Page 1

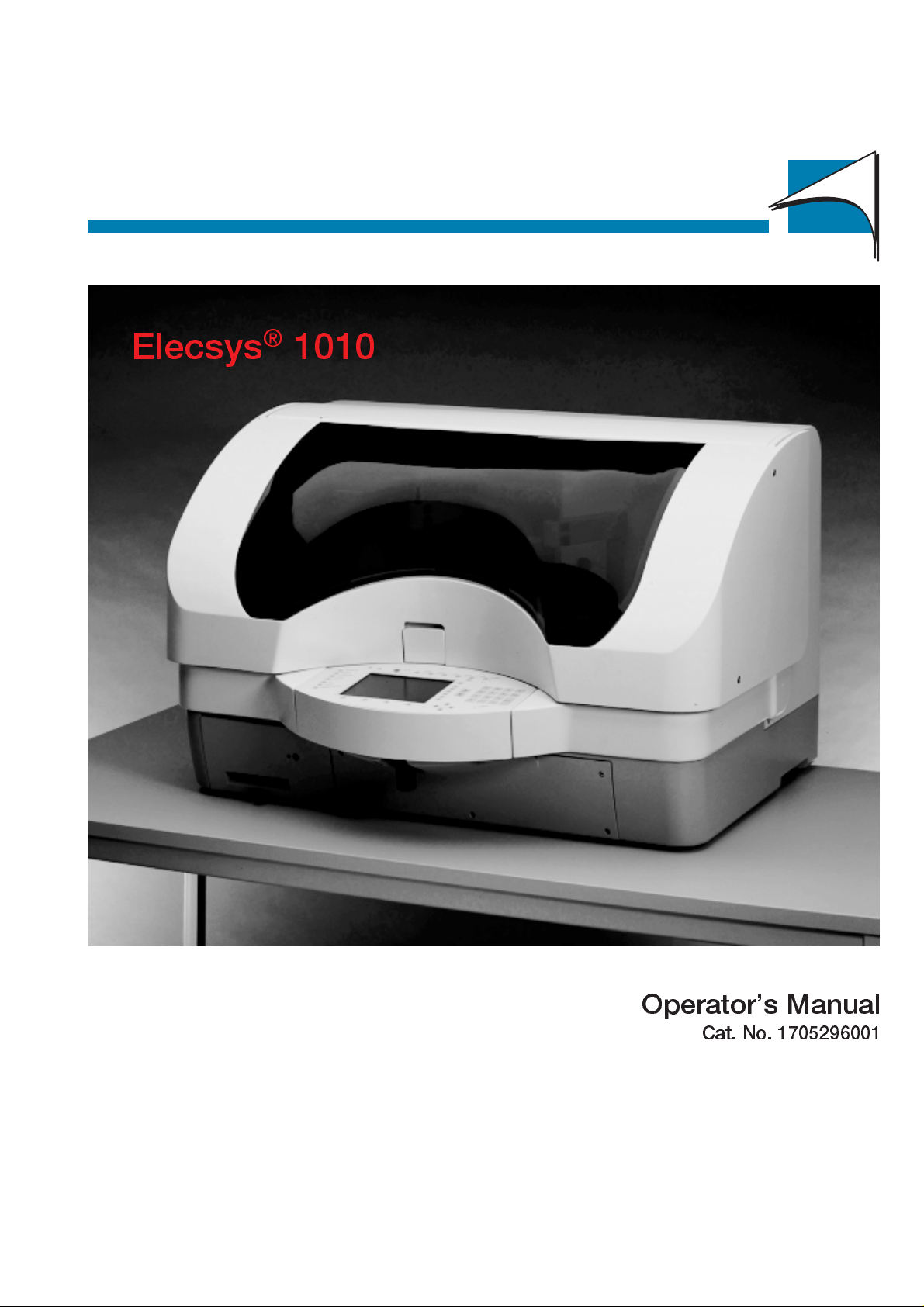

Elecsys® 1010

Operators Manual

Cat. No. 1705296001

Page 2

© 2000, Roche Diagnostics, a member of the Roche Group. All rights

reserved.

The contents of this manual, including all graphics and photographs are the

property of Roche Diagnostics. Information in this document is subject to

change without notice. Roche Diagnostics shall not be liable for technical or

editorial errors or omissions contained herein.

No part of this document may be reproduced or transmitted in any form or

by any means, electronic or mechanical, for any purpose, without the

express written permission of Roche Diagnostics.

Elecsys is trademark of a member of the Roche Group. All other trademarks

are the property of their respective holders.

This manual was created by SCRIPTOR DOKUMENTATIONS SERVICE GmbH,

Bielefeld, Germany, on behalf of Roche Diagnostics. Questions/comments

regarding the content of this manual can be directed to your local Roche

Diagnostics representative.

V 3.0 – Reference Guide

Page 3

Roche Diagnostics Elecsys® 1010 Immunoassay System

Revised Manual Pages

Revised pages for this manual are provided by Roche Diagnostics when

necessary. No part of this publication may be reproduced in any form or by any

means without prior written permission.

Publication Date Pages Affected

Reference No.

Version Gamma Nov 1996 Reference Guide

Software Guide

User’s Guide

Tutorial Guide

Version 1.1 May 1997 Reference Guide

Software Guide

User’s Guide

Tutorial Guide

Version 2.0 Feb 1999 Reference Guide

Software Guide

User’s Guide

Tutorial Guide

Version 3.0 Jan 2000 Reference Guide

Software Guide

User’s Guide

Tutorial Guide

V 3.0 – Reference Guide

Page 4

Reference Guide

Reference Guide

Page 5

Reference Guide - Table of Contents

Table of Contents - Reference Guide

V 3.0 – Reference Guide 1

Page 6

Roche Diagnostics Elecsys® 1010 Immunoassay System

1. Introduction 1-1

1.1 Manual Outline 1-2

1.2 The Elecsys 1010 Analyzer 1-3

1.3 Reagents, Calibrators and Controls 1-5

1.3.1 Reagent Kits (Reagent Packs) 1-6

1.3.2 Package Insert 1-7

1.3.3 Product Information Sheet 1-7

1.3.4 Calibrator and Control Kits 1-7

1.3.5 Reagent Bar Code Labels 1-8

1.3.6 Calibrator and Control Bar Code Labels 1-9

1.3.7 Calibrator and Control Bar Code Cards 1-9

1.4 Potential Hazards and Safety Precautions 1-10

1.4.1 Safety Notes 1-10

1.4.2 Accident Prevention 1-15

1.5 Approvals 1-17

2. System Description 2-1

2.1 Introduction 2-2

2.2 Control Unit 2-3

2.3 Sample/Reagent Disk 2-5

2.4 Sample/Reagent Arm 2-7

2.5 Incubator 2-9

2.6 Sipper Arm 2-10

2.7 Liquid System 2-11

2.8 Measuring Cell 2-13

2.9 Power Switch 2-15

2.10 Printer 2-15

2.11 Floppy Disk Drive 2-16

2.12 Interfaces 2-17

2.13 Technical Data 2-18

2 V 3.0 – Reference Guide

Page 7

Reference Guide - Table of Contents

3. Functional Sequence of Analysis 3-1

3.1 Introduction 3-2

3.2 General Analysis Sequence 3-4

3.3 Test Sequences 3-6

3.3.1 Test protocol 3-7

3.4 Example of an Analysis Process 3-8

3.4.1 Reagent 1, Reagent 2 and Sample Pipetting 3-10

3.4.2 First Incubation 3-13

3.4.3 Resuspension of the Microparticles 3-14

3.4.4 Microparticle Pipetting 3-15

3.4.5 Second Incubation 3-16

3.4.6 Measurement Stage 3-17

3.4.7 Measurement and Evaluation 3-20

3.4.8 Measurement Cell Cleaning and

Preparation for the Next Measurement 3-20

4.

ECL

Technology 4-1

4.1

ECL

Technology 4-2

5. Test Principles for Immunoassays 5-1

5.1 Test Principles 5-2

5.1.1 Competitive Principle 5-2

5.1.2 Sandwich Principle 5-4

5.1.3 Bridging Principle 5-6

6. Calibration 6-1

6.1 Introduction 6-2

6.2 Calibration Concept of Elecsys 6-3

6.3 Laboratory Calibration 6-4

6.4 Stability of Calibrations on Elecsys 1010 6-5

6.5 Automatic Validation of Calibrations 6-6

6.6 Calibration of Quantitative Assays 6-9

7. Glossary 7-1

V 3.0 – Reference Guide 3

Page 8

Roche Diagnostics Elecsys® 1010 Immunoassay System

4 V 3.0 – Reference Guide

Page 9

1. Introduction

Header

V 3.0 – Reference Guide 1 - 1

Page 10

Roche Diagnostics Elecsys® 1010 Immunoassay System

1.1 Manual Outline

The Reference Guide is part of the Elecsys® 1010 Operator’s Manual, which also

includes the Software Guide, Tutorial Guide, User’s Guide and Short Guide.

The Reference Guide gives a comprehensive insight into the technical/theoretical

operation of the Elecsys 1010 analyzer.

Chapter 1. Introduction

This chapter introduces the analyzer and describes the packaging concept for

reagents, calibrators and controls. Important safety instructions are also provided

in this section.

Chapter 2. System Description

This chapter describes in detail the individual components of the analyzer, their

tasks and technical data.

Chapter 3. Functional Sequence of Analysis

This chapter describes the individual stages of the immunological analysis process

on the analyzer.

Chapter 4.

Chapter 5. Test Principles

Chapter 6. Calibration

Chapter 7. Glossary

ECL

Technology

This chapter describes the fundamental principle of the electrochemiluminescent

process.

This chapter describes the principles of the various immunoassay processes.

This chapter describes the validation criteria in theory, as well as the various

calibration methods used on Elecsys 1010.

This chapter provides definitions of commonly used terms.

1 - 2 V 3.0 – Reference Guide

Page 11

The Elecsys 1010 Analyzer

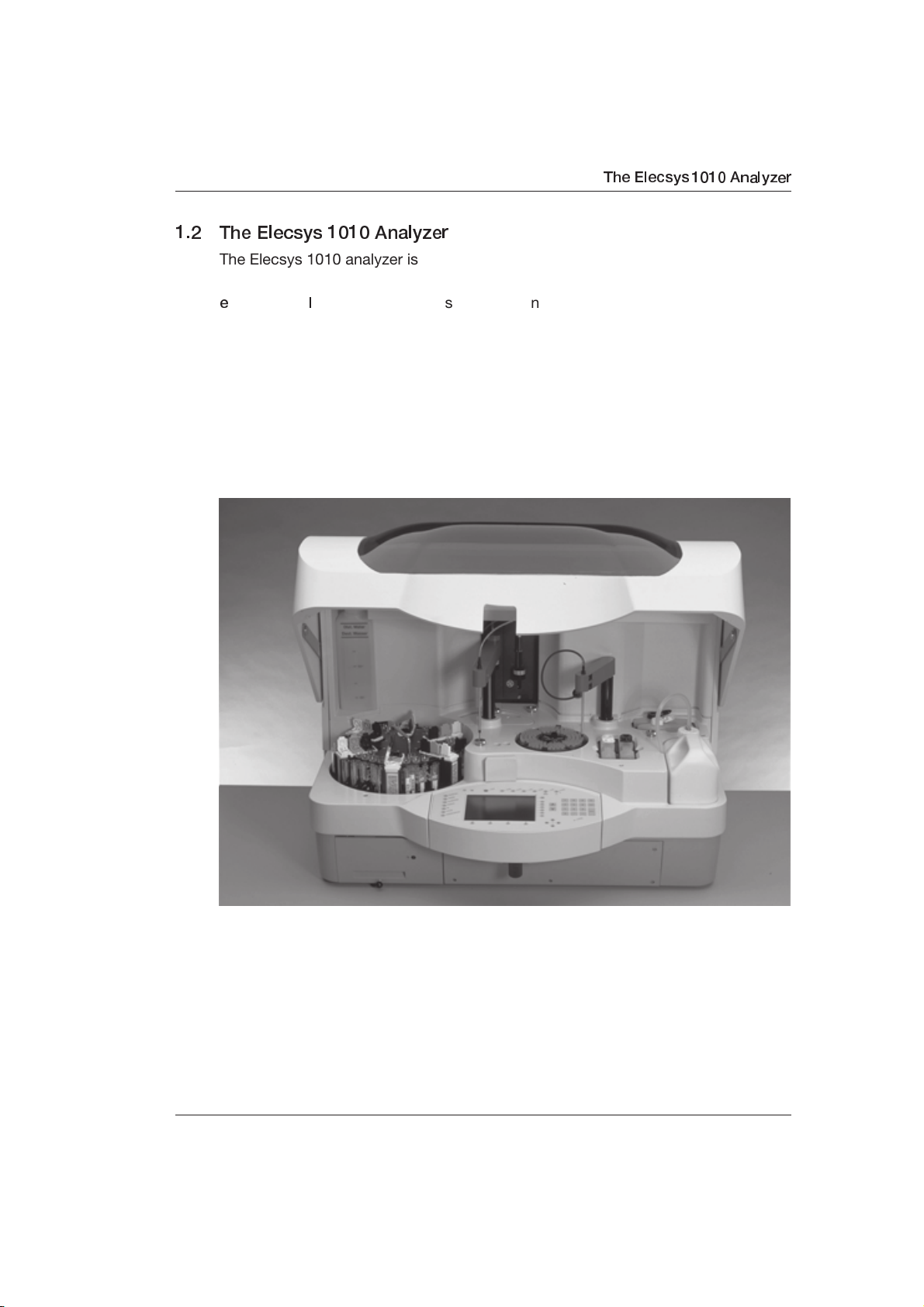

1.2 The Elecsys 1010 Analyzer

The Elecsys 1010 analyzer is a fully automatic, run-oriented analyzer system for

determination of immunological tests using the

e

lectrochemiluminescent process. All components and reagents for routine

analysis are integrated in or on the analyzer.

