Page 1

PHOTOSWITCH

R

Photoelectric Sensors

ColorSight Series 9000

User Manual

Introduction

This manual explains how to

install, adjust, and program

ColorSight Series 9000

photoelectric sensors

Page 2

2 ColorSight Series 9000 PHOTOSWITCHRPhotoelectric Sensor

T able of Contents

General Specifications 3..................................

Summary of ColorSight Features 4..........................

User Interface 5........................................

Pushbutton 5..........................................

8 Turn Knob 5.........................................

Dip-Switches 6........................................

Indicators 6...........................................

Mounting the Sensor 7...................................

Installing the Fiber Optic Cables 8...........................

Aligning the Fiber Optic Cable Head (A--B #60--2694) 9............

Wiring the Sensor 9.....................................

Dimensions 12........................................

Accessories 13........................................

75027--031--01(A), November 1999

Page 3

ColorSight Series 9000 PHOTOSWITCHRPhotoelectric Sensor 3

General Specifications

2m cable 42QA--G5LE-- A2

5-pin DC micro 42QA--G5LE-- D5

Cat No.

5-pin DC mini 42QA--G5LE-- N5

Sensing Mode Fixed Focus

Sensing Distance 27mm (with A--B #60--2694 fiber optic cable)

Spot Size 5mm (with A--B # 60--2694 fiber optic cable) nominal

Transmitting LED Tri-color red, green, blue

Optical

Color Discrimination Operating Mode Color only, color plus intensity (selectable via dip-switch)

Precision Adjustment 8 position rotary switch

Color Sampling Operating Mode Single, Average (selectable via dipswitch)

Supply Voltage 10 to 30V DC

Current Consumption 50mA nominal

Response Time (single mode) 1.3ms; (average mode) 10ms (C + I mode)

Protection False pulse, reverse polarity on all leads, output short-circuit

Electrical

Output Type (Sensor and Diagnostic) Transistor

Output Load Voltage/Current (Sensor

and Diagnostic)

Sensor Output Energized Match/No match- -operate (selectable via DIP switch)

Diagnostic Output Energized Normal operation, i.e., successful learn

Housing Material Valox

Housing Cover Material Radel R5000

Indicators See table on page 6

Mechanical

HF ambient light rejection 25 foot candles

Incandescent light rejection 500 foot candles

Operating Temperature 0_Cto+55_C(32_F to +131_F)

Temperature Drift +/--10_C from learned temperature

Operating Environment Sensor body: NEMA 4 IP54;

Vibration 10--55Hz, 1mm amplitude, Meets or exceeds IEC 60947--5--2

Environmental

Shock 30G with 1ms pulse duration, Meets or exceeds IEC

Relative Humidity Up to 95% noncondensing

Approvals UL, cUL ,CE (applied for) marked for all applicable directives

(single mode) 2.6ms; (average mode) 10ms (C only)

protected (100mA), transient/burst

30V DC, 100mA

Optics assembly: IP40

60947--5--2

75027--031-- 01(A), November 1999

Page 4

4 ColorSight Series 9000 PHOTOSWITCHRPhotoelectric Sensor

Summary of ColorSight Features

Single color detection with adjustable precision settings

Local and remote self teach operation

Color only and color plus intensity operating modes

Single and averaging sampling rates

Selectable gating input

Fixed selectable OFF delay

Output SCP

Reversible supply leads for Source or Sink (PNP or NPN) operation

75027--031-- 01(A), November 1999

Page 5

ColorSight Series 9000 PHOTOSWITCHRPhotoelectric Sensor 5

User Interface

Using an instrument screwdriver, open the top cover of the sensor to gain

access to the user interface panel. This panel contains a pushbutton,

8-turn knob, 6 dip-switches, and LED indicators for configuring and

viewing the sensor’s operation and status. A more complete description of

each item is described below.

