Page 1

Installation Instructions

Solar Combiner Enclosure

Catalog Numbers

Description

1000-SB006, 1000-SB012

Top ic Pag e

Description 1

Important Safety Instructions 3

Nameplate Data 4

Planning for Installation 4

Install the Solar Combiner Enclosure 5

Wire the Solar Combiner Enclosure 8

Dimensions 10

Specifications 12

Additional Resources 12

The solar combiner enclosure combines inputs from multiple solar arrays into an

output circuit. Two catalog numbers are available.

Table 1 - Product Selection

Cat. No. Number of Poles Voltage Rating

1000-SB006 6

1000-SB012 12

600V DC (continuous duty)

Solar combiner enclosures support these features:

• Listed to UL 1741 – Inverters, Converters, Controllers, and

Interconnecting System Equipment for Use with Distributed Energy

Sources

• Line and load terminals marked for using 90 °C (194 °F) copper wire

• UL Type 3, 4/4X, 12, and 13 enclosure ratings

• Fuse holders and power distribution blocks

• Configured for positive and negative grounded arrays

Page 2

2 Solar Combiner Enclosure

IMPORTANT

Important User Information

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SG I - 1 . 1

your local Rockwell Automation® sales office or online at http://www.rockwellautomation.com/literature

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

available from

) describes some

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may

lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property damage, or

economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may be

present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach

dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

These symbols are used in this publication.

Ground symbol

Direct current symbol

Rockwell Automation Publication 1000-IN002B-EN-P - April 2012

Page 3

Solar Combiner Enclosure 3

IMPORTANT

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS.

This publication contains important instructions for 6- and 12-pole solar

combiner enclosures, catalog numbers 1000-SB006 and 1000-SB012, that must

be followed during installation and maintenance:

• Use 90 °C (194 °F) copper wire only.

• This product is intended for operation in an environment with a

maximum temperature rating of 40 °C (104 °F)

• For entry into the enclosure, use only UL-Listed raintight or wet location

hubs (for UL Type 3R, 12, and 13) that comply with the requirements in

the Standard for Conduit, Tubing, and Cable fittings (UL514B).

• Use only UL-Listed watertight hubs (for UL Type 4/4X) that comply

with the requirements in the Standard for Conduit, Tubing, and Cable

fittings (UL514B).

Bonding between conduit connections is not automatic and must be provided as part

of the installation.

SHOCK HAZARD: Disconnect and lock out power before entering or performing

maintenance on the enclosure.

SHOCK HAZARD: Normally-grounded conductors may be ungrounded and energized

when a ground fault is indicated.

SHOCK HAZARD: When the photovoltaic array is exposed to light, it supplies a DC

voltage to this equipment.

Follow National Electric Code, ANSI/NFPA 70, Requirements

The system installer is responsible for the following:

• Follow National Electric Code wiring methods

• Follow cUL certification requirements, including

CSA C22.2 No. 107.1-01, clause 154.5.2

• For Canadian installations, following the wiring methods per the

Canadian Electrical Code, Part II

• System grounding, if required by Section 250 of the National Electric

Code (DC input and output circuits are isolated from the enclosure)

