Page 1

Roche Diagnostics / Hitachi

cobas e 411

Service Manual Version 1.0

May 2006

Page 2

Service Manual

for

cobas e411

Immunoassay

System

Page 3

Revision Record

Date Number Version New Chapter

January 2006 Draft

May 2006 1.0

Note

Part No. and Part name are different depending on the manufacturing time.

Please refer to Parts List for details

.

Page 4

RD/Hitachi Immunoassay System cobas e411 Service

Manual

1. Application/Introduction

1.1 Instrument

1.2 Specifications

1.3 Operating Precautions and Hazards

1.4 Service Concept

1.5 Rack Sampler/Rack Conveyor System

2. Installation / Set Up

2.1 Site Requirements

2.2 Inventory

2.3 Analyzer Installation

2.4 Software Installation

2.5 Rack Sampler Connected to CLAS 1 System Installation

2.6 Check/Adjustment During Installation

3. Fludics

3.1 Description of Flow Path

3.2 System Volume

3.3 Cleaning Procedures

3.4 SysWash

4. Mechanics

4.1 Overview

4.2 Location of Mechanisms

4.3 List of Motors, Sensors and Other Mechanisms

4.4 Detailed Explanation of Each Mechanism

4.5 Mechanical Adjustment

4.6 Rack Sampler System

5. Electronics

5.1 Boards

5.2 Power Source

5.3 Electronic Modules

5.4 Printed Circuit Boards

5.5 Cross Wiring Diagrams

5.6 How to Check Photo Interrupters

6. Service Software

6.1 Overview

1

Page 5

7. Troubleshooting

7.1. Alarms List

7.2 Data Alarms

7.3 Troubleshooting List

7.4 Data File Load Errors

7.5 Quality Control Check

8. Spare Parts/Recommended Parts

8.1 Special Service Tools

8.2 Complete Recommended Parts List

8.3 Printed Circuit Boards List

9. Host Interface (not applicable)

10. Maintenance

10.1 Operator Maintenance

10.2 Preventive Maintenance

10.3 Maintenance Material

Appendix

Timing Chart Tables

Assay Timetable

2

Page 6

System Description

Chapter 1 System Description

1.1

INSTRUMENT ..............................................................................................................................................1 - 1

1.1.1 System Configuration........................................................................................................................ 1 - 1

1.1.2 System Introduction........................................................................................................................... 1 - 2

1.1.3 Control Unit Components ................................................................................................................. 1 - 5

1.1.4 Sample/Reagent Area Components................................................................................................... 1 - 7

1.1.5 Consumables Area Components...................................................................................................... 1 - 22

1.1.6 Measuring Area Components.......................................................................................................... 1 - 27

1.1.7 Power Components ......................................................................................................................... 1 - 33

1.1.8 Mechanical Theory.......................................................................................................................... 1 - 35

1.1.9 Detailed Assay Sequence................................................................................................................. 1 - 38

1.1.10 Dilution Steps................................................................................................................................ 1 - 47

1.1.11 Analyzer Status Conditions ...........................................................................................................1 - 48

1.2 TECHNICAL DATA ....................................................................................................................................1 - 52

1.2.1 Technical Data for Operation of Instrument................................................................................... 1 - 52

1.3 POTENTIAL HAZARD AND SAFETY PRECAUTIONS ....................................................................................1 - 61

1.3.1 Safety Classifications ...................................................................................................................... 1 - 61

1.3.2 Safety Information........................................................................................................................... 1 - 62

1.3.3 Safety Labels on the cobas e411...................................................................................................... 1 - 68

1.3.4 Approvals ........................................................................................................................................ 1 - 70

1.4 SYSTEM LABEL ........................................................................................................................................1 - 71

1.4.1 Disk System ..................................................................................................................................... 1 - 71

1.4.2 Rack System..................................................................................................................................... 1 - 73

Contents - 1

Page 7

Installation / Set Up

Chapter 2 Installation / Set Up

2.1

SITE REQUIREMENTS..................................................................................................................................2 - 1

2.1.1 Delivery Space Requirements............................................................................................................ 2 - 1

2.1.2 Physical Space and weighs Requirements......................................................................................... 2 - 1

2.1.3 Ambient Condition Requirements...................................................................................................... 2 - 3

2.1.4 Electrical Requirements.................................................................................................................... 2 - 3

2.1.5 Water Requirements.......................................................................................................................... 2 - 3

2.2 INVENTORY ................................................................................................................................................2 - 4

2.3 ANALYZER INSTALLATION .........................................................................................................................2 - 7

2.3.1 Unpacking ......................................................................................................................................... 2 - 7

2.3.2 Explanation of Packaging Position in the System...........................................................................2 - 14

2.3.3 Panel PC Installation and confirmation of AC Power Supply ........................................................ 2 - 21

2.3.4 Setup................................................................................................................................................ 2 - 25

2.3.5 Mounting a Measuring Cell ............................................................................................................ 2 - 25

2.3.6 Installation of System Software....................................................................................................... 2 - 26

2.3.7 Fill Liquid System ........................................................................................................................... 2 - 26

2.3.8 Adjustments to be Checked During Installation and After Replacement......................................... 2 - 26

2.3.9 Measuring Cell Preparation ........................................................................................................... 2 - 27

2.3.10 System Volume Check....................................................................................................................2 - 28

2.3.11 High Voltage Check/Adjustment ................................................................................................... 2 - 28

2.3.12 Initial BlankCell Calibrations....................................................................................................... 2 - 35

2.3.13 Instrument Checks......................................................................................................................... 2 - 39

2.3.14 Assay Calibration.......................................................................................................................... 2 - 51

2.3.15 Installation Procedures Overview / Checklist............................................................................... 2 - 51

2.3.16 Procedure for Multiple Installations............................................................................................. 2 - 51

2.4 SOFTWARE INSTALLATION .......................................................................................................................2 - 53

2.4.1 Application Instruction.................................................................................................................... 2 - 53

2.4.2 Printer Driver Instruction............................................................................................................... 2 - 58

2.4.3 System Parameter Setup.................................................................................................................. 2 - 69

2.5 RACK SAMPLER SYSTEM INSTALLATION..................................................................................................2 - 70

2.5.1 Rack Sampler System Installation................................................................................................... 2 - 70

2.6 CHECKS/ADJUSTMENTS DURING INSTALLATION .....................................................................................2 - 84

2.6.1 Bead Mixer......................................................................................................................................2 - 84

2.6.2 Pipetter Adjustment......................................................................................................................... 2 - 86

2.6.3 Sipper adjustment............................................................................................................................ 2 - 86

2.6.4 Electronic adjustments.................................................................................................................... 2 - 86

2.6.5 Rack Sampler adjustments ..............................................................................................................2 - 86

2.7 TABLE OF CONTENTS ...............................................................................................................................2 - 92

2.7.1 Method to detach the external covers..............................................................................................2 - 92

2.7.2 Method to attach the external covers .............................................................................................. 2 - 99

2.7.3 Mmethod to detach the PC Unit.................................................................................................... 2 - 107

2.7.4 Method to attach the PC Unit ....................................................................................................... 2 - 109

Contents - 1

Page 8

Fluidics

Chapter 3 Fluidics

3.1

DESCRIPTION OF FLOW PATH .....................................................................................................................3 - 1

3.1.1 Overall Piping Diagram.................................................................................................................... 3 - 2

3.1.2 List of Parts.......................................................................................................................................3 - 3

3.2 SYSTEM VOLUME.......................................................................................................................................3 - 3

3.2.1 Definition of System Volume ............................................................................................................. 3 - 3

3.2.2 Determination of System Volume ...................................................................................................... 3 - 3

3.2.3 Storage of the System Volume Value / Data Handling...................................................................... 3 - 4

3.3 CLEANING PROCEDURES ............................................................................................................................3 - 5

3.3.1 Liquid Flow Cleaning .......................................................................................................................3 - 5

3.3.2 Cleaning Procedure for Fluidics System........................................................................................... 3 - 6

3.4 SYSWASH ..................................................................................................................................................3 - 8

3.4.1 Introduction....................................................................................................................................... 3 - 8

3.4.2 SysWash Rinsing Procedure.............................................................................................................. 3 - 8

Contents - 1

Page 9

Mechanics

Chapter 4 Mechanics

4.1

OVERVIEW .................................................................................................................................................4 - 1

4.1.1 Location ............................................................................................................................................4 - 1

4.1.2 Outline of Mechanical Units ............................................................................................................. 4 - 1

4.2 LOCATION OF MECHANISMS ......................................................................................................................4 - 3

4.2.1 Analyzer ............................................................................................................................................4 - 3

4.2.2 Rack Sampler System ........................................................................................................................ 4 - 6

4.3 LIST OF MOTORS, SENSORS, AND OTHER MECHANISMS ..........................................................................4 - 10

4.3.1 List of Motors.................................................................................................................................. 4 - 10

4.3.2 Motor Reference List....................................................................................................................... 4 - 10

4.3.3 List of Sensors ................................................................................................................................. 4 - 10

4.3.4 List of Peltier, Heater and Fan Motor ............................................................................................ 4 - 11

4.3.5 List of Motors for Rack Sampler System ......................................................................................... 4 - 12

4.3.6 List of Sensors for Rack Sampler System ........................................................................................4 - 12

