Page 1

Installation Instructions

IMPORTANT: SAVE THESE INSTRUCTIONS FOR FUTURE USE.

Yellow LED

Push button

Green LED

42JT VisiSight™ Photoelectric Diffuse Sensors with IO-Link

Default Settings:

The factory default settings are configured so that no teaching is

required for a vast majority of the applications.

Sensing Range: Maximum Setting

Output Mode: Light Operate (Output ON when target is

detected)

Output Type: Auto PNP/NPN or IO-Link. In Auto PNP/NPN mode,

the sensor continuously monitors the load connection and

automatically configures the output to PNP or NPN.

Sensor User Interface

LED Status

The table below provides LED status in the RUN mode, during

operation. The sensor is always in RUN mode, except when being

taught.

Auto PNP/NPN Operation

OFF Power is OFF

Green

Yel lo w

IO-Link Operation

Green

Yel lo w

Connection Types

Cat. No. Suffix Description

-A2 2 m cable

-P4 Integral 4-pin pico (M8) QD

-F4 4-pin DC micro (M12) QD on 150 mm (6in.) pigtail

ON Power is ON

Flashing (6 Hz) Unstable light level (0.5 < margin < 2)

Flashing (1.5 Hz) Output short circuit protection active

OFF Output de-energized

ON Output energized

OFF Power is OFF

Flashing (1 Hz) Power is ON

OFF Output de-energized

ON Output energized

General Specifications

42JT-D2LAT1- 42JT-D8LAT1-

Environmental

Certifications cULus and CE Marked for all applicable directives

Operating Environment

Operating Temperature [C (F)]

Storage Temperature [C (F)] -20…+80° (-4…+179°)

Optical

Light Source Visible red 660 nm Class 1 laser 650 nm

Sensing Range

Adjustments Push button

Electrical

Volta ge

Current Consumption 30 mA max.

Sensor Protection

Outputs

Response Time 0.5 ms max. 0.33 ms max.

Output Type Auto NPN or PNP

Output Function Selectable light operate or dark operate

Output Current 100 mA max.

Output Leakage Current 10 μA max.

Mechanical

Housing Material ABS

Lens Material PMMA

Cover Material PMMA

see Connection Types table

ECOLAB on P4 and A2 models only.

UL: -20…+50°C (-4…122°F)

UL: Class 2 source

IP67, IP69K, ECOLAB

-20…+60° (-4…+140°)

3…800 mm

(0.12…31.5 in.)

10…30V DC

Reverse polarity, short circuit, overload

protection

1…250 mm

(0.04…9.8 in.)

Mounting the Sensor

Securely mount the sensor on a firm, stable surface or support.

An application which is subject to excessive vibration or shifting

may cause intermittent operation. For installation convenience,

Rockwell Automation offers a wide range of mounting brackets

(see the Accessories section for more details).

Alignment Indication

For short range applications the visible light beam of the sensor

suffices as alignment aid.

The alignment feature may be used for longer range applications.

Alignment of the sensor is indicated via change in intensity of the

green LED in the Alignment Mode, as follows:

