Page 1

URISYS 2400

Operator’s Manual

Version 1.0

Page 2

Revision History

URISYS 2400

Version Revision date

1.0 April 2001

Language Order No.

English

Edition notice URISYS 2400 Operator’s Manual

This manual is for users of the URISYS 2400.

Every effort has been made to ensure that all the information contained in this

manual is correct at the time of printing. However, Roche Diagnostics GmbH

reserves the right to make any changes necessary without notice as part of

ongoing product development.

Any customer modification to the instrument will render the warranty or

service agreement null and void.

Intended use The URISYS 2400 is a fully automated urinalysis system intended for in vitro

qualitative or semi-quantitative determination of urine analytes, including

pH, leukocytes, nitrite, protein, glucose, ketones, urobilinogen, bilirubin, and

erythrocytes.

Copyrights © 2001, Roche Diagnostics GmbH. All rights reserved.

Trademarks The following trademarks are acknowledged:

, URISYS 2400 are registered trademarks of the Roche group. All other

trademarks that are mentioned in this manual are the property of the

respective trademark holders: KOVA® and Monovette®.

03184315.018

Instrument approvals The URISYS 2400 analyzer meets the requirements stated in

Directive 98⁄79⁄EC of the European Parliament and the Council of the

European Union (EU) on in vitro diagnostic medical devices. Furthermore,

the URISYS 2400 analyzer is manufactured and tested according to

International Standard IEC 1010-1, "Safety requirements for electrical

equipment for measurement, control, and laboratory use, Part 1: General

requirements". This International Standard is equivalent to the standards UL

3101-1 for the USA, CSA C 22.2 No. 1010.1 for Canada, and DIN EN 61010-1

for Germany.

The URISYS 2400 fulfils the EMC immunity requirements for laboratory use

equipment in industrial areas, according to the EMC standards EN 50082-2

and EN 61326-A1. According to EN 55011, the URISYS 2400 analyzer is a

device of limit class A.

Roche Diagnostics

ii Operator’s Manual · Version 1.0

Page 3

URISYS 2400

Contact addresses

Compliance is demonstrated by the following marks:

Complies with the IVD directive 98⁄79⁄EC.

Issued by Underwriters Laboratories, Inc. (UL) for

CUS

®

Canada and the US.

Manufacturer:

Hitachi Science Systems

Ltd.

Ibaraki

Japan

Warranty

Authorized Representative

EC REP

USA Roche Diagnostics

Roche Diagnostics GmbH

Sandhofer Strasse 116

D-68305 Mannheim

Germany

Corporation

9115 Hague Road

PO Box 50457

Indianapolis, IN 46250

USA

Refer to the URISYS 2400 analyzer purchase agreement for warranty

conditions. Contact your local Roche Technical Support for further

information.

Roche Diagnostics

Operator’s Manual · Version 1.0 iii

Page 4

URISYS 2400

Roche Diagnostics

iv Operator’s Manual · Version 1.0

Page 5

URISYS 2400

Table of contents

Revision History ii

Table of contents v

Preface vii

How to use this manual vii

Conventions used in this manual viii

Safety classifications x

Safety information xi

Overview Part A

1 Introduction to the system

Description of the URISYS 2400 analyzer A-2

System description Part B

2Hardware

Hardware description B-2

Installation B-5

3Software

Installation B-12

4 Cassette

First-time installation B-30

Maintenance Part D

7 General maintenance actions

Maintenance procedures D-2

Maintenance menu D-4

Exchange user-replaceable parts D-8

Troubleshooting Part E

8 Data alarms (flags)

Flags on result data printout E-2

Handle alarms E-3

Reset the analyzer E-9

9 Instrument alarms (messages)

Instrument alarms (messages) E-12

Appendix Part F

10 Technical specifications

Technical specifications F-2

Barcode specifications F-3

Concentration ranges F-5

Operation Part C

5 Daily operation

Initial preparations C-3

System start C-4

Sample preparation C-8

Termination of analysis C-11

Remove processed samples C-12

Process additional samples C-13

Process STAT (emergency) samples C-14

Process control samples C-17

Replace an empty URISYS 2400 cassette C-18

Replace an expired URISYS 2400 cassette C-19

Re-insert a used URISYS 2400 cassette C-20

Analysis and documentation of results C-21

Switch off the analyzer C-34

6 Special operations

Calibration C-36

Checks C-41

Glossary and index Part G

Glossary G-1

Index G-5

Roche Diagnostics

Operator’s Manual · Version 1.0 v

Page 6

URISYS 2400

Roche Diagnostics

vi Operator’s Manual · Version 1.0

Page 7

URISYS 2400

Preface

The URISYS 2400 analyzer is a fully automated, benchtop urine analyzer. It is

designed for use with URISYS 2400 cassettes.

The URISYS 2400 is optimized for workloads of between 100 and 1000 urine

samples per day. Only trained personnel working in a professional laboratory

environment must operate the URISYS 2400. The analyzer has been

developed and designed to assay urine samples only.

It is important that the operator reads this manual thoroughly before using

the analyzer.

Any disregard of the instructions in the Operator’s Manual may result in a

safety risk.

How to use this manual

This manual is designed to help you perform all tasks required as part of your

work with the URISYS 2400.

Content The manual is divided into the following parts:

o Part A – Overview: The overview provides general information about the

URISYS 2400 analyzer and specific details about the safety precautions.

o Part B – System description: The system description outlines the hardware

and software components of the analyzer, the installation procedure, and

the use of the touch screen.

o Part C – Operation: This section defines the daily and special operations of

the URISYS 2400 analyzer in a step-by-step guide.

o Part D – Maintenance: This section provides details on all of the general

maintenance actions.

o Part E – Troubleshooting: This section contains information on how to

respond to data and instrument alarms, and provides troubleshooting

guidelines for alarms that cannot be solved by the operator. Alarms that

require intervention by trained Roche Technical Support personnel are

indicated.

o Part F – Appendix: This section contains additional information,

including technical specifications, glossary, and index.

Roche Diagnostics

Operator’s Manual · Version 1.0 vii

Page 8

Conventions used in this manual

Visual cues are used to help locate and interpret information in this manual

quickly. This section explains formatting conventions used in this manual.

Symbols The following symbols are used:

Symbol Used for

a Procedural step

o List item

e Cross-reference

i Note and tip

[Parameter] Name of screen (enclosed in brackets)

<Start> Name of button (enclosed in less and greater)

URISYS 2400

Abbreviations The following abbreviations are used:

Abbreviation Definition

A

ASCII American Standard Code for Information Interchange

B

BIL Bilirubin

C

CCD Charge-coupled device

C/D Check digit

CLA Clarity

COL Color

COM Compensation pad

COMM.Parameter Communication parameters for host-communication

available on the [System Parameters] screen

E

EMC Electromagnetic Compatibility

EN European Standard

ERY Erythrocytes

G

GLU Glucose

Roche Diagnostics

viii Operator’s Manual · Version 1.0

Page 9

URISYS 2400

Abbreviation Definition

I

ID Identification number

IEC International Electrotechnical Commission

K

KET Ketones

L

LED Light Emitting Diode

LEU Leukocytes

L.TRB Lightly turbid

N

NEG Negative

NIT Nitrite

nm Nanometer

NORM Normal

O

ORANG Orange

P

P.YEL Pale Yellow

POS Positive

PRO Protein

S

SG Specific Gravity

SI Standard International

T

TS Test strip

TURBD Turbid

U

UBG Urobilinogen

Y

YELLO Yellow

Roche Diagnostics

Operator’s Manual · Version 1.0 ix

Page 10

Safety classifications

Before operating with the URISYS 2400 it is essential that the warnings,

cautions, and safety requirements contained in this manual are read and

understood by the user. This section explains how precautionary information

is formatted in the manual.

The safety precautions and important user notes are classified according to

ANSI Z535 standards. Familiarize yourself with the following meanings and

icons:

Warning

Indicates a possibly hazardous situation which, if not avoided, may result in death or

serious injury.

Examples of a “serious injury” include loss of eyesight, burn (high temperature, low

temperature), electric shock, bone fracture, or poisoning. These injuries require

medical assistance.

URISYS 2400

Biohazard

Samples containing material of human origin must be treated as potentially

infectious. The relevant laboratory guidelines on safe use must be observed.

Caution

Indicates a possibly hazardous situation which, if not avoided, may result in slight or

minor injuries, and/or damage to equipment.

“Minor injury” refers to injuries that may require medical assistance.

“Equipment” refers to extended damage to buildings, furniture, and so on.

Spillage

Avoid all liquid spills on the analyzer.

Roche Diagnostics

x Operator’s Manual · Version 1.0

Page 11

URISYS 2400

Safety information

Electrical safety

Connect the analyzer to grounded power outlets only (protection class 1). All

peripheral devices that are connected to the URISYS 2400 must comply with safety

standard IEC 950 (UL 1950) for information technology equipment, or with IEC

1010 (UL 3101) for laboratory use instruments.

Instrument in use

Keep hands or other objects away from the sampling probe area to prevent personal

injury while the instrument is in use. Do not touch parts of the analyzer other than

those specified.

User qualification

Only appropriately trained operators are qualified to operate the analyzer.

Correct use

Any disregard of the instructions in the Operator’s Manual may result in a safety risk.

Use the URISYS 2400 analyzer to analyze urine samples only. It is not intended for

any other application.

Transport

At least two persons must carry the analyzer, by holding the baseplates on the left

side and right side of the analyzer. Be careful not to hurt your hands or fingers when

putting the analyzer in place.

Environmental conditions

The URISYS 2400 is approved for indoor use only.

Biological safety

Liquid waste and strip waste are potentially biologically hazardous. Always wear

gloves if handling those materials. Do not touch parts of the analyzer other than

those specified. Consult your laboratory protocol for handling biohazardous

materials.

