Page 1

POINT OF CARE

TESTING

Roche OMNI C

Reference Manual

Page 2

Roche Diagnostics GmbH

D-68298 Mannheim / Germany

www.roche.com

Copyright © 2003 Roche Diagnostics GmbH, all rights reserved

The contents of this document may not be reproduced in any form or communicated to any third party without

the prior written consent of Roche Diagnostics. While every effort is made to ensure its correctness, Roche

Diagnostics assumes no responsibility for errors or omissions which may occur in this document. Subject to

change without notice.

REF/No. 03261018001

Rev. 5.0, Juli 2003

First edition: October 2001

Page 3

– Important information! – Always follow! –

This Reference Manual contains vital warning and safety information.

This instrument is intended to be used only for the specialized purpose described in the instructions. The

most important prerequisites for use, operation, and safety are explained to ensure smooth operation. No

warranty or liability claims will be covered if the instrument is used in ways other than those described or if

the necessary prerequisites and safety measures are not observed.

The instrument may be operated only by persons whose qualifications enable them to comply with the safety

measures that are necessary during operation of the machine.

Adjustments and maintenance performed with removed covers and connected power may be attempted only

by a qualified technician who is aware of the associated dangers.

Instrument repairs are only to be performed by the manufacturer or qualified service personnel.

Only accessories and supplies either delivered by or approved by Roche are to be used with the instrument.

These items are manufactured especially for use with this instrument and meet the highest quality requirements.

Operation of the instrument with solutions whose composition is not consistent with that of the original

solutions can negatively affect, above all, the long-term measurement accuracy. Deviations in the composition of the solutions can also decrease the service life of the electrodes.

The quality control requirements must be completed at least once daily for safety reasons.

Because accurate measurement results depend not only on the proper functioning of the instrument, but also on a number of other factors (such as preanalytics), the results produced by the

instrument should be examined by a trained expert before subsequent decisions are reached

that are based on the measurement values.

Explanation:

Meaning: "Caution, refer to accompanying documents“.

– Important information! – Always follow! –

Page 4

– Operating safety information –

• The instrument has been constructed and tested according to the protective measures stipu-

lated by EN 61010-1: 1993 / IEC 1010-1 for electrical measurement, control, IVD, and laboratory instruments and was delivered from the factory in flawless condition with regards to

safety features. In order to preserve this condition and ensure safe operation, the user must

respect the notices and warnings that are contained in these Instructions for Use.

• This instrument is classified under the protection class I according to EN 61010-1 / IEC

1010-1.

• The instrument meets the conditions for overvoltage category II.

• The instrument meets the conditions for contamination level 2.

• Do not operate the instrument in an explosive environment or in the vicinity of explosive

anesthetic mixtures containing oxygen or nitrous oxide.

• If an object or liquid enters the internal areas of the instrument, remove the instrument

from its power supply and allow an expert to check it thoroughly before using it again.

• The instrument is suitable for long-term operation indoors.

CAUTION:

• The power cord may be plugged into a grounded socket only. When using an extension

cord, make sure it is properly grounded.

• Any rupture of the ground lead inside or outside the instrument or a loose ground connec-

tion may result in hazardous operating conditions. Intentional disconnection of the

grounding is not permitted.

• The instrument is not suitable for operation with a direct current power supply.

Use only the original mains plug delivered with the Roche OMNI C.

– Operating safety information –

Page 5

1 Introduction

2 Specifications

3 Operating modes

4 Performance data

5 Trouble shooting

6 Interfaces

7 Theoretical foundations

8 Appendix

9 Index

Page 6

Page 7

1 Introduction

1 Introduction

1.1 General notes ................................................................................................................... 1-1

1.1.1 General operating instructions.................................................................................................................1-1

1.1.2 Symbols.............................................................................................................................................................1-1

1.2 Safety instructions for specific dangers .................................................................... 1-2

1.2.1 Disposal of waste water, bottles, electrodes, and the instrument ..............................................1-2

1.2.2 Decontamination ...........................................................................................................................................1-2

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003 1-I

Page 8

1 Introduction

1-II

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003

Page 9

1 Introduction

1.1 General notes

1.1.1 General operating instructions

The Roche OMNI C should be enabled at all times!

Always perform shutdown procedures when the instrument will remain switched off for a

longer period of time (longer than 24 hours). For additional information, please see the

Instructions for Use, chapter 1 "Introduction", section "Shutdown").

Avoid leakage of fluids inside the analyzer.

Complete at least one quality control test every day (please see the Instructions for Use,

chapter 5 , "Quality control", for more information) in order to quickly recognize error

functions in the Roche OMNI C.

1.1.2 Symbols

1 Introduction

Reference manual

All sections / passages that are marked with this symbol (refer to Instructions for

Use) describe information to avoid possible potential for personal injury (for

patients, user or third person)

Risk of infection!

All sections / passages that are marked with this symbol describe procedures and/or

indicate conditions or dangers that could damage or lead to a malfunction in the

Roche OMNI C, and which therefore should never be attempted.

TIP: All sections / text locations marked with "TIP" describe safe procedures that are

intended to provide the user with additional "Help."

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003 1-1

Page 10

1 Introduction

1.2 Safety instructions for specific dangers

1.2.1 Disposal of waste water, bottles, electrodes, and the instrument

Dispose of the waste container in accordance with local regulations for hazardous waste.

1.2.2 Decontamination

After use, components of the Roche OMNI C, including tubing, waste container, filling port, etc., contain biological fluids and represent therefore a possible infectious

risk. Handle these components with care and avoid contact with skin.

Always wear gloves!

The purpose of this procedure is to minimize risk when replacing items that were in contact

with biological samples.

Roche recommends following a decontamination procedure in addition to regulations specific to the laboratory.

These decontamination procedures should be performed periodically to minimize the risk

of infections.

For more detailed information about decontamination, see the chapter "Maintenance" in

the Instructions for Use.

1-2

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003

Page 11

2 System description and functionality

2 System description and functionality

2.1 Screen ............................................................................................................................... 2-1

2.1.1 Screen arrangement.....................................................................................................................................2-1

2.1.2 Header line.......................................................................................................................................................2-2

2.1.3 Parallel operating modes............................................................................................................................2-3

2.1.4 Status line.........................................................................................................................................................2-4

2.2 Printer ................................................................................................................................ 2-4

2.3 Measuring chamber ....................................................................................................... 2-5

2.3.1 Electrodes.........................................................................................................................................................2-5

2.3.2 tHb/SO2 module.............................................................................................................................................2-6

2.4 Sample port module ....................................................................................................... 2-6

2.5 Pump .................................................................................................................................. 2-7

2.6 Bottle compartment ........................................................................................................ 2-8

2.6.1 Bottle compartment cover..........................................................................................................................2-8

2.7 Reverse side ..................................................................................................................... 2-8

2.8 Instrument cover ............................................................................................................. 2-9

2.9 Tubing system .................................................................................................................. 2-9

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003 2-I

Page 12

2 System description and functionality

2-II

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003

Page 13

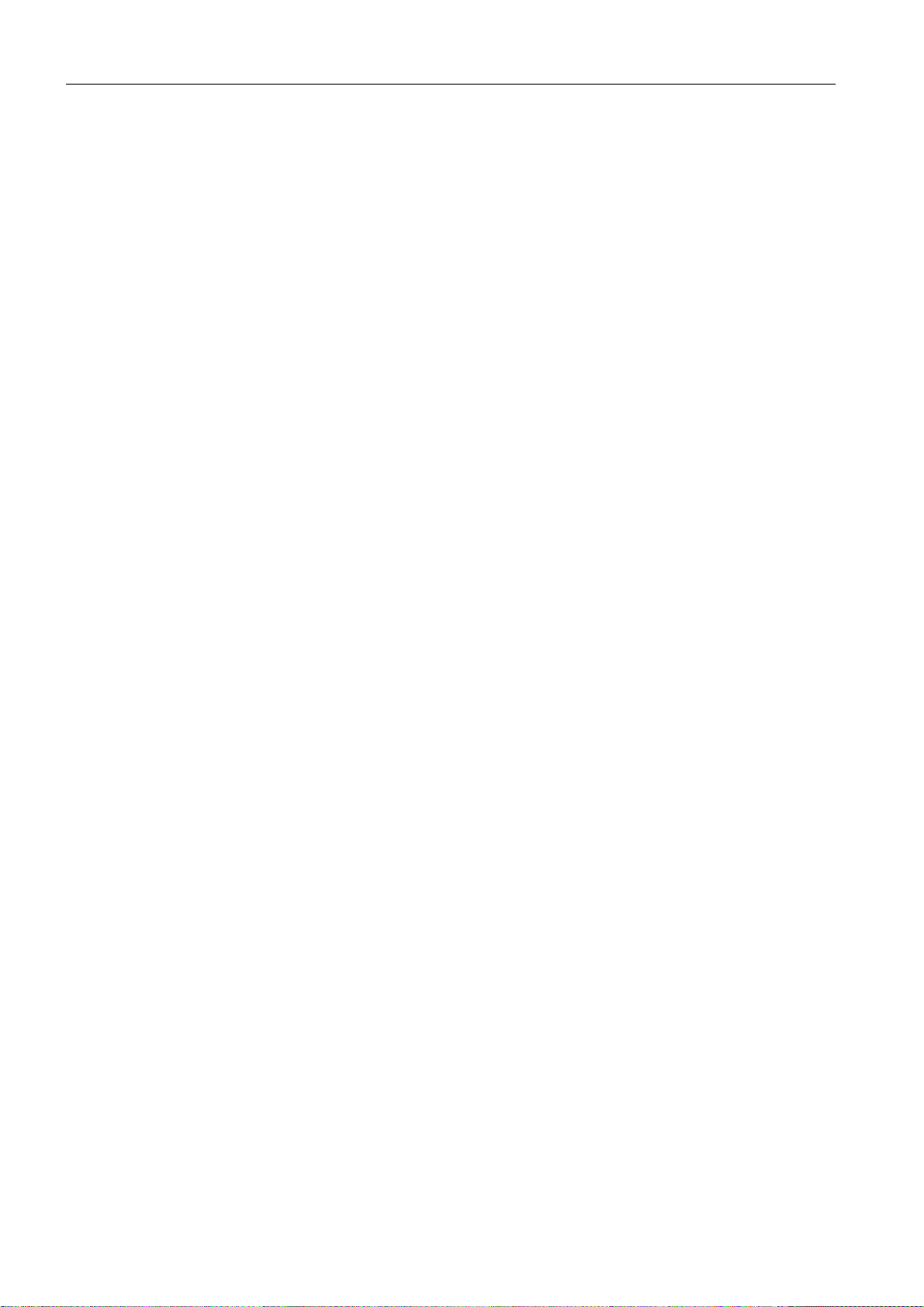

2System description

screen

flap

2 System description

printer cover

contrast setting

instrument cover

bottle compartment cover

Fig. 1

2.1 Screen

All information (results, error messages, warnings, etc.) is displayed on the screen. The

screen consists of a 5.7" colour LCD that is covered with a touch-sensitive film.

2.1.1 Screen arrangement

The Roche OMNI C screen is divided into three main areas:

reverse side

power pack /

mains switch

unlocking knob

for the AutoQC

module

header line

operating mode area

status line

Fig. 2

This screen division applies to all areas of the Roche OMNI C software. The header and status lines are always available in the same division, the operating mode area depicts the status

of the currently active operating mode and serves the interaction of the operating modes

with the user.

