Page 1

Elecsys 1010 Service Manual

Service ManualService Manual

Service Manual

Service ManualService Manual

Elecsys 1010Elecsys 1010

Elecsys 1010

Elecsys 1010Elecsys 1010

FINAL 2.1 - February 2000

Page 2

Elecsys 1010 Service Manual

This manual is published by

Roche Diagnostics GmbH,

Technical Product Management

and Service Department.

© Roche Diagnostics GmbH

All rights reserved.

No part of this publication may be

reproduced without the expressed written

permission of Roche Diagnostics GmbH.

Disclaimer

Roche Diagnostics GmbH makes no representation or warranties with respect to

the contents of this documentation and

specifically disclaims any implied warranties,

including the implied warranties of

merchantability and fitness for a particular

purpose.

In no case shall

Roche Diagnostics GmbH be liable for

incidental or consequential damages.

FINAL 2.1 - February 2000

Page 3

Elecsys 1010 Service Manual

How to Use this ManualHow to Use this Manual

How to Use this Manual

How to Use this ManualHow to Use this Manual

It may occur that identical components occur several times in Elecsys 1010 and perform different functions. Every component

has an ID number in the figures.

Photo Coupler Assy, preadjusted (416)Photo Coupler Assy, preadjusted (416)

Photo Coupler Assy, preadjusted (416)

e.g.

Photo Coupler Assy, preadjusted (416)Photo Coupler Assy, preadjusted (416)

Photo Coupler Assy, preadjusted (418)Photo Coupler Assy, preadjusted (418)

Photo Coupler Assy, preadjusted (418)

Photo Coupler Assy, preadjusted (418)Photo Coupler Assy, preadjusted (418)

416

418

D-10

In Chapter 5 Electronics the components are referred to as functional units.

Photo Coupler Magnet Home (418)Photo Coupler Magnet Home (418)

Photo Coupler Magnet Home (418)

e.g .

Photo Coupler Magnet Home (418)Photo Coupler Magnet Home (418)

Photo Coupler Magnet Cell (416)Photo Coupler Magnet Cell (416)

Photo Coupler Magnet Cell (416)

Photo Coupler Magnet Cell (416)Photo Coupler Magnet Cell (416)

FINAL 2.1 - February 2000

Page 4

Elecsys 1010 Service Manual

In Chapter 4 Mechanics the part name is used. In addition, the information is contained whether the part can be ordered as a spare

part ,or if it consists of several components.

Photo Coupler Assy, preadjusted (418)Photo Coupler Assy, preadjusted (418)

Photo Coupler Assy, preadjusted (418)

e.g.

Photo Coupler Assy, preadjusted (418)Photo Coupler Assy, preadjusted (418)

Replaceable Components:

- Peltier Assy Preheater (302)

- Preheater Sipper (306)

- PCB Preamp High Voltage (310)

- Holder Photo Coupler MD1 (326) consisting of:

- Photo Coupler Holder (419)

- Photo Coupler Holder (327)

--

Photo Coupler Assy, preadjusted (418)Photo Coupler Assy, preadjusted (418)

-

Photo Coupler Assy, preadjusted (418)

--

Photo Coupler Assy, preadjusted (418)Photo Coupler Assy, preadjusted (418)

In Chapter 8.2 Part Identification shows where this part is used in Chapter 4 or 5.

Photo Coupler Assy, preadjusted (416)Photo Coupler Assy, preadjusted (416)

Photo Coupler Assy, preadjusted (416)

e.g.

Photo Coupler Assy, preadjusted (416)Photo Coupler Assy, preadjusted (416)

Photo Coupler Assy, preadjusted (418)Photo Coupler Assy, preadjusted (418)

Photo Coupler Assy, preadjusted (418)

Photo Coupler Assy, preadjusted (418)Photo Coupler Assy, preadjusted (418)

NoNo

Part Name EnglishPart Name English

No

Part Name English

NoNo

Part Name EnglishPart Name English

412 TUBING SIPPER (2) 0,8 Detection Module

416416

Photo Coupler Assy, preadjustedPhoto Coupler Assy, preadjusted

416

Photo Coupler Assy, preadjusted

416416

Photo Coupler Assy, preadjustedPhoto Coupler Assy, preadjusted

417 Eccentric Ring, 2 pcs Detection Module

418418

Photo Coupler Assy, preadjustedPhoto Coupler Assy, preadjusted

418

Photo Coupler Assy, preadjusted

418418

Photo Coupler Assy, preadjustedPhoto Coupler Assy, preadjusted

419 Photo Coupler Holder Detection Module

527 Cable M10 Detection Module

In Chapter 8.3 Spare Parts, components that cannot be ordered individually do not have an ID. The part name is followed by a

cross reference to the spare part, in which the component is contained.

Photo Coupler Assy, preadjusted (416)Photo Coupler Assy, preadjusted (416)

Photo Coupler Assy, preadjusted (416)

e.g.

Photo Coupler Assy, preadjusted (416)Photo Coupler Assy, preadjusted (416)

Photo Coupler Assy, preadjusted (418)Photo Coupler Assy, preadjusted (418)

Photo Coupler Assy, preadjusted (418)

Photo Coupler Assy, preadjusted (418)Photo Coupler Assy, preadjusted (418)

NoNo

No

NoNo

IDID

ID

IDID

Part Name EnglishPart Name English

Part Name English

Part Name EnglishPart Name English

ElectronicsElectronics

Electronics

ElectronicsElectronics

BP 1BP 1

BP 1

BP 1BP 1

BP 1BP 1

BP 1

BP 1BP 1

MechanicsMechanics

Mechanics

MechanicsMechanics

Detection ModuleDetection Module

Detection Module

Detection ModuleDetection Module

Detection ModuleDetection Module

Detection Module

Detection ModuleDetection Module

Spare PartSpare Part

Spare Part

Spare PartSpare Part

BTOBTO

BTO

BTOBTO

RR

AA

R

RR

ABCABC

A

ABC

AA

ABCABC

326 1234567890 HOLDER PHOTO COUPLER MD1 X A

416416

416

416416

418418

418

418418

419 Photo Coupler Holder, Part of 326

327 Photo Coupler Holder, Part of 326

FINAL 2.1 - February 2000

Photo Coupler Assy, preadjusted, Part of 326Photo Coupler Assy, preadjusted, Part of 326

Photo Coupler Assy, preadjusted, Part of 326

Photo Coupler Assy, preadjusted, Part of 326Photo Coupler Assy, preadjusted, Part of 326

Photo Coupler Assy, preadjusted, Part of 326Photo Coupler Assy, preadjusted, Part of 326

Photo Coupler Assy, preadjusted, Part of 326

Photo Coupler Assy, preadjusted, Part of 326Photo Coupler Assy, preadjusted, Part of 326

Page 5

Elecsys 1010 Service Manual

11

Application / IntroductionApplication / Introduction

1

Application / Introduction

11

Application / IntroductionApplication / Introduction

22

InstallationInstallation

2

Installation

22

InstallationInstallation

33

FluidicsFluidics

3

Fluidics

33

FluidicsFluidics

44

MechanicsMechanics

4

Mechanics

44

MechanicsMechanics

55

ElectronicsElectronics

5

Electronics

55

ElectronicsElectronics

66

SoftwareSoftware

6

Software

66

SoftwareSoftware

77

Trouble ShootingTrouble Shooting

7

Trouble Shooting

77

Trouble ShootingTrouble Shooting

88

Spare PartsSpare Parts

8

Spare Parts

88

Spare PartsSpare Parts

1010

10

1010

99

Host InterfaceHost Interface

9

Host Interface

99

Host InterfaceHost Interface

MaintenanceMaintenance

Maintenance

MaintenanceMaintenance

AppendixAppendix

Appendix

AppendixAppendix

FINAL 2.1 - February 2000

Page 6

Elecsys 1010 Service Manual

FINAL 2.1 - February 2000

Page 7

Elecsys 1010 Service Manual

11

1

11

Application / IntroductionApplication / Introduction

Application / Introduction

Application / IntroductionApplication / Introduction

1.11.1

1.1

1.11.1

1.21.2

1.2

1.21.2

11

1

11

System DescriptionSystem Description

System Description

System DescriptionSystem Description

1.1.11.1.1

1.1.1

1.1.11.1.1

1.1.21.1.2

1.1.2

1.1.21.1.2

1.1.31.1.3

1.1.3

1.1.31.1.3

System SpecificationSystem Specification

System Specification

System SpecificationSystem Specification

.3.3

Operator Precautions andOperator Precautions and

.3

Operator Precautions and

.3.3

Operator Precautions andOperator Precautions and

HazardsHazards

Hazards

HazardsHazards

1.3.11.3.1

1.3.1

1.3.11.3.1

Instrument IntroductionInstrument Introduction

Instrument Introduction

Instrument IntroductionInstrument Introduction

Principles of the AnalysisPrinciples of the Analysis

Principles of the Analysis

Principles of the AnalysisPrinciples of the Analysis

Pipetting SchemePipetting Scheme

Pipetting Scheme

Pipetting SchemePipetting Scheme

1.1.3.11.1.3.1

1.1.3.1

1.1.3.11.1.3.1

Contact PersonsContact Persons

Contact Persons

Contact PersonsContact Persons

Timing DiagramTiming Diagram

Timing Diagram

Timing DiagramTiming Diagram

__________________________________________________________________________________________

_____________________________________________

__________________________________________________________________________________________

________________________________________________________________________________

________________________________________

________________________________________________________________________________

______________________________________________________________________________________________

_______________________________________________

______________________________________________________________________________________________

__________________________________________________________________________

_____________________________________

__________________________________________________________________________

____________________________________________________________________________________________

______________________________________________

____________________________________________________________________________________________

____________________________________________________________________________________

__________________________________________

____________________________________________________________________________________

________________________________________________________________________________

________________________________________

________________________________________________________________________________

__________________________________________________________________________________

_________________________________________

__________________________________________________________________________________

1515

15

1515

1818

18

1818

2020

20

2020

2020

20

2020

11

1

11

11

1

11

55

5

55

66

6

66

1.41.4

1.4

1.41.4

1.3.21.3.2

1.3.2

1.3.21.3.2

1.3.31.3.3

1.3.3

1.3.31.3.3

Service ConceptService Concept

Service Concept

Service ConceptService Concept

1.4.11.4.1

1.4.1

1.4.11.4.1

1.4.21.4.2

1.4.2

1.4.21.4.2

Proved SecurityProved Security

Proved Security

Proved SecurityProved Security

Precautions and HazardsPrecautions and Hazards

Precautions and Hazards

Precautions and HazardsPrecautions and Hazards

Service LevelService Level

Service Level

Service LevelService Level

RA-Procedure (Replacement of defective parts)RA-Procedure (Replacement of defective parts)

RA-Procedure (Replacement of defective parts)

RA-Procedure (Replacement of defective parts)RA-Procedure (Replacement of defective parts)

