) Monitoring

The External Device monitoring function (EDM) is an input signal

to the GuardShield receiver from the Final Switching Device (FSD),

usually relay contactors, which control the hazardous motion of

equipment or machinery. The EDM circuit is required to see a

change of state of the FSD within 300ms of the restoration of the

GuardShield’s sensing field after its interruption. Detection of an

unsafe condition such as a welded contact causes the

GuardShield receiver to go to a lockout condition (OSSDs OFF).

The activation and use of this GuardShield functionality usually

allows the GuardShield’s OSSDs to be connected directly to a

machine’s FSD and attain a Category 4 safety circuit. It is necessary

to have the EDM circuit connected to two separate FSDs which

are wired in series to attain the Category 4 rating. Activation of

this functionality is accomplished by setting the EDM dipswitch

no. three to the OFF position and then performing the “Teach”

function. It is also necessary to connect the GuardShield receiver’s

EDM (yellow) wire to a N.C. output from the FSD.

IMPORTANT

System Testing

The GuardShield PAC performs a complete system self-test at

power up and switches to the ON state if the system is properly

aligned and the protective field is unobstructed and the start/

restart interlock modes of operation are deactivated.

External Test (Machine Test Signal)

A test cycle of the system can be triggered by an external test

signal to the GuardShield PAC’s transmitter. Supplying or

removing a signal (+24V DC) via a N.C. or N.O. switch at the test

input deactivates the transmitter for the duration of the test

signal, simulating an interruption of the protective sensing field.

Page 9

GuardShield™ PAC Safety Light Curtain Installation Instructions

Beam coding improves resistance to optical

interference.

Beam coding increases the system’s response

time, which may also increase the required

safety distance. Refer to Safety Distance

calculations on page 9 of this manual.

GuardShield GuardShield

PAC

Transmitter

PAC

Receiver

Corner Mirror

Roller Work Path

Power

Supply

Work

Piece

Muting

Module

Work

Piece

The test input must be configured via a dip-switch located in the

GuardShield PAC transmitter.

Beam Coding

If several safety light curtains are operating in close proximity to

one another, it is possible that the transmitter’s infrared light from

one GuardShield PAC system is “seen” by another GuardShield

PAC system’s receiver. This would cause a “nuisance” stop. To

prevent this optical interference, the GuardShield PAC has the

ability to have the transmitter generate different beam patterns,

which is referred to as “Beam coding.” Selection and activation of

beam coding is accomplished through dip-switch settings in both

the transmitter and receiver.

The following settings are available in the GuardShield PAC safety

light curtain; noncoded and coded.

IMPORTANT

Applications and Application Requirements

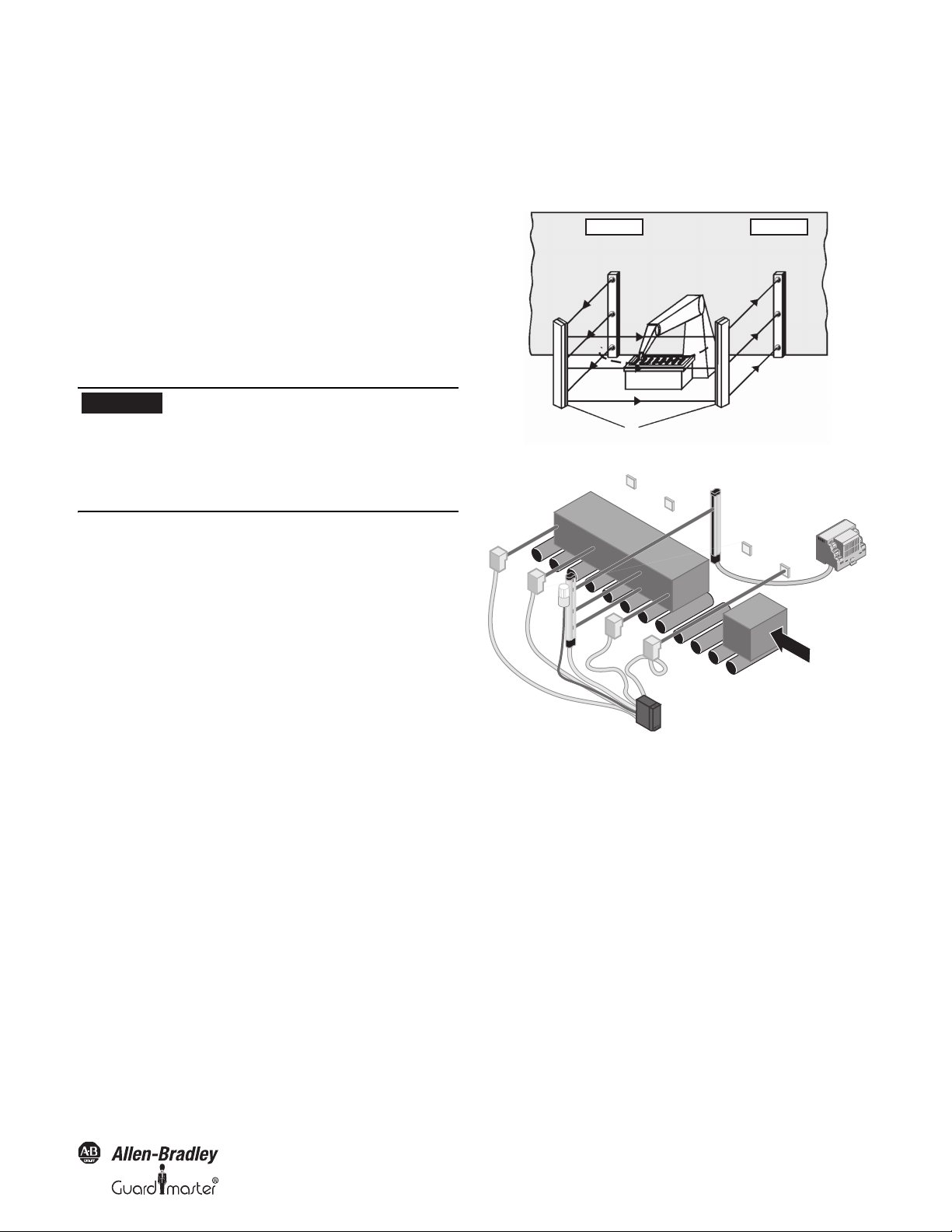

Figure 2 is an example of a GuardShield PAC three-beam safety

light curtain used as an opto-electronic fence with corner mirror

columns.

Figure 3 is an example of a GuardShield PAC three beam with four

retroreflective sensors and an external muting module.

