Page 1

Installation Instructions

DeviceNet Serial Interface Module

Catalog Number 1799-DASCII

Top ic Pa ge

Important User Information 2

Environment and Enclosure 3

Prevent Electrostatic Discharge 3

About the Module 4

Install the Module 5

Set the Node Address 5

Mount the Board 6

Product Dimensions 7

Set Up the DeviceNet I/O Connections 7

DeviceNet Wiring 10

Serial Port DB9 Wiring 10

Set Software Parameters + 12

Configuring the Parameters 19

Set Up the Serial Link 19

Receive Serial Data from the ASCII Device 21

Produce Received-serial Data onto DeviceNet Network 23

Set Up and Use Pad Mode (parameters 11 and 12) 24

Set Up and Use the Swap Bytes Mode (parameter 13) 25

Serial Status Byte Description and Transmission 27

Consume Data Assembly Formats from DeviceNet Master 28

Transmit Serial Data to the ASCII Device 30

Status Indicators 32

Specifications 33

Page 2

2 DeviceNet Serial Interface Module

Important User Information

Solid state equipment has operational characteristics differing from those of electromechanical equipment.

Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls (Publication

SGI-1.1 available from your local Rockwell Automation sales office or online at

http://literature.rockwellautomation.com

equipment and hard-wired electromechanical devices. Because of this difference, and also because of the

wide variety of uses for solid state equipment, all persons responsible for applying this equipment must

satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages

resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many

variables and requirements associated with any particular installation, Rockwell Automation, Inc. cannot

assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits,

equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell

Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

) describes some important differences between solid state

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information about practices or circumstances that can cause an explosion in

a hazardous environment, which may lead to personal injury or death, property

damage, or economic loss.

Identifies information that is critical for successful application and understanding of

the product.

Identifies information about practices or circumstances that can lead to personal injury

or death, property damage, or economic loss. Attentions help you identify a hazard,

avoid a hazard and recognize the consequences.

Labels may be on or inside the equipment (for example, drive or motor) to alert people

that dangerous voltage may be present.

Labels may be on or inside the equipment (for example, drive or motor) to alert people

that surfaces may reach dangerous temperatures.

Publication 1799-IN012B-EN-P - July 2008

Page 3

Environment and Enclosure

DeviceNet Serial Interface Module 3

ATTENTION

This equipment is intended for use in a Pollution Degree 2 industrial environment, in

overvoltage Category II applications (as defined in IEC publication 60664-1), at altitudes

up to 2000 m (6562 ft.) without derating.

This equipment is considered Group 1, Class A industrial equipment according to

IEC/CISPR Publication 11. Without appropriate precautions, there may be potential

difficulties ensuring electromagnetic compatibility in other environments due to

conducted as well as radiated disturbance.

This equipment is supplied as open type equipment. It must be mounted within an

enclosure that is suitably designed for those specific environmental conditions that will

be present and appropriately designed to prevent personal injury resulting from

accessibility to live parts. The interior of the enclosure must be accessible only by the use

of a tool. The enclosure must have suitable flame-retardant properties to prevent or

minimize the spread of flame, complying with a flame spread rating of 5VA, V2, V1, V0 (or

equivalent) if nonmetallic. Subsequent sections of this publication may contain additional

information regarding specific enclosure type ratings that are required to comply with

certain product safety certifications.

In addition to this publication, see:

• Industrial Automation Wiring and Grounding Guidelines, Allen-Bradley publication

1770-4.1, for additional installation requirements.

• NEMA Standards publication 250 and IEC publication 60529, as applicable, for

explanations of the degrees of protection provided by different types of enclosure.

Prevent Electrostatic Discharge

ATTENTION

This equipment is sensitive to electrostatic discharge, which can cause internal damage

and affect normal operation. Follow these guidelines when you handle this equipment:

• Touch a grounded object to discharge potential static.

• Wear an approved grounding wriststrap.

• Do not touch connectors or pins on component boards.

• Do not touch circuit components inside the equipment.

• Use a static-safe workstation, if available.

• Store the equipment in appropriate static-safe packaging when not in use.

ATTENTION

To comply with the CE Low Voltage Directive (LVD), the DeviceNet network must be

powered from a source compliant with Safety Extra Low Voltage (SELV) or Protected

Extra Low Voltage (PELV).

Publication 1799-IN012B-EN-P - July 2008

Page 4

4 DeviceNet Serial Interface Module

ATTENTION

To comply with UL restrictions, the DeviceNet network must be powered from a source

compliant with a Class 2 or UL Listed/recognized power supply with isolated outputs

limited to 200 volt-amperes in each ungrounded output line. This equipment and its

power source must be mounted in a suitable enclosure with proper spacings maintained.

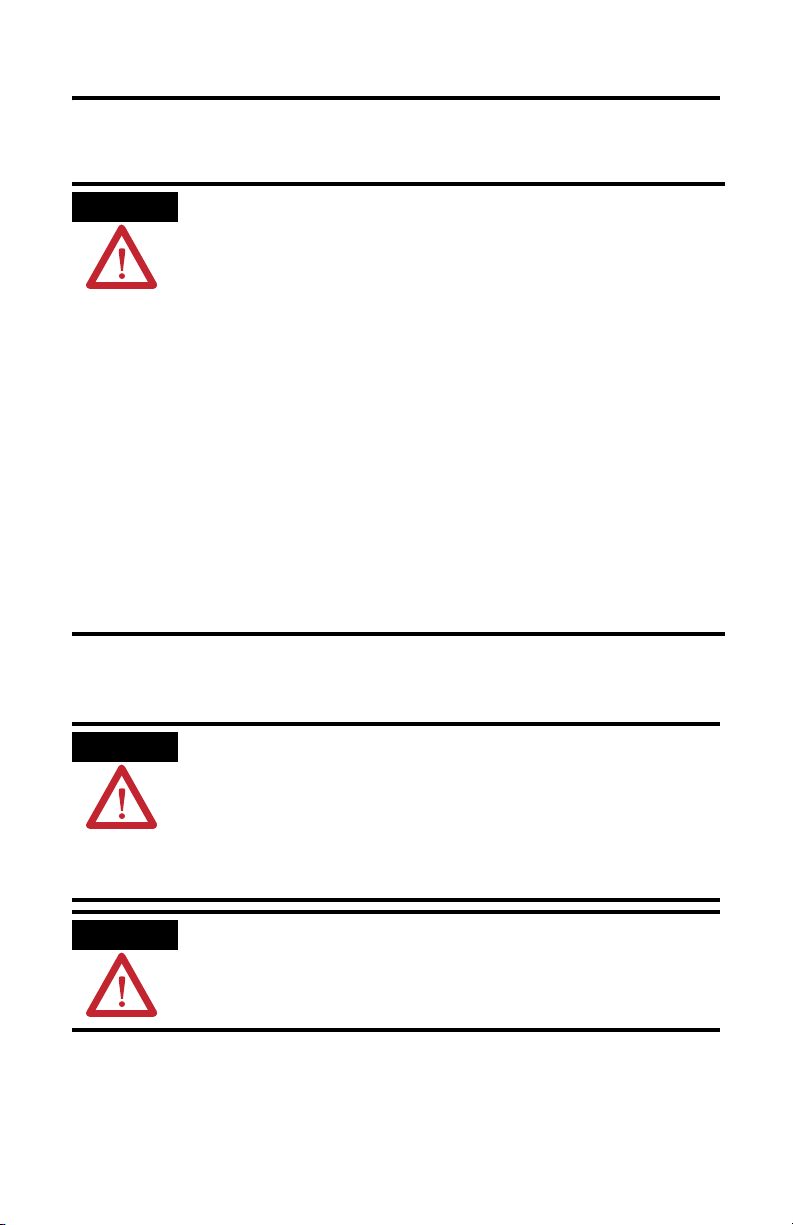

About the Module

The 1799-DASCII module provides DeviceNet system interoperability to one RS-232

or multiple RS-485 devices that do not have DeviceNet network capability. The

DeviceNet port (J1) provides power to the module and DeviceNet network

communication. The serial communication port (J2) is isolated from the DeviceNet

network and the module logic power.

J1

J2

44322

The 1799-DASCII module supports modes of data transfer of the serial buffer that

include the following:

• Polled I/O

• Change-of-State I/O

• Cyclic I/O

• Explicit Message

Publication 1799-IN012B-EN-P - July 2008

Page 5

DeviceNet Serial Interface Module 5

Mating connectors and mounting hardware are optional and must be ordered

separately. This table identifies these optional connectors and hardware.