Spilling and cleaning

If a sample is spilled on the analyzer, wipe up immediately and apply disinfectant.

When handling the washing solution, ensure that you wear gloves and safety

goggles to avoid direct contact with the solution. If the solution contacts the body,

wash immediately with a large volume of water. Consult your laboratory protocol for

handling biohazardous materials.

Roche Diagnostics

Operator’s Manual · Version 1.0 xi

Page 12

URISYS 2400

Radio interference

URISYS 2400 is a class A device. In residential areas it may cause radio

interference. The user must take precautions as required.

Installation

Follow the specified installation conditions carefully. Otherwise, inaccurate results,

or damage to the analyzer may occur.

Waste

Handle liquid waste and used test strips properly, according to legislation on water

pollution, and on the treatment of drainage and waste matter.

Electromagnetic waves

Devices that emit electromagnetic waves may affect measured data, or cause the

analyzer to malfunction. Do not operate the following devices in the same room

where the analyzer is installed: mobile phone, transceiver, cordless phone, other

electrical devices that generate electromagnetic waves.

o

Operating and maintenance

Carefully follow the procedures specified in the Operator’s Manual for the

operation and maintenance of the analyzer. Leave maintenance of other areas to

trained Roche Technical Support personnel.

o

Calibration

Calibrate the analyzer every four weeks to ensure the analyzer operates

optimally. Failure to do so may lead to inaccurate results.

o

Test strips

Handle and store test strips according to the instructions provided by Roche

Diagnostics. Refer to the instructions in the package insert of the URISYS 2400

cassette.

o

Particular care must be taken when performing the following procedures:

Preparing and processing samples (routine, STAT and control)

Using the washing solution

Draining the liquid waste tank

Cleaning the TS transfer base

Disposing of used test strips

Cleaning the waste box

Roche Diagnostics

xii Operator’s Manual · Version 1.0

Page 13

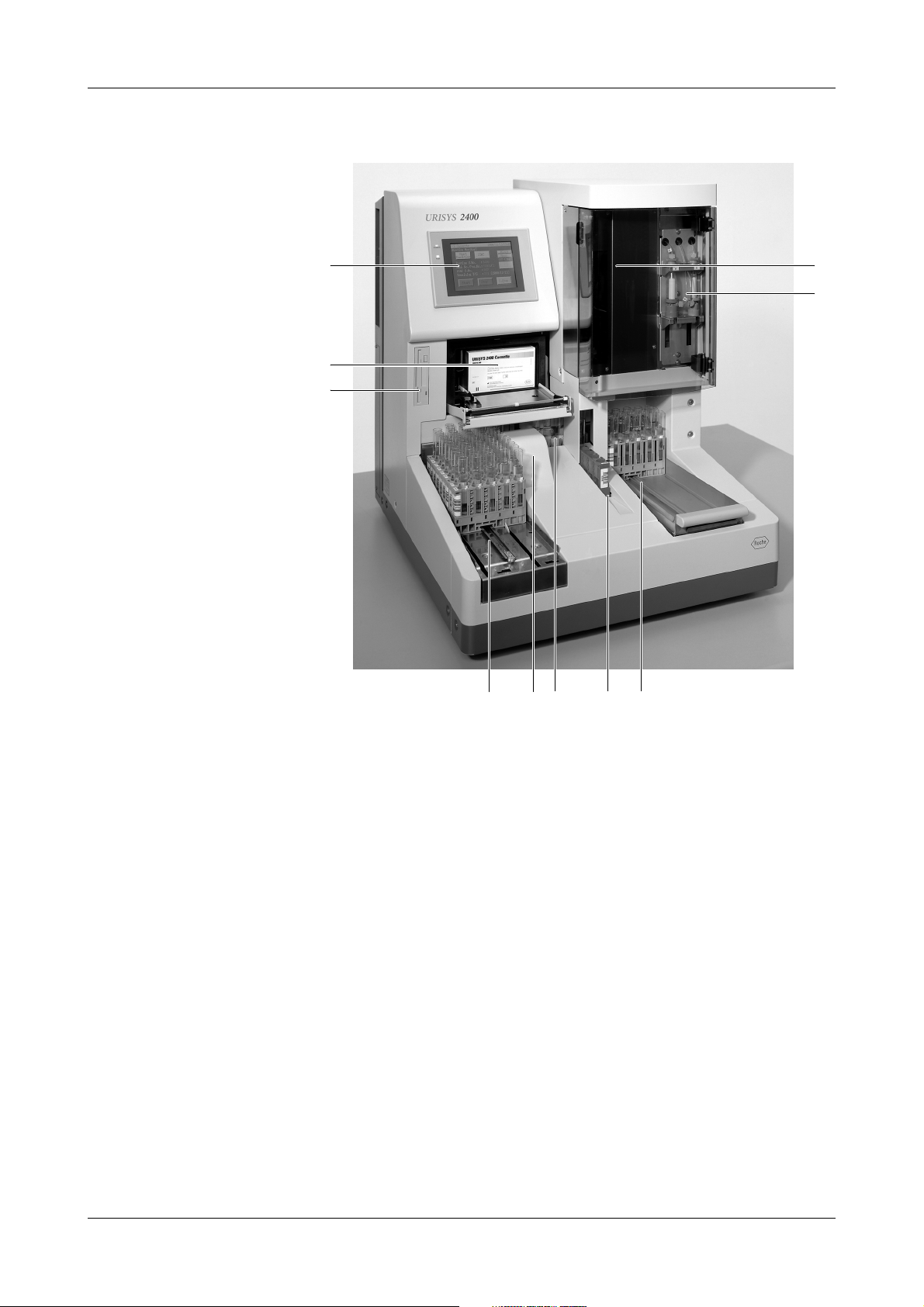

URISYS 2400

D

C

B

A

E

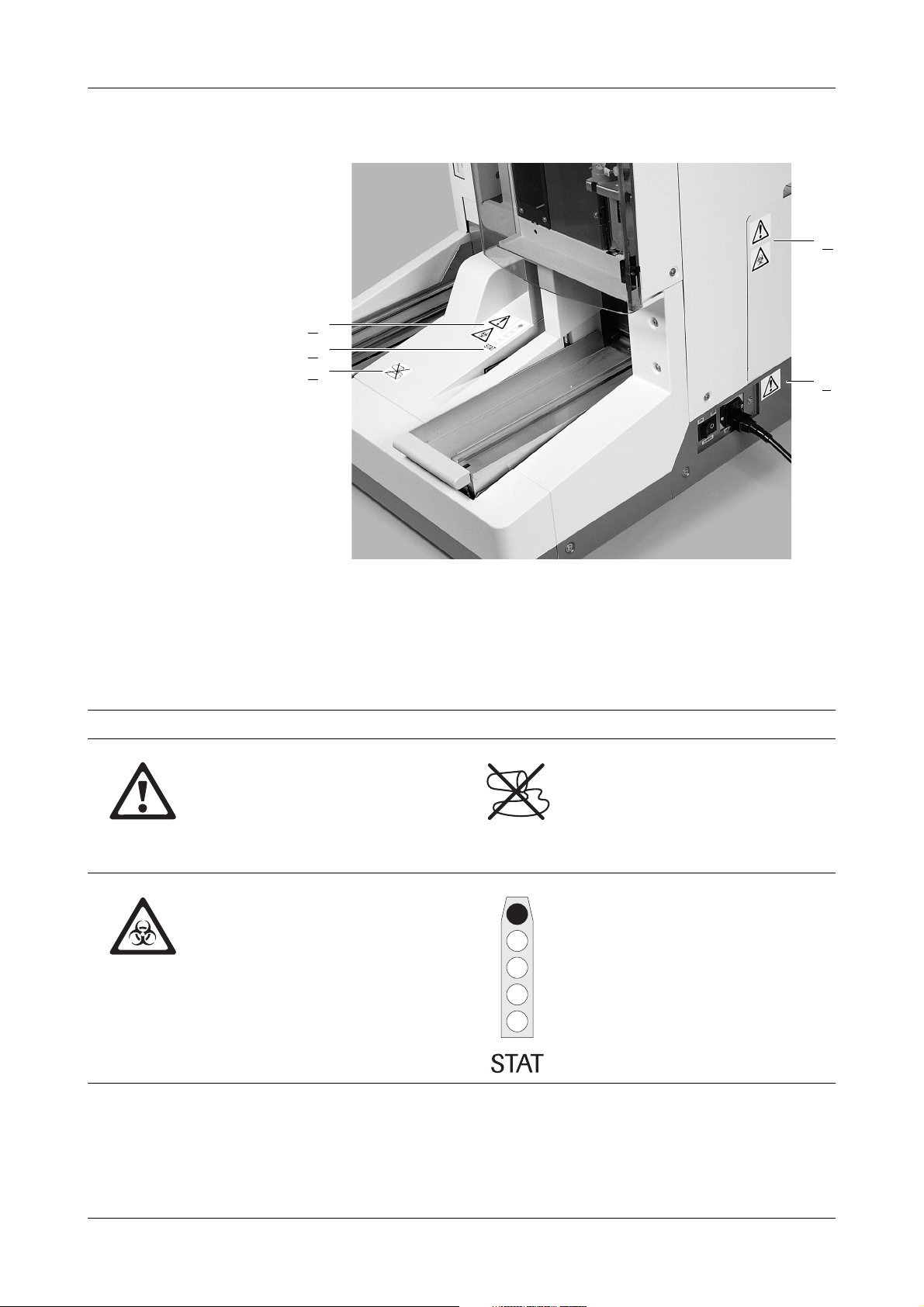

Figure 0-1 URISYS 2400 analyzer with labels

A

Housing

B STAT sample position

D Strip waste container door

E Power supply

C Housing before sampling area

Symbol Validity Symbol Validity

o STAT position

o Rack transfer

o STAT position

o Rack transfer

o Waste box

o TS transfer base

o Power supply

o Sampling probe

o STAT sample position

o Rack transfer

o Rinsing station

o Waste box

o TS transfer base

Roche Diagnostics

Operator’s Manual · Version 1.0 xiii

Page 14

URISYS 2400

Roche Diagnostics

xiv Operator’s Manual · Version 1.0

Page 15

Overview

Part A is an overview of the URISYS 2400.