Operation of the analyzer is simple and intuitive. The reagents are stable and can

be directly loaded onto the analyzer. The consistent use of bar-coded reagents

greatly reduces the need for time-consuming manual entries in the daily routine.

Additional automation can be achieved by connecting a laboratory EDP (host)

system.

ECL/Origen

You can use serum and plasma samples in primary tubes, Hitachi standard cups,

microcups or cups on primary sample tubes. Bar-coded sample tubes are

recognized. Two STAT positions for STAT samples are also available.

Results are produced either qualitatively or quantitatively depending on the test.

The typical test throughput is approximately 50 results per hour.

V 3.0 – Reference Guide 1 - 3

Page 12

Roche Diagnostics Elecsys® 1010 Immunoassay System

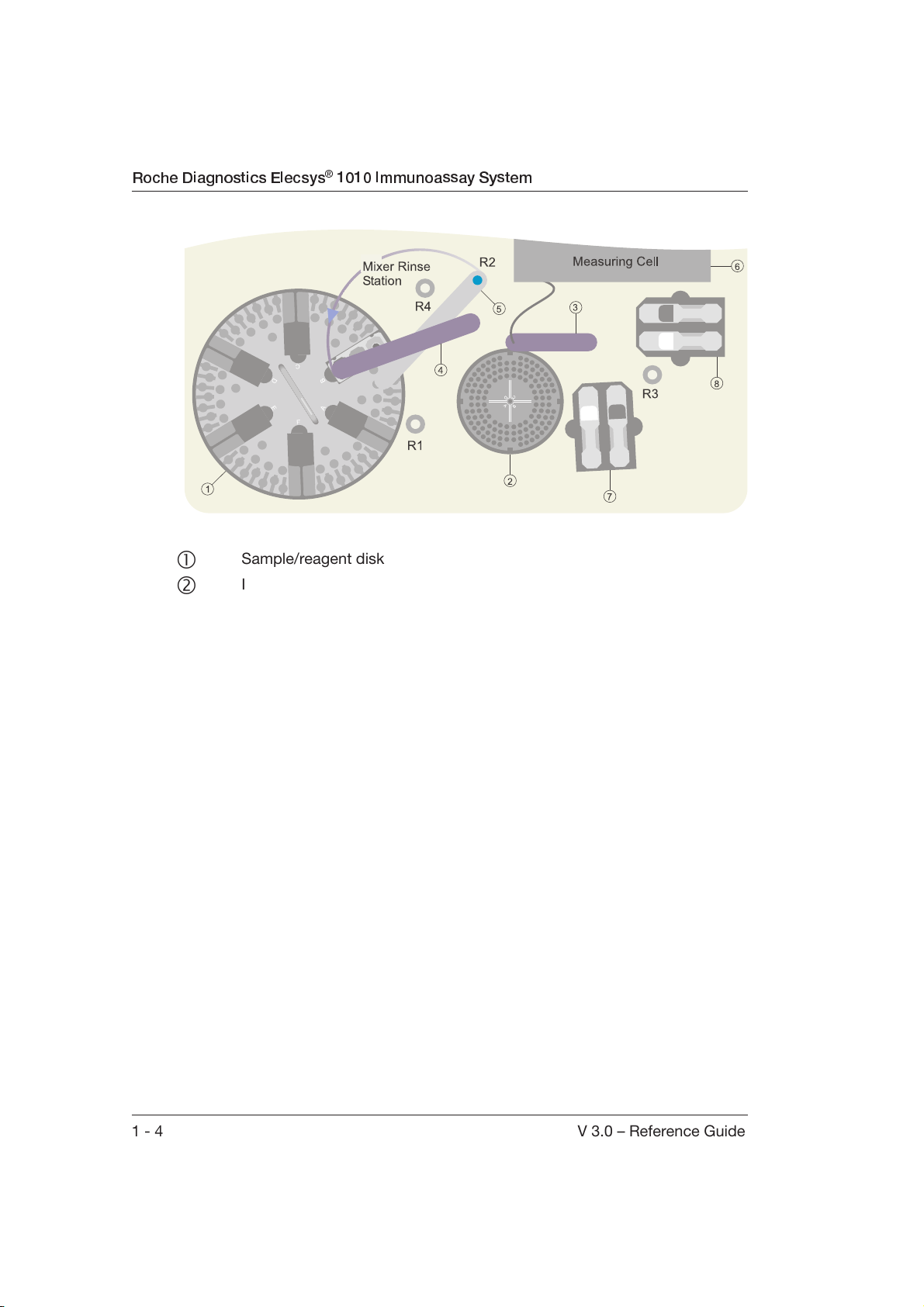

R1/R2 S/R probe rinse station

R3 Sipper probe rinse station

R4 Mixer rinse station

Sample/reagent disk

Incubator

Sipper arm

+ Sample/reagent arm (S/R probe and mixer)

Detection unit (measuring cell)

+ Positions for ProCell and CleanCell bottles

1 - 4 V 3.0 – Reference Guide

Page 13

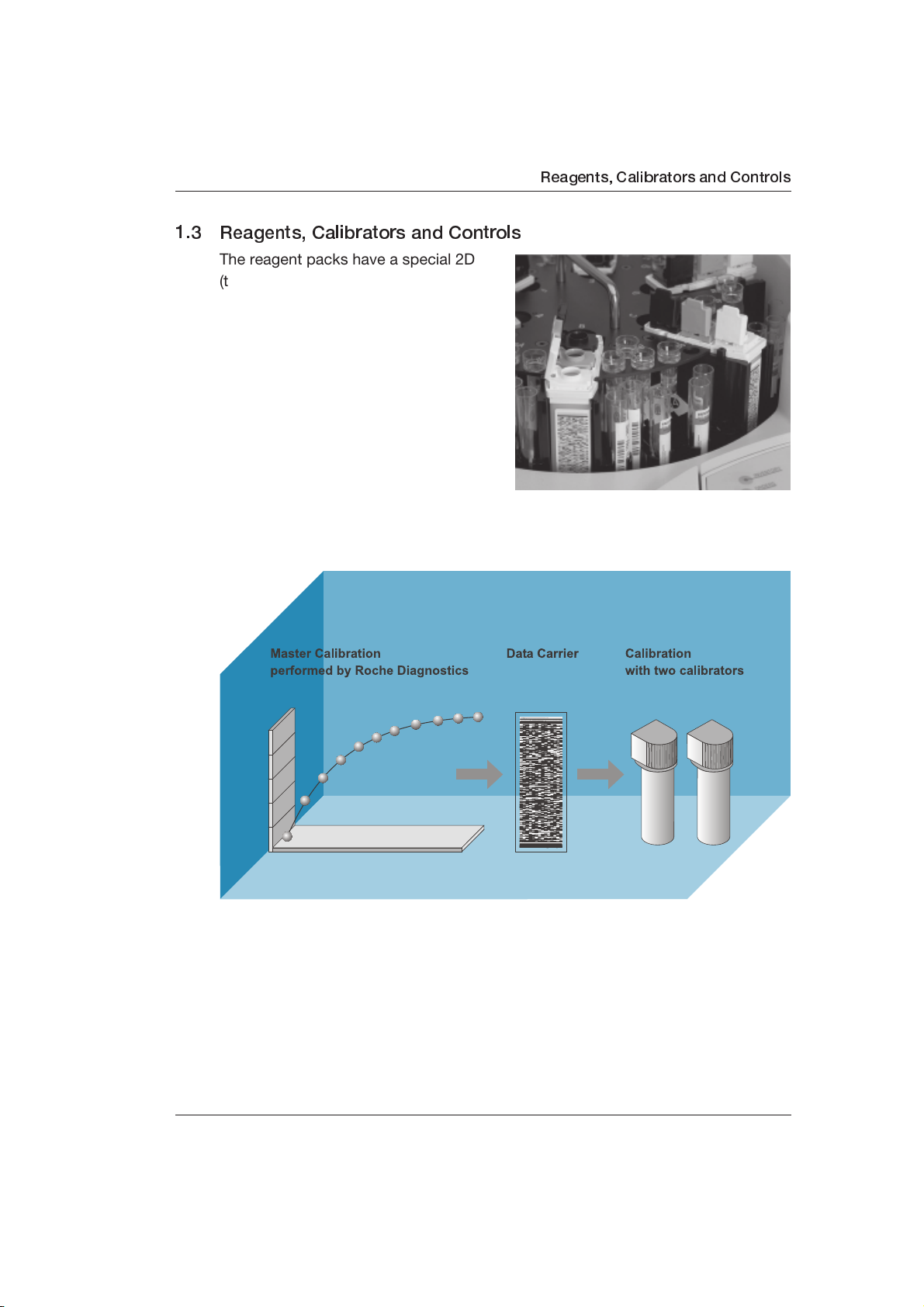

1.3 Reagents, Calibrators and Controls

The reagent packs have a special 2D

(two dimensional) bar code, which

allows fully automatic registration and

management of reagent information.

Manual input or additional monitoring is

not necessary. The ready-to-use, liquid

reagents are loaded into one of the six

positions on the sample/reagent disk.

Reagents are available for analysis

after their bar codes have been

scanned.

Reagents, Calibrators and Controls

The handling of calibrators and Roche Diagnostics controls corresponds to that of

reagents. Most calibrators are ready-to-use. Lyophilized controls and some

calibrators must be prepared and transferred into the appropriate container.

Calibrator and control information is stored on 2D bar code cards (see Chapter

1.3.7, Calibrator and Control Bar Code Cards).