Optional Connectors and Hardware

Option Catalog Number Supplier and Part Number

2 DIN-rail brackets (4 screws) 1799-BRKD N/A

5-position, open-style plug for DeviceNet

network (2 locking screws)

1799-DNETSCON

DeviceNet Buyer’s Guide at

http://www.odva.org

Your package contains:

• one 1799 I/O board.

• installation instructions.

Install the Module

Follow these steps to install the module.

1. Set the node address.

2. Mount the board by using brackets or mounting screws.

3. Connect serial communication cable (232 or 485) to DB9 connector.

4. Connect the DeviceNet network and DeviceNet power to the unit.

5. Configure the parameters.

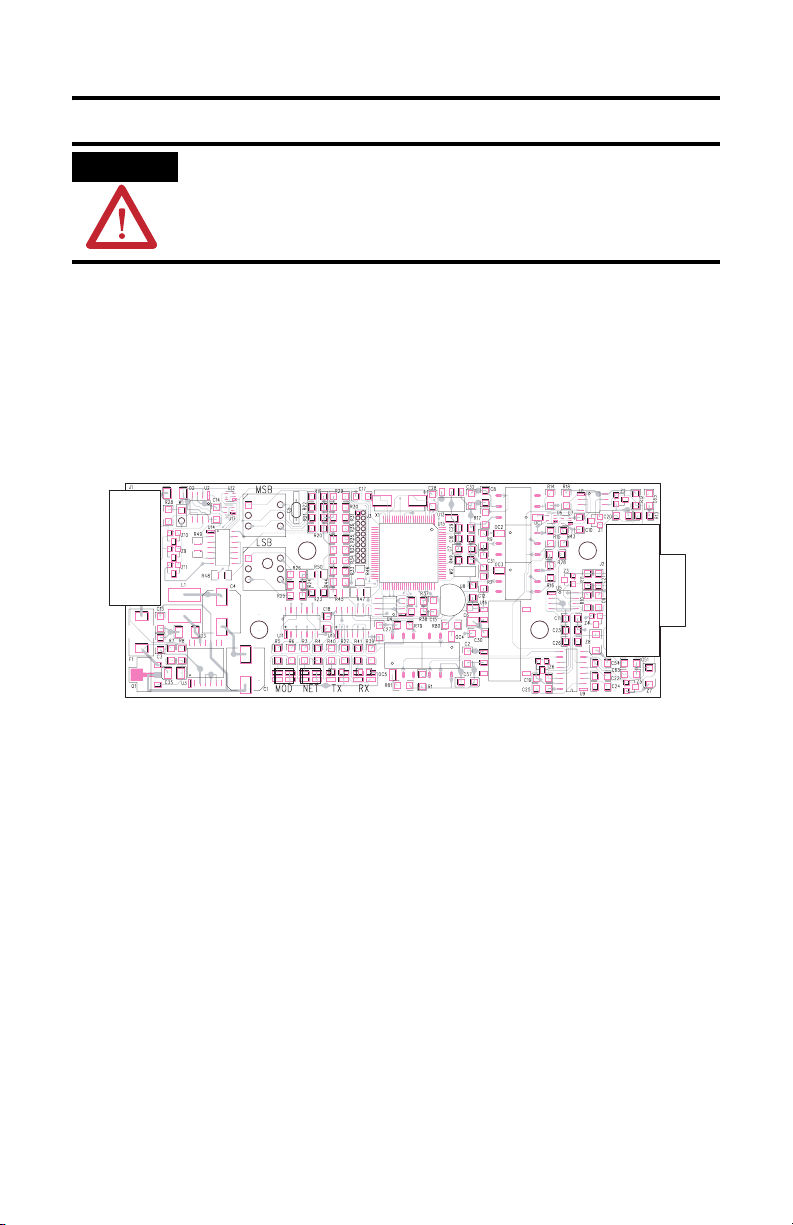

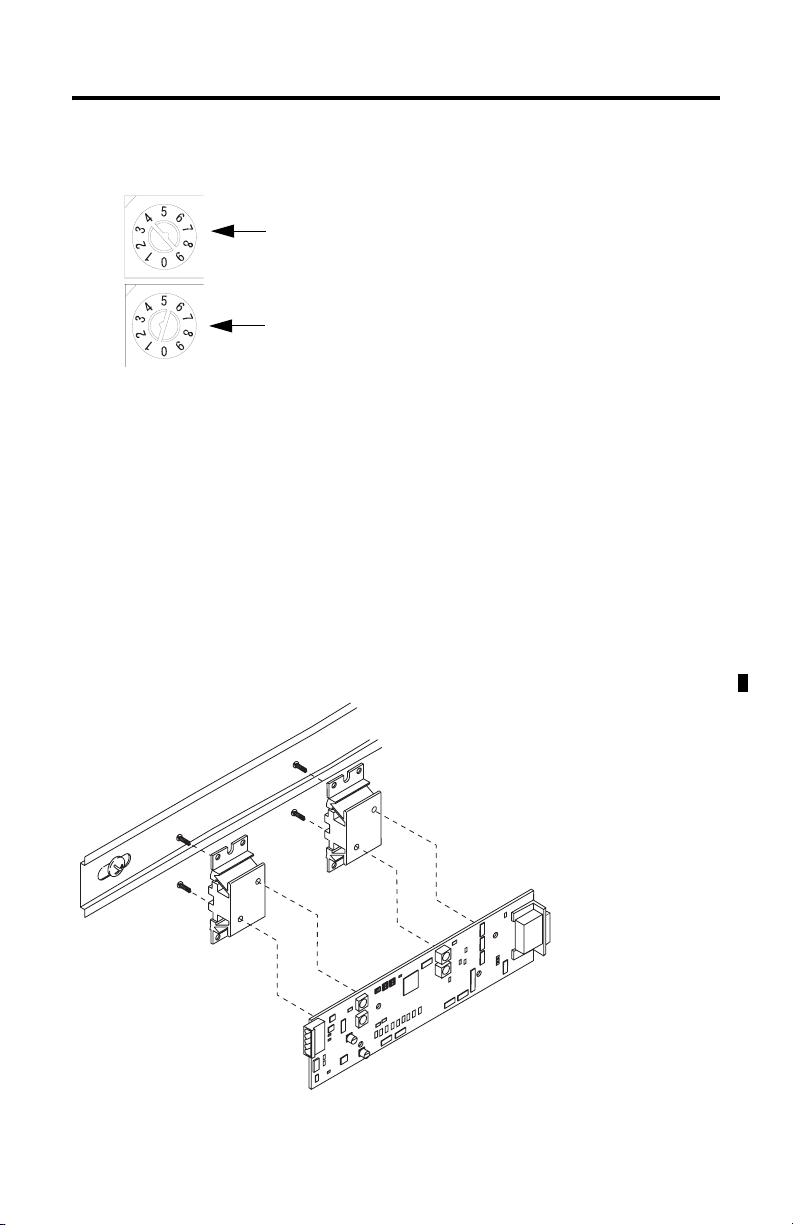

Set the Node Address

Valid node addresses are 00…63.

Set the node address by using the rotary switches or a DeviceNet configuration tool

such as RSNetWorx for DeviceNet software. The software has address control when

you set the switches to 64…99.

Each board is shipped with the node address set to 63 in the board’s memory;

rotary switches are shipped with the node address set to 99. The switches are near

the center of the board. The two switches are as follows:

• MSB (most significant bit)

• LSB (least significant bit)

Publication 1799-IN012B-EN-P - July 2008

Page 6

6 DeviceNet Serial Interface Module

To reset the node address, use a screwdriver to rotate the switches. Align the small

arrow on the switch with the number setting you wish to use.

MSB

The LSB and MSB switches are

shown in the 63 position.

LSB

42558

The rotary switches are read when you apply power to the board. The board uses

the last valid node address stored in board memory when you set the switches to

64…99. For example, the last setting in memory is 40. If you change the switch

setting to 68 and apply power to the board, the address defaults to 40.

The board is equipped with AutoBaud detect. With AutoBaud, the board detects

the communication rate on your DeviceNet network and automatically adjusts to

that rate. The board is shipped with AutoBaud enabled.

Mount the Board

You can mount the board to a DIN rail by using DIN-rail brackets (catalog

number 1799-BRKD) or to a mounting plate.

Publication 1799-IN012B-EN-P - July 2008

44623

Page 7

DeviceNet Serial Interface Module 7

You can also mount the board in an enclosure with pretapped holes to

accommodate M3 x 0.5 mm screws.