A

Page 16

Page 17

URISYS 2400 1 Introduction to the system

Table of contents

Introduction to the system

This chapter contains an introduction to the URISYS 2400 analyzer.

In this chapter A

Description of the URISYS 2400 analyzer .........................................................2

Measuring principle ......................................................................................2

Chapter

1

Roche Diagnostics

Operator’s Manual · Version 1.0 A-1

Page 18

1 Introduction to the system URISYS 2400

Description of the URISYS 2400 analyzer

Description of the URISYS 2400 analyzer

The URISYS 2400 analyzer is a fully automated urinalysis system intended for

in vitro qualitative or semi-quantitative determination of urine analytes,

including pH, leukocytes, nitrite, protein, glucose, ketones, urobilinogen,

bilirubin, and erythrocytes. In addition, the analyzer determines specific

gravity, color, and clarity. The URISYS 2400 is intended for professional use

only.

The primary functions of the URISYS 2400 analyzer include:

o Sample identification

o Automatic dispensing of test strips

o Robotic pipetting of samples

o Controlled incubation period

o Photometric measurements

o Result memory

o Optional formats for data output

Measuring principle

The URISYS 2400 analyzer uses the URISYS 2400 cassette containing 400 test

strips. Each test strip has ten individual test pads that are used to test for

different substances or characteristics. The test strips are analyzed as they

move automatically through the analyzer. One strip is used per sample. When

a strip is dispensed for use, an aliquot of the urine sample is pipetted onto

each of the test pads. The test results are based on the measurement of

reflected light intensity. The specific gravity, color, and clarity of each sample

are also measured.

The URISYS 2400 is a fully automated reflectance photometer for in vitro

semi-quantitative measurements of urine test strips. The light sources (LED’s

[light-emitting diodes]) and reading times are optimized for the reaction

chemistry and color development that occur on the test pads.

The measuring head of the URISYS 2400 contains LED’s of three different

wavelengths. The test strip remains stationary at the measuring position as the

measuring head moves over each test pad. Measurement starts at the reference

plate, which is used to test the optical system.

The URISYS 2400 verifies that the test strip is properly positioned under the

measuring head, by measuring the reflected light. If a test strip is not properly

positioned under the measuring head, the URISYS 2400 displays a message.

Roche Diagnostics

A-2 Operator’s Manual · Version 1.0

Page 19

URISYS 2400 1 Introduction to the system

Description of the URISYS 2400 analyzer

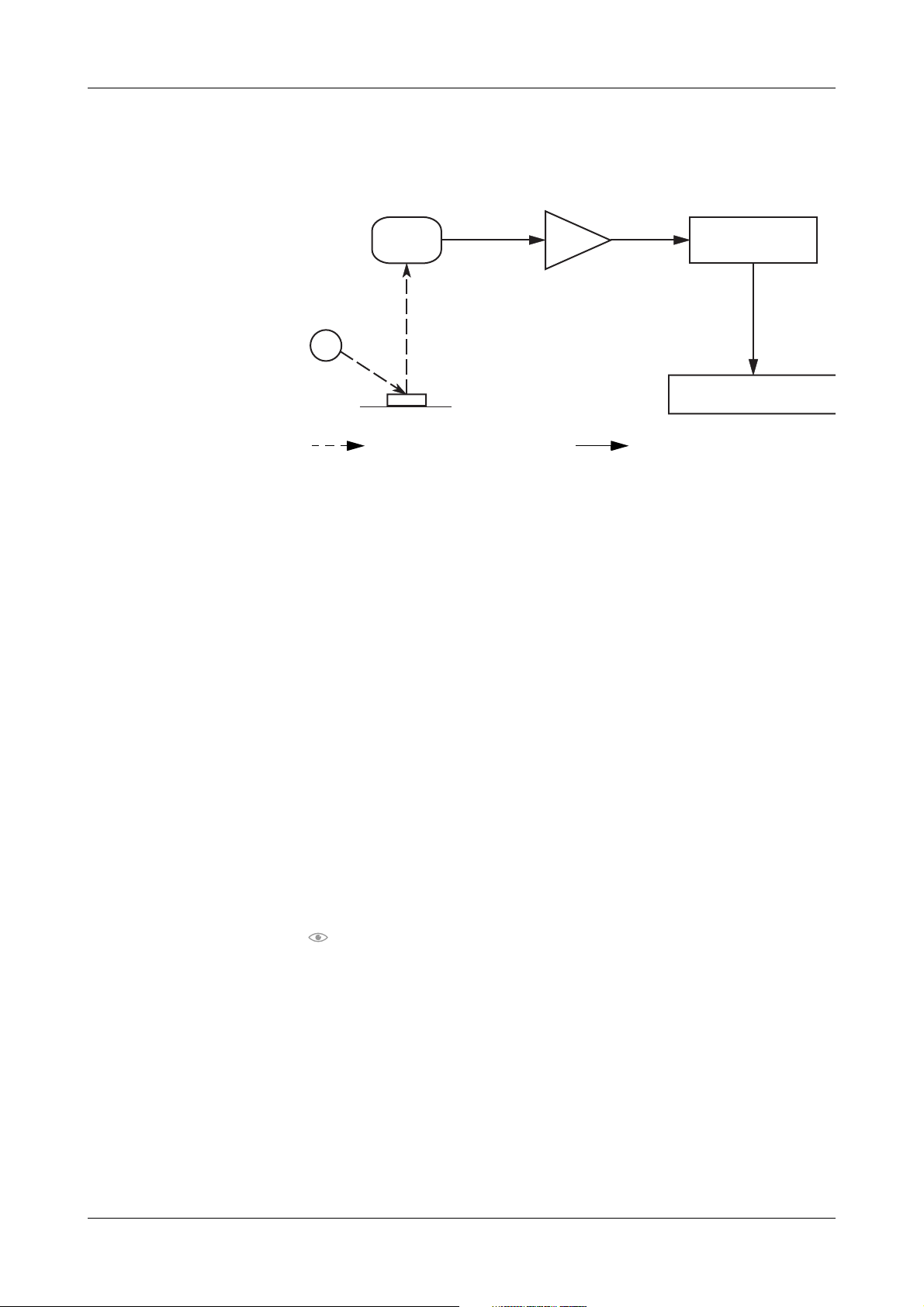

Reflected light is measured electro-optically, and the process is illustrated in

the following figure.

C

A

B

Optical transmission Electronic transmission

Figure A-1 Process of measuring

LED

A

B Te st pad

C Photodiode detector

An LED (

A) transmits light of a defined wavelength, at an optimum angle,

onto the surface of a test pad (

B). The light hits the surface of the test pad and

D

D Analog-to-digital converter

E Microprocessor

F Concentration result

E

F

is reflected with an intensity that is dependent on the color of the test pad.

A photodiode detector (

C), positioned directly above the test pad, receives the

reflected light. The photodiode detector transmits an analog electrical signal

to the analog-to-digital converter (

D), which changes the analog signal to a

digital value.

A microprocessor (

E) adjusts the digital value, based on a value from an

internal reference plate. It converts the digital value to a relative value by using

a calibration standard scale. Then, the microprocessor calculates a reflectance

value.

The semi-quantitative concentration result (

F) is determined by comparing

the reflectance value with the so-called range limits (parameter-specific

reflectance values stored in the analyzer). The full list of concentration range

values for all test parameters is shown in:

Table F-1 on page F-5

The results are stored in the memory and can be printed, saved to a diskette,

or sent to another computer.

Each of the three LED’s transmits light of a different wavelength. The use of

different wavelengths improves the results that are obtained from measuring

each of the test strip parameters. The wavelengths used to measure the

different parameters are listed in the table below.

Roche Diagnostics

Operator’s Manual · Version 1.0 A-3

Page 20

1 Introduction to the system URISYS 2400

Description of the URISYS 2400 analyzer

Test parameter Measuring wavelength (nm)

pH 555, 620

Leukocytes 555

Nitrite 555

Protein 555

Glucose 555

Ketones 555

Urobilinogen 555

Bilirubin 555

Erythrocytes 555, 620

Color 470, 555, 620

Table A-1 Wavelengths used to measure the reflectance values

The photometric reflectance measurement for all of the test parameters is

performed after an incubation time of 60 seconds. As with previous urine

analyzers from Roche Diagnostics, compensation for intrinsic urinary color,

which is a recognized interfering factor, is made through the measurement of

a blank compensation pad on the test strip. The compensation pad assists in

the prevention of false positives when a urine sample is strongly colored.

The URISYS 2400 determines the urine color by evaluating the reflectance

values of all three measuring wavelengths (470 nm, 555 nm, and 620 nm) on

the compensation pad. Color results are reported as PALE YELLOW,

YELLOW, AMBER, BROWN, ORANGE, RED, GREEN, or OTHERS.

The measurement of specific gravity (SG) is performed in a flow cell that is

filled with a urine sample during aspiration of the sample. An LED (650 nm)

transmits light to the flow cell. A charge-coupled device (CCD) determines

the angle of total reflection. The refractive index of the sample is calculated

from the angle of total reflection using a calibration curve. Transformation

into the SG value is performed by a nomogram stored in the analyzer.

The flow cell that is used to measure specific gravity also determines the

clarity of the sample. However, light of a different LED is used to measure

clarity. This LED (660 nm) transmits light to the flow cell, and the amount of

light that passes through the flow cell is measured.

