Page 1

Installation Instructions

Cutout Adapter Kit

for PanelView Plus 400 Keypad and 600 Touch Terminals

2711P-RAK4

Inside...

English....................................................... 3

Français..................................................... 9

Deutsch ................................................... 15

Italiano.................................................... 21

Español.................................................... 27

Português................................................ 33

Publication 2711P-IN020A-MU-P

Page 2

2 Cutout Adapter Kit

Important User Information

Solid state equipment has operational characteristics differing from those of electromechanical equipment.

Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls (Publication

SGI-1.1 available from your local Rockwell Automation sales office or online at

http://www.ab.com/manuals/gi) describes some important differences between solid state equipment and

hard-wired electromechanical devices. Because of this difference, and also because of the wide variety of

uses for solid state equipment, all persons responsible for applying this equipment must satisfy themselves

that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages

resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many

variables and requirements associated with any particular installation, Rockwell Automation, Inc. cannot

assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits,

equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell

Automation, Inc. is prohibited.

Throughout this manual we use notes to make you aware of safety considerations.

WARNING

Identifies information about practices or circumstances that can cause an explosion in a

hazardous environment, which may lead to personal injury or death, property damage,

or economic loss.

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information that is critical for successful application and understanding of the

product.

Identifies information about practices or circumstances that can lead to personal injury

or death, property damage, or economic loss. Attentions help you:

• identify a hazard

• avoid a hazard

• recognize the consequence

Labels may be located on or inside the drive to alert people that dangerous voltage may

be present.

Labels may be located on or inside the drive to alert people that surfaces may be

dangerous temperatures.

Publication 2711P-IN020A-MU-P

Page 3

Installation Instructions

Cutout Adapter Kit

for PanelView Plus 400 Keypad and 600 Touch Terminals

Catalog Number 2711P-RAK4

English

Description

This document provides instructions on how to mount a PanelView Plus 400 Keypad or 600

Touch terminal using an adapter plate into an existing PanelView Standard 550 Keypad

cutout.

Package Contents

The Cutout Adapter Kit includes:

• cutout adapter plate with gasket

• 6 #8-32 nuts with lock washers

Tools Required

The following tools are required for installation:

• socket driver with 11/32 inch socket

• torque wrench capable of 12 in-lb (1.36 N•m)

Publication 2711P-IN020A-MU-P

Page 4

4 Cutout Adapter Kit

Disconnect the Terminal

1. Disconnect power at the source and remove the power cord from the

PanelView terminal.

2. Disconnect all communication cables from the terminal.

ATTENTION

Make sure the power cord of the PanelView terminal is

disconnected and that all cables have been

disconnected from the terminal.

!

