Page 1

MagNA Pure Compact Instrument

Addendum 5 to Operator’s Manual, Version 1.3

Software Version 1.1 July 2016

For general laboratory use.

Page 2

Page 3

Updated Information about the MagNA Pure Compact System

Updated Information about the

MagNA Pure Compact System

Dear Valued User of the MagNA Pure Compact System,

Please be informed that Section III, Declaration of Conformity is replaced by the following

section:

Approvals

The MagNA Pure Compact System meets the requirements laid down in:

Directive 2014/30/EU of the European Parliament and Council of 26 February 2014 relating

to electromagnetic compatibility (EMC).

Directive 2014/35/EU of the European Parliament and Council of 26 February 2014 relating

to electrical equipment designed for use within certain voltage limits.

Compliance with the applicable directive(s) is provided by means of the Declaration of

Conformity.

The following marks demonstrate compliance:

Complies with the provisions of the applicable EU directives.

Issued by Underwriters Laboratories, Inc. (UL) for Canada and the US.

Equipment de Laboratoire /

Laboratory Equipment

‘Laboratory Equipment’ is the product identifier as shown on the type

plate.

MagNA Pure Compact Instrument – Addendum 5 to Operator’s Manual, Version 1.3

3

Page 4

If you have any questions regarding the MagNA Pure Compact System Instrument,

please contact your Roche Diagnostics representative.

Published by

Roche Diagnostics GmbH

Sandhofer Straße 116

68305 Mannheim

Germany

©

2013 Roche Diagnostics

0805521100110716

For general laboratory use.

MAGNA PURE, LIGHTCYCLER, AND TAQMAN are trademarks of Roche.

Page 5

MagNA Pure Compact Instrument

Addendum 4 to Operator’s Manual, Version 1.3

Software Version 1.1 November 2013

For general laboratory use.

Page 6

Page 7

Updated Information for the MagNA Pure Compact Instrument

Updated Information for the

MagNA Pure Compact Instrument

Dear Valued User of the MagNA Pure Compact Instrument,

This addendum is to inform you that the floppy disk drive for the MagNA Pure Compact

Instruments has been removed for serial numbers starting with MPCC1550.

If you have any questions regarding the MagNA Pure Compact System, please contact your

Roche Diagnostics representative. To call, write, fax, or email us, visit the Roche Applied

Science homepage at www.roche-applied-science.com and select your home country. Coun-

try-specific contact information will be displayed.

Addendum 4 to Operator’s Manual, Version 1.3

3

Page 8

Updated Information for the MagNA Pure Compact Instrument

Please note the following correction to the MagNA Pure Compact Operator’s Manual:

The floppy disk drive on the MagNA Pure Compact Instruments starting with serial number

MPCC1550 has been removed.

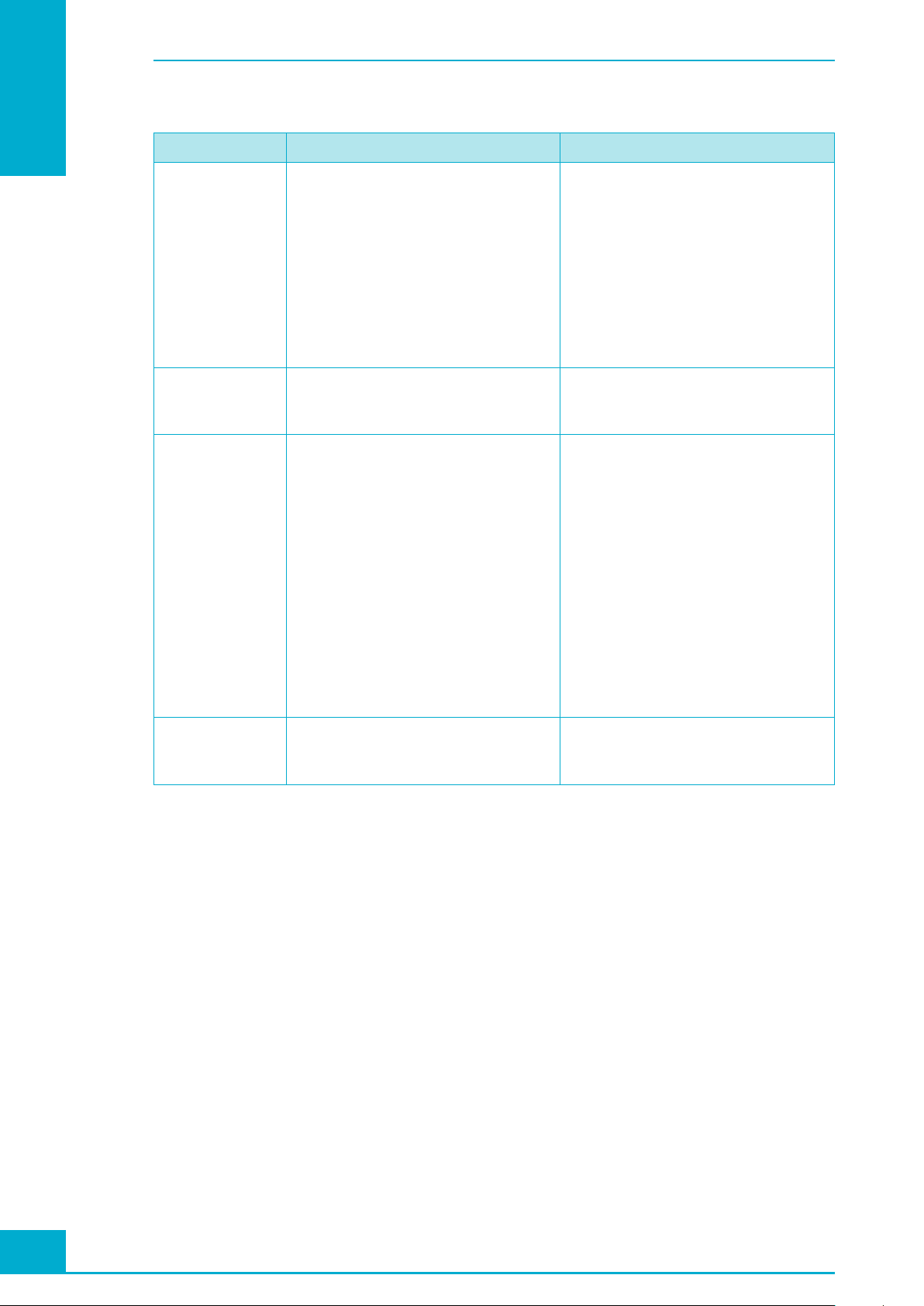

Old Version New Version without Floppy Disk Drive

4

MagNA Pure Compact Instrument

Page 9

Updated Information for the MagNA Pure Compact Instrument

The MagNA Pure Compact Operator’s Manual is corrected as shown below:

Section Current Version Changes

A 3.3.1

8 Disk Drive

(p 24)

A 3.3.4

Sides of the

Instrument

(p 29)

B 4

Data Transfer

to or from

the MagNA

Pure Compact

Instrument

(p 67)

8 Disk Drive

The disk drive allows the operator to

store the data generated as well as

transfer it easily to other instruments

or computers (e.g., for sample tracking,

documentation, or troubleshooting).

In addition, new MagNA Pure Compact

purification protocols can be uploaded

from commercially available disks.

9 USB Ports

There are two USB ports. USB 1 and

USB 2 ports can be used for any

accessories that are not included with

the MagNA Pure Compact Instrument.

The data from the result screen can be

saved to a disk. In future applications

with the LightCycler

®

System and the

COBAS TaqMan® 48 Analyzer, these

data files can be transferred to the

respective instruments.

Section 8 Disk Drive no longer valid.

9 USB Ports

There are two USB ports. USB 1 and

USB 2 ports can be used for any

accessories that are not included with

the MagNA Pure Compact Instrument.

A USB memory stick allows the

operator to store the data generated or

transfer it easily to other instruments

or computers (e.g., for sample tracking,

documentation, or troubleshooting).

In addition, new MagNA Pure Compact

purification protocols can be uploaded.

To save data from the result screen,

use a USB storage device.

Addendum 4 to Operator’s Manual, Version 1.3

5

Page 10

Updated Information for the MagNA Pure Compact Instrument

Section Current Version Changes

B 4.2

Upload of

New Updated

Purification

Protocols

(p 67)

As new or updated purification

protocols are created, they may be

added to the MagNA Pure

Compact Instrument via external data

carrier disks (e.g., software update

disk) during program startup.

Additional protocols will be available

for download from www. magnapure.

com. Follow the download instructions

on this webpage.

Update disks will automatically be

checked for viruses by the instrument

software.

Workflow:

1. MagNA Pure Compact Instrument

must be shut down.

2. Insert update disk.

3. Switch on instrument.

4. Software is automatically updated.

5. After Main Screen is displayed,

remove update disk.

6. Update complete.

7. The instrument is ready for use.

To upload new protocols, use a USB

storage device.

No longer valid.

Workflow:

1. MagNA Pure Compact Instrument

must be shut down.

2. Insert USB.

3. Switch on instrument.

4. Software is automatically updated.

5. After Main Screen is displayed, shut

down the MagNA Pure Compact

Software, remove USB, and start

the MagNA Pure Compact Software

again.

6. Update complete.

7. The instrument is ready for use.

C 5

Documentation

(p 97)

The result screen of the respective run

will be displayed and can be printed or

saved to a disk or LIMS.

To save data from the result screen,

use a USB storage device or save them

directly to a LIMS.

6

MagNA Pure Compact Instrument

Page 11

Page 12

Published by

Published by

Roche Diagnostics GmbH

Sandhofer Straße 116

68305 Mannheim

Germany

©

2013 Roche Diagnostics

1

1113

For general laboratory use.

MAGNA PURE, LIGHTCYCLER, AND TAQMAN are trademarks of Roche.

Page 13

MagNA Pure Compact Instrument

Addendum 3 to

Operator’s Manual, Version 1.3

Software Version 1.1 August 2012

For general laboratory use.

Page 14

Information regarding

MagNA Pure Compact Instrument

Dear Valued User of the MagNA Pure Compact Instrument,

Roche Diagnostics Ltd. has merged into Roche Diagnostics International Ltd and therefore

the company name has changed to

Roche Diagnostics International Ltd

In order to harmonize and improve our support, the legal manufacturer changes as follows:

Roche Diagnostics GmbH

Sandhofer Strasse 116

68305 Mannheim

Germany

If you have any further questions regarding this matter, please do not hesitate to contact your

Roche Diagnostics representative. To call, write, fax, or email us, visit the Roche Applied Science

home page, http://www.roche-applied-science.com and select your home country.

