Page 1

FLEX I/O Isolated Input/Output HART

Analog Modules

Catalog Numbers 1794-IF8IH and1794-OF8IH

User Manual

Page 2

Important User Information

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Solid state equipment has operational characteristics differing from those of electromechanical equipment. Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls (publication SGI-1.1

http://literature.rockwellautomation.com

) describes some important differences between solid state equipment and hard-wired electromechanical

devices. Because of this difference, and also because of the wide variety of uses for solid state equipment, all persons responsible for applying this

equipment must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or application of this

equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and requirements associated

with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for actual use based on the examples and

diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software described in this

manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

available from your local Rockwell Automation sales office or online at

Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may

lead to personal injury or death, property damage, or economic loss.

Identifies information that is critical for successful application and understanding of the product.

Identifies information about practices or circumstances that can lead to: personal injury or death, property damage, or

economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Labels may be on or inside the equipment, such as a drive or motor, to alert people that dangerous voltage may be present.

Labels may be on or inside the equipment, such as a drive or motor, to alert people that surfaces may reach dangerous

temperatures.

Allen-Bradley, Rockwell Automation, FLEX I/O, RSLogix, RSLinx, RSLogix 5000 and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Summary of Changes

This manual contains new and updated information. Changes throughout this

revision are marked by change bars, as shown to the right of this paragraph.

New and Updated Information

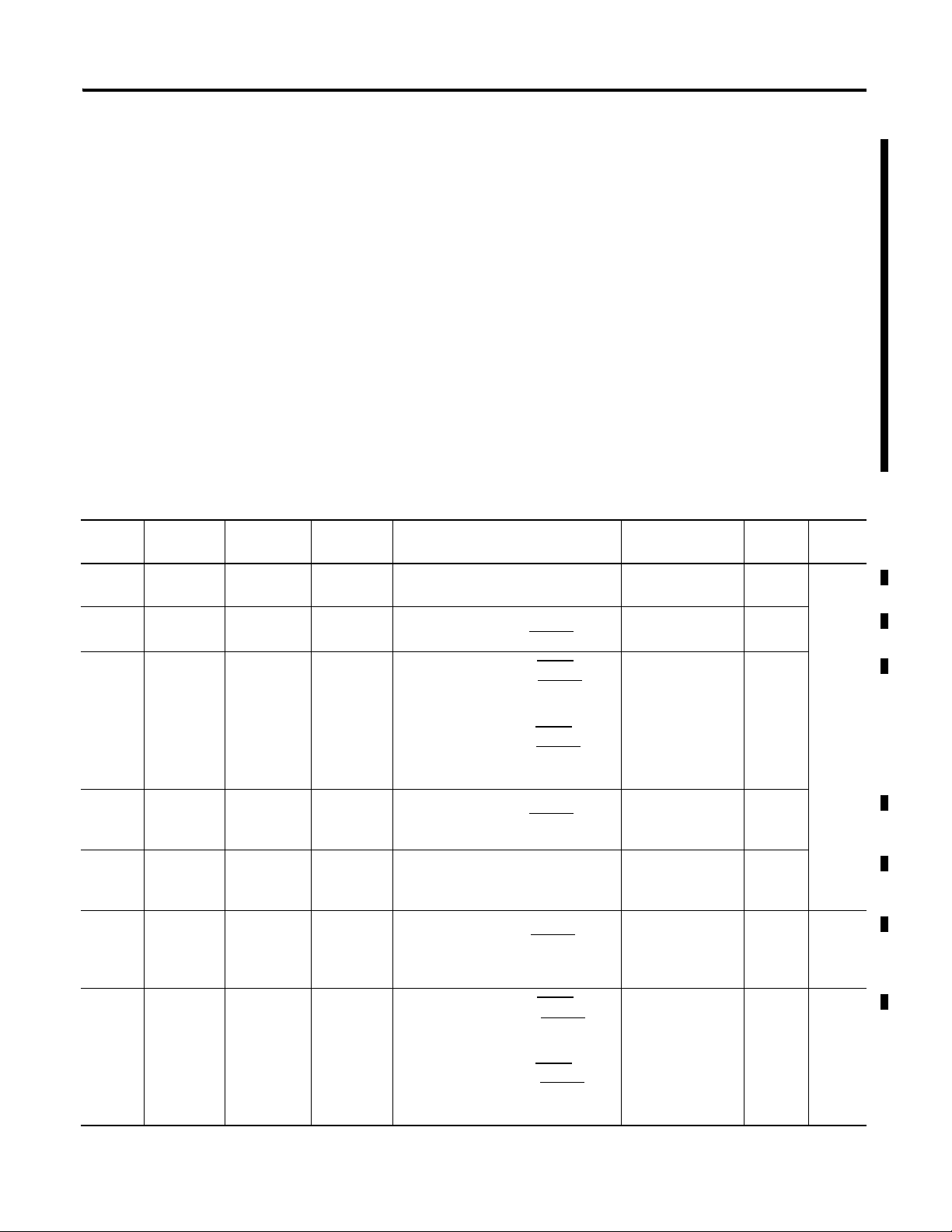

This table contains the changes made to this revision.

Topic Page

Overview 1

Communicate with Programmable Controllers 2

Events Following Power-up 2

Use Alarms on the Input Module 3

Remote Fault Alarm 4

Programming the Remote Fault Alarm 5

Configurable FLEX I/O Analog Module Features 7

Data Format 9

Install the Terminal Base Unit 16

Mount the Analog Modules on the Terminal Base Unit 21

Connections for the 1794-IF8IH HART Analog Input Module

on a 1794-TB3 Terminal Base Unit

Connections for the 1794-OF8IH HART Analog Output Module

on a 1794-TB3 or 1794-TB3S Terminal Base Unit

Ground the Module 24

About the ControlNet and EtherNet Adapters 26

Communication Over the FLEX I/O Backplane 26

I/O Structure 28

23

24

Fault State Data 28

Data Transfer Types 31

Interpret the Status Indicators 57

Use the 1794-IF8IH Module with the Generic Profile 119

Use the 1794-OF8IH Module with the Generic Profile 133

Publication 1794-UM065B-EN-E - September 2010

Page 4

iv Summary of Changes

Notes:

Publication 1794-UM065B-EN-E - September 2010

Page 5

Preface

Why Read This Manual

Who Should Use This Manual

About the Vocabulary

This manual shows you how to use your FLEX I/O analog modules with the

ControlNet products and ControlNet network, and EtherNet products and

EtherNet network. The manual helps you install, program, and troubleshoot

your module. This manual:

You must be able to program and operate a ControlNet product and

ControlNet or Ethernet network to make efficient use of a FLEX I/O

module.

In this manual, we refer to the:

• 1794-IF8IH as the input module

• 1794-OF8IH as the output module

Related Documentation

The following documents contain additional information concerning Rockwell

Automation products. To obtain a copy, contact your local

Rockwell Automation office or distributor.

Resource Description

FLEX I/O 8 Isolated Input HART Analog Module

Installation Instructions, publication 1794-IN115

FLEX I/O 8 Isolated Output Analog Module Installation

Instructions, publication 1794-IN120

FLEX I/O and FLEX XT I/O Selection Guide, publication

1794-SG002

DTM Library FLEX and FLEX EX Release Notes,

publication 1794-RN068

Industrial Automation Wiring and Grounding

Guidelines, publication 1770-4.1

Allen-Bradley Industrial Automation Glossary, AG-7.1

.

.

Common Techniques Used

.

The following conventions are used throughout this manual:

in this Manual

Information on wiring and installing the 1794-IF8IH HART input module.

Information on wiring and installing the 1794-OF8IH HART output module.

A description and overview of the 1794 and 1797 series FLEX I/O modules

compatible control platforms, and overview of how to specify a FLEX I/O system.

Web updates for FLEX I/O and FLEX EX I/O DTM libraries.

More information on proper wiring and grounding techniques.

. A glossary of industrial automation terms and abbreviations.

• Bulleted lists such as this one provide information, not procedural steps.

• Numbered lists provide sequential steps or hierarchical information.

• Italic type is used for emphasis.

v Publication 1794-UM065B-EN-E - September 2010

Page 6

vi Preface

Notes:

Publication 1794-UM065B-EN-E - September 2010

Page 7

Table of Contents

Summary of Changes

About the FLEX I/O HART Analog

Module

Configurable FLEX I/O Analog

Module Features

Install Your FLEX I/O Analog

Modules

New and Updated Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Why Read This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Who Should Use This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

About the Vocabulary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Related Documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Common Techniques Used in this Manual. . . . . . . . . . . . . . . . . . . . . . . v

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

What FLEX I/O Analog Modules Do . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Communicate with Programmable Controllers . . . . . . . . . . . . . . . . . . . 2

Events Following Power-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Physical Features of Your Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Use Alarms on the Input Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Overrange Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Underrange Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Remote Fault Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Local Fault Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Use the HART Capabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

HART Implementation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Chapter Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Select Your Analog Input Module Operating Features . . . . . . . . . . . . . 8

Fault Enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Input Filter Cutoff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Data Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Select Your Analog Output Module Operating Features. . . . . . . . . . . 10

Local Fault Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Latch Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Global Reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Data Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Fault Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Understand Image Table Mapping and Bit/Word Descriptions . . . . . 13

Chapter Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Before You Install Your Analog Module . . . . . . . . . . . . . . . . . . . . . . . 15

Removal and Insertion Under Power . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Install the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Mount on a DIN Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Mount on a Panel or Wall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Mount the Analog Modules on the Terminal Base Unit . . . . . . . . 21

The HART analog input and output modules mounts

on a 1794-TB3 or 1794-TB3S terminal base unit. . . . . . . . . . . . . . 21

Wire the Terminal Base Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Connect Wiring to the FLEX I/O HART Analog Modules . . . . . . . . 22

Connections for the 1794-IF8IH HART Analog Input Module

on a 1794-TB3 Terminal Base Unit . . . . . . . . . . . . . . . . . . . . . . . 23

i Publication 1794-UM065B-EN-E - September 2010

Page 8

ii Table of Contents

Input, Output and Configuration of

the FLEX I/O HART Analog I/O

Modules

1794-IF8IH and 1794-OF8IH

Configuration

Connections for the 1794-OF8IH HART Analog Output Module

on a 1794-TB3 or 1794-TB3S Terminal Base Unit . . . . . . . . . . . . 24

Ground the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Chapter Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Use Programming Software in Your FLEX I/O Application. . . . . . . 25

About the ControlNet and EtherNet Adapters . . . . . . . . . . . . . . . . . . 26

Communication Over the FLEX I/O Backplane . . . . . . . . . . . . . . . . 26

Scheduled Data Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Unscheduled Data Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Module I/O Mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

I/O Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Fault State Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Device Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Communication Fault Behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Idle State Behavior. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Chapter Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Data Transfer Types. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Configuration Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Fault Mode (8 of 1 bit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Input Filter Cutoff (8 of 3 bits). . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

ADC Conversion Rate, Channel Update Time and Repeatability. 39

Data Format (8 of 4 bits). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Remote Low Low Alarm Limit (8 of 16 bit) . . . . . . . . . . . . . . . . . 41

Remote High High Alarm Limit (8 of 16 bit). . . . . . . . . . . . . . . . . 42

Low Alarm Limit (8 of 16 bit). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

High Alarm Limit (8 of 16 Bit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

HART Disable Channel 0 to 7 (8 of 1 bit). . . . . . . . . . . . . . . . . . . 43

HART Current Fault Limit (8 of 5 bits) . . . . . . . . . . . . . . . . . . . . . 43

Command 3 Disable (8 of 1 bit) . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Real Time Data (RTD) Profile, Primary Input Parameters . . . . . . . . . 45

Primary Input Data (8 of 16 bits each) . . . . . . . . . . . . . . . . . . . . . . 45

Real Time Data (RTD) Profile, Primary Status Parameters. . . . . . . . . 46

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

High Alarm (8 of 1 bit each) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Low Alarm (8 of 1 bit each) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Remote Alarm (8 of 1 bit each). . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Loop Alarm (8 of 1 bit each). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Module Diagnostic Status (1 of 8 bits) . . . . . . . . . . . . . . . . . . . . . . 49