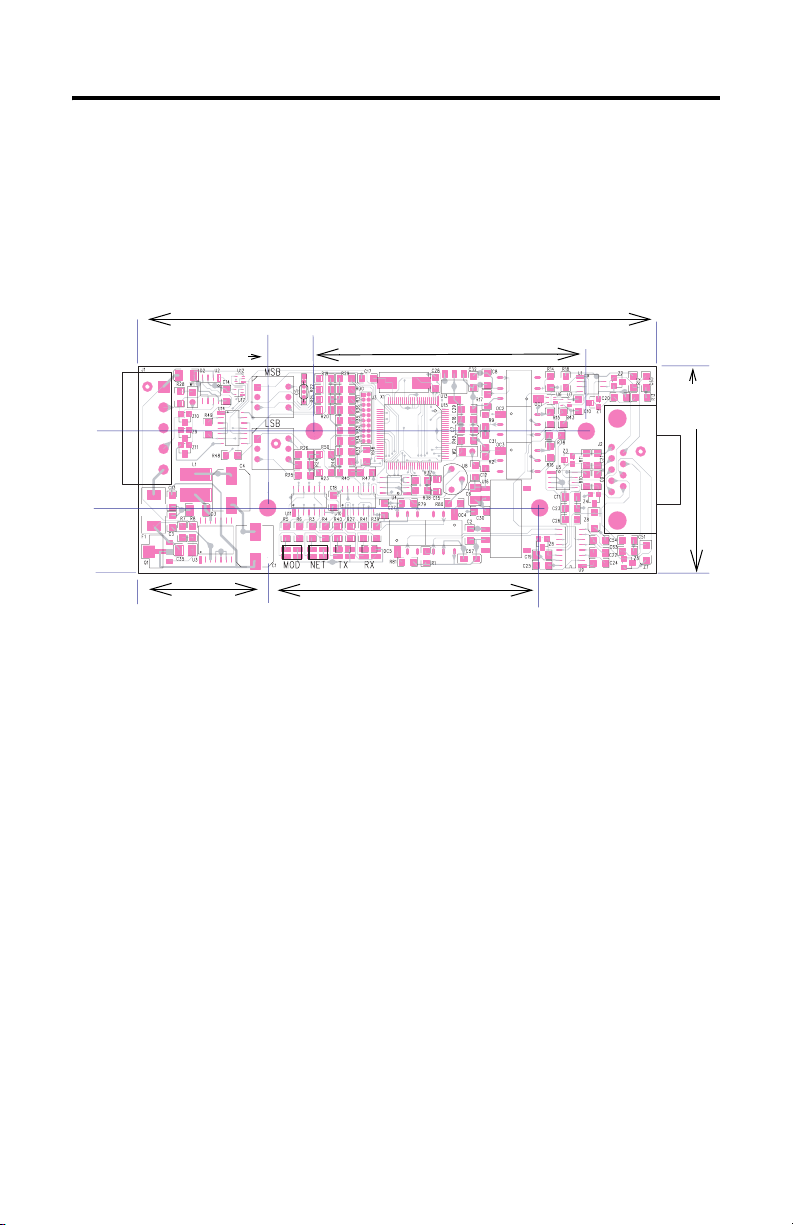

Product Dimensions

See the drawing that shows product dimensions.

Dimensions are in mm (in.).

mm

(in.)

18.8

(0.74)

16

(0.63)

11.43

(0.45)

127 (5.0)

67.3 (2.625)

50.8

(2.00)

31.75 (1.25)

67.3 (2.625)

44323

Set Up the DeviceNet I/O Connections

Set up the serial link before setting up the connection. To set up communication

with the network configuration tool, you typically need to know the connection

input and output sizes.

See Set Up the Serial Link on page 19 for instructions on setting up the serial

connection and receive and transmit sizes.

If you are using a network configuration tool with some type of scanner or

scanning software, the scanner must be directed to set up the connections. This

often requires some device information, such as input and output sizes. The input

and output sizes are computed from the transmit and receive sizes. These sizes are

defined in the parameter object of the device. The transmit size of the poll

connection is computed by adding 2 to the transmit buffer size on the 1799-DASCII

module. The transmit size for the change-of-state and cyclic connections are set to

0, because these connections do not initiate a transmission on the serial link. The

receive size of all three connections is computed by adding the number of option

bytes to the receive buffer size.

Publication 1799-IN012B-EN-P - July 2008

Page 8

8 DeviceNet Serial Interface Module

IMPORTANT

Remember to remap the data (if necessary) after setting the sizes, because

many configuration tools automatically unmap data when the connection sizes

change.

The 1799-DASCII module supports modes of data transfer of the serial buffer that

include the following:

• Polled I/O

• Change-of-state I/O

• Cyclic I/O

• Explicit Message

Polled I/O

The polled connection is the only way you can send serial output data to the I/O

and I/O devicce. The DeviceNet master initiates the polled connection transfer.

The master sends the 1799-DASCII module its serial output buffer with a record

number and length byte. The 1799-DASCII module monitors the record number for

a change. If the record number changes, the 1799-DASCII module transmits the

data buffer on its serial link. If the record number does not change, the device

does not transmit the data buffer.

After the device has transmitted its data out to the serial link, the 1799-DASCII

module takes any information that is stored in its current serial input buffer and

sends this data to the DeviceNet master. It sends all characters up to and including

the received delimiter, padding only if specified in the parameter object. When the

1799-DASCII module receives a new message with a delimiter or with an overflow

condition without a delimiter), the device increments the receive record, updates

the length byte, and copies the new information from the last receive delimiter into

the buffer. If an overflow occurs, the 1799-DASCII module indicates so in its

receive status bit. The receive status byte also reflects other errors in the device.

Cyclic I/O

The cyclic connection initiates a transmission every time the connection timer

expires. The cyclic connection can only send data from the 1799-DASCII module. If

you need to transmit on the I/O link, the polled connection is necessary. The

polled and cyclic connections can exist simultaneously. The manner in which

cyclic connection reports its data is the same as the polled connection. The cyclic

connections transmit buffer is the same as the polled connections transmit buffer,

so overflows and received delimiters act the same over any connection.

Publication 1799-IN012B-EN-P - July 2008

Page 9

DeviceNet Serial Interface Module 9

Change-of-State I/O

The change-of-state (COS) connection is the same as the cyclic connection except

that the COS connection also initiates a transfer on the receipt of the delimiter or an

overflow. The COS connection is mutually exclusive with the cyclic connection,

but can coexist with the polled connection. The COS connection operation is

useful in conserving bandwidth and provides the master with the most current data

as fast, or faster, than a poll connection. The COS connection automatically turns

on the COS mechanism when the connection is created.

Set Up the Connection Timer

The 1799-DASCII module sets the connection timer to the expected packet rate

(EPR), sometimes referred to as scan rate, value for the cyclic and polled

connection. It also uses this value in the connections to calculate the time the

device waits before signaling a timeout. If you are using a scanner or scanning

software, the EPR must be configured. The scanner configures the EPR in the

1799-DASCII module at the beginning of communication. Refer to the scanner

manual for how to configure the EPR.

IMPORTANT

The EPR can be set manually by performing a set (Service 10hex) on the

connection class (Class 5hex) attribute 9. The polled connection uses

instance 2. The COS and cyclic connections use instance 4. This must be done

after allocating the connection.

Serial Data Strings and the Scanner's I/O Rate

Serial gateways typically use more bandwidth on the DeviceNet bus than other

types of I/O devices. If long data strings are implemented and/or multiple devices

are on the DeviceNet network, make sure the scan rate is set accordingly.