-Y4 4-pin pico (M8) QD on 150 mm (6in.) pigtail

Page 2

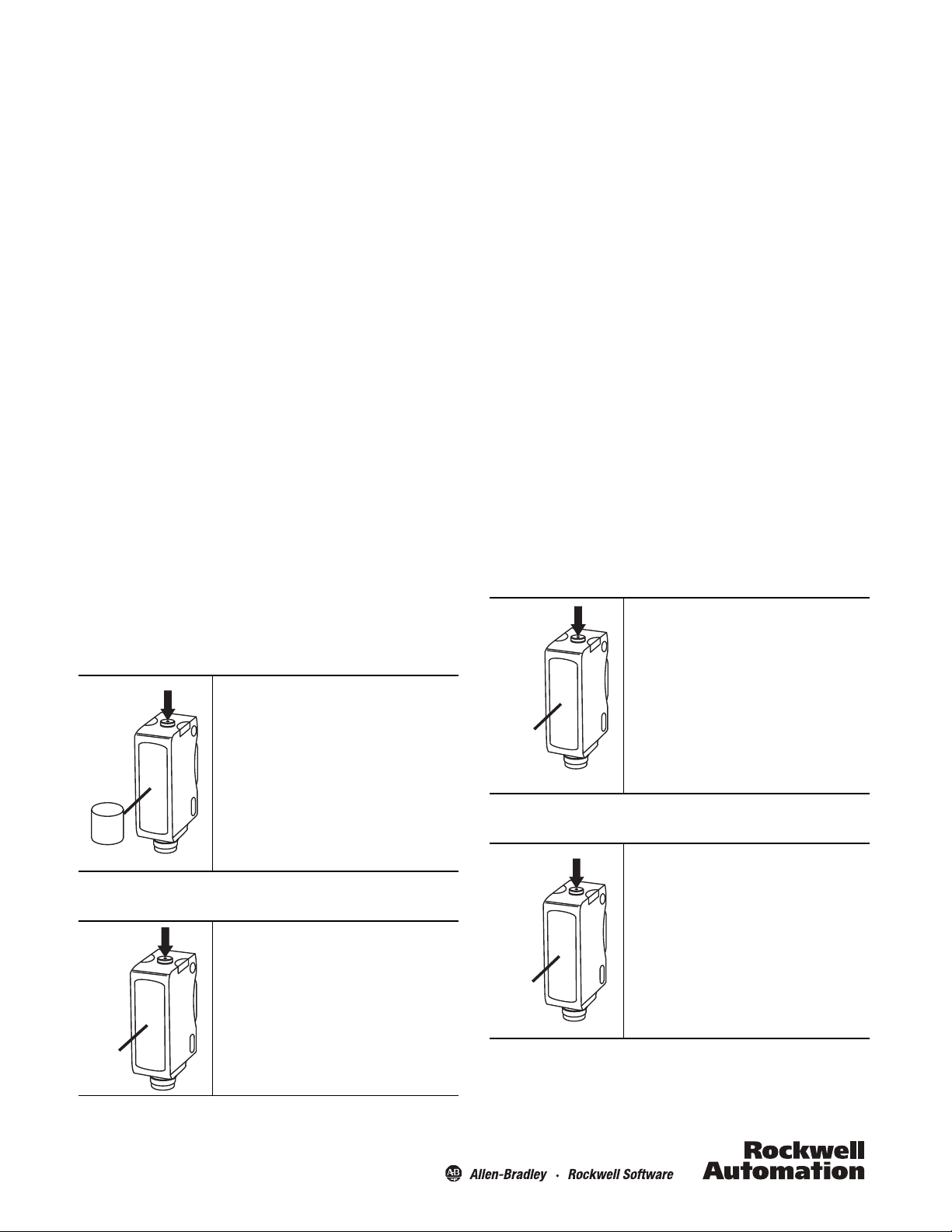

1. Press and release the push button twice within three seconds.

t > 3 s

Tar ge t

t < 0.5 s

t > 6 s

t < 0.5 s

After three seconds, the green LED turns OFF for 0.5 second

indicating the sensor is in the alignment mode.

2. Align sensor to the target to be detected. Intensity of green

LED increases with better alignment. Secure it in a position that

yields the highest intensity of the green LED. Press and release

the button once to return to the RUN mode, or the sensor

automatically returns to RUN mode in two minutes.

VisiSight™ Configuration

The 42JT VisiSight is configured using the push button or Remote

Teach or IO-Link and the LED indicators on the sensor. Five

features may be configured:

• Static Teach: Standard or precision teach for sensitivity/

sensing range

• Dynamic Teach (running process)

• Light operate (LO) or dark operate (DO) output

• Auto PNP/NPN, dedicated NPN or dedicated PNP

• Push button lock/unlock

The sensor output is disabled during Teach.

Teach Sensitivity/Sensing Range

The default setting is the maximum sensitivity/range.

Static Teach:

Teaching the sensitivity/sensing range is a two step process: teach

“target” (1st condition) and teach “no target” (2nd condition).

Switching threshold for output ON vs. OFF is set in between the

two conditions.

Note: The sensor can also be taught by teaching “no target” as

the first condition and “target” as the second condition.

