Page 1

Installation Instructions

16 Input/16 Output Digital and 2 Input/2 Output

Analog Embedded I/O Boards

Catalog Numbers 1799-D16U16VAGL,

1799-D16U16BAGL

Topic Page

Important User Information 2

Environment and Enclosure 3

About the Board 3

Install the Board 4

Set the Node Address 5

Mount the Board 6

Connect the Board 8

Configure the Parameters 17

Calibrate Your Analog Inputs and Outputs 19

Troubleshoot the I/O Boards 26

Specifications 28

About This Publication

This publication provides information on the selection, installation, configuring and

troubleshooting the 36-point I/O boards.

Publication 1799-IN011A-EN-P - February 2007

Page 2

2 16 Input/16 Output Digital and 2 Input/2 Output Analog Embedded I/O Boards

Important User Information

Solid state equipment has operational characteristics differing from those of electromechanical equipment.

Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls (Publication

SGI-1.1 available from your local Rockwell Automation sales office or online at

http://www.literature.rockwellautomation.com

equipment and hard-wired electromechanical devices. Because of this difference, and also because of the

wide variety of uses for solid state equipment, all persons responsible for applying this equipment must

satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages

resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many

variables and requirements associated with any particular installation, Rockwell Automation, Inc. cannot

assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits,

equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell

Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

) describes some important differences between solid state

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information about practices or circumstances that can cause an explosion in

a hazardous environment, which may lead to personal injury or death, property

damage, or economic loss.

Identifies information that is critical for successful application and understanding of

the product.

Identifies information about practices or circumstances that can lead to personal injury

or death, property damage, or economic loss. Attentions help you identify a hazard,

avoid a hazard and recognize the consequences.

Labels may be on or inside the equipment (for example, drive or motor) to alert people

that dangerous voltage may be present.

Labels may be on or inside the equipment (for example, drive or motor) to alert people

that surfaces may reach dangerous temperatures.

Publication 1799-IN011A-EN-P - February 2007

Page 3

16 Input/16 Output Digital and 2 Input/2 Output Analog Embedded I/O Boards 3

Environment and Enclosure

ATTENTION

This equipment is intended for use in a Pollution Degree 2 industrial environment, in

overvoltage Category II applications (as defined in IEC publication 60664-1), at altitudes

up to 2000 m (6562 ft.) without derating.

This equipment is considered Group 1, Class A industrial equipment according to

IEC/CISPR Publication 11. Without appropriate precautions, there may be potential

difficulties ensuring electromagnetic compatibility in other environments due to

conducted as well as radiated disturbance.

This equipment is supplied as open type equipment. It must be mounted within an

enclosure that is suitably designed for those specific environmental conditions that will

be present and appropriately designed to prevent personal injury resulting from

accessibility to live parts. The interior of the enclosure must be accessible only by the use

of a tool. The enclosure must have suitable flame-retardant properties to prevent or

minimize the spread of flame, complying with a flame spread rating of 5VA, V2, V1, V0 (or

equivalent) if nonmetallic. Subsequent sections of this publication may contain additional

information regarding specific enclosure type ratings that are required to comply with

certain product safety certifications.

In addition to this publication, see:

• Industrial Automation Wiring and Grounding Guidelines, Allen-Bradley publication

1770-4.1, for additional installation requirements.

• NEMA Standards publication 250 and IEC publication 60529, as applicable, for

explanations of the degrees of protection provided by different types of enclosure.

About the Board

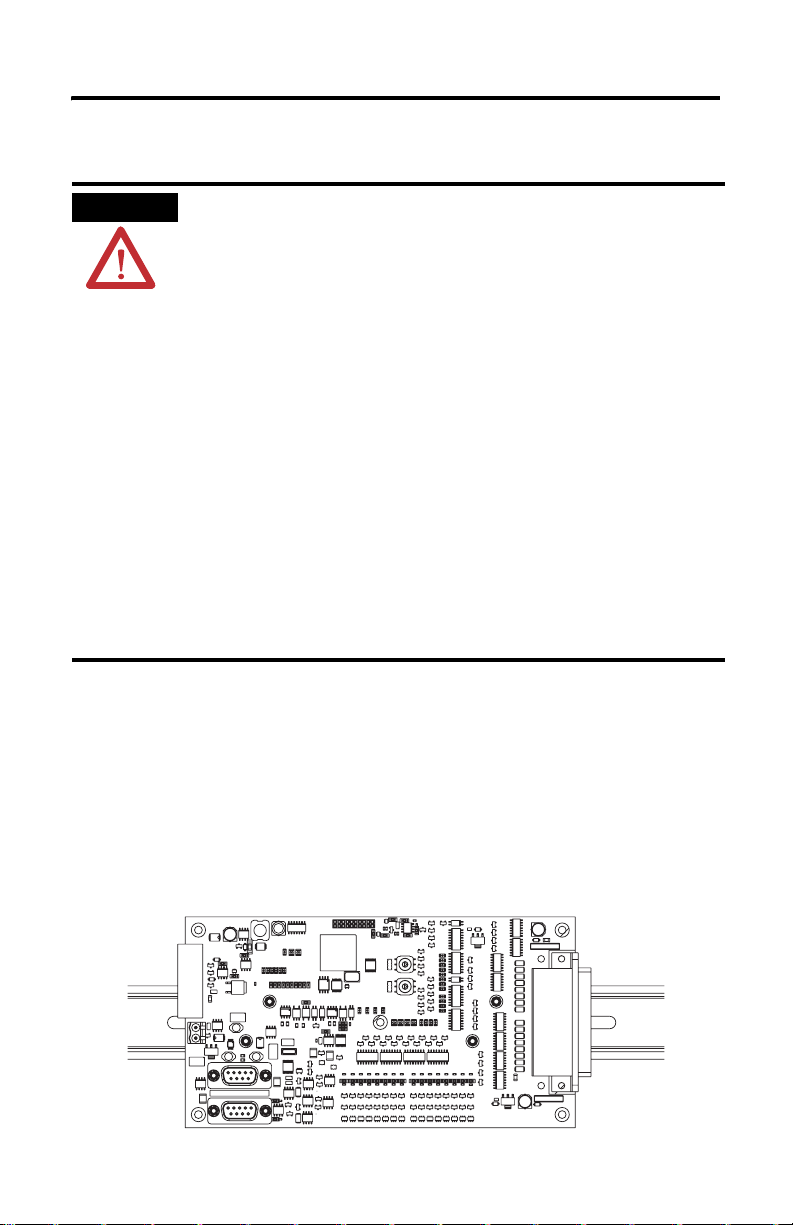

The board is a 36-point I/O board that communicates via a DeviceNet network.

This board has 16 digital inputs, 16 digital outputs, 2 analog inputs, and 2 analog outputs.

Inputs are 24V dc sourcing or sinking. Digital outputs are self-protected 24V dc sourcing

(1799-D16U16BAGL) or sinking (1799-D16U16VAGL). Analog outputs support both

current and voltage outputs.

42557

Publication 1799-IN011A-EN-P - February 2007

Page 4

4 16 Input/16 Output Digital and 2 Input/2 Output Analog Embedded I/O Boards

Parts List

Your package contains:

• one 1799 I/O board.

• installation instructions.