OUTPUT

TD CI SG GT

0CAVLRN

LRN

PWR

LEARN

PRECISION

HI

LO

SCP

FAULT

Pushbutton

A single momentary pushbutton, labeled LRN, is used to “teach” the

sensor the color of the target being sensed. With the target in place,

momentarily depress this pushbutton. The yellow LED will flash indicating

that the sensor is “learning” the target. With the release of the pushbutton,

the yellow and red LED will turn OFF indicating a successful learn. If the

yellow LED turns OFF, but the red LED turns ON then the learn was

unsuccessful.

8 Turn Knob

Labeled PRECISION, an 8 position knob is provided to select the desired

level of precision for c olor discrimination. Turning the knob toward HI

provides the highest level of color discrimination, with lessening degrees

approaching LO.

75027--031-- 01(A), November 1999

Page 6

6 ColorSight Series 9000 PHOTOSWITCHRPhotoelectric Sensor

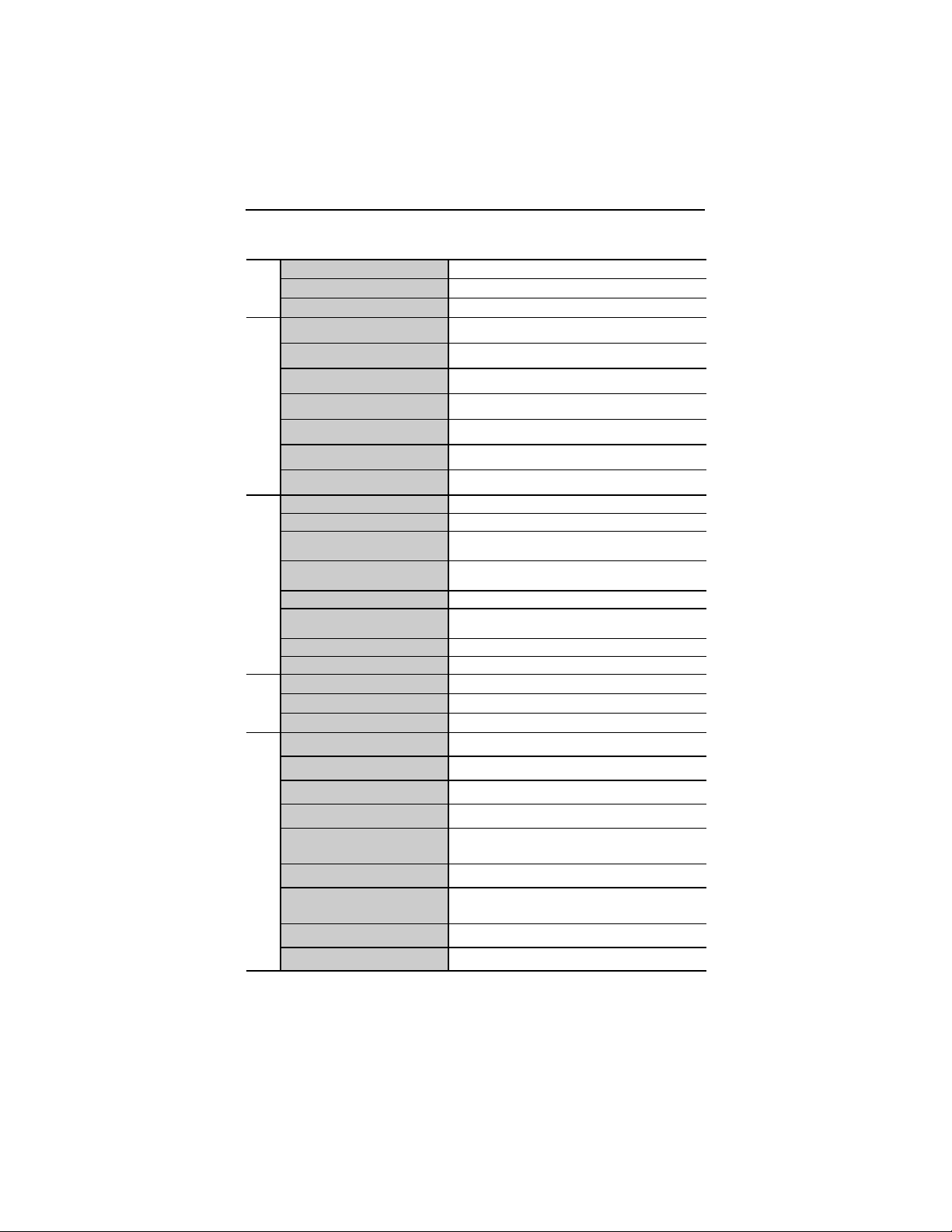

Dip-Switches

A bank of 6 dip-switches are provided for configuring various operating

modes and parameters available with ColorSight. These are defined in the

table below and explained in further detail in the Configuration section on

page 10.

Switch Label Function Switch Up Switch Down

S1 None Not used — —

S2 /= Select target match/no match Output inactive Output active

S3 TD/0 Enable/disable time delay 50ms time delay active No time delay

S4 CI/C Select color + intensity

S5 SG/AV Select single/average mode Single sample mode