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003 2-1

Page 14

2 System description

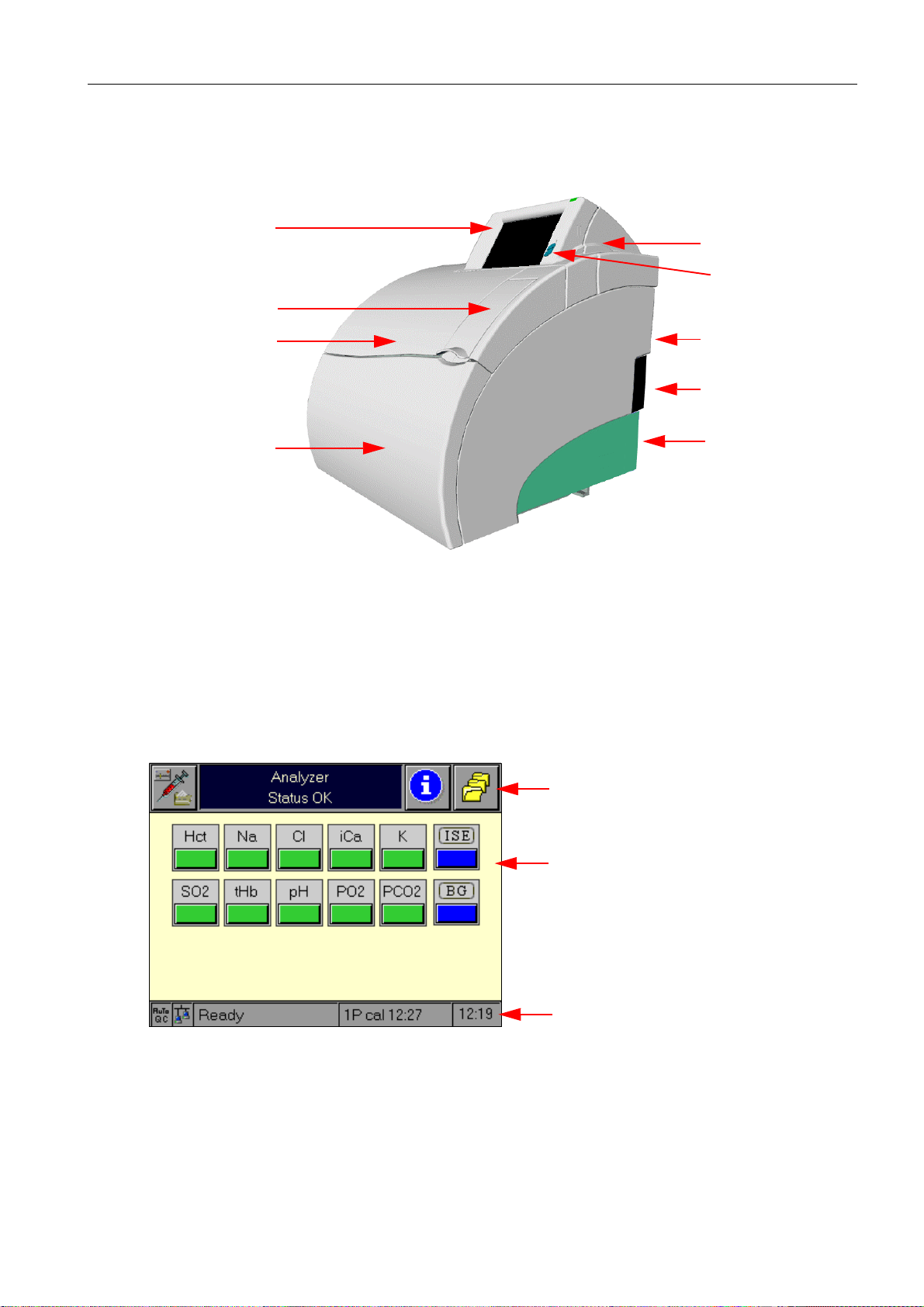

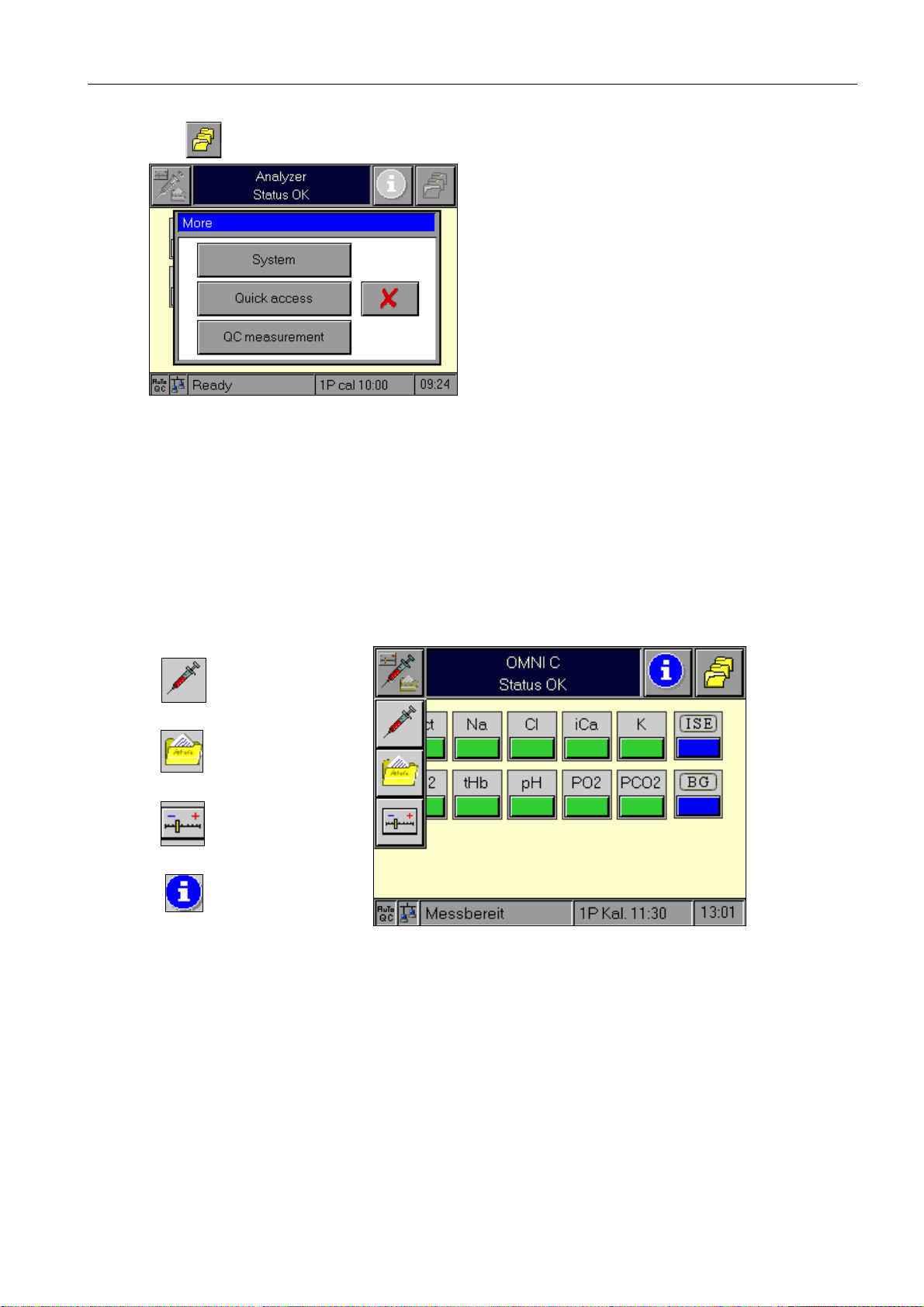

2.1.2 Header line

The header line contains the following elements:

operating mode selection button

general information window

Fig. 3

The operating mode selection button enables switching between the individual

operating modes: Analyzer, Database, and Setup.

Pressing one of these buttons initiates a switch to the desired operating mode.

The menu times out after 5 seconds. In other words, when the user does not take

any action, the menu disappears automatically after this length of time. Pressing

the operating mode selection button again while the menu is visible closes the

menu. Upon selection of an operating mode, the display switches to the corresponding side of the screen.

info button

button for "More functions"

The info button activates the Info operating mode. The Info operating mode has a special

status because it is virtually superimposed on top of the other operating modes. The Info

operating mode contains information on everything that could be associated with the

instrument, specifically all status information (fill levels, electrodes, log entries), user information, and on-line help. Upon exit, the Info operating mode terminates completely.

Cancel

Fig. 4

2-2

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003

Page 15

2 System description

The button calls up a window with which the following functions may be activated:

Fig. 5

The keys are used for navigation through various operating modes or to functions in the

current view. The "Cancel" button or a timeout closes the window without action.

The currently active operating mode uses the general information window to display navigation notes and/or detailed information about the displayed window.

2.1.3 Parallel operating modes

Analyzer

Database

Setup

Information,

Help

Fig. 6

For more detailed information about the operating modes, please see the respective chapters

in this Reference Manual or in the Instructions for Use.

More

functions

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003 2-3

Page 16

2 System description

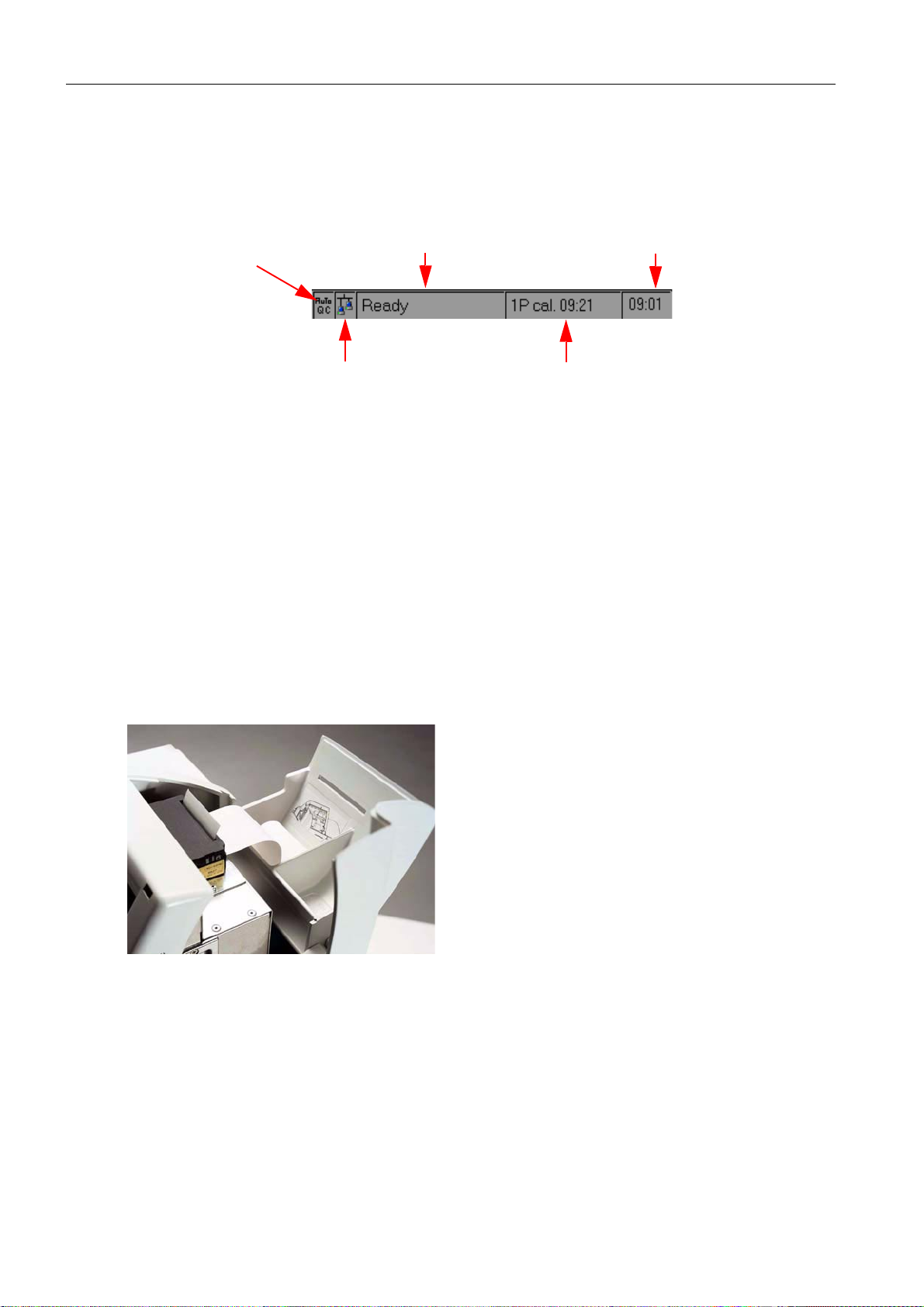

2.1.4 Status line

The status line permanently displays information about the Analyzer operating mode. The

following information is displayed :

AutoQC logo

(option available)

Fig. 7

1)

Logo background: green: activated and ready

2)

Logo background: green: connected

2.2 Printer

1)

remote control logo

actual analyzer status current time

red: activated, not ready

gray: not installed

gray: not connected

2)

time and type of the next action

that will interrupt the "Ready" status

Low-noise 2" thermal printer with integrated paper cutter.

