Page 1

POINT OF CARE

TESTING

Roche OMNI C

Service Manual

Page 2

Roche Diagnostics GmbH

D-68298 Mannheim / Germany

www.roche.com

Copyright © 2002 Roche Diagnostics GmbH, all rights reserved

The contents of this document may not be reproduced in any form or communicated to any third party without the prior written consent of Roche Diagnostics. While every effort is made to ensure its correctness, Roche Diagnostics assumes no responsibility for errors or omissions which may appear in this document. Subject to change without notice.

REF/No. 03273199001

Rev. 3.0, September 2002

First edition: October 2001

Page 3

£*NQPSUBOUJOGPSNBUJPO£"MXBZTGPMMPX£

5IJTService ManualDPOUBJOTWJUBMwarning and safety information

5IJTJOTUSVNFOUJTJOUFOEFEUPCFVTFEPOMZGPSUIFTQFDJBMJ[FEQVSQPTFEFTDSJCFEJOUIFJOTUSVDUJPOT5IF

NPTUJNQPSUBOUQSFSFRVJTJUFTGPSVTFPQFSBUJPOBOETBGFUZBSFFYQMBJOFEUPFOTVSFTNPPUIPQFSBUJPO/P

XBSSBOUZPSMJBCJMJUZDMBJNTXJMMCFDPWFSFEJGUIFJOTUSVNFOUJTVTFEJOXBZTPUIFSUIBOUIPTFEFTDSJCFEPSJG

UIFOFDFTTBSZQSFSFRVJTJUFTBOETBGFUZNFBTVSFTBSFOPUPCTFSWFE

5IFJOTUSVNFOUNBZCFPQFSBUFEPOMZCZQFSTPOTXIPTFRVBMJGJDBUJPOTFOBCMFUIFNUPDPNQMZXJUIUIFTBGFUZ

NFBTVSFTUIBUBSFOFDFTTBSZEVSJOHPQFSBUJPOPGUIFNBDIJOF

"EKVTUNFOUTBOENBJOUFOBODFQFSGPSNFEXJUISFNPWFEDPWFSTBOEDPOOFDUFEQPXFSNBZCFBUUFNQUFEPOMZ

CZBRVBMJGJFEUFDIOJDJBOXIPJTBXBSFPGUIFBTTPDJBUFEEBOHFST

*OTUSVNFOUSFQBJSTBSFPOMZUPCFQFSGPSNFECZUIFNBOVGBDUVSFSPSRVBMJGJFETFSWJDFQFSTPOOFM

0OMZBDDFTTPSJFTBOETVQQMJFTFJUIFSEFMJWFSFECZPSBQQSPWFECZ3PDIFBSFUPCFVTFEXJUIUIFJOTUSVNFOU

5IFTFJUFNTBSFNBOVGBDUVSFEFTQFDJBMMZGPSVTFXJUIUIJTJOTUSVNFOUBOENFFUUIFIJHIFTURVBMJUZSFRVJSF

NFOUT

0QFSBUJPOPGUIFJOTUSVNFOUXJUITPMVUJPOTXIPTFDPNQPTJUJPOJTOPUDPOTJTUFOUXJUIUIBUPGUIFPSJHJOBM

TPMVUJPOTDBOOFHBUJWFMZBGGFDUBCPWFBMMUIFMPOHUFSNNFBTVSFNFOUBDDVSBDZ%FWJBUJPOTJOUIFDPNQPTJ

UJPOPGUIFTPMVUJPOTDBOBMTPEFDSFBTFUIFTFSWJDFMJGFPGUIFFMFDUSPEFT

5IF RVBMJUZ DPOUSPM SFRVJSFNFOUT NVTU CF DPNQMFUFE BU MFBTU PODFEBJMZ GPS TBGFUZ SFBTPOT

#FDBVTFBDDVSBUFNFBTVSFNFOUSFTVMUTEFQFOEOPUPOMZPOUIFQSPQFSGVODUJPOJOHPGUIFJOTUSV

NFOUCVUBMTPPOBOVNCFSPGPUIFSGBDUPSTTVDIBTQSFBOBMZUJDTUIFSFTVMUTQSPEVDFECZUIF

JOTUSVNFOUTIPVMECFFYBNJOFECZBUSBJOFEFYQFSUCFGPSFTVCTFRVFOUEFDJTJPOTBSFSFBDIFE

UIBUBSFCBTFEPOUIFNFBTVSFNFOUWBMVFT

&YQMBOBUJPO

.FBOJOH$BVUJPOSFGFSUPBDDPNQBOZJOHEPDVNFOUTl

£*NQPSUBOUJOGPSNBUJPO£"MXBZTGPMMPX£

Page 4

£0QFSBUJOHTBGFUZJOGPSNBUJPO£

• 5IFJOTUSVNFOUIBTCFFODPOTUSVDUFEBOEUFTUFEBDDPSEJOHUPUIFQSPUFDUJWFNFBTVSFTTUJQV

MBUFECZ&/*&$GPSFMFDUSJDBMNFBTVSFNFOUDPOUSPM*7%BOEMBCP

SBUPSZJOTUSVNFOUTBOEXBTEFMJWFSFEGSPNUIFGBDUPSZJOGMBXMFTTDPOEJUJPOXJUISFHBSETUP

TBGFUZGFBUVSFT*OPSEFSUPQSFTFSWFUIJTDPOEJUJPOBOEFOTVSFTBGFPQFSBUJPOUIFVTFSNVTU

SFTQFDUUIFOPUJDFTBOEXBSOJOHTUIBUBSFDPOUBJOFEJOUIFTF*OTUSVDUJPOTGPS6TF

• 5IJTJOTUSVNFOUJTDMBTTJGJFEVOEFSUIFQSPUFDUJPODMBTT*BDDPSEJOHUP&/*&$

• 5IFJOTUSVNFOUNFFUTUIFDPOEJUJPOTGPSPWFSWPMUBHFDBUFHPSZ**

• 5IFJOTUSVNFOUNFFUTUIFDPOEJUJPOTGPSDPOUBNJOBUJPOMFWFM

• %POPUPQFSBUFUIFJOTUSVNFOUJOBOFYQMPTJWFFOWJSPONFOUPSJOUIFWJDJOJUZPGFYQMPTJWF

BOFTUIFUJDNJYUVSFTDPOUBJOJOHPYZHFOPSOJUSPVTPYJEF

• *GBOPCKFDUPSMJRVJEFOUFSTUIFJOUFSOBMBSFBTPGUIFJOTUSVNFOUSFNPWFUIFJOTUSVNFOU

GSPNJUTQPXFSTVQQMZBOEBMMPXBOFYQFSUUPDIFDLJUUIPSPVHIMZCFGPSFVTJOHJUBHBJO

• 5IFJOTUSVNFOUJTTVJUBCMFGPSMPOHUFSNPQFSBUJPOJOEPPST

$"65*0/

• 5IF QPXFS DPSE NBZ CF QMVHHFE JOUP B HSPVOEFE TPDLFU POMZ 8IFO VTJOH BO FYUFOTJPO

DPSENBLFTVSFJUJTQSPQFSMZHSPVOEFE

• "OZSVQUVSFPGUIFHSPVOEMFBEJOTJEFPSPVUTJEFUIFJOTUSVNFOUPSBMPPTFHSPVOEDPOOFD

UJPO NBZ SFTVMU JO IB[BSEPVT PQFSBUJOH DPOEJUJPOT *OUFOUJPOBM EJTDPOOFDUJPO PG UIF

HSPVOEJOHJTOPUQFSNJUUFE

• 5IFJOTUSVNFOUJTOPUTVJUBCMFGPSPQFSBUJPOXJUIBEJSFDUDVSSFOUQPXFSTVQQMZ

6TFPOMZUIFPSJHJOBMNBJOTQMVHEFMJWFSFEXJUIUIF3PDIF0./*$

£0QFSBUJOHTBGFUZJOGPSNBUJPO£

Page 5

1 Introduction

2 Revisions

3 Components

4 AutoQC

5 Fluidic procedures

6 Service area

7 Annual maintenance

8 Troubleshooting

9 Index

Page 6

Service Manual, Roche OMNI C

Page 7

1 Introduct ion

1 Introduction........................................................ 1-1

1.1 General notes ......................................................................................... 1-1

1.2 Symbols.................................................................................................. 1-1

1.3 Important notes and warni ngs ................................................................ 1-2

1.4 Disinfectants........................................................................................... 1-3

1.4.1 Roche Deproteinizer ..........................................................................................1-3

Composition ............................................................................................................... 1-3

Potential dangers ........................................................................................................1-3

First aid m easures ......................................................................................................1-3

1.4.2 Commercial disinfectants ...................................................................................1-3

1.5 Decontamination..................................................................................... 1-4

1.5.1 Surfaces........................................................................................................... 1-4

1.5.2 Touch screen....................................................................................................1-4

1.5.3 Barcode scanner...............................................................................................1-4

1.5.4 Sample port module ..........................................................................................1-5

1.5.5 Measuring chamber...........................................................................................1-5

1.5.6 Tubing paths.....................................................................................................1-5

1.6 ESD protection measures....................................................................... 1-6

1.6.1 Causes of electrostatic charges .........................................................................1-6

1.6.2 Effects of ESD on electronic componen ts ...........................................................1-6

1.6.3 Why is ESD protection so important today? ........................................................1-7

1.6.4 How can ESD protection be guaranteed?............................................................1-7

1.6.5 Conclusion........................................................................................................1-7

Service Manual, Roche OMNI C, Rev. 3.0, September 2002 1-I

Page 8

1 Introduct ion

1-II Service Manual, Roche OMNI C, Rev. 3.0, September 2002

Page 9

1 Introduction

1.1 General notes

This man ual con tains all of the information required for the maintenance and repair of the OMNI C.

You must be familiar with the fun ction and operation of the instrument to full y understand the

processes described here. Please refer to the OMNI C Instructions for Use or OMNI C Reference

Man ual for th is in forma tion .

