Page 1

Service Manual

Light Cycler

Final 1.0 - January 1999

Page 2

Light Cycler Service Manual

Chapter 1 Application/Introduction

Chapter 2 Installation

Chapter 3 omitted

Chapter 4 Mechanics

Chapter 5 Electronics

Note: In some wiring diagrams the

fluorimeter is termed photometer !

Chapter 6 Software

Chapter 7 T r oub le Shooting

Chapter 8 Spare Parts

Chapter 9 omitted

Chapter 10 Maintenance

Final 1.0 - January 1999

Page 3

Light Cycler Service Manual

1 Application/Introduction _________________________________2

1.1 LightCycler W orkstation ______________________________________ 2

1.2 Technical Data ______________________________________________ 5

1.2.1 Instrument Specifications __________________________________________ 5

1.2.2 Application Specifications __________________________________________ 6

1.2.3 Detector Specifications ____________________________________________ 7

1.3 System Description __________________________________________ 8

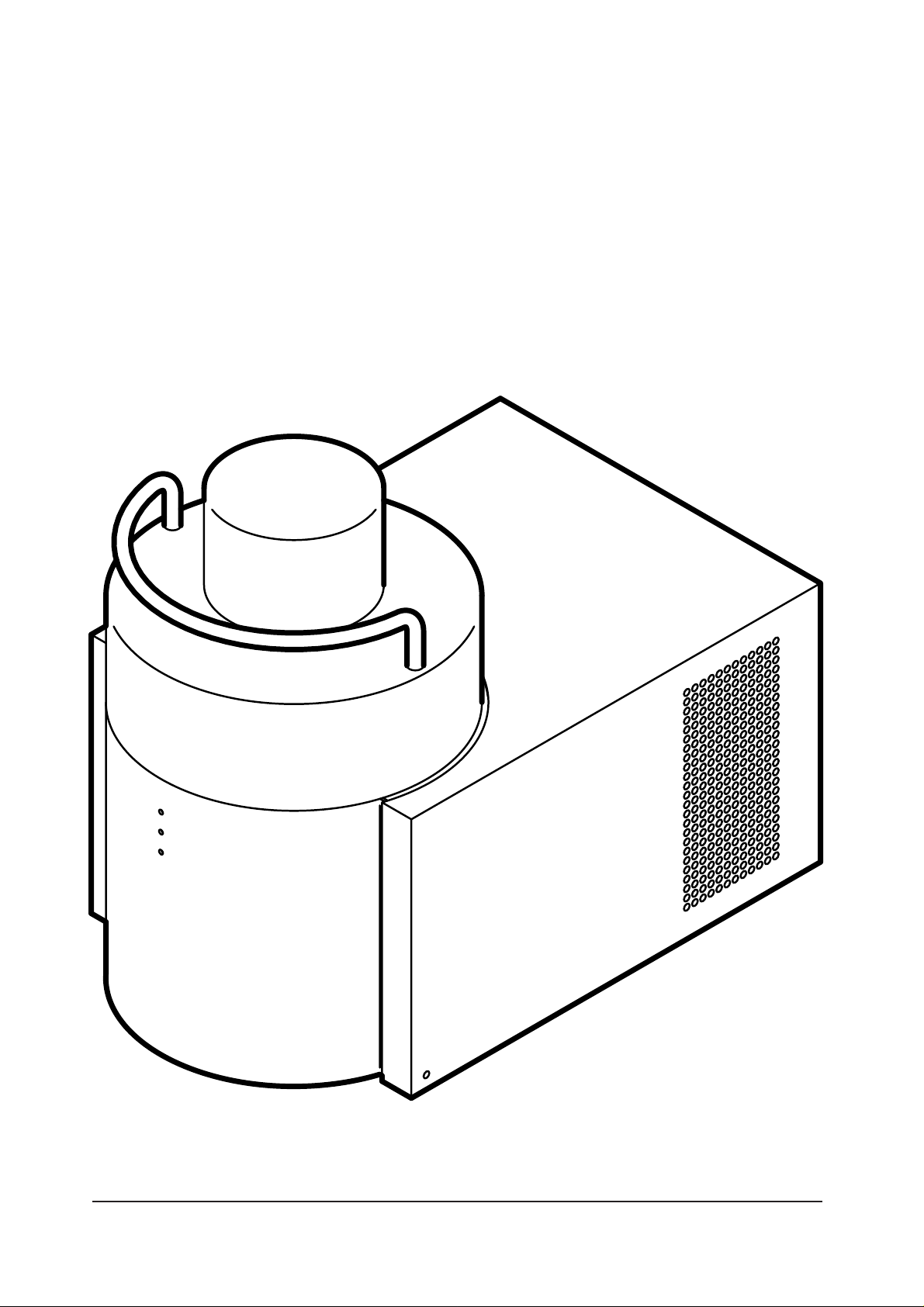

1.3.1 The LightCycler ___________________________________________________ 8

1.4 Introduction _______________________________________________ 11

1.4.1 Instrument ______________________________________________________ 11

1.4.1.1 Principle of the LightCycler Technology ______________________________ 11

1.4.2 Instrument Components of the LightCycler___________________________ 12

1.4.2.1 The Cycler Component_____________________________________________ 12

1.4.2.2 The Fluorimeter Component ________________________________________ 13

1.5 Warranty__________________________________________________ 14

Final 1.0 - January1999 Chapter 1Page 1

Page 4

Light Cycler Service Manual

1 Application/Introduction

1.1 LightCycler Workstation

Contents of the Workstation

The LightCycler components are listed in the following

table:

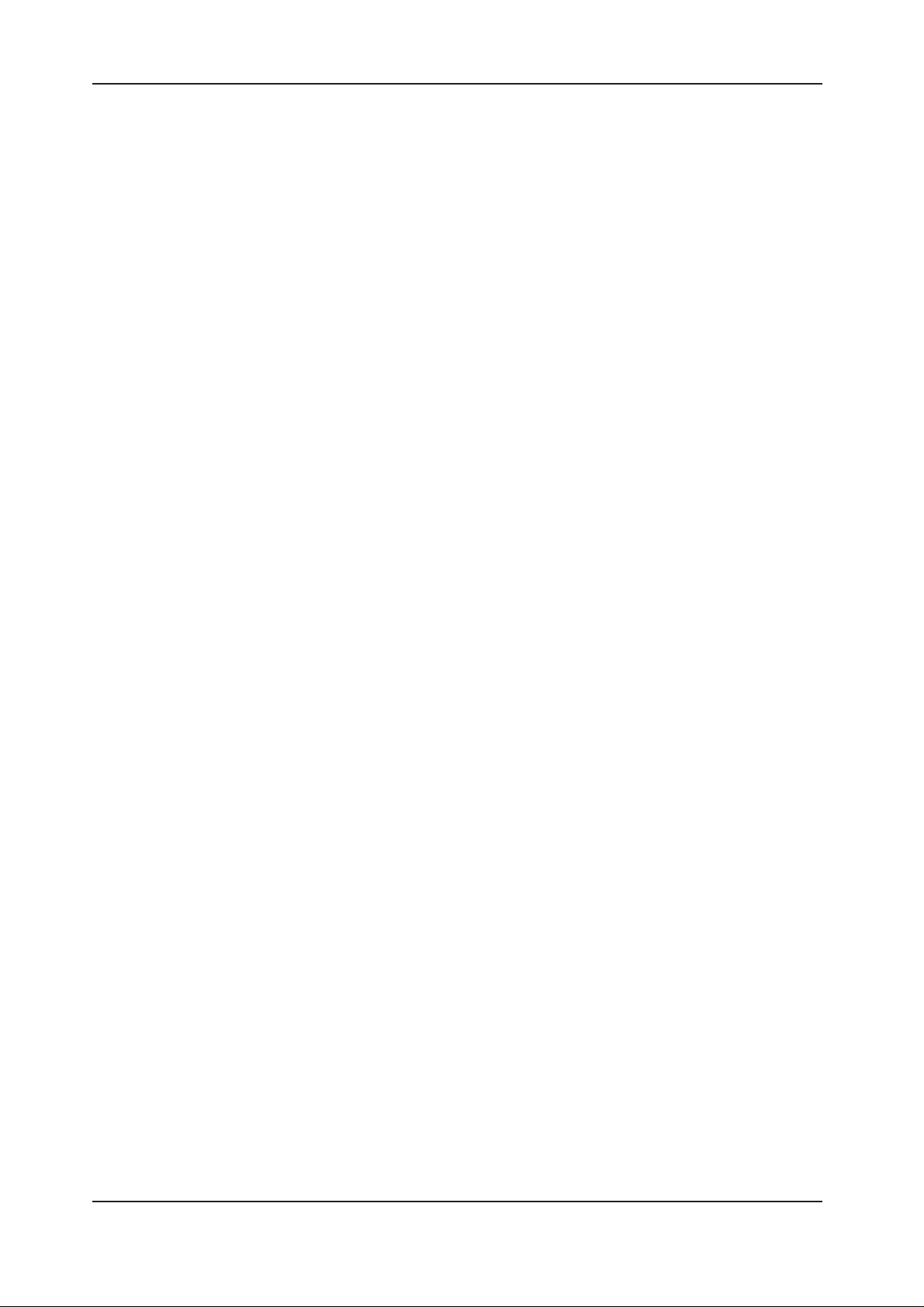

Component Description

System component 1 · LightCycler™ Instrument

· Sample Carousel (for Ø 1.5 mm capillary), premounted in LightCycler™

Instrument

System component 2 · Capillaries, (96 capillaries and caps/box)

· 32 Centrifuge adapters with 1 cooling block in an aluminium cooling block

· LightCycler™ Operator´s Manual

· Software Package

· Cable (to connect LC to computer)

· Power cord (German plug)

· Power cord (U.S. plug)

· Mouse Pad

Recommended PC Hardware /8/98 · Vectra VE4 5/200 MMX Model 3200 Desktop

· Intel Pentium MMX processor, 200 MHz

· 64 MB SDRAM DIMM

· 3.2 GB ultra-ATA/33 hard disk

· On-board PCI vide: S3 Trio 64 V2, 2MB 50 ns DRAM

· 24x speed DIE CD-ROM disk drive

· Keyboard and PS/2 mouse

Operating system Windows NT 4.0, including service pack III

ZIP drive Internal Iomega ZIP drive, DIE interface (ATAPI)

Monitor HP Ergo 1280, 17" monitor (HP# D2840A)

Printer HP Deskjet 890C Color Inkjet Printer

Tab.: cap1-1

Final 1.0 - January 1999 Chapter 1Page 2

Page 5

Light Cycler Service Manual

Marks of Conformity

TM

The LightCycler

with EN 61010-1 (Safety Regulations for Measuring,

Control and Laboratory Instruments; Part 1: General

Requirements (IEC 1010-1 + A1: 1992, modified) and

has been checked according to all relevant safety

standards prior to leaving the factory.

The instrument has been approved for use by recognized

testing institutions.

This is confirmed by the following test/conformity

symbols:

GS Certificated by VDE institute (Association of German

CE The instrument conforms to current directives as issued by the

has been manufactured in accordance

Electrotechnical Engineers)

European Union

UL Certificated by Underwriters Laboratories Inc.

CUL Certificated by Underwriters Laboratories for Canada – a

testing facility recognized by the Standards Council of Canada

(SSC)

All equipment to be connected must fulfill the standards

set by IEC 950 (Safety of Information of Technology

Equipment, Including Electrical Business Equipment).

Tab.: cap1-2

Final 1.0 - January1999 Chapter 1Page 3

Page 6

Light Cycler Service Manual

Classification

- ISM instrument, medium-sized, for industrial,

laboratory and domestic use.

- The instrument is designed for stationary operation.

- Any false measurements produced are irrelevant

from the safety point of view.

- The instrument is designated for worldwide marketing.

- It is intended for evaluating pre-processed biological

material.

The following should be noted:

- The instrument may not be used in conjunction with

infectious material without additional safety measures

being taken.