Publication 1799-IN012B-EN-P - July 2008

Page 10

10 DeviceNet Serial Interface Module

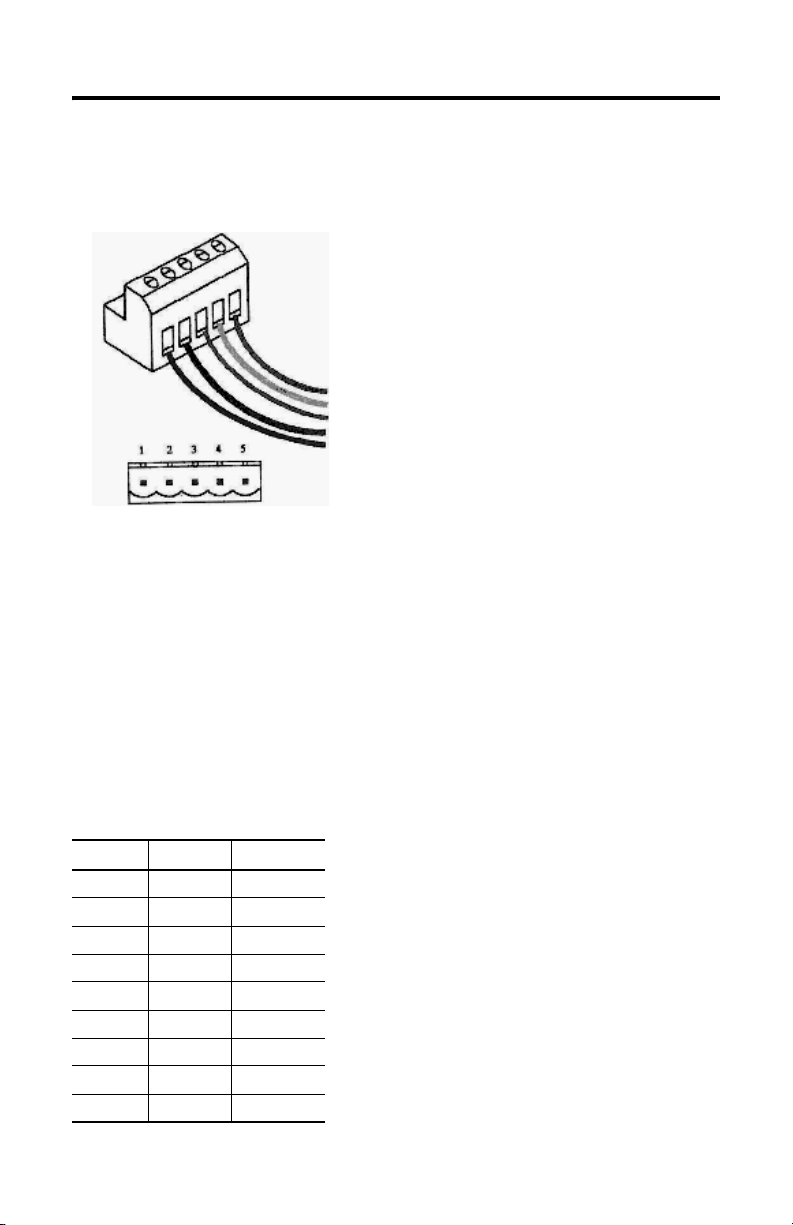

DeviceNet Wiring

DeviceNet wiring connections are made to the plug-in connector. The connector

plugs into connector J1 on the circuit board.

Network Connector (female contacts)

5 V+ Red

4 CAN_H White

3 Drain Bare

2 CAN_L Blue

1 V- Black

Network Connector (male contacts)

Serial Port DB9 Wiring

The module operates as an RS-232 or RS-485 device, depending on how the serial

communication lines are attached. For information about serial port connections,

see the DB9 9-Pin Connector Signal Assignments table and description. All signal

lines are isolated.

Serial Port Connection

The ASCII devices are connected to the 1799-DASCII module by using a three-wire

(or five-wire for RS232 hardware handshaking) communication cable.

DB9 9-Pin Connector Signal Assignments

Pin RS-232 RS-485

1 TRXD-

2RX

3TX

4

5 Common Common

6

7RTS

8CTS

9 TRXD+

Publication 1799-IN012B-EN-P - July 2008

Page 11

DeviceNet Serial Interface Module 11

RS-232 without Hardware Handshaking

Follow these steps to connect the RS-232 wiring without hardware handshaking.

1. Connect the receive wire to pin 2 (RXD).

2. Connect the transmit wire to pin 3 (TXD).

3. Connect common to pin 5 (common).

The channel automatically operates in RS-232 mode when these pins are

connected.

The RS-232 electrical interface uses a MAX232 transceiver or electrical equivalent.

IMPORTANT

All pins are active. Do not connect to other pins.

RS-232 with Hardware Handshaking

When implementing RTS/CTS handshaking, follow these steps to connect RS-232

wiring.

1. Connect receive to pin 2 (RXD).

2. Connect transmit to pin 3 (TXD).

3. Connect transmit/handshaking to pin 7 (RTS).

4. Connect receive/handshaking to pin 8 (CTS).

5. Connect common to pin 5 (Common).

The channel automatically operates in RS-232 mode when these pins are

connected.

IMPORTANT

All pins are active. Do not connect to other pins.

Publication 1799-IN012B-EN-P - July 2008

Page 12

12 DeviceNet Serial Interface Module

RS-485 Mode

To operate in RS-485 mode, follow these steps.

1. Connect TRXD+ to pin 9.

2. Connect TRXD- to pin 1.

3. Connect common to pin 5.

The channel automatically operates in RS-485 mode by connecting these

pins.

Set Software Parameters

The 1799-DASCII module is configured by using the EDS parameters as defined in

the EDS Parameters table.

EDS Parameters

Parameter # Access Description Parameter Choices Default

Setting

Serial Port Parameters

Serial port

character

framing

Serial port

comm speed

Serial port

handshaking

1 Get/Set Defines

number of

data bits, stop

bits, and

parity in data

character

frame.

2 Get/Set Defines baud

rate of serial

port.

3 Get/Set Enables

RTS/CTS

hardware

handshaking

on serial port.

0 = 7N2

1 = 7E1

2 = 7O1

3 = 8N1

4 = 8N2

0 = 9600

1 = 1200

2 = 2400

3 = 4800

0 = RTS/CTS disabled

1 = RTS/CTS enabled

5 = 8E1

6 = 8O1

7 = 7E2

8 = 7O2

4 = 19.2 k

5 = 38.4 k

6 = 57.6 k

7 = 115.2 k

8N1 3 USINT

9600

baud

Disabled 0 USINT

Publication 1799-IN012B-EN-P - July 2008

Default

Valu e

0USINT

Data

Ty pe

Page 13

DeviceNet Serial Interface Module 13

Parameter # Access Description Parameter Choices Default

Setting

Serial Port Receive from ASCII Device

Max

number of

receive

characters

Receive

Record

Start mode

Receive

start

delimiter

Receive

Record End

mode

Receive end

delimiter

4 Get/Set Max number of

characters the

module expects

to receive into

its ASCII port

from the serial

port.

5 Get/Set Determines

whether start

delimiter is

included with

the received

data.

6 Get/Set Character

identifies the

beginning of the

data string from

the ASCII device

when the length

is specified as 0.

7 Get/Set Selects whether

the End delimiter

is included with

the received

data.

8 Get/Set Character

identifies the

end of the data

string from the

ASCII device

when the length

is specified as 0.

1…250 20

characters

0 = No start delimiter

1 = Exclude start

delimiter

2 = Include start

delimiter

Any valid standard

ASCII character

(0…127 with 7-bit

data)

(0…255 with 8-bit

data)

0 = No end delimiter

1 = Exclude end

delimiter

2 = Include end

delimiter

Any valid standard

ASCII character

(0…127 with 7-bit

data)

(0…255 with 8-bit

data

No start

delimiter

Colon 0x3A USINT

Include

end

delimiter

Carriage

return

Default

Valu e

20 USINT

0USINT

2USINT

0D

hex

Data

Ty pe

USINT

Publication 1799-IN012B-EN-P - July 2008

Page 14

14 DeviceNet Serial Interface Module

Parameter # Access Description Parameter Choices Default

Setting

Receive

message

time-out

Receive

string data

type

Receive Pad

mode

Receive pad

character

Receive

Swap mode

9 Get/Set Number of ms to

wait for the next

character in the

string before

defining the

current message

complete and

marking it to

produce on the

DeviceNet

network.

10 Get/Set Defines the

format of the

data string sent

to the master.

11 Get/Set Indicates

whether to pad

the invalid data

region after the

delimiter with

the pad

character, or to

use variable

length ASCII

responses.

12 Get/Set The value to use

to pad the

invalid data

portion of the

poll response.

13 Get/Set If enabled, the

position of the

bytes in the

serial messages

is swapped

every 2, 3, or 4

bytes.

0 = Not active

1…65,635 =

milliseconds to wait f

0 = Array

1 = Short string

2 = String

0 = Pad mode

disabled

1 = Pad mode enabled

Any valid standard

ASCII character

0 = Disabled

1 = 16-bit Swap

Enabled

2 = 24-bit Swap

Enabled

3 = 32-bit Swap

Enabled

Not active 0 USINT

Short

string

Enabled 1 USINT

Null 0 USINT

Disabled 0 USINT

Default

Valu e

1USINT

Data

Ty pe

Publication 1799-IN012B-EN-P - July 2008

Page 15

DeviceNet Serial Interface Module 15

Parameter # Access Description Parameter Choices Default

Setting

DeviceNet

Handshake

mode

Gateway

produce

assembly

size

Receive

data string

Receive

data size

Receive

record

number

14 Get/Set If enabled,

master must

acknowledge it

is ready for next

new data before

1799-DASCII

module sends

the new data.