Figure 2: GuardShield PAC three beam with corner mirror columns

Applications

The GuardShield PAC multi-beam safety light curtain may be used

as an opto-electronic fence; detecting the presence of personnel

as they pass through the sensing field or for safeguarding access

to a hazardous area or machine process. Used in combination

with corner mirrors, the GuardShield PAC multi-beam safety light

curtains provide multiple-side access detection.

When using corner mirrors to protect multiple sides of a machine

or work cell, the GuardShield PAC with integrated laser alignment

is the preferred solution. Activation of visible laser light allows

positioning and adjustment of the transmitter, receiver and

corner mirrors.

A typical system configuration for access detection to a hazardous

area or machine process is to have the GuardShield PAC multibeam safety light curtain connected to an external module along

with two or four sensors. The external module allows material to

pass through the GuardShield PAC multi-beam’s sensing field

without stopping the machine or equipment as long as the

muting conditions are met. As the material is moving through the

process, the GuardShield PAC multi-beam’s sensing field is

interrupted and the outputs switch to the OFF state. However, if

the muting module sensors are interrupted with the proper

timing, the module disregards the GuardShield PAC multi-beam’s

outputs and remains in the ON condition, allowing the machinery

or equipment to continue operation.

If the muting sensors are not interrupted and maintained in the

required timing and or sequence, the muting module will switch

OFF when the GuardShield PAC multi-beam’s sensing field is

interrupted.

Figure 3: GuardShield PAC three beam with muting module

Application Requirements

The protective functions of the PAC can only be used properly

when the following conditions are satisfied:

• The machine or installation must be controlled electrically.

• It must be possible to stop hazardous machine movement.

• The PAC must be installed so that entry into the danger

zone interrupts one or more of the light beams.

The light beam diameter of 23 mm (0.90 in.) must be fully

covered, to assure a change in state of outputs.

Release can only be achieved with the use of a restart switch.

The restart switch must be located such that it cannot be pressed

from inside the danger zone.

The GuardShield PAC should be mounted such that upon

interruption of the light beam, the dangerous location can only

be reached if the dangerous condition of the machine has been

stopped. The requirement for this is that there is a proper safety

Original instructions

7

Page 10

GuardShield™ PAC Safety Light Curtain Installation Instructions

Tran smit ter

Receiver

Mounting Stand with Corner Mirror

Transmitter

Receiver

Mounting Stand with Corner Mirror

Transmitter Receiver

Mounting Stand with Corner Mirror

Configuration is not allowed.

distance between the light beams and the nearest point of

danger.

Persons situated inside the danger zone, but outside the

protection field are not recognized. It must therefore be ensured

that a dangerous condition is only possible when there is nobody

present in the danger zone.

The relevant legal and government regulations are to be

complied with the implementation of protection installations.

These regulations vary, depending on areas of application.