4.3.7 List of LEDs and Fan Motor for Rack Sampler System .................................................................. 4 - 12

4.4 DETAILED EXPLANATION OF EACH MECHANISM .....................................................................................4 - 13

4.4.1 Sample Disk Drive Mechanism ....................................................................................................... 4 - 13

4.4.2 Reagent Disk Drive Mechanism......................................................................................................4 - 19

4.4.3 Cap Open/Close Mechanism........................................................................................................... 4 - 28

4.4.4 Beads Mixer Mechanism................................................................................................................. 4 - 33

4.4.5 Pipetter Mechanism ........................................................................................................................ 4 - 40

4.4.6 Gripper Mechanism ........................................................................................................................ 4 - 52

4.4.7 Sipper Mechanism...........................................................................................................................4 - 66

4.4.8 System Reagent Mechanism ............................................................................................................ 4 - 74

4.4.9 Syringe Mechanism ......................................................................................................................... 4 - 77

4.4.10 System Water Container (Float SW) Mechanism / Pump Assembly.............................................. 4 - 81

4.4.11 Liquid Waste Container Mechanism............................................................................................. 4 - 87

4.4.12 Solid Waste Mechanism ................................................................................................................4 - 91

4.4.13 Detection Unit............................................................................................................................... 4 - 94

4.4.14 Magnet Drive Mechanism........................................................................................................... 4 - 105

4.4.15 Matrix BCR Mechanism.............................................................................................................. 4 - 110

4.4.16 SIPPER SAFETY COVER (INTER ROCK Mechanism).............................................................. 4 - 121

4.5 MECHANICAL ADJUSTMENT...................................................................................................................4 - 123

4.5.1 Overview .......................................................................................................................................4 - 123

4.5.2 Mechanical Adjustment Procedure............................................................................................... 4 - 123

4.5.3 Mechanical Adjustment Procedure for Rack Sampler .................................................................. 4 - 129

4.6 RACK SAMPLER SYSTEM........................................................................................................................4 - 132

4.6.1 Overview .......................................................................................................................................4 - 132

4.6.2 Rack Sampler Movement............................................................................................................... 4 - 132

4.6.3 A Line............................................................................................................................................ 4 - 133

4.6.4 B Line............................................................................................................................................ 4 - 134

4.6.5 C Line............................................................................................................................................ 4 - 137

Contents - 1

Page 10

Electronics

Chapter 5 Electronics

5.1

BOARDS .....................................................................................................................................................5 - 1

5.1.1 System Overview ............................................................................................................................... 5 - 1

5.1.2 Location of Boards............................................................................................................................ 5 - 2

5.2 POWER SOURCE .......................................................................................................................................5 - 10

5.2.1 AC Power ........................................................................................................................................ 5 - 10

5.2.2 DC Power Supply............................................................................................................................ 5 - 11

5.3 ELECTRONIC MODULES / ELECTRONIC ADJUSTMENTS .............................................................................5 - 17

5.3.1 Principle of Temperature Control................................................................................................... 5 - 17

5.3.2 Principle of LLD ............................................................................................................................. 5 - 18

5.3.3 Principle of Clot Detection ............................................................................................................. 5 - 20

5.3.4 Adjustment / Check Procedure of LLD/Clot Detection ................................................................... 5 - 20

5.3.5 Functional Details of FRONT SW (Operation Switch) ................................................................... 5 - 27

5.3.6 Details of Temperature Control / Troubleshooting of Temp. Units ................................................5 - 28

5.3.7 Serial Data Communication............................................................................................................ 5 - 31

5.3.8 Adjustment of Mixer Speed.............................................................................................................. 5 - 32

5.4 PRINTED CIRCUIT BOARDS.......................................................................................................................5 - 33

5.4.1 ECPU550 Board ............................................................................................................................. 5 - 33

5.4.2 EECL300 Board..............................................................................................................................5 - 36

5.4.3 EMOT300 Board............................................................................................................................. 5 - 38

5.4.4 EIO3 Board..................................................................................................................................... 5 - 42

5.4.5 DO1 Board...................................................................................................................................... 5 - 44

5.4.6 DO2 Board...................................................................................................................................... 5 - 47

5.4.7 DO3 Board...................................................................................................................................... 5 - 48

5.4.8 DIST-PA Board............................................................................................................................... 5 - 50

5.4.9 DIST-SA Board................................................................................................................................ 5 - 51

5.4.10 DIST-TVA Board........................................................................................................................... 5 - 52

5.4.11 DIST-F Board................................................................................................................................ 5 - 52

5.4.12 DIST-F3 Board.............................................................................................................................. 5 - 54

5.4.13 DIST232C Board........................................................................................................................... 5 - 55

5.4.14 ANG-EP2 Board............................................................................................................................ 5 - 56

5.4.15 PMT-SHV2 Board ......................................................................................................................... 5 - 59

5.4.16 L-AMP(3) Board ........................................................................................................................... 5 - 60

5.4.17 LLD-SA Board............................................................................................................................... 5 - 62

5.4.18 LLD-P3 Board............................................................................................................................... 5 - 63

5.4.19 UIRS-C Board............................................................................................................................... 5 - 64

5.4.20 MVLB110 Board ........................................................................................................................... 5 - 65

5.4.21 S.AB-CE Board .............................................................................................................................5 - 66

5.4.22 DET-A Board ................................................................................................................................5 - 67

5.4.23 DET-B Board ................................................................................................................................5 - 68

5.4.24 DET-C Board ................................................................................................................................ 5 - 68

5.4.25 DETECT1 Board........................................................................................................................... 5 - 69

5.4.26 RS CONTD Doard......................................................................................................................... 5 - 69

5.4.27 PS CONTA Board .........................................................................................................................5 - 71

5.4.28 DO4A Board ................................................................................................................................. 5 - 73

5.4.29 BCR Board .................................................................................................................................... 5 - 75

5.4.30 PH-D Board .................................................................................................................................. 5 - 76

5.4.31 PH-T Board................................................................................................................................... 5 - 76

5.5 CROSS WIRING DIAGRAMS ......................................................................................................................5 - 77

5.5.1 Cross Wiring Diagrams for Rack Sampler System.......................................................................... 5 - 77

5.5.2 Cross Wiring Diagrams for Rack Sampler...................................................................................... 5 - 77

5.6 HOW TO CHECK PHOTO INTERRUPTERS ...................................................................................................5 - 78

5.6.1 Photo Interrupters........................................................................................................................... 5 - 78

5.6.2 How to check the PCPs................................................................................................................... 5 - 80

Contents - 1

Page 11

Service Software

Chapter 6 Service Software

6.1

OVERVIEW .................................................................................................................................................6 - 1

6.1.1 Utility Screen of Print ....................................................................................................................... 6 - 4

6.1.2 Interface Setup ................................................................................................................................ 6 - 10

6.1.3 System Setup.................................................................................................................................... 6 - 13

6.1.4 Storage Utility ................................................................................................................................. 6 - 15

6.1.5 Documentation and Printer Setting................................................................................................. 6 - 18

6.1.6 Keep Function Setup ....................................................................................................................... 6 - 20

6.1.7 Retry Function Setup....................................................................................................................... 6 - 20

6.1.8 Sample Reception Mode.................................................................................................................. 6 - 21

6.2 MAINTENANCE.........................................................................................................................................6 - 22

6.2.1 Detailed Description of Each Maintenance Function..................................................................... 6 - 24

6.3 MECHANISM CHECK ................................................................................................................................6 - 27

6.3.1 System Volume Check......................................................................................................................6 - 31

6.3.2 Assay Performance Check............................................................................................................... 6 - 31

6.3.3 Voltage Monitor .............................................................................................................................. 6 - 39

6.3.4 Temperature Monitor...................................................................................................................... 6 - 40

6.3.5 Sensor Monitor................................................................................................................................ 6 - 41

6.4 SERVICE ...................................................................................................................................................6 - 43

6.4.1 Manual Adjustment ......................................................................................................................... 6 - 44

6.4.2 Adjustment Rack.............................................................................................................................. 6 - 47

6.4.3 BCR Setup ....................................................................................................................................... 6 - 49

6.4.4 Service Setup ................................................................................................................................... 6 - 52

6.4.5 Service Maintenance ....................................................................................................................... 6 - 53

6.4.6 Alarm Setting................................................................................................................................... 6 - 55

6.4.7 Initial Blank Cell............................................................................................................................. 6 - 56

6.4.8 Automatic Adjustment ..................................................................................................................... 6 - 59

Contents - 1

Page 12

Troubleshooting

Chapter 7 Troubleshooting

7.1

ALARM LIST...............................................................................................................................................7 - 1

7.2 DATA ALARM LIST ....................................................................................................................................7 - 2

7.3 TROUBLESHOOTING LIST ............................................................................................................................7 - 4

7.3.1 Reagent Disk ..................................................................................................................................... 7 - 4

7.3.2 Cap Opener....................................................................................................................................... 7 - 5

7.3.3 Beads Mixer ......................................................................................................................................7 - 6

7.3.4 Barcode Reader Mechanism ............................................................................................................. 7 - 8

7.3.5 Sample Disk Mechanism ................................................................................................................... 7 - 8

7.3.6 Pipetter Mechanism .......................................................................................................................... 7 - 9