Obser ve the s ervi ce an d repair pr ocedur es descr ibed i n th is manu al and use onl y genuin e Roche

replacement parts an d Roche-approved materials to guarantee the full functionality of your OMNI C.

For th e order number s of rep lacem ent part s, plea se ref er t o the OMNI C spar e part l ist.

Chapter 2 of this manual contains an overview of possible revisions and available software version s.

1.2 Symbols

1 Introduct ion

All sections or text passage s marked wi th this symbol describe

procedures that may involve risk of infection.

Sections marked wi th this symbol contain information that must be observed for the

prevention of personal injury to patients, users or third parties.

All sections or text passage s that are marked with this symbol describe procedures

and/or indicate conditions or dangers that could damage or lead to malfunctions in the

Roche OMNI C.

All sections or text passage s marked wi th this symbol refer to situations and/or

potential dangers affecting personne l performing the se rvicing or repair work.

All sections or text passage s marked wi th this symbol refer to components t hat require

special precautions related to e lectrostatic discharge. Pack aging marked wit h this

symbol may only be ope ned by trained personnel (also see page 1-6, section 1, ESD

protection measures)

Service Manual, Roche OMNI C, Rev. 3.0, September 2002 1-1

Page 10

1 Introduct ion

1.3 Importa nt note s and warni ngs

• Never use the analyzer near highly inflammable or explosive gasses (anaesthetic

gasses, e tc.).

• Use only 2-pin, grounded AC power sockets for the instrument.

• Ensure that the A C power cable and plug are in good condition.

Damaged AC cables or plugs must be replaced immediately.

• Switch the instrume nt off and unplug the AC power cabl e before opening its rear

panel.

• Be sure to replace blo wn fuses with new fuses of the same type.

• Always follow the i nstructions in this manual when servicing or repairing the

instrume nt.

• Always use suitable tools and testing equi pment for servicing or re pairs.

• To avoid damage t o the instrument's e lectronic components, prevent l iquids from

entering it.

• To clean the instrument, use lightly moistened tissue or cotton swabs.

1-2 Service Manual, Roche OMNI C, Rev. 3.0, September 2002

Page 11

1.4 Disinfectants

Use only liquid disinfectant suc h as Roche Deprote inizer or an alcohol -based (about

70%) surface disinfectant.

Do not use sprays, as they may enter the instrument and cause its electronic

components to malfunction.

Do not attempt to decont aminate any part of the instrument before shutting it down and

unplugging it from the AC power socket.

Before plugging the instrume nt back in and turning it on, always wait 15 minutes to

allow the disinfectant to ev aporate.

There is the risk of f ire or explosion especi ally in the vicinity of the power supply!

1.4.1 Roche Deproteinizer

1 Introduct ion

Composition

Aqueous NaOCl solution with active chlorine (≤ 2%)

Potential da ngers

Due to the alkaline and oxidizing character of this prepar ation, we cannot rule out local irritation to

the skin, eyes, and mucous membranes.

First aid measures

After in ha lati on: Fr esh a ir, drink larg e amount s of water

After skin con tact: Wash with large amounts of water, remove contaminated cloth ing

After eye con tact: Rinse with large amounts of water , con sult an eye specialist

After swallowing: Drink large amounts of water, do not induce vomiting, consult a physician

1.4.2 Commercial disinfectants

Use a comm erci al alcohol -based (70% ) di sinfect an t as a sur face dec ont amin ant. P lease ob serv e th e

relevant product information!

Do not use commercial disinfectants to decontaminate the tubing under any

circum stances!

Service Manual, Roche OMNI C, Rev. 3.0, September 2002 1-3

Page 12

1 Introduct ion

1.5 Decontamination

Use the following decontamination procedures to minimize the risk of infection (including hepatitis

and HIV) when r epla ci ng pa rt s th at h ave c ome i n con tact wit h bl ood or ot h er bi olog ica l l i qui ds.

Always wear gloves!

Observe section 1.4, Disinfect ants, on page 1-3.

1.5.1 Surfaces

Decon taminate all outside surfaces, including all covers (e.g. the measuring chamber cover, bottle

compartment cover , instrument cover) as well as the outside surfaces of the AutoQC module if

presen t, with a cl oth m oisten ed with disin fecta nt.

1.5.2 Touch screen

1. Select

"Mo re functio ns – System – Wash and clean – Clean screen".

The touch screen will be disabled for 30 seconds.

The remaining number of seconds will be displayed on the screen.

2. You may n ow clean th e screen with a cl oth m oist ened wit h dis infecta n t.

3. After 30 seconds have elapsed, the menu will reappear.

1.5.3 Barcode scanner

Decont am inat e the outer sur faces of t he ba rcode sca nn er wi th a cl oth moi sten ed with disin fecta nt.

1-4 Service Manual, Roche OMNI C, Rev. 3.0, September 2002

Page 13

1.5.4 Sample port module

1. Select

"Mo re functio ns – System – Wash and clean – Clean sampl e port modul e".

2. Open the flap completel y (capillary position).

3. Remove t he sa mple dr ip tr ay and decont amin ate i t usin g a cotton swab dip ped i n di sinfect an t.

If the sample drip tray is heavily contaminated, replace it with a new one.

Before r epl acin g it, decont amin ate th e samp le dr ip tray with a cott on swa b dipp ed in

disinfectant.

4. Open the bottle compartment cover.

5. Remove t he red tube con nect or fr om th e wash p late.

6. Push the wash plate down to unlock and pull it out.

(The was h pla te is l ocked a nd cann ot be r emoved when the pl ug is in sert ed.)

7. Decontaminate the wash plate with a cotton swab dipped in disin fectant.

8. Push the wash plat e back in complet el y and at tach the tube p lug.

9. Push the drip tray in.

10. Decontaminate the fill port and the visible part of the needle with a cotton swab dipped in

disinfectant.

11. Close the flap to the syringe position (half-opened position).

12. C lean the ti p of the n eedle.

13. C lose th e fla p.

14. Close the bottle compartment cover.

1 Introduct ion

1.5.5 Measuring chamber

1. Remove t he in str ument cover an d open the mea surin g ch amber co ver.

2. Open th e elect r ode locki ng lever an d rem ove the el ectr odes.

3. Clean the mea surin g ch amber wi th a t owel soak ed in disin fecta nt ( e.g. Roch e Depr otein iz er).

4. Reinser t th e el ectr odes.

5. Close th e mea sur ing cha mber cover an d repl ace th e inst rum ent cover .

1.5.6 Tubing paths

To decontaminate the tubing system, use Roche Deproteinizer only!

Press

"Mo re functio ns – System – Wash and clean – Automatic rou tin es – Decontaminat e all

tubes" and follow th e on- screen instr uct ion s.

For a detailed descr iption of this procedure, please refer to section 6.1, Decontamination,

in th e Roche OMNI C Ins tru ction s for Use.

Service Manual, Roche OMNI C, Rev. 3.0, September 2002 1-5

Page 14

1 Introduct ion

1.6 ESD pr otec tion me asur es

ESD protection measures are designed to prevent electronic components from being

damaged or destroyed by uncont rolled electrostatic discharges.

1.6.1 Causes of electrostatic charges

The most frequent causes of electrostatic charges are friction or the separation of various materials

such a s pla sti cs, synt h eti c fi bre s, har d ru bber or p ap er, or el ectr on bea ms i n CRT uni ts .

They can also be ca used with in an object by flexur e or pressu re – such a s the fr icti on of in dividu al

fibr es with in a pi ece of fa bric.

The resu ltin g el ectri cal voltag es ma y become a h azar d when "char ged" bodi es or com pon en ts do not

have a conductive connection permitting a discharge (poten tial equalization).

The resulting charges generally do not have high energy, but nevertheless may have differences in

poten tial of several thousan d volts, resulting in perceptible electr ic shocks or visible sparks.

Example:

• Shoes with rubber soles:

The friction of walking charges th e per son wearing the shoes in relation to the floor. A

disch arg e occurs when the per son tou ches an object.

• Cloth ing made of syn thetic fabrics:

Audibl e disch ar ge; sp arks vi sible i n th e dark.

• The formation of electrostatic charges through friction is promoted by dry air.

• This tendency is reduced in high humidity, especially in saturated air.

• The occurrence of electrostatic phenomena is thus especially pronounced in the

winter (northern hemisphere) in centrally heated rooms with low humidity.

1.6.2 Effects of ESD on electronic components

When an electr osta ti cally cha r ged per son t ouches an electr on ic devi ce, th e disch ar ge may ta ke pl ace

via t he pin s of an IC or a s emi con du ctor com pon ent . If a di scha rg e t o grou n d is p ossi ble, t he

resulting voltage may damage the component.

This would be th e case, for ex amp le, if th e uni t has a conn ecti on t o a protect ive g roun d – thi s

therefore also applies to uni ts that are switch ed off, but have th eir AC cables pl ugged in.

Critical situations may also occur when repairing or testing electronic assemblies if they are placed

on a mor e or less condu ctive su rfa ce (e.g . ta ble top ) and ar e touch ed b y an elect rost ati call y char ged

person . In this case, the discharge may also take place via a critical component con nection.

1-6 Service Manual, Roche OMNI C, Rev. 3.0, September 2002

Page 15

1.6.3 Why is ESD protection so important today?

In th e past, cu rren t-con tr ol semi condu ctor s (TTL, norma l trans istor s, etc. ) wer e most com monl y

used.

Toda y, the pr inci pl e of volta ge cont rol is used a lmost exclus ivel y in MOS an d CMOS comp onen ts

that are thus highly sensitive to the effects of externally applied voltages.

The voltages occurring in electrostatic discharges (up to sever al kV!) damage or destroy t he

sensitive component inputs.

An additional factor is the shrinking in ternal dimensions of ICs.

With the decreasing size of the internal con ductor s, the permissible maximum input voltages are

also becoming lower and the effects of electrostatic disch arges th us becoming ever more critical.

1.6.4 How can ESD protection be guaranteed?

A contin uous disch ar ge must be ensur ed when han dling el ectr oni c assem blies.