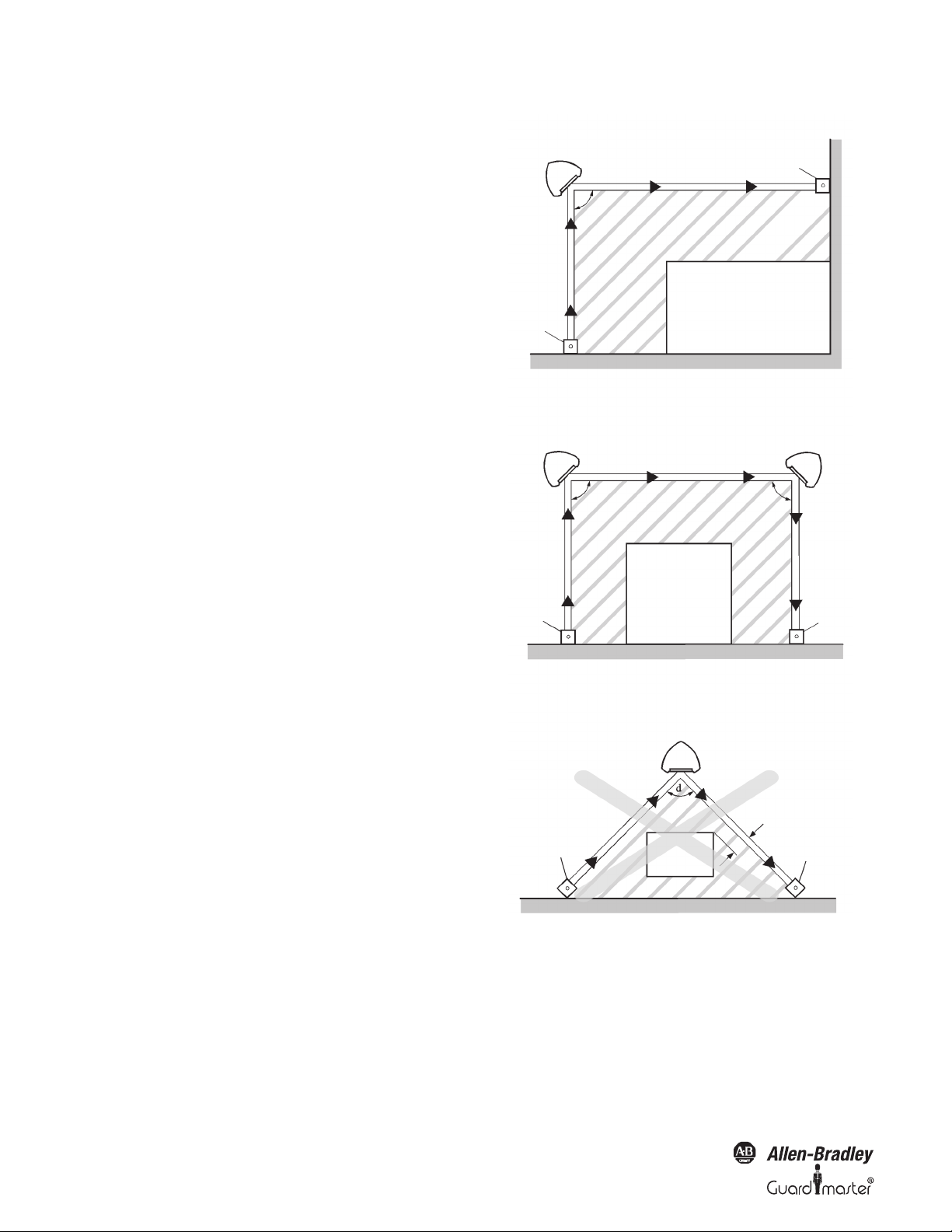

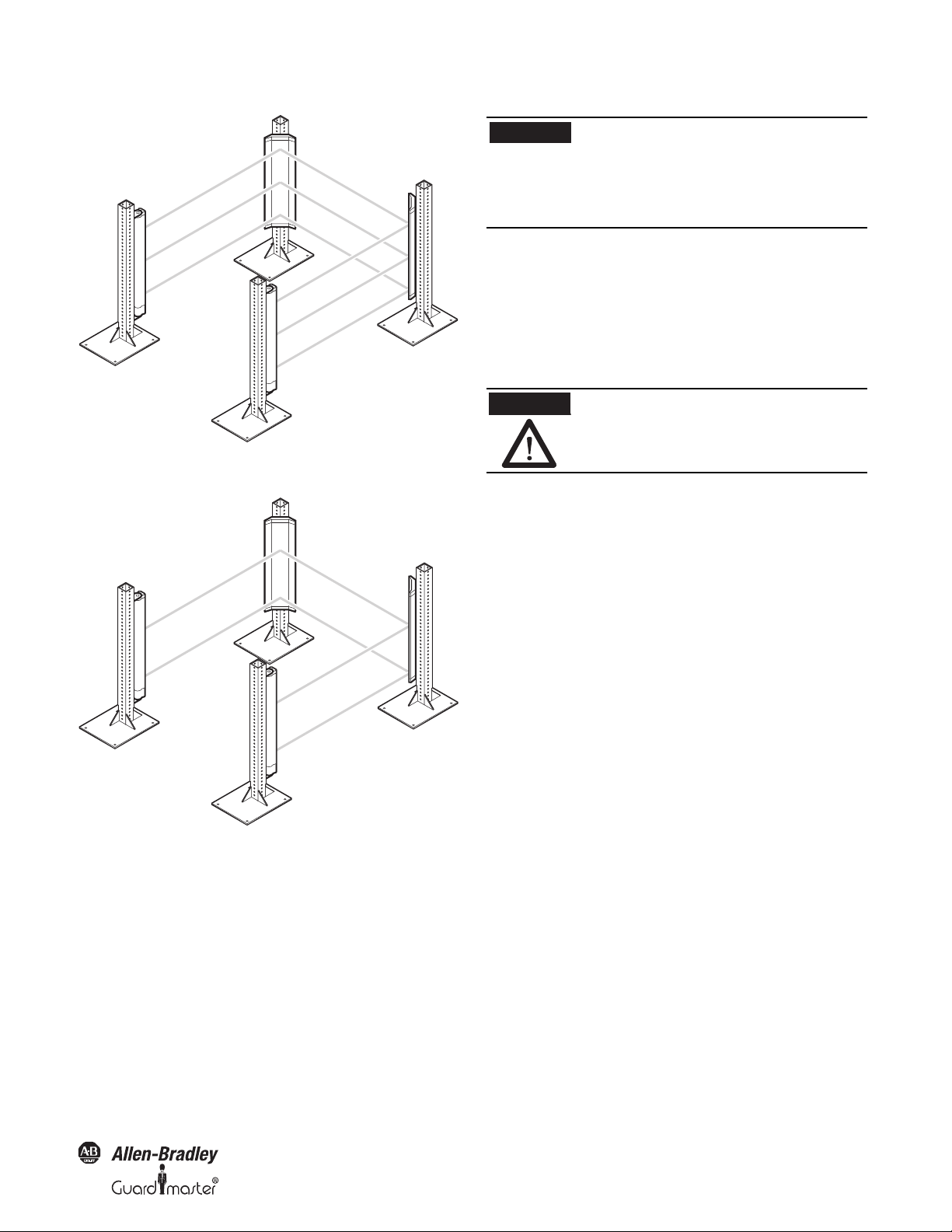

Corner Mirrors and Mounting Columns

The GuardShield two- and three-beam PACs can be used with one

or two corner mirrors to provide two- or three-sided protection.

The use of each corner mirror reduces the maximum range of the

GuardShield PAC by at least 10% per mirror.

It is possible to use full length corner mirrors (440L-AM075 series,

440L-AM125 series).

Rockwell also offers pedestal floor mounting stands (440LAMSTD) which will accommodate the mounting of the

GuardShield two- or three-beam PAC with the appropriate full

length corner or mirror column mirrors.

Figure 4: Multi-sided access control to danger zones with PAC multibeam safety light barrier

8

Original instructions

Page 11

Figure 5: GuardShield three-beam PAC and corner mirrors mounted

Determining Stop Time: The measurement of

stopping time (Ts) must include the stopping

times of all devices in the stop circuit. Not

including all device and control system

elements when calculating Ts will result in an

inaccurate safety distance calculation.

ATTENTION

The GuardShield PAC safety light curtains

must be mounted at a sufficient distance

from the hazardous motion to ensure that the

machine stops before a person’s body reaches

the hazard.

to pedestal floor stands

GuardShield™ PAC Safety Light Curtain Installation Instructions

IMPORTANT

Determining the Safety Distance

The light curtain must be mounted with proper safety distance

• From the point of danger

• From reflecting surfaces

US Safety Distance Formula

This distance, referred to as the safety distance, must be properly

calculated prior to mounting the light curtains around the

machinery. Failure to properly calculate this safety distance may

result in operator injury.

Figure 6: GuardShield two-beam PAC and corner mirrors mounted to

pedestal floor stands

Figures 5 and 6 show two- and three-beam GuardShield PACs

with two corner mirrors providing three-sided detection. Mirrors

are offered in either narrow or wide styles in heights to

accommodate two- or three-beam GuardShield PACs.

Response Time

The response time of the two- and three-beam GuardShield PAC

safety light curtain is 20 ms without beam coding or 30ms with

beam coding.

In the United States there are two formulas that are used to

properly calculate the safety distance. The first, the OSHA formula,

is the minimum requirement for the calculation of the safety

distance. The second formula, the one recommended by Rockwell

Automation, is the ANSI formula, which incorporates additional

factors to be considered when calculating the safety distance.

OSHA Safety Distance Calculation Formula

The OSHA safety distance formula as specified in CFR Subpart O

1910.217 is as follows:

Ds = 63 X T

Ds Safety Distance

63 Is the OSHA recommended hand speed constant in

inches per second

Ts Is the total stop time of all devices in the safety circuit,

measured in seconds. This value must include all

components involved in stopping the hazardous

motion of the machinery. For a mechanical power press

it is the stopping time measured at approximately the

90º position of the crankshaft rotation.