Final 1.0 - January 1999 Chapter 1Page 4

Page 7

Light Cycler Service Manual

1.2 Technical Data

1.2.1 Instrument Specifications

General Data

Dimensions Height 45 cm

Width 30 cm

Depth 45 cm

Weight 20 kg

Power supply 110-240 V ± 10%, 47-63 Hz

Wattage 800 W

Noise acc. to DIN 43635 < 80 dBA

Heat emission, including PC, monitor and printer Max. 860 kcal/h

Safety symbols CE, GS, UL, CSA or CUL

Tab.: cap1-3

Environmental Parameters

Temperature during operation 15 – 35°C

Temperature required during operation to maintain

specifications

Temperature during transport/storage/packaging 20 – 60°C

Relative humidity 20 – 80%

Altitude / pressure 0 – 2000 m above sea level1030 – 850 hp

Samples

No. of samples 32

Sample volume 2 – 20 µl

15 – 30°C

Tab.: cap1-4

Tab.: cap1-5

Final 1.0 - January1999 Chapter 1Page 5

Page 8

Light Cycler Service Manual

1.2.2 Application Specifications

PCR Temperatures

Temperature range 40 – 98°C

Temperature accuracy of measuring system ± 0.3°C

Heating rate

Heating rate 40 – 95°C, step 40 – 95°C, time 10 – 90% 8s

Heating rate 50 – 72°C, step 50 – 72°C, time 10 – 90% 4s

Heating rate 72 – 98°C, step 72 – 95°C, time 10 – 90% 5s

Cooling rate

Cooling rate 95 – 40°C, step 95 – 40°C, time 10 – 90% 8s

Cooling rate 95 – 60°C, step 95 – 60°C, time 10 – 90% 4s

Temperature stability

Temperature stability with respect to time, 95°C +1°C / -0.5°C range

Temperature stability with respect to time, 65°C +1°C / -1.0°C range

Temperature stability with respect to time, 40°C +1°C / -0.3°C range

Temperature homogeneity

Temperature homogeneity over all capillaries and time, 95°C ± 1.5°C range

Temperature homogeneity over all capillaries and time, 65°C + 0.7°C / -1.5°C range

Temperature homogeneity over all capillaries and time, 45°C + 1.5°C / -0.5°C range

Temperature Gradients

Temperature gradient 0.1 °C/s, 0.2°C/s

Temperature homogeneity for one capillary, 70 – 95°C ± 1.5°C range

Temperature homogeneity for one capillary, 50 – 70°C ± 1.0°C range

Temperature homogeneity for one capillary, all positions, 70 – 95°C ± 2.0°C range

Temperature homogeneity for one capillary, all positions, 50 – 70°C ± 1.5°C range

Temperature gradient 1.0 °C/s

Temperature homogeneity for one capillary, 70 – 95°C ± 2.0°C range

Temperature homogeneity for one capillary, 50 – 70°C ± 2.0°C range

Temperature homogeneity for one capillary, all positions, 70 – 95°C ± 3.0°C range

Temperature homogeneity for one capillary, all positions, 50 – 70°C ± 3.0°C range

Tab.: cap1-6

Temperature homogeneity for control of temperature peaks

Stability at 95°C for dynamic cycles, 72 – 95 – 50°C, 0s maintained +2.0°C / -1.0°C range

Homogeneity of capillary /capillary at 95°C for dynamic cycles, 72 – 95 –

+3.0°C / -1.0°C range

50°C, 0s maintained

Temperature homogeneity in capillary

20 µl, 70°C ± 1.0°C range

15 µl, 70°C ± 0.5°C range

Final 1.0 - January 1999 Chapter 1Page 6

Tab.: cap1-7

Page 9

Light Cycler Service Manual

1.2.3 Detector Specifications

Illumination

Type LED

Median wavelength 470 nm

Output at 470 – 490 nm 0.1 mW

Tab.: cap1-8

Detector

Type Photohybrid

Receptor surface 2.5* 2.5 mm²

Sensitivity at 520 nm, 20 µl sample volume 15 nM fluorescein (1s)

Sensitivity at 650 nm, 20 µl sample volume x nM fluorescein /LightCycler Red 640

Sensitivity at 700 nm, 20 µl sample volume x nM fluorescein / n.d.

Electronic dynamic 12 bit

Electronic bandwidth 1 kHz

Integration time 20 ms

Alteration of amplification range Factor 1 – 256

Filter

Detector 1 Bandpass 520 nm HBW 20 nm, dichroitic

Detector 2 Bandpass 645 nm HBW 30 nm, dichroitic

Detector 3 Bandpass 710 nm HBW 40 nm, dichroitic

Time

Measuring time for 32 capillaries < 5s

Tab.: cap1-9

Tab.: cap1-10

Tab.: cap1-11

Final 1.0 - January1999 Chapter 1Page 7

Page 10

Light Cycler Service Manual

1.3 System Description

1.3.1 The LightCycler

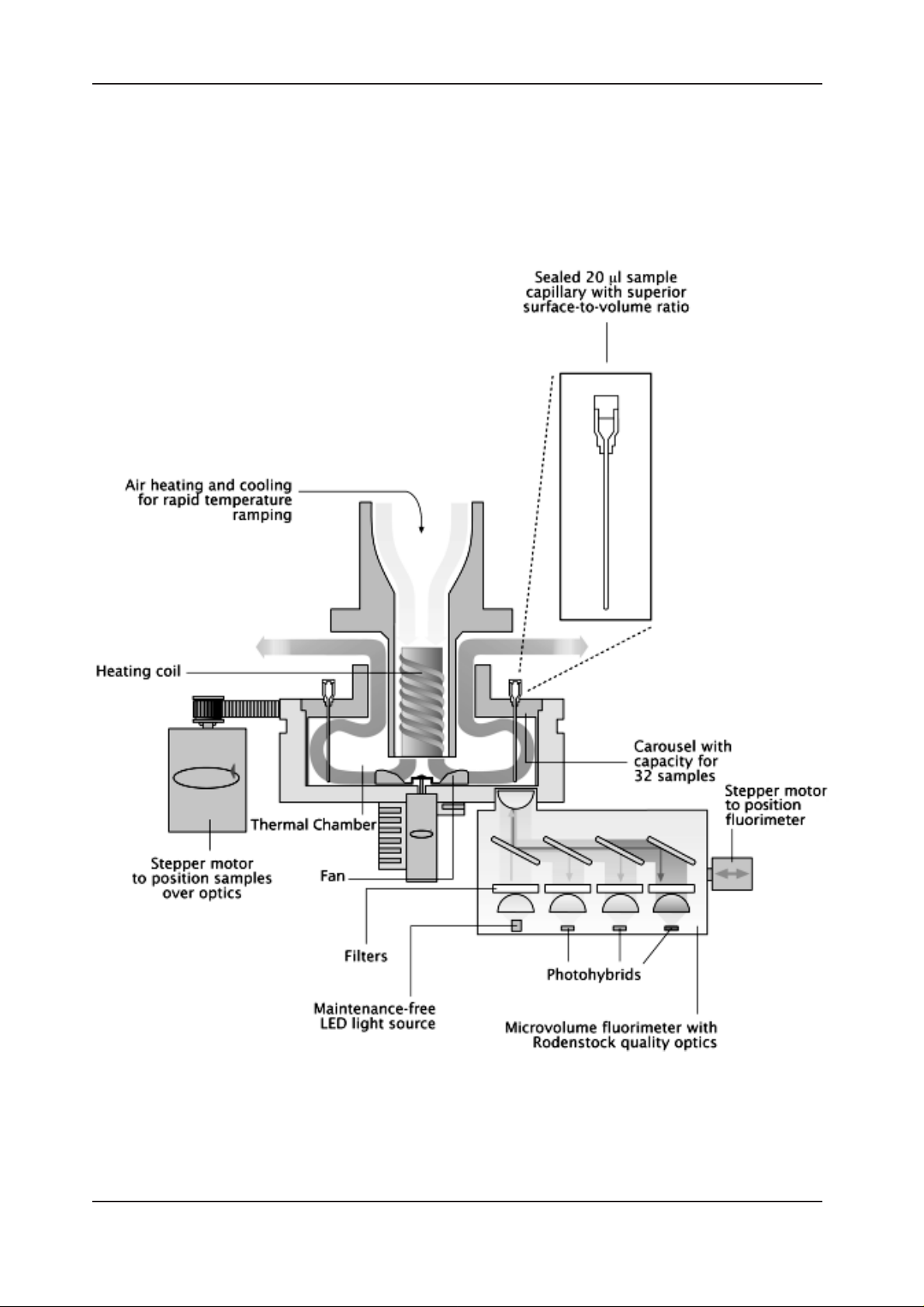

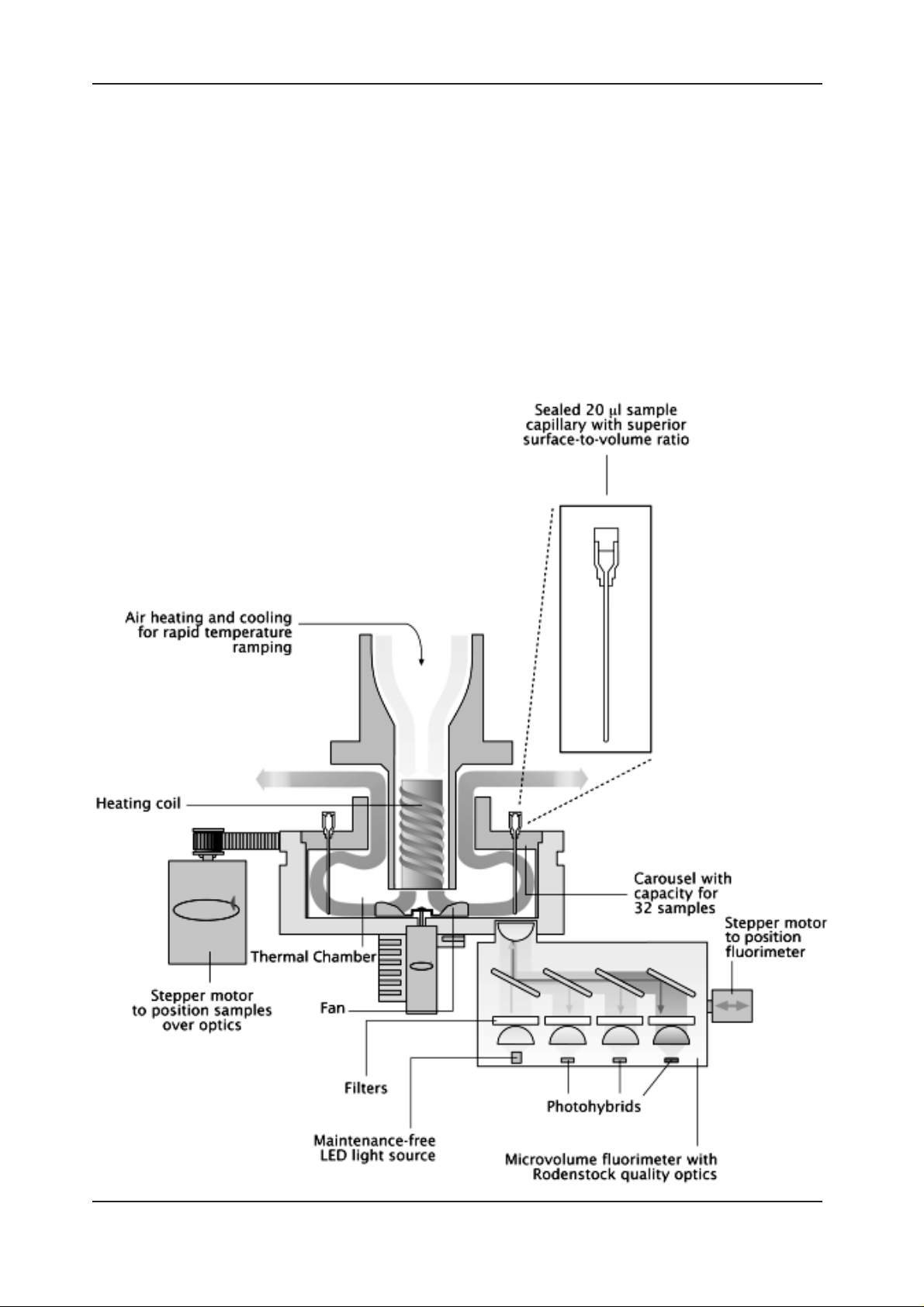

Scheme of the Instrument

Fig. scheme1

Final 1.0 - January 1999 Chapter 1Page 8

Page 11

Light Cycler Service Manual

Description of the Instrument

The sample capillaries are thermostatted with hot air in

the thermal chamber; a ventilator ensures efficient

aspiration, distribution and temperature homogeneity of

the air during the heating process. During the cooling

process, the ventilator operates at a higher speed in

order to ensure adequate cooling. A heating coil controls

the temperature.

For measurement, the sample rotor is propelled by a

stepper motor; this brings the capillary tip precisely to

the focal point of the photometer optics. The photometer

itself is placed in a radial position in relation to the signal

maximum in order to compensate for any radial deviation

of the capillary tip.

3 microprocessors incorporated in the instrument control

the process. Processor 1 is for communication, processor

2 regulates the temperature and processor 3 controls

the measurement procedure as well as the rotor and

photometer movements.

For online display, data are transmitted to the PC. Here,

sample data are entered, the PCR reaction temperature

is monitored, measurement modes and initial evaluation

of melting point temperatures are carried out.

Structure of the LightCycler

The instrument comprises a basic lower and an upper

unit.

Basic Lower Unit Thermo-chamber, photometer, drive units, circuit boards and power supply are located in

the basic unit. The base of the unit is a 10 mm cast aluminum plate onto which the various

elements are fixed. This guarantees stability, especially for the thermo-chamber and

photometer.

Upper Unit The upper unit contains the heating coil, an excess temperature sensor and a cooler with

sectional converter.

Tab.: cap1-12

Final 1.0 - January1999 Chapter 1Page 9

Page 12

Light Cycler Service Manual

Thermo-Chamber Thermostatting

Thermostatting is done by using hot and cold air. A

sensor with thermal time constants identical with those

of the capillaries provides reference values for control

purposes. The process is controlled by varying the

heating coil voltage. During the heating phase, only the

ventilator in the thermo-chamber is in operation; this

guarantees a high degree of temperature homogeneity.

During the cooling phase, both the capillaries and the

heating coil must be cooled. The ventilator is then

operated at a higher speed.

2 sensors are incorporated in order to prevent excess

temperatures:

Sensor I Sensor I is responsible for the temperature regulation.

Sensor II Sensor II monitors the actual temperature.

Tab.: cap1-13

Fluorescence Photometer

A 3-channel fluorescence photometer is used for

detection purposes. Sample excitation is initiated by a

blue LED with an emission maximum of 470 nm.

Fluorescence is detected by means of a separate photohybrid for each wavelength.