Remove the Existing Terminal

1. Remove the self-locking nuts that secure the terminal to the panel.

2. Slide the existing terminal out from panel.

Publication 2711P-IN020A-MU-P

Page 5

Cutout Adapter Kit 5

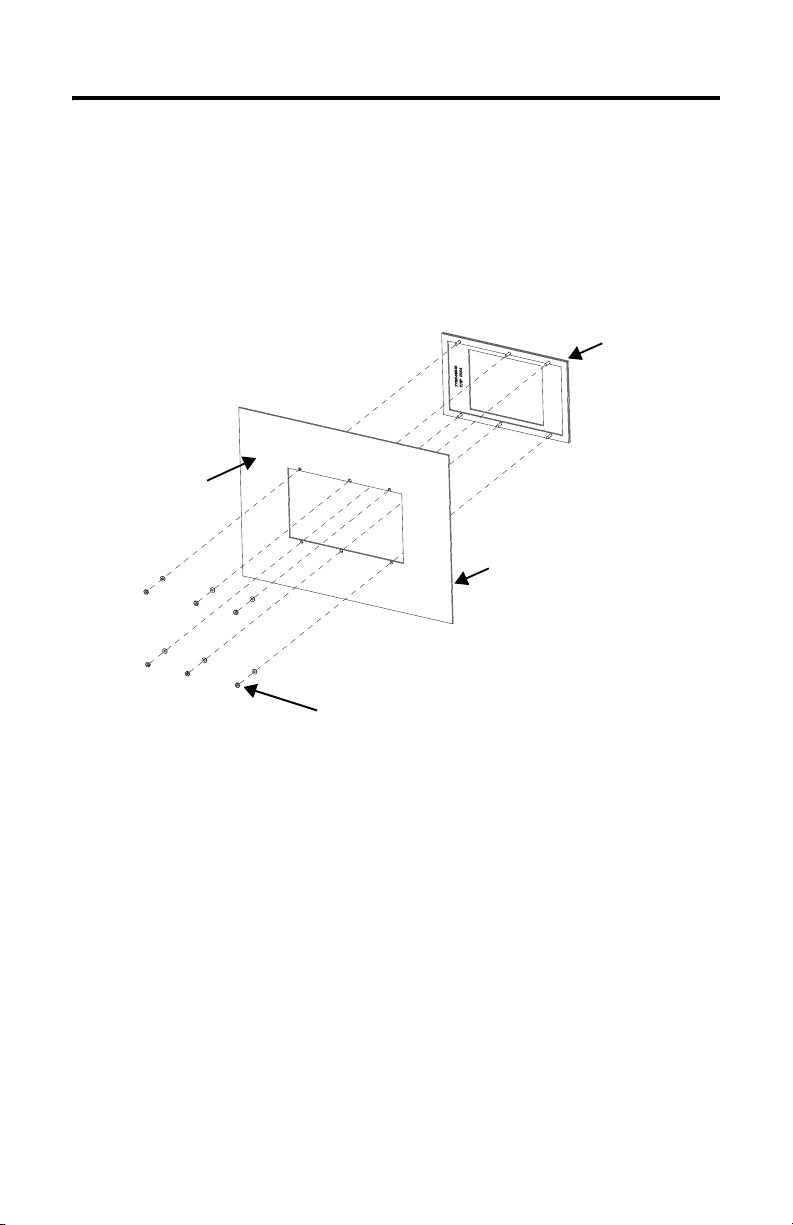

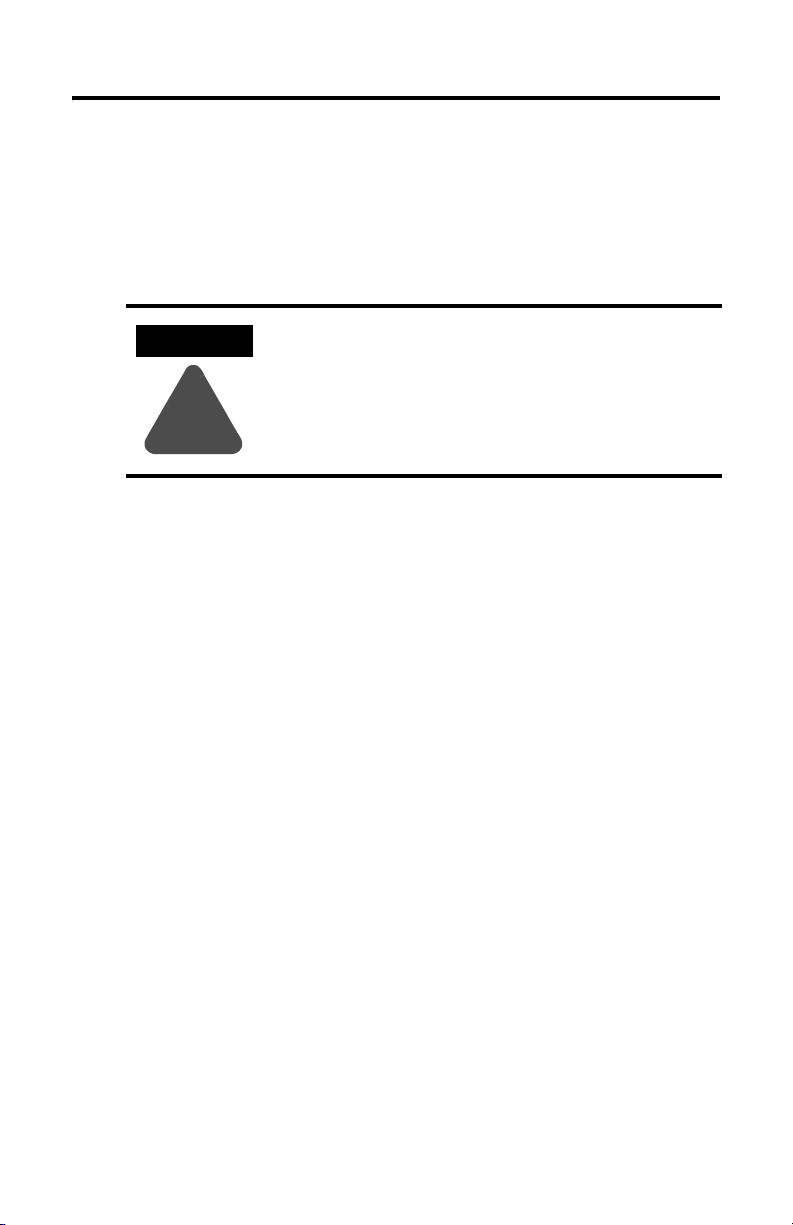

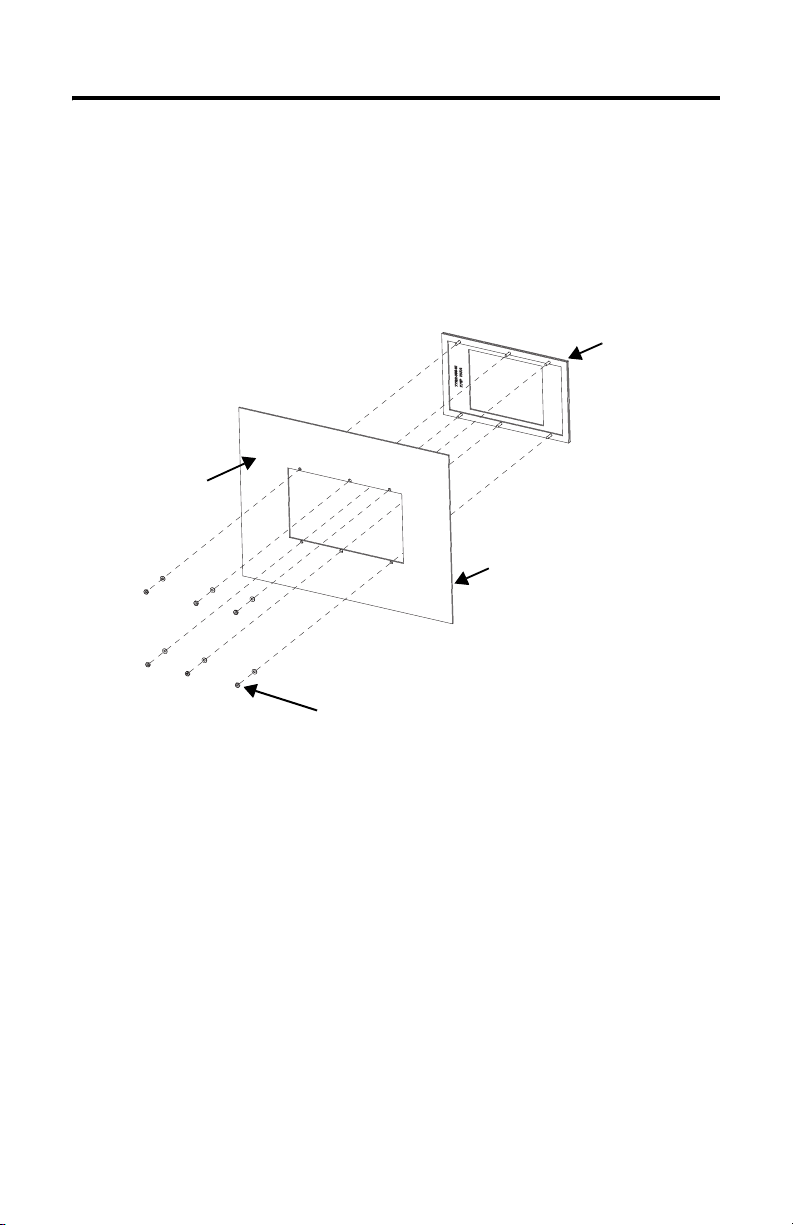

Attach the Adapter Plate to the Panel

1. Align the studs on the cutout adapter plate with the existing stud holes on

the front of the panel.

2. Place the adapter plate into the front of the panel cutout until the sealing

gasket material is firmly against the front of the panel.

Inside of Panel or

Enclosure

Front of Panel or Enclosure

Front Adapter Plate

Nut and Washer

3. Using the supplied nuts with lock washers, fasten the cutout plate onto the studs until

the sealing gasket is slightly compressed against the front of the panel.

4. Using the torque wrench, tighten the nuts to not more than 1.36 N•m

in-lb) to maintain a NEMA Type 4X rating. Do not overtighten.