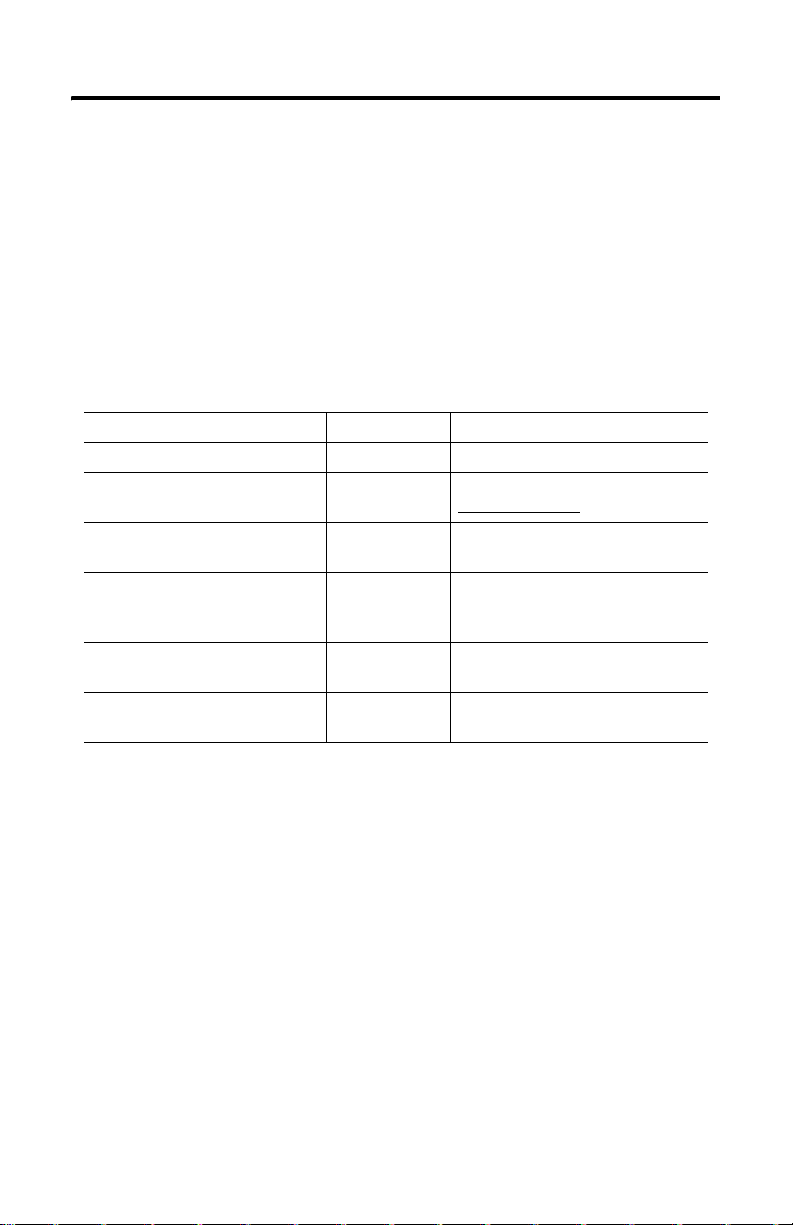

Optional Hardware

All mating connectors and mounting hardware must be ordered separately. The following

table identifies the different connector and hardware options.

Option Catalog Number Third Party Supplier & Part Number

2 DIN rail brackets (4 screws) 1799-BRKD N/A

5-position, open-style plug for

DeviceNet network (2 locking screws)

50-pin, D-sub I/O mating connector solder cup

50-pin, D-sub I/O mating connector header and crimp pins

9-pin, D-sub I/O mating connector solder cup

9-pin, D-sub I/O mating connector header and crimp pins

1799-DNETSCON DeviceNet Buyer’s Guide at

http://www.odva.org

1799-DSSCON Amphenol Corp. - 777DF-D50P

ITT Cannon - DDM50PK127

1799-DSCCON Tyco Electronics - 205212-1 (header)

Tyco Electronics - 66506-4 (pins)

EBY Co. - DR50-P02-0S (header only)

1799-DSS9CON Tyco Electronics - 747904-5

1799-DSC9CON Tyco Electronics - 6-66506-1

Install the Board

To install the board do the following:

• Set the node address.

• Mount the board (brackets or mounting screws).

• Connect the board (DeviceNet network, I/O).

• Connect the board (power).

• Communicate with your board.

• Configure the parameters.

More detailed information about each of these steps is included in the following procedures.

Publication 1799-IN011A-EN-P - February 2007

Page 5

16 Input/16 Output Digital and 2 Input/2 Output Analog Embedded I/O Boards 5

ATTENTION

Prevent Electrostatic Discharge

This equipment is sensitive to electrostatic discharge, which can cause internal damage

and affect normal operation. Follow these guidelines when you handle this equipment:

• Touch a grounded object to discharge potential static.

• Wear an approved grounding wriststrap.

• Do not touch connectors or pins on component boards.

• Do not touch circuit components inside the equipment.

• Use a static-safe workstation, if available.

• Store the equipment in appropriate static-safe packaging when not in use.

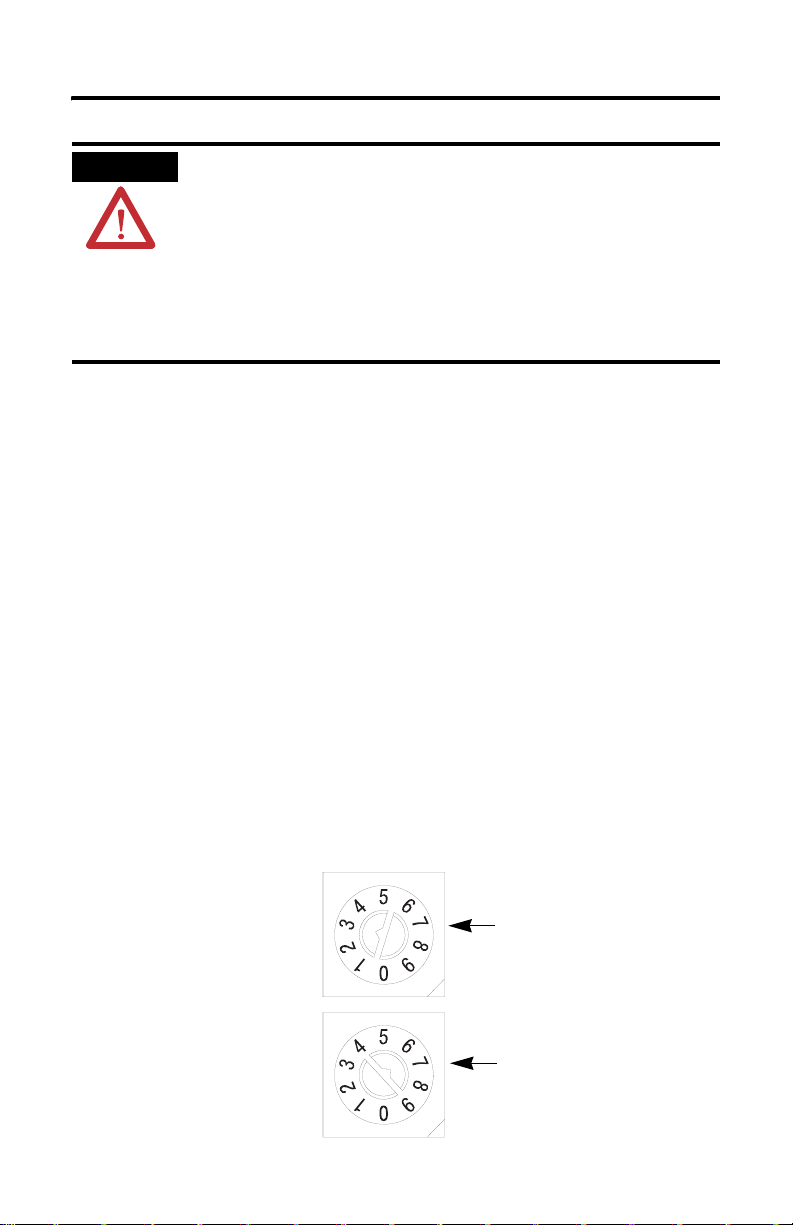

Set the Node Address

Valid node addresses are 00…63.

Set the node address using the rotary switches or a DeviceNet configuration tool such as

RSNetWorx for DeviceNet software. Setting the switches between 64 and 99 lets the software

have address control.

Each board is shipped with the node address set to 63 in the board’s memory. The rotary

switches are set for position 99 at shipment. The switches are located near the center of the

board. The two switches are:

• MSD (most significant digit).

• LSD (least significant digit).

To reset the node address, use a small blade screwdriver to rotate the switches. Line up the

small arrow on the switch with the number setting you wish to use.

The rotary switches are only read when you apply power to the board. Settings between 64

and 99 cause the board to use the last valid node address stored in the board’s memory.

For example, the last setting in memory is 40. If a change is made to 68, and then you apply

power to the board, the address will default to 40.

LSD (S2)

The LSD (S2)

and MSD (S1)

switches are

shown in the

63 position.

