Page 1

Miditron® Junior II

Service Manual

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 1

Page 2

Table of contents

Short operating instructions ........................................................................6

1. General Note..................................................................................................7

1.1 Limitations .............................................................................................................7

1.2 Mailing / telephone address................................................................................. 7

1.3 Security advice ......................................................................................................8

1.4 Confirmation declaration.................................................................................... 10

2. Documentation ............................................................................................ 11

2.1 Update service for this manual ..........................................................................11

2.2 Instrument code for service ...............................................................................11

3. Introduction ................................................................................................. 1 2

3.1 System description .............................................................................................12

3.1.1 Function Elements ............................................................................................ 13

3.1.2 Measuring Principle .......................................................................................... 15

3.1.3 Concentration Table (Program I) ....................................................................... 17

3.1.4 Changing Range Remisson Bordes.................................................................. 18

3.2 System Specification .......................................................................................... 19

3.3 Service Concept ..................................................................................................20

3.3.1 Service level....................................................................................................... 20

3.3.2 Handling of warranty and repairs ..................................................................... 20

4. Installation................................................................................................... 25

4.1 Checking for Damage in Transit......................................................................... 25

4.2 Unpacking ............................................................................................................25

4.3 Proper Setting ..................................................................................................... 25

4.4 Setting Up ............................................................................................................ 25

4.5 Inserting Printer Paper ....................................................................................... 27

5. Calibration ...................................................................................................2 8

6. Operation ..................................................................................................... 3 1

6.1 Overview ..............................................................................................................31

6.2 Normal Mode........................................................................................................ 32

6.3 Accelerated Mode................................................................................................ 32

6.4 Fast Mode.............................................................................................................32

6.5 Principle movement of the Miditron® Junior II.................................................33

7. Service mode and adjustment .................................................................... 3 4

7.1 How to make adjustments .................................................................................. 34

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 2

Page 3

Table of contents

7.2 General ................................................................................................................. 35

7.3 Procedure............................................................................................................. 35

8. Adjustment / Dismantling ........................................................................... 4 0

9. Mechanics .................................................................................................... 41

9.1 Mechanical moduls..............................................................................................41

9.1.1 T ransport arm .................................................................................................... 41

9.1.2 Tray..................................................................................................................... 41

9.1.3 T op of housing................................................................................................... 42

9.1.4 PCB Main ........................................................................................................... 43

9.1.5 PCB Interface ..................................................................................................... 44

9.1.6 Display ............................................................................................................... 45

9.1.7 Printer ................................................................................................................ 46

9.1.8 Status LED ......................................................................................................... 47

9.1.9 Keyboard ............................................................................................................ 48

9.1.10 PCB Measuring Head......................................................................................... 49

9.1.11 LB Measuring Head Home Position.................................................................. 5 0

9.1.12 LB Home P osition.............................................................................................. 51

9.1.13 Motor Belt Drive Cross T ransport...................................................................... 52

9.1.14 Motor Measuring Head Unit .............................................................................. 53

9.1.15 Tooth Bar Measuring Head Unit........................................................................ 54

9.1.16 Carrier for tray.................................................................................................... 55

9.1.17 Reference Field Carrier...................................................................................... 56

9.1.18 Crossbar complete ............................................................................................ 57

9.1.19 Cross Transport ................................................................................................. 58

10. Electronics................................................................................................. 5 9

10.1 Overview Electronics ..........................................................................................59

10.2 Power supply ....................................................................................................... 60

10.3 Electronic modules .............................................................................................62

10.3.1 PCB Main ........................................................................................................... 6 2

10.3.2 PCB Interface ..................................................................................................... 65

10.3.3 Display ............................................................................................................... 67

10.3.4 Printer ................................................................................................................ 67

10.3.5 Status LED ......................................................................................................... 67

10.3.6 Keyboard ............................................................................................................ 68

10.3.7 PCB Measuring Head......................................................................................... 68

10.3.8 LB Measuring Head Home Position.................................................................. 69

10.3.9 LB Home Position.............................................................................................. 69

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 3

Page 4

Table of contents

10.3.10 LB reference position ........................................................................................ 70

10.3.11 Motor Belt Drive Cross Transport...................................................................... 70

10.3.12 Motor Measuring Head Drive............................................................................. 71

10.4 Circuit diagram .................................................................................................... 72

10.4.1 PCB Main ........................................................................................................... 7 2

10.4.2 PCB Interface ..................................................................................................... 77

10.4.3 PCB Measuring Head......................................................................................... 81

11. Software..................................................................................................... 8 2

11.1 Overview ..............................................................................................................82

11.2 Flow Diagram of Menu Selection ....................................................................... 83

11.2.1 Flow Diagram of the W orklist Men u.................................................................. 84

11.2.2 Flow Diagram of the Working Mode Menu ....................................................... 85

11.2.3 Flow Diagram of the Reprint Menu ................................................................... 8 6

11.2.4 Flow Diagram of the Setup Menu ..................................................................... 8 7

11.2.4.1 Flow Diagram of Color Setup ........................................................................... 89

11.2.4.2 Flow Diagram of Clarity Setup .......................................................................... 90

11.2.4.3 Flow Diagram of Parameter Setup .................................................................... 91

11.3 Service/Status Software .....................................................................................92

11.4 Software update ..................................................................................................92

11.4.1 Software update via chip cards......................................................................... 92

11.4.2 Software update via printer interface................................................................ 93

11.5 Loading instrument settings via Download...................................................... 97

11.5.1 Specification of the INI-file................................................................................ 98

11.6 Saving instrument settings via Upload ...........................................................100

12. Interface ................................................................................................... 1 01

12.1 Host Interface .................................................................................................... 101

12.2 Character definitions, representation conventions........................................ 102

12.3 Protocols ............................................................................................................103

12.4 Upload timing and handshake ......................................................................... 106

12.5 Download timing and handshake ....................................................................108

12.6 Protocol structure ............................................................................................. 110

12.6.1 Protocol "/REP/": Repeat request ....................................................................110

12.6.2 Protocol "/SPM/": Start Communication .........................................................110

12.6.3 Protocol "/MOR/": Receipt confirmed/Request for next set ............................110

12.6.4 Protocol "/END/": End of communication .......................................................11 0

12.6.5 Protocol "/SPE-D/ + Data": Data protocol color + turbidity...........................11 1

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 4

Page 5

Table of contents

12.6.6 Protocol "/SPE-E/ + Data": Data protocol results .........................................11 1

12.6.7 Protocol "/SPE-A/ + Pat-Id.": Data protocol Pat-Id. .......................................112

12.7 Format of results-data : ....................................................................................112

12.7.1 Structure of results-data Programm-1 (International) : ...................................112

12.8 Procedures for checking test bytes................................................................. 114

12.8.1 European language variations of Miditron® software: LRC test bytes ..........114

12.8.2 American/Canadian language version of Miditron® Junior II software:........11 5

12.8.3 Automatic adaption to the test procedure used by the host ..........................11 6

13. T roubleshooting....................................................................................... 117

13.1 Error at self-test................................................................................................. 117

13.2 Repairable errors during normal mode........................................................... 118

13.3 Non-repairable errors during normal mode (Major Error) ............................ 119

13.4 Errors during INI-file Download....................................................................... 120

13.5 List of all error codes ........................................................................................121

14. Spare Parts .............................................................................................. 12 7

14.1 Complete spare part list.................................................................................... 127

14.2 Part i dentification ..............................................................................................128

14.3 Exploded view Miditron® Junior II...................................................................131

15. Instrument, Strips, Accessories ............................................................. 133

15.1 Complete list ...................................................................................................... 133

16. Interface Assignment .............................................................................. 1 3 4

16.1 Host/PC interface ..............................................................................................134

16.2 External Printer interface.................................................................................. 135

16.3 Barcode reader interface .................................................................................. 135

17. Routine Care and Cleaning ..................................................................... 1 3 6

17.1 General ............................................................................................................... 136

17.2 Cleaning .............................................................................................................136

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 5

Page 6

Short operating instructions

Directions in Brief

Please read carefully the sections marked with this symbol in the margin!

Miditron® Junior II is designed for ease of use. To carry out routine strip measurements in Normal Mode

(sequential reading with automatic consecutive numbering), proceed as follows :

Switch on Miditron

Please empty the waste tray.

Once the waste tray is empty and the self-check has finished, the analyz er is

ready . Y ou see displa yed.

1. Press <Start> and follow the display messages:

2. When the status LED flashes green and the beep tone sounds ("Dip Strip 1" is displayed), briefly dip

the test strip in the urine sample (for about 1 second) and then remove it again, drawing the edge of

the strip over the rim of the specimen container to wipe off excess urine.

3. While the status LED is green, you may insert the test strip, reagent zones upwards , into the insertion

area between the two guides on the leading edge of the strip receiving tray.

The end of the test strip must be supported by the rear inside edge of the strip receiving tray

(Fig. 10).

WARNING: To prevent injury, keep hands a way fr om the analyzer when it is transporting

test strips!

4. After about 20 seconds the first test strip will be transported from the waiting position to the

measuring position and "Please W ait" will be display ed. When the display shows "Dip Strip 2", repeat

the procedure for the second and any subsequent test strips.

®

Junior II. You see displayed:

Empty Waste Tray

"Please empty the waste tray"

READY - <START>

"The analyzer is ready to

measure"

5. The first test strip will be measured 60 seconds after it was dipped and the result will be automatically

printed as long as the internal printer was not disabled in the SETUP menu. When a strip is no longer

detected at the measuring position, Miditron® Junior II automatically returns to the initial state

("READ Y - <START>" is display ed).

IMPORTANT:

Before operating Miditron® Junior II for the first time, y ou have the option of entering various

settings in the SETUP menu.

For your own safety, and to avoid operator err ors, please read the f ollowing operating

instructions carefully .

Please refer to the relevant sections of the Operator’s Manual for information on selection of SET-

UP menu options, calibration, working with Patient ID’s, cleaning and maintenance.

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 6

Page 7

1. General Note

1.1 Limitations

The data and information provided in this manual correspond

to the state of knowledge existing at the time of introducing

the Miditron® Junior II on the market. Any important

changes will be taken into account in the next edition of this

manual.

The packaging leaflet should be regarded as authoritative.

This service manual was created for the telephone service

and technical service staff.

The operation manual contains special information for the

telephone service.

1.2 Mailing / telephone address

Service department, DA-ST

Telephone: +49 (0) 621 / 759 / 3227

Fax: +49 (0) 621 / 759 / 3985

Hot-line logistic (RA)

Telephone: +49 (0) 621 / 759 / 8094

Fax : +49 (0) 621 / 759 / 8093

When calling from outside Germany , add the international

dialing code at the beginning and omit the first ‘0’.

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 7

Page 8

1. General Note

1.3 Security advice

Please carefully read the paragraphs marked by a

warning triangle!

This instrument was constructed in accordance with DIN

VDE 0750, P art 1/DIN IEC 601, Part 1, “Medical Electrical

Equipment; Part 1: General Requirements for Safety”

and checked to meet all technical demands on safety

before leaving the factory .

The instrument received the „GS“ (Geprüfte Sicherheit =

safety-tested) label for meeting the safety requirements of

the VDE (V erein Deutscher Elektronik-Hersteller = Society of

German Electronics Manufacturers) and meets the

requirements of the MedGV (Medizinische Geräteverordnung

= Medical Instrument Regulation).