S6 GT/LRN Select gate/remote learn mode Input functions as gating

Factory default

mode/color only mode

Color + intensity mode

active

active

input

Color only mode active

Average sample mode

active

Input functions as remote

learn

Indicators

Three LED indicators are provided to indicate a variety of conditions

making it easy for installation and troubleshooting. The function of each is

described in the table below.

Label Color State Condition

PWR Green OFF Sensor power not present

Steady Sensor power present

OUTPUT/LEARN Yellow OFF Output inactive

Steady Output active

Flash Learn mode activated

FAULT/SCP Red OFF Sensor operating normally

Steady Marginal detection of target

Flash Output SCP active

LED also OFF when LEARN pushbutton depressed.

Includes failure to learn color during LEARN process.

75027--031-- 01(A), November 1999

Page 7

ColorSight Series 9000 PHOTOSWITCHRPhotoelectric Sensor 7

Mounting the Sensor

Securely mount the sensor on a firm, stable, surface or support using one

of the many mounting brackets available from Allen-Bradley. The sensor is

supplied with hardware kit #129--130 which contains a plastic mounting

nut, lock washer, 2 M5 x 0.8 x 53 screws and nuts.

M5x0.8x53

Combination

Screws and Nuts

(Supplied)

Hardware Kit

(Supplied)

Optional Swivel/Tilt Bracket A -- B #60--2439

1.100

(27.94)

0.500

(12.7)

1.150

(29.21)

1.125

(28.6)

2.0

(50.8)

2.6

(66.04)