• Install photovoltaic system grounding per the requirements of

Sections 690.41…690.47 of the National Electric Code

Rockwell Automation Publication 1000-IN002B-EN-P - April 2012

Page 4

4 Solar Combiner Enclosure

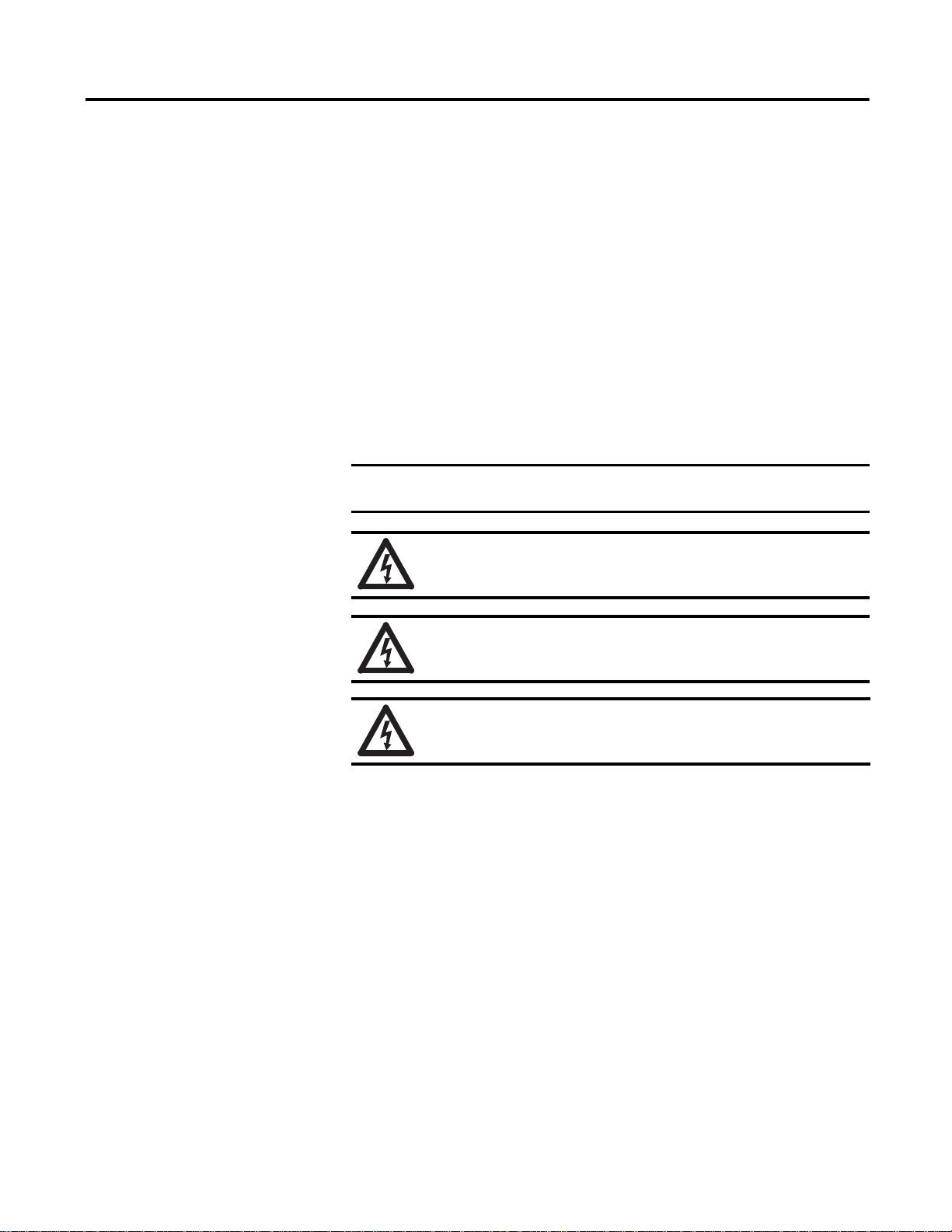

The following product information is provided on the nameplate.

Table 2 - Nameplate Fields

Field Description

CATALOG NO. Catalog number

SERIES Series letter of the product

A-B SERIAL NO. Product serial number

MAX. SYSTEM VOLTAGE [V] Voltage of the system in volts, max

MAX. AIR AMBIENT TEMP. Air ambient temperature in degrees Celsius, max

ENCL. TYPE UL enclosure type

RATED INPUT Operating output current, max

MAX. FUSE RATING Fuse rating, max

FUSE TYPE Fuse type

WIRING DIAGRAM Schematic number

MAX. Isc PER STRING [A] Short circuit current per string, max

Nameplate Data

Figure 1 - Nameplate Sample

Each solar combiner enclosure has a nameplate on the enclosure or enclosure

door, similar to the example shown below.

Planning for Installation

When planning the location for your solar combiner enclosure, consider the

following:

• Conduits

• Type of installation

• Product dimensions (see pages 10

and 11)

• Mounting requirements

• Connection to other equipment

• Enclosure rating

• Environmental conditions

• Future needs

Environment and Enclosure

Most applications require installation in an industrial enclosure to reduce the

effects of electrical interference and environmental exposure. Locate your

controller as far a possible from power lines, load lines, and other sources of

electrical noise, such as hard-contact switches, relays, and AC motor drives.