T o maintain these conditions and guarantee saf e operation,

the operator should read this information and observe the

warnings given in these operating instructions.

The instrument should be used only with the external power

supply included in the delivery .

This instrument belongs to Protection Class I (protective

conductor).

Do not insert the plug into any type of AC outlet other than a

shock-proof outlet. Do not use an extension cord without a

protective conductor to prevent that the protective effect is

circumvented.

Interrupting the earth conductor inside or outside of the

instrument or disconnecting the earth conductor lug

may create a hazardous situation for the operator .

Do not open the covers or remove parts that cannot be

opened or removed by hand, as this can e xpose live parts.

Connectors may also be live. Any adjustment, maintenance

or repair on an opened instrument with the power on should

be carried out only by trained personnel authorized by Roche

Mannheim who are aware of the danger involved.

If you suspect that the instrument can no longer be operated

safely, turn it off and take steps to ensure that it cannot be

turned on accidentally . Make certain that the Miditron

Junior II is oper ated by trained personnel only.

®

T o prevent injury , keep hands a way from the analyzer

when it is transporting a strip.

A personal computer or printer connected to the analyzer

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 8

Page 9

1. General Note

must meet the regulations of EN 60950, UL 1950 or CSA

C22.2 No. 950.

General Information:

The data and information contained in this manual are

current as of issue. Any basic changes will be included in

subsequent editions. In case of uncertainty, the package

insert included with the product in question shall prevail.

The instrument meets the requirements of Overvoltage

Class 2 and Pollution Class 2.

Medical Instrument Regulation („MedGV“)

MedGV is a safety regulation for technical medical

instruments (effective only in Germany).

According to the MedGV of 01/14/85, the Miditron® Junior II

is classified in Group 3. The user m ust follow the proper

guidelines for Group 3.

Reference:

Regulation on Safety of Technical Medical Instruments.

Author: Adolf Krebs, ISBN 3-921958-41-S, 1985 Bibliomed.

Published by: Medizinische V erlagsgesellschaft mbH,

Melsungen.

Miditron® Junior II should be used by qualified persons

only.

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 9

Page 10

1. General Note

1.4 Confirmation dec laration

Confirmation declaration for electromagnetic compatibility

according to the laws of the European Union.

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 10

Page 11

2. Documentation

2.1 Update service for this manual

New information and modifications will be sent via T echnical

News. Please send us your name and address to ensure

you receive updates automatically.

Update Service:

Fax this page to Technical Service-Roche Mannheim

+49 (0)621 759 3985

Name:......................................................

Address:..................................................

..................................................................

..................................................................

F AX No. + ____ _____________________

You will find the version identification in the bottom line of

every page.

Explanation of the index:

Service Manual Miditron® Junior II / ID 1702602 / MJ / Vers.

1.0 - June 1998 / P age 5

Instrument: Miditron® Junior II

Order- number: 1702602

Instrument code: MJ

Version: 1.0

Date of edition: June 1998

Page: 5

2.2 Instrument code for service

The service code of Miditron® Junior II is: MJ

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 11

Page 12

3. Introduction

3.1 System description

Urine test strips simplify laboratory diagnosis through their

ease of use, sensitivity and specificity. These benefits allo w

you to identify pathological changes in the urine quickly and

reliably.

Automated urinalysis with Miditron® Junior II assures that

the reading of results is standardized by eliminating

potential sources of error associated with visual reading of

test strips (such as unfavourab le lighting conditions at the

workplace, differences in operators’ ability to discriminate

between colours and keep to prescribed times, etc.). The

test strips used are multi-parameter strips for measuring

specific gravity, pH, leukocytes, nitrite, protein, glucose,

ketone, urobilinogen, bilirubin and erythrocytes in urine.

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 12

Page 13

3. Introduction

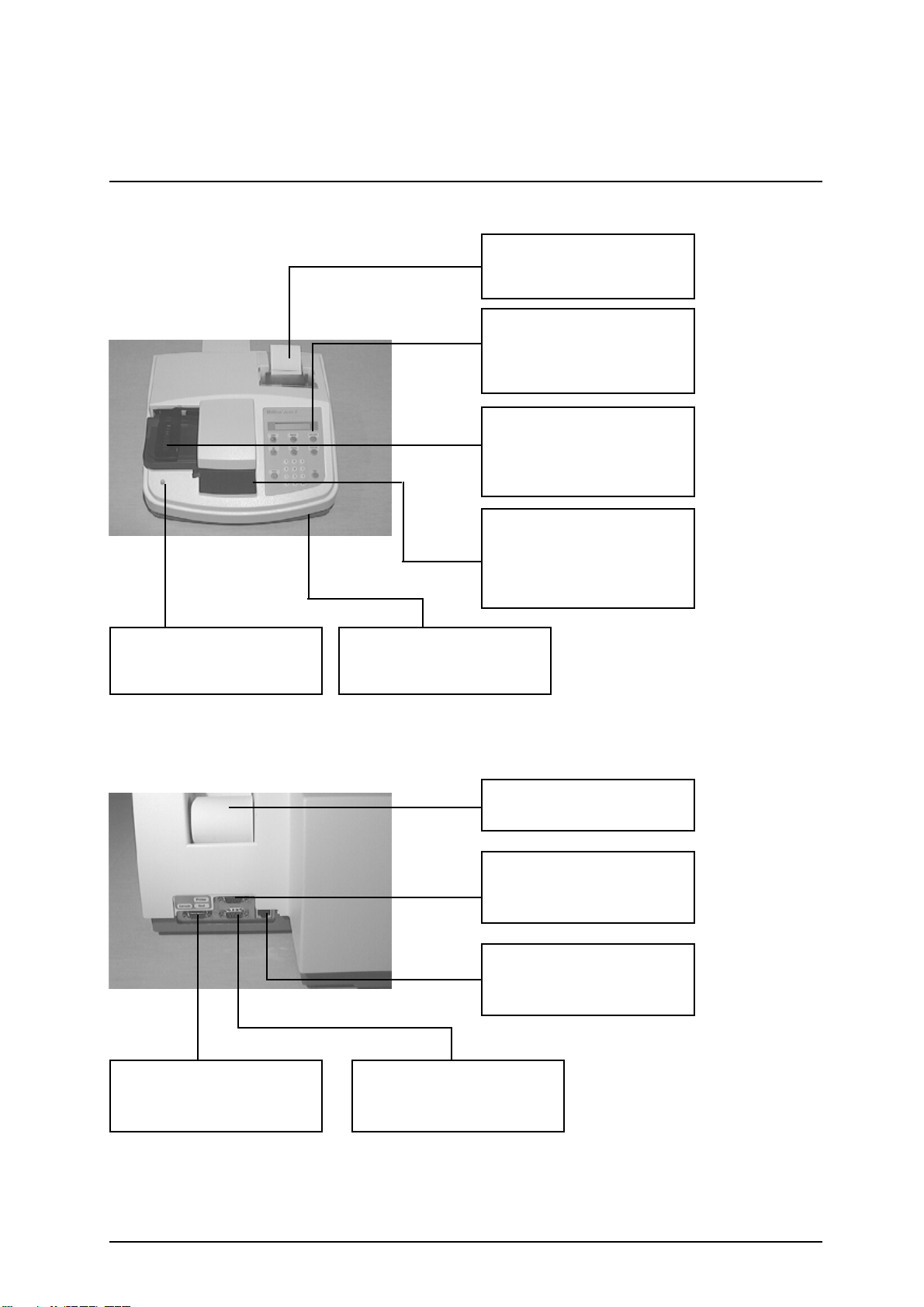

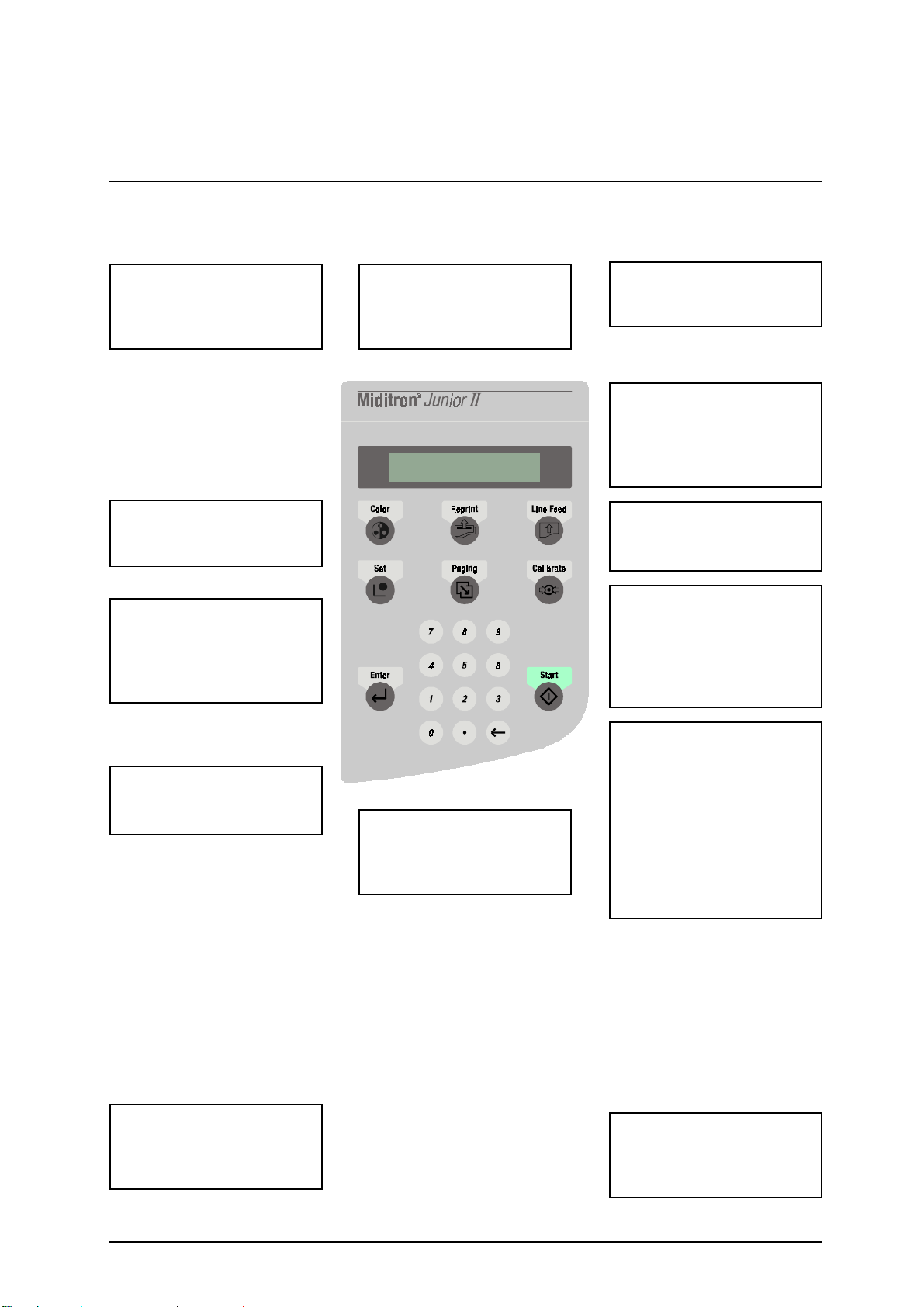

3.1.1 Function Elements

Built in printer with lid

for documentation of the

results

Keyboard/ Displa y

Contains 6 function keys , 10

num. k eys and liquid crystal

display

T ransport arm

Transports test strip from

wait position into measuring

position

Waste tray

Three functional areas, test

strip insertion, incubation/

measurement area and

waste container

Status LED

3 different colours indicates

the status of the instrument

Serial interface

Used to connect to a

barcode reader

Program chip card

Contains program f or SW

update

Printer paper

Thermal paper

Serial interface

Used to connect to external

printer

DC- socket

To connect the external

power supply

Serial interface

Used to connect to a host,

PC

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 13

Page 14

3. Introduction

Color

For manually selecting

colour and clarity for

inclusion with results.