7.3.7 Pipetter / Sipper Syringe ................................................................................................................. 7 - 11

7.3.8 Gripper Mechanism ........................................................................................................................ 7 - 12

7.3.9 Solid Waste...................................................................................................................................... 7 - 15

7.3.10 Sipper Mechanism.........................................................................................................................7 - 16

7.3.11 Magnet Drive Mechanism............................................................................................................. 7 - 17

7.3.12 Pipetter Buffer............................................................................................................................... 7 - 18

7.3.13 Distilled Water Float Switch......................................................................................................... 7 - 18

7.3.14 System Reagent Unit ..................................................................................................................... 7 - 19

7.3.15 Liquid Waste Mechanism .............................................................................................................. 7 - 19

7.3.16 Rack Sampler System .................................................................................................................... 7 - 21

7.3.17 CF card problem...........................................................................................................................7 - 22

7.4 QUALITY CONTROL CHECK......................................................................................................................7 - 26

7.4.1 Covers ............................................................................................................................................. 7 - 26

7.4.2 Sample/Assay Reagent Rotation Mechanism...................................................................................7 - 26

7.4.3 Cap Open/Close Mechanism........................................................................................................... 7 - 26

7.4.4 Beads Mixer Mechanism................................................................................................................. 7 - 26

7.4.5 Barcode Reader Mechanism ........................................................................................................... 7 - 26

7.4.6 Pipetter, Sipper Mechanism............................................................................................................ 7 - 27

7.4.7 Syringes Mechanism (after exchange); ........................................................................................... 7 - 27

7.4.8 Gripper Mechanism ........................................................................................................................ 7 - 27

7.4.9 solid Waste Mechanism................................................................................................................... 7 - 27

7.4.10 1Incubation Unit ........................................................................................................................... 7 - 27

7.4.11 1Detection Unit ............................................................................................................................. 7 - 28

7.4.12 1Pump Module (after exchange);.................................................................................................. 7 - 28

Contents - 1

Page 13

Spare Parts/Recommended Parts

Chapter 8 Spare Parts/Recommended Parts

8.1

SPECIAL SERVICE TOOLS ...........................................................................................................................8 - 1

8.2 COMPLETE PARTS LIST ..............................................................................................................................8 - 2

Contents - 1

Page 14

Host Interface

Chapter 9 Host Interface

9.1

HOST INTERFACE .......................................................................................................................................9 - 1

Contents - 1

Page 15

Maintenance

Chapter 10 Maintenance

10.1

MAINTENANCE PROCEDURE OVERVIEW ................................................................................................10 - 6

10.1.1 Replace pipettor tube 510 ............................................................................................................. 10 - 8

10.1.2 Replace pipettor tube 465 with nozzle seal .................................................................................10 - 10

10.1.3 Replace Pinch Valve Tubing ....................................................................................................... 10 - 13

10.1.4 Replace Pipettor Seals ................................................................................................................ 10 - 15

10.1.5 Exchange packings for sipper & pipettor syringe....................................................................... 10 - 22

10.1.6 Clean Rinse Stations for S/R Probe, Mixer and Sipper Probe.................................................... 10 - 24

10.1.7 Clean Sipper and S/R probe........................................................................................................ 10 - 26

10.1.8 Clean water filter main pump...................................................................................................... 10 - 29

10.1.9 Clean System Water Container ................................................................................................... 10 - 31

10.1.10 Clean Liquid Waste Container.................................................................................................. 10 - 33

10.1.11 Clean ProCell/CleanCell Compartments.................................................................................. 10 - 34

10.1.12 Clean Reagent Disk and Compartment ..................................................................................... 10 - 35

10.1.13 Check drain tubes for contamination and exchange if necessary ............................................. 10 - 37

10.1.14 Drain the outlet pipettor wash station and waste pipe.............................................................. 10 - 39

10.1.15 Perform Liquid Flow Cleaning ................................................................................................. 10 - 39

10.1.16 Perform system volume check ................................................................................................... 10 - 41

10.1.17 Exchange mixer belt S............................................................................................................... 10 - 41

10.1.18 Clean mixer paddle ................................................................................................................... 10 - 42

10.1.19 Check mixer speed; adjust if necessary..................................................................................... 10 - 43

10.1.20 Check / Clean gripper finger..................................................................................................... 10 - 44

10.1.21 Clean light barriers and mechanic parts................................................................................... 10 - 45

10.1.22 Clean Incubator and Aspiration Station.................................................................................... 10 - 45

10.1.23 Check LLD voltage pipettor ...................................................................................................... 10 - 47

10.1.24 Check LLD voltage sipper......................................................................................................... 10 - 47

10.1.25 Check clot voltage..................................................................................................................... 10 - 47

10.1.26 Check Temperature Monitor for Detection unit........................................................................ 10 - 47

10.1.27 Check Temperature Monitor for Incubator............................................................................... 10 - 47

10.1.28 Check Temperature Monitor for Reagent.................................................................................. 10 - 47

10.1.29 Check Temperature Monitor for PC / CC................................................................................. 10 - 47

10.1.30 Clean peltier elements from dust if necessary........................................................................... 10 - 47

10.1.31 Clean BCR window and window reagent disk .......................................................................... 10 - 49

10.1.32 Perform artificial media check.................................................................................................. 10 - 50

10.1.33 Perform TSH assay test............................................................................................................. 10 - 50

10.1.34 Perform initial blank cell .......................................................................................................... 10 - 50

10.1.35 Perform assay calibration......................................................................................................... 10 - 50

10.1.36 Perform assay control............................................................................................................... 10 - 50

10.1.37 Exchange measuring cell .......................................................................................................... 10 - 51

10.1.38 Exchange tube B for MC ........................................................................................................... 10 - 52

10.1.39 Exchange tube B for sipper with nozzle seal............................................................................. 10 - 54

10.1.40 Exchange tube B for sipper syringe .......................................................................................... 10 - 56

10.1.41 Clean the valve body on the system water container................................................................. 10 - 58

10.1.42 Exchange O-ring SV 1 / 2 / 5 / 6 / 7 .......................................................................................... 10 - 59

10.1.43 Exchange sipper wash station................................................................................................... 10 - 61

10.1.44 Exchange the spring at the gripper finger................................................................................. 10 - 64

10.2 OPERATOR MAINTENANCE...................................................................................................................10 - 66

10.3 MAINTENANCE MATERIALS .................................................................................................................10 - 67

Contents - 1

Page 16

RD/Hitachi cobas e411 Service Manual

1.1 Instrument

1.1.1 System Configuration

Figure 1.1-1 cobas e411 disk system

Figure 1.1-2 cobas e411 rack system

Version 1.0 – May 2006 1 - 1 Chapter 1.1

Page 17

RD/Hitachi cobas e411 Service Manual

1.1.2 System Introduction

The Roche Diagnostics cobas e411 Immunoassay System is a fully automated, software-controlled

system for immunoassay analysis. It is designed for both quantitative and qualitative in vitro

determinations using a large variety of tests for analysis.

To assist you in quickly identifying which component is specific to either the disk or rack system, one

of the following graphics appears to the right of the subsection header. If no graphic appears next to

the header, then that component is common to both systems.

Figure 1.1-3 Disk

Figure 1.1-4 Rack

1.1.2.1 The Control Unit

The control unit of the e411 analyzer is a touchscreen, no-keyboard type computer, which is located

on the left-center of the analyzer unit. This monitor unit contains the controlling software and also has

an on-screen keyboard function.

Figure 1.1-5 Control unit

Version 1.0 – May 2006 1 - 2 Chapter 1.1

Page 18

RD/Hitachi cobas e411 Service Manual

1.1.2.2 The Analyzer Unit

Figure 1.1-6

The analyzer unit on the disk system consists of the:

• sample/reagent area

• consumables area

• measuring area

• operation switch

The only difference on the rack system is in the sample area. The sample disk is replaced by a rack

sampling unit.

Refer to the photo below.

Figure 1.1-7

Version 1.0 – May 2006 1 - 3 Chapter 1.1

Page 19

RD/Hitachi cobas e411 Service Manual

1.1.2.3 Sample/Reagent Area

The sample/reagent area comprises the left half of the analyzer and consists of a sample disk or rack

sampler (rack system), rack bar code reader (rack system), sample/reagent (S/R) probe, bar code

reader, bar code card reading station, reagent disk, a cap open/close mechanism, a microparticle

mixer, probe/ mixer rinse station and sample/reagent (S/R) pipettor.

The sample disk accommodates up to 30 samples. The A-Line of the rack sampler accommodates 75

samples on a single tray (15 racks at a time; each rack with five positions) and 25 samples in the input

buffer for a total capacity of 100 samples. The reagent disk, temperature controlled at 20 ± 3 °C,

accommodates up to 18 reagent packs.

1.1.2.4 Consumables Area

The consumables area is on the right of the analyzer, consisting of three tip trays, three AssayCup

trays, a gripper unit, cup disposal opening, liquid waste container, solid waste tray and liner and

system water container.

1.1.2.5 Measuring Area

The measuring area includes the incubator, the sipper probe, sipper rinse station, system reagents

(ProCell and CleanCell), an aspiration station, sipper pipettor and the detection unit. The sipper probe

aspirates the incubated reaction mixture into the detection unit for result determination.

