Page 1

cobas c111 system

Operator’s Manual

Version 3.0

Page 2

Document information

cobas c111

Revision history

Edition notice The cobas c111 instrument is a continuous random-access analyzer intended for the

Manual version Software version Revision date Changes

1.0 July 2006 First publication.

2.0 2.0 December 2007 Full mode added.

Improved calibration concept.

Additional maintenance and

troubleshooting information.

Additions, improvements, and

corrections.

3.0 3.0 June 2009 Inventory, processing sequence,

and ratio functions added.

Improvements and corrections.

Layout upgraded.

in vitro determination of clinical chemistry and electrolyte parameters in serum,

plasma, urine or whole blood (HbA1c). It is optimized for small throughput

workloads of approximately samples per day, utilizing photometric analysis and an

optional unit for ion selective electrodes (ISE).

This manual is for users of the cobas c 111 instrument.

Every effort has been made to ensure that all the information contained in this

manual is correct at the time of printing. However, Roche Diagnostics GmbH reserves

the right to make any changes necessary without notice as part of ongoing product

development.

Any customer modification to the instrument will render the warranty or service

agreement null and void.

Software updates are done by service representatives.

Intended use The cobas c111 instrument is a continuous random-access analyzer intended for the

in vitro determination of clinical chemistry and electrolyte parameters in serum,

plasma, urine or whole blood (HbA1c).

It is important that the operators read this manual thoroughly before using the

system.

Copyrights © 2009, Roche Diagnostics GmbH. All rights reserved.

Tr ad e m ar k s The following trademarks are acknowledged:

COBAS, COBAS C and LIFE NEEDS ANSWERS are trademarks of Roche.

All other trademarks are the property of their respective owners.

Roche Diagnostics

2 Operator’s Manual · Version 3.0

Page 3

cobas c111

CUS

®

Instrument approvals The cobas c111 instrument meets the protection requirements laid down in IVD

Directive 98/79/EC and the European Standard EN 591. Furthermore, our

instruments are manufactured and tested according to the following international

standards:

o EN/IEC 61010-1 2

o EN/IEC 61010-2-101 1

The Operator’s manual meets the European Standard EN 591.

Regulatory compliance is demonstrated by the following marks:

nd

Edition

st

Edition

Complies with European Union (EU) Directive 98/79/EC.

Issued by Underwriters Laboratories, Inc. (UL) for Canada and the

US.

Contact addresses

Manufacturer

Distributor

Roche Diagnostics Ltd.

Forrenstrasse

CH-6343 Rotkreuz

Switzerland

Roche Diagnostics GmbH

Sandhofer Strasse 116

D-68305 Mannheim

Germany

Roche Diagnostics

Operator’s Manual · Version 3.0 3

Page 4

cobas c111

Roche Diagnostics

4 Operator’s Manual · Version 3.0

Page 5

cobas c111

Table of contents

Document information 2

Contact addresses 3

Table of contents 5

Preface 7

How to use this manual 7

Online Help system 7

Conventions used in this manual 8

System Description Part A

1Safety

Safety classification A–5

Safety information A–5

Data security A–10

License notices A–11

Legal liability A–11

Disposal recommendation A–12

Safety labels A–13

2 Introduction to the instrument

Overview A–17

User interface A–20

Wizards A–21

Daily operation A–22

Maintenance A–34

System status A–35

3 Hardware

Covers and panels A–39

LEDs A–41

Main components A–43

Hardware overview A–44

Technical specifications A–66

5Software

Introduction A–71

Screen layout A–72

Display items A–73

Workflows and wizards A–74

Working with the user interface A–75

Key screens A–84

Color interpretation for LEDs A–122

Buttons A–124

Operation Part B

6 Daily operation

Introduction B–5

Starting the shift B–10

Preparing the system B–12

Analyzing samples B–34

Validating sample results B–51

Performing calibrations B–59

Performing QC B–68

Finishing the shift B–77

Logging off B–88

Switching off the system B–88

Using the barcode scanner B–89

6 Special operations

Deleting sample orders B–93

Deleting sample results B–94

Calibration B–95

Deleting QC results B–96

Lot handling B–98

Exporting data B–104

Importing data B–111

Preparing a new disk B–116

Assigning tests to test tabs B–119

Deleting bottle sets from the Inventory list B–120

Refilling printer paper B–122

Removing condensation water

from the reagent cooler B–124

Replacing the probe B–125

Connecting and disconnecting the

external fluid containers B–127

Adjusting the touchscreen B–130

Cleaning the touchscreen B–131

7 Configuration

Introduction B–135

Applications B–137

Configuration B–157

Maintenance Part C

8 General maintenance

Overview C–5

Maintenance actions C–8

Roche Diagnostics

Operator’s Manual · Version 3.0 5

Page 6

cobas c111

Troubleshooting Part D

9 Messages and alarms

About messages D–5

Message screen D–5

Acoustic signals D–6

Alarm monitor D–6

List of alarm messages D–10

10 Result flags

About flags D–25

Safety D–27

List of flags D–28

11 Troubleshooting

Introduction D–41

Dealing with exceptional situations D–42

Reacting to messages D–44

Detailed procedures D–46

ISE Part E

12 ISE description

Overview E–5

Hardware E–9

Basic operation E–12

Technical specifications E–13

Glossary and Index Part F

Glossary F–3

Index F–11

Revisions Part G

18 Revisions

13 ISE operation

Daily operation E–17

Replacing ISE fluid bottles E–30

Replacing electrodes E–32

Cleaning the ISE tower off the instrument E–36

14 ISE maintenance

Introduction E–41

ISE maintenance actions E–42

15 ISE troubleshooting

Introduction E–69

Safety E–70

List of ISE flags E–71

Reacting to error messages E–80

Roche Diagnostics

6 Operator’s Manual · Version 3.0

Page 7

cobas c111

Preface

The cobas c111 instrument is a continuous random-access analyzer intended for the

in vitro determination of clinical chemistry and electrolyte parameters in serum,

plasma, urine or whole blood (HbA1c). It is optimized for small throughput

workloads of approximately samples per day, utilizing photometric analysis and an

optional unit for ion selective electrodes (ISE).

This manual describes the cobas c111 features and general operational concepts, and

it provides operating, maintenance, and emergency procedures.

How to use this manual

o Keep this Operator’s Manual in a safe place to ensure that it is not damaged and

remains available for use.

o This Operator’s Manual should be easily accessible at all times.

Online Help system

To help you find information quickly, there is a table of contents at the beginning of

the manual and each chapter. In addition, a complete index can be found at the end.

The cobas c111 instrument has a context-sensitive online Help feature to aid in its

operating. “Context-sensitive” means that wherever you are located within the

cobas c 111 software, choosing Help ( ) displays Help text relating to that area of

the software. The online Help offers a quick and convenient way of finding

information, such as explanations of screens and dialog boxes and on how to perform

particular tasks.

Roche Diagnostics

Operator’s Manual · Version 3.0 7

Page 8

Conventions used in this manual

Visual cues are used to help locate and interpret information in this manual quickly.

This section explains the formatting conventions used in this manual.

Symbols The following symbols are used:

Symbol Used for

a Start of procedure

o List item

e

h Call-up (software navigation path)

Color of display item on the screen

Cross-reference

Tip

Safety alert

cobas c111

Electrical and electronic equipment marked with this symbol are

covered by the European directive WEEE.

The symbol denotes that the equipment must not be disposed of in

the municipal waste system.

Buttons When used for identification purposes, a generic form of the buttons is used, without

color or navigation indicators.

Screenshots The screen representations shown in this publication are for illustrative purposes

only. The screens do not necessarily show valid data.

Roche Diagnostics

8 Operator’s Manual · Version 3.0

Page 9

cobas c111

Abbrev iations The following abbreviations are used:

Abbreviation Definition

C

Cfas Calibrator for automated systems

D

DIL Diluent

DM Data management

DRAM Dynamic random access memory

E

e.g. Exempli gratia – for example

EMC Electromagnetic compatibility

EN European standard

I

i.e. Id est – that is to say

IEC International Electrical Commission

ISE Ion selective electrode

L

LED Light-emitting diode

LIS Laboratory information system

LLD Liquid level detection

N

n/a Not applicable

Q

QC Quality control

R

REF Reference solution for ISE unit

ROM Read only memory

S

SD Standard deviation

SRAM Static random access memory

Roche Diagnostics

Operator’s Manual · Version 3.0 9

Page 10

cobas c111

Units

Abbreviation Description

°C degree centigrade

µL microliter

µm micrometer

Aampère

cm centimeter

hhour

Hz hertz

LB pound (weight)

in inch

kg kilogram

kVA kilo volt-ampere

Lliter

mmeter

MB megabytes

min minute

mL milliliter

mm millimeter

nm nanometer

ssecond

Vvolt

VA v o l t - a m p è r e

V AC volt alternating current

V DC volt direct current

Wwatt

Roche Diagnostics

10 Operator’s Manual · Version 3.0

Page 11

System Description

A

1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

2 Introduction to the instrument . . . . . . . . . . . . . . . . . . . . . . . . . A-15

3 Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-37

5 Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-69

Page 12

Page 13

cobas c111 1Safety

Table of co ntents

Safety

Protecting yourself and the environment

In this chapter, you will find information on the safe operation of the cobas c111

instrument.