S

Original instructions

9

Page 12

GuardShield™ PAC Safety Light Curtain Installation Instructions

The TS number must include the response

times of all devices, including the response

time of the safety light curtain, the safety light

curtain controller (if used), the machine’s

control circuit and any other devices that

react to stop the hazardous motion of the

machinery. Not including the response time

of a device or devices in the stop time

calculation will result in insufficient safety

distance for the application. This may result in

operator injury.

IMPORTANT

The ANSI Safety Distance Formula

The ANSI safety distance formula, which is the Rockwell

Automation recommended formula, is as follows:

D

= K x (TS + TC + Tr + Tbm) + D

S

Ds Minimum safety distance between the safe guarding

device and the nearest point of operation hazard, in

inches.

K Hand speed constant in inches per second. The ANSI

standard value is 63 in. per second when the operator

begins reaching toward the point of operation hazard

from rest. NOTE: ANSI B11.19 1990 E4.2.3.3.5 states “The

value of the hand speed constant, K, has been

determined by various studies and although these

studies indicate speeds of 63 inches/second to over 100

in./second, they are not conclusive determinations. The

employer should consider all factors, including the

physical ability of the operator, when determining the

value of K to be used.”

Ts Stop time of the machine tool measured at the final

control element.

Tc Response time of the control system

pf

Ds= 63 in./sec X ( 0.250 + 0.050+ 0.02) + 48 in.

Ds = 20.16 in. + 48 in.

Ds = 68.16 in. from hazardous motion

The GuardShield three beam PAC should be mounted at least 68.2

in. from the closest reachable hazard point of the protected

machinery or equipment.

European Safety Distance Formula

A safety distance must be maintained between the light curtain

and the point of danger. This safety distance ensures that the

point of danger can only be reached after the dangerous state of

the machine has been completely removed.

The safety distance as defined in EN ISO 13855 and ENISO13857

depends on:

• Stopping/run-down time of the machine or system. (The

stopping/run-down time is shown in the machine

documentation or must be determined by taking a

measurement.)

• Response time of the protective device

• The person’s speed of approach

• Resolution of the light curtain and/or beam separation

When using the GuardShield PAC three beam with 400 mm beam

spacing, EN 999 requires that the first beam should be mounted

at 300 mm above the floor. When mounted in this configuration, it

is necessary to add 850 mm as the value for “C” in the safety

distance calculation equation.

Note: Ts and Tc are usually measured by a stop time

measuring device.

Tr Response time of the presence sensing device (safety

light curtain) and its interface, if any. This value is

generally stated by the device manufacturer or it can be

measured by the user.

Tbm Additional time allowed for the brake monitor to

compensate for variations in normal stopping time.

Dpf Depth penetration factor. It is an added distance to

allow for how far into the protective field an object, such

as a finger or hand, can travel before being detected. D

is related to the safety light curtain’s object sensitivity.

Object sensitivity is the smallest diameter object which

will always be detected anywhere in the sensing field.

Example—Reach Over

In this example, the value of K is the hand speed constant of 63 in.

per second, the Ts machine stop time is 250 ms (0.250sec), the

20% brake wear factor is 0.05 sec and the GuardShield PAC

response time is 20 ms (0.020 sec). The Dpf is 48 in. for reach over

applications.

10

Original instructions

Figure 7: Safety distance from the point of danger

pf

Page 13

GuardShield™ PAC Safety Light Curtain Installation Instructions

a

Distance D (meters)

The installation of the GuardShield PAC safety

light curtain must adhere to the ANSI

standard B11.19/E4.2.3.3.6, which requires

that a presence sensing device shall prevent

the operator or others from reasonably

reaching over, around, or under the sensing

field into the hazardous area. Auxiliary

safeguarding may be required in conjunction

with the GuardShield PAC to meet this

requirement.

How to Calculate the Safety Distance S

According to EN ISO 13855 and EN ISO 13857:

® First, calculate S using the following formula:

S = 1600 × (Ts + Tr) + C

Where …

Ts = stopping/run-down time of the machine

+ response time of the protective device [s]

Tr = response time of the GuardShield PAC

S = safety distance [mm]

C = safety supplement

S = 1600 x (0.250 + 0.020) + 850 mm

S = 1600 x (0.270) + 850 mm

S = 432 + 850 mm

S = 1282 mm

Minimum Distance from Reflecting Surfaces

The infrared light from the sender may be reflected off of shiny

surfaces and be received by the system’s receiver. If this condition

occurs, it can result in an object not being detected when it enters

the GuardShield PAC’s sensing field.

All reflecting surfaces and objects (e.g. material bins) must

therefore be located at a minimum distance a from the protective

field of the system. The minimum distance a depends on the

distance D between sender and receiver.

The effective aperture angle for the GuardShield PAC system is +/-

2.5° at a mounting distance of > 3.0 m (9.8 ft). Calculate the

minimum distance to reflecting surfaces depending on the

distance between the transmitter and the receiver, using an

aperture angle of +/- 2.5°, or take the appropriate value from the

following table:

Distance Between Transmitter and Receiver

Note: Note: formula: a = tan 2.5° x D [mm]

a = minimum distance to reflecting surfaces

D = distance between transmitter and receiver

(Range L) [m (ft)]

0.2 to 3.0 (0.65 to 9.8) 135 (5.31)

4.0 (13.1) 175 (6.88)

5.0 (16.4) 220 (8.66)

6.0 (19.6) 265 (10.43)

7.0 (22.9) 310 (12.2)

10.0 (32.8) 440 (17.32)

16.0 (52.4) 700 (27.55)

Minimum Distance

a [mm (in.)]

Installation and Mounting

This section describes the preparation, selection and installation

of the GuardShield PAC safety light curtain.

The GuardShield PAC safety light curtain is suitable for most

operating environments (IP65 environmental rating). Proper

safety distance must be observed.

Figure 8: Minimum distance from reflecting surfaces

How to Determine the Minimum Distance from the

Reflecting Surfaces:

® Determine the distance D [m] sender-receiver

® Read the minimum distance a [mm] from the graph:

Figure 9: Graph, minimum distance from reflecting surfaces

Original instructions

IMPORTANT

Determine if the machinery, on which the GuardShield PAC is to

be mounted, meets the requirements as specified in the

beginning of this manual, i.e., machinery must be able to be

stopped anywhere in its stroke or cycle, consistently and

repeatedly.

The GuardShield PAC must be mounted at the proper distance

from the point of operation hazard. This distance is referred to as

the Safety Distance.

ANSI/RIA 15.06 requires that the first beam of the GuardShield

PAC be mounted at 300 mm (12 in.) off of the floor in vertical

applications. The protective height of the GuardShield PAC three

beam is 820 mm. The combination of 300 mm (12in.) and 820

mm equals 1120 mm which meets the ANSI/RIA 15.06

requirements of a “reach over” application. This requires that the

depth penetration factor (Dpf ) be 48 in. when performing the

safety distance calculation.