Fig. 8

TIP: The printer paper is heat sensitive on one side only.

Please be certain that you insert the thermal paper correctly! Observe the instructions on the

label on the inside of the printer cover.

2-4

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003

Page 17

2.3 Measuring chamber

The measuring chamber consists of the following components

• Electrical ground contact: grounds electrode amplifier's electrical currents.

• tHb/SO

• Val ve V 3, V5 : these valves serve to control the transport of fluid.

• Sample sensors SS1, SS2: these two sensors are located under the black sample sensor

covering plate. They detect the operating fluids and the sample.

• Tubi ng

• Measuring chamber trough: this is held at 37 °C. The electrodes are pushed through the

spring contacts against the retainers into the socket.

• Measuring chamber cover: it is held at 37 °C, contains the electrode window and the

switching magnet for the measuring chamber cover sensor.

• Contact bank: the contact bank contains the replaceable spring contacts for the elec-

trodes and the cover sensor. The electrode amplifiers are located behind the contact

bank.

A colour-coded strip is located above the contact bank and is used to identify the electrodes.

• Left retainer: serves to secure the electrodes as well as the tubes used with the reference

electrode.

• Locking lever: movable part of the left retainer.

module: see section 2.3.2!

2

2 System description

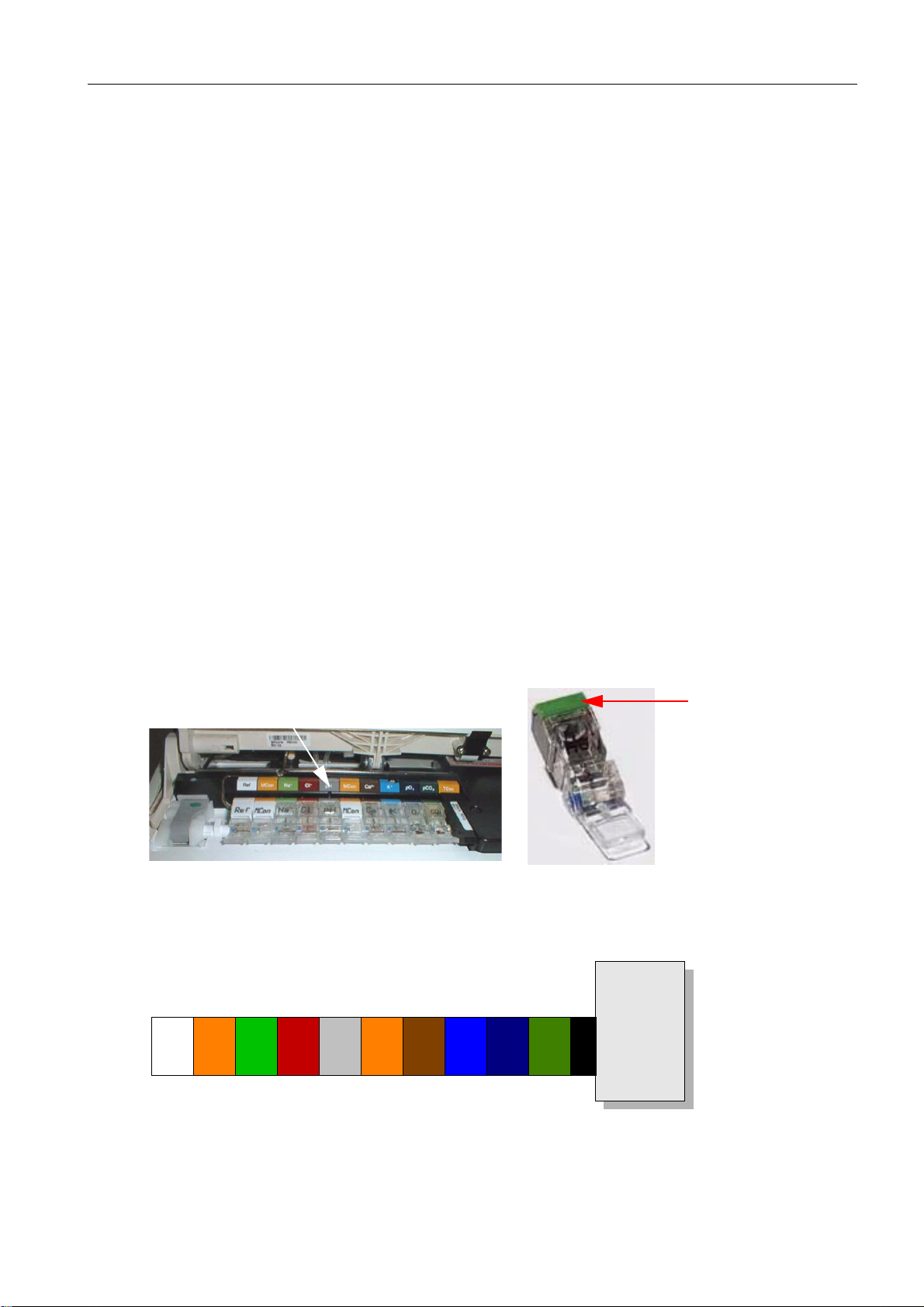

2.3.1 Electrodes

The correct positions of the various electrodes are easy to determine by the colours on their

contact caps and/or by their labelling (see "Contact bank").

contact bank

Fig. 9

Colours of the electrode contact caps:

MCon pH MCon K

Ref

Na+Cl

contact cap

tHb / SO

-

Ca

+

2+

PO

PCO

2

TCon

2

2

Fig. 10

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003 2-5

Page 18

2 System description

2.3.2 tHb/SO2 module

The tHb/SO2 module is an optical sensor module for determining the levels of total hemoglobin (tHb) and oxygen saturation (SO

Fig. 11

The complete module is sealed and calibrated at the factory ("Factory setting") and

may be exchanged only as a complete unit.

) in whole blood.

2

Never open the module!

2.4 Sample port module

The sample port module consists of the flap, the fill port holder (including fill port), the

needle and the sample drip tray.

Flap

When opening the flap, notice two definitive locking positions:

• Flap position 1 (half opened) – syringe mode—for syringes and ampoules

2-6

Fig. 12

syringe

ampoule

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003

Page 19

2 System description

• Flap position 2 (completely opened) – Capillary mode—for capillaries and

Roche MICROSAMPLERS

Fig. 13

Needle, fill port holder with fill port and sample drip tray

suction tube fill port holder and fill port sample drip tray

Fig. 14

2.5 Pump

The peristaltic pump transports the sample and the operating fluids inside the instrument.

pump open

Fig. 15

tension lever

pump head

linear clamp

pump closed

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003 2-7

Page 20

2 System description

2.6 Bottle compartment

Docking mechanism

C3 fluid pack

C2 calibration solution 2

W waste container

Fig. 16

C1 calibration solution 1

2.6.1 Bottle compartment cover

A microswitch detects the status of the cover (open / closed).

The following image appears when the cover is opened (bottle exchange):

Fig. 17

2.7 Reverse side

See Instructions for Use, chapter 1 "Introduction"!

2-8

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003

Page 21

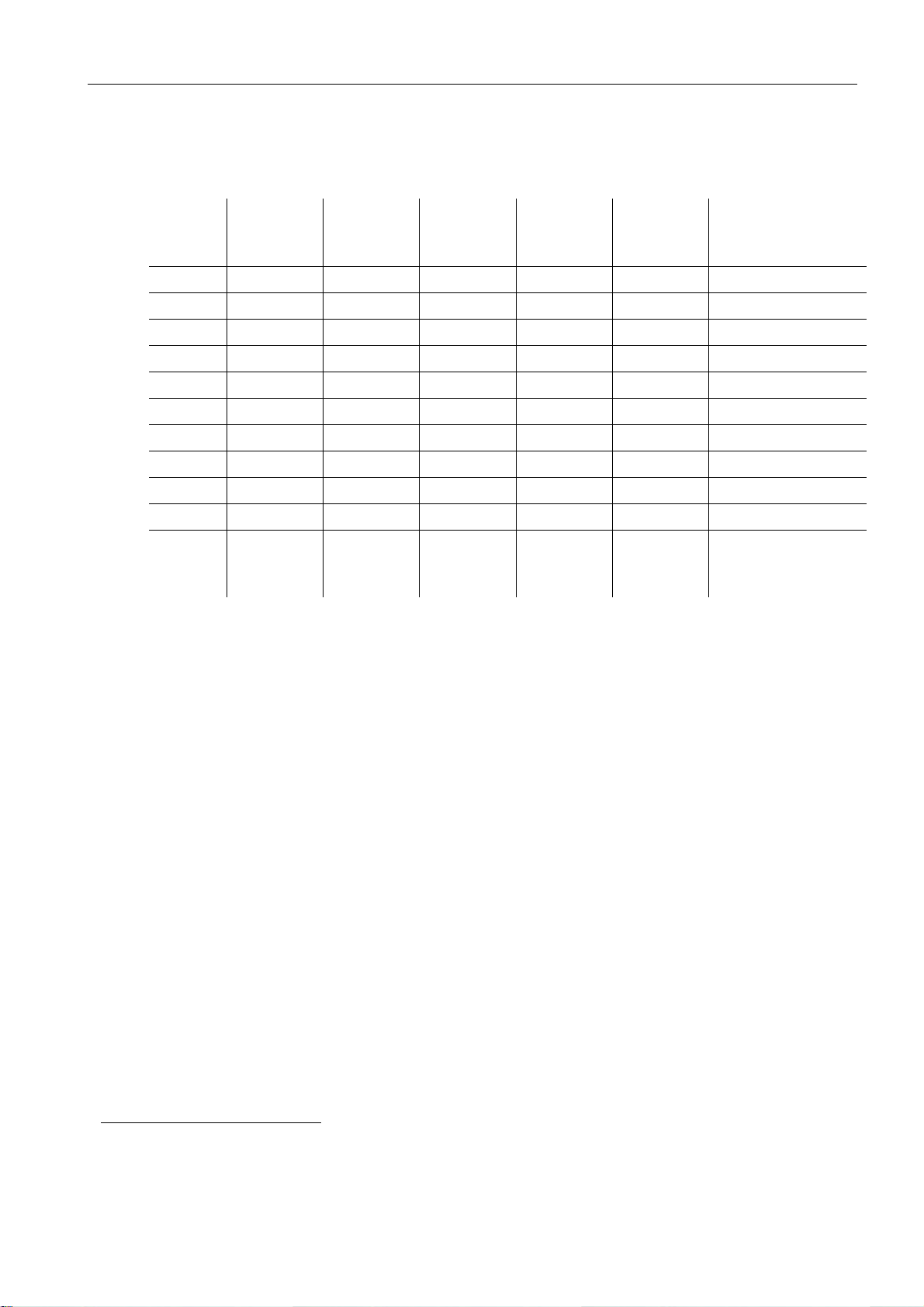

2.8 Power rating1- power supply

2 System description

Comments /

operating

conditions

Test No.