______________________________________________________________________________________________

_______________________________________________

______________________________________________________________________________________________

______________________________________________________________________________

_______________________________________

______________________________________________________________________________

__________________________________________________________________________________

_________________________________________

__________________________________________________________________________________

__________________________________________________________________________________________________

_________________________________________________

__________________________________________________________________________________________________

________________________________________

____________________

________________________________________

2020

20

2020

2020

20

2020

2222

22

2222

2222

22

2222

2222

22

2222

FINAL 2.1 - February 2000 Chapter 1

Page 8

Elecsys 1010 Service Manual

FINAL 2.1 - February 2000 Chapter 1

Page 9

Elecsys 1010 Service Manual

1.11.1

1.1

1.11.1

1.1.11.1.1

1.1.1

1.1.11.1.1

System DescriptionSystem Description

System Description

System DescriptionSystem Description

Instrument IntroductionInstrument Introduction

Instrument Introduction

Instrument IntroductionInstrument Introduction

F-9F-9

F-9

F-9F-9

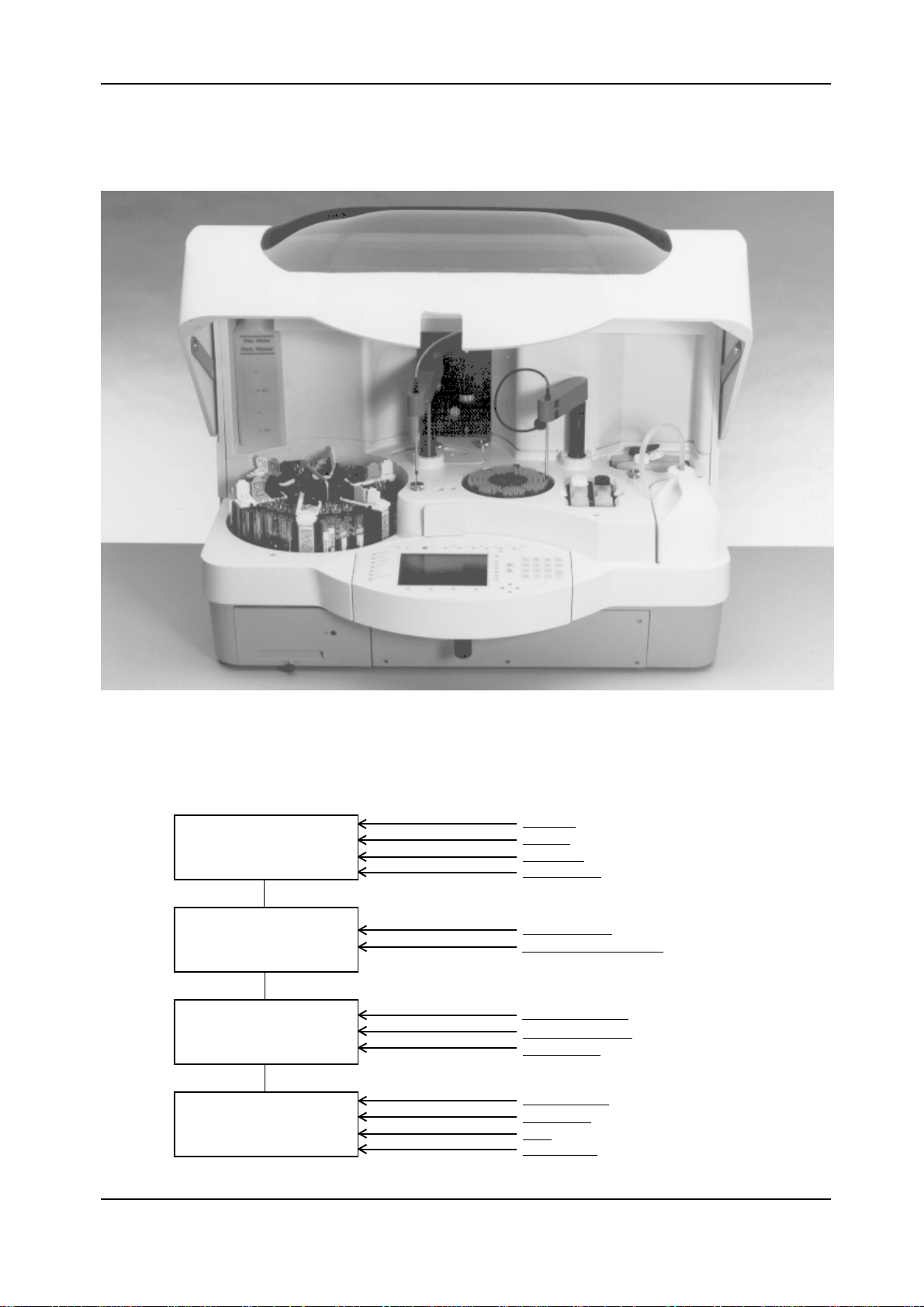

The sequence of operation of Elecsys 1010 is as follows:

Pick-up of sample and

reagents

Incubation

Pick-up of incubate and

addition of wash and buffer

solutions

Measurement of

luminescence, data

evaluation and output

S/R rotor

MFA s/r

S/R dilutor

Clot detection

Incubation rotor

Temperature (incubator)

Bottle temperature

MFA assy (sipper)

Sipper dilutor

Measuring cell

Potentiostat

PMT

Temperature

FINAL 2.1 - February 2000

Chapter 1Page 1

Page 10

Elecsys 1010 Service Manual

IntroductionIntroduction

Introduction

IntroductionIntroduction

When the instrument cover top is closed, loading of two

This System Description explains functions and their

interrelationship.

Short Description of the InstrumentShort Description of the Instrument

Short Description of the Instrument

Short Description of the InstrumentShort Description of the Instrument

The Elecsys 1010 is a Multi-Batch-Analyzer which analyzes

immunological tests according to the principle of electrochemical luminescence (ECL). This measuring system is

also called ORIGEN® technology. The emitted photons are

measured with a photomultiplier (photon counts).

STAT (short-turn-around-time) samples is possible outside

of the direct range of action of the MFA arms and rotors. Pull

out the control panel like a drawer, behind which the holder

for the above mentioned STAT samples is located. By

pushing the control panel back in, the STAT samples are

within the direct range of the pipette needle under the closed

instrument cover without mechanically or logically

interrupting an ongoing process.

Elecsys 1010 has two driving blocks for the sample/

reagent rotor and the incubation rotor.

Elecsys 1010 has all the modules and components

necessary for executing the entire analysis including the

measurements and evaluation. When operating the

instrument (e.g. for test selection and sample placement),

the user is guided by menus on the keyboard. Softkeys and

function keys can be used for interacting with the

instrument. Samples (both in primary tubes and in secondary

cups), reagents and calibrators are to be positioned on the

sample/ reagent (s/r) rotor. A special reagent bottle

combination (RackPack) contains the reagents needed for

a test. Each RackPack has a 2-dimensional bar code with

all data specific of the test. Positive user identification

(PSID) is possible with samples in primary tubes. With

samples in secondary cups, patients are identified manually

by using the keyboard. After reading the bar code, the RUN

is started and performed automatically.

CalibrationCalibration

Calibration

CalibrationCalibration

At the beginning of a RUN a calibration can be performed.

The system imposes a full calibration

- if a new reagent (with a new batch number) is put in.

- at regular time intervals (specific of the reagent)

This is done by calibrators specific of the test (normally 2

levels).

Quality ControlQuality Control

Quality Control

Quality ControlQuality Control

The instrument software contains all programs necessary

for the quality control. Data input, management and security

is done by using the keyboard.

Instrument AssemblyInstrument Assembly

Instrument Assembly

Instrument AssemblyInstrument Assembly

ELECSYS 1010 is a desk top model and is suitable for a

standard laboratory bench. The instrument can be loaded

from the front. The instrument cover top must be closed

during the RUN.

The sample/reagent rotor is divided into 6 segments. The

two outer trays can hold samples in so-called primary tubes

of various diameters and heights. Control and calibrator

liquids are normally also positioned in these trays. A

maximum of 6 RackPacks with 2 reagents and one bead

container each are arranged radially between the sample

segments. The two inner trays are provided for secondary

cups. The labels on the primary tubes on the two outer trays

and the RackPacks can be read by a bar-code reader

(BCR).

The rotor assy is equipped with toothed disks and LEDs for

controlling and checking the rotor functions. The sample/

reagent rotor is removable.

The incubation rotor is an aluminum block heated to 37°C.

It can hold 4 identical segments with 32 incubation vessels

each. These incubation vessels are small conical plastic

tubes that hold the incubation material. When preparing the

RUN, the user loads the incubation rotor with the 4 segments.

The incubation rotor is not removable.

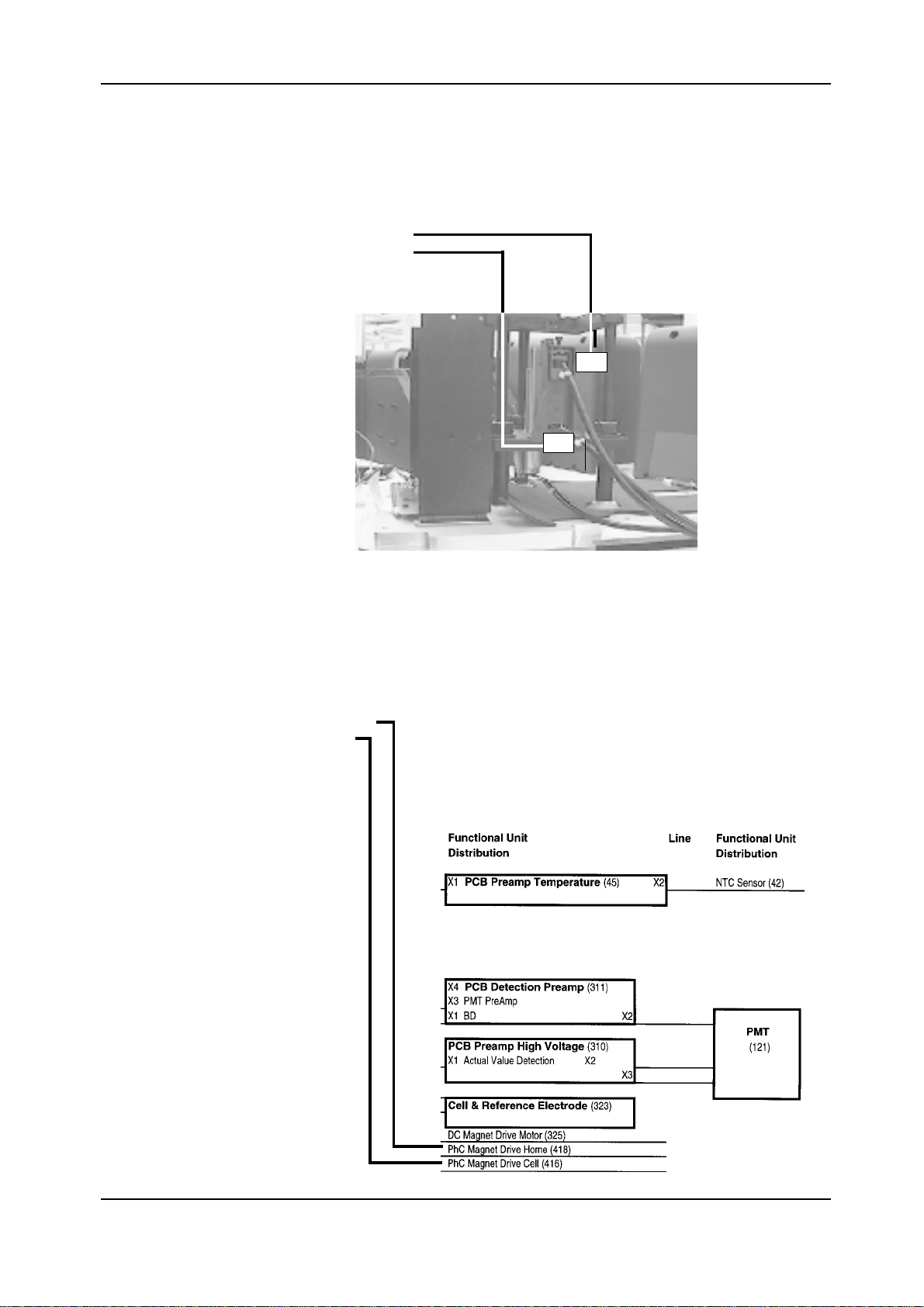

Detection ModuleDetection Module

Detection Module

Detection ModuleDetection Module

The ECL measuring cell is located in the detection module.

The photomultiplier (PMT), which is shielded from

electromagnetic radiation by a special housing, as well as

the holder for the pre-amplifier and the high-voltage module

are located above the measuring cell. The magnet with the

drive for the bead capturing is under the measuring cell. The

magnet is moved vertically from below to the bottom of the

measuring cell by a motor/spindle unit. This internal

assembly is incorporated in a housing, which serves as an

optical, electrical and thermal shield. The optimum

temperature for the process of ORIGEN

®

technology is

28°C. Therefore, the temperature of the entire detection

module is set at 28°C.

MFA AssysMFA Assys

MFA Assys

MFA AssysMFA Assys

The instrument is designed to be serviced exclusively from

the front, i.e. all components can be taken out and exchanged

from the front.

The functional elements (dilutors, rotors, wash stations,

bottle temperature assys) have covers that can be easily

removed for service. The keyboard is located outside of

the closed instrument cover top.

FINAL 2.1 - February 2000

The MFA assys transport the

a) sample/reagent from the sample/reagent rotor to

the incubation vessels and

b) incubation material as well as ProCell and CleanCell

to the measuring cell.

The ProCell is a liquid required for generating the ECL

signal. CleanCell is an auxiliary liquid used for cleaning the

measuring cell and preparing it for the next measurement.

Page 2

Chapter 1

Page 11

Elecsys 1010 Service Manual

All components involved in the sample/reagent processes

are cleaned with system water.

Arms are mounted on the MFAs. The sample arm holds the

sample needle and the bead mixer. The sipper arm holds

the sipper needle. The LLD electronic system and the

contact sensory system (crash detection) are also located

in the arms. The assembly of both MFAs is identical except

for the arm adapters.