75027--031-- 01(A), November 1999

Page 8

8 ColorSight Series 9000 PHOTOSWITCHRPhotoelectric Sensor

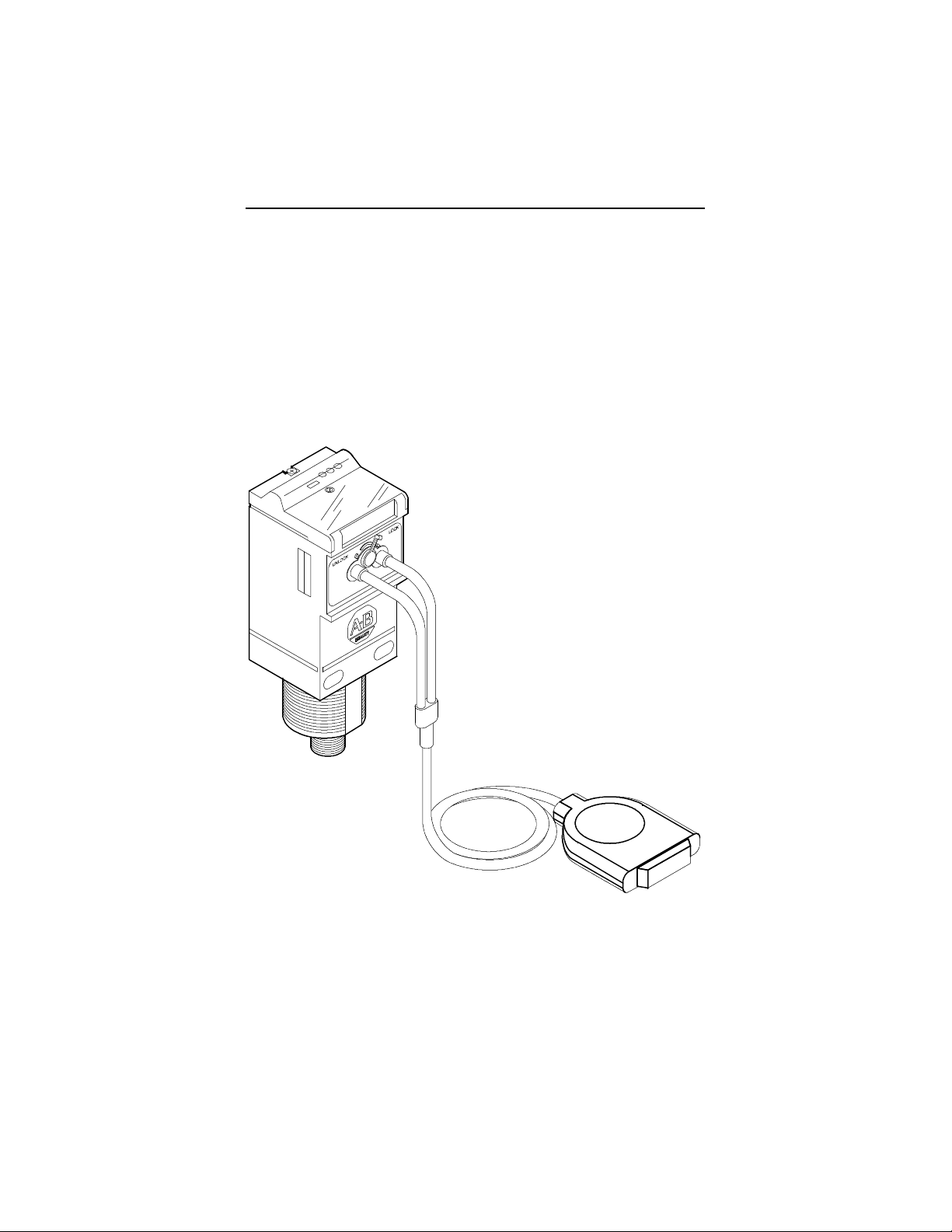

Installing the Fiber Optic Cables

ColorSight has been optimized to work with the Allen-Bradley #60--2694

Fiber Optic Assembly. Other cables may be used also, but with a possible

reduction in performance.

Ensure that the fiber optic cable is installed with the emitter end in the

source side of the sensor (left entry when viewed from the sensor front

face) and the receiver end in the receive side of the sensor. The emitter

portion is identified in blue. Care should be taken to ensure that the fiber

optic cavity and fiber optic cables are s ecurely seated.

UNLOCK

1. Set lever to UNLOCK position. 2. Insert fibers.

LOCK

3. Rotate lever to LOCK position.

Damage to fiber optic cable may occur if inserted and removed with lever in locked position. Always grip by plastic

tips, not cable sheathing.

75027--031-- 01(A), November 1999

Page 9

ColorSight Series 9000 PHOTOSWITCHRPhotoelectric Sensor 9

Aligning the Fiber Optic Cable Head (A--B #60--2694)

The head assembly should be positioned and securely fastened so that

the lens is 27mm (1 1/16in) from the target to be sensed. When operating

the sensor in COLOR ONLY mode this tolerance should not exceed

+/-- 3mm (1/8in). For high precision color discrimination applications using

the COLOR PLUS INTENSITY mode, the tolerance can be no more than

+/-- 0.75mm (1/32in).