Rockwell Automation Publication 1000-IN002B-EN-P - April 2012

Page 5

Solar Combiner Enclosure 5

Environmental Ratings

The enclosure is rated for IP 66 and UL Type 3, 4, 4X, 12, and 13 applications

when used with the proper UL Type hub or conduit fittings. The enclosures are

constructed for either indoor or outdoor use, and provide a degree of protection

to personnel against incidental contact with the enclosed environment. They

provide a degree of protection against snow, windblown dust, splashing water,

and hose-directed water. They will be undamaged by the external formation of ice

on the enclosure and provide corrosion protection.

The unit is rated to function with a temperature range of -20 °C…40 °C

(-4 °F…104 °F).

Install the Solar Combiner Enclosure

Follow these requirements during installation:

• Bonding between the grounding bushings and the equipment grounding

terminals must be provided in accordance with applicable codes.

• A 1/2-in. minimum electrical clearance must be maintained between the

grounding adapter wire terminal and electrically live components.

Prepare the Enclosure

Follow these steps to prepare the enclosure.

1. From the table below, select the appropriate combination of conduit

connector and grounding adapter based on your type of installation, and

determine the required hole size in the bottom or side of the enclosure.

4/4X Conduit Connector (Hub) Grounding Adapter

Conduit Size

19.1 mm (3/4 in.) 28.6mm (1-1/8 in.) 1490-N9 1490-N20 12-8 14-8

25.4 mm (1 in.) 34.9 mm (1-3/8 in.) 1490-N10 1490-N21 12-8 14-8

31.8 mm (1-1/4 in.) 44.5 mm (1-3/4 in.) 1490-N11 1490-N22 12-4 14-4

38.1 mm (1-1/2 in.) 50.8 mm (2 in.) 1490-N5 1490-N23 8-1/0 8-1/0

50.8 mm (2 in.) 63.5 mm (2-1/2 in.) 1490-N6 1490-N24 8-1/0 8-1/0

Hole Size Cat. No. Cat. No.

Ground Wire Range (AWG)

1000-SB006 1000-SB012

Holes must be at least 6 in. (15.24 cm) below the output terminal in the

enclosure side of the 12-pole assembly. When using 4 AWG wire in the

6-pole assembly, the hole must be at least 2 in. (5.08 cm) below the output

terminal in the enclosure side.

For more details, reference table 7.2 of UL 1741.

Rockwell Automation Publication 1000-IN002B-EN-P - April 2012

Page 6

6 Solar Combiner Enclosure

TIP

IMPORTANT

IMPORTANT

TIP

Condu it

Condu it

Connector (hub)

O-ring

(outside enclosure)

Enclosure

Hole Size

Locknu t

Posit ioning Tab

Wiring Terminal

Grounding Adapter

Locknu t

2. Use a hole cutter or hole saw to create holes at the top and bottom of the

enclosure.

When using a hole cutter, place the punch on the inside of the enclosure and

draw it through to the outside.

Install the Conduit Connector and Grounding Adapter

Install the conduit connector (hub) and grounding adapter by following these

steps.

To guard against enclosure damage, align the conduit to prevent unnecessary stress on

the enclosure walls.

For conduit hubs, use only raintight or wet-location hubs that comply with the

requirements in the UL514B standard for Fittings for Conduit and Outlet Boxes.

1. Place the conduit connector (hub) and O-ring onto the conduit in the

desired locations.

2. Secure the conduit connector to the enclosure by using the locknut.

3. Install the grounding adapter as shown in Figure 2

and secure with the

locknut.

Make sure that the wiring terminal is positioned so that it will be accessible

after installation.

Figure 2 - Connector and Adapter Installation

Rockwell Automation Publication 1000-IN002B-EN-P - April 2012

Page 7

Solar Combiner Enclosure 7

10.0 mm

(.40 in.)

7.0 mm

(.28 in.)

57.0 mm

(2.25 in.)

16.0 mm

(.63 in.)

25.2 mm

(.98 in.)

Ø24 mm

(.94 in.)

Ø6.83 mm

(.27 in.)