11

Page 14

GuardShield™ PAC Safety Light Curtain Installation Instructions

Transmitters emit in opposite direction.

Each receiver receives only the beams of

the appropriate transmitter.

Transmitters emit in same direction:

➡Coding necessary

Positioning of the light curtain:

Transmitters emit in opposite direction.

Noncoded Coded

The standard GuardShield PAC has an LED in the receiver which is

used as an alignment aid. This LED will begin flashing when the

infrared light from the transmitter is “seen” by the receiver. This

LED turns off when optimal alignment is attained. An external

laser (440L-ALAT) and mounting bracket (440L-AF6109) is offered

as an accessory for aligning the GuardShield PAC.

Alignment Procedure: Standard GuardShield PAC

Mount and connect both transmitter and receiver. They must be

parallel to each other and be positioned at the same height.

Turn on power to GuardShield PAC system.

Rotate the Transmitter while watching the amber LED on the

receiver to find the point where the indicator for the ON state

(Green LED) illuminates and the amber LED goes off.

Determine the maximum left and right turning angles and

position unit in center. Tighten all hardware assuring that the

alignment indicator is not illuminated.

Cycle power to assure that the system powers up and goes to the

ON state (alignment indicator is OFF)

The GuardShield PAC meets the requirements of IEC 61496 which

requires that the optics of the transmitter and receiver emit and

receive infrared light at a maximum of +/-2.5°. This requirement

creates a tight optical path of infrared light and as such may make

the GuardShield PAC somewhat difficult to align at maximum

range or when corner mirrors are being used in the application to

provide two or three sided perimeter guarding.

When using the GuardShield PAC in perimeter guarding

applications, particularly with corner mirrors, it is best to use the

Allen Bradley GuardMaster laser alignment tool to ease the

alignment process. The laser alignment tool part number is 440L-

ALAT. It is also necessary to use the GuardShield mounting

bracket (440L-AF6109) to mount the laser alignment tool to the

GuardShield PAC housing

The GuardShield PAC is also offered with an integrated laser

alignment system. Select the appropriate cat. nos. for this model

of GuardShield PAC.

Multiple GuardShield PACs

When two or more GuardShield PACs are mounted in close

proximity to one another, it may be possible for the receiver of

one GuardShield PAC pair to receive infrared light from the

transmitter of another GuardShield PAC pair. This optical

interference can be over come by the GuardShield PAC feature of

Beam Coding. Beam coding changes the pulse pattern of infrared

light emitted by a GuardShield PAC transmitter.

Figure 5: Multiple GuardShield PAC alignment options

Alignment Procedure for GuardShield PAC

with Integrated Laser Alignment

1. Properly locate the GuardShield PAC pair from the point of

operation hazard after performing the safety distance

calculation.

2. Using the GuardShield PAC mounting brackets, mount the

transmitter and receiver so that they are facing one another

and are positioned in the same direction. A reference would be

that the indicator LEDs are opposite one another.

3. Turn on each laser by placing a finger or hand in front of each

laser.

4. Adjust the transmitter and receiver in such a way that both

visible laser beams hit the laser targets opposite each laser. A

small deviation from the center of the target is allowable.

12

Mounting Brackets

The GuardShield PAC is mounted using right angle brackets

attached to the endcaps of both transmitter and receiver. Each

GuardShield PAC is supplied with standard right angle mounting

brackets and self-threading screws. It may be necessary to use

additional brackets to mount the GuardShield PAC at a proper

safety distance from the machinery hazard.

Original instructions

Page 15

Figure 6: Mounting brackets

42

(1.65)

20

(0.79)

40 (1.57)

18.9

(0.74)

14.5

(0.57)

52 (2.04)

3.0

(0.11)

32

(1.25)

6.5 (0.26)

Horizontal

Application

Vertica l

Application

GuardShield™ PAC Safety Light Curtain Installation Instructions

Shock Isolation Kits

Rockwell Automation offers a shock and vibration isolation kit

(440L-AF6120) for attenuating excessive shock and vibration in

vertical applications of the GuardShield PAC safety light curtain.

This kit is most effective in extending the operational life of the

GuardShield PAC safety light curtains in excessive shock and

vibration applications, particularly in applications where shock

levels can exceed 50 g.

Figure 7: Shock isolation kit

Rockwell Automation also offers pedestal floor stands for

mounting the GuardShield light curtains when the shock and

vibration levels of the equipment are excessively high. These

mounting stands isolate the GuardShield light curtains from

receiving the shock through the equipment, however, the area

immediately around the machine may also experience high levels

of shock and vibration therefore, it may be necessary to use the

shock mount kits when mounting the light curtains to the

mounting stands.

Figure 8: Pedestal floor stand

Electrical Installation

Connections

Power Supply

The external voltage supply (+24V DC) must meet the

requirements of IEC 61496-1. In addition, the following

requirements have to be fulfilled:

• A short-term power failure of 20 ms must be bridged by the

power supply.

• The power supply has double insulation between the

primary and the secondary side.

• The power supply is protected against overload.

• The power supply corresponds to the guidelines of the EWG

(industrial environment).

• The power supply corresponds to the Low Voltage

Directives.

• The grounded conductor of the power supply device must

be connected to a grounded conductor PE.

• The maximum deviation of the voltage levels is 24V DC +/20%.

Original instructions

13

Page 16

GuardShield™ PAC Safety Light Curtain Installation Instructions

Hazardous

voltage level

Hazardous

voltage level

Hazardous voltage level

Motor, etc.

Basic Insulation

Basic Insulation

0V (blue)

+24V (brown)

Re-inforced

insulation or

double insulation

Guard

Shield

Output (pink

and grey)

Basic Insulation (see

note)

Double Insulation

Power

Supply Unit 2

Unit 1

K1

K1

K2

K2

Contactor

Coils

k2

k1

k2

Contacts

k1

Contacts

6

Tra nsmi tter Re ceiv er

24V Pin 4 5

Not available for GuardShield PAC with

ArmorBlock Guard I/O connectivity.

Reset/restart button

Pin 8

24V

Transmitter Receiver

24V

Not available for GuardShield PAC with

ArmorBlock Guard I/O connectivity.

15

(0.57)

42 (1.7)

2

1

5

8

7

6

4

3

EDM Connection

Connections [mm (in.)]

Cables/Connectors

The GuardShield PAC transmitter connector is a four-pin DC micro

connector offered in cable lengths from 2 to 30 meters. The

GuardShield PAC receiver connector is an 8-pin DC micro

connector offered in cable lengths of 2 to 30 meters.