Distance

plus tolerance

Target

Wiring the Sensor

Models of ColorSight are available in one of three different connection

types as identified in the following table. Allen-Bradley recommends the

use of the 889 Series of cordsets and patchcords on the quick-disconnect

models. All external wiring should conform to the National Electric Code

and all applicable local codes.

Lead Color Pin Assignment

Designation

V+ or V-- Brown 1 4

V-- or V+ Blue 3 2

Signal output Black 4 1

Fault output Orange 5 3

Learn/Gate input White 2 5

2m Cable 5-pin Micro QD 5-pin Mini QD

1

132

5

4

5

2

4

3

Polarity of supply voltage defines sensor output type –i.e. PNP or NPN

PNP when brown lead connected to V+ and blue lead connected to V- -

NPN when brown lead connected to V-- and blue lead connected to V+

Function determined by selector switch S6

75027--031-- 01(A), November 1999

Page 10

10 ColorSight Series 9000 PHOTOSWITCHRPhotoelectric Sensor

Wiring Diagrams

Cable version wired with PNP outputs

Brown

White

Diagnostic

Orange

Black

Blue

Micro QD wired with PNP outputs Micro QD wired with NPN outputs

1

2

5

4

3

Sensor

Diagnostic

Sensor

Load

Load

Load

Load

+

10--30V DC

Teach/Gate

--

+

10--30V DC

Teach/Gate

--

Cable version wired with NPN outputs

Brown

White

Orange

Black

Blue

1

2

5

4

3

Diagnostic

Sensor

Diagnostic

Sensor

Load

Load

Load

Load

--

Teach/Gate

+

10--30V DC

--

10--30V DC

Teach/Gate

+

Mini QD wired with PNP outputs Mini QD wired with NPN outputs

4

5

3

Diagnostic

Sensor

1

2

Load

Load

+

10--30V DC

Teach/Gate

--

4

5

3

Diagnostic

Load

Sensor

1

2

Load

--

10--30V DC

Teach/Gate

+

Configuring the Sensor

ColorSight can be configured to meet a wide variety of industrial

applications. Various levels of coarse and fine color discrimination can be

selected along with time delay, gating input, and remote learn options.

Before initial use, it will be necessary to configure the sensor for the

application at hand.

Using the table on page 6 as a reference, set the dip-switches on the

user interface to define the following operating parameters.

1. Set the output operation, S2

The sensor output may be activated upon either a match or no match

color condition. The principal is the same as a light or dark operate

condition in monochrome photoelectric sensors. The factory default

setting of dip switch S2 is (=) which activates the output upon a c olor

match condition. Move this switch to (≠) for the opposite effect.

2. Set the time delay, S3

In some high speed applications it may be desirable to “stretch” the

output signal to support slower PLCs. For this reason, ColorSight

provides the option of selecting a 50ms time delay. This delay may be

activated by moving dip-switch S3 to the (TD) position. The factory

default setting is (0).

3. Set the color match operating mode, S4

Not all applications will require the same level of color discrimination.

Therefore, ColorSight offers two distinctly different modes of operation:

1. Color Only: which measures proportions of the RGB values, and

75027--031-- 01(A), November 1999

Page 11

ColorSight Series 9000 PHOTOSWITCHRPhotoelectric Sensor 11

2. Color Plus Intensity which measures the absolute RGB values.

The selection of one of these modes is made by toggling dip switch

S4. For most applications, the Color Only mode will be suitable. When

minute changes in target color must be recognized the Color Plus

Intensity mode should be used.