This can be accomplished as follows:

• When tran spor tin g electr on ic assem blies, be sur e to use E SD prot ecti on pa ckag ing

sui ta ble s tor ag e/ shi pp ing pa ck ag ing ( i. e. th e or ig ina l pac ka gin g ma ter ia l).

• Test and r epair elect roni c ass embli es onl y on tabl es wi th ESD mats

• Wear a grou nded ESD wri st str ap.

• Han dle electronic components/assemblies by the edges only. Avoid touch ing printed circuits or

compon ent p ins .

• Do n ot wear shoes with r ubber soles or items of cloth ing containing syn thetic fibres in facilities

in whi ch elect r onic equ ipm ent is ser viced .

• If necessa ry, u se a hu midi fier to en sur e optimal humidity (>20% rel.) in the room.

• Take care not to touch assemblies or individual compon ents directly with your han d after

testing.

• When sen ding el ectr onic com ponen ts or assem blies i n for r epair s, alwa ys use E SD pr otecti on

packaging

of the fault.

1

to preven t fur th er dama ge that ma y resul t in an incorr ect int erpret ati on of th e cau se

1 Introduct ion

1

or oth er

1

.

1.6.5 Conclusion

Natur all y, not al l prin ted circu it boar ds and elect roni c assem blies requ ire s uch car eful trea tment . An

assembly that featur es simple plug con nectors, for example, is insensitive to electrostatic discharge

and th erefor e does n ot n eed ES D protecti on p acka gin g.

When in doubt , however, always take ESD pr ecautions!

1

These a re materi als w ith a ve ry lo w , defined co nduc tivity (10

cannot damage components.

Service Manual, Roche OMNI C, Rev. 3.0, September 2002 1-7

12

ohms), which do not accumulate charges with friction and thus

Page 16

1 Introduct ion

1-8 Service Manual, Roche OMNI C, Rev. 3.0, September 2002

Page 17

2 Revisions

2 Revisions............................................................ 2-1

2.1 Software.................................................................................................. 2-1

2.2 Service Manual ....................................................................................... 2-2

2.2.1 Revision 1.0......................................................................................................2-2

2.2.2 Revision 2.0......................................................................................................2-2

2.2.3 Revision 3.0......................................................................................................2-3

Service Manual, Roche OMNI C, Rev. 3.0, September 2002 2-I

Page 18

2 Revisions

2-II Service Manual, Roche OMNI C, Rev. 3.0, September 2002

Page 19

2 Revisions

2 Revisions

2.1 Software

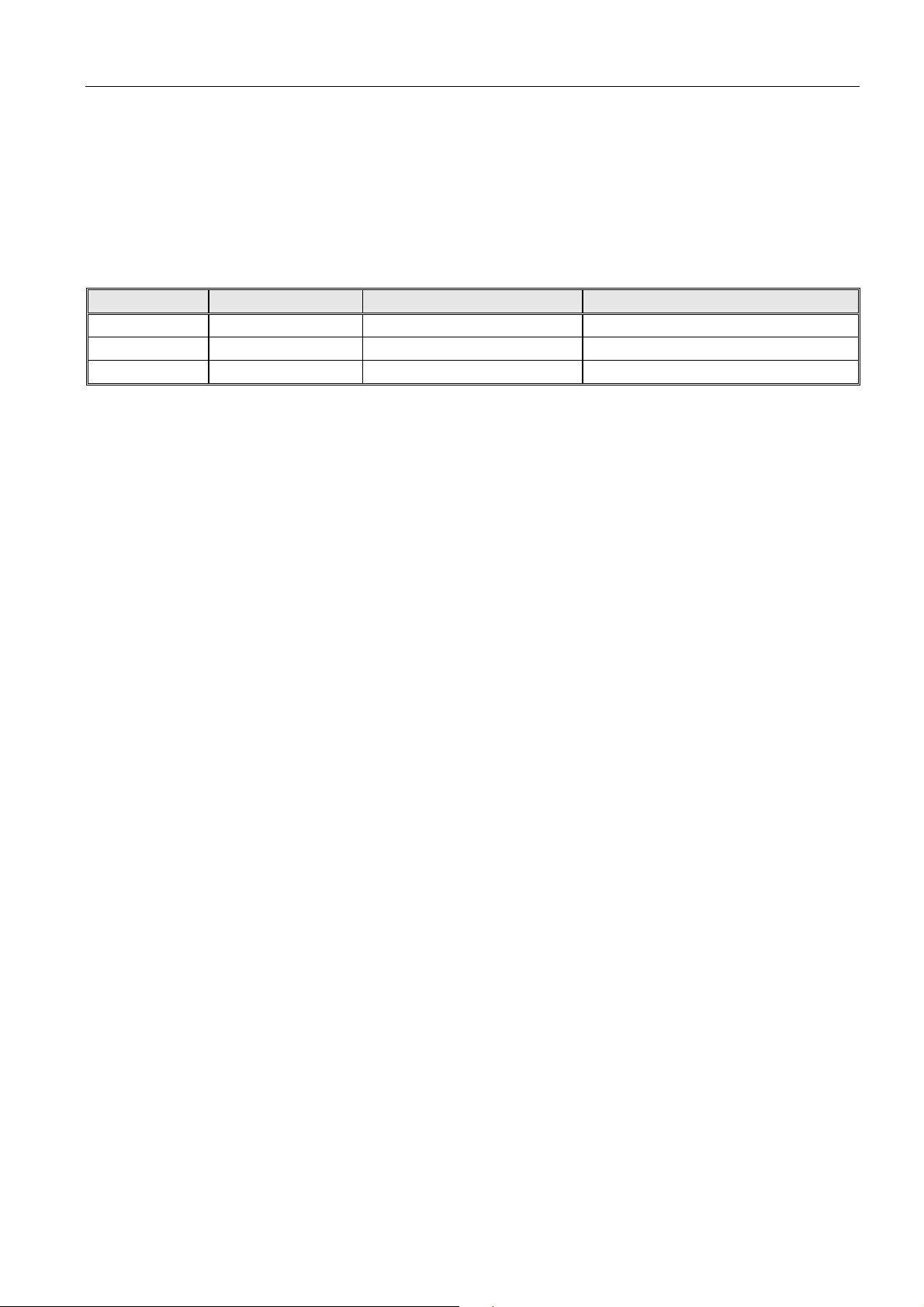

Version Nr. Date of Release Remark Installed from OMNI C Serial Nr.

1.01 15.10.2001 First Release

1.22 15.02.2002

1.33 06.12.2002

≥1000

≥1251

≥1558

Service Manual, Roche OMNI C, Rev. 3.0, September 2002 2-1

Page 20

2 Revisions

2.2 Service Manual

2.2.1 Revision 1.0

Revision Nr. Date of Release Modified Chapters Applicable from Software Version

1.0 October 2001 First Release 1.01

2.2.2 Revision 2.0

Revision Nr. Date of Release Modified Chapters Applicable from Software Version

2.0 January 2002 2, 3, 6, 8, 9 1.22

Chapter-Page Modifica tion / Addition

Cover Page Revision No. and Dat e

2-I Table of contents

2-1 Revision List

3-II Table of contents

3-34 Changi ng the MBX board battery

6-I Table of contents

6-1 Password

6-3 Delete databases

6-3 – 6-4 Reset set tings

6-12 Consequence ac tion delay

6-13 – 6-14

6-15 Boot parameters

6-16 Database

8-I – 8-II Table of contents

8-1 – 8-9 System Stops

8-10 – 8-18 Error Messages

8-21 Leaks in the Sample port / Needle / Barex tube area

8-22 Electrode limit values

8-22 – 8-23 Contact path limi t values

9-1 – 9-6 Index

Log unit

2-2 Service Manual, Roche OMNI C, Rev. 3.0, September 2002

Page 21

2 Revisions

2.2.3 Revision 3.0

Revision Nr. Date of Release Modified Chapters Applicable from Software Version

3.0 September 2002 2, 5, 6, 8, 9 1.33

Chapter-Page Modifica tion / Addition

Cover Page Revision No. and Dat e

2-I Table of contents

2-3 Revision List

5-I Table of contents

5-13 Cal ibrating the Sample Sensors

5-15 Calibration Flow Chart

5-19 Measurement procedure

5-21 System c alibration procedure

6-I Table of contents

6-2 Roche Servic e 1 – new Screenshot

6-5 AQC XY adjustment

6-7 Calibration of tHb temperature sensor

6-15 Start button for measurement

6-20 O2 zero interval

8-II Tabl e of c ontents

8-10 Error Messages

8-10 Li st of error messages (sorted by Inf o No.)

8-23 Electrode calibration limit values

8-23 Conductivity calibration limit values

8-24 Conductivity calibration limit values

8-25 Power-up component test

9-1 – 9-6 Index

Additional page Start button for measurem ent

Service Manual, Roche OMNI C, Rev. 3.0, September 2002 2-3

Page 22

2 Revisions

2-4 Service Manual, Roche OMNI C, Rev. 3.0, September 2002

Page 23

3 Components

3 Components....................................................... 3-1

3.1 Important Instructions ............................................................................ 3-1

3.2 Shutdown ................................................................................................ 3-2

3.2.1 The OMNI C stays switched off shorter than 24 hours .........................................3-2

3.2.2 The OMNI C stays switched off longer than 24 hours ..........................................3-2

3.3 Dismounting the rear panel.................................................................... 3-3

3.4 FMS (Fluid Mixing System) ..................................................................... 3-5

3.4.1 General Information...........................................................................................3-5

3.4.2 Changing the FMS unit......................................................................................3-5

3.5 Measuring chamber ................................................................................ 3-7

3.5.1 General Information...........................................................................................3-7

3.5.2 Changing the measuring chamber ......................................................................3-9

3.5.3 Changing the measuring chamber cover...........................................................3-11

3.5.4 Changing the analog board ..............................................................................3-12

3.5.5 Changing the measuring chamber actuators ..................................................... 3-13

3.5.6 Changing the sample sensor board .................................................................. 3-14

3.5.7 Changing the TCon......................................................................................... 3-15

3.5.8 Changing the electrode locking lever................................................................ 3-16

3.5.9 Changing the measuring chamber tubing.......................................................... 3-16

3.5.10 Changing the Barex tube .................................................................................3-17

3.5.11 Changing the FMS connector sealing 1 ............................................................3-18

3.5.12 Changing the FMS connector sealing 2 ............................................................3-18

3.5.13 Changing the tHb/SO2 module..........................................................................3-19

3.6 Sample port module.............................................................................. 3-20

3.6.1 Changing the sample port module ....................................................................3-20

3.6.2 Changing the sample port ................................................................................ 3-21

3.6.3 Changing the needle .......................................................................................3-22

3.6.4 Changing the needle sealing............................................................................3-22

3.6.5 Changing the flap detection board.................................................................... 3-23

Service Manual, Roche OMNI C, Rev. 3.0, September 2002 3-I

Page 24

3 Components

3.7 Peristaltic pump .................................................................................... 3-24

3.7.1 Changing the peristaltic pump .......................................................................... 3-24

3.7.2 Changing the pump head .................................................................................3-25

3.7.3 Changing the pump tube..................................................................................3-25

3.7.4 Changing the tension lever.............................................................................. 3-26

3.7.5 Changing the pump plate sealing ..................................................................... 3-26

3.7.6 Testing the peristaltic pump.............................................................................3-27

3.8 PC tower................................................................................................ 3-27

3.8.1 General Information......................................................................................... 3-27

3.8.2 Changing the PC tower.................................................................................... 3-29

3.8.3 Screen............................................................................................................3-30