MSD (S1)

42558

Publication 1799-IN011A-EN-P - February 2007

Page 6

6 16 Input/16 Output Digital and 2 Input/2 Output Analog Embedded I/O Boards

The board is equipped with AutoBaud detect. AutoBaud lets the board detect the

communication rate on your DeviceNet network and automatically adjusts to that rate.

The board is shipped with AutoBaud enabled.

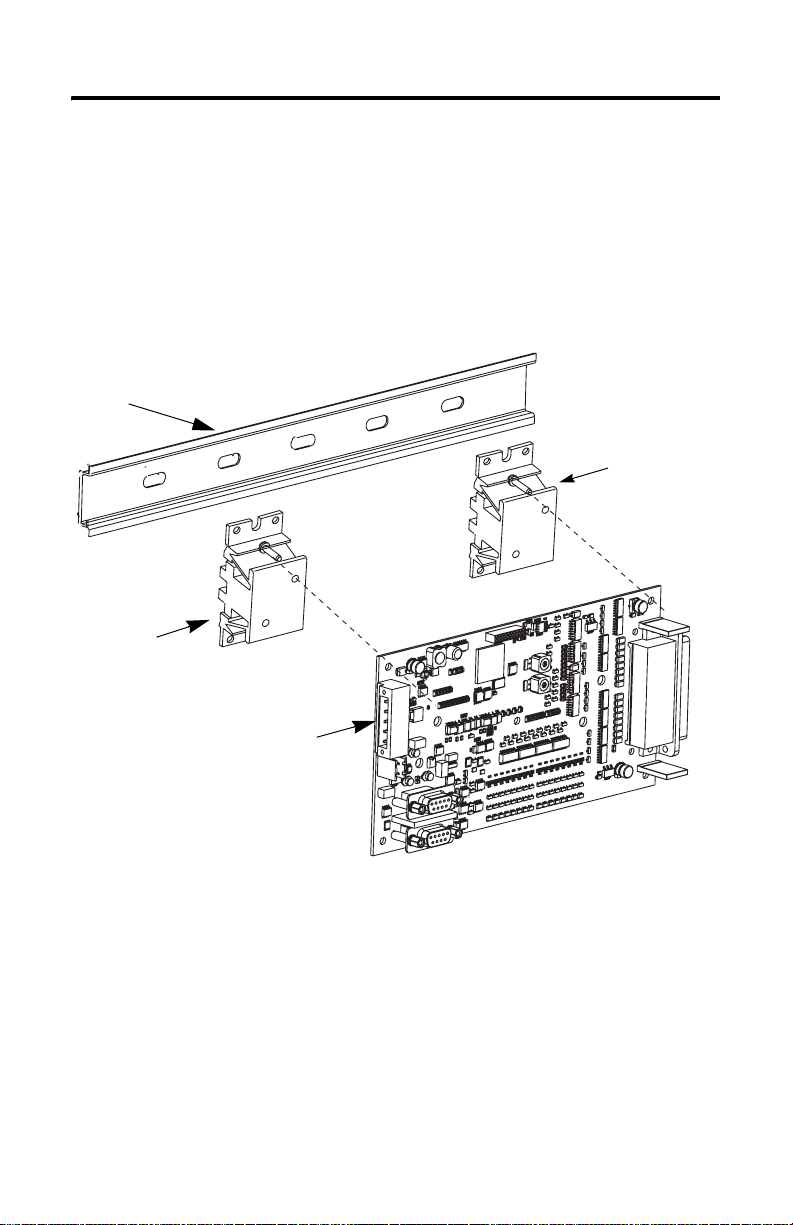

Mount the Board

You can mount the board to a DIN rail using DIN-rail brackets (1799-BRKD) or to a

mounting plate.

DIN Rail

DIN-rail Bracket

DIN-rail Bracket

Circuit Board

42559LC

You can also mount the board in an enclosure with pre-tapped holes, which accommodate

M3 x 0.5 mm screws.

Publication 1799-IN011A-EN-P - February 2007

Page 7

16 Input/16 Output Digital and 2 Input/2 Output Analog Embedded I/O Boards 7

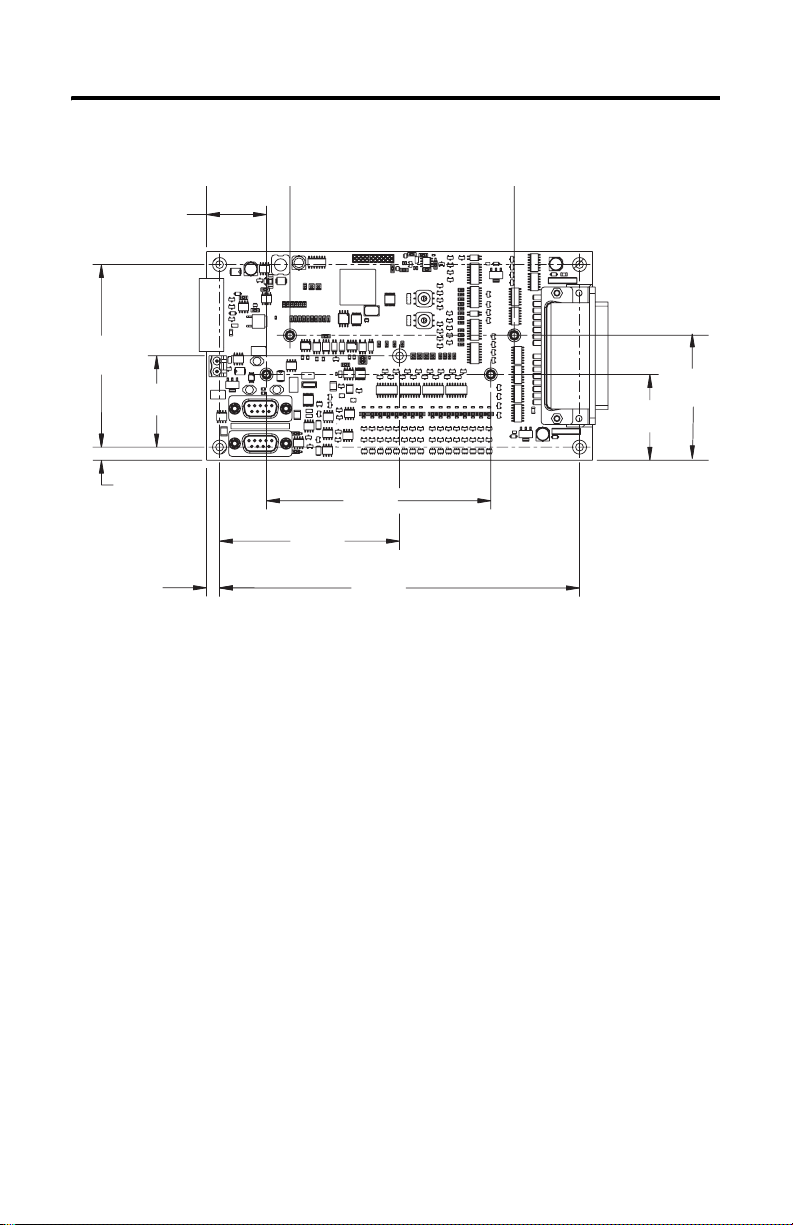

Board Dimensions

29.21

(1.15)

88.90

(3.50)

44.45

(1.75)

41.66

(1.64)

60.71

(2.39)

6.35

(0.25)

6.35

(0.25)

87.63

(3.45)

109.22

(4.30)

175.26

(6.90)