The contact sensory system consists of mechanical and

electronic hardware components. It records the contact of

the needle and the bead mixer with a solid surface, e.g. the

bottom of the container or a closed RackPack.

Rotation and lifting are controlled by toothed disks / vanes

and photo couplers. Horizontal and vertical movements are

normally performed in succession.

Bottle TemperatureBottle Temperature

Bottle Temperature

Bottle TemperatureBottle Temperature

Elecsys 1010 has 2 bottle temperature systems, one for

ProCell bottle and one for CleanCell bottle. Bottles are

refrigerated to approx. 8°C and will reach the desired

temperature of 28°C after approx. 1hr. The actual

temperature is controlled by NTC resistors in the housing

walls.

by two membrane pumps.

Another membrane pump is located on the back of the

s/r dilutor. This pump has the following functions:

1. Fill the s/r system with system water.

2. Rinse s/r tubing and needle after pipetting.

ValvesValves

Valves

ValvesValves

The flow of system water to the wash stations for bead

mixer, s/r needle and sipper needle is controlled by four

valves (2-way).

The water discharge from the wash stations is controlled by

four valves (3-way).

Various liquid levels in the wash stations are possible by

setting the 3-way valves at different positions.

Another valve controls the flow of the measuring material

to the measuring cell.

Wash StationsWash Stations

Wash Stations

Wash StationsWash Stations

Elecsys 1010 has four wash stations. There are two wash

stations for the s/r needle and one wash station each for the

sipper needle and the bead mixer. The wash stations use

system water.

LLDLLD

LLD

LLDLLD

DilutorsDilutors

Dilutors

DilutorsDilutors

Elecsys 1010 has 2 dilutors. These are glass cylinders in

which pistons are precisely moved at a defined number of

increments. When going down, liquids are aspirated. When

going up, an exact amount of liquid is discharged by

displacement. The direction of the liquid flow can be

controlled by reversing valves at the entrance of the dilutors.

The dilutors are moved by stepping motors.

The two dilutors have different functions:

The needle of the s/r dilutor aspirates the sample, reagents

and microparticles in a defined sequence. The media are

separated from the system liquid (H

The aspirated material is discharged into the incubation

O) by an air bubble.

2

vessels through the sample needle. After the sample/

reagent process, the needle is internally cleaned with

system water by means of the rinsing pump.

The sipper dilutor is located behind the measuring cell and

pulls the incubate, ProCell and CleanCell in a defined

sequence through the measuring cell. Then the

measurement is performed. After that the needle is internally

rinsed with CleanCell. The needle is externally cleaned with

system water.

PumpsPumps

Pumps

PumpsPumps

The s/r and the sipper needle have one liquid level detection

unit (LLD) each. The s/r-LLD detects samples, reagents,

incubate and wash water. The sipper LLD detects incubate,

ProCell, CleanCell and wash water.

Clot DetectionClot Detection

Clot Detection

Clot DetectionClot Detection

On the sample/reagent side, there is a risk of (blood) clot

formation in the samples. This can be caused by pollution

and/or belated clotting of the samples. Changes in the

vacuum profile when picking up the samples are identified

as clots by means of a differential pressure converter. The

appropriate cleaning steps will be taken.

PMTPMT

PMT

PMTPMT

The photomultiplier tube (PMT) receives and amplifies the

luminescence signal and converts it to an equivalent voltage.

The PMT window is located at a defined distance vertically

above the cell work electrode. High-voltage power supply

is required for amplification.

High-VoltageHigh-Voltage

High-Voltage

High-VoltageHigh-Voltage

High-voltage is used for amplifying the luminescence signal

generated in the measuring cell. The control range spans

from 500 V to1100 V.

The instrument has 4 built-in pumps. The waste pump, a

peristaltic pump, pumps the measuring material and system

liquids into the waste container. The wash stations are fed

FINAL 2.1 - February 2000

PotentiostatPotentiostat

Potentiostat

PotentiostatPotentiostat

The potentiostat controls the electrochemical redox process

in the cell.

Chapter 1Page 3

Page 12

Elecsys 1010 Service Manual

Measuring CellMeasuring Cell

Measuring Cell

Measuring CellMeasuring Cell

Power Supply AssyPower Supply Assy

Power Supply Assy

Power Supply AssyPower Supply Assy

The cell has three electrodes: the work electrode (on which

the microparticles are deposited), the counter electrode

and the reference electrode. For the measurement, a

constant voltage is applied between work electrode and

counter electrode.

It is equipped with an input for input voltages of approx. 80

- 260 volts and 50-60 Hz. The fuses are not accessible to

the customer and can only be exchanged by service

personnel.

Rotor / Dilutor / MFA DrivesRotor / Dilutor / MFA Drives

Rotor / Dilutor / MFA Drives

Rotor / Dilutor / MFA DrivesRotor / Dilutor / MFA Drives

The rotors, dilutor pistons and the MFAs are moved by

stepping motors. In order to avoid the loss of steps, the

motions are controlled by photo couplers and toothed

disks. Moreover, forward/backward motions can be

recognized by two photo couplers placed at an angle of 90°.

TemperaturesTemperatures

Temperatures

TemperaturesTemperatures

Elecsys 1010 has 4 systems for setting the temperatures

of liquids.

The luminescence liquid is measured at a temperature of

28°C. The temperatures of the incubate picked up by the

incubator and the liquids used for the measurements

(CleanCell and ProCell) are preset inside the detection

module. The immunological reaction occurs at 37°C

(incubator temperature).

PCPC

PC

PCPC

The PC is a standard PC assembly (CPU 486 DX 2,

66MHz, 8MB RAM) with Roche-owned functions. An 1.44

MB floppy disk drive serves as drive a. The system can be

started and reloaded from disk drive a:. A flash-E

2

PROM

serves as a hard disk replacement. The general program

and changeable parameters are filed here. The LC display

is controlled by the VGA controller.

Barcode Reader / BCRBarcode Reader / BCR

Barcode Reader / BCR

Barcode Reader / BCRBarcode Reader / BCR

A bar-code reader (BCR) is attached to the sample/reagent

rotor. It reads and decodes primary sample tubes (on the

1st and 2nd tray on the rotor) and reagent RackPacks

whenever the rotor passes the reader and transfers the

data to the PC by a built-in RS 232 interface. The reader

decodes 2-dimensional (PDF 417) and all standard bar

codes.

Software Distribution /ProcessorsSoftware Distribution /Processors

Software Distribution /Processors

Software Distribution /ProcessorsSoftware Distribution /Processors

The entire Elecsys 1010 software is distributed over a total

of 8 processors. The master board has a 486 processor.

The measuring, sipper, temperature, rotor and s/r modules

have an 80196 processor. The incubation module and the

clot detection are controlled by an 8051derivative. The

keyboard assy and the printer have one CPU each.

Keyboard AssyKeyboard Assy

Keyboard Assy

Keyboard AssyKeyboard Assy

The keyboard assy consists of the keyboard, the keyboard

controller, an acoustic signal transmitter, the LC display

and some LEDs. The keys are short-stroke touch contact

keys. An additional keyboard can be connected to the

bottom side of the keyboard assy by using a 5-pin plug

(standard keyboard plug). One non-standard function is a

signal transmitter (piezo) that can be activated on several

frequencies. The display is a 640 x 480 dot LC display. In

order to prevent reflections when reading the display in the

keyboard assy drawer, it is possible to incline it.

PrinterPrinter

Printer

PrinterPrinter

Elecsys 1010 has a thermoprinter with a printing width of

640 pixels. This corresponds to the display resolution. An

immediate hard copy output is possible.

FINAL 2.1 - February 2000

Page 4

Chapter 1

Page 13

Elecsys 1010 Service Manual

1.1.21.1.2

1.1.2

1.1.21.1.2

Principles of the AnalysisPrinciples of the Analysis

Principles of the Analysis

Principles of the AnalysisPrinciples of the Analysis

See Chapter 5 of the Operator's Manual for

details of the test principles used on Elecsys

1010.

FINAL 2.1 - February 2000

Chapter 1Page 5

Page 14

Elecsys 1010 Service Manual

1.1.31.1.3

1.1.3

1.1.31.1.3

Run

This chapter describes processes going on in different

tests, e g. the placement of STAT samples during the run,

the automatic rerun and the system preparation after

start, as well as system evaluation at the end of a run.

Assay Protocols

There are 24 independent assay protocols used for

determining the pipetting scheme of tests. Further

protocols (no. 24 to no. 26) are used for checking the

instrument.

The assay protocols are stored in the system (max. 64)

and can only be modified and/or extended by a software

update.

In each test a minimum of four liquids, the sample itself,

reagent 1, reagent 2 and the microparticles, are processed.

The following abbreviations will be used for the liquids:

MP: Microparticles

B: Microparticles (test RackPack, assay RackPack)

R0: Diluent ("all-purpose diluent", special RackPack)

RM: Pretreatment solution for IgM or IgG tests

PS: Prereaction solution (pretreatment solution in

RI: Reagent 1 (assay RackPack )

R2: Reagent 2 (assay RackPack )

S: Undiluted sample/ calibrator/ check

DL: Diluted sample/ calibrator/ check

D: Aspiration into the measuring cell and optical

i: Incubation time

Pipetting SchemePipetting Scheme

Pipetting Scheme

Pipetting SchemePipetting Scheme

(in special RackPack)

special RackPack)

detection

5. Aspirate R2 --> discharge R2 into the third incubation

vessel.

6. Wait until incubation time i2 is over.

7. Measurement.

One step is taken after the other, allowing for the incubation

time. The last step is always the measurement.

The processing of these liquids is determined by the four basic

protocols 0 through 3. They define which liquids are processed

in which pipetting step. On the basis of the basic protocols, the

processing with pretreatment liquids (RO, RM or PS) is

defined in the protocols 4 through 23. Read the sequence of

pipetting steps within one protocol from left to right. The

example

shows the following sequence:

1. Aspirate R0 and sample S --> discharge both liquids

2. Aspirate R0 and the diluted sample DL from the first

3. Aspirate microparticles, R1 and the diluted sample

4. Wait until the incubation time i1 is over.

FINAL 2.1 - February 2000

Protocol 9 (dilution with 2 different assays)Protocol 9 (dilution with 2 different assays)

Protocol 9 (dilution with 2 different assays)

Protocol 9 (dilution with 2 different assays)Protocol 9 (dilution with 2 different assays)

into the first incubation container.

incubation vessel --> discharge both liquids into the

second incubation vessel.

DL from the second incubation vessel --> discharge

all three liquids into the third incubation vessel.