15 Get Total number of

I/O data bytes

that are sent to

the master from

the 1799-DASCII

module. This

should be the RX

size of your

scanner.

16 Get Serial data in the

receive buffer.

17 Get Number of

characters in the

Receive data

buffer.

18 Get/Set The Receive

Record Number

sent from the

master.

0 = Master/Slave

Handshake

1 = Auto Increment

(No handshake)

4…254 20 bytes of

Any data string Empty Null USINT

0…250 0 0 USINT

0…255 0 0 USINT

Auto

Increment

array data

and 4

header

bytes

Default

Valu e

1USINT

24 USINT

Data

Ty pe

Publication 1799-IN012B-EN-P - July 2008

Page 16

16 DeviceNet Serial Interface Module

Parameter # Access Description Parameter Choices Default

Setting

Serial Port Receive to ASCII Device

Max number

of transmit

characters

19 Get/Set Max number of

characters the

1799-DASCII

0…250 20 chars 20 USINT

module

expects to

transmit out its

serial port to

the serial

device.

Transmit End

Delimiter

mode

20 Get/Set Selects

whether the

End delimiter

is included

with the

0 = No end delimiter

1 = Exclude end

delimiter

2 = Include end

delimiter

Include 2 USINT

received data.

Transmit end

delimiter

character

21 Get/Set Character that

identifies the

end of the

transmit data

string from

DeviceNet to

the ASCII

Any valid standard

ASCII

character

(0…127 with 7-bit

data)

(0…255 with 8-bit

data)

Carriage

return

device when

the length is

specified as 0.

Default

Valu e

0D

hex

Data

Ty pe

USINT

Publication 1799-IN012B-EN-P - July 2008

Page 17

DeviceNet Serial Interface Module 17

Parameter # Access Description Parameter Choices Default

Setting

Gateway Consume on DeviceNet Network from Master

Consume

string data

type

Transmit

Swap mode

Gateway

consume

assembly

size

Parameter # Access Description Parameter

Serial Port Transmit/Explicit Messages from EDS Editor

Transmit

data string

Transmit

data length

22 Get/Set Defines the

format of the

data string

received from the

master.

23 Get/Set If enabled, the

position of the

bytes in the serial

messages is

swapped every 2

or 4 bytes.

24 Get Total number of

I/O data bytes

that are received

from the master.

This should be

the TX size of

your scanner.

25 Get/Set Serial data to be

sent to the serial

transmit buffer.

26 Get/Set Length of the

Transmit Serial

Data.

0 = Array

1 = Short string

2 = String

0 = Disabled

1 = 16-bit Swap

Enabled

2 = 24-bit Swap

Enabled

3 = 32-bit Swap

Enabled

4…254 20 bytes

Choices

ASCII block data Empty USINT

0…250 0 0 USINT

Short

string

Disabled 0 USINT

of array

data and

4 header

bytes

Default

Setting

Default

Valu e

1USINT

24 USINT

Default

Valu e

Data

Ty pe

Data

Ty pe

Publication 1799-IN012B-EN-P - July 2008

Page 18

18 DeviceNet Serial Interface Module

Parameter # Access Description Parameter

Choices

Transmit

record

number

Status 28 Get The Combined

Autobaud 29 Get/Set DeviceNet Baud

27 Get/Set The record

number of the

current transmit

data buffer.

status byte for

the Serial Port

Object. The

Receive Record

object and the

Transmit Record

object.

Rate

0…255 0 0 USINT

0 = fixed baud

rate

1 = Enable

Autobaud

Default

Setting

No status 0 USINT

Enable

Autobaud

Default

Valu e

1USINT

Data

Ty pe

Configuration Assembly

The 1799-DASCII module supports a configuration assembly as shown below. The

configuration assembly is accessed through the Assembly Object (Class 4) Instance

103. The configuration assembly data size is 22 bytes.

Byte Parameter Definition EDS Parameter

0 ASCII Serial Character Format 1

1 ASCII Serial Comm Speed 2

2 ASCII Hardware Handshake 3

3 ASCII Max Number of Receive Characters 4

4 ASCII Receive Record Start Mode 5

5 ASCII Receive Start Delimiter 6

6 ASCII Receive Record End Mode 7

7 ASCII Receive End Delimiter 8

8, 9 ASCII Receive Message Timeout 9

10 ASCII Receive String Data Type 10

11 ASCII Receive Pad Mode 11

12 ASCII Receive Pad Character 12

13 ASCII Receive Swap Mode 13

Publication 1799-IN012B-EN-P - July 2008

Page 19

DeviceNet Serial Interface Module 19

Byte Parameter Definition EDS Parameter

14 DeviceNet Handshake Mode 14

15 ASCII Receive Record Number 18

16 ASCII Max Number of Transmit Characters 19

17 ASCII Transmit End Delimiter Mode 20

18 ASCII Transmit End Delimiter Character 21

19 ASCII Consume String Data Type 22

20 ASCII Transmit Swap Mode 23

21 Autobaud 29

Configuring the Parameters

The 1799 I/O modules have parameters that are configurable through a DeviceNet

configuration tool, such as RSNetWorx for DeviceNet software. The DeviceNet

configuration tools require an electronic data sheet (EDS) for the 1799 I/O modules

to configure the module’s parameters. Find the EDS files at

http://www.rockwellautomation.com/support/

.

Set Up the Serial Link

Parameters 1, 2, and 3 let you define the serial link communication options.

See these parameters in the EDS Parameters table on page 12.

Publication 1799-IN012B-EN-P - July 2008

Page 20

20 DeviceNet Serial Interface Module

Parameter # Access Description Parameter Choices Default

Setting

Serial Port Parameters

1

Serial port

character

framing

Serial port

comm

speed

Serial port

handshaking

Get/Set Defines number

of data bits,

stop bits, and

parity in data

character

frame.

2

Get/Set Defines baud

rate of serial

port.

3

Get/Set Enables

RTS/CTS

hardware

handshaking on

serial port.

0 = 7N2

1 = 7E1

2 = 7O1

3 = 8N1

4 = 8N2

0 = 9600

1 = 1200

2 = 2400

3 = 4800

0 = RTS/CTS disabled

1 = RTS/CTS enabled

5 = 8E1

6 = 8O1

7 = 7E2

8 = 7O2

4 = 19.2 k

5 = 38.4 k

6 = 57.6 k

7 = 115.2 k

8N1 3 USINT

9600

baud

Disabled 0 USINT

Default

Valu e

0USINT

Data

Ty pe

Serial Character Framing (parameter 1)

This defines the number of data bits and stop bits used in each character's data

frame. It also defines the type of character frame parity used.

Serial Comm Speed (parameter 2)

This defines the baud rate options available on the serial port.

RTS/CTS Hardware Handshaking (parameter 3)

With an RS232 connection, the 1799-DASCII module supports hardware

handshaking for data exchange via RTS/CTS control lines on the DB9 connectors.

When used with an ASCII device that also supports hardware handshaking, the RTS

and CTS lines are used to meter data flow between the module and device and

prevent data buffer overflow. This option can be enabled and disabled via

software.

Publication 1799-IN012B-EN-P - July 2008

Page 21

DeviceNet Serial Interface Module 21

Receive Serial Data from the ASCII Device

The 1799-DASCII module receives a number of characters at its serial port and

transmits these to the DeviceNet master (produces on the DeviceNet network) via

the following:

• Polled I/O

• Change-of-state (COS)

• Cyclic

• Explicit Message

The received character string is captured when one of the following occurs:

• The specific number of bytes defined (max number of Receive characters) is received.

• The defined End-of-String Terminator character is detected.

• The specified non-zero time-out value (Message Time-out) is reached.

When any of these events occur, the 1799-DASCII module stores the received

message string in its internal buffer and transmits (produces) it onto the DeviceNet

network at the next opportunity.

Set Up the Receive-character Buffer Length (parameter 4)

The receive character buffer length is the number of characters that the

1799-DASCII module can receive from the serial device into its buffer at one time.

The length of the data string sent to the DeviceNet master is less than or equal to

this size, plus a 4-byte header.

When the 1799-DASCII module receives the character that fills the buffer, it sets the

nondelimited RECORD status flag and forces the data in the receive buffer to be

Publication 1799-IN012B-EN-P - July 2008

Page 22

22 DeviceNet Serial Interface Module

sent to the master. If the 1799-DASCII module receives a character while the buffer

is full, it internally generates an overflow error in the status byte.

The subsequent received characters are received into the buffer and handled as the

start of the next incoming message string.