Country-specific contact information will be displayed.

The address of the legal manufacturer in section

“Prologue/Contact Addresses” changes as follows:

Old adress New adress

Roche Diagnostics Ltd.

Forrenstrasse

CH-6343 Rotkreuz

Switzerland

MAGNA PURE is a trademark of Roche.

Roche Diagnostics GmbH

Sandhofer Strasse 116

68305 Mannheim

Germany

06845070001 a 0812

For general laboratory use. ©2012 Roche Diagnostics.

All rights reserved.

Page 15

Information regarding the

MagNA Pure Compact Instrument

Operator’s Manual Version 1.3

Versatile Nucleic Acid Purification -

Smart. Small. Simple

Page 16

nd

MagNA Pure Compact Instrument Operator’s Manual - 2

Addendum

Dear valued user of the

MagNA Pure Compact Instrument,

With this document Roche Applied Science releases information on safety standards to provide a maximum of

health and environment assurance. Please read the following information carefully, which updates information

given in the MagNA Compact Instrument Operator’s Manual.

If you have any further questions regarding this matter, please do not hesitate to contact our Technical Services

Department at your best convenience. To call, write, fax, or email us, visit the Roche Applied Science home page,

http://www.roche-applied-science.com and select your home country. Country-specifi c contact information

will be displayed.

New Prologue Chapters:

Warnings and Precautions

In an emergency, immediately turn the power switch off and unplug the Instrument.

This Instrument is an electromechanical device, that could cause electrical shock or injury if not operated

according to the procedures in this Operator’s Manual.

Disposal Recommendations

All electrical and electronic products should be disposed off separately from the municipal waste system. Proper

disposal of your old appliance prevents potential negative consequences for the environment and human health.

The Instrument must be treated as biologically contaminated-hazardous waste. Decontamination

(i.e., a combination of processes, including cleaning, disinfection and/or sterilization) is required

before reuse, recycling, or disposal.

Dispose of the Instrument according to local and/or labor regulations.

For more information, contact your local Roche representative.

Components of your Control Unit, such as the computer, monitor, keyboard etc., which are marked

with the crossed-out wheeled bin symbol are covered by the European Directive 2002/96/EC on

waste electrical and electronic equipment (WEEE) of the European Parliament and the Council of

27 January 2003.

These items must be disposed of via designated collection facilities appointed by government or

local authorities.

For more information about disposal of your old product, please contact your city offi ce, waste

disposal service or your local Roche representative.

Constraint

It is left to the responsible laboratory organization to determine whether control unit components are

contaminated or not. If contaminated, treat in the same way as the Instrument.

2

Important Information regarding the MagNA Pure Compact Instrument Operator’s Manual

Page 17

MagNA Pure Compact Instrument Operator’s Manual - 2nd Addendum

Symbols used in the Manual, page 8

Current Version

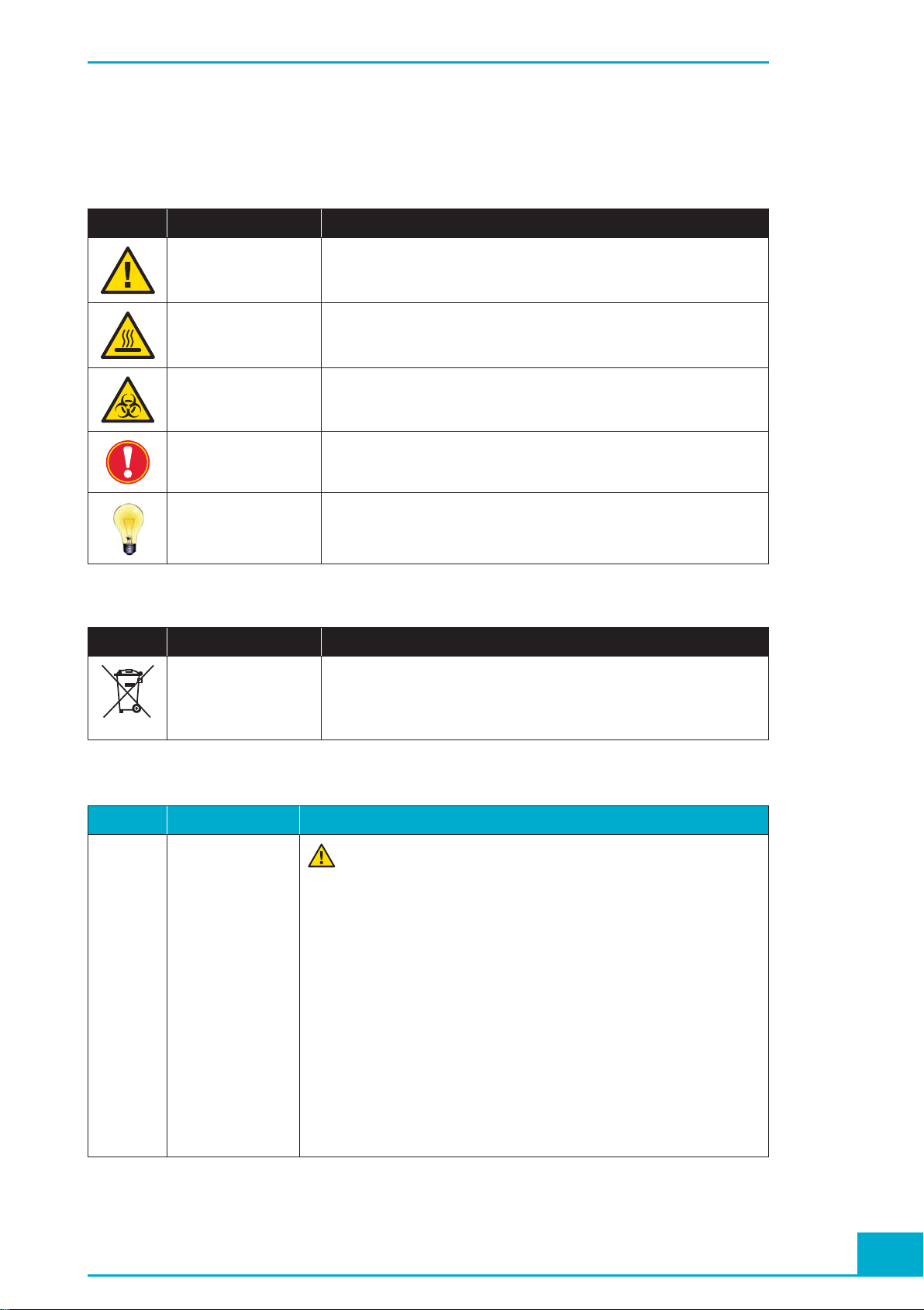

Symbol Heading Description

WARNING

RISK OF DANGER

HOT SURFACE This symbol is used to label potentially hot instrument surfaces.

BIOHAZARD This symbol is used to indicate that certain precautions must be taken

IMPORTANT NOTE This symbol is used to bring your attention to an important annotation.

INFORMATION NOTE Designates a note that provides additional information concerning the

This symbol is used to indicate that noncompliance with instructions or

procedures may lead to physical injury or even death or could cause

damage to the instrument.

when working with potentially infectious material.

current topic or procedure.

Additional Information:

Symbol Heading Description

WEE Electrical and electronic equipment marked with this symbol are covered

by the European directive WEEE.

The symbol denotes that the equipment must not be disposed off in the

municipal waste system.

General Information, page 11

Current Version Additional Information

Electrical

Safety

General Information:

Protection Class I

All peripheral devices that are connected to the MagNA Pure Compact

The MagNA Pure Compact Instrument is designed in accordance

with Protection Class I (IEC). The chassis/housing of the Instrument is connected to protection earth (PE) by means of a cable. For

protection against electrical shock hazards, the Instrument must be

directly connected to an approved power source, such as a three-wire

grounded receptacle for the 230V line. Where an ungrounded receptacle

is encountered, a qualifi ed electrician must replace it with a properly

(PE) grounded receptacle, in accordance with the local electrical code.

An extension must not be used. Any break in the electrical ground path,

whether inside or outside the Instrument, could create a hazardous

condition. Under no circumstances should the user attempt to modify

or deliberately defeat the safety features of this Instrument. If the power

cord becomes cracked, frayed, broken, or otherwise damaged, it must be

replaced immediately with the equivalent part from Roche Diagnostics.

Instrument must comply with safety standard IEC 60950 for information

technology equipment, or with IEC 61010-1, UL 61010-1 for laboratory

instruments.

Important Information regarding the MagNA Pure Compact Instrument Operator’s Manual

3

Page 18

MagNA Pure Compact Instrument Operator’s Manual - 2nd Addendum

Setup, page 16

Current Version Additional Information

Selecting a

Location

The MagNA Pure Compact Instrument requires

very little setup. Choose for the MagNA

Pure Compact Instrument a clean, dry, level,

stable surface within 3 m of a compatible

electrical outlet. To ensure proper ventilation,

leave 10 cm of space behind the instrument and

15 cm at each side of the instrument. No space is

needed at the back of the instrument.

Description of the Instrument, page 22

Current Version Additional Information

UV Light

Protection

The door permits a good view of the interior of

the instrument. During the decontamination

cycle, the door prevents escape of UV light from

the interior.

Description of the Instrument, page 29

To carry the instrument, place your hands under

the base of the instrument. For this purpose, the

instrument base plate provides four recessed

carrier grips. The weight of the MagNA Pure

Compact Instrument is approx. 60 kg, ensure that

enough manpower is available for transportation.

The Front Door is impervious to UV light from

inside the Instrument, in case the decontamination function is activated, but permits good view

to the inside of the Instrument. However do not

look at the UV source directly.

Locking of the door is controlled by the software.

Movement of the Robotic Arm is only possible

after the Instrument Door is closed and locked.

Current Version Additional Information

Socket

for power

cable

This is the plug-in for the power cable. There

are two power cables included in the instrument

package, one for US and one for German wall

outlets.

Performing a Purifi cation Run, page 43

Current Version Additional Information

For kit specifi c details regarding the handling of

Reagent Cartridges, please see the corresponding pack insert of the kit.