Final 1.0 - January 1999 Chapter 1Page 10

Page 13

Light Cycler Service Manual

1.4 Introduction

1.4.1 Instrument

1.4.1.1 Principle of the LightCycler Technology

System Description

The LightCycler comprises two different instrument

components: a cycler component and a fluorescence

detection component. The combination of both

components allows complex applications such as product

analysis, quantification and mutation analysis.

The cycler component has been optimized for rapid

PCR applications. Compared with classical PCR where

typical cycling programs take several hours, PCR

analyses carried out in the LightCycler can be completed

in only 15-30 min. This considerable time saving effect

is due to very short temperature transfer times, the socalled „ramping“ times, of the LightCycler instrument.

„Ramping“ times are the time periods necessary to

reach the next pre-set temperature of a „cycling“ protocol

in a PCR experiment. An example is the transition from

94°C to 55°C after sample denaturation for primer

hybridization during the annealing phase. This sort of

high-speed cycling is made possible by an optimized

surface / volume ratio of the samples and the use of air

as a temperature transfer medium.

Fluorimetric Detection

The combination of an optimized thermocycler and a

fluorimeter not only enables “online” presentation of the

PCR data obtained and efficient analysis of results, but

also offers the user utmost flexibility. To meet individual

requirements, different detection formats can be used

by choosing and combining fluorescent dyes and

detection probes.

Fluorimetric detection of the PCR products formed

consists of two different procedures:

- sequence-specific detection by the double stranded

DNA binding dye SYBRÒ

- sequence-specific oligonucleotides are coupled to

suitable fluorophores as hybridization probes.

Analysis of Results

By means of the special LightCycler software, the data

obtained from fluorimetric analysis can be evaluated

and displayed. Additional cumbersome analytical

procedures subsequent to PCR, e.g. restriction and gel

analysis as well as blotting and hybridization experiments

are no longer necessary. The direct and simple analysis

of results also minimizes the contamination risk posed

by samples and working materials due to a reduction of

working steps required.

Green I, or

Final 1.0 - January1999 Chapter 1Page 11

Page 14

Light Cycler Service Manual

1.4.2 Instrument Components of the LightCycler

1.4.2.1 The Cycler Component

Sample Carousel

The central element of the cylindrical thermal chamber

is the sample rotor. The rotor takes 32 samples in glass

capillaries with a diameter of 1.55 mm and a length of 35

mm. PCR analysis carried out in these specially

manufactured glass capillaries reduces the reaction

volume to only 5 to 20 ml max. The optimized surfaceto-volume ratio thus obtained allows for very short cycle

times of only 15 to 20 seconds per cycle. The very

favorable surface-to-volume ratio also guarantees an

extremely rapid temperature change in the reaction

mixture during each PCR cycle. At the same time, the

glass capillaries serve as cuvettes for the fluorimetric

determination of the PCR products formed.

Thermal Chamber

The cylindrical thermal chamber is supplied with hot air

and air at ambient temperature by means of a fan with

coupled heating coils. The incoming air is homogeneously

distributed by a high-velocity fan at the base of the

instrument, thus creating an even temperature throughout

the reaction chamber. Surplus air is vented through an

opening at the side of the chamber. The temperature is

controlled by using an integrated measuring system with

a temperature sensor installed in the direct vicinity of the

sample capillaries of the sample carousel. The PCR

thermal chamber is directly coupled to the optical system

of the fluorimeter.

Fig. scheme1

Final 1.0 - January 1999 Chapter 1Page 12

Page 15

Light Cycler Service Manual

1.4.2.2 The Fluorimeter Component

Optics

The fluorescent optical components of the LightCycler

are schematically illustrated in chapter 1.3.1 The Light

Cycler. A blue high-performance diode (blue LED) serves

as energy source for sample excitation. The diode emits

radiation which is spectrally filtered to a wavelength of

470 nm and an energy of 1 mW and is collimated

(brought to the same wavelength) by means of a special

optical system. The homogeneous light beam of 470 nm

generated is subsequently focused onto the individual

glass capillaries and then onto the samples to be

measured in the sample carousel. The glass capillaries

are moved by a high-precision stepper motor and placed

in the optimal position for excitation and measurement.

According to the spectral properties of the fluorophore

used, the light emitted from the excited samples is

guided into one of three channels (see drawing in

chapter 1.3.1 The Light Cycler) via dichroitic mirrors for

subsequent evaluation. In this channel, the emitted light

beam is further collimated and spectrally concentrated

by means of a special filter optical system. For final

evaluation, the light beam is then focused onto a

photomultiplier.

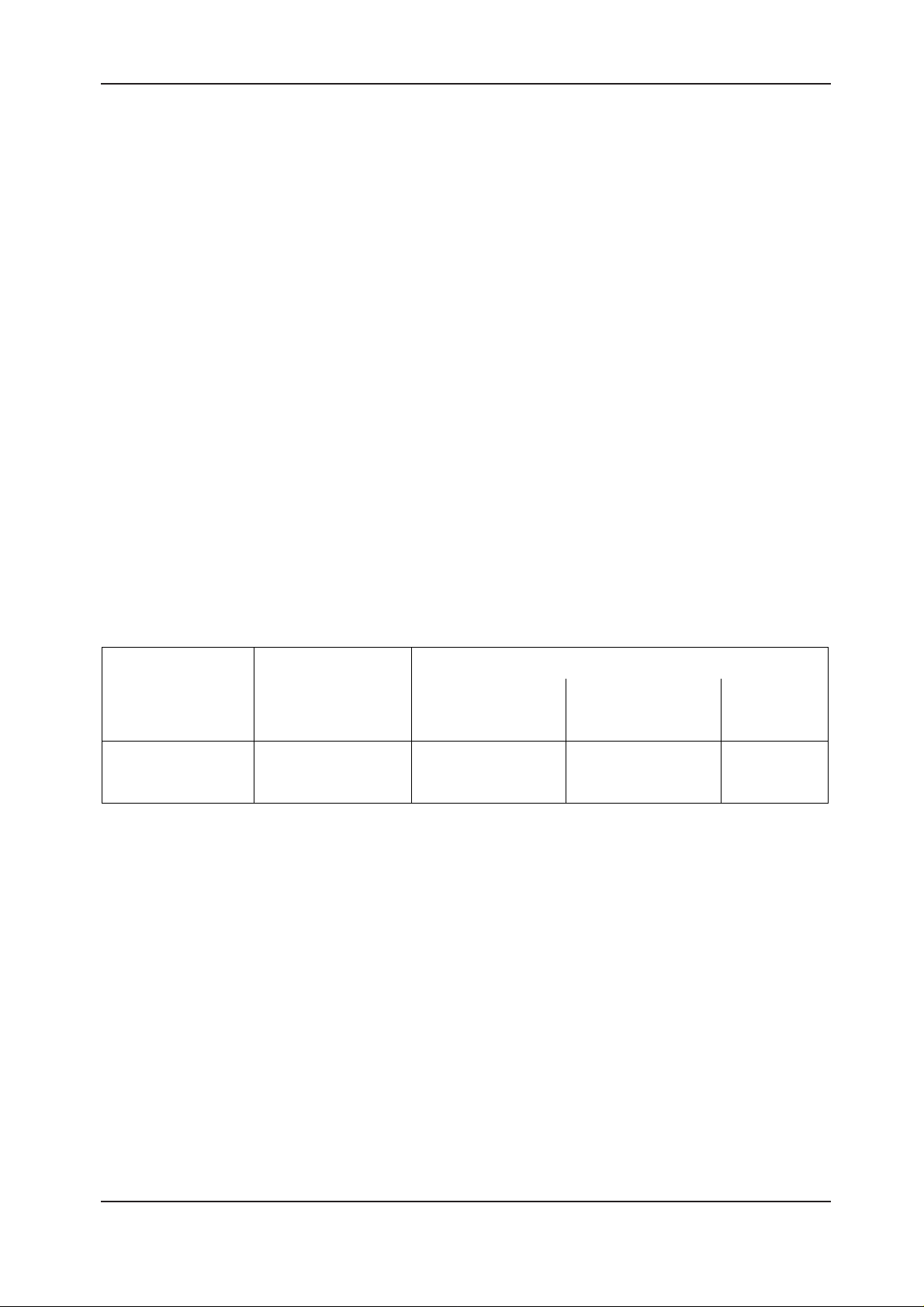

The three evaluation channels of the LightCycler are

fitted with filter combinations. Thus, analysis at the given

emission wavelengths is possible and exact sample

measurement can be carried out in parallel with the

fluorophores given in Tab.: cap 1-14:

Fluorophore Excitation Channel Analysis Channel

1 2 3

470 nm±40 530 nm±20 640 nm±20 710 nm±40

Fluorescein

SYBR Green I

490 nm

494 nm

525 nm

521 nm

LC-Red 640*

Table cap 1-14

Specification of excitation and measuring channels of

the fluorimeter component of the Roche Diagnostics

LightCycler: Comparison of the spectral properties of

selected fluorophores.

TM

Abbreviations *: LC-Red = Light Cycler

**

: LC-Red is not excited by the blue LED, but is a FRET

-Red 640

partner of fluorescein.

For further information, refer to the Operating Manual.

640 nm

Tab.: cap1-14

Final 1.0 - January1999 Chapter 1Page 13

Page 16

Light Cycler Service Manual

1.5 Warranty

Processing of Warranty Claims

A warranty claim has to be processed by way of the

Return Authorization procedure or any accepted

equivalent. Please answer all the questions on the RA

form with the greatest care.

The warranty claim will only be accepted by the

manufacturer if a detailed fault description is supplied.

Complete instruments are accepted only in agreement

with the Technical Product Management or with the

responsible person of Roche Diagnostics Technical

Support.

Important Information:

- Only parts marked with „A“ in the price list are

generally accepted under warranty.

- Return only parts marked with „R“ in the spare parts

price list.

- Warranty claim for “R” parts will be accepted, if the

part has been returned to Mannheim.

- All defective parts ( non-“R“ and „A“ parts ) should

be kept for a period of 7 months, should the

manufacturer need to investigate the part, in which

case it will be requested.

- All parts unduly returned to Mannheim will be sent

back at the expense of each country's respective

service center.

- RA warranty claims are accepted no later than 8

weeks after the problem date.

Repairs

As a general rule, all instrument repairs should be

carried out by authorized and trained personnel only.

Repair of Parts Marked with „R“

Parts which are worth repairing are marked with „R“ in

the spare parts price list. New and repaired parts can

be distinguished from each other by different material

numbers (language version).

(e.g. new part: 1234567-001, repaired part: 1234567-

984)

Repaired parts should be ordered together with new

parts via the order processing depar tment in Mannheim (OU-VDG). Defective parts should be returned

together with order of repair, including the filled out

RA form (giving full details of the defect and marked

choice box with repair), to Logistic Instruments

(Incoming Goods) in Mannheim-Wohlgelegen (LI-LV).

Repair of Instruments

Complete instruments are accepted only, if the

problem is definitety located in the photometer unit.

The replacement should have been agreed with the

Technical Product Management or with the

responsible person of the Roche Diagnostics

Technical Suppor t.

Terms of Delivery

Shipments to countries with the routine truck are c.i.f./

other shipments are ex works Mannheim .

Exclusion from Warranty

The aforementioned warranties do not apply in case of

improper use, handling, transportation or storage, faulty

installation, repair or maintenance, chemical influence

or contamination as well as damages resulting from that,

failure to follow operating instructions, alterations or

modifications of instruments or parts thereof not

authorized or recommended by Roche Diagnostics and

resulting damages, normal wear and tear and in case of

other circumstances beyond the control of Roche

Diagnostics.

Final 1.0 - January 1999 Chapter 1Page 14

Emergency shipments incur additional charges.

Charges

"Repaired" parts (material no. 1234567-984) are

supplied at a "repair price. There will be a subsequent charge consisting of the price difference

between a new and repaired part, should the

defective parts not be returned within 3 weeks (for

European countries) and 8 weeks (for Overseas

countries).

Page 17

Light Cycler Service Manual

After receipt of a warranty claim for “A” parts, BMG

will credit 100 % of the currently effective ex MA price.

In case the manufacturer does not accept the

warranty claim, each country's respective service

center will be charged the R-price for "R" parts and

the new price for non "R" parts.

RA Form

Return Authorization

Please answer all the questions on the RA form with

the greatest care and sign the form.

- Country code

- Problem date

- Type of instrument

- Serial no. of the instrument

- Installation date of instrument

- Defective instrument or spare part

- Part number and material number of the spare

part

- Old / new serial no.

- Fault description

- Alarm code

- Service / workshop report no.