HART Status Fields. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

HART Failure (8 of 1 bit each) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

HART Current Fault (8 of 1 bit each) . . . . . . . . . . . . . . . . . . . . . . 52

HART Transmitter List (8 of 1 bit each) . . . . . . . . . . . . . . . . . . . . 52

Secondary Input Data Table, Cyclic EDT Input Data. . . . . . . . . . . . . 52

Publication 1794-UM065B-EN-E - September 2010

Page 9

Table of Contents iii

HART Command 3 Communication Status (8 of 1 bits): . . . . . . . 53

HART Field Device Command and Communication

Status (8 of 8 bits) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

HART Field Device Status (8 of 8 bits) . . . . . . . . . . . . . . . . . . . . . 54

HART Loop Status (8 of 8 bits):. . . . . . . . . . . . . . . . . . . . . . . . . . . 55

HART PV Status (8 of 8 bits): . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Primary HART Variable (8 of 32 bits):. . . . . . . . . . . . . . . . . . . . . . 56

Secondary HART Variable (8 of 32 bits):. . . . . . . . . . . . . . . . . . . . 56

Third HART Variable (8 of 32 bits):. . . . . . . . . . . . . . . . . . . . . . . . 56

Fourth HART Variable (8 of 32 bits): . . . . . . . . . . . . . . . . . . . . . . 56

Primary HART Variable Units Code (8 of 8 bits):. . . . . . . . . . . . . 56

Secondary HART Variable Units Code (8 of 8 bits):. . . . . . . . . . . 56

Third HART Variable Units Code (8 of 8 bits):. . . . . . . . . . . . . . . 57

Fourth HART Variable Units Code (8 of 8 bits): . . . . . . . . . . . . . 57

Interpret the Status Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Module Configuration for the 1794-OF8IH. . . . . . . . . . . . . . . . . . . . . 57

Output Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Configuration Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Analog Output Module (1794-OF8IH) . . . . . . . . . . . . . . . . . . . . . 59

Byte Order (2 of 2 bits) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Fault Mode (8 of 1 bit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Bus Communications and Module Fault Mode (1 of 1 bit). . . . . . 64

HART Disable Channel 0 to 7 (8 of 1 bit). . . . . . . . . . . . . . . . . . . 65

HART Current Fault Limit (8 of 5 bits) . . . . . . . . . . . . . . . . . . . . . 65

Analog Data Format (8 of 4 bits each) . . . . . . . . . . . . . . . . . . . . . . 65

Latch Mode (8 of 1 bit each). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Analog/Digital Output Mode (8 of 1 bit each) . . . . . . . . . . . . . . . 67

Analog Mode Fault State (8 of 2 bits each) . . . . . . . . . . . . . . . . . . 68

Analog Mode Channel Fault State Value (8 of 16 bits each). . . . . 68

Digital Mode Fault State (8 of 1 bit each). . . . . . . . . . . . . . . . . . . . 69

Command 3 Disable (8 of 1 bit) . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Real Time Data (RTD) Profile, Status Parameters . . . . . . . . . . . . . . . . 70

Fault Alarm (8 of 1 bit each) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Diagnostic Data (1 of 8 bits) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

HART Status Fields. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

HART Current Fault (8 of 1 bit each) . . . . . . . . . . . . . . . . . . . . . . 73

HART Transmitter List (8 of 1 bit each) . . . . . . . . . . . . . . . . . . . . 73

Real Time Data (RTD) Profile, Output Parameters. . . . . . . . . . . . . . . 73

Analog Output Data (8 of 16 bits each) . . . . . . . . . . . . . . . . . . . . . 73

Digital Output Data (8 of 1 bit each) . . . . . . . . . . . . . . . . . . . . . . . 73

Global Reset (1 of 1 bit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Fault (1 of 1 bit) and Run/Prog (1 of 1 bit) . . . . . . . . . . . . . . . . . . 74

Secondary Input Data Table, Cyclic EDT Input Data. . . . . . . . . . . . . 75

Secondary Data Table Section Created by the Adapter. . . . . . . . . 75

HART Command 3 Communication Status (8 of 1 bits) . . . . . . . 75

Publication 1794-UM065B-EN-E - September 2010

Page 10

iv Table of Contents

Configure Module Messaging

Troubleshoot Your Module

FLEX I/O HART Module Commands

Additional HART Protocol

Information

FLEX I/O HART Modules Network

Messaging

Use the 1794-IF8IH Module with

the Generic Profile

Status Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Chapter Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

HART Configuration Quick Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Pick HART Input Data Format . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Enable HART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Enable Publishing HART Command 3 Variables . . . . . . . . . . . . . 79

Accessing HART Data Using CIP Message Instruction (MSG) . . 79

Fill in The Information Needed for a MSG Instruction . . . . . . . . 79

Select the Attribute Value for the Operation You Want

to Perform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Retrieve Additional Information About the HART Device . . . . . 81

Get Device Info Block 1 Message . . . . . . . . . . . . . . . . . . . . . . . . . 82

Get Device Info Block 2 Message . . . . . . . . . . . . . . . . . . . . . . . . . 84

Get Device Info Block 3 Message . . . . . . . . . . . . . . . . . . . . . . . . . 85

Reset the Device Info Changed Status Bit Message. . . . . . . . . . . . 87

HART Pass through Message Overview . . . . . . . . . . . . . . . . . . . . 88

Format a HART Pass through Init Request Message . . . . . . . . . . 89

Format a "Get Pass through Message Status" Request . . . . . . . . . 90

HART Failed Reason Code. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Format a "Read Pass through Reply" Request . . . . . . . . . . . . . . . . 93

Chapter Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Interpret Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Chapter Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Protocol Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Universal Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Common Practice Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Device-specific Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Message Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Master-slave Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Multiple Master Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Transaction Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Burst Mode (not supported) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Universal Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Common Practice Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

HART Frame Enhancements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Background Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Byte Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Publication 1794-UM065B-EN-E - September 2010

Page 11

Use the 1794-OF8IH Module with

the Generic Profile

Index

Table of Contents v

Fault Enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

HART Disable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Channel Data Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Digital Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

High Alarm Limit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Low Alarm Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Remote High High Alarm Limit . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Remote Low Low Alarm Limit. . . . . . . . . . . . . . . . . . . . . . . . . . . 127

HART Command 3 Disable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Input Map. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Input Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

High Alarm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Low Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Out of Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Second Alarm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Diagnostic Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

HART Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

HART Current Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

HART Transmitter Present. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Background Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Byte Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Fault Enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Local Fault Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

HART Disable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Channel Data Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Analog Fault Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Digital Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Digital Fault Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Analog Fault Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

HART Command 3 Disable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Digital Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Fault Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Analog Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Diagnostic Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Module Diagnostic Status (1 of 8 bits) . . . . . . . . . . . . . . . . . . . . . 143

HART Current Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

HART Transmitter Present. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Publication 1794-UM065B-EN-E - September 2010

Page 12

vi Table of Contents

Notes:

Publication 1794-UM065B-EN-E - September 2010

Page 13

Chapter

IMPORTANT

1

About the FLEX I/O HART Analog Module

Overview

This chapter describes the FLEX I/O Highway Addressable Remote

Transducer (HART) analog modules and what you must know and do before

you begin to use them.

Read this chapter to familiarize yourself with the HART analog modules.

Topic Page

What FLEX I/O Analog Modules Do 1

Communicate with Programmable Controllers 2

Use Alarms on the Input Module 3

Use the HART Capabilities 6

HART Implementation Overview 6

Chapter Summary 6

To use all of the features of this module it must be used with the

1794-ACN(R)15 with version 5.1 firmware or later, or the 1794-AENT

with version 4.2 firmware or later.

For more information about using this module with 1794-ACN(R)15

with version 5.1 (or greater) firmware, see 1794-RN071

.

What FLEX I/O Analog Modules Do

1 Publication 1794-UM065B-EN-E - September 2010

The FLEX I/O HART input and output modules must be used in a

ControlNet or EtherNet network.

The 1794-IF8IH module accepts up to 8 analog inputs. The inputs are isolated

and will accept current in either of the following two ranges: 4…20 mA or

0…20 mA. The default input range is 0…20 mA. The inputs have both fixed

hardware filters and selectable firmware digital filters.

Similarly, the 1794-OF8IH module provides as many as 8 analog outputs. The

outputs are isolated and will provide current in either of the following two

ranges: 4…20 mA or 0…20 mA. The default output range is 0…20 mA.

Each module offers:

• local microprocessor intelligence for advanced features.

• full functionality without switches or jumpers.

Page 14

2 About the FLEX I/O HART Analog Module

• multiple data ranges that can be independently programmed for each

channel.

• lead breakage detection.

• overrange/underrange alarms.

• remote transmitter alarm.

Communicate with Programmable Controllers

Data connections are established between the FLEX I/O module and an

Allen-Bradley programmable controller (PLC) to transfer information

between the two at a scheduled rate.

Input module information is then automatically made available in the PLC

data table through the data connection. Reciprocally, output data information

determined by the PLC program is also automatically transferred from the

PLC data table to the output module through the data connection.

In addition, when the data connection is originally established, configuration

information for the module is automatically transferred to it via the network.

Events Following Power-up

You must apply +24V DC power to your FLEX I/O analog I/O modules.

The following sequence of events occurs after power has initially been applied

to your module:

1. The module status indicator will blink red until a connection is

established and a valid configuration is passed to the module.

Publication 1794-UM065B-EN-E - September 2010

2. After the diagnostic check, module configuration information, selected

by the user and downloaded over the network, is applied by the module.

For more information on configuration options, refer to Configurable

FLEX I/O Analog Module Features.

3. Following the module configuration download for the 1794-IF8IH

module, the module begins producing runtime data for the PLC

processor.

Following the module configuration download for the 1794-OF8IH

module, the module applies configuration data to output channels.

4. If any diagnostics or alarms are generated during normal module

operation, the data is returned to the PLC processor.

Page 15

About the FLEX I/O HART Analog Module 3

Module type

Removable label

Keyswitch position

indicator (#3)

Power On indicator

Input designators

44811

Physical Features of Your Module

The module label identifies the keyswitch position, wiring and module type.

Use the removable label to note individual designations per your application.

Indicators

Indicators are provided to identify input or output fault conditions, and to

show when power is applied to the module. For example, the 1794-IF8IH

module is shown below.