The system is blanked (zeroed) during the washing process, between sample

measurements, by setting the water transmission to 100%. The transmission

values of samples are transformed to clarity results (CLEAR, LIGHT TURBID

or TURBID), by using the clarity range table that is programmed in the

software of the URISYS 2400.

Roche Diagnostics

A-4 Operator’s Manual · Version 1.0

Page 21

URISYS 2400 1 Introduction to the system

Description of the URISYS 2400 analyzer

When a sample has been pipetted onto the test pads of a test strip, and the

specific gravity and clarity have been measured, the remaining urine is ejected

into the rinse station. The needle and the flow cell are washed with water

before the next sample is taken.

Roche Diagnostics

Operator’s Manual · Version 1.0 A-5

Page 22

1 Introduction to the system URISYS 2400

Description of the URISYS 2400 analyzer

Roche Diagnostics

A-6 Operator’s Manual · Version 1.0

Page 23

System description

Part B is the system description of the URISYS 2400.

B

Page 24

Page 25

URISYS 2400 2 Hardware

Table of contents

Hardware

This chapter contains the description of the system hardware.

In this chapter B

Hardware description ........................................................................................2

Standard accessories .....................................................................................4

Additional items ............................................................................................5

Installation .........................................................................................................5

Basic requirements .......................................................................................5

Surface and space measurements ............................................................5

Power supply ............................................................................................6

Water supply .............................................................................................6

Assemble the parts .........................................................................................7

Set up the water supply tank ..................................................................7

Liquid waste tank ....................................................................................8

TS transfer base ........................................................................................8

External printer ............................................................................................9

External host connection ............................................................................9

Environmental conditions .........................................................................10

Chapter

2

Roche Diagnostics

Operator’s Manual · Version 1.0 B-1

Page 26

2 Hardware URISYS 2400

Hardware description

Hardware description

The URISYS 2400 analyzer consists of several major components:

o Rack transport system

o Liquid handling system

o Test strip cassette compartment

o Automated test strip processing area

o 3-wavelength reflectance photometer

o Combined, flow-through refracto-/turbidimeter

o User interface screen

o Inbuilt computer

o Battery-buffered memory

o Diskette drive (for MS-DOS compatible diskettes)

Roche Diagnostics

B-2 Operator’s Manual · Version 1.0

Page 27

URISYS 2400 2 Hardware

Hardware description

C

B

A

Figure B-1 The URISYS 2400 analyzer

Diskette drive

A

B URISYS 2400 test strip cassette

compartment

C Touch screen

D Pipette mechanism

E Wash and sample syringes

D

E

FGHIJ

F Rack output line

G STAT sampling position

H Rack cross-feed line

I Barcode reader

J Rack input line

Roche Diagnostics

Operator’s Manual · Version 1.0 B-3

Page 28

2 Hardware URISYS 2400

Hardware description

Standard accessories

The standard accessories that accompany the URISYS 2400 analyzer are:

o Water supply tank with a liquid level detector

o Water supply tube with filter

o Two rack trays

o Liquid waste tube 5 m (16.4 ft) length

o Strip waste container

o Standard maintenance kit (O-rings, seals)

o Fuses

o Power cord

o Three software installation diskettes

o Operator’s Manual (English version)

Water supply tank with liquid

level detector

Rack trays Two identical trays are supplied with the analyzer. Each tray holds up to 15

Strip waste container Used test strips are deposited in a strip waste container that has a minimum

The water supply tank that supplies deionized water to the analyzer is located

externally. It has a maximum capacity of 5 L (5.3 qts). This volume is

sufficient to process approximately 1000 samples.

racks at one time. One tray is used to load the racks onto the rack input line.

The second tray is used as a stationary rack output tray during sample

processing and serves to remove racks from the rack output line.

capacity of 420 test strips. (The capacity is calculated on the basis of the

contents of one URISYS 2400 cassette plus a safety margin.)

The strip waste container is located on the right side of the analyzer, behind

the door panel. The container is designed to minimize the contact an operator

has with potentially infectious and toxic materials.

When the strip waste container is full, a message is displayed on the touch

screen.

Roche Diagnostics

B-4 Operator’s Manual · Version 1.0

Page 29

URISYS 2400 2 Hardware

Installation

Additional items

Items that are necessary or optional for the installation and operation of the

URISYS 2400 analyzer, but are not supplied with the analyzer, are:

o Liquid waste tank (with or without an optional overflow sensor)

o Racks

o Sample tubes

o Wash in g solu tion

o URISYS 2400 cassette

o URISYS 2400 calibration strip

o External printer and standard printer cable (parallel/Centronics interface)

o Waste container cartons

o Serial interface (host) cable

o 1.44 MB diskette for storage of data

Installation

Basic requirements

Surface and space

measurements

Read this manual carefully before installation, to ensure correct operation of

the analyzer.

If you have any questions after initial installation, contact Technical Support.

Only trained Roche Technical Support personnel, or similarly qualified personnel

supervised by authorized service agents of Roche Diagnostics, are qualified to

install the URISYS 2400 analyzer.

At least two persons must carry the analyzer, by holding the baseplates on the left

side and right side of the analyzer. Be careful not to hurt your hands or fingers when

putting the analyzer in place.

Follow the specified installation conditions carefully. Otherwise, inaccurate results,

or damage to the analyzer may occur.

The following surface and space requirements must be met for the use of the

URISYS 2400 analyzer, and the proper ventilation of the analyzer when it is in

use:

o 5 cm (2.0 inches) or more (rear)

o 20 cm (7.9 inches) or more (left side)

o 30 cm (11.8 inches) or more (right side)

Use a table that is able to support the mass of the analyzer, which is

approximately 85 kg (187 lbs). The table must be level. Any inclination must

be less than 1.5 degrees in every direction.

Roche Diagnostics

Operator’s Manual · Version 1.0 B-5

Page 30

2 Hardware URISYS 2400

Installation

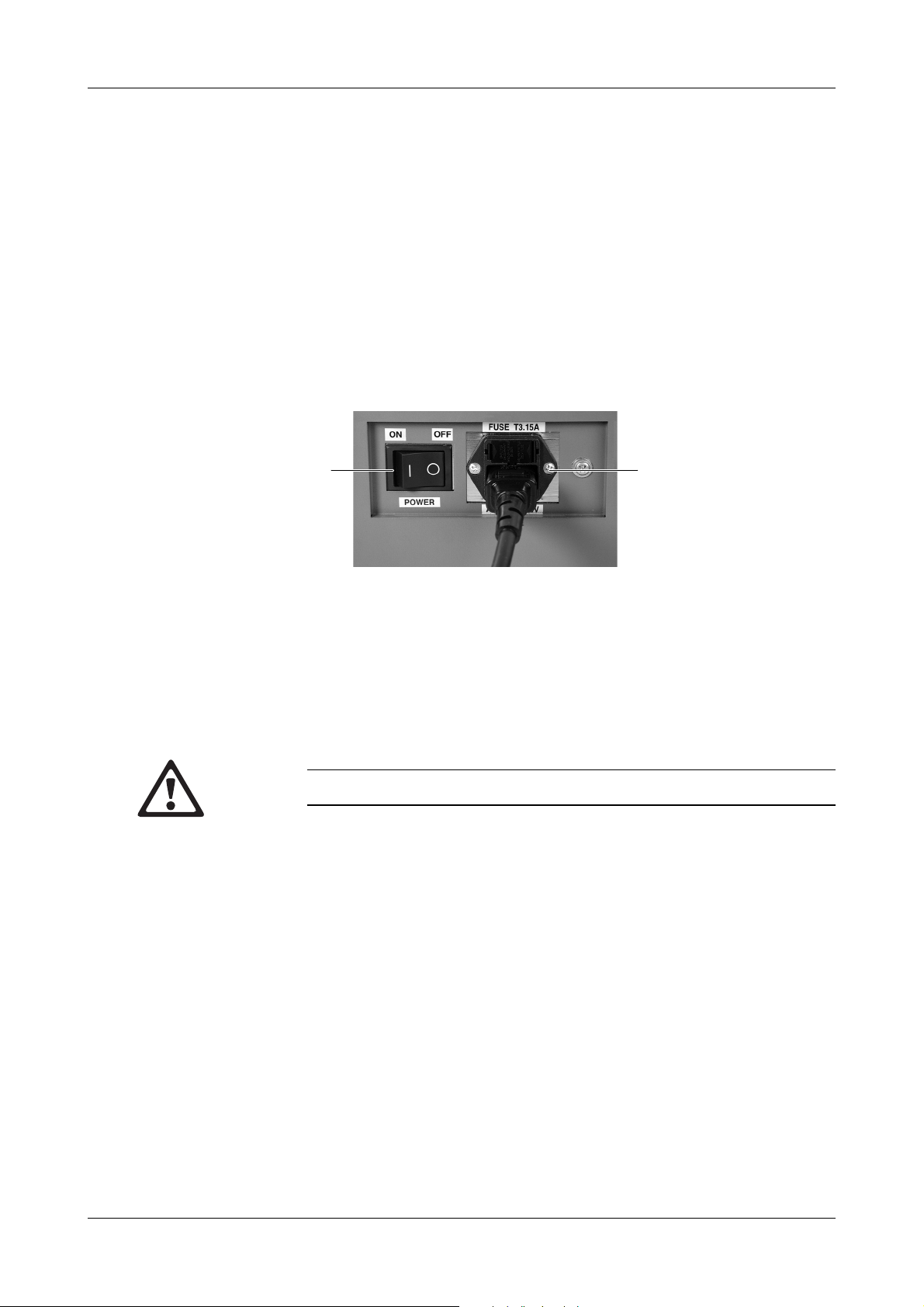

Power supply A standard 230 V/50 Hz or 115 V/60 Hz power line is required to operate the

analyzer. It must be connected to a grounded power supply socket (protection

class 1).

Although the maximum power consumption of the instrument is 200 VA, the

external power supply should fulfill the following minimum requirements to

cover for peaks at switching on.