In this chapter

Safety classification ...................................................................................................... A-5

Safety information ...................................................................................................... A-5

Transport ...............................................................................................................A-5

Electrical safety ...................................................................................................... A-5

Optical safety .........................................................................................................A-6

Mechanical safety ..................................................................................................A-6

Instrument covers ..................................................................................................A-6

Operation and maintenance .................................................................................A-6

Biohazardous materials ......................................................................................... A-6

Waste ......................................................................................................................A-7

Reagents and other working solutions .................................................................A-7

Installation .............................................................................................................A-7

Environmental conditions ....................................................................................A-7

Power interruption ................................................................................................A-8

Electromagnetic devices ........................................................................................ A-8

Approved parts ...................................................................................................... A-8

Third-party software .............................................................................................A-8

Operator qualification ........................................................................................... A-9

Operation over an extended period of time ......................................................... A-9

Cross contamination of sample ............................................................................ A-9

Insoluble contaminants in sample ........................................................................A-9

Spillage ...................................................................................................................A-9

Data security ..............................................................................................................A-10

License notices ...........................................................................................................A-11

Legal liability ..............................................................................................................A-11

Chapter

1

Roche Diagnostics

Operator’s Manual · Version 3.0 A-3

Page 14

1Safety cobas c111

Tab l e o f c o nt en ts

Disposal recommendation ........................................................................................A-12

Disposal label .......................................................................................................A-12

Disposal of external components .......................................................................A-12

Disposal of the instrument .................................................................................A-12

Constraint ............................................................................................................A-12

Safety labels ................................................................................................................ A-13

Roche Diagnostics

A-4 Operator’s Manual · Version 3.0

Page 15

cobas c111 1Safety

WARNING

CAUTION

NOTICE

WARNING

WARNING

Safety classification

Safety classification

Before you attempt to use the cobas c111 instrument, you must be fully familiar with

the following symbols and their meanings:

Warning

Indicates a hazardous situation which, if not avoided, could result in death or serious

injury.

Caution

Indicates a hazardous situation which, if not avoided, may result in minor or moderate

injury.

Notice

Indicates a hazardous situation which, if not avoided, may result in property damage.

Safety information

Transport

Electrical safety

Before operating the cobas c111 instrument, it is essential that you both read and

understand the safety information listed below.

Read all Roche safety notices carefully and make sure you understand them.

Injury from heavy loads

You may injure your hands, fingers, or back when putting the analyzer in place. Carry the

analyzer according to the transport instructions.

Electrical shock by electronic equipment

Do not attempt to work in any electronic compartment. Installation, service, and repair

must only be performed by authorized and qualified personnel.

Electrical safety

Connect the analyzer to grounded power outlets only (IEC protection class 1). All peripheral devices that are connected to the cobasc111 instrument must comply with safety

standard IEC 60950 for information technology equipment, or with IEC 61010-1, UL 610101 for laboratory use instruments.

Roche Diagnostics

Operator’s Manual · Version 3.0 A-5

Page 16

1Safety cobas c111

WARNING

WARNING

WARNING

WARNING

WARNING

Safety information

Optical safety

Loss of sight

The intense light of the LEDs may severely damage you eyes. Do not stare into the LEDs.

Scanning equipment using LED technology is covered by the international standard IEC

60825-1 LED Safety: Class 1.

Mechanical safety

Personal injury or damage to the analyzer due to contact with instrument

mechanism

Do not touch moving parts during instrument operation.

Instrument covers

Personal injury or damage to the analyzer due to contact with instrument

mechanism

Keep all covers closed, operate them as instructed on the screen.

Operation and maintenance

Personal injury or damage to the analyzer due to contact with instrument

mechanism

Do not touch any parts of the instrument other than those specified. During operation and

maintenance of the instrument, proceed according to the instructions.

Biohazardous materials

Infection by biohazardous materials

Contact with samples containing material of human origin may result in infection. All

materials and mechanical components associated with samples of human origin are

potentially biohazardous.

o Be sure to wear protective equipment. Take extra care when working with protective

gloves; these can easily be pierced or cut, which can lead to infection.

o If any biohazardous material is spilled, wipe it up immediately and apply disinfectant.

o If waste solution contacts your skin, wash it off immediately with water and apply a dis-

infectant. Consult a physician.

Roche Diagnostics

A-6 Operator’s Manual · Version 3.0

Page 17

cobas c111 1Safety

WARNING

WARNING

WARNING

WARNING

Safety information

Waste

Infection by waste solution

Contact with waste solution may result in infection. All materials and mechanical components associated with the waste systems are potentially biohazardous.

o Be sure to wear protective equipment. Take extra care when working with protective

gloves; these can easily be pierced or cut, which can lead to infection.

o If any biohazardous material is spilled, wipe it up immediately and apply disinfectant.

o If waste solution contacts your skin, wash it off immediately with water and apply a dis-

infectant. Consult a physician.

Reagents and other working solutions

Injury through reagents and other working solutions

Direct contact with reagents, cleaning solutions, or other working solutions may cause

personal injury.

When handling reagents, exercise the precautions required for handling laboratory

reagents, observe the cautions given in the package insert, and observe the information

given in the Safety Data Sheets available for Roche Diagnostics reagents and cleaning

solutions.

Skin inflammation caused by reagents

Direct contact with reagents may cause skin irritation, inflammation, or burns.

When handling reagents, be sure to wear protective equipment and observe the cautions

given in the package insert.

Installation

Incorrect results or damage to the analyzer due to wrong installation

Follow the specified installation instructions carefully.

Environmental conditions

Incorrect results or damage to the analyzer due to heat and humidity

Use the instrument indoor only.

e

For details on the required environmental conditions, see Environmental conditions on

page A-66.

Roche Diagnostics

Operator’s Manual · Version 3.0 A-7

Page 18

1Safety cobas c111

NOTICE

WARNING

NOTICE

WARNING

WARNING

Safety information

Power interruption

Data loss or damage to the system due to voltage drop

By a power failure or momentary voltage drop the operation unit or software of this system

may get damaged or data loss may occur. Use only uninterruptible power supply.

Electromagnetic devices

Malfunction of instrument and incorrect results due to interfering electromagnetic

fields

Devices that emit electromagnetic waves may cause the instrument to malfunction. Do not

operate the following devices in the same room where the system is installed:

o Mobile phone

o Transceiver

o Cordless phone

o Other electrical devices that generate electromagnetic waves

Approved parts

Instructions for in vitro diagnostic (IVD) equipment for professional use

The IVD equipment complies with the emission and immunity requirements described in

the particular requirements for IVD medical equipment of the EN/IEC 61326-2-6 standard.

The electromagnetic environment should be evaluated prior to operation of the device.

Class B FCC rule compliance

This equipment has been tested and found to comply with the limits for Class B digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interferences when the equipment is operated in a residential area. However, this equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the present manual, may cause

harmful interference to radio communications.

The electromagnetic environment should be evaluated prior to operation of the device.

Malfunction of instrument and incorrect results due to nonapproved parts

Use of nonapproved parts or devices may result in malfunction of the instrument and may

render the warranty null and void. Only use parts and devices approved by Roche Diagnostics.

Third-party software

Malfunction of instrument and incorrect results due to third-party software

Installation of any third-party software that is not approved by Roche Diagnostics may

result in incorrect behavior of the system. Do not install any nonapproved software.

Roche Diagnostics

A-8 Operator’s Manual · Version 3.0

Page 19

cobas c111 1Safety

WARNING

CAUTION

WARNING

WARNING

NOTICE

Safety information

Operator qualification

Incorrect results or damage to the analyzer due to wrong operation

Operators are required to have a profound knowledge of relevant guidelines and norms as

well as the information and procedures contained in the Operator’s Manual.

o Do not carry out operation and maintenance unless you have been trained by Roche

Diagnostics.

o Carefully follow the procedures specified in the Operator’s Manual for the operation

and maintenance of the system.

o Leave maintenance that is not described in the Operator’s Manual to trained service

representatives.

o Follow standard laboratory practices, especially when working with biohazard material.

Operation over an extended period of time

Fatigue due to long hours of operation

Looking at the monitor screen over an extended period of time may lead to fatigue of your

eyes or body. Take a rest for 10 to 15 minutes every hour to relax. Avoid spending more

than 6 hours per day looking at the monitor screen.

Cross contamination of sample

Incorrect results due to carryover

Traces of analytes or reagents may be carried over one test to the next. Take adequate

measures (e.g. sample aliquoting) to safeguard additional testing and to avoid potentially

false results.

Insoluble contaminants in sample

Incorrect results and interruption of analysis due to contaminated samples

Insoluble contaminants in samples may cause clogging or pipetting volume shortage and

deterioration in measurement accuracy. When loading samples on the instrument, make

sure that samples contain no insoluble contaminants such as fibrin or dust.