Instruments Not Under Warranty

- Installation date of spare part

All returned parts should be individually labeled with

the corresponding RA no. and shipped together with

the completed RA form to:

Roche Diagnostics

Logistic Instruments

RA Management

Friedrich Ebert Str. 100

D - 68167 Mannheim

Germany

Final 1.0 - January1999 Chapter 1Page 15

Page 18

Light Cycler Service Manual

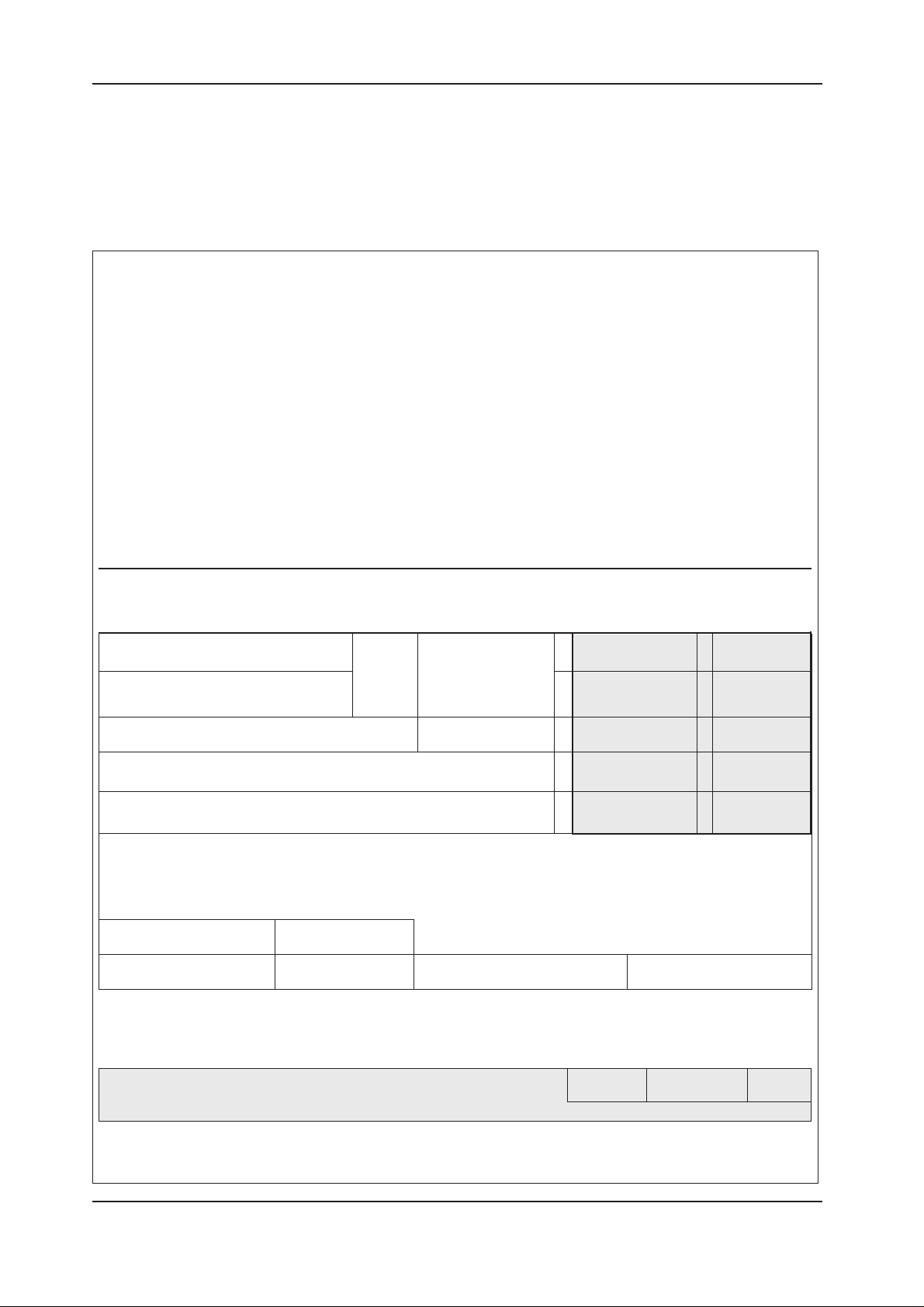

RA Form

(Example)

ROCHE DIAGNOSTICS GmbH

Friedrich-Ebert-Strasse 100 Telefon : +49 (621) 759 81 84

D-68167 Mannheim Fax : +49 (621) 759 80 93

Germany

Return Authorization

No.:

Country code:

Date:

Instrument:

Serial No.:

Installation date:

Spare Part:

Customer: Address:

(will be filled in by BM)

Part No.: Qty .: Part Name: Repair Comments

Mat.-No.: Warranty

Installation date of Spare Part: Warranty Repair

OLD serial No.: Modification

NEW serial No.: Replacement

Fault Description:

Alarm Code:

Service Report No.: Workshop Report No.:

Place: Date: Signature:

Remarks (will be filled in by BM) NOS Credit FC

BM

Final 1.0 - January 1999 Chapter 1Page 16

Page 19

Light Cycler Service Manual

2. Installation_____________________________________________2

2.1 Installation Requirements ____________________________________ 2

2.2 Installation of the LightCycler _________________________________ 4

2.3 Computer and Software Installation ____________________________ 5

2.4 LightCycler De-installation ____________________________________ 6

2.5 Operation and Maintenance of the LightCycler ___________________ 7

Final 1.0 - January 1999 Chapter 2Page 1

Page 20

Light Cycler Service Manual

2. Installation

2.1 Installation Requirements

Note

- The LightCycler should not be set up next to

instruments that cause electromagnetic

interference or have high inductance, e.g.

centrifuges or mixers.

- All connected peripheral instruments must fulfill

the requirements of Standard IEC 950 (UL 1950).

- All plugs used in the LightCycler workstation (PC,

printer, monitor) should have the same phasing in

order to prevent switch-on peaks and electronic

noise generated by other instruments or the power

supply itself. Use of an appropriate distributor plug

with the LightCycler workstation is recommended.

Working Place Requirements

See the following table for the working place

requirements:

Dimensions and weight The LightCycler has a width of 30 cm, a depth of 45 cm and a height of 45 cm.

It weighs approximately 20 kg.

Voltage requirements The LightCycler operates on 120 – 240 V (50 – 60 Hz) and need not be

adjusted.

Power consumption The LightCycler requires approximately 800 W; PC and printer require a further

500 W.

Tab.: cap2-1

The LightCycler must not be opened by the

user

The fuse may only be replaced if the instrument

has been switched off at the mains.

Environmental Requirements

Please refer to the following table for the environmental

requirements:

Ambient temperature 15 – 35 °C (all specifications maintained between 15 and 30°C)

Humidity 20 – 80 %, no condensation

Altitude Sea level to 2000 m

Excess voltage category II

Degree of contamination 2

Final 1.0 - January 1999 Chapter 2Page 2

Tab.: cap2-2

Page 21

Light Cycler Service Manual

Storage Conditions

The LightCycler™ can be stored on5 the following

conditions:

Ambient temperature -20 - +60°C

Humidity 20 – 80%, no condensation

Tab.: cap2-3

Final 1.0 - January 1999 Chapter 2Page 3

Page 22

Light Cycler Service Manual

2.2 Installation of the LightCycler

Installation of the Instrument

Please refer to the following table for the installation of

the LightCycler instrument:

Step Action

1 Unpack the instrument.

2 Position instrument on bench, working surface. Allow 10 cm space left, right and behind.

3 Electrical connections:

- Connect LightCycler to the PC using an R 232 cable (serial inter-face).

- Connect LightCycler, PC, monitor and printer to same distributor plug.

Tab.: cap2-4

Ensure that printer, monitor and PC have

been set to the correct voltage.

Final 1.0 - January 1999 Chapter 2Page 4

Page 23

Light Cycler Service Manual

2.3 Computer and Software Installation

Installation of the PC

After unpacking the computer, carry out the following

steps:

Step Action

1 Connect mouse, keyboard and monitor to the computer.

2 Connect the LightCycler to the computer with an R 232 cable (serial interface).

3 Connect computer, monitor and LightCycler to the distributor plug.

The computer is now ready for operation

Tab.: cap2-5

Software

The complete software package is installed by Roche

Diagnostics.

Installation of Updates / Reinstallation

In the following table you find information about the

reinstallation and loading of updates:

Step Action

1 Store any data, e.g. DATA, PROFILES and PROTOCOLs

2 Place LightCycler CD-ROM in appropriate disk drive (e.g. F)

3 Start set-up program (e.g. F:\SETUP.EXE).

Tab.: cap2-6

Final 1.0 - January 1999 Chapter 2Page 5

Page 24

Light Cycler Service Manual

2.4 LightCycler De-installation

De-installation of the Instrument

Please refer to the following table for the de-installation

of the instrument:

Step Action

1 Switch off the instrument.

2 - Disconnect the RS 232 and power cables.

- Clean according to the chapter on service and decontaminate if necessary.

3 Dispatch instrument in its original packaging.

Tab.: cap2-7

Final 1.0 - January 1999 Chapter 2Page 6

Page 25

Light Cycler Service Manual

2.5 Operation and Maintenance of the LightCycler

Guidelines for Operation

- The instrument may be operated only if protected

from the weather. It may not be operated in

buildings without temperature regulation facilities.

If necessary, additional drying agents may be

used to eliminate humidity.

- The instrument should not be operated near

dripping, spraying, splashing or running water.

- The instrument is thus suitable for use according

to classification 3K3 in accordance with Standard

EN 60721-3-3.

- The instrument may be used at locations subject

to noticeable or significant vibration; however, it

should not be exposed to higher levels of shock

waves.

- The instrument is thus suitable for use according

to classification 3M4 in accordance with Standard

EN 60721-3-3. The instrument is able to tolerate

vibrations up to classification 3M6. However,

based on expected locations of use, no significant

and permanent vibrations or shock waves are to

be expected.

Transport and Storage

When storing or transporting the instrument, it should

not be exposed to extreme cold, e.g. as in the case of air

freight. Temperatures lower than –25°C should be

avoided (damage to optical systems). The optical

systems are equipped with open ventilation systems

and should therefore be protected from dirt and humidity.

There are no further specifications for transport and

storage.

General Maintenance

The instrument is maintenance-free.

Cleaning the Instrument

- Use 70% ethanol for disinfecting the incubator.

- Use only alcohol and an optical cloth for cleaning

the optical window.

- Use a mild commercial detergent for domestic use

for cleaning the housing.