VoltageVFrequencyHzCurrentAPower in WPower in

VA

1 90 50 2.01 145 174 warm-up

2 100 50 1.78 145 175 warm-up

3 240 50 0.78 133 188 warm-up

4 264 50 0.72 137 191 warm-up

5 90 60 2.18 148 196 warm-up

6 100 60 1.95 142 194 warm-up

7 120 60 1.67 138 200 warm-up

8 132 60 1.54 139 203 warm-up

9 240 60 0.97 133 233 warm-up

10 264 60 0.89 131 235 warm-up

11 240 50 0.29 44 70 Standby / normal

operating conditi-

ons

2.9 Instrument cover

The instrument cover provides mechanical protection for the measuring chamber, pump

and valves. The cover is removable, but must remain closed while the unit is in operation.

1

Taken from the report of VDE: Testing and Certification Institute

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003 2-9

Page 22

2 System description

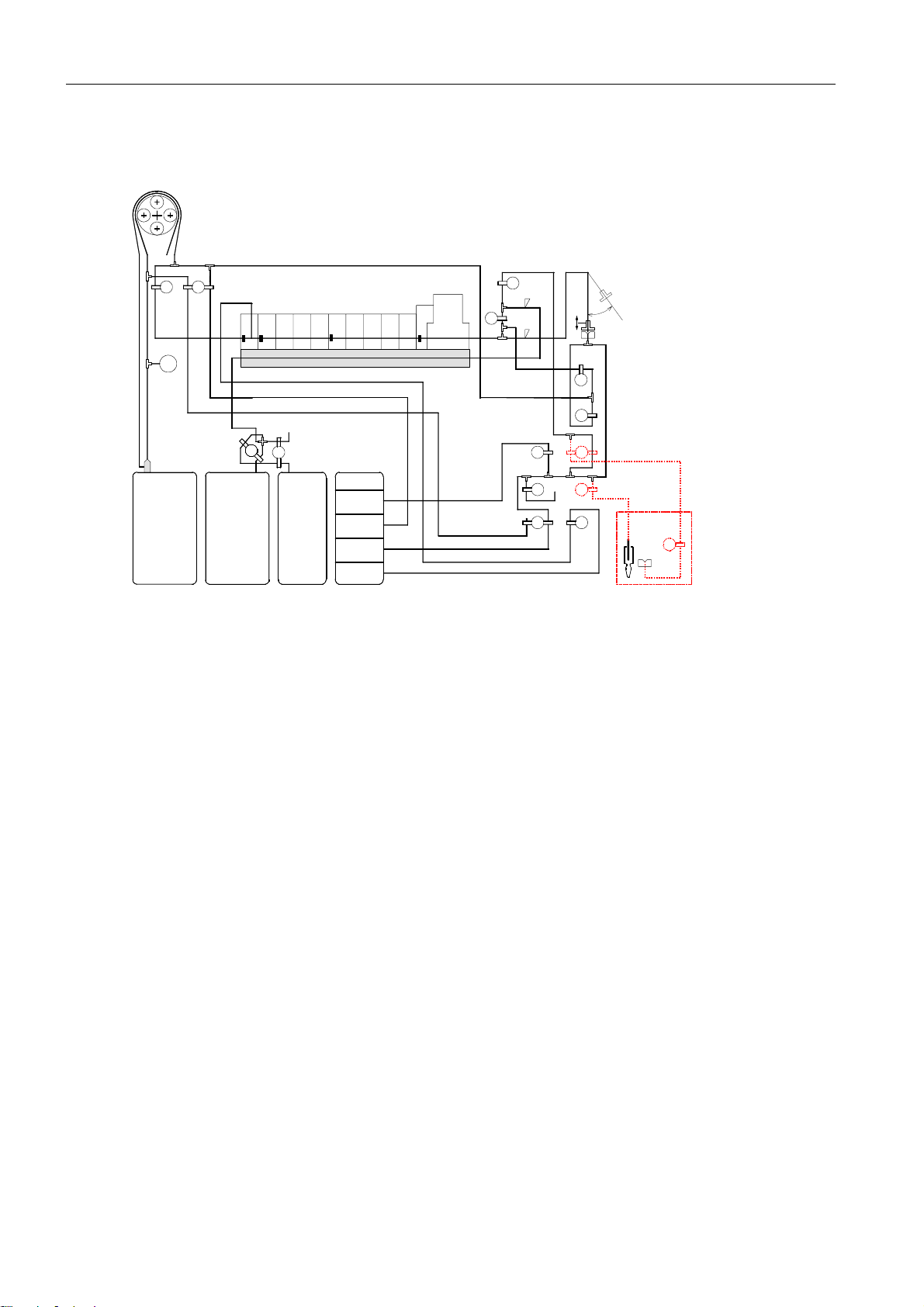

2.10 Tubing system

Peristaltic Pump

Air

V6 V7

Ref MConMCon

Pa

FMS

W

Waste Solution C1

V1

Measuring Chamber

Na Cl pH Ca K

MCMMCCMCO

Air

V2

O2 Zero Point

Solution

C2C1

Conditioning

Solution

Solution C2

Fig. 18

V1 ........ C1/C2 mixing valve

V2 ........ Air mixing valve

V3 ........ MC wash valve

V4 ........ MC bypass valve

V5 ........ Wash needle

V6 ........ MC out

V7 ........ Conditioner

V8 ........ Reference solution

V9 ........ Ventilation

V10 ...... Cleaning solution

V11 ...... Zero point solution

V14 ...... Bypass

C3

Cleaning

Solution

Reference

Solution

O2 CO2

V5

SS2

TCon

tHb/sO2

MCI

V3

SS1

V11

Air

V9

Air

V10 V8

Needle

V4

V14

V13

V12

AutoQC

V17

2-10

SS1, SS2....... Sample sensors

If the AutoQC module has been installed:

V12 ...... AQC valve

V13 ...... AQC wash valve

V17 ...... AQC wash valve II

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003

Page 23

3 Operating modes

3 Operating modes

3.1 Analyzer ............................................................................................................................ 3-1

3.1.1 "Ready" screen...............................................................................................................................................3-1

Parameter – depiction and buttons ................................................................. 3-1

Mandatory input ............................................................................................ 3-2

Password ........................................................................................................ 3-2

3.1.2 System ...............................................................................................................................................................3-3

Wash and clean .............................................................................................. 3-4

Tools .............................................................................................................. 3-6

Test .............................................................................................................. 3-13

Calibrations ................................................................................................. 3-26

3.1.3 Quick access ................................................................................................................................................ 3-26

3.1.4 QC measurement........................................................................................................................................ 3-26

3.2 Setup ................................................................................................................................ 3-27

3.2.1 Parameter ...................................................................................................................................................... 3-27

Miscellaneous settings .................................................................................. 3-28

Reference / critical ranges ............................................................................. 3-31

Correlations ................................................................................................. 3-32

3.2.2 Times & intervals ........................................................................................................................................ 3-33

Date and time ............................................................................................... 3-33

Calibration intervals ..................................................................................... 3-34

QC times ...................................................................................................... 3-34

Economy mode ............................................................................................. 3-34

Timeouts ...................................................................................................... 3-38

3.2.3 QC material................................................................................................................................................... 3-39

Set ranges ..................................................................................................... 3-39

AutoQC mat setup ........................................................................................ 3-39

3.2.4 Interfaces....................................................................................................................................................... 3-40

Network ....................................................................................................... 3-40

ASTM communication .................................................................................. 3-42

COM 1 ......................................................................................................... 3-42

COM 2 ......................................................................................................... 3-44

3.2.5 Displays & reports ...................................................................................................................................... 3-45

Measuring data ............................................................................................. 3-46

Parameter: display ranges ............................................................................. 3-54

QC ............................................................................................................... 3-54

Calibration ................................................................................................... 3-54

Patient database ........................................................................................... 3-54

Instrument data ............................................................................................ 3-55

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003 3-I

Page 24

3 Operating modes

3.2.6 Instrument ..................................................................................................................................................... 3-56

Language ...................................................................................................... 3-57

Roche info .................................................................................................... 3-58

Brightness level ............................................................................................. 3-59

Speaker ......................................................................................................... 3-59

Automatic patient ID .................................................................................... 3-60

Other units ................................................................................................... 3-60

Clinic info .................................................................................................... 3-61

Cleaning counter .......................................................................................... 3-61

AutoQC ........................................................................................................ 3-62

Ext. patient query ......................................................................................... 3-62

3.2.7 Password........................................................................................................................................................ 3-63

Security level ................................................................................................ 3-63

User management ......................................................................................... 3-63

Group administration ................................................................................... 3-64

3.2.8 Service area (password protected)...................................................................................................... 3-64

3.3 Database ......................................................................................................................... 3-65

3.3.1 Patient data................................................................................................................................................... 3-65

3.3.2 Measuring data ........................................................................................................................................... 3-66

3.3.3 Calibration data ........................................................................................................................................... 3-67

3.3.4 QC data .......................................................................................................................................................... 3-67

3.3.5 Instrument data ........................................................................................................................................... 3-68

3.3.6 Data export ................................................................................................................................................... 3-69

3.3.7 Delete data....................................................................................................................................................3-70

3-II

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003

Page 25

3 Operating modes

The Roche OMNI C is a combined bloodgas, electrolyte, and tHb/SO2 analyzer. It is possible

to complete database procedures or to make adjustments simultaneously during measurement or calibration.

The individual, mutually independent operating modes are defined as follows:

a) Analyzer: measuring, QC, system, calibration, quick access

b) Setup: instrument settings

c) Database: contains data on patients, measuring, calibration, QC, and the instrument

d) Info: Roche info, version numbers, fill levels, help, sensor status

3.1 Analyzer

The Analyzer operating mode has a special status among the operating modes.