(12

Publication 2711P-IN020A-MU-P

Page 6

6 Cutout Adapter Kit

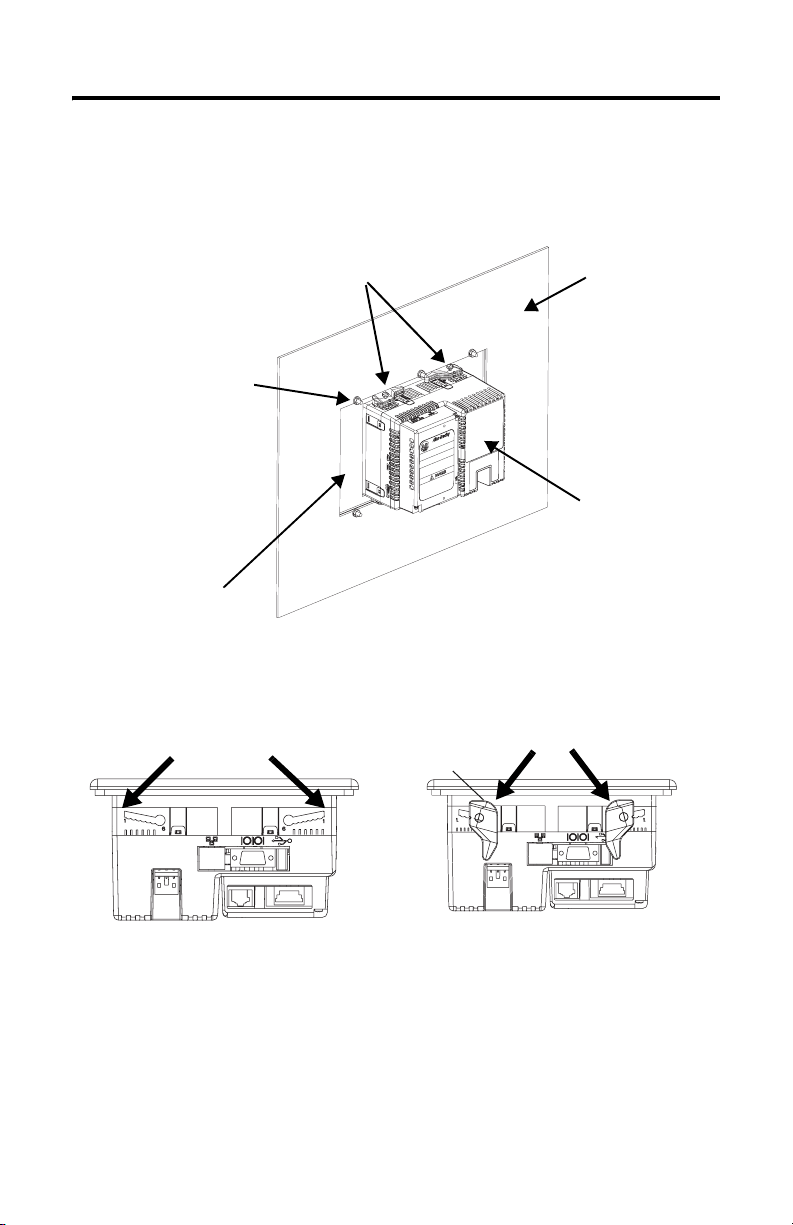

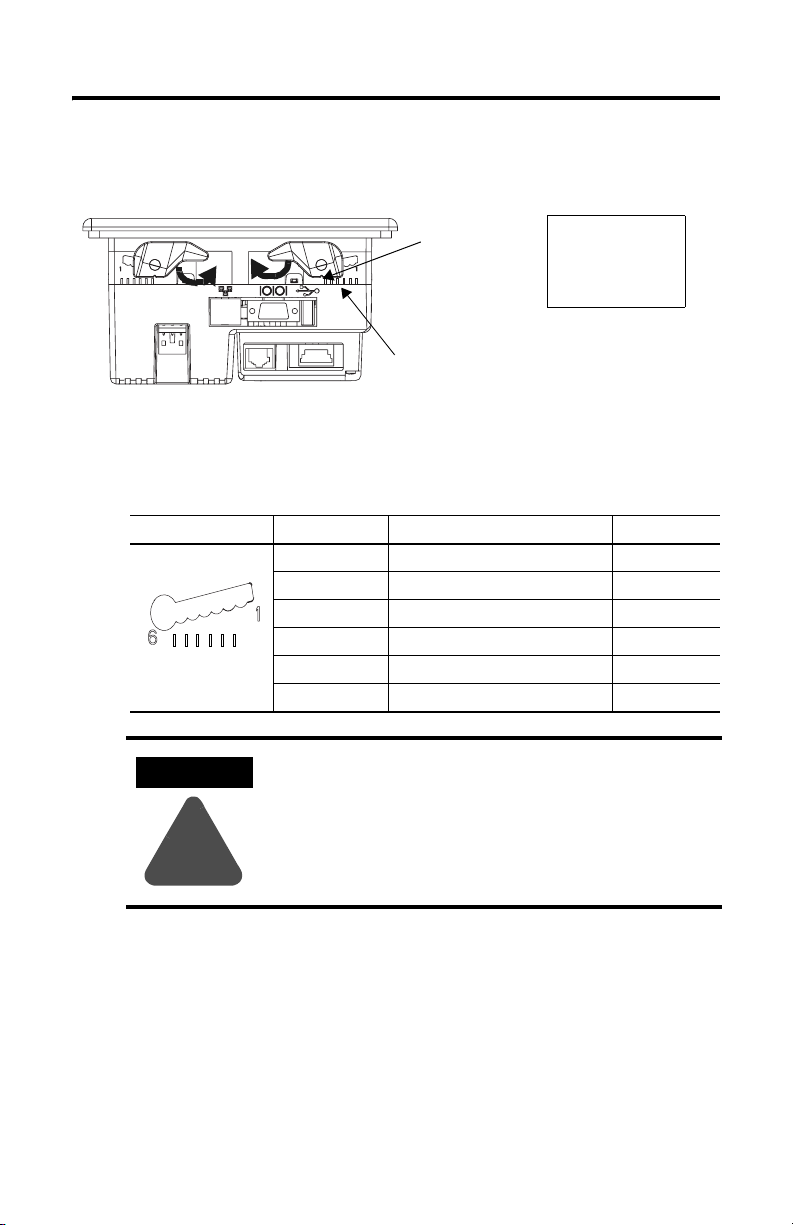

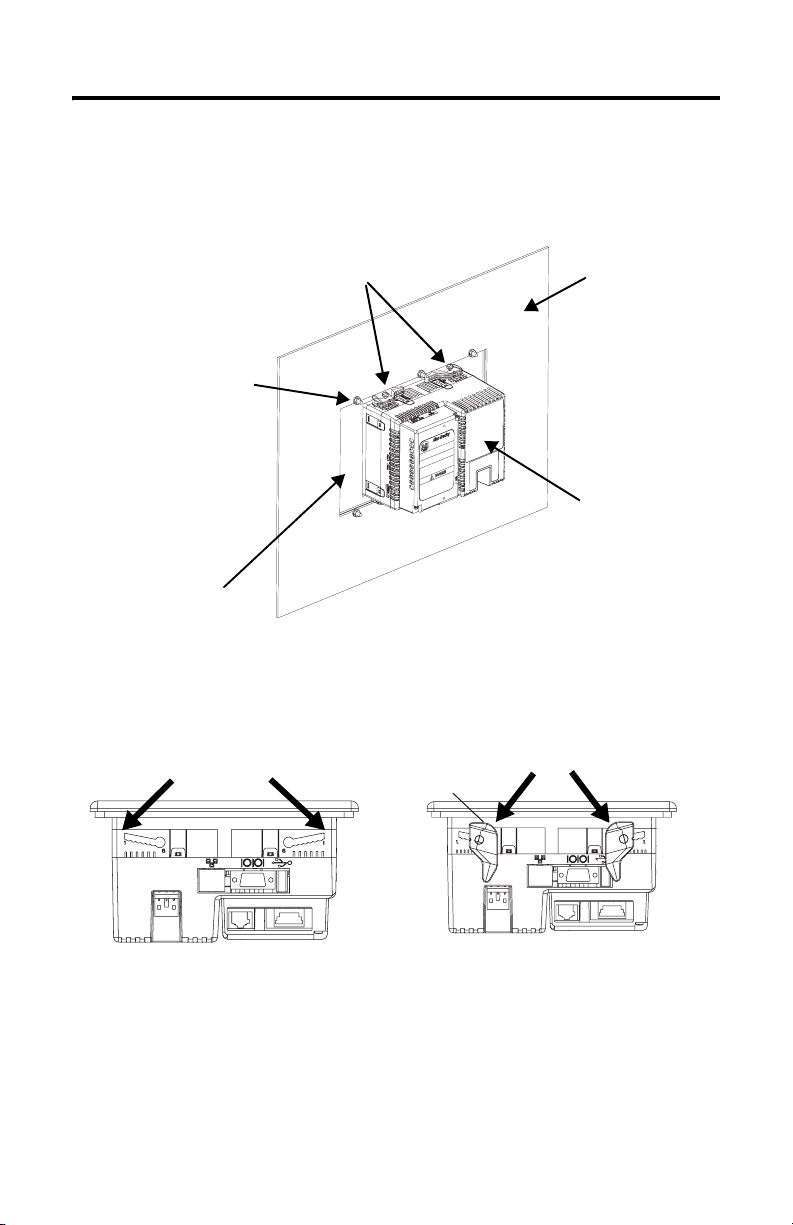

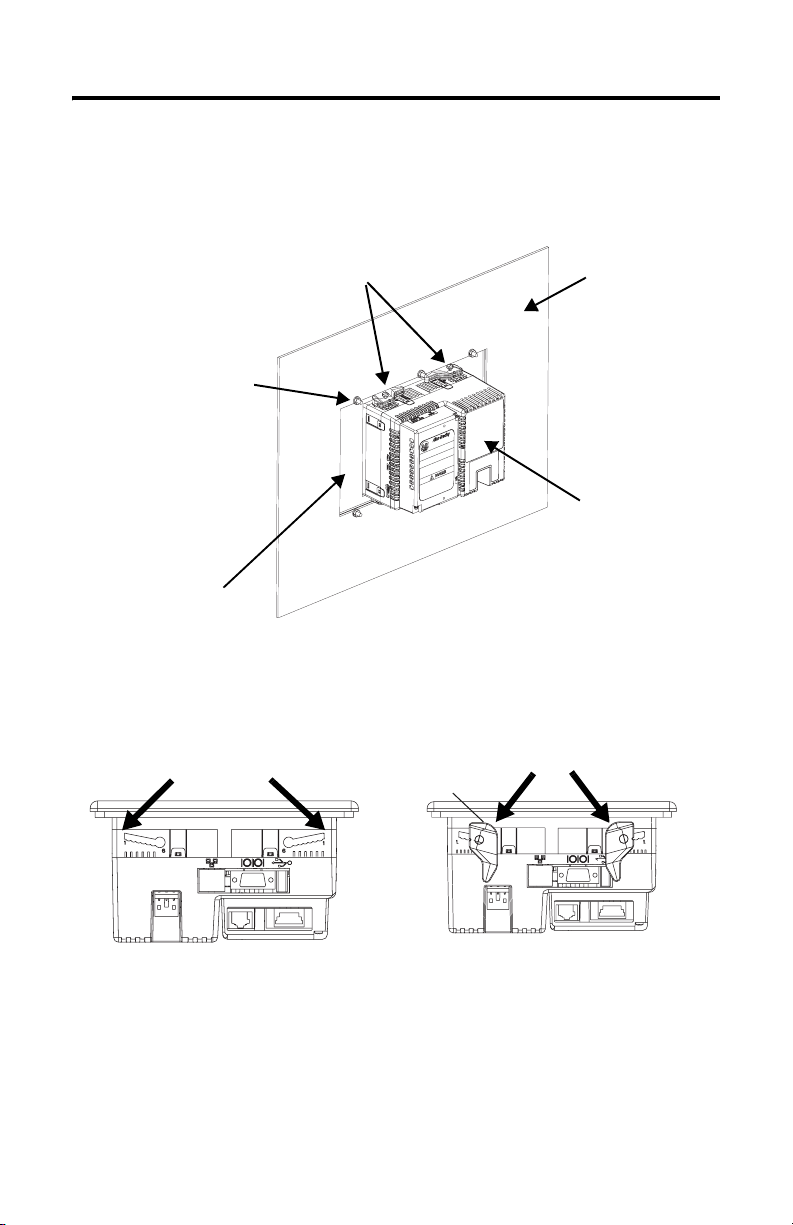

Attach Terminal to the Adapter Plate

1. Insert the new terminal into the front of the enclosure until the terminal gasket is

flush with the adapter plate.

Mounting Levers

Nut and Washer

Adapter Plate

Rear of Panel or

Enclosure

Rear of PanelView Plus

400 Keypad or 600

Touch Terminal

2. Insert 4 mounting levers into the mounting slots of the terminal (as shown below).

Slide each lever until flat side of lever touches the surface of the panel.

Mounting Slots

Flat Side of Lever

Mounting Lever

3. When all levers are in place, slide each lever an additional notch or two until you hear

a click.

Publication 2711P-IN020A-MU-P

Page 7

Cutout Adapter Kit 7

4. Rotate each lever in the direction indicated until lever is in final latch position. Follow

the latching sequence below to obtain optimum terminal fit.