1.1.2.6 Operation Switch

The operation ON/OFF switch is located on the front left of the analyzer. In addition, there is a circuit

breaker for the analyzer located on the right side panel and a rack sampler circuit breaker located on

the left side of the rack sampler.

Version 1.0 – May 2006 1 - 4 Chapter 1.1

Page 20

RD/Hitachi cobas e411 Service Manual

1.1.3 Control Unit Components

The control unit consists of a color touchscreen monitor, host interface and external printer.

1.1.3.1 Touchscreen Monitor

The touchscreen monitor is located on the left-center of the analyzer and displays the software. For

details on the cobas e411 software, refer to the Software Guide.

Figure 1.1-8 Touchscreen monitor

Version 1.0 – May 2006 1 - 5 Chapter 1.1

Page 21

RD/Hitachi cobas e411 Service Manual

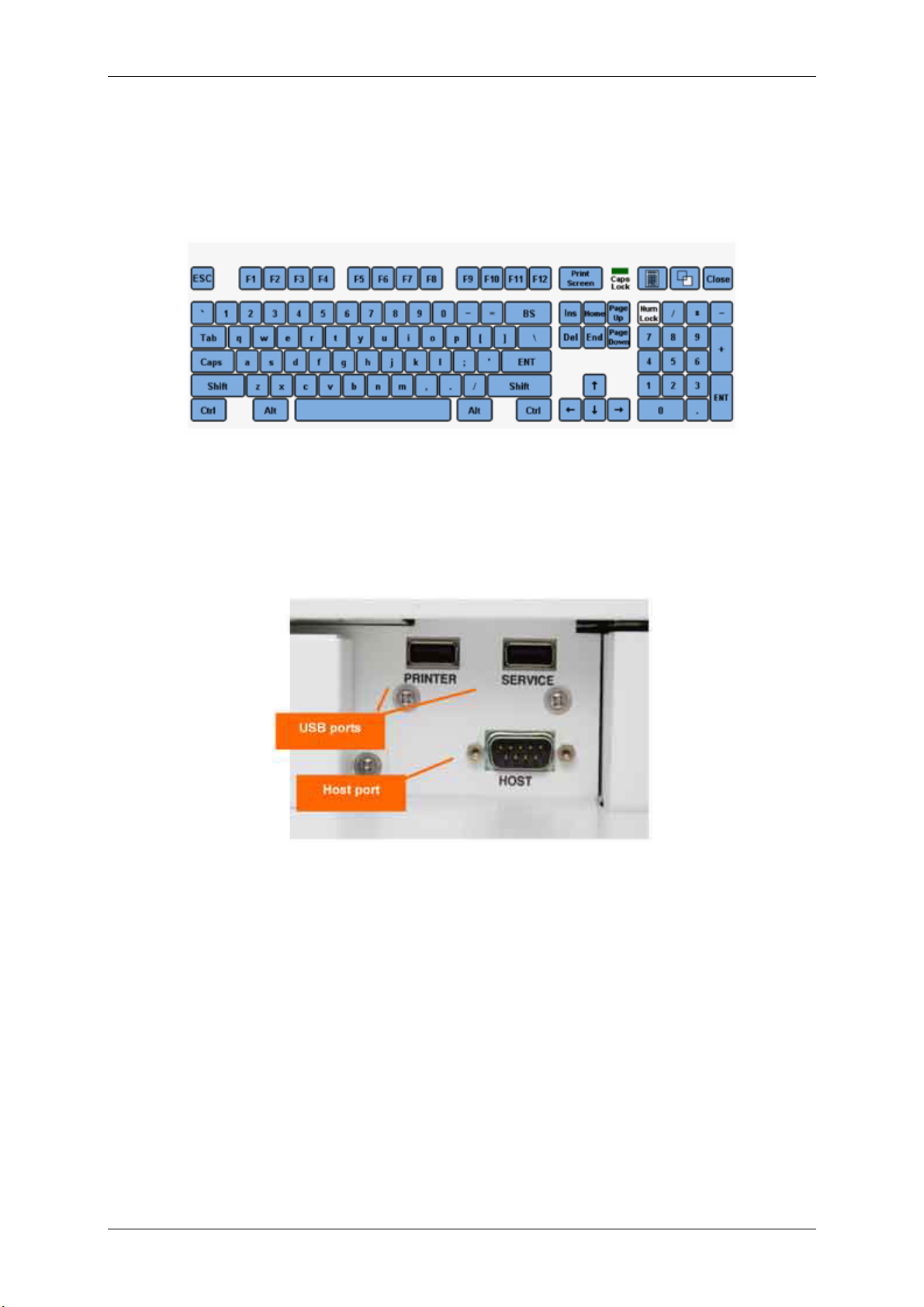

1.1.3.2 On-screen Keyboard

The e411 software has an on-screen keyboard. For details refer to the Software Guide.

Figure 1.1-9 On-screen keyboard

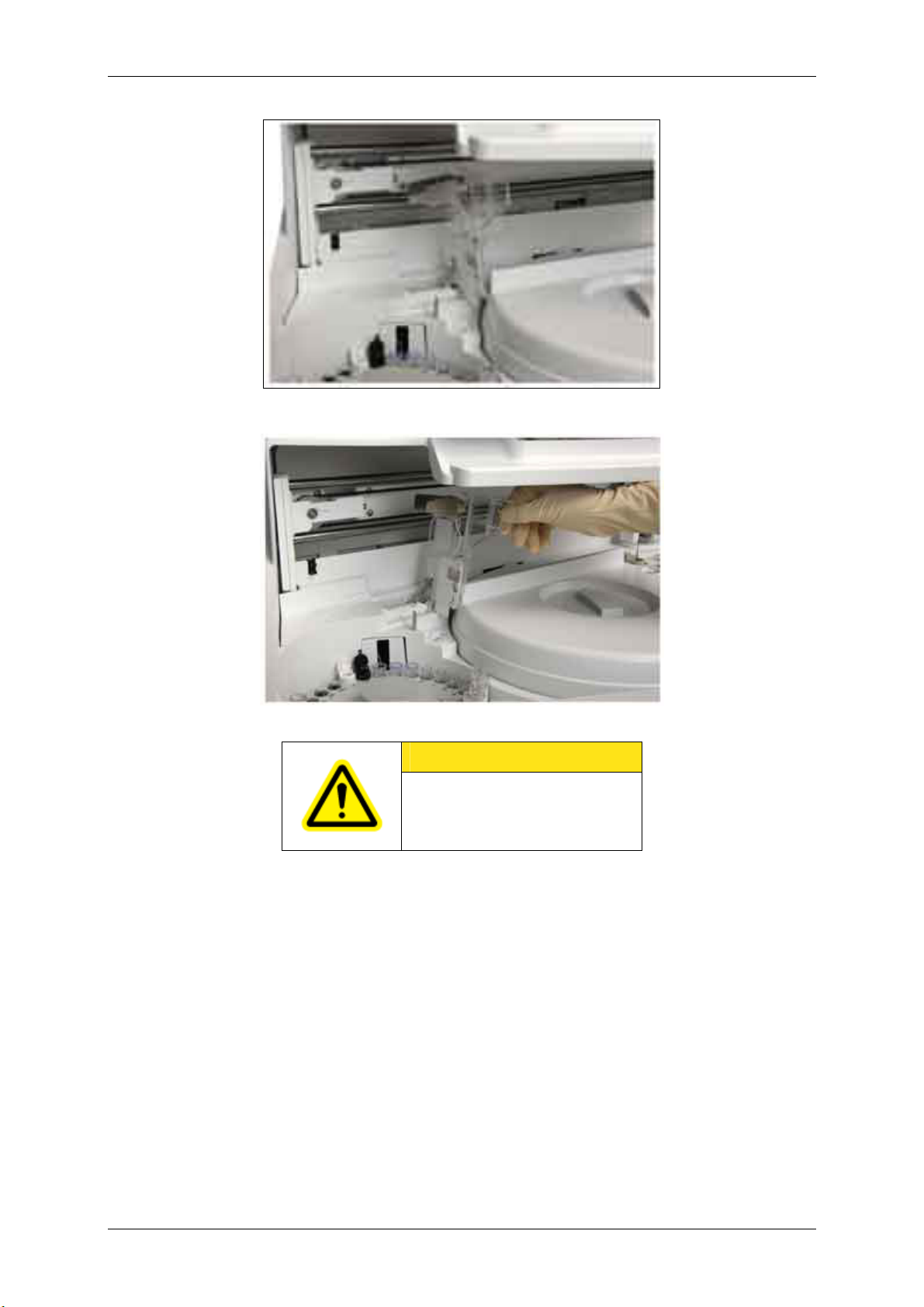

1.1.3.3 External Printer

The instrument uses an 80-column, graphics-capable, dot matrix printer.

The printer is connected to the analyzer via a USB port. The analyzer has two USB ports on its left

side.

Figure 1.1-10 Location of the USB ports and Host port

1.1.3.4 Host Interface

The instrument can be bidirectionally interfaced with a host computer.

Please refer the Host Interface manual in detail.