Page 6

Chapter 1

Page 15

Elecsys 1010 Service Manual

Assay ProtocolsAssay Protocols

Assay Protocols

Assay ProtocolsAssay Protocols

TableTable

Table

TableTable

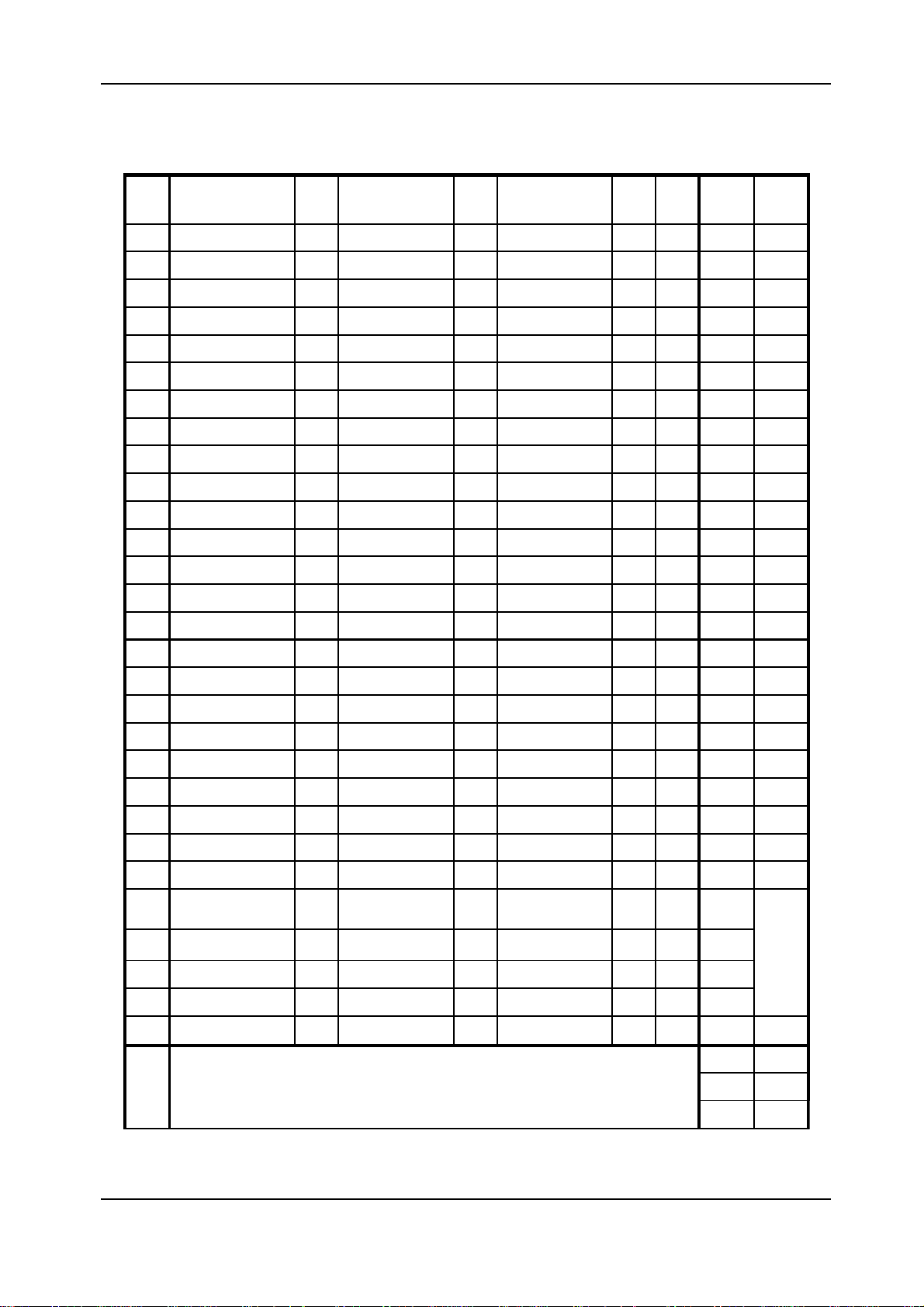

No. Pipetting Step 0 Inc 0

Pipetting Step

1

Inc 1

Pipetting Step

2

Inc 2 Det.

0 B R1 R2 S i1 D X

1 B R1 S i1 R2 i2 D X

2 R1 R2 S i1 B i2 D X

3 R1 S i1 B R2 i2 D X

4 R0 S B R1 R2 DL i1 D

5 R0 S B R1 DL i1 R2 i2 D

6 R0 S R1 R2 DL i1 B i2 D

7 R0 S R1 DL i1 B R2 i2 D

8 R0-> DL1 R0 B R1 R2 DL i1 D

9 R0 S-> DL1 R0 B R1 DL i1 R2 i2 D

10 R0 S-> DL1 R0 R1 R2 DL i1 B i2 D

11 R0 S-> DL1 R0 R1 DL i1 B R2 i2 D

12 PS S i0 B R1 R2 i1 D

13 PS S i0 B R1 i1 R2 i2 D

14 PS S i0 R1 R2 i1 B i2 D

Main assay Remarks

15 PS S i0 R1 i1 B R2 i2 D

16 RM S i0 B R1 R2 DL i1 D

17 RM S i0 B R1 DL i1 R2 i2 D

18 RM S i0 R1 R2 DL i1 B i2 D

19 RM S i0 R1 DL i1 B R2 i2 D

20 RM S-> DL1 RM i0 B R1 R2 DL i1 D

21 RM S-> DL1 RM i0 B R1 DL i1 R2 i2 D

22 RM S-> DL1 RM i0 R1 R2 DL i1 B i2 D

23 RM S-> DL1 RM i0 R1 DL i1 B R2 i2 D

24 R1 R1 D X

25 R1 R2 D X

26 R2 R2 D X

27 R1 B i1 D X

28

29...

... Reserve

only needed

for instrument

checks,

not part of

the RUN

...63

E-Tab1: Assay Protocols

FINAL 2.1 - February 2000

Chapter 1Page 7

Page 16

Elecsys 1010 Service Manual

Pipetting StepsPipetting Steps

Pipetting Steps

Pipetting StepsPipetting Steps

The processing of the assay protocols is divided into four

pipetting steps: pipetting step 0, the so-called pretreatment

step, pipetting steps1 and 2, and the measuring step. The

pipetting steps are divided into partial steps (e.g. pipette R1).

The sequence of the partial steps is (regarding the liquid pickup by the s/r needle): R1, R2, B, S.

The pipetting steps / partial steps according to the assay

protocols are described below. The pick-up sequence

during pretreatment is always: reagent before sample (in

both steps).

For each pipetting step and/or measuring step, a generally

applicable step can be described. Figures 1 to 3 give an

overview of these pipetting steps.

Pipetting Step 0Pipetting Step 0

Pipetting Step 0

Pipetting Step 0Pipetting Step 0

In pipetting step 0 the sample is pretreated. It has one or two

increments. In the figure, these increments are called "Block

1 and 2".

- Block 1 is passed through for protocols 4 through 23.

- Block 2 is passed through for protocols 8 through 11

and 20 through 23.

Each block consists of

- aspiration of the separation air bubble

- aspiration of the pretreatment liquid from the sample

rotor

- washing in wash station 1

- aspiration of the sample

- washing and rinsing in wash station 1 or

rinsing in wash station 2, rehomogenizing of the

microparticles and washing

Rinsing and washing in wash station 2 with simultaneous

rehomogenizing of the microparticles can only be

performed one time, always at the end of a pipetting step.

The difference between block 1 and block 2 is the

aspiration of the diluted sample from the incubation rotor.

- In block 1, the sample is aspirated from the sample

rotor, and the samples are discharged into the first

incubation vessel.

- In block 2, the sample is aspirated from the first

incubation vessel, and the liquids are discharged into

the second incubation vessel.