Publication 1799-IN011A-EN-P - February 2007

Page 8

8 16 Input/16 Output Digital and 2 Input/2 Output Analog Embedded I/O Boards

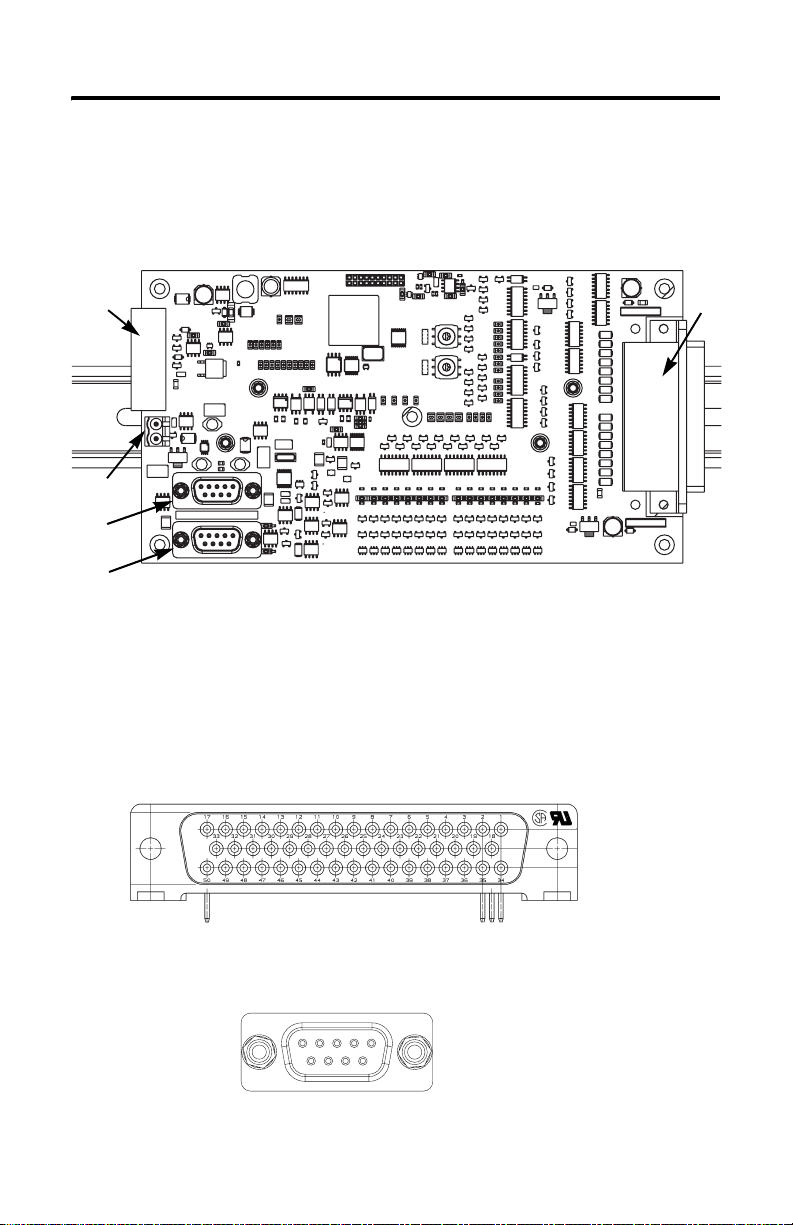

Connect the Board

Use the following pictures and tables to help you connect the DeviceNet connectors and I/O

connectors to the board.

P1

P8

P7

P6

P1 = DeviceNet Connector

42561A

P5 = I/O Connector

P6 = Analog I/O Connector

P7 = Analog I/O Connector

P8 = Analog Power Connector

The following illustration shows the pin number assignments of the digital I/O connector

(P5).

P5

This illustration shows the analog connectors, P6 and P7.

5

9

1

4

3

2

6

7

8

Publication 1799-IN011A-EN-P - February 2007

42606

Page 9

16 Input/16 Output Digital and 2 Input/2 Output Analog Embedded I/O Boards 9

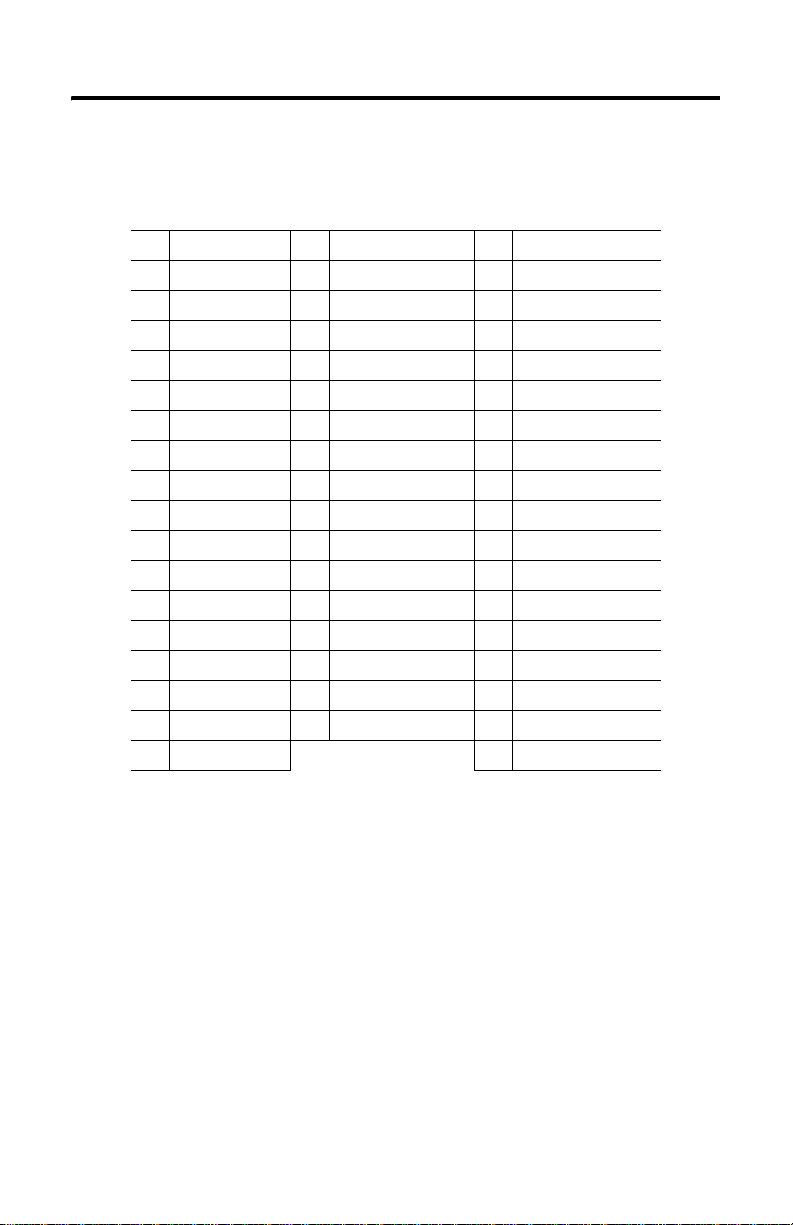

The following table identifies the signal for each 1799-D16U16BAGL pin number on the I/O

connector.

P5 1799-D16U16BAGL I/O Connector

Pin Signal Pin Signal Pin Signal

1 Output 15 18 Output 13 34 Output 12

2 Output 9 19 Output 8 35 Output 14

3 Output 11 20 Output 10 36 GRP 1 Return

4 +24V dc-GRP 1 21 Input 1 37 Input 0

5 +24V dc-GRP 1 22 Common In GRP 0 38 Input 2

6 Input 3 23 Input 6 39 Input 4

7 Input 5 24 GRP 1 Return 40 Input 7

8 GRP 0 Return 25 Input 11 41 Input 10

9 Output 4 26 Input 9 42 Input 8

10 +24V dc-GRP 0 27 Input 14 43 Common In GRP 1

11 Output 5 28 Input 12 44 Input 13

12 Output 7 29 Output 6 45 Input 15

13 Output 0 30 GRP 0 Return 46 Not Used

14 Output 1 31 Not Used 47 Not Used

15 +24V dc-GRP 0 32 Not Used 48 Not Used

16 Output 2 33 Not Used 49 Not Used

17 Output 3 50 Not Used

Publication 1799-IN011A-EN-P - February 2007

Page 10

10 16 Input/16 Output Digital and 2 Input/2 Output Analog Embedded I/O Boards

The following table identifies the signal for each 1799-D16U16VAGL pin number on the I/O

connector.