Version 1.0 – May 2006 1 - 6 Chapter 1.1

Page 22

RD/Hitachi cobas e411 Service Manual

1.1.4 Sample/Reagent Area Components

The sample/reagent area consists of a sample disk or rack sampler (rack system), rack ID bar code

reader (rack system), sample/reagent (S/R) probe, bar code reader, bar code card reading station,

reagent disk, cap open/close mechanism, microparticle mixer, probe/mixer rinse station and

sample/reagent (S/R) pipettor.

Figure 1.1-11 Sample Disk

The sample disk has 30 positions for samples, calibrators and controls. Patient samples may be

placed in either primary sample tubes or sample cups. Built-in adapters allow intermixing of different

size primary sample tubes.

Sample tubes that may be used are listed in chapter 2.7 Technical Data.

Sample cups [2 mL (Standard) Hitachi cups only] may be placed directly on the sample disk or on top

of 16 mm primary sample tubes.

Figure 1.1-12 Sample disk

CAUTION

Micro cups cannot be used on the

e411 analyzer!

Version 1.0 – May 2006 1 - 7 Chapter 1.1

Page 23

RD/Hitachi cobas e411 Service Manual

Note: How to raise the sample disk protective cover

To take out the sample disk, first you must raise the sample disk protective cover. The cover can be

held at a certain angle. To lay the cover down, release the hold by raising the cover up to its limit

angle. Be sure to lay it down before you start operation.

Figure 1.1-13 Sample disk protective cover

Figure 1.1-14 n Raising the sample disk protective cover

Version 1.0 – May 2006 1 - 8 Chapter 1.1

Page 24

RD/Hitachi cobas e411 Service Manual

Figure 1.1-15 Standing angle

Figure 1.1-16 Limit angle

CAUTION

Be sure to lay down the sample disk

protective cover before you start

operation.

Version 1.0 – May 2006 1 - 9 Chapter 1.1

Page 25

RD/Hitachi cobas e411 Service Manual

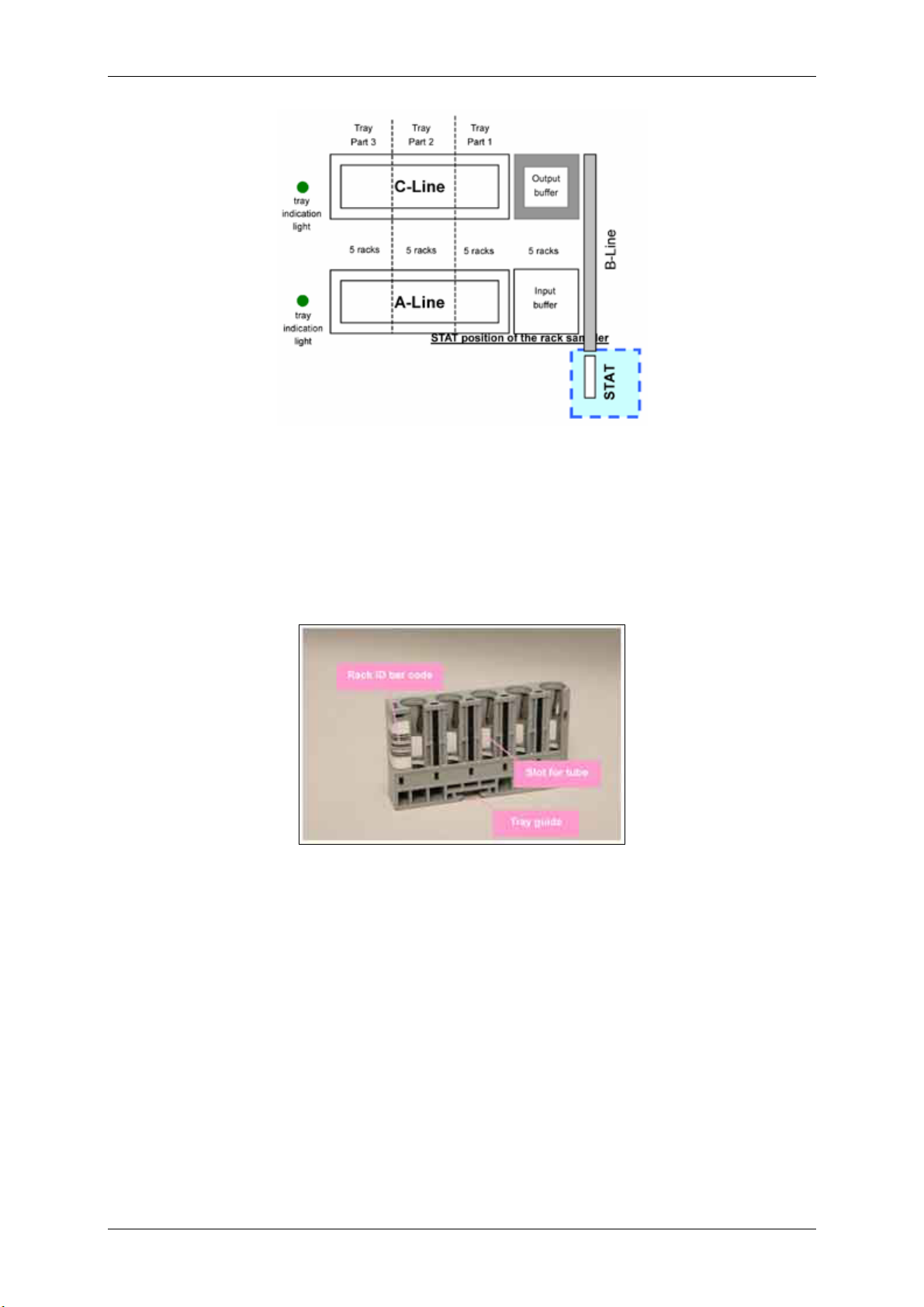

Figure 1.1-17

Rack Sampler

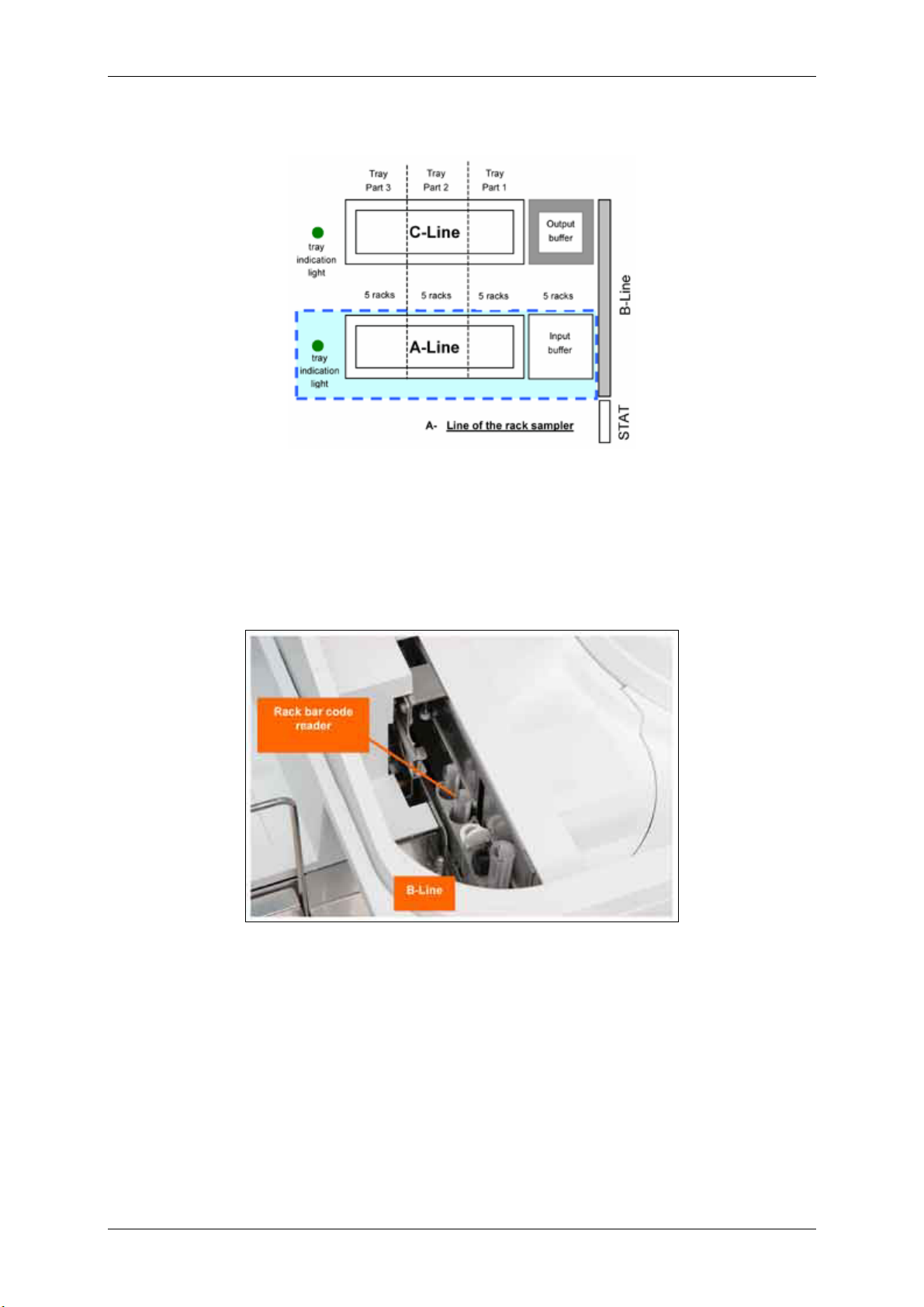

The rack sampler consists of an A-Line, B-Line, C-Line and STAT position.