FINAL 2.1 - February 2000

Page 8

Chapter 1

Page 17

Elecsys 1010 Service Manual

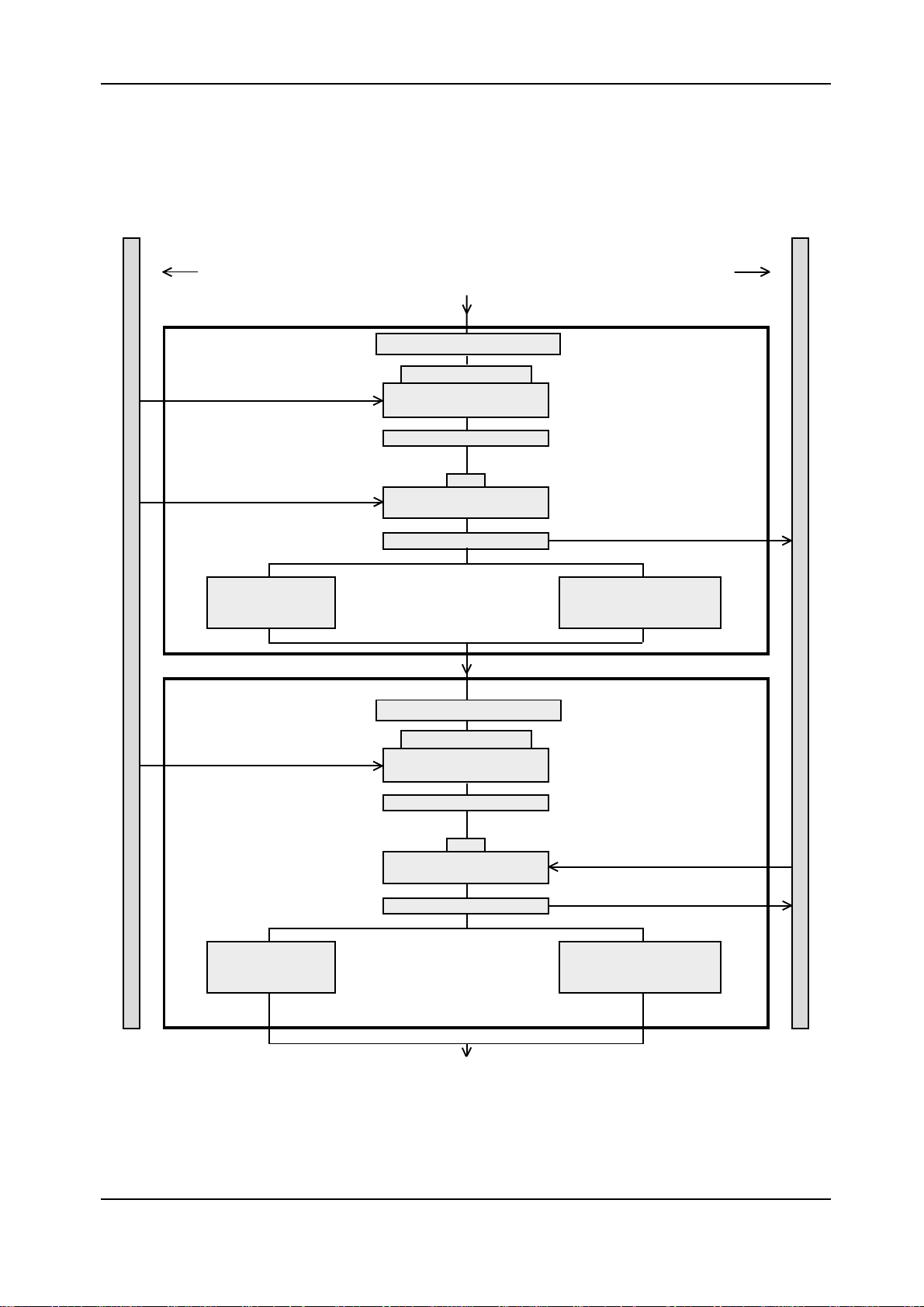

Pipetting Step 0Pipetting Step 0

Pipetting Step 0

Pipetting Step 0Pipetting Step 0

Sample rotor Incubation rotor

Block 1Block 1

Block 1

Block 1Block 1

Aspirate

Aspirate

Block 2Block 2

Block 2

Block 2Block 2

Aspirate

Wash and rinse in

wash station 1

Aspirate separation air bubble

R0 or PS or RM

Aspirate sample by using

LLD

Wash in wash station 1

S

Aspirate sample by using

LLD

Discharge

Aspirate separation air bubble

R0 or RM

Aspirate pretreatment

liquid by using LLD

Discharge

Wash and rinse in

wash station 2 and

rehomogenize microparticles

Wash and rinse

in wash station 1

Figure 1: Pipetting step 0

FINAL 2.1 - February 2000

Wash in wash station 1

DL

Aspirate pretreated sample

by using LLD

Discharge

Aspirate

Discharge

Wash and rinse in

wash station 2 and

rehomogenize microparticles

Chapter 1Page 9

Page 18

Elecsys 1010 Service Manual

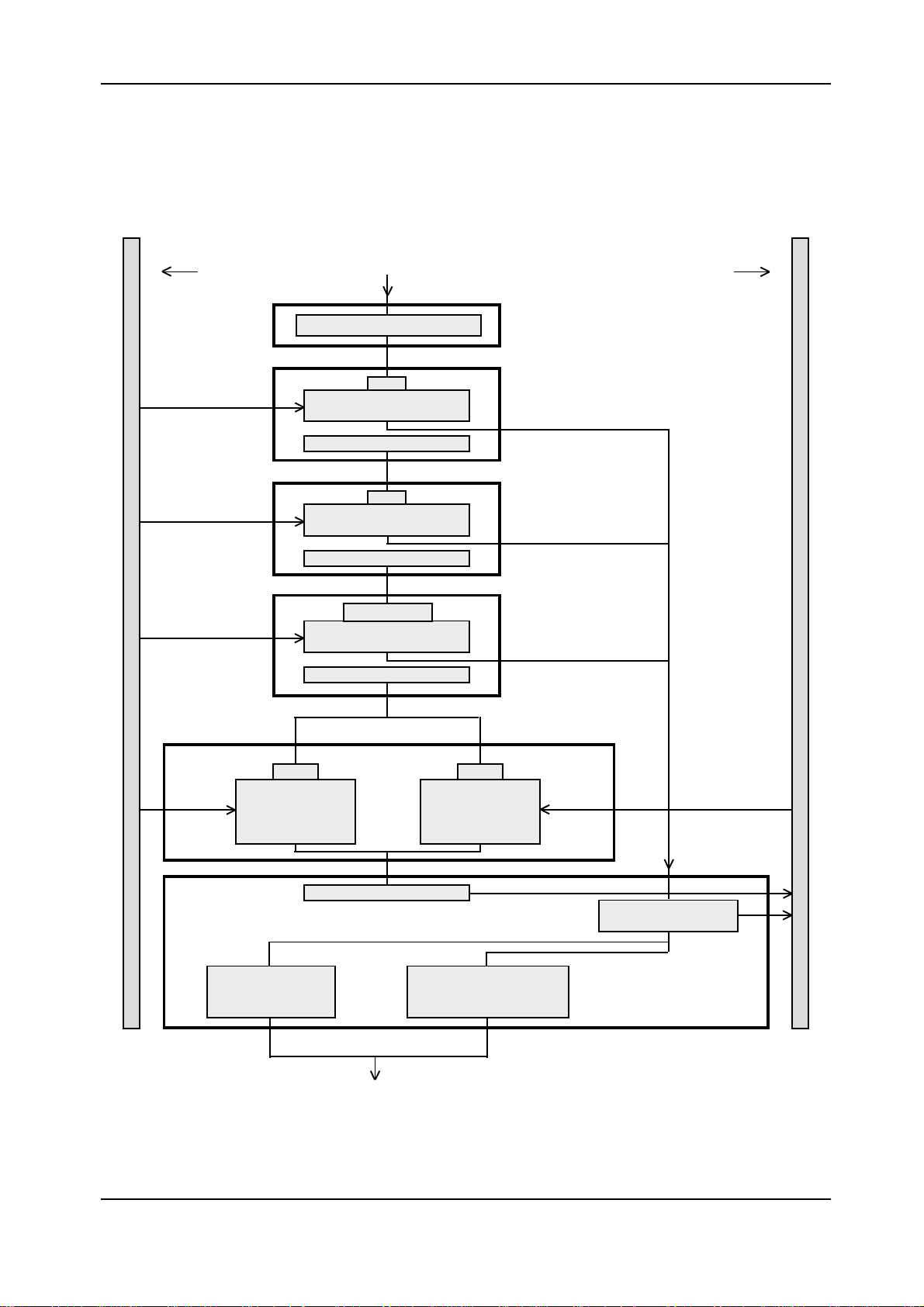

Pipetting Step 1Pipetting Step 1

Pipetting Step 1

Pipetting Step 1Pipetting Step 1

Pipetting step 1 is also divided into blocks and always

starts with block 1.

- Aspirate the separation air bubble.

In blocks 2, 3 and 4, reagents are aspirated. All three

blocks are passed through in the following sequence:

- Aspiration of R1, R2 or microparticles.

- Discharging of fluids after the last reagent has been

picked up and the sample pretreated with PS. The

sample pretreated with PS will be further processed in

block 6.

- Washing in wash station 1.

The assay protocols determine which and how many of the

blocks will be passed through in pipetting step 1.

In block 5, the sample is aspirated. The pretreated sample DL

is

- aspirated from the first incubation vessel and is

discharged into a second incubation vessel in block 6,

if it has been pretreated with R0 or RM in one

increment (see pipetting step 0).

- aspirated from the second incubation vessel and is

discharged into a third incubation vessel in block 6, if

it has been pretreated with R0 or RM in two increments

(see pipetting step 0).

If sample S has not been pretreated, it will be aspirated from

the sample rotor and discharged into the first incubation vessel

in block 6.

In block 6, the liquids are discharged into the incubation rotor,

and the s/r needle is washed and rinsed. If the sample has been

pretreated with PS, the aspirated liquids will be added to the

first incubation vessel (see pipetting step 0).

The rehomogenizing of the microparticles and the washing /rinsing in wash station 2 will be performed if in the

next cycle microparticles are pipetted in one pipetting

step 1.

FINAL 2.1 - February 2000

Page 10

Chapter 1

Page 19

Elecsys 1010 Service Manual

Pipetting Step 1Pipetting Step 1

Pipetting Step 1

Pipetting Step 1Pipetting Step 1

Sample rotor Incubation rotor

Block 1Block 1

Block 1

Aspirate

Aspirate

Block 1Block 1

Block 2Block 2

Block 2

Block 2Block 2

Block 3Block 3

Block 3

Block 3Block 3

Aspirate separation air bubble

R1

Aspirate reagent 1

by using LLD

Wash in wash station 1

R2

Aspirate reagent 2

by using LLD

Aspirate

Block 5Block 5

Block 5

Block 5Block 5

Aspirate

Block 6Block 6

Block 6

Block 6Block 6

Block 4Block 4

Block 4

Block 4Block 4

Aspirate sample by

using LLD (clot and

foam detection)

Wash and rinse

in wash station 1

Wash in wash station 1

Microparticles

Aspirate microparticles

by using LLD

Wash in wash station 1

Discharge

Wash and rinse in wash

station 2 and rehomogenize

DLS

Aspirate pretreated

sample by using LLD

microparticles

Aspirate

Discharge sample

pretreated with PS

Figure 2: Pipetting step 1

FINAL 2.1 - February 2000

Chapter 1Page 11

Page 20

Elecsys 1010 Service Manual

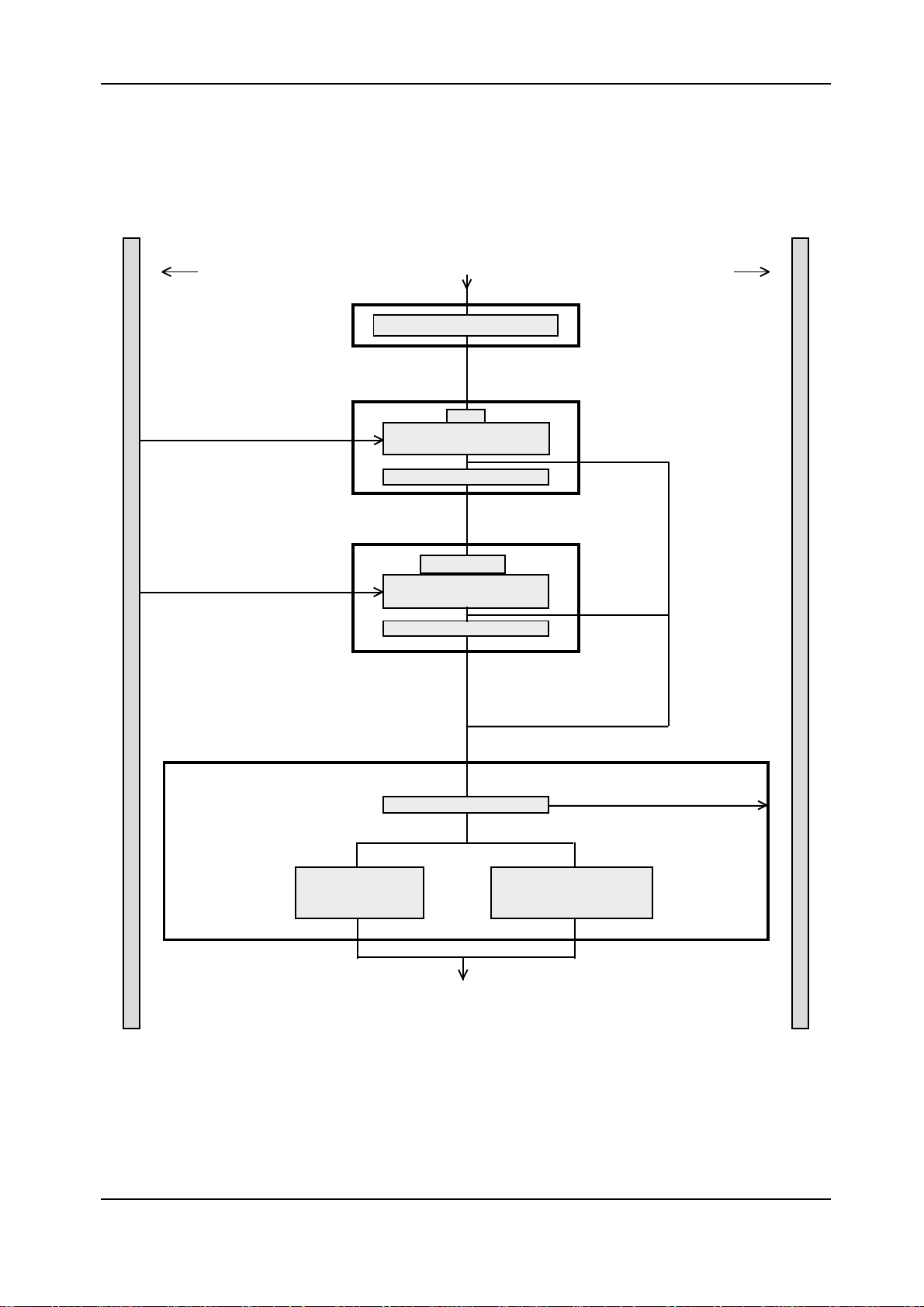

Pipetting Step 2Pipetting Step 2

Pipetting Step 2

Pipetting Step 2Pipetting Step 2

Pipetting step 2 is divided into 4 blocks. Like pipetting

step 1, it always starts with block 1:

- Aspirate the separation air bubble.

In blocks 2 and 3, reagents are aspirated. Both blocks are

passed through in the following sequence:

- Aspirate R2 or microparticles.

- Discharge liquid into the incubation rotor after the last

reagent has been picked up.

- Wash in wash station 1.

The assay protocols determine which and how many of the

blocks will be passed through in pipetting step 2.

In block 4, the liquids are discharged into the incubation rotor,

and the s/r needle is washed and rinsed. The liquids will be

- added to the first incubation vessel, if the sample has

not been pretreated or pretreated with PS.

- added to the second incubation vessel, if the sample

has been pretreated with R0 or RM in one increment.

- added to the third incubation vessel, if the sample

has been pretreated with R0 or RM in two increments.

The rehomogenizing of the microparticles and the washing /rinsing in wash station 2 will be performed if in the

next cycle microparticles are pipetted in one pipetting

step 1.

FINAL 2.1 - February 2000

Page 12

Chapter 1

Page 21

Elecsys 1010 Service Manual

Pipetting Step 2Pipetting Step 2

Pipetting Step 2

Pipetting Step 2Pipetting Step 2

Sample rotor Incubation rotor

Block 1Block 1

Block 1

Aspirate

Block 1Block 1

Block 2Block 2

Block 2

Block 2Block 2

Aspirate separation air bubble

R2

Aspirate reagent 2

by using LLD

Wash in wash station 1

Aspirate

Block 4Block 4

Block 4

Block 4Block 4

Block 3Block 3

Block 3

Block 3Block 3

Wash and rinsei n

wash station 1

Microparticles

Aspirate microparticles by

using LLD

Wash in wash station 1

Discharge

wachen und spülen in

Wash and rinse in

wash station 2 and

rehomogenize microparticles

Figure 3: Pipetting step 2

FINAL 2.1 - February 2000

Chapter 1Page 13

Page 22

Elecsys 1010 Service Manual

Measuring StepMeasuring Step

Measuring Step

Measuring StepMeasuring Step

Measuring step actions take place around the measuring

cell, e.g. in the incubator, sipper needle, measuring cell

or in the sipper system dilutor. The measuring step has

the following increments:

- Pick-up of the incubate ( - sampling, pick -up ) (preconditioning with ProCell included).

- Transport of the incubate with ProCell (preconditioning with ProCell included).