GuardShield PAC Standard and GuardShield PAC with

ArmorBlock Guard I/O Connectivity

Transmitter Connection

Face V iew of

Female DC Micro Color Pin No.

Brown 1 +24V DC

32

1

4

White 2 No Connection

Blue 3 0V DC

Black 4 Machine Test Signal

Signal

Transmitter

Figure 9: Connecting the contact elements to the EDM

IMPORTANT

Figure 10: Connecting the reset button/restart button

IMPORTANT

14

Note: The transmitter is not expected to be connected to the

ArmorBlock Guard I/O module.

Standard GuardShield PAC Receiver Connector

Receiver Connection

Face V iew of

Female DC Micro Color Pin No.

GuardShield PAC Receiver Connector for ArmorBlock Guard I/O Connectivity

Top View Co lor P in N o.

Original instructions

Signal

Receiver

White 1 Auxiliary Output

Brown 2 +24V DC

Green 3 Ground

Yel lo w 4 ED M

Grey 5 OSSD 1

Pink 6 OSSD 2

Blue 7 0V DC

Red 8 Start/Restart

Signal

Receiver

Brown 1 +24V

White 2 OSSD 2

Blue 3 0V

Black 4 OSSD 1

Grey 5 NC

Page 17

GuardShield PAC Receiver Interconnecting Patch cords to ArmorBlo ck I/O

M

8

2

6

5

1

4

7

3

Blue

24V Ground

White (Aux cht)

OSSD 1

Blue -

Brown +

Transmitter

Black

Bulletin 100S

Safety Contactors

or 700S Safety Relays

Auxiliary

Signal

Machine

Tes t

Signal

S2

Start/Restart

+24V DC

MPCE/EDM

S1

Tes t

Brown

OSSD 2

Grey

Red

Yellow

Green

Pink

K2

K1

L1 L2 L3

Receiver

Cat. No. D escription

889D-F5ACDM-0M3

889D-F5ACDM-1

889D-F5ACDM-2

889D-F5ACDM-5

889D-F5ACDM-10

5-pin M12 patchcord, 12 inches

5-pin M12 patchcord, 1 meter

5-pin M12 patchcord, 2 meters

6-pin M12 patchcord, 5 meters

7-pin M12 patchcord, 10 meters

Typical Wiring Diagram—Direct to Contactors

GuardShield™ PAC Safety Light Curtain Installation Instructions

Nonsafety auxiliary output can be connected to a lamp, motor or status to a PLC.

Note: If MPCE/EDM is activated in the GuardShield PAC, the application requires a safety contactor. If MPCE/EDM is not used K1

& K2 can be standard contactors.

15

Original instructions

Page 18

GuardShield™ PAC Safety Light Curtain Installation Instructions

M

8

65

1

4

7

3

A1A2S52

S21

S12

S22

13

14S34

2324333441

42

Blue

OSSD 1

Blue

Transmitter

No Connection

+24V

MSR127

Brown

OSSD 2

Grey

Reset

Pink

K4

K5

L1 L2 L3

Receiver

Brown +

+24V

K4

K5

K4 K5

A1+ X44 S43 S44 S12 S14 S21 S22 S24 S23 S34S32S31 S33 S41 S42

A2- 48M2M1 3313 23 1434 24

58

K1 K2

K1

K2

7 Blue

START

3 Blue

Transmitter

Power

Maintained

P/B

+24V DC

MSR22LM

440R-P23071

1 Brown

Muting

Sensor

1

5 Grey 6 Pink

Receiver

2 Brown

Muting

Sensor

2

Muting

Lamp

Bulletin 100S

Safety Contactors

or 700S Safety Relays

Restart

Required

Lamp

DC Common

Typical Wiring Diagram—To MSR127 Safety Relay Module

GuardShield Light Curtain Connected to MSR22LM with Two Sensor Muting

Original instructions

16

Page 19

GuardShield™ PAC Safety Light Curtain Installation Instructions

A1+ X44 S43 S44 S12 S14 S21 S22 S24 S23 S34S32S31 S33 S41 S42

A2- 48M2M1 3113 23 1432 24 58

K1 K2

K1

K2

56

2

7

1

3

START

Transmitter

NOTES:

1. Muting sensors are N.C. PNP type

2. Wire reset switch to S43 & S44 when

external monitoring is not required. Terminal

X44 is not used.

3. Muting lamp must meet the following

current specs:

Minimum current: 25 mA

Maximum current: 100 mA

+24V DC

MSR22LM

440R-P23071

Muting

Sensor

3

Receiver

Muting

Sensor

4

Muting

Lamp

Bulletin 100S

Safety Contactors

or 700S Safety Relays

Restart

Required

Lamp

DC Common

Muting

Sensor

1

Muting

Sensor

2

Blue Blue

+24V DC

Brown

Grey

Pink

Brown

Lamp

+24V

MSR42 MSR45E

OSSD 2

OSSD 1

Reset/MDO

EDM

Sen 1

Sen 2

0V DC

0V

GPIO 4

GPIO 3

GPIO 2

GPIO 1

IN 1

IN 2

GuardShield Light Curtain Connected to MSR22LM with Four Sensor Muting

GuardShield Light Curtain Connected to MSR42/MSR45E with Two Sensor Muting

Note: It is necessary to use the optical interface (445L-AF6150) to program the MSR42.

3

21

6

5

7

K1

Original instructions

K2

13

14

23

24

K2K1

17

Page 20

GuardShield™ PAC Safety Light Curtain Installation Instructions

Blue Blue

+24V DC

Brown

Grey

Pink

Brown

Lamp

+24V

MSR42

OSSD 2

OSSD 1

Reset/MDO

EDM

Sen 1

Sen 2

0V DC

0V

GPIO 4

GPIO 3

GPIO 2

GPIO 1

IN 1

IN 2

OSSD 2

OSSD 1

GuardShield Light Curtain Connected to MSR42 with Two Sensor Muting

21

6

3

5

7

K1

K2

Note: It is necessary to use the optical interface (445L-AF6150) to program the MSR42.

K2K1

Original instructions

18

Page 21

GuardShield™ PAC Safety Light Curtain Installation Instructions

Door Status

Switch

Tea ch

Button

After each reconfiguration of the GuardShield

PAC, test the system for proper configuration

and operation before placing the guarded

machine in operation.

ATTENTION

Every modification at the DIP switches must

be stored in the memory of the device

through the Teach function. Simply changing

the position of a dip switch will not change

the GuardShield. It is necessary to first change

the dip switch position and then perform the

teach function. If the changes have been

enabled in the GuardShield, the amber LED

will flash three times as a visual confirmation

that the change has been accepted.