Set

Used to select a menu

option.

Enter

Used to terminate keyboard

input, e.g. <0-9> and to

confirm an option or a

procedure.

Reprint

Reprints the patient report(s)

as defined in the Reprint

menu.

Display

The display consists of 1 line

of 16 characters.

Line Feed

advances paper one line at a

time or advances

continously while key is

depressed

Calibrate

Starts the calibration

procedure.

Paging

Used to scroll forwards

vertically through menus

without branching to menu

options and without saving

settings.

<0-9> and <.>

Used to enter (alpha)

numeric values.

External power supply ,

provides the instrument with

+5V DC and +12V DC

ç

Backspace ke y f or correcting

input, scrolling backwards or

jumping back one

Start

Used to start test strip

measurement, also to

escape from menus back to

"READ Y - <Start>", "ACC

MODE Start" or "FAST

MODE <START>", to stop

printing during Reprint, and

to acknowledge warning

messages and prompts.

Power cord

(Country specific)

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 14

Page 15

3. Introduction

3.1.2 Measuring Principle

Miditron® Junior II is a semi-automated reflectance

photometer for in-vitro semi-quantitative reading of urine test

strips from Roche Mannheim. The light sources (lightemitting diodes, LED’s for short) and reading times are

optimized for the reaction chemistry and colour development

occurring on the test pads.

The measuring head of Miditron® Junior II contains 3 LED’s

of differing wav elengths. The test strip is held stationary at

the measuring position and the measuring head moves over

each test pad in turn, starting from a "Reference position"

used to test the optical system.

During measurement, Miditron® Junior II checks that the

test strip is properly positioned under the measuring head by

carrying out a plausibility check on the light that is reflected.

If the strip is not properly positioned under the measuring

head, Miditron® Junior II prints an error message.

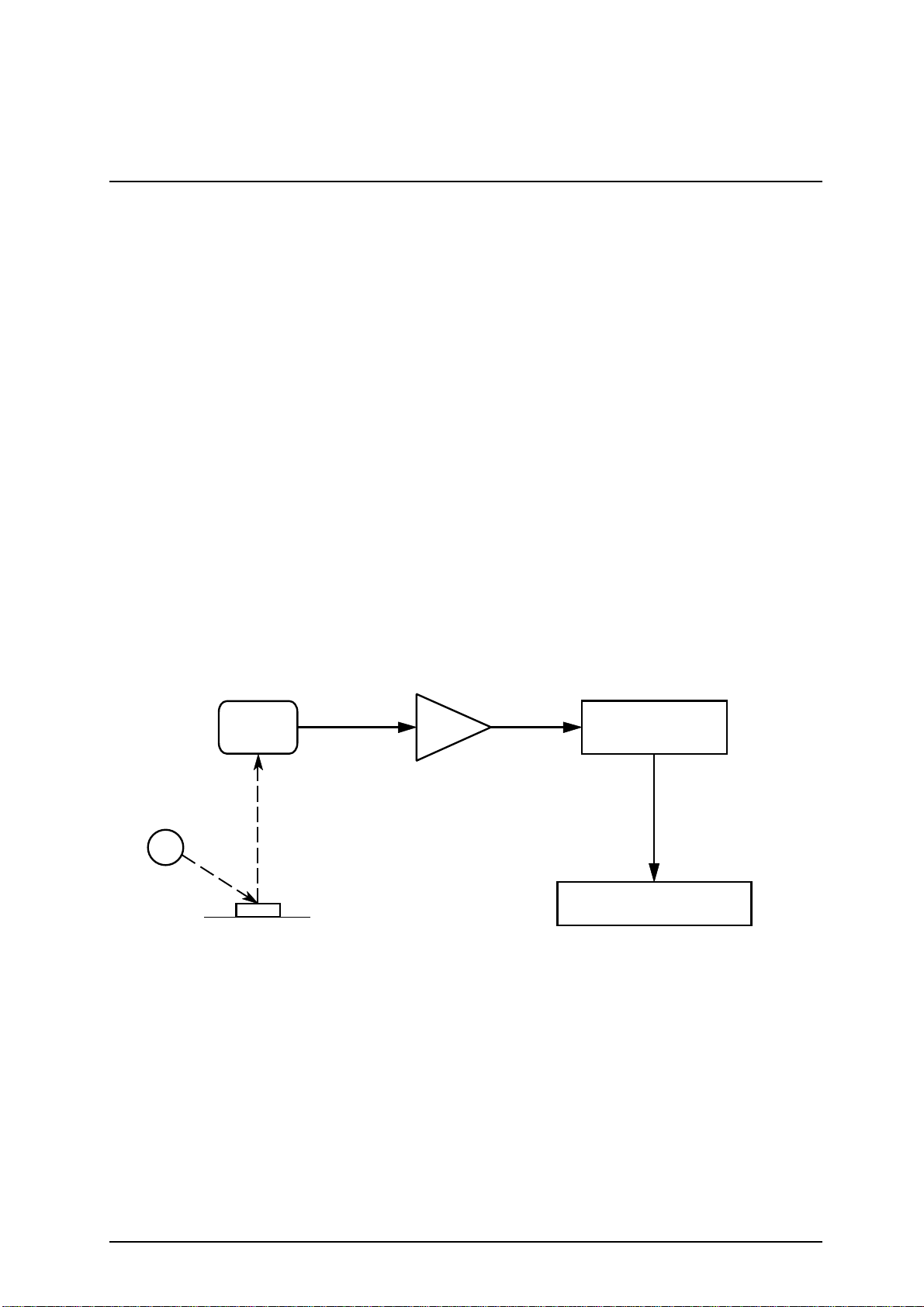

LED

1

Reading is done electro-optically , as f ollows:

Detector Analog-to-Digital Converter Microprocessor

3

2

4

Test Area

Concentration Result

An LED (1) flashes light of a defined wavelength at an

optimum angle onto the surface of the test pad (2). The light

hitting the surface is reflected with an intensity that is

dependent on the colour of the test pad, and is received by

a photodiode detector (3) positioned directly above the test

pad. The detector sends an analogue electrical signal to the

analogue-to-digital converter (4), which converts it to a digital figure. The microprocessor (5) corrects the digital figure

based on a value from an internal reference pad and

converts it to a relative value by scaling to a calibration

standard, and then computes the absolute reflectance value.

5

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 15

Page 16

3. Introduction

The semi-quantitative concentration result is determined by

comparing the absolute reflectance value with the so-called

range boundaries ( = constant, parameter-specific

reflectance values stored in the analyzer).

Results can be printed out, saved in memory, and sent to a

computer.

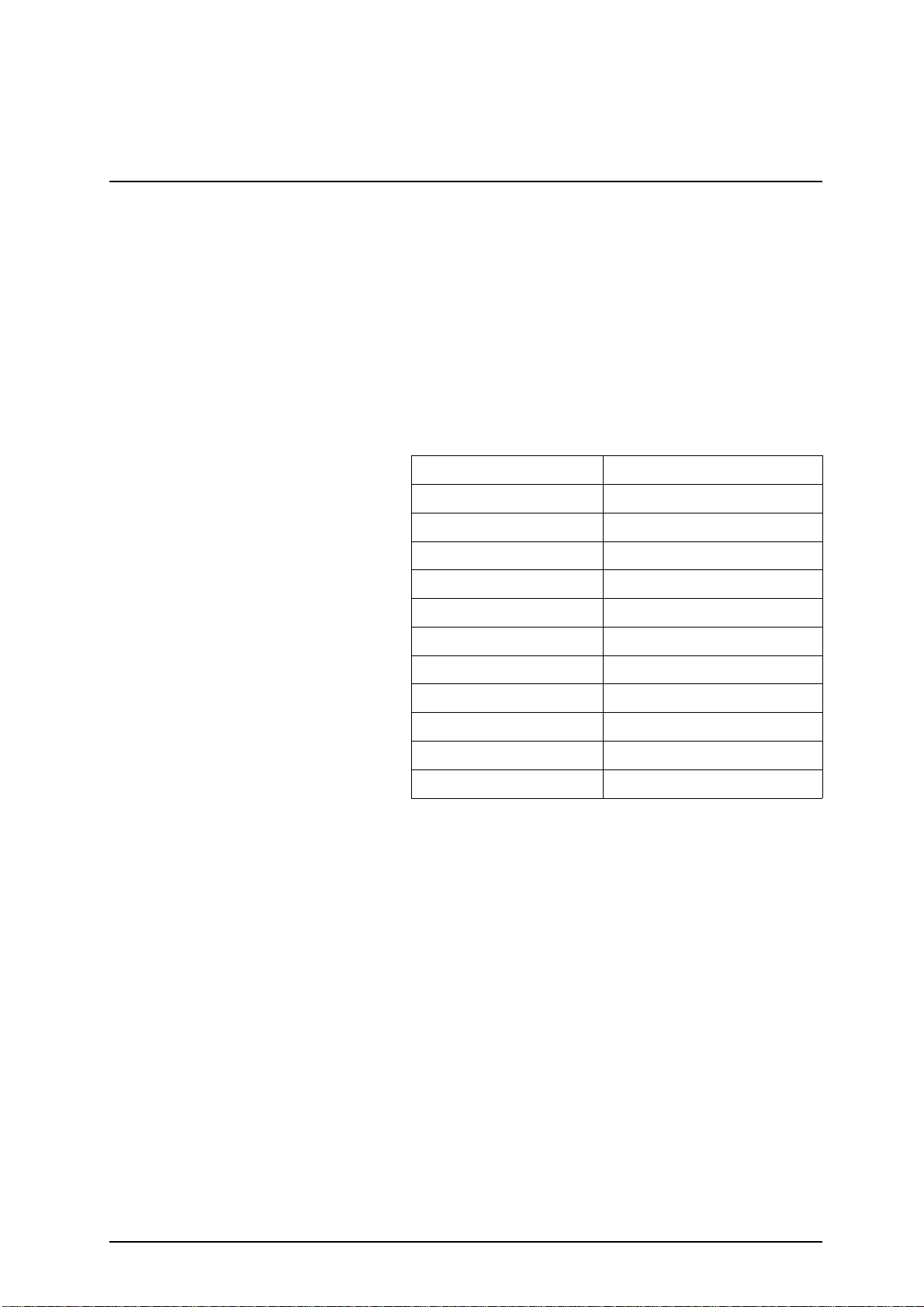

The wav elengths of the LED’s used to measure each of the

urine test strip parameters are listed in the table below . The

results of certain parameters are improved through the use

of two different wa velengths . The third LED is for future

options

Parameter Measuring Wave length [nm]

Specific Gravity 620

pH 557 and 620

Leukocytes 557

Nitrite 557

Protein 557

Glucose 557

Ketone 557

Urobilinogen 557

Bilirubin 557

Erythrocytes 557 and 620

Color 557 and 620

The photometric reflectance measurement for all of the

parameters is carried out after an incubation time of 60

seconds. As with earlier urine analyzers from Roche Mannheim, allowance for intrinsic urinary colour, which is a

recognized interfering factor , is made through measurement

of a blank reagent pad, the so-called "compensation pad".