8 CH HART ISOLATED ANALOG INPUT

IN1IN0 IN2 IN3 IN4

IN5

1794-IF8IH

IN6 IN7

3

PWR

Use Alarms on the Input Module

The 1794-IF8IH FLEX I/O module is capable of generating four alarms:

•Underrange

•Overrange

•Remote Fault

•Local Fault

These alarm conditions are described in general terms and as they relate to bits

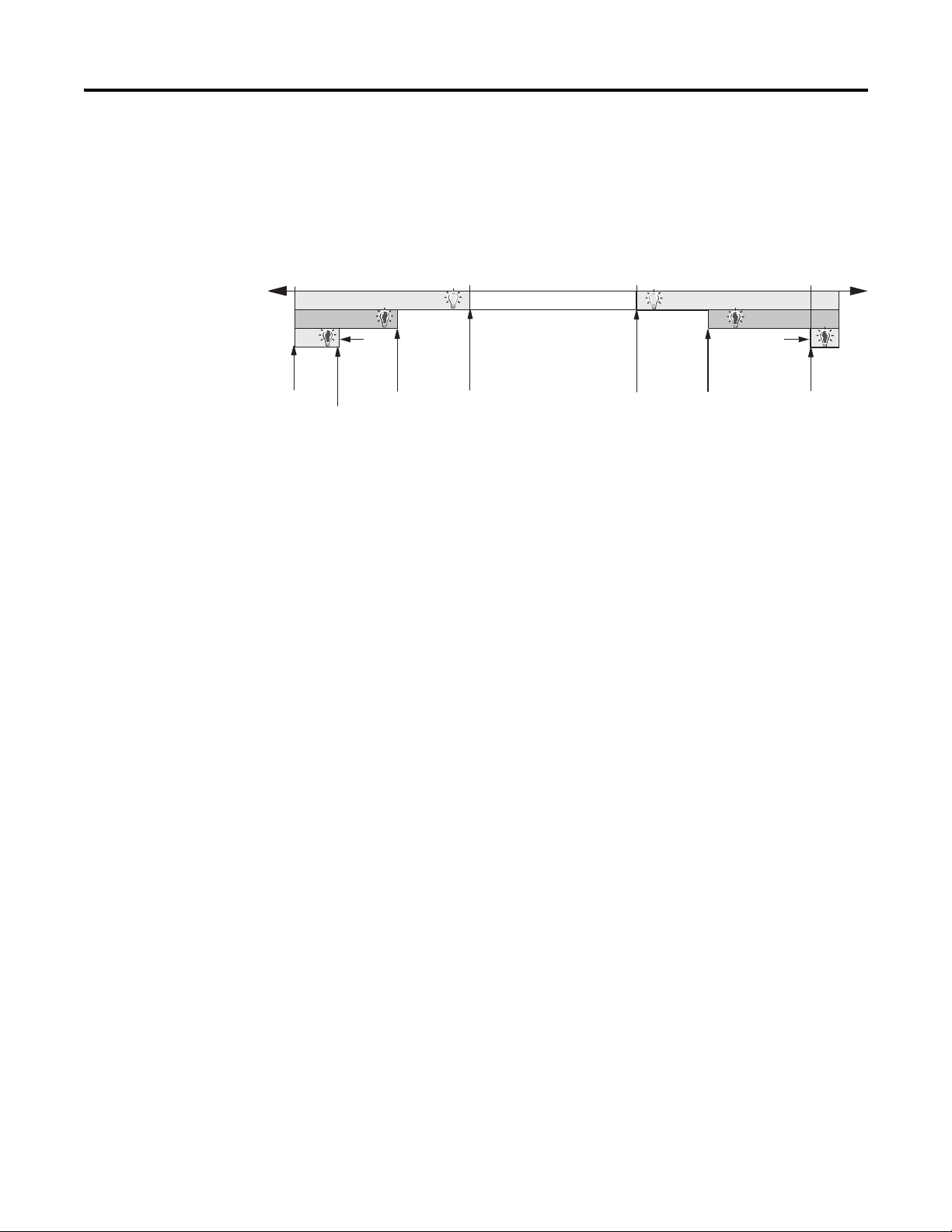

on the FLEX I/O module on the following pages. The following graphic

shows at what values these alarms are generated for

4…20 mA 1000/mA range.

Publication 1794-UM065B-EN-E - September 2010

Page 16

4 About the FLEX I/O HART Analog Module

0 mA 4 mA 20 mA 22 mA

Remote Fault

Remote Fault

Local

Fault

Local

Fault

Underrange Overrange

Programmable

in 20 0.1 mA

steps by Error

Level 0.1 mA

Steps

parameter

-12.50%

0.00%

-25.00%

Programmable

in 20 0.1 mA

steps by Error

Level 0.1 mA

Steps

parameter

100.00% 112.50%

45149

Data Format Alarm Example

In this example, the normal active data range is 4…20 mA. The alarms are

generated in three overlapping bands.

Physical Input Signal Ranges

Publication 1794-UM065B-EN-E - September 2010

Overrange Alarm

The overrange alarm notifies you when module input is overrange. When the

input signal exceeds 100% (20 mA), an Overrange Alarm is generated.

This alarm stays active at any value above 100% of range and is always enabled

by the module.

Underrange Alarm

The underrange alarm works converse to the overrange. This feature notifies

you when the input signal falls underrange. If the input signal falls below

0% (4 mA), an Underrange Alarm is generated.

This alarm stays active at any value below 0% of range and is always enabled by

the module.

Remote Fault Alarm

The remote fault alarm is intended for use with remote transmitter loops.

For example, the remote transmitter may be measuring temperature and

converting it to a standard mA signal. In such a loop, though, the input module

cannot determine the state of the loop on the far side of the transmitter.

Page 17

About the FLEX I/O HART Analog Module 5

IMPORTANT

IMPORTANT

However, the remote transmitter may be capable of diagnosing a problem in

the remote loop and signal the input module local loop with a preprogrammed

out of range (high or low) value.

The Fault Enable bit allows the 1794-IF8IH module to work with transmitters

like the one just described.

Once the alarm is issued, it remains active as long as the input signal

value remains above the programmed value.

Use Remote Fault Alarm to Determine High-High or Low-Low Alarm Levels

If you do not have a remote transmitter in your loop, this alarm can also be

used to program a high-high or low-low alarm level between the levels which

actuate the overrange or underrange alarms and the high or low local fault

alarms.

Programming the Remote Fault Alarm

For the remote fault alarm, you must program the threshold in 0.1 mA steps at

any level on the high or low end of input signal range. The remote fault alarm

activates if your I/O module receives input signal values of:

• 100.63…111.88% (20.1…21.9 mA) on the high end of input signal

range

or

• -0.63…-11.88% (3.9…2.1 mA) on the low end of input signal range.

Local Fault Alarm

The local fault alarm notifies you when the loop to the transmitter or field

device, if no transmitter is used, is open or shorted.

Once the alarm is issued, it remains active as long as the input signal

value remains in the programmed range.

• 112.50% (22 mA) or higher on the high end of input signal range.

This value indicates a short in the loop.

or

• -12.50% (2 mA) or lower on the low end of input signal range.

Publication 1794-UM065B-EN-E - September 2010

Page 18

6 About the FLEX I/O HART Analog Module

Processor

User program

Adapter FLEX I/O

HART

module

HART

Field Device

Command

Response

for example, HART

Command 3)

Flexbus

4…20 mA with

HART signal

This value indicates an open wire condition in the loop.

The remote fault and local fault alarms are issued with the same bit whether

the cause is an under or overrange. Monitor the overrange and underrange bits

in your programming software to determine if the problem is a high current or

low current.

Use the HART Capabilities

HART Implementation Overview

Before using the HART capabilities, be sure that:

• the I/O module and the associated field device are working properly in

the analog 4 to 20 mA mode.

• the I/O module is configured for 4 to 20 mA range.

• the field device is HART capable.

• no more than one HART field device is connected to each channel.

• input filtering is set to a valid (defined) value.

The FLEX I/O HART modules act as intelligent HART multiplexers.

Basically, the module learns which HART devices are attached to its channels

and then routes HART messages, as appropriate, between the HART field

devices and the flexbus. Since the HART modules act as intelligent HART

multiplexers, HART commands can be issued to the HART modules

themselves.

Communication on the flexbus occurs between the adapter and the HART

module. The adapter converts these messages to the appropriate network

format for communication with the controlling processor. The controlling

processor gets its command from the user program, storing the responses in

its memory.

Chapter Summary

Publication 1794-UM065B-EN-E - September 2010

In this chapter, you learned about FLEX I/O analog I/O modules and HART

module capabilities. Read the next chapter to learn about configurable features

on your module.