V 3.0 – Reference Guide 1 - 5

Page 14

Roche Diagnostics Elecsys® 1010 Immunoassay System

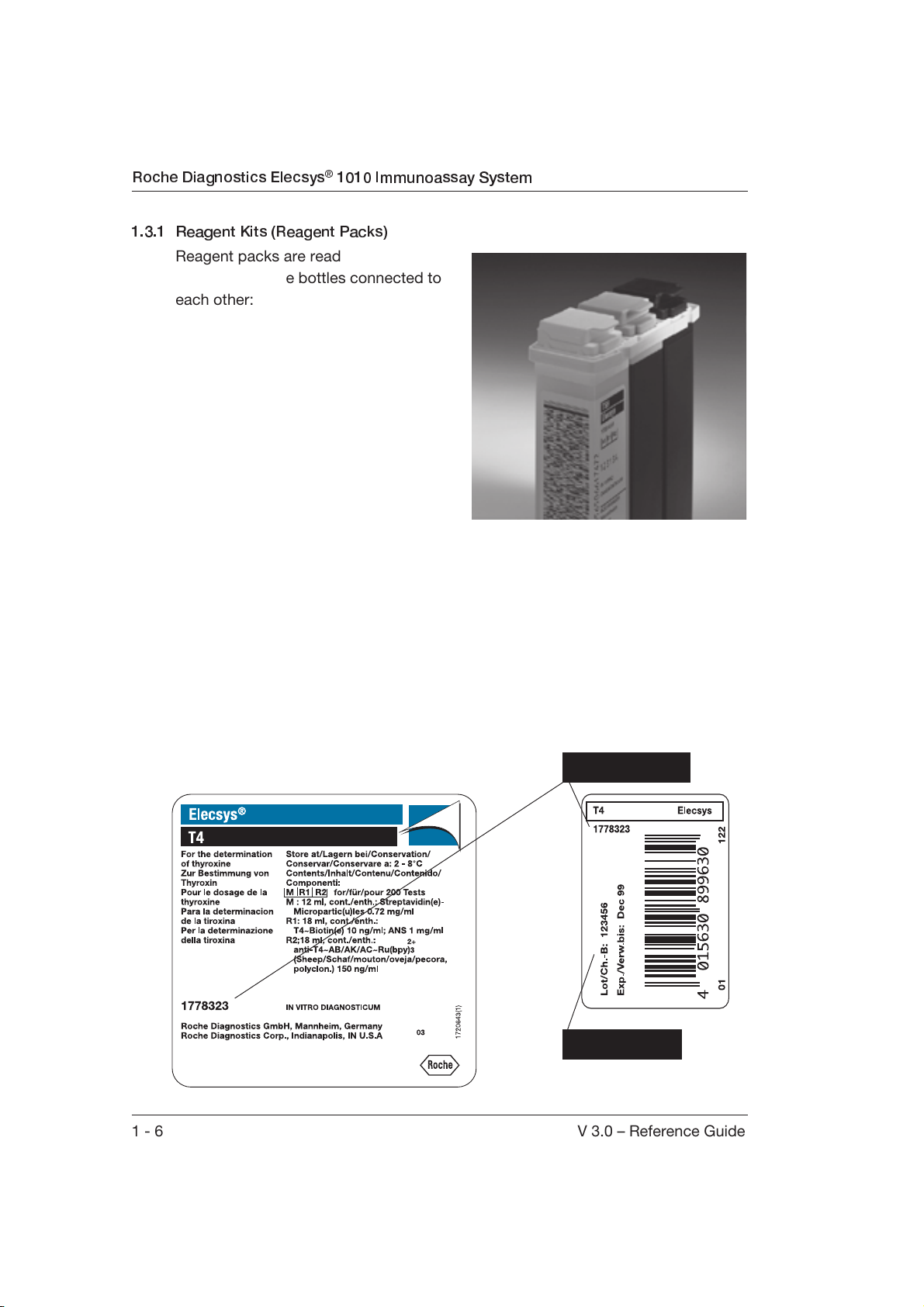

1.3.1 Reagent Kits (Reagent Packs)

Reagent packs are ready-to-use and

incorporate three bottles connected to

each other:

●

The white bottle with a transparent

lid contains suspended magnetic

microparticles that act as the carrier

material of the ruthenium-labeled

complex during measurement.

●

The black bottle with a gray lid

contains R1.

●

The black bottle with a black lid

contains R2.

The test application, calibration data,

control information, sample and reagent volumes, as well as special measurement

conditions are contained in the reagent bar code and therefore do not have to be

entered separately by the operator.

The following are examples of typical box labels for an Elecsys reagent kit. The

large label contains the intended use statement, storage temperature, contents

and catalog number of the kit. The smaller side box label contains the lot and

expiration date of the kit as well as a bar code number. This bar code number is

used for tracking purposes and is not used by the analyzer.

Catalog number

Kit lot number

1 - 6 V 3.0 – Reference Guide

Page 15

Reagents, Calibrators and Controls

1.3.2 Package Insert

Each reagent kit includes a package insert. This insert contains information

required to perform the assay. Detailed information is contained in the product

information sheet supplied separately.

1.3.3 Product Information Sheet

Each assay applied to this analyzer has a product information sheet that provides

general information about the assay. Data contained in the product information

sheets is more detailed than what is in the package insert. Instrument settings are

encoded in reagent bar codes and not entered by the operator. This type of

information, such as sample volume, reagent volume, etc., are found in the

overview section of the product information sheet.

Product information sheets can be obtained from Roche Diagnostics as required.

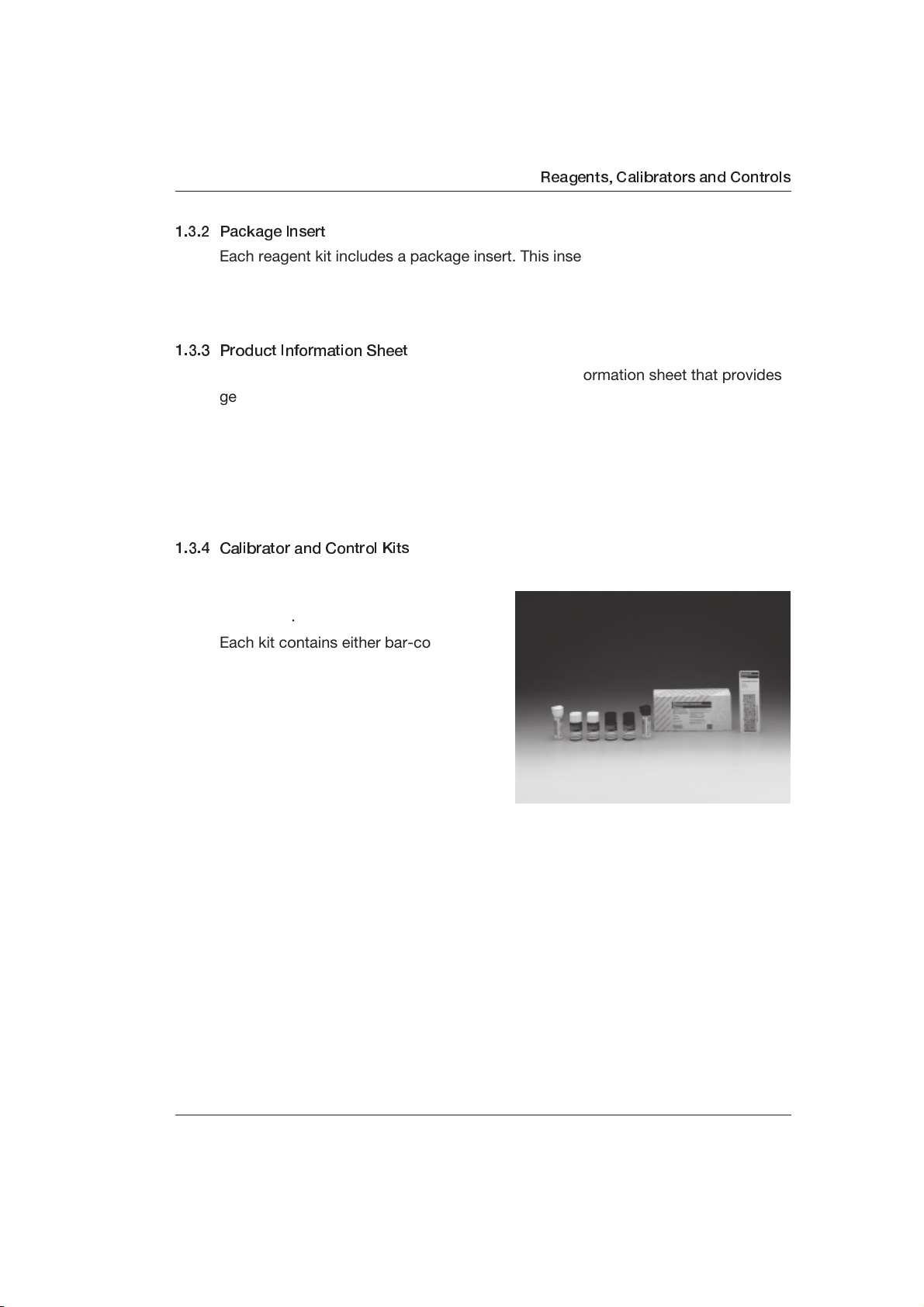

1.3.4 Calibrator and Control Kits

In most cases, calibrators and controls

for Elecsys reagents come packaged

separately.

Each kit contains either bar-coded

calibrator or bar-coded control vials

ready for use on the analyzer. Most

calibrators are in ready-to-use liquid

form and require no further action other

than to place them on the sample/

reagent disk when a calibration is

necessary.

A few of the calibrators and controls

are lyophilized in glass bottles and must be reconstituted before being transferred

into plastic bar coded-labeled vials. (Empty bar coded-labeled vials are packaged

in these kits with lyophilized calibrators and controls.) Reconstituted calibrators

and controls can be stored in the plastic vials after transfer.

Calibrators and controls also have color-coded caps to assist you in identification.

A white cap is a level one calibrator/control and a black cap is a level two

calibrator/control. In the course of the year 2000, black and white color-coded

caps for controls will be phased out in favor of beige/light brown (level one) and

caramel/dark brown (level two).

Calibrator and control bar code cards are packed with calibrator and control kits,

respectively (see Chapter 1.3.7, Calibrator and Control Bar Code Cards).

V 3.0 – Reference Guide 1 - 7

Page 16

Roche Diagnostics Elecsys® 1010 Immunoassay System

1.3.5 Reagent Bar Code Labels

Reagent packs have a bar code label that

contains information required to run the assay.

This information includes:

●

test number

●

lot number

●

master calibration curve parameters

(e.g. Rodbard parameters)

●

instrument settings

●

calibrator lot numbers and target values

●

expiration date

●

calibration frequency

The following information can be identified on

each reagent bar code label:

kit catalog number

reagent pack number

reagent bar code number

kit lot number

expiration date.

The reagent bar code label is in a new format. The new symbology utilizes

portable data files (PDF) and is called PDF417. Traditional linear bar codes serve

as a link to a database that contains the appropriate information. PDF417 is a two

dimensional (2D), stacked bar code that contains an actual entire data record. The

large amount of data that can be encoded allows all instrument settings to be

included, as well as the master calibration curve and additional information for the

assay. It is from this master curve and from the operator 2-point calibration that

the analyzer derives the update of the master calibration curve. For further

information, refer to Chapter 6, Calibration.

“Every PDF417 symbol (bar code) contains two error detection codewords that are

used like the check digit in linear bar code symbologies to detect decode errors

and verify that all data have been read and decoded accurately. Additionally,

PDF417 provides error correction in the event that portions of symbol have been

damaged, destroyed or are unreadable.”

1

It is a combination of this error detection and error correction that ensures a

reliable bar code. If the bar code cannot be read and the reagent lot has been

previously used by the analyzer, the 15-digit number can be entered manually in

the software.

1. Itkin S, Martell J. A PDF417 Primer: A Guide to Understanding Second Generation Bar Codes

and Portable Data Files. Bohemia, NY: Symbol Technologies, Inc; 1992:17-18.

1 - 8 V 3.0 – Reference Guide

Page 17

Reagents, Calibrators and Controls

1.3.6 Calibrator and Control Bar Code Labels

Each calibrator and control bottle has a

traditional linear bar code label that

contains an identifier to link it to information

encoded in the reagent bar code label and

the calibrator or the control bar code card

(see Chapters 1.3.5 and 1.3.7).

1.3.7 Calibrator and Control Bar Code Cards

Each calibrator and control kit comes with one or two 2D bar code cards. The

following information is included but not limited to:

●

test number

●

calibrator/control lot number

●

control code (e.g., PCU1) (control card only)

●

lot number of the calibrator/control bar code

label

●

information about which calibrator is to be

used and the number of determinations

(calibrator card only)

●

target values

●

control ranges (control card only)

●

expiration date.

Roche Diagnostics produces a factory master

calibration for each calibration lot. The results

are encoded into the corresponding reagent bar

code. Scan the new bar code card when a new

lot of calibrators or controls is used.

V 3.0 – Reference Guide 1 - 9

Page 18

Roche Diagnostics Elecsys® 1010 Immunoassay System

1.4 Potential Hazards and Safety Precautions

1.4.1 Safety Notes

To protect yourself from potential hazards, you must review all safety precautions

and regulations concerning the handling of materials and the system's electrical

and mechanical components.

The important safety notes in this manual are listed and classified below. Make

yourself acquainted with the following visual cues and icons:

WARNING

$

Warning messages contain information which, if not followed, could cause serious

personal injury and/or damage to the analyzer.

CAUTION

Caution messages contain information which, if not observed, could result in loss

of data and/or damage to the analyzer.

Note

Notes contain important information about a topic in the text.

1 - 10 V 3.0 – Reference Guide

Page 19

Potential Hazards and Safety Precautions

Electricity

To avoid an electric shock DO NOT attempt to open the instrument panels and

work in any electronic compartment.