Cleaning, page 81

Current Version Additional Information

The surface of the MagNA Pure Compact

Instrument as well as removable internal parts

should be cleaned on a weekly basis with a lint

free cloth moistened with deonized water. If a

spill of reagents occurs, the instrument should

be cleaned with a 70% ethanol solution or any

acceptable PCR laboratory cleaner. Turn the

instrument power Off and disconnect or unplug

the power cord before cleaning the instrument.

Always connect the Instrument to a grounded

wall outlet.

Reagents might be fl ammable. For kit specifi c details regarding the handling of Reagent

Cartridges, please consult the package insert of

the respective reagent kit for further information.

Mixtures of water and ethanol, that contain

70% ethanol, are highly fl ammable.

4

Important Information regarding the MagNA Pure Compact Instrument Operator’s Manual

Page 19

Information regarding the

MagNA Pure Compact Software Update 1.1.2

Versatile Nucleic Acid Purification -

Smart. Small. Simple

Page 20

Information regarding the

MagNA Pure Compact Software Update 1.1.2

Please read the following information, which updates information given in the MagNA Pure

Compact Instrument Operator’s Manual!

Dear valued user of the MagNA Pure Compact Instrument,

In March 2009, Roche Applied Science introduced an updated version of the MagNA Pure

Compact Software: Version 1.1.2.

This latest version:

䉴 fi xes some bugs, found in previous versions

䉴 improves some of the text messages

䉴 updates the start up functions of the instrument, including the Plausibility Check

䉴 improves tip handling

䉴 includes updated and improved protocols; a list of installed protocols has also been

implemented in the Maintenance Menu

䉴 improves Sample Ordering

䉴 includes a Create Problem Report function

If you have any further questions regarding this matter, please do not hesitate to contact our

Technical Services Department at your best convenience. To call, write, fax, or email us, visit

the Roche Applied Science home page, http://www.roche-applied-science.com and select

your home country. Country-specifi c contact information will be displayed.

Information regarding the MagNA Pure Compact Software Update 1.1.2

2

Page 21

Important Information regarding the

MagNA Pure Compact Instrument

Operator’s Manual

Versatile Nucleic Acid Purification -

Smart. Small. Simple

Page 22

Prologue

Important Information regarding the MagNA

Pure Compact Instrument Operator’s Manual

Please read the following information, which updates information given in the MagNA Pure

Compact Instrument Operator’s Manual!

Prologue

Contact Addresses, page 5

Current Version Changes

Manufactured by Roche Instrument Center AG

Forrenstrasse

CH-6343 Rotkreuz

Switzerland

Marks of Conformity, page 6

Current Version Changes

The MagNA

Pure Compact

Instrument has

been investigated

according to:

CE – Testing

Information

EN 61326:1997 + A1:1998 + A2:2001

Class B (“Electrical equipment for

measurement, control and laboratory

use – EMC requirements”)

CAN/CSA C22.2 No. 1010.1-92 CAN/CSA C22.2 CSA C22.2.61010.1

The instrument conforms to following

directives as issued by the European

Union according to the Council Directive

89/336/EEC (Electromagnetic Compatibility)

and 73/23/EEC (Electrical equipment for

use within certain voltage limits).

Roche Diagnostics Ltd.

Forrenstrasse

CH-6343 Rotkreuz

Switzerland

EN 61326:2006

Class B (“Electrical equipment for

measurement, control and laboratory

use – EMC requirements”)

The instrument conforms to the

following directives as issued by

the European Union according to

the Council Directive 2004/108/EC

(Electromagnetic Compatibility) and

2006/95/EC (Electrical equipment for

use within certain voltage limits).

Please Note: the sentence “Equipment to be connected must fulfi ll the standards set by IEC 950

(Information security in technical equipment, including electronic business machines).”, should

be disregarded.

Important Information regarding the MagNA Pure Compact Instrument Operator’s Manual

4

Page 23

Chapter A

Chapter A:

2. Installation of the Instrument

2.4 Setup, page 16

Current Version Changes

2.4.1

Selecting a

Location

The MagNA Pure Compact Instrument

requires very little setup. Choose for

the MagNA Pure Compact Instrument

a clean, dry, level, stable surface within

3 m of a compatible electrical outlet.

To ensure proper ventilation, leave 10

cm of space behind the instrument and

15 cm at each side of the instrument.

No space is needed at the back of the

instrument.

3. Description of the Instrument

3.3.5 MagNA Pure Compact Accessories

7 Barcode Scanner – Scanner Specifi cations, page 33

Current Version Changes

Drop Resistance IEC 68-2-32 Test ED; withstands

repeated drops from 1.8 m onto a

concrete surface

The MagNA Pure Compact Instrument

requires very little setup. Choose for

the MagNA Pure Compact Instrument

a clean, dry, level, stable surface within

3 m of a compatible electrical outlet. To

ensure proper ventilation, leave 10 cm

of space behind the instrument and

15 cm at each side of the instrument.

DIN EN 60068-2-32 Test ED;

withstands repeated drops from 1.8 m

onto a concrete surface

Important Information regarding the MagNA Pure Compact Instrument Operator’s Manual

5

Page 24

Chapter B

Chapter B:

1. Handling the MagNA Pure Compact Software

1.1 Starting the MagNA Pure Compact Instrument, page 37

Current Version Changes

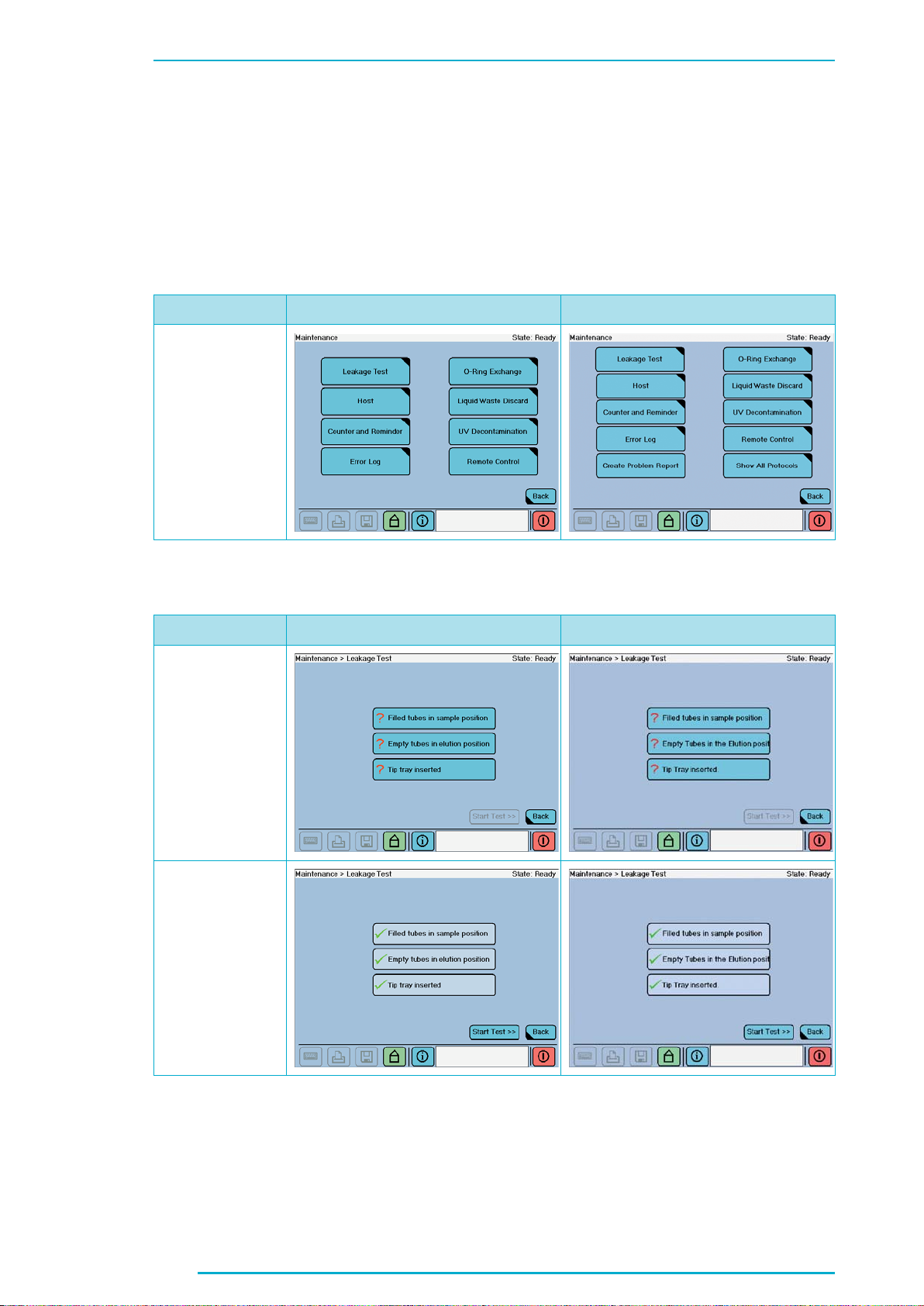

New Screenshot

1.1 Starting the MagNA Pure Compact Instrument, page 38

Current Version Changes

New Screenshot

1.2 Overview of Main Menu Screen

Table 4: Overview of menu and submenu structure, page 41

Current Version Changes

Maintenance:

Detailed Actions

Maintaining:

Leakage Test

䉴

Counter and Reminder

䉴

Error Log

䉴

O-ring Exchange

䉴

Liquid Waste Discard

䉴

UV Decontamination

䉴

Maintaining:

Leakage Test

䉴

Counter and Reminder

䉴

Error Log

䉴

O-ring Exchange

䉴

Liquid Waste Discard

䉴

UV Decontamination

䉴

Create Problem Report

䉴

Important Information regarding the MagNA Pure Compact Instrument Operator’s Manual

6

Page 25

Chapter B

2. Performing a Purifi cation Run, page 45

Current Version Changes

For the MagNA

Pure Compact

RNA Isolation

Kit:

The selection of an appropriate

endogenous IC is of high importance

when developing a quantitative RTPCR assay. The IC is co-amplifi ed with

the target of interest and serves as a

control for several factors: differences

in initial template concentrations

between different samples, sample-tosample variations in the PCR, presence

of PCR inhibitors or the extent of any

RNA degradation. The advantage of

using an endogenous IC is that both

internal control mRNA and target

mRNA is extracted from cells or tissue

and reverse transcribed together.