Final 1.0 - January 1999 Chapter 2Page 7

Page 26

Light Cycler Service Manual

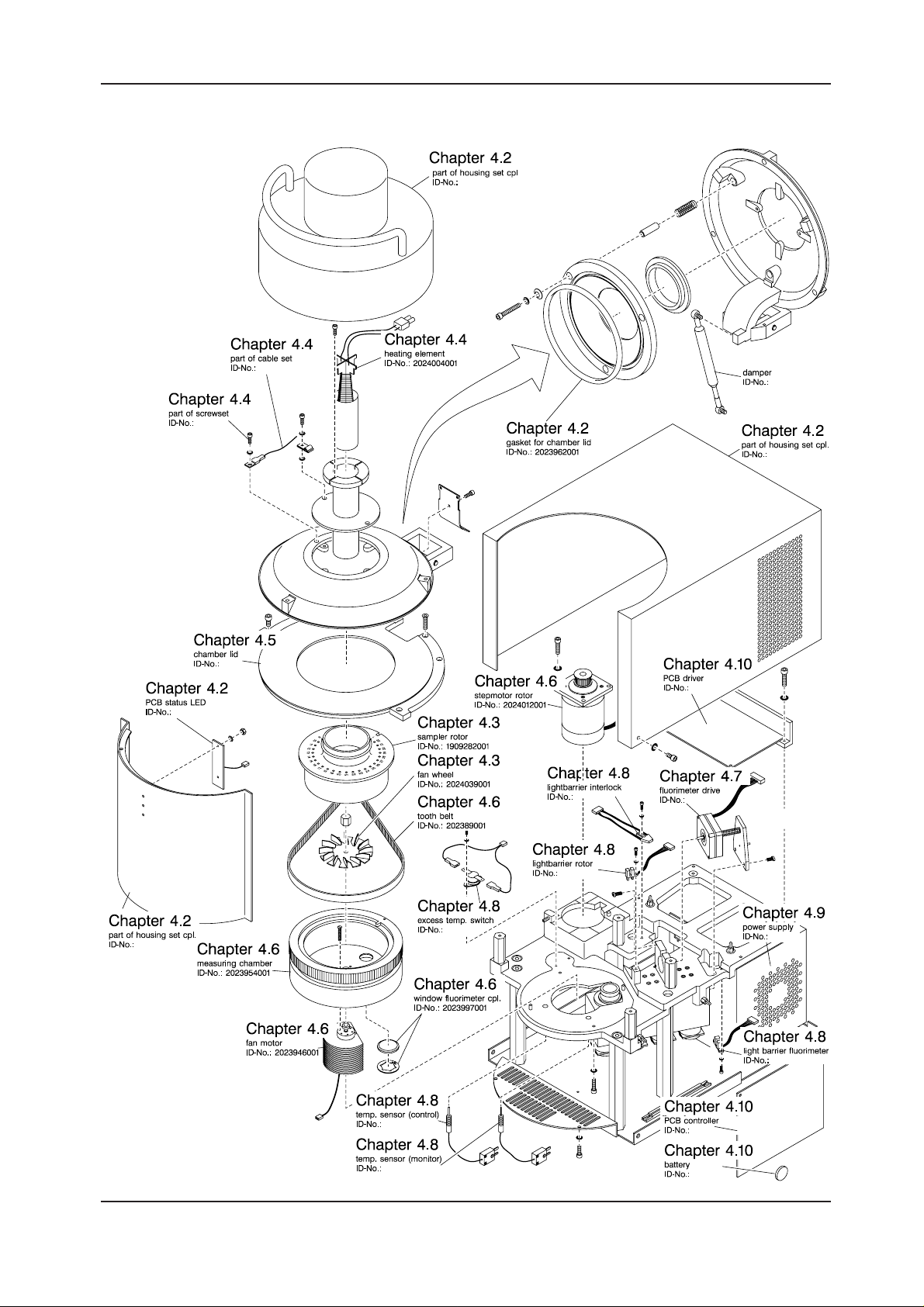

4 Mechanics _____________________________________________ 3

4.1 Overview __________________________________________________ 3

4.2 Disassembly of the Housing Parts _____________________________ 4

4.2.1 Housing Lid ______________________________________________________ 4

4.2.2 Housing _________________________________________________________ 6

4.2.3 Panel ____________________________________________________________ 8

4.3 Sample Rotor and Fan Wheel _________________________________ 10

4.4 Heating Element ___________________________________________ 12

4.5 Chamber Lid_______________________________________________ 14

4.6 Rotor _____________________________________________________ 16

4.6.1 Stepper Motor Rotor ______________________________________________ 16

4.6.2 Fan Motor _______________________________________________________ 18

4.6.3 Measuring Chamber ______________________________________________ 20

4.7 Fluorimeter Drive___________________________________________ 22

4.8 Lightbarriers and Sensors ___________________________________ 2 4

4.8.1 Location ________________________________________________________ 24

4.8.2 Rotor Lightbarrier ________________________________________________ 25

4.8.3 Interlock Lightbarrier _____________________________________________ 25

4.8.4 Fluorimeter Lightbarrier ___________________________________________ 26

4.8.5 Monitor Temperature Sensor _______________________________________ 26

4.8.6 Control Temperature Sensor _______________________________________ 27

4.8.7 Excess Temperature Switch ________________________________________ 27

Final 1.0 - January 1999 Chapter 4Page 1

Page 27

Light Cycler Service Manual

4.9 Power Supply______________________________________________ 28

4.9.1 Location ________________________________________________________ 28

4.10 PCBs _____________________________________________________ 30

4.10.1 Location ________________________________________________________ 30

4.10.2 PCB Controller und Battery ________________________________________ 31

4.10.3 PCB Driver ______________________________________________________ 31

4.10.4 Status Board ____________________________________________________ 31

Final 1.0 - January 1999 Chapter 4Page 2

Page 28

Light Cycler Service Manual

4 Mechanics

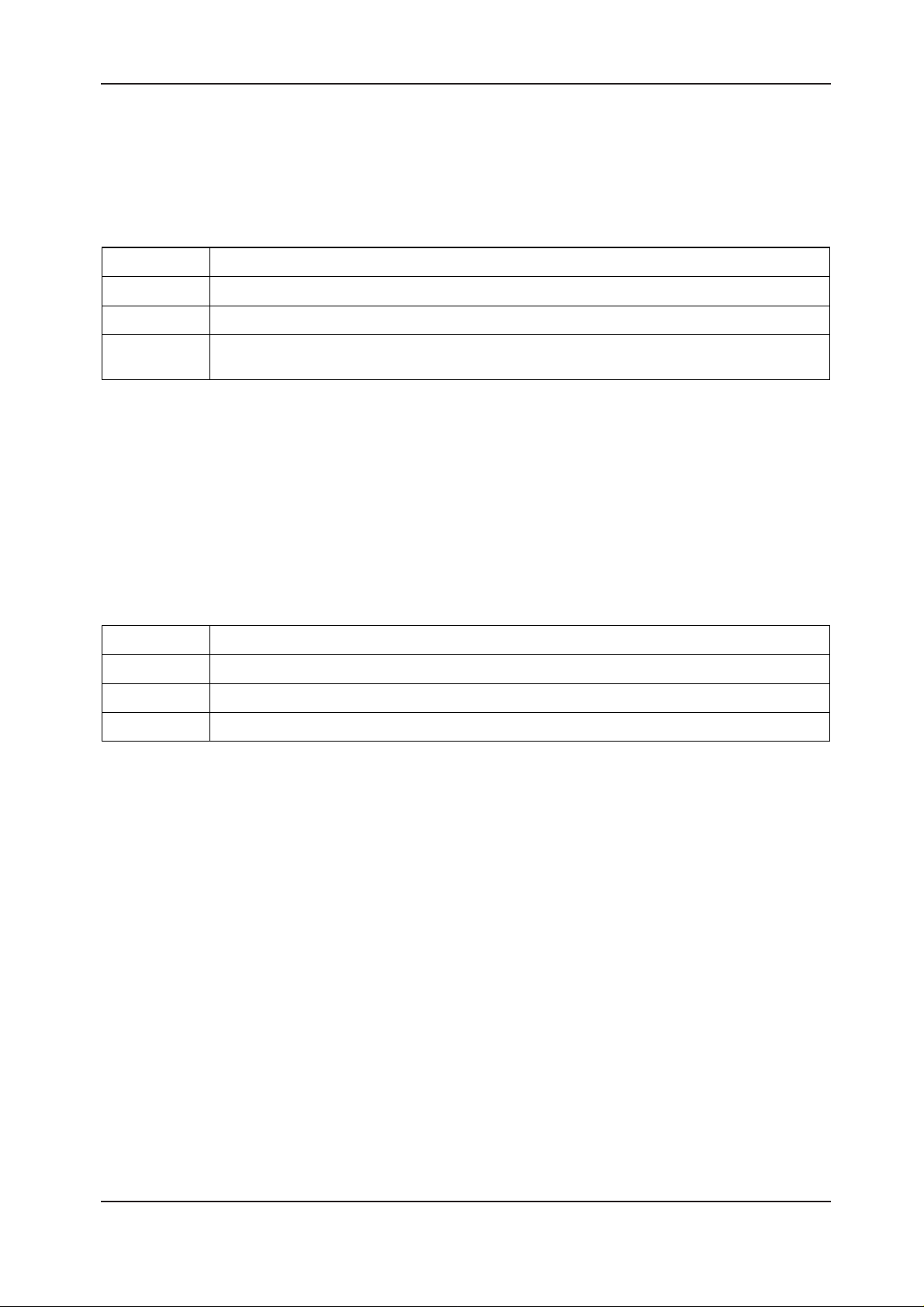

4.1 Overview

Fig. 160798k1

Final 1.0 - January 1999 Chapter 4Page 3

Page 29

Light Cycler Service Manual

4.2 Disassembly of the Housing Parts

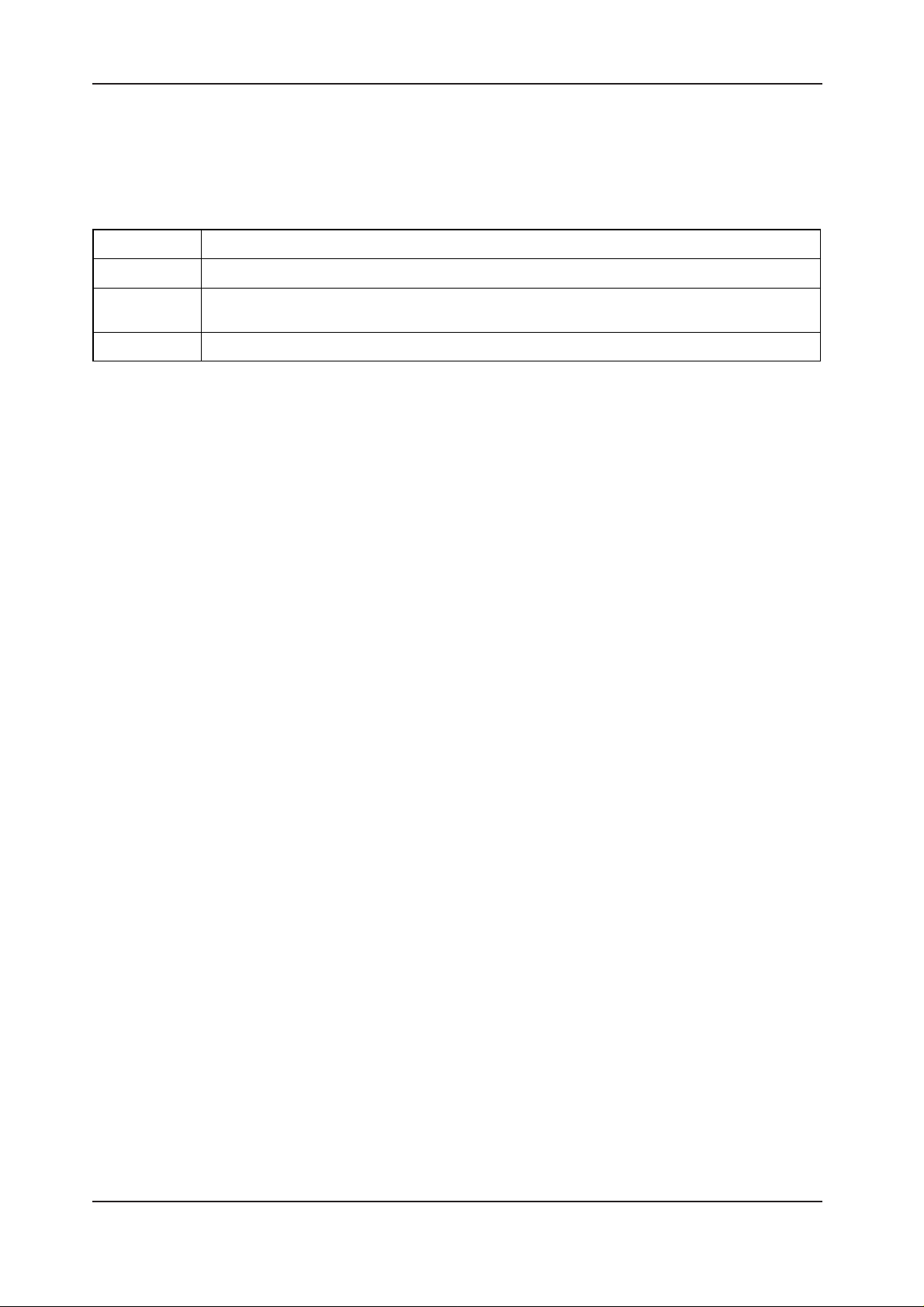

4.2.1 Housing Lid

4.2.1.1 Location

Fig. 140798k2

Final 1.0 - January 1999 Chapter 4Page 4

Page 30

Light Cycler Service Manual

4.2.1.2 Service Procedure

Replaceable Components:

- Housing lid (1) (is part of the housing set)

- Screw (2) (is part of the screw set)

- Gasket (61)

Disassembly of the Housing Cover:

- Flap housing lid (1) backwards

- Remove all screws (2)

- Remove housing lid (1)

Disassembly of Gasket:

- Flap housing lid (1) backwards

- Remove gasket (61).

Final 1.0 - January 1999 Chapter 4Page 5

Page 31

Light Cycler Service Manual

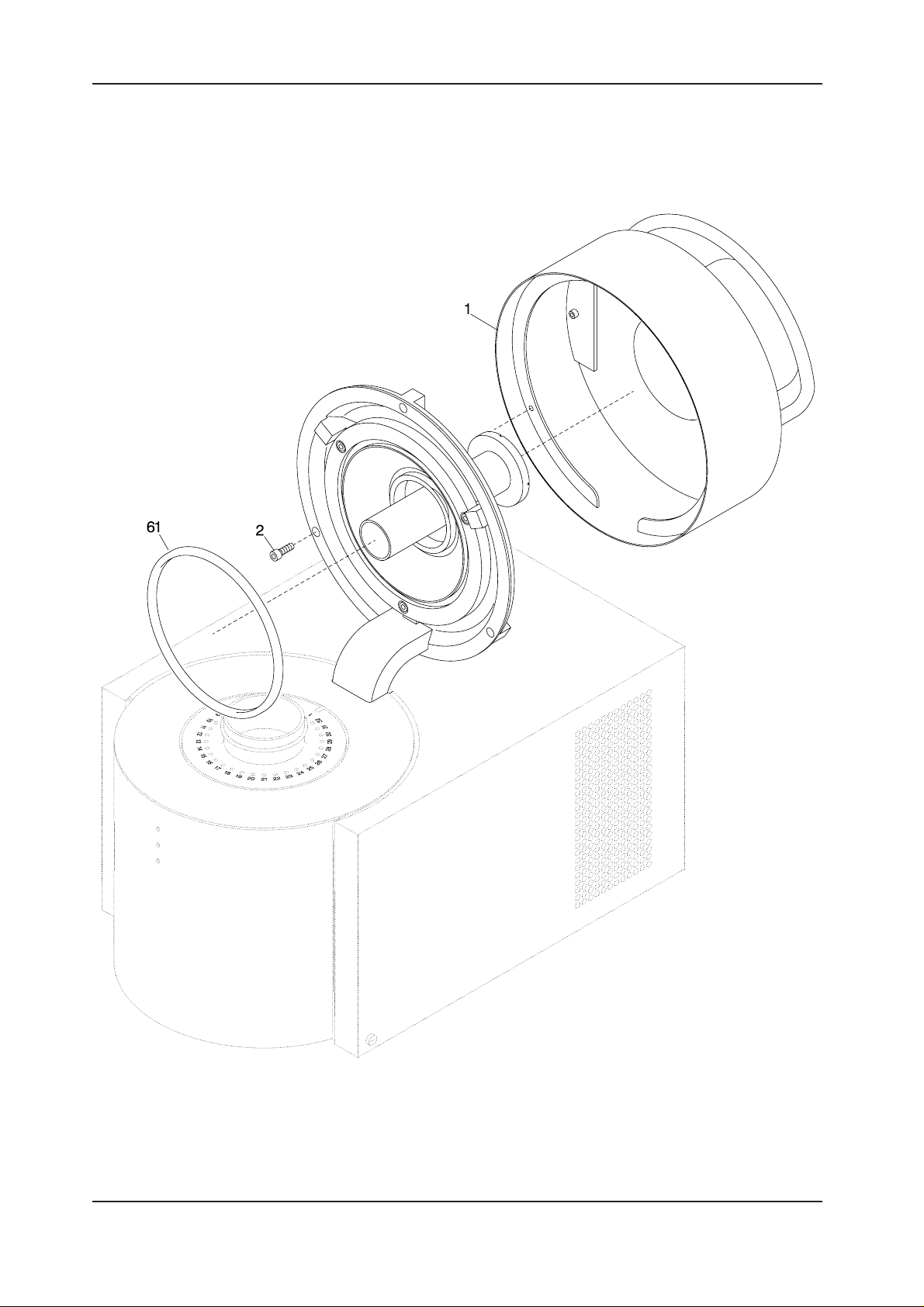

4.2.2 Housing

4.2.2.1 Location

Fig. 151298k1

Final 1.0 - January 1999 Chapter 4Page 6

Page 32

Light Cycler Service Manual

4.2.2.2 Service Procedure

Replaceable Components:

- Housing (3) (is part of the housing set)

- Screw (4) (is part of the srew set)

- Washer (5) (is part of the screw set)

Disassembly of the Housing:

- Remove all the screws (4) with washers (5)

- Lift off housing (3)

Note:

Please take care that the edges of the cover (3) do not

scratch the front of the cover (3)

Final 1.0 - January 1999 Chapter 4Page 7

Page 33

Light Cycler Service Manual

4.2.3 Panel

4.2.3.1 Location

Fig. 140798k1

Final 1.0 - January 1999 Chapter 4Page 8

Page 34

Light Cycler Service Manual

4.2.3.2 Service Procedure

Replaceable Components:

- Screws (6) (are part of the screw set)

- Washers (7) (are part of the screw set)

- Panel (8) (is part of the housing set)

- Status board (9)

- Washers (10) (are part of the screw set)

- Nut (11) (is part of the screw set)

- Cable (12) (is part of the cable set)

Disassembly of the Panel:

- Remove housing,

see chapter 4.2.2

- Loosen all screws (13)

- Remove all the screws (6) with washers (7)

- Pull cable (12)

- Lift chamber lid (14)

- Take off panel (8)

Disassembly of the Status Board:

- Disassemble the panel (8)

- Remove nuts (11) with washers (10)

- Remove status board (9)

4.2.3.3 Wiring

Cable (12) connects status board (9) to PCB controller

see chapter 4.10.4

JP12,

Final 1.0 - January 1999 Chapter 4Page 9

Page 35

Light Cycler Service Manual

4.3 Sample Rotor and Fan Wheel

4.3.1 Location

Fig. 140798k7

Final 1.0 - January 1999 Chapter 4Page 10

Page 36

Light Cycler Service Manual

4.3.2 Service Procedure

Replaceable Components:

- Sample rotor (13)

- Fan wheel (15)

Disassembly of the Sample Rotor:

- Flap housing lid (1) backwards

- Remove sample rotor (13)

Disassembly of Fan Wheel:

- Disassemble the sample rotor (13)

- Remove nut (14)

- Remove fan wheel (15) by lifting it out

Note:

Do not tighten nut (14) too tight when mounting the fan

wheel (15), or this might cause damage to the plastic fan

motor thread.

Final 1.0 - January 1999 Chapter 4Page 11

Page 37

Light Cycler Service Manual

4.4 Heating Element

4.4.1 Location

Fig. 150798k1

Final 1.0 - January 1999 Chapter 4Page 12

Page 38

Light Cycler Service Manual

4.4.2 Service Procedure

Replaceable Components:

- Heating element (16)

- Cable (17) (is part of the cable set)

- Ground cable (29) (is part of the cable set)

Disassembly of the Heating Element:

- Flap housing lid (1) backwards,

see chapter 4.2.1

- Disassemble the housing (3),

see chapter 4.2.2

- Remove screw (23) with washer (24)

- Remove cable clip (25) with washer (26)

- Remove cable (17) from cable clip (25)

- Remove screws (18)

- Remove screw (19)

- Pull off cover sheet (20)

- Pull cable (17)

- Remove heating element (16) by lifting it out

- Remove sheathing (21) if necessary

Disassembly of the Flange:

- Disassemble the heating element (16)

- Remove screw (23)

- Remove flange (22) by lifting it out

Disassembly of the Grounding:

- Remove screw (27) with washer (28)

- Remove grounding (29)

4.4.3 Wiring

Cable (17) connects heating element (16) to power

supply,

Ground cable (29) connects base plate (30) to lower part

of the housing (31)

see chapter 4.9

Final 1.0 - January 1999 Chapter 4Page 13

Page 39

Light Cycler Service Manual

4.5 Chamber Lid

4.5.1 Location

Fig. 140798k3

Final 1.0 - January 1999 Chapter 4Page 14

Page 40

Light Cycler Service Manual

4.5.2 Service Procedure

Replaceable Components:

- Chamber lid (33)

- Damper (84)

- Screw (34) (is part of the screw set)

- Screw (35) (is part of the screw set)

- Washer (85) (is part of the screw set)

- Nut (65) (is part of the screw set)

Disassembly of the Chamber Lid:

- Disassembly of the housing parts,

see chapter 4.2

- Disassembly of the heating element,

see chapter 4.4

- Remove screws (34)

- Remove nut (86) and washer (85)

- Push damper (84) slightly to the side

- Lift out base plate (36) with chamber lid (33) and

damper (84)

- Remove screws (35) and base plate (36)

- Unscrew damper (84) from base plate (36)

Final 1.0 - January 1999 Chapter 4Page 15

Page 41

Light Cycler Service Manual

4.6 Rotor

4.6.1 Stepper Motor Rotor

4.6.1.1 Location

Fig. 151298k2

Final 1.0 - January 1999 Chapter 4Page 16

Page 42

Light Cycler Service Manual

4.6.1.2 Service Procedure

Replaceable Components:

- Stepper motor rotor (43)

- Tooth belt (42)

- Cable (38) (is part of the cable set)

- Screw (39) (is part of the screw set)

- Washer (40) (is part of the screw set)

- Set screw (41) (is part of the screw set)

Disassembly of the Tooth Belt:

- Disassembly of the housing parts,

see chapter 4.2

- Disassembly of the heating element,

see chapter 4.4

- Disassembly of the chamber lid,

see chapter 4.5

- Pull cable (38) from PCB driver

- Remove screws (39) and washers (40)

- Turn set screw (41) in order to reduce tooth belt (42)

tension

- Lift out tooth belt (42)

Disassembly of the Stepper Motor Rotor:

- Disassembly of the tooth belt

- Lift out stepper motor rotor (43)

4.6.1.3 Wiring

Cable (38) connects stepper motor rotor (43) to PCB

see chapter 4.10.3

driver,

4.6.1.4 Adiustments

Belt tension of the sample rotor drive

Fig. 030898k1

Fix the fixation srews (39) of the stepper motor (43) and

check again for proper movement.

An adjustment of the belt tension is necessary if one of

the following components is removed or replaced:

- stepper motor (rotor) (43)

- tooth belt (42)

- measuring chamber (47)

Proper adjustment of the belt tension ensures a minimum

of friction between motor, belt and rotor.

To adjust the belt tension, please proceed as follows:

- Open the fixation screws (39) of the stepper motor

(rotor) (43) about 1/4 of a turn, so that the motor can

be moved in a horizontal direction

- Adjust the tension with the adjustment screw (41) until

the teeth of the belt fit properly into the grooves of the

rotor drive, see drawing

Final 1.0 - January 1999 Chapter 4Page 17

Page 43

Light Cycler Service Manual

4.6.2 Fan Motor

4.6.2.1 Location

Fig. 151298k3

Final 1.0 - January 1999 Chapter 4Page 18

Page 44

Light Cycler Service Manual

4.6.2.2 Service Procedure

Replaceable Components:

- Fan motor (44)

- Screw (45) (is part of the screw set)

- Cable (46) (is part of the cable set)

- Cable (92) (is part of the cable set)

Disassembly off the Fan Motor:

- Disassembly of the housing parts,

see chapter 4.2

- Disassembly of the sample rotor and fan wheel,

see chapter 4.3

- Pull cable (46)

- Pull cable (92)

- Remove screws (45)

- Remove fan motor (44) by pulling it in a downward

direction

4.6.2.3 Wiring

Cable (46) and calbe (92) connects fan motor (44) to PCB

see chapter 4.10.3

driver,

4.6.2.4 Adjustmemt

When assembling the heat dissipator of the fan motor

(44), it is important that its edge is parallel to that of the

fluorimeter.

Please ensure that the dissipator does not touch the

fluorimeter.

Fig. 030898k1

Final 1.0 - January 1999 Chapter 4Page 19

Page 45

Light Cycler Service Manual

4.6.3 Measuring Chamber

4.6.3.1 Location

Fig. 140798k8

Final 1.0 - January 1999 Chapter 4Page 20

Page 46

Light Cycler Service Manual

4.6.3.2 Service Procedure

Replaceable Components:

- Measuring chamber (47)

- Glass window for fluorimeter (56)

- Screw (52) (is part of the screw set)

- Washer (53) (is part of the screw set)

- Cable (48) (is part of the cable set)

- Cable (49) (is part of the cable set)

- Control temp. sensor (50)

- Monitor temp. sensor (51)

Disassembly of the Measuring Chamber and Glass

Window for the Fluorimeter:

- Disassembly of the housing parts,

see chapter 4.2

- Disassembly of the sample rotor and fan wheel,

see chapter 4.3

- Disassembly of the heating element,

see chapter 4.4

- Disassembly of the chamber lid,

see chapter 4.5

- Disassembly of the tooth belt,

see chapter 4.6.1

- Disassembly of the fan motor,

see chapter 4.6.2

- Pull cable (48) and cable (49)

- Unscrew control temp. sensor (50)

- Unscrew monitor temp. sensor (51)

- Remove screws (52) and washers (53)

- Lift out measuring chamber (47)

- Remove spring washer (54)

- Remove glass window (55)

Disassembly of the Rotor Lightbarrier:

- Pull cable (60)

- Remove screws (57) and washers (58)

- Lift out rotor lightbarrier (59)

4.6.3.3 Wiring

Cable (48) connects control temp. sensor (50) to PCB

controller,

Cable (49) connects monitor temp. sensor (51) to PCB

controller,

Cable (60) connects rotor lightbarrier (59) to PCB

controller,

4.6.3.4 Adjustment

see chapter 4.8.6.1

see 4.10.2.

see 4.10.2.

see 4.10.2.

Attention:

Do not touch the window (55) with your fingers!

A fingerprint would generate an additional flourecence

signal, which would affect the measurement results!

Carefully clean the window (55) with 70% ethanol,

polishing it with a lint-free tissue afterwards.

Assembly of the Window:

- Please use the new spring washer (54) in case of a

window (55) replacement

- Ensure that the window (55) is placed in the

correct position

Fig. 040898k1

Final 1.0 - January 1999 Chapter 4Page 21

Page 47

Light Cycler Service Manual

4.7 Fluorimeter Drive

The fluorimeter (65) is preadjusted by the manufacturer

and is adjusted for the second time when it is assembled

in the Light Cycler production plant in Germany.

In case of a defective fluorimeter, the complete instrument

is to be sent to Mannheim for repairing.

Please use the RA procedure for the shipment to Mann-

see chapter 1.5

heim,

The repaired instruments will be sent to you as soon as

possible.

Note:

Please do not touch any of the fluorimeter (65)

adjustment screws (especially focus screws).

4.7.1 Location

Fig. 150798k2

Final 1.0 - January 1999 Chapter 4Page 22

Page 48

Light Cycler Service Manual

4.7.2 Service Procedures

Replaceable Components:

- Screw (62) (is part of the screw set)

- Screw (64) (is part of the screw set)

- Fluorimeter drive (64)

- Cable (66) (is part of the cable set)

Disassembly:

- Pull cable (66)

- Remove screws (62) and screws (63)

- Lift out fluorimeter drive (64)

Note:

If the fluorimeter drive is replaced, it is necessary to

check the distance between stepper motor and the

plate.

When assembling the photometer drive, the distance

between them should be 18mm +/- 1mm.

If an adjustment is necessary, turn the plate until the

required distance is reached.

4.7.3 Wiring

Cable (66) connects fluorimeter drive (64) to PCB driver,

see 4.10.3.

Final 1.0 - January 1999 Chapter 4Page 23

Page 49

Light Cycler Service Manual

4.8 Lightbarriers and Sensors

4.8.1 Location

Fig. 150798k3

Final 1.0 - January 1999 Chapter 4Page 24

Page 50

Light Cycler Service Manual

4.8.2 Rotor Lightbarrier

The rotor lightbarrier monitirs the rotations of the rotor.

Replaceable Components:

- Rotor lightbarrier (59)

- Screw (57) (is part of the screw set)

- Washer (58) (is part of the screw set)

- Cable (60) (is part of the cable set)

Disassembly:

- Disassembly of the housing parts,

see chapter 4.2

- Disassembly of the sample rotor and fan wheel,

see chapter 4.3

- Disassembly of the heating element,

see chapter 4.4

- Disassembly of the chamber lid,

see chapter 4.5

- Disassembly of the tooth belt,

see chapter 4.6.1

- Pull cable (60)

- Remove screw (57) and washer (58)

- Lift out rotor lightbarrier (59)

4.8.3 Interlock Lightbarrier

The interlock lightbarrier is a reflection lightbarrier. It

senses whether the housing lid is open or closed.