Chemical

The operator is responsible for taking all necessary precautions against hazard

associated with the use of clinical laboratory chemicals. Specific

recommendations for each reagent used on the analyzer are found on the box

label, package insert or product information sheet for each chemistry. Material

Safety Data Sheets (MSDS) are available for Roche Diagnostics reagents.

Immediately remove any reagent spillage from the instrument.

Mechanical

As with any mechanical system, certain precautions must be taken when

operating the instrument. DO NOT wear loose garments or jewelry that could

catch in moving mechanisms. DO NOT put your hand into the pathway of any

moving parts while the analyzer is operating. Operate the instrument with the

cover down. DO NOT attempt mechanical repairs unless the instrument is in

Stand-by or OFF.

Biohazardous Materials

As with all in vitro diagnostic equipment, patient samples and serum-based quality

control (QC) products that are assayed on this system, as well as all waste from

the waste container, should be treated as potentially biohazardous. All materials

and mechanical components associated with the sampling and waste system

should be handled according to your facility’s biohazard procedure. Use the

personal protective equipment recommended by your facility when handling any of

these components.

V 3.0 – Reference Guide 1 - 11

Page 20

Roche Diagnostics Elecsys® 1010 Immunoassay System

Safety Precautions During Operation

Samples

1. Treat all samples as potential biohazards. If sample spills on the instrument,

use correct personal protective equipment (PPE-gloves, lab coat, etc.) and

wipe off the spillage immediately.

2. Make sure that the sample does not contain any fibrin, dust or other insoluble

contaminants. If insoluble contaminants are contained in the sample, correct

measuring values may not be obtained.

Waste Solution and Solid Wastes

1. Avoid direct contact with waste solution and/or solid wastes. Both should be

handled as potential biohazards.

2. Dispose of waste solution and/or solid wastes according to the relevant

governmental regulations.

3. Consult the reagent manufacturer for information on the concentrations of

heavy metals and other toxic constituents in each reagent.

4. $ WARNING

Do not add bleach to the liquid waste container. Bleach combined

with the contents of the liquid waste could cause potentially harmful

fumes.

Biohazardous Parts

1. Avoid direct contact with the sample/reagent probe, sipper probe and rinse

station. Treat these areas as potentially biohazardous.

Reagents

1. Avoid direct contact with reagents. Direct contact may result in skin irritation

or damage. Refer to the reagent kit box labels or package insert for specific

instructions.

2. Avoid direct contact with CleanCell. Direct contact may result in skin irritation

or damage. Refer to the CleanCell box label or package insert for specific

instructions.

1 - 12 V 3.0 – Reference Guide

Page 21

Potential Hazards and Safety Precautions

Additional Precautions

Flammables

Avoid using dangerous flammables near the instrument. Fire or explosion may be

caused by naked flames.

Accuracy/Precision of Measured Results

For proper use of the instrument, measure control samples and monitor the

instrument during operation.

An incorrectly measured result may lead to an error in diagnosis, therefore posing

a danger to the patient.

Application

The instrument is designed for clinical immunological test analysis using watersoluble samples and reagents.

Please note that other analyses may not be applicable to this instrument.

Operator Qualification

1. Operation should be conducted under the management of a technician who

has undergone training at the facility specified by the sales agent.

2. For clinical tests, the instrument should be used under the management of a

doctor or clinical inspector.

Operation and Maintenance

1. During operation and maintenance of the instrument, proceed according to

the instructions and do not touch any parts of the instrument other than those

specified.

2. Do not open the cover while the analyzer is running or operation will be

stopped.

Installation Requirements

Installation is performed by a Roche Diagnostics representative. The customer is

responsible for providing the necessary facilities as detailed in Section 2.13,

Technical Data.

V 3.0 – Reference Guide 1 - 13

Page 22

Roche Diagnostics Elecsys® 1010 Immunoassay System

Restriction on Samples and Reagent Solutions

1. The assay cups, detection unit and liquid waste container are not guaranteed

to be chemically resistant against organic solvents. Therefore, do not use

organic solvents on these parts.

2. Avoid using samples and reagent solutions that are likely to adhere to the

assay tips, assay cups, liquid waste container or detection unit.

Handling Reagent Solutions

Follow the manufacturer’s instructions for use of reagent solutions.

Loading Samples and Reagents

Be sure to load samples and reagents only into the specified positions on the

instrument.

If sample or reagent is spilled, malfunction of the instrument may occur.

Sample/Reagent Disk

Never load new samples onto the sample/reagent disk during the scan process.

When loading the sample/reagent disk, follow the instructions in the manual.

Microparticle Mixer

Be careful not to bend the microparticle mixer. A bent mixer could lead to

inaccurate results.

Switching On the Instrument

After the analyzer has been switched off, wait approximately 10 seconds before

switching it back on.

Instrument Unused for a Long Time

If the instrument will not be used for a long period of time, contact Technical

Support. Different shutdown procedures are recommended depending upon the

duration of inactivity. In addition, certain procedures require the assistance of a

Roche Diagnostics service representative.

1 - 14 V 3.0 – Reference Guide

Page 23

Potential Hazards and Safety Precautions

1.4.2 Accident Prevention

Elecsys 1010 is a fully automatic analyzer designed according to the most up-todate safety requirements. This ensures the highest possible protection for the

operator from accidents and ensures correct functioning of the system.

Before using the Elecsys 1010, review the safety precautions described in this

chapter to avoid operational interruptions and to protect you from potential

hazards.

The following overview describes specific features for optimal analyzer and

operator protection.

Operator Training

Roche Diagnostics provides system training after which an operator not only

works with the Elecsys 1010 but is also familiar with the relevant safety aspects.

Stand-by Operation and Analyzer Preparation

(Stand-by = the analyzer has power, however, the motion functions of the

individual components are disabled). In Stand-by mode, the tips of the S/R and

sipper probe and the paddle of the microparticle mixer are stowed in their home

positions in the rinse stations. Therefore, the operator cannot be injured by the

probes.

The sample/reagent disk can be removed from the analyzer. Therefore, loading of

samples, reagent packs, calibrators and controls can either be performed on the

analyzer or away from the analyzer.

The consumable containers (CleanCell, ProCell, water and waste containers) are

replaced or refilled in Stand-by mode.

When all the necessary substances have been loaded on the analyzer, the scan

process can be started after closing the cover.

V 3.0 – Reference Guide 1 - 15

Page 24

Roche Diagnostics Elecsys® 1010 Immunoassay System

Analyzer Cover

The analyzer cover must be closed prior to starting a run. A run cannot be started

when the cover is open. If the cover is opened during initialization, the analyzer

stops immediately.

If the cover is opened during a run, the analyzer moves the probes and

microparticle mixer to their home positions in the rinse stations within 2 seconds

to prevent accidental contact. As a result, the run is stopped.

CAUTION

Opening the analyzer cover during a run may cause results to be lost.

STOP

Key

Press the STOP key to stop all operations that Elecsys 1010 is performing as soon

as possible. This process is the same as that described for the analyzer cover.

STAT

Samples

STAT (Short Turn Around Time) samples can be placed on the analyzer in the

designated positions behind the control unit, even when the cover is closed and a

run is being performed. Contact with the probes or microparticle mixer is not

possible. To load STAT samples, the drawer is pulled forward to expose the STAT

positions. There is a mechanical lock present when access is not permitted.

1 - 16 V 3.0 – Reference Guide

Page 25

1.5 Approvals

The Elecsys 1010 analyzer was manufactured and tested according to

international standard IEC 1010-1, “Safety requirements for electrical equipment

for measurement, control and laboratory use, Part 1: General requirements”. This

international standard is equivalent to the national standard Underwriters

Laboratories (UL) 3101-1.

The analyzer was tested and approved by the VDE and UL and received the

following safety marks:

Approvals

C

U

®

U

V

D E

L

L

®

¨

geprufte

Sicherheit

Issued by

Association of German Electrical Engineers (VDE).

Issued by Underwriters Laboratories, Inc. (UL).

Issued by Underwriters Laboratories, Inc. for Canada as

a Certification and Testing Organization by the

Standards Council of Canada (SCC).

The analyzer complies with the European Union (EU)

directive 89/336/EEC (Electromagnetic Compatibility).

VDE Testing and Certification Institute,

V 3.0 – Reference Guide 1 - 17

Page 26

Roche Diagnostics Elecsys® 1010 Immunoassay System

1 - 18 V 3.0 – Reference Guide

Page 27

2. System Description

Control Unit

V 3.0 – Reference Guide 2 - 1

Page 28

Roche Diagnostics Elecsys® 1010 Immunoassay System

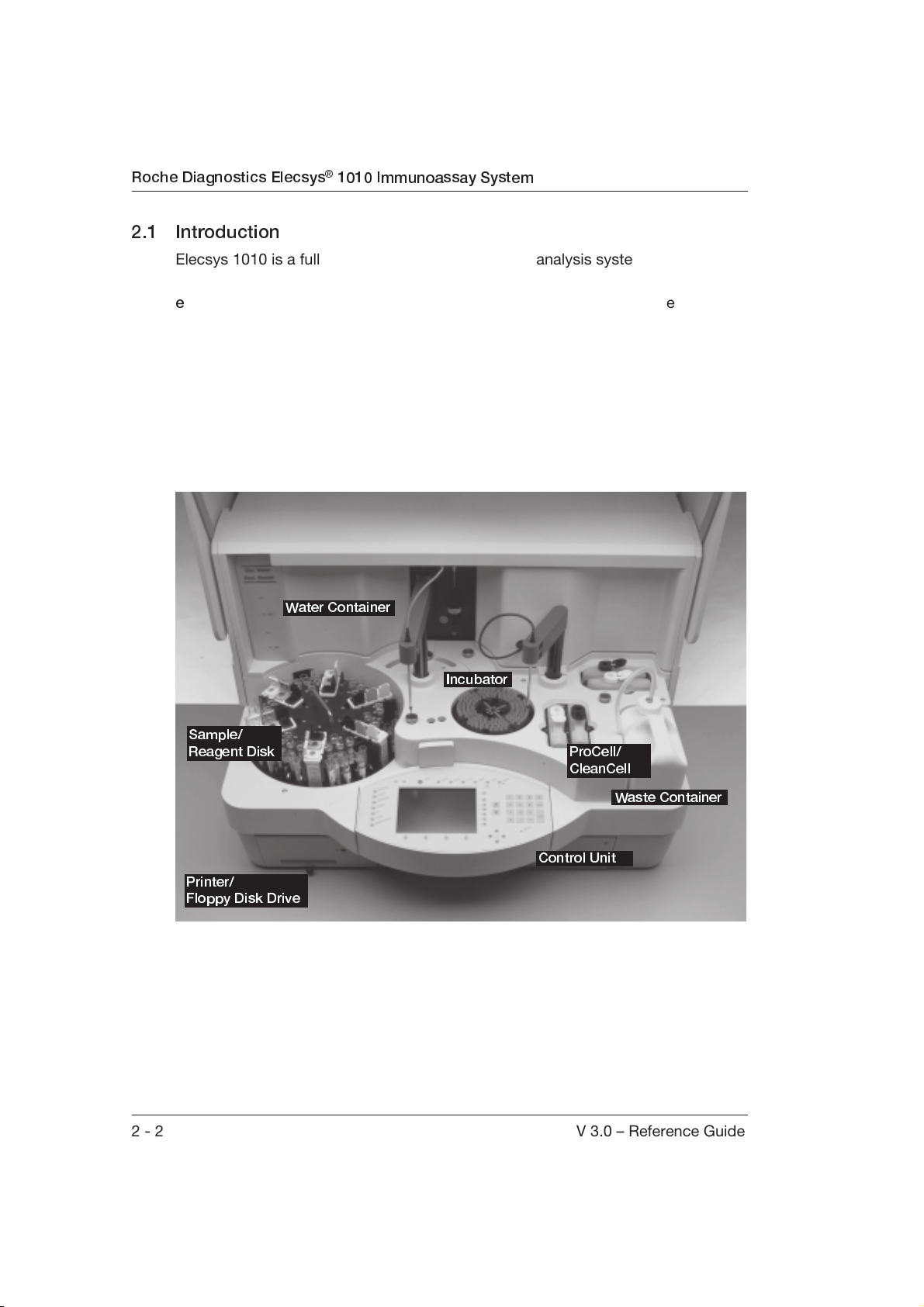

2.1 Introduction

Elecsys 1010 is a fully automated routine and STAT analysis system for the

determination of immunological tests using the ECL/Origen

e

lectrochemiluminescent process. The system measures samples in the form of

serum and plasma. Depending on the test used, the results are produced either

as quantitative or qualitative results.