1.1.4.1 A-Line

Specimens are placed in 5-position sample racks and are loaded onto a tray. Once a tray is loaded,

additional racks can be added to the tray one at a time during Operation, provided the tray indication

light is green (ON). If the light is out (OFF), the pusher arm is preparing to move. The pusher arm is

located at the far left of the A-Line and pushes the sample racks forward and onto the B-Line.

The A-Line holds a tray that accommodates 15 racks at one time. Another five racks can be in the

input buffer. Therefore, you can have a total of 100 specimens loaded at any one time. Refer to the

photo and graphic below.

Figure 1.1-18

Version 1.0 – May 2006 1 - 10 Chapter 1.1

Page 26

RD/Hitachi cobas e411 Service Manual

Figure 1.1-19

1.1.4.2 B-Line

The B-Line transports the sample racks, single file, first to the rack bar code reader. Here each

position in the rack is scanned for a sample bar code. After the last position is scanned, the bar code

reader scans the rack ID. After the last specimen is sampled, the rack is transferred via the output

buffer onto the tray on the C-Line. Refer to the photo and graphic below.

Figure 1.1-20

Version 1.0 – May 2006 1 - 11 Chapter 1.1

Page 27

RD/Hitachi cobas e411 Service Manual

Figure 1.1-21 B-Line of the rack sampler

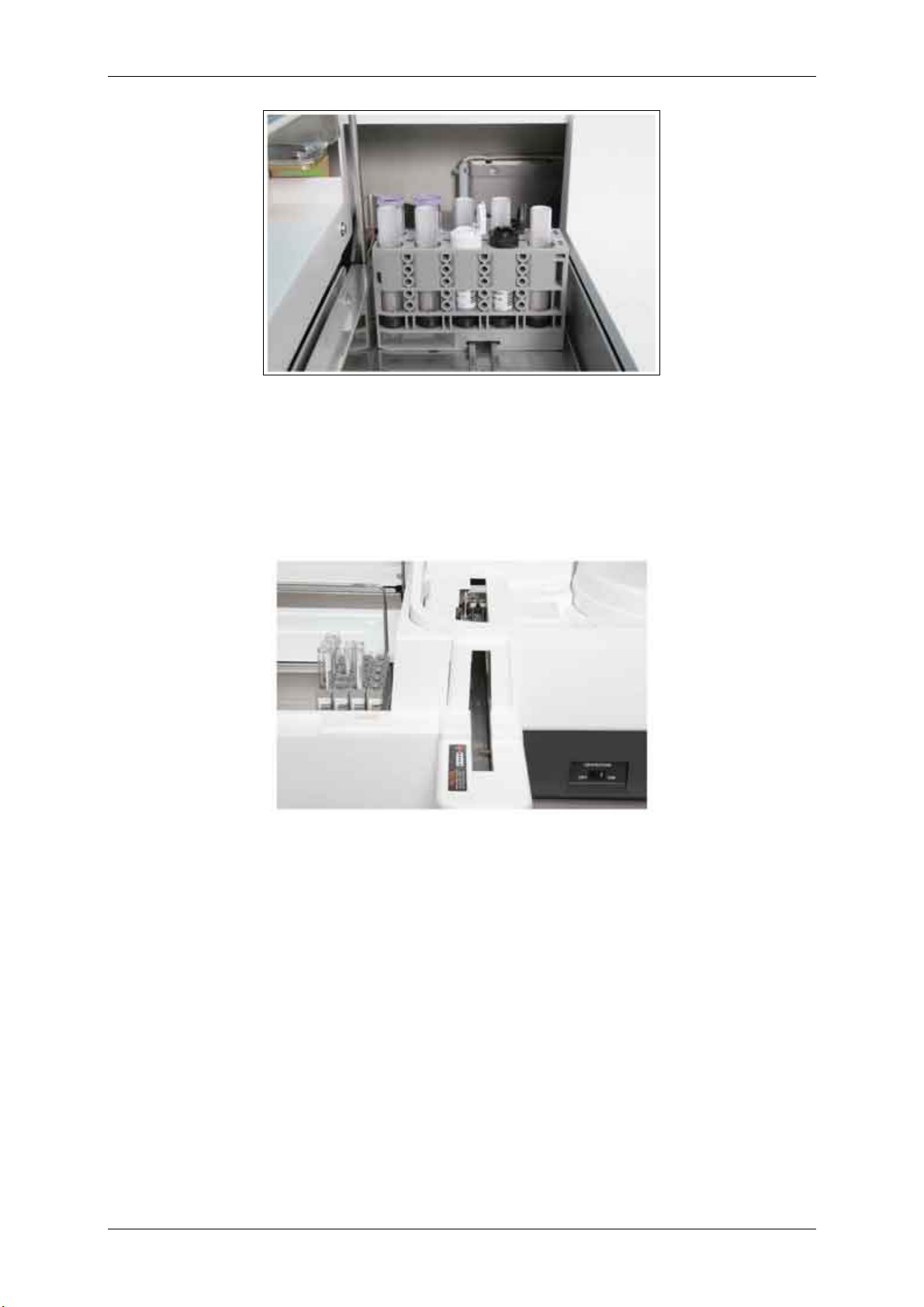

1.1.4.3 Rack Bar Code Reader

The rack bar code reader reads both sample bar code labels and the rack bar code label. The bar

code reader is auto-discriminating, allowing the use of various types of bar codes during operation.

Bar code symbologies read include:

• NW7 (Codabar)

• Code 39

• Code 128

• Interleaved 2 of 5

Figure 1.1-22 Rack bar code reader

Version 1.0 – May 2006 1 - 12 Chapter 1.1

Page 28

RD/Hitachi cobas e411 Service Manual

1.1.4.4 C-Line

Racks are off-loaded from the B-Line into the output buffer. If there is no tray, up to 5 racks can enter

the output buffer, thereafter the sampling procedure is stopped. When the sixth rack is moved into the

output buffer, a rack is pushed onto the tray on the C-Line. You can remove the tray from the C-Line

any time the tray indication light is green (ON). If the light is out (OFF), the system is preparing to push

a rack onto the C-Line tray. You cannot remove single racks from the C-Line. You must remove an

entire tray at one time.

Figure 1.1-23

Figure 1.1-24 C-Line of the rack sampler

If the tray is removed, the system continues to push racks into the output buffer. If the buffer fills and

there is no tray, the analyzer issues an alarm and stops sampling racks.

Version 1.0 – May 2006 1 - 13 Chapter 1.1

Page 29

RD/Hitachi cobas e411 Service Manual

Figure 1.1-25 Output buffer with racks

1.1.4.5 STAT Position

The STAT position is located at the front of the analyzer and is in line to feed directly onto the B-Line.

Place a rack in the position as directed on the label and press the STAT key. When the rack currently

being sampled is completed, the STAT rack is pushed onto the B-Line and is sent on to the rack bar

code reader and sampling position.

Figure 1.1-26

Version 1.0 – May 2006 1 - 14 Chapter 1.1

Page 30

RD/Hitachi cobas e411 Service Manual

Figure 1.1-27 STAT position of the rack sampler

1.1.4.6 Sample Rack

Sample cups, primary sample tubes, calibrator or control vials are placed in sample racks shown

below. Each sample rack holds a maximum of five samples. Each tube slot contains adapters that

allow the rack to hold different sizes of primary sample tubes. Each rack has a unique ID found on the

bar code label on the back end of the rack. This rack ID is read by the bar code reader and transferred

to the system. This ID appears on the screens in the software and on the reports.

Figure 1.1-28 Sample rack

1.1.4.7 Sample/Reagent (S/R) Probe

The sample/reagent probe is located on the back left wall of the analyzer and is mounted on an arm

(S/R arm) that moves horizontally between the sample and reagent disk. The probe uses disposable

tips to avoid sample carryover, and has liquid level and clot detection for accurate pipetting. Liquid

level detection is accomplished by capacitance measurement. Clot detection is accomplished by a

pressure transducer.

A new AssayTip is utilized with every new pipetting sequence. For example, TSH = 1 tip for R1, R2

and sample, then one new tip for microparticles. The tip is washed externally at the rinse station

between each aspiration. Additional tips are used for sample dilutions or pretreatment.

Version 1.0 – May 2006 1 - 15 Chapter 1.1

Page 31

RD/Hitachi cobas e411 Service Manual

Figure 1.1-29 S/R probe with tip

Note: Ensure that there is no foam on the surface of the sample.

Version 1.0 – May 2006 1 - 16 Chapter 1.1

Page 32

RD/Hitachi cobas e411 Service Manual

1.1.4.8 Bar Code Reader

During a sample scan, the bar code reader scans the information on the bar code-labeled primary

sample tubes, calibrators or controls, and transmits it to the software. During a reagent scan, the

reader rotates to the reagent disk side to read the 2-dimensional bar code labels on the reagent packs.

The bar code reader is located toward the back wall of the analyzer.