- Capturing with ProCell

- Washing with ProCell

- Measuring -> optical measurement

- Pick-up of CleanCell solution for cleaning 1

- Pick-up of air and CleanCell alternately

- Solution for cleaning 2

- Pick-up of ProCell for cleaning 3

- Pick-up of ProCell for post -conditioning

FINAL 2.1 - February 2000

Page 14

Chapter 1

Page 23

Elecsys 1010 Service Manual

1.1.3.11.1.3.1

1.1.3.1

1.1.3.11.1.3.1

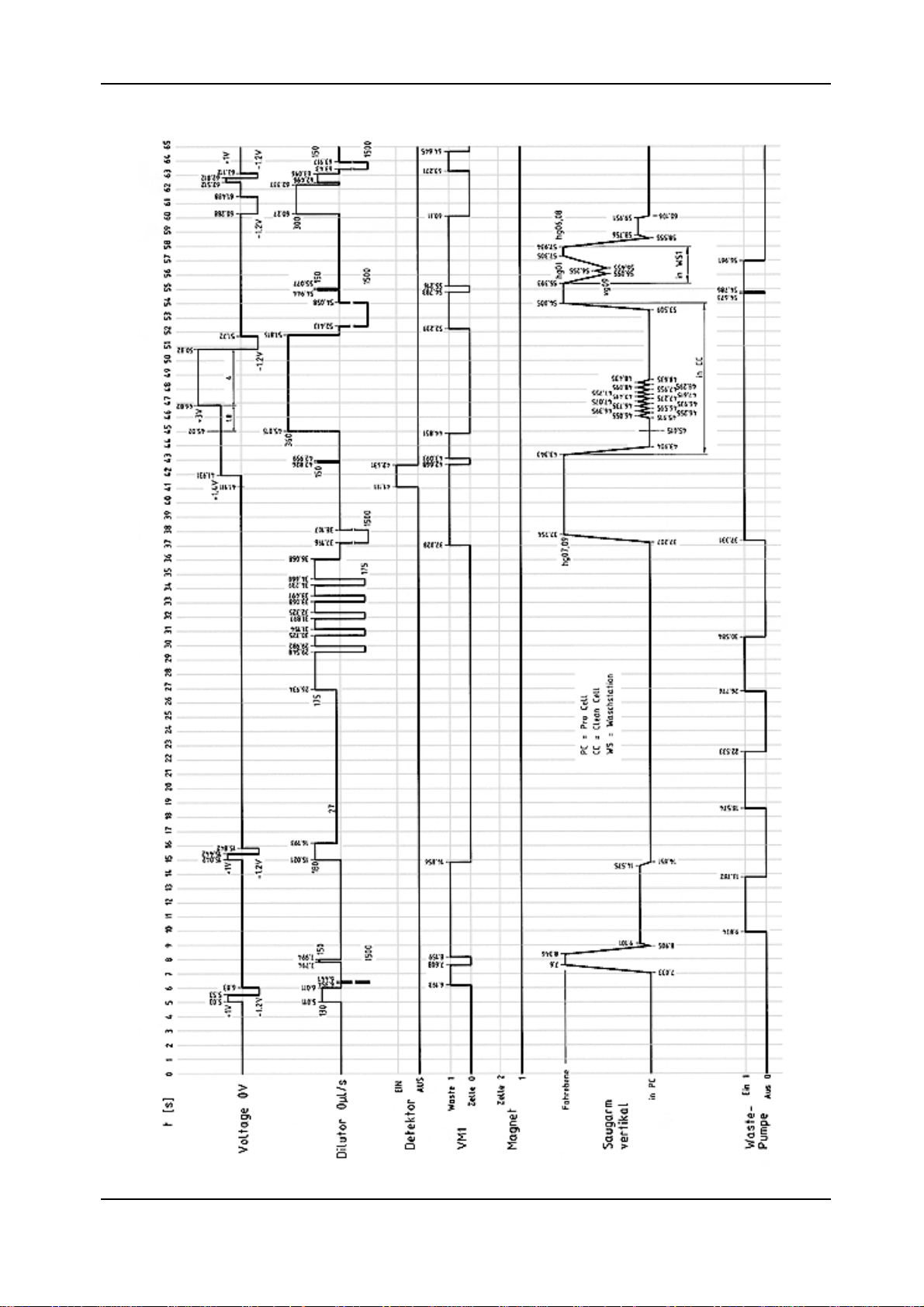

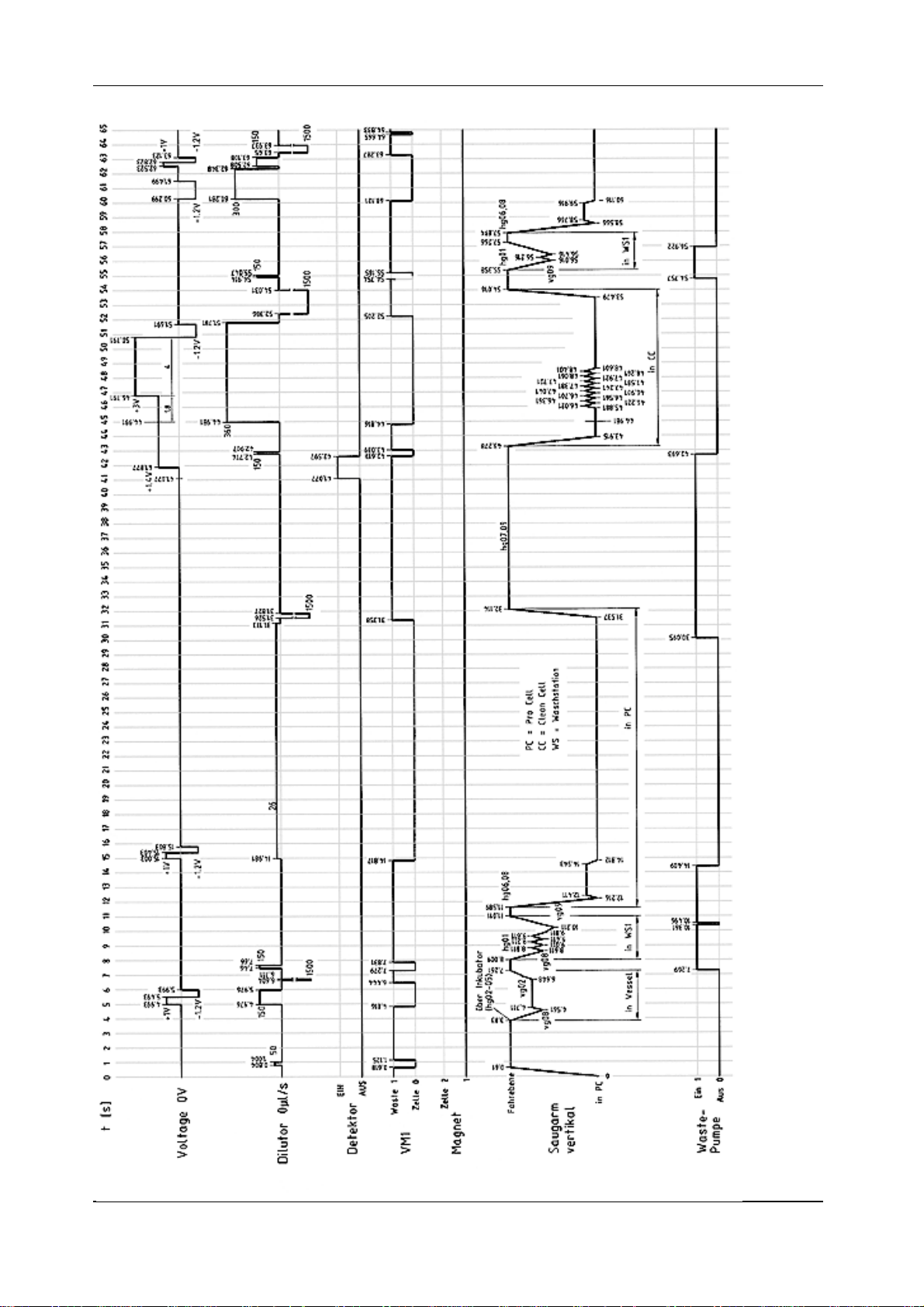

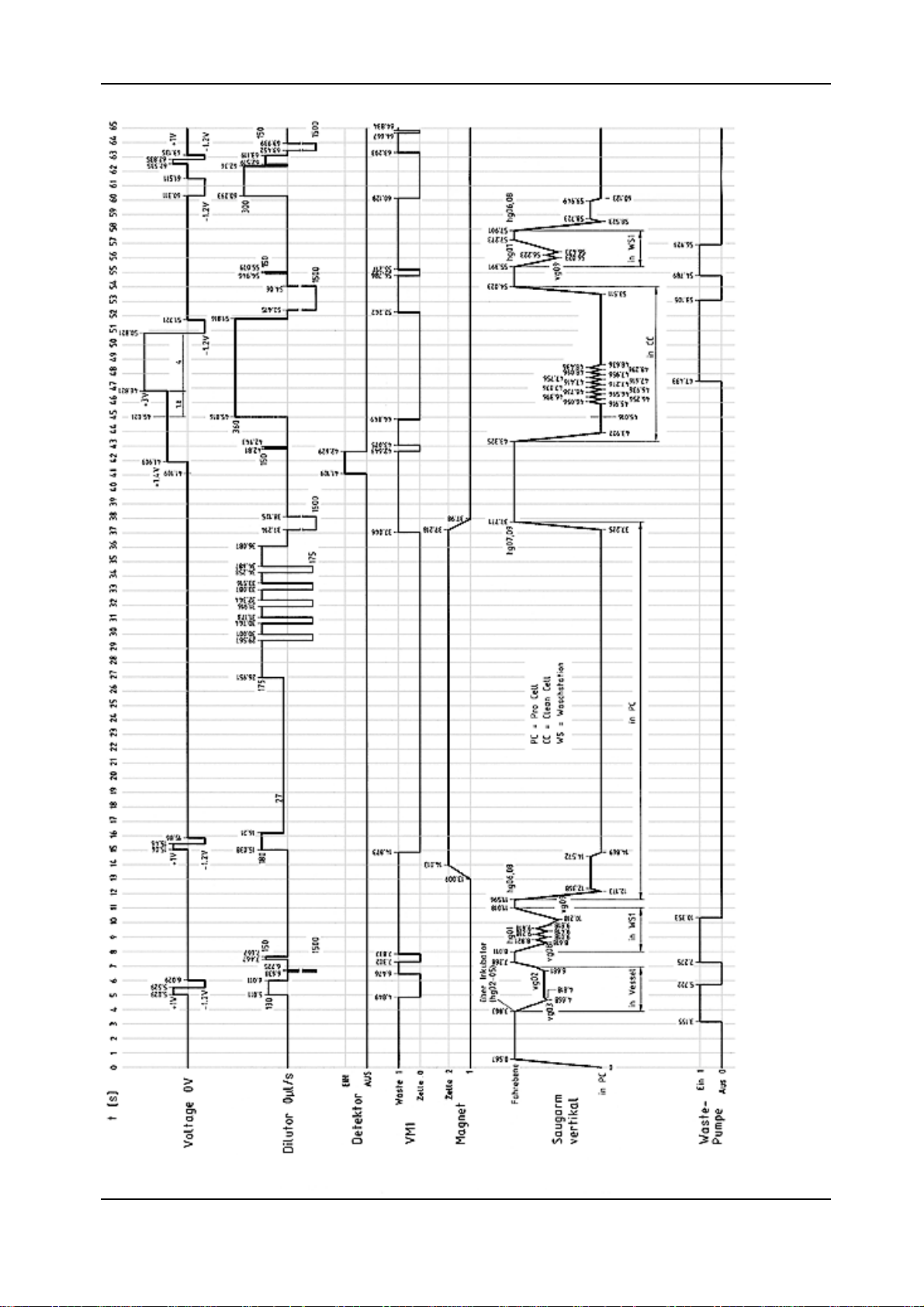

Timing DiagramTiming Diagram

Timing Diagram

Timing DiagramTiming Diagram

FINAL 2.1 - February 2000

diag1.tif

Chapter 1Page 15

Page 24

Elecsys 1010 Service Manual

FINAL 2.1 - February 2000

Page 16

diag2.tif

Chapter 1

Page 25

Elecsys 1010 Service Manual

FINAL 2.1 - February 2000

diag3.tif

Chapter 1Page 17

Page 26

Elecsys 1010 Service Manual

1.21.2

1.2

1.21.2

Analyzer dimensions Height: 620 (mm)

Electrical Supply voltage 100 - 240 (V) AC at 50/60 (Hz)

Environmental conditions Temperature 18 (°C) to 32 (°C)

System SpecificationSystem Specification

System Specification

System SpecificationSystem Specification

Depth: 780 (mm)

Width: 960 (mm)

Weight approx. 110 (kg)

Power consumption max 0.61 (kVA)

Fuse circuit 16 (A) time-lag at 230 (V) AC

Heat generation

Ambient temperature note change during

one batch run

approx. 2000 (kJ/h) resp. 481 (kcal/h)

resp. 1912 (BTU/h)

max. ± 3 (°C)

rel. humidity 20 (%) to 85 (%) without condensation

Noise level according to DIN

43635

Water supply Water tank approx. 4,2 (l)

Waste water connection

Throughput ECL measurements approx. 50 (tests/h)

Samples Sample volume per test 10 (µl) to 50 (µl)

Continuous operation max. 60 (dBA)

Peak level max. 65 (dBA)

Water quality (conductivity) sub-micron filtered <10 µS/cm

Water consumption approx. 3 (l) for 128 test

Waste container for measuring material,

system water, ProCell, CleanCell

Sample detection

Sample rotor for routine samples,

calibrators and controls

Usable sample bar codes

approx. 5 (l)

by Liquid Level Sensor and Clot

Detector of the sample / reagent needle

42 positions for primary tubes, 18

positions for secondary cups

2 positions for STAT samples

NW7 (Codabar), Code 39, Code 128,

Interleave 2 of 5

Reagent Reagent capacity 6 reagent channels

by Liquid Level Sensor of the sample/

reagent needle

E-Tab2

FINAL 2.1 - February 2000

Reagent detection

Page 18

Chapter 1

Page 27

Elecsys 1010 Service Manual

Bottle volume for CleanCell and ProCell 380 (ml)

Reagent ID by 2-dim. bar code (PDF 417)

Incubator Incubator capacity 128 plastic assay cups (4 x 32)

Volume of assay cups 200 (µl)

ambient temperature 18°C to 20°C

Incubation temperature

Incubation time 9 / 18 (min)

37°C + 0.3°C - 0.8°C

ambient temperature 20°C to 32°C

37°C + 0.3°C - 0.3°C

Measuring system Measuring method

Calibration method 2 point calibration

PC Disk drive Floppy disk 3,5" / 1.44 MB

Interfaces

LCD

Thermoprinter Paper width 110 (mm)

E-Tab3

Integral measurement of luminescence

signal

1 Centronics for printer, 1 RS 232 for

laboratory EDP

Black-and-white VGA LCD with 640 x

480 pixels

FINAL 2.1 - February 2000

Chapter 1Page 19

Page 28

Elecsys 1010 Service Manual

1.3.3 Precautions and Hazards1.3.3 Precautions and Hazards

1.3.3 Precautions and Hazards

1.31.3

1.3

1.31.3

The data and information provided in this manual correspond

to the state of knowledge existing at the time of introducing

the Elecsys 1010 onto the market. Any important changes

will be taken into account in the next edition of this manual.