Elecsys 1010 was designed to be placed on a table. The photograph below

shows where the components for the daily routine are located on the analyzer.

The analyzer has an interface for the connection of a laboratory

An external printer and a PC-compatible keyboard can also be connected.

Water Container

EDP (host) system.

Incubator

Sample/

Reagent Disk

Printer/

Floppy Disk Drive

ProCell/

CleanCell

Waste Container

Control Unit

The system was designed to be powered on and operated 24 hours a day. Power

the analyzer on with the cover down. After configuration run is complete, the

analyzer goes into Stand-by and is ready for operation.

2 - 2 V 3.0 – Reference Guide

Page 29

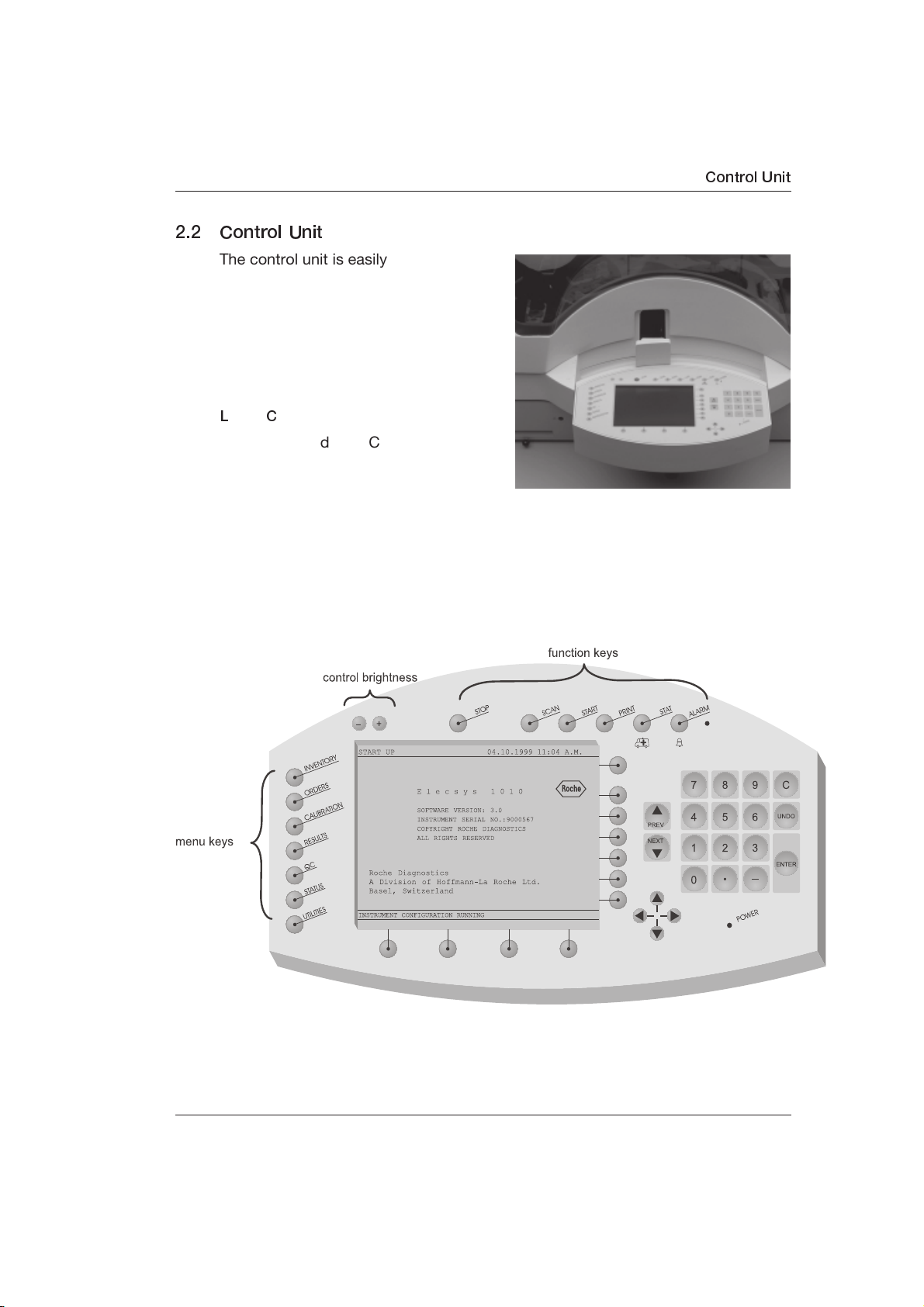

2.2 Control Unit

The control unit is easily accessible from

the front of the analyzer. It is used by the

operator to enter the tasks that the

analyzer is to perform.

The control unit is comprised of a

keyboard, covered by a plastic

protection cover and an

L

iquid Crystal).

Located around the LC display (to the

right and below the display) are

unlabeled keys, called soft keys, which

point to the display. The functions of

these keys change according to the screen displayed.

All keys with a fixed function [to the left (menu keys) and above the display

(function keys)] are labeled accordingly. For example, pressing the SCAN key

initiates a scan of bar code-labeled tubes and reagent packs loaded on the

sample/reagent disk.

LC display (LC =

Control Unit

As an option, a PC-compatible keyboard can be connected for entering text and

special characters. For this purpose, there is a 5-pin standard connector

underneath and to the right of the control unit.

V 3.0 – Reference Guide 2 - 3

Page 30

Roche Diagnostics Elecsys® 1010 Immunoassay System

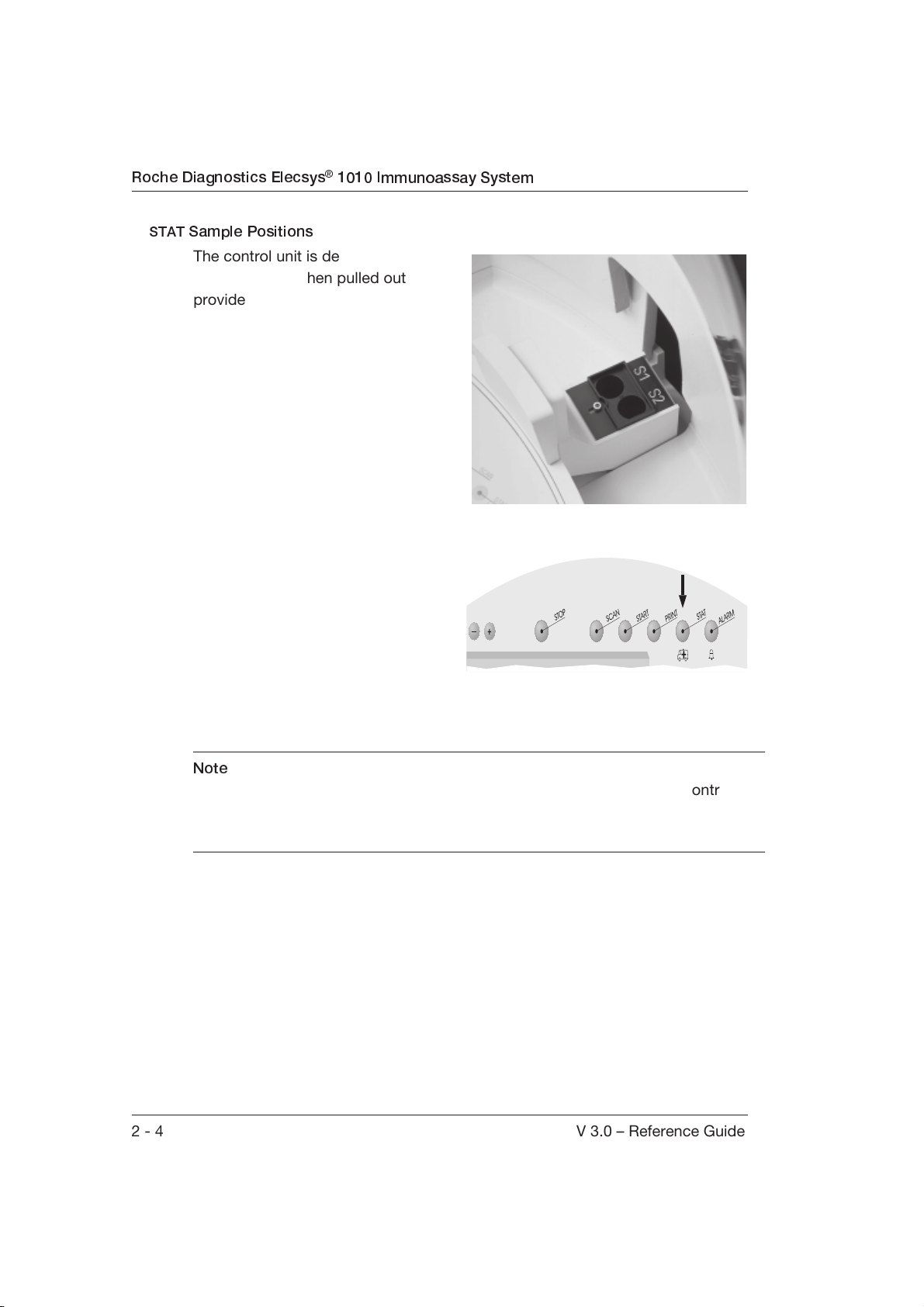

STAT

Sample Positions

The control unit is designed like a

drawer, which when pulled out

provides access to the two STAT

positions. During a run, up to two

STAT samples at a time can be

loaded in primary tubes or when

using a special adapter (supplied) in

secondary cups.

Normally, access to both STAT

positions is always possible. When

the STAT key is pressed, the

requests for one or both STAT

samples can be entered.

When the STAT requests have been

confirmed, the control unit is locked into

position by the analyzer until all of the

requested tests have been pipetted.

The control unit is then immediately

unlocked so that further STAT samples

can be processed during a run.

Note

A power failure during the pipetting of the STAT samples may lock the control

unit. The locking device can be temporarily overridden by inserting a screwdriver

below the control unit.

2 - 4 V 3.0 – Reference Guide

Page 31

Sample/Reagent Disk

2.3 Sample/Reagent Disk

Patient samples, reagents, diluents,

calibrators and controls required for a

run are loaded on the sample/reagent

disk.

During a run, the disk positions the

sample containers so that they can be

reached by the S/R probe and the

microparticle mixer.

Reagent Positions

The disk has six positions laid out in

the form of a star. These positions are

used to load six reagent packs for use in a run. The reagent pack positions are

labeled from A to F.

Sample, Calibrator and Control Positions

The sample/reagent disk has 66 numbered positions for patient samples,

calibrators and controls. The positions 1 to 42 are scanned by the bar code reader

and can be loaded, for example, with bar code-labeled primary tubes. The

positions 43 to 66 are intended for secondary cups (e.g., Hitachi standard cups).

The bar code positions can be converted into 36 secondary cup positions by

using six adapters. This is useful in laboratories that do not want to use primary

tubes on Elecsys 1010.

V 3.0 – Reference Guide 2 - 5

Page 32

Roche Diagnostics Elecsys® 1010 Immunoassay System

Bar Code Card Holder

At each reagent pack position, there is

a slot for inserting a bar code card for

calibrators and controls.

The control or calibrator 2D bar code

cards contained in the packaging is

inserted in an available bar code card

slot and is scanned by the bar code

scanner (SCAN key).

2 - 6 V 3.0 – Reference Guide

Page 33

Sample/Reagent Arm

2.4 Sample/Reagent Arm

The sample/reagent (S/R) arm is

located between the sample/reagent

disk and the incubator. On one side

there is the sample/reagent (S/R) probe

and on the other side, the microparticle

mixer. During a run the S/R arm moves

the mixer or S/R probe to the

appropriate pipetting, mixing or rinsing

position.

Sample/ Reagent Probe

The S/R probe transfers sample,

reagent and microparticles into the

assay cups in the incubator.

The S/R probe has an automatic liquid detection system (

D

etection) that can detect whether or not there is liquid present. The probe

detects the liquid surface when it is lowered into the container. This prevents air

from being pipetted when there is insufficient liquid available.

An abnormal descent sensor stops further probe movement when the bottom of

the container is detected. This sensor also prevents the probe from being

damaged when a reagent pack has not been opened.

Possible clot formation is recognized by a pressure sensor in the S/R pipetting

system (clot detection).