Spillage

Malfunction due to spilled liquid

Any liquid spilled on the instrument may result in malfunction of the instrument. If liquid

does spill on the instrument, wipe it up immediately and apply disinfectant.

Roche Diagnostics

Operator’s Manual · Version 3.0 A-9

Page 20

1Safety cobas c111

CAUTION

Data security

Data security

Unauthorized access and data loss due to malicious software and hacker attacks

Portable storage media can be infected with and transmit computer malware, which may

be used to gain unauthorized access to data or cause unwanted changes to software.

The cobas c111 is not protected against malicious software and hacker attacks.

The customers are responsible for IT security of their IT infrastructure and for protecting it

against malicious software and hacker attacks. Failure to do so may result in data loss or

render the cobas c111 unusable.

Roche recommends the following precautions:

o Allow connection to authorized external devices only.

o Ensure that all external devices are protected by appropriate security software.

o Ensure that access to all external devices is protected by appropriate security equip-

ment.

o Do not copy or install any software on the cobasc111 unless it is part of the system

software or you are instructed to do so by a Roche service representative.

o If additional software is required, contact your Roche service representative to ensure

validation of the software in question.

o Do not use the USB ports to connect other storage devices unless you are instructed to

do so by official user documentation or a Roche service representative.

o Exercise utmost care when using external storage devices such as USB flash drives,

CDs, or DVDs. Do not use them on public or home computers while connecting to the

cobasc111.

o Keep all external storage devices in a secure place and ensure that they can be

accessed by authorized persons only.

e

For further information, contact your Roche service representative.

Roche Diagnostics

A-10 Operator’s Manual · Version 3.0

Page 21

cobas c111 1Safety

WARNING

License notices

License notices

Malfunction of instrument and incorrect results due to software modifications by

the customer

The cobas c111 instrument uses open source software. Among other things, the holders

of the proprietary rights grant licenses under the terms of the GNU General Public Licence

(GPL edition 2 or above) as well as under the GNU Lesser General Public License (LGPL).

The cobas c111 instrument has been designed to be operated with the unmodified software as shipped. The user assumes full responsibility for changing any part of the open

source software, which excludes any liability of Roche Diagnostics Ltd.

This program is distributed without any warranty; without even the implied warranty of

merchantability or fitness for a particular purpose. See the GNU General Public License for

more details (www.gnu.org/copyleft/gpl.html).

The source code of the used open source software is part of MIKRAPs CPUX255LCDNET

board support package and may be obtained from SYSGO (http://www.sysgo.com/products/board-support-packages/).

Legal liability

Roche Diagnostics Ltd. assumes only limited liability when using the cobas c111

instrument in conjunction with the cobas c 111 Development Channel Programming

Software.

For detailed information on this matter refer to the latest version of the Development

Channel Registration Form cobas c111 and the cobas c 111 Development Channel

Operator’s Manual.

Roche Diagnostics

Operator’s Manual · Version 3.0 A-11

Page 22

1Safety cobas c111

WARNING

Disposal recommendation

Disposal recommendation

All electrical and electronic products should be disposed of separately from the

municipal waste system. Proper disposal of your old appliance prevents potential

negative consequences for the environment and human health.

Disposal label

Electrical and electronic equipment marked with this symbol are covered by the European

directive on waste electrical and electronic equipment (WEEE) 2002/96/EC.

The symbol denotes that the equipment must not be disposed of in the municipal waste

system.

Disposal of external components

External components such as the scanner and the ISE power supply, which are marked

with the crossed-out wheeled bin symbol, are covered by the European Directive

2002/96/EC (WEEE).

These items must be disposed of via designated collection facilities appointed by government or local authorities.

For more information about disposal of your old products, contact your city office, waste

disposal service or your local service representative.

Disposal of the instrument

The instrument must be treated as biologically contaminated hazardous waste. Final disposal must be organized in a way that does not endanger waste handlers. As a rule, such

equipment must be sterile before it is passed on for final disposal.

For more information contact your local service representative.

Constraint

It is left to the responsible laboratory organization to determine whether control unit

components are contaminated or not. If contaminated, treat in the same way as the

instrument.