Precision Teach: If there is nothing in the field of view in step

two, the sensing range will be set farther than the target to

maximize excess gain and improve detection reliability. For a

more precise setting with less excess gain, do not remove the

target in step two (i.e. the target is present for both step one and

step two). Also use precision teach for contrast applications.

Restore to factory default setting of maximum range: Perform

steps one and two with “no target” in the sensor’s field of view.

Dynamic Teach (Running Process):

If the targets to be detected are moving with the sensor aimed at

the running process, press and hold the button for three seconds

until the yellow LED starts flashing. The sensitivity will

automatically be taught in the next 30 seconds provided the

sensor sees two cycles of “target” and “no target.” The switching

threshold for output ON vs. OFF is set in between the two

conditions.

Teach Light Operate (L.O.) or Dark Operate (D.O.)

The default setting of the output is light operate (L.O.)

The L.O. setting means that output turns ON when the target is

detected. If the application requires the output to turn OFF when

the target is detected, the setting may be changed to dark

operate (D.O.).

1. To access the teach output mode setting:

Standard Teach:

1. To teach the “target” (first condition):

Place the target at the desired maximum distance.

Press and hold the button for three seconds until the

yellow LED starts flashing. Release the button. The

first condition has now been taught.

2. Teach “no target” (second condition):

Remove the target. Press and release the button. The

teach process is complete.

If the push button is not pressed within 30 seconds,

the sensor exits teach mode a nd returns to RUN mode

without learning the new setting.

Press and hold button for six seconds until green LED

starts flashing. Release the button. The current setting

is indicated by the yellow LED:

L.O.: Yellow LED ON

D.O.: Yellow L ED OFF

2. To change the sensor output mode setting:

Press and release the button within ten seconds to

toggle from L.O. to D.O., the selection indicated by the

yellow LED.

The sensor retains the setting per the last button

depression and returns to the RUN mode ten seconds

after the last button is depressed.

2

Page 3

Output Type Selection:

M12 Male

M8 Male

Brown (1)

White (2)

Black (4)

Blue (3)

+V

Remote Teach/Lock

Output: Auto PNP/NPN or IO-Link

-V

12

(0.47)

34

(1.34)

22.9

(0.90)

25.4

(1.0)

2.6

(0.10)

20

(0.79)

2.8

(0.11)

Clearance for

M3 or #4-40 screw

(2 places)

12

(0.47)

M8 x 1

34

(1.34)

22.9

(0.90)

25.4

(1.0)

2.6

(0.10)

20

(0.79)

Clearance for

M3 or #4-40 screw

(2 places)

Auto PNP/NPN, Dedicated NPN, Dedicated PNP

The default setting is Auto PNP/NPN. This means the sensor

monitors the load connection and automatically configures for

the proper operation, i.e., PNP or NPN. If no load is connected, the

sensor defaults to PNP.

The following applications are covered with dedicated PNP or

dedicated NPN selection:

a. Parallel wiring of multiple sensor outputs: select dedicated

PNP or dedicated NPN setting, as needed.

b. If the load is connected for NPN configuration but to a

different power supply than the power to the sensor or via a

load enabling contact (e.g., a relay contact in series with the

load): select dedicated NPN.

Selection can be made as follows:

1. To access output type: Press and hold the push button for 12

seconds (until both LEDs start flashing synchronously). At the

release of the button, the current setting of output type is

indicated by the slow flashing of the LED (or LEDs) as follows:

• Auto PNP/NPN: both LEDs flashing

• Dedicated NPN: green LED flashing

• Dedicated PNP: yellow LED flashing

2. To change output type: Press and release the push button

within ten seconds to select desired type. Each press of the

button will cycle to the next output setting. The type selected

is indicated by the LEDs. The sensor retains the setting per the

last button depression and returns to the RUN mode ten

seconds after the last button is pressed.

IO-Link

See instructions for IO-Link on www.ab.com. Remote Teach (pin 2)

is disabled in IO-Link operation. If output is selected as dedicated

NPN, IO-Link communication is unavailable.

Wiring Diagrams

The quick-disconnect connector is shown in the following

diagrams. The pin numbers correspond to male connectors on

the sensor.