Page 19

Chapter

IMPORTANT

Configurable FLEX I/O Analog Module

Features

2

Overview

Read this chapter to familiarize yourself with configurable features on the

input and output analog modules

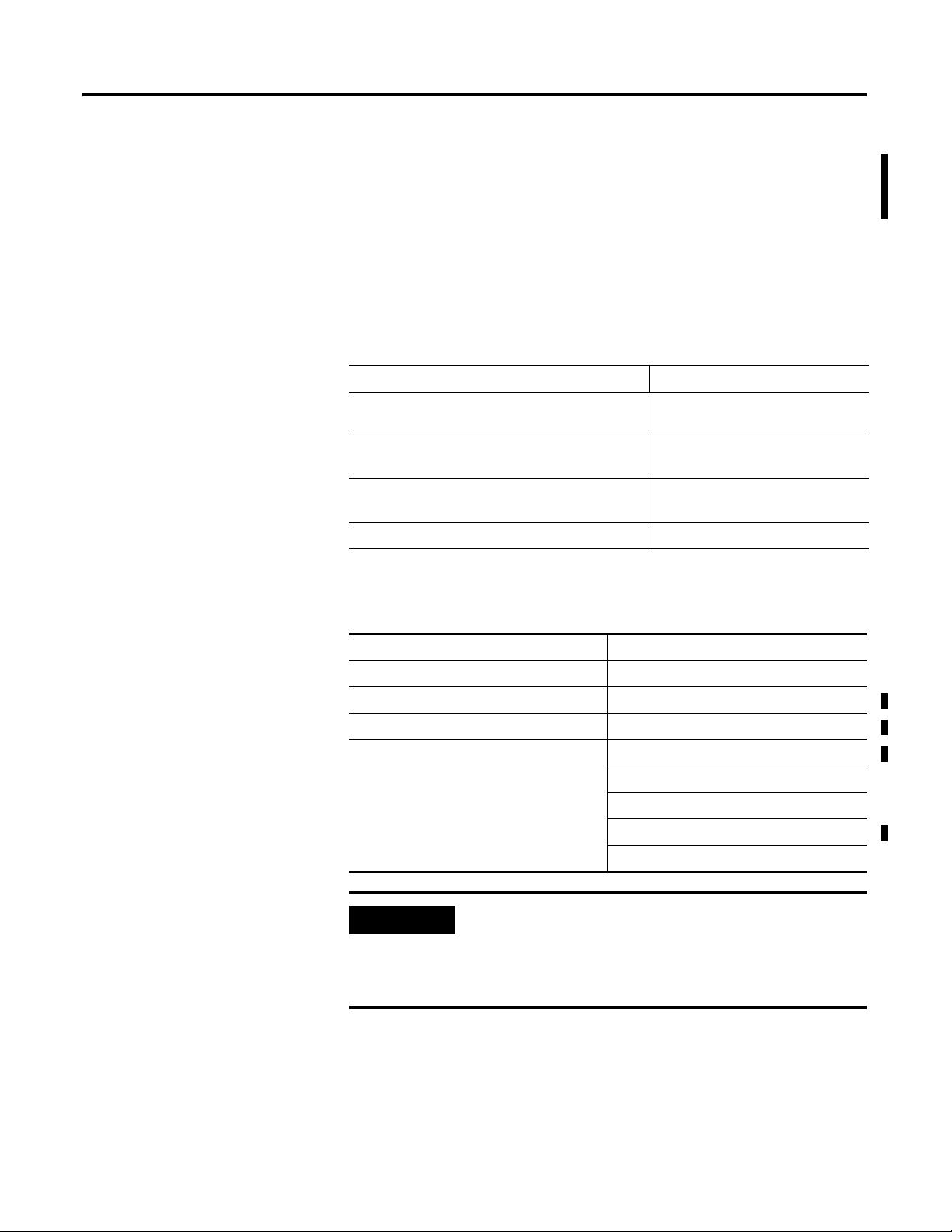

Topic Page

Select Your Analog Input Module Operating

Features

Select Your Analog Output Module Operating

Features

Understand Image Table Mapping and Bit/Word

Descriptions

Chapter Summary 14

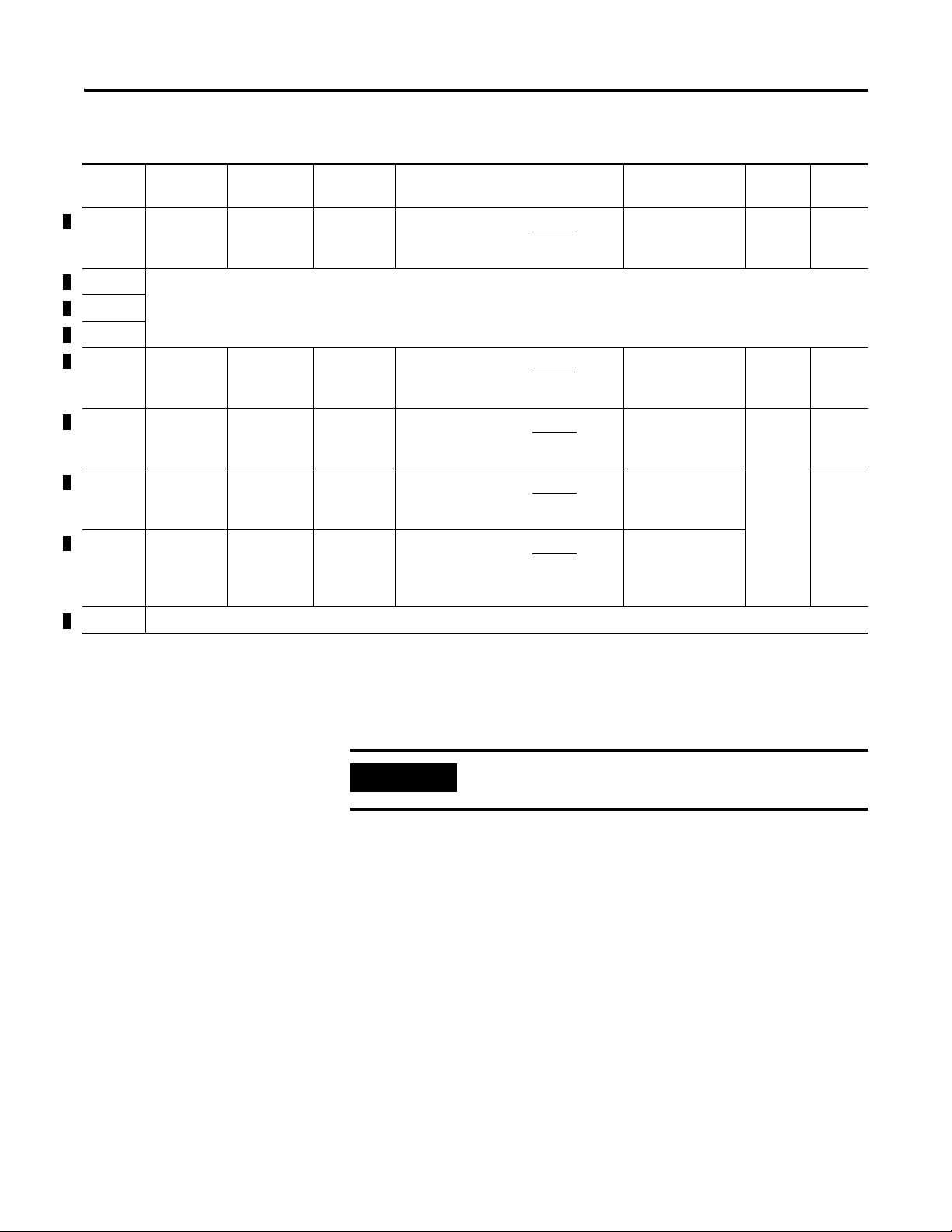

HART configurable features described in this chapter include the following

Analog/Digital Configurable Features on FLEX I/O Analog I/O Modules

1794-IF8IH Input Module 1794-OF8IH Output Module

Fault Mode Output Enable

High Low Error Level Module Fault State Mode

Input Filter Cutoff Local Fault Mode

Data Format Data Format

8

10

13

Global Reset

7 Publication 1794-UM065B-EN-E - September 2010

Analog Fault State

Latch Retry Mode

Fault Alarm

You must use the I/O configuration portion of your PLC programming

software to select and configure these features. This manual assumes

familiarity with the programming software. A brief description of

each module feature is provided here. For more information on your

programming software, refer to the software user manual.

Page 20

8 Configurable FLEX I/O Analog Module Features

IMPORTANT

IMPORTANT

Select Your Analog Input Module Operating Features

All features of the 1794-IF8IH analog input module are independently

configurable.

The default selection value for all parameters is 0.

Fault Enable

Your input modules are capable of indicating various fault conditions,

depending on the input signal value. Use the Fault Enable feature to enable or

disable two alarms:

•Remote Fault Alarm

•Local Fault Mode

Use your programming software to set the Fault Enable bit to 0 to disable

these alarms. Set the bit to 1 to enable them.

Fault Enable will only enable or disable the Remote and Local Fault

alarms. It does not affect the Underrange and Overrange alarms. They

are always active.

For more information refer to Remote Fault Alarm and Local Fault Alarm.

Input Filter Cutoff

Six available input filter settings allow you to choose the best rolloff frequency

for input channels on your I/O module. When choosing a filter, remember

that time filter selection affects your input signal’s accuracy.

For example, if you choose the highest frequency of 470 Hz (filter 0), signal

noise is more likely to affect the reading, but the slowest frequency of 4.17 Hz

(filter 5) provides the most accurate signal due to incoming noise filtering.

Refer to the Input Filter Frequency table to decide which input filter to use in

your FLEX I/O analog I/O application:

Input Filter Frequency

01234567

470 Hz 62 Hz 19.6 Hz 16.7 Hz 10 Hz 4.17 Hz n/a n/a

Choose the best input filter cutoff in your programming software.

Publication 1794-UM065B-EN-E - September 2010

Page 21

Configurable FLEX I/O Analog Module Features 9

input

(

20

)

Datatable = 10000

Datatable = 10000

√

input

20

IF...Square_Root_Threshold

< 10000

√

input

20

Else...datatable = 0

input

(

20

)

Datatable = 65535

input-4

(

16

)

Datatable = 10000

Datatable = 10000

√

IF...Square_Root_Threshold

< 10000

√

Else...datatable = 0

input-4

16

input-4

16

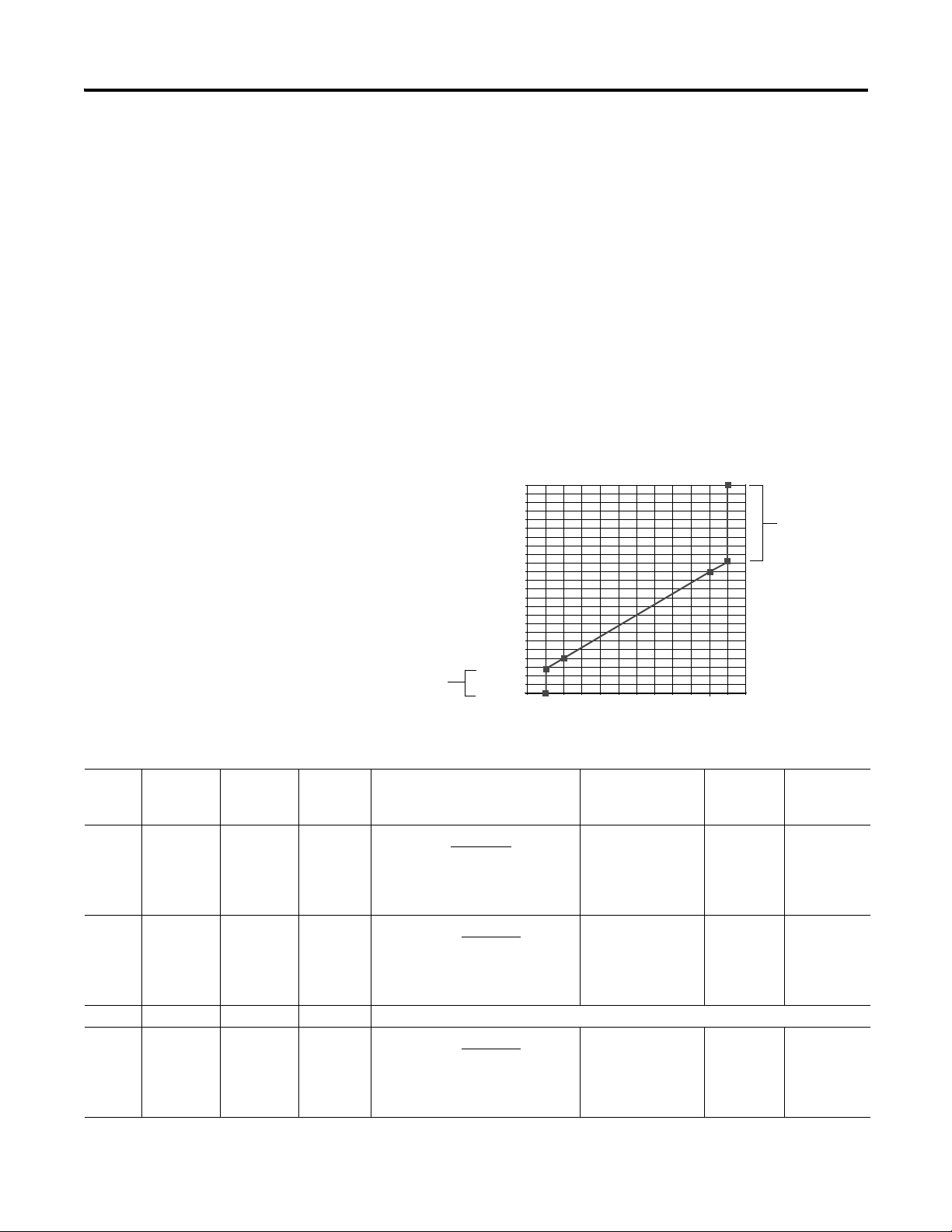

Data Format

You must choose a module data format in your user program. Formats 8, 9, 10

and 15 are not used. If they are selected for a channel quad, a configuration

fault will occur and will be reported as Diagnostic Data 2. All data for that

channel quad will be set to zero (0).

Formats 5, 12, 13 and 14 are 2’s complement data formats, and will return data

in that form.

12 Formats are available

1794-IF8IH Data Formats

Data

Format

0 0…20 mA

1 0…20 mA

2 0…20 mA

3 0…20 mA

4 4…20 mA

5 4…20 mA

Format Resolution Input

as mA

as %

as √%

as unsigned

integer

as mA

as %

0.1 % of

0…20 mA

0.2 % of

0…20 mA

0.19 % of

0…20 mA

0.03 % of

0…20 mA

0.1 % of

4…20 mA

0.16 % of

4…20 mA

Default format is 0

The data format selected interprets input readings and returns them to the

PLC.

Module Data Processing Data Table Value

Range

0…22 mA Datatable = 1000 (input) 0…22000

0…22 mA 0…11000

0…22 mA 0…10488

0…20 mA 0…65535

2…22 mA Datatable = 1000 (input) 2000…22000

2…22 mA -1250…+11250

…20 mA

(Interpretation)

(0…22.000 mA)

(0…110.00%)

(0…104.88%)

(0…22 mA)

(2.000…22.000

mA)

(2’s complement)

(-12.50%…+112.5

0%)

Count

per mA

1000 With

500

524

3276

1000

625 With

Error

Steps

error

steps

error

steps

6 4…20 mA

as √%

0.17 % of

4…20 mA

4…22 mA 0…10607

(0…106.07%)

Publication 1794-UM065B-EN-E - September 2010

With

error

steps,

under-r

ange

not

allowed

Page 22

10 Configurable FLEX I/O Analog Module Features

input-4

(

16

)

Datatable = 65535

input

(

22

)

Datatable = 55000

input-4

(

16

)

Datatable = 10000

input-4

(

16

)

Datatable = 10000

input-4

(

16

)

Datatable = 10000

IMPORTANT

1794-IF8IH Data Formats

Data

Format

7 4…20 mA

8 Not assigned

9

10

11 0…20 mA

12 4…20 mA

13 4…20mA

14 4…20 mA

15 Not assigned

Format Resolution Input

as unsigned

integer

as A/D

count

as %

as %

as %

0.03% of

4…20 mA

0.04% of

0…20 mA

0.16% of

4…20 mA

0.16% of

4…20 mA

0.16% of

4…20 mA

Module Data Processing Data Table Value

Range

0…22 mA 0…55000

3.6…21 mA -250 … +10625

3…21 mA -625 … +10625

2…22 mA -1250 … +11250

(Interpretation)

0…65535

(4…20 mA)

(0…22 mA)

(2’s complement)

(-2.50…+106.25%)

(2’s complement)

(-6.25…+106.25%)

(2’s complement)

(-12.50…+112.50

%)

Count

per mA

4095 With

2500 All

625 NAMU

Error

Steps

error

steps

fixed

R NE 4

all fixed

All

fixed

Select Your Analog Output Module Operating Features

All features of the 1794-OF8IH analog output module are independently

configurable.