LLD =

L

iquid Level

Mixer

At regular intervals, the mixer resuspends the microparticles contained in every

reagent pack that are required for analysis.

V 3.0 – Reference Guide 2 - 7

Page 34

Roche Diagnostics Elecsys® 1010 Immunoassay System

Rinse Stations

The rinse stations W1 and W2 are used to clean or rinse the S/R probe. A cleaning

or rinsing process is performed between the individual aspirations of the liquids

(sample, reagent and microparticles).

The mixer has a separate rinse station. The mixer is cleaned before and after

resuspension of the microparticles.

Mixer Rinse

Station

W2 S/R Probe

Rinse Station

W1

2 - 8 V 3.0 – Reference Guide

Page 35

2.5 Incubator

The immunochemical reaction is

performed in assay cups located in the

incubator. The temperature of the

incubator is maintained at a constant

37 °C (±0.3 °C).

Assay Cups

The reaction of sample, reagent and

microparticles takes place in the assay

cups. The incubator can hold four preloaded segments containing assay

cups. These segments are loaded into

the positions labeled A through D. Each segment can hold 32 assay cups, thus

the maximum number of assay cups is 128 (four segments each with 32

positions).

The Incubator

Assay Cup Segments

The pre-loaded segments can be easily

placed into and removed from the

analyzer.

The operator must remove used

segments and reload with new

segments before or after each run.

The photosensor does not detect the

presence or absence of individual

cups. Removal and replacement of

individual cups will lead to erroneous

results. ReSegments in which all the

assay cups have been used must be replaced. Partially used segments can

remain in the incubator until all 32 assay cups have been used. The

screen can be used to display the status of each assay cup.

INVENTORY

V 3.0 – Reference Guide 2 - 9

Page 36

Roche Diagnostics Elecsys® 1010 Immunoassay System

2.6 Sipper Arm

The sipper probe, located on the sipper

arm, transports the reaction mixture

from the assay cups to the measuring

cell. It also transports CleanCell and

ProCell to the measuring cell. The

sipper arm can reach all assay cups

loaded in the incubator as well as both

sets of CleanCell and ProCell.

Sipper Probe

The sipper probe has an automatic

liquid detection system (

L

evel Detection) that can detect

LLD =

L

iquid

whether or not there is liquid in an

assay cup. The probe detects the liquid

surface when it is lowered into a

ProCell or CleanCell bottle. This

prevents air from being pipetted when there is insufficient liquid available.

An abnormal descent sensor prevents the probe from hitting the bottom of an

assay cup to avoid damage to the probe and to ensure correct aspiration of the

reaction mixture. This sensor also prevents the probe from being damaged when

a ProCell/CleanCell bottle has not been opened by the operator.

Sipper Probe

Rinse Station

ProCell/

CleanCell Set 2

ProCell/

CleanCell Set 1

Rinse Station

The sipper probe is cleaned in its own rinse station after each pipetting process.

2 - 10 V 3.0 – Reference Guide

Page 37

2.7 Liquid System

The liquid system transports sample, reagent, microparticles, CleanCell, ProCell,

diluent and distilled water, as well as liquid waste. The components that can be

seen by the operator are the pipettors, the tube connections and the containers

for distilled water and waste.

Pipettors

Two pipettors, as well as several

pumps (behind the housing cover)

transport the liquids. The left pipettor is

responsible for aspirating and

dispensing liquids for the S/R probe

and the right pipettor controls liquid

transportation through the sipper and

detection unit.

L

iquid System

Distilled Water Container

The distilled water container is located

on the left of the analyzer. It can hold

up to 4 liters of distilled water. The

container can be easily removed

before and after every run in order to

refill it.

Note

Use caution when removing or

replacing the distilled water container

to ensure no water drips onto the S/R

disk.

V 3.0 – Reference Guide 2 - 11

Page 38

Roche Diagnostics Elecsys® 1010 Immunoassay System

ProCell and CleanCell

The analyzer has two bottles

containing the system reagent ProCell

Set 2

(white caps) and two bottles containing

the system reagent CleanCell (black

ProCell

caps). ProCell is the buffer solution

required by the measuring cell for the

ECL reaction. CleanCell is used to clean

the measuring cell.

The compartments where the bottles

are located are maintained at a

ProCell

CleanCell

Set 1

temperature of 28 °C to prevent

temperature fluctuations in the

measuring cell (also maintained at

28 °C).

One bottle of ProCell and one bottle of

CleanCell forms a set. As soon as a set

is empty, the other set is used. An empty set should be replaced by two new

bottles before or after a run.

CleanCell

Waste Container

Waste Container

The entire waste liquid is pumped into the waste container located on the right

side of the analyzer. The waste container can hold approximately 5.5 liters of

waste and can be easily removed and replaced before and after each run to

empty it.

2 - 12 V 3.0 – Reference Guide

Page 39

2.8 Measuring Cell

The measuring cell is the core of the system. It is located in a light-proof capsule

in a housing behind the sipper arm and the temperature is precisely controlled at

28 °C (±0.3 °C). The measurement signals produced are used by the Elecsys

1010 to calculate the results.

The measuring cell is a sealed chamber and consists of a working electrode,

counter electrodes, a magnet and a photomultiplier.

Measuring Cell

V 3.0 – Reference Guide 2 - 13

Page 40

Roche Diagnostics Elecsys® 1010 Immunoassay System

When the reaction mixture, consisting of sample and reagent, is placed in the

measuring cell, three processes are performed to produce the measurement

signals:

Bound/Free Separation

Using a magnet, the streptavidin microparticles coated with antigen-antibody

complexes are uniformly deposited on a defined spot of the working electrode.

They remain there for the entire measurement period. For a few seconds, a buffer

solution (ProCell) is flushed through the measuring cell to wash the microparticles

on the working electrode and to flush out excess reagent and sample material.

ECL

Reaction

A voltage is applied to the working electrode to initiate the ECL reaction. The light

emission, produced by the complex radical reaction, is measured by a

photomultiplier. These signals are used by the system to calculate the results.

Releasing the Microparticles and Cleaning the Cell

Once the measurement is complete, the measuring cell is reconditioned with a

special cleaning solution (CleanCell) and is ready for a new measurement.

A detailed description of the ECL reaction can be found in Chapter 4, ECL

Technology.

2 - 14 V 3.0 – Reference Guide

Page 41

2.9 Power Switch

The ON/OFF switch is located on the

left of the analyzer. This switch applies

voltage to the main power supply (110

to 240 VAC).

2.10 Printer

A thermal printer is located at the front

left of the analyzer behind a door.

All results and the most of the

displayed screen information can be

printed out. To replace the paper, the

door can be opened.

Power Switch

Additionally, a standard parallel

interface enables the connection of an

external printer (Epson or HP

compatible).

V 3.0 – Reference Guide 2 - 15

Page 42

Roche Diagnostics Elecsys® 1010 Immunoassay System

2.11 Floppy Disk Drive

The floppy disk drive is located at the front left of the analyzer next to the thermal

printer.

The disk drive can be used to archive data (i.e., store results) and read reference

data into the system. To insert or remove a disk, simply open the door to access

the disk drive.

2 - 16 V 3.0 – Reference Guide

Page 43

2.12 Interfaces

Elecsys 1010 can be connected to a laboratory EDP (host) system to transfer

information. An external printer and an external keyboard can also be connected.

There are three connections for these purposes.

Printer Connection (Parallel Interface)

To the left of the analyzer, there is a

parallel interface connection for an

optional external printer (Epson or HP

compatible). This printer can be used

instead of the internal printer for

printing results. The printer type is set

in

UTILITIES (INTERFACE SETUP screen).

Refer to the relevant printer

documentation to see how the

connected printer operates.

Printer connection

Host connection

Interfaces

Host Connection (Serial Interface)

To the left of the analyzer, below the printer connection, there is a bidirectional

serial interface connection for a laboratory EDP (host) system. The host

specifications must be set in UTILITIES (INTERFACE SETUP screen and INSTRUMENT

screen).

SETUP

External Keyboard Connection

To the right of the control unit, there is

a connection for an optional standard

PC keyboard. The keyboard can be

used to enter text and special

characters which are not possible with

the control unit keyboard. Once the

external keyboard is connected, no

further settings are required. Both

keyboards can be used together. The

External keyboard

connection

keys on the external keyboard that can

be used for specific functions are

specified in Chapter 1, Introduction.

V 3.0 – Reference Guide 2 - 17

Page 44

Roche Diagnostics Elecsys® 1010 Immunoassay System

2.13 Technical Data

Analyzer Dimensions

Height 24.68 in (62 cm)

Depth 31.04 in (78 cm)

Width 38.21 in (96 cm)

Weight Approx. 243 pounds (110 kg) empty

Electrical Connection

Installation requirements Pollution degree: 2 (IEC 1010-1)

Overvoltage category II (IEC 664)

Elecsys 1010 should only be connected to

a grounded power supply.

Voltage 110-240 VAC ± 10%, single phase

Frequency 50/60 Hz

Power consumption Max. 610 VA

Heat generation Approx. 1800 kJ/h

Environmental Conditions

Temperature 18 °C to 32 °C (during run),

15 °C to 35 °C (in Stand-by mode),

-25 °C to +70 °C (for transportation)

Temperature variation ≤ 3 °C (during run)

≤ 5 °C (in Stand-by mode)

20 K/h (for transportation)

Relative humidity 20% to 85% without condensation (during

run and in Stand-by mode)

10% to 90% (for transportation)

Atmospheric pressure 70 to 106 kPa (2200 m during run and in

(height above sea level) Stand-by mode),

4300 m (for transportation)

2 - 18 V 3.0 – Reference Guide

Page 45

Noise level (DIN 43635)

Continuous noise Max. 60 dBA

Peak noise Max. 65 dBA

Water Supply

Water container Approx. 4 L

Water quality < 10 µS/cm or > 0.1 megohm, bacteria-

free

Water consumption Approx. 2.8 L for 100 tests

L

iquid waste

Liquid waste container Approx. 5.5 L

(can be cleaned in a dishwasher)

Throughput

Determinations Typically 50/h, max. 60/h

(tests with pretreatment and dilution

reduce the throughput by approx. 50%)

Technical Data

Samples

Sample/ Reagent pipettor < 1.5% CV at 10 µL

precision <1% CV at 50 µL

Sample volume per test 10 µL to 50 µL

Sample detection Liquid level detection of S/R probe

Positions on sample/ 42 positions for primary tubes or

reagent disk for samples, 36 positions with secondary cups

adapters,

calibrators and controls 24 positions for secondary cups,

2 additional positions for STAT samples

Sample bar codes NW7 (Codabar), Code 39, Code 128,

Interleaved 2 of 5

V 3.0 – Reference Guide 2 - 19

Page 46

Roche Diagnostics Elecsys® 1010 Immunoassay System

Sample Cups

Primary Tubes

Type Volume

(mL)

SARSTEDT MONOVETTE

SARSTEDT MONOVETTE

SARSTEDT SERUM-GEL

MONOVETTE

BECTON DICKENSON

SST 3206

BECTON DICKENSON

VACUTAINER + GEL SST

3202

BECTON DICKENSON

VACUTAINER + GEL SST

3200

TERUMO VENOJECT II

TERUMO VENOJECT II

10.0 16.5 92 500

4 15.3 57 500

9.0 16.5 92 500

5.0 13.0 75 300

10.0 16.0 75 400

10.0 16.0 100 400

5.0 13.25 100 300

10.0 15.65 100 500

External

Diameter

(mm)

Height

(mm)

Dead

Volume

(µL)

SEKISUI Primary cup 10.0 16.2 100 500

SEKISUI Primary cup 7.0 14.0 100 500

2 - 20 V 3.0 – Reference Guide

Page 47

Secondary Cups

Technical Data

Type Dead

Note

Volume

(µL)

HITACHI Sample Cup

in secondary positions

60 The sample volume may not be less than

or equal to 60 µL.

(42-66)

HITACHI Sample Cup

60

in secondary adapter

HITACHI Micro Cup

in secondary positions

30 The sample volume may not be less than

or equal to 30 µL.

(42-66)

HITACHI Micro Cup

30

in secondary adapter

Secondary or pour-off

280

tube, 16 mm X 100 mm

Secondary or pour-off

235

tube, 13 mm X 75 mm

Others It is recommended that secondary cups other than

those specified here be checked before they are used

on the analyzer. The operator must ensure that there is

sufficient sample in the cup.