Commonly used endogenous ICs

include so-called housekeeping gene

mRNAs. (Note that Roche Applied

Science offers several LightCycler®

Housekeeping Gene Sets for the

detection of human housekeeping

genes, incl. G6PDH, HPRT, ALAS,

and _2-microglobulin.) The level

of expression of an appropriate

endogenous IC should not vary

with the experimental conditions or

treatments to be compared.

The selection of an appropriate

endogenous IC is of high importance

when developing a quantitative RTPCR assay. The IC is co-amplifi ed with

the target of interest and serves as a

control for several factors: differences

in initial template concentrations

between different samples, sample-tosample variations in the PCR, presence

of PCR inhibitors or the extent of any

RNA degradation. The advantage of

using an endogenous IC is that both

internal control mRNA and target

mRNA is extracted from cells or tissue

and reverse transcribed together.

Commonly used endogenous ICs

include so-called housekeeping gene

mRNAs. The level of expression of an

appropriate endogenous IC should not

vary with the experimental conditions

or treatments to be compared.

Important Information regarding the MagNA Pure Compact Instrument Operator’s Manual

7

Page 26

Chapter C

Chapter C:

1. User Maintenance

1.1 Leakage Test, page 72

Current Version Changes

New Screenshot

1.1 Leakage Test, page 73

Current Version Changes

New Screenshot

New Screenshot

Important Information regarding the MagNA Pure Compact Instrument Operator’s Manual

8

Page 27

Chapter C

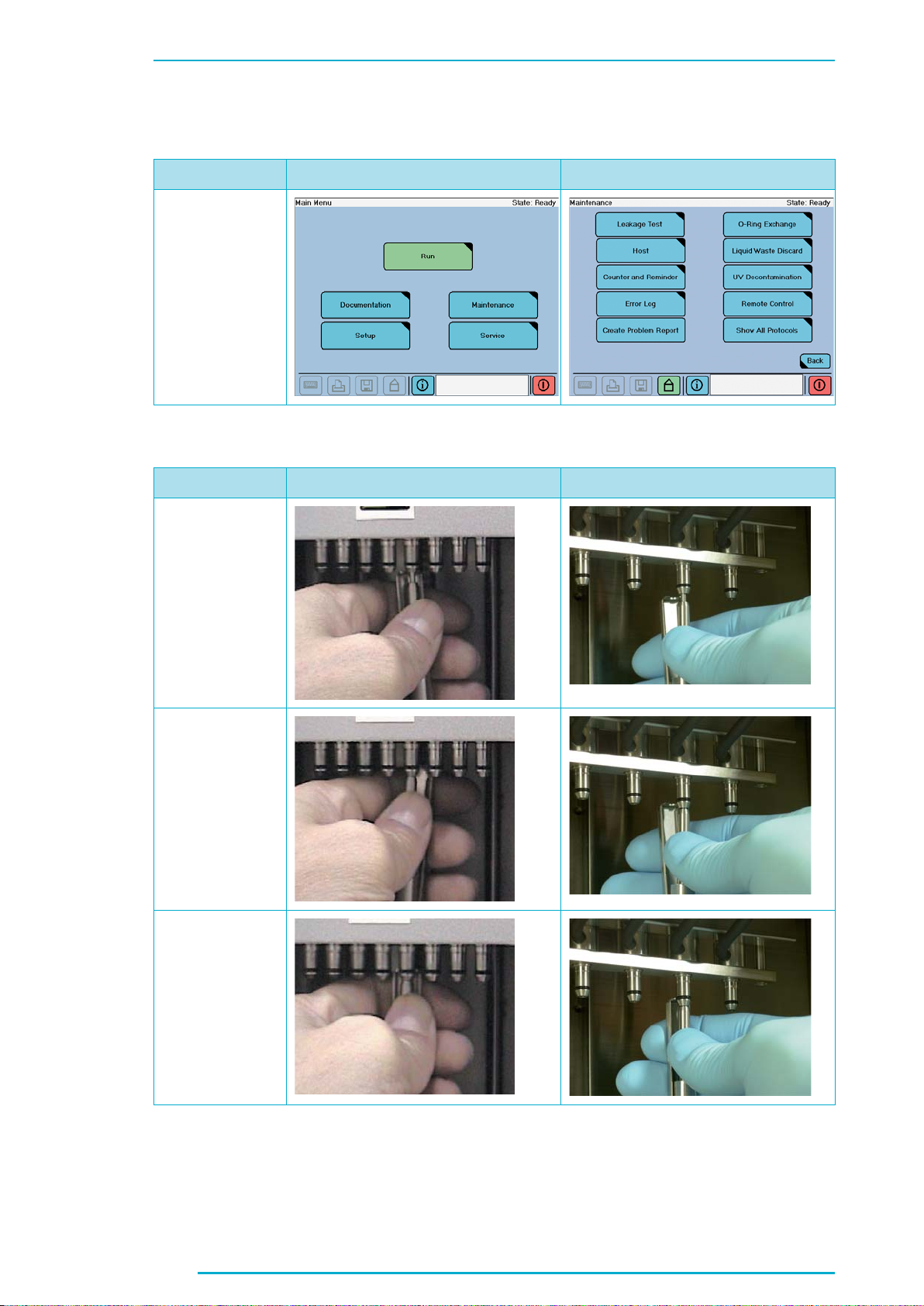

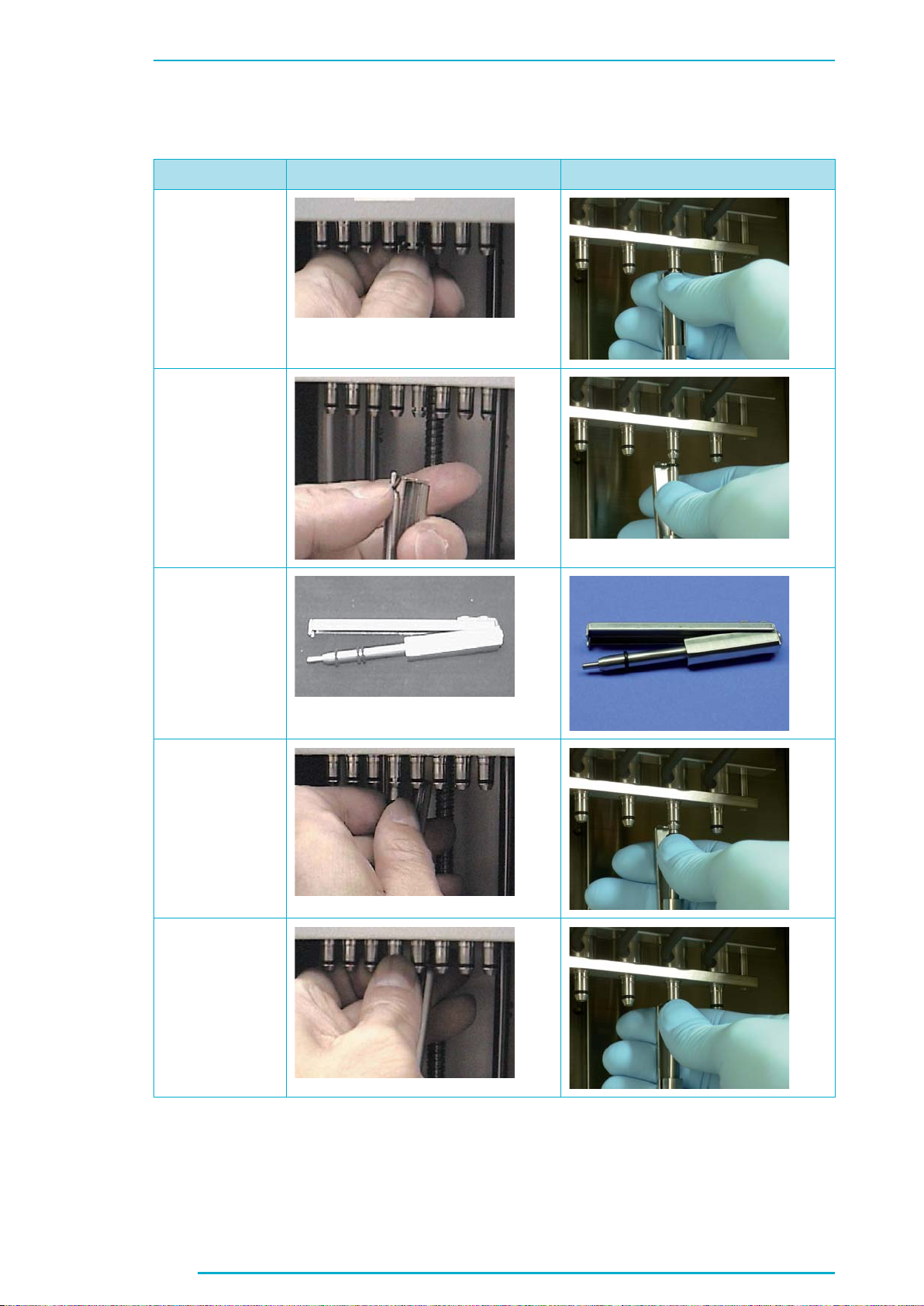

1.2.2 O-Ring Exchange, page 77

Current Version Changes

New Screenshot

1.2.2 O-Ring Exchange, page 78

Current Version Changes

New Pictures

New Pictures

New Pictures

Important Information regarding the MagNA Pure Compact Instrument Operator’s Manual