Upon immersion into the urine sample, the compensation

pad absorbs the sample liquid and assumes the intrinsic

colour of the urine. Measuring the compensation pad helps

prevent false positives when the urine sample is strongly

coloured.

In strongly alkaline urine samples, Miditron® Junior II

automatically corrects the result obtained when the test pad

for specific gravity is read.

Miditron® Junior II reads the strip and determines urine

colour by ev aluating the compensation pad. The settings

necessary for this are selected in the Setup menu. Whether

the colour is to be printed together with the results is also

defined in the Setup menu.

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 16

Page 17

3. Introduction

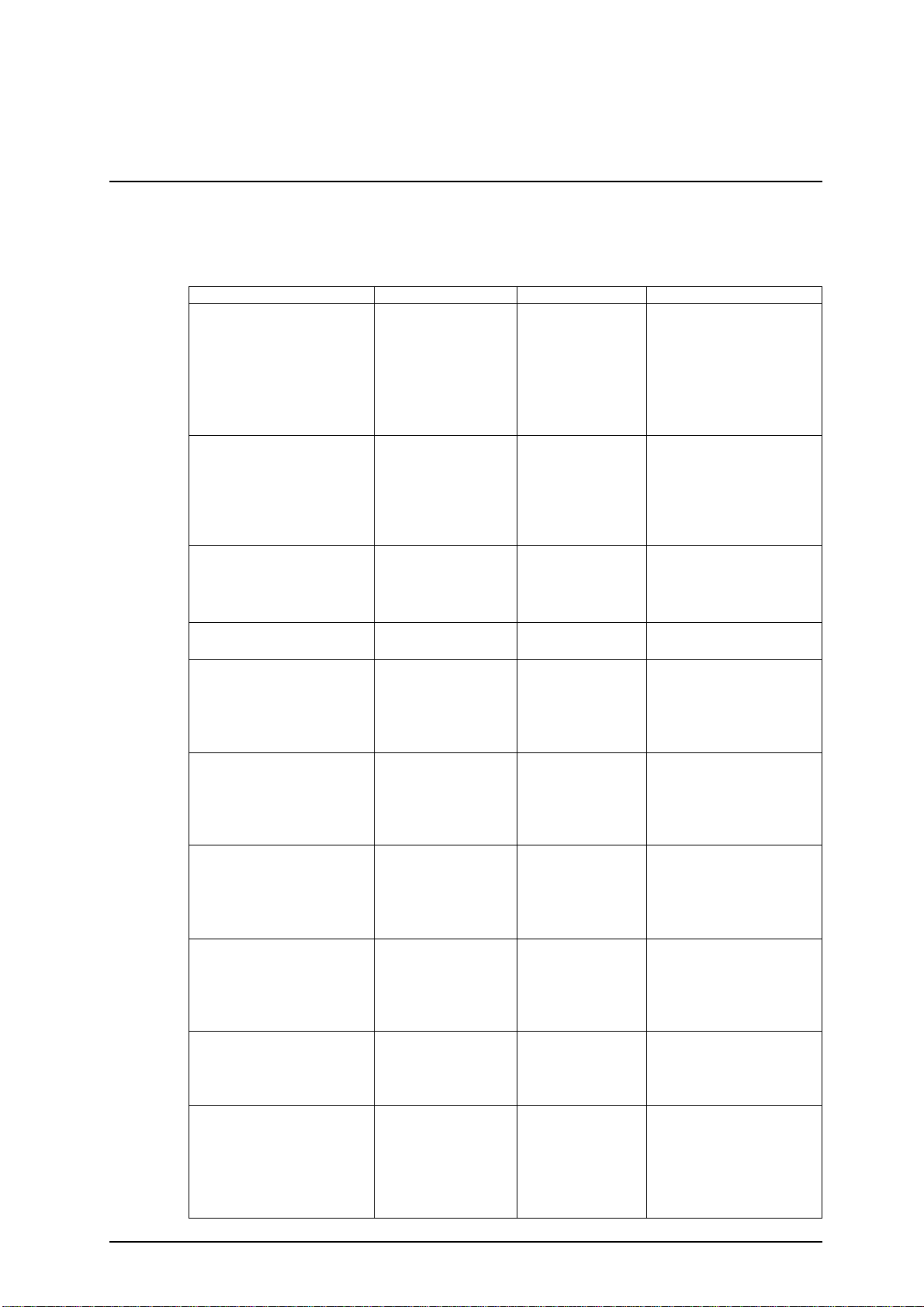

3.1.3 Concentration T able (Program I)

Miditron® Junior II prints the test results in the following

concentration ranges:

Parameter Conventional SI Arbitrary (Standard)

Specific Gravity 1.000 1.000 1.000

(SG) 1.005 1.005 1.005

1.010 1.010 1.010

1.015 1.015 1.015

1.020 1.020 1.020

1.025 1.025 1.025

1.030 1.030 1.030

pH 5 5 5

666

6.5 6.5 6.5

777

888

999

Leukocytes neg. neg. neg.

(LEU) 25 /µl 25 /µl +

100 /µl 100 /µl ++

500 /µl 500 /µl +++

Nitrite neg. neg. neg.

(NIT) pos. pos. pos.

Protein neg. neg. neg.

(PRO) 25 mg/dl 0.25 g/l +

75 mg/dl 0.75 g/l ++

150 mg/dl 1.5 g/l +++

500 mg/dl 5 g/l ++++

Glucose norm. norm. neg.

(GLU) 50 mg/dl 3 mmol/l +

100 mg/dl 6 mmol/l ++

300 mg/dl 18 mmol/l +++

1000 mg/dl 56 mmol/l ++++

Ketone neg. neg. neg.

(KET) 5 mg/dl 0.5 mmol/l +

15 mg/dl 1.5 mmol/l ++

50 mg/dl 5 mmol/l +++

150 mg/dl 15 mmol/l ++++

Urobilinogen norm. norm. neg.

(UBG) 1 mg/dl 17 µmol/l +

4 mg/dl 68 µmol/l ++

8 mg/dl 135 µmol/l +++

12 mg/dl 203 µmol/l ++++

Bilirubin neg. neg. neg.

(BIL) 1 mg/dl 17 µmol/l +

3 mg/dl 50 µmol/l ++

6 mg/dl 100 µmol/l +++

Erythrocytes neg. neg. neg.

(ERY) 10 /µl 10 /µl +

25 /µl 25 /µl ++

50 /µl 50 /µl +++

150 /µl 150 /µl ++++

250 /µl 250 /µl +++++

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 17

Page 18

3. Introduction

3.1.4 Changing Range Remisson Bordes

The boundaries of the reflectance ranges used by Miditron

Junior II to compute and output the test results were derived

from rigorous comparative tests carried out by Roche Mannheim with native urine. If required, the factory-set default

ranges for Miditron® Junior II may be changed to suit

individual laboratories’ requirements. Results obtained based

on individually modified ranges are flagged with an asterisk *

under the "Urinalysis" headline on the patient report.

The ranges for the parameters pH and SG cannot be

modified; nor can the thresholds for wavelength changes for

pH and ER Y .

Operator´s Manual outlines how ranges can be selected.

Roche Mannheim can give no guarantee as to the

accuracy of results when range boundaries have

been changed.

®

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 18

Page 19

3. Introduction

3.2 System Specification

Dimensions: Height: 195 mm

Width: 349 mm

Depth: 470 mm

Weight: 7.45 kg

Interfaces: 3 serial RS 232 C interfaces

(host/PC, barcode reader , external printer)

Po wer Supply: External Universal Pow er Supply Model No. 78-095-0300

with integral ON/OFF s witch

Input: 110 V - 240 V; 50-60 Hz; 0.4-0.2 A

Output: 5 V 2.0 A

12 V 2.0 A

Power Consumption: Operation: 30 W

Standby: 15 W

System Description: Type: reflectance photometer

Light source: LED’s (light emitting diodes)

Wavelengths: 557 nm, 620 nm

(the 656 nm LED is for future options)

Measuring head: 1 measuring head with 3 LED’s

Work flow: approx. 36 seconds (Normal Mode)

approx. 20 seconds (Accelerated Mode)

approx. 12 seconds (F ast Mode)

Incubation time: 60 seconds

Printer: Seiko thermal line printer

Display: liquid crystal display , 1 line, 16 characters

Environmental conditions:

Operating Non-Operating

Temperature: +15°C - +34°C -20°C - +60°C

Relative humidity: 20 % 80 % 20 % 95 %

Optimum Opt. T emperature: +22°C - +26°C

operating conditions: Opt. Rel. Humidity: 30 % 60 %

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 19

Page 20

3. Introduction

3.3 Service Concept

3.3.1 Service level

From the early stage of development, Miditron® Junior II

was designed for simple error detection and easy

exchangeability of modules. This gives the service

workshops the possibility of a fast and easy repair of the

instrument on service level A (module level). No big stock or

expensive equipment is necessary and service technicians

are easier to train. Also, a permanent technical

improvement in la yout and economic production.

SMD-technology increases reliability on better economical

basis in production. Repair costs often do not relate to

production costs for ne w parts with the latest improvement.

This cuts the number of repairable parts.

On repairable modules the quality and function is alwa ys

provided by the manufacturer according to the latest

technology . This keeps Miditron

highest quality level.

®

Junior II alwa ys on the

The exchange price for modules will be kept on a lo w le v el

to guarantee repairs, on economical basis.

3.3.2 Handling of warranty and repairs

Warranty period f or instruments and spare parts

The warranty period for instruments is 16 months

starting with the date of shipment ex works Mannheim/

Federal Republic of Germany or 12 months starting with

the date of the first installation, whichever period is

shorter.

The warranty period for spare parts is 6 months from

installation date of the part, however not longer than 24

months after having delivered ex w orks Mannheim/

Federal Republic of Germany.

Hint:

In case the instrument has a remaining warranty period

of more than 6 months, the parts remain under warranty

until the warranty period of the instrument expires.

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 20

Page 21

3. Introduction

Handling of warranty claims

The warranty claim has to be handled via Return

Authorization procedure or accepted equivalent. Please

answer all the questions on the RA form with the greatest

care.

Especially a detailed fault description is needed or the

warranty claim will not be accepted by the manuf acturer .

Complete instruments are not accepted unless this has

been agreed with the service department of the relevant

product group responsible at RD GmbH.

Important information:

- Only parts marked with „A“ in the price list are

generally accepted under warranty .

- Only return those parts marked with „R“ in the spare

parts price list.

- Warranty claim f or “R” parts will be accepted, if the

part was returned to Mannheim.

- All defective parts ( non-“R“ and „A“ parts ) should

be kept on stock for a period of 7 months. In case the

manufacturer needs the part for inv estigation it will be

requested from Mannheim.

- All parts returned to Mannheim and not requested by

Mannheim will be send back at the expense ofthe

countries.