C

up on Tube (COT)

Type Dead Volume

(µL)

HITACHI Sample Cup

Cup on Tube 16x95, COT Parameter

50

V 3.0 – Reference Guide 2 - 21

Page 48

Roche Diagnostics Elecsys® 1010 Immunoassay System

Special cups

Dead Volume

(µL)

Control / calibrator vials 80

Reagents

Reagent capacity 6 reagent positions

Reagent detection Liquid level detection by S/R probe

Bottle volume of ProCell and

CleanCell 380 mL

Reagent ID 2D bar code, PDF 417

Incubator

Incubator capacity 128 assay cups

Volume of assay cups typically 200 µL, max. 400 µL

Incubation temperature 37 °C ± 0.3 °C

Incubation period 9/18 minutes

Measurement System

Measurement method Integral measurement of an

electrochemiluminescent signal

Calibration mode 2-point calibration

2 - 22 V 3.0 – Reference Guide

Page 49

PC

Processor 486 X

Floppy disk 3.5 FD/1.44 MB

Interfaces

Printer Centronics

HOST computer CCITT V.24/RS-232-C (bidirectional)

The host computer must comply with the

requirements of IEC 950

LCD S/W VGA - LCD with 640 x 480 pixels

Thermal Printer Paper width 110 mm

V 3.0 – Reference Guide 2 - 23

Page 50

Roche Diagnostics Elecsys® 1010 Immunoassay System

2 - 24 V 3.0 – Reference Guide

Page 51

3. Functional Sequence of Analysis

Übersicht

V 3.0 – Reference Guide 3 - 1

Page 52

Roche Diagnostics Elecsys® 1010 Immunoassay System

3.1 Introduction

The basic functional sequence of the system is detailed in this chapter using a

flow chart and a short description. An overview of the sequence of events for each

test protocol is graphically displayed. A detailed description using the test TSH as

an example provides insight into how the Elecsys 1010 operates.

3 - 2 V 3.0 – Reference Guide

Page 53

Flow Chart of the Analysis Sequence

Introduction

V 3.0 – Reference Guide 3 - 3

Page 54

Roche Diagnostics Elecsys® 1010 Immunoassay System

3.2 General Analysis Sequence

An immunological ECL test is made up of various pipetting steps, at least one

incubation period and a measurement step. Generally, at least three test

components (sample, reagent and microparticles) are pipetted into an assay cup.

After the appropriate incubation period, the reaction mixture is aspirated into the

measuring cell where the measurement process takes place. Each of these

pipetting cycles is performed within a defined period (approximately 60 seconds).

The number of pipetting steps and assay cups used, as well as the make up of

the reaction mixture, are dependent on the test method (refer to Chapter 3.3, Test

Sequences).

After each pipetting step, the sample/reagent probe is cleaned and, if necessary,

the microparticle mixer and sipper probe are also cleaned.

The following steps apply in principal to all methods. The sequence of the

individual processes differs from test to test.

Resuspension of the Microparticles

During this step the microparticles are resuspended by the mixer on the sample/

reagent arm at the beginning of a new run. Resuspension takes place before the

microparticle suspension is aspirated. At the same time, the S/R probe is

thoroughly cleaned. After resuspension, the mixer is cleaned with water in its

special rinse station.

Pipetting of at Least Two Liquids (e.g. Reagent 1 and Sample)

At the beginning of a run, at least one reagent and the sample or microparticles

are aspirated one after the other by the S/R probe. After each aspiration of a

liquid, the outside of the S/R probe is quickly rinsed at a rinse station. Afterwards,

all liquids are dispensed into an unused assay cup. The inside and outside of the

probe is then thoroughly cleaned again.

3 - 4 V 3.0 – Reference Guide

Page 55

General Analysis Sequence

First Incubation at 37 °C

The incubation period is 4.5 or 9 minutes, depending on the test. Tests without

pretreatment have two incubation periods, whereas tests with pretreatment

require additional incubation periods.

Pipetting of Additional Reagents (e.g. Reagent 2 and Microparticles)

In the second pipetting step, one or two liquids are pipetted (refer to Scan be

selected using the arrow keys Chapter 3.3, Test Sequences). The outside of the S/

R probe is rinsed at the rinse station after every aspiration of a liquid. The liquid is

then dispensed into an assay cup that contains the sample and the other liquids

from the first pipetting process.

Second Incubation at 37 °C

If necessary, a second incubation period of 4.5 or 9 minutes occurs, depending

on the test.

Additional Reagent Pipetting (Pretreatment assays)

For pretreatment assays, reagent pipetting similar to that described above for

“Pipetting of Additional Reagents” occurs.

Third Incubation at 37 °C

If necessary, a third incubation step (9 min) occurs for pretreatment assays.

Reaction Mixture Aspiration and Measurement

In this process, the sipper probe first aspirates ProCell to prepare the measuring

cell. Then, the sipper probe aspirates the reaction mixture and transfers it to the

measuring cell. After the sipper probe is washed at the rinse station and ProCell is

aspirated again, the ECL reaction can take place in the measuring cell.

Measuring Cell Cleaning and Results

Once the measurement is complete, the measuring cell is cleaned with CleanCell

and prepared for a new measurement process. At the same time, Elecsys 1010

calculates the results according to the measured signals.

V 3.0 – Reference Guide 3 - 5

Page 56

Roche Diagnostics Elecsys® 1010 Immunoassay System

3.3 Test Sequences

Legend

0 to 29 Test protocols

Test analysis steps

Diluent pipetting

Reagent 1 pipetting

Reagent 2 pipetting

Pretreatment reagent pipetting

Diluted sample pipetting once

Diluted sample pipetting twice

Symbols

Microparticle pipetting

Sample pipetting

Pretreatment

First incubation

Second incubation

Measurement

Addition of

Result of the addition

Transfer

New assay cup

3 - 6 V 3.0 – Reference Guide

Page 57

3.3.1 Test protocol

Test Sequences

V 3.0 – Reference Guide 3 - 7

Page 58

Roche Diagnostics Elecsys® 1010 Immunoassay System

3.4 Example of an Analysis Process

The following describes an analysis process on Elecsys 1010 using the test TSH

as an example. Test protocol number 2, used for the TSH test, is described in this

example (refer to the table on page 3-7).

In this example, sample position number 8 (bar code readable) is used and the

TSH reagent pack is loaded in position B. All positions on the sample/reagent disk

theoretically can be freely chosen for samples as well as reagent packs. The

system automatically recognizes the positions loaded with reagents and barcoded primary tubes due to the presence of a bar code. Samples in non-barcoded primary tubes or secondary cups (43-66) must be manually assigned a

position number.

There are four assay cup segments that can be loaded before the run. Elecsys

1010 uses the next unused assay cup for the first pipetting process. The position

of this cup is stored after it is initially used so that, if necessary, the relevant liquid

(e.g. Reagent 2) is pipetted into this assay cup during the second pipetting

process.

The diagrams below show the sample/reagent disk (S/R disk) and the incubator,

respectively.

Sample / Reagent disk

3 - 8 V 3.0 – Reference Guide

Page 59

Example of an Analysis Process

Incubator

The sample/reagent arm, with the S/R probe on one side and the microparticle

mixer on the other, can reach each of the 66 positions on the S/R disk and the

two STAT positions.

Each of the 128 incubator positions can be reached by the S/R probe as well as

the sipper probe.

V 3.0 – Reference Guide 3 - 9

Page 60

Roche Diagnostics Elecsys® 1010 Immunoassay System

3.4.1 Reagent 1, Reagent 2 and Sample Pipetting

The sample/reagent disk and the sample/reagent arm rotate in such a way that

the probe can reach the TSH reagent pack. While the S/R arm is rotating to the S/

R disk, 50 µL of air are aspirated into the S/R probe to form an air buffer between

the water in the liquid system and the liquids to be aspirated in the following

steps.

When the S/R arm has reached the TSH reagent pack, the probe is lowered into

the TSH reagent pack containing Reagent 1 until the probe has reached the liquid

surface, then 60 µL of Reagent 1 are aspirated.

To prevent carryover of Reagent 1, the outside of the probe is quickly cleaned.

The arm rotates to rinse station 1, the front rinse station for the S/R probe, and is

lowered for cleaning. In the meantime, the S/R disk has rotated so that the S/R

probe can reach the bottle containing Reagent 2.

3 - 10 V 3.0 – Reference Guide

Page 61

Example of an Analysis Process

The arm rotates out of the rinse station and back to the S/R disk. The S/R probe

aspirates 50 µL of Reagent 2.

V 3.0 – Reference Guide 3 - 11

Page 62

Roche Diagnostics Elecsys® 1010 Immunoassay System

The arm then returns to rinse station 1 where the S/R probe is cleaned again. At

the same time, the S/R disk rotates so that the probe can reach the necessary

sample cup. In this example, this is the sample cup at position number 8. After the

S/R arm has rotated back, it is lowered over position 8 until the probe reaches the

liquid surface. The probe aspirates 50 µL of sample. During aspiration, the probe

tip is kept just below the falling liquid level. Additionally, a check occurs to detect

whether clots have formed in the sample container. This clot detection check is

performed during every sample aspiration.

3 - 12 V 3.0 – Reference Guide

Page 63

Example of an Analysis Process

3.4.2 First Incubation

The probe now contains Reagent 1, Reagent 2 and sample. Next, the S/R arm

rotates to the incubator.

The probe dispenses the liquids in the next, unused assay cup.

The reaction mixture is incubated at 37 °C for 9 minutes. In the meantime, other

samples/tests can be processed.

After the liquids have been dispensed into an assay cup, the S/R arm rotates to

rinse station 2 and the inside and outside of the S/R probe are thoroughly

cleaned.

V 3.0 – Reference Guide 3 - 13

Page 64

Roche Diagnostics Elecsys® 1010 Immunoassay System

3.4.3 Resuspension of the Microparticles

While the S/R arm is rotating to rinse station 2, the microparticle mixer rotates to

the S/R disk so that the mixer can be lowered into the TSH reagent pack bottle

containing the microparticles. The S/R disk has already rotated to the correct

position.

At the same time as the S/R probe is being cleaned at rinse station 2, the

microparticle mixer starts to mix (resuspend) the microparticles. This process

takes place before each pipetting of the microparticles.

3 - 14 V 3.0 – Reference Guide

Page 65

Example of an Analysis Process

3.4.4 Microparticle Pipetting

After the resuspension of the microparticles and the thorough cleaning of the S/R

probe at rinse station 2, the S/R arm and the S/R disk rotate in such a way that

the probe can reach the bottle containing the microparticles.

On reaching the TSH reagent pack, the probe aspirates 40 µL of the microparticle

suspension. During the aspiration process, the automatic LLD check occurs.

Afterwards, the arm rotates to the incubator.

The probe now contains the microparticles. The incubator rotates so that the S/R

arm can reach the assay cup that contains the reaction mixture, Reagent 1,

Reagent 2 and sample, from the first pipettor step. The probe dispenses the

microparticles into the assay cup.

V 3.0 – Reference Guide 3 - 15

Page 66

Roche Diagnostics Elecsys® 1010 Immunoassay System

3.4.5 Second Incubation

The liquid mixture is again incubated at 37 °C for 9 minutes (Second incubation).

During this period, other samples/tests can be processed.

3 - 16 V 3.0 – Reference Guide

Page 67

Example of an Analysis Process

3.4.6 Measurement Stage

Before the reaction mixture is transferred to the measuring cell, the measuring cell

is pretreated with ProCell.

The sipper arm rotates to the bottle containing ProCell and the probe aspirates

ProCell. In this example, this is the ProCell and CleanCell Set 2 location. The

liquid is drawn through to the measuring cell.

Note

One ProCell and one CleanCell bottle form a set. The volumes of both bottles are

matched to one another. If a set is empty, the system automatically uses the

second set.

V 3.0 – Reference Guide 3 - 17

Page 68

Roche Diagnostics Elecsys® 1010 Immunoassay System

The sipper arm and incubator rotate towards one another so that the sipper probe

can reach the cup containing the TSH reaction mixture.

The arm is lowered and the sipper probe aspirates 130 µL of the reaction mixture;

the liquid is transferred to the measuring cell. The sipper arm then rotates to the

separate rinse station for the sipper probe and is lowered. The probe is quickly

cleaned from the outside.

3 - 18 V 3.0 – Reference Guide

Page 69

Example of an Analysis Process

The arm rotates to the bottle containing ProCell and the sipper probe aspirates

ProCell. In this example, this is Set 2. The liquid is drawn through to the

measuring cell.