3.8.4 Changing the screen .......................................................................................3-30

3.8.5 Changing the backlight.................................................................................... 3-31

3.8.6 Changing the printer........................................................................................3-32

3.8.7 Changing the MBX board .................................................................................3-33

3.8.8 Changing the MBX board battery...................................................................... 3-34

3.9 Cables.................................................................................................... 3-35

3.9.1 Changing the data bus cable............................................................................ 3-35

3.9.2 Changing the DC power cable..........................................................................3-35

3.10 Fan.........................................................................................................3-36

3.10.1 Changing the fan............................................................................................. 3-36

3.11 Micro switch unit (Bottle compartment cover switch) .......................... 3-37

3.11.1 General Information......................................................................................... 3-37

3.11.2 Changing the micro switch unit ........................................................................ 3-38

3.12 Micro switches ......................................................................................3-39

3.12.1 Changing the W aste container micro switch ...................................................... 3-39

3.12.2 Changing the C3 docking mechanism micro switch ...........................................3-39

3.12.3 Testing the micro switches............................................................................... 3-40

3.13 Power supply unit..................................................................................3-40

3.13.1 Technical data ................................................................................................ 3-40

3.13.2 Changing the power supply unit....................................................................... 3-41

3-II Service Manual, Roche OMNI C, Rev. 3.0, September 2002

Page 25

3 Components

3.14 Valves ................................................................................................... 3-41

3.14.1 General Information.........................................................................................3-41

3.14.2 Single valve head............................................................................................ 3-41

3.14.3 Double valve head........................................................................................... 3-42

3.14.4 Changing the valves........................................................................................3-42

3.14.5 Testing the valves...........................................................................................3-43

3.15 Actuator board...................................................................................... 3-44

3.15.1 Changing the Actuator board ........................................................................... 3-44

3.16 Pump board .......................................................................................... 3-45

3.16.1 Changing the Pump board ............................................................................... 3-45

3.17 Docking mechanisms............................................................................ 3-45

3.17.1 Changing the docking mechanism Waste W ...................................................... 3-45

3.17.2 Changing the docking mechanisms Calibration solution C1 and C2 ....................3-47

3.17.3 Changing the docking mechanism Pack C3....................................................... 3-48

3.18 Analyzer tubing..................................................................................... 3-49

3.18.1 Preparation ..................................................................................................... 3-49

3.18.2 Tubing in the area of docking mechanism Pack C3 ...........................................3-49

3.18.3 Tubing in the right bottle compartment area without AutoQC..............................3-50

3.18.4 Tubing in the right bottle compartment area with AutoQC..................................3-50

3.18.5 Tubing in the FMS area (Fluid Mixing System)..................................................3-51

3.18.6 Tubing in the pump area..................................................................................3-51

3.18.7 Tubing of the ref erence electrode connector..................................................... 3-52

3.19 Barcode scanner................................................................................... 3-53

3.19.1 General Information.........................................................................................3-53

3.19.2 Testing the barcode scanner ............................................................................3-54

Service Manual, Roche OMNI C, Rev. 3.0, September 2002 3-III

Page 26

3 Components

3-IV Service Manual, Roche OMNI C, Rev. 3.0, September 2002

Page 27

3 Components

3.1 Important Instructions

Components of the OMNI C (sample port, tubing, Waste container, et c.) contain

remnants of biological fluids afte r use, resulting in possible risk for infections.

Handle these components with care and avoid skin contact.

Wear rubber gloves while working on the analyzer!

The tubes may drip a little after being disconnected.

Remove excess fluids with a clean, absorbent cloth.

After changing components, cali bration parameters coul d have changed or some values

have to be entered again.

After finishing modifications, a system calibration must be performed to adapt the

calibration parameters to the new conditions.

3 Components

Service Manual, Roche OMNI C, Rev. 3.0, September 2002 3-1

Page 28

3 Components

3.2 Shutdown

Switch off the OMNI C before you begin with the modifications!

Determined by the time the analyzer was switched off, one of the following procedures

has to be performed:

3.2.1 The OMNI C stays switched off shorter th an 24 hours

• Perf orm th e decont amin ati on pr ocedur e accor din g to secti ons 1.5. 1 to 1.5.6 on page 1-4.

• Press „More - Syst em – Tools– S oftware communi cation – Shu t down software“

and swi tch off the an alyzer

If the Docking mechanisms C1, C2 or C3 have been opened while the analyzer was

switched off, the respective soluti ons have to be prepared again under „More -

System – Tools– Fluid actions – Auto preparation routines“ to avoid improper

operation!

3.2.2 The OMNI C stays switched off longer than 24 hours

• Perf orm th e decont amin ati on pr ocedur e accor din g to secti ons 1.5. 1 to 1.5.5 on page 1-4.

• Press „More - Syst em – Tools- Shutdown“ an d foll ow the in str ucti ons on the scr een.

Only Roche Deproteinizer may be used for the decontamination of the tubing.

3-2 Service Manual, Roche OMNI C, Rev. 3.0, September 2002

Page 29

3.3 Dismounting the rear panel

1. Switch off the OMNI C (please pay atten tion to section 3.2 Sh utdown on page 3-2!).

2. Pull off the power cord from the power supply unit.

3. Remove t he thr ee m ountin g scr ews from the r ear pan el (s ee Fig. 3-1 ) and pul l off th e rear p anel

from the analyz er (if needed, remove the power supply unit from the rear panel; a certain

amoun t of force i s n eeded beca us e of th e mount ing wit h Vel cro t ape).

1

3 Components

2

3

Fig. 3- 1 O MNI C r ear p anel mou nti ng scr ews

4. Pull off the plug of the power supply cable from the PC tower (see Fig. 3-2).

Fig. 3-2 Plug of the power supply cable

Assembly is done in reverse order.

Service Manual, Roche OMNI C, Rev. 3.0, September 2002 3-3

Page 30

3 Components

When installing the rear panel, please pay attention to the correct routing of the power

supply cable inside the OMNI C (see Fig. 3-3)!

Fig. 3- 3 R out ing of t he p ower su ppl y c able

3-4 Service Manual, Roche OMNI C, Rev. 3.0, September 2002

Page 31

3.4 FMS ( Flui d Mi xi ng Sy stem )

3.4.1 General Information

The OMNI C uses a method which allows the simultaneou s calibr ation of the PCO2, pH, Na+, K+,

++

and Cl- sensors by usin g only two solutions (C1and C2).

Ca

Principle:

The Mix is produced by the mixing valve V1 (two inputs, one output) in conjunction with the

peristaltic pump. For an optimal mixing process, the synchronous function of pump and th e mixin g

valve is essential.

The Mix consists of alternating fluid packages from solution C1 and solution C2. Homogenization is

accomplished by small packages of either solution in relation to the distance.

3 Components

3.4.2 Changing the FMS unit

1. Dismou nt the rear panel accordi ng t o section 3. 3 Dismoun tin g the r ear pan el on p age 3-3 .

2. Pull off th e cable con nect ion s from the Act uator board (see Fi g. 3- 4).

Fig. 3- 4 F MS c on nect in g c abl es at th e Ac tu ator bo ard

3. Remove the bottle compartment cover .

4. Take out the bottles W, C1 and C2.

5. Pull off the tubing con nections from the FMS.

Service Manual, Roche OMNI C, Rev. 3.0, September 2002 3-5

Page 32

3 Components

6. Open th e four moun ting screws of the FMS (see Fig. 3-5, 1 to 4).

(Do not remove the screws completely!)

1 2

3 4

Fig. 3-5 F MS unit

Assembly is done in reverse order.

Test the FMS-valve s (V1 and V2) under

„More - System – T est – valves and Aggreg ates - valves“.

(see a ls o sec ti on 3.1 4. 5 Te sti ng th e va lve s on pa ge 3 -43)

3-6 Service Manual, Roche OMNI C, Rev. 3.0, September 2002

Page 33

3.5 Measuring chamber

3.5.1 General Information

3 Components

Baro

µC

AVR8535

Analog-Board

Temp.

Regulation

Fill Level

P r e - A m p l i f i e r

37 °C

FMS-Preheater

Peltier 1

Fig. 3- 6 B loc k di ag ram me asur in g c ham ber

µC

8515

AVR

ADC

Communication

µC

AVR2313

Sinus

Power

SS1/SS2

V3 / V5

PCO2PO2CaRCon KClNa pHRConREF

Peltier 2

tHb-Electronic

tHb / SO2

Preheater

Con

V5

SS1

SS2

V3

Analog-Board

Sample-

Sensor 1,2

Peltier 1

NTC 1

Fan 1

Peltier 2

NTC 2

Fan 2

Cover

bidir. over

3 Ampere

Pre-Amp.