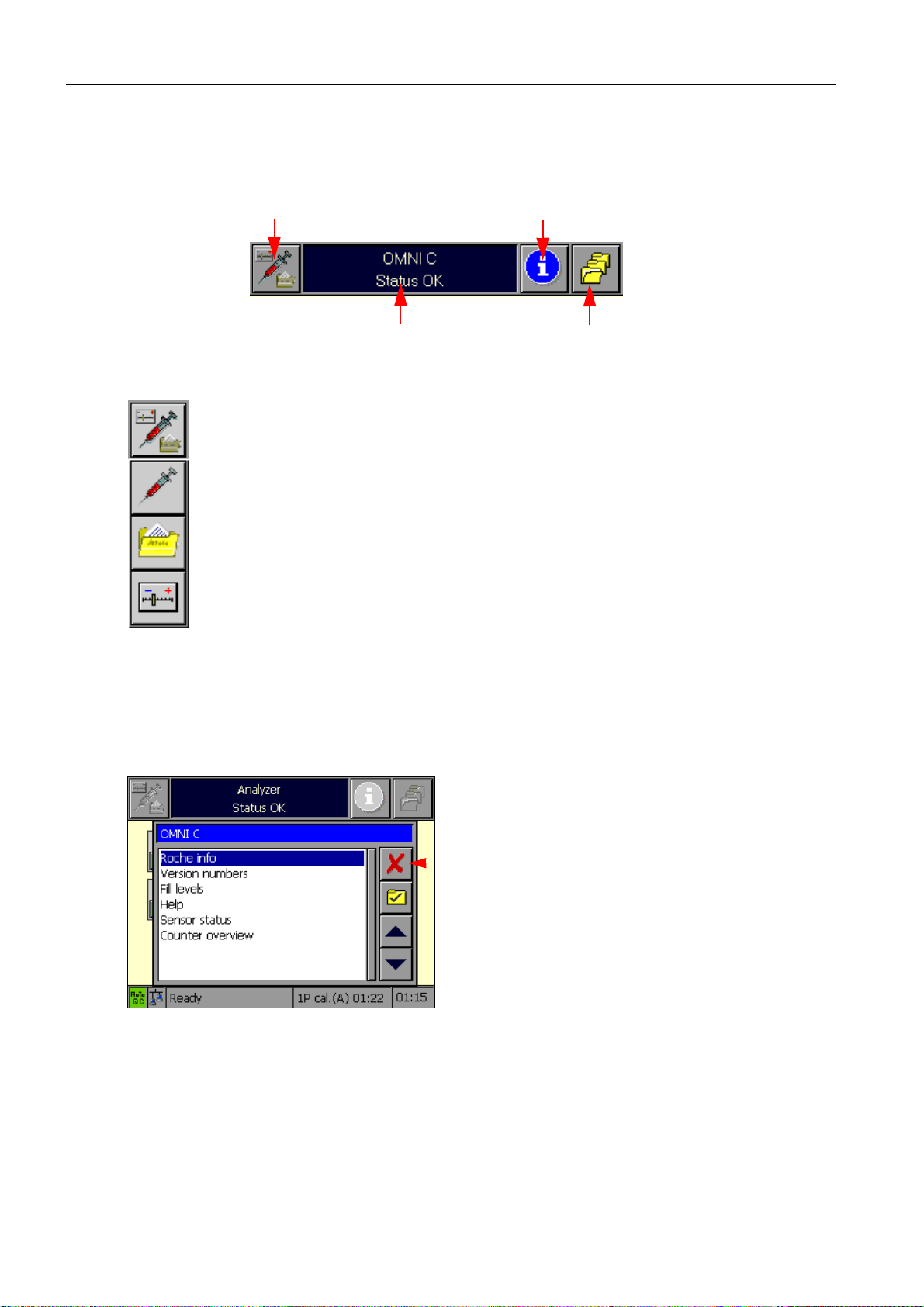

3.1.1 "Ready" screen

3 Operating modes

The Ready screen is the central starting point for all operations.

Fig. 1

Parameter – depiction and buttons

For a description of the parameter depiction and buttons, please see Instructions for Use,

chapter 1, "Introduction."

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003 3-1

Page 26

3 Operating modes

Mandatory input

Furthermore, the "Ready" screen can be modified by the activation of a "Mandatory input"

field. If this function is activated in the "Setup" mode, a measurement can be started only

when the entry has been completed.

In the following example, the access code has been defined as a mandatory entry.

Fig. 2

Password

If the measurement is equipped with password protection, the "Ready" screen is covered by

the password window but the parameter section remains visible (parameter information).

Fig. 3

3-2

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003

Page 27

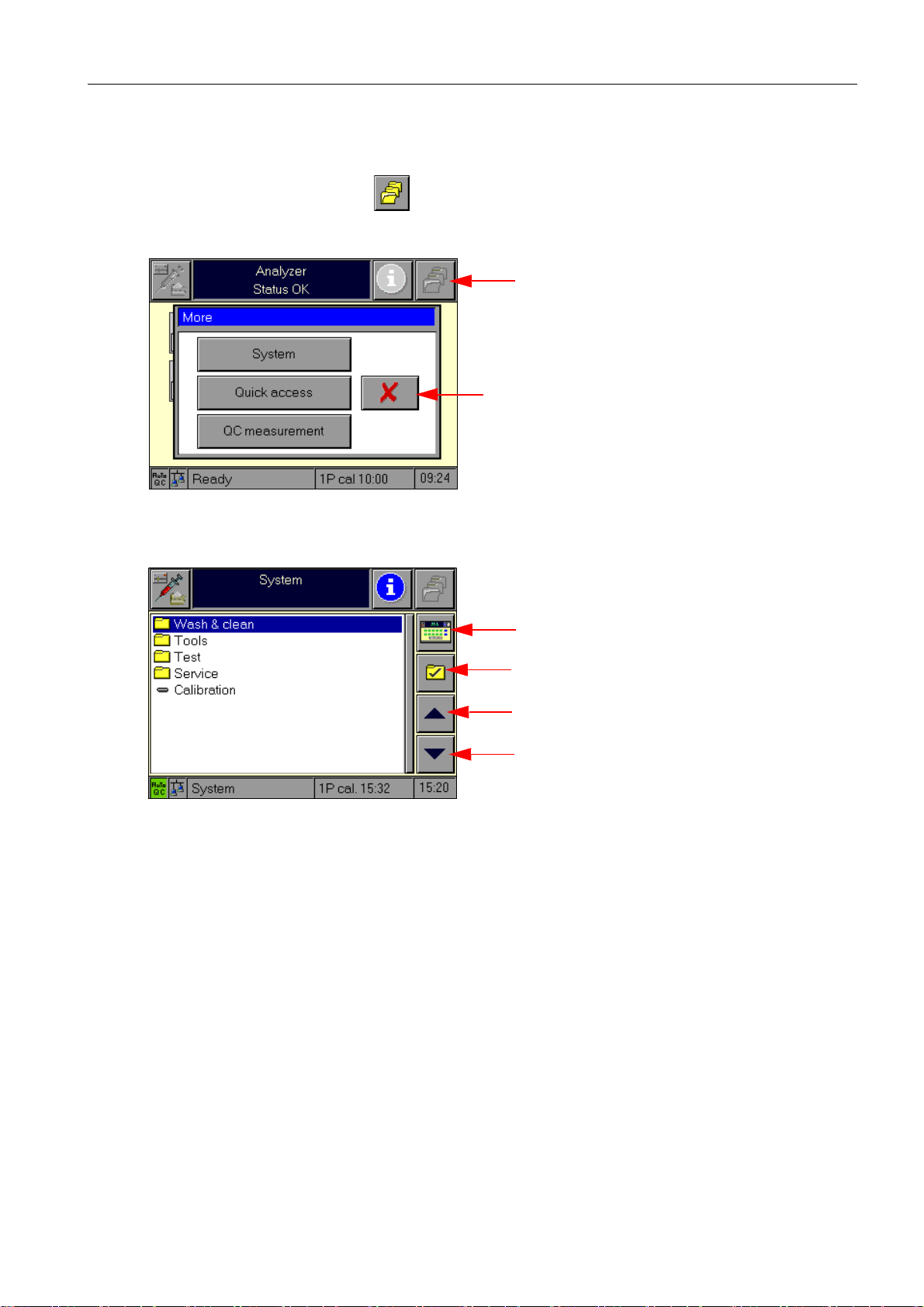

3.1.2 System

The system section can be reached directly and only from the "Ready" screen.

This occurs by pressing the button.

This button calls up a window with which the following functions may be activated:

Fig. 4

3 Operating modes

more functions

pressing this button or a defined timeout closes

the window without action

The following main menus are available:

Fig. 5

highest level of the Analyzer mode

select / deactivate

move one line up

move one line down

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003 3-3

Page 28

3 Operating modes

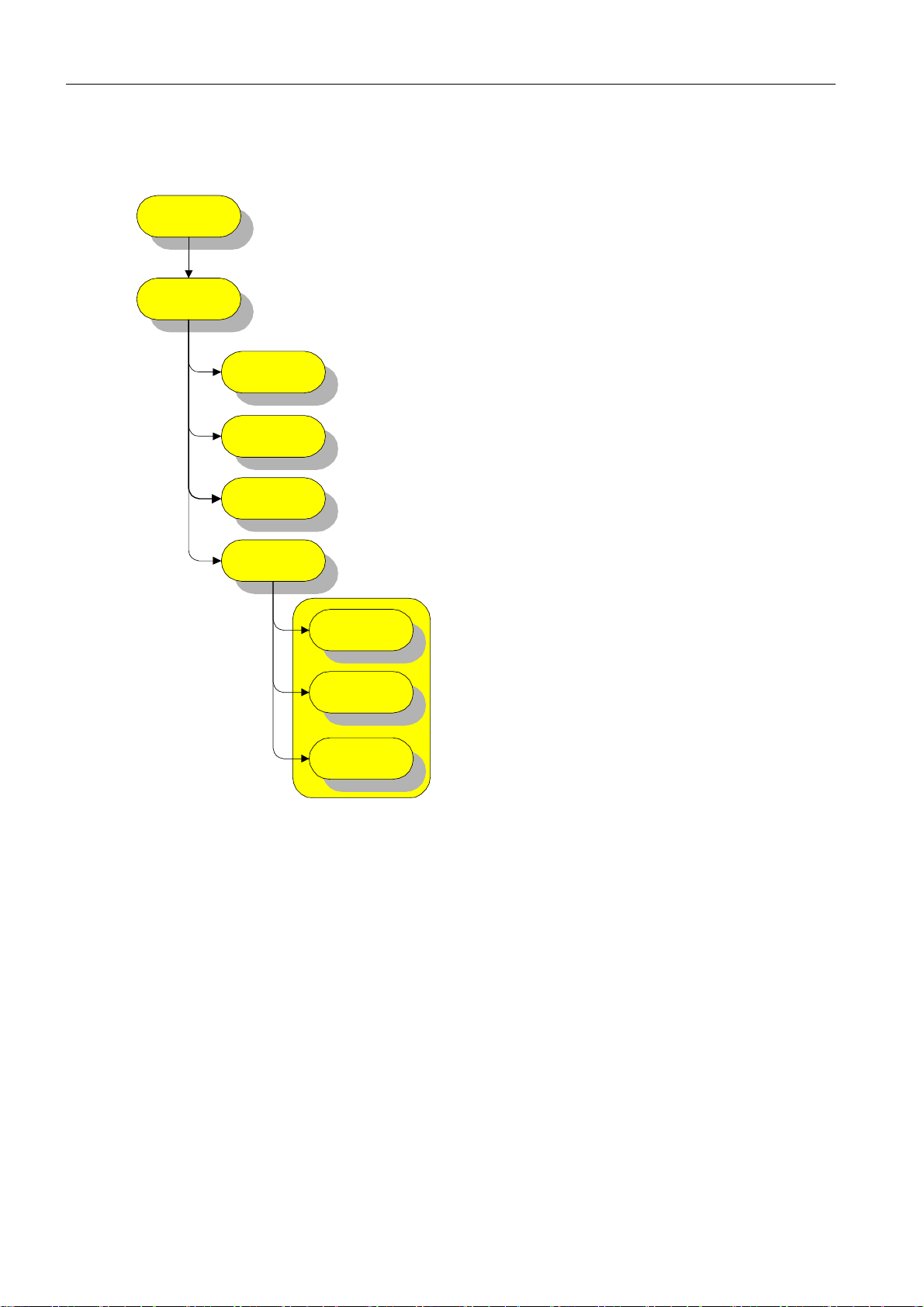

Wash and clean

System

Wash & Clean

Clean screen

Decont. sample

port module

Decontaminate

all tubes

Automatic

routines

Wash sample

path

Wash AutoQC

Internal cleaning

of sample path

Fig. 6

Clean screen

Upon entry into this function, the screen clears (white) and the touch screen deactivates for

30 seconds. A counter on the screen indicates the remaining number of seconds.

After expiration of the 30 seconds, the next highest level menu appears again. Please see

chapter "Maintenance" in the Instructions for Use for instructions on this cleaning procedure.

3-4

Decontaminate sample port module

This function assists in the decontamination of the sample port module, which consists of

flap, needle, filling port holder, filling port, and wash plate.

Please see chapter "Maintenance" in the Instructions for Use for instructions on this cleaning procedure.

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003

Page 29

3 Operating modes

Decontaminate all tubes

Follow the instructions on the screen. Confirm every step with !

The shutdown kit gives instructions on decontaminating all tubing.

For a description, please see Instructions for Use, chapter 6, "Maintenance",

section "Decontamination – Tubing paths."

Automatic routines

Wash sample path

This function washes out the sample path. It is not possible to interrupt this routine.