9

Page 28

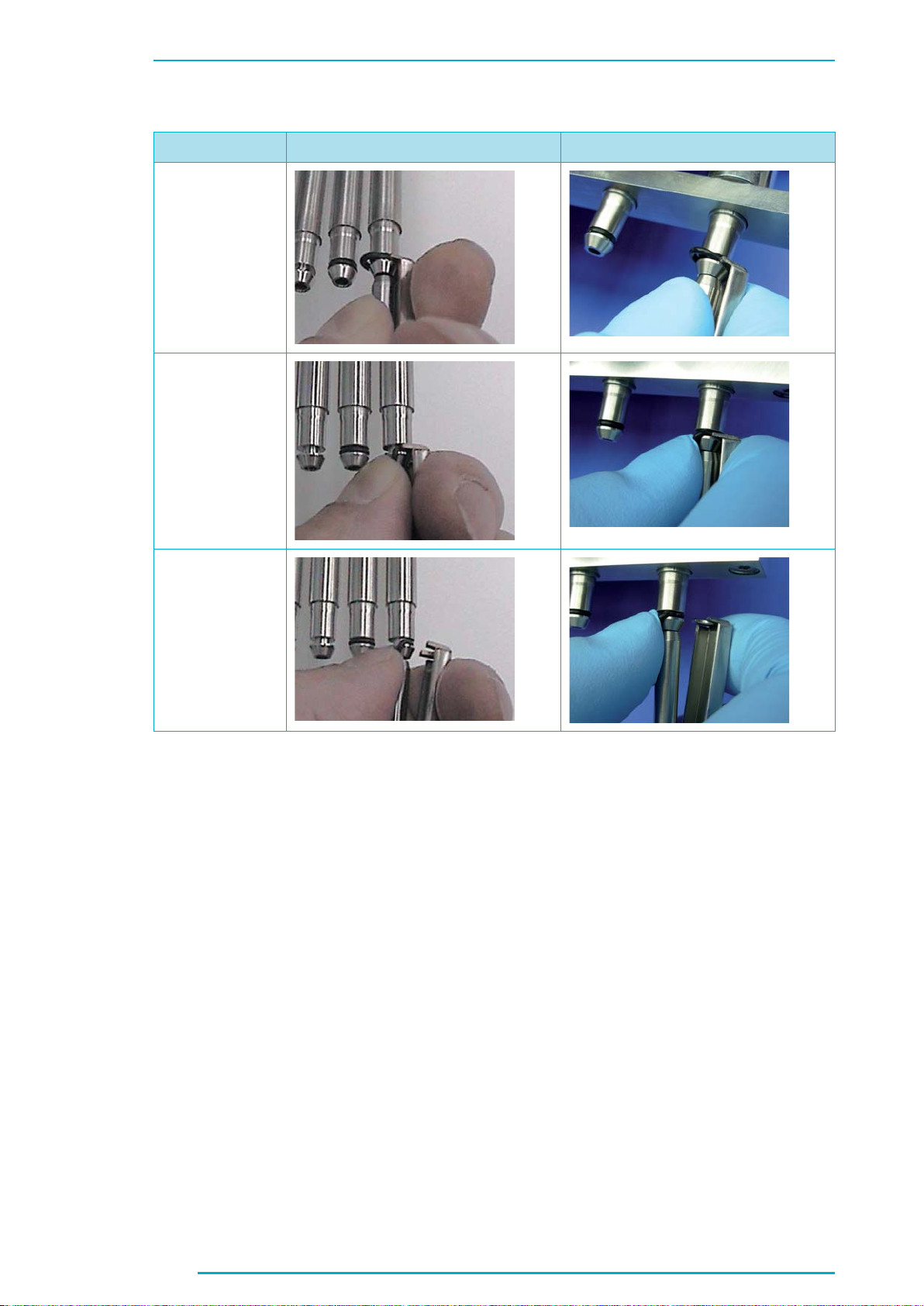

Chapter C

New Pictures

New Pictures

Current Version Changes

New Pictures

10

Important Information regarding the MagNA Pure Compact Instrument Operator’s Manual

Page 29

Chapter C

1.2.2 O-Ring Exchange, page 79

Current Version Changes

New Pictures

New Pictures

New Pictures

New Pictures

New Pictures

11

Important Information regarding the MagNA Pure Compact Instrument Operator’s Manual

Page 30

Chapter C

2. Service Maintenance, page 81

Current Version Changes

Note: Service Maintenance may only be

performed by a Roche Diagnostics

service engineer. Contact your local

Roche representant for maintenance

assistance and for more details on

country-specifi c service contracts.

2. Exchange: Hepa Filter HEPA Filter

Service Maintenance may only be performed by a Roche Diagnostics service

engineer. Contact your local Roche

representative for maintenance assistance and for more details on countryspecifi c service contracts.

3. Cleaning Instructions and UV Decontamination

3.2 UV Decontamination, page 85

Current Version Changes

New Screenshot

12

Important Information regarding the MagNA Pure Compact Instrument Operator’s Manual

Page 31

4. Error Codes and Trouble Shooting Guide

4.1 Error Log, page 86

Current Version Changes

Important Note: In case you want to trouble shoot

an error together with a local Roche

representant, have these informations

ready or make sure the remote service

option is enabled.

New Screenshot

In the event that you want to trouble

shoot an error, together with a local

Roche representative, have this

information ready, or ensure that the

remote service option is enabled.

13

Important Information regarding the MagNA Pure Compact Instrument Operator’s Manual

Page 32

Chapter C

6. Administrator Authorization, page 98

Current Version Changes

Your local Roche Diagnostics

representant will defi ne an

administrator authorization during

instrument installation. The

administrator rights are secured

with a password and enable to

defi ne additional operators. During

the administrator authorization the

password will be displayed hidden,

to guarantee confi dentiality. In case

you should forget the administrator

password, contact your local Roche

Diagnostics representant and you will

receive a new one.

Your local Roche Diagnostics

representative will defi ne an

administrator authorization during

installation of the Instrument. The

administrator rights are secured with

a password and enable the ability to

defi ne additional operators. During

the administrator authorization the

password will be displayed hidden,

to guarantee confi dentiality. In the

event that you forget the administrator

password, contact your local Roche

Diagnostics representative and you will

receive a new one.

14

Important Information regarding the MagNA Pure Compact Instrument Operator’s Manual

Page 33

Chapter C

7. Ordering Guide

7.1 Related Products, page 99

Current Version Changes

Recommended

Printer for Use

with the MagNA

Pure Compact

Instrument:

Hewlett Packard Laserjet 1015 Please contact your local Roche

representative for details.

For installation with the MagNA Pure

Compact Instrument, please contact

your local Roche representantative.

For installation with the MagNA Pure

Compact Instrument, please contact

your local Roche representative.

7.3 MagNA Pure Compact Accessories, page 100

Current Version Changes

Waste Tank 03 788 270 001 03 788 300 001

Drop Catcher 03 788 300 001 03 788 270 001

Trademarks MAGNA PURE, LIGHTCYCLER,

COBAS, and TAQMAN are trademarks

of Roche.

MAGNA PURE, LIGHTCYCLER, LC,

HYBPROBE, COBAS and TAQMAN are

trademarks of Roche.

15

Important Information regarding the MagNA Pure Compact Instrument Operator’s Manual

Page 34

Additional Information

Chapter C:

1. User Maintenance

1.3 Create a Problem Report

For troubleshooting by a Roche representative, error messages and confi guration fi les can be

exported to a Problem Report.

The Problem Report is a zipped fi le containing log, confi guration and version fi les.

To create a Problem Report:

Insert an empty USB Memory Stick on the right side of the Instrument. On the “Main Menu”

1

screen, press the ‘Maintenance’ button. Press the ‘Create Problem Report’ button and select “OK”

in the pop-up window.

The Problem Report is created and stored on the attached USB Memory Stick. A pop-up window

2

will open when the Problem Report has been saved.

1. User Maintenance

1.3 Show All Protocols

The “Show All Protocols” option lists all the protocols which are installed on the MagNA

Pure Compact Instrument.

To “Show All Protocols”

On the “Main Menu” screen, press the ‘Maintenance’ button. Select the “Show All Protocols”

1

button.

All protocols that are installed on the Instrument will be displayed, as shown in the screenshot

2

below.

16

Important Information regarding the MagNA Pure Compact Instrument Operator’s Manual

Page 35

MagNA Pure Compact Operator’s Manual

Instrument Version 1.0

Software Version 1.1

www.roche-applied-science.com

Page 36

Page 37

Table of Contents

Table of Contents

Prologue Page

Intended Use of the Instrument...................................................................................................................5

Contact Adresses....................................................................... .............................................................................5

Revision History.................................................................... ....................................................................................5

Marks of Conformity..............................................................................................................................................6

How to Use this Manual....... ................................................................................................................................7

Symbols used in the Manual...............................................................................................................................8

A General Overview Page

1. Specification of the Instrument.................................................................................................................11

1.1 General Information................................................................... ...........................................................................11

1.2 Operating Environment.......................................................................................................................................12

1.3 Operating Parameters........................................................ ..................................................................................12

2. Installation of the Instrument.....................................................................................................................13

2.1 Shipping....................................................................................................................................................................13

2.2 Unpacking................................................................................................................................................................13

2.3 Additional Items Required for Operation and Maintenance................................................................. 14

2.3.1 Operating Reagents......................................................................................................................................14

2.3.2 Maintenance Items......................................... ..............................................................................................15

2.4 Set-up........................................................................................................................................................................16

2.4.1 Selecting a Location.....................................................................................................................................16

2.4.2 Easy Teaching Procedure.............................. ..............................................................................................16

2.4.3 Software Setup...............................................................................................................................................17

3. Description of the Instrument....................................................................................................................21

3.1 General Description..............................................................................................................................................21

3.2 Function Principle..................................................................................................................................................21

3.3 Description of the Instrument...........................................................................................................................22

3.3.1 Front View of the Instrument.....................................................................................................................22

3.3.2 Detailed View..................................................................................................................................................25

3.3.3 Back View of the Instrument.....................................................................................................................27

3.3.4 Sides of the Instrument...............................................................................................................................28

3.3.5 MagNA Pure Compact Accessories.. ............................................................................. ........................30

3.3.6 Position and Meaning of Warning Labels............................................................................................34

1

Page 38

Table of Contents

Table of Contents

B How to Operate the MagNA Pure Compact Instrument Page

1. Handling the MagNA Pure Compact Software..................................................................................37

1.1 Starting the MagNA Pure Compact Instrument ...................... ..................................................................37

1.2 Overview of Main Menu Screen..................................................................................................................... 39

1.3 Flow Diagram for Preparation of a Purification Run................................................................................42

2. Performing a Purification Run.....................................................................................................................43

2.1 Purification..............................................................................................................................................................46

2.2 Liquid Waste Discard..........................................................................................................................................62

3. Use of Internal Controls................................................................................................................................66

3.1 Function of Internal Control................................... ...........................................................................................66

3.2 How to program the instrument for an internal control......................................................................... 66

4. Data Transfer to or from the MagNA Pure Compact Instrument............................................67

4.1 Data Transfer to other Instruments........ ............................................................................. ............................67