Replaceable Components:

- Interlock lightbarrier (66)

- Screw (68) (is part of the screw set)

- Washer (67) (is part of the screw set)

- Cable (69) (is part of the cable set)

Disassembly:

- Disassembly of the housing,

see chapter 4.2.2

- Pull cable (69)

- Remove screw (68) and washer (67)

- Lift out interlock lightbarrier (66)

4.8.3.1 Wiring

Cable (66) connects interlock lightbarrier (66) to PCB

controller,

see chapter 4.10.2

4.8.2.1 Wiring

Cable (60) connects rotor lightbarrier (59) to PCB

controller,

see chapter 4.10.2

Final 1.0 - January 1999 Chapter 4Page 25

Page 51

Light Cycler Service Manual

4.8.4 Fluorimeter Lightbarrier

The fluorimeter lightbarrier monitirs the fluorimeter

movements.

Replaceable Components:

- Fluorimeter lightbarrier (70)

- Screw (72) (is part of the cable set)

- Washer (71) (is part of the screw set)

- Cable (73) (is part of the cable set)

Disassembly:

- Disassembly of the housing,

see chapter 4.2.2

- Pull cable (73)

- Remove screw (72) and washer (71)

- Lift out fluorimeter lightbarrier (70)

4.8.4.1 Wiring

Cable (73) connects fluorimeter lightbarrier (70) to PCB

controller,

see chapter 4.10.2

4.8.5 Monitor Temperature Sensor

The monitor temperature sensor monitors the measuring

chamber temperature and prevents excess temperature.

Replaceable Components:

- Monitor temperature sensor (51)

- Cable (49) (is part of the cable set)

Disassembly:

- Disassembly of the panel,

see chapter 4.2.3

- Pull cable (49)

- Unscrew monitor temperature sensor (51)

4.8.5.1 Adjustment

see chapter 4.8.6.1

4.8.5.2 Wiring

Cable (49) connects monitor temperature sensor (51) to

PCB controller,

see chapter 4.10.2.

Final 1.0 - January 1999 Chapter 4Page 26

Page 52

Light Cycler Service Manual

4.8.6 Control Temperature Sensor

The control temperature sensor controls excess

temperature in the measuring chamber.

Replaceable Components:

- Control temperature sensor (50)

- Cable (48) (is part of the cable set)

Disassembly:

- Disassembly of the panel,

see chapter 4.2.3

- Pull cable (48)

- Unscrew control temperature sensor (50)

4.8.6.1 Adjustment

Temperature Sensors

Two temperature sensors for temperature control and

temperature monitoring are located in the measuring

chamber of the light cycler. The sensors should be placed

close to the capillaries in the sample rotor so that the

temperature can be monitored as accurately as possible.

However, the sensors must not touch the capillaries

when the rotor is moving.

For this reason, the height of these sensors needs to be

adjusted.

4.8.7 Excess Temperature Switch

The excess temperature switch is a bimetal switch which

protects the Light Cycler from overheating, e.g due to

excess periods of operation.

Replaceable Components:

- Excess temperature switch (74)

- Screw (76) (is part of the screw set)

- Washer (75) (is part of the screw set)

- Cable (77) (is part of the cable set)

Disassembly:

- Disassembly of the housing,

see chapter 4.2.2

- Pull cable (77)

- Remove screw (76) and washer (75)

- Lift out excess temperature switch (74)

4.8.7.1 Wiring

Cable (77) connects excess temperature switch (74) to

PCB controller,

see chapter 4.10.2

See drawing below:

Fig. 030898k1

The height can be adjusted by turning the sensor fixation

screws clockwise or counterclockwise.

4.8.6.2 Wiring

Cable (48) connects control temperature sensor (50) to

PCB controller,

see chapter 4.10.2.

Final 1.0 - January 1999 Chapter 4Page 27

Page 53

Light Cycler Service Manual

4.9 Power Supply

4.9.1 Location

Fig. 230998k1

Final 1.0 - January 1999 Chapter 4Page 28

Page 54

Light Cycler Service Manual

4.9.2 Service Procedure

Replaceable Components:

- Power supply (81)

- Cable (17) (is part of the cable set)

- Cable (90) (is part of the cable set)

- Cable (91) (is part of the cable set)

- Screw (88) (is part of the screw set)

- Screw (89) (is part of the screw set)

Disassembly of the Power Supply:

- Disassembly of the housing parts,

see chapter 4.2

- Pull cable (17)

- Pull cable (90)

- Pull cable (91)

- Remove screws (88)

- Remove screw (89)

- Pull out the power supply (81)

4.9.3 Wiring

Cable (17) connects power supply (81) to heating element,

see chapter 4.4.

Cable (90) connects power supply (81) to PCB controller,

see chapter 4.10.2.

Cable (91) connects power supply (81) to PCB driver,

see

chapter 4.10.23

Final 1.0 - January 1999 Chapter 4Page 29

Page 55

Light Cycler Service Manual

4.10 PCBs

4.10.1 Location

Fig. 100898k1

Final 1.0 - January 1999 Chapter 4Page 30

Page 56

Light Cycler Service Manual

4.10.2PCB Controller und Battery

The PCB controller of the Light Cycler houses the essential control functions, data recording and communication

with the PC via interface RS232.

Replaceable Components:

- PCB controller (78)

- Battery (79)

Disassembly of the PCB Controller:

- Disassembly of the housing,

see chapter 4.2.2

- Pull all the connecting cables from the PCB controller

(78)

- Remove the PCB controller (78) located on the side

Disassembly of the Battery:

- Disassembly of the housing,

see chapter 4.2.2

- Remove battery (79) from the PCB controller (78)

4.10.2.1 Wiring

4.10.4Status Board

was macht dieses?

Disassembly:

- Disassembly of the panel (8)

see chapter 4.2.3

- Remove nuts (11) with washers (10)

- Remove status board (9)

- Pull cable (12)

4.10.4.1 Wiring

Cable (12) connects status board (9) to PCB controller

see chapter 4.10.2

JP12,

Aufzählung der Kabel, die zum PCB Controller gehen!

4.10.3PCB Driver

was macht dieses?

Replaceable Components:

- PCB Driver (80)

- Screws (82) (are part of the screw set)

- Washers (83) (are part of the screw set)

Disassembly:

- Disassembly of the housing,

see chapter 4.2.2

- Pull all the connecting cables from the PCB driver (80)

- Remove screws (82) and washers (82)

- Lift out PCB driver (80)

4.10.3.1Wiring

Aufzählung der Kabel, die zum PCB Controller gehen!

Final 1.0 - January 1999 Chapter 4Page 31

Page 57

Light Cycler Service Manual

5 Electronics ____________________________________________3

5.1 Overview __________________________________________________ 3

5.2 Cable Connections __________________________________________ 4

5.3 PCB Controller______________________________________________ 5

5.3.1 Location _________________________________________________________ 5

5.3.2 Block Diagram PCB Controller ______________________________________ 6

5.3.3 Printed Circuit Diagram PCB Controller _______________________________ 7

5.3.4 Layout Diagram PCB Contr oller ____________________________________ 11

5.4 PCB Driver ________________________________________________ 13

5.4.1 Location ________________________________________________________ 13

5.4.2 Block Diagram PCB Driver _________________________________________ 14

5.4.3 Printed Circuit Diagram PCB Driver _________________________________ 15

5.4.4 Layout Diagram PCB Driver ________________________________________ 18

5.5 Status Board ______________________________________________ 20

5.5.1 Location ________________________________________________________ 20

5.5.2 Printed Circuit Diagram Status Board________________________________ 21

5.5.3 Layout Diagram Status Boar d ______________________________________ 22

5.6 Lightbarriers and Sensors ___________________________________ 2 3

5.6.1 Location ________________________________________________________ 23

5.7 Power Supply______________________________________________ 24

5.7.1 Location ________________________________________________________ 24

Final 1.0 - January 1999 Chapter 5Page 1

Page 58

Light Cycler Service Manual

5.8 Heating Element ___________________________________________ 25

5.8.1 Location ________________________________________________________ 25

5.9 Fluorimeter________________________________________________ 26

5.9.1 Location ________________________________________________________ 26

5.9.2 Block Diagram Fluorimeter ________________________________________ 27

5.9.3 Printed Circuit Diagram PCB Fluorimeter_____________________________ 28

5.4.4 Layout Diagram PCB Fluorimeter ___________________________________ 29

Final 1.0 - January 1999 Chapter 5Page 2

Page 59

Light Cycler Service Manual

5 Electronics

5.1 Overview

Fig. 5-2

Final 1.0 - January 1999 Chapter 5Page 3

Page 60

Light Cycler Service Manual

5.2 Cable Connections

Fig. cap5-2

Final 1.0 - January 1999 Chapter 5Page 4

Page 61

Light Cycler Service Manual

5.3 PCB Controller

5.3.1 Location

Functional Description of the PCB Controller of the

LightCycler

The PCB controller of the Light Cycler houses the essential control functions, data recording and communication

with the PC via RS232.

These functions are:

- Interface RS232, galvanically isolated via optocoupler,

serves for communication with the PC.

- Interface management between PC and temp.

and/or step processor by means of a PIC processor

- 2 microprocessors (temp. processor and step

processor) for temperature regulation, positioning

of the stepper motors and recording of the measuring

values

- 2 temperature measuring channels:

- Channel 1 for regulating the chamber temperature

by means of the temp. processor, indication of the

actual temperature in the measuring chamber

and control of excess temperature.

- Channel 2 for control of excess temperature

- EEPROM for storing the device-specific calibration

data and various parameters as well as the serial

numbers of the instrument and the fluorimeter

- Digital-to-analog converter and driver for regulating

theLED current for the blue fluorimeter LED

- 12 bit analog-to-digital converter for converting the

voltage analog to the temperature for temperture

regulation by means of the temp. processor

- Multi-channel 12 bit analog-to-digital converter for

converting the measuring values of the 3 fluorimeter

channels and the temperature for the display

- Data interface with the power supply for transferring

the actual set values for the heating voltage (this

serial interface is also galvanically isolated from the

power supply via optocoupler)

Fig. 221298k1

Final 1.0 - January 1999 Chapter 5Page 5

PCB Controller

Page 62

Light Cycler Service Manual

5.3.2 Block Diagram PCB Controller

Fig. cap5-3-2

Final 1.0 - January 1999 Chapter 5Page 6

Page 63

Light Cycler Service Manual

5.3.3 Printed Circuit Diagram PCB Controller

Page 1 of 4

Fig. main-a

Final 1.0 - January 1999 Chapter 5Page 7

Page 64

Light Cycler Service Manual

5.3.3 Printed Circuit Diagram PCB Controller

Page 2 of 4

Fig. main-c

Final 1.0 - January 1999 Chapter 5Page 8

Page 65

Light Cycler Service Manual

5.3.3 Printed Circuit Diagram PCB Controller

Page 3 of 4

Fig. main-b

Final 1.0 - January 1999 Chapter 5Page 9

Page 66

Light Cycler Service Manual

5.3.3 Printed Circuit Diagram PCB Controller

Page 4 of 4

Fig. main-d

Final 1.0 - January 1999 Chapter 5Page 10

Page 67

Light Cycler Service Manual

5.3.4 Layout Diagram PCB Controller

Page 1 of 2

Fig. main-e

Final 1.0 - January 1999 Chapter 5Page 11

Page 68

Light Cycler Service Manual

5.3.4 Layout Diagram PCB Controller

Page 2 of 2

Fig. main-f

Final 1.0 - January 1999 Chapter 5Page 12

Page 69

Light Cycler Service Manual

5.4 PCB Driver

5.4.1 Location

Functional Description of the LightCycler Power Board

The LightCycler power board houses the following

functions:

- Driver for the stepper motor of the rotor

- Driver for the linear stepper motor of the fluorimeter

drive

- Linear controller for driving the chamber fan, setting

the actual setpoint value by means of a serial 12 bit

digital-to-analog converter

- The speed of the chamber fan which is equipped with

an encoder is controlled by means of a frequency

converter and one comparator each for minimum and

maximum speed (releasing or blocking of the heating

voltage depends on this)

PCB Driver

Fig. 221298k2

Final 1.0 - January 1999 Chapter 5Page 13

Page 70

Light Cycler Service Manual

5.4.2 Block Diagram PCB Driver

Fig. cap5-4-2

Final 1.0 - January 1999 Chapter 5Page 14

Page 71

Light Cycler Service Manual

5.4.3 Printed Circuit Diagram PCB Driver

Page 1 of 3

Fig. power-a

Final 1.0 - January 1999 Chapter 5Page 15

Page 72

Light Cycler Service Manual

5.4.3 Printed Circuit Diagram PCB Driver

Page 2 of 3

Fig. power-b

Final 1.0 - January 1999 Chapter 5Page 16

Page 73

Light Cycler Service Manual

5.4.3 Printed Circuit Diagram PCB Driver

Page 3 of 3

Fig. power-c

Final 1.0 - January 1999 Chapter 5Page 17

Page 74

Light Cycler Service Manual

5.4.4 Layout Diagram PCB Driver

Page 1 of 2

Fig. power-d

Final 1.0 - January 1999 Chapter 5Page 18

Page 75

Light Cycler Service Manual

5.4.4 Layout Diagram PCB Driver

Page 2 of 2

Fig. power-e

Final 1.0 - January 1999 Chapter 5Page 19

Page 76

Light Cycler Service Manual

5.5 Status Board

5.5.1 Location

Statusboard

Fig. 221298k3

Final 1.0 - January 1999 Chapter 5Page 20

Page 77

Light Cycler Service Manual

5.5.2 Printed Circuit Diagram Status Board

Fig. c5-5-3

Final 1.0 - January 1999 Chapter 5Page 21

Page 78

Light Cycler Service Manual

5.5.3 Layout Diagram Status Board

grün

rot

gelb

Fig. c5-5-4

Final 1.0 - January 1999 Chapter 5Page 22

Page 79

Light Cycler Service Manual

5.6 Lightbarriers and Sensors

5.6.1 Location

Rotor Lightbarrier

The rotor lightbarrier controls the rotations of the rotor.

