Page 1

Installation Instructions

IMPORTANT

Low-profile Connector Kit for I/O and

Cascading Safe Torque-off Signals

Catalog Number 2090-K6CK-D44S0

About the Low-profile Connector Kit

The low-profile 44-pin connector kit provides termination points for I/O and safe torque-off

connections on the IOD connector of Kinetix® 6200 and Kinetix 6500 servo drives. When used

with the 2094-xx02x-M0x-S0 (safe torque-off ) control modules, you can use this kit and

2090-CS0DSDS-AAxx safe torque-off cables to cascade the safe torque-off signals from one

drive to another. This kit also includes two identical motion-allowed jumpers that you install

when the safe torque-off functionality of 2094-xx02x-M0x-S0 control modules is not desired.

This kit and the cables apply to only 2094-xx02x-M0x-S0 (safe torque-off) control modules.

They do not apply to 2094-xx02x-M0x-S1 (safe speed) control modules.

In addition, this kit provides access to the digital input connections for standard cables or

discrete wires. Refer to the Kinetix 6200 and Kinetix 6500 Modular Multi-axis Servo Drive User

Manual, publication 2094-UM002

Refer to the Kinetix 6200 and Kinetix 6500 Safe Torque-off Safety Reference Manual,

publication 2094-RM002

, for more information on wiring safe torque-off functions.

, for more information on wiring digital inputs.

Safe Torque-off Cables

Safe torque-off cables for cascading drive-to-drive connections are available in three lengths.

Cable Cat. No. Length Description

2090-CS0DSDS-AA02 0.2 m (7.1 in.) Drive-to-drive connections (single-wide IAM or AM power module)

2090-CS0DSDS-AA03 0.3 m (1.0 ft) Drive-to-drive connections (double-wide IAM or AM power module)

2090-CS0DSDS-AA10 1.0 m (3.2 ft) Connect to next 2094 power rail or other safe torque-off device

Page 2

2 Low-profile Connector Kit for I/O and Cascading Safe Torque-off Signals

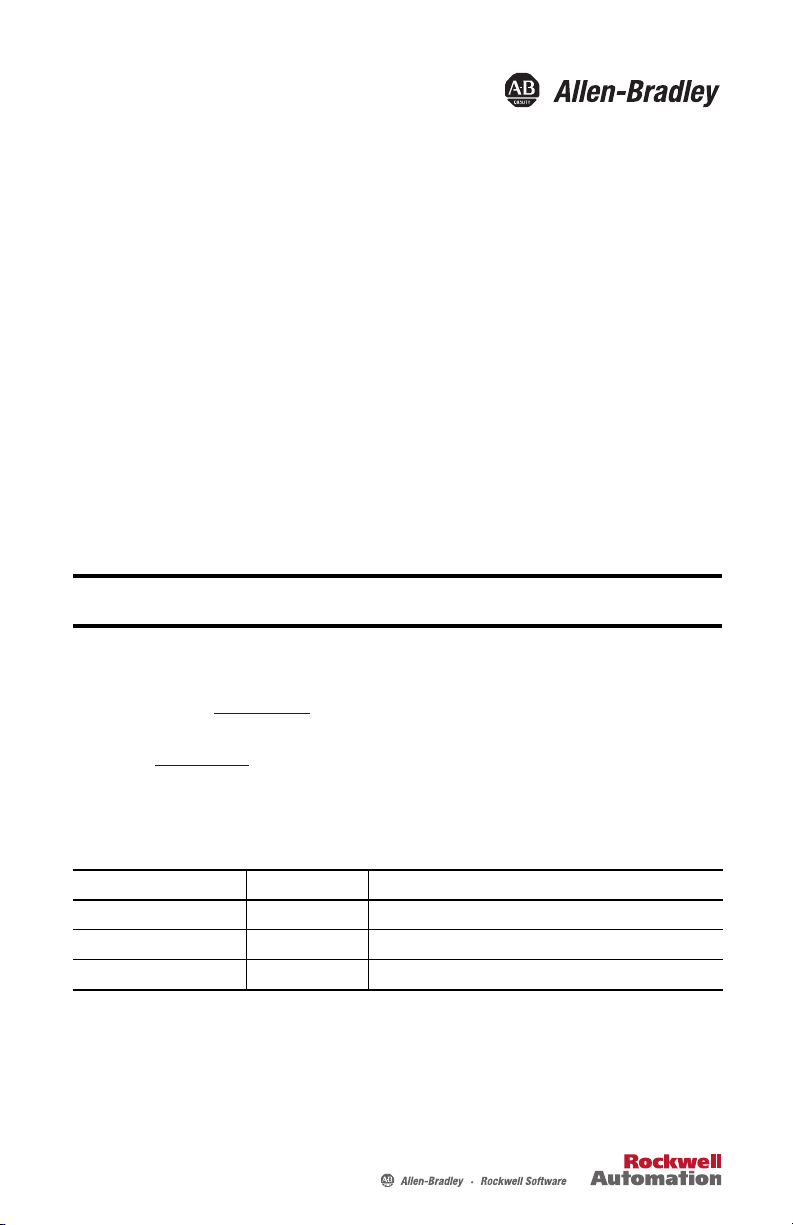

Follow these steps to form a compact

connection on I/O and safety wires.