4.2 Upload of New or Updated Purification Protocols....................................................................................67

C Maintenance and Trouble Shooting Page

1. User Maintenance............................................................................................................................................ 71

1.1 Leakage Test ......................................................................................................................................................... 71

1.2 O-ring Maintenance.............................................................................................................................................75

1.2.1 Greasing the O-rings....................................................................................................................................75

1.2.2 O-ring Exchange................................................ ............................................................................................76

2. Service Maintenance......................................................................................................................................81

2.1 Counter and Reminder.................................................................................. ......................................................82

2.2 Remote Control and Host...................................................................................................................................82

3. Cleaning Instructions and UV Decontamination .............................................................................83

3.1 Cleaning....................................................................................................................................................................83

3.2 UV Decontamination............................................................................................................................................85

4. Error Codes and Trouble Shooting Gui de ............................................................................................ 86

4.1 Error Log....................................................................... ...........................................................................................86

4.2 Instrument Error Codes.......................................................................................................................................87

4.3 Trouble Shooting Guide...................................................................................................................................... 94

5. Documentation................................................................................................................................................... 96

6. Administrator Authorization....................................................................................................................... 98

7. Ordering Guide .................................................................................................................................................. 99

7.1 Related Products................................................................................................................................................. 99

7.2 MagNA Pure Compact System Products...................................................................................................100

7.3 MagNA Pure Compact Accessories............................................................................................................100

2

MagNA Pure Compact Operator’s Manual - Version 1.3

Page 39

Prologue

Page 40

4

MagNA Pure Compact Operator’s Manual - Version 1.3

Page 41

Intended Use of the Instrument

Contact Addresses

Prologue

Intended Use of the Instrument

The MagNA P ur e C ompact I nstrument is a r obotic w orkstation f or the aut o mat ed pr eparation of nucleic acids from a broad variety of sample materials (e.g., mammalian blood,

serum, plasma, or blood cells; cultured cells; tissue) with the assistance of specially

designed MagNA Pure Compact reagent kits. The isolated high-quality nucleic acids are

suitable for PCR and RT-PCR reactions on the LightCycler System, as well as on standard

block cyclers, and for many other downstream applications.

The instrument is intended for nucleic acid preparation in general laboratory use by

trained professionals.

Contact Addresses

Manufactured by Roche Instrument Center AG

Forrenstrasse

CH-6343 Rotkreuz

Switzerland

for Roche Diagnostics GmbH

Sandhofer Straße 116

D-68305 Mannheim

Germany

Distribution in USA Roche Diagnostics Corporation

9115 Hague Road

PO Box 50457

Indianapolis, IN 46250

USA

Revision History

Manual

Version

1.1 1.0 1.0 December 2003

1.2 1.0 1.1 August 2004

1.3 1.0 1.1 February 2006

Instrument

Version

Software

Version

Revision Date

Prologue

Copyright 2006, Roche Diagnostics GmbH. All rights reserved.

5

Page 42

Intended Use of the Instrument

Marks of Conformity

Marks of Conformity

The MagNA Pure Compact Instrument had been investigated according to:

䉴 IEC 61010-1, 2nd Edition ("Safety requirements for electrical equipment for

measurement, control and laboratory use; Part 1: General requirements")

䉴 EN 61326:1997 + A1:1998 + A2:2001 Class B ("Electrical equipment for measurement,

control and laboratory use - EMC requirements")

䉴 UL 61010A-1

䉴 CAN/CSA C22.2 No. 1010.1-92

The instrument has been manufactured and checked in accordance with all relevant

safety standards prior to leaving the factory. The instrument has been app ro v ed for use by

recognized testing institutions. This is confirmed by the following conformity symbols:

Acronym Test Symbol Testing Information

CE The instrument conforms to following directives as

CUL Certified by the Underwriters Laboratories Inc.

issued by the European Union according to the Council

Directive 89/336/EEC (Electromagnetic Compatibility)

and 73/23/EEC (Electrical equipment for use within

certain voltage limits).

Equipment to be connected must fulfill the standards set by IEC 950 (Informationsecurity in technical equipment, including electronic business machines).

Classification Note on Use with Infectious Material

The Instrument is classified as: 䉴 The Instrument may not be used to

analyze

䉴 Designed for stationary operation.

䉴 Intended f or worldwide use.

䉴 Intended for evaluating preprocessed

infectious materials unless

additional safety measures to ensure

safe sample handling are taken

beforehand.

biological material.

6

MagNA Pure Compact Operator’s Manual - Version 1.3

Page 43

How to Use this Manual

Important: Before operating the MagNA Pure Compact Instrument, be sure to read and

understand the warnings, cautions and safety requirements in this manual. Failure to

follow the instructions contained in this manual may hav e hazardous consequences.

Chapter A General Overview describes

䉴 contents of the MagNA Pure Compact system package

䉴 design of the instrument

䉴 accessories and disposable plastics required for instrument operation

䉴 isolation method of the MagNA Pure Compact Instrument

Intended Use of the Instrument

How to Use this Manual

Chapter B How To Operate the MagNA Pure Compact Instrument describes how to

䉴 use the MagNA Pure Compact Software

䉴 prepare the instrument for a purification run

䉴 perform a purification run

Chapter C Presents additional information on maintenance

of the instrument and troubleshooting

䉴 User Maintenance

䉴 Service Maintenance by the Roche service

䉴 Cleaning of the instrument

䉴 Troubleshooting

Prologue

7

Page 44

Intended Use of the Instrumentl

Symbols used in this Manual

Symbols used in this Manual

Symbol Heading Description

WARNING

RISK OF DANGER

HOT SURFACE This symbol is used to label potentially hot

BIOHAZARD This symbol is used to indicate that certain

IMPORTANT NOTE This symbol is used to bring your attention to

INFORMATION NOTE Designates a note that provides additional

This symbol is used to indicate that noncompliance with instructions or procedures

may lead to physical injury or even death or

could cause damage to the instrument.

instrument surfaces.

precautions must be taken when working with

potentially infectious material.

an important annotation.

information concerning the current topic or

procedure.

8

MagNA Pure Compact Operator’s Manual - Version 1.3

Page 45

General

Overview

Page 46

A

A

10

MagNA Pure Compact Operator’s Manual - Version 1.3

Page 47

Specifications of the Instrument

General Information

General Overview

1 Specifications of the Instrument

Do not use the equipment in a manner not specified by the manufacturer . Otherwise, the

protection provided by the equipment might be impaired.

1.1 General Information

Cat. No.

Dimensions

Weight

Power supply

Frequency 50/60 Hz +/- 5%

Power consumption

Fuses

Heat emission

Protection Class

Installation Category

Electromagnetic Emission:

Terminal disturbances voltage

Electromagnetic radiation

disturbances

03 731 146 001

W 540 mm; D 610 mm; H 570 mm

approx. 60 kg

100 - 240 V AC +/- 10%

Max. 400 VA

4.0 AT, 2 pieces

1440 kJ/h (max.)

860 kJ/h (average value during operation)

I

II

Class B

Class B

A

A

General Overview

11

Page 48

Specifications of the Instrument

Operating Environment

1.2 Operating Environment

A

A

Temperatures allowed during

transportation/storage/packaging

Temperatures allowed during

operation

Pollution Degree: 2

Maximum relative humidity

Altitude

1.3 Operating Parameters

Note: Exact values depend on the purification protocol used.

Processing capability

Processing time

Pipetting Accuracy

-25°C to +70°C

+18°C to +30°C

Indoor use

80% (for operating temperatures up to 31°C);

decreases linearly to 50% for operating

temperatures up to 40°C

up to 2000 m

1 to 8 samples per batch

20 to 45 min (depending on protocol)

25 µl to 100 µl: ⱕ5%

⬎100 µl ⱕ2%

Sample Volume

Elution Volume

Internal Control Volume

100 – 1000 µl

50 – 200 µl

5 – 20 µl

12

MagNA Pure Compact Operator’s Manual - Version 1.3

Page 49

Installation of the Instrument

Shipping

2 Installation of the Instrument

2.1 Shipping

The MagNA Pure Compact Instrument is shipped in a styrofoam container surrounded

by a cardboard box. Before opening it, inspect the container carefully for damage. Report

any damage to your local Roche Diagnostics office before accepting the unit.

2.2 Unpacking

Note: The following steps will be done by your local Roche Diagnostics representative.

Standard Component List

䉴 1 MagNA Pure Compact Instrument body

A

A

Individual parts:

䉴 1 Cartridge Rack

䉴 1 Tube Rack

䉴 1 Elution Tube Rack

䉴 1 Waste Tank

䉴 1 Drop Catcher

䉴 1 Drip Tray

䉴 1 Barcode Scanner and cable

䉴 US power cable

䉴 German power cable

䉴 1 package High Vacuum Grease

䉴 1 package O-rings (8 pieces)

䉴 2 fuses for line filter

䉴 Operator’s Manual

The MagNA Pure Compact Instrument is a standalone instrument, which needs no

additional computer. The computer is already included in the instrument housing and

and may be operated via a touch-screen.

General Overview

13

Page 50

Installation of the Instrument

Additional Required Items for Operation and Maintena nce

2.3 Additional Items Required for Operation and Maintenance

2.3.1 Operating Reagents

Before operating the MagNA Pure Compact Instrument for the first time, you must have

one of the following reagen t k its:

Cat. No. Purific ation Kit For Preparation Of

A

A

03 730 964 001 MagNA Pure Compact Nucleic

Acid Isolation Kit I

03 730 972 001 MagNA Pure Compact Nucleic

Acid Isolation Kit I - Large Volume

04 802 993 001 MagNA Pure Compact

RNA Isolation Kit

These three kits for the purification of genomic DNA, viral total nucleic acid (DNA and

RNA) or total RNA are currently available from Roche Diagnostics. The instrument software

already contains operating protocols that can be used with

Nucleic Acid Isolation Kits. Purification protocols for the MagNA Pure Compact RNA

Isolation Kit are available for download from http://www.roche-applied-science.com/sis/

magnapure/magna_compact_protocols.htm. Please contact your local Roche representative or visit www.magnapure.com for the latest information on additional purification

kits and protocols. See section 4.2 for details on how to install new purification protocols

into the MagNA Pure Compact software.

Each purification kit includes the reagents and disposables needed for a standard

purification run. If you need additional tubes, e.g. for an internal control or maintenance

activities (leakage test), you must order them from Sarstedt. (See the Appendix for

detailed ordering information.)