Roche Diagnostics

A-12 Operator’s Manual · Version 3.0

Page 23

cobas c111 1Safety

A

B

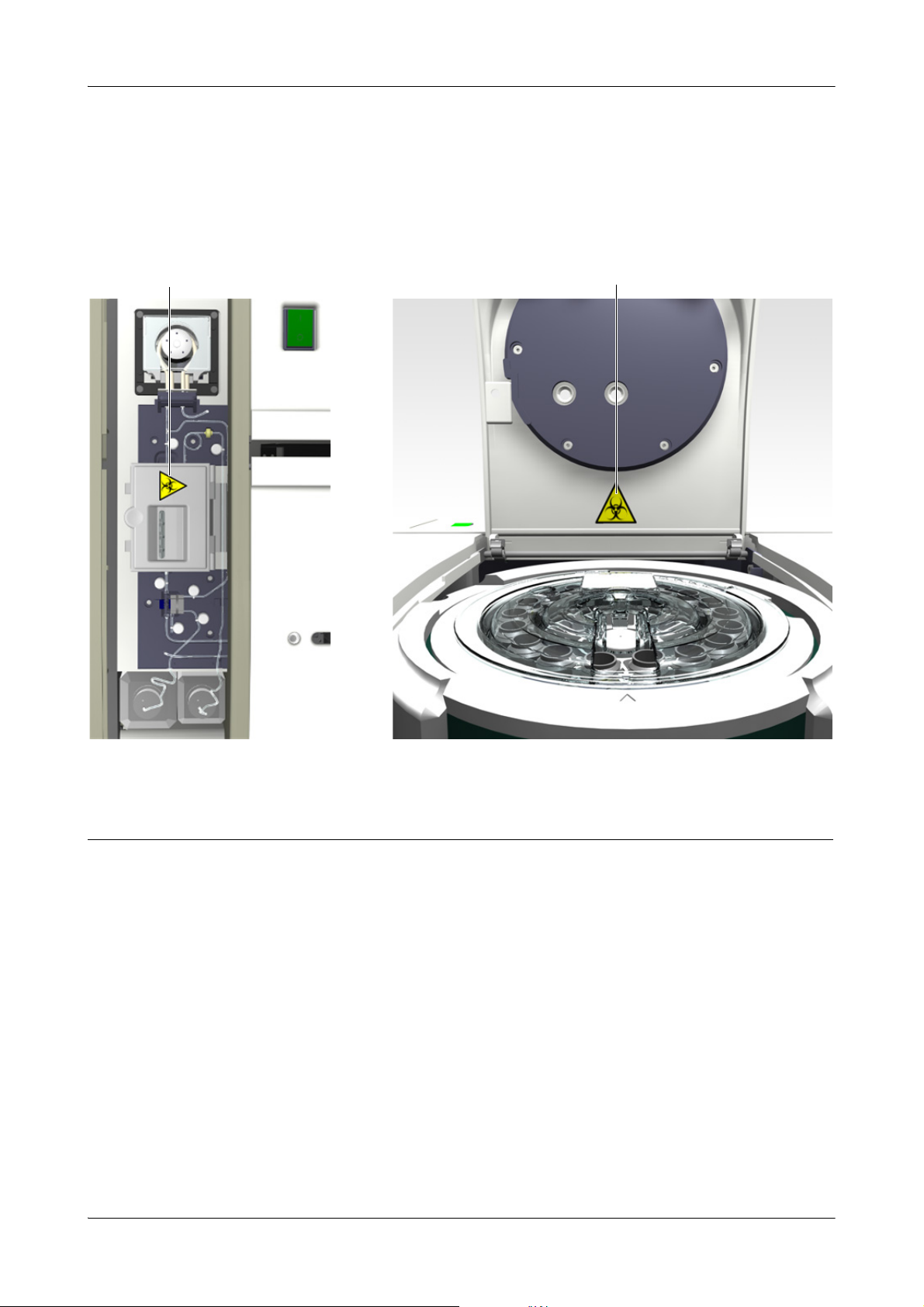

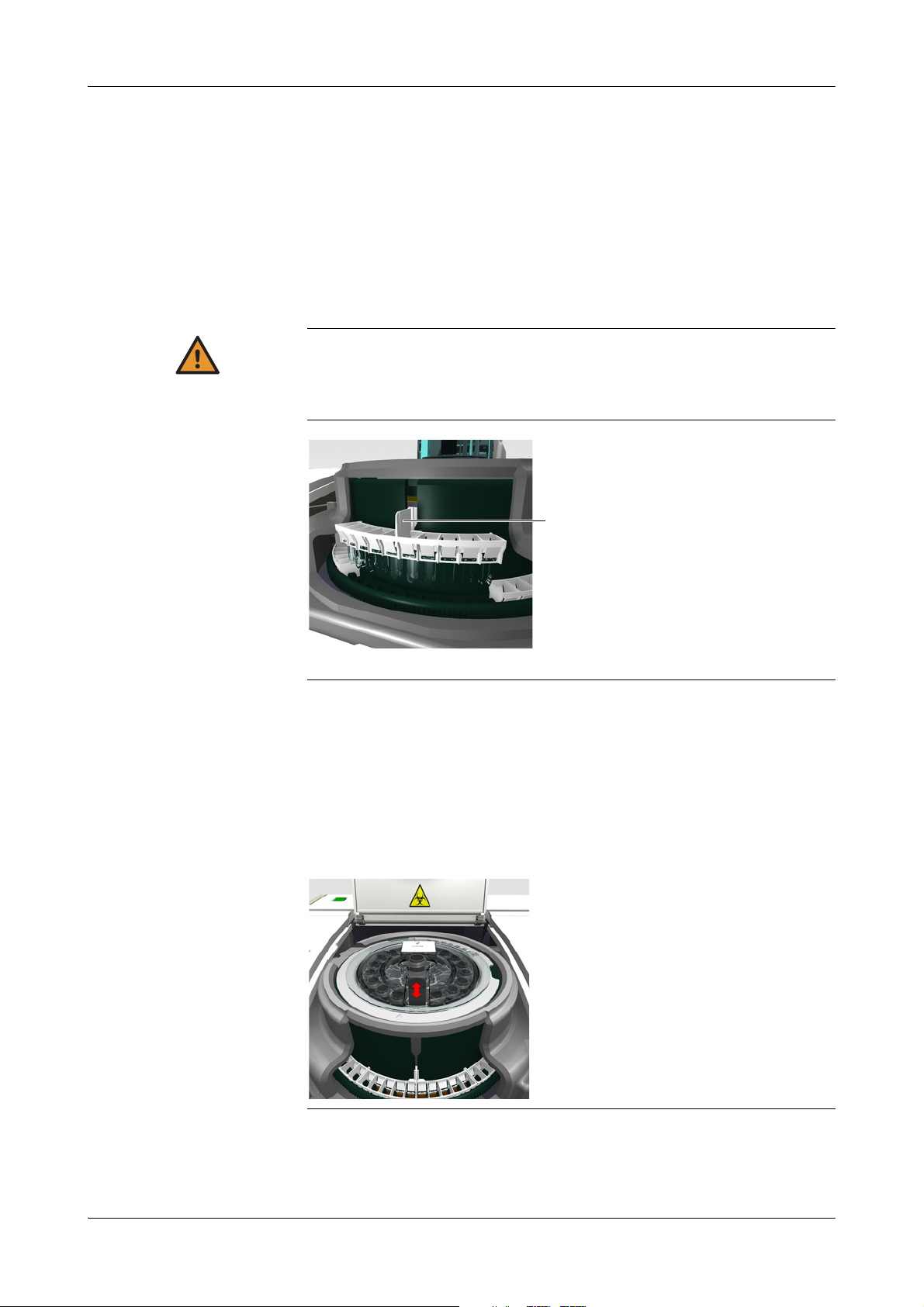

Safety labels

Safety labels

Read all safety labels on the instrument and equipment.

The following illustration shows where on the instrument labels are displayed.

A This label on the electrode block of the ISE unit indicates that

there is a danger of hazardous situations arising within the vicinity

of this label, which may result in death or serious injury. The relevant laboratory procedures on safe use must be observed.

(You will find this label only if an ISE unit is installed.)

Figure A-1 Safety labels on the cobasc111 instrument

In addition to safety labels on the instrument, there are safety notes in the

corresponding parts of the Operator’s Manual.

These safety notes give more detailed information about potentially hazardous

situations that may arise during daily operation or when carrying out maintenance

procedures.

When working with the instrument, be sure to observe both the safety labels on the

instrument and the safety notes in the Operator’s Manual.

B This label on the main cover indicates that there are potential bio-

hazards within the vicinity of this label, which may result in death

or serious injury.

The relevant laboratory procedures on safe use must be observed.

Roche Diagnostics

Operator’s Manual · Version 3.0 A-13

Page 24

1Safety cobas c111

Safety labels

Roche Diagnostics

A-14 Operator’s Manual · Version 3.0

Page 25

cobas c111 2 Introduction to the instrument

Table of co ntents

Introduction to the instrument

What you need to know before you start

In this chapter, you will find basic information on the features that are relevant for

working with the cobas c111 instrument.

In this chapter

Overview .................................................................................................................... A-17

Principles of operation ........................................................................................A-19

User interface .............................................................................................................A-20

Wizards ......................................................................................................................A-21

Daily operation ..........................................................................................................A-22

Overview .............................................................................................................. A-22

Reagent and diluent handling ............................................................................. A-25

Calibration ...........................................................................................................A-26

Calibration type ............................................................................................. A-27

Calibration sequence ..................................................................................... A-28

Calibration status of a set ..............................................................................A-28

Calibration result storage ..............................................................................A-28

Validating calibration results ........................................................................A-29

Calibration procedures .................................................................................. A-29

Quality control (QC) ..........................................................................................A-30

Sample handling ..................................................................................................A-31

Order handling .................................................................................................... A-32

Results ..................................................................................................................A-34

Maintenance ..............................................................................................................A-34

System status ..............................................................................................................A-35

Chapter

2

Roche Diagnostics

Operator’s Manual · Version 3.0 A-15

Page 26

2 Introduction to the instrument cobas c111

Tab l e o f c o nt en ts

Roche Diagnostics

A-16 Operator’s Manual · Version 3.0

Page 27

cobas c111 2 Introduction to the instrument

WARNING

Overview

Overview

The cobas c111 instrument is a continuous random-access analyzer intended for the

in vitro determination of clinical chemistry and electrolyte parameters in serum,

plasma, urine or whole blood (HbA1c). It is optimized for small throughput

workloads of approximately samples per day, utilizing photometric analysis and an

optional unit for ion selective electrodes (ISE).

Only trained personnel working in a professional laboratory environment may

operate the cobas c111 instrument.

Incorrect results or damage to the analyzer due to wrong operation

Operators are required to have a profound knowledge of relevant guidelines and norms as

well as the information and procedures contained in the Operator’s Manual.

o Do not carry out operation and maintenance unless you have been trained by Roche

Diagnostics.

o Carefully follow the procedures specified in the Operator’s Manual for the operation

and maintenance of the system.

o Leave maintenance that is not described in the Operator’s Manual to trained service

representatives.

o Follow standard laboratory practices, especially when working with biohazard material.

Features As part of the cobas family of instruments, the cobas c 111 instrument offers small

laboratories the following advantages:

o High analytical performance

The same bulk reagents, 12-wavelength photometer and disposable cuvettes

generate results that are highly correlated to other cobas instruments.

o Efficient operation

Cooled, exchangeable reagent disks ensure economical reagent use; disposable

cuvette segments allow for easy cuvette loading and removal.

o High reliability, low maintenance

Innovative "low impact" instrument design and software-driven preventive

maintenance improves up-time and reduces maintenance costs.

o Adaptable user interface

The built-in color touchscreen, process-driven software, and reagent and sample

barcode entry adapts to users of different skills and access levels.

o High safety standards

Built-in safety devices, such as level detection, tube bottom detection, cuvette

quality control, and ISE clot detection anticipate potential hazards during

operation.

o Flexible sampling

Eight on-board sample positions accommodate virtually any type of sample

carrier, and enable continuous sample placing and removal during operation.

o Data management

Bidirectional RS-232 and USB ports, on-board thermal printer, and drivers offer

the latest in data management capabilities.

Roche Diagnostics

Operator’s Manual · Version 3.0 A-17

Page 28

2 Introduction to the instrument cobas c111

A

L NM

B D

I

F

E

G

H

O

J

K

C

Overview

Measuring principles Measurements are performed by means of an absorbance photometer and optionally

an ISE (ion selective electrode) module that uses ion selective potentiometry.