Electric power supply capacity:

o Minimum 500 VA

o Minimum 5 Amp, 3-pin power supply socket

The power switch and power supply socket are located on the right side of the

analyzer.

AB

Figure B-2 Power switch and power supply socket

Power switch B Power supply socket

A

Water supply An external water supply tank for deionized water is supplied with the

URISYS 2400. The deionized water must be germ free and have an electric

conductance value that is less than or equal to 1 µS/cm.

Do not connect the analyzer directly to a pressurized water supply.

Roche Diagnostics

B-6 Operator’s Manual · Version 1.0

Page 31

URISYS 2400 2 Hardware

Installation

Assemble the parts

Set up the water supply

tank

The external water supply tank provides water to the analyzer for washing.

The tank has a volume of approximately 5 liters (5.3 quarts), which allows for

the measurement of about 1000 samples.

a To set up the water supply tank

1 Fill the tank with deionized water.

2 Connect the cable of the liquid level detector to the water level connection

on the analyzer.

3 Connect the water supply tube with filter to the water inlet connection on

the analyzer.

4 Press the water tube into the slit of the rubber stopper that is on top of the

liquid level detector, so the filter, at the end of the water supply tube will be

long enough to reach the bottom of the tank.

5 Put both the liquid level detector and the water supply tube with filter

through the opening of the tank, so the filter touches the bottom of the

tank, while the level detector with rubber stopper align vertically into the

tank.

B

A

Figure B-3 Connecting the water supply tank and liquid waste tank to the analyzer

A Water inlet connection

B Liquid waste tube connection

If the water is contaminated by the growth of bacteria or algae, it may result in faulty

liquid detection and rinsing in the pipetting mechanism and rinse circuits of the

analyzer.

C Connector for water level detector

D Connector for liquid waste level detector

C

D

Roche Diagnostics

Operator’s Manual · Version 1.0 B-7

Page 32

2 Hardware URISYS 2400

Installation

Liquid waste tank The liquid waste tank is located outside the analyzer. The capacity of the tank

depends on the specific tank that is used. The tank must have a volume of at

least 5 L (5.3 qts). An overflow sensor is available as an option.

A 5 m (16.4 ft) liquid waste tube is supplied for the connection of the liquid

waste tank to the analyzer.

a To set up the liquid waste tank

1 Ensure the liquid waste tank is empty before use. The liquid waste tank

must be positioned well below the level of the analyzer, to allow for the

reliable flow of the liquid waste into the tank.

2 Connect the liquid waste tube to the drain socket on the analyzer. If

necessary, shorten the liquid waste tube to ensure smooth and even flow.

3 If an overflow sensor is used, connect it to the drain level connector on the

analyzer and place it into the liquid waste tank.

TS transfer base

a To set up the TS transfer base and the strip waste container

1 Open the strip waste container door on the right side of the analyzer.

2 Insert the TS transfer base smoothly to its end position, and ensure that it

is positioned correctly.

Figure B-4 Inserting the TS transfer base into the URISYS 2400 analyzer

3 Turn the screw on the TS transfer base until it locks to secure the base.

4 Insert a waste box carton into the strip waste container and place it into its

correct position.

Roche Diagnostics

B-8 Operator’s Manual · Version 1.0

Page 33

URISYS 2400 2 Hardware

Installation

5 Close the strip waste container door.

Figure B-5 Installing the strip waste container

External printer

External host connection

An external printer can be connected via a standard parallel interface

(Centronics type).

Recommended printers are:

Country Printer

For Japan: EPSON VP600

FUJITSU M3388C

For Europe: FUJITSU M3388B

FUJITSU DL 3700 Pro

For USA: FUJITSU M3388A

Table B-1 Table of recommended printers

If another type of printer is used, ensure that it is compatible with the

analyzer.

The analyzer can be connected to a host computer via a serial interface using

ASTM protocol.

For specifications of serial host interfacing, contact Technical Support.

Roche Diagnostics

Operator’s Manual · Version 1.0 B-9

Page 34

2 Hardware URISYS 2400

Installation

Environmental conditions

The URISYS 2400 analyzer must be used in an environment that meets the

following conditions:

o Free from excessive dust

o Well-ventilated area

o Not exposed to direct sunlight

o Floor that is level (with an inclination of less than 1.5 degrees in every

direction) and firm

o Table that can support the mass of the instrument, which is approximately

85 kg (187 lbs)

o Ambient temperature ranging from 15-30°C (59-86°F), with an acceptable

variation of ±2°C (±3°F) during measurement

o Relative humidity ranging from 20% to 80%, without moisture

condensation

o Free from vibrations

o Availability of a 3-pin power supply socket within 3 m (9.8 ft) of the

analyzer

o Free from abrupt mains voltage fluctuation (±10 V)

o Well-distanced from a machine generating a high frequency voltage (for

example, a centrifuge)

o Free from electromagnetic wave interference

Roche Diagnostics

B-10 Operator’s Manual · Version 1.0

Page 35

URISYS 2400 3 Software

Table of contents

Software

This chapter describes the URISYS 2400 software.

In this chapter B

Installation .......................................................................................................12

The URISYS 2400 touch screen ..................................................................13

Setting the parameters .................................................................................16

Test parameters ......................................................................................17

Sieve and abnormal values ....................................................................17

Print order ..............................................................................................18

Controls ..................................................................................................19

Range table .............................................................................................21

Units ........................................................................................................24

System parameters .......................................................................................24

Sample barcode ......................................................................................25

Printer .....................................................................................................25

COMM. parameter ..............................................................................26

Date/Time ...............................................................................................26

Password .................................................................................................27

Register the wash rack ...........................................................................27

Parameter media ..........................................................................................28

Load ........................................................................................................28

Save .........................................................................................................28

Print ........................................................................................................28

Chapter

3

Roche Diagnostics

Operator’s Manual · Version 1.0 B-11

Page 36

3 Software URISYS 2400

Installation

Installation

The software supplied with the analyzer supports all functions of the

URISYS 2400 analyzer. Specific functions are password-protected to avoid

accidental modifications.

The English software is pre-installed and ready for use on delivery of the

analyzer.

In case re-installation of the software is necessary, proceed as follows.

a To install the software

1 Save the system parameters, test parameters, routine sample results, STAT

sample results, control results and the alarm trace onto a diskette as safety

backup.

“Setting the parameters” on page B-16

“Data of routine and STAT samples” on page C-21

“Control sample data” on page C-28

“Handle alarms” on page E-3

2 Switch off the power.

3 Insert System Disk 1 into the diskette drive.

4 Switch on the power, located on the right side of the analyzer. The [Wait]

screen is displayed.

5 While the [Wait] screen is displayed, press both the lower left and lower

right corners of the LCD panel simultaneously. The [System Menu] screen

is displayed.

6 Press <Transmit Mode>.

7 Press <Tool Transmit>.

8 Follow the instructions on the screen to complete the installation.

9 If necessary, restore the system parameters, test parameters, routine sample

results, STAT samples results, and control results from the backup diskette.

Step 1

Roche Diagnostics

B-12 Operator’s Manual · Version 1.0

Page 37

URISYS 2400 3 Software

Installation

The URISYS 2400 touch screen

The touch screen has been designed to make navigation through the menus

consistent and convenient. Press the buttons on the touch screen once to

perform the various functions. Operators wearing gloves can easily use the

touch screen. A special pointer can be used to operate the keyboard displayed

on the touch screen, if necessary.

Basic screen composition Generally, the status of the analyzer is indicated in the upper left of the yellow

line of the main screen. There are three main status types. For information on

the different status types displayed on the touch screen, see:

Table B-2 on page B-13

Other status types are displayed during special operations.

The date and time are displayed in the upper right of the screen.

Figure B-6 Example of a touch screen

Status type Explanation

Stand-By The analyzer must always be in Stand-By status for

the processing of data, inputting of criteria, or

setting the parameters. The analyzer is idle in this

status.

Operation The analyzer processes samples in this status. This

status allows the operator to load additional samples

without interrupting sampling and measurement of

samples currently being processed.

Sampling Stop

Table B-2 Main status types displayed on the touch screen

Roche Diagnostics

Operator’s Manual · Version 1.0 B-13

The status of the analyzer changes to Sampling Stop

when there are no more racks on the rack input line

or to S.Stop when the analyzer cannot continue with

a procedure. This generally coincides with a

message that indicates the reason for the stop.

Page 38

3 Software URISYS 2400

Installation

Immediately below the line indicating the status of the analyzer, the name of

the current screen is displayed. For example, the name of the screen displayed

above is [Routine Monitor].

Figure B-6 on page B-13

Press <Home> on the initial [Copyright] screen to display the [Routine Monitor]

screen.

There are a number of buttons that consistently appear on the screens. The

following table summarizes these buttons and their functions.

Button Explanation

<Home> Press this button to display the [Routine Monitor] screen.

<Alarm> This button flashes to signal an alarm. Press this button to

read the message.

<Menu> Press this button to display the [Menu] screen.

<PgUp> Page up. Press this button to return to the previous screen.

<CLR> The data entered is cleared. The CLR button only works

before the Enter button is pressed.

<Cancel> Cancels any data that has been entered and returns to the

previous screen without having made any changes. The

Cancel button only works before the Enter button is pressed.

<OK> Confirms the data on-screen and proceeds to the next

screen.

“<“ Press < to move through the different fields.

“>“ Press > to move through the different fields.

<+> Increases values on the touch screen.

<-> Decreases values on the touch screen.

<>

Table B-3 Main buttons displayed on the touch screen

Enter. Press this button to confirm the newly entered data.

Roche Diagnostics

B-14 Operator’s Manual · Version 1.0

Page 39

URISYS 2400 3 Software

Installation

As the operator navigates through the different screens, there are various

windows that can appear. These serve different functions, such as

confirmation of a selection. The figure shows an example:

Figure B-7 Example of a window that can appear on the touch screen

Some of the buttons for selecting settings work with a toggle function.