1. Push the insulation down-and-over itself.

2. Move the insulation so it butts against the

outside wall of the cover.

3. Tape or shrink-wrap the end of the

insulation to the cable.

Mounting

Screws (3)

If necessary, turn clamps over

to hold small wires securely.

Shrink-wrapped Insulation

Use shield clamps (2) to maximize contact with

cable shield for high-frequency bonding.

Use tie wraps (2) for stress relief.

I/O

Cable/Wires

Cascadin g S0

Safe-off Cables

Safety

Cable/Wire s

Install the Low-profile Connector Kit

P2

P4

40

40

42

44

39

39

41

40

0

Attribute 2090-K6CK-D44S0

Cascading cable connectors

Screw terminal wire size 0.2…0.75 mm

Recommended wire strip length 5 mm (0.2 in.) single conductor

Recommended torque

P5

P6

39

27

14

39

28

25

43

19

17

40

20

26

23

P3

P1

Mounting screw

Ter mi nal scr ew s

Clamp and cover screws

18

24

15

21

0

22

0

M8 sockets (female) S0 output connector

M8 pins (male) S0 input connector

2

(24…18 AWG)

0.4 N•m (3.5 lb•in)

0.2 N•m (2.1 lb•in)

0.4 N•m (3.5 lb•in)

P2

P4

40

42

39

39

41

40

0

40

44

P5

39

39

43

40

P3

P1

S0INS0

OUT

P6

27

28

19

20

23

24

21

22

14

25

17

26

18

15

0

0

ATTENTION: This connector kit contains electrostatic discharge (ESD) sensitive parts that can be

damaged if you do not follow ESD control procedures. If you are unfamiliar with ESD control

procedures, refer to Guarding Against Electrostatic Damage, publication 8000-4.5.2

applicable ESD protection handbook.

Rockwell Automation Publication 2090-IN043A-EN-P - December 2011

, or any other

Page 3

Low-profile Connector Kit for I/O and Cascading Safe Torque-off Signals 3

Motion-allowed Jumper Installation Example

for P5 and P6 Connectors (P6 is shown)

Applies to 2094-xx02x-M0x-S0

(safe torque-off) control modules. Kit includes

two identical jumpers. Install jumpers when

safe torque-off functionalit y is not used.

Pin numbering corresponds to the IOD (44 pin) connector. Pins 39 and 40 are given multiple

terminals to accommodate connections for each of the inputs.