P5 1799-D16U16VAGL I/O Connector

Pin Signal Pin Signal Pin Signal

1 Output 15 18 Output 13 34 Output 12

2 Output 9 19 Output 8 35 Output 14

3 Output 11 20 Output 10 36 GRP 1 Return

4 +24V dc-GRP 1 21 Input 1 37 Input 0

5 +24V dc-GRP 1 22 Common In GRP 0 38 Input 2

6 Input 3 23 Input 6 39 Input 4

7 Input 5 24 GRP 1 Return 40 Input 7

8 GRP 0 Return 25 Input 11 41 Input 10

9 Output 4 26 Input 9 42 Input 8

10 +24V dc-GRP 0 27 Input 14 43 Common In GRP 1

11 Output 5 28 Input 12 44 Input 13

12 Output 7 29 Output 6 45 Input 15

13 Output 0 30 GRP 0 Return 46 Not Used

14 Output 1 31 Not Used 47 Not Used

15 +24V dc-GRP 0 32 Not Used 48 Not Used

16 Output 2 33 Not Used 49 Not Used

17 Output 3 50 Not Used

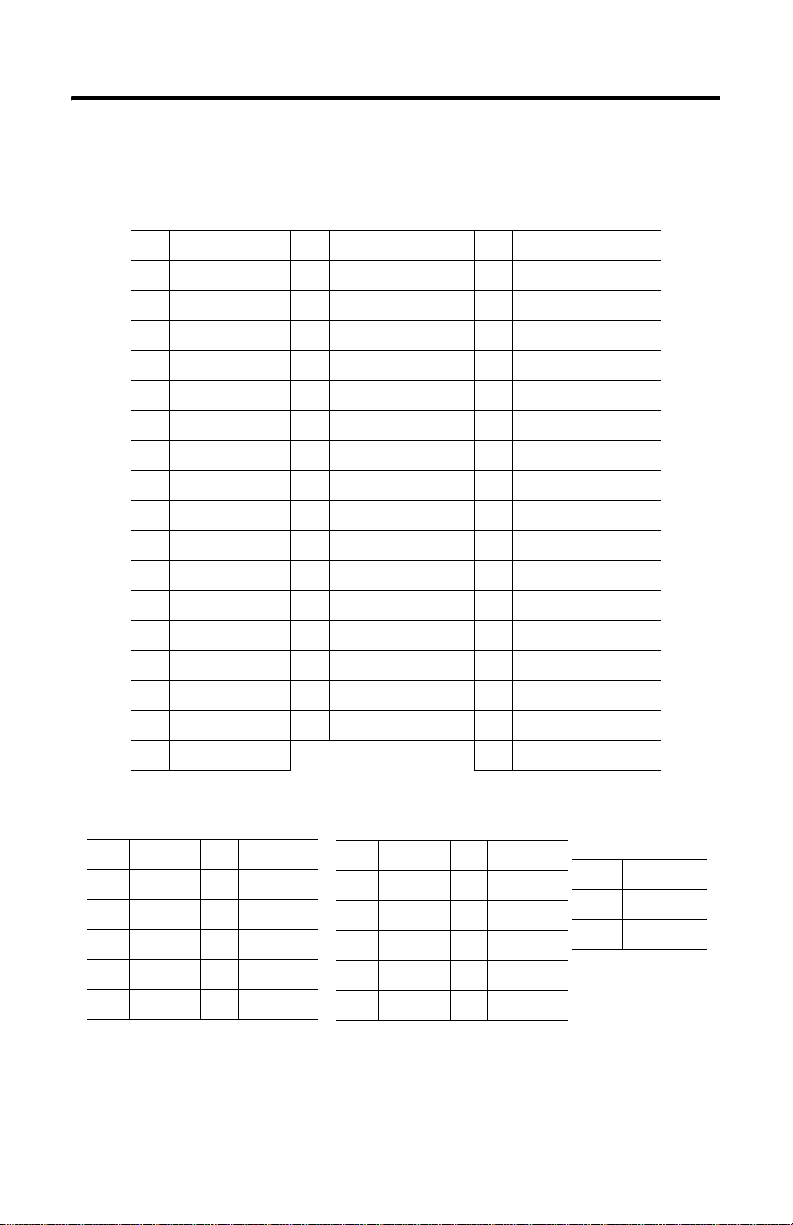

P6 Analog I/O Connector

Signal

Pin

1

2

3

4

5

V_Out 0

NC

V_In 0

A_24V

AGND

Pin Signal

6 C_Out 0

7NC

8 C_In 0

9

P7 Analog I/O Connector

Pin

1

2

3

4

5

Publication 1799-IN011A-EN-P - February 2007

Signal

V_Out 1

NC

V_In 1

A_24V

AGND

Pin Signal

6 C_Out 1

7NC

8 C_In 1

9NC

P8 Analog Power

Connector

Signal

Pin

24V

1

AGND

2

Page 11

16 Input/16 Output Digital and 2 Input/2 Output Analog Embedded I/O Boards 11

The DeviceNet wire insulation colors are shown below.

P1 DeviceNet Connector

Pin Insulation Colors

1Black

2Blue

3Shield

4White

5Red

Auxiliary Power Specifications

The power source used to supply the auxiliary power to the outputs and analog circuitry must

meet the following:

ATTENTION

ATTENTION

To comply with the CE Low Voltage Directive (LVD), all connections to this equipment must be

powered from a source compliant with the following:

Safety Extra Low Voltage (SELV) or Protected Extra Low Voltage (PELV) with isolated outputs

limited to 200

To comply with UL restrictions, this equipment must be powered from a source compliant

with the following:

Class 2 or UL Listed /Recognized Power Supply with isolated outputs limited to

200 volt-amperes in each ungrounded output line. This condition requires that

the board and power source be mounted in a suitable ultimate enclosure with

proper spacings maintained.

volt-amperes in each ungrounded output line.

These conditions requires that the board and power source be mounted in a suitable,

ultimate enclosure with proper spacings maintained.

ATTENTION

Do not wire more than 2 conductors on any single terminal.

Publication 1799-IN011A-EN-P - February 2007

Page 12

12 16 Input/16 Output Digital and 2 Input/2 Output Analog Embedded I/O Boards

Connect the Field Output Device to the I/O Connector (P5)

The 1799-D16U16BAGL boards have outputs that supply current to your field output device

(sourcing outputs).

The outputs on these boards are isolated in two groups of eight, with each group requiring

24V dc power and 24V dc ground. Outputs 0…7 are powered from +24V GRP 0 and return

power via GRP 0 Return. Outputs 8…15 are powered from +24V GRP 1 and return power

via GRP 1 Return.

Use the following wiring diagrams to connect both groups of outputs on these boards.

1799-D16U16BAGL Outputs (Sourcing)

GRP 1

Pins 4, 5

+24V

GRP 1

+

+

_

_

Pins 1-3,

18-20, 34, 35

Output X

Load

Load

42563

Pin 8,30

GRP 0

Return

GRP 0

Pins 10, 15

+24V

GRP 0

+

_

Pins 9, 11-14,

16, 17, 29

Output X

Load

Pin 24, 36

GRP 1

Return

The 1799-D16U16VAGL board has outputs that receive current from your field output

device (sinking outputs). The outputs on these boards are in two groups of eight, with each

group requiring 24V dc power and 24V dc ground. Outputs must be from a single 200 VA

supply powered from +24V GRP and return power via GRP Return.

1799-D16U16VAGL Outputs (Sinking)

GRP 0 GRP 1

Pin 8,

30

GRP

Return

Pins 9, 11-14,

16, 17, 29

Output X

Pins 10, 15

+24V

GRP

Pin 24,

36

GRP

Return

Pins 1-3,

18-20, 34, 35

Output X

Pins 4, 5

+24V

GRP

Load

+

_

Publication 1799-IN011A-EN-P - February 2007

Load

+

_

42564

Page 13

16 Input/16 Output Digital and 2 Input/2 Output Analog Embedded I/O Boards 13

Connect the Field Input Device to the I/O Connector (P5)

The inputs on these boards are isolated in two groups of eight, with each group providing a

separate common signal. Inputs 0…7 share the common in GRP 0 signal. Inputs 8…15 share

the common in GRP 1 signal.

The 1799-D16U16BAGL and 1799-D16U16VAGL boards have universal inputs that allow

operation with either sourcing or sinking input devices. The universal feature lets you

configure the inputs as either sinking or sourcing. Use the following wiring diagrams to

connect each group of inputs on the boards.

IMPORTANT

Inputs (Sinking)

Inputs (Sourcing)

All field input devices in each group of eight must be of the same type,

either sinking or sourcing. The board will not operate if the types are

mixed.