The default selection value for all parameters is 0.

Local Fault Mode

The Local Fault Mode can be programmed to determine how the module

responds to communications faults and internal module faults.

When setting the Local Fault Mode feature in your programming software, set

this feature’s bit to 0 to use the analog fault state or digital fault state only if a

communications fault occurs. Set the bit to 1 to use the Analog Fault state or

Digital Fault state if any fault occurs.

Publication 1794-UM065B-EN-E - September 2010

Page 23

Configurable FLEX I/O Analog Module Features 11

Latch Mode

Latch Mode determines channel operation under wire-off or lead-break fault

conditions. This feature is available for each channel. Channel detection occurs

on a continuous basis. If a fault is detected, the channel fault alarm is set.

If Latch mode is enabled when a fault occurs, the fault will remain latched in

its fault state until a Global Reset (see below) is issued. If Latch mode is

disabled when a fault occurs, the channel reports a fault until the fault is

corrected. Global Reset is not necessary if Latch mode is disabled.

When using your programming software, set the Latch mode bit to 0 to disable

the feature. Set the bit to 1 to enable it.

Global Reset

Global Reset works in conjunction with Latch mode during fault conditions. If

Latch mode is enabled and a fault condition occurs, the channel operating with

a fault remains in this condition (with analog or digital fault state implied) until

a Global Reset is issued. The Global Reset feature resets all outputs of a

particular channel group to accept normal system output data.

The Global Reset feature is an edge triggered signal. Use your programming

software to set the Global Reset bit to 1 for normal operation. Resetting of

outputs occurs during the 1 to 0 transition.

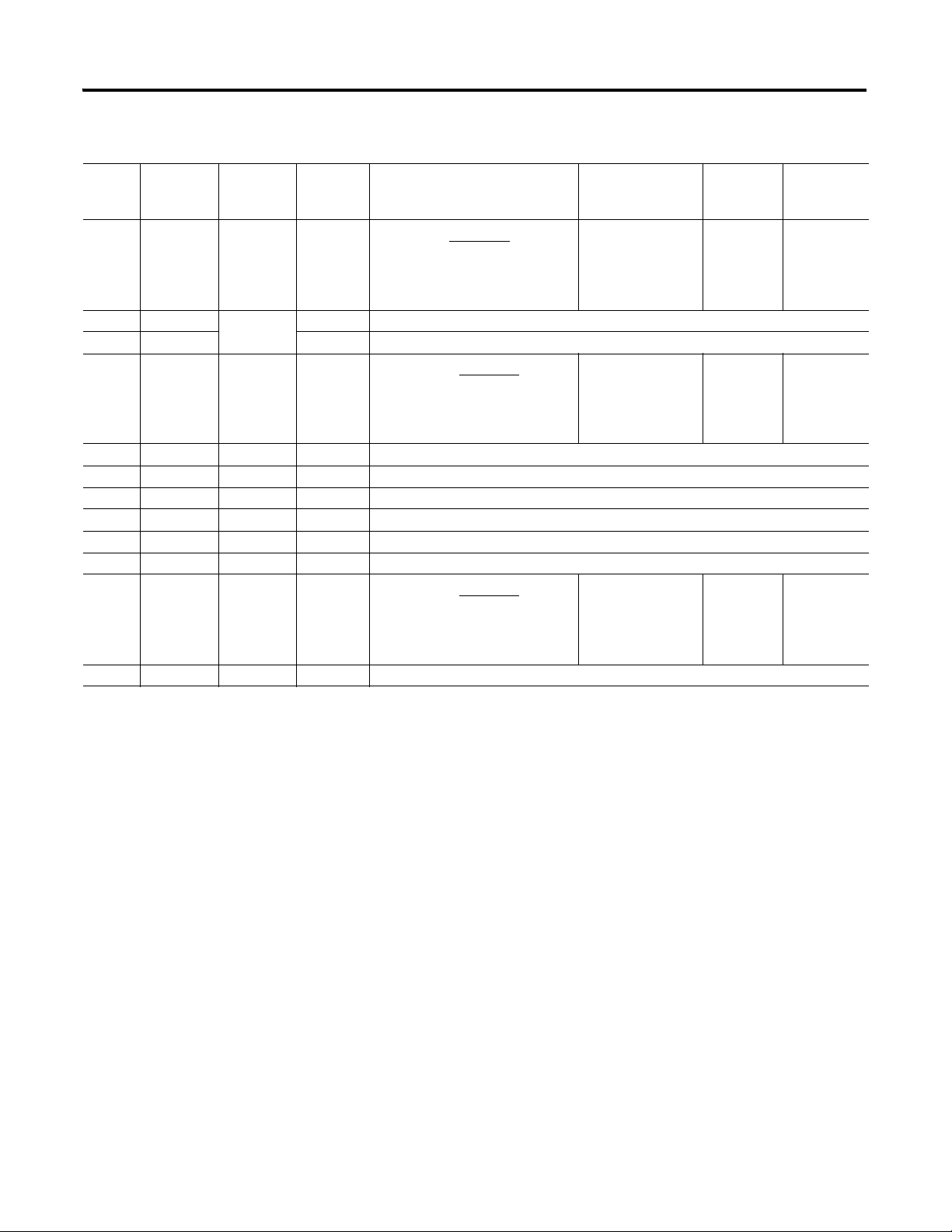

Data Format

You must choose a module data format in your user program. Refer to

1794-OF8IH Data Formats for an explanation of each bit. Data Formats 2, 5,

6, 8, 9, 10, 11, 12, 13 and 15 are not assigned.

When choosing a data format, remember the following:

• If an unassigned Analog Data Format is selected, the module sets

Diagnostic Data to 2 for configuration failure and puts affected

channels in the corresponding fault state.

• An unconfigured module channel can be assumed to have the default

configuration Analog Data Format 0, 0 to 20 mA and Analog Mode

Fault State minimum range. If a non-assigned format is selected, then

the diagnostic 2 for configuration failure is set and the module channel

goes to the default fault state minimum range.

Publication 1794-UM065B-EN-E - September 2010

Page 24

12 Configurable FLEX I/O Analog Module Features

Diagnostic Data error 11

= data out of range

Diagnostic Data error 11

= data out of range

04812162024

Output mA

datatable

20.000

16.000

12.000

8.000

4.000

0.000

-4.000

Output =

datatable

(

1000

)

Output = 20

datatable

(

10000

)

Output = 20

datatable

(

65535

)

• If on the other hand, the configuration had been changed, from the

default, and then it was changed again to a non-assigned format, then

the diagnostic bit 2 for configuration failure is set and the module goes

to the fault state for the last valid configuration.

• Formats 13 and 14 are 2’s complement data formats, and require data to

the module in that form.

• Range: 0…15

•Default: 0

• Data Table Reference: data format, word 12 and 13, bits 0…3, bits 4…7

If data is sent to the module which is out of range, the value will be clipped

and Diagnostic Data will be set to 11 data out of range.

Example of Analog Format 14 and Data Clipping Performance.

1794-OF8IH Data Formats

Data

Format

0mA as

1 % as

2 0…20 mA — 0…22 mA Not Assigned

3 Unsigned

Publication 1794-UM065B-EN-E - September 2010

Format Resolution Full

Output

Range

0…20 mA

0…20 mA

integer as

0…20 mA

0.1% of

0…20 mA

0.2% of

0…20 mA

0.03% of

0…20 mA

0…22 mA 0…22000

0…22 mA 0…11000

0…20 mA 0…65535

Module Data Processing Data Table Value

(Interpretation)

(0…22.000 mA)

(0…110.00%)

(0…20 mA)

Count per

mA/

Resolution

1000/

1.0 µA

500/

2.0 µA

3276/

0.305 µA

Analog Fault

State

Min=0 mA

Max=22 mA

hold

Last=hold

FS value

Min=0 mA

Max=22 mA

hold

Last=hold

FS value

Min=0 mA

Max=20 mA

hold

Last=hold

FS value

Page 25

1794-OF8IH Data Formats

Output =

datatable

(

1000

)

Output = 16

datatable

(

65535

)

+ 4

Output = 16

datatable

(

10000

)

+ 4

Configurable FLEX I/O Analog Module Features 13

Data

Format

4mA as

5 4…20 mA — 4…20 mA Not assigned

6 4…20 mA 4…20 mA Not assigned

7 Unsigned

8 0…20 mA 0…20 mA Not assigned

9 0…20 mA 0…20 mA Not assigned

10 0…20 mA 0…20 mA Not assigned

11 0…20 mA 0…20 mA Not assigned

12 4…20 mA Not assigned

13 4…20 mA Not assigned

14 % as

15 4…20 mA 4…20 mA Not assigned

Format Resolution Full

Output

Range

4…20 mA

integer as

4…20 mA

4…20 mA

0.1% of

4…20 mA

0.03% of

4…20 mA

0.16% of

4…20 mA

2…22 mA 2000…22000

4…20 mA 0…65535

2…22 mA -1250 … +11250

Module Data Processing Data Table Value

(Interpretation)

(2.000…22.000 mA)

(4…20 mA)

(2’s complement)

(-12.50% …

+112.50%)

Count per

mA/

Resolution

1000/

1.0 µA

4095/

0.244 µA

625/

1.6 µA

Analog Fault

State

Min=2 mA

Max=22 mA

hold

Last=hold

FS value

Min=4 mA

Max=20 mA

hold

Last=hold

FS value

Min=2 mA

Max=22 mA

hold

Last=hold

FS value

Understand Image Table Mapping and Bit/Word Descriptions

Fault Alarm

Fault Alarm selects whether the channel fault detection is enabled or disabled.

There is a 100 Hz (10 ms) filter for wire off or lead break detection.

Use your programming software to set the Fault Alarm. Set the feature bit to 0

to disable the alarm. Set the bit to 1 to enable wire off/lead break fault

detection.

All Allen Bradley FLEX I/O modules have a sixteen word table of Real Time

Data (RTD) to be transferred between the controller and the I/O module.

Publication 1794-UM065B-EN-E - September 2010

Page 26

14 Configurable FLEX I/O Analog Module Features

Not all 16 words need be allocated. The 1794-IF8IH has the following RTD

I/O Profile:

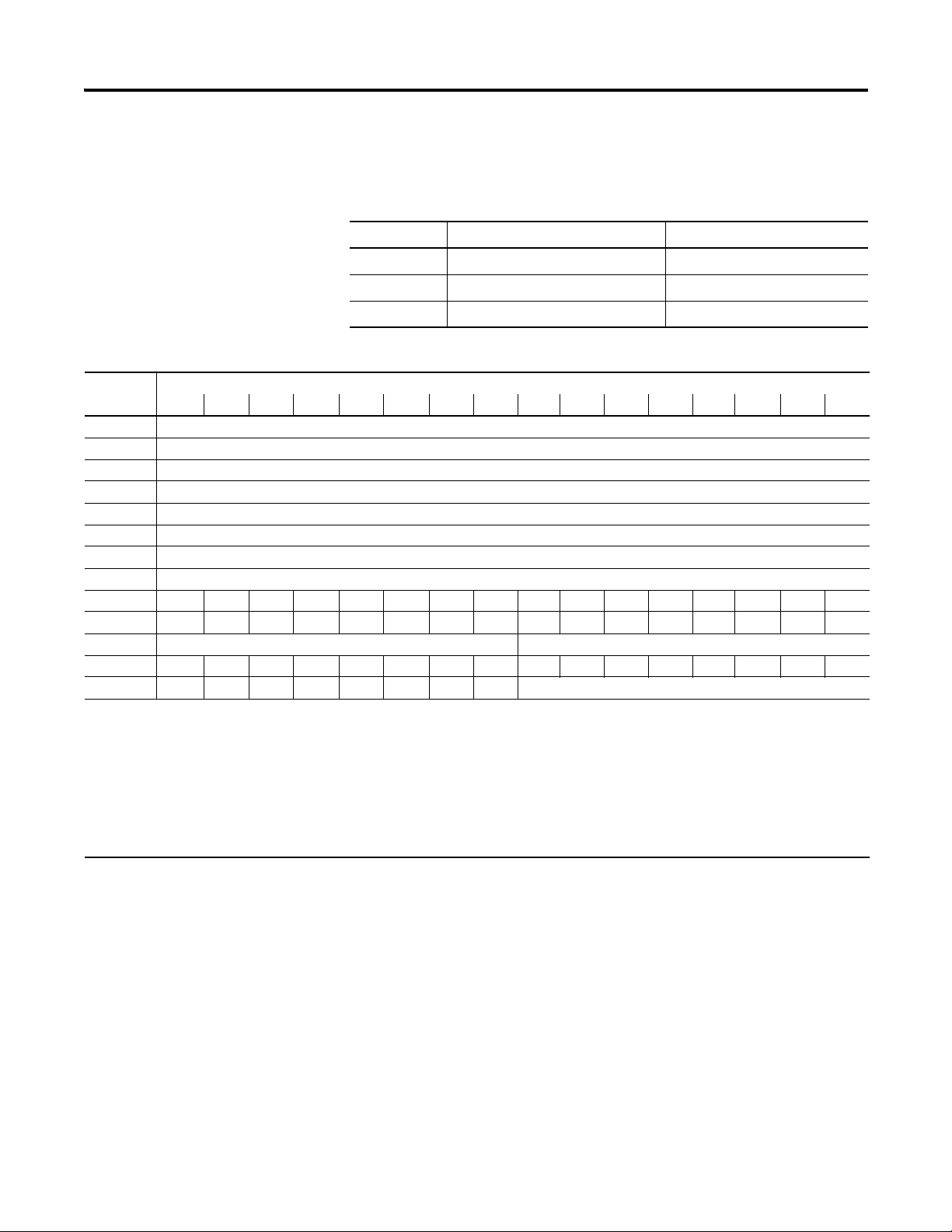

1794-IF8IH RTD I/O Profile

RTD Index Assembly Index Assembly

RTD 0 MSW Module Status Word

RTD 1 EDT Read Word EDT Read Word

RTD 2…9 I:0…I:7 RTD Input Data

1794-IF8IH Analog data table

Word Bit

1514131211109876543210

0 Channel 0 Input Data

1 Channel 1 Input Data

2 Channel 2 Input Data

3 Channel 3 Input Data

4 Channel 4 Input Data

5 Channel 5 Input Data

6 Channel 6 Input Data

7 Channel 7 Input Data

8 H7H6H5H4H3H2H1H0L7L6L5L4L3L2L1L0

9 R7 R6R5R4R3R2R1R0P7P6P5P4P3P2P1P0

10 Reserved Diagnostic Status

11 C7 C6 C5 C4 C3 C2 C1 C0 F7 F6 F5 F4 F3 F2 F1 F0

12 X7 X6 X5 X4 X3 X2 X1 X0 Reserved

Where: Hn: Channel n High Alarm

Ln: Channel n Low Alarm

Pn: Channel n Out Of Range Alarm

Rn: Channel n Second (Remote) Alarm

Fn: Channel n HART Failure

Cn: Channel n HART Current Fault

Xn: Channel n HART Transmitter Present

0: False 1: True

Chapter Summary

Publication 1794-UM065B-EN-E - September 2010

In this chapter, we told you about the FLEX I/O system and the analog I/O

modules, and how they communicate with programmable controllers. Move

on to the next chapter to learn how to install your FLEX I/O analog module.

Page 27

Chapter

ATTENTION

WARNING

Install Your FLEX I/O Analog Modules

3

Overview

Before You Install Your Analog Module

Read this chapter to install the input and output analog modules.

Topic Page

Before You Install Your Analog Module 15

Removal and Insertion Under Power 15

Install the Module 16

Wire the Terminal Base Units 22

Connect Wiring to the FLEX I/O HART Analog Modules 22

Ground the Module 24

Chapter Summary 24

Before installing your FLEX I/O analog module:

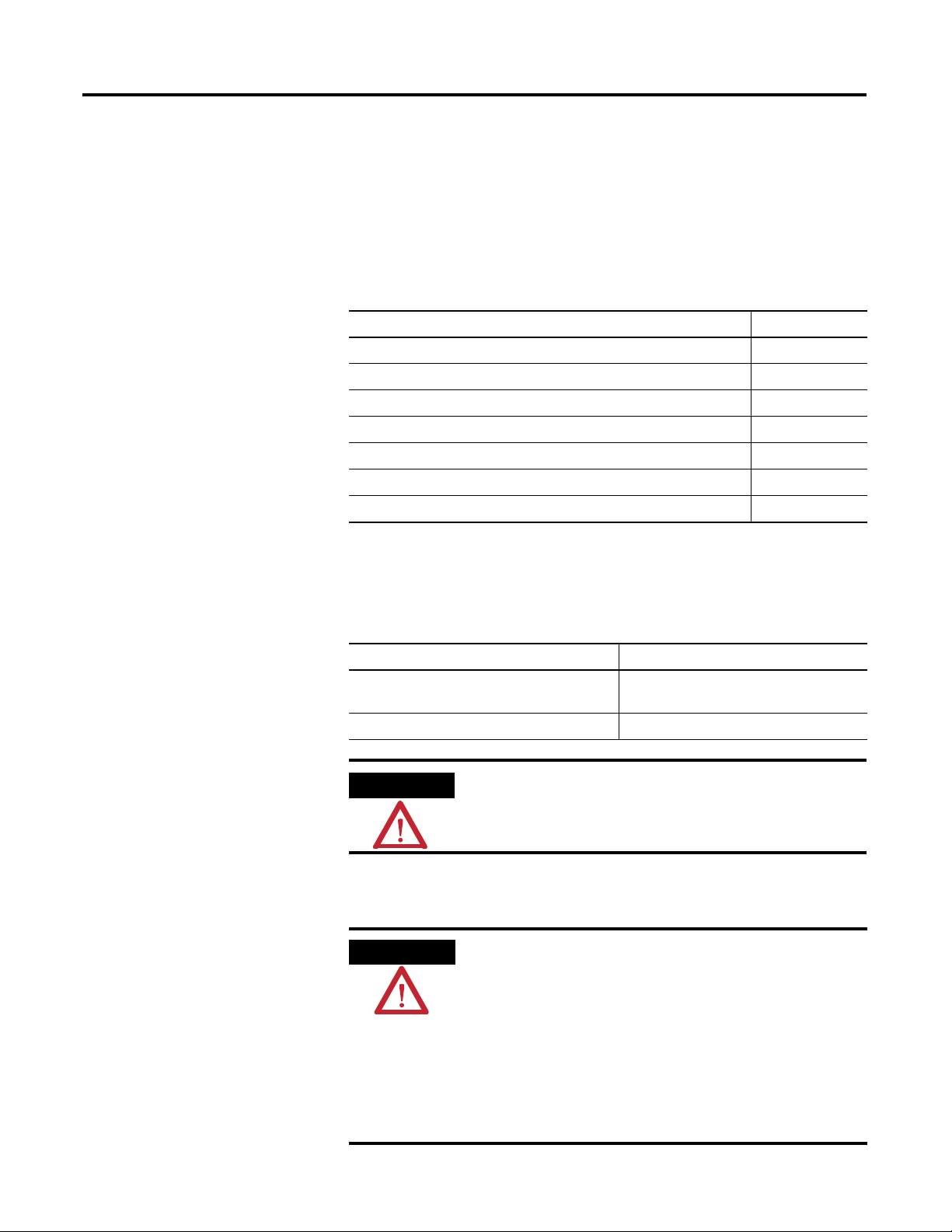

Steps to Complete Before Installation

You Need To As Descibed Under

Verify that the module will be installed in a

suitable enclosure

Position the keyswitch on the terminal base Install the Module, page 18

Removal and Insertion Under Power,

page 17

These modules do not receive primary operational power from the

backplane. +V and -V DC power must be applied to your module

before installation. If power is not applied, the module position will

appear to the adapter as an empty slot in your chassis.

Removal and Insertion Under Power

15 Publication 1794-UM065B-EN-E - September 2010

These module are designed so you can remove and insert them under

power. However, take special care when removing or inserting these

modules in an active process. I/O attached to any module being

removed or inserted can change states due to its input/output signal

changing conditions.

If you insert or remove the terminal base while backplane power is on,

an electrical arc can occur. This could cause an explosion in hazardous

location installations.

Be sure that power is removed or the area is nonhazardous before

proceeding.

Page 28

16 Install Your FLEX I/O Analog Modules

WARNING

ATTENTION

ATTENTION

When used in a class I, division 2, hazardous location, this equipment

must be mounted in a suitable enclosure with proper wiring method

that complies with the governing electrical codes.

Install the Module

Installation of the module consists of the following:

• Mounting the terminal base unit.

• Installing the analog I/O module into the terminal base unit.

• Installing the connecting wiring to the terminal base unit.

If you are installing your module into a terminal base unit that is already

installed, proceed to page 21.

Do not use the unused terminals on the terminal base unit. Using the

terminals as supporting terminals can result in damage to modules

and/or unintended operation of your system.

Mount on a DIN Rail

Do not remove or replace a terminal base unit when power is applied.

Interruption of the flexbus can result in unintended operation or

machine motion.

Install the Terminal Base Unit

1. Remove the cover plug in the male connector of the unit to which you

are connecting this terminal base unit.

2. Check to make sure that the 16 pins in the male connector on the

adjacent device are straight and in line so that the mating female

connector on this terminal base unit will mate correctly.

3. Make certain that the female flexbus connector is fully retracted into

the base unit.

Publication 1794-UM065B-EN-E - September 2010

Page 29

Install Your FLEX I/O Analog Modules 17

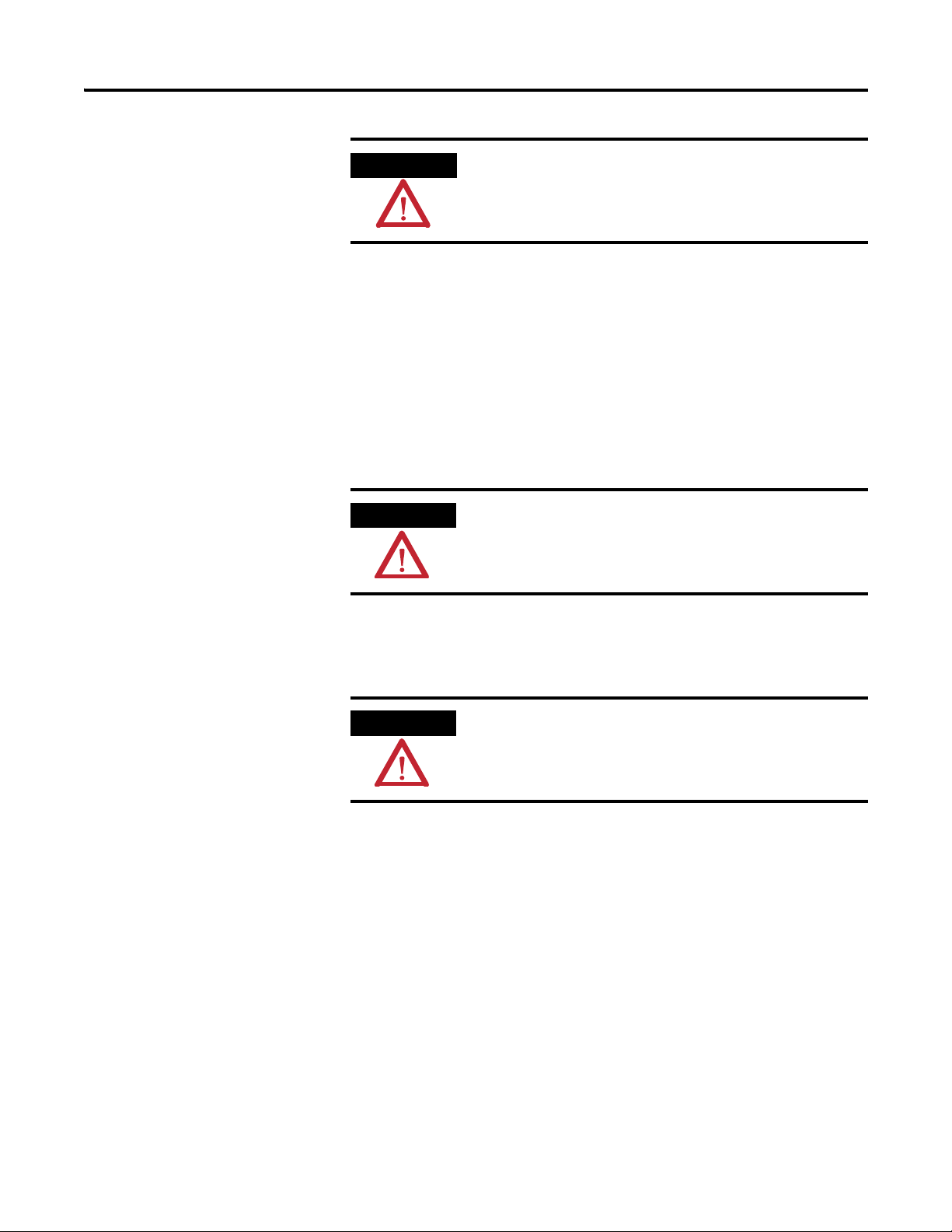

ATTENTION

A

A

41106

41107

4. Position the terminal base at a slight angle and hooked over the top of

the 35 x 7.5mm DIN rail A

(Allen Bradley part number 199-DR1)

5. Slide the terminal base over tight against the adapter (or proceeding

terminal base). Make sure the hook on the terminal base slides under the

edge of the adapter (or proceeding terminal base) and the FLEXbus

connector is fully retracted.