Roche Diagnostics

Operator’s Manual · Version 1.0 B-15

Page 40

3 Software URISYS 2400

Installation

Setting the parameters

A number of parameters can be set individually according to laboratory

requirements if they deviate from the default factory settings.

The settings are automatically stored so that the data or analytical parameters

do not need to be re-specified each time, except when required. They can be

printed or saved to a diskette for documentation.

If any mistakes related to the consistency of values occurred during setting of

parameters, the corresponding error alarm message does not appear until <Start>

is pressed for starting analysis. Check the alarm and correct the settings.

The setting of parameters is only possible when the analyzer is in Stand-By

status. For starting the analyzer, see:

“System start” on page C-4

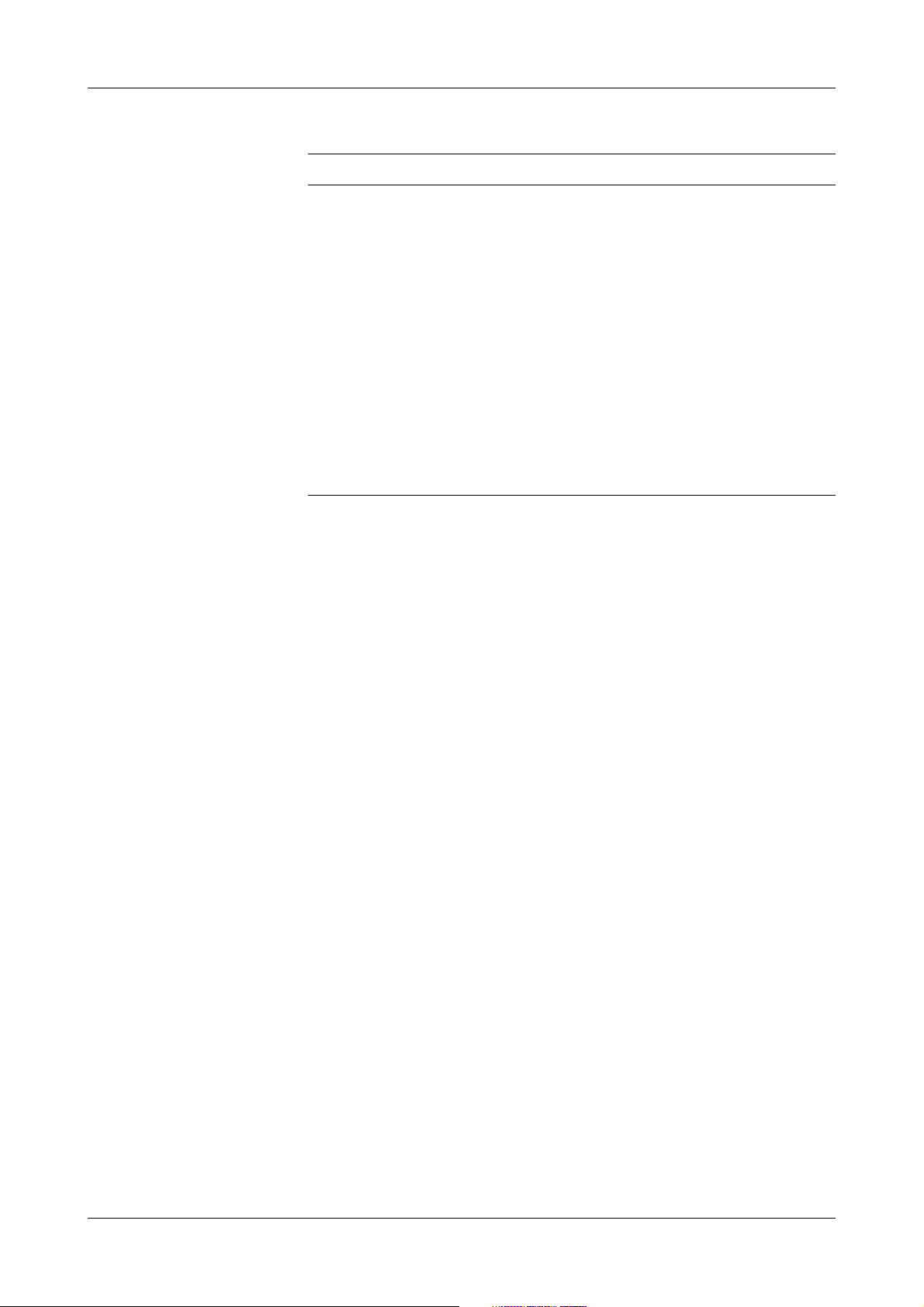

Parameters

Test Parameters System Parameters Parameter Media

Sieve & Abnormal

Print Order

Controls

Range Table

Units

Figure B-8 System hierarchy chart of the progression through the different

screens of the Parameters menu

Sample Barcode

Printer

COMM.Parameter

Date / Time

Password

Regist. Wash Rack

Load Parameters

Save Parameters

Print Parameters

Roche Diagnostics

B-16 Operator’s Manual · Version 1.0

Page 41

URISYS 2400 3 Software

Installation

Test para me t er s

a To set test parameters

1 Press <Menu> on the [Routine Monitor] screen. The [Menu] screen is

displayed.

2 Press <Parameters>. The [Parameters] screen is displayed.

3 Press <Test Parameters>. The [Test Parameters] screen is displayed.

4 Press any of the following five buttons to gain access to the option you

require:

o <Sieve & Abnormal>

o <Print Order>

o <Controls>

o <Range Table>

o <Units>

Sieve and abnormal

values

Use the sieve settings to define the criteria for a flag (S) on the corresponding

test parameter result. These flags can be used to identify urine samples to be

examined by additional methods, for example, sediment microscopy.

Use the abnormal settings to define the criteria that indicate potentially

pathological values. An asterisk (*) flags the corresponding test parameter

results.

The concentration values which are specified on the screen represent the

lowest concentration ranges from which on the test parameter results are

flagged.

For more information, see:

Table E-1 on page E-2

Figure B-9 Sieve & Abnormal screen

Roche Diagnostics

Operator’s Manual · Version 1.0 B-17

Page 42

3 Software URISYS 2400

Installation

a To set the criteria for defining sieve and abnormal values

1 Press <Sieve & Abnormal> on the [Test Parameters] screen. The [Sieve &

Abnormal] screen is displayed listing the sieve criteria for each test.

2 Press <Select> to change the display of the items from sieve to abnormal

criteria and back.

3 Press <Set> to change the criteria. The [Password] window appears.

4 Enter the 4-digit password using the keyboard on the screen.

5 Press <Enter>. The [Sieve & Abnormal Setting] screen is displayed with

both the sieve and abnormal values listed for each test parameter,

beginning with specific gravity (SG).

6 Press <Test> to select another test parameter.

7 Press “<” or “>” to select sieve or abnormal settings.

8 Press <+> or <-> to select the desired concentration range.

9 Press <Enter> after each selection to accept the chosen values.

10 Press <PgUp> to return to the [Sieve & Abnormal] screen and check if the

settings correspond to your requirements.

11 Press <PgUp> to return to the [Test Parameters] screen.

Print order The operator can define the order of the test parameters on the screen and on

the result printout, in order from 1 to 12. If an item is not to be printed, enter

zero.

Figure B-10 Screen showing Print Order settings and options

Roche Diagnostics

B-18 Operator’s Manual · Version 1.0

Page 43

URISYS 2400 3 Software

Installation

a To set the print order

1 Press <Print Order> on the [Test Parameters] screen. The [Print Order]

screen is displayed.

2 Enter the test parameter order if the requirements of the laboratory differ

from the default settings.

3 Press “<” or “>” to move through the different fields.

4 Press <Enter> after each entry.

5 Press <PgUp> to return to the [Test Parameters] screen.

Controls The operator can define the following:

o Control sample rack number

o Position of the control samples on the rack

o Control sample name

o Lot number

When the control sample rack number has been registered, the analyzer

automatically recognizes this rack as a rack carrying urine control samples,

and measures the samples like normal samples; however, the results are stored

in a special control sample data memory.

For each specified position on the control rack, a separate memory for 100

results is available. Up to three different controls can be measured in one rack.

The specified position on the rack of each control level must be used each

time to avoid the mixing of results in the assigned memory.

a To specify the control rack number and control sample rack

position

1 Press <Controls> on the [Test Parameters] screen. The [Controls] screen is

displayed.

2 Press <Regist. Control Rack>. The [Regist. Control Rack] screen is

displayed.

3 Enter the range of the control rack ID numbers in the fields provided. The

control rack ID numbers must consist of five digits and overlapping ranges

(for example, with routine racks) are not allowed.

If the 5-digit number of the chosen rack is not known, read and print the rack ID via

the Barcode Check function (see “Checks” on page C-41).

4 Press <Enter> after each value has been entered.

5 Enter the position number on the rack for each level of control sample, for

example, position one for normal level and position two for abnormal

level. The input positions range from 1 to 5 on the registered rack, or zero.

If a level is not to be measured, enter zero.

Roche Diagnostics

Operator’s Manual · Version 1.0 B-19

Page 44

3 Software URISYS 2400

Installation

6 Press <Enter> after each entry.

7 Press <PgUp> to return to the [Controls] screen.

Mark the specified rack as a control rack. Do not use the control rack for

routine samples, otherwise the routine sample results will be stored in the

control data memory.

a To specify the control name and lot number

1 Press <Control Name/Lot No.> on the [Controls] screen. The [Control

Name/Lot No.] screen is displayed.

2 Press <Level> to select a level, for example, Level 1, Level 2 or Level 3.

3 Type the name of the control material, using a maximum of 16

alphanumeric characters. Press <Enter>.