ATTENTION

Incoming characters could be missed in the process of handling a string longer than the

defined max length.

This value can be set and retrieved by EDS parameter 4.

Set Up and Using Delimiter Operation (parameters 5, 6, 7, 8)

When receiving data strings from the serial device, the 1799-DASCII module can

take advantage of Start and Stop (End) delimiters. The Start Delimiter is the

start-of-string indicator and the End Delimiter is the end-of-string indicator. This lets

explicit control over which characters are sent to the master.

When Start Delimiter operation is selected, a character must be defined that

prompts the 1799-DASCII module to start storing the incoming data string. All

characters up to this Start Delimiter (after the previous message was completed) are

ignored. Once the Start Delimiter is received, all characters are stored until the End

Delimiter is received or the Max Receive Char Length is reached (or the RX

Time-out time is exceeded, if that option is selected). Once the End Delimiter is

reached, the data string is captured and prepared to send to the DeviceNet master.

If either delimiter is used, you can also elect whether to include those characters in

the string sent to the master. The Start Delimiter mode parameter is 5, the Delimiter

character is 6. The End Delimiter mode is parameter 7 and the End Delimiter

character is 8.

Rx Message Time-out (parameter 9)

The 1799-DASCII module has a receive time-out value configurable in 1 ms

increments. When this value is non-zero, the module's timeout counter resets on

the receipt of each new byte of data. If the timeout counter expires, the module

sets the nondelimited flag in the Status Byte and updates the Produce buffer with

the current data string.

Message Time-out Values

Value Time-out Action

0 Disabled

1…65,535 Time-out time in milliseconds (ms)

Publication 1799-IN012B-EN-P - July 2008

Page 23

DeviceNet Serial Interface Module 23

Produce Received-serial Data onto DeviceNet Network

Received-string Data Type (parameter 10)

The format of the data is Array, Short_String,

or String - sent to the DeviceNet master, as

shown below. Choose the one best suited for

your application and that modifies the format

of the data field.

The format of the data sent to the 1799-DASCII module is Array, Short_String, or

String. Choose the one best suited for your application and modifies the format of

the data field.

The Array data type has no length associated with it. It is equivalent to specifying a

length of zero by using a string or short_string data type.

The Short_String data type is the default data type of the device. This suffices for

most applications. The Short_String data type has only 1 byte of length, and the

rest of the data bytes are appended after the length.

The String data type has 2 bytes of length. The String data type is useful in talking

to programmable controllers or other devices that have a data file specifically made

to handle this data type. The length is Little Endian (low byte, high byte), and the

high order byte should be set to zero. The 1799-DASCII module only receives up

to 250 bytes of information, so the extra byte, although required for this data type,

is 0.

IMPORTANT

If the Short_String or String data type is used, the length is not sent to the

ASCII device.

Received-string Data DeviceNet Assembly Formats

The following tables define the format that the 1799-DASCII module produces on

DeviceNet network and sends to the DeviceNet master. In all cases, the size of the

assembly is equal to the length of the received ASCII string plus a 4-byte header.

Produce Data DeviceNet Format - Array String Type

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5-X (250 bytes max)

Transaction ID Status byte Reserved Reserved ASCII data (including optional <terminator>.

Publication 1799-IN012B-EN-P - July 2008

Page 24

24 DeviceNet Serial Interface Module

Produce Data DeviceNet Format - String_String Type

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5-X (250 bytes max)

Transaction ID Status byte Reserved Length ASCII data (including optional <terminator>.

Produce Data DeviceNet Format - String String Type

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5-X (250 bytes max)

Transaction ID Status byte Length (low byte) Length (high byte) ASCII data (including optional

<terminator>.

Set Up and Use Pad Mode (parameters 11 and 12)

Pad mode operation is the method used by

the 1799-DASCII module to add extra

characters to the end of its received data

string (after the delimiter character) from the

external I/O device before sending the string

to the DeviceNet scanner (master) as an I/O Response. The quantity added is such

that the data string returned to the scanner is a constant length, and that length is

the number specified in the Receive Character Length parameter, plus any header

options. The quantity of pad characters sent can vary from message to message,

depending on the size of the incoming string.

Pad Mode Selection (parameter 11)

Pad mode is included for compatibility with scanners that cannot receive variable

length I/O messages. For such scanners, you must turn on Pad mode (a value of 1).

Turning Pad mode on does not harm scanners that do support variable length

receive messages. The default value for Pad mode is off. If the scanner does

support variable I/O messaging lengths, the Pad mode option can be set to off (a

value of 0) to conserve some network bandwidth.

The selection of Pad mode is valid only for the DeviceNet message that the

1799-DASCII produces. It has no effect on DeviceNet messages sent from the

scanner to the 1799-DASCII module. This value can be set and retrieved by using

the standard set and get services on Use parameter 11 of Table 4.

Pad Mode Character (parameter 12)

You can specify the character that Pad mode uses to pad the received serial data.

This can be set to any valid I/O value (0…127 in 7-bit modes, 0…255 in 8-bit

modes). This value can be set and retrieved by using the standard set/get services

on parameter 12. See the EDS Parameters table starting on page 12.

Publication 1799-IN012B-EN-P - July 2008

Page 25

DeviceNet Serial Interface Module 25

Set Up and Use the Swap Bytes Mode (parameter 13)

This option may be helpful if the 1799-DASCII module is connected to a DeviceNet

scanner that organizes the data string characters into data type elements that are

larger than 1 byte each. An example is the Allen-Bradley SLC 500 module. In such

cases, the bytes of the data in the master's memory organization can be reversed

from the order in which they are sent or received on the DeviceNet network and

the serial link to the ASCII device. This may cause anomalies in some cases.

The message received or desired "ABCDEFGH" string may appear in memory as

"BADCFEHG" for 2-byte word organization, and "DCBAHGFE" for 4-byte word

organization.

Transmit Byte Swapping

By setting parameter 23, the bytes from the master are swapped by the

1799-DASCII module before transmitting the string to the ASCII device.

Rules for Usage

The rules for usage are the following:

• This feature is set for transmit and receive independently.

• Byte swapping works better if the string length is an even multiple of the byte-swap size.

• If a delimiter is received, then all characters up to and including the defined delimiter are sent to the

DeviceNet master.

If Pad mode = 1, then the 1799-DASCII module fills the Poll Response data

with the Pad Char up to the defined size.

If Pad mode = 0, then the 1799-DASCII module sends only the data up to

and including the delimiter.

• If no delimiter is received, then the 1799-DASCII module receives up to

Max_Number_of_Receive_Chars, and sends this string to the DeviceNet network with an overflow

error.

It continues to receive and send strings of size

Max_Number_of_Receive_Chars, along with the overflow error, until a

delimiter is received. This could continue indefinitely if the I/O device does

not transmit the specified delimiter.

Master-Slave Handshake versus Immediate Mode (parameter 14)

If DeviceNet Master-Slave Handshake mode is selected, the DeviceNet master can

inhibit the 1799-DASCII module from sending new ASCII data until the master is

ready to receive and process the new data.

Publication 1799-IN012B-EN-P - July 2008

Page 26

26 DeviceNet Serial Interface Module

In this mode the two required for the complete transaction are the following:

• A "New Data Available" flag is set by the 1799-DASCII module in the status byte. This informs the

master that the 1799-DASCII module has received a new data string and is waiting for the OK to send

it.

• The first byte of the message the master sends to the 1799-DASCII module is the RX ID Record. By

setting the value of this byte to the value of the new record number pending, it indicates to the

1799-DASCII module that the master is ready to receive the new data.

The master monitors this new data flag and when the master is ready to receive

new serial data, it sets a new number in the new record number byte of the next

poll command message. This applies only to data being sent from the 1799-DASCII

module to the master.

The operation proceeds as follows.

1. The 1799-DASCII module receives a new data string.

2. The 1799-DASCII module sets the New Data flag in the Status byte of its next

produce message.

3. The master sends out messages to the 1799-DASCII module in the normal

fashion. If the master is not ready to receive new data, the New Record Data

byte remains set.

4. When the master is ready to receive the new data string, it changes the New

Record Data byte to any value different than what it had been sending.

5. The 1799-DASCII module sends the new data upon receipt of a record from

the master in which the New Record Data byte has been changed.

6. If the 1799-DASCII module receives an updated New Record Data byte and

has no new data, it sets the Handshake Error bit in its Produce Status byte.

In Immediate mode, this handshaking is not active and the 1799-DASCII module

sends new data as soon as it is received from the ASCII device with the new

Transaction ID. It is the master's responsibility to be ready to accept and process

the new data string when it is presented.