Wash AutoQC (option)

This function washes the optional AutoQC module if it is installed. It is possible to interrupt

this sequence.

Internal cleaning of sample path

This function cleans the sample path. It is not possible to interrupt this sequence.

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003 3-5

Page 30

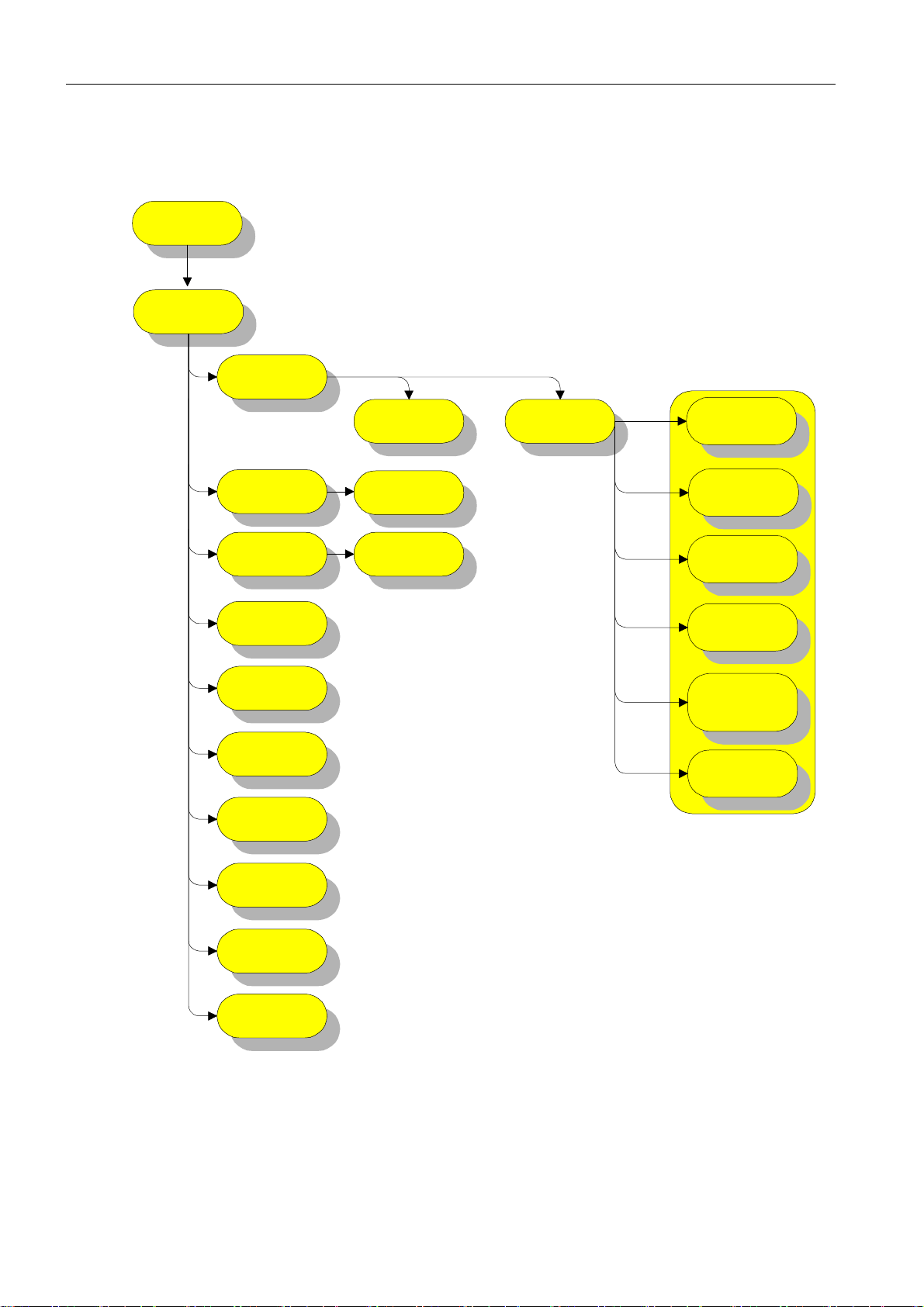

3 Operating modes

Tools

System

Tools

Fluid actions

Tubing

exchange

Software

communication

Manual

economy mode

Software

shutdown

Shutdown

Installation

Conditioning

cycle

Replace PP

tubing

Software update

Auto

preparation

routines

Fill reference

electrode

Prepare

Calibration

Solution C1

Prepare

Calibration

Solution C2

Prepare

conditioning

solution

Prepare O2 zero

solutiom

Prepare

cleaning

solution

3-6

Export log data

Maintenance

PCMCIA-card

Fig. 7

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003

Page 31

3 Operating modes

Fluid actions

Conditioning cycle

This function conditions the unit. It starts a sequence as with other automatic suction routines. The sequence may not be interrupted and displays a message in the event of a fault.

Auto preparation routines

Fill reference electrode

This function suctions the reference solution to the reference sensor. The sequence may not

be interrupted and displays a message in the event of a fault.

Prepare Calibration Solution C1

This function provides upward suction of the C1 calibration solution 1. The sequence may

not be interrupted and displays a message in the event of a fault.

Prepare Calibration Solution C2

This function provides upward suction of the C2 calibration solution 2. The sequence may

not be interrupted and displays a message in the event of a fault.

Prepare conditioning solution

This function provides upward suction of the conditioning solution. The sequence may not

be interrupted and displays a message in the event of a fault.

Prepare PO2 zero solution

This function provides upward suction of the PO2 zero solution. The sequence may not be

interrupted and displays a message in the event of a fault.

Prepare cleaning solution

This function provides upward suction of the cleaning solution. The sequence may not be

interrupted and displays a message in the event of a fault.

Tubing exchange

PP tubing exchange

This function is used to perform the exchange of the peristaltic pump tubing.

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003 3-7

Page 32

3 Operating modes

Software communication

Software update

Use this function to load a new program. The required parameters may also be entered. The

following parameters are currently available:

Source:FTP, PCMCIA

Update file:update information file

Source path:path to the location of the update file

Host address:IP address of the remote computer if FTP was selected as the source

Start the execution with the button.

Manual economy mode

Use this function to manually activate a pause mode if you do not intend to use the Roche

OMNI C for an extended period of time.

Fig. 8

The units uses smaller quantities of solutions during this time. A system maintenance process ensures that the electrodes remain optimally conditioned, however.

Software shutdown

This function brings the instrument to shutdown status.

It is necessary to follow the proper shutdown procedure because a sudden shutdown can

lead to the loss of data!

A message appears on the screen that instructs the user to switch off or restart the instrument.

3-8

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003

Page 33

Fig. 9

Shutdown

This function enables program-supported shutdown of the instrument.

3 Operating modes

Each of the actions that should be performed are listed in the listbox as the final entry. Confirm the manually completed actions.

If any of the actions are to be performed by the instrument, this will be indicated by the

blocking of the confirmation button and activation of the "Start action" button. The next

step to be performed will be automatically entered into the listbox as the final line. Following completion of instrument actions, the status "OK" or "not OK" is displayed at the end

of each line.

For information on the shutdown procedure, please see chapter 1 "Introduction", section

"Shutdown" in the Instructions for Use!

TIP: After successfully shutting down the instrument, it will be in the "System stop" mode (shut

down). This can be reversed only by a renewed startup procedure.

Installation

This routine enables program-supported startup of an instrument. Each of the actions that

should be performed are listed in the listbox as the final entry. Confirm the manually completed actions.

If any of the actions are to be performed by the instrument, this will be indicated by the

blocking of the confirmation button and activation of the "Start action" button. The next

step to be performed will be automatically entered into the listbox as the final line. Following completion of instrument actions, the status "OK" or "not OK" is displayed at the end

of each line.

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003 3-9

Page 34

3 Operating modes

Fig. 10

For information on the startup procedure, please see chapter 1 "Introduction", section

"Installation" in the Instructions for Use!

TIP: If an error appears following the start of the action "Begin installation routine" (final step

of installation), a system stop is displayed but the instrument is regarded as having been

brought into operation.

Export log data

You can use this function to export log data.

TIP: Selection of all or single log data is possible.

Fig. 11

Use the "line up/down" buttons to select the log data. Then press the key and select

where you wish to store the log files.

Only available destinations, such as FTP and PCMCIA, are indicated. Confirm here, all log

files are copied. With the PCMCIA card, it is additionally checked whether enough memory

is available.

The log files are copied to a fixed "Export" path with the serial number at the front. With

the PCMCIA card, an "Export" directory is automatically created, with an FTP transfer, it

must already be available.

3-10

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003

Page 35

If log files are available, they can be deleted using the button.

3 Operating modes

If no log file is available, a corresponding

error message is issued in the file list

and the and buttons are deactivated.

Maintenance

Use this function to call up an overview of all maintenance entries and their status.

Fig. 12

The following maintenance is entered by default and can be neither deactivated nor

renamed:

• Annual maintenance

• PP tubing exchange

• Decontaminate bottle compartment

• Decontaminate sample port module

• Decontaminate screen

• Exchange fill port holder

If a maintenance is planned, it is displayed in "red" in the list.

Use to mark the maintenance as performed. The next cycle time is calculated.

Use to enter the maintenance as "skipped" in the device database.

Use to create a separate entry that is saved in the device database.

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003 3-11

Page 36

3 Operating modes

PCMCIA card

Use this function to create a defined PCMCIA card.

Fig. 13

Status:The current status of the PCMCIA card is displayed. The properties (application purpose) of the card are marked with a green check mark.

Use the button to change the properties of the card.

TIP: If a card is not assigned, no setting can be performed.

Serial number of the card: The serial number of the PCMCIA card is displayed.

Free memory: Call up information about the assignment status of the card.

Remove PCMCIA card: Use this function to remove the card.

Remove the card only by using the "Remove PCMCIA card" menu item, since a sudden

removal can lead to data loss!

Assign card: The card used is assigned to the device.

Create export card: Create an export card on which database files and log files can

not be stored.

Initialize card: Delete all data on the card.

3-12

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003

Page 37

Test

3 Operating modes

MBX boar d

AutoQC

Baro sensor

control

Temperature

sensors

Monitoring

position test

Peristaltic pump

sensor

Waste Container

Contact paths

Flash file

PCMCIA card

system

Barcode

System

Test

Valves &

aggregates

Valves

Sample sensor s

Control sensors

Screen Touch screen Printer

sensors

PC components

Measuring

Fig. 14

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003 3-13

Page 38

3 Operating modes

Valves and aggregates

Valves

This test checks the switching function of all valves. To perform a check, a single valve may

be switched or 10 separate switches (5 times open/close or close/open) may be performed

automatically.

overview of valve positions in the instrument

depiction of valve status

individually switch a valve

automatic switching procedures

Fig. 15

In addition, the status of each valve is displayed schematically (for example: V1).

Fig. 16

Peristaltic pump

This test checks the peristaltic pump in four defined speeds.

3-14

Only suction is possible because reverse rotation of the pump would remove fluid from

the W waste container!

In addition, the following is displayed:

• pump volume in µl per revolution

• the FMS volumes in µl

Service technicians and certain users are able to start a calibration sequence for the pump.

They are then also able to re-establish the FMS volumes and save these as new settings.

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003

Page 39

Press the key and follow the instructions on the screen.

Fig. 17

AutoQC position test

This function tests the positions of the ampoule block.

3 Operating modes

The following positions are possible:

Fig. 18

Position:

"Home position": the needle is positioned over the wash port

"Service position": NOTE: remove the ampoule block before going to the service posi-

tion.

The carriage moves to position 106.

"Go to position": goes to any ampoule position from 1 to 120.

Needle:

"End position":the carriage with the needle moves upwards to the end position.

"Aspiration position": the carriage with the needle moves downwards to the aspira-

tion position.

CAUTION: danger of injury from moving parts!