The respective packaging leaflet should be regarded as

authoritative.

Operator Precautions andOperator Precautions and

Operator Precautions and

Operator Precautions andOperator Precautions and HazardsHazards

Hazards

HazardsHazards

1.3.3 Precautions and Hazards1.3.3 Precautions and Hazards

All electrical equipment is potentially hazardous. Never

remove covers without first ensuring that it is isolated from

the AC supply, unless specific maintenance instructions or

repairs are being carried out by authorized Roche

Diagnostics personnel.

The hard- and software is subject to a program of continuous

evaluation and improvement and, therefore, may be changed

in the future. This also concerns service requirements.

This service manual was created for the telephone and

technical service staff.

1.3.1 Contact Persons1.3.1 Contact Persons

1.3.1 Contact Persons

1.3.1 Contact Persons1.3.1 Contact Persons

Technical Product Management and Support

Department: LI-TT

Phone: 0621 / 759 / 3227

8802

Fax No: 0621/ 759 / 4591

Logistics Hotline (RA):

Phone: 0621 / 759 / 4389

Fax No.: 0621 / 759 / 4613

8093

When calling from abroad, drop the "0" and add the country

code (+ 49).

1.3.2 Proved Security1.3.2 Proved Security

1.3.2 Proved Security

1.3.2 Proved Security1.3.2 Proved Security

All samples and reagents should be treated with caution

accorded to those known to contain pathogenic organisms.

Similarly, the cleaning of component part of Elecsys 1010

should be done with respect to human health.

Warning:Warning:

Warning:

Warning:Warning:

All components used on Elecsys 1010 must be regarded

as potentially dangerously contaminated when doing repair

work. Use rubber gloves or double gloves whenever cleaning

or sterilizing components. the most frequently used

components (tubings, cuvette, measuring chamber flap,

sip. lever and waste container) should be cleaned and

treated with a suitable disinfecting solution (75% alcohol)

prior to doing any service work.

Disinfect and wash hands after work is completed.

This instrument has been constructed and checked in

accordance with Standards IEC 1010. When the instrument

leaves our factory it is in perfect order from the point of view

of work safety. To keep it that way and to ensure safe

operation the user must follow the instructions and warnings

given in the operation instruction manual.

The electrical protection of the apparatus to Class I (it has

a protective earth).

This instrument has been constructed according to the

regulations of DIN IEC 601, part: "Security of Electromedical

Instruments: General Guidelines" and left our factory in

perfect condition regarding work safety.

The instrument obtained the GS mark for proved security

from the TÜV.

In order to ensure safe operation the user must follow the

instructions and warnings given in the instruction manual.

This instruments meets protection 1 (earth conductor wire).

FINAL 2.1 - February 2000

The power plug must only be inserted into a socket that has

a protective contact. The protection must not be abolished

by using an extension lead that does not have a protective

earth wire.

Warning:Warning:

Warning:

Warning:Warning:

Any break in the earth wire inside or outside the apparatus

and any loose connection of the earth wire can make the

operation of the apparatus dangerous. A deliberate break

or interruption is not allowed.

When the housing is opened or components are being

removed (except when this can be done by hand), live parts

may be exposed. Connection may also be live.

Therefore, if the carrying out of an adjustment, service or

repair on the open apparatus in the live state is unavoidable,

this must be done by an expert who is familiar with the

dangers involved.

Page 20

Chapter 1

Page 29

Elecsys 1010 Service Manual

Make sure you only use fuses of the specified type and

rated amperage when replacing. Repaired fuses must not

be used and the fuse holder must not be bypassed.

If you have any reason to believe that the instrument can no

longer operate safely, take it out of use and make sure no

one can use it accidentally.

It must be assumed that safe operation is no longer possible

when the instrument:

- shows visible signs of damage

- fails to operate

- has been stored under unfavourable conditions for

a fairly long time

- has been transported under rough conditions

The Elecsys 1010 should be used by appropriately qualified

persons only.

Warning:Warning:

Warning:

Warning:Warning:

In order to avoid electrostatic charging when working on the

electronics, use a grounding strap and a grounding mat.

For more information, please refer to operator manual.

FINAL 2.1 - February 2000

Chapter 1Page 21

Page 30

Elecsys 1010 Service Manual

1.4 Service Concept1.4 Service Concept

1.4 Service Concept

1.4 Service Concept1.4 Service Concept

1.4.11.4.1

1.4.1

1.4.11.4.1

From the early stage of development, Elecsys 1010 was

designed for simple error detection and easy exchangeability

of modules. This gives the service workshops the possibility

of a fast and easy repair of the instrument on service level

A (module level). No big stock or expensive equipment is

necessary and service technicians are easier to train.

Also, a permanent technical improvement in layout and

components took and takes place for better productivity

and economic production.

On repairable modules the quality and function is always

provided by the manufacturer according to the latest

technology. This keeps Elecsys 1010 always on the highest

quality level.

The exchange price for modules will be kept on a low level

to guarantee repairs, on an economical basis.

1.4.21.4.2

1.4.2

1.4.21.4.2

Service LevelService Level

Service Level

Service LevelService Level

RA-Procedure (Replacement ofRA-Procedure (Replacement of

RA-Procedure (Replacement of

RA-Procedure (Replacement ofRA-Procedure (Replacement of

defective parts)defective parts)

defective parts)

defective parts)defective parts)

- All defective parts ( non-"R" and "A" parts ) should be

kept on stock for a period of 7 months. In case the

manufacturer needs the part for investigation it will be

requested from Mannheim.

- All parts returned to Mannheim and not requested by

Mannheim will be send back at the expense of the

countries.

- The RA claim for warranty has to be in Mannheim no

later than 8 weeks after the problem date.

Exclusion of warrantyExclusion of warranty

Exclusion of warranty

Exclusion of warrantyExclusion of warranty

The aforementioned warranties do not apply in case of

improper use, handling, transportation or storage, faulty

installation, repair or maintenance, chemical influence or

contamination as well as damages resulting from that,

failure to follow operating instructions, alterations or

modifications of instruments or parts thereof not authorized

or recommended by RD GmbH and resulting damages,

normal wear and tear and in case of other circumstances

beyond the control of RD GmbH.

Handling of repairsHandling of repairs

Handling of repairs

Handling of repairsHandling of repairs

As a general rule, all instrument repairs should be carried

out by authorized and trained personnel only.

Warranty period for instruments and spare partsWarranty period for instruments and spare parts

Warranty period for instruments and spare parts

Warranty period for instruments and spare partsWarranty period for instruments and spare parts

The warranty period for instruments is 16 months starting

with the date of shipment ex works Mannheim/Federal

Republic of Germany or 12 months starting with the date of

the first installation, whichever period is shorter.

The warranty period for spare parts is 6 months from

installation date of the part, however not longer than 24

months after having delivered ex works Mannheim/Federal

Republic of Germany. Note: In case the instrument has a

remaining warranty period of more than 6 months, the parts

remain under warranty until the warranty period of the

instrument expires.

Handling of warranty claimsHandling of warranty claims

Handling of warranty claims

Handling of warranty claimsHandling of warranty claims

The warranty claim has to be handled via Return

Authorization procedure or accepted equivalent. Please

answer all the questions on the RA form with the greatest

care.Especially a detailed fault description is needed or the

warranty claim will not be accepted by the manufacturer.

Complete instruments are not accepted unless this has

been agreed with the service department of the relevant

product group responsible at RD GmbH.

Repair of parts marked with "R"Repair of parts marked with "R"

Repair of parts marked with "R"

Repair of parts marked with "R"Repair of parts marked with "R"

Parts which are economically worth repairing are marked

with "R" in the spare parts price list. New and repaired parts

could be recognized by different material numbers (language

version).

(e.g. new part: 1234567-001, repaired part: 1234567-984)

Repaired parts should be ordered together with new parts

via the order processing department in Mannheim (OUVDG). Parallel to the ordering process of a repaired part,

the defective part should be returned together with the filled

RA form (giving full details of the defect and marked choice

box with repair) to Logistic Instruments (Goods Receipt) in

MA-Wohlgelegen (LI-GS). Repair of instrumentsComplete

instruments are not accepted for replacement or repair

unless this has been agreed with the product group

responsible at RD GmbH. Before replacement or repair

can take place, the validity of the request must be examined

and the question of costs must be settled in a written

agreement with RD GmbH.

Terms of deliveryTerms of delivery

Terms of delivery

Terms of deliveryTerms of delivery

Important informationImportant information

Important information

Important informationImportant information

- Only parts marked with "A" in the price list are generally

accepted under warranty.

- Only return those parts marked with "R" in the spare

parts price list.

- Warranty claim for „R“ parts will be accepted, if the

part was returned to Mannheim.

FINAL 2.1 - February 2000

Shipments to the countries with the routine truck are c.i.f./

shipments outside this procedure are ex works Mannheim.

Emergency shipments require additional costs to be

charged.

Page 22

Chapter 1

Page 31

Elecsys 1010 Service Manual

Handling of costsHandling of costs

Handling of costs

Handling of costsHandling of costs

„Repaired“-parts (Material-No. 1234567-984) are shipped

at a repair price. In case the defective parts are not returned

within 3 or 8 weeks for european or oversea countries after

ordering the repaired part, the countries will be charged

later on with the difference to the new price.After the receipt

of a warranty request for „A“-parts, RDG will credit 100 %

of the currently effective ex MA price.In case the

manufacturer does not accept the warranty request, the

countries will be charged lateron with the R-price for Rparts and the new price for non R-parts.

RA formRA form

RA form

RA formRA form

Return Authorization. Please answer all the questions on

the RA form with the greatest care and sign the form.

- Country code

- Problem date

- Type of instrument

- Serial no. of the instrument

- Installation date of instrument

- Defective instrument or spare part

- Part number and material number of the spare part

- Old / new serial no.

- Fault description

- Alarm code

- Service / workshop report no.

In case of instrument out of warrantyIn case of instrument out of warranty

In case of instrument out of warranty

In case of instrument out of warrantyIn case of instrument out of warranty

- Installation date of spare part.

All returned parts should be individually labeled with the

corresponding RA No. and shipped together with the

completed RA form to:

Roche Diagnostics GmbH

Logistic Instruments

RA Management

Friedrich Ebert Str. 100

D - 68167 Mannheim

Germany

FINAL 2.1 - February 2000

Chapter 1Page 23

Page 32

Elecsys 1010 Service Manual

R

RA Form:RA Form:

RA Form:

RA Form:RA Form:

A copy of the RA Form is shown below.