GRP 1

Pin 43

Common In

GRP 1

42565

GRP 1

Pins 25-28,

41, 42, 44, 45

Input X

+

_

Pin 22

Common In

GRP 0

GRP 0

Pins 6, 7, 21,

23, 37-40

Input X

GRP 0

Pin 22

Common In

GRP 0

Pins 6, 7, 21,

23, 37-40

Input X

Pins 25-28,

41, 42, 44, 45

Input X

+

_

Pin 43

Common In

GRP 1

+

_

+

_

42566

Publication 1799-IN011A-EN-P - February 2007

Page 14

14 16 Input/16 Output Digital and 2 Input/2 Output Analog Embedded I/O Boards

Communicate With Your Board

This board exchanges I/O with the master on the DeviceNet network through a cyclic,

polled, or change-of-state connection.

The 1799-D16U16BAGL board consumes and produces I/O data as follows.

I/O Connection Type Consumes Produces

Cyclic 6 Bytes 11 Bytes

Polled 6 Bytes 11 Bytes

Change-of-state 6 Bytes 11 Bytes

The 1799-D16U16VAGL board consumes and produces I/O data as follows.

I/O Connection Type Consumes Produces

Cyclic 6 Bytes 11 Bytes

Polled 6 Bytes 11 Bytes

Change-of-state 6 Bytes 11 Bytes

Cyclic — the board produces and consume its I/O cyclically at the rate configured by the

master on the DeviceNet network.

Polled — the master initiates communication by sending its polled I/O message to the board.

The board consumes the message, updates any outputs, and produces a response containing

the input data.

Change-of-state — a production occurs when an input changes. A heartbeat production

occurs if no input condition change occurs within the expected packet rate. This heartbeat

production tells the master that the board is ready to communicate. Consumption occurs

when data changes and the master produces new output data to the board.

Publication 1799-IN011A-EN-P - February 2007

Page 15

16 Input/16 Output Digital and 2 Input/2 Output Analog Embedded I/O Boards 15

Word and bit definitions for the 1799-D16U16BAGL board are shown below.

1799-D16U16BAGL Board Word and Bit Definitions:

Produced Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 In8 In7 In6 In5 In4 In3 In2 In1

1 In16 In15 In14 In13 In12 In11 In10 In9

2 Rsvd Logic En Rsvd Rsvd OW1 OW0 OFLT 1 OFLT 0

3 Analog Input Channel 0 (LSB)

4 Analog Input Channel 0 (MSB)

5 Analog Input Channel 1 (LSB)

6 Analog Input Channel 1 (MSB)

7 ORI0 URI0 HHAI0 LLAI0 HAI0 LAI0 CMI0 STI0

8 ORI1 URI1 HHAI1 LLAI1 HAI1 LAI1 CMI1 STI1

9 Reserved HCO0 LCO0 CMO0 STO0

10 Reserved HCO1 LCO1 CMO1 STO1

Consumed Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 O8 O7 O6 O5 O4 O3 O2 O1

1 O16 O15 O14 O13 O12 O11 O10 O9

2 Analog Output Channel 0 Data (LSB)

3 Analog Output Channel 0 Data (MSB)

4 Analog Output Channel 1 Data (LSB)

5 Analog Output Channel 1 Data (MSB)

Where: I = Digital input

O = Digital output

AI = Analog Input Channel (channel 0 = AI0; channel 1 = AI1)

AO = Analog Output Channel (channel 0 = AO0; channel 1 = AO1)

ST = Analog Input Channel Status (channel 0 = ST0; channel 1 = ST1) (0 = no error; 1 = fault)

CM = Calibration mode (0 = run; 1 = calibration mode)

LA = Low alarm (0 = no error; 1 = fault)

HA = High alarm (0 = no error; 1 = fault)

LLA = Low low alarm (0 = no error; 1 = fault)

HHA = High high alarm (0 = no error; 1 = fault)

UR = Underrange (0 = no error; 1 = fault)

OR = Overrange (0 = no error; 1 = fault)

LC = Low clamp (0 = no error; 1 = fault)

HC = High clamp (0 = no error; 1 = fault)

OW = Analog output open wire (OW0 = channel 0; OW1 = channel 1)

OFLT = Output fault on one or more outputs in a group (OFLT0 = group 0; OFLT1 = group 1)

Rsvd = Reserved

Publication 1799-IN011A-EN-P - February 2007

Page 16

16 16 Input/16 Output Digital and 2 Input/2 Output Analog Embedded I/O Boards

Word and bit definitions for the 1799-D16U16VAGL board are shown below.

Word and Bit Definitions for the 1799-D16U16VAGL Board

Produced Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 In8 In7 In6 In5 In4 In3 In2 In1

1 In16 In15 In14 In13 In12 In11 In10 In9

2 Rsvd Logic En Rsvd Rsvd OW1 OW0 OFLT 1 OFLT 0

3 Analog Input Channel 0 (LSB)

4 Analog Input Channel 0 (MSB)

5 Analog Input Channel 1 (LSB)

6 Analog Input Channel 1 (MSB)

7 ORI0 URI0 HHAI0 LLAI0 HAI0 LAI0 CMI0 STI0

8 ORI1 URI1 HHAI1 LLAI1 HAI1 LAI1 CMI1 STI1

9 Reserved HCO0 LCO0 CMO0 STO0

10 Reserved HCO1 LCO1 CMO1 STO1

Consumed Byte Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 O8 O7 O6 O5 O4 O3 O2 O1

1 O16 O15 O14 O13 O12 O11 O10 O9

2 Analog Output Channel 0 Data (LSB)

3 Analog Output Channel 0 Data (MSB)

4 Analog Output Channel 1 Data (LSB)

5 Analog Output Channel 1 Data (MSB)

Where: I = Digital input

O = Digital output

AI = Analog Input Channel (channel 0 = AI0; channel 1 = AI1)

AO = Analog Output Channel (channel 0 = AO0; channel 1 = AO1)

ST = Analog Input Channel Status (channel 0 = ST0; channel 1 = ST1) (0 = no error; 1 = fault)

CM = Calibration mode (0 = run; 1 = calibration mode)

LA = Low alarm (0 = no error; 1 = fault)

LLA = Low low alarm (0 = no error; 1 = fault)

HA = High alarm (0 = no error; 1 = fault)

HHA = High high alarm (0 = no error; 1 = fault)

UR = Underrange (0 = no error; 1 = fault)

OR = Overrange (0 = no error; 1 = fault)

LC = Low clamp (0 = no error; 1 = fault)

HC = High clamp (0 = no error; 1 = fault)

OW = Analog output open wire (OW0 = channel 0; OW1 = channel 1)

OFLT = Output fault on one or more outputs in a group (OFLT0 = group 0; OFLT1 = group 1)

Rsvd = Reserved

Publication 1799-IN011A-EN-P - February 2007

Page 17

16 Input/16 Output Digital and 2 Input/2 Output Analog Embedded I/O Boards 17

Configure the Parameters

The 1799 I/O boards have parameters that are configurable through a DeviceNet

configuration tool such as RSNetWorx for DeviceNet software. The DeviceNet

configuration tools require an Electronic Data Sheet (EDS) for the 1799 I/O boards to

configure the module’s parameters. Find the EDS files at http://www.odva.org

Use the descriptions in the following table to help you configure the parameters.

Parameter Description

AutoBaud Enables the board to match the network’s communication

rate. When enabled, Baud Rate parameter is ignored.

Input Off-to-On Filter Time Controls the amount of time the input must be in the on

state before the board reports the input as on.

Input On-to-Off Filter Time Controls the amount of time the input must be in the

off-state before the board reports the input as off.

Output Idle State Controls the state of each output when the DeviceNet

master is in an idle-state.

Output Fault State Controls the state of each output when the board loses

communication with the DeviceNet master.

Output Idle Value Controls the value that outputs will have when the output

idle-state is set to use idle value.

Output Fault Value Controls the value that outputs will have when the output

fault-state is set to use fault value.

.

The DeviceLogix capable boards, 1799-D16U16BAGL and 1799-D16U16VAGL, have

additional parameters, which are described in the DeviceLogix User Manual, publication

number ACIG-UM001, and in the Embedded I/O for DeviceNet Technical Data,

publication number 1799-TD001.