REF

3xPWM

Relais

Temp.

Regulation

ADC ADCADC

Pre-Amp.

pH

Fig. 3- 7 Block di agr am anal og board

AVR-8535

ADC

11x12bit

4x Temp

2 x S.S.

1x Filllevel

Pre-Amp.ClPre-Amp.

AVR logic

Bus logic

ADC

AVR 2313

MK cover sensor

AVR 8515

Pre-Amp.

Na

K

Pre-Amp.

Ca

Sinus generator

Conductivity

measurement

Baro

opto coupler

DC/DC

Pre-Amp.

pO2

Pre-Amp.

pC02

Driver

V3 u. V5

V3

V5

thb/SO2

Service Manual, Roche OMNI C, Rev. 3.0, September 2002 3-7

Page 34

3 Components

Analog board - functions:

• Con trolling and measuring of all functions integrated in the measuring chamber

• Producing pol arisation voltage O2

• Read-in and controlling tHb/SO

• Con ductivity measurement

• Control lin g the m easur ing cham ber an d the mea surin g ch amber cover t emper atur e

• Con trolling and read-in the two sample sensors

• Read-i n bar o sen sor va lue to d eter min e a ir- pr essu r e

• Read-in baro sen sor value to determin e the Waste contain er fill level

• Con trolling of two valves (V3 and V5)

• Read-in measuring chamber cover switch

module

2

AVR measuring sensors

I2C-Bus

Sinus generator

Conductivity

measurement

K1...K4

Baro

Leit-

wert

ADC-BG

MUX

1:4

Amp.pHAmp.

3

2

pCO2

AVR 8515

2

Amp.NaAmp.KAmp.ClAmp.

ADC-ISE

MUX

1:4

ADC-Bus

K

3

Laser diodes control

S

C

*

5

+

3

opto coupler DC/DC

ADC-O2

MUX

Amp.

O2

MC coverl

Fan

1:2

Upol

(DAC)

tHb-SO2

4 x Laser

2 x ADC

EEPROM

Fig. 3- 8 Block di agr am AVR m easurin g sens ors

3-8 Service Manual, Roche OMNI C, Rev. 3.0, September 2002

Page 35

3.5.2 Changing the measuring chamber

1. Switch off the OMNI C (please pay atten tion to section 3.2 Sh utdown on page 3-2!).

2. Pull off the power cord from the power supply unit.

3. Remove t he an alyzer cover .

4. Dismount the sample port module (see section 3.6.1, Changing the sample port module on page

3-20).

5. Dismou nt the scr een cover (see s ecti on 3. 8.4, Chang ing the scr een on page 3 -30)

6. Open th e mea surin g cham ber cover .

7. Remove a ll el ectr odes fr om th e measu rin g chamber .

8. Dismou nt the cover of the MC cover cable a nd pu ll the cable out ( see Fig . 3- 9)

3 Components

Fig. 3- 9 D ism ount i ng th e m eas ur ing c ham ber c over c able

9. Dismount the measuring chamber cover by pressing it to the left and then upwards

(see Fig. 3-10).

Fig. 3- 10 Dis mou nt ing t he meas uri ng ch amb er c over

Service Manual, Roche OMNI C, Rev. 3.0, September 2002 3-9

Page 36

3 Components

10. Pull the measuring chamber cover to th e front, by doing this also the connection to the gas

spring to the housin g is disconnected (see Fig. 3-11, 1).

Fig. 3- 11 G as spr in g c onn ecti on

1

11. Remove the 4 allen screws of the measuring chamber.

12. Open the tube connections an d the Barex tube conn ection (see Fig. 3-12, 1 to 4)

2

4

1

3

Fig. 3- 12 Me asur ing c h amb er t ube c on nec ti ons

13. Li ft th e meas urin g cham ber car efull y an d pull of f the tw o cables an d the pr essur e sen sor tu be

from th e an alog boar d .

Assem bly is done in reverse order. Please note the following instructions!

3-10 Service Manual, Roche OMNI C, Rev. 3.0, September 2002

Page 37

3 Components

When installing the measuring chamber, the FMS pipe must slide exactly into the

holder of FMS connector sealing 1 (see Fig. 3-13, 1) and the t wo pipes at t he

right side must slide through t he two hol es at the right side of the measuring

chamber (see Fig. 3-13, 2 and 3).

1

Fig. 3- 13 Me asur ing c h amb er pip e c onnec tions

After installing the measuring chamber a Waste container fill check must be

performed:

1. Insert a full

mechanism W.

2. Press „More - System – T est – Waste Cont ainer sensor“ and measure

the Waste container level by pressing the button „W“ on t he screen.

3. The measured fill level must be equivalent to the actual fill level in the Waste

container W.

4. If the fill levels are not equivalent, check whether the tube at the pressure

sensor (on the analog board) is connected properly.

Waste container W into the analyzer and close the docking

2

3

After installing a new measuring chamber a FMS volume determination must

be performed (see chapter 6).

3.5.3 Changing the measuring chamber cover

Follow steps 1 to 10 of section 3.5.2 on page 3-9.

Service Manual, Roche OMNI C, Rev. 3.0, September 2002 3-11

Page 38

3 Components

3.5.4 Changing the analog board

1. Dismount the measuring chamber (Follow section 3.5.2 on page 3-9).

2. Follow steps 2 to 5 of sect ion 3.5.13 on page 3-19.

3. Open th e screws at th e measuring chamber contact part (see Fig. 3-14, 1 and 2).

1 2

Fig. 3- 14 Me asur ing c h amb er c ont act par t

4. Pull off all cable con nect ion s from the ana log boar d (see Fi g. 3 -15)

Fig. 3-15 Anal og boar d

5. Take ou t th e analog b oar d (by doin g thi s also th e elect rod e lockin g l ever d iseng ages) .

Assembly is done in reverse order.

3-12 Service Manual, Roche OMNI C, Rev. 3.0, September 2002

Page 39

3.5.5 Changing the measuring chamber actuators

1. Dismount the measuring chamber (Follow section 3.5.2 on page 3-9).

2. The hol ders of the va lve h eads can be di smount ed on ly in on e dir ection .

Turn th e holders into the positions according to Fig. 3-16.

3. To disen ga ge the h older s, pr ess int o the d irect ion of t he ar rows at Fig. 3-16.

If neces sar y, move t he va lve hea d by tur nin g the br ass di sk at th e backsi de of th e val ve

(see Fig. 3-17).

4. Open th e moun tin g screws at th e rear of t he mea surin g cham ber a ctuat ors

(see Fig. 3-17) an d take out the actuator .

5. Pull off th e cable con nect ion from th e anal og boar d (see Fig . 3- 17).

3 Components

Fig. 3- 16 Me asur ing c h amb er actu ator s

Fig. 3- 17 Me asur ing c h amb er actu at ors (r e ar vi ew)

Assembly is done in reverse order.

Service Manual, Roche OMNI C, Rev. 3.0, September 2002 3-13

Page 40

3 Components

3.5.6 Changing the sample sensor board

1. Switch off th e OMNI C (please pay attention to

section 3.2 Shutdown on page 3-2!).

2. Pull off the power cord from the power supply unit.

3. Remove t he an alyzer cover .

4. Open th e mea surin g cham ber cover .

5. Open th e scr ew of th e samp le sen sor cover (see Fi g. 3-1 8, 1 ) and rem ove th e cover .

1

Fig. 3- 18 Sam ple s ens or c over

6. Pull th e tube out of the FMS connector sealing 2 (see Fig. 3-19, 1).

1

Fig. 3- 19 Tub e c onn ecti on at F MS c onnec tor s eal i ng 2

3-14 Service Manual, Roche OMNI C, Rev. 3.0, September 2002

Page 41

3 Components

7. Open th e tube c onn ecti on and th e Barex tube con nect ion (see Fi g. 3- 20, 1 an d 2).

2

1

Fig. 3-20 Tube connection and Barex tube connection

8. Push th e tube conn ections to the side and take out the sample sensor boar d (see Fig. 3-21).

9. Pul l of f th e ca ble from th e sa mpl e sen sor boa r d (see Fi g. 3-2 1, 1 ).

Fig. 3- 21 Sam ple s ens or b oard

Assembly is done in reverse order.

3.5.7 Changing the TCon

1. Remove t he an alyzer cover .

2. Open th e mea surin g cham ber cover .

3. Open th e elect r ode locki ng lever .

4. Push the el ectr odes to th e left.

5. T ake out the TCon, by pushing to the rear and upwa rds.

Assembly is done in reverse order.

1

Service Manual, Roche OMNI C, Rev. 3.0, September 2002 3-15

Page 42

3 Components

3.5.8 Changing the electrode locking lever

1. Remove t he an alyzer cover .

2. Open th e mea surin g cham ber cover .

3. Open th e elect r ode locki ng lever .

4. Disenga ge the electrode lockin g lever at the upper side (see Fig. 3-22, 1).

5. Pull off th e tube fr om th e electr ode lock in g lever (see Fi g. 3 -22, 2).

2

1

Fig. 3-22 Electr ode l ocking l ever

Assembly is done in reverse order.

3.5.9 Changing the measuring chamber tubing

1. Press „Mo re - System – Test – valves and Agg regates - val ves“

(see a ls o sec ti on 3.1 4. 5 Te sti ng th e va lve s on pa ge 3 -43)

2. Remove t he an alyzer cover .

3. Open th e mea surin g cham ber cover

4. Switch the valves V3 an d V5 into the opened position in order to lift them fr om the tubes.

5. Open th e scr ew of th e sampl e sen sor boar d cover (see Fi g. 3 -23, 1) an d rem ove the co ver.

6. Pull off the Barex tube from the sample port module (see Fig. 3-23, 2).

7. Pull off the two tubes from the pipes (see Fig. 3-23, 3 and 4).

4

2

1

Fig. 3- 23 Sam ple sens or c ov er / B are x tu be

3-16 Service Manual, Roche OMNI C, Rev. 3.0, September 2002

3

Page 43

8. Ta ke ou t th e me asu rin g ch am ber tu bin g.

Assembly is done in reverse order.