Do not force the terminal base into the adjacent modules. Forcing the

units together can bend or break the hook and allow the units to

separate and break communication over the backplane.

6. Rotate the terminal base onto the DIN rail with the top of the rail

hooked under the lip on the rear of the terminal base.

Use caution to make sure that the female flexbus connector does

not strike any of the pins in the mating male connector.

Publication 1794-UM065B-EN-E - September 2010

Page 30

18 Install Your FLEX I/O Analog Modules

41108

41109

7. Press down on the terminal base unit to lock the terminal base on the

DIN rail. If the terminal base does not lock into place, use a screwdriver

or similar device to open the locking tab, press down on the terminal

base until flush with the DIN rail and release the locking tab to lock the

base in place.

Gently push the Flexbus connector into the side of the adapter (or

proceeding terminal base) to complete the backplane connection.

8. For specific wiring information, refer to the installation instructions for

the module you are installing in this terminal base unit.

Terminal assignments are also given later in this chapter, see page 22.

9. Repeat the above steps to install the next terminal base unit.

Be sure the Flexbus connector cover on the last terminal base unit is in

place.

Mount on a Panel or Wall

Installation of a FLEX I/O system on a wall or panel consists of:

• laying out the drilling points on the wall or panel.

• drilling the pilot holes for the mounting screws.

• mounting the adapter mounting plate.

• installing the terminal base units and securing them to the wall or panel.

If you are installing your module into a terminal base unit that is already

installed, proceed to Mount the Analog Modules on the Terminal Base Unit on

page 21.

Publication 1794-UM065B-EN-E - September 2010

Page 31

Install Your FLEX I/O Analog Modules 19

4

1

2

(35.5)

1.4

41547

3

35.5

(1.4)

15.6

(0.61)

58.5

(2.3)

40.5

(1.6)

8 (0.3)

35.5

(1.4)

58.5

(2.3)

35.5

(1.4)

0.83 (21)

50

(2.0)

Measurements are in mm (in.)

40871

TIP

Use the mounting kit Cat. No. 1794-NM1 for panel/wall mounting.

Description Description

1 Mounting plate for adapter 3 Terminal base unit (not included)

2 #6 Self-tapping screws 4 Adapter module (not included)

To install the mounting plate on a wall or panel:

1. Lay out the required points on the wall/panel as shown in the drilling

dimension drawing.

Cable is either 292.1 mm (11.5 in.) or 901.0 mm (35.5 in.) from upper

connector — depending if you use 0.3 m (1 ft) or 0.91 m (3 ft) cable.

Publication 1794-UM065B-EN-E - September 2010

Page 32

20 Install Your FLEX I/O Analog Modules

ATTENTION

IMPORTANT

Be careful of metal chips when drilling cable mounting holes.

Do not drill holes above a system that has any modules installed.

2. Drill the necessary holes for the #6 self-tapping mounting screws.

3. Mount the mounting plate for the adapter module using two #6

self-tapping screws (18 included for mounting up to 8 modules and the

adapter).

Make certain that the mounting plate is properly grounded to

the panel. Refer to Industrial Automation Wiring and Grounding

Guidelines, publication 1770-4.1

.

4. Hold the adapter at a slight angle and engage the top of the mounting

plate in the indention on the rear of the adapter module.

5. Press the adapter down flush with the panel until the locking lever locks.

6. Position the terminal base unit up against the adapter and push the

female bus connector into the adapter.

7. Secure to the wall with two #6 self-tapping screws.

8. Repeat for each remaining terminal base unit.

Publication 1794-UM065B-EN-E - September 2010

Page 33

Install Your FLEX I/O Analog Modules 21

3

2

4

5

6

1

8

7

Label here

40231

or under here

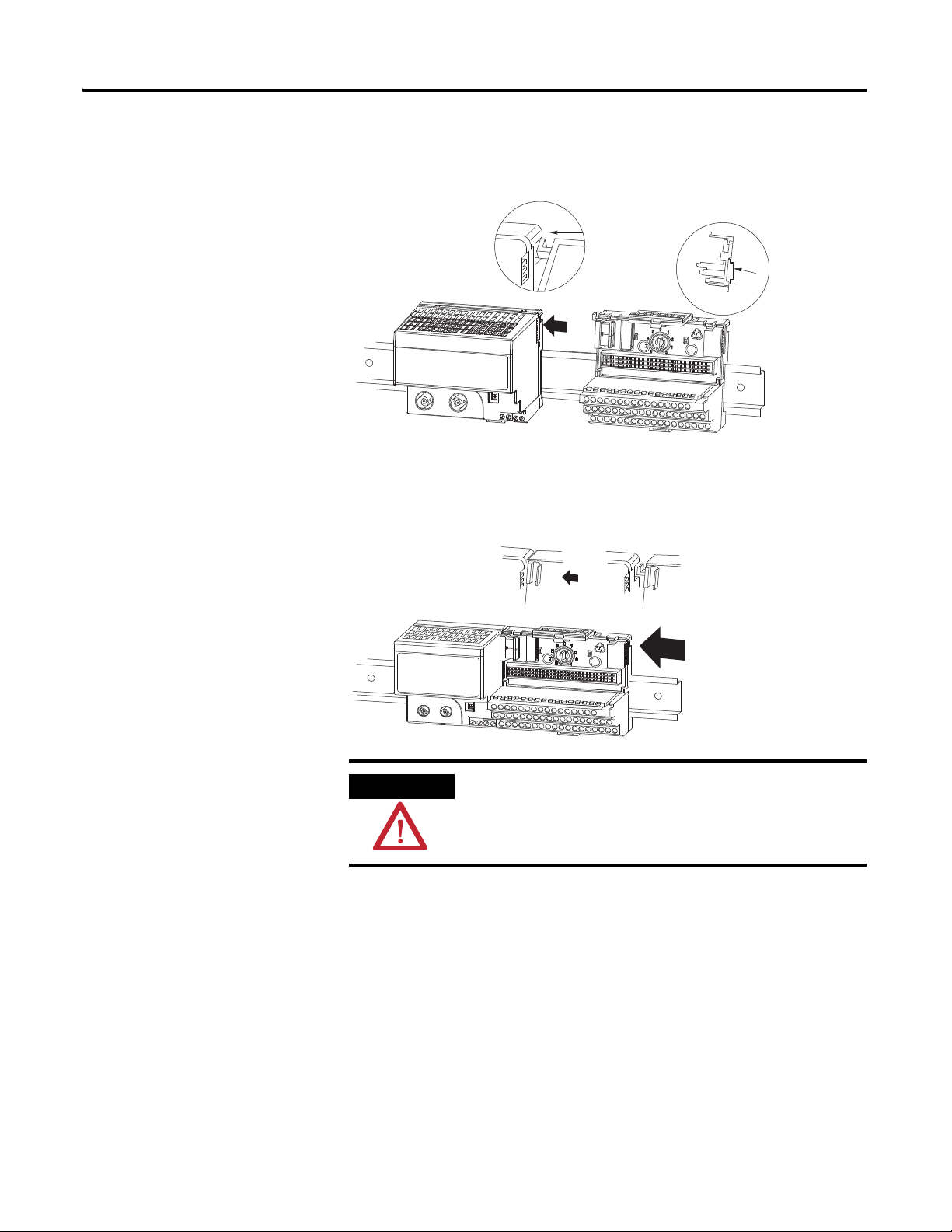

Mount the Analog Modules on the Terminal Base Unit

The HART analog input and output modules mounts on a 1794-TB3 or 1794-TB3S terminal base unit.

1. Rotate keyswitch on terminal base unit clockwise to position 3 for the

1794-IF8IH or position 4 for the 1794-OF8IH as required for each type

of module.

Do not change the position of the keyswitch after wiring the terminal

base unit.

Description Description

1 FLEXbus connector 5 Base unit

2 Latching mechanism 6 Alignment groove

3 Keyswitch 7 Alignment bar

4 Cap plub 8 Module

2. Make certain the Flexbus connector is pushed all the way to the left to

connect with the neighboring terminal base/adapter.

You cannot install the module unless the connector is fully extended.

3. Make sure the pins on the bottom of the module are straight so they will

align properly with the connector in the terminal base unit.

4. Position the module with its alignment bar aligned with the groove on

the terminal base.

Publication 1794-UM065B-EN-E - September 2010

Page 34

22 Install Your FLEX I/O Analog Modules

41307

IMPORTANT

ATTENTION

IMPORTANT

5. Press firmly and evenly to seat the module in the terminal base unit.

The module is seated when the latching mechanism is locked into the

module.

6. Remove cap plug and attach another terminal base unit to the right of

this terminal base unit if required.

Make sure the last terminal base has the cap plug in place.

The adapter is capable of addressing eight modules. Do not

exceed a maximum of eight terminal base units in your system.

Wire the Terminal Base

Wiring the FLEX I/O HART analog input modules is done using the

1794-TB3 or the 1794-TB3S terminal base unit.

Units

Connect Wiring to the FLEX

Each 1794-IF8IH input can be operated from an analog field device signal,

and each 1794-OF8IH output channel can operate an analog field device.

I/O HART Analog Modules

The FLEX I/O analog modules do not receive primary operational

power from the backplane. +24V DC power must be applied to your

module before operation. If power is not applied, the module position

will appear to the adapter as an empty slot in your chassis. If the

adapter does not recognize your module after installation is

completed, cycle power to the adapter.

When interconnecting several lines, you must consider the total

accumulated power.

Publication 1794-UM065B-EN-E - September 2010

Page 35

Install Your FLEX I/O Analog Modules 23

ATTENTION

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

18 19 20 21 22 23 3324 25 26 27 28 29 30 31 3217

35 36 37 38 47 48 49 5034

51

16

39 40 41 42 43 44 45 46

44319

Row A

Row B

Row C

Row B

Row C

Row A

1794-TB3S shown

Label placed at top of wiring area

Current

input

Current

input

Current

input

AC or DC

four-wire

current

transmitter

DC only

three-wire

current

transmitter

DC only

two-wire

current

transmitter

Connections for the 1794-IF8IH HART Analog Input Module on a 1794-TB3

Terminal Base Unit

Do not use the unused terminals on the terminal base unit. Using

these terminals as supporting terminals can result in damage to the

module and/or unintended operation of your system.