14

4 Levers

3

2

Rotate until notch in levers

1

6

align with proper alignment

mark on terminal.

Alignment Marks

Notch

Use the table below as a guide to insure an adequate gasket seal between terminal and

panel.

Lever Position Panel Thickness Range Typical Gauge

1 0.15 - 2.01 mm (0.060 - 0.079 in) 16

1

2

3

4

5

6

Terminal Markings

for Alignment

ATTENTION

2 2.03 - 2.64 mm (0.08 - 0.104 in) 14

3 2.67 - 3.15 mm (0.105 - 0.124 in) 12

4 3.17 - 3.66 mm (0.125 - 0.144 in) 10

5 3.68 - 4.16 mm (0.145 - 0.164 in) 8/9

6 4.19 - 4.75 mm (0.165 - 0.187 in) 7

Follow instructions above to provide a proper seal and

to prevent potential damage to the terminal.

Allen-Bradley assumes no responsibility for water or

chemical damage to the terminal or other equipment

within the enclosure because of improper installation.

!

Publication 2711P-IN020A-MU-P

Page 8

8 Cutout Adapter Kit

Publication 2711P-IN020A-MU-P

Page 9

Notice d'installation

Kit d'adaptation de découpe

pour terminal PanelView Plus 400 à clavier et 600 dalle tactile

Référence 2711P-RAK4

Français

Description

Ce document indique comment monter un terminal PanelView Plus 400 à clavier ou un

terminal PanelView

PanelView

Standard 550 à clavier, à l'aide d'un kit d'adaptation.

Contenu du kit

Le kit d'adaptation pour découpe contient les éléments suivants :

• plaque d'adaptation pour découpe avec joint ;

• 6 écrous n° 8-32 avec rondelles frein.

Plus 600 à dalle tactile dans une découpe existante prévue pour un

Outils nécessaires

Les outils suivants sont nécessaires pour l'installation :

• une clé à douille avec douille de 11/32 pouce ;

• une clé dynamométrique permettant d'effectuer un serrage avec un couple de

Nm.

1,36

Publication 2711P-IN020A-MU-P

Page 10

10 Kit d'adaptation de découpe

Déconnexion du terminal

1. Déconnectez l'alimentation à la source et débranchez le cordon d'alimentation du

terminal PanelView.

2. Déconnectez tous les câbles de communication du terminal.

ATTENTION

Assurez-vous que le cordon d'alimentation du terminal

PanelView est déconnecté et que tous les autres câbles sont

déconnectés du terminal.

!

Retrait du terminal existant

1. Retirez les écrous autobloquants qui maintiennent le terminal sur le panneau.

2. Retirez le terminal du panneau.

Publication 2711P-IN020A-MU-P

Page 11

Kit d'adaptation de découpe 11

Fixation de la plaque d'adaptation sur le panneau

1. Alignez les goujons de la plaque d'adaptation sur les trous existants sur le panneau.

2. Placez la plaque d'adaptation dans la découpe du panneau de manière à bien

positionner le joint d'étanchéité contre l'avant du panneau.

Plaque

d'adaptation avant

Intérieur

du panneau

ou de l'armoire

Avant du panneau

ou de l'armoire

Ecrou et rondelle

3. Fixez la plaque d'adaptation sur les goujons à l'aide des écrous et des rondelles frein

fournis en les serrant jusqu'à ce que le joint d'étanchéité soit légèrement comprimé

contre le panneau.

4. Utilisez la clé dynamométrique pour serrer les écrous avec un couple d'1,36 Nm

maximum, afin de conserver une classification NEMA type

4X. Veillez à ne pas trop

serrer.

Publication 2711P-IN020A-MU-P

Page 12

12 Kit d'adaptation de découpe

Fixation du terminal à la plaque d'adaptation

1. Placez le nouveau terminal dans l'ouverture de manière à ce que son joint affleure la

plaque d'adaptation.

Attaches

de fixation

Ecrou et

rondelle

Plaque

d'adaptation

Arrière

du panneau

ou de l'armoire

Arrière du terminal

PanelView Plus 400 à

clavier ou un terminal

PanelView Plus 600 à

dalle tactile

2. Introduisez les 4 attaches de fixation dans les encoches situées sur le terminal (comme

illustré ci-dessous) et faites-les glisser jusqu'à que la partie plate des attaches soit en

contact avec la surface du panneau.

Encoches de

fixation

Partie plate

de l'attache

Attaches de fixation

3. Une fois toutes les attaches en place, faites-les glisser d'un ou deux crans

supplémentaires jusqu'à ce que vous entendiez un déclic.

Publication 2711P-IN020A-MU-P

Page 13

Kit d'adaptation de découpe 13

4. Faites-les ensuite pivoter dans la direction indiquée jusqu'à ce qu'elles soient

verrouillées. Suivez la séquence de verrouillage ci-dessous afin que votre terminal

soit maintenu le mieux possible.

14

4 attaches

3

2

Faites pivoter l'attache jusqu'à

ce que la petite encoche

1

6

située sur l'attache soit en

face du repère d'alignement

qui convient sur le terminal.

Repères

d'alignement

Encoche

Aidez-vous du tableau suivant pour assurer une bonne étanchéité du joint entre le

terminal et le panneau.

1

2

3

4

5

6

Repères d'alig nement

du terminal

ATTENTION

Position de

l'attache

1 0,1 - 2 mm 16

2 2 - 2,6 mm 14

3 2,6 - 3,1 mm 12

4 3,1 - 3,6 mm 10

5 3,6 - 4,1 mm 8/9

6 4,2 - 4,7 mm 7

Suivez les instructions ci-dessus pour assurer une bonne

étanchéité et éviter d'endommager le terminal. Allen-Bradley

Epaisseur du panneau Calibre type

ne saurait être tenu pour responsable des dégâts causés par

une infiltration d'eau ou de produit chimique dans le terminal

ou dans tout autre équipement présent dans l'armoire, suite à

!

une installation incorrecte.

Publication 2711P-IN020A-MU-P

Page 14

14 Kit d'adaptation de découpe

Publication 2711P-IN020A-MU-P

Page 15

Installationsanleitung

Adapter-Kit

für den Einbau von PanelView Plus 400-Terminals / 600-Terminal mit

Touchscreen

Bestellnummer 2711P-RAK4

Deutsch

Beschreibung

Das vorliegende Dokument erläutert, wie Sie ein PanelView Plus 400-Terminal mit Tastatur

oder ein PanelView Plus 600-Terminal mit Touchscreen mithilfe einer Adapterplatte in einen

vorhandenen Montageausschnitt für ein PanelView Standard 550-Terminal mit Tastatur

einbauen.