Micro (M12) Male QD on Pigtail and

Integral Pico (M8) Male QD

1

2

Output Wiring

Normal operation: No connection. Disabled in IO-Link operation.

Remote Teach: Refer to the Remote Teach section.

Push Button Lock: Connect to -V. See the Push button Lock/Unlock

section.

4

2

1

3

4

3

Push Button Lock/Unlock

The push button or remote teach (RT) can be used to prevent

unauthorized users from changing teach settings.

To lock the push button: press and release the button three

times within three seconds. Both LEDs flash synchronously for

three seconds indicating that the push button is now locked.

To unlock the push button: press and release the button three

times within three seconds. Both LEDs flash asynchronously for

three seconds indicating that the push button is now unlocked.

Permanent lock: The push button may be permanently locked by

connecting the white wire (pin 2) to –V.

Remote Teach (RT)

The sensor can be taught remotely via the white wire (pin 2).

Connection to +V acts the same as the button being pressed and

no connection is the same as the button not being pressed. The

sensor can be taught by following the same teach/timing

sequence as used in the push button teach (e.g., connect to the

+V for more than three seconds to teach the “target,” disconnect

from the +V; remove the target and connect to the +V for less

than one second to teach the “no target” condition. All push

button functions can also be carried out via RT.

Approximate Dimensions [mm (in.)]

3

Page 4

Power, Control and Information Solutions Headquarters

Americas: Rockwell Automation, 1201 South Second Street, Milwaukee, WI 53204-2496 USA, Tel: (1) 414.382.2000, Fax: (1) 414.382.4444

Europe/Middle East/Africa: Rockwell Automation NV, Pegasus Park, De Kleetlaan 12a, 1831 Diegem, Belgium, Tel: (32) 2 663 0600, Fax: (32) 2 663 0640

Asia Pacic: Rockwell Automation, Level 14, Core F, Cyberport 3, 100 Cyberport Road, Hong Kong, Tel : (852) 2887 4788, Fax: (852) 2508 1846

www.rockwel lautomation.com

Accessories

30°

20°

63.5

(2.5)

8

(0.32)

14

(0.55)

R 25.4

(1.0)

12

(0.47)

18.6

(0.73)

33

(1.3)

10°

1000

100

1

10

10

(0.4)

800

(31.5)

600

(23.6)

400

(15.75)

200

(7.87)

Distance [mm (in.)]

Excess Gain

Distance [mm (in.)]

Size [mm]

Distance [mm (in.)]

Excess Gain

0

0.0

0.5

1.0

1.5

2.0

horizontal = vertical

200

(7.87)

150

(5.91)

100

(3.94)

50

(1.96)

250

(9.84)

Distance [mm (in.)]

Size [mm]

Stainless Steel Mounting Brackets

1) 60-BJS-L1

°

15

12

(0.47)

Spot Size (800 mm)

70

60

horizontal = verticalhorizontal = verticalhorizontal = verticalhorizontal = verticalhorizontal = verticalhorizontal = verticalhorizontal = verticalhorizontal = verticalhorizontal = verticalhorizontal = verticalhorizontal = verticalhorizontal = verticalhorizontal = verticalhorizontal = vertical

50

40

18.6

(0.73)

33

(1.3)

R 25.4

8 (0.32)

24

(0.95)

(R 1.0)

14

(0.55)

2) 60-BJT-L2

3) 60-2619 VisiSight-compatible swivel/tilt mounting bracket

Typical Response Curves

Standard Diffuse (800 mm)

30

20

10

0

0

200

(7.87)

Laser Diffuse (250 mm)

30

25

20

15

10

5

0

0

50

(1.96)

Laser Spot Size (250 mm)

100

(3.94)

400

(15.75)

150

(5.91)

600

(23.6)

200

(7.87)

800

(31.5)

250

(9.84)

Rockwell Automation maintains current product environmental information on its website at

http//www.rockwellautomation.com/rockwellautomation/about-us/sustainability-ethics/product-environmental-compliance.page.

The spot size is square in shape with one side dimension per the graph.

10000205876 Ver 03

Printed in Germany

May 2014

068-14545

Loading...

Loading...