Identify the Scanner I/O Receive Size (parameter 15)

The 1799-DASCII module automatically calculates the number of bytes it sends the

DeviceNet master. Its value is determined by a combination of the incoming data

and the options you selected. Parameter 15 is a read-only value that defines the size

of the DeviceNet message to be sent by the 1799-DASCII module to the master.

Publication 1799-IN012B-EN-P - July 2008

Page 27

DeviceNet Serial Interface Module 27

IMPORTANT

If you are using a scanner that must receive a constant message length, set its

Rx (receive) value to this number of bytes.

Explicit Messages to Receive the Serial Data String (parameters 16, 17, 18)

Parameters 16, 17, and 18 contain the status of the most-recent incoming serial data

string. You can use the data to read the device's ASCII data via the Explicit

Messaging technique.

Parameter 16 holds the most recent received data.

Parameter 17 defines the size, in bytes, of the DeviceNet message to be sent by the

1799-DASCII module to the master.

Parameter 18 holds the record number of the data string in parameter 16 if the

Header option is selected.

Serial Status Byte Description and Transmission

The Serial Status byte is an OR'd bitfield of a number of status and exceptions flags.

Serial Status Byte

Bit Exception Description

0Tx I/O

overflow

1Rx I/O

overflow

2 Rx parity error The message has a parity error. One or more of the characters has a parity error.

3 Rx overrun

error

4 Rx framing

error

The transmit queue has overflowed resulting in a loss of data. The transmit I/O is full

of data waiting to be transmitted. Some of the data added has been lost. When

space becomes available in the TX I/O, this bit resets.

The receive queue has overflowed resulting in a loss of data. The receive I/O is full

of data waiting to be processed. A new character arrives before the buffer is

emptied, thus setting the overflow bit. The data character is lost. When space

becomes available in the RX I/O, this bit resets.

A byte that has not been read has been overwritten by another received byte,

resulting in data loss.

When the stop bit of a received character is a logic zero, a framing error occurs.

Publication 1799-IN012B-EN-P - July 2008

Page 28

28 DeviceNet Serial Interface Module

Serial Status Byte

Bit Exception Description

5 Nondelimited

string

6 Handshake

error

7 New data flag This bit is used only when the Master-Slave Handshake option is active. When the

Concerning transmitting serial data to an ASCII device, the 1799-DASCII module

transmits character strings to the serial device that it has received from the

DeviceNet master via the following:

• Poll I/O

• Explicit Message

The character string is transmitted when either of the following conditions occurs in

the data within the DeviceNet message data field:

• The specific number of bytes defined (Transmit Character Buffer Length) is received.

• The defined End-of-String Terminator character is detected.

When either of these events occurs, the 1799-DASCII module stores the DeviceNet

string data into its internal buffer and transmits it out its serial port.

To transmit data to the serial device, the data must first be sent to the 1799-DASCII

module and then the 1799-DASCII module must send the data to the serial device.

The set-up for transmitting from the master to the 1799-DASCII module are

discussed first.

The current message has filled the buffer without a termination character, and is

being transmitted in total. This is not an error. It is caused by characters filling, but

not overflowing the receive buffer. This causes the 1799-DASCII module to transmit

the characters to the master.

This error occurs in Master-Slave Handshake mode. It indicates that the master has

requested a new data record from the 1799-DASCII module, but the 1799-DASCII

module has not indicated new data is available to be sent.

1799-DASCII module receives a new data string into its serial port, it sets this flag in

its DeviceNet response message. The bit remains set for 1 produce message after

the master requests the new data. It resets.

Consume Data Assembly Formats from DeviceNet Master

The assembly format options of the data to be sent from the DeviceNet master to

the 1799-DASCII module are shown below. The one selected depends on the

application. Refer to Transmit String Data Type Formats (parameter 22).

Consume Data DeviceNet Format - Array Data Type

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5-X (128 bytes max)

Rx ID Byte (Handshake

mode only)

Publication 1799-IN012B-EN-P - July 2008

Transaction ID

Byte

Reserved Reserved ASCII data (including optional

<terminator>.

Page 29

DeviceNet Serial Interface Module 29

Consume Data DeviceNet Format - Short_String Data Type

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5-X (128 bytes max)

Rx ID Byte (Handshake

mode only)

Transaction ID

Byte

Reserved Length ASCII data (including optional

<terminator>.

Consume Data DeviceNet Assembly Format - String Data Type

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5-X (max 128 bytes)

Rx ID Byte (Handshake

mode only)

Transaction ID

Byte

Length (low byte) Length (high byte) ASCII data (including optional

<terminator>.

Transmit String Data Type Formats (parameter 22)

This is the format of the data sent from the 1799-DASCII module - array,

short_string, or string - to the DeviceNet master. These are shown in the following

sections. Which one you pick depends on the application and modifies the format

of the data field. To change the string format, use parameter 22.

Set Up and Use the TX Byte Swap Mode (parameter 23)

This option is helpful if the 1799-DASCII module is connected to a DeviceNet

scanner that organizes the data string characters into data type elements that are

larger than 1 byte each. An example is an Allen-Bradley PLC, such as the SLC 500

controller. In such cases, the bytes of the data in the master's memory organization

can be reversed from the order in which they are sent or received on the DeviceNet

network and the serial link to the ASCII device. This may cause anomalies in some

cases.

Identify Scanner I/O Transmit Size (parameter 24)

The 1799-DASCII module automatically calculates the number of bytes it expects

from the DeviceNet master. Its value is determined by a combination of the

incoming data and the options selected. Parameter 24 is a read-only value that

defines the size of the DeviceNet message sent to the 1799-DASCII module from the

master.

IMPORTANT

Set the scanner’s produce size value to this number of bytes.

Publication 1799-IN012B-EN-P - July 2008

Page 30

30 DeviceNet Serial Interface Module

Transmit Serial Data to the ASCII Device

Read this section for information about transmitting serial data to the ASCII device.

Set Up the Transmit-character Buffer Length (parameter 19)

The Transmit-character buffer length is the number of characters that the

1799-DASCII module can receive in its transmit buffer from the DeviceNet system.

This size contributes to the I/O's Consume Size. This size can be found in the

Parameter object.

Set Up and Use the Transmit Delimiter (parameters 20 and 21)

The transmit delimiter is an end-of-string character that is used by the 1799-DASCII

module to determine how many bytes to transmit over the serial link to the

1799-DASCII device. This transmit delimiter is used if the Transmit Buffer Length

equals 0. If the buffer length is not 0, the 1799-DASCII module ignores the transmit

delimiter.

The 1799-DASCII module transmits up to and including the delimiter when the

above condition is met. The transmit delimiter can be set to any valid I/O character

that can be received over the link (parameter 21). Be careful not to set the

delimiter to a value outside of the valid range for the number of data bits. (Note

that a data bit size setting of 7 lets a delimiter range of 0…127 dec., 00…7Fhex). If

the delimiter is not valid, or the delimiter is never received, the device updates the

output buffer on detection of a buffer filled condition. These values can be set and

retrieved by using the standard set/get services in the Transmit Record Class 0x71.

Publication 1799-IN012B-EN-P - July 2008

Page 31

DeviceNet Serial Interface Module 31

Transmitting Serial Data

The length of the string set determines the use of a delimiter in transmitting data to

a serial device from the 1799-DASCII module.

If the string length is zero, or the data type is type Array, the following happens:

• The 1799-DASCII module receives data sent from the DeviceNet master and uses the End Delimiter to

determine how much data is sent to the serial device. The 1799-DASCII module computes the length

and stores this as the new length in the string attribute. (This does not appear if the data type is array.

You see the string truncated and the length is in the background.)

• If a delimiter is contained within the string, all characters in the data field up to and including the

defined delimiter are stored.

• If no delimiter is contained within the string, the 1799-DASCII module stores the data in the data field

received.

If the string length > 0 or the data type is String or Short_String, the following

happens:

• The 1799-DASCII receives data sent from the DeviceNet master, ignoring any embedded terminator. It

stores the number of characters defined in Max_Number_of_Transmit_Chars, or the total sent by the

master, whichever is less.

Now, the 1799-DASCII sends the data immediately if attribute X is set to 1. You can

cause this data to be transmitted by incrementing the record counter.