P5 (safety) Terminal Block

Drive Pin Kit Pin Signal

IOD-19 P5-19 SS_IN_CH0

IOD-20 P5-20 SS_IN_CH1

IOD-21 P5-21 SS_OUT_CH0

IOD-22 P5-22 SS_OUT_CH1

IOD-23 P5-23 SS_IN_CH2

IOD-24 P5-24 SS_IN_CH3

IOD-27 P5-27 TEST_OUT_0

IOD-28 P5-28 TEST_OUT_1

P6 (safety) Terminal Block

IOD-14 P6-14 24VPWR

IOD-15 P6-15 24VCOM

IOD-17 P6-17 SPWR

IOD-18 P6-18 SCOM

IOD-25 P6-25 RESET_REF

IOD-26 P6-26 RESET_IN

Shield P6-0 Shield

Shield P6-0 Shield

P1 (I/O) Terminal Block

Drive Pin Kit Pin Signal

IOD-39 P1-39 24VPWR

IOD-41 P1-41 INPUT 1

IOD-40 P1-40 24VCOM

Shield P1-0 Shield

P2 (I/O) Terminal Block

IOD-40 P1-40 24VCOM

IOD-42 P1-42 INPUT 2

IOD-39 P1-39 24VP WR

P3 (I/O) Terminal Block

IOD-39 P1-39 24VP WR

IOD-43 P1-43 INPUT 3

IOD-40 P1-40 24VCOM

P4 (I/O) Terminal Block

IOD-40 P1-40 24VCOM

IOD-44 P1-44 INPUT 4

IOD-39 P1-39 24VP WR

Connector Data

P2

P4

40

42

39

39

41

40

0

40

44

39

39

43

40

P3

P1

S0INS0

P5

P6

27

28

19

20

23

24

21

22

OUT

14

25

17

26

18

15

0

0

14

25

17

26

18

15

0

0

Rockwell Automation Publication 2090-IN043A-EN-P - December 2011

Page 4

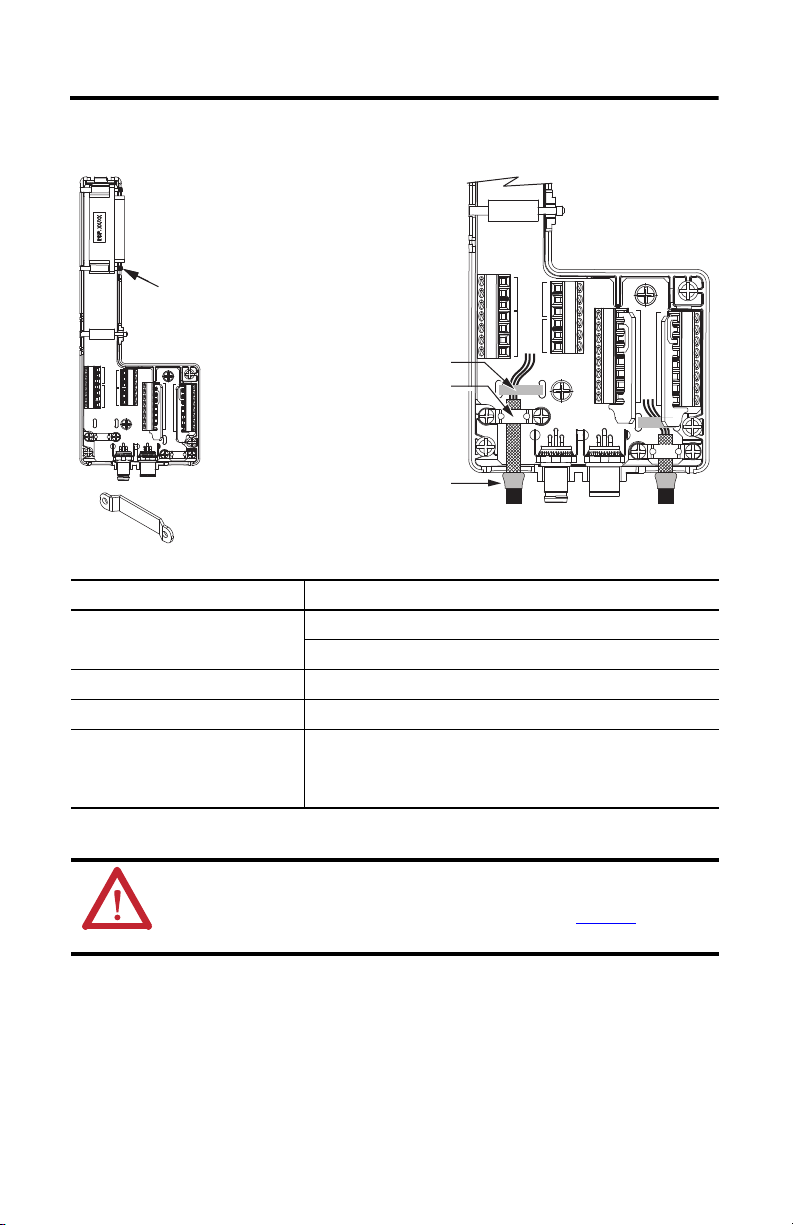

Cascading Safe Torque-off Signals

2090-CS0DSDS-AAxx

Cascading Safe Torque-off Cables

Input cable from previous

2094 power rail or

other cascading device.

Output cable to next

2094 power rail or

other cascading device.

2094-BCxx-Mxx-M

IAM Power Module

with

2094-xx02x-M0x-S0

Control Mo dule

2094-BMxx-M

AM Power Module

with

2094-xx02x-M0x-S0

Contro l Modules (2)

2094-K6CK-D44S0

Cascadin g Connector Kit s (3)

2094-K6CK-D15M

Feedback Connector Kits (3)

I/O Wiring

Input Connector

Output Connector

Safety Wiring

Bottom View

All right-angled cable connectors are keyed to exit left as shown. Cables loop back and cascade to

the next drive or other device. Route input wires through the I/O and safety wiring access holes.

Additional Resources

These documents contain additional information concerning related products from Rockwell

Automation.

Resource Description

Kinetix 6200 and Kinetix 6500 Safe Torque-off Servo

Drives Safety Reference Manual, publication 2094-RM002

Kinetix 6200 and Kinetix 6500 Modular Multi-axis Servo

Drive User Manual, publication 2094-UM002

Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

Information on wiring, configuring, and troubleshooting the safe

torque-off features of your Kinetix 6200 and Kinetix 6500 drives.

Information on installing, configuring, startup, troubleshooting, and

applications for your Kinetix 6200 and Kinetix 6500 servo drives.

Provides general guidelines for installing a Rockwell Automation

industrial system.

You can view or download publications at http://www.rockwellautomation.com/literature/

order paper copies of technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

Allen-Bradley, Kinetix, Rockwell Software, and Rockwell Automation are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Rockwell Automation Publication 2090-IN043A-EN-P - December 2011

Copyright © 2011 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

. To

Loading...

Loading...