- The RA claim for warranty has to be in Mannheim no

later than 8 weeks after the problem date.

Exclusion of warranty

The aforementioned warranties do not apply in case of

improper use, handling, transportation or storage, faulty

installation, repair or maintenance, chemical influence or

contamination as well as damages resulting from that,

failure to follow operating instructions, alterations or

modifications of instruments or parts thereof not

authorized or recommended by RD GmbH and resulting

damages, normal wear and tear and in case of other

circumstances beyond the control of RD GmbH.

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 21

Page 22

3. Introduction

Handling of repairs

As a general rule, all instrument repairs should be carried

out by authorized and trained personnel only .

Repair of parts marked with „R“

Parts which are economically worth repairing are marked

with „R“ in the spare parts price list. N ew and repaired

parts could be recognized by different material numbers

(language version).

(e.g. ne w part: 1234567-001, repaired part: 1234567- 984)

Repaired parts should be ordered together with new parts

via the order processing department in Mannheim (OUVDG). P arallel to the ordering process of a repaired part,

the defectiv e part should be returned together with the

filled RA form (giving full details of the defect and marked

choice box with repair) to Logistic Instruments (Goods

Receipt) in MA-Wohlgelegen (LI-L V).

Repair of instruments

Complete instruments are not accepted for replacement

or repair unless this has been agreed with the product

group responsible at RD GmbH.

Before replacement or repair can take place, the validity

of the request must be examined and the question of

costs must be settled in a written agreement with RD

GmbH.

Terms of delivery

Shipments to the countries with the routine truck are

c.i.f./ shipments outside this procedure are ex works

Mannheim .

Emergency shipments require additional costs to be

charged.

Handling of costs

“Repaired”-parts (Material-No. 1234567-984) are

shipped at a repair price. In case the defective parts

are not returned within 3 or 8 weeks for european or

oversea countries after ordering the repaired part, the

countries will be charged later on with the difference

to the new price.

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 22

Page 23

3. Introduction

After the receipt of a warranty request for “A”-parts, RD-G

will credit 100 % of the currently effective ex MA price.

In case the manufacturer does not accept the warranty

request, the countries will be charged lateron with the Rprice for R-parts and the new price for non R-parts.

RA form

Return Authorization

Please answer all the questions on the RA form with the

greatest care and sign the form.

- Country code

- Problem date

- Type of instrument

- Serial no. of the instrument

- Installation date of instrument

- Defective instrument or spare part

- Part number and material number of the spare part

- Old / new serial no.

- Fault description

- Alarm code

- Service / workshop report no.

In case of instrument out of warranty

- Installation date of spare part

All returned parts should be individually labeled with the

corresponding RA no. and shipped together with the

completed RA form to:

Roche Diagnostic Mannheim GmbH

Logistic Instruments

RA Management

Friedrich Ebert Str. 100

D - 68167 Mannheim

Germany

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 23

Page 24

3. Introduction

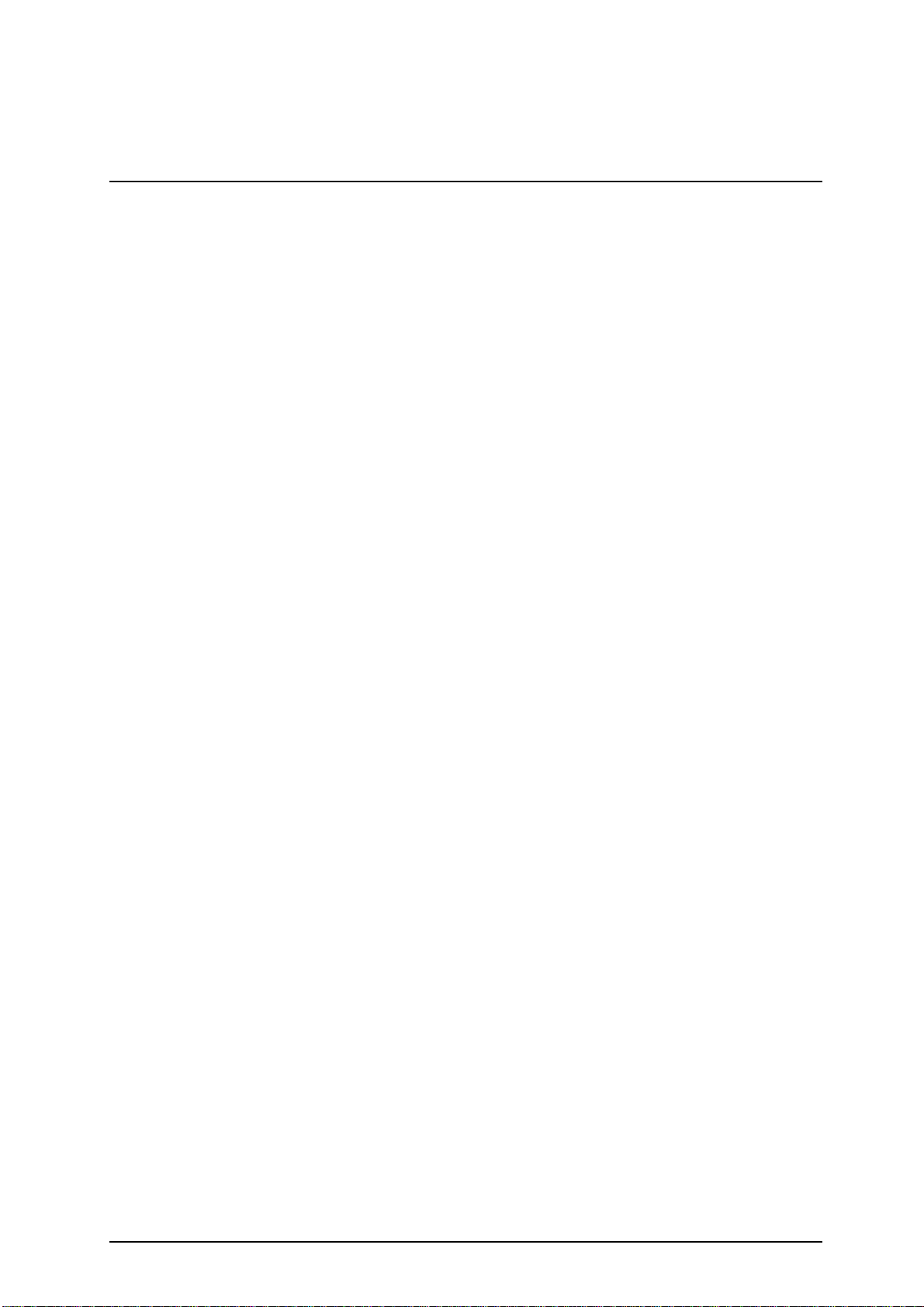

RA form

In the following please find important hints on how to fill in

the RA-Form correctly .

ROCHE DIAGNOSTICS MANNHEIM GmbH

Friedrich-Ebert-Strasse 100 T elefon : +49 (621) 759 81 84

D-68167 Mannheim Fax : +49 (621) 759 80 93

Germany

Return Authorization

No.:

Country code:

Date:

Instrument:

Serial No.:

Installation date:

Spare Part:

Customer: Address:

(will be filled in by RD)

Part No.: Qty.: Part Name: Repair Comments

Mat.-No.: Warranty

Installation date of Spare Part: Warranty Repair

OLD serial No.: Modification

NEW serial No.: Replacement

Fault Description:

Alarm Code:

Service Report No.: Workshop Report No.:

Place: Date: Signature:

Remarks (will be filled in by RD) NOS Credit FC

RD

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 24

Page 25

4. Installation

4.1 Chec king f or Dama ge in Transit

Miditron® Junior II is shipped in one package. Please

contact the supplier or carrier immediately regarding any

damage that may hav e occurred in transit.

4.2 Unpacking

Unpack the Miditron® Junior II accessories and check that

all are present:

- Operator’s Manual

- T r ansport Arm

- Universal Pow er Adapter with Connecting Cable

- Printer Paper (5 Rolls)

- Power Cord

Fig. 31

4.3 Proper Setting

Set up Miditron® Junior II on a firm and straight surf ace. Do

not expose the analyzer to direct sunlight or to an y other

direct light source.

4.4 Setting Up

Do not start the analyzer immediately if it has

been subject to an abrupt change in

temperature or humidity .

1. Check that the strip receiving tray / waste tray is correctly

positioned in its holder.

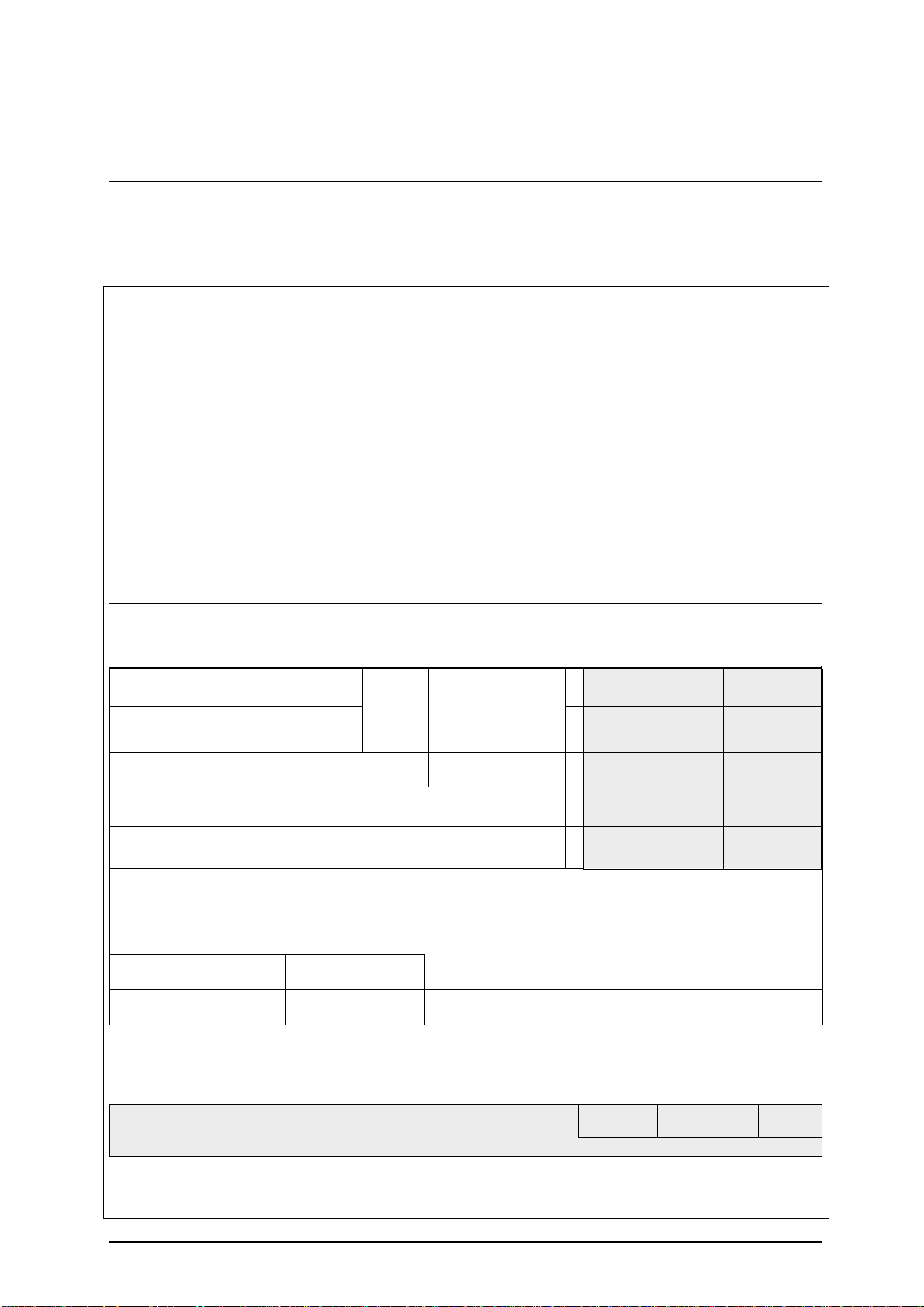

2. Attach the transport arm. Grasp the handle end and,

while holding it at an angle of 45° from the vertical, insert

it as far as it will go along the visible guide, then push

down so it snaps into position (Fig. 31).