Genomic DNA from mammalian whole blood, plasma

and culture cells. Total nucleic acids from mammalian

plasma and whole blood.

Genomic DNA from mammalian whole blood,

plasma and culture cells. Total nucleic acids from

mammalian plasma and whole blood.

Total RNA from mammalian whole blood, blood cells,

cultured cells, and tissue.

the MagNA Pure Compact

Note: The actual amount of reagents and disposables may vary between the different

available MagNA Pure Compact purification kits.

Kit content:

䉴 Prefilled Reagent Cartridges (individually packed in a sealed foil pouch, with barcode)

䉴 Sample Tubes (35 tubes per package, 2.0 ml each, with stand, without barcode)

14

MagNA Pure Compact Operator’s Manual - Version 1.3

Page 51

Installation of the Instrument

Additional Required Items for Operation and Maintenance

Kit content:

䉴 Elution Tubes (35 tubes per package, 2.0 ml each, with stand, with barcode)

䉴 Caps for Elution Tubes (35 caps per caps)

䉴 Tip Trays (including Piercing Tool and tips). The tips are placed in the following order

into the Tip Tray: one Piercing Tool, one small tip, two large tips.

A

A

2.3.2 Maintenance Items

Cat. No. Purification Kit Contents

03 561 429 001 MagNA Pure LC O-Ring Maintenance Kit O-rings (12 x 8),

High Vacuum Grease (1)

03 753 166 001 MagNA Pure Compact Tip Tray Kit 10 Tip Trays

Note:

䉴 To ensure that they work correctly, you must grease the O-rings once per week (or

after every 20 purification runs). If the O-rings malfunction, the instrument nozzles

may leak. For details, please see the Maintenance section in Chapter C.

䉴 Perform a leakage test every two months (or after every 50 purifi cation runs) to deter-

mine whether the O-rings should be changed. For details please see the Maintenance

section in Chapter C.

There is an O-Ring Exchange Tool available, which simplifies the O-ring changing process. Please contact your local Roche Diagnostics representative if you need O-rings

changed or want one of these tools.

General Overview

15

Page 52

A

A

Installation of the Instrument

Setup

2.4 Setup

2.4.1 Selecting a Location

The MagNA Pure Compact Instrument requires very little setup. Choose for the MagNA

Pure Compact Instrument a clean, dry, level, stable surface within 3 m of a compatible

electrical outlet. To ensure proper ve ntilation, lea ve 10 cm of space behind the in strument

and 15 cm at each side of the instrument. No space is needed at the back of the instrument.

Protect the MagNA Pure Compact Instrument from heat and excessive sunlight and

always ventilate the r oom well. The instrument is for „indoor use only“ and should not be

operated in areas of excessive humidity or extremes of temperature. Do not use the

instrument where there is a risk of explosion.

2.4.2 Easy Teaching Procedure

The software has been preinstalled by the manufacturer. The installer (service user) must

perform an adjustment procedure, called Easy Teaching, before the instrument can be

used. Only a service operator, not a regular operator, can access the menu for the Easy

Teaching procedure. This is done by your local Roche Diagnostics representative.

Note: The Easy Teaching Procedure must be performed before the instrument will work

correctly. If the adjustment is not done pr operly, either the instrument could be damaged

or the instrument performance could be affected (e.g. pipetting accuracy, y ield in nucleic

acids, etc.).

16

MagNA Pure Compact Operator’s Manual - Version 1.3

Page 53

Installation of the Instrument

Setup

2.4.3 Software Setup

Either a service operator or a regular operator can access the menu for software setup.

This menu enables the operator to

䉴 set the time and date

䉴 preset the location (folder) where all generated data will be sav ed

䉴 enter a laboratory name

䉴 choose the types (and loudness) of alarm sounds the instrument will generate

䉴 manage the list of operators that have access to the instrument

䉴 specify the types of sample materials to be handled with the instrument

Note: The type of sample material used for a purification run can be selected later on

during Sample Ordering 2 (see chapter B for details). It is used for documentation purposes only and does not influence the purification protocol.

Action Software Screen

Turn on the MagNA Pure Compact Instrument by pressing the Power On button

1

on the front of the instrument.

During initialisation/self test of the system components the start-up screen

2

appears.

The MAIN MENU Screen appears

3

A

A

Touch the SETUP Button on the touch-screen

4

The SETUP Screen appears

5

Note: Touch the Back button

(at the lower right corner of the

SETUP Screen) to return to the

MAIN MENU Screen.

Touch the SETTINGS Button

6

The SETTINGS Screen appears.

7

Note: Touch the Back button (at the lower right corner of the SETTINGS Screen)

to return to the SETUP Screen without changing any of the current settings.

General Overview

17

Page 54

A

A

Installation of the Instrument

Setup

Action Software Screen

8

8a

Basic Settings

Program the actual time and date by pressing the buttons next to the time

and date displays. A pop up window opens to allow you to set the correct values.

Touch the Up and Down buttons (to the right of each number) to change the

values for hours and minutes (see figure). The Up button increases values

by one unit, the Down button decreases values by one unit. Touch the OK button

to confirm the changes and return to the SETTINGS Screen. Touch the Cancel

button to return to the Settings Screen without changing any settings.

Note: The hour setting uses a 24-hour clock, where 11:00 PM is hour 23, and

midnight is hour 0. The hour and minute values can be set independently; that is,

you can change from minute 59 to minute 0 (or vice versa) without causing the

hour setting to change.

8b

8c

Touch the Up and Down buttons (to the right of each number) to change the

values for year, month and day (see figure). The Up button increases values;

the Down button decreases values. Touch the OK button to confirm the changes

and return to the SETTINGS Screen. Touch the Cancel button to return to the

SETTINGS Screen without changing any settings.

Note: These values can be set independently . You can change from December to

January (or vice versa), without causing the year to change. Y ou can change from

day 30 (or 31) to day 1 (or vice versa) without causing the month to change.

To specify the default folder where all generated data will be saved, touch the

Folder field, then use the pop-up virtual keyboard to type the name of the folder

into the field .

18

MagNA Pure Compact Operator’s Manual - Version 1.3

Page 55

Action Software Screen

8d

To specify the default laboratory name that will be mentioned with all generated

data, touch the Laboratory Name field, then use the pop-up virtual keyboard to

type the laboratory name into the field.

Installation of the Instrument

Setup

8e

10

Alarm Settings

To specify the types of alarm that the instrument software should give, as well as

the loudness of each alarm, touch appropriate buttons on the "Acoustic Signals“

panel.

Note: You can choose to sound an alarm each time an error message is displayed

(Error), each time a button has been touched on the virtual keyboard (Keyboard),

and each time the purification run has ended (End of the run). If you don’t want

one of these alarms, just select for that particular alarm. For each alarm you

want, choose whether the alarm sound should be given at low, medium or high

volume.

Select Back to return to the Settings Menu without modification.

9

Select the Operator List button from the Setup menu.

A

A

General Overview

To enter a new operator type a new name into the entry field below the Operator

List and select the Add button.

Note: Only an administrator can define a new user. The administrator is asked for

his admin password when this button is used. If no administrator should be

defined, set the first time the Return key.

19

Page 56

A

A

Installation of the Instrument

Setup

Action Software Screen

11

Select the Material List button from the Setup menu.

To enter a new type of sample material type a new name into the entry field below

the material list.

12

Select the Add button to add the new name to the Material List.

The MagNA Pure Compact Instrument is now ready for use.

20

MagNA Pure Compact Operator’s Manual - Version 1.3

Page 57

Description of the Instrument

General Description

3 Description of the Instrument

3.1 General Description

The MagNA Pure Compact Instrument is a robotic workstation that can automatically

isolate nucleic acids from crude sample material. It is a compact benchtop instrument

with an integral touch-screen computer. The central processing unit of the instrument is

a robotic arm with an 8-nozzle pipette head. This pipette head can process 1–8 samples

per run. In addition, this pipette head has a specialized sensor unit, which can detect clots

in sample material and loss of reaction tips.

3.2 Function Principle

When it is purifying DNA, the basic operations of the instrument are:

A

A

General Overview

For details on the purification kits (provided in prefilled cartridges) please refer to their

pack inserts. All kit pack inserts can be obtained at the Roche home page: http://

www.roche-applied-science.com

21

Page 58

A

A

Description of the Instrument

Description of the Instrument

3.3 Description of the Instrument

3.3.1 Front View of the Instrument

1 Housing

Painted sheet metal housing contains the main body of the instrument and protects it

from electromagnetic influences, chemicals, and UV-light.

2 Front Door

The nozzle head can only be moved after the instrument door is closed and locked. This

door lock is controlled by the software. This prevents anyone from reaching inside the

instrument during the purification, which might lead to injuries.

The door permits a good view of the interior of the instrument. During the decontamination cycle, the door prevents escape of UV light from the interior. It also protects

reagents, disposable plastics and samples from environmental contamination.

The front door has to be opened to get access to the liquid waste tank and drip tray.

22

MagNA Pure Compact Operator’s Manual - Version 1.3

Page 59

Description of the Instrument

Description of the Instrument

3 Nozzle Head

The nozzle head moves over the processing stage up and down (vertically along the zaxis). It carries the pipetting unit, the sensor unit and the magnet unit. The pipetting unit

consists of 8 independent working air-filled plungers, each connected to a nozzle (1)

which takes up the Reaction Tip. The Reaction Tip (3) is held by the O-ring (2) on the

nozzle. A specially designed sensor unit checks all 8 channels indiviually for clots in the

sample material, correct position of the reagent cartridge and piercing tool, loss of reaction

tips, as well as for the presence of sample tube and internal co ntrol tube (if appropriate).

A

A

4 Processing Stage

The processing stage holds the cartridge rack with the reagent cartridges, the tip trays, the

tube rack with elution tube rack, the heating units and the waste tank. It moves back and

forth (horizontally along the y-axis), thereby moving the cartridge rack with the prefilled

reagent cartridges into position so they can be processed. It contains a loading mechanics

that lifts the cartridge rack to the top position for easy insertion and removal of the cartridge rack or the cartridges. The equipped cartr idge ra ck is then manually pushed down

to the low position of the loading mechanics inserting the respective cartridge wells into

the heating unit.

5 Touch-screen

From the touch-screen, you can operate all instrument features. E.g., you can program a

run, install a new protocol, maintain the instrument or search for accumulated data. You

can activate the functions on the touch-screen either with your fingertips or with a PDM

pencil.

General Overview

23

Page 60

A

A

Description of the Instrument

Description of the Instrument

6 Buttons for Setting Screen Contrast

By pressing the + and – buttons, you can set the brightness of the touch screen.

7 Status Indicator LEDs and Power On Button

The instrument is turned on pressing the "power on" button.

Three LEDs indicate the current status of the instrument:

䉴 The green LED of the "power on" button indicates that the instrument is powered on

䉴 the red "processing" LED indicates the status of processing

䉴 the yellow "run c ompleted" LED signalizes that the run is completed.

8 Disk Drive

The disk drive allows the operator to st ore the data generated as well as transfer it easily to

other instruments or computers, e.g for sample tracking, documentation or troubleshooting. In addition, new MagNA Pure Compact Purification protocols can be

uploaded from commercially available disks.

9 Barcode Scanner

The barcode scanner enables the use of barcodes to track samples through the entire

purification process as well as prior (sample preparation) and subsequent steps (e.g.

PCR, storage of the eluate). Moreover, when you scan the cartridge barcode, the touchscreen will display the name of the correct MagNA Pure Compact Purification Kit and

the instrument will automatically load the appropriat e purificatio n protocol.

24

MagNA Pure Compact Operator’s Manual - Version 1.3

Page 61

3.3.2 Detailed view

Description of the Instrument

Description of the Instrument

A

A

1 Nozzle Head

The nozzle head performs all pipetting steps. Its 8 nozzles can hold up to 8 reaction tips

per time. It also contains the tip-loss & clot-detection system (pressure sensor).

2 Magnet Unit

The magnet unit contains permanent magnets and can move forward and backward

from the rear of the chamber. For separation of magnetic beads from the buffers, the

magnetic plate moves closer to the reaction tips, thereby immobilizing the magnetic

beads on the inner surfaces of the reaction tips. The distance between magnet and reaction tips is controlled by the software. The magnet unit also holds the drop catcher .

General Overview

25

Page 62

A

A

Description of the Instrument

Description of the Instrument

3 Heating Block

The heating block has two independantly working units for two dedicated wells (for the

lysis and elution step) per one reagent cartridge. These wells are separated from each

other and from the wells with ambient temperature by a little distance.

4 Tip Rack

The tip rack holds up to 8 Tip Trays, each carrying 2 large tips, 1 small tip, and a disposable piercing tool, which pierces the aluminum foil on every cartridge well before purification starts. After it uses them, the instrument places the tips back into their original

positions on the tip tray for easy disposal.

5 Front Door

The front door can be opened for maintenance purposes or to remove the trays, the liquid waste tank, or the drip tray. It is opened by moving the lever at the right door side to

the left.

26

Instrument parts 6-11 are accessories and are described in detail under section 3.3.5

MagNA Pure Compact Accessories.

6 Drop Catcher

7 Cartridge Rack

8 Tube Rack

9 Elution Tube Rack

10 Waste Tank

11 Drip Tray

MagNA Pure Compact Operator’s Manual - Version 1.3

Page 63

Description of the Instrument

Description of the Instrument

3.3.3 Back View of the Instrument Description of Instrument Backmber Instrument Part Description

A

A

1 Exhaust fans with HEPA filter

The housing is cooled by air. The instrument has air inlets with dust filters on both sides

of the instrument. An exhaust fan expels this air from the back of the instrument through

a HEPA (glass fiber) filter.

Note: This HEPA filter retains some aerosols. However, the MagNA Pure Compact

Instrument is not guaranteed to be fully air-tight. Although the total air flow from the

platform goes through the HEPA filter , air does flo w unde r the platform as well as ov e r it.

Thus, there is a possibility that some of the air surrounding the platform will escape from

the instrument without HEPA filtration.

General Overview

27

Page 64

A

A

Description of the Instrument

Description of the Instrument

3.3.4 Sides of the Instrument

Description of Right Side of Instrument

1 Air Inlet

Air inlet for electronic compartment, with dust filter.

2 Air Outlet

Air outlet for electronic compartment.

3 Main Switch

Use the Main Switch t o turn the instrument on and off, e.g. in case of an emergency or if

the instrument is not in use for longer time periods. In routine daily use the instrument

should be turned off via the software button on the touch-screen as described in chapter B.

28

MagNA Pure Compact Operator’s Manual - Version 1.3

Page 65

Description of the Instrument

Description of the Instrument

4 Socket for power cable

This is the plug-in for the power cable. There are two power cables included in the

instrument package, one for US and one for German wall outlets.

5 Fuse

Next to the power inlet is a socket for the 2 main fuses. In case the fuses need to be

replaced, make sure to first unplug the instrument from electrical power. A set of spare

fuses is enclosed with the instrument.

6 Barcode Scanner port

The PS/2 port marked „Barcode Scanner“ is to be used for the barcode scanner.

7 Parallel Port

The parallel port is intended to be used for the connection with a local printer.

8 Serial Port (RS232)

The serial port might be used for additional external devices for LIMS.

9 USB Ports

There are two USB ports, USB 1 and USB 2 port, can be used for any accessories that are

not included with the MagNA Pure Compact Instrument.

Description of Left Side of Instrument

A

A

General Overview

1 Air Inlet

Air Inlet for the processing area with dust filter. Dust filters keep dust particles away fr om

the inside of the instrument. Air is expelled by a fan through the HEPA filter on the backside of the instrument.

29

Page 66

A

A

Description of the Instrument

Description of the Instrument

3.3.5 MagNA Pure Compact Accessories

All MagNA Pure Compact Accessories described below can be ordered separately. For

ordering information see chapter C, Orderi ng Guide.

1 Cartridge Rack

The cartridge stage holds the cartridge rack, where the individual prefilled reagent/processing cartridges (up to 8 per purification run) are inserted. The Cartridge Rack can be

equipped in and outside of the instrument.

2 Tube Rack

In row 1, the Tube Rack holds up to 8 sample tubes (capacity 2.0 ml), which are provided

with the purification kits. If you are running an Internal Control, you can purchase up to

8 additional sample tubes (capacity 2.0 or 1.5 ml) from Sarstedt and place them in row 2

(the Internal Control T ube Rack). (For details see the Related Products section in Chapter

C). In row 3, primary sample tubes (not provided) may be placed prior to starting the

purification process. To discriminate it from row 1 and 2 the positions of row 3 have a

wider diameter.

The rack has numbered positions (1-8) and can stand upright on e.g. a bench. The tubes

can be screwed down with one hand, as they are secured against turning by a mechanical

anti-twist device.

30

Note: To ensure correct pipetting, use only these recommended types of tubes for the

Internal Control: 2.0 ml Sarstedt Tubes (without cap: Sarstedt #72.608; with cap: Sarstedt

#72.693).

MagNA Pure Compact Operator’s Manual - Version 1.3

Page 67

Description of the Instrument

Description of the Instrument

3 Elution Tube Rack

The Tube Rack also contains a separate rack for elution tubes. The Elution Tube Rack will

sit on the tube rack, after both have been equipped. The two holes of the Elution Tube

Rack match with the two pins of the tube rack. After assembly the elution tube rack hides

the row for primary sample tubes. The elution tube rack holds up to 8 tubes (capacity 2.0

ml), each labelled with an individual barcode. These tubes are provided with the reagent

kits. The rack has numbered positions (1-8) and can stand upright on e.g. a bench.

A

A

4 Drip Tray

The Drip Tray keeps any accidentally spilled liquid away from the interior of the instrument housing, especially from the electrical components of the instrument which are

located below the Processing Stage. It can be removed for cleaning. (For details see the

Maintenance section in chapter C.) See chapter C for details on cleaning the drip tray.

General Overview

31

Page 68

A

A

Description of the Instrument

Description of the Instrument

5 Waste Tank

The instrument contains an integral waste tank, where liquid waste accumulates during

each purification run. It can hold all the liquid waste from one purification run.

Note: To avoid contamination, always remember to empty the waste tank after every

purification run. The tank is located beneath the tube racks, which must be removed

before you can reach the tank. The waste tank sensor will determine whether the tank is

inserted correctly or not. See chapter C for details on emptying the liquid waste tank.

6 Drop catcher

The drop catcher is carried by the upper side of the magnet unit and is placed directly

below the nozzle head each time it moves anywhere except from one well to the next. If a

drop should leave the pipet, it is caught by the drop catcher.

The drop catcher can be removed from its place for cleaning purposes. See chapter C for

details on possible causes and how to avoid.

7 Barcode Scanner

32

The barcode scanner is intended for protocol selection (automatically when the kit cartridge is scanned) and positive sample tracking.

MagNA Pure Compact Operator’s Manual - Version 1.3

Page 69

Scanner Specifications

Description of the Instrument

Description of the Instrument

Power Supply

Consumption

Max. Resolution

Scan Rate

Min. Print Contrast Ratio

Reading Angle

Reading Indicators

Readable Barcodes

Enhanced Features

Weight

Case Material

Cable Length

5 VDC ±5%

250 mA operating, 330 mA max.; 250 µA sleep mode

0.076 mm (3 mils)

270 scans/sec.

15%

Skew: ±80°, Pitch: 65°, Tilt ±35° (EAN13, M=0.8,

PCS=0.9)

Good Read LED, „green spot“ on the code, adjustable

tone „beeper“

2/5 family, Code 39 (plus Code 32, Cip 39), EAN/UPC,

EAN 128, Code 128, Code 93, CODABAR, TELEPE N,

PLESSEY, Code 49, Code MSI, Code Delta IBM, Code 11,

CODABLOCK, and Code 16K, PDF 417

Puzzle SolverTM, data editing and data concatenation

(approx.) 200 g

ABS and Polycarbonate

2 m (6.1 ft.) linear or coiled

A

A

Ambient Light Conditions

MTBF

Operating Temperatures

Storage Temperature

Humidity

Drop Resistance

ESD Protection

Environmental Protection

Up to 100.000 lux

>240,000 hours (MIL-HDBK-217F ground benign)

0 to 55 °C

-20 to 70 °C

90% non-condensing

IEC 68-2-32 Test ED; withstands repeated drops from

1.8 m onto a concrete surface

16 kV

IP30

General Overview

33

Page 70

A

A