V 3.0 – Reference Guide 3 - 19

Page 70

Roche Diagnostics Elecsys® 1010 Immunoassay System

3.4.7 Measurement and Evaluation

The measurement in the cell is performed at 28 °C. As soon as the ECL reaction

has taken place, the photomultiplier detects the emitted light and converts this

into measurement signals. Elecsys 1010 calculates the result from these signals.

The ECL process is described in Chapter 4, ECL Technology.

3.4.8 Measurement Cell Cleaning and Preparation for the Next Measurement

The sipper probe again aspirates ProCell to clean the measuring cell and to

prepare it for the next measurement. The measuring cell is rinsed out using this

liquid. The sipper arm then rotates to the bottle containing CleanCell and

aspirates CleanCell. Using this strong alkaline liquid, the measuring cell is

thoroughly cleaned and thus ready for the next measurement.

3 - 20 V 3.0 – Reference Guide

Page 71

4. ECL Technology

ECL

Technology

V 3.0 – Reference Guide 4 - 1

Page 72

Roche Diagnostics Elecsys® 1010 Immunoassay System

4.1 ECL Technology

The last decade has seen the development and refinement of many new

immunoassay measurement principles and systems. The major trend has been

away from liquid phase assays with radioisotopic labels and towards fast solidphase assays based on monoclonal antibodies. This development is moving

further towards precise and reliable non-isotopic, automated or semi-automated

laboratory assays with detection limits measured in the picomolar (10

attomolar (10

ECL Assay Principles

Electrochemiluminescent (ECL) processes are known to occur with numerous

molecules including compounds of ruthenium, osmium, rhenium or other

elements.

ECL is a process in which highly reactive species are generated from stable

precursors at the surface of an electrode. These highly reactive species react with

one another producing light.

The development of ECL/Origen immunoassays is based on the use of a

ruthenium(II)-tris(bipyridyl) [Ru (bpy)

final chemiluminescent product is formed during the detection step.

The chemiluminescent reactions that lead to the emission of light from the

ruthenium complex are initiated electrically, rather than chemically. This is

achieved by applying a voltage to the immunological complexes (including the

ruthenium complex) that are attached to streptavidin-coated microparticles. The

advantage of electrically initiating the chemiluminescent reaction is that the entire

reaction can be precisely controlled.

-18

) range.

2+

] complex and tripropylamine (TPA). The

3

-12

) and

4 - 2 V 3.0 – Reference Guide

Page 73

ECL

Use of the Ruthenium Complex

ECL technology uses a ruthenium chelate as the complex for the development of

light. Salts of ruthenium-tris(bipyridyl) are stable, water-soluble compounds. The

bipyridyl ligands can be readily modified with reactive groups to form activated

chemiluminescent compounds.

For the development of ECL immunoassays, [Ru(bpy)

2+

] N-hydroxysuccinimide

3

(NHS) ester is used because it can be easily coupled with amino groups of

proteins, haptens and nucleic acids. This allows the detection technology to be

applied to a wide variety of analytes.

Technology

The ruthenium complex

V 3.0 – Reference Guide 4 - 3

Page 74

Roche Diagnostics Elecsys® 1010 Immunoassay System

The ECL Reaction at the Electrode Surface

Detection of a ruthenium-labeled immune complex

Two electrochemically active substances, the ruthenium complex and

tripropylamine (TPA), are involved in the reactions that lead to the emission of

light. Both substances remain stable, as long as a voltage is not applied.

The ECL reaction of ruthenium tris(bipyridyl)2+ and tripropylamine occurs at the

surface of a platinum electrode. The applied voltage creates an electrical field,

which causes all the materials in this field to react. Tripropylamine is oxidized at

the electrode, releases an electron and forms an intermediate tripropylamine

radical-cation, which further reacts by releasing a proton (H+) to form a TPA

radical (TPA•).

In turn, the ruthenium complex also releases an electron at the surface of the

electrode thus oxidizing to form the [Ru(bpy)

3+

] cation. This ruthenium cation is

3

the second reaction component for the following chemiluminescent reaction with

the TPA radical.

4 - 4 V 3.0 – Reference Guide

Page 75

The ECL reaction at the electrode surface

ECL

Technology

TPA• and Ru(bpy)

Ru(bpy)

2+

and at the same time forms an excited state via energy transfer. This

3

3+

react with one another, whereby Ru(bpy)

3

3+

is reduced to

3

excited state is unstable and decays with emission of a photon at

620 nm to its original state. The reaction cycle can now start again. The

tripropylamine radical reduces to by-products which do not affect the

chemiluminescent process. TPA is used up and therefore must be present in

excess. The reaction is controlled by diffusion of the TPA and the amount of

ruthenium complex present. As TPA in the electrical field is depleted, the signal

strength (light) is slowly reduced once the maximum is reached.

Although during measurement, TPA is used up, the ruthenium ground state

complex is continually regenerated. This means that the ruthenium complex can

perform many light-generating cycles during the measurement process, therefore

showing an inherent amplification effect which contributes to the technology’s

sensitivity. Many photons can be created from one antigen-antibody complex.

V 3.0 – Reference Guide 4 - 5

Page 76

Roche Diagnostics Elecsys® 1010 Immunoassay System

ECL Signal Generation

The graph displays a typical ECL signal generation. Viewed from an electrical

perspective, the reaction can be explained as follows: When a voltage is applied

to the detection cell electrode, a peak of light emission occurs over a short time

interval and can be detected as the resulting ECL signal. A defined area under the

curve is measured around the intensity maximum.

ECL intensity (counts) applied voltage [mV]

1500

350,000

300,000

250,000

200,000

150,000

100,000

50,000

0

0.00

0.20

0.40 0.60 0.80

1.00

1.20

time [sec.]

1200

900

600

300

0

ECL signal generation

The dotted line indicates the voltage at the electrode used to generate the ECL

signal. The solid line is the actual light output measured by the photomultiplier

detector.

4 - 6 V 3.0 – Reference Guide

Page 77

ECL

ECL Measuring Cell

The core of the system is the ECL detection cell, which is designed as a flowthrough cell. Essentially, three operating steps are performed in the measuring cell:

•

Bound/Free Separation

Using a magnet, the streptavidin microparticles that are coated with antigenantibody complexes, are uniformly deposited on the working electrode. A

system buffer (ProCell) is used to wash the particles on the working electrode

and to flush out the excess reagent and sample materials from the measuring

cell.

•

ECL Reaction

The magnet is removed and a voltage is then applied to the electrode on which

the microparticles, coated with antigen-antibody complexes, are deposited to

initiate the ECL reaction. The light emission is measured with a

photomultiplier. The system then uses the corresponding signals for the

calculation of results.

•

Release of Microparticles and Cell Cleaning

Once the measurement is completed, the paramagnetic microparticles are

washed away from the electrode surface with a special cleaning solution

(CleanCell). The surface of the measuring cell is regenerated by varying the

potential on the electrode. The cell is then ready for another measurement.

Technology

ECL measuring cell

V 3.0 – Reference Guide 4 - 7

Page 78

Roche Diagnostics Elecsys® 1010 Immunoassay System

Advantages of ECL Technology

Electrochemiluminescence is a highly innovative technology that offers distinct

advantages over other detection techniques.

• Extremely stable non-isotopic label allows liquid reagent convenience.

• Enhanced sensitivity in combination with short incubation times means high

quality assays and fast result turnaround.

• Large measuring range of five orders of magnitude minimizes dilutions and

repeats, reducing handling time and reagent costs.

• Applicable for the detection of all analytes providing a solid platform for

menu expansion.

Sandwich assay for high

molecular weight analytes

Competitive assay for low

molecular weight haptens

surface magnetic

microparticle

analyte

Bridge assay to determine

IgG and IgM

DNA/RNA probe assays

antibody

Streptavidin-biotin

binding

DNA probe

ECL label

ECL assay types

4 - 8 V 3.0 – Reference Guide

Page 79

5. Test Principles for Immunoassays

V 3.0 – Reference Guide 5 - 1

Page 80

Roche Diagnostics Elecsys® 1010 Immunoassay System

5.1 Test Principles

Three test principles are available on the Elecsys 1010 analyzer: competitive

principle for extremely small analytes, sandwich principle (one or two steps) for

larger analytes and a bridging principle to detect antibodies in the sample.

5.1.1 Competitive Principle

This principle is applied to analytes of low molecular weight, such as FT3.

●

In the first step, sample and a specific anti-T3 antibody labeled with a

ruthenium complex are combined in an assay cup.

●

After addition of biotinylated T3 and streptavidin-coated paramagnetic

microparticles, the still free binding sites of the labeled antibody become

occupied with formation of an antibody-hapten complex. The entire complex

is bound to the microparticle via interaction of biotin and streptavidin.

●

After the second incubation, the reaction mixture containing the immune

complexes is transported into the measuring cell. The immune complexes are

magnetically entrapped on the working electrode, but unbound reagent and

sample are washed away by ProCell.

●

In the ECL reaction, the conjugate is a ruthenium-based derivative and the

chemiluminescent reaction is electrically stimulated to produce light. The

amount of light produced is indirectly proportional to the amount of antigen in

the patient sample.

Evaluation and calculation of concentration of the antigen are carried out by a

calibration curve established using standards of known antigen concentration.

5 - 2 V 3.0 – Reference Guide

Page 81

Test Principles

V 3.0 – Reference Guide 5 - 3

Page 82

Roche Diagnostics Elecsys® 1010 Immunoassay System

5.1.2 Sandwich Principle

The sandwich principle is applied to higher molecular weight analytes, such as

thyroid-stimulating hormone (TSH).

●

In the first step, the patient sample is combined with a reagent containing

biotinylated TSH antibody and a ruthenium-labeled TSH-specific antibody in an

assay cup. During a nine-minute incubation step, antibodies capture the TSH

present in the sample.

●

In the second step, streptavidin-coated magnetic microparticles are added.

During a second nine-minute incubation, the biotinylated antibody attaches to

the streptavidin-coated surface of the microparticles.

●

After the second incubation, the reaction mixture containing the immune

complexes is transported into the measuring cell; the immune complexes are

magnetically entrapped on the working electrode, but unbound reagent and

sample are washed away by ProCell.

●

In the ECL reaction, the conjugate is a ruthenium-based derivative and the

chemiluminescent reaction is electrically stimulated to produce light. The

amount of light produced is directly proportional to the amount of antigen in

the sample.

Evaluation and calculation of concentration of the antigen or analyte are carried

out by a calibration curve established using standards of known antigen

concentration.

5 - 4 V 3.0 – Reference Guide

Page 83

Test Principles

V 3.0 – Reference Guide 5 - 5

Page 84

Roche Diagnostics Elecsys® 1010 Immunoassay System

5.1.3 Bridging Principle

The bridge principle is similar to the sandwich principle, except that the assay is

designed to detect antibodies, not antigens, (e.g., IgG, IgM and IgA). This is

accomplished by including biotinylated and ruthenium-labeled antigens in the

reagents for which the targeted antibody has affinity.

●

In the first step, serum antibodies bind with the biotinylated and rutheniumlabeled antigens to form an immune complex.

●

The immune complex then reacts with streptavidin-coated microparticles via

the biotinylated antigen.

●

After the second incubation, the reaction mixture containing the immune

complexes is transported into the measuring cell; the immune complexes are

magnetically entrapped on the working electrode, but unbound reagent and

sample are washed away by ProCell.

●

In the ECL reaction, the conjugate is a ruthenium-based derivative and the

chemiluminescent reaction is electrically stimulated to produce light. The

amount of light produced is directly proportional to the amount of analyte in

the sample.

Evaluation and calculation of the concentration of the antibody are carried out by

a calibration curve established using standards of known antibody

concentrations.

5 - 6 V 3.0 – Reference Guide

Page 85

Test Principles

V 3.0 – Reference Guide 5 - 7

Page 86

Roche Diagnostics Elecsys® 1010 Immunoassay System

5 - 8 V 3.0 – Reference Guide

Page 87

6. Calibration

V 3.0 – Reference Guide 6 - 1

Page 88

Roche Diagnostics Elecsys® 1010 Immunology System

6.1 Introduction

Calibrations are performed to determine the exact concentration of unknown

substances. This allows a result to be determined as accurately as possible

independent of the reagent lot, reagent conditions and the analysis system.

Roche Diagnostics produces a master calibration curve during production of the

reagent that is then encoded in the 2D bar code of the relevant reagent pack. This

information is then transferred to the Elecsys 1010. This master calibration curve

is then updated by measuring two calibrators under routine laboratory conditions.