GuardShield PAC light curtains with

ArmorBlock Guard I/O connectivity are

configured from the factory as standard

GuardShield PAC light curtains. However, the

only configurable functionality is beam

coding. All other configurable functions have

been disabled.

System Configuration

DIP-Switch Selection Settings—Transmitter

DIP-Switch Selection Settings—Receiver

After mounting, electrically connecting and aligning the

GuardShield PAC safety light curtain, it is now possible to

configure your system.

To begin system configuration, use the security tool provided to

loosen the screw in the configuration door.

Note: The configuration door screw is a captive screw.

Note: The transmitter can only be configured for beam

coding and Machine Test Signal. If neither of these

configurations are required, then it is only necessary

to configure the GuardShield PAC receiver.

Receiver—Factory Settings

Switch Switch Func tion

1

Mode Activation—Combination

activates

2

one of the following modes:

Guard only, Start interlock,

Restart Interlock

3

MPCE Monitoring disable ON Disabled

4

Not used OFF

5

Not used OFF

6

Not used OFF

7

Set Beam Coding OFF Disabled

8

Not used OFF

Default

Setting Description

ON G uard Only

ON

Transmitter—Factory Settings

Switch Switch Function

1

Set Beam Coding OFF Dis abled

2

Machine Test Signal OFF OFF: Signal High active—No

Settings for Mode of Operation—Receiver

Switch 1 Switch 2 Condition Operation

ON ON

OFF ON

OFF OFF

ON OFF

Guard Only ON/OFF

Start Interlock

(Push Button

Reset)

Restart

Interlock

Start

Interlock

Default

Setting Description

connection or connect normally open

ON: Signal Low active—Connect N/C

Operation

Interlock at start up—Reset by actuation of

pushbutton switch

Interlock at interruption of sensing

area—Reset by actuation of pushbutton

switch

Interlock at start up—Reset by Interruption/

restoration of sensing area for <1 sec

Identify and set the appropriate dip-switches for the

configuration desired.

Dip-switch identification and function is explained in the tables

below.

Follow the Teach Function Procedure to reconfigure the

GuardShield PAC.

IMPORTANT

When delivered from the factory, the following settings are

configured.

Original instructions

IMPORTANT

19

Page 22

GuardShield™ PAC Safety Light Curtain Installation Instructions

The doors on the transmitter and receiver

must be closed for the GuardShield PAC to

operate.

If the GuardShield PAC teach procedure is not

properly completed, the unit will remain in

the previous operating mode.

Once the teach function is completed and the

door secured, verify that the operating mode

has changed to the intended mode.

Teach Function

Procedure:

Step 1 Open cover of the end cap (LED blinks: Receiver is

red LED, Transmitter is amber LED).

Step 2 Select the desired switch setting.

Step 3 Press and hold the Teach button. The yellow LED

flashes at 10 Hz (10x per second).

Step 4 The yellow LED will stop blinking while the button is

depressed. After the yellow stops flashing, release

the teach button within 2 seconds.

• After 3 flashes of the yellow LED the function is

activated.

Step 5 Close and secure the cover.

IMPORTANT

Troubleshooting Guide

The light curtain carries out an internal self-test after startup. If an

error occurs, an appropriate signal combination is sent through

the LEDs to the transmitter and receiver.

Condition

No. Error Description Action

6

Internal fault, receiver • Check configuration of transmitter

7

Internal fault, transmit ter • Check con figuration of transmitter

8

External fault • Check connections of OSSD outputs

9

External fault (MPCE error)

The function Relay monitoring is

activated and after clearing the OSSD

the input Relay monitoring does not

recognize a change of state.

10

11

Configuration mode (Receiver)

Configuration mode (Transmitter)

and receiver

• Replace receiver

and receiver

• Check protective field transmitter/

receiver

• Check connections transmitter/

receiver

• Exchange transmitter

for short circuit against +24V DC

and GND (ca ble, connected dev ices)

• Exchange receiver

• Check connection Relay monitoring

• Check connected relay for closed

contact (if OSSD ON—input Relay

monitoring must have GND level, if

OSSD OFF—input Relay monitoring

must have +24V)

• Switch on only after POWER OFF/ON

• Cover for DIP switch setting at the

receiver is open

• Cover for DIP switch setting at

transmitter is open

20

Original instructions

Page 23

GuardShield™ PAC Safety Light Curtain Installation Instructions

Receiver Transmitter

OSSDs OFF Emitting

OSSDs ON

Interlock

Alignment

POWER ON

ATTENTION

Assure that all power to the machine, and

safety system is disconnected during

electrical installation.

System Status Indicators

Receiver LEDs Transmitter LEDs

OSSDs

OFF

Condition No.

1 OFF ON OFF OFF OFF ON ON

2 ON OFF OFF OFF OFF ON ON

3 ON OFF OFF ON OFF ON ON

4 ON OFF OFF OFF ON ON ON

5 ON OFF OFF OFF OFF ON OFF

6 FLASH OFF OFF OFF OFF ON ON

7 ON OFF OFF OFF OFF FLASH ON

8 FLASH OFF OFF ON OFF ON ON

9 FLASH OFF OFF OFF ON ON ON

10 FLASH OFF DATA TRANS OFF OFF ON ON

11 ON OFF OFF OFF OFF FLASH DATA TRANS

Red

6 through 11 = Fault conditions

Data transmission—factory configuration interface—not available for use outside factory

Flash rate is approximately. 2 Hz (2 times per second)

OSSDs

ON

Green Yellow

Alignment

Amber

Interlock

Yellow

Power

On

Amber

Emitting

Yellow

Condition No. Description

1

2

3

4

5

6

7

8

9

10

11

Guard only mode, light curtain unobstructed (aligned, not in interlock)

Guard only mode, light curtain interrupted (aligned, not in interlock)

Guard only mode, misaligned (not in interlock)

In start or restart interlock (aligned)

Transmitter test input active (pin 4)

Internal fault, receiver

Internal fault, transmitter

External fault (OSSD short to ground, +V, or cross connection)

External fault (MPCE/EDM error)

Configuration mode (receiver access door open)

Configuration mode (transmitter access door open)

Note: Note: For fault conditions 6 through 11, see Troubleshooting guide on page 20.

Original instructions

21

Page 24

GuardShield™ PAC Safety Light Curtain Installation Instructions

Prior to powering up the GuardShield PAC

system, the responsible person should review

the following Checklist.