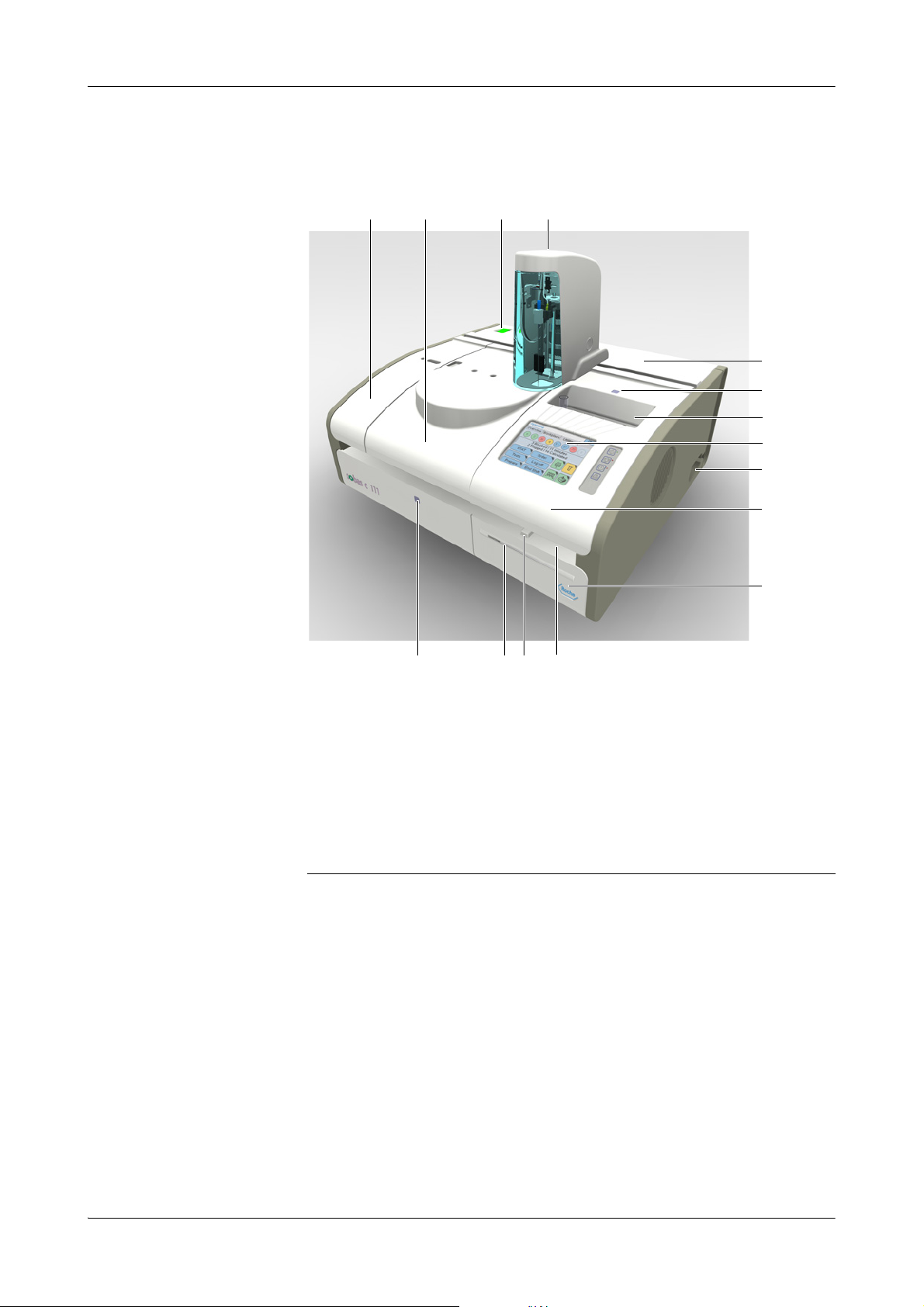

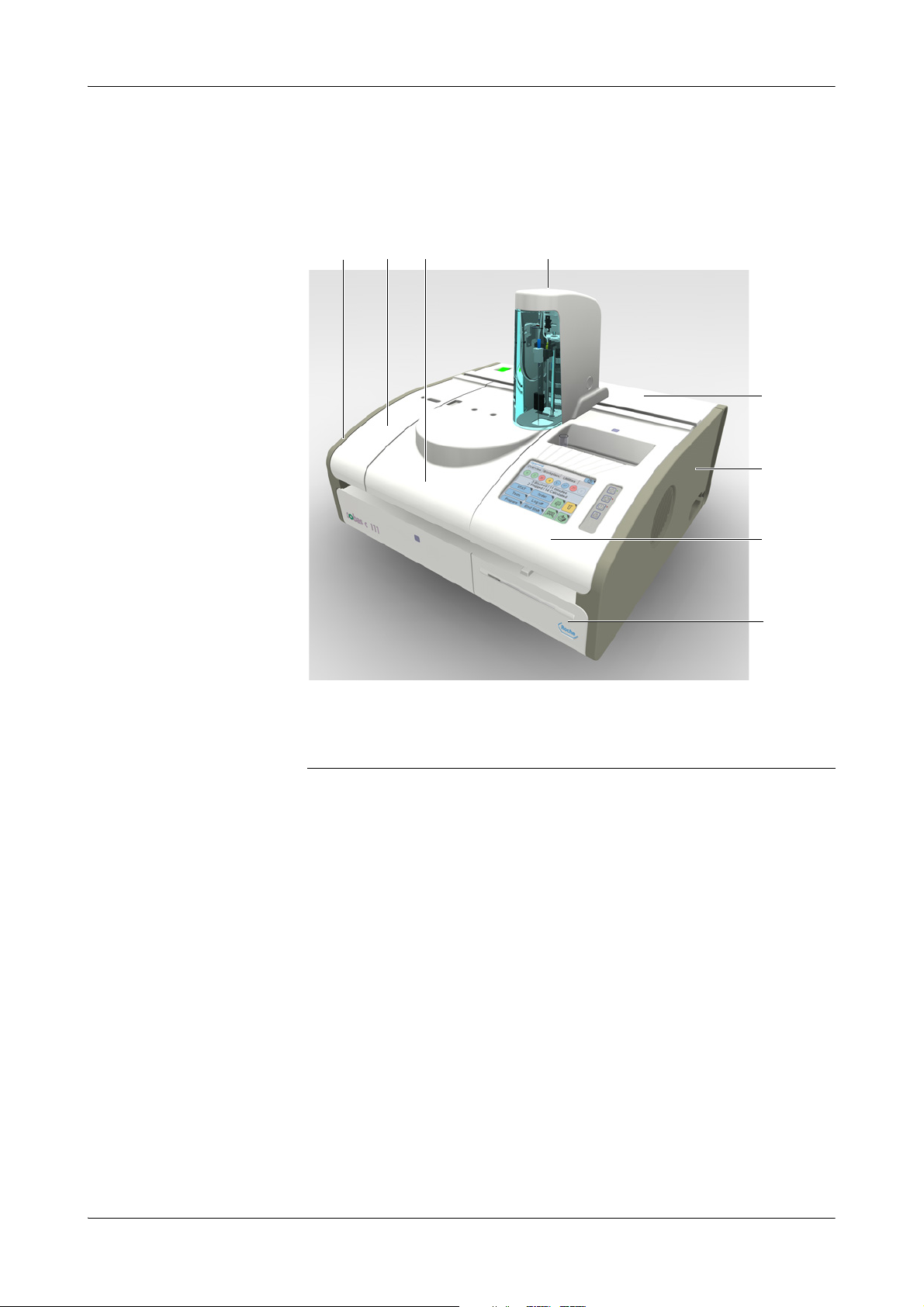

A first look at the instrument

A Left service flap (covers wash station, ISE

tower, tubing)

B Main cover (covers rotor, reagents, cuvettes,

photometer unit)

C Main switch

D Transfer head (holds probe)

E Rear service flap (covers computer boards,

power supply, degasser)

F Sample area LED

G Sample area (space for 8 sample tubes)

Figure A-2 The cobas c 111 instrument

H Touchscreen

I Fluid connectors

J Right service flap (covers photometer unit,

sample area)

K Printer panel

L Main cover LED

M Paper slot

N Release button for printer panel

O USB connector (not shown)

Roche Diagnostics

A-18 Operator’s Manual · Version 3.0

Page 29

cobas c111 2 Introduction to the instrument

Overview

Principles of operation

The cobas c111 main instrument uses absorption photometry for determining the

amount of absorbance in a fluid. The absorbance is used to calculate the

concentration in the solution.

Loading the sample The operator identifies the sample, places it on the instrument, and defines the order.

(If you work with a host system, the order is defined automatically.)

Measuring process The measuring process for each test consists of forty regular cycles, each lasting 18

seconds. In each of these cycles, a measurement is taken, irrespective of what other

actions take place during this cycle. The application definitions determine what is

done in which cycle, and they also define which results are taken into account for the

result calculation.

With each cycle, a new test can be started.

The basic process works as follows:

1. Checking the cuvette.

A measurement is taken to check the quality of the cuvette.

2. Pipetting reagent (R1) to the cuvette.

After each pipetting action, the system performs a wash cycle to minimize carryover. During this cycle, the probe and tubing are flushed with water and cleaner.

3. Wait.

The fluid needs to reach the prescribed temperature. Such a phase can last several

cycles.

During the wait cycles, activities for other tests are performed.

4. Pipetting the next fluid.

Typically, this would be the sample. The details are defined in the application

definitions.

5. Wait.

6. Pipetting the next fluid.

7. Wait.

8. And so on.

Calculating the results The test result is calculated on the basis of the photometric measurement results.

During this process, various checks are performed to ensure that the whole measuring

process was technically correct. If values are above or below predefined limits, the test

result is flagged.

The results are stored on the system. This includes both the forty measurement results

(raw data) and the calculated test result.

Sequence of processing For a given sample, the tests are processed in the order defined by the time required

for their processing (number of cycles), starting with the one that takes the longest.

This order can be altered manually by defining a specific process sequence list.

Status of the measuring process At any stage of the measuring process, the user can check its status on the screen.