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 25

Page 26

Fig. 32

4. Installation

3. Plug one end of the power connector cable into the

power sock et at the rear of the instrument and the other

end into the AC power adapter (Fig. 32). Plug the AC

power cord first into the AC po wer adapter and then into

an appropriate AC wall socket.

4. When the AC power adapter is switched on (Fig. 33),

Miditron® Junior II automatically runs a self-check. The

message "Empty Waste T ray" is then displa y ed. This

message is displayed whene ver the analyz er has been

left switched off or in Standby Mode ov ernight. Press

<Start> to cancel the "Empty Waste Tray" message. The

analyzer will display "READY - <ST AR T>" or "Please

Calibrate".

5. If "Please Calibrate" is displayed, press <Start>. This will

allow you to b ypass calibration at this point if y ou wish to

change the user interface language. (The def ault

language setting is English.)

Fig. 33

6. Press <Paging> until "Setup" is display ed. Press <Set>

until the desired language appears in the display, then

<Enter> to confirm your selection. Pressing <Start>

closes the setup routine and returns you to "READY <ST AR T>" or "Please Calibrate".

7. Insert the roll of printer paper as shown in Figs 34 to 37.

(refer to Section 4.5).

8. Y ou ma y then calibrate the analyz er (ref er to Section 6).

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 26

Page 27

4. Installation

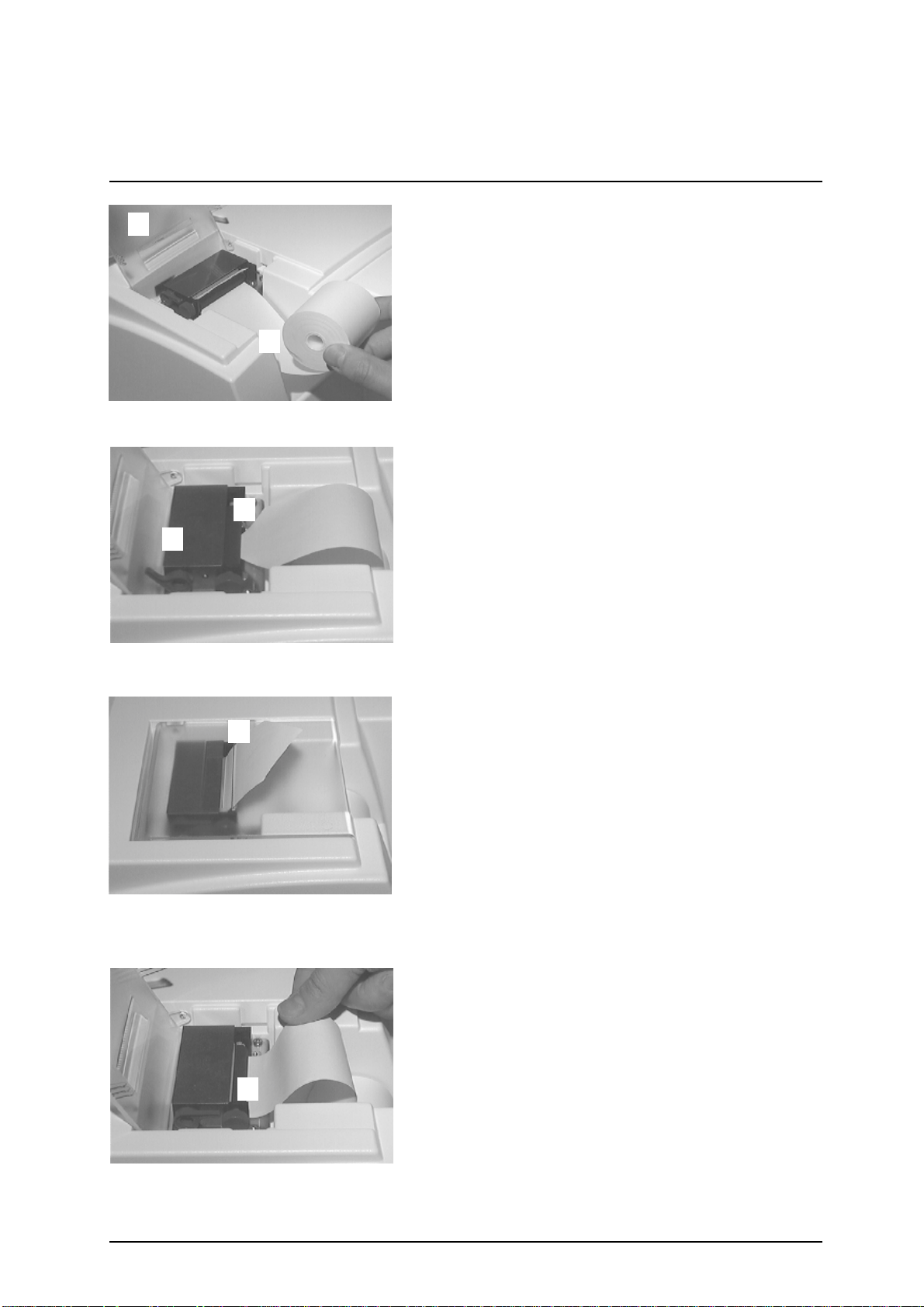

Fig. 34

Fig. 35

4.5 Inserting Printer Paper

The printer paper (thermal paper) is heat-sensitive and

must be kept aw a y from direct sunlight and high

temperatures. Chec k that there is sufficient printer paper in

the printer paper compartment. To insert a new roll of printer

paper, follo w one of the tw o methods below:

Method 1:

1. Open the printer cover (Fig. 34).

2. Remove the old core and any remaining paper (Fig.

34).

3. Place a new roll of paper in the printer paper

compartment (with the end of the paper pointing

downwards and towar ds the printer) (Fig. 34).

4. Lift the lever on the printer (Fig. 35).

5. Cut off the end of the paper at an angle and insert it into

the paper slot on the printer (Fig. 35).

6. Pull the paper through the printer and lower the le ver

(Fig. 35).

Fig. 36

7. Feed the paper through the slot in the printer cover and

then close the printer cover (Fig. 36).

8. Press <Line Feed> to advance the paper.

Method 2:

1. Open the printer cover (Fig. 34).

2. Remove the old core and any remaining paper (Fig.

34).

3. Place a new roll of paper in the printer paper

compartment (with the end of the paper pointing

downwards and towar ds the printer) (Fig. 34).

4. Cut off the end of the paper square and insert it into the

paper slot on the printer (Fig. 37).

5. Press <Line Feed> to advance the paper.

6. Feed the paper through the slot in the printer cover and

then close the printer cover (Fig. 36).

Fig. 37

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 27

Page 28

5. Calibration

Miditron® Junior II is factory-calibrated bef ore shipment.

The analyzer must be calibrated again before being used f or

the first time, and then every 14 da ys. The message "Please

Calibrate" will appear in the display whene v er the 14-da y

period has expired.

Calibration is a procedure in which allowance is made f or

changes in the optical system by reference to an internal

compensation pad. If there hav e been marked changes ,

caused for instance b y soiling of the ref erence pad or

because of low-level light output from a def ectiv e LED, an

error message is printed out.

Control-Test M calibration strips (Catalogue Number 1 379

194) are standardized grey plastic strips that hav e constant,

defined reflectance characteristics. Calibration strips should

not be removed from their container until shortly before use,

and should be used once only. Do not touch the elevated

grey areas on the strip (see the package insert for more

details). Before calibr ating, ensure that the tr ansport arm

and strip receiving tray / waste tra y are clean and dry.

READY - <START>

"The analyzer is ready to

measure in Normal mode"

ACC MODE <START>

"The analyzer is ready to

measure in Accelerated mode"

FAST MODE<START>

"The analyzer is ready to

measure in Fast mode"

Please Calibrate

"The analyzer needs calibrating"

Insert Cal Strip

"Insert calibration strip"

Press <Calibr.>

"Press the Calibrate key"

Calibrating

"Calibration being carried out"

To calibrate, proceed as follo ws:

Press <Calibrate> when you see displa yed:

Note:

The "Please Calibrate" message can be bypassed by

pressing <Start>. In this case, a message will be printed

on the patient report.

Two messages will appear alternately in the display:

Place the Control-Test M calibration strip in the centre of the

strip receiving tray.

Press <Calibrate> again. The calibration strip is transported

into the analyzer and you see the follo wing display ed:

After about 60 seconds, a printout will occur as long as the

printer has not been disabled in the Setup menu.

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 28

Page 29

5. Calibration

SW.Vers. 1 1.00

22.01.1998 9:21

Calibration o.k.

557 620 657

0 64.50 63.60 63.20

1 64.49 63.76 63.11

2 64.40 63.73 64.56

3 64.44 63.82 63.48

4 64.44 63.70 63.39

5 64.32 63.76 63.37

6 64.05 63.50 63.34

7 64.40 63.67 63.26

8 64.55 63.64 63.22

9 64.17 63.70 63.04

10 64.55 63.67 63.28

11 64.35 63.71 63.43

SW.Vers. 1 1.00

22.01.1998 9:21

Cal. Err. ##

Calibration successful:

Printout of reflectance

values in % R.

Calibration unsuccessful:

Recalibration necessary.

The printout quotes the current software version number ,

the date and time of calibration, and the positions of the

individual test pads on the calibration strip, together with the

measured reflectances in % R at the respective

wav elengths. Position 0 is the internal reference pad.