4. Set the sampling rate, S5

ColorSight can be configured to operate at one of two fixed sampling

rates. The factory default setting is (AV), or, averaging mode. In this

mode the sensor will take multiple samples of the target and average

the results for further processing. This type of operation is ideal for

textured targets such as lumber and fabric. For smooth targets such as

plastic, metal, or glass, selection of the (SG), or single sample,

operating mode will yield acceptable results.

5. Set gating or remote learn operation, S6

A fifth lead (white) is provided on the sensor for use as either a gating

input or remote learn input. The function of this lead is determined by

the position of dip-switch S6. The factory default setting for S6 is LRN

which will set this function for remote learn. In this mode, the sensor’s

self-teach will be activated whenever a momentary (at least 120ms)

signal is applied to this lead. Acknowledgement of a successful learn,

will be indicated by an active output on the orange fault lead. This lead

may be tied to a PLC or pilot light for visual indication. In the event that

the learn was not successful, this output will be inactive.

With dip-switch S6 in the (GT) position, the white lead will serve as a

gating input. In this mode, the sensor output will be enabled only when

this input is active (logical AND).

6. Congratulations, the sensor is now ready to learn the target color.

7. Apply power to the sensor.

8. Position the target 27mm from and perpendicular to the fiber optic

head. Ensure that the target color fill the entire spot size provided by

the sensor.

9. For local self--teach operation follow step 10, otherwise, follow step 11.

10. Momentarily depress the LRN pushbutton. The yellow LED will flash

indicating that the sensor is “learning” the target. With the pushbutton

released, the yellow and red LED will turn OFF indicating a successful

learn. If the yellow LED turns OFF, but the red LED turns ON then the

learn was unsuccessful.

11. Applying a momentary (at least 120ms) signal of to the white lead of

the sensor has the same effect as depressing the LRN pushbutton.

Acknowledgement of a successful learn will be indicated both locally

and via the orange diagnostic lead. Note that the fault output remains

active with the exception of an unsuccessful learn and during the learn

process.

75027--031-- 01(A), November 1999

Page 12

12 ColorSight Series 9000 PHOTOSWITCHRPhotoelectric Sensor

12. Sequence the target in and out of the sensors field of view to ensure

proper color discrimination. It may be necessary to adjust the 8-turn

knob to a higher setting to provide a higher degree of color

discrimination.

13. Congratulations! The sensor has successfully learned the target.

Dimensions—inches (mm)

2.190

(55.62)

40

(1.58)

74.93

(2.950) Ref

M30 X 1.5

External Thread

1/2 NPSM

Internal Thread

40.00

(1.575)

41.91

(1.650)

24.64

(0.970)

30.35

(1.195)

Mounting Hole

Centerline

Connector Version

Micro Style Mini Style

13.97 (0.550)

Thread Size

Micro Style

Mini St yle

75027--031-- 01(A), November 1999

DC

M12 x 1

1Keyway

7/8--16 UN

1Keyway

17.78 (0.700)

Page 13

ColorSight Series 9000 PHOTOSWITCHRPhotoelectric Sensor 13

Accessories

Description Catalog Number

1.8m (6ft) mini QD

Cordset

2m (6.5ft) micro QD

Cordset

889N- F5AF- 6F

889D- F5AC- 2

Swivel/Tilt Bracket 60- 2439

360_ Rotation Mounting

Bracket

Universal Mounting

Assembly

60- 2513

60- 2421

Universal Mounting

Assembly (for Fiber

Optic cable)

60- 2008

75027--031-- 01(A), November 1999

Page 14

14 ColorSight Series 9000 PHOTOSWITCHRPhotoelectric Sensor

Terms and Definitions

Average Mode

A mode of operation, which takes multiple samples of the target being

sensed. A typical application using this mode would be the color

discrimination of textured materials such as textiles and lumber.