ATTENTION

Never operate the GuardShield PAC before

carrying out the following inspection.

Improper inspection can lead to serious or

even deadly injury.

If any of the above conditions do not result in

the hazardous motion of the machine

ceasing, do not allow the protected machine

to be placed in operation.

IMPORTANT

Checklist

Before the initiation of the GuardShield PAC the responsible

person should work through the following checklist.

Cable check prior to initiation:

1. o The power supply is solely connected to the

GuardShield PAC.

2. o The power supply is a 24V DC device, that must comply

to all applicable standards of the Machinery Directive

2006/42/EC, and the product standard (IEC 61496).

3. o Proper polarity of the power supply at the GuardShield

PAC .

4. o The transmitter connection cable is properly connected

to the transmitter, the receiver connection cable is

properly connected to the receiver.

5. o The double insulation between the light curtain output

and an external potential is ensured.

6. o The OSSD outputs are not connected to +24V DC.

7. o The connected switching elements (load) are not

connected to 24V DC.

8. o No connection to a conventional power supply.

9. o If two or more GuardShield PAC are to be used, make

sure that each system is properly installed, in order to

avoid optical interference.

Daily Inspection

1. o Approach to hazardous machine parts must only be

possible through the protective field of GuardShield

PAC .

2. o Operators cannot step through the sensing area while

working on dangerous machine parts.

3. o The safety distance of the application is bigger than the

calculated value.

4. o The optic front cover is neither scratched nor dirty.

Operate the machine and check, if the hazardous movement will

stop under the following circumstances.

5. o The protective field is interrupted.

6. o Hazardous machine movement stops immediately, if

the protective field is interrupted by the test rod

directly in front of the transmitter, directly in front of

the receiver and in the middle between transmitter and

receiver.

7. o No hazardous machine movement while completely

interrupting any of the PAC beams.

8. o The power supply of the GuardShield PAC is turned off.

IMPORTANT

Switch the GuardShield PAC on and check its

function by observing the following:

10. o 2 seconds after switching on, the system starts to work

properly, if the protective field is free of obstructions.

Safety Instructions—Maintenance

Note:

1. For safety reasons all inspection results should be recorded.

2. Only persons, who clearly understand the functioning of the

GuardShield PAC and of the machine, may carry out an

inspection.

3. If installer, planning engineer and operator are different

people, make sure that the user has sufficient information

available to carry out the inspection.

22

Original instructions

Page 25

GuardShield™ PAC Safety Light Curtain Installation Instructions

Ref No.

Part No.

Rev

Rev

Ser

GuardShield

TM

Response Time with Coding

Response Time w/o Coding

Protective Height

Range

# of Beams/Spacing

Degree of Protection

2 Executive Dr. Chelmsford MA. 01824

Product of Mexico

978-441-9500

Electro-Sensitive

Protective Equip.

19KP

440L

Bul/Type

R4A2500YD

A

B

Ser

440L

Bul/Type

Part No.

R4A2500YD

A B

Ambient Temp

Power Consumption

Supply Voltage

Safety Parameters

Operating Instructions

Jun, 2010

PN-11790

7W max.

IP65

2/520mm

0.3-16m

500mm

<30ms

<20ms

-10.....+55C

24V DC +/-20%

PAC

Rockwell Automation

PLe/SIL CL3,SIL3

IEC61496/ EN ISO 13849

EN62061/ IEC61508

Type 4/Cat.4

Made in

AA00AA00

Six-Month Inspection

Check the following items every six months or whenever a

machine setting was changed.

1. o Machine stops or does not obstruct any safety function.

2. o The latest machine or connection modifications have

no effect on the control system.

3. o The outputs of the GuardShield PAC are properly

connected to the machine.

4. o The total response time of the machine is shorter than

the calculated value.

5. o Cables and plugs of the GuardShield PAC are in flawless

condition.

6. o Mounting brackets, caps and cables are tightly secured.

Cleaning

If the optic front cover of the GuardShield PAC is dirty, the outputs

of the GuardShield PAC may turn off. Take a clean, soft cloth and

rub without pressure. Do not apply aggressive, abrasive or

scratching cleansing agents, which might attack the surface.

Date Code

Location of Manufacture Year of Manufacturer Week of Manufacturer

XX*XX

M or 4K R 02

M represented Manchester, NH replaced by 4K for Monterrey, Mexico

* J=2004

K=2005

L=2006

M=2007

N=2008

P=2009

R=2010

Figure 4: Explanation of data code

S=2011

T=2010

U=2013

V=2014

W=2015

Y=2016

Z=2017

Original instructions

23

Page 26

GuardShield™ PAC Safety Light Curtain Installation Instructions

Technical Specifications

Light Beams 3/400 mm spacing (440L-P4A3400YD)2/500 mm spacing (440L-P4A2500YD)

Protective Field 820 mm (31.8 in.) 3 beam, 520 mm (20.4 in.) 2 beam

Range 16 m (52.5 ft)

Response Time OSSD – ON to OFF: (Reaction times); 20 ms uncoded; 30 ms coded

Power Supply 24V DC +/-20%; Power supply must meet the requirements of IEC 60204-1 and IEC 61496-1.

Power Consumption 400 mA max. (unloaded)

IR Transmitter Infrared LED (wave length 870 nm)

Aperture Angle Within ± 2.5° for transmitter and receiver

Operating Condition IR transmitter ON

Functions Guard Only: On/Off operation with clear/obstructed detection area

Inputs Transmitter

Inputs Receiver

Outputs: Safety Outputs (OSSDs)

Status Indicators Receiver

Status Indicators Sender

QD Connectors Transmitter: M12 plug 4 pin; receiver: M12 plug 8 pin for standard GuardShield PAC and PAC with integrated laser alignment system, GuardShield

Cable Length Maximum 30 m (100 ft), Maximum resistance: 5 ohms

Ambient Temperature During operation: –10…55°C (14…131°F); For storage: –25…75°C (-13…167°F)

Humidity of the Air Up to 95% (without condensation) between 20…55°C (68…131°F)

Enclosure Rating IP65

Vibration Resistance Per IEC 61496-1, IEC 60068-2-6 Frequency 10…55 Hz Amplitude 0.35 mm

Shock Per IEC 61496-1, IEC 60068-2-29 Acceleration 10 g, Duration 16 ms

Material

Dimensions (cross section) Approx. 40 mm x 50 mm (1.57 in. x 1.96 in.)

Accessories Included Mounting brackets, operating instructions, security tool, plastic tool for setting dipswitch and teach function

Approvals IEC 61496 Parts 1and 2, UL 61496 Parts 1 and 2, UL 1998