Lieferumfang

Das Adapter-Kit umfasst:

• Adapterplatte mit Dichtung für den Montageausschnitt

• 6 Muttern #8–32 mit flachen Sicherungsscheiben

Erforderliche Werkzeuge

Folgende Werkzeuge benötigen Sie zur Installation:

• Steckschlüssel mit 11/32-Zoll-Einsatz

• Drehmomentschlüssel für 1,36 N•m

Publikation 2711P-IN020A-MU-P

Page 16

16 Adapter-Kit

Unterbrechen der Stromversorgung zum Terminal

1. Unterbrechen Sie die Stromversorgung direkt an der Quelle und ziehen Sie das

Netzkabel vom PanelView-Terminal ab.

2. Ziehen Sie alle Kommunikationskabel vom Terminal ab.

ACHTUNG

Vergewissern Sie sich, dass das Netzkabel des

PanelView-Terminals sowie alle übrigen Kabel vom Terminal

abgezogen sind.

!

Ausbau des bestehenden Terminals

1. Entfernen Sie die selbstsichernden Muttern, mit denen das Terminal an der

Montageplatte befestigt ist.

2. Schieben Sie das vorhandene Terminal aus der Montageplatte heraus.

Publikation 2711P-IN020A-MU-P

Page 17

Adapter-Kit 17

Anbringen der Adapterplatte an der Montageplatte

1. Richten Sie die Stifte an der Adapterplatte mit den dafür in der Vorderseite der

Montageplatte vorgesehenen Montagelöcher aus.

2. Setzen Sie die Adapterplatte von vorne in den Montageausschnitt, bis die Dichtung

fest an der Vorderseite der Montageplatte anliegt.

Vordere

Adapterplatte

Innenseite der

Montageplatte

oder des Gehäuses

Vorderseite der Montageplatte

oder des Gehäuses

Mutter und Unterlegscheibe

3. Befestigen Sie die Adapterplatte, indem Sie die mitgelieferten Muttern und

Sicherungsscheiben mit den Stiften verschrauben, bis die Dichtung leicht an die

Vorderseite der Montageplatte angedrückt wird.

4. Verwenden Sie dazu einen Drehmomentschlüssel und ziehen Sie die Muttern mit

einem Drehmoment von nicht mehr als 1,36 N•m fest, um die Zulassung nach

NEMA Type 4X aufrechtzuerhalten. Achten Sie darauf, die Muttern nicht zu stark

anzuziehen.

Publikation 2711P-IN020A-MU-P

Page 18

18 Adapter-Kit

Anbringen des Terminals an der Adapterplatte

1. Setzen Sie das neue Terminal so in die Vorderseite des Gehäuses ein, dass die

Dichtung des Terminals bündig mit der Adapterplatte ist.

Montagehebel

Mutter und

Unterlegscheibe

Adapterplatte

Rückseite der

Montageplatte oder

des Gehäuses

Rückseite des

PanelView Plus

400-Terminals/

600-Terminal mit

Touchscreen

2. Führen Sie die 4 Montagehebel in die entsprechenden Montageschlitze auf dem

Terminal ein (siehe unten). Schieben Sie jeden Hebel in den Schlitzen so weit

vorwärts, bis die flache Seite des Hebels die Oberfläche der Montageplatte berührt.

Montageschlitze

Flache Seite des Hebels

Montagehebel

3. Wenn sich alle Hebel in der richtigen Position befinden, schieben Sie jeden Hebel um

eine oder zwei Kerben weiter, bis Sie ein Klicken hören.

Publikation 2711P-IN020A-MU-P

Page 19

Adapter-Kit 19

4. Drehen Sie jeden Hebel in die angegebene Richtung, bis sie sich in der endgültigen

Verriegelungsposition befinden. Halten Sie die nachfolgend dargestellte Reihenfolge

ein, um einen optimalen Sitz des Terminals zu erreichen.

14

4 Hebel

3

Drehen, bis die Kerbe in den

1

6

Hebeln mit der entsprechenden

Ausrichtungsmarkierung auf dem

Terminal übereinstimmt.

Ausrichtungsmarkierungen

Kerbe

Verwenden Sie die nachfolgende Tabelle als Richtlinie, um eine angemessene

Abdichtung zwischen Terminal und Montageplatte sicherzustellen.

1

2

3

4

5

6

Terminalmarkierungen

für die Ausrichtung

ACHTUNG

Hebelposition Stärke Montageplatte Typisches

1 0,15–2,01 mm 16

2 2,03–2,64 mm 14

3 2,67–3,15 mm 12

4 3,17–3,66 mm 10

5 3,68–4,16 mm 8/9

6 4,19–4,75 mm 7

Befolgen Sie die voranstehenden Anweisungen, um eine

ordnungsgemäße Abdichtung sicherzustellen und eine

Gauge-Maß

mögliche Beschädigung des Terminals zu vermeiden.

Rockwell Automation übernimmt keine Verantwortung für

Schäden durch Wasser oder Chemikalien am Terminal oder an

!

anderen Geräten innerhalb des Gehäuses, wenn diese durch

unsachgemäßen Einbau verursacht wurden.

2

Publikation 2711P-IN020A-MU-P

Page 20

20 Adapter-Kit

Publikation 2711P-IN020A-MU-P

Page 21

Istruzioni per l'installazione

Kit adattatore finestra

per terminale PanelView Plus 400 con Tastierino / 600 Touchscreen

Numero di catalogo 2711P-RAK4

Italiano

Descrizione

Questo documento descrive le istruzioni per il montaggio di un terminale PanelView Plus 400

con Tastierino o 600 Touchscreen su una finestra esistente per PanelView Standard 550 con

tastierino, utilizzando una piastra adattatrice.

Contenuto dell'imballo

Il kit adattatore per la finestra include:

• piastra adattatrice per la finestra con guarnizione

• 6 dadi num. 8-32 con rondelle di sicurezza

Strumenti richiesti

Per l'installazione sono richiesti i seguenti attrezzi:

• operatore per chiave a bussola da 11/32 di pollice

• chiave dinamometrica capace di 12 poll-lb. (1.36 N•m)

Pubblicazione 2711P-IN020A-MU-P

Page 22

22 Kit adattatore finestra

Scollegare il terminale

1. Scollegare l'alimentazione dalla sorgente e rimuovere il cavo di

alimentazione dal terminale PanelView.

2. Scollegare tutti i cavi di comunicazione dal terminale.

ATTENZIONE

Assicurarsi che il cavo di alimentazione e tutti gli altri

cavi del terminale PanelView siano stati scollegati.

!