Publication 1794-UM065B-EN-E - September 2010

Page 36

24 Install Your FLEX I/O Analog Modules

ATTENTION

44319x

Row A

Row B

Row C

Row B

Row C

Row A

1794-TB3S shown

Label placed at top of wiring area

Actuator Actuator

Actuator

IN0 IN1 IN2 IN3

8 CH HART ISOLATED ANALOG INPUT

1794-xx8iH

I/O

IN4 IN5 IN6 IN7

PWR

3

44398

Connections for the 1794-OF8IH HART Analog Output Module on a 1794-TB3 or 1794-TB3S Terminal Base Unit

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

16

18 19 20 21 22 23 3324 25 26 27 28 29 30 31 3217

35 36 37 38 47 48 49 5034

39 40 41 42 43 44 45 46

Do not use the unused terminals on the terminal base unit. Using

these terminals as supporting terminals can result in damage to the

module and/or unintended operation of your system.

51

Ground the Module

Chapter Summary

In this chapter, we told you how to install your input module in an existing

programmable controller system and how to wire to the terminal base units.

Go to the next chapter to learn about input, output and configuration files for

HART analog I/O modules on ControlNet and EtherNet networks.

Publication 1794-UM065B-EN-E - September 2010

Page 37

Chapter

IMPORTANT

Input, Output and Configuration of the

FLEX I/O HART Analog I/O Modules

4

Overview

Read this chapter to familiarize yourself with input, output and configuration

files for analog I/O modules on the ControlNet or EtherNet network.

Topic Page

Use Programming Software in Your FLEX I/O Application 25

About the ControlNet and EtherNet Adapters 26

Communication Over the FLEX I/O Backplane 26

I/O Structure 28

Fault State Data 28

Device Actions 28

Chapter Summary 29

In this chapter, you will learn about:

• using software to configure the FLEX I/O modules.

• the ControlNet and EtherNet adapter.

•I/O structure.

• fault state data.

• communication fault data.

• idle state behavior.

• input data behavior upon module removal.

Use Programming Software in Your FLEX I/O Application

25 Publication 1794-UM065B-EN-E - September 2010

This chapter provides a brief description of the steps you must

take in your programming software to configure FLEX I/O

modules and an overview of what occurs during configuration.

For a full explanation of how to use your programming software

to perform module configuration, use the software online help.

When using FLEX I/O analog modules, you must perform I/O mapping and

configure the ControlNet network before generating configuration data for

your I/O modules.

For example, you may use RSNetWorx software to connect FLEX I/O

modules to a ControlNet processor or scanner through a FLEX I/O

Page 38

26 Input, Output and Configuration of the FLEX I/O HART Analog I/O Modules

IMPORTANT

ControlNet adapter (cat. no. 1794-ACNR15). The I/O configuration portion

of another programming software, for example RSLogix5 software, could be

used to generate the configuration data for each I/O module in the control

system.

Configuration data is transferred from the controller to the I/O modules

when communication to the modules is first established.

Follow these general guidelines when configuring I/O modules.

1. Perform I/O mapping.

2. Configure all I/O modules.

3. Change to Run mode to initiate communication.

4. Download module configuration.

About the ControlNet and EtherNet Adapters

Communication Over the FLEX I/O Backplane

The FLEX I/O ControlNet and EtherNet adapter interfaces up to 8

FLEX I/O modules to a ControlNet processor or scanner. The adapter can

support ControlNet real-time data connections to individual modules or

module groups. Each connection is independent of the others and can be from

different processors or scanners.

The FLEX HART modules utilize cyclic extended data transfer

(CEDT) for configuration and data management. Your adapter

must support the CEDT functionality to fully take advantage of

the modules data.

Make sure your ControlNet adapter firmware supports the

cyclic EDT functionality (Version 5 or greater), and that your

EtherNet adapter firmware is Version 4.2 or greater. If using

RSLogix 5000 software, you must use V17 or later.

One adapter can interface up to eight terminal base units with installed

FLEX I/O modules, forming a FLEX I/O system of up to eight slots.

The adapter communicates to other network system components (typically

one or more controllers, scanners, or programming terminals) over the

network. The adapter communicates with its I/O modules over the

FLEX I/O backplane.

Publication 1794-UM065B-EN-E - September 2010

Page 39

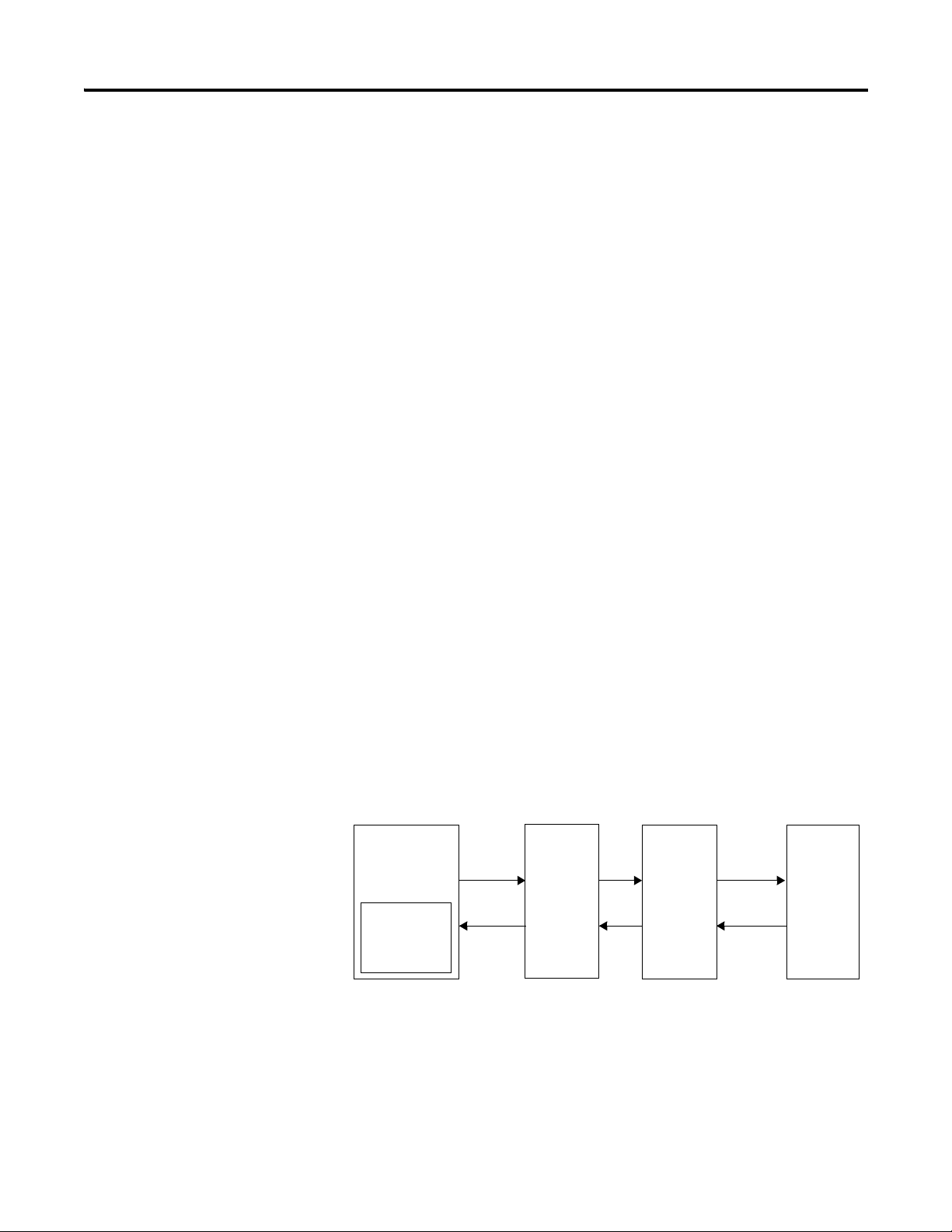

Input, Output and Configuration of the FLEX I/O HART Analog I/O Modules 27

I/O Module I/O ModuleI/O Module

Configuration Configuration Configuration

Inputs Inputs Inputs

Status

Outputs

StatusStatus

OutputsOutputs

Read

Words

Write

Words

0

X

Slot 0 Slot 1 Slot 7

Network

Network

Adapter

Read

Write

Configuration data is not continuously updated to the module.

Scheduled Data Transfer

Scheduled data transfer:

• is continuous.

• is asynchronous to the controller program scan.

• occurs at the actual rate displayed in the Actual Packet Interval field on

the programming software ControlNet I/O mapping (monitor) screen.

Unscheduled Data Transfer

Unscheduled operations include:

• unscheduled nondiscrete I/O data transfers – through ControlNet I/O

Transfer (CIO) instructions.

• peer-to-peer messaging–through message (MSG) instructions.

• messaging from programming devices.

Unscheduled messaging on a network is nondeterministic. Your application

and your configuration (for example, number of nodes, application program,

NUT, and amount of scheduled bandwidth used), determine how much time

there is for unscheduled messaging.

Module I/O Mapping

The I/O map for a module is divided into read words and write words. Read

words consist of input and status words, and write words consist of output and

Publication 1794-UM065B-EN-E - September 2010

Page 40

28 Input, Output and Configuration of the FLEX I/O HART Analog I/O Modules

configuration words. The number of read words or write words can be 0 or

more.

The length of each I/O module’s read words and write words vary in size

depending on module complexity. Each I/O module will support at least 1

input word or 1 output word. Status and configuration are optional, depending

on the module.

I/O Structure

Fault State Data

Device Actions

Output data is received by the adapter in the order of the installed I/O

modules. The output data for slot 0 is received first, followed by the output

data for slot 1, and so on up to slot 7.

Input data is sent by the adapter. The first word is the Adapter status word.

This is followed by the input data from each slot, in the order of the installed

I/O modules. The input data from slot 0 is first after the status word, followed

by input data from slot 1, and so on up to slot 7.

The FLEX I/O HART modules provides storage for alternate module output

data during communication faults or processor idle state. This fault state data

assures that a known output will be applied to the output devices during the

previously mentioned modes.

The processor or scanner software must include the means to specify this fault

state data for each module. If applicable, this data is sent in the configuration

block, see page 13.

Device actions include:

Publication 1794-UM065B-EN-E - September 2010

• Communication fault behavior

• Idle state behavior

• Input data behavior upon module removal

Communication Fault Behavior

You can configure the response to a communication fault for each I/O

module in its system. Upon detection of a communication fault, the module

can:

• Leave the module output data in its last state (hold last state)

• Reset the module output data to zero (reset)

• Apply fault state data to the module output

Page 41

Input, Output and Configuration of the FLEX I/O HART Analog I/O Modules 29

Idle State Behavior

The FLEX I/O HART module can detect the state of the controlling

processor or scanner. Only 2 states can be detected: Run mode, or Program

mode (idle).

When Run mode is detected, the adapter copies the output data received from

the processor to the corresponding module output. When Program mode is

detected, the I/O module can be configured to:

• Leave the module output data in its last state (hold last state)

• Reset the module output data to zero (reset)

• Apply fault state data to the module output

Chapter Summary

In this chapter you learned about input, output and configuration files for the

analog I/O modules on ControlNet or EtherNet networks.

Publication 1794-UM065B-EN-E - September 2010

Page 42

30 Input, Output and Configuration of the FLEX I/O HART Analog I/O Modules

Notes:

Publication 1794-UM065B-EN-E - September 2010

Page 43

Chapter

5

1794-IF8IH and 1794-OF8IH Configuration

Overview

This chapter explains how to configure your FLEX I/O module. Use RSLogix

programming software to install and configure your HART module. This

chapter describes how to configure your HART analog I/O modules, but is

limited to a relatively brief explanation of how to use the software. For more

information on the full capabilities of the software, see the software's online

help by clicking Help from dialogs.

See the table for a list of where to find specific information in this chapter.

Topic Page

Data Transfer Types 31

Real Time Data (RTD) Profile, Primary Input Parameters 45

Real Time Data (RTD) Profile, Primary Status Parameters 46

Secondary Input Data Table, Cyclic EDT Input Data 52

Interpret the Status Indicators 57

Module Configuration for the 1794-OF8IH 57

Real Time Data (RTD) Profile, Status Parameters 70