If, after sev eral repeat calibrations , y ou still receive the

message "Recalibrate !", please refer to Section 8

"Troubleshooting". During the calibration procedure, the

values read from the calibration strip are compared with the

stored calibration values. The calibration procedure is as

follows:

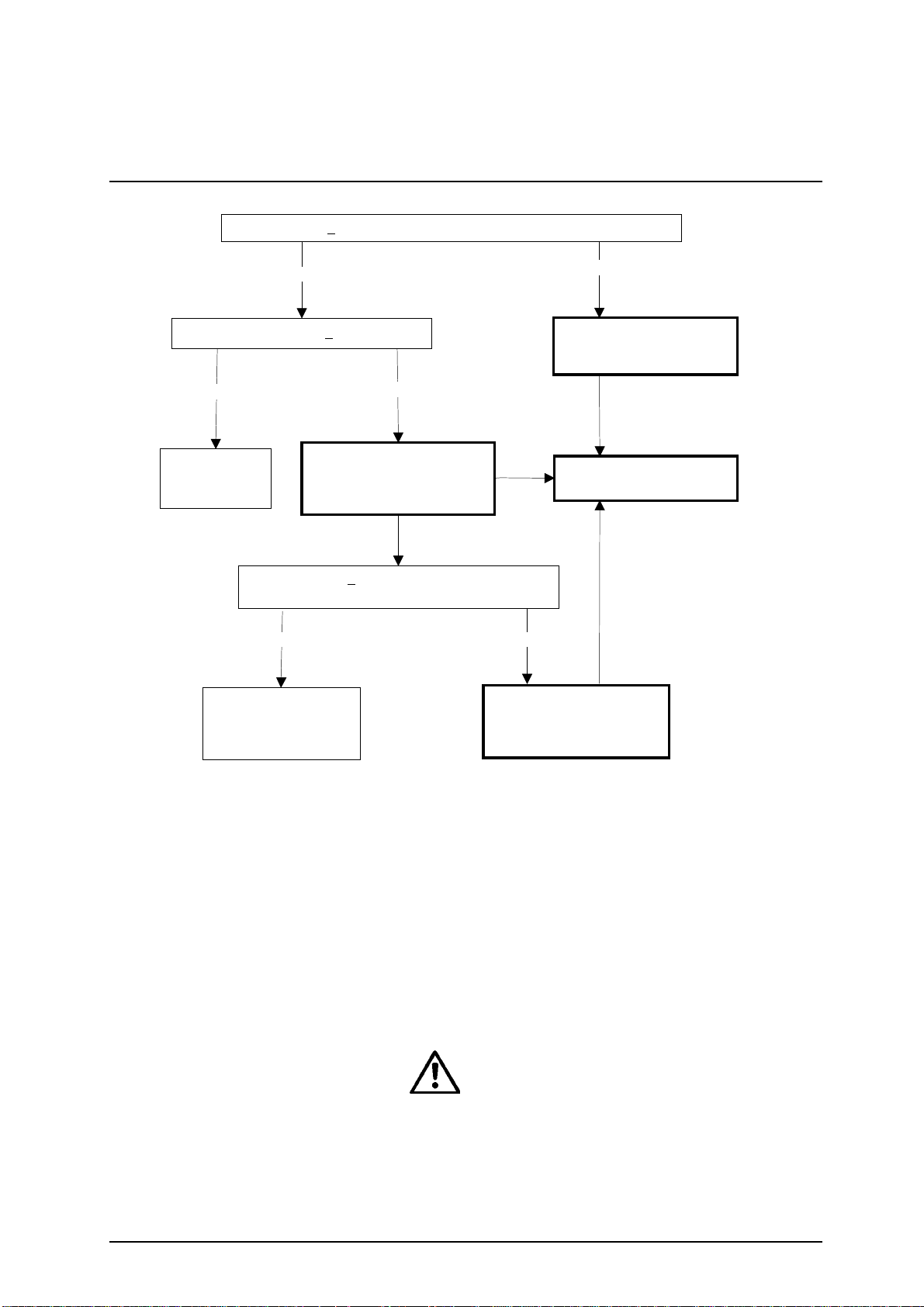

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 29

Page 30

5. Calibration

Difference of < 10 % between measured value and reference value

Difference of < 1 % R

Yes

Stored

calibration is still

valid.

Calibration is valid.

New calibration values

will be stored.

Yes

No

Cal. Error 10 - 45

Calibration not valid.

Measurement of a second

calibration strip necessary

Difference of < 1 % R between 1st and 2nd

calibrat i o n st r ip

No Yes

Calibration not valid.

Recalibration necessary.

No

Cal. Error 50 - 85

Calibration not valid.

Recalibration necessary.

Display message:

"Recalibrate !"

Cal. Error 10 - 45

Miditron® Junior II is ready to read as long as there are

valid calibration values stored in the analyzer . Calibration

every 2 weeks is recommended. If calibration cannot be

carried out for any reason, e.g. because there are no

Control-Test M calibration strips available, y ou can bypass

the calibration procedure and continue reading by pressing

<Start> at the "Please Calibrate !" prompt. Miditron® Junior

II then uses the stored calibration values to carry out further

readings.

Note: In this case, "Calibration is necessary" will be printed

on the results report.

Roche Mannheim can give no guarantee as to the

accuracy of results if the analyzer has not been

calibrated.

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 30

Page 31

6. Operation

6.1 Overview

Miditron® Junior II is e xtremely easy to use. For normal,

routine reading of test strips (Normal Mode) simply press

<Start> to begin reading when you see "READ Y <START>".

The user is guided by display messages and the status

LED . The status LED appears in one of three states:

- Red = Read display messages,

- Flashing green = Dip a test strip,

- Green = Insert the test strip.

There is also a choice of three operating modes (further

details see Operators´Manual):

- Normal Mode

- Accelerated Mode

- Fast Mode

Fig. 60

When dipping a test strip in the sample, always ensure that

all of the test pads are completely covered. Place the test

strip, with its test pads facing upwards, to the right of the

"NO STRIP" warning and between the two elev ations along

the front edge of the strip receiving tray. The far end of the

test strip must be resting on the inner lip at the rear of the

tray (Fig. 60).

Miditron® Junior II automatically terminates the series

when no further strip is inserted.

You can change between the three operating modes by

making the appropriate selection in the Working Mode

menu (see Operators´Manual).

Miditron® Junior II automatically assigns consecutive

sequence numbers to samples. Numbering automatically

starts with 1:

a) whenever the date has changed (also , the displa y reads

"Empty Waste Tray"), and

b) following er asure of the results memory.

The waste container integrated into the strip receiving tray

can hold up to 75 used test strips. When the container

needs emptying, the message "Empty W aste Tra y" is

display ed. The same message also appears when you

press <Start> at the beginning of each day . Should the

container already be empty, you can bypass the message

by pressing <Start> again and then proceed with

measurements.

The results memory can hold up to 150 results.

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 31

Page 32

6. Operation

If the analyzer has not been used for more than 10 minutes ,

it automatically enters Standby Mode. The displa y blanks

out and the status LED is red. When you press any function

key (e xcept <Line F eed>), the analyz er performs a selfcheck and returns to "READY - <STAR T>" , "A CC MODE

<START>" or "F AST MODE <START>", depending in which

mode was selected most recently.

6.2 Normal Mode

In Normal Mode the displa y reads "READY - <ST ART>".

Press <Start>, dip a test strip and then insert it in the

analyzer. You can repeat this procedure every 36 seconds.

The sample throughput is about 100 test strips per hour.

Before a test strip is read, you can enter the colour and/or

clarity of the sample, in which case "Color Manual" and/or

"Clarity On" must be selected in the Setup menu. In

addition, the Patient ID ma y be entered with the aid of a

barcode reader or through the numeric keypad.

6.3 Accelerated Mode

In Accelerated Mode (a batch mode f or processing series

of samples) the display reads "A CC MODE <START>". After

you have pressed <Start>, you may dip and insert a test

strip, when prompted, into the analyzer ev ery 20 seconds.

The sample throughput is about 180 tests per hour. In

Accelerated Mode, the colour and/or clarity of a sample

may be entered bef ore the test strip is read, in which case

"Color Manual" and/or "Clarity On" must be selected in the

Setup menu. In addition, the Patient ID may be entered with

the aid of a barcode reader or through the numeric keypad.

In Accelerated Mode, there are up to 3 test strips incubating

outside the analyzer.

6.4 F ast Mode

In Fast Mode (a batch mode f or processing series of

samples) the display reads "FAST MODE <ST AR T>". After

you have pressed <Start>, you may dip and insert a test

strip into the analyzer every 12 seconds. The theoretical

sample throughput is 300 tests per hour. In Fast Mode,

there are up to 5 test strips incubating outside the analyzer .

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 32

Page 33

6. Operation

6.5 Principle mo vement of the

Miditron® Junior II

Base-Position

Insert Strip

Test strip

Measuring head

Grid

Insert position

Insert position

Measuring head

Waste

Measuring head

Waste

T r ansport arm

starts moving to

the waste

position, moves

upwards and

back. over the

waiting strip,

turns and

moves

downwards,

takes the strip

with.

to the

measuring

position.

The next strip

can be inserted

Measuring

head moves

over the strip,

field by field,

leaded in y- and

z-dimension

from the

transport arm

Teststrip

Waste

GridTeststrip

M.h.

Waste

M.h.

Grid

Waste

Insert position

After returning

to the parking-

Measuring head

position, over

the ref.field, the

Teststrip

M.h.

Grid

transport arm

starts its next

run, pushes the

Waste

measured strip

into the waste

box and fetches

the next strip to

be measured.

Waste

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 33

Page 34

7. Service mode and adjustment

7.1 Ho w to make adjustments

To be able to measure Combur X M strips it will be

necessary to position them in such a way ov er the

respective test field that the receiv er can register the

accessible core zone of the test field.

The strip is pushed by the transport grid in cross direction.

This strip takes up a reproducible position in longitudinal

direction by means of a control edge on the strip tray.

At the same time the cross movement and the friction of the

strip on the tray ensures that the strip runs up against the 2

catch teeth of the grid. The strip is still free heightwise

because the double leaf suspension system keeps the

transport arm held upwards.

If the measuring head now travels o v er the transport grid,

the suspension presses the transport grid down and clamps

the strip in position.

At the same time, one component of the suspension system

measuring head ensures that the strip runs along the

guiding edge of the grid. In this w a y we ensure that the

cross positioning is within the indexing accuracy of

measuring head and grid.

The measuring head is likewise positioned in height directly

over the grid. The grid has an appropriate height section to

compensate the varying thickness of the different test fields .

With its runners the measuring head slides over the height

section. In this w a y the distance of the measuring head to

the surface of the test field is determined within the

tolerances of the measuring head, grid and test field.

Position in longitudinal direction of the strip:

The drive train of the measuring head has a light barrier as

reference. The switching point of the light barrier in the

direction of travel on the instrument user TEXT??? side is

such that the measuring head with its measuring patch (2.7

mm in diameter) is on the reference field (14 x 14 mm).

From this reference position the measuring head is tra v eled

by step motor a specific number of steps to the first test

field and from there from test field to test field in a fixed

number of steps. Since a long chain of tolerances is given

from the light barrier to the middle of the test patch the first

number of steps (to the test field) is kept variable and

adjusted depending on the actual instrument.

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 34

Page 35

7. Service mode and adjustment

Adjustment is made with the help of an optical signal from

the measuring head. A special adjustment strip has a bright

bar 2 mm in width on a dark background in the test field

position 7.

If this test field is now trav eled ov er stepwise and measured,

a measurement curve will be produced which will then show

a maximum when the measuring head with its optical center

is centered over the bright bar . The adjustment program of

the Miditron® Junior II counts the steps to this maximum

and calculates from these the number of steps from the

reference position to the center of the first test field. The

number of steps is saved as adjustment position.

7.2 General

The adjustment procedure should be undertaken by trained

service staff only . It is used to clear unexpected errors and

after repair work. No special service tools are necessary

although adjustment strips will be used. The strips are

availab le as a spare part with ID 1 704 656.

SET=Protocol

"The analyzer is in Service

mode"

SET=Protocol

"The analyzer is in Service

mode"

7.3 Pr ocedure

The service mode can be reached by two different ways:

1) During the self-test after power on:

During the self-test enter numbers <1,7,0,4> via the

keyboard and confirm by pressing <Enter>. The display

shows:

Any other or incomplete input stops the process and the

instrument changes to normal mode.