Rimuovere il terminale esistente

1. Rimuovere i dadi autobloccanti che fissano il terminale al pannello.

2. Estrarre il terminale dal pannello.

Pubblicazione 2711P-IN020A-MU-P

Page 23

Kit adattatore finestra 23

Inserire la piastra adattatrice sul pannello

1. Allineare i perni della piastra adattatrice con gli appositi fori presenti sulla

parte frontale del pannello.

2. Inserire la piastra adattatrice sul frontale dell'apertura fino a quando la

guarnizione non risulti aderente al pannello.

Interno del pannello

o della custodia

Frontale del pannello o

della custodia

Frontale della

piastra adattatrice

Dado e rondella

3. Utilizzando i dadi e le rondelle di sicurezza forniti, avvitare la piastra fino a quando la

guarnizione non risulti leggermente compressa sul frontale del pannello.

4. Usando la chiave dinamometrica, stringere i dadi con una coppia non

superiore a 1.36 N•m (12

poll.-lb) per mantenere la classificazione NEMA

Tipo 4X. Non stringere troppo.

Pubblicazione 2711P-IN020A-MU-P

Page 24

24 Kit adattatore finestra

Inserire il terminale nella piastra adattatrice

1. Inserire il nuovo terminale sul frontale della custodia fino a quando la guarnizione del

terminale risulti allineata con la piastra adattatrice.

Levette di montaggio

Dado e rondella

Piastra adattatrice

Retro del pannello o

della custodia

Retro del terminale

PanelView Plus 400 con

Tastierino / 600

Touchscreen

2. Inserire le 4 levette di montaggio nelle apposite fessure del terminale (come mostrato

sotto). Fare scorrere ogni levetta fino a quando il lato piatto non tocchi la superficie

del pannello.

Fessure di montaggio

Lato piatto della levetta

Levetta di montaggio

3. Quando tutte le levette sono state inserite, spostarle di una o due tacche fino a quando

si sente un clic.

Pubblicazione 2711P-IN020A-MU-P

Page 25

Kit adattatore finestra 25

4. Ruotare le levette nella direzione indicata fino a portarle nella posizione finale di

blocco. Attenersi alla sequenza di chiusura indicata sotto per ottenere un blocco

ottimale del terminale.

14

4 Levette

3

2

Ruotare fino a quando la

1

6

tacca delle levette risulti in

linea con il segno di

allineamento del terminale.

Riferimenti per l'allineamento

Tac c a

Usare la tabella sottostante come guida per garantire un'adeguata tenuta tra terminale

e pannello.

2

3

4

5

6

Riferimenti del

terminale

ATTENZIONE

Posizione

levetta

1 0,15 - 2,01 mm 16

1

2 2,03 - 2,64 mm 14

3 2,67 - 3,15 mm 12

4 3,17 - 3,66 mm 10

5 3,68 - 4,16 mm 8/9

6 4,19 - 4,75 mm 7

Attenersi alle istruzioni descritte sopra per fornire una

tenuta corretta ed evitare potenziali danni al terminale.

Spessore pannello Calibro tipico

Allen-Bradley non è responsabile per eventuali danni al

terminale o ad altre apparecchiature all'interno della

custodia, provocati da acqua o agenti chimici e dovuti

!

ad un'installazione errata.

Pubblicazione 2711P-IN020A-MU-P

Page 26

26 Kit adattatore finestra

Pubblicazione 2711P-IN020A-MU-P

Page 27

Instrucciones de instalación

Kit de adaptador de corte

para terminal de teclado PanelView Plus 400/

pantalla táctil PanelView Plus 600

Número de catálogo 2711P-RAK4

Español

Descripción

Este documento proporciona instrucciones para montar un terminal de teclado PanelView

Plus 400 ó de pantalla táctil PanelView Plus 600 usando la placa adaptadora dentro del corte

existente para teclado PanelView estándar 550.

Contenido del paquete

El juego adaptador de corte incluye:

• placa adaptadora de corte con empaquetadura

• 6 tuercas #8-32 con arandelas de presión

Herramientas requeridas

Se requieren las siguientes herramientas para la instalación:

• llave de cubo con casquillo de 11/32 pulg.

• llave dinamométrica con capacidad para 12 pulg.-lb (1.36 N•m)

Publicación 2711P-IN020A-MU-P

Page 28

28 Kit de adaptador de corte

Desconecte el terminal

1. Desconecte la alimentación en la fuente y extraiga el cable de alimentación del

terminal PanelView.

2. Desconecte todos los cables de alimentación del terminal.

ATENCIÓN

Asegúrese de que el cable de alimentación del terminal

PanelView esté desconectado y que todos los cables hayan

sido desconectados del terminal.

!

Extraiga el terminal existente

1. Quite las tuercas de autotrabado que fijan el terminal al panel.

2. Deslice el terminal existente fuera del panel.

Publicación 2711P-IN020A-MU-P

Page 29

Kit de adaptador de corte 29

Acople la placa adaptadora al panel

1. Alinee los pernos en la placa adaptadora de corte con los orificios para pernos

existentes en la parte frontal del panel.

2. Coloque la placa adaptadora dentro de la parte frontal del corte de panel hasta que el

material de la empaquetadura selladora esté ubicado firmemente contra la parte

frontal del panel.

Placa adaptadora

frontal

Parte interior del

panel o

envolvente

Parte frontal del panel o envolvente

Tuerca y arandela

3. Con las tuercas con arandelas de presión suministradas, fije la placa de corte sobre los

pernos hasta que la empaquetadura selladora esté ligeramente comprimida contra la

parte frontal del panel.

4. Con la llave dinamométrica, apriete las tuercas a un par no mayor de 1.36 N•m

(12 pulg.-lb) para mantener la clasificación NEMA Tipo 4X. No las apriete

demasiado.

Publicación 2711P-IN020A-MU-P

Page 30

30 Kit de adaptador de corte

Acople el terminal a la placa adaptadora

1. Inserte el nuevo terminal en la parte frontal del envolvente hasta que la

empaquetadura del terminal quede al ras con la placa adaptadora.

Palancas de montaje

Tue rca y

arandela

Placa adaptadora

Parte trasera del

panel o

envolvente

Parte trasera del terminal

PanelView Plus 400/pantalla

táctil PanelView Plus 600

2. Inserte 4 palancas de montaje en las ranuras de montaje del terminal (como se

muestra a continuación). Deslice cada palanca hasta que el lado plano quede en

contacto con la superficie del panel.

Ranuras de montaje

Lado plano de la

palanca

Palanca de montaje

3. Una vez que las palancas estén ubicadas, deslice cada una de ellas una o dos muescas

más hasta que escuche un clic.