4 Type the Lot No., using a maximum of 10 digits.

5 Press <Enter> after each entry.

6 Press <Level> again to enter the Name and Lot No. for the remaining

levels.

7 Repeat steps 3-5.

8 Press <PgUp> twice to return to the [Test Parameters] screen.

Roche Diagnostics

B-20 Operator’s Manual · Version 1.0

Page 45

URISYS 2400 3 Software

Installation

Range table The operator can view the concentration ranges, reflectance values,

wavelengths and compensation data for each test parameter. The operator

gains access to the range and reflectance values by using the password that is

supplied with the analyzer.

Figure B-11 Screen showing Range Table settings and options

The wavelength data (W) that are displayed are fixed values. These values

cannot be changed.

The compensation data (C) designate factors for the compensation of the

intrinsic urine color, for example, 0 means no color compensations. Higher

numbers mean stronger compensation.

Changing ranges leads to result reports which differ from the default

concentration ranges as shown in:

Table F-1 on page F-5

Changing reflectance values leads to different evaluation sensitivities of the

respective test parameters. Lowering the reflectance value of the negative (NEG)

range leads to a decrease of the sensitivity of the test evaluation, and vice versa. In

this way, the sensitivity can be adjusted to the requirements of the individual

laboratory.

The correctness of results obtained after the user has altered the ranges or

reflectance values is not warranted by Roche Diagnostics. The user is responsible

for validating the consistency of results after changes have been made.

The concentration ranges and reflectance values can be reset to the default

values using the <Default> button.

Roche Diagnostics

Operator’s Manual · Version 1.0 B-21

Page 46

3 Software URISYS 2400

Installation

a To change the range values

1 Press <Range Table> on the [Test Parameters] screen. The [Range Table]

screen is displayed.

2 Press <Test> to select the test parameter to be viewed. For each test

parameter, the range and reflectance values can be changed.

3 Press <Set Range> to change the range. The [Password] window appears.

4 Enter the 4-digit password.

5 Press <Enter>. When the correct password is entered, the [Set Range]

screen is displayed.

6 Press <Test> to select a test parameter.

7 Enter the range values. Press “<” or “>” to move through the different

fields.

8 Press <Enter> after each value is entered.

9 Repeat steps 6-8 if the ranges of other test parameters need to be changed.

10 Press <PgUp> to return to the [Range Table] screen.

o

The screen allows for eight ranges to be set for each parameter. However, not all

of the ranges are used by the default settings.

o

If ranges are changed for conventional concentration units, these changes are

not transferred to the SI concentration units memory, and vice versa. To be

consistent, corresponding changes must be made in both range tables. (See

Table F-1 on page F-5.)

a Using arbitrary units

If arbitrary units (1+, 2+, 3+) should be used instead of concentration values

or in addition to concentration values, proceed as follows:

1 Call up the [Set Range] screen.

2 Press <Test> to select a test parameter.

3 Enter the arbitrary unit in the corresponding field and delete the

concentration value by pressing <Space> if you want to replace the

conventional or SI units.

4 Enter the arbitrary unit in the corresponding field without deleting the

concentration value if you want to used combined units, for example,

“2+ 25”.

If combined units are used for the parameter Glucose, the entry of “4+1000” is not

possible because of the limitation of 5 digits per field. Use “4+999” instead.

Roche Diagnostics

B-22 Operator’s Manual · Version 1.0

Page 47

URISYS 2400 3 Software

Installation

a To change the reflectance values

1 Press <Set Reflect>. on the [Range Table] screen. The [Password] window

appears.

2 Enter the 4-digit password.

3 Press <Enter>. When the correct password is entered, the [Set Reflectance]

screen is displayed.

4 Press <Test> to select a test parameter.

5 Enter the new reflectance values between the indicated values. Apply

moderate changes and validate the effect to the evaluation sensitivity.

6 Press <Enter> after each value is entered.

7 Repeat steps 4-6 if reflectance values of other test parameters need to be

changed.

8 Press <PgUp> to return to the [Range Table] screen.

o

The screen allows for eight values to be set for each parameter. However, not all

of the values are used by the default settings.

o

Reflectance values that have been changed will be marked with a “#” flag on

the [Range table] screen as well as in the Parameter Settings printout. This flag

will also appear with the corresponding test parameter on the result printout.

a To set default concentration ranges and reflectance values

1 Press <Default> on the [Range Table] screen. The [Password] window

appears.

2 Enter the 4-digit password.

3 Press <Enter>. When the correct password is entered, the [Default]

window appears to confirm the change to the default settings.

4 Press <OK> to confirm. The changed concentration ranges and reflectance

values are set to default.

5 Press <PgUp> to return to the [Test Parameters] screen.

Roche Diagnostics

Operator’s Manual · Version 1.0 B-23

Page 48

3 Software URISYS 2400

Installation

Units

a To select the concentration units

The operator can select the units for reporting results (conventional or SI).

1 Press <Units> on the [Test Parameters] screen. The [Units] screen is

displayed. The units currently in use are displayed.

2 Press <Units> to change the type of units to be displayed on the screen and

on the printouts, and to be sent to the host computer. The [Confirmation]

window appears.

3 Press <OK> to change units.

When the units are changed, results are reported in the newly chosen units.

Therefore, it is important to set units before starting measurements. The change of

units also applies when re-printing previously measured results.

System parameters

The operator can select six system parameter settings. They are:

o Sample barcode

o Printer (includes the paper length, the number of samples printed per

page, and the page heading)

o Communication

o Date and time

o Password

o Registration of the wash rack

a To set system parameters

1 Press <System Parameters> on the [Parameters] screen. The [System

Parameters] screen is displayed.

Roche Diagnostics

B-24 Operator’s Manual · Version 1.0

Page 49

URISYS 2400 3 Software

Installation

Sample barcode

a To select the type of barcode

1 Press <Sample Barcode> on the [System Parameters] screen. The [Sample

Barcode] screen is displayed.

2 Press <Sample Barcode> to enable or disable the use of a barcode.

If sample barcode is enabled, any sample with no barcode label or an unreadable

barcode, results in an alarm message. In this case, samples are still tested. If sample

barcode is disabled, no sample barcodes are read.

3 Press <Code39 C/D>, <NW7 C/D>, and <ITF C/D> to enable or disable

the use of a check digit function for each type of barcode. A [Warning]

window will alert the operator of the increased probability for misreads

when check digits are disabled.

Printer

4 Press <PgUp> to return to the [System Parameters] screen.

If using an ITF barcode type, Roche/Hitachi recommends its use only with a check

digit function.

a To define printer settings

1 Press <Printer> on the [System Parameters] screen. The [Printer] screen is

displayed.

2 Press <Paper Length> to define the paper size.

3 Press <Samples/Page> to define the number of samples to be printed per

page.

4 Press <Headline edit>. The [Headline edit] screen is displayed.

5 Enter the new headline (up to 26 characters per line).

6 Press <Enter> at the end of each line.

7 Press <PgUp> twice to return to the [System Parameters] screen.

Roche Diagnostics

Operator’s Manual · Version 1.0 B-25

Page 50

3 Software URISYS 2400

Installation

COMM. parameter

a To define the communication parameters

Changing the settings is only possible when the analyzer is set to “Host Off-line”

(see “Start conditions before sampling” on page C-5).

1 Press <COMM. Parameter> on the [System Parameters] screen. The

[COMM. Parameter] screen is displayed.

2 Press <Baud Rate>, <Parity>, <Bits Per Char.>, and <Stop Bit> to select

the settings for communicating with the host computer.

These settings must match the corresponding settings of the host computer. Only

specialists or trained supervisors should change these settings.

3 Press <PgUp> to return to the [System Parameters] screen.

Date/Time The operator can change the format of the date and time, and set the correct

local dates, which are displayed on the touch screen and reported with the

measurement results and in the alarm messages.

a To select format and local settings for date and time

1 Press <Date/Time> on the [System Parameters] screen. The [Date/Time]

screen is displayed.

2 Press <Order> to change the format of the date.

3 Press <Time> to change the format of the time from 12 hour to 24 hour.

4 Enter the correct local date and time.

5 Press <Enter> after each entry.

6 Press <PgUp> to return to the [System Parameters] screen.

Roche Diagnostics

B-26 Operator’s Manual · Version 1.0

Page 51

URISYS 2400 3 Software

Installation

Password The operator can change the password used to gain access to the

[Sieve & Abnormal Setting], [Set Range], [Set Reflectance], and [Default]

screens. The password is identical in each case. Only numerical characters can

be used.

a To change the password

1 Press <Password> on the [System Parameters] screen. The [Password]

window appears.

2 Enter the old (current) 4-digit password.

3 Enter the new 4-digit password.

4 Re-enter the new password.

5 Press <Enter> after each entry.

6 Press <PgUp> to return to the [System Parameters] screen.

Register the wash rack The operator can define the ID of the rack to be used for washing. If the

washing procedure is performed using a rack on the rack input line, the

analyzer recognizes the specified rack and performs the washing procedure.

a To register the wash rack

1 Press <Regist. Wash Rack> on the [System Parameters] screen. The

[Regist.Wash Rack] screen is displayed.

2 Enter the consecutive range of the wash rack ID numbers in the fields

provided. The wash rack ID numbers must consist of five digits, and

overlapping ranges (for example, with routine sample racks) are not

allowed.

If the 5 digit number of the chosen rack is not known, read and print the rack ID via

the Barcode Check function (see “Checks” on page C-41).

3 Press <Enter> after each entry.

4 Press <PgUp> to return to the [System Parameters] screen.

Mark the specified rack as a wash rack. Do not use the wash rack for routine or

control samples; otherwise, the samples will not be measured.

Roche Diagnostics

Operator’s Manual · Version 1.0 B-27

Page 52

3 Software URISYS 2400

Installation

Parameter media

The operator can select three media functions. They are to Load, Save, and

Print the parameter settings.

a To select the functions

1 Press <Parameter Media> on the [Parameters] screen. The [Parameter

Media] screen is displayed.