Ø15.95 mm

(.63 in.)

4.0 mm

(.16 in.)

5.7 mm

(.22 in.)

3.0 mm

(.12 in.)

X

Y

Threaded brass insert

M5 x 0.8 mm

(4) places

Mounting Bracket

Base (Bottom View)

Enclosure X Y

1000-SB006

1000-SB012

238 mm (9.38 in.) 238 mm (9.38 in.)

340 mm (13.38 in.) 241 mm (9.50 in.)

Install an External Mounting Bracket (optional)

You can install an optional mounting bracket, catalog number 598-N13, for the

enclosure.

Use four #8 hardware with mounting brackets or four #10 hardware without

mounting brackets.

Figure 3 - Mounting Bracket Dimensions

Rockwell Automation Publication 1000-IN002B-EN-P - April 2012

Page 8

8 Solar Combiner Enclosure

Wire the Solar Combiner Enclosure

Refer to the wiring diagrams below when installing the enclosure.

Figure 4 - Wiring the 6-pole Solar Combiner Enclosure

Rockwell Automation Publication 1000-IN002B-EN-P - April 2012

Page 9

Figure 5 - Wiring the 12-pole Solar Combiner Enclosure

Solar Combiner Enclosure 9

Rockwell Automation Publication 1000-IN002B-EN-P - April 2012

Page 10

10 Solar Combiner Enclosure

280 mm REF.

(11.02 in.)

280 mm REF.

(11.02 in.)

95.3 mm

(3.75 in.)

13.9 mm

(0.55 in.)

14.2 mm

(0.56 in.)

165 mm

(6.48 in.)

69.3 mm

(2.73 in.)

214 mm

(8.42 in.)

CUSTOMER SIDE

105 mm

(4.13 in.)

42.9 mm

(1.69 in.)

38.1 mm

(1.50 in.)

Dimensions are in inches (mm).

Dimensions

Figure 6 - 6-pole Solar Combiner Enclosure (Catalog Number 1000-SB006)

Rockwell Automation Publication 1000-IN002B-EN-P - April 2012

Page 11

95.3 mm

(3.75 in.)

14.2 mm

(0.56 in.)

57.9 mm

(2.28 in.)

37.3 mm

(1.47 in.)

63.8 mm

(2.51 in.)

77.2 mm

(3.08 in.)

95.3 mm

(3.75 in.)

380 mm

(14.96 in.)

351 mm

(13.82 in.)

100 mm

(3.94 in.)

100 mm

(3.94 in.)

50.3 mm

(1.98 in.)

13.9 mm

(0.55 in.)

251 mm

(9.88 in.)

280 mm

(11.02 in.)

180 mm

(7.09 in.)

59.7 mm

(2.35 in.)

57.7 mm

(2.27 in.)

30.0 mm

(1.18 in.)

Dimensions are in inches (mm).

Solar Combiner Enclosure 11

Figure 7 - 12-pole Solar Combiner Enclosure (Catalog Number 1000-SB012)

Rockwell Automation Publication 1000-IN002B-EN-P - April 2012

Page 12

Specifications

Attribute 1000-SB006 1000-SB012

Number of input circuits, max 6 12

Number of poles 6 12

Voltage rating (continuous duty) 600V DC 600V DC

Operating current (DC), max 72 144

Rated input current (DC) 12 A

Fuse rating (Class CC), max 15 A 12 A

Ambient air temperature, max 40 °C (104 °F) 40 °C (104 °F)

(1) Consult the factory for higher currents up to 15 A.

(1)

12 A

(1)

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

Product Certifications website, http://www.ab.com Provides declarations of conformity, certificates, and other

Provides general guidelines for installing a Rockwell

Automation industrial system.

certification details.

You can view or download publications at

http://www.rockwellautomation.com/literature/

. To order paper copies of

technical documentation, contact your local Allen-Bradley® distributor or

Rockwell Automation sales representative.

Allen-Bradley, Rockwell Software, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Publication 1000-IN002B-EN-P - April 2012 PN-126891

Supersedes Publication 1000-IN002A-EN-P - July 2011 Copyright © 2012 Rockwell Automation, Inc . All rights reserved. Printed in the U.S.A.

Loading...

Loading...