Result data management The system provides storage space for the results of one working day. For backup

purposes, the results must be exported to an external storage device once a day.

Roche Diagnostics

Operator’s Manual · Version 3.0 A-19

Page 30

2 Introduction to the instrument cobas c111

E

G

F

D

C

B

A

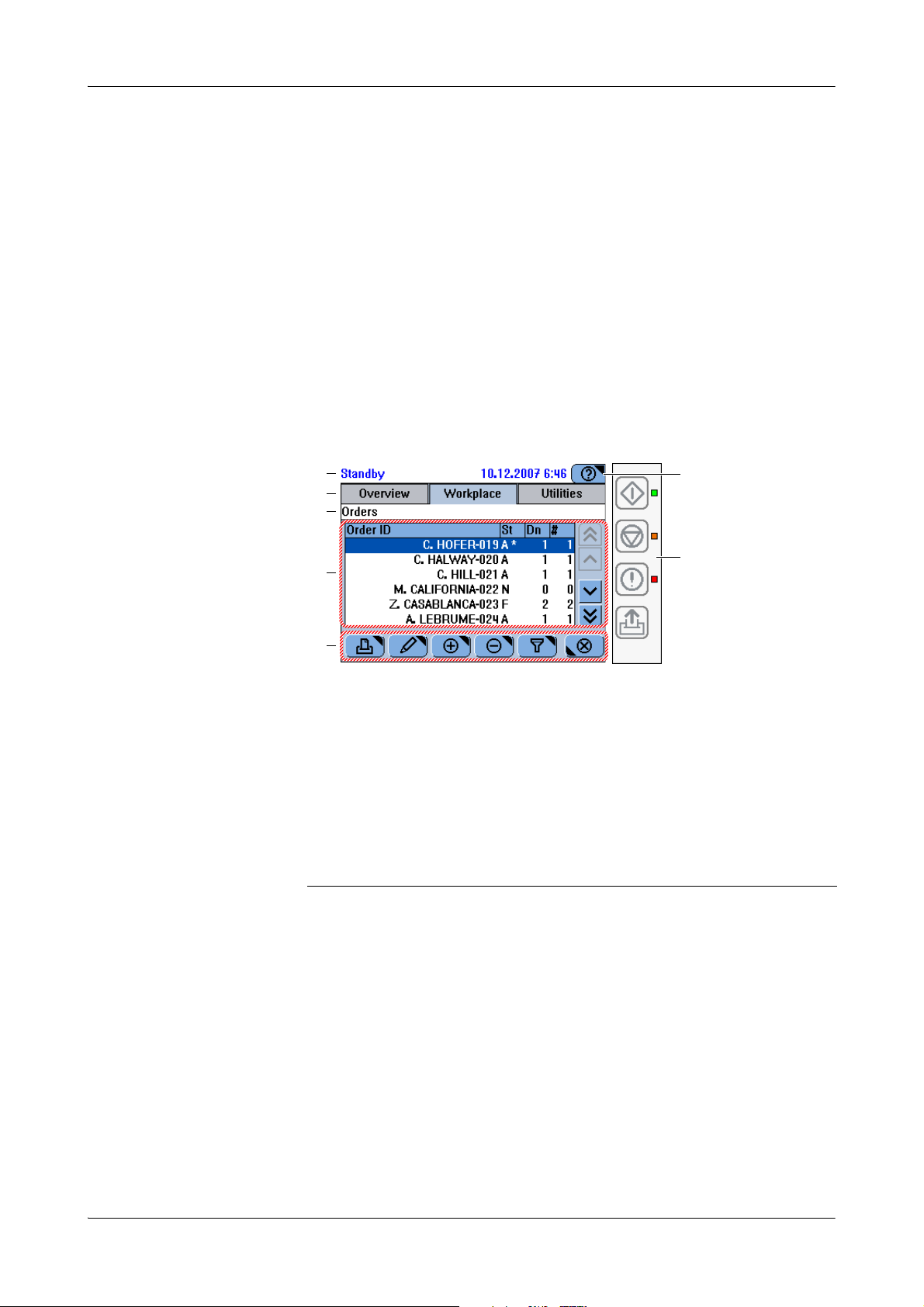

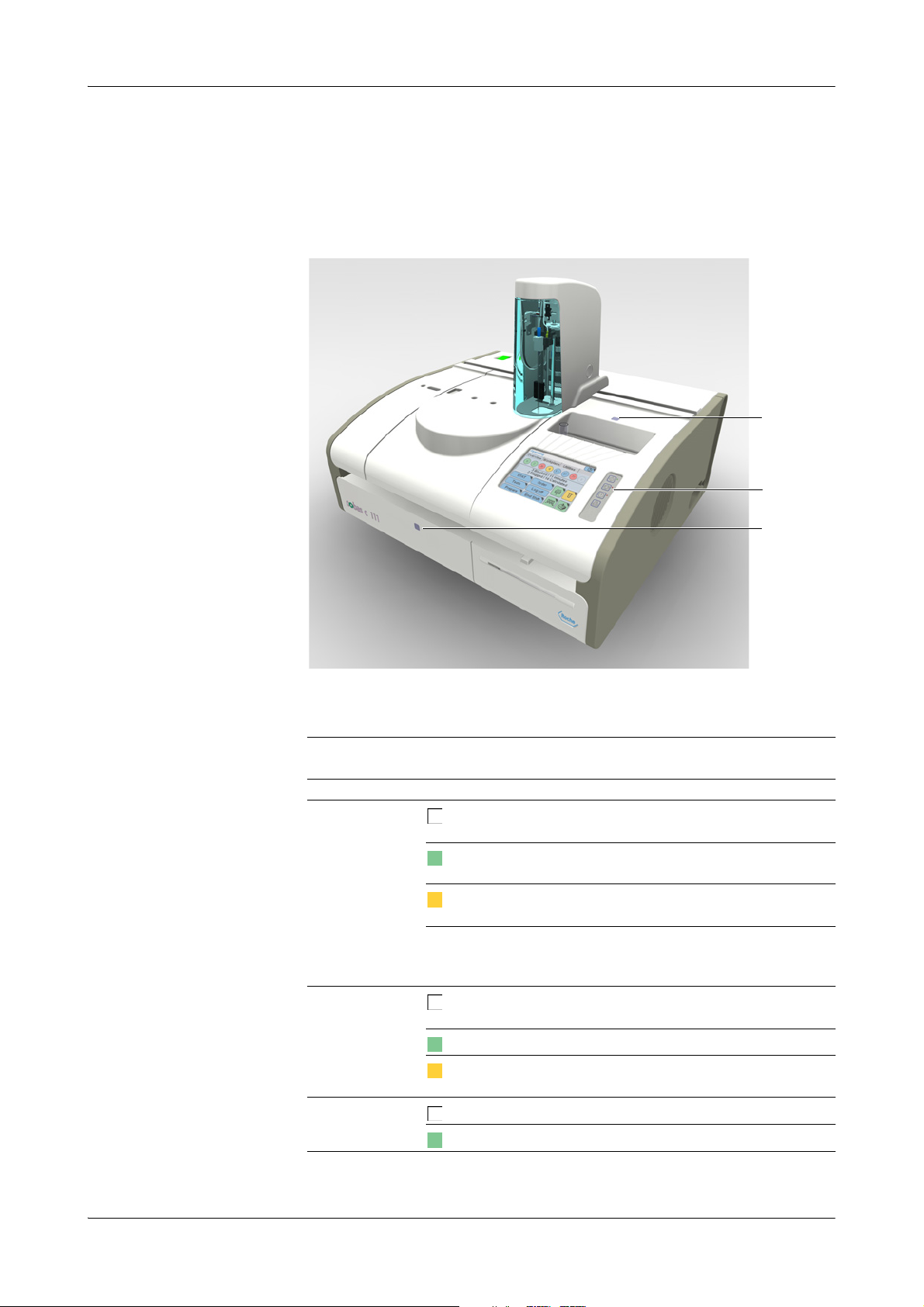

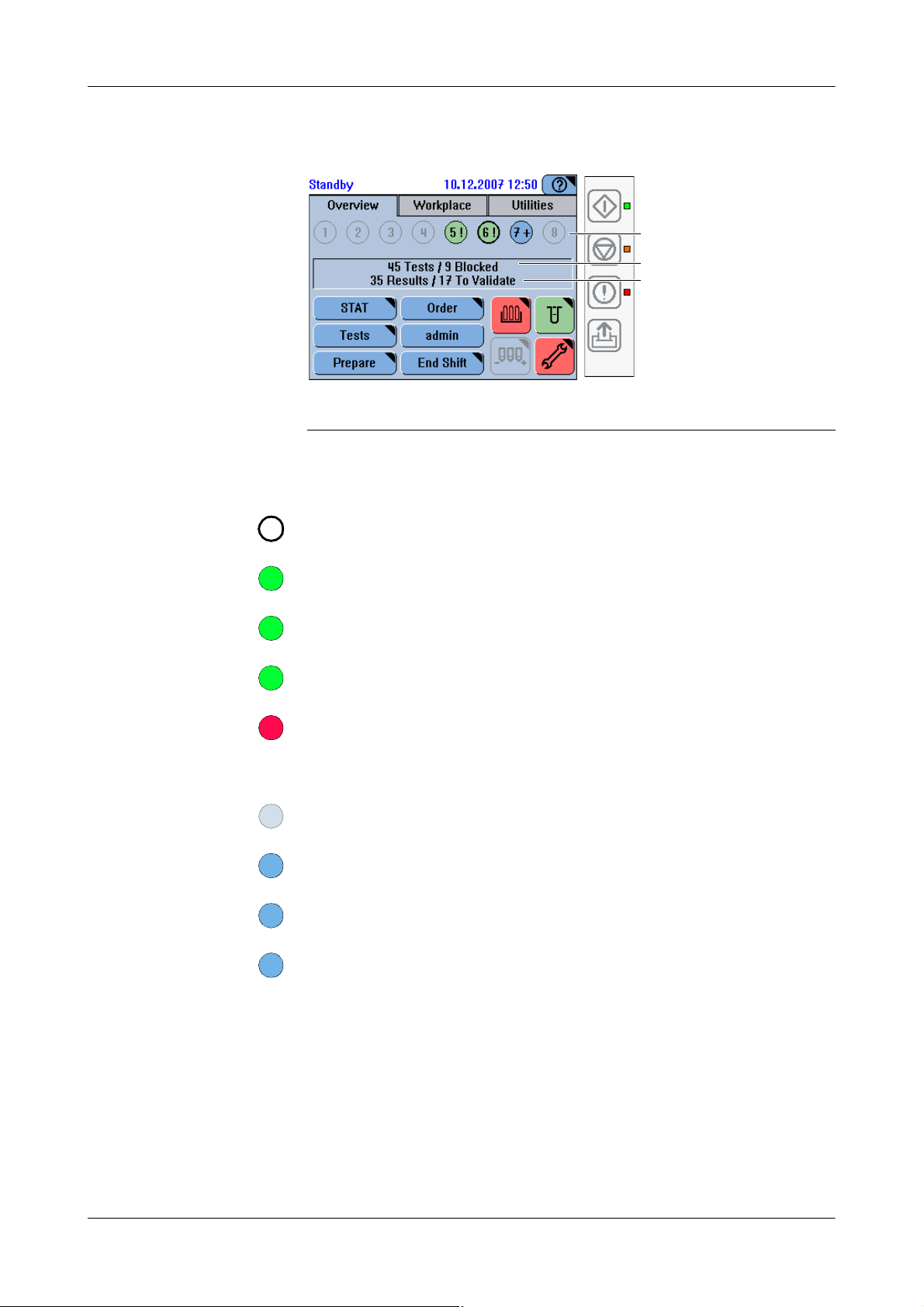

User interface

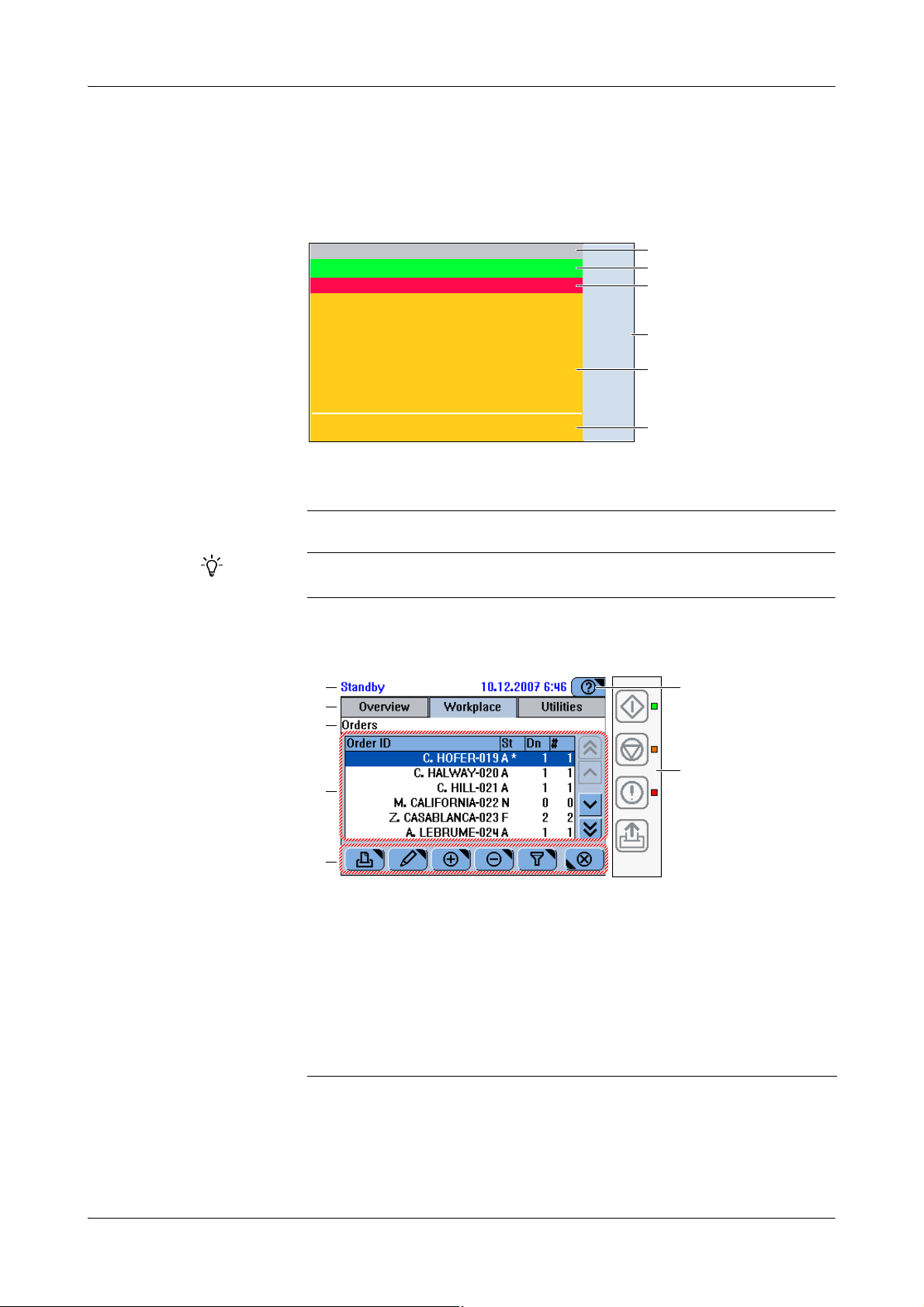

User interface

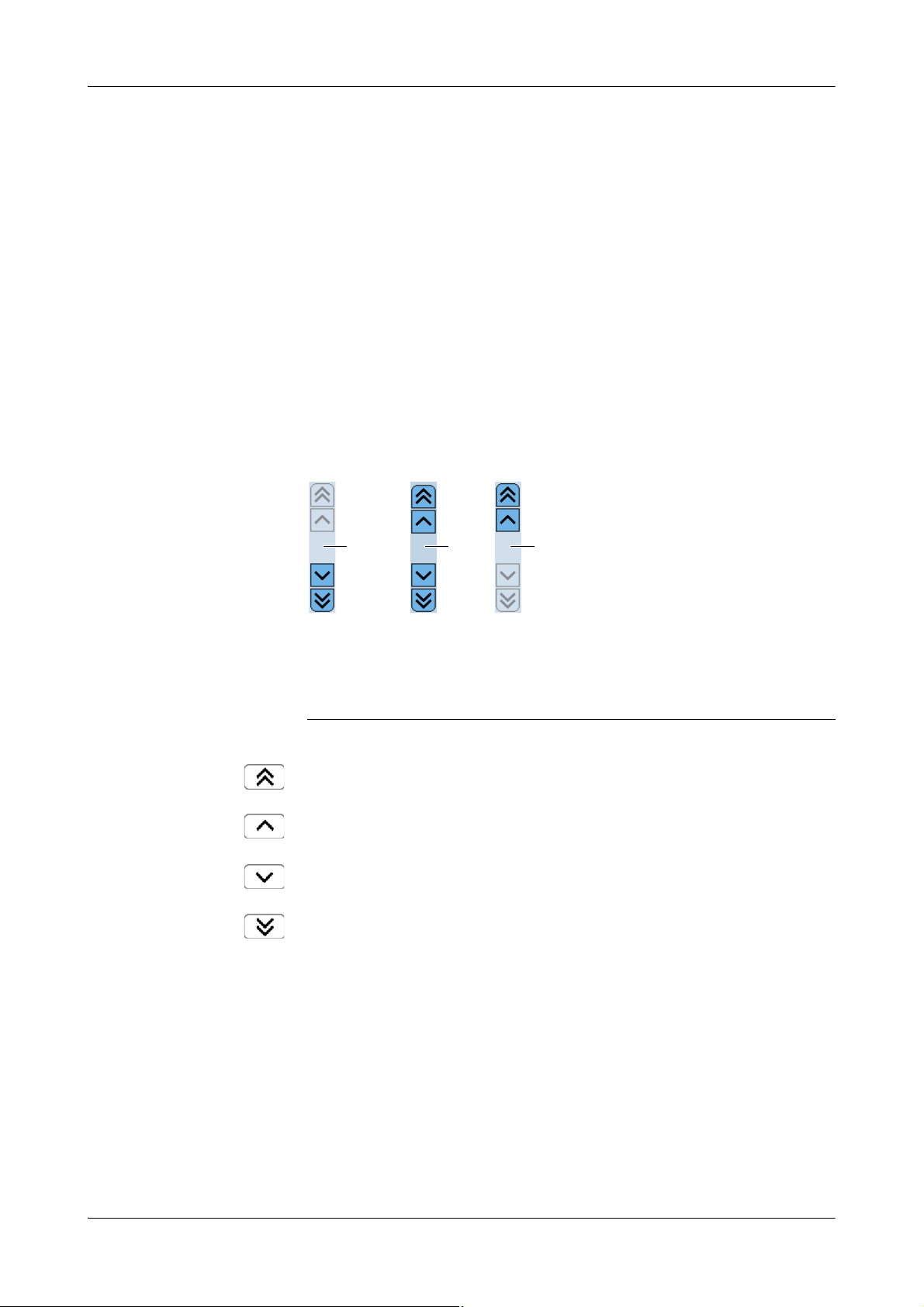

The cobas c111 instrument is equipped with a touchscreen, an on-screen keyboard

and four global action buttons. LEDs and acoustic signals let you know when it is safe

to add or remove samples, reagents and other fluids.

With buttons and other display items, “traffic light” color coding is used: Green

means OK, yellow: watch out, you need to do something, and red means that your

intervention is required for processing to continue.

The screens have a clear and consistent layout and are easy to use. The topics are

divided in the proven work areas: Overview for order and fluid handling, Wo rk p la ce

for result handling and details on orders, and Utilities for administration tasks.

e

For details on the user interface, see Chapter 5 Software.

The following is an example of a screen. It contains the full range of display items.

A The status line displays the system status.

B Tab s represent the major work areas.

C The headline characterizes the content or

function of the screen. If the screen is part of

a sequence of screens (wizard), the headline

tells you where you are within this sequence.

D The working area displays the main content

of the screen.