Load

a To load the parameter settings

1 Insert the backup diskette with the parameter settings.

2 Press <Load Parameters> on the [Parameter Media] screen. The [Load

Parameters] window appears.

3 Select <Test> or <System>.

Save

Print

4 Press <OK> to confirm loading of the parameters from the diskette to the

analyzer.

a To save parameter settings to a diskette

1 Insert a 1.44 MB diskette.

2 Press <Save Parameters> on the [Parameter Media] screen. The [Save

Parameters] window appears.

3 Press <OK> to confirm downloading of the parameters to a diskette from

the analyzer.

For further diskette options, see:

“FD utilities” on page C-43

a To print the parameter settings

1 Press <Print Parameters> on the [Parameter Media] screen. The [Print

Parameters] window appears.

2 Press <OK> to confirm the printing of the parameters. All parameter

settings (test parameters and system parameters) are printed.

Roche Diagnostics

B-28 Operator’s Manual · Version 1.0

Page 53

URISYS 2400 4 Cassette

Table of contents

Cassette

This chapter describes installation and handling of the URISYS 2400 cassette.

In this chapter B

First-time installation ....................................................................................30

Unpack and install the cassette ...................................................................30

Chapter

4

Roche Diagnostics

Operator’s Manual · Version 1.0 B-29

Page 54

4 Cassette URISYS 2400

First-time installation

First-time installation

Unpack and install the cassette

The cassette is delivered in an airtight polyethylene-coated aluminum bag,

which is tightly placed in an outer package box. This secure packaging ensures

the shelf life of the cassette in the unopened package as printed on the package

box.

When the aluminum bag is opened, the cassette must be placed into the cassette

compartment of the instrument and the compartment door firmly closed within

three minutes to prevent damage of the test strips by humidity or nitrous gases in

the air.

The test strips are stable within the tightly closed cassette compartment for

fourteen days. After this time, the cassette must be replaced by a new one.

Carefully unpack the URISYS 2400 cassette to prevent damage to the test

strips. Use the [Change Cassette] screen in the Maintenance menu to install

the cassette for the first time. The instrument must be in Standby.

a To unpack and install the cassette for the first time

1 Press <Menu> on the [Routine Monitor] screen. The [Menu] screen is

displayed.

2 Press <Maintenance>. The [Maintenance] screen is displayed.

3 Press <Change Cassette>. The [Change Cassette] screen is displayed.

4 Press <Remove> to set the cassette holder mechanism to the exchange

position.

5 A confirmation window “Press <Execute> to start change cassette”

appears.

6 Press <Execute>. A window “Do not open the door” appears, followed by

“Exchange Cassette, then press <Yes> key”.

7 Open the URISYS 2400 package, unfold the aluminum bag and cut it open

with scissors.

8 Remove the cassette from the packaging as shown below and remove the

two protection pads.

Roche Diagnostics

B-30 Operator’s Manual · Version 1.0

Page 55

URISYS 2400 4 Cassette

First-time installation

Figure B-12 URISYS 2400 cassette with protective covers

9 Open the cassette compartment door on the analyzer.

10 Place the cassette on the opened door and move it smoothly into the

cassette compartment with the label facing out.

Figure B-13 Inserting cassette into URISYS 2400 analyzer

11 Move the cassette completely to the rear of the cassette compartment,

ensure it fits correctly, and close the door firmly.

12 Press <Yes> on the window screen for confirmation to return to the

[Change Cassette] screen.

13 Enter the Lot Number of the cassette from the outer packaging box. Press

<Enter> to confirm.

14 Enter for “Alarm level” the number of remaining strips that will lead to an

alarm message indicating a low number of strips (default setting is 40).

15 Press <New> to set the cassette mechanism to the working position. A

window “Do not open the door” appears.

16 After completing the setting, a confirmation window “Initialization

complete, press <OK> to continue” appears.

17 Press <OK> to return to the [Change Cassette] screen.

Roche Diagnostics

Operator’s Manual · Version 1.0 B-31

Page 56

4 Cassette URISYS 2400

First-time installation

18 Press <Home> to return to the [Routine Monitor] screen. The screen

shows the number of remaining strips as 400, followed by the date the

cassette was installed.

When a cassette becomes empty during sample processing, replacement by a new

cassette can be performed through the [Routine Monitor] screen by activating the

<Change Cassette> button, (see “Replace an empty URISYS 2400 cassette” on

page C-18).

Handling precautions When handling test strips, the following precautions must be observed:

o Only use a URISYS 2400 cassette that has not exceeded its expiration date.

o Store cassette packages at a temperature between 2-30°C (36-86°F).

o Refrigerated cassettes must be at room temperature for at least two hours

before opening the package and using the cassette.

o Check the package for damage.

o After removing the cassette from the packaging, ensure the test strip layers

are correctly aligned and the test pads are not unusually discolored.

o Do not directly touch the test pads of the test strip.

o Do not let the strips come in contact with water or with any volatile,

strongly acidic, or alkaline chemicals.

o Install the cassette into the analyzer within 3 minutes of opening the seal.

o Keep the cassette in the firmly locked cassette compartment until the test

strips are completely used up.

o Do not open the cassette compartment door as long as the cassette is not

empty or the on-board stability has not expired.

o Follow the instructions provided with the URISYS 2400 cassette by the

manufacturer and read carefully all information on the package insert.

Roche Diagnostics

B-32 Operator’s Manual · Version 1.0

Page 57

Operation

Part C contains the operating procedures for the URISYS 2400.

C

Page 58

Page 59

URISYS 2400 5 Daily operation

Table of contents

Daily operation

This chapter describes daily operation for the URISYS 2400.

In this chapter C

Initial preparations .............................................................................................3

System start ........................................................................................................4

Start conditions before sampling .................................................................5

Sample preparation .........................................................................................8

Preparation of sample racks and tubes .......................................................8

Loading the rack(s) onto the analyzer ..........................................................9

Start analysis of samples .............................................................................10

Termination of analysis ...................................................................................11

Completion of analysis ................................................................................11

Interrupting analysis ...................................................................................11

Automatic termination ...............................................................................12

Termination due to an alarm .....................................................................12

Remove processed samples ..............................................................................12

Process additional samples ...............................................................................13

Process STAT (emergency) samples ...............................................................14

During routine sampling ............................................................................14

After interruption or completion of routine sampling .............................16

Start from Stand-By status ..........................................................................16

Process control samples ...................................................................................17

Replace an empty URISYS 2400 cassette ........................................................18

Replace an expired URISYS 2400 cassette .......................................................19

Re-insert a used URISYS 2400 cassette ............................................................20

Chapter

5

Roche Diagnostics

Operator’s Manual · Version 1.0 C-1

Page 60

5 Daily operation URISYS 2400

Analysis and documentation of results ...........................................................21

Data of routine and STAT samples .............................................................21

Display the result data ...........................................................................22

Search sample data ................................................................................22

Entering the sample ID number ...........................................................23

Edit result data .......................................................................................24

Print routine and STAT sample data .....................................................24

Presentation of results on the printout ................................................25

Send result data to the host computer .................................................26

Write/read routine or STAT sample data to/from a diskette ................26

Delete routine or STAT sample data .....................................................27

Control sample data ....................................................................................28

Display control sample data .................................................................28

Search for control sample data .............................................................29

Print control sample data ......................................................................30

Presentation of result data on the printout .........................................30

Send control sample data to the host computer .................................32

Write/read control sample data to/from a diskette ..............................32

Delete control sample data ....................................................................33

Switch off the analyzer .....................................................................................34

Roche Diagnostics

C-2 Operator’s Manual · Version 1.0

Page 61

URISYS 2400 5 Daily operation

Initial preparations

Initial preparations

Before switching on the power to operate the analyzer, perform the following

tasks:

o Fill the water supply tank with deionized water and place the liquid level

detector in the water supply tank.

o Ensure that the TS transfer base is inserted correctly.

o Empty the strip waste container and ensure that it is positioned correctly.

o Empty the liquid waste tank.

o Place an empty rack tray on the rack output line.

o Remove all air bubbles from the syringes after switching on the analyzer.

“Air purge” on page D-7

Roche Diagnostics

Operator’s Manual · Version 1.0 C-3

Page 62

5 Daily operation URISYS 2400

System start

System start

a To start the URISYS 2400 analyzer

The power switch is located on the right side of the analyzer. The OFF position is

represented by

1 Turn the power switch to the ON (|) position. The [Please Wait] screen

appears. Loading and initializing of the software takes approximately 5

minutes. After the first loading stage, the progress is indicated on-screen.

2 Check and remedy any alarm messages. Clear the alarm messages.

“Instrument alarms (messages)” on page E-12

3 Press <Home> on the [Copyright] screen. The [Routine Monitor] screen

is displayed.

4 Wait until the analyzer is in Stand-By status before continuing.

Ο.

Figure C-1 Routine Monitor screen

Roche Diagnostics

C-4 Operator’s Manual · Version 1.0

Page 63

URISYS 2400 5 Daily operation

System start

Start conditions before sampling

After powering on the analyzer, the operating conditions must be specified

and checked. These include the following:

o Specify the sample details.

o Specify the operator ID.

o Activate or deactivate the host connection as required.

o Select the print mode.

a To confirm the start conditions

For input of numbers or change of the host and printer settings, the analyzer must

be in Stand-By.

1 Press <Start Condition> on the [Routine Monitor] screen. The [Start

Condition] screen is displayed.

2 Confirm that the details on the [Start Condition] screen are correct.

Figure C-2 Start Condition screen

Roche Diagnostics

Operator’s Manual · Version 1.0 C-5

Page 64

5 Daily operation URISYS 2400

System start

a To enter the routine sequence number, STAT sequence number and

operator ID

1 Ensure the [Start Condition] screen is displayed.