Roche Diagnostics

Friedrich-Ebert-Strasse 100 Telefon : +49 (621) 759 81 84

D-68167 Mannheim Fax : +49 (621) 759 80 93

Germany

Return Authorization

No.:

Country code:

Date:

Instrument:

Serial No.:

Installation date:

Spare Part:

Customer: Address:

(will be filled in by BM)

Part No.: Qty.: Part Name: Repair Comments

Mat.-No.: Warranty

Installation date of Spare Part: Warranty Repair

OLD serial No.: Modification

NEW serial No.: Replacement

Fault Description:

Alarm Code:

Service Report No.: Workshop Report No.:

Place: Date: Signature:

Remarks

D

(will be filled in byRD)

NOS Credit FC

Fig.: RA.eps

FINAL 2.1 - February 2000

Page 24

Chapter 1

Page 33

Elecsys 1010 Service Manual

1010

10

1010

MaintenanceMaintenance

Maintenance

MaintenanceMaintenance

10.110.1

10.1

10.110.1

10.210.2

10.2

10.210.2

10.310.3

10.3

10.310.3

10.410.4

10.4

10.410.4

IntroductionIntroduction

Introduction

IntroductionIntroduction

10.1.110.1.1

10.1.1

10.1.110.1.1

Maintenance ScheduleMaintenance Schedule

Maintenance Schedule

Maintenance ScheduleMaintenance Schedule

Bi-weekly Analyzer MaintenanceBi-weekly Analyzer Maintenance

Bi-weekly Analyzer Maintenance

Bi-weekly Analyzer MaintenanceBi-weekly Analyzer Maintenance

10.3.110.3.1

10.3.1

10.3.110.3.1

10.3.210.3.2

10.3.2

10.3.210.3.2

10.3.310.3.3

10.3.3

10.3.310.3.3

10.3.410.3.4

10.3.4

10.3.410.3.4

10.3.510.3.5

10.3.5

10.3.510.3.5

Maintenance, As RequiredMaintenance, As Required

Maintenance, As Required

Maintenance, As RequiredMaintenance, As Required

10.4.110.4.1

10.4.1

10.4.110.4.1

10.4.210.4.2

10.4.2

10.4.210.4.2

10.4.310.4.3

10.4.3

10.4.310.4.3

Cleaning MaterialsCleaning Materials

Cleaning Materials

Cleaning MaterialsCleaning Materials

Perform SYSTEM CLEANING INTENSIVEPerform SYSTEM CLEANING INTENSIVE

Perform SYSTEM CLEANING INTENSIVE

Perform SYSTEM CLEANING INTENSIVEPerform SYSTEM CLEANING INTENSIVE

Clean the Microparticle MixerClean the Microparticle Mixer

Clean the Microparticle Mixer

Clean the Microparticle MixerClean the Microparticle Mixer

Clean the Sipper ProbeClean the Sipper Probe

Clean the Sipper Probe

Clean the Sipper ProbeClean the Sipper Probe

Clean the S/R ProbeClean the S/R Probe

Clean the S/R Probe

Clean the S/R ProbeClean the S/R Probe

Perform CELL CLEANING NORMALPerform CELL CLEANING NORMAL

Perform CELL CLEANING NORMAL

Perform CELL CLEANING NORMALPerform CELL CLEANING NORMAL

Clean the Analyzer Surfaces and CoverClean the Analyzer Surfaces and Cover

Clean the Analyzer Surfaces and Cover

Clean the Analyzer Surfaces and CoverClean the Analyzer Surfaces and Cover

Replacing Printer PaperReplacing Printer Paper

Replacing Printer Paper

Replacing Printer PaperReplacing Printer Paper

Clean the Rinse StationsClean the Rinse Stations

Clean the Rinse Stations

Clean the Rinse StationsClean the Rinse Stations

__________________________________________________________________________________________

_____________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

_____________________________________________

__________________________________________________________________________________________

________________________________________________________________________

____________________________________

________________________________________________________________________

______________________________________________________

___________________________

______________________________________________________

__________________________________________________

_________________________

__________________________________________________

________________________________________________________________________

____________________________________

________________________________________________________________________

__________________________________________________________________________________

_________________________________________

__________________________________________________________________________________

________________________________________________________________________________________

____________________________________________

________________________________________________________________________________________

____________________________________________________________

______________________________

____________________________________________________________

________________________________________________________________

________________________________

________________________________________________________________

____________________________________________________

__________________________

____________________________________________________

________________________________________________________________________________

________________________________________

________________________________________________________________________________

______________________________________________________________________________

_______________________________________

______________________________________________________________________________

1010

10

1010

1010

10

1010

1010

10

1010

1010

10

1010

11

1

11

11

1

11

33

3

33

55

5

55

55

5

55

66

6

66

66

6

66

77

7

77

88

8

88

10.510.5

10.5

10.510.5

10.6 Preventive Maintenance10.6 Preventive Maintenance

10.6 Preventive Maintenance

10.6 Preventive Maintenance10.6 Preventive Maintenance

10.710.7

10.7

10.710.7

Half-yearly, Yearly, Special Maintenance Half-yearly, Yearly, Special Maintenance

Half-yearly, Yearly, Special Maintenance

Half-yearly, Yearly, Special Maintenance Half-yearly, Yearly, Special Maintenance

Maintenance MaterialsMaintenance Materials

Maintenance Materials

Maintenance MaterialsMaintenance Materials

______________________________________

___________________

______________________________________

____________________________________________________________________

__________________________________

____________________________________________________________________

______________________________________________________________________

___________________________________

______________________________________________________________________

1212

12

1212

2020

20

2020

2222

22

2222

FINAL 2.1 - February 2000 Chapter 10

Page 34

Elecsys 1010 Service Manual

FINAL 2.1 - February 2000 Chapter 10

Page 35

Elecsys 1010 Service Manual

1010

10

1010

10.110.1

10.1

10.110.1

Before maintenance procedures are performed on the

analyzer, refer to the warnings in Section 1.4, Potential

Hazard and Safety Precautions, of the Reference Guide.

All analyzer components that can come in contact with

biological substances are potentially biohazardous and

can endanger the health of an operator. Therefore, only

perform care and maintenance procedures according to

national, international and general laboratory safety

regulations.

Analyzer care entails all procedures that are periodically

performed by the operator. These procedures, listed

below, serve to ensure a problem-free run and thus the

correct operation of the Elecsys 1010 analyzer. Refer to

the maintenance schedule on the next page. The correct

operation of the analyzer can only be ensured when the

maintenance procedures are performed periodically.

Regular care and maintenance avoids analyzer

downtimes, failures, and measurement and run problems.

MaintenanceMaintenance

Maintenance

MaintenanceMaintenance

IntroductionIntroduction

Introduction

IntroductionIntroduction

WARNINGWARNING

WARNING

WARNINGWARNING

10.1.110.1.1

10.1.1

10.1.110.1.1

The following materials are generally required for care

and maintenance procedures:

- Alcohol (70% isopropyl alcohol)

- Normal common disinfectant

- Distilled/deionized water

- Rubber gloves

- 0.5 % Edisonite

- Cleaning brush

- Cleaning solution (SysClean)

- Cloths (clean, lint-free, absorbent)

- Ultrasonic bath (if available; use only when the

Cleaning MaterialsCleaning Materials

Cleaning Materials

Cleaning MaterialsCleaning Materials

®

(to clean sampling system)

rinse stations and probes are highly contaminated;

15 minutes with distilled water, 25000 Hz, at 60 °C)

FINAL 2.1 - February 2000 Chapter 10

1

Page 36

Elecsys 1010 Service Manual

FINAL 2.1 - February 2000 Chapter 10

2

Page 37

Elecsys 1010 Service Manual

10.210.2

10.2

10.210.2

Detailed descriptions of the maintenance procedures listed

below can be found later in this chapter.

DailyDaily

Daily

DailyDaily

Bi-weeklyBi-weekly

Bi-weekly

Bi-weeklyBi-weekly

As requiredAs required

As required

As requiredAs required

Maintenance ScheduleMaintenance Schedule

Maintenance Schedule

Maintenance ScheduleMaintenance Schedule

None

Perform SYSTEM CLEANING INTENSIVE

Clean the microparticle mixer

Clean the sipper probe

Clean the S/R probe

Perform CELL CLEANING NORMAL

Clean the analyzer surfaces and cover

Replace printer paper

Clean the rinse stations

RD Service onlyRD Service only

RD Service only

RD Service onlyRD Service only

Perform CELL CLEANING INTENSIVE

FINAL 2.1 - February 2000 Chapter 10

3

Page 38

Elecsys 1010 Service Manual

FINAL 2.1 - February 2000 Chapter 10

4

Page 39

Elecsys 1010 Service Manual

10.310.3

10.3

10.310.3

10.3.110.3.1

10.3.1

10.3.110.3.1

Perform the SYSTEM CLEANING INTENSIVE function

to prevent deposits and bacterial contamination. The

analyzer displays a message when a maintenance

procedure is required. This function should be performed

on a bi-weekly basis.

NoteNote

Note

NoteNote

The frequency with which the cleaning function is

performed is dependent on the test throughput and can

be set thus allowing longer maintenance intervals to be

defined.

Safety PrecautionsSafety Precautions

Safety Precautions

Safety PrecautionsSafety Precautions

None.

Materials NecessaryMaterials Necessary

Materials Necessary

Materials NecessaryMaterials Necessary

Edisonite.

Bi-weekly Analyzer MaintenanceBi-weekly Analyzer Maintenance

Bi-weekly Analyzer Maintenance

Bi-weekly Analyzer MaintenanceBi-weekly Analyzer Maintenance

Perform SYSTEM CLEANINGPerform SYSTEM CLEANING

Perform SYSTEM CLEANING

Perform SYSTEM CLEANINGPerform SYSTEM CLEANING INTENSIVEINTENSIVE

INTENSIVE

INTENSIVEINTENSIVE

1. Press the UTILITIES key and then the

MAINTENANCE key. The MAINTENANCE,

SYSTEM CLEANING screen is displayed.

2. Press the SYSTEM CLEANING INTENSIVE key

and follow the instructions displayed on screen.

3. When all requirements that are displayed on

screen have been fulfilled, press the START key.

Elecsys 1010 starts the cleaning process and

displays the time remaining until the cleaning

process is complete. After half of the necessary

time of the cleaning process you have to empty

the waste container and clean it with distilled

water. Press PAUSE (at the bottom right of the

screen) to interrupt the cleaning process. The

process can be continued by pressing CONTINUE

(same key).

4. Elecsys 1010 displays a message when the

cleaning process is complete.

SYSTEM CLEANING INTENSIVE is now complete.

FINAL 2.1 - February 2000 Chapter 10

5

Page 40

Elecsys 1010 Service Manual

10.3.210.3.2

10.3.2

10.3.210.3.2

MixerMixer

Mixer

MixerMixer

Wipe the microparticle mixer clean every second week

to remove any contamination. Do not bend the

microparticle mixer.

Safety PrecautionsSafety Precautions

Safety Precautions

Safety PrecautionsSafety Precautions

The analyzer must be switched off. Ensure that the

normal laboratory safety precautions are heeded and

wear rubber gloves.

Materials NecessaryMaterials Necessary

Materials Necessary

Materials NecessaryMaterials Necessary

Absorbent, lint-free cloth and alcohol.

Clean the MicroparticleClean the Microparticle

Clean the Microparticle

Clean the MicroparticleClean the Microparticle

10.3.310.3.3

10.3.3

10.3.310.3.3

Wipe the sipper probe clean every second week to

remove any contamination.

Safety PrecautionsSafety Precautions

Safety Precautions

Safety PrecautionsSafety Precautions

The analyzer must be switched off. The sipper probe is

potentially biohazardous. Ensure that the normal

laboratory safety precautions are heeded and wear

rubber gloves.

Materials NecessaryMaterials Necessary

Materials Necessary

Materials NecessaryMaterials Necessary

Absorbent, lint-free cloth and alcohol.

NoteNote

Note

NoteNote

Water droplets on the tip of the probe indicate possible

contamination. This can affect the LLD function which

may lead to analyzer problems.

Clean the Sipper ProbeClean the Sipper Probe

Clean the Sipper Probe

Clean the Sipper ProbeClean the Sipper Probe

1. Power off the analyzer. Gently raise the S/R arm up

and out of rinse well.

2. Rotate the sample/reagent arm manually so that the

microparticle mixer can be easily accessed.

3. Clean the mixer with a lint-free cloth soaked in

alcohol.

CAUTIONCAUTION

CAUTION

CAUTIONCAUTION

Handle the microparticle mixer with care. Do not bend.

A bent mixer can cause analyzer errors.

1. Power off the analyzer. Gently raise the sipper probe

up and out of the rinse well.

2. Rotate the sipper arm manually so that the probe can