The following identifies which parameters transmit serial data to the ASCII device:

• Explicit Messages to Transmit Serial Data String

• Parameters 26, 27, and 28 can be used to set up the serial data string and send it to the ASCII device

via the Explicit Messaging technique

• Parameter 26 holds the data to be sent

• Parameter 27 defines the size, in bytes, of the DeviceNet message to be sent from the 1799-DASCII

module to the device

• Parameter 28 holds the record number of the data string in parameter 24 if the Header option is

selected. Changing the record causes the data in parameter 24 to be transmitted immediately from the

master to the 1799-DASCII module

Publication 1799-IN012B-EN-P - July 2008

Page 32

32 DeviceNet Serial Interface Module

Status Indicators

The 1799-DASCII module has two indicators that provide visual status information

about the module and the DeviceNet network. Refer to the Module Status and

Network Status tables to interpret the status indications.

Module Status Indicator (labeled MS)

Indicator Module Status Description

Off No power There is no power through the DeviceNet network.

Solid green Device operational 1799-DASCII module is operating normally.

Flashing green Device in standby 1799-DASCII module needs commissioning (for

Flashing red Minor fault Recoverable fault.

Solid red Unrecoverable fault Replace 1799-DASCII module.

Flashing red/green Device self-testing 1799-DASCII is in self-test mode.

Network Status Indicator (labeled NS)

Indicator Network Status Description

Off No power or not online 1799-DASCII module has no power, has not completed the

Solid green Online, connected 1799-DASCII module operating correctly.

Flashing green Online, not connected 1799-DASCII module is online but is not allocated to a master.

Flashing red Connection time-out One or more I/O connections are timed out.

Solid red Critical link failure 1799-DASCII module detected an error that makes it

example, attempting autobaud).

Dup_MAC_ID test, or needs commissioning.

incapable of communicating on the link (bus off or duplicate

MAC ID).

Serial Port Indicator (labeled TX and RX)

Indicator Serial Port Status Description

Off No data communication active 1799-DASCII module has no active data communication on

the data line.

On Data communication active 1799-DASCII module has active data communication on

The 1799-DASCII module has two RS-232 activity indicators: one for transmit (TX)

and one for receive (RX). Each of these indicators illuminates when data

communication is active on the respective data lines.

Publication 1799-IN012B-EN-P - July 2008

the data line.

Page 33

DeviceNet Serial Interface Module 33

Specifications

DeviceNet Serial Interface Module- 1799-DASCII

Attribute Value

Description Communication gateway between a serial-capable device over an RS-232 or RS-485

Device type Rockwell Miscellaneous, 115, 0x73 hex

Product code 220, 0xDChex

Vendor ID Allen-Bradley/Rockwell Automation

Device profile Identity Object 0x01

Product revision 1.01

DeviceNet Baud rate: autobaud operation and software selection

Serial port RS-232 and RS-485

Indicators DeviceNet network:

Isolation voltage 50V (continuous), Basic Insulation Type

Power 1.8 W: 75 mA @ 24V DC max

Enclosure type rating None (open-style)

Weight, approx. 34.6 g (1.22 oz)

interface and a DeviceNet network

Message Router Object 0x02

DeviceNet Object 0x03

Assembly Object 0x04

Connection Object 0x05

Parameter Object 0x0F

Acknowledge Handler 0x2B

Serial I/O Object 112, 0x70 (vendor-specific)

Transmit Serial Object 113, 0x71 (vendor-specific)

Receive Serial Object 114, 0x72 (vendor-specific)

Address selection: address number 0…63 with rotary switches

DeviceNet connection: 5-pin open connector

Baud rate: 1200, 2400, 4800, 9600, 19.2 k, 38.4 k, 57.6 k, 115.2 k

Parity: odd/even/none

Connector: - pin D-shell, 9-pin male D-shell

Module status - red/green

Network status - red/green

Serial port:

Transmit active - green

Receive active - green

Type tested at 1500V DC for 60 s, DeviceNet network to Serial, and Logic to

Communication ports

Publication 1799-IN012B-EN-P - July 2008

Page 34

34 DeviceNet Serial Interface Module

Environmental Specifications

Attribute Value

Temperature, operating IEC 60068-2-1 (Test Ad, Operating Cold),

IEC 60068-2-2 (Test Bd, Operating Dry Heat),

IEC 60068-2-14 (Test Nb, Operating Thermal Shock):

-20…70 °C (-4…158 °F)

Temperature, nonoperating IEC 60068-2-1 (Test Ab, Unpackaged Nonoperating Cold),

IEC 60068-2-2 (Test Bb, U npackaged Nonoperating Dry Heat),

IEC 60068-2-14 (Test Na, Unpackaged Nonoperating Thermal Shock):

-40…85 °C (-40…185 °F)

Relative humidity IEC 60068-2-30 (Test Db, Unpackaged Nonoperating Damp Heat):

5…95% noncondensing

Shock, operating IEC 60068-2-27 (Test Ea, Unpackaged Shock)

30 g peak acceleration

Shock, nonoperating IEC 60068-2-27 (Test Ea, Unpackaged Shock)

Vibration IEC 60068-2-6 (Test Fc, Operating)

ESD immunity IEC 61000-4-2:

Radiated RF immunity IEC 61000-4-3:

EFT/B immunity IEC 61000-4-4:

Surge transient immunity IEC 61000-4-5:

Conducted RF immunity IEC 61000-4-6:

Emissions CISPR 11

Wire Size

Wiring category

(1)

Use this Conductor Category information for planning conductor routing. Refer to Industrial Automation Wiring and

Grounding Guidelines, publication 1770-4.1.

(1)

50 g peak acceleration

5 g @ 10…500 Hz

8 kV indirect contact discharges

10V/m with 1 kHz sine-wave 80%AM from 30…2000 MHz

10V/m with 200 Hz 50% Pulse 100%AM at 900 MHz

10V/m with 200 Hz 50% Pulse 100%AM at 1890 MHz

3V/m with 1 kHz sine-wave 80%AM from 2000…2700 MHz

2 kV at 5 kHz on communication ports

+

2 kV line-earth (CM) on shielded ports

+

10V rms with 1 kHz sine-wave 80% AM from 150 kHz…80 MHz

Group 1, Class A

2

0.25...2.5 mm

(22...14 AWG) solid or stranded shielded copper wire

rated at 80 °C (176 °F) or higher. Refer to DeviceNet Media Design And

Installation Guide, publication DNET-UM072.

2 - on communication ports

Publication 1799-IN012B-EN-P - July 2008

Page 35

DeviceNet Serial Interface Module 35

Certifications

(1)

Certification

c-UL-us UL Recognized Component Industrial Control Equipment, certified for US and Canada.

CE European Union 2004/108/EC EMC Directive, compliant with:

C-Tick Australian Radiocommunications Act compliant with AS/NZS

ODVA ODVA conformance tested to DeviceNet specifications

(1)

See the Product Certification link at http:// www.ab.com for Declaration of Conformity, Certificates, and other certification

details.

Valu e

See UL File E65584.

EN 61326-1; Meas./Control/Lab., Industrial Requirements

EN 61000-6-2; Industrial Immunity

EN 61000-6-4; Industrial Emissions

EN 61131-2; Programmable Controllers (Clause 8, Zone A & B)

CISPR 11, Industrial Emissions

Publication 1799-IN012B-EN-P - July 2008

Page 36

Rockwell Automation Support

Rockwell Automation provides technical information on the Web to assist you in

using its products. At http://support.rockwellautomation.com

technical manuals, a knowledge base of FAQs, technical and application notes,

sample code and links to software service packs, and a MySupport feature that you

can customize to make the best use of these tools.

For an additional level of technical phone support for installation, configuration and

troubleshooting, we offer TechConnect support programs. For more information,

contact your local distributor or Rockwell Automation representative, or visit

http://support.rockwellautomation.com

.

Installation Assistance

If you experience a problem within the first 24 hours of installation, please review

the information that's contained in this manual. You can also contact a special

Customer Support number for initial help in getting your product up and running.

, you can find

United States 1.440.646.3434

Monday – Friday, 8 a.m. – 5 p.m. EST

Outside United

States

Please contact your local Rockwell Automation representative for any

technical support issues.

New Product Satisfaction Return

Rockwell Automation tests all of its products to ensure that they are fully

operational when shipped from the manufacturing facility. However, if your

product is not functioning and needs to be returned, follow these procedures.

United States Contact your distributor. You must provide a Customer Support case number

Outside United

States

Allen-Bradley, Rockwell Automation, RSNetWorx for DeviceNet, SLC 500, and TechConnect are trademarks of Rockwell

Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

(see phone number above to obtain one) to your distributor in order to

complete the return process.

Please contact your local Rockwell Automation representative for the return

procedure.

Publication 1799-IN012B-EN-P - July 2008 PN-29563

Supersedes Publication 1799-IN012A-EN-P - November 2007 Copyright © 2008 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

Loading...

Loading...