Publicación 2711P-IN020A-MU-P

Page 31

Kit de adaptador de corte 31

4. Gire cada palanca en la dirección indicada hasta que llegue a la posición de

enclavamiento final. Continúe con la secuencia de enclavamiento indicada a

continuación para obtener un ajuste óptimo del terminal.

14

4 palancas

3

2

Gire hasta que la muesca de

1

6

las palancas esté alineada

con la marca correcta de

alineación del terminal.

Marcas de

alineación

Muesca

Utilice la siguiente tabla como referencia para asegurar un sello de empaquetadura

adecuado entre el terminal y el panel.

1

2

3

4

5

6

Marcas del terminal

para alineación

Posición de la

palanca

1 0.15 – 2.01 mm

2 2.03 – 2.64 mm

3 2.67 – 3.15 mm

4 3.17 – 3.66 mm

5 3.68 – 4.16 mm

6 4.19 – 4.75 mm

Rango de grosor del panel Medidor

típico

16

(0.060 – 0.079 pulg.)

14

(0.08 – 0.104 pulg.)

12

(0.105 – 0.124 pulg.)

10

(0.125 – 0.144 pulg.)

8/9

(0.145 – 0.164 pulg.)

7

(0.165 – 0.187 pulg.)

ATENCIÓN

!

Siga las instrucciones previamente detalladas para lograr un

sellado adecuado y evitar un daño potencial del terminal.

Allen-Bradley no asumirá responsabilidad alguna por daños

ocasionados por agua o productos químicos al terminal u

otros equipos dentro del envolvente debido a una instalación

incorrecta.

Publicación 2711P-IN020A-MU-P

Page 32

32 Kit de adaptador de corte

Publicación 2711P-IN020A-MU-P

Page 33

Instruções de Instalação

Kit Adaptador de Corte

para Terminal PanelView Plus 400 Keypad / 600 Touch

Código de catálogo 2711P-RAK4

Português

Descrição

Este documento fornece instruções sobre como montar um terminal PanelView Plus 400

Keypad ou 600 Touch usando uma placa adaptadora em um corte de PanelView Standard 550

Keypad existente.

Conteúdo do pacote

O Kit Adaptador de Corte inclui:

• placa adaptadora de corte com junta

• 6 porcas #8-32 com arruelas de pressão

Ferramentas necessárias

As seguintes ferramentas são necessárias para a instalação:

• chave para soquete com soquete de 11/32 polegadas

• chave de torque com capacidade para 12 pol-lb (1,36 N•m)

Publicação 2711P-IN020A-MU-P

Page 34

34 Kit Adaptador de Corte

Desconecte o terminal

1. Desconecte a alimentação na fonte e remova o cabo de alimentação do terminal

PanelView.

2. Desconecte todos os cabos de comunicação do terminal.

ATENÇÃO

Certifique-se de que o cabo de alimentação do terminal

PanelView esteja desconectado e todos os cabos tenham sido

desconectados do terminal.

!

Remova o terminal existente

1. Remova as porcas de autotravamento que fixam o terminal ao painel.

2. Deslize o terminal existente para fora do painel.

Publicação 2711P-IN020A-MU-P

Page 35

Kit Adaptador de Corte 35

Fixe a placa adaptadora ao painel

1. Alinhe os pinos na placa adaptadora de corte aos furos dos pinos existentes na parte

frontal do painel.

2. Posicione a placa adaptadora na parte frontal do corte do painel até que o material da

junta de vedação esteja fixo firmemente na parte frontal do painel.

Placa adaptadora

frontal

Parte interna do

painel ou gabinete

Parte frontal do painel ou gabinete

Porca e arruela

3. Usando as porcas com as arruelas de pressão fornecidas, aperte a placa de corte nos

pinos até que a junta de vedação esteja ligeiramente comprimida contra a parte frontal

do painel.

4. Usando a chave de torque, aperte as porcas até no máximo 1,36 N•m (12 pol-lb) para

manter uma classificação NEMA Tipo 4X. Não aperte demais.

Publicação 2711P-IN020A-MU-P

Page 36

36 Kit Adaptador de Corte

Fixe o terminal à placa adaptadora

1. Insira o novo terminal na parte frontal do gabinete até que a junta do terminal esteja

rente à placa adaptadora.

Travas de instalação

Porca e arruela

Placa adaptadora

Parte traseira do

painel ou gabinete

Parte traseira do terminal

PanelView Plus 400 / 600

Touch

2. Insira as 4 travas de instalação nos slots do terminal (como exibido abaixo). Deslize

cada trava até que o lado plano toque a superfície do painel.

Slots de instalação

Lado plano da trava

Trava de instalação

3. Quando todas as travas estiverem posicionadas, deslize cada uma delas até um entalhe

ou dois a mais até que ouça um clique.

Publicação 2711P-IN020A-MU-P

Page 37

Kit Adaptador de Corte 37

4. Gire cada trava na direção indicada até que a trava esteja no ponto de retenção final.

Siga a seqüência de travamento abaixo para obter o melhor encaixe do terminal.

14

4 travas

3

2

Gire até que o entalhe nas

travas esteja alinhado com

1

6

a marca de alinhamento

adequada no terminal.

Entalhe

Marcas de alinhamento

Use a tabela abaixo como um guia para garantir uma vedação adequada da junta entre

o terminal e o painel.

1

2

3

4

5

6

Marcas de terminal

para alinhamento

ATENÇÃO

Posição da

trava

1 0,15 - 2,01 mm (0,060 - 0,079 pol.) 16

2 2,03 - 2,64 mm (0,08 - 0,104 pol.) 14

3 2,67 - 3,15 mm (0,105 - 0,124 pol.) 12

4 3,17 - 3,66 mm (0,125 - 0,144 pol.) 10

5 3,68 - 4,16 mm (0,145 - 0,164 pol.) 8/9

6 4,19 - 4,75 mm (0,165 - 0,187 pol.) 7

Siga as instruções acima para obter uma vedação adequada e

evitar possíveis danos ao terminal. A Allen-Bradley não se

Faixa de espessura do painel Bitola típica

responsabiliza por danos causados por água ou por produto

químico ao terminal ou a outro equipamento dentro do

gabinete devido à instalação incorreta.

!

Publicação 2711P-IN020A-MU-P

Page 38

38 Kit Adaptador de Corte

Publicação 2711P-IN020A-MU-P

Page 39

39

Publication 2711P-IN020A-MU-P

Page 40

Publication 2711P-IN020A-MU-P - November 2003 PN 41061-323-01(1)

Copyright © 2003 Rockwell Automation, Inc. A ll rights reserved. Printed in t he U.S.A.

Loading...

Loading...