E The buttons vary depending on the content

of the working area and the screen position

within a series of steps (wizard).

Figure A-3 Example of a screen

F The Help button leads to concise information

that is relevant to the current screen and

situation.

G The global action buttons represent the

functions that are permanently available:

Start, Stop, Alarm, Line Feed. The LEDs next

to them point to their status.

Roche Diagnostics

A-20 Operator’s Manual · Version 3.0

Page 31

cobas c111 2 Introduction to the instrument

Wizard s

Wizards

Screens help you perform your tasks. If not all steps of a task can be performed from

one screen, the workflow is realized as a sequence of screens, a so-called wizard.

cobas c 111 wizards do not usually force you to perform a task at a certain stage, they

just make your work easier.

e

For details on workflows, see Workf low s and w izar ds on page A-74.

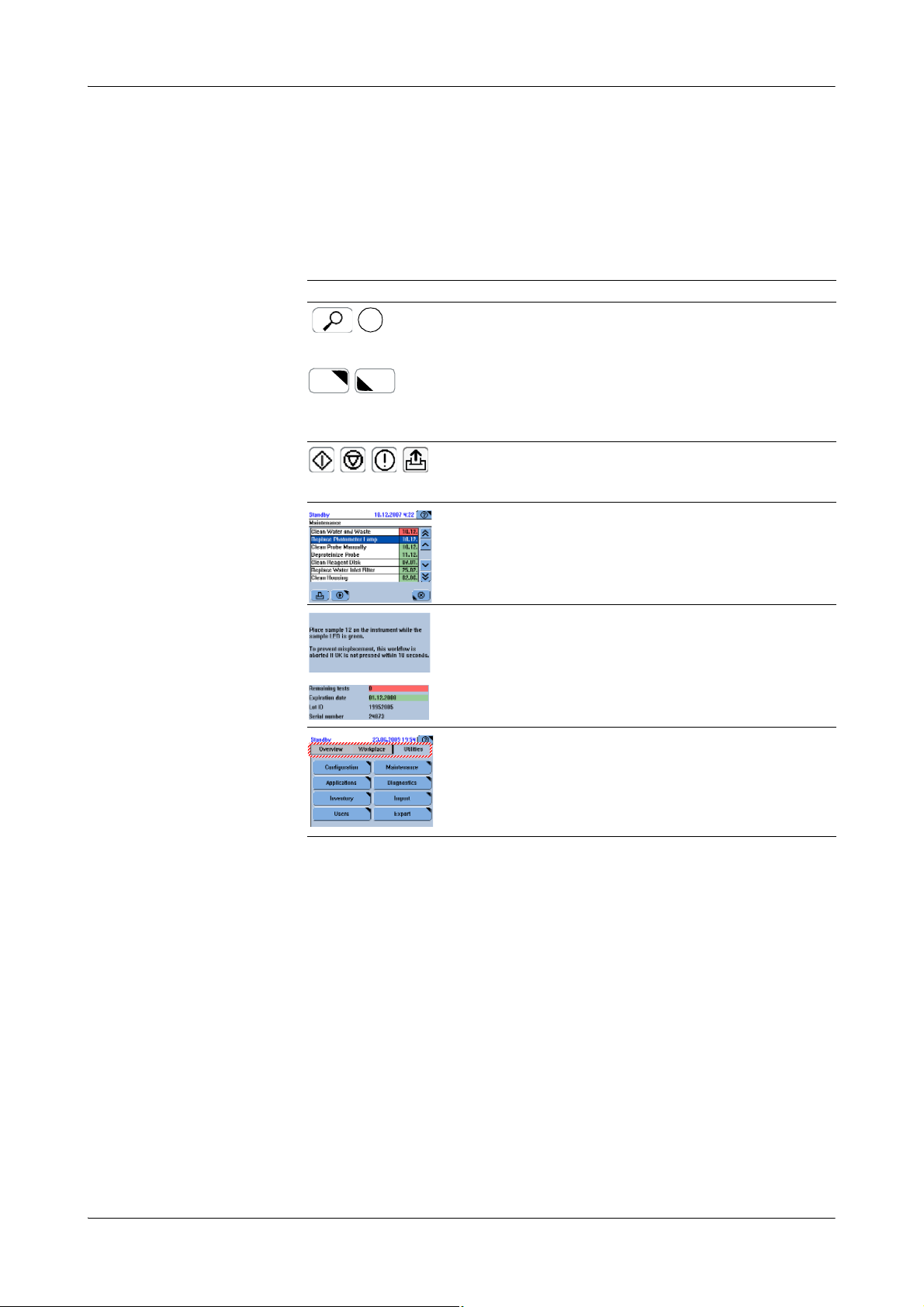

When intervention is required On the screen, there are several methods of telling when your intervention is required:

o Buttons and texts are color coded.

Everything is fine.

To ensure smooth operation, you need to perform some task.

The current process or action has not started yet or stopped. You need to

do something for it to start or continue.

o Screens can contain instructions. For example the text may ask you to place the

sample on the sample area or to remove a reagent bottle from the reagent disk.

o Messages inform you about the status of current actions.

o A permanent alarm monitor alerts you to events you should know about.

Wizards There are three major wizards: Prepare wizard, Orders wizard, and End Shift wizard.