Figure 1.1-30 On the disk system:

• it can be seen when either the sample disk or reagent disk is removed.

• to read bar code labels, the bar code reader rotates between the sample and reagent disks, and

the card reading station.

Figure 1.1-31

On the rack system:

• it can only be seen when the reagent disk is removed.

• to read bar code labels, the bar code reader rotates between the reagent disk and the card

reading station.

• A second bar code reader scans sample bar codes and rack ID bar codes.

The bar code reader is auto-discriminating, allowing the use of various types of bar codes during

operation. In addition, this bar code reader also reads PDF417.

Note: PDF417 can only be used for reagent bar codes and bar code cards.

Figure 1.1-32 Bar code reader (sample disk side)

Version 1.0 – May 2006 1 - 17 Chapter 1.1

Page 33

RD/Hitachi cobas e411 Service Manual

Figure 1.1-33 Bar code reader (reagent disk side)

1.1.4.9 Bar Code Card Reading Station

At this station, the bar code reader scans calibrator and control information from the calibrator or

control bar code card. These cards are packed in calibrator or control kits.

Figure 1.1-34

On the disk system:

• it is located between the sample disk and reagent disk.

Figure 1.1-35

On the rack system:

• it is located to the back left of the reagent disk.

Figure 1.1-36 Bar code card reading station

Version 1.0 – May 2006 1 - 18 Chapter 1.1

Page 34

RD/Hitachi cobas e411 Service Manual

1.1.4.10 Reagent Disk

The reagent disk contains 18 positions for assays, diluent or pretreatment reagent. These 18 positions

can be used in any combination, with the following restrictions: max. 18 assays, max. 8 diluents, max.

9 pretreatments.

The reagent disk is temperature controlled at 20 ± 3 °C.

Note: Diluents or pretreatment reagents can be placed in ANY position on the reagent disk. More

than one reagent pack can be loaded on the reagent disk for each test.

Figure 1.1-37 Reagent disk

1.1.4.11 Reagent Cap Open/Close Mechanism

To prevent reagents from evaporating, and to promote ease of use for the operator, the reagent disk

utilizes a reagent cap open/close mechanism during reagent pipetting. The mechanism is located on

the back wall of the reagent disk compartment and emerges when reagents need to be opened or

closed. Caps are opened prior to pipetting or mixing the specific reagent (e.g., M, R1 or R2) and are

closed when pipetting or mixing for the specific reagent (e.g., M, R1 or R2) is completed.

Figure 1.1-38 Reagent cap open/close mechanism

Version 1.0 – May 2006 1 - 19 Chapter 1.1

Page 35

RD/Hitachi cobas e411 Service Manual

1.1.4.12 Microparticle Mixer

The mixer is utilized to mix the microparticles to ensure a homogeneous suspension before aspiration.

The mixer is located to the right of the reagent disk. In its home position, it occupies the space directly

to the left of the S/R probe.

Figure 1.1-39 Microparticle mixer

1.1.4.13 Probe/Mixer Rinse Station

The rinse station rinses the AssayTip or mixer externally with system water between aspirations, or

before and after microparticle mixing. The rinse station is located below the S/R probe and mixer

when the probe is in its Stand-by position and the mixer is in its home position.

Figure 1.1-40 Rinse station

Version 1.0 – May 2006 1 - 20 Chapter 1.1

Page 36

RD/Hitachi cobas e411 Service Manual

1.1.4.14 Sample/Reagent (S/R) Pipettor

The S/R pipettor is located on the back right of the analyzer. The pipettor is filled with system water

and uses positive displacement to aspirate and dispense from the S/R probe.

Figure 1.1-41 Sample/reagent pipettor

Version 1.0 – May 2006 1 - 21 Chapter 1.1

Page 37

RD/Hitachi cobas e411 Service Manual

1.1.5 Consumables Area Components

The consumables area consists of three AssayCup trays, three tip trays, gripper, incubator, cup

disposal opening, pipetting station, liquid waste container, system water container and solid waste tray

and liner.

One tip tray holds up to 120 tips, and one cup tray holds up to 60 cups. Therefore, a total of 360 tips

and 180 cups can be placed on the analyzer.

Figure 1.1-42 Tip tray and cup tray

Version 1.0 – May 2006 1 - 22 Chapter 1.1

Page 38

RD/Hitachi cobas e411 Service Manual

1.1.5.1 Gripper

The gripper can move in three directions:

• X (left and right)

• Y (forward and back)

• Z (up and down)

It is also equipped with gripping fingers for gripping a tip or AssayCup. The gripping fingers grip a tip

from the tip tray, or a cup from the cup tray and deliver it to the pipetting station. Then, at the

appropriate time, the gripper moves the AssayCup to the incubator, then to the aspiration station, and

finally to the cup disposal opening.

During operation, the analyzer starts utilizing tips and cups from tray 1, position 1. As soon as tray 1 is

empty, the analyzer starts using tray 2. As soon as tray 2 is empty, the analyzer continues with tray 3.

When tray 3 is empty, the analyzer returns to tray 1, if a new tray has been reloaded.

Figure 1.1-43 Gripper and trays

1.1.5.2 Cup Disposal Opening

AssayCups are discarded through a cup opening located directly to the left of the incubator.

Figure 1.1-44 Cup disposal opening

Version 1.0 – May 2006 1 - 23 Chapter 1.1

Page 39

RD/Hitachi cobas e411 Service Manual

1.1.5.3 Pipetting Station

A five position pipetting station is located to the upper left of the incubator. AssayCups and tips are

moved by the gripper to this location for sample and reagent pipetting, sample dilution and sample

pretreatment. The AssayTips are discarded at the tip eject station at the far right of the station.

Positions 1 and 2 are used for tips and positions 3 and 4 are used to hold cups for dilution or

pretreatment. Position 5 is the position where the S/R probe pipettes sample and reagent.

Figure 1.1-45 Pipetting station

1.1.5.4 System Water Container

The system water container is located in front of the pipettors and to the right of the liquid waste

container. It holds three liters of system water. An alarm is issued when the system water container is

empty. A float mechanism sensor located beneath the aspiration inlet, triggers the alarm on the

System Overview screen.

Note: Removing the system water container while the analyzer is in Operation causes the

analyzer to enter P. Stop status.

Figure 1.1-46 System water container

Version 1.0 – May 2006 1 - 24 Chapter 1.1

Page 40

RD/Hitachi cobas e411 Service Manual

1.1.5.5 Liquid Waste Container

The liquid waste container is located in front of the ProCell and CleanCell reagents. It holds four liters

of waste and issues an alarm when approximately three-quarters full. The alarm is triggered by a

weight-sensitive mechanism that activates a photosensor located in the compartment holding the

container. An alarm is also issued when the container is improperly positioned. This alarm is triggered

by a plate mechanism that activates a photosensor located at the front of the compartment.

Note: Removing the liquid waste container while the analyzer is in Operation or an improperly

positioned container causes the analyzer to enter E. Stop status.

Figure 1.1-47 Liquid waste container

Version 1.0 – May 2006 1 - 25 Chapter 1.1

Page 41

RD/Hitachi cobas e411 Service Manual

1.1.5.6 Solid Waste Tray and Liner

The solid waste tray and liner is located behind the front access door on the analyzer. Used

AssayCups and tips are discarded into the waste tray during operation.

A disposable liner (Clean-Liner) made of polystyrene is placed inside the solid waste tray. The CleanLiner has a sliding cover to reduce potential splashing and to prevent tips and cups from falling out of

the tray upon removal from the analyzer. During operation, the sliding cover must be open. The tray

shakes periodically during operation so that used tips and cups do not accumulate at one end of the

tray.

An alarm is issued when either the tray is full (max. 1100 tips and cups) or if the tray and liner are

missing. The presence of a tray is monitored by a photosensor.

Note: Removing the solid waste tray while the analyzer is in Operation causes the analyzer to

enter E. Stop status.

Figure 1.1-48 Solid waste tray and liner

Version 1.0 – May 2006 1 - 26 Chapter 1.1

Page 42

RD/Hitachi cobas e411 Service Manual

1.1.6 Measuring Area Components

The measuring area includes the incubator, aspiration station, sipper probe, sipper rinse station,

sipper pipettor, system reagents (ProCell and CleanCell) and the detection unit.

1.1.6.1 Incubator

The incubator is maintained at a specific temperature (37.0 °C ± 0.3° C) for the reaction of the sample

and the reagents that have been dispensed into a cup. The incubator is equipped with 32 positions.

When an assay is ready for measurement, the AssayCup is transferred by the gripper to the aspiration

station, and the sipper probe aspirates the reaction mixture for measurement. The aspiration station,

located in the lower right corner of the incubator, is not temperature controlled.

Figure 1.1-49 Incubator

Version 1.0 – May 2006 1 - 27 Chapter 1.1

Page 43

RD/Hitachi cobas e411 Service Manual

1.1.6.2 Sipper Probe

The sipper probe aspirates the reaction mixture into the measuring cell. ProCell and CleanCell are

also aspirated by the sipper probe. The sipper probe is located to the right of the incubator. The sipper

rinse station externally washes the sipper probe with system water between measurements. When the

sipper probe is in its Stand-by position, the probe is located directly above the rinse station.