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003 3-15

Page 40

3 Operating modes

Control sensors

Sample sensors

This test completes a check of the optical sample sensors 1 and 2.

The following is also displayed:

• calibration value of the sensor

• actual measurement value in mV

• actual measurement value in % based on the calibration value

• evaluation of the actual measurement value or notification that plausibility test is not

acceptable

Service technicians and certain users are able to start a calibration sequence for the sample

sensors. This sequence determines the calibration value for the specific sensor and adopts

this as the new setting.

Press the button and follow the instructions on the screen.

Fig. 19

Contact paths

The actual entered conductivity values are displayed (in mV) for the specified contact paths

with the fluid available in the sample channel.

Fig. 20

3-16

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003

Page 41

3 Operating modes

Waste container sensor

Display of the actual values for the waste water sensor.

• actual value: signal in mV

• slope in mV/mbar

• zero point in mV (determined in advance during the measurement)

• fill level in %

• fill level in mm (last measured value, manually or by a system calibration)

Fig. 21

Use the button to determine the current fill level in mm (see Fig. 20).

Fig. 22

Monitoring sensors

This test window displays the status of all monitoring sensors.

These are:

• Sample port module

status: closed, syringe position, capillary position

• MC cover

status: open, closed

• Bottle compartment

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003 3-17

Page 42

3 Operating modes

status: open, closed

• C3 docking mechanism

status: open, closed

• W waste container

status: open, closed

• AutoQC cover

status: open, closed

Fig. 23

Temperature control

Actual temperature display.

Fig. 24

Limit values are established for the following boards:

with AutoQC

3-18

MBX board: 1 - 55 °C

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003

Page 43

3 Operating modes

Baro sensor

Display of the actual values for the baro sensor.

These are:

• actual value in mV

• calibration point in mV

• slope in mV/bar

• calculated air pressure in the unit according to adjustments

Service technicians and certain users are able to start a calibration sequence for the baro

sensor. This sequence determines the calibration value for the baro sensor and adopts this

as the new setting.

Press the button and follow the instructions on the screen.

Fig. 25

PC components

Screen

Fig. 26

The "Test" function helps to check the functionality of the screen.

These are:

• checking for failure of individual picture elements

• checking for failure of colours

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003 3-19

Page 44

3 Operating modes

• checking the illumination lamps (on/off/?)

The following test procedure will be executed:

1. Black screen (for 5 seconds)

2. White screen (for 5 seconds)

3. Display of complete colour palette (for up to 2 minutes) (see Fig. 27).

Fig. 27

Use the "Lamps to 30%" function to switch the illumination lamps from 100% to 30% power. The lamps are set back to 100% when exiting this function (see Fig. 26).

Touch screen

This test function checks the functionality of the touch screen. It is also possible to adjust

the offsetting of the touch screen in relation to the display.

Fig. 28

3-20

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003

Page 45

3 Operating modes

By pressing the "Test" button, you can check if the entire (black) area is active as a touchsensitive surface (see Fig. 29).

Fig. 29

By pressing the "Calibrate" button, you can use a pencil or other pointed object (but which

is not too hard, to avoid scratching the surface) to touch the white points in the upper left

and lower right corners.

Fig. 30

After release, the instrument will accept the exact position. From this time on, the instrument will use the touched points to calculate the offset between the displayed pixels and the

touch screen. After a point has been accepted, the arrow disappears. The point itself remains

visible and active (pressing the position again re-establishes the point).

After leaving the window, the new correction values take effect.

Printer

The printer test screen shows the current status of the printer. If there is a print job in the

printer queue when switching into the printer window, all buttons, with the exception of

the reset button, are made inactive. As soon as the printer is ready again, the additional

functions are made active and the printer queue blocked.

The additional functions (for example: Paper feed) can be used only when the printer status

is "Ready". Pressing the "Reset" button resets the printer before the status is redetermined.

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003 3-21

Page 46

3 Operating modes

IMPORTANT: The printer queue remains blocked as long as this screen is open, because this

Fig. 31

is where the printer is accessed. The printer queue is enabled as soon as you

leave this screen.

Test print: starts a test print with all available symbols.

Fig. 32

Barcode

Test functions check the functionality of the interface. A variety of barcodes (including barcodes not belonging to the unit) can be read in.

3-22

Fig. 33

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003

Page 47

Flash file system

This test function can check the status of a flash file system.

Fig. 34

3 Operating modes

PCMCIA card

These test functions can check the PCMCIA interface or check if the inserted card is recognized.

Press:

Fig. 35

The following additional functions are also available:

• Formatting card

• Card info

• Check card

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003 3-23

Page 48

3 Operating modes

MBX board

This test function provides you with information about the main board and the IO board.

Fig. 36

The following data are provided:

Board type MBX

CPU MPC821 / MPC860

Clock frequency 40 / 50 Mhz

Board level standard or entry level

Size of the main memory in MB

Size of the flash memory in MB

Status of the board battery OK / empty

Status of NVRam battery OK / empty

Ethernet address instrument-dependent

Serial number of the MBX board instrument-dependent

IO board version beta / series 0 /...

LCD controller MPC821 on chip / Epson SED1375

Operating system version

Board support package version

Bootloader version

3-24

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003

Page 49

3 Operating modes

Measuring sensors

Display of the actual electrode values. If the contents of the measuring chamber have not

changed since entering "system" (e.g. by drawing fluids), signal evaluation.

Fig. 37

Display of the four laser diodes' actual values for the transmitted light and diffused light

channels.

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003 3-25

Page 50

3 Operating modes

Calibrations

System

Calibration

Calibration for

Ready

System

calibration

Conductivity

calibration

2P cal. incl. O2

2P cal. excl. O2

Fig. 38

Use this function to manually start the calibrations.

3.1.3 Quick access

See Instructions for Use, chapter 8 "Operating modes", section "Analyzer – Additional functions."

1P calibration

2P O2

calibration

3.1.4 QC measurement

This function starts a QC measurement.

Please see Instructions for Use, chapter 5 "Quality control" for the procedures of this QC

measurement!

3-26

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003

Page 51

3.2 Setup

Use this function to make the following settings:

Fig. 39

3 Operating modes

3.2.1 Parameter

Setup

Parameters

Misc. settings

Act. / deact. f. measurement

Act. / deact. f. calibration

Units

Multirules

QC conseq.

QC unlock

pH --> H+

Ref. / crit. ranges

Correlations

Fig. 40

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003 3-27

Page 52

3 Operating modes

Miscellaneous settings

Fig. 41

Activate / deactivate for measurement

Use this function to activate or deactivate measurement parameters (please see Instructions

for Use, chapter 1 "Introduction", for the depiction of the parameters).

Activated parameters are displayed green in the "Ready" screen, deactivated parameters are

gray. The parameters are calibrated regardless of the setting and, if they are shown in gray,

can be switched on (in the "Ready" screen) for a measurement.

Activate / deactivate for calibration

The parameter(s) are not calibrated and cannot be measured.

TIP: Be certain to insert a dummy in place of the deactivated electrode(s)!

The deactivated parameter's symbol is struck out with gray and red and cannot be activated

in the "Ready" screen.

Units

Use this function to define the format and the unit for each individual parameter.

3-28

select format and unit

Fig. 42

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003

Page 53

3 Operating modes

Using the "line up / line down" buttons , you can now select the parameter for which you

want to set the format and unit.

Pressing the "SI" button converts all parameters to SI units.

Pressing the "Def." button establishes predefined formats and units.

The following formats and units can be defined:

Measured values

Designation Format & unit 1 [Def.] Format & unit 2 [SI] Format & unit 3

pH x.xxx [-]

+

H

PO

PCO

2

2

xxx.x nmol/L

xxx.x mmHg xx.xx kPa

xxx.x mmHg xx.xx kPa

Hct xx.x % xxx.x [-]

Na

K

Ca

Cl

+

+

2+

-

xxx.x mmol/L

xx.xx mmol/L xxx.x mmol/L

x.xxx mmol/L x.xxx mg/dL

xxx.x mmol/L

tHb(I) xx.x g/dL xxx.x g/L xx.x mmol/L

(I) xxx.x % xxx.x %

SO

2

Multirules

Fig. 43

Use this function to assign to each parameter one or several rules (rules 1-6) or a range

examination (2SD range).

For a precise description, please see the operating manual, chapter 5 "Quality control"!

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003 3-29

Page 54

3 Operating modes

QC consequences

Use this function to assign to each individual parameter one of these QC consequences.

Fig. 44

For a precise description, please see the operating manual, chapter 5 "Quality control"!

QC unlock

This overview displays all parameters that are blocked by QC measurements. Pressing the

button lifts this block individually for each blocked parameter.

Pressing the "All" key lifts the block for all listed parameters.

Fig. 45

3-30

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003

Page 55

3 Operating modes

pH -> H+

Use this function to convert from pH to H+. Upon activation, H+ is displayed and converted

instead of pH.

Default parameter: pH

Fig. 46

Reference / critical ranges

In this menu you can enter the upper and lower limits of the reference and critical measurement ranges.

Fig. 47

Use the "line up/down" buttons to select the gender, age and sample type.

Press – the following choices are available for the gender, age and sample type:

Gender: unknown, male, female

Age: unknown, fetus, 2 days - 1 year, older than 1 year

Sample type: blood, serum/plasma, aqueous solution, acetate, bicarbonate

"Def.": the default values will be loaded.

"Reference": enter the upper and lower limits of the reference range.

"Critical": enter the upper and lower limits of the critical measurement range.

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003 3-31

Page 56

3 Operating modes

Correlations

By pressing the "Offset" button, you can enter an addition or subtraction value for the

selected parameter. This value corrects the measurement value.

By pressing the "Slope" button, you can enter a multiplicative factor for the selected parameter to correct the measurement value.

Use this function to select the range to be displayed: "Reference", "Critical" or "No

display".

Fig. 48

3-32

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003

Page 57

3.2.2 Times & intervals

Setup

Times &

intervals

Date / Time

Calibration

intervals

QC times

3 Operating modes

Economy mode

Maintenance

scheduler

Timeouts

Fig. 49

Date and time

Use the numerical keypad to enter the date and time.

The time and date display formats can also be set with this function.

Fig. 50

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003 3-33

Page 58

3 Operating modes

Calibration intervals

Use this function to enter the automatic calibration times for system calibration, 2P calibration and 1P calibration, as well as the start time (when the system calibration should be

performed).

Fig. 51

Intervals:

Sys.cal: 8, 12 and 24 hours

2P cal: 4, 6, 8 and 12 hours

1P cal: 0 and 60 minutes

The time scale uses markers to show the selected interval for the 2P calibration and the start

time for the system calibration.

The green markers indicate the start time of the 2P calibration, based on the start time of

the system calibration (blue marker).

QC times

See "Instructions for Use", chapter 5 "Quality Control"!

Economy mode

Use this function to select the start time(s) and end time(s) for the Economy mode.

3-34

Fig. 52

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003

Page 59

Select the day from the "Day of Week" list on which the Economy mode should

be performed.

You can edit the attributes of the time entries.

Add a new time entry (you can remove it again with ).

The following screen appears:

3 Operating modes

Fig. 53

Enter the starting time or end time.

Mark the appropriate box ("Start" / "Stop").

Press .

Copying a time entry

Select a day of the week and a time entry and press – the selected start and end

time(s) of this weekday will be copied.

Select another day of the week and press – the copied time entry will be entered for

the new weekday.

These entries can be transferred to as many other weekdays as required.

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003 3-35

Page 60

3 Operating modes

Maintenance scheduler

This function can be used to add further maintenance to the list.

Fig. 54

The following maintenance is entered by default and can be neither deleted nor renamed:

• Annual maintenance

• PP tubing exchange

• Decontaminate bottle compartment

• Decontaminate measuring chamber

• Decontaminate sample port module

• Decontaminate tubing paths

• Fill level check

• Decontaminate surfaces

• Printer paper check

• Decontaminate screen

• Exchange fill port holder

TIP: The attributes of standard maintenance can only be edited to a limited extent.