With most tasks that involve more than one step, such as exchanging reagent or other

fluid bottles, you are supported by wizards.

Prepare wizard The Prepare wizard guides you through the tasks that need to be performed at the

beginning of a shift. When this wizard is done, the system is ready for processing

orders.

Orders wizard The Orders wizard guides you through the process of creating and changing orders.

End Shift wizard The End Shift wizard guides you through the tasks that need to be performed at the

end of the day or to prepare the instrument for handing over to another operator.

Individual tasks can be performed outside the wizards

Most tasks that make up a workflow can be performed without using a wizard.

If you perform a task independently, you first need to navigate to the appropriate screen

and then start the task from there; whereas if you use a wizard, the appropriate screen is

displayed automatically.

Using the wizards also ensures that all necessary steps are performed and in the right

order.

Roche Diagnostics

Operator’s Manual · Version 3.0 A-21

Page 32

2 Introduction to the instrument cobas c111

Daily operation

Daily operation

Overview

Daily operation includes the routine tasks that are required to prepare and monitor

the system, and to analyze samples.

When you switch on the system, it performs several checks to make sure that all

preconditions are met, for example that all covers are closed or that there are cuvettes

available. It then performs self-tests to ensure that all modules function properly.

At the end of the startup phase, the screen is updated to display the current status of

the system.

The following table gives an overview of the tasks you might need to perform during

daily operation.