Do not bend the Bare x tube! Damaged areas appear white-coloured.

If this happens, replace t he Barex tube!

3.5.10 Changing the Barex tube

1. Remove t he an alyzer cover .

2. Open th e mea surin g cham ber cover .

3. Open th e scr ew of th e sampl e sen sor boar d cover (see Fi g. 3 -23, 1) an d rem ove the co ver.

4. Pull off the Barex tube from the sample port module (see Fig. 3-23, 2).

5. Pull out the Barex tube from the tube connection (see Fig. 3-24, 1).

3 Components

1

Fig. 3- 24 Bar ex tube c onnect ion

Assembly is done in reverse order.

Do not bend the Bare x tube! Damaged areas appear white-coloured.

If this happens, replace t he Barex tube!

Service Manual, Roche OMNI C, Rev. 3.0, September 2002 3-17

Page 44

3 Components

3.5.11 Changing the FMS connector sealing 1

1. Dismount the measuring chamber (Follow section 3.5.2 on page 3-9).

2. Remove the holder of the FMS conn ector sealing 1 by turnin g left ( see Fig. 3-25, 1)

3. T ake out the FMS conn ector sealing 1 ( see Fig. 3-25, 2).

1

Fig. 3- 25 FMS c onnec t or s eali ng 1

2

Assembly is done in reverse order.

3.5.12 Changing the FMS connector sealing 2

1. Follow steps 1 to 6 of sect ion 3.5.6 Changing the sample sensor board on page 3-14.

2. Pull off the FMS connector sealing 2 fr om the pipe (see Fig. 3-26, 1).

1

Fig. 3- 26 FMS c onnec t or s eali ng 2

Assembly is done in reverse order

3-18 Service Manual, Roche OMNI C, Rev. 3.0, September 2002

Page 45

3.5.13 Changing the tHb/SO2 module

The tHb/SO

can only be replaced as a unit.

Never try to open or disassemble the tHb/SO

calibrated any longer in this case!

1. Dis mou nt th e mea sur ing cha mber co ver (Fol lo w step s 1 to 1 0 of s ect ion 3. 5. 2 on pa ge 3-9 .)

2. T ake out the TCon.

3. Open the two mounting screws at the tHb/SO2 – Module.

(Do not remove the screws completely!)

4. T ake out the tHb/SO

chamber side (see Fig. 3-27, 1).

5. Discon nect the ca ble conn ecti on t o the an alog boa rd (see Fig. 3-2 7, 2).

module is calibrated and sealed at the factory („Fac tory calibration“) and

2

module (pay attention to the tube connection at the right measuring

2

3 Components

module – the module would not be

2

2

Fig. 3-27 tHb/SO2 module

Assembly is done in reverse order.

1

Service Manual, Roche OMNI C, Rev. 3.0, September 2002 3-19

Page 46

3 Components

3.6 Sample port module

3.6.1 Changing the sample port module

1. Switch off the OMNI C (please pay atten tion to section 3.2 Sh utdown on page 3-2!).

2. Pull off the power cord from the power supply unit.

3. Open th e fla p compl etel y.

4. Push th e sample por t upwards until it disen gages from the axis (see Fig. 3-28).

Fig. 3- 28 samp le port

5. Push the need le to th e left , then upwar ds an d take it out (see Fi g. 3 -29).

Fig. 3-29 Needl e

6. Remove the sample drip tray by pulling to the fr ont.

7. Pull off th e connect or fr om th e wash pla te.

8. T ake out the wash pla te by pushing downwards at the front and then pulling out.

9. Position th e flap h orizontally.

10. Open (do not remove) the two mounting screws (see Fig. 3-30, 1 and 2).

3-20 Service Manual, Roche OMNI C, Rev. 3.0, September 2002

Page 47

11. Rem ove th e an alyzer cover .

12. Op en th e meas urin g cham ber cover .

13. Pull off the Barex tube fr om the sample port modul e (see Fig. 3-30, 3).

14. Take out the sample por t module by push ing it upwards and to th e front.

15. Pull off the cable from the flap detection board (Fig. 3-30, 4).

3 Components

1

2

Fig. 3- 30 samp le port modul e

Assembly is done in reverse order.

Pay attention to correct connection of the cable!

4

3

3.6.2 Changing the sample port

1. Press „M ore – System – Wash & cl ean – Clean sampl e port modu le“.

2. Open th e fla p compl etel y.

3. Push th e sample por t upwards until it disen gages from the axis (see Fig. 3-28).

4. Pull off the sample port from the n eedle (see Fig. 3-28).

Assembly is done in reverse order.

Service Manual, Roche OMNI C, Rev. 3.0, September 2002 3-21

Page 48

3 Components

3.6.3 Changing the needle

1. T ake out the sample port (see sect ion 3.6.2).

2. Push the need le to th e left , then upwar ds an d take it out (see Fi g. 3 -29).

Assembly is done in reverse order.

3.6.4 Changing the needle sealing

1. Dismou nt the needl e accor din g to sect ion 3 .6. 3 Chan ging th e needl e on pa ge 3-2 2.

2. Pull off the Barex tube from the sample port module.

3. The need le seal in g fall s out wh en re- conn ectin g the Ba rex tube (see Fig . 3- 31) .

Fig. 3- 31 Need l e s eali ng

Assembly is done in reverse order.

Pay attention to correct ori entation of the needle sealing (see Fig. 3-31)!

3-22 Service Manual, Roche OMNI C, Rev. 3.0, September 2002

Page 49

3.6.5 Changing the flap detection board

1. Dismount the sample port module accor ding to section 3.6.1 Chan ging the sample por t module

on page 3-20.

2. Open th e two scr ews of the side cover (see Fig. 3-32).

3 Components

Fig. 3- 32 Sid e c over of th e sam pl e p ort mod ule

3. Dismount the flap detection board by carefully disengaging the clips (see Fig. 3-33, 1 and 2).

1 2

Fig. 3-33 Flap d etecti on boar d

Assembly is done in reverse order.

Service Manual, Roche OMNI C, Rev. 3.0, September 2002 3-23

Page 50

3 Components

3.7 Peristaltic pump

3.7.1 Changing the peristaltic pump

1. Dismou nt the rear panel accordi ng t o section 3. 3 Dismoun tin g the r ear pan el on p age 3-3 .

2. Remove t he an alyzer cover .

3. Pull off the two cables from the pump (see Fig. 3-34, 1 and 2).

1

2

Fig. 3- 34 Perist altic pump ( rear vi ew)

4. Open th e ten sion l ever ( tran slucen t cover ) of t he per ista ltic p ump and push th e lin ear cl amp

(white plastic part) upwar ds (see Fig. 3-35).

5. T ake out the pump tube.

1

4

2

Fig. 3-35 Perist altic pump

3-24 Service Manual, Roche OMNI C, Rev. 3.0, September 2002

3

Page 51

6. Open the mounting screws of the peristaltic pump (see Fig. 3-35, 1 to 4) and take out the pump.

Assembly is done in reverse order.

Test th e pr oper ope ra ti on of t he per is talt i c pum p un der

„More - System – T est – valves and Aggreg ates - Perist altic pu mp“

(see also sect ion 3.7.6 Testing the peristaltic pump on page 3-27).

3.7.2 Changing the pump head

1. Press „M ore – System“.

2. Remove t he an alyzer cover .

3. Open th e ten sion l ever ( tran slucen t cover ) of t he per ista ltic p ump and push th e lin ear cl amp

(white plastic part) upwar ds (see Fig. 3-35 on pa ge 3-24).

4. T ake out the pump tube.

5. Open th e thr eaded bol t (1, 5 mm al len wr ench) at the pum p hea d.

6. Pull off the pump head.

7. Slid e the new pu mp h ead over the a xis and tigh ten th e threa ded bol t.

The thr eaded bolt must be located at th e flat side of the axis.

3 Components

The pump head must have some clearance below!

8. Place the pump tube around the pump head (the tubes must not be crossed!).

9. Close the ten sion lever (translucent cover ).

10. Pu t th e anal yzer co ver back ont o the an alyzer .

3.7.3 Changing the pump tube

1. Press „More – System“.

2. Remove the an al yzer cov er.

3. Open the ten si on lever (tran slu cent cover ) o f the p erista lti c pum p and pu sh the lin ear cl amp

(white plastic part) upwar ds (see Fig. 3-35 on pa ge 3-24).

4. Take out the pump tube.

5. Place the pump tube around th e pump head (the tubes must not be crossed!).

6. Close the tension lever (translucent cover ).

7. Put the an alyzer cover back on to th e anal yzer.

Service Manual, Roche OMNI C, Rev. 3.0, September 2002 3-25

Page 52

3 Components

3.7.4 Changing the tension lever

1. Press „M ore – System“.

2. Remove t he an alyzer cover .

3. Open th e ten sion l ever ( tran slucen t cover ).

4. Open th e mounting scr ews of the left linear clamp guide (see Fig. 3-36, 1 an d 2).

5. T ake out the linear cla mp guide.

6. Push the lin ear clamp to the left (see Fig. 3-36) and take out the tension lever.

1

2

Fig. 3-36 mount ing sc rews th e left lin ear cl amp gui de

Assembly is done in reverse order.

3.7.5 Changing the pump plate sealing

1. Follow the instructions in section 3.7.1 Changing the peristaltic pump on page 3-24.

2. Pull off th e pump pl ate sea lin g from th e pla te.

Assembly is done in reverse order.

3-26 Service Manual, Roche OMNI C, Rev. 3.0, September 2002

Page 53

3.7.6 Testing the peristaltic pump

Press „Mo re – System – Test – Valves and agg regates – Peristal tic pu mp“.

The peristaltic pump can be tested at four speeds via this fun ction.

The pump can be a ctivated only coun ter-clockwise because a clock wise rotation would draw flui d

out of th e Was te con tain er.