Use the button to add a new maintenance entry (use to remove it again).

TIP: It is not possible to add a new maintenance entry between two standards services.

Use to enter a name.

Switch to the following view by pressing the button:

3-36

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003

Page 61

Fig. 55

Use to define the properties of the maintenance.

Name: Enter the name of the maintenance.

3 Operating modes

Cycle: Select the maintenance cycle. Available maintenance cycles are: Never,

Once, Daily, Weekly, Monthly, Every 3 months, Every 6 months, Annually.

TIP: Use the maintenance cycle "Never" for time-independent mainte-

nance (e.g. if a maintenance is dependent upon the number of samples).

Time: Enter the start time of the maintenance. This setting can not be defined

if no cycle is set.

Date: Enter the date that forms the basis for the cycle. This setting can not be

defined if no cycle is set.

Sample counter: Enter the sample number at which the maintenance should be per-

formed.

TIP: A maintenance can also be dependent upon cycle and sample

counter – it must be performed at the event that occurs first.

Reminder: Off/On; Mode that specifies whether a scheduled maintenance is dis-

played on the Ready screen.

Archive: Off/On; Mode that specifies whether a conducted maintenance is

entered in the device database.

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003 3-37

Page 62

3 Operating modes

Timeouts

Use this function to define a timeout for the action that is displayed.

Fig. 56

Activate password: waiting time before the password entry field in the "analyzer"

operating mode's "Ready" screen appears.

Close window: begins with the opening of the window or the last entry in the

window: 10 sec. - infinite.

Back to analyzer: from the operating modes "Database" and "Setup" back to the

"Ready" screen of the "Analyzer" operating mode.

Close result screen: back to the "Ready" screen of the "Analyzer" operating mode

Close input screen: starts after completed measurement and final input – back to

the "Ready" screen of the "Analyzer" mode.

3-38

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003

Page 63

3.2.3 QC material

Setup

QC materials

Fig. 57

3 Operating modes

Set ranges

Auto QC mat

setup

Set ranges

Use this function to define the QC material (product name, level, lot number, expiration

date, and ranges (target values)).

Fig. 58

Please see the Instructions for Use, chapter 5 "Quality control" for the procedures of this

QC measurement!

AutoQC mat setup

See the Instructions for Use, chapter 5 "Quality control"!

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003 3-39

Page 64

3 Operating modes

3.2.4 Interfaces

Setup

Interfaces

Net

ASTM

communication

COM 1

COM 2

Fig. 59

Network

Use this function to set the instrument-specific network addresses. In addition, you can

switch on or off automatic network initialization (performed upon startup of the instrument). If network initialization does not occur upon startup of the instrument, use the button "Initialize" to start this process.

3-40

Fig. 60

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003

Page 65

3 Operating modes

Networktest

Switch to the following view by pressing the button:

Fig. 61

Use this function to perform a networktest.

Press the "ping" button to check the network interfaces – this requests an echo reply from

other instruments.

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003 3-41

Page 66

3 Operating modes

ASTM communication

This function is used to transfer data from measurements, quality controls, calibrations and

maintenance either in serial form or via network.

Using the enter the IP address of the host system and the port address stated by the

manufacturer of the host software. With this, you specify where the data are to be sent.

TIP: If ASTM is assigned via COM 2 interface, then host address and host port can not be

entered.

If the "activated" check box is marked, the data transfer for measurements and quality controls is activated.

If the "Additional data/DC" check box is marked, the data transfer for calibrations and

maintenance is activated.

Fig. 62

TIP: If DataCarePOC (DC) is linked via this interface, the control box "additional data/DC"

should be activated.

COM 1

This interface can be assigned to a ticket printer or a host FMT.

Fig. 63

3-42

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003

Page 67

3 Operating modes

Use the button to perform the following entries:

Baud rate

Enter the transfer rate

Options: 1200, 2400, 4800, 9600

Stop bits:

The stop bit follows the actual "character bits" in a serial data transfer. It refers to the completeness of the character transfer.

Options: 1, 2

Handshake

Select the desired function for the data transfer.

Options: Xon/Xoff, Hardware, None

Parity

This function ensures that no data is lost during the data transfer or arrives in a defective

state.

Options: None, Even, Odd

Type

Select the desired use of the interface.

Options: Not activated, Ticket printer, Host FMT

Not activated: The interface is deactivated.

Ticket printer: The interface is assigned to a ticket printer.

The form layout can be created under Windows using a tool

specifically supplied by Roche.

Host FMT: Use this function to issue freely defined reports via serial inter-

face.

For more detailed information contact a Roche Diagnostics

representative.

Use the button to start the "Import format file" function.

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003 3-43

Page 68

3 Operating modes

COM 2

ASTM can be assigned to this interface in a serial way. Use this function to transfer data

from measurements, quality controls, calibrations and maintenance (see also the section

"Interfaces > ASTM communication" on page 3-42).

Fig. 64

Use the button to perform the following entries:

Baud rate: Enter the transfer rate

Options: 1200, 2400, 4800, 9600

Stop bits: The stop bit follows the actual "character bits" in a serial data

transfer. It refers to the completeness of the character transfer.

Options: 1, 2

Handshake: Select the desired function for the data transfer.

Options: Xon/Xoff, Hardware, None

Parity: This function ensures that no data is lost during the data trans-

fer or arrives in a defective state.

Options: None, Even, Odd

Type: Service interface, ASTM

TIP: In general, the service interface is always deactivated. If this is not the case, it must be

deactivated by customer service in the password-protected service area.

3-44

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003

Page 69

3.2.5 Displays & reports

3 Operating modes

Instrum ent data

Patient data

CalibrationQC

query

Instrument DB

Patient D B query

report

Calibration

overview

Instrument DB

overview

Patient DB

Cal DB query

Cal DB overview

Fig. 65

QC report

Input values

Setup

reports

Displays &

Measuring data

QC DB query

Mandatory input

Result screen

QC DB overview

info

report

Measurement

DB query

Measuremen t

Measurement DB

overview

Default settings

Enter

Enter patient info

measurement

Parameter:

display ranges

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003 3-45

Page 70

3 Operating modes

Measuring data

Input values

Use this function to define the input values that are displayed in the results display.

Fig. 66

Use the "+" button to insert a new form ("No name").

Use to enter a new name.

By pressing the button you switch to the following view:

Fig. 67

Press "line up/down" and select a parameter from the left list ("Options").

This list can be expanded with patient data and parameter inputs (see sections "Enter patient

info" and "Parameter entry").

Press / to add the selected entry to / remove the selected entry from the selection list.

During a measurement and as soon as the input screen appears, press and select one

of the defined forms.

This form remains the standard until a new form is selected.

3-46

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003

Page 71

3 Operating modes

Mandatory input

In the setup of the input parameters, any of the input parameters can be selected to require

a mandatory input by the operator.

Fig. 68

Select an input parameter and press:

"1:before measurement": you can assign only one input parameter and you must enter it

before the measurement

"2:during measurement": it is possible to assign this mandatory input to as many input

parameters as desired, but they must be entered during (or

after) the measurement.

Result screen

Use this function to define the measurement and calculation values as well as additional

information that are shown in the results display.

Fig. 69

Use the "+" button to insert a new form ("No name").

Use to enter a new name.

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003 3-47

Page 72

3 Operating modes

By pressing the button you switch to the following view:

Fig. 70

Press "line up/down" and select a parameter from the left list ("Options").

Press / to add the selected entry to / remove the selected entry from the selection list.

During a measurement and as soon as the results screen appears, press twice.

This form remains the standard until a new form is selected.

Measurement report

Use this function to define the input, default, measurement and calculation values as well

as additional information that are printed in the measurement report.

Fig. 71

Use the "+" button to insert a new form ("No name").

3-48

Use to enter a new name.

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003

Page 73

3 Operating modes

By pressing the button you switch to the following view:

Fig. 72

Press "line up/down" and select a parameter from the left list ("Options").

Press / to add the selected entry to / remove the selected entry from the selection list.

During a measurement and as soon as the input screen appears, press and

and select one of the defined reports.

This form remains the standard until a new form is selected.

Number of reports

Switch to the following view by pressing the button:

Fig. 73

Use this function to specify how many reports are printed following the measurement.

Press and select the number of reports.

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003 3-49

Page 74

3 Operating modes

Measurement DB query

Use this function to set the request criteria for the measurement database in order to limit

the results to a reasonable number.

Example: A query that provides all of the measurements of the last month. The last name and

Use the "+" button to insert a new form ("No name").

Use to enter a name (e.g. "Measurements last month").

first name are to be selected directly during the query.

Fig. 74

Press the button twice.

Fig. 75

3-50

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003

Page 75

3 Operating modes

"Field selection": select "First name" from the list and confirm your selection with .

Fig. 76

"Operator": select "=" and confirm your selection with .

Fig. 77

"Search option 1": select "User defined option" and confirm your selection with . You

will then be able to select the first name that you would like to find in the database.

Press twice.

Use the "+" button to insert a new criterion ("last name").

Press the button.

"Field selection": select "Last name" from the list and confirm your selection with .

"Operator": select "=" and confirm your selection with .

"Search option 1": select "User-defined option" and confirm your selection with .

You will then be able to select the last name that you would like to find in the database.

Press twice.

Use the "+" button to insert a new criterion ("date").

Press the key.

"Field selection": select "Date" from the list and confirm your selection with .

"Operator": select "<x<" and confirm your selection with .

"Search option 1": select "Actual date". An input field will appear.

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003 3-51

Page 76

3 Operating modes

Enter "31" days for the last month and confirm your selection with .

"Search option 2": select "Actual date".

TIP: Search option 2 is only used with the operators "<x<" and "x<...<x" which require the

entry of a value range.

Press three times.

You can now query the measuring data with the aid of the "Measurements last month" filter

in database mode. Enter the first and last name and the date and you will receive the desired

measuring data.

Measurement DB overview

Use this function to set the screen display of the measurement database overview.

Use the "+" key to add a new form ("No name"). You can remove it again with "-".

Use to enter a new name.

Press the button.

Fig. 78

Press "line up/down" and select a parameter from the left list ("Options").

Press / to add the selected entry to / remove the selected entry from the selection list.

You can assign a view to the listed queries in the "Database – Measuring data" operating

mode. Select "All measurement data", for example.

Press the button and and select one of the listed views.

3-52

Selection: standard (default view), all, user-defined views.

This view will remain the standard until the selection of a new view.

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003

Page 77

3 Operating modes

Default settings

By pressing the "Data entry" button you can define the standard settings for the selected

parameter.

Fig. 79

Enter patient info

Use this function to expand the list of possible input values.

Fig. 80

Enter measurement info

Use this function to expand the list of possible input values.

Fig. 81

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003 3-53

Page 78

3 Operating modes

Parameter: display ranges

Use this function to specify whether normal, critical or no areas are printed on the measurement report and displayed on the result screen.

See also the section "Parameter – Reference/critical ranges" on page 3-31!

QC

QC report

Use this function to activate / deactivate the QC report!

QC DB query

Use this function to establish the request criteria for the QC database.

See "Measurement DB query", page 3-50!

QC DB overview

Use this function to set the screen display of the QC database overview.

See "Measurement DB overview", page 3-52!

Calibration

Calibration report

Use this function to activate / deactivate the calibration report!

Calibration DB query

Use this function to establish the request criteria for the calibration database.

See "Measurement DB query", page 3-50!

Calibration DB overview

Use this function to set the screen display of the calibration database overview.

See "Measurement DB overview", page 3-52!

3-54

Patient database

Patient DB query

Use this function to establish the request criteria for the patient database.

See "Measurement DB query", page 3-50!

Reference Manual, Roche OMNI C, Rev. 5.0, Juli 2003

Page 79

3 Operating modes

Patient DB overview