2) With connected service computer:

When the display shows "READY-<START>" type

keywords <PW 1704> via terminal program of the computer

which is connected to the printer interface. The display

shows:

Any other or incomplete input stops the process and the

instrument changes to normal mode.

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 35

Page 36

7. Service mode and adjustment

Service Mode:

SET=Protocol

"The analyzer is in Service

mode"

SW.Vers. 1 1.00

29.01.1998 15:01

hours of work: 68:50

cycles: 248

last meas.: 29.01.98

calibration: ok

last cali.: 29.01.98

pga g:107 o: 75 r:134

557 620 657

0 64.50 63.60 63.20

1 64.49 63.76 63.11

2 64.40 63.73 64.56

3 64.44 63.82 63.48

4 64.44 63.70 63.39

5 64.32 63.76 63.37

6 64.05 63.50 63.34

7 64.40 63.67 63.26

8 64.55 63.64 63.22

9 64.17 63.70 63.04

10 64.55 63.67 63.28

11 64.35 63.71 63.43

This display reading indicates that you are in the Service

Mode:

Press <Paging> to select the ne xt menu item "Check Keys"

or initiate a printout of the status protocol with <Set>. The

printout will start after approx. 3 seconds.

The follo wing information is shown:

- The current software version of the instrument.

- Current date and time.

- The total number of hours the instrument has already

worked.

- The total number of cycles the instrument has already

performed.

- The date of the last measurement.

- The result of the last calibration.

- The last calibration date.

- The strength of the LEDs.

- The wavelengths of the LEDs.

- The adjustment values.

- The current adjustment position.

- The number of results in the memory.

- Information about the current instrument settings.

- The most recent error statistics.

adjust position: 643

results in memory: 0

settings :

English

24 hours

Format: dd:mm:yy

Host/PC No

Int. Printer <1>

Ext. Printer Off

PatID.13-digits

Color Off

Clarity Off

Combur-10M

SG PH LEU NIT PRO GLU

KET UBG BIL ERY

Conv & Arb

Ranges Default

Flag default On

MICRO: No Space

Memory Ignore

Normal Mode

Last 1 result

error statistic :

no errors

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 36

Page 37

7. Service mode and adjustment

SET=Check Keys

"All keys can be checked"

SET=Check LCD

"Display test can be performed"

SET=Delete Data

"All data can be reset to their

default settings"

When "Check Ke ys" is selected the displa y reads:

Press <Paging> to select the ne xt menu item "Check LCD",

or initiate the key test b y pressing <Set>.

To carry out the key test, all ke ys ha v e to be pressed one

after another. The key test routine can be aborted only after

all keys ha v e been tested.

When "Check LCD" is selected the display reads:

Press <Paging> to select the ne xt men u item "Delete Data",

or initiate the display test with <Set>.

During the display test it is possible to displa y up to six

different test patterns by pressing <Set>. Press <Paging>

to select the next menu item.

When "Delete Data" is selected the display reads:

Press <Paging> to select the next menu item

"INI-Download", or reset all instrument settings to the

factory default settings by pressing <Set>.

SET=INI-Download

"The download of an INI-file can

be started"

SET=Save INI

"All instrument settings can be

saved"

SET=ADJUST

"The position of the test field on

the adjustment strip can be

adjusted"

Insert ADJ.STRIP

"Insert first adjustment strip"

When "INI-Download" is selected the display reads:

Press <Paging> to select the next menu item

"SET=Save INI", or press <Set> to initiate the download of

an INI-file from the connected service PC. All instrument

settings are contained in the INI-file. Do wnloading can be

aborted by pressing <Paging>.

When "SET=Save INI" is selected the display reads:

Press <Paging> to select the next menu item

"SET=ADJUST", or press <Set> to start the upload of all

instrument settings to the connected PC. Uploading can be

aborted by pressing <Paging>.

When "SET=ADJUST" is selected the display reads:

During adjustment, the motor measuring head unit counts

the number of steps to the center of the test field of the

adjustment strip. The number of steps derived from this is

saved as the ne w step number to reach the test field.

Press <Paging> to terminate the Service Mode or initiate

the adjustment procedure with <Set>. The displa y reads:

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 37

Page 38

7. Service mode and adjustment

Insert ADJ.STRIP

"Insert second adjustment strip"

READY <START>

"Analyzer is in the Normal

Mode"

Place the first adjustment strip in the middle of the insertion

area and initiate the adjustment procedure by pressing

<Start>.

The adjustment of the first adjustment strip begins. Once

adjustment is completed, a report will be printed and sent to

the printer interface. If the adjustment w as carried out

correctly the display reads:

Place the second adjustment strip in the middle of the

insertion area and initiate the adjustment procedure by

pressing <Start>.

The adjustment of the second adjustment strip begins.

Once adjustment is completed, a report will be printed and

sent to the printer interface. If the adjustment w as carried

out correctly the display reads:

After the adjustment has been completed, the Service

Mode is terminated and the analyzer returns to the Normal

Mode.

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 38

Page 39

7. Service mode and adjustment

Selfcheck

Password (1704)

Tabelle Service Mode

SET= Protocol

Paging

ç

SET= Check Keys

Paging

ç

SET= Check LCD

Paging

ç

SET= Delete Data

Paging

ç

Set

Set

Set

Set

Print

Service-Prot.

Echo Key

Echo Key

Key = XXXX

Paging

Set

Testpattern No.1..6

Paging

Data deleting

blinking

3 sec.

SET= INI-Download

Paging

ç

SET= Save INI

Paging

ç

SET= ADJUST

Paging

READY - <START>

Set

Paging or EOF

Set

Paging or EOF

Set

Error

Adjust.ok

Comm unicating

Comm unicating

Insert ADJ.STRIP

1.Adjustment

Start 2.adjustment

Report to

RS232 and printer

Start

Start

Start 1.adjustment

Report to

RS232 and printer

Error

Insert ADJ.STRIP

Paging

1.Adjust.ok

2.Adjustment

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 39

Page 40

8. Adjustment / Dismantling

Adjustment and dismantling are described in detail:

Chapter 9 (Mecanics)

9.1.1 T r ansport arm

9.1.2 Tray

9.1.3 T op of housing

9.1.4 PCB Main

9.1.5 PCB Interface

9.1.6 Display

9.1.7 Printer

9.1.8 Status LED

9.1.9 Keyboard

9.1.10 PCB Measuring Head

9.1.11 LB Measuring Head Home P osition

9.1.12 LB Home P osition

9.1.13 Motor Belt Drive Cross T ransport

9.1.14 Motor Measuring Head Unit

9.1.15 Tooth Bar Measuring Head Unit

9.1.16 Carrier for T ra y

9.1.17 Reference Field Carrier

9.1.18 Crossbar complete

9.1.19 Cross Transport

Chapter 10 (Electronics)

10.1 Overview Electronics

10.2 P ower Supply

10. 3 Elekctronic Moduls

10.3.1 Main Board

10.3.2 Interface Board

10.3.3 Display

10.3.4 Printer

10.3.5 Status LED

10.3.6 Keyboard

10.3.7 Measuring Head PCB

10.3.8 LB Measuring Head Homeposition

10.3.9 LB Home P osition

10.3.10 LB Referenzposition

10.3.11 Motor Belt Drive Cross Transport

10.3.12 Motor Measuring Head Unit

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 40

Page 41

Fig. 1

9. Mechanics

9.1 Mechanical moduls

Pull power plug before working on the open

instrument.

9.1.1 Transport arm

The transport arm (1) is snapped in from diagonally above.

1

Exchangeable components:

- Transport arm (1).

Dismantling:

- Pull power plug

- Lift transport arm (1) up until it snaps out

- Remove transport arm (1)

Fig. 12

Assembling:

- Insert transport arm (1) from diagonally above and push

down until it snaps in.

9.1.2 Tray

The tray (2) is in front of the instrument.

Exchangeable components:

2

- T r a y including waste container (2).

Dismantling:

- Pull tray (2) forw ard, out of the instrument

Assembling:

- Push tray (2) from the front into the instrument until it

snaps in.

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 41

Page 42

9. Mechanics

9.1.3 Top of housing

The top of housing (3) is connected to the lower casing (33)

with 6 screws (4).

Exchangeable components:

- Top of housing (3).

Dismantling:

Fig. 14

Fig. 16

3

33

2

1

7

9

4

5

3

6

- Remove transport arm (see chapter 9.1.1)

- Remove tra y (see chapter 9.1.2).

- Take out paper roll (5).

- Remove 6 screws (4) of the lower cacing (33)

- Remove top of housing (3).

Watch for cable connections between top of housing

(3) and PCB Main (9). Plugs or cables could be

damaged.

- Loosen 2 cable connection (6) and (7) from the PCB

Main (9).

- Carefully , first remov e the metal clamp (8) of the flat cab l e

(6).

The metal clamp (8) is hard to remo v e. Do not pull

the cable.

Assembling:

- Make two cable connections (6) and (7) to the PCB Main

(9).

- Mount metal clamp (8) to protect flat cable (6).

- Put on top of housing (3) and screw on with six screws

(4).

Fig. 17

Adjustment:

6

8

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 42

An adjustment is not necessary .

Page 43

16

9. Mechanics

9.1.4 PCB Main

The PCB Main (9) is screwed to the base plate (10) with 4

screws (18).

Exchangeable components:

- PCB Main (9)

Fig. 20

Fig. 19

Fig. 21

17

15

9

14

13

12

11

9

19

18

10

10

Dismantling:

- Remove top of housing (see chapter 9.1.3).

- Remove cable (16) to PCB Measuring Head.

- Remove 6 screws (17) at the interface plugs.

- Remove five remaining plug connections of PCB Main (9).

plug (11) to motor belt drive cross transport

plug (12) to motor measuring head unit

plug (13) to LB reference position

plug (14) to LB home position

plug (15) to LB measuring head home position

- Remove 4 screws (18) of the PCB Main (9).

- Push PCB Main (9) forward and pull out upwards

- Nose of chip card slot (19) has to be infront of base plate

(10) so that PCB Main (9) can be pulled out upwards.

Assembling:

- Insert PCB Main (9).

- Push PCB Main (9) forward.

- Nose of chip card slot (19) has to be under base plate

(10).

- Push PCB Main (9) backwards and screw on with 4

screws (18).

- Screw on 6 screws (17) to the interface plugs.

- Connect all plugs and connections.

Be sure to use correct order of plugs to the light

barriers.

Plug (13) to LB reference position

Plug (14) to LB home position

Plug (15) to LB measuring head home position

- Put on metal clamp (8) to protect flat cable (6)

Fig. 17

6

8

Service Manual Miditron® Junior II / ID 1997491 / MJ / 1.2 - February 2000 / Page 43

Adjustment:

While inserting the PCB Main (9) the nose of the chip card

slot (19) has to be under the base plate (10).

Another adjustment is not necessary .

Page 44

Fig. 23

22

27

23

20

26

24

25

9. Mechanics

9.1.5 PCB Interface

The PCB Interface (20) is screw ed to the top of housing (3)

with 4 screws (21).

Exchangeable components:

- PCB Interface (20).

Dismantling:

- Remove top of housing (see chapter 9.1.3).

3

21