Followi ng 4 speeds a r e selecta ble:

• 5 µl/s

• 12 µl/s

• 40 µl/s

• 80 µl/s

Additionally displayed values are:

• The pump volume in µl/Revolution

• The FMS volume in µl

3 Components

Fig. 3- 37 T esting t he P eris tal tic pu mp

3.8 PC tower

3.8.1 General Information

The PC tower con tains following components:

PC unit

Colour screen

2” Thermo p rin ter

• MBX board (with PCMCIA sl ot)

• Connectors: 2x RS232, 1x Ethernet, 1x PS/2 (Barcode)

• Connector for the power supply un it

• Connect ors t o the modu les

• 20 pin communi cation cable

• see secti on 3. 8.3

• see secti on 3. 8.6

Service Manual, Roche OMNI C, Rev. 3.0, September 2002 3-27

Page 54

3 Components

Modul

J34

LCD EL0290

Backlight

(2)

DISPLAY

MODUL

BP2550

BV2259

(2)

FAN

(2)

BV2259

ZPA

(16)

BV2219

Power Supply

EN0364

BV2220

Printer

ST8

Interface

Board

BV2225

Thermal line

(7)

(26)

J13ST7

BV2227

(15)

J2

J5

BV2224

J8

J9

J3

J4

(8)

Touch panel

J3

Display

Interface

Board

BB0979

J1

J4

(40)

J2

J7

MBX Driver

Board

BB0978

P1

J1

(144)

J5

J12

MBX

Board

EN0366

J15

BV2229

(6)

EN0365

(20)

J6

(7)

BV2233

BV2218

(25)

BV2217

BV2226

J12

BV2226

J13

BV2228

J10

Tower

BP2464

Actuator

PP

MC

(10)

Modem

(10)

RS 232

(6)

Barcode

Scanner

DATA BUS

printer

POWER BUS

10BASE-T

EN0369

Fig. 3- 38 Bloc k d i agram P C to wer

3-28 Service Manual, Roche OMNI C, Rev. 3.0, September 2002

Page 55

3.8.2 Changing the PC tower

1. Dismou nt the rear panel accordi ng t o section 3. 3 Dismoun tin g the r ear pan el on p age 3-3 .

2. Remove t he an alyzer cover an d the prin ter cover.

3. Pull off all cables from the PC tower.

4. Remove the mounting screws of the PC t ower (see Fig. 3-39, 1 to 3).

1

3 Components

2

3

Fig. 3- 39 PC tower (rear view)

5. Pull out the PC tower to the rear .

6. Remove the screen cover by open ing the screws (see F ig. 3-40, 1 to 3).

1

2

3

Fig. 3- 40 sc reen c o ver m ounti ng s cr ews

Assembly is done in reverse order.

Service Manual, Roche OMNI C, Rev. 3.0, September 2002 3-29

Page 56

3 Components

3.8.3 Screen

Type: KYOCERA KCS057QV1AA-A47 with touch screen

Resolution: ¼ VGA Display 5,7”

Dimensions: 154,6 x 114,8 x 8,5 mm

Contrast: min. 10, typ. 25

Reaction t ime: typ. 220 ms

Screen format: 320 x 3 (B) x 240 (H)

Pixel dimensions: 0,1 x 0,34

Line format: 0,12 x 0,36

Operating temperature: 0°C to 50°C

Power consumption: 200 t o 300mW (wit hout backlight)

Backlight : CFL, ch angeable, lifetime approx. 40.000h

Displ ay Int er face Boar d (in clud ing t ouch scr een el ectron ics)

3.8.4 Changing the screen

1. Switch off the OMNI C (please pay atten tion to section 3.2 Sh utdown on page 3-2!).

2. Pull off the power cord from the power supply unit.

3. Remove t he an alyzer cover an d the prin ter cover.

4. Dismount the sample port module accor ding to section 3.6.1. Ch anging the sample port module

on page 3-20).

5. Dismount the screen cover by op ening the mounting screws (see Fig. 3-41, 1 to 3).

1

Fig. 3- 41 Scr een c over mou ntin g sc r ews

2

3

3-30 Service Manual, Roche OMNI C, Rev. 3.0, September 2002

Page 57

6. Remove t he t wo screws of th e scr een (see Fi g. 3 -42, 1 an d 2).

1

2

Fig. 3-42 Screen

7. Unplu g th e two conn ector s, p ull off t he ca ble an d take out the scr een .

Assembly is done in reverse order.

3 Components

Reinstall the two contact strips at the housing sides according to Fig. 3-43, 1 and 2.

1 2

Fig. 3- 43 Cont ac t st ri ps

3.8.5 Changing the backlight

1. Follow section 3.8.4 Changing the screen on page 3-30.

2. Pull off th e connect or fr om th e fluor escent tube ( see Fi g. 3-4 4, 1) .

3. Open th e mounting scr ew (see Fig. 3-44, 2) an d take out the fluor escen t tube.

Service Manual, Roche OMNI C, Rev. 3.0, September 2002 3-31

Page 58

3 Components

Fig. 3- 44 Scr een (r ear vi ew)

Assembly is done in reverse order.

1

2

Reinstall the two contact strips at the housing sides according to Fig. 3-43, 1 and 2.

3.8.6 Changing the printer

1. Switch off the OMNI C (please pay atten tion to section 3.2 Sh utdown on page 3-2!).

2. Pull off the power cord from the power supply unit.

3. Rem ove t h e pr in ter cover .

4. Remove the printer mounting screws (s ee Fig. 3-45, 1 and 2).

1

2

Fig. 3-45 Print er moun ting sc rews

5. Lift th e prin ter careful l y and unp lug th e two cabl es.

3-32 Service Manual, Roche OMNI C, Rev. 3.0, September 2002

Page 59

Assembly is done in reverse order.

Test th e pr inter un der „More - System – T est – PC componen ts- print er“.

3.8.7 Changing the MBX board

1. Follow section 3.8.2 Changing the PC tower on page 3-29.

2. Open th e mounting scr ews of the PC tower rear panel (see Fig. 3-46, 1 to 4).

1 2

3 Components

3 4

Fig. 3- 46 PC tower (rear view)

3. Lift th e rear panel and un plug th e cabl e conn ecti ons (see Fi g. 3 -47, 1).

1

Fig. 3-47 PC tower (open ed)

4. Pull off all cable con nect ion s from the MBX boar d.

5. Dismount the PCMC IA slot.

6. Open th e mounting scr ews and take out the MBX board.

Service Manual, Roche OMNI C, Rev. 3.0, September 2002 3-33

Page 60

3 Components

Assembly is done in reverse order.

Pay attention to proper cable connections and correct orientation of the PCMCIA slots

to the MBX board!

3.8.8 Changing the MBX board battery

Type: Sanyo CR14250SE (Primary Lithium Battery)

Voltag e: 3V

Capacity: 850mAh

Dimensions: 14,5 x 25mm

1. Dismou nt the rear panel accordi ng t o section 3. 3 Dismoun tin g the r ear pan el on p age 3-3 .

2. Rem ove t h e pr in ter cover .

3. Open th e mounting scr ews of the PC tower rear panel (see Fig. 3-46, 1 to 4 on page 3-33).

4. T ake the MBX boar d battery out of t he holder (see Fig. 3-48, 1)

1

Fig. 3- 48 MBX boar d batt ery

Assembly is done in reverse order.

3-34 Service Manual, Roche OMNI C, Rev. 3.0, September 2002

Page 61

3.9 Cables

3 Components

1

Fig. 3-49 Cables

3.9.1 Changing the data bus cable

1. Dismou nt the rear panel accordi ng t o section 3. 3 Dismoun tin g the r ear pan el on p age 3-3 .

2. Pull off th e data bus ca ble (g ra y flat ca ble) fr om al l comp onent s (see Fi g. 3 -49, 1).

(Dism ount th e mea sur ing cham ber i f necessa ry).

Assembly is done in reverse order.

3.9.2 Changing the DC power cable

2

1. Dismou nt the rear panel accordi ng t o section 3. 3 Dismoun tin g the r ear pan el on p age 3-3 .

2. Pull off th e DC power ca ble fr om al l compon ent s (see Fi g. 3-49, 2).

(Dism ount th e mea sur ing cham ber i f necessa ry).

Assembly is done in reverse order.

Service Manual, Roche OMNI C, Rev. 3.0, September 2002 3-35

Page 62

3 Components

3.10 Fan

3.10.1 Changing the fan

1. Dismou nt the rear panel accordi ng t o section 3. 3 Dismoun tin g the r ear pan el on p age 3-3 .

2. Dismou nt the left s ide co ver by rem ovin g th e three m ount ing scr ews in the r ear comp art ment

and in the bottle compartment (see Fig. 3-50, 1 to 3).

1

3

2

Fig. 3- 50 Mou nti ng s cr ews of th e left s ide c o ver

3. Dismount the measuring chamber accor ding to section 3.5.2 on page 3-9.

4. Open th e mounting scr ews of the fan an d take it out (see Fig. 3-51).

Fig. 3-51 Fan

3-36 Service Manual, Roche OMNI C, Rev. 3.0, September 2002

Page 63

5. Pull off th e fan ca ble from the Pu mp boar d (see Fi g. 3- 52, 1).

1

Fig. 3- 52 Fan c able c on nect i on at th e P ump boar d

Assembly is done in reverse order.

3 Components

3.11 Micr o sw itch uni t (Bo ttle com par tmen t co ver swit ch)

3.11.1 General Information

The micro switch unit detects the position of the bottle compartment cover.

The wh ite plastic part of the micro switch unit can be lock ed in the closed position by pushing back

and upwards to simulate a closed bottle compartment cover (see Fig. 3-53).

Fig. 3- 53 Mic ro s wi tch in u nloc k ed / l ock ed p ositi on

Test the micro switc h unit by moving the bottl e compartment cover!

Service Manual, Roche OMNI C, Rev. 3.0, September 2002 3-37

Page 64

3 Components

3.11.2 Changing the micro switch unit

1. Dismou nt the rear panel accordi ng t o section 3. 3 Dismoun tin g the r ear pan el on p age 3-3 .

2. Dismou nt the left s ide co ver by rem ovin g th e three m ount ing scr ews in the r ear comp art ment

and in the bottle compartment (see Fig. 3-50, 1 to 3).