Color Only Mode

A mode of operation found in some color recognition sensors in which the

target color is determined by measuring the hue and chroma attributes

only. This type of mode is ideal when there is a large contrast between the

targets being sensed. An example being, the discrimination of yellow

versus red caps in a bottling application.

Color Plus Intensity

A mode of operation found in some color recognition sensors in which the

target color is determined by measuring the absolute RGB values (hue,

value, chroma). This type of mode is intended for applications where very

high precision levels of color discrimination are required. An example is

the discrimination of close shades of red.

NPN

A solid state output type for low voltage DC sensors with a sinking output.

The load is connected between the (+) power connection and the sensor

output. Low leakage currents, fast response times, and high switching

currents are typical c haracteristics of this output type.

OFF Delay

A type of time delay which will delay the operation of the output for a set

period of time after the target being sensed is no longer detected. An OFF

time delay is typically used to “stretch” the output signal to provide ample

scanning time for slower PLCs.

PNP

A solid state output type for low voltage DC sensors with a sourcing

output. The load is connected between the sensor output and the (-- )

power connection. Low leakage currents, fast response times, and high

switching currents are typical characteristics of this output type.

Single Mode

A mode of operation, which takes only single sample of the target being

sensed. This mode of operation is suited for color discrimination on flat or

untextured surfaces.

75027--031-- 01(A), November 1999

Page 15

ColorSight Series 9000 PHOTOSWITCHRPhotoelectric Sensor 15

Troubleshooting

Green LED does not

illuminate

Target cannot be

learned

Target is learned but

color discrimination is

not consistent over time

Ensure power is connected to the sensor.

Ensure fiber optic cables are securely

seated in sensor cavity.

Ensure emitter (blue) side of fiber optic

cable is inserted in the emitter cavity

(blue).

Ensure the fiber optic head is 27mm (plus

tolerance) over and perpendicular to the

target.

Ensure fiber optic cable is not damaged

by checking the spot size for intensity.

Ensure the target being sensed is not

directly over high-frequency fluorescent

lighting.

Targets with glossy surfaces may require

positioning the fiber optic cable head at an

angle to prevent interference from

reflections.

Ensure target color, shape, and distance

to fiber optic LED are consistent. If target

surface is textured such as textiles or

lumber, ensure that the Average mode is

being used. Single operating mode is best

used for smooth surfaces such as metal

or glass.

Ensure the proper operating mode is

activated. Color only mode is intended for

targets with large contrast, i.e., blue vs.

red. Color Plus Intensity mode is best for

targets with little contrast, i.e., light red vs.

medium red. Ensure ambient temperature

is within operating temperature and

tolerance of the sensor.

75027--031-- 01(A), November 1999

Page 16

16 ColorSight Series 9000 PHOTOSWITCHRPhotoelectric Sensor

Visit our web site at:

http://www.ab.com

Reach us no w at www.rockwellauto mation .com

Wherever you need us, Rockwell Automati on brings together l eading brands

in industri al automati on including Al len-Bradley controls, Reliance El ectric

power transmi ssion products, D odge mechanical power transmission

components, and Rockwel l Software. Rockwel l Automat ion’s unique fl exible

approach to helping customers achieve a competitive advantage is supported

by thousands of authorized part ners, distri butors and system integr ators

around the world.

Americas Headquarters, 1201 South Second Street, Milwaukee, WI 53204, USA, Tel: (1) 414 382--2000, Fax: (1) 414 382--4444

European Headquarters SA/NV, avenue Herrmann Debroux, 46, 1160 Brussels, Belgium, Tel: (32) 2 663 06 00, Fax: (32) 2 663 06 40

Asia Pacific Headquarters, 27/F Citicorp Centre, 18 Whitfield Road, Causeway Bay, Hong Kong, Tel: (852) 2887 4788, Fax: (852) 2508 1846

Publication 75027--031--01 (A), November 1999

75027--031-- 01(A), November 1999

Copyright 1999 Rockwell Automation

Loading...

Loading...