Publication 1799-IN011A-EN-P - February 2007

Page 18

18 16 Input/16 Output Digital and 2 Input/2 Output Analog Embedded I/O Boards

Additional Parameters

Parameter Description

AI Low Scaling Analog input low scaling value or low engineering units.

AI High Scaling Analog input high scaling value or high engineering units.

AI Digital Filter Controls digital filter time constant.

AI Alarm (Low/High Low)

Low/High High)

AI Input Range Defines type and range of input signal. Controls way of calibration.

AI Enable Alarm Latch Controls latch of alarm status until a reset latch service is issued.

AI Disable Alarms Controls function of alarm.

AI Notch Filter Controls sample rate of A/D converter.

AI Update Rate Assigns the rate at which the inputs are sampled by firmware.

AO Fault Value Controls output value during communication fault.

AO Idle Value Controls output value during idle or program mode.

AO Low Scaling Analog output low scaling value or low engineering units.

AO High Scaling Analog output high scaling value or high engineering units.

AO Low Clamp The lowest value of the output. If the output value is set below this

AO High Clamp The highest value of the output. If the output value is set above this

AO Output Range Defines type and range of output signal. Controls way of calibration.

AO Fault State Controls the output choices during a communication fault.

AO Idle State Controls the output choices during idle or program mode.

AO Enable Alarm Latch Controls latch of alarm status until a reset latch service is issued.

AO Disable Alarms Controls function of alarm.

Control alarm status when input exceed alarm threshold.

value, the output will be set to the low clamp value.

value, the output will be set to the high clamp value.

Publication 1799-IN011A-EN-P - February 2007

Page 19

16 Input/16 Output Digital and 2 Input/2 Output Analog Embedded I/O Boards 19

Calibrate Your Analog Inputs and Outputs

Follow the example calibrations shown below to learn how to calibrate your card.

Input Calibration

The wiring method decides the operating mode of current or voltage inputs. Calibration data

of both voltage and current are stored in nonvolatile memory and selected according to the

parameter value of AI INPUT RANGE.

Example current calibration of channel 0

Perform the following steps to calibrate your current input.

1. Set input channel range to 0…20 mA.

2. Select the input channel.

3. Send command to Begin Calibration.

Publication 1799-IN011A-EN-P - February 2007

Page 20

20 16 Input/16 Output Digital and 2 Input/2 Output Analog Embedded I/O Boards

4. Apply 4.000 mA ±0.5 μA and allow to settle for a minimum of 200 ms.

TIP

5. Send the Accept Low Calibration command.

6. Apply 20.00 mA ( ±0.5 μA) and allow to settle for a minimum of 200 ms.

7. Send the Accept High Calibration command.

Always apply 4 mA to inputs as low reference when calibrating current

inputs.

8. If both samples were successful the module saves data to Dataflash, recalculates

module parameters and exits calibration automatically.

Calibration can be aborted or restarted at any time. Data is not saved until the end of step 7.

Publication 1799-IN011A-EN-P - February 2007

Page 21

16 Input/16 Output Digital and 2 Input/2 Output Analog Embedded I/O Boards 21

Example voltage calibration of channel 0

1. Set input channel range 0…10V.

2. Select the input channel.

3. Send command to Begin Calibration.

4. Apply 0.000V (±) 500 μV and allow to settle for a minimum of 200 ms.

5. Send the Accept Low Calibration command.

Publication 1799-IN011A-EN-P - February 2007

Page 22

22 16 Input/16 Output Digital and 2 Input/2 Output Analog Embedded I/O Boards

6. Apply 10.000V (±500 μV) and allow to settle for a minimum of 200 ms.

7. Send the Accept High Calibration command.

8. If both samples were successful the module saves data to Dataflash, recalculates

module parameters and exits calibration automatically.

Calibration can be aborted or restarted at any time. Data is not saved until the end of step 7.

Output Calibration

The wiring method decides the operating mode of current or voltage output. Calibration data

of both voltage and current are stored in nonvolatile memory and selected according to

parameter value of AO OUTPUT RANGE.

So select output range of either current or voltage prior to calibration.

Example current calibration of channel 0.

1. Set output channel range to 0…20 mA.

2. Select output channel 0.

Publication 1799-IN011A-EN-P - February 2007

Page 23

16 Input/16 Output Digital and 2 Input/2 Output Analog Embedded I/O Boards 23

3. Apply a 220 Ω (±15%) load resistor to channel 0.

4. Send Begin Calibration command.

5. Send the Output Low Reference command

6. Record the actual output current.

7. Send the Output High Reference command.

8. Record the actual output current.

9. Set parameter values with recorded values.

Publication 1799-IN011A-EN-P - February 2007

Page 24

24 16 Input/16 Output Digital and 2 Input/2 Output Analog Embedded I/O Boards

10. Send the Finish Calibration command.

11. If LED indicators are no longer blinking, calibration is complete.

Calibration can be aborted or restarted at any time. Data is not saved until the end of step 10.

Example voltage calibration of channel 0.

1. Set output channel range to 0…10V.

2. Select output channel 0.

3. Apply a 10 KΩ (± 1%) load resistor to channel 0. (10V output/10 K = 1 mA load)

4. Send Begin Calibration command.

Publication 1799-IN011A-EN-P - February 2007

Page 25

16 Input/16 Output Digital and 2 Input/2 Output Analog Embedded I/O Boards 25

5. Send the Output Low Reference command

6. Record the actual output current.

7. Send the Output High Reference command.

8. Record the actual output voltage.

9. Set parameter values with recorded values.

10. Send the Finish Calibration command.

11. If LED indicators are no longer blinking calibration is complete.

Calibration can be aborted or restarted at any time. Data is not saved until the end of step 10.

Publication 1799-IN011A-EN-P - February 2007

Page 26

26 16 Input/16 Output Digital and 2 Input/2 Output Analog Embedded I/O Boards

Troubleshoot the I/O Boards

This board has the following indicators:

• Board status indicator

• Network status indicator

• Logic status

• Digital I/O state indicators

• Analog I/O state indicators

Status Indicators

DL NSInput LEDs

P1

P8

P7

P6

MS

Analog LEDs Output LEDs

Board Status Indicator (Labeled MS)

Indication Status

None No power

Green Blinking Green Needs commissioning

Solid Green Device operational

Red Blinking Red Minor fault

Solid Red Critical fault

LSD

MSD

P5

42567A

Publication 1799-IN011A-EN-P - February 2007

Page 27

16 Input/16 Output Digital and 2 Input/2 Output Analog Embedded I/O Boards 27

Network Status Indicator (Labeled NS)

Indication Status

None Not on-line

Green Blinking Green On-line/no connections

Solid Green On-line/connected

Red Blinking Red Connection timed out

Solid Red Failed communication: a duplicate node address exists or

module is at the wrong communication rate

DeviceLogix Status Indicator (Labeled DL)

Indication Status

None Logic disabled

Green Solid Green Logic enabled

Blinking Green Local forces applied and local logic enabled

I/O State Indicators (Labeled Inputs and Outputs)

Color Indication Status

None Input or output point off

Yellow Solid Yellow Input or output point on

Analog Input Indicators

Color Indication Status

None No power or calibration started

Green Blinking Green Calibration in process

Solid Green Normal operation

Red Blinking Red Open wire or out of range

Solid Red No AD communications

Analog Output Indicators

Color Indication Status

None No power or calibration started

Green Blinking Green Calibration in progress

Solid Green Normal operation

Red Blinking Red Open wire or out of range

Publication 1799-IN011A-EN-P - February 2007

Page 28

28 16 Input/16 Output Digital and 2 Input/2 Output Analog Embedded I/O Boards

Specifications

16 Input/16 Output Board - Cat. No. 1799-D16U16BAGL and 1799-D16U16VAGL

Attribute Value

Power

DeviceNet voltage range 11…25V dc

DeviceNet current 125 mA

DeviceNet power circuit type Class 2

Digital I/O voltage range 10…30V dc

Digital I/O current max 8 A (all outputs on)

Digital I/O current min 20 mA

Supply power/current ratings Isolated outputs limited to 200 VA in each ungrounded output line