Figure 1.1-50 Sipper probe and rinse station

Version 1.0 – May 2006 1 - 28 Chapter 1.1

Page 44

RD/Hitachi cobas e411 Service Manual

1.1.6.3 Sipper Pipettor

The sipper pipettor is located directly to the right of the sample/reagent syringe. They use positive

displacement of water to aspirate and dispense from the sipper probe.

Figure 1.1-51 Sipper pipettor

Version 1.0 – May 2006 1 - 29 Chapter 1.1

Page 45

RD/Hitachi cobas e411 Service Manual

1.1.6.4 System Reagents (ProCell and CleanCell)

ProCell and CleanCell are located behind the liquid waste container. ProCell is the buffer solution

containing tripropylamine (TPA). These bottles are identified with white caps.

CleanCell is the cleaning solution used to clean the measuring cell after measurement. CleanCell

bottles are identified with black caps.

The reagent compartment is keyed to ensure the correct reagent is placed in the proper position. Two

bottles of each reagent are stored on the analyzer, temperature controlled at 28.0 °C ± 2.0 °C.

Figure 1.1-52 ProCell (PC) and CleanCell (CC)

When starting from Stand-by, the sipper probe always attempts to first use ProCell and CleanCell from

bottle set 2. If the quantity is insufficient, bottle set 1 is used. When starting from S. Stop or R. Stop,

the bottle set in use when the analyzer was previously in Operation is pipetted.

The analyzer can operate with one bottle set of ProCell and CleanCell reagent, but they must be

placed in positions 1 & 2 or 3 & 4. Refer to the photograph above.

Note:

Note:

To have access to system reagent bottles, you must open the sipper safety cover. To open

this cover, push the cover’s metal part as shown in the picture below to release the hold. To

close the cover, push the same part until a click is heard.

How to open the sipper safety cover

Figure 1.1-53 Opening/closing the sipper safety cover (Push the circled point)

Version 1.0 – May 2006 1 - 30 Chapter 1.1

Page 46

RD/Hitachi cobas e411 Service Manual

Figure 1.1-54 Sipper safety cover (when opened)

CAUTION

• Do not open the sipper safety cover while the analyzer is in Operation.

Otherwise, the operation will stop.

• Be sure to close the cover after you placed/replaced system reagents, or

performed maintenance. Otherwise, the instrument will not operate.

Version 1.0 – May 2006 1 - 31 Chapter 1.1

Page 47

RD/Hitachi cobas e411 Service Manual

1.1.6.5 Detection Unit

The detection unit is the core of the cobas e411 system. The detection unit contains the

photomultiplier tube, peltier, flow-through measuring cell, magnet drive assembly and an amplifier

circuit board. The temperature is maintained at 28.0 °C ± 0.3 ° C.

Figure 1.1-55 Measuring cell of the detection unit

Version 1.0 – May 2006 1 - 32 Chapter 1.1

Page 48

RD/Hitachi cobas e411 Service Manual

1.1.7 Power Components

1.1.7.1 Operation Switch

The operation switch is located on the lower left front side of the analyzer. Use this switch to turn OFF

the analyzer to perform certain maintenance procedures or when the system is not in use for extended

periods of time (e.g., overnight).

Provided the circuit breaker is ON, the reagent disk and system reagent compartment temperatures

are maintained while the operation switch is OFF.

Figure 1.1-56 Operation ON/OFF switch

1.1.7.2 Circuit Breaker

The circuit breaker is located on the right side panel of the analyzer above the power supply cord. The

circuit breaker controls the power supplied to the temperature controlled reagent compartments when

the operation switch is OFF. The circuit breaker must be in the I (ON) position whenever reagents are

stored on the analyzer and to maintain liquid in the measuring cell.

When connecting or disconnecting the host cable, power the analyzer off at the circuit breaker only

Note: To disconnect the analyzer from the supply source, the circuit breaker must be in the O

(OFF) position and the power cord must be removed.

Figure 1.1-57 Circuit breaker

Version 1.0 – May 2006 1 - 33 Chapter 1.1

Page 49

RD/Hitachi cobas e411 Service Manual

Figure 1.1-58

1.1.7.3 Rack Circuit Breaker

There is a circuit breaker located on the left side of the rack sampler. This controls power to the

sampler unit. The circuit breaker should be kept in the I (ON) position at all times. Use the operation

switch to power ON and OFF the rack system.

Note: To disconnect the analyzer from the supply source, the circuit breaker must be in the O

(OFF) position and the power cord must be removed.

Figure 1.1-59 Rack circuit breaker

Version 1.0 – May 2006 1 - 34 Chapter 1.1

Page 50

RD/Hitachi cobas e411 Service Manual

1.1.8 Mechanical Theory

1.1.8.1 Introduction

The cobas e411 analyzer automates the immunoassay reactions utilizing electrochemiluminescence

(ECL). These reaction methods are described in detail in Chapter 4, ECL Technology. The individual

test steps and how the system performs the necessary procedures are discussed here.

1.1.8.2 Test Protocols

There are 28 test protocols or test steps that can be used on the analyzer. These protocols are

predefined by Roche Diagnostics for each test and cannot be changed by the operator.

1.1.8.3 General Assay Sequence

An immunological ECL test is made up of various pipetting steps, at least one incubation period and a

measurement step. Generally at least three test components (sample, reagent and microparticles) are

pipetted into an AssayCup. After the appropriate incubation period, the reaction mixture is aspirated

into the measuring cell where the measurement process takes place. Each of the required pipetting

cycles is performed within a defined period (42 seconds).

The number of pipetting steps, as well as the make up of the reaction mixture are dependent on the

test method (1 or 2 step test). For some methods, predilution with diluent and/or pretreatment with a

special reagent is necessary. Thus the number of pipetting steps is increased.

After each pipetting step the sample/reagent (S/R) probe tip is cleaned and, if necessary, the

microparticle mixer and sipper probe are also cleaned.

The following steps apply in principle to all methods. The sequence of the individual processes differ

from test to test.

1.1.8.4 Preparative Operations

Once the analyzer's power is switched ON, the initialization process is started. During initialization, the

mechanisms are reset to their home positions.

1.1.8.5 Run Operation

After the appropriate test selections are made in the software for patient samples, operation is started

according to the predetermined test protocol for each assay selected. Initially, at least one reagent (R1

or R2) and the sample or microparticles (M) are aspirated one after another by the S/R probe. After

each aspiration, the outside of the S/R probe tip is cleaned at the rinse station. The sample and

reagents are dispensed into a new AssayCup and the AssayTip is ejected into the solid waste tray.

For some tests that require sample dilution or pretreatment, diluent or pretreatment reagent is pipetted

together with sample into an AssayCup. An aliquot of the diluted/pretreated sample is then dispensed

with reagent into a second AssayCup. Therefore, certain tests with predilution/pretreatment may

require two or more AssayCups.

1.1.8.6 First Incubation at 37 °C

The incubation times are 4.5 or 9 minutes long, depending on the test. Some tests require only two

incubation periods, whereas tests with pretreatment tests can require three incubation periods. During

the incubation step(s) the immune complex products are formed.

Version 1.0 – May 2006 1 - 35 Chapter 1.1

Page 51

RD/Hitachi cobas e411 Service Manual

1.1.8.7 Additional Reagent Pipetting

Some assays (usually those with multiple incubation steps) require additional reagent pipetting. As in

the initial reagent pipetting step, a new pipette tip is picked up prior to reagent aspiration. The S/R

probe tip is washed at the rinse station after each liquid aspiration. The liquid is then dispensed into

the corresponding AssayCup where the sample and other liquids were dispensed in the first pipetting

step.

The probe rises while dispensing the reaction mixture back into the cup, thereby mixing the solution

and accelerating the reaction in the cup. The pipette tip is ejected into the solid waste tray when

pipetting is complete.

1.1.8.8 Second Incubation at 37 °C

If necessary, a second incubation step (4.5 or 9 minutes) occurs.

If using a pretreatment assay, the second incubation is similar to that described above for "First

Incubation at 37 °C".

1.1.8.9 Additional Reagent Pipetting (Pretreatment assays)

For pretreatment assays, reagent pipetting similar to that described above for “Additional Reagent

Pipetting” occurs.

1.1.8.10 Third Incubation at 37 °C (Pretreatment assays)

If necessary, a third incubation step (9 minutes) occurs for pretreatment assays.

1.1.8.11 Reaction Mixture Aspiration and Measurement

In this process the sipper probe first aspirates ProCell (tripropylamine solution, TPA) to prepare the

measuring cell. Then, the sipper probe aspirates the reaction mixture from the AssayCup and

transfers it to the measuring cell. The sipper probe is washed at the rinse station and ProCell is

aspirated again to rinse away the unbound reagent and sample constituents. Next, the ECL reaction in

the measuring cell occurs.

1.1.8.12 Measuring Cell Cleaning

Once the measurement is complete, the measuring cell is cleaned with CleanCell and prepared for a

new measurement process.

It takes 42 seconds (one pipetting cycle) from the aspiration of the reaction mixture by the sipper

probe until the measuring cell is filled with ProCell and ready for the next sample.

1.1.8.13 Finalization

30 Minutes after documentation of the last result, the sipper pipettor flushes system water through the

sipper probe, and then fills the measuring cell with ProCell before the analyzer returns to Stand-by.