3. Pull off the micro switch unit cable from the Pump board (see Fig. 3-54).

Fig. 3- 54 Mic ro s wi tch unit

4. Open the mounting screws of the micro switch unit in the bottle compartment

(see Fig. 3-1) and take out the micro switch unit.

2

1

Fig. 3-55 Micr o switch u nit m ounting screws

Assembly is done in reverse order.

3-38 Service Manual, Roche OMNI C, Rev. 3.0, September 2002

Page 65

3.12 Micro switches

3.12.1 Changing the Waste container micro switch

1. Dismou nt the rear panel accordi ng t o section 3. 3 Dismoun tin g the r ear pan el on p age 3-3 .

2. Dismou nt the left s ide co ver by rem ovin g th e three m ount ing scr ews in the r ear comp art ment

and in the bottle compartment (see Fig. 3-50, 1 to 3).

3. Pull off th e connect ors fr om th e micr o switch (see F ig. 3-56 ).

4. Open th e mounting scr ews (see Fig. 3-56) an d take out the micr o switch.

3 Components

Fig. 3- 56 W aste c ont ai ner micr o s w itch (r ear view )

Assembly is done in reverse order.

3.12.2 Changing the C3 docking mechanism micro switch

1. Dismou nt the rear panel accordi ng t o section 3. 3 Dismoun tin g the r ear pan el on p age 3-3 .

2. Dismount the measuring chamber accor ding to section 3.5.2 on page 3-9.

3. Pull off th e connect ors fr om th e micr o switch (see F ig. 3-57 ).

4. Open th e mounting scr ews (see Fig. 3-57) an d take out the micr o switch.

Fig. 3- 57 C3 d oc ki ng m ech anis m micr o s witc h

Assembly is done in reverse order.

Service Manual, Roche OMNI C, Rev. 3.0, September 2002 3-39

Page 66

3 Components

3.12.3 Testing the micro switches

Press „More – System – T est – Cont rol sensors – Moni toring sen sors“.

Fig. 3- 58 T esting t he micr o s witc hes

3.13 Power supply unit

3.13.1 Technical data

Pin assignment:

15 Pin Sub-D, fema le

Pin No. Assignment

1 +12V

2

3 5V (5-Dig)

4 5V (5-Dig)

5 5V (PWR)

6 5V (PWR)

7 5V (PWR)

8 24V

9 -12V

10 GND (5-Dig)

11 GND (PWR)

12 GND (PWR)

13 GND (PWR)

14 GND (24V)

15 24V

GND (±12V)

3-40 Service Manual, Roche OMNI C, Rev. 3.0, September 2002

Page 67

3.13.2 Changing the power supply unit

1. Dismou nt the rear panel accordi ng t o section 3. 3 Dismoun tin g the r ear pan el on p age 3-3 .

2. Remove the power supply unit from the r ear panel; a cer tain amount of for ce is needed because

of the mounting with Velcro tape

Assembly is done in reverse order.

3.14 Valves

3.14.1 General Information

The 3 va lve t ypes used i n th e anal yzer h ave diff eren t cable len gth s (S , L, XL):

Valve No. Name Description

V4 MC bypass valve VALVE XL OMNI C

V6 MC out VALVE S OMNI C

V7 Conditioner VALVE S OMNI C

V8 Refer ence Sol u ti o n VALVE S OMNI C

V9 Venti lation VALVE S OMNI C

V10 Cleaning Solution VALVE S OMNI C

V11 Zero point solut ion VALVE L OMNI C

V12 AQC valve VALVE S OMNI C

V13 AQC wash valve VALVE S OMNI C

V14 Bypass VALVE L OMNI C

3 Components

The needed valve head configuration has to be installed before mounting the valve

in the analyzer (see sect ion 3.14.2 Single valve head and 3.14.3 Double valve head).

3.14.2 Single valve head

1. Insta ll th e sin gle val ve hea d.

2. Press on th e holder ont o the axi s from the sid e. If neces sar y, move t he val ve hea d by tur nin g the

brass disk at the back side o f the va lve.

Fig. 3- 59 Sin gle V al ve head

Service Manual, Roche OMNI C, Rev. 3.0, September 2002 3-41

Page 68

3 Components

3.14.3 Double valve head

1. In stall the double valve h ead.

2. Press on th e holder ont o the axi s from the sid e. If neces sar y, move t he val ve hea d by tur nin g the

brass disk at the back side o f the va lve.

3. Atta ch th e bar and place th e scr ews in th e open ing s.

4. Push th e screws thr ough the plate and tigh ten them.

Fig. 3- 60 Dou bl e Val ve head

3.14.4 Changing the valves

Never connect or disconnect the valves while the analyzer is running!

Pay attention to proper connection of the valves at the respect ive boards!

1. Dismou nt the rear panel accordi ng t o section 3. 3 Dismoun tin g the r ear pan el on p age 3-3 .

2. Discon nect the va lve ca ble from th e respect ive b oar d.

3. Ta ke ou t th e tu be(s ) - d is mou nt the val ve h ead an d/ or th e bar if n ecessa r y.

4. Press ou t th e valve from th e backs ide.

Assembly is done in reverse order.

3-42 Service Manual, Roche OMNI C, Rev. 3.0, September 2002

Page 69

3.14.5 Testing the valves

Press „More - Syst em – Test – valves“.

The val ves can be swit ched once or for cons ecut ive 10 tim es.

The st ate of th e sel ected va lve i s disp la yed gra phical ly.

3 Components

Fig. 3- 61 T esting t he valv es

Schematic drawings of the measur ing chamber and the bottle compartment help to locate the

select ed val ve.

Fig. 3-62 Schem atic dr awin g of the meas uri ng cham ber

Fig. 3- 63 Schem atic dr awin g of the b ottle c ompart ment w ithout A utoQC (left) and with A utoQC (right )

Service Manual, Roche OMNI C, Rev. 3.0, September 2002 3-43

Page 70

3 Components

3.15 Actuator board

3.15.1 Changing the Actuator board

1. Dismou nt the rear panel accordi ng t o section 3. 3 Dismoun tin g the r ear pan el on p age 3-3 .

2. Pull off all cable con nections from the Actuator board.

3. Disen gag e the Act uator boar d from th e cli ps by pres sin g them t ogeth er at th e top

(see Fig. 3-64, 1 an d 2).

4. Ta ke ou t th e A ctu ator boa rd.

1

Fig. 3- 64 Act uat or b oar d

Assembly is done in reverse order.

Pay attention to proper cable connections!

2

3-44 Service Manual, Roche OMNI C, Rev. 3.0, September 2002

Page 71

3.16 Pump board

3.16.1 Changing the Pump board

1. Dismou nt the rear panel accordi ng t o section 3. 3 Dismoun tin g the r ear pan el on p age 3-3 .

2. Pull off all cable con nections from the Pump board.

3. Remove the mounting screw of t he Pump board (see Fi g. 3-65, 1).

4. Ta ke ou t th e P ump boa r d.

1

3 Components

Fig. 3-65 Pump b oard

Assembly is done in reverse order.

Pay attention to proper cable connections!

3.17 Docking mechanisms

3.17.1 Changing the docking mechanism Waste W

1. Open the bottle compartment cover.

2. Open th e docki n g mechan ism Wa ste W.

3. Take ou t th e Wast e contain er.

Service Manual, Roche OMNI C, Rev. 3.0, September 2002 3-45

Page 72

3 Components

4. Open th e moun tin g screw o f the d ocking mechan ism Waste W (see F ig. 3-66 ).

Fig. 3- 66 docki ng mech anis m-m ountin g scr ew

5. Pull off th e tube fr om the t op of th e docki ng mech ani sm Wast e W and cl ose th e flap in order t o

prot ect th e tran slucen t pl asti c from bei ng damaged when p ullin g out th e docki ng m echan ism

(see Fig. 3-67).

Fig. 3- 67 Tub e c onn ecti ons at th e top of doc ki ng m ech anis m W

6. Pull out th e dockin g mech ani sm Wast e W to the fr ont.

7. Pull off th e tube fr om th e backsi de of th e docki ng m echan ism (see F ig. 3-68 ).

Fig. 3- 68 dock ing mec hanis m W (r ear view)

Assembly is done in reverse order.

3-46 Service Manual, Roche OMNI C, Rev. 3.0, September 2002

Page 73

3 Components

3.17.2 Changing the docking mechanisms Calibration solution C1 and C2

1. Open the bottle compartment cover.

2. Open the docking mechanism calibration solution C1 (or C2).

3. Take out the C1 (or C2) bottle.

4. Open th e mounting scr ew of docki ng mechanism C1 (or C2) (see Fi g. 3-69).

Fig. 3-69 Docki ng mec hanis m mount ing sc rew

5. Pull out the respective docking mechan ism C1 (or C2) to the front.

6. Pull off th e tube fr om th e backsi de of th e docki ng m echan ism (see F ig. 3-70 ).

Fig. 3- 70 Docki ng mec hanis m C1 and C2 (rear vi ew)

Assembly is done in reverse order.

Service Manual, Roche OMNI C, Rev. 3.0, September 2002 3-47

Page 74

3 Components

3.17.3 Changing the docking mechanism Pack C3

1. Open the bottle compartment cover.

2. Open th e docki n g mechan ism Pa ck C3.

3. T ake out the Pack C3.

4. Pull out th e dockin g mech ani sm Pack C3 to th e front (a cer tain a mount of force i s n eeded)

5. Pull off the tubes from the docking mechanism (see Fig. 3-71).

1...Reference Solution

2...Conditioning Sol.

3...Zero point Solution

4...Cleaning Solution

Fig. 3-71 Docki ng mec hanis m C3

Assembly is done in reverse order.

Pay attention to correct connection of the tubes to the upper row of connectors at the

docking mechanism (see Fig. 3-71)!

3-48 Service Manual, Roche OMNI C, Rev. 3.0, September 2002

Page 75

3.18 Analyzer tubing

3.18.1 Preparation