Page 1

Installation Instructions

IMPORTANT

Communication Modules

Catalog Numbers 2711P-RN6, 2711P-RN6K, 2711P-RN15S, 2711P-RN15SK, 2711P-RN20

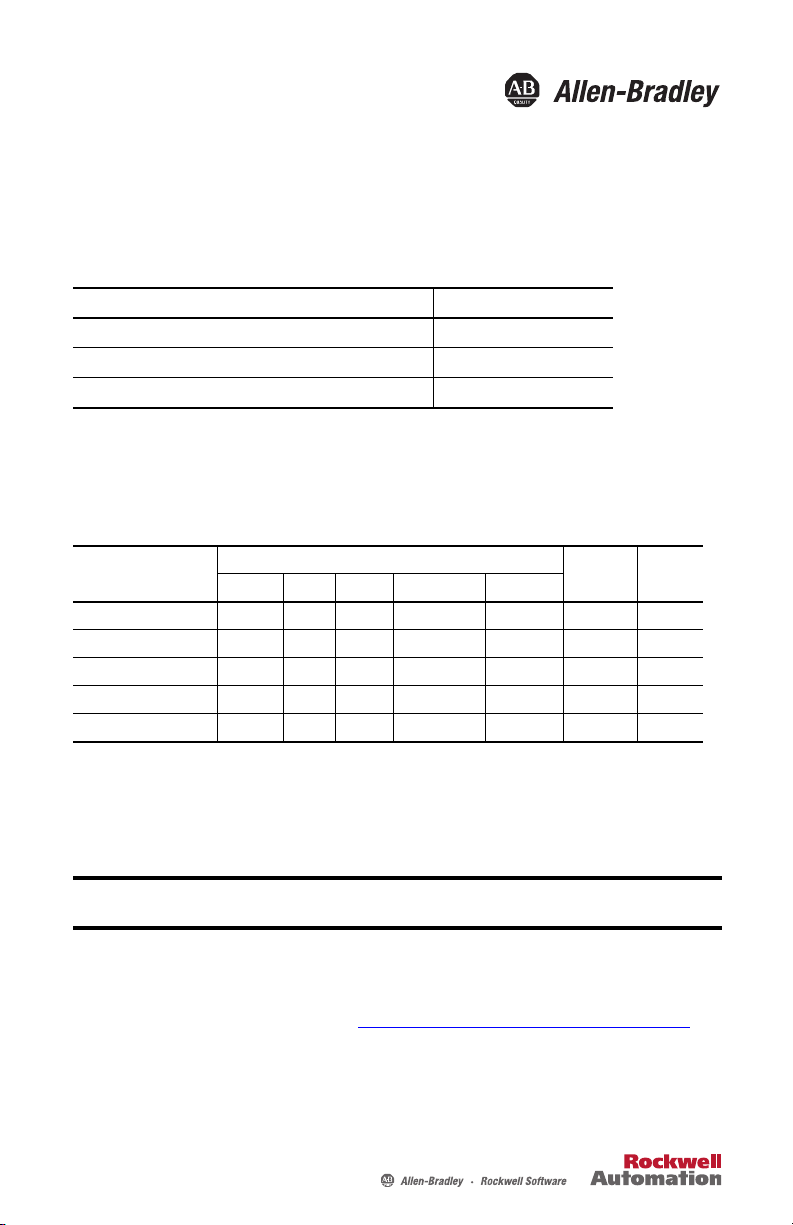

Topi c Pag e

Important User Information 2

Install a Communication Module 3

Replace a Communication Module 4

About This Publication

This document provides instructions on how to install or replace a communication module on a

PanelView Plus™ 6 or PanelView Plus 700, 1000, 1250, or 1500 terminal.

(1)

Cat. No.

2711P-RN6 • • •

2711P-RN6K • • • •

2711P-RN15S • •

2711P-RN15SK • •

2711P-RN20

(1) These installation instructions also apply to other cat. no. 2711P-RNxx communication modules.

(2) Only supported on PanelView Plus 6 - 700 to 1500 terminals running firmware revision 6.10.17 or later.

(3) Only supported on PanelView Plus 700 to 1500 terminals running FactoryTalk® View Machine Edition software, version 5.1 or earlier.

(2)

Ethernet DH+™ DH-485 Remote I/O

•

Communication

(3)

ControlNet

Conformal

Coated

Marine

Certified

The communication module installs over the logic module. The installation is the same for all

communication modules regardless of communication type.

The logic module must be attached to a PanelView Plus display module before you attach the

communication module.

Additional Resources

You can view or download publications at http://www.rockwellautomation.com/literature/. To

order paper copies of technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

Page 2

2 Communication Modules

Important User Information

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety Guidelines for

the Application, Installation and Maintenance of Solid State Controls (Publication SGI-1.1

Automation sales office or online at http://www.rockwellautomation.com/literature/

between solid-state equipment and hard-wired electromechanical devices. Because of this difference, and also because of the wide

variety of uses for solid-state equipment, all persons responsible for applying this equipment must satisfy themselves that each

intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or

application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibil ity or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNIN G: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

available from your local Rockwell

) describes some important differences

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death,

property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard and recognize the

consequences.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, drive or motor, to alert people that

dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, drive or motor, to alert people that

surfaces may reach dangerous temperatures.

IMPORTANT Identifies information that is critical for successful application and understanding of the product.

Rockwell Automation Publication 2711P-IN003E-EN-P - November 2012

Page 3

Communication Modules 3

TIP

Connector for

Communication Module

Connector

Commun ication M odule

Logic Mo dule

Install a Communication Module

WARNIN G: Explosion Hazard

Do not connect or disconnect any communication cable with power applied to this device or

any device on a network. An electrical arc could cause an explosion in hazardous location

installations. Be sure power is removed or the area is known to be nonhazardous before

proceeding.

ATTENTION: Work in a static-free environment and wear a properly grounded electrostatic

discharge (ESD) wristband. Do not touch the communication module connector or its internal

circuitry to avoid ESD.

Follow these steps to install a new communication module.

1. Disconnect power from the terminal.

2. If the display module is removed from the panel, set the terminal, display side down, on a

clean, flat, stable surface.

Logic module might look different depending on catalog number.

3. Position the communication module over the logic module so that the connector on the

bottom of the communication module aligns with the connector on the logic module.

4. To prevent ESD between the modules, allow the communication module to touch the

logic module before making the connection.

Rockwell Automation Publication 2711P-IN003E-EN-P - November 2012

Page 4

5. Push down on the communication module until the connectors are seated.

6. Tighten the four screws that

secure the communication

module to the logic module

to a torque of 0.58 N•m

(5…7 lb•in).

Replace a Communication Module

Follow these steps to replace a communication module.

1. Disconnect power from the terminal.

2. Disconnect communication cables from the module.

WARNI NG: Explosion Hazard

Do not connect or disconnect any communication cable with power applied to this device or

any device on a network. An electrical arc could cause an explosion in hazardous location

installations. Be sure power is removed or the area is known to be nonhazardous before

proceeding.

3. Remove the four screws that secure the communication module.

4. Carefully lift the communication module away from the logic module.

5. Install the new communication module by following steps 3…6 under Install a

Communication Module on page 3.

Allen-Bradley, DH+, FactoryTalk, PanelView, Rockwell Software, and Rockwell Automation are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

Rockwell Automation Publication 2711P-IN003E-EN-P - November 2012 PN-172825

Supersedes Publication 2711P-IN003D-EN-P - June 2010 Copyright © 2012 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

Loading...

Loading...