Page 1

Roche Molecular Biochemicals

LightCycler Oper ator’s Manual

Version 3.0

May 1999

Page 2

Prologue

The LightCycler Instrument of Roche Molecular Biochemicals, Mannheim, Germany, is a thermocycler for the rapid analysis of PCR applications.

LightCycler technology is the most innovative and rapid possibility for carrying

out and simultaneously evaluating PCR experiments. 30 amplification steps including analysis of results can be carried out in less than 30 minutes. Fluorimetric

analysis of the PCR products formed is performed as real-time measurement either continuously or at a specifically defined time during each PCR cycle. The

analyses can be monitored online by the LightCycler’s user-friendly software, i.e.

directly during the reaction.

This Operator’s Manual contains all the necessary technical information required

to place the LightCycler instrument in operation and to carry out practical analyses. It contains background information on some of the applications and enables

the quick and safe optimization of individual applications.

Page 3

Symbols and Notes

Symbols and

Headings

Trademarks

and License

Disclaimers

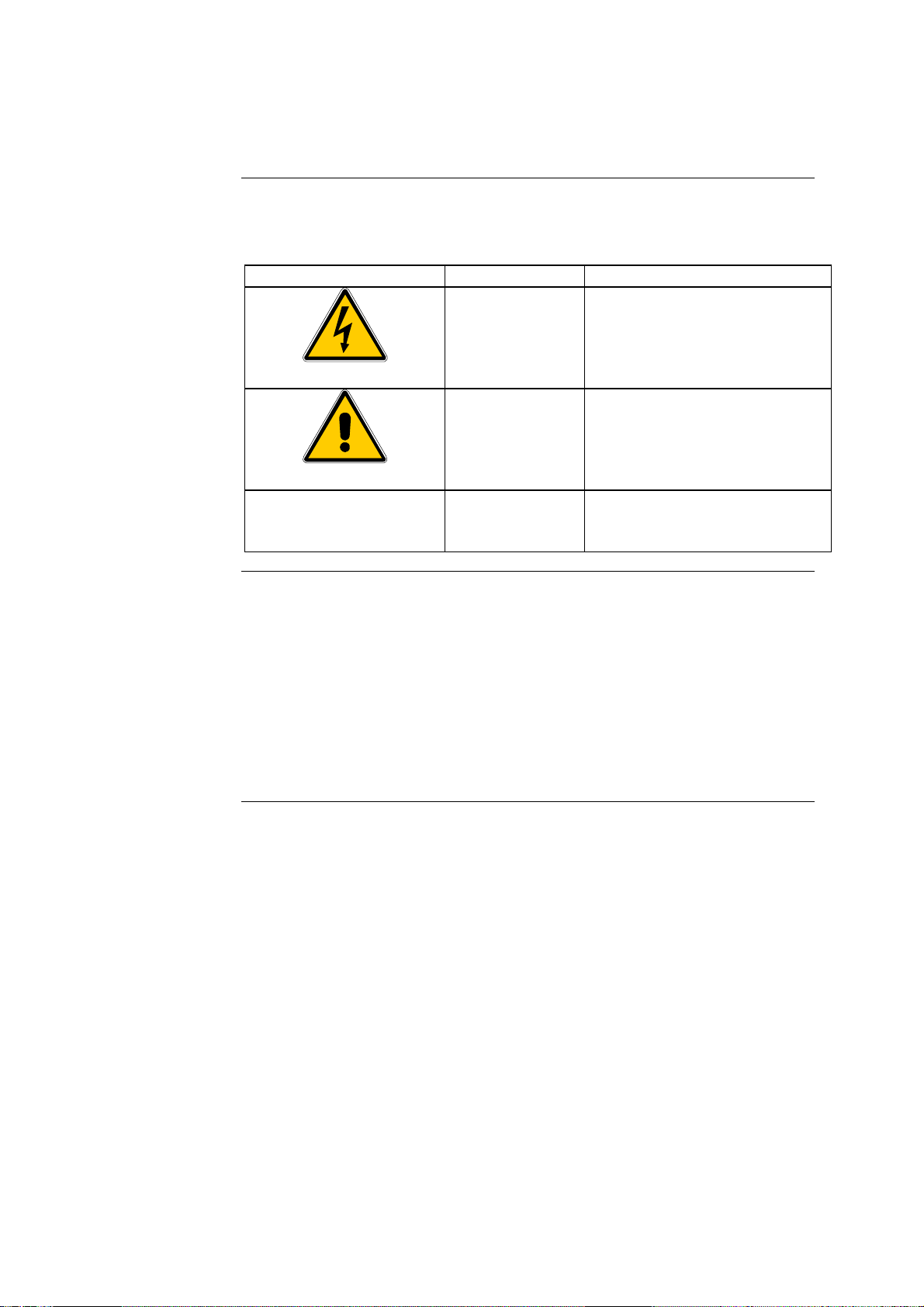

The following symbols and headings are used in this manual:

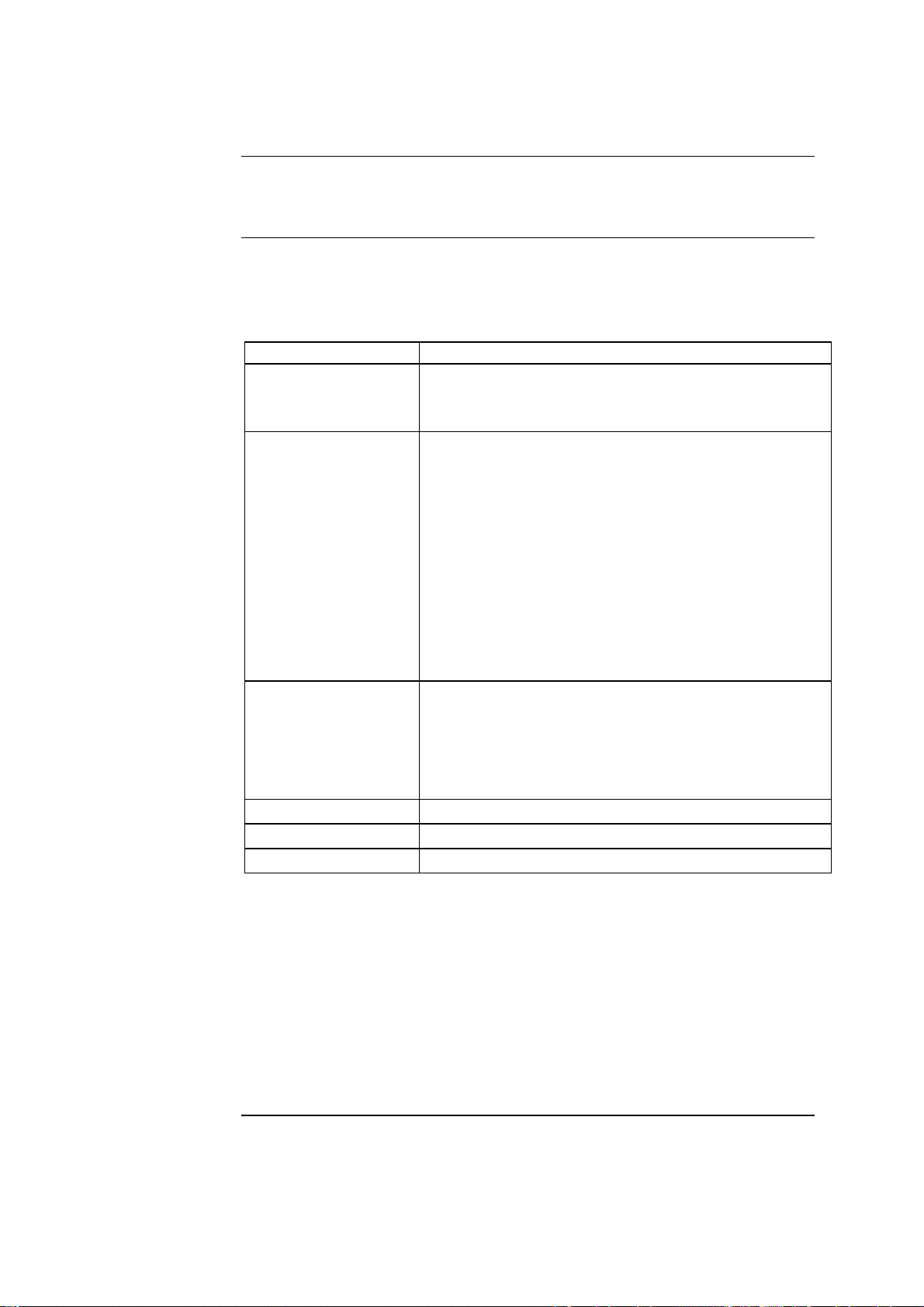

Symbol Heading Description

WARNING This heading and symbol are

used to indicate that noncompliance with instructions

or procedures may lead to injury or even death.

CAUTION This heading and symbol are

used to indicate that noncompliance with instructions

or procedures may cause damage to the instrument.

NOTE This heading is used to bring

your attention to topics of importance

• The LightCycler technology is licensed from Idaho Technology Inc., Idaho

Falls, ID, USA

• LightCycler is a trademark of Idaho Technology Inc., Idaho Falls, ID, USA,

in the United States and some other countries.

• SYBR Green I is a trademark of Molecular Probes Inc., Eugene, OR, USA.

• TaqStart is a trademark of Clontech Laboratories, Inc., Palo Alto, CA, USA

• Expand is a trademark of a Member of the Roche Group.

For License statements, please refer to LightCycler reagent package inserts.

Page 4

LightCycler Software and License Agreement

Software License Agreement

Program License Agreement

Grant of License

READ THIS LICENSE AGREEMENT BEFORE REMOVING THE

PROGRAM CD (HEREINAFTER REFERRED TO AS PROGRAM MEDIA)

OR DOCUMENTATION FROM ITS PROTECTIVE COVER. REMOVING

THE PROGRAM MEDIA OR DOCUMENTATION WILL CONSTITUTE

AGREEMENT TO THE TERMS AND CONDITIONS OF THIS SINGLEUSE, END-USER LICENSE AGREEMENT. IF YOU ARE NOT WILLING TO

BE BOUND BY THE TERMS AND CONDITIONS OF THIS LICENSE

AGREEMENT, PROMPTLY RETURN THE UNOPENED PACKAGE TO

ROCHE DIAGNOSTICS GMBH WITH A COPY OF THE RECEIPT, AND

YOUR LICENSE FEE WILL BE REFUNDED.

You assume all responsibility and liability for the selection of this software

program, hereinafter referred to as Product, to achieve your intended results,

and for its installation and subsequent use.

Roche Diagnostics GmbH hereby grants to Licensee a non-exclusive, singleuse license to use the Product upon the terms and conditions contained in

this agreement. You may:

1. Use the Product on a single workstation owned, leased or otherwise con-

trolled by you, whether in a network or other configuration.

2. Make one (1) copy of the Product for backup purposes in support of your

use of the Product on the single workstation.

3. Transfer the Product and license to another party if the other party agrees

to accept the terms and conditions of this Agreement. If you transfer the

Product, you must, at the same time, either transfer thel copy of Product

to the same party, or destroy any copies not transferred.

You must reproduce and include the copyright notice on all copies of the

product documentation.

Continued on next page

Page 5

LightCycler Software and License Agreement,

Grant of Licence (continued)

YOU MAY NOT:

1. use or copy the Product, in whole or in part, except as expressly provided

in this Agreement,

2. use the Product on more than one workstation concurrently,

3. copy, rent, distribute, sell, license or sublicense, or otherwise transfer the

Product or this license, in whole or in part, to another party, except as

specifically set forth in this Agreement,

4. use the Product, or any portion of the Product, to develop, or incorporate

into, other software that can be executed without a licensed copy of the

Roche Diagnostics Image.

The use of the Product, or any portions of the Product, to develop, or incorporate into, other software capable to executing without a licensed copy of

Roche Diagnostics Image, is specifically prohibited under the terms of this

Agreement. Further, the use of the Product, or any portion of the Product on

more than one workstation at one time is specifically prohibited under the

terms of this Agreement. For further information, please contact

Terms

Roche Diagnostics GmbH

Roche Molecular Biochemicals

Sandhoferstraße 116

D-68298 Mannheim.

Germany

The license is effective until terminated. You may terminate this Agreement at

any time by destroying the Product together with the copy and documentation in any form. It will also terminate automatically and without notice from

Roche Diagnostics GmbH if you fail to comply with any term or condition of

this Agreement. You agree to destroy the Product and the copy ,if any, of the

Product upon termination of this Agreement.

Continued on next page

Page 6

LightCycler Software and License Agreement,

Limited Warranty

Limitations of

Remedies

The Product is provided as is without warranty of any kind, either expressed

or implied, including, but not limited to the implied warranties of merchantability and fitness for a particular purpose. The entire risk as to the quality and

performance of the Product is with you as Licensee, should the Product prove

to be defective. You assume the entire costs of all necessary servicing, repair,

or correction.

However, Roche Diagnostics GmbH warrants that the program media on

which the software is furnished is free from defects in materials and workmanship under normal use for a period of ninety (90) days from the date of

delivery as evidenced by a copy of your receipt. ROCHE DIAGNOSTICS

GMBH MAKES NO FURTHER WARRANTIES OR GUARANTEES NOR

EXPLICIT NOR IMPLIED.

Roche Diagnostics GmbH’s sole liability and your sole remedy shall be:

1. the replacement of the program media not meeting Roche Diagnostics

GmbH’ s limited warranty and which is returned to Roche Diagnostics

GmbH with a copy of your receipt;

2. if Roche Diagnostics GmbH is unable to deliver replacement program

media which is free of defects in workmanship, you may terminate this

Agreement by returning the Product and a copy of your receipt to Roche

Diagnostics GmbH, and your money will be refunded.

In no event will Roche Diagnostics GmbH be liable to you for any damages,

including any lost profits, lost savings, or other indirect, special, exemplary,

incidental or consequential damages, claims or actions, arising out of the use

or inability to use the Product, even if Roche Diagnostics GmbH has been advised of the possibility of such damages, claims or actions. Further, in no

event will Roche Diagnostics GmbH be liable for any claim by any other party

arising out of your use of the Product.

Continued on next page

Page 7

LightCycler Software and License Agreement,

General Information

You may not sublicence, assign or transfer the license or the Product, in

whole or in part, except as expressly provided in this Agreement. Any attempt

otherwise to sublicense, assign or transfer any of the rights, duties or obligations hereunder is void.

• This Agreement will be governed by the laws of Germany.

• Should any part of this agreement be declared void or unenforceable by a

court of competent jurisdiction, the remaining terms shall remain in full

force and effect.

• Failure of Roche Diagnostics GmbH to enforce any of its rights in this

Agreement shall not be considered a waiver of its rights, including but not

limited to its rights to respond to subsequent breaches.

By opening and using this software you acknowledge that you have read this

Agreement, understand it, and agree to be bound by its terms and conditions.

You further agree that this agreement is the complete and exclusive statement

of the Agreement between you and Roche Diagnostics GmbH and supersedes

any proposal or prior agreement, oral or written, any other communications

between you and Roche Diagnostics GmbH relating to the subject matter of

this Agreement.

Page 8

Chapter A

Technical Aspects of the LightCycler

Instrument

A 1

Page 9

1. Technical Aspects of the LightCycler Instrument

1.1 Table of Contents

1.

1.1

1.2

1.3

1.3.1

1.3.2

1.3.3

1.3.4

1.4

2.

2.1

2.2

3.

3.1

3.2

3.3

3.4

3.5

4. Operation and Maintenance of the LightCycler

Technical Aspects of the LightCycler Instrument

Table of Contents

LightCycler System

Technical Data

Specifications of the LightCycler

Specifications for Applications

Specifications for the Detectors

Temperature Control

Safety Precautions for the LightCycler

System Description

The LightCycler

PC Configuration

Installation

Installation Requirements

Installation of the LightCycler

Installation of the Computer

Installation of LightCycler Software Version 3

Dismantling the LightCycler System

Topic See Page

A 1

A 2

A 3

A 6

A 6

A 7

A 8

A 9

A 11

A 12

A 12

A 16

A 17

A 17

A 19

A 20

A 21

A 29

A 30

A 2

Page 10

1.2 LightCycler System

1

Note

Components

of the LightCycler System

Using the system improperly may compromise the integrity of the results, result in poor performance, or even permanently damage the equipment.

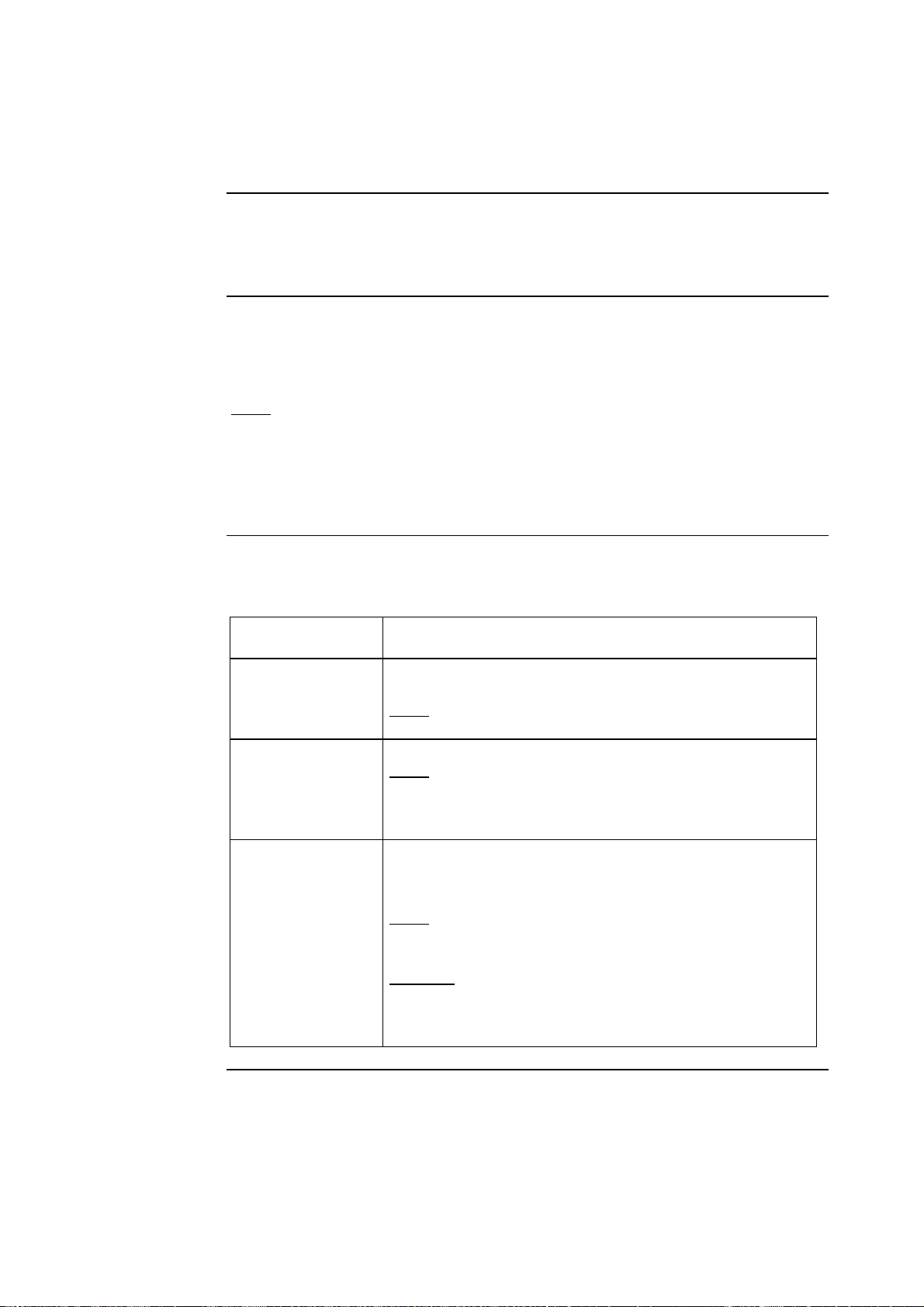

The components of the LightCycler System are listed in the following table.

Please note that these components may vary from country to country.

Component Description

System component 1

• LightCycler Instrument

• Sample Carousel (for Ø 1.5 mm capillary)1 pre-

mounted in LightCycler Instrument

System component 2

• LightCycler Capillaries (96 capillaries and stop-

pers/box)

• 32 LightCycler Centrifuge Adapters in an alumi-

num cooling block

1

1

• 1 LightCycler Operator’s Manual

• 1 LightCycler Software Package

1

• Cable to connect LightCycler Instrument to the

computer

• Power Cord (German)

• Power Cord (U.S.)

• Mouse Pad

Hardware

• PC with Pentium processor

2

• 64 MB SDRAM (minimum configuration)

• 24x CD-ROM drive

• Keyboard and PS/2 mouse

• Internal Iomega ZIP drive

Operating system

Monitor

Printer

• Windows NT 4.0, including Service Pack III

• 17" monitor

• Hewlett-Packard Color Inkjet Printer

2

2

Also available as single components:

LightCycler Sample Carousel

LightCycler Capillaries

LightCycler Centrifuge Adapters

LightCycler Software Package

2

Computer workstation configuration may vary from country to country and

Cat. no. 1 909 282 (1 piece)

Cat. no. 1 909 339 (1 set, 768 capillaries)

Cat. no. 1 909 312 (1 Set)

Cat. no. 1 909 304

may change due to component availability and technical advances. To confirm

exact computer configuration, please contact your local Roche Molecular Biochemicals representative.

Continued on next page

A 3

Page 11

1.2 LightCycler System, Continued

Marks of

Conformity

The LightCycler has been manufactured according to EN 61010-1 (Safety

regulations for Measuring, Control and Laboratory Instruments; Part 1: General Requirements [IEC 1010-1 + A1: 1992, modified]) and has been checked

in accordance with all relevant safety standards prior to leaving the factory.

The instrument has been approved for use by recognized testing institutions.

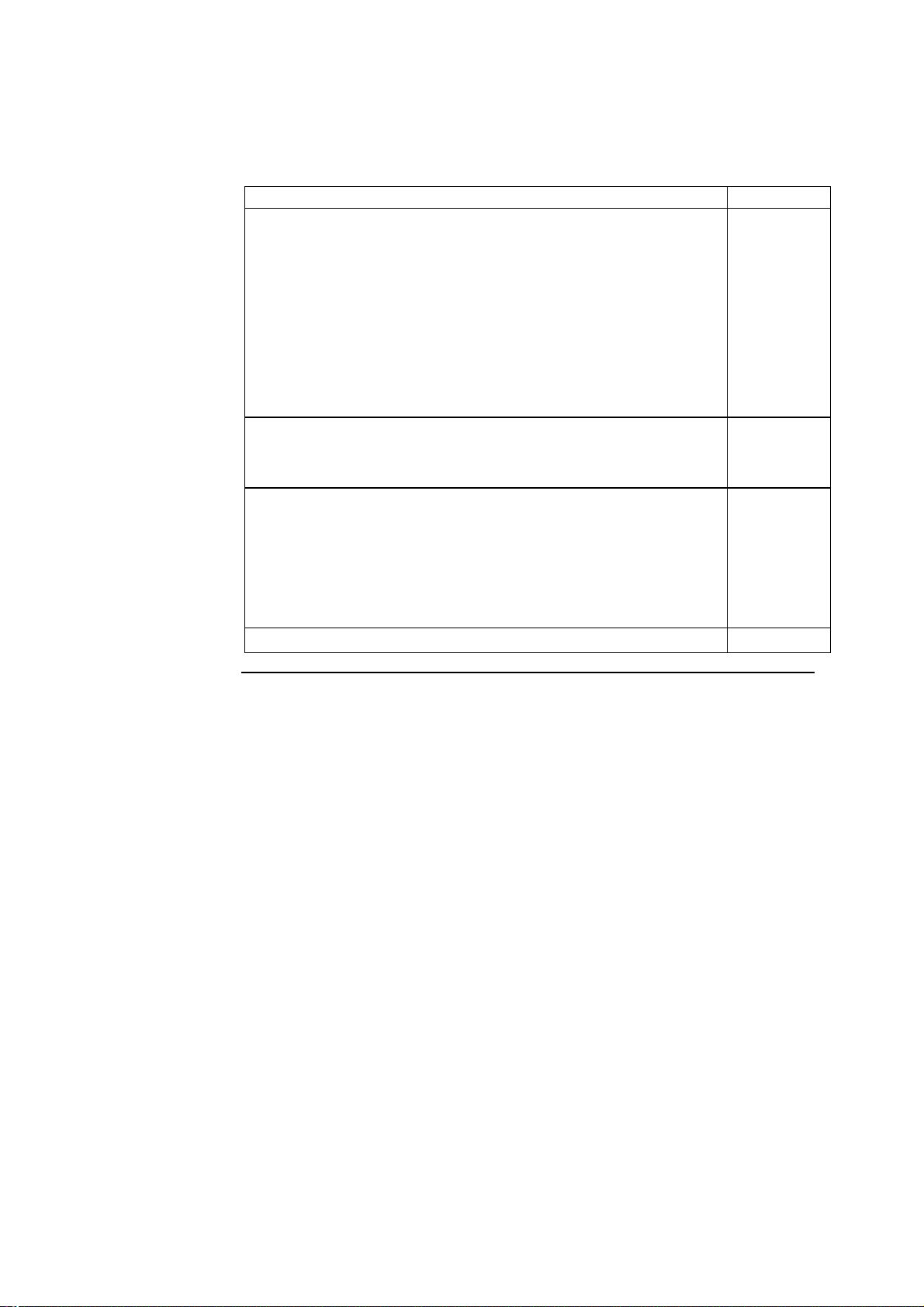

This is confirmed by the following test/conformity symbols:

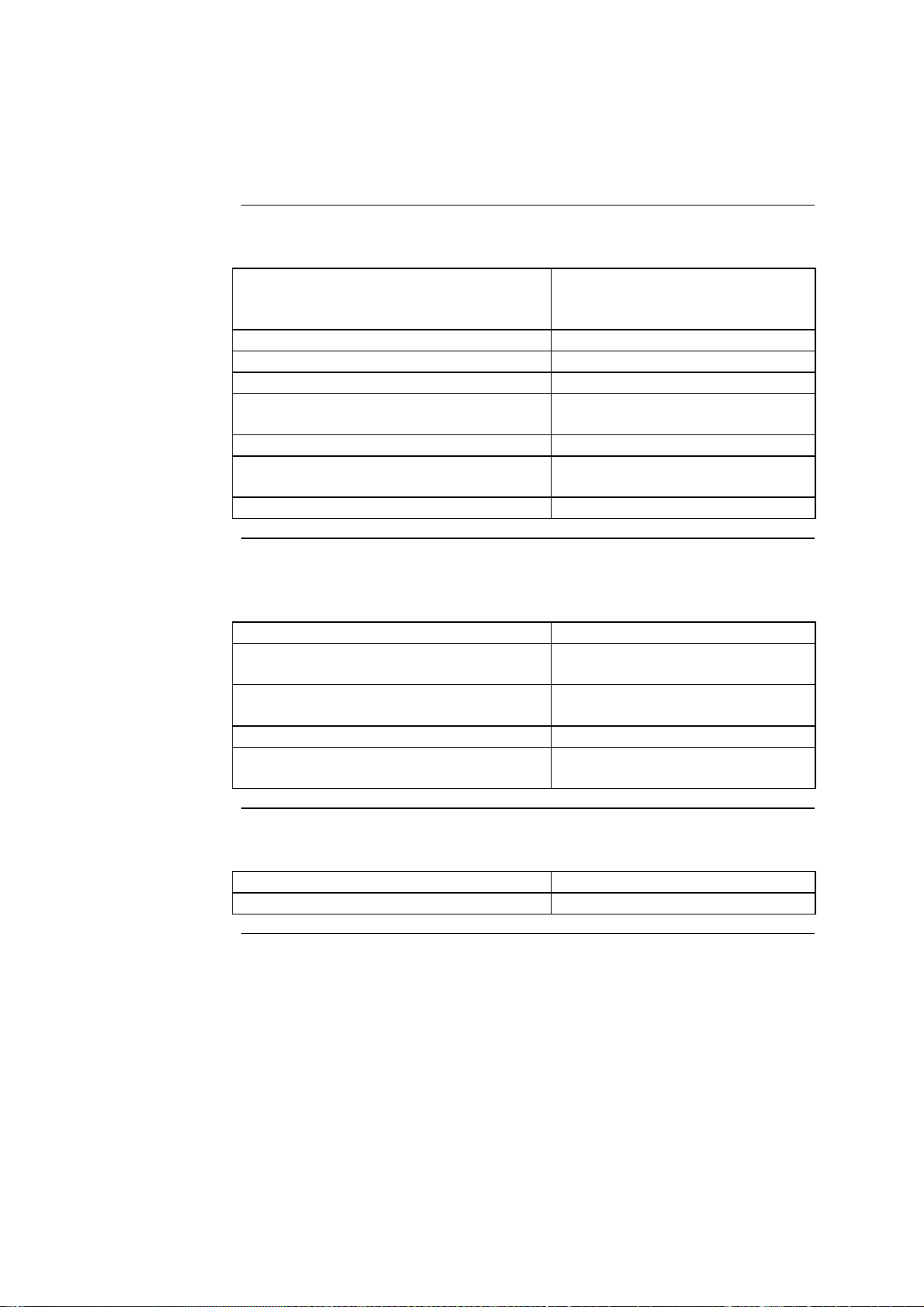

Acronym Test Symbol Testing Institution

GS

CE

UL

Certified by TÜV Product Service

The instrument conforms to

current directives as issued by

the European Union

Certified by Underwriters Laboratories Inc.

CUL

Equipment to be connected must fulfill the standards set by IEC 950 (Information security in technical equipment, including electronic business machines).

Certified by Underwriters Laboratories for Canada – a testing

facility recognized by the Standards Council of Canada (SSC)

Continued on next page

A 4

Page 12

1.2 LightCycler System, Continued

Classification

Note on Use

with Infectious

Material

The LightCycler Instrument is classified as:

• ISM instrument (Industrial Scientific Medical Device), medium-sized, for

industrial, laboratory and domestic use.

• Designed for stationary operation.

• Intended for worldwide use.

• Intended for evaluating preprocessed biological material.

• The instrument may not be used to analyze infectious materials unless ad-

ditional safety measures to ensure safe sample handling (e.g., placing the

instrument in a laminar flow biological safety cabinet) are taken beforehand.

A 5

Page 13

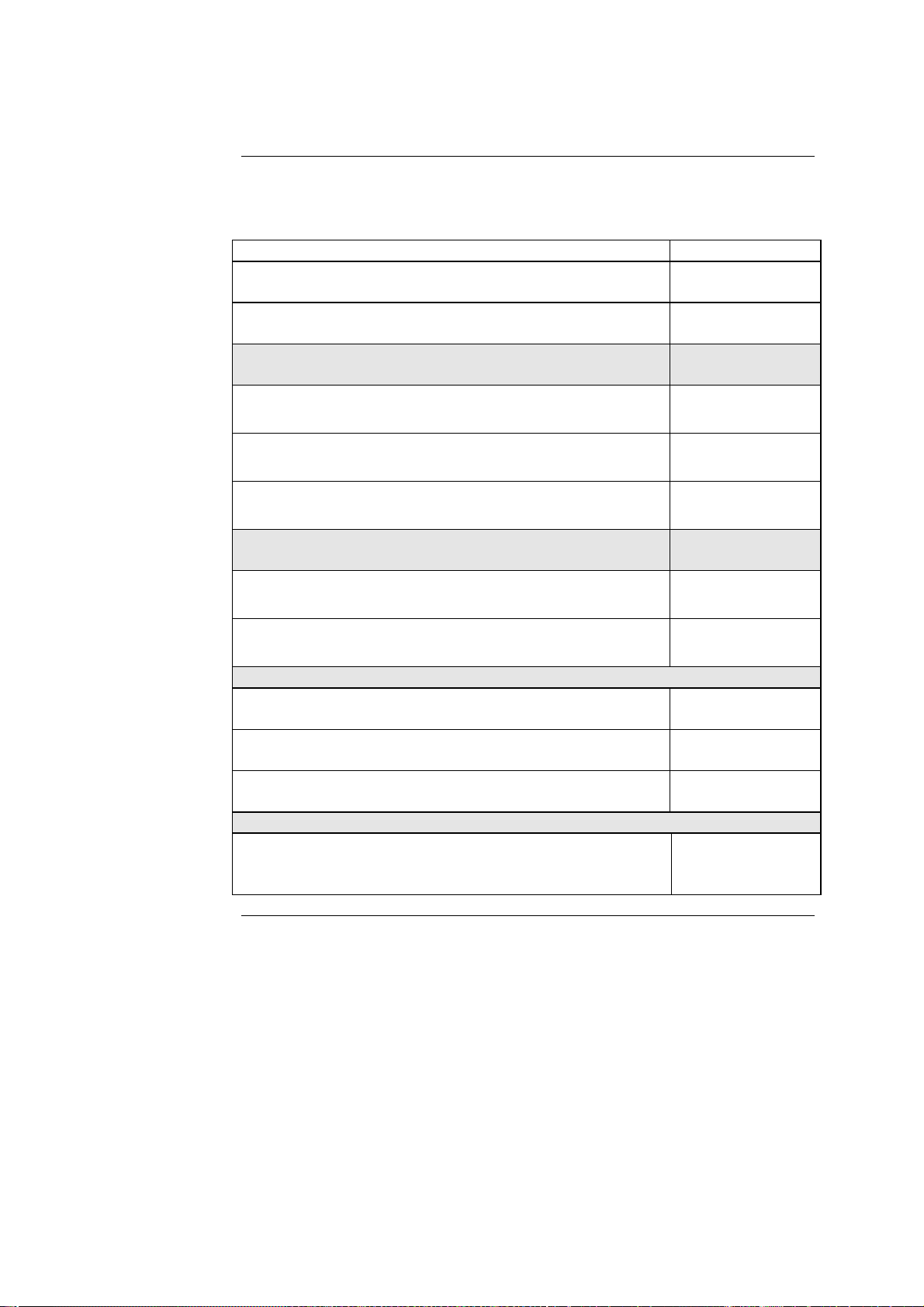

1.3 Technical Data

1.3.1 Specifications of the LightCycler

General Data

Environmental

Parameters

Dimensions Length:

Width:

Height:

Weight 19.2 kg

Power supply 110–240 V, +/–10%, 47–63 Hz

Wattage max. 800 W

Maximum current Europe:

US:

Noise in accordance with DIN 43635 <60 dBA

Heat emission, including PC, monitor

and printer

Safety symbols CE, GS, UL, CSA or CUL

Temperatures allowed during operation 15° to 35°C

Temperatures required to maintain

specifications during operation

Temperatures allowed during transportation/storage/packaging

Relative humidity 20 to 80%, no condensation

Altitude/pressure 0 to 2000 m above sea level,

max. 850 W

18° to 30°C

–20° to +60°C

1030 to 850 hp

45 cm

30 cm

40 cm

4 A (220 V)

8 A (110 V)

Samples

Number of samples per run 32

Sample volume 10 to 20 µl

A 6

Page 14

1.3.2 Specifications for Applications

Temperature

for PCR

Temperature range 40° to 98°C

Accuracy of “capillary temperature” at thermal equilibrium

Accuracy of “displayed temperature” with respect to

capillary temperature at thermal equilibrium

Capillary Heating Rates Volume : Heating

Heating rate 40° to 95°C (non-linear)

Heating rate 50° to 72°C (non-linear)

Heating rate 72° to 95°C (non-linear)

Capillary Cooling Times Volume : Cooling

Cooling rate 95° to 40°C (non-linear)

Cooling rate 95° to 60°C (non-linear)

Temperature Tolerances, Short Term

Precision of capillary temperature over all capillary positions when measured for 30 s at 95°C

Precision of capillary temperature over all capillary positions when measured for 30 s at 70°C

Precision of capillary temperature over all capillary positions when measured for 30 s at 45°C

Temperature Difference, Melting Curves

Systematic difference between sensor temperature and

capillary temperatures when chamber is heated from

50°C to 95°C at a rate of 0.2°C/s

±0.4°C

±0.4°C

Time Required

10 µl: ≤13 s

20 µl: ≤15 s

10 µl: ≤6 s

20 µl: ≤8 s

10 µl: ≤6 s

20 µl: ≤8 s

Time Required

10 µl: ≤23 s

20 µl: ≤24 s

10 µl: ≤7 s

20 µl: ≤7 s

±1.5°C

±1.0°C

±0.5°C

<0.1°C

A 7

Page 15

1.3.3 Specifications for the Detectors

Excitation

Type LED

Median wavelength 470 nm

Wattage at 470 to 490 nm 0.1 mW

Filter

Detector 1 Bandpass 530 nm, HBW 20 nm, dichroic

Detector 2 Bandpass 640 nm, HBW 20 nm, dichroic

Detector 3 Bandpass 710 nm, HBW 40 nm, dichroic

Detector

Type Photohybrid

Sensitivity at 530 nm, 20 µl sample volume 10 fM fluorescein

Resolution 12 bit

Range of detection sensitivity Adjustable by a factor of 1 to

256

Typical Time

Signal acquisition time for 32 capillaries

≈ 5.0 s

A 8

Page 16

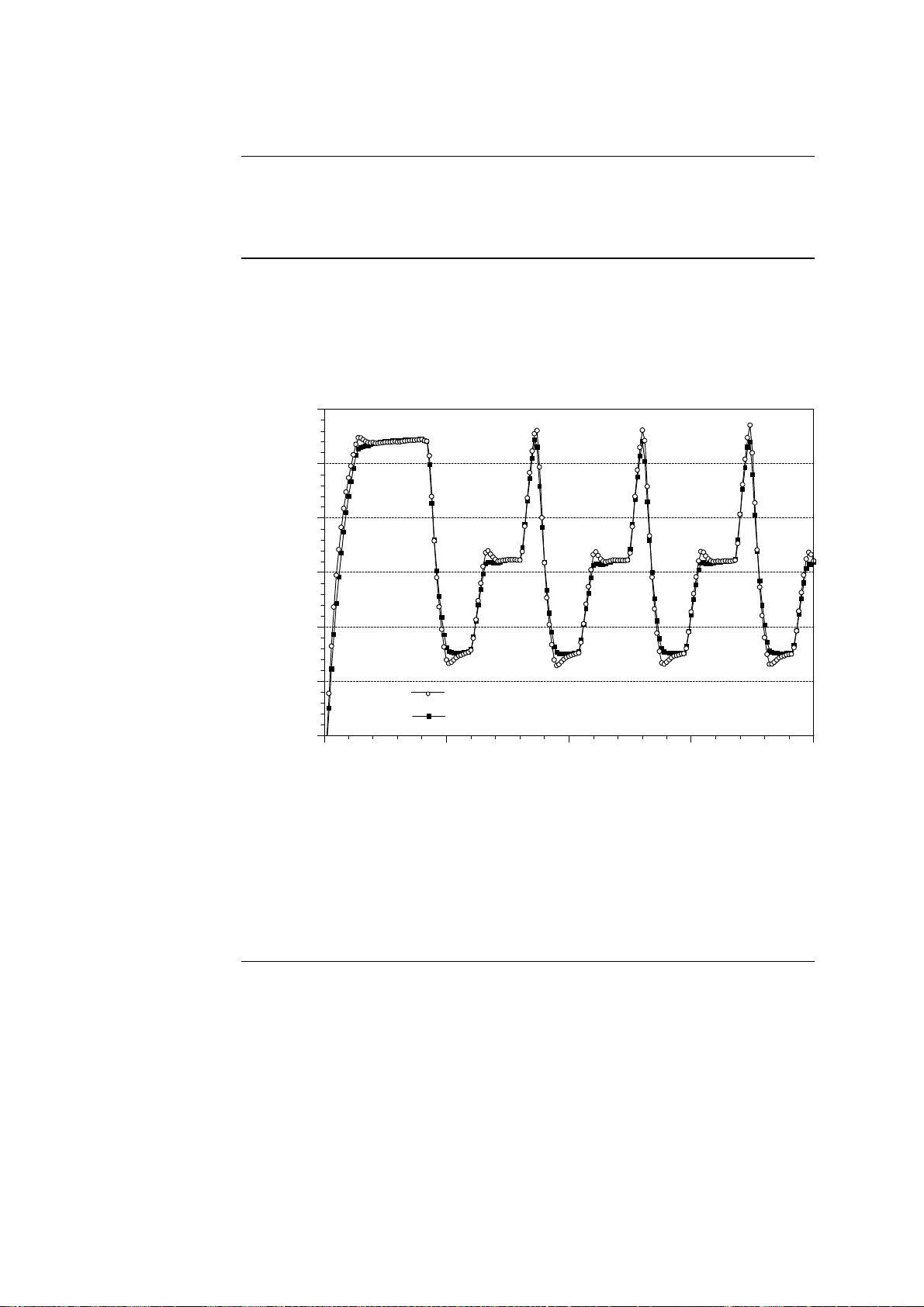

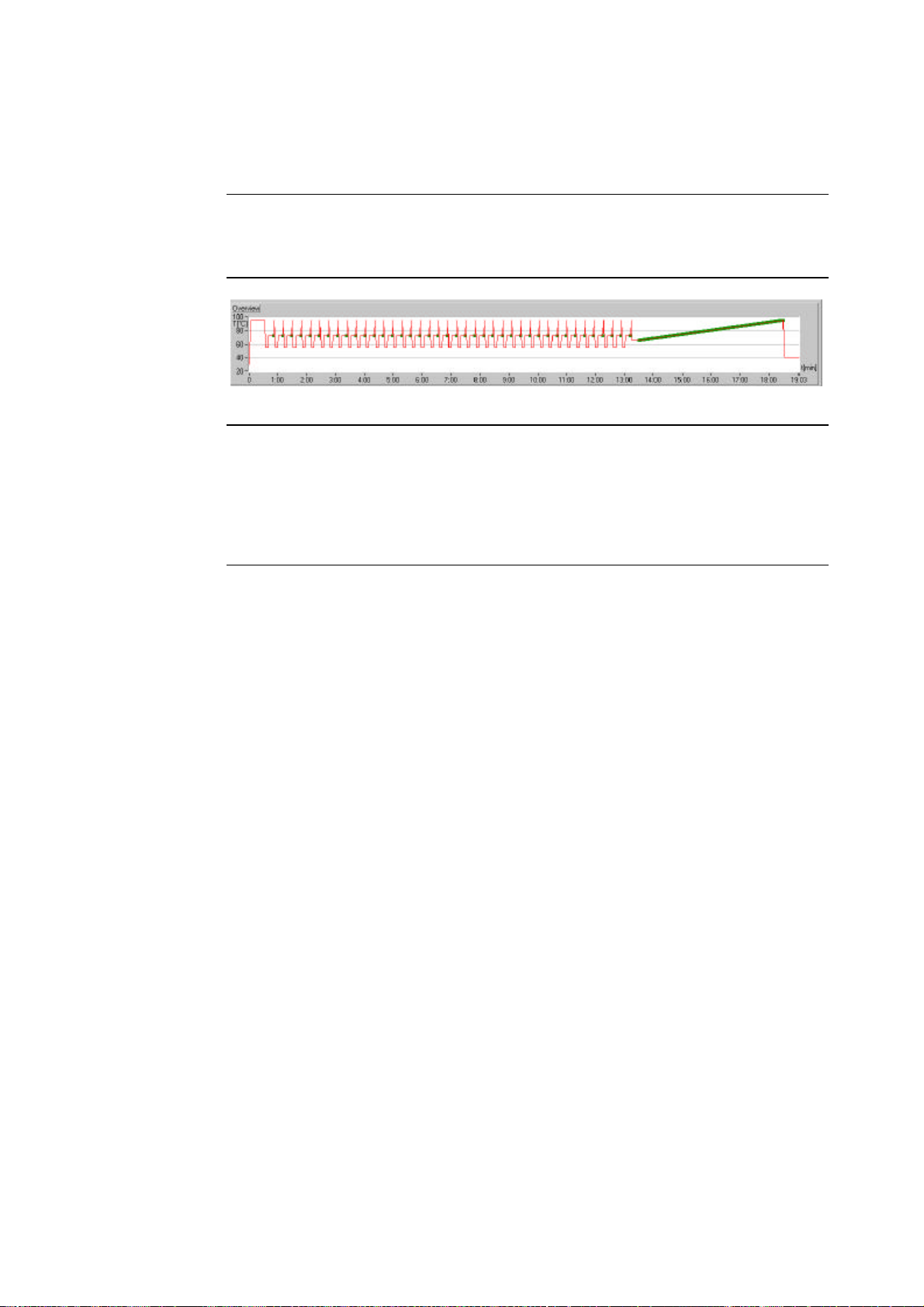

1.3.4 Temperature Control

Visual Display

of Temperature Profiles

The LightCycler software graphically displays the current temperature in the

thermal chamber. These graphs appear under Temperature History on the

Running Screen (see below).

The graphs show “overshoots” and “undershoots” for each temperature transition (see arrows below).

A 9

Continued on next page

Page 17

1.3.4 Temperature Control, Continued

100

Temperature [ C]

200

Fluid temperature in capillary

Ambient temperature in thermal chamber

Autocorrection

Effectiveness of

Autocorrection

Autocorrection compensates for physical differences in heat capacity in air

and water. This specific autocorrection ensures that every programmed temperature is adjusted within the sample capillaries during thermal cycling.

The graph below shows the changes in temperature in both the thermal

chamber and a sample capillary during thermal cycling. Differences at any

given time between the temperature in the two locations are shown as spaces

between the two temperature curves.

90

80

o

70

60

50

40

0 50 100 150

Time [sec]

Conclusion: This graph demonstrates that:

• The temperature profile shown under Temperature History on the Running Screen exactly corresponds to the capillary temperature, and

• The fluid temperature in the capillaries coincides with the programmed

profile.

A 10

Page 18

1.4 Safety Precautions for the LightCycler

General Safety

Precautions

Always observe these precautions when using the LightCycler Instrument:

• Follow all safety instructions printed on, or attached to, the analytical in-

struments.

• Observe all general safety precautions which apply to electrical instruments.

• Never touch switches or power cord with wet hands.

• Do not open the housing of the LightCycler.

Note: Only authorized service personnel should perform service or repairs

required for this unit.

• Do not open the LightCycler thermal chamber during operation.

• The chamber lid and the sample rotor are hot while the instrument is op-

erating.

Note: The corresponding symbol is attached to the front side of the

LightCycler.

• Always wear safety goggles and gloves when dealing with toxic, caustic, or

infectious materials .

• When analyzing infectious materials, use the LightCycler only in specially

equipped rooms with controlled exhaust equipment, e.g., biological safety

cabinets.

Safety Precautions for Centrifuge Adapters

Loading capillaries to perform fluorescence measurement with the LightCycler requires a centrifugation step in a tabletop centrifuge with specially designed adapters. A centrifuge adapter with capillary weighs approximately 6.2

grams. Always observe the following precautions during the centrifugation

step:

• Always distribute the adapters in the rotor so the weight in the rotor is

balanced, and

• Adjust the speed of the centrifuge so the centrifugal force does not exceed

700 x g.

Note: For details on the maximum weight that can be processed in your centrifuge, refer to the product specification sheet for that centrifuge.

A 11

Page 19

2.1. The LightCycler

Schematic of

the LightCycler

2. System Description

A 12

Continued on next page

Page 20

2.1 The LightCycler, Continued

Description of

the Instrument

Communication between

LightCycler

and PC

The LightCycler basically consists of an upper unit and a lower unit. The upper unit contains the heating coil. The lower unit contains the thermal chamber, fluorimeter, drive units, electronic boards and power supply. The various

elements are mounted on a 10-mm cast aluminum base plate. This guarantees

stability, especially for the thermal chamber and fluorimeter.

Hot or ambient temperature air, introduced into the thermal chamber, regulates the temperature of the sample capillaries. A heating coil heats the air,

which is then fed into the chamber by a fan. The fan ensures efficient air circulation and temperature homogeneity during the heating cycle.

During the cooling cycle, the fan operates at a higher speed to ensure adequate cooling.

During measurements, a stepper motor rotates the sample carousel to position the capillary tip precisely at the focal point of the fluorimeter optics. The

fluorimeter itself is positioned radially to the maximum signal to compensate

for any radial deviation of the capillary tip.

For online display, data are transmitted to and from the PC via a serial interface.

Control is made possible by three microprocessors that are integrated into the

instrument:

• Processor 1 is for communication,

• Processor 2 regulates the temperature, and

• Processor 3 controls the measurement procedures as well as the move-

ment of the rotor and fluorimeter.

Users enter data on samples (number of samples, name, concentration, etc.)

and on the experimental protocol into the PC; the PC transmits the data to

the LightCycler. The PC also monitors the temperatures and fluorescence signals during the PCR run and operates all the analytical programs.

Power Supply

Unit

All high-voltage components are located in the power-supply unit.

Note: Electrical safety information and test symbols apply to this unit.

To minimize interference to the detector electronics, the electronics that control the drive units are located on a separate circuit board.

Continued on next page

A 13

Page 21

2.1 The LightCycler, Continued

Temperature

Setting of the

Thermal

Chamber

Fluorimeter

Temperature is controlled with hot air and air at ambient temperature. Varying the voltage supplied to the heating coil regulates the temperature. A sensor

provides reference values for control purposes.

During the heating phase, the fan in the thermal chamber operates at low

speeds to ensure homogenous distribution of temperature.

During the cooling phase, the fan operates at higher speeds so that the capillaries and the heating coil can be cooled efficiently.

Two sensors are integrated into the LightCycler to prevent unduly high temperatures:

• Sensor I is located in the thermal chamber and switches off the heat when a

temperature of 125°C has been reached.

• Sensor II monitors the temperature on the aluminum base plate, and

switches off the entire LightCycler to protect the electronics when the temperature exceeds 55°C.

A three-channel fluorimeter is used for detection purposes. A blue diode

(LED) with maximum emission of 470 nm serves as the energy source for

sample excitation. Screens are used to diffuse the light emitted by the LED to

ensure uniformity. The exhaust and ventilation channels have been designed

to prevent ambient light from entering directly into the thermal chamber.

Fluorescence is detected at 530 nm, 640 nm, and 710 nm with the aid of

photohybrids.

Note: Acquisition time for fluorescence acquisition time is 20 msec (16.6 msec

in the U.S.).

Measurement

of Samples

The thermal chamber and the fluorimeter are placed optimally for sample

measurement. Only the sample carousel, which holds the capillary, rotates

during measurement of the various samples.

Continued on next page

A 14

Page 22

2.1 The LightCycler, Continued

LightCycler

Diodes

Position of

Diode

Top Power on Green On Instrument is switched on

Middle Cycling Red On Instrument is running

Bottom Run Yellow On PCR run is completed

Three diodes are located at the front of the LightCycler. All of the diodes

come on when the instrument is switched on. In this way, the instrument tests

for proper functioning of the diodes.

During instrument operation, the diodes function as described in the table

below:

Label Color of Diode Function Indication

Off

Flashing Instrument is defective

completed Off Instrument is running

• No power

• Instrument is defective

A 15

Page 23

2.2 PC Configuration

General

The computer workstation contains the following components:

Hardware

• PC with a Pentium processor

1

• 64 MB SDRAM (minimum configuration)

• 24x CD-ROM drive

• Keyboard and PS/2 mouse

• Internal Iomega ZIP drive

Operating system

Monitor

Printer

1

Computer workstation configuration may vary from country to country and

• Windows NT 4.0, including Service Pack III

• 17" monitor

• Hewlett-Packard Color Inkjet Printer

1

1

may change due to component availability and technical advances. To confirm exact computer configuration, please contact your local Roche Molecular

Biochemicals representative.

A 16

Page 24

3. Installation

3.1 Installation Requirements

Note

Space and

Power Requirements

• Do not place the LightCycler next to instruments that cause electromag-

netic interference or have high inductance (e.g., centrifuges or mixers).

• Peripheral instruments connected to the LightCycler System must meet

the IEC 950 (UL 1950) standard.

• All plugs used in the LightCycler System (PC, printer, monitor) should

have the same phasing in order to prevent switch-on peaks and electronic

noise generated by other instruments or by the power supply itself. We

recommend using a dedicated multiple-outlet surge protector for the

LightCycler System.

• Use only the supplied power lines and RS 232 connector.

Place the instrument in a site that can support the following instrument requirements:

Dimensions The LightCycler is 30 cm wide, 45 cm long, and 40 cm

high. .

Weight Approximately 20 kg

Voltage Requirements

The LightCycler operates between 120 and 240 V (50 to 60

Hz).

Note: The LightCycler adjusts automatically to the avail-

able voltage when the instrument is plugged in. The user

does not have to set the instrument to the correct voltage

manually.

Power Consumption

Do not open the LightCycler

housing.

The LightCycler uses 800 W max.

PC and printer consume an additional 500 W (approx.).

Continued on next page

A 17

Page 25

3.1 Installation Requirements, Continued

Environmental

Parameters

Storage Conditions

The instrument requires the following environment for accurate operation:

Ambient temperature 15° to 35°C

Ambient temperature required

to main specifications during

operation

Humidity 20 to 80%, no condensation

Altitude Sea level to 2000 m

Excess voltage Category II

Degree of contamination 2

The LightCycler can be stored under the following conditions:

Ambient temperature –20° to +60°C

Humidity 20 to 80%, no condensation

18° to 30°C

A 18

Page 26

3.2 Installation of the LightCycler

Installation of

the LightCycler

Instrument

Your Roche Molecular Biochemicals representative will normally install the

LightCycler Instrument at your site. Should this not be possible, follow these

steps to install the instrument successfully:

Step Action

1 Unpack the instrument.

2 Position the instrument on the workbench. Allow 10-cm spaces to

the left, right and behind the instrument to ensure sufficient cooling of the electronic components.

Note: The workbench should not be covered with paper.

3 Make the following electrical connections:

• Connect the LightCycler to the PC using the RS 232 cable (serial interface) provided with the system.

• Connect the LightCycler, PC, monitor, and printer to the same

multiple-outlet distributor plug.

Ensure that PC, monitor, and printer have

been set to the correct voltage.

A 19

Page 27

3.3 Installation of the Computer

Installation of

the PC

To install the PC, do the following:

Step Action

1 Connect mouse, keyboard, and monitor to the computer.

2 Connect the LightCycler to the computer with the RS 232 cable

(serial interface) provided with the system.

3 Connect the computer, monitor, and LightCycler to the same

multiple-outlet distributor plug.

The computer is now ready for operation.

A 20

Page 28

3.4 Installation of LightCycler Software Version 3

Logging In

Installation of

LightCycler

Software

A prerequisite for the software installation is that the operating system WINNT 4.0 (Service Pack 3) has been installed. For the installation of the software

and the setting up of users it is recommended that you log in as administrator.

All instructions are based on the English WIN NT 4.0 version. The operating

system programs and folders in the German versions have different names.

Insert the CD with the LightCycler Software version 3 into the CD-ROM drive

of your computer. The autorun function will automatically start the Setup

program. If the autorun function is not available, the CD must be opened

from the Explorer, and the 'setup' program started manually by doubleclicking on it. The Setup program displays the following start screen:

Click the “Next” button to continue with the installation. Click “Cancel” to

abort the program.

Continued on next page

A 21

Page 29

3.4 Installation of LightCycler Software Version 3, Continued

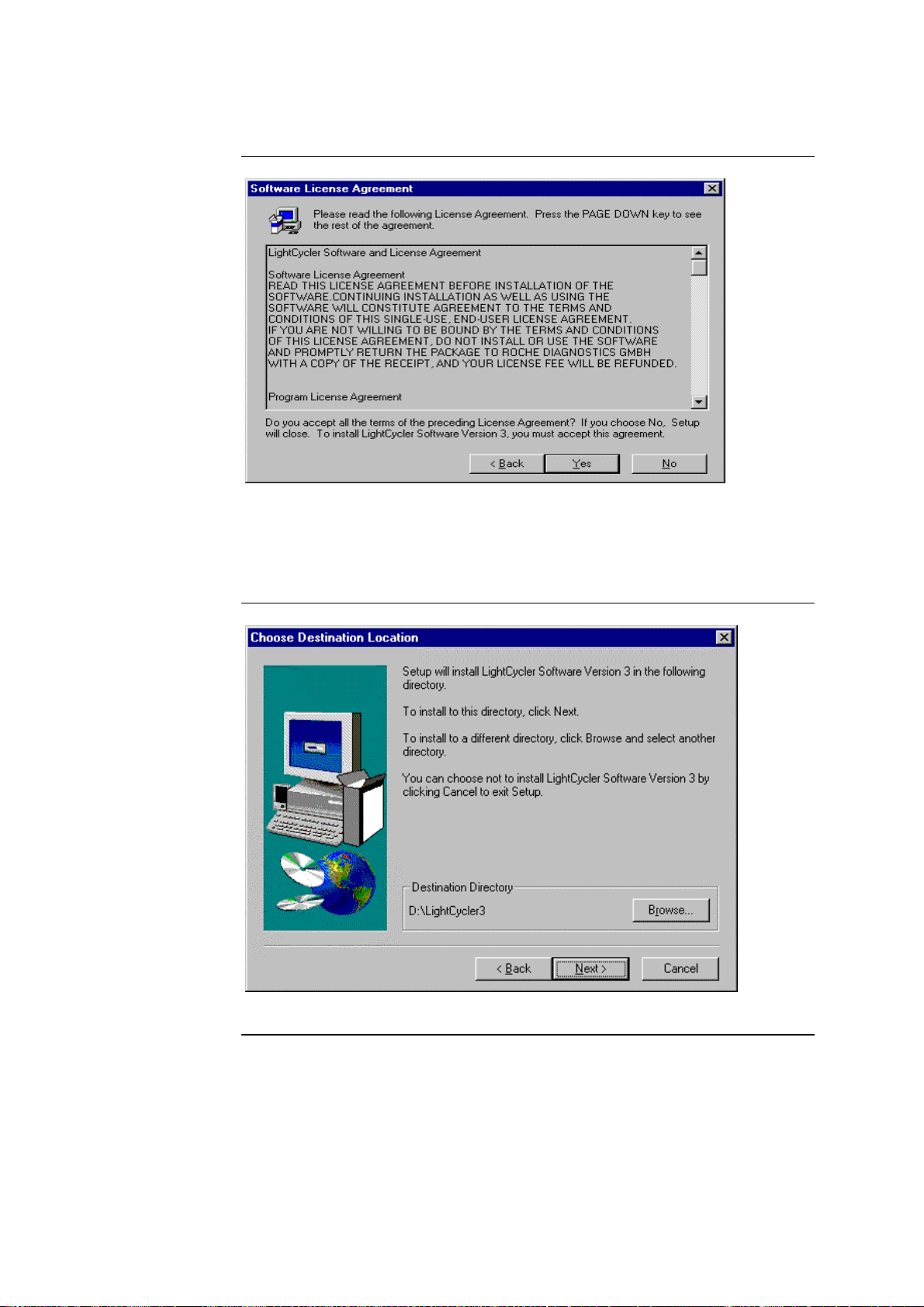

License

Agreement

Information of

LightCycler

Software

Here, the customer is provided with a display of the license agreement. Scroll

bars can be used to view the entire text.

Choose “Yes” to accept the license agreement. If you choose “No”, the program will be exited. Clicking on “Back” will redisplay the start screen.

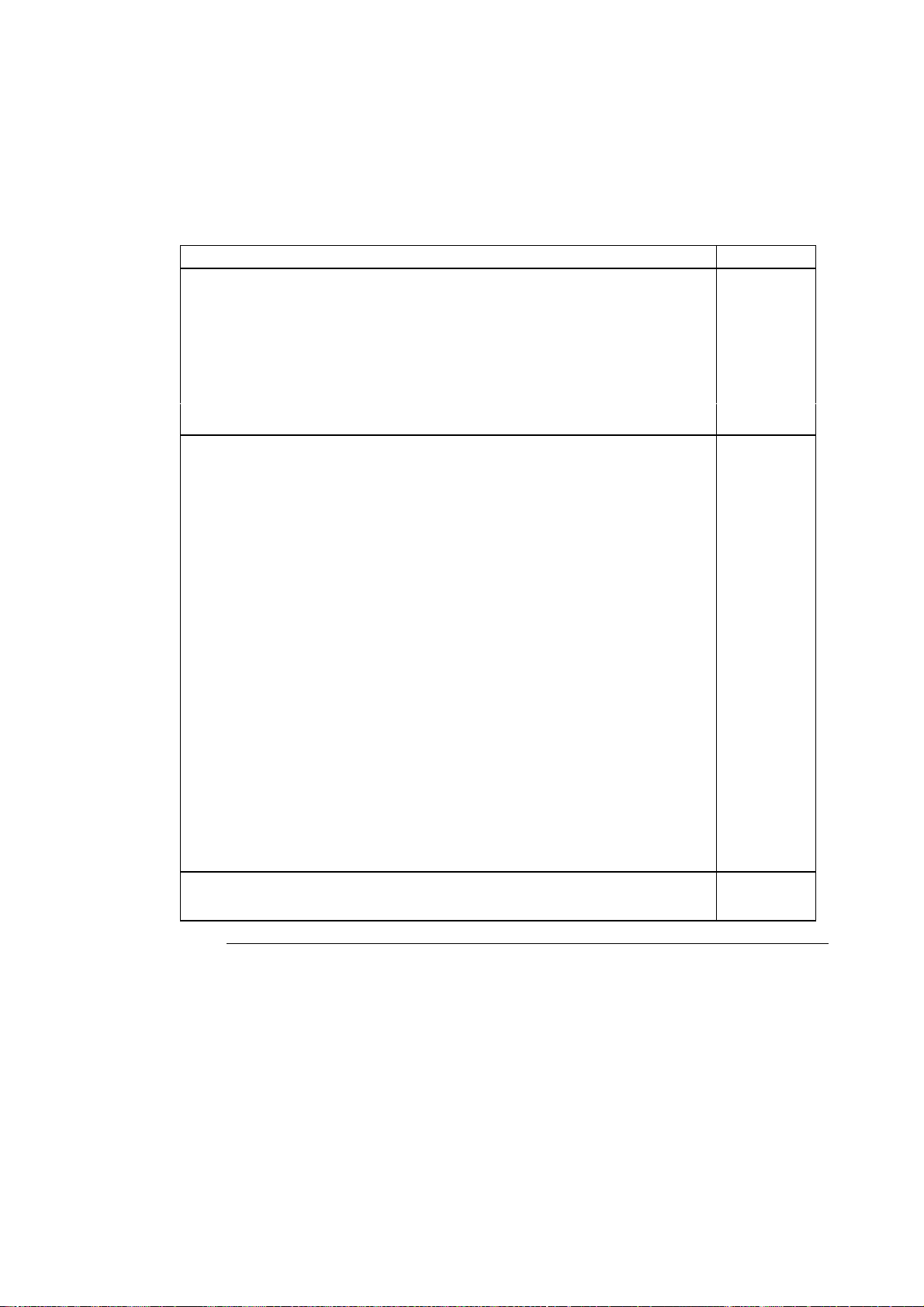

Installation

Directory of

LightCycler

Software

Continued on next page

A 22

Page 30

3.4 Installation of LightCycler Software Version 3, Continued

Installation

Directory of

LightCycler

Software,

Continued

The software will be installed to the recommended directory “LightCycler3”.

The disk drive corresponds to the drive to which WIN NT was installed, here:

drive “D”.

If “Next” is clicked on, the installation will be continued. If “Cancel” is chosen, the installation will be exited, and “Back” will redisplay the previous

screen.

If you wish to change the disk drive or the directory, click the “Browse” button. A popup window will display permitting the desired path and directory to

be entered.

The installation to the “LightCycler3” directory will have no consequence for

any previous installations of version V1.22 since that version was installed in

the directory named “LightCycler”. It is therefore recommended that directory “LightCycler3” be used so as to avoid any conflict with respect to future

versions and to be able to quickly locate the relevant versions.

Continued on next page

A 23

Page 31

3.4 Installation of LightCycler Software Version 3, Continued

LightCycler

Software Program Folder

The program folder contains icons to start the various LightCycler Programs.

A folder named “LightCycler3” is set up in the Start menu under 'Programs'.

This name should be retained, if possible, to be able to locate the folder

quickly.

Click “Next” to continue with the installation. If “Cancel” is chosen, the installation will be exited, and ”Back” will redisplay the previous screen.

Starting the

LightCycler

Software Installation

Prior to the start of the installation, a summary of the current settings is displayed. You are provided with one last chance to make changes, or to exit the

installation.

Click “Next” to start the installation. If “Cancel” is chosen, the installation

will be exited, and 'Back' will redisplay the screen below.

Continued on next page

A 24

Page 32

3.4 Installation of LightCycler Software Version 3, Continued

Starting the

LightCycler

Software Installation, Con-

tinued

LightCycler

Software Installation Progress

After the start of the installation, a progress bar is displayed indicating the

progress of the installation. Please wait until the installation is complete and

the “Setup Complete” screen appears.

It is possible to exit the installation by clicking “Cancel”. This should, however, only be done in emergencies. Any program parts that have been installed

up to this point will not be removed automatically.

At the end of the installation, the program registration takes place.

A start icon for the “Front” program will be installed on the desktop and

added to the Start menu. The folder “LightCycler3” containing the programs

“Front”, “BMRun” and “LCDA” will be set up in the Start menu under “Programs”.

Continued on next page

A 25

Page 33

3.4 Installation of LightCycler Software Version 3, Continued

LightCycler

Software Installation Progress, Continued

Terminating

Setup

The installation has been carried out successfully. Click “Finish” to complete

the Setup program. If the check box “Launch the program file” is selected, the

LightCycler program “LightCycler3 Front Screen” (Front) will start when the

“Finish” button is clicked.

A 26

Continued on next page

Page 34

3.4 Installation of LightCycler Software Version 3, Continued

System File For the LightCycler3 program to be able to run, the system file “mfc42.dll” is

required. If an earlier version of this file is installed on your computer, it will

be overwritten with the more recent version in the directory

Winnt\system32\.

Acrobat

Reader

Num2Dot

The Acrobat Reader is required to be able to read the Help files. This program

is also included on the CD. It needs only to be installed if the program has not

previously been installed on the computer.

To install Acrobat-Reader, open the CD from the Explorer and start the

“ar40eng” program by double-clicking on it in the “Acrobat Reader” subdirectory. The installation procedure is similar to that of the LightCycler Software.

Num2Dot is a tool that allows use of the “comma” of the numerical pad of

your keyboard to enter a decimal point. As the LightCycler Software is designed to be run under english country settings, the Software expects a “point”

as a decimal point. The ability to convert the decimal “comma” on a variety of

non-english keyboards to write a “point” instead significantly improves the

convenience of the system.

Note: It is not required to install Num2Dot if your keyboard´s numerical pad

is equipped with a “point” as decimal point.

To install Num2Dot, open the CD from the Explorer and start the install

Num2Dot by double-clicking “Setup.exe” in the “Num2Dot” subdirectory.

The installation procedure is similar to that of the LightCycler Software.

Num2Dot will automatically be started whenever you launch Windows-NT

on your PC.

Verify activation of the numerical pad on your keyboard. The green light built

into the “Num” key must be on.

After installation of Num2Dot, the “comma” key will be converted to a

“point” key.

The Short cut command “AltGr + DecimalComma” can be used to deactivate

Num2Dot, as well as to reactivate the conversion.

Continued on next page

A 27

Page 35

3.4 Installation of LightCycler Software Version 3, Continued

Uninstall To uninstall programs under WIN NT, use the “Add/Remove Programs”

tool. This auxiliary program appears in the Start menu under Settings-Control

Panel. A list of the programs installed is displayed. Select the program you

wish to uninstall from the list and remove it by clicking the “Add/Remove”

button.

A 28

Page 36

3.5 Dismantling the LightCycler System

Dismantling

the System

To dismantle the LightCycler system, do the following:

Step Action

1 Switch off the instrument.

2

3 Ship instrument in its original packaging.

• Disconnect the RS 232 cable and power cables.

• Clean the instrument (according to the guidelines in Topic 4 of

this chapter).

• Decontaminate the instrument if necessary.

A 29

Page 37

4. Operation and Maintenance of the LightCycler

Guidelines for

Operation

Transport and

Storage

• The LightCycler instrument should only be operated in locations which

are protected from the weather. It may not be operated in buildings that

lack facilities for regulating temperature. If necessary, additional drying

agents may be used to eliminate humidity. Neither ice nor moisture

should be allowed to form on the instrument.

• The instrument should be placed on an even work surface and protected

from direct sunlight and outside light.

• The instrument should not be operated near dripping, spraying, splashing

or running water.

• The instrument is suitable for use according to classification 3K3 in accor-

dance with Standard EN 60721-3-3.

• The instrument should be protected from effects generated by fauna and

flora.

• The instrument may be used at locations subject to noticeable or signifi-

cant vibration. However, it should not be exposed to higher levels of

shock waves.

• The instrument is suitable for use according to classification 3M4 in ac-

cordance with EN 60721-3-3. The instrument is able to tolerate vibrations

up to classification 3M6.

When storing or transporting the instrument, do not allow it to be exposed to

extreme cold (e.g., placing it in an airfreight cargo bin). Avoid temperatures

lower than –25°C (since such temperatures may damage optical systems).

The optical systems have open ventilation systems and should therefore be

protected from dirt and humidity.

Guarantee

The terms of the guarantee are incorporated in the purchase agreement. For

further details, please contact your Roche Molecular Biochemicals representative.

Continued on next page

A 30

Page 38

4. Operation and Maintenance of the LightCycler, Continued

General Maintenance

Cleaning the

Instrument

The instrument is maintenance-free.

• Use 70% ethanol for disinfecting the thermal chamber.

• Clean the optical window with alcohol and an optical polishing cloth.

• Clean the housing with a mild commercial household detergent.

• Use a mild commercial household detergent for cleaning the housing.

• Do not pour fluids into the thermal chamber.

A 31

Page 39

B 1

Chapter B

LightCycler Software

Version 3

Page 40

B 2

1.1. Table of Contents

1. Software

Topic See Page

1. Software

1.1 Table of Contents B 2

1.2 Introduction B 4

1.3 The Front Screen B 7

1.4 Functions of Buttons on the Front Screen B 8

1.5 Edit Graphics Defaults Window B 9

2. Programming a Run

2.1 Programming Screen B 11

2.1.1 Menu Options Available on the Programming Screen B 14

2.1.2 Programming Screen: User / Experiment Window B 17

2.1.3 Programming Screen: Experiment / RUN / EXIT Window B 19

2.1.4 Programming Screen: Sample Data Entry B 21

2.1.4.1 Loading Screen Activated by the Edit Samples Button B 22

2.1.4.2 Naming Samples at the Beginning of a Run B 25

2.1.5 Real Time Fluorimeter (RTF) B 29

2.1.6 Programming Screen: Color Compensation Window B 32

2.1.7

Programming Screen: Display Mode / Fluorimeter Gains

Window

B 1

B 11

B 34

2.1.8 Programming Screen: Cycle Program Data and

Temperature Targets Window

2.1.9 Programming Screen: Graphic Simulation Window B 40

2.1.10 Programming Screen: Cycle Program Overview Window B 41

3. Running the LightCycler

3.1 LightCycler Run Screen B 42

Continued on next page

B 36

B 42

Page 41

B 3

1.1 Table of Contents (continued)

Topic See Page

4. Data Analysis

4.1 Introduction B 46

4.2 Select Data File / Data Analysis Window B 47

4.3 LCDA Front Screen B 49

4.3.1 LCDA Front Screen: Temperature vs. Time Graph B 50

4.3.2

4.3.3 LCDA Front Screen: Using Color Compensation Files B 54

4.4 LCDA Front Screen: Data Retrieval B 56

4.5 Further Analysis B 56

Fluorescence vs. Cycle Number / Time / Temperature

Graph

B 46

B 52

5. Display and Analysis of Quantification Data

5.1 Introduction B 57

5.2 Quantification: Selection of Analysis Method B 58

5.3 Quantification Step 1: Baseline B 61

5.4 Quantification Step 2: Noise Band B 64

5.5 Quantification Step 3: Analysis B 66

5.6 A Procedure for Analyzing Quantification Data B 72

6. Display and Analysis of Melting Curve Data

6.1 Introduction B 85

6.2 Melting Curve Step 1: Melting Peaks B 87

6.3 Melting Curve Step 2: Peak Areas B 91

6.4 Melting Curve Step 3: Manual T

6.5 A Procedure for Analyzing Melting Curve Data B 95

m

B 57

B 85

B 93

Page 42

B 4

1.2. Introduction

Before

Beginning

Program Start

Your LightCycler should have been installed and set up according to the

instructions described in Section 3 of Chapter A.

During installation, the LightCycler software will automatically be loaded

into the part of the hard disc that contains the Windows NT operating

system.

Prior to the start of the program, an account must be set up for each user

granting him access privileges that enable him to use the computer. Such

accounts must be used by the users to log on to Win NT.

If the check box 'Yes, launch the program file' was selected at the end of the

installation, the 'LightCycler3 Front Screen' (Front) program will now start.

Log On

Procedure

The current user may log on using the 'Log On As Different User' button.

The information message to the effect that all programs will be closed must

be acknowledged by clicking 'OK'. Subsequently, all programs are closed and

WIN NT displays its log-on screen. The user must now log on by entering his

user name and password.

Note: The LightCycler does not allow to log on as a different user as long as a

LightCycler Run is performed to prevent loss of data by interrupting the run.

Continued on next page

Page 43

B 5

1.2. Introduction, Continued

Program Start, In the event that the check box 'Yes, launch.....' was not selected at the end

of the installation, the user needs to log on first. This may be accomplished

in the Start menu using the 'Shut Down' command.

Select the option button 'Close all Programs and log on as different user'

and click the 'Yes' button. Windows now closes all programs and displays

its log-on screen. The user must now log on by entering his user name and

password.

Following the log-in procedure, the LightCycler3 program may be started.

The start should always be carried out from the desktop or the Start menu

by clicking the 'LightCycler3 Front Screen' icon. Only this procedure will

ensure that the user is logged on properly to the program and that the

required work directories are created upon the initial startup.

Continued on next page

Page 44

B 6

1.2. Introduction, Continued

How to Start Follow the steps in the table to start.

Step Action

1 Turn on the computer by pressing the power button on the front

of the computer.

Result: Windows NT will automatically load.

2 Type in your User Name and Password to log into Windows NT

and the LightCycler software.

Note: User management requirements for the LightCycler software

are set up through the Windows NT operating system.

3

4

Flip the switch on the back panel of the LightCycler to the On

position.

Click on the LightCycler 3 Front Screen icon; this will bring up the

LightCycler Front Screen.

Note: Alternatively, you may use Windows NT Explorer to start

each software function independently, without first entering the

LightCycler Front Screen. For instance, from Windows NT

Explorer, do the following:

Important

Note about

the PC

To start from... Click on...

LightCycler Front Screen

Programming / Run Screen

LightCycler Data Analysis Front Screen

Tip: Accessing the screens through Windows NT Explorer allows

you to graphically display and evaluate data generated in previous

experiments while other experimental protocols are in progress.

The PC supplied with the LightCycler should be used exclusively with the

LightCycler software. We strongly advise against installing and running

additional software on this PC.

Front.exe

(BM) Run32.exe

LCDA.exe

Continued on next page

Page 45

B 7

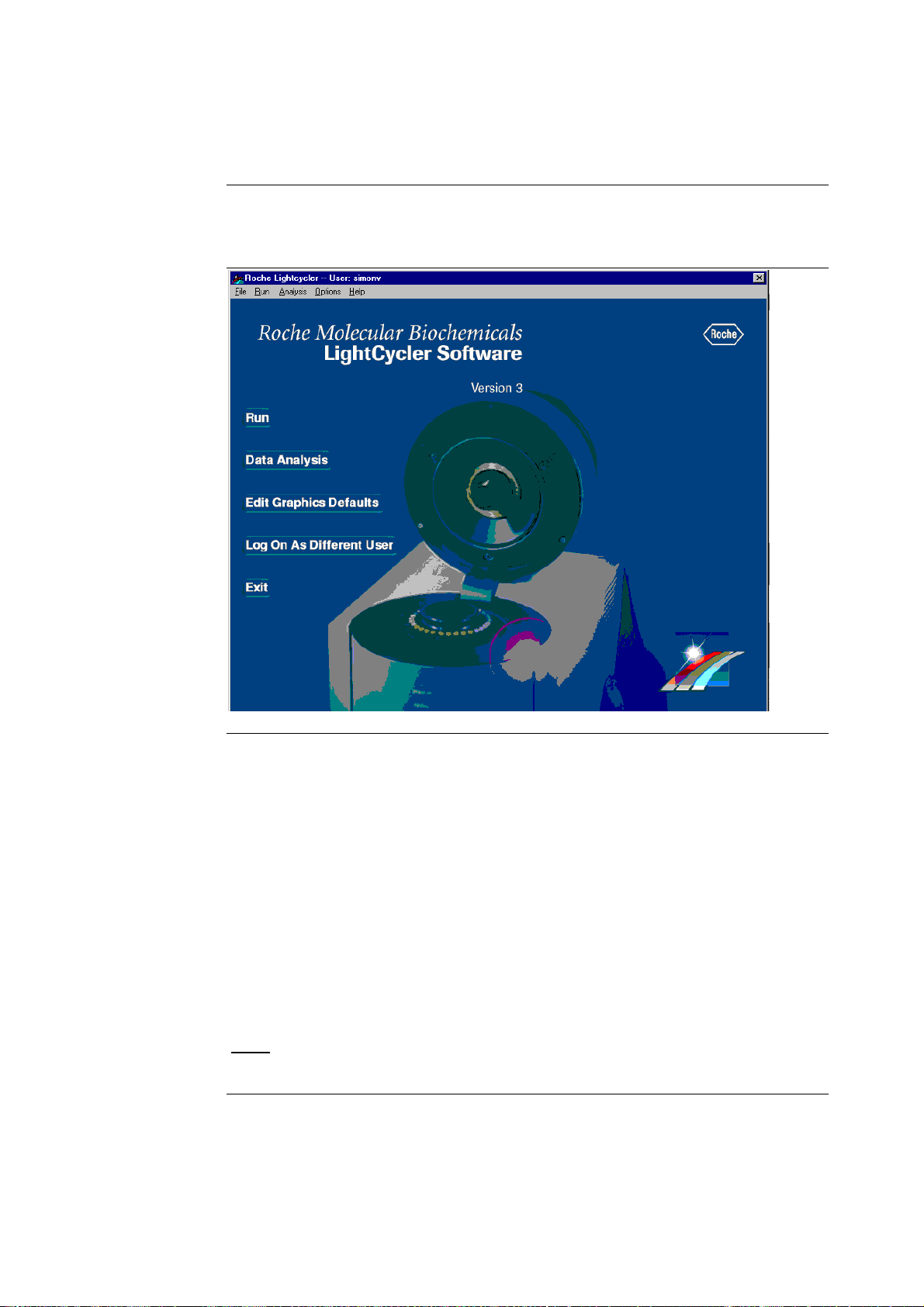

1.3. The Front Screen

LightCycler

Front Screen

In Version 3 of the LightCycler software, the front screen looks like this:

Introduction When you click on the LightCycler Front Screen icon on the Windows NT

desktop, the LightCycler software is activated and the LightCycler Front

Screen will appear on the monitor. This screen provides access to the

functions of the LightCycler software via a set of menus.

Alternatively, you may also directly access the most important instrument

functions by clicking on these screen buttons:

• Run

• Data Analysis

• Edit Graphics Defaults

• Log On As Different User

• Exit

Note: The functions of these buttons are explained in more detail on the

pages of the next section.

Page 46

B 8

1.4. Functions of Buttons on the Front Screen

Run Button The Run button starts the LightCycler Run Software which allows you to

program and execute cycle experimental protocols.

Note: The Front Screen Run menu may be used for the same purpose.

Data Analysis

Button

Edit Graphics

Defaults

Button

Log On As

Different User

Button

The Data Analysis button provides access to the LightCycler Data Analysis

(LCDA) software.

Note: The Front Screen Analysis menu may be used for the same purpose.

The Edit Graphics Defaults button allows a user to change the colors and line

styles used in the data display graphs (see Section 1.5 of this chapter).

Note: The Front Screen Options menu may be used for the same purpose.

Each user only has access to a unique set of files. To access files belonging to a

different user, click on the Log On As Different User button. This allows you

to exit all LightCycler programs and reactivate the software with a different

user name and password (as prompted by the system).

Note: The LightCycler does not allow to log on as a different user as long as a

LightCycler Run is performed to prevent loss of data by interrupting the run.

The Front Screen Options menu may be used for the same purpose.

Exit Button The Exit button allows you to quit the LightCycler program.

Note:

• You may also quit the program by closing the Front Screen window. The

Exit function is also part of the Front Screen File menu.

• After exiting the software, you still must turn off the LightCycler instrument

separately.

Help Menu The Operator Manual can be called by Acrobat Reader.

Note: Acrobat reader 4.0 is provided as part of the Software CD.

Page 47

B 9

1.5. Edit Graphics Defaults Window

Edit Graphics

Defaults

Window

The Edit Graphics Defaults button allows a user to change the color and style

of the line used to represent each sample in LightCycler data displays. When

you click on the button, the Edit Graphics Defaults window will appear (as

shown below):

Continued on next page

Page 48

B 10

1.5. Edit Graphics Defaults Window, Continued

Changing the

Line Display

After entering the Edit Graphics Defaults window, change the appearance of

the graph lines as follows:

Caution: Changes made to graphics defaults will not be accepted if the

LightCycler Data Analysis (LCDA) software is active. Before changing the

graphics defaults, first close LCDA. Then, edit and save your graphic defaults

and reload LCDA. The changes are then accepted by LCDA.

User specific default settings are stored in a file „defaults.ini“ in the user

directory. You may store your settings with another user by copying your

user default.ini file into the other user directory.

Step Action

1

2

3

4

5 If you do not like the appearance of the sample lines in the data

Right-Click on the sample number you wish to change.

Result: A pop-up menu will appear. The menu contains the

following graphics options: Color, Point Style and Line Style.

From the menu, click on the display option you wish to change.

Result: One of the Graphics Default Options windows (pictured

below) will appear.

Click on the option you prefer and then click the OK button.

Result: The Graphics Default Options window will close.

Note: Changes made to the graphic defaults of one user do not

affect the graphics defaults of any other user.

From the Edit Graphics Defaults window, click on the Save button

to save your new graphics defaults.

Note: After saving them, you may always return to your display

options (defined in Steps 1–4) at any time by clicking on the

Restore button (in the Edit Graphics Defaults window).

display, you may open the Edit Graphics Defaults window and do

one of the following:

• Click on the Restore Defaults button to return all options to the

system default settings.

• Repeat Steps 1–4 above and choose different options.

Graphics

Default

Options

Windows:

Color, Point

Styles and Line

Styles

Page 49

B 11

2. Programming a Run

2.1. Programming Screen

Introduction The descriptions given in the following pages explain how to use the

Programming Screen for:

• Defining the parameters of a PCR protocol,

• Starting a PCR run, or

• Viewing online a PCR experiment that is currently in progress.

Activation of

Programming

Screen

To set up a new experimental protocol or to order a new run with a protocol

that has already been defined and stored, you must first activate the Run

function from the LightCycler Front Screen. Follow the steps below to

activate the Run function and open the Programming Screen:

Step Action

1

2

Click the Run button on the LightCycler Front Screen.

Result: A data-entry screen opens. This screen will henceforth be

referred to as Programming Screen.

If you have not already switched on the LightCycler instrument,

the software will prompt you to do so.

Note: It is possible to ignore this message, by simply clicking OK.

This will allow you to become familiar with the LightCycler

software without running an experiment.

Continued on next page

Page 50

B 12

2.1. Programming Screen, Continued

Programming

Screen

Functions

Available on the

Programming

Screen

Defining Cycle

Programs

The rest of the topics in Section 2.1 of this chapter describe the software

functions that may be activated by either using the menu bars or clicking on

various buttons available on the Programming Screen. Menu options are

listed in the top-to-bottom order in which they appear on each menu.

Function buttons are described according to the screen areas in which they

appear.

Note: Use the Programming Screen diagram above to locate the screen areas,

menus, and buttons as they are described below.

Use the Programming Screen to define the cycle programs for an

Experimental Protocol (*.exp-file). Once you have defined your

Experimental Protocol, you will be ready to run a LightCycler experiment.

Tip: You can use the descriptions in the following sections to familiarize

yourself with the actions necessary to define an Experimental Protocol. For

instance, as you read the descriptions below, you may activate each function

by clicking on the menu option or button, and then enter typical

experimental parameters in the tables or fields that appear.

Continued on next page

Page 51

B 13

2.1. Programming Screen, Continued

Program 3:

Melt

Program 1:

Program 2:

Amplification

Program 4:

Cooling

Initial

Denaturation

Definitions:

Protocol /

Program /

Segment

Experimental Protocol

An Experimental Protocol in general contains one or more Cycle Programs.

In the PCR profile shown above, a typical Experimental Protocol contains

four programs: 1) an Initial Denaturation Program, 2) an Amplification

Program, 3) a Melting Program and 4) a Cooling Program.

A Program (e.g. Cycle Program) contains several Temperature Segments,

each of which defines the time and temperature parameters that will be used

for denaturation, annealing, extension and/or melting, cooling as well as the

fluorescence acquisition mode used to monitor the amplification signal.

Page 52

B 14

2.1.1. Menu Options Available on the Programming Screen

Options

Available on

the

Programming

Screen Menus

The Menu bar on the Programming Screen offers a variety of options for

programming, managing, and displaying Experimental Protocols (*.exp-

files). The following list gives you a brief description of the menu functions.

Note: You may also activate a number of the options listed on these menus

key by clicking the buttons found in various areas on the screen. The use of

these buttons is discussed in detail in later sections of this chapter.

Menu Offers these options

File Allows you to:

• Create or Open existing *.exp-files,

• Save the current *.exp-file,

• Print the current window contents, and

• Exit the Run program.

Note: Experimental files (*.lin-files) made with older

versions of LightCycler software will be automatically

converted to *.exp-files when they are first opened.

If you had used the Lightcycler Software 1.2x, we

recommend converting all *.lin-files into *.exp-files

and then deleting the *.lin- and *pro-files. As a *.profile may have been used by several *.lin-files, *.profiles should only be deleted after converting all *.linfiles.

Edit

Allows you to:

• Cut, Copy, and Paste,

• Edit Sample Defaults ,

• Display Cycle Program Simulation,

• Edit Experimental Notes to your *.exp-files, and

• Show Experimental Notes.

Note: The Cycle Program Simulation and

Experimental Notes will appear in the window in the

right portion of the Programming Screen under the

User / Experiment window.

Continued on next page

Page 53

B 15

2.1.1. Menu Options Available on the Programming Screen,

Continued

Options Available on the Programming Screen Menus (continued)

Menu Offers these options

Tools

Options

Allows you to:

• Display the Real Time Fluorimeter, and

• Activate a Service Utility function.

Note:

1) The Real Time Fluorimeter option permits

continuous fluorescence measurement of samples to

allow adjustment of fluorimeter gain by the user.

2) The Service Utility function facilitates adjusting

and testing to permit the instrument to be serviced

by an authorized specialist from Roche Molecular

Biochemicals Technical Support.

Caution: Do not activate the Service Utility function

unless Roche Molecular Biochemicals service

personnel ask you to do so. Settings of the Service

Utility function will not be stored and used by the

Run program.

Allows you to:

• Choose (color compensation,-*.ccc-)-files

containing color compensation data, or

• Disable (color compensation,-*.ccc-)-files,

• Set LED Power (to turn the LED light source on

and off),

• Edit Sample Defaults (to specify and alter sample

information), or

• Use Seek Threshold.

Continued on next page

Page 54

B 16

2.1.1. Menu Options Available on the Programming Screen,

Continued

Options (continued)

Menu Offers these options

Options

Note:

1) Choose (color compensation, -*.ccc-)-files

activates the Color Compensation function for use

with multicolor reaction systems (see Section 4.3.3 of

this chapter and Section 5 of Chapter D for more

information).

2) The numerical value below the instrument switch

indicates the current LED level on a scale of 0-100%.

If the Calibrated box is checked, the LED power is set

to 75% and cannot be adjusted. If the Calibrated box

has been cleared, choosing Set LED Power causes a

yellow box to be displayed on the Programming

Screen, indicating the LED light source level chosen

and allowing the value to be changed.

Help

Note: We strongly recommend to use Calibrated

LED.

3) The Use Seek Threshold function may be

inactivated when a capillary, containing no

fluorescent dye is not found by the “Seek” function at

the beginning of a calibration run.

Allows you to

• Access the Online LightCycler Manual.

Note: The Operator Manual can be called by Acrobat

Reader. Acrobat reader 4.0 is provided as part of the

Software CD.

Page 55

B 17

2.1.2. Programming Screen: User / Experiment Window

Location of

Window

Contents and

Functions of

User /

Experiment

Window

The User / Experiment Window is in the right upper corner of the

Programming Screen.

• The following information is available in the User / Experiment Window

(left photo above):

• The User name that you used to log onto the LightCycler software appears

in the User Name Field.

• The Experiment Field displays the name of the Experimental Protocol

(*.exp)-file that is currently loaded into the programming software.

• The Cycle Program list (below the Experiment Field) displays the names

of the cycle programs contained in the active *.exp-file.

• Use the Cycle Program list in the User / Experiment Window, along with

the buttons below the list to:

• Define a new *.exp-file, or

• Modify an already existing *.exp-file.

Note: See the next page for a description of the functions activated by

these buttons.

Caution: Although you can edit an *.exp-file in this window, you must use

another window to open or create that file. Go to the left side of the

Programming Screen, find the Experiment / RUN / EXIT window (right

photo above) and:

• Click on the Open Experiment File button to open an existing file that you

want to edit, or

• Click on the New Experiment button to create a new *.exp-file.

Continued on next page

Page 56

B 18

2.1.2. Programming Screen: User / Experiment Window, Continued

Cycle

Programs

Order of Cycle

Programs

Cycle Program

Buttons

As mentioned in Section 2.1 of this chapter, each Experimental Protocol

(*.exp-file) contains one or more cycle programs that are defined by the user,

e.g.:

Cycle Program No. Example of operation described in program

1 Initial denaturation

2 PCR amplification, with repeated cycles of

denaturation, annealing, and elongation

3 Melting curve for analysis of the PCR data

4 Cooling

In the Cycle Program window, all cycle programs in the current *.exp-file

are displayed in the order they will be executed during a run.

Use the buttons below the Cycle Program window to perform the following

modifications of the programs in a new or existing *.exp-file.

Use this button To modify an *.exp-file in this way

Add To create a new program in the *.exp-file

Remove To delete a program from the *.exp-file

Import To import cycle programs from other *.exp-files

Move Up To change the order in which programs will be

executed

Continued on next page

Page 57

B 19

2.1.3. Programming Screen: Experiment / RUN / EXIT Window

Location of

Window

Experiment /

RUN / EXIT

Window

Functions of

Window

Buttons

The Experiment / RUN / EXIT Window is on the left side of the

Programming Screen.

The Experiment / RUN/ EXIT Window contains seven buttons. Use the

buttons to perform the following software functions:

Use this button To perform this function

New

Create a new *.exp-file (see Section 2.1.2 above).

Experiment

Open

Select and open an existing *.exp-file.

Experiment File

Note: Any *.lin-files, used in the previous version of the

LightCycler software (Versions 1.2 and 1.22) to contain

protocol information, are automatically converted when

opened with this button. The *.lin-files are copied,

converted, and saved with an exp suffix.

Save

Save a newly defined or modified *.exp-file.

Experiment File

Continued on next page

Page 58

B 20

2.1.3. Programming Screen: Experiment / RUN / EXIT Window,

Continued

Functions of Window Buttons (continued)

Use this button To perform this function

Edit Samples

Real Time

Fluorimeter

RUN

Name samples in a given run and include additional

sample information, e.g. carousel position, type of sample,

whether the sample is a replicate of another sample,

concentration (if known), and descriptive notes.

Note: See the next section (Section 2.1.4) in this chapter

for details on sample information.

Monitor fluorescence over time without running a cycle

program. This function allows you to set optimum

fluorimeter gain values for your specific protocol.

Note: See Section 2.1.5 in this chapter for details on the

Real Time Fluorimeter.

Start a LightCycler run.

EXIT

Note: When you click on this button, the Loading Screen

window will appear and you will be prompted to enter

your sample data.

Leave the Programming Screen window.

Page 59

B 21

2.1.4. Programming Screen: Sample Data Entry

Introduction The LightCycler offers you several opportunities to name and describe your

samples. You may define sample data in either of two similar windows:

• Click on the Edit Samples button in the Experiment / RUN / EXIT window

(left side of screen).

Result: The Loading Screen will appear. This screen contains a Sample Data

table (see Section 2.1.4.1 below for details).

Note: This option allows you to include sample information in the *.exp-file

so it will be available for every run performed with that file. If you are going

to repeatedly run the *.exp-file with the same number of samples, use this

option.

• Click on the RUN button (in the Experiment / RUN / EXIT window) to

start the LightCycler run. Whether or not you have previously stored sample

data in the active *.exp-file, the software will prompt you to enter sample

data for this particular run.

Result: The Loading Screen with the Sample Data table will appear. Note,

however, that the options available at this stage differ slightly from those

available when the Edit Samples button is used (see Section 2.1.4.2 below

for details).

Note: Use this option if the number or the type of samples varies from run

to run.

Page 60

B 22

2.1.4.1. Loading Screen Activated by Edit Samples Button

Appearance of

Loading Screen

Activated by

Edit Samples

Button

When you click on the Edit Samples Button in the Experiment / RUN / EXIT

window, the Loading Screen below appears. The software will prompt you to

enter your sample default into the Sample Data table.

Note: Start entering data for carousel position #1 and continue through the

last carousel position that contains samples, including any gaps in the sample

order.

Fields in

Sample Data

Table

To define sample data that will become a part (i.e., the sample default data)

of the *.exp-file, describe a sample set in these fields of the Sample Data table:

This field Contains this sample data

Rotor Position Indicates the position of the sample in the 32-sample

carousel.

Sample Name Lists the name of the sample as it will appear in the

sample loading dialog and the analysis results.

Type Indicates whether a sample is a positive control, negative

control, quantification standard, or an unknown.

Replicate of Indicates whether a sample is a replicate of another

sample located at another position in the carousel.

Note: Enter the carousel position of the replicated sample.

Concentration Lists the concentration of a sample if it is known, e.g. if

the sample is a quantification standard.

Notes Allows additional sample information to be included.

Continued on next page

Page 61

B 23

2.1.4.1. Loading Screen Activated by Edit Samples Button,

Continued

Additional

Fields on This

Loading Screen

After entering the sample description into the fields of the Sample Data table,

enter additional sample information into three fields along the bottom of the

Loading Screen:

Field Location Contains this information

Temperature

Number of

Samples

Left lower corner

of Loading Screen

Left lower corner

of Loading Screen

Lists the temperature that the sample

chamber holds during the “Seek

Process” at the beginning of a run. As

a default during editing the sample list

the LightCycler holds a temperature of

30°C.

Examples: For instance when

preparing for an RT-PCR, the

temperature during editing the sample

list and the subsequent seek may be set

to a higher temperature (e.g. 55°C).

Higher temperature during the seek

may also be set, when using low

concentrations of probes, that are

fluorescent only at higher

temperatures (e.g. beacon probes).

Lists the total number of samples in

the carousel.

Concentration

Units

Right lower corner

of Loading Screen

Note: If you want to leave space in

between the capillaries, indicate the

number of samples and the number of

free positions in between the

capillaries.

Lists the units of concentration to be

used during data analysis (i.e., the

units appropriate for the values in the

Concentration fields).

Note: This information is only used to

correctly label the axis of the analysis

program. It has no relevance for

calculation of data as such.

Page 62

B 24

2.1.4.1. Loading Screen Activated by Edit Samples Button,

Continued

Additional

Functions on

This Loading

Screen

This Loading Screen contains four buttons that perform the following useful

functions:

Use this button To do the following

Done To confirm the values entered in the sample data

fields and return to the Programming Screen.

Cancel To interrupt the entry of sample data.

Clear Sample List To make all fields in the Sample Data table blank.

Default Sample List To reset the values in the Sample Data table to

values previously defined and stored in the *.exp-

file by the user.

Page 63

B 25

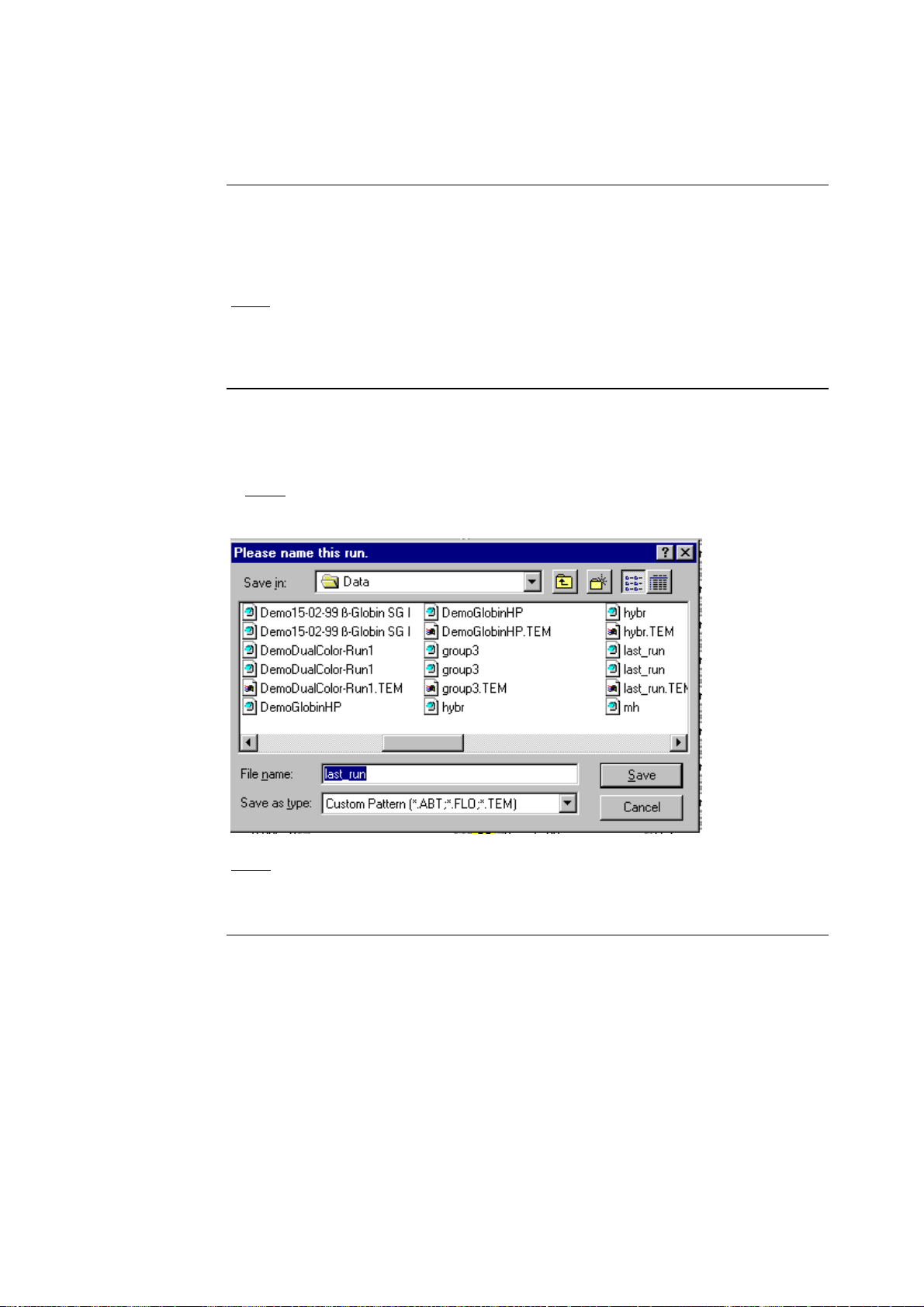

2.1.4.2. Naming Samples at the Beginning of a Run

Introduction When you start a run (by clicking on the RUN button in the Experiment /

RUN / EXIT window, the software will offer you an opportunity to enter

descriptions of the samples in this particular run.

Note: This option is useful if you have not previously defined a default set of

samples in the active *.exp-file. Even if you have previously defined the

samples in the active *.exp-file, you may wish to define a different sample set

that is unique to this run.

Create a Run

Data File

• After you click on the Run button, a dialog box (shown below) will open

and prompt you to name the file where the run data will be stored.

• Enter a name for the run data file and click the Save button.

Note: To close the dialog box without specifying a file name, click on the

Cancel button.

Note: After you save the data run file and the dialog box closes, the Loading

Screen will appear and the software will prompt you to enter sample data for

the current run (see next page).

Continued on next page

Page 64

B 26

2.1.4.2. Naming Samples at the Beginning of a Run, Continued

Loading Screen

that Appears at

the Beginning

of a Run

After you click on the RUN button in the Experiment / RUN / EXIT Window,

the Loading Screen (shown below) will appear. The software will prompt you

to enter sample data for this run in the Sample Data table.

Note: Start entering data for rotor position #1 and continue through the last

rotor position that contains samples, including any gaps in the sample order.

Fields in

Sample Data

Table

To define sample data for the current run, describe your samples in these

fields of the Sample Data table:

This field Contains this sample data

Rotor Position Indicates the position of the sample in the 32-sample

carousel.

Sample Name Lists the name of the sample as it will appear in the

sample loading dialog and the analysis results.

Type Indicates whether a sample is a positive control, negative

control, quantification standard, or an unknown.

Replicate of Indicates whether a sample is a replicate of another

sample located at another position in the carousel.

Note: Enter the carousel position of the replicated sample.

Concentration Lists the concentration of a sample if it is known, e.g. if

the sample is a quantification standard.

Notes Allows additional sample information to be included.

Continued on next page

Page 65

B 27

2.1.4.2. Naming Samples at the Beginning of a Run, Continued

Additional

Fields on This

Loading Screen

After entering the sample description into the fields of the Sample Data table,

enter additional sample information into three fields along the bottom of the

Loading Screen:

Field Location Contains this information

Temperature

Number of

Samples

Left lower corner

of Loading Screen

Left lower corner

of Loading Screen

Lists the temperature that the sample

chamber holds during the “Seek

Process” at the beginning of a run. As

a default during editing the sample list

the LightCycler holds a temperature of

30°C.

Examples: For instance when

preparing for an RT-PCR, the

temperature during editing the sample

list and the subsequent seek may be set

to a higher temperature (e.g. 55°C).

Higher temperature during the seek

may also be set, when using low

concentrations of probes, that are

fluorescent only at higher

temperatures (e.g. beacon probes).

Lists the total number of samples in

the carousel.

Concentration

Units

Right lower corner

of Loading Screen

Note: If you want to leave space in

between the capillaries, indicate the

number of samples and the number of

free positions in between the

capillaries.

Lists the units of concentration to be

used during data analysis (i.e., the

units appropriate for the values in the

Concentration fields).

Note: This information is only used to

correctly label the axis of the analysis

program. It has no relevance for

calculation of data as such.

Page 66

B 28

2.1.4.2. Naming Samples at the Beginning of a Run, Continued

Additional

Functions on

This Loading

Screen

This Loading Screen contains four buttons that perform the following useful

functions:

Use this button To do the following

Done Closes the Loading Screen and opens the Run

Screen.

Note: The instrument will begin to search for the

indicated number of samples.

Enter Samples Later Allows user to define sample data after the

beginning of the run.

Note: The Edit Samples button on the Run Screen

will flash red as a reminder that sample data still

must be entered.

Clear Sample List Makes all fields in the Sample Data table blank.

Default Sample List To reset the values in the Sample Data table to

values previously defined and stored in the *.exp-

file by the user.

Page 67

B 29

2.1.5. Real Time Fluorimeter (RTF)

Introduction The Real Time Fluorimeter (RTF) permits continuous monitoring of

fluorescence, even when a cycle program is not running.

Whenever you set up a new experiment, e.g. with new primers, nucleic acid

templates, or with a new detection format, use the RTF to optimize the

measuring sensitivity of the LightCycler fluorimeter. For example, you may

adjust the fluorimeter gains to optimize the fluorescence response to

variations in temperature or illumination.

Real Time

Fluorimeter

(RTF) Screen

From the Programming Screen, click on the Real Time Fluorimeter button.

The RTF screen will appear (as in the photo below)

RTF Data

Display

The graph that will appear on the gridlines of the RTF screen shows

temperature and fluorescence output of a sample over time. The Real Time

Fluorimeter reads the raw output from the fluorimeters, so fluorescence

outputs are plotted in tenths of a volt (i.e. a reading of 67 units equals 6.7

volts). Time is measured in seconds.

Note: You may adjust the scale on the temperature axis by selecting the upper

limit on the graph and typing in a new upper limit value. You may use the

scroll bar at the bottom of the screen to move the display back and forth along

the time axis.

Continued on next page

Page 68

B 30

2.1.5. Real Time Fluorimeter (RTF), Continued

RTF Settings Use the fields at the bottom of the RTF screen to enter all RTF settings

described below. Fields are listed as they appear on screen from left to right.

Use this field... To alter this value

Target Temp.

Gains

Changes the temperature in the thermal chamber. The current

temperature in the thermal chamber is displayed in the Value field to

the left of Target Temp.