L

Interlock Lightbarrier

The interlock lightbarrier is a reflection lightbarrier. It

senses whether the housing lid is open or closed.

Fluorimeter Lightbarrier

The fluorimeter lightbarrier controls the fluorimeter

movements.

Monitor Temperature Sensor

The monitor temperature sensor controls the measuring

chamber temperature and prevents excess temperature.

Excess temperature

switch

Control Temperature Sensor

The control temperature sensor controls excess

temperature in the measuring chamber.

Excess Temperature Switch

The excess temperature switch is a bimetal switch which

protects the Light Cycler from overheating, e.g due to

excess operating periods.

Interlock

lightbarrier

Control temperature

sensor

Lightbarrier

home position

Rotor

Lightbarrier

home position

Fluorimeter

S2

Fig. cap5-6

S1

Monitor temperature

sensor

Final 1.0 - January 1999 Chapter 5Page 23

Page 80

Light Cycler Service Manual

5.7 Power Supply

5.7.1 Location

Functional Description of the LightCycler Power

Supply

The power supply is a functional unit and is accommodated

in a metal housing closed on all sides. It is connected to

the mains by means of an integrated rubber connector.

Fuses are "off limits" to the customer because all outputs

are short-circuit proof. A blown fuse is an indication of a

defect that cannot and should not be fixed by the customer.

The power supply has three output plugs:

- a 12-pin plug with the following outputs:

- 5 V for the supplying of digital functions on the

PCB controller.

- +/- 12V for the supplying of analog switching

functions on the PCB controller; furthermore for

serial data transfer for the supplying of the heating

element integrated in the power supply.

- a 10-pin plug with the following outputs:

- 5V for the supplying of digital functions on the

power board.

- 24V as driver voltage for the stepper motor drivers

and the chamber fan driver.

- a 2-pin plug for connecting the heating element;

voltage range of this output: 0 - 90V DC.

Power supply

Fig. 221298k4

Final 1.0 - January 1999 Chapter 5Page 24

Page 81

Light Cycler Service Manual

5.8 Heating Element

5.8.1 Location

Heating element

Fig. 240998k2

Final 1.0 - January 1999 Chapter 5Page 25

Page 82

Light Cycler Service Manual

5.9 Fluorimeter

5.9.1 Location

Functional Description of the Fluorimeter

The fluorimeter is located on a linear bearing below the

measuring chamber. It can be moved radially with the

help of a linear stepper motor. It has an excitation channel

and 3 measuring channels with different wavelengths.

The essential features of the fluorimeter are its metallic

body with a system of optical lenses and filters and 4

printed circuit boards with the following functions:

- a LED PCB with a blue light emitting diode for

illuminating the capillaries.

- three identical printed circuit boards with optohybrids

(photodiode with integrated amplifier) and programmable amplifiers.

A 12 bit analog-to-digital converter is used for

programming the amplifiers as well as for the offset

adjustment, with which a negative output value of the

optohybrids can be corrected.

Both 12 bit analog-to-digital converters are

accommodated in a housing and are serially activated

via a 24 bit string.

For activating and transferring the measuring values,

the fluorimeter PCBs are connected to the PCB

controller with a cable (plug JP1 on PCB controller).

Fig. 221298k2

Final 1.0 - January 1999 Chapter 5Page 26

Fluorimeter

Page 83

Light Cycler Service Manual

5.9.2 Block Diagram Fluorimeter

Fig. cap5-9-2

Final 1.0 - January 1999 Chapter 5Page 27

Page 84

Light Cycler Service Manual

5.9.3 Printed Circuit Diagram PCB Fluorimeter

Fig. flour-a

Final 1.0 - January 1999 Chapter 5Page 28

Page 85

Light Cycler Service Manual

5.4.4 Layout Diagram PCB Fluorimeter

Page 1 of 2

Fig. flour-b

Final 1.0 - January 1999 Chapter 5Page 29

Page 86

Light Cycler Service Manual

5.4.4 Layout Diagram PCB Fluorimeter

Page 2 of 2

Fig. fluor-c

Final 1.0 - January 1999 Chapter 5Page 30

Page 87

Light Cycler Service Manual

6 Service Software________________________________________ 2

6.1 Hardware requirements ______________________________________ 2

6.2 Installation of Windows NT ____________________________________ 2

6.3 BIOS Settings_______________________________________________ 2

6.4 Basic setup actions__________________________________________ 2

6.4.1 Logon as administrator ____________________________________________ 2

6.4.2 Create directory and set run mode of a program _______________________ 2

6.4.3 Check desktop properties __________________________________________ 2

6.4.4 Change the reginonal settings ______________________________________ 2

6.4.5 Set system parameters_____________________________________________ 2

6.4.6 Set administrator passwor d/create LC_Service and LC_User account _____ 3

6.4.6.1 Change Administrator passw ord_____________________________________ 3

6.4.6.2 Create LC_Service account _________________________________________ 3

6.4.6.3 Create LC_User account ___________________________________________ 3

6.5 Setup LC_User account ______________________________________ 3

6.5.1 Desktop properties ________________________________________________ 3

6.5.2 Regional settings _________________________________________________ 3

6.6 Setup LC_Service account ____________________________________ 3

6.6.1 Desktop properties ________________________________________________ 3

6.6.2 Reginonal settings ________________________________________________ 4

6.7 Install LightCycler service and customer software ________________ 4

Final 1.0 - January 1999 Chapter 6Page 1

Page 88

Light Cycler Service Manual

6 Service Software

6.1 Hardware requirements

This chapter descripes the minimal system to control the

LightCycler:

Vectra VE4 5/200 MMX Modell 3200 Desktop

HP# D5606N

- Intel Pentium MMX Processor, 200 MHz

- 64 MB SDRAM DIMM

- 3,2 GB Ultra-ATA/33 Hard disk

- On-board PCI-Video: S3 Trio 64 V2, 2MB 50ns

DRAM

- 24-times Speed IDE CD-ROM drive

- Keyboard and PS/2 Mouse

- Operatingd system:

Windows NT 4.0 inclusive service pack 3 and hotfixes,

english version

Internal Iomega ZIP-drive, IDE-interface (ATAPI)

HP Ergo 1280, 17” Monitor (HP# D2840A)

Optional component not generally supplied with the

instrument:

6.4 Basic setup actions

6.4.1 Logon as administrator

Logon User name: Administrator

Password: *****

Only “Password never expires” should be marked!

6.4.2 Create directory and set run mode of a program

Start the explorer and ...

- create folder:

C:\Users

- select file:

C:\Winnt\Profiles\AllUsers\Start Menu\Programs\

Startup\Iomega Quick Tools NT

with right mouse button -> Properties -> Shortcut

->Run: Mininized -> OK

6.4.3 Check desktop properties

HP DeskJet 890C, Color InkJet printer

6.2 Installation of Windows NT

During installation of Windows NT the following

parameters should be set:

- Display mode settings:

1024*768 pixels, 256 colors, small fonts

- Hard disk format:

one NTFS partition

6.3 BIOS Settings

This parameters are recommended. The changed boot

priority is the best protection against boot viruses.

Advanced ->

Boot-time diagnostic screen: disabled

Boot ->

Boot device priority ->

1. Hard disk

2. Removable devices

3. ATAPI CD-ROM device

Display properties:

Background -> Pattern -> Weave

ScreenSaver -> Logon Screen Saver

Password protected

Wait: 10 min

Settings -> Color palette: 256 colors

Desktop area: 1024 by 768 pixels

Font size: Small fonts

Refresh frequency: 75 Hertz

6.4.4 Change the reginonal settings

Start -> Settings -> Control Panel -> Regional Settings

Reginal settings properties:

- Regional settings: english (United States)

- Number -> Measurement System: Metric

- Time -> Time style: HH:mm:ss

- Date -> Short date style: dd-MMM-yy

-> Long date style: dddd, dd MMMM, yyyy

-> OK

6.4.5 Set system parameters

Start -> Settings -> Control Panel -> System

Final 1.0 - January 1999 Chapter 6Page 2

- Startup/Shutdown -> System startup -> Show list for 3

seconds

- Recovery -> Write an event to the system log

-> Automatically reboot

Page 89

Light Cycler Service Manual

6.4.6 Set administrator password/create LC_Service and LC_User account

Start -> Programs -> Administrative Tools (Common) ->

User Manager

6.4.6.1 Change Administrator password

Double click “Administrator” ->

Password: ******

Confirm Password: ******

-> OK

6.4.6.2 Create LC_Service account

Select “ Administrator” -> User -> Copy

Username: LC_Service

Full name: LightCycler Service

Description: Password: ******

Confirm password: ******

Only “Password never expires” should be marked !

-> Groups -> Member of: Administrators

-> OK

-> Profile -> Home directory -> Local Path: C:\LC_Service

6.5 Setup LC_User account

Logon as LC_User:

CTRL + ALT + DEL -> Logon window:

Logon User name: LC_User

Password: *****

6.5.1 Desktop properties

Display properties:

Background -> None / None

ScreenSaver -> Starfield Simulation

No Password protection

Wait: 15 min

6.5.2 Regional settings

Start -> Settings -> Control Panel -> Regional Settings

Reginal settings properties:

- Regional settings: english (United States)

- Number -> Measurement System: Metric

- Time -> Time style: HH:mm:ss

- Date -> Short date style: dd-MMM-yy

-> Long date style: dddd, dd MMMM, yyyy

-> OK

-> OK -> OK

6.4.6.3 Create LC_User account

-> User -> New User

Username: LC_User

Full name: LightCycler User

Description: Password: *****

Confirm password: *****

Only “Password never expires” should be marked !

-> Groups -> Member of: Poweruser

-> OK

-> Profile -> Home directory -> Local Path:

C:\Users\LC_User

-> OK -> OK

-> Exit

Start -> Shutdown -> Close all programs and logon as

different user -> YES

6.6 Setup LC_Service account

Logon as LC_Service:

CTRL + ALT + DEL -> Logon window:

Logon User name: LC_Service

Password: *****

6.6.1 Desktop properties

Display properties:

Background -> Pattern -> None

Wallpaper -> LcService -> Display: Tile

ScreenSaver -> Logon Screen Saver

Password protected

Wait: 15 min

Settings -> Color palette: 256 colors

Desktop area: 1024 by 768 pixels

Font size: Small fonts

Refresh frequency: 75 Hertz

Final 1.0 - January 1999 Chapter 6Page 3

Page 90

Light Cycler Service Manual

6.6.2 Reginonal settings

Start -> Settings -> Control Panel -> Regional Settings

Reginal settings properties:

- Regional settings: english (United States)

- Number -> Measurement System: Metric

- Time -> Time style: HH:mm:ss

- Date -> Short date style: dd-MMM-yy

-> Long date style: dddd, dd MMMM, yyyy

-> OK

6.7 Install LightCycler service and customer software

Logon as LC_Service:

CTRL + ALT + DEL -> Logon window:

Logon User name: LC_Service

Password: *****

After logon process is ready insert LightCycler service

CD-ROM. The setup routine of ServiceTools starts after

some seconds automaticallly. -> Next -> Next -> Finish

Please copy the links of the little LC_Service window to

the desktop (TestAdj and LcEdit).

The setup of the customer software must be started with

the command Drive:\LightCycler\Setup.exe

Final 1.0 - January 1999 Chapter 6Page 4

Page 91

Light Cycler Service Manual

7 Troubleshooting

Error Description Possible Reason`s What To Do

- Chanber fan or rotor stepper

are not running

- no heating function - seeabove about interlock sensor

- no flourimeter signal on all

channel`s

- Interlock sensor not adjusted

- reflex area at the lid is not

shiny

- Sensor defect

- the heating coil is broken

- the power supply for heating is

out of order

- the overheat latch is seted

- the blue LED dosent work - check the blue LED from

- check output from sensor:

voltage on pin3 from JP6 must

be 0.2V(+0.2), if the lid is closed

(if open, then +5V)

- control the reflex are and clean

it if necessery

- change and adjust the light

barrier

- see above

- change the heating coil

- check pin8 from IC14 (must be

+5V if the cover is closed), if not

then check pin7 from IC23 and

IC24 (both must be low, if not, a

overheat is detected)

Photometer

- check the interlock sensor

cap7.tbl

Final 1.0 - January 1999 Chapter 7Page 1

Page 92

Light Cycler Service Manual

8 Spare Parts ____________________________________________2

8.1 Part Identification ___________________________________________ 2

8.2 Complete Spare Part List _____________________________________ 3

8.3 Tools ______________________________________________________ 4

Final 1.0 - January 1999 Chapter 8Page 1

Page 93

Light Cycler Service Manual