Analog I/O voltage range 10…28.8V dc

Analog I/O current max 200 mA

Analog I/O current min 100 mA

Digital input specifications

Inputs per block 16 sinking or sourcing (2 groups of 8), Type 1 + compatible

Off-state voltage 5V dc

Off-state current 1.5 mA

On-state voltage max 30V dc

On-state voltage min 10V dc

On-state current max 6 mA

On-state current min 2 mA

Digital output specifications

Outputs per block 16 sinking or sourcing, 0.5 A, short-circuit protected, pilot duty

Output voltage range 10…30V dc

Output voltage min 10V dc

Output voltage range nominal 24V dc

Output voltage range max 30V dc

On-state Voltage Drop 250 mV

On-state current 0.5 A max

Off-state leakage 65 μA

Surge current - for 10 ms, repeatable

every 2 s (individual outputs)

1.0 A

Publication 1799-IN011A-EN-P - February 2007

Page 29

16 Input/16 Output Digital and 2 Input/2 Output Analog Embedded I/O Boards 29

Analog input specifications

Voltage, power 10…28.8V

Input current range 0…21 mA

Input resolution 0.32 μA/count (16 bits)

Input voltage range 0…10.5V max; 21 mA max

Current input impedance 238 Ω

Voltage input impedance 190 kΩ

Accuracy current

voltage

Analog output specifications

Output current range 0…21.5 mA

Output voltage range 0…10.5V

Output resolution - current 2.8 μA/count (13 bits)

Output resolution - voltage 180 μV/count

Voltage drive capability 3 mA max

Number of outputs 2 single-ended, nonisolated

Absolute accuracy - current output 0.03%

Absolute accuracy - voltage output 0.06%

Current load on voltage output 21 mA max

Resistive load on current output 790 Ω max

General specifications

Power dissipation 1.8 W max @ 30.0V dc (whole board)

Thermal dissipation 6.14 BTU/hr max @ 30.0V dc (whole board)

Isolation voltage (continuous-voltage

withstand rating)

Wire size - power

Wire size - DeviceNet

Wire size - I/O

Wiring category

(1)

0.012% of FS

0.007% of FS

50V (continuous), Basic Insulation Type, between DeviceNet, I/O,

and I/O power

Tested at 1000V dc for 60 seconds.

No isolation between individual channels

0.80…2.5 mm2 (18...14 AWG) solid or stranded copper wire rated at

°F) or higher, 1.2 mm (3/64 in.) insulation max

75 °C (167

0.25...2.5 mm2 (22...14 AWG) solid or stranded copper wire rated at

°F) or higher (See Publication DNET-UM072)

75 °C (167

0.13...0.5 mm2 (26...20 AWG) solid or stranded copper wire rated at

75 °C (167

°F) or higher, 1.2 mm (3/64 in.) insulation max

2 - on signal ports

2 - on power ports

2 - on communications ports

Publication 1799-IN011A-EN-P - February 2007

Page 30

30 16 Input/16 Output Digital and 2 Input/2 Output Analog Embedded I/O Boards

Enclosure type rating None (open-style)

Pilot Duty Rating

Pilot duty DC-14

LED indicators Board Status indicator - red/green

Network Status indicator - red/green

DeviceLogix Status indicator - green

Input Point indicator - yellow

Output Point indicator - yellow

Dimensions (H x W x D), approx.

millimeters

(inches)

19.05 x 77.85 x 189.33 mm

(0.75 x 3.07 x 7.45 in.)

Weight 0.10 kg (0.22 lb)

(1)

Use this Conductor Category information for planning conductor routing. Refer to Industrial Automation Wiring and

Grounding Guidelines, Publication 1770-4.1.

Environmental Specifications

Attribute Value

Temperature, operating

Temperature, storage

Relative humidity IEC 60068-2-30 (Test Db, Unpackaged Damp Heat):

Vibration IEC 60068-2-6 (Test Fc, Operating):

Shock, operating IEC 60068-2-27 (Test Ea, Unpackaged Shock):

Shock, nonoperating IEC 60068-2-27 (Test Ea, Unpackaged Shock):

Emissions CISPR 11:

ESD immunity IEC 61000-4-2:

Radiated RF immunity IEC 61000-4-3:

IEC 60068-2-1 (Test Ad, Operating Cold),

IIEC 60068-2-2 (Test Bd, Operating Dry Heat),

IEC 60068-2-14 (Test Nb, Operating Thermal Shock):

-20...70 °C (-4...158 °F)

IEC 60068-2-1 (Test Ab, Unpackaged Nonoperating Cold),

IEC 60068-2-2 (Test Bb, Unpackaged Nonoperating Dry Heat),

IEC 60068-2-14 (Test Na, Unpackaged Nonoperating Thermal Shock):

-40...85 °C (-40...185 °F)

5...95% noncondensing

5 g @ 10…500 Hz

30 g

50 g

Group 1, Class A

6 kV indirect contact discharges

10 V/m with 1 kHz sine-wave 80%AM from 80 MHz...2 GHz

1 V/m with 1 kHz sine-wave 80%AM from 2...2.7 GHz

10 V/m with 200 Hz 50% Pulse 100%AM at 900 MHz

10 V/m with 200 Hz 50% Pulse 100%AM at 1890 MHz

Publication 1799-IN011A-EN-P - February 2007

Page 31

16 Input/16 Output Digital and 2 Input/2 Output Analog Embedded I/O Boards 31

EFT/B immunity IEC 61000-4-4

±2 kV at 5 kHz on power ports

±2 kV at 5 kHz on signal ports

±2 kV at 5 kHz on communications ports

Surge transient immunity IEC 61000-4-5:

±1 kV line-line (DM) and ±2 kV line-earth (CM) on power ports

±1 kV line-line (DM) and ±2 kV line-earth (CM) on signal ports

±2 kV line-earth (CM) on communications ports

Conducted RF immunity IEC 61000-4-6:

10V rms with 1 kHz sine-wave 80%AM from 150 kHz...80 MHz

Certifications

Certifications

marked)

C-UR-US UL Recognized Component Industrial Control Equipment, certified for

CE European Union 2004/108/EC EMC Directive, compliant with:

C-Tick Australian Radiocommunications Act, compliant with:

ODVA ODVA conformance tested to DeviceNet specifications

(1)

See the Product Certification link at www.ab.com for Declarations of Conformity, Certificates, and other certification

details.

(1)

(when product is

US and Canada. See UL File E65584.

EN 50082-2; Industrial Immunity

EN 61326; Meas./Control/Lab., Industrial Requirements

EN 61000-6-2; Industrial Immunity

EN 61000-6-4; Industrial Emissions

EN 61131-2; Programmable Controllers (Clause 8, Zone A & B)

AS/NZS CISPR 11; Industrial Emissions

Publication 1799-IN011A-EN-P - February 2007

Page 32

Rockwell Automation Support

Rockwell Automation provides technical information on the Web to assist you in using its

products. At http://support.rockwellautomation.com

knowledge base of FAQs, technical and application notes, sample code and links to software

service packs, and a MySupport feature that you can customize to make the best use of these

tools.

For an additional level of technical phone support for installation, configuration and

troubleshooting, we offer TechConnect Support programs. For more information, contact

your local distributor or Rockwell Automation representative, or visit

http://support.rockwellautomation.com

.

Installation Assistance

If you experience a problem with a hardware module within the first 24 hours of installation,

please review the information that's contained in this manual. You can also contact a special

Customer Support number for initial help in getting your module up and running:

, you can find technical manuals, a

United States 1.440.646.3223

Outside United

States

Monday – Friday, 8am – 5pm EST

Please contact your local Rockwell Automation representative for any

technical support issues.

New Product Satisfaction Return

Rockwell tests all of its products to ensure that they are fully operational when shipped from

the manufacturing facility. However, if your product is not functioning and needs to be

returned:

United States Contact your distributor. You must provide a Customer Support case number

Outside United

States

RSNetWorx for DeviceNet, TechConnect, and DeviceLogix are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are properties of their respective companies.

(see phone number above to obtain one) to your distributor in order to

complete the return process.

Please contact your local Rockwell Automation representative for return

procedure.

Publication 1799-IN011A-EN-P - February 2007 PN 953030-32

Copyright © 2007 Rockwell Automation, Inc. A ll rights reserved. Printed in t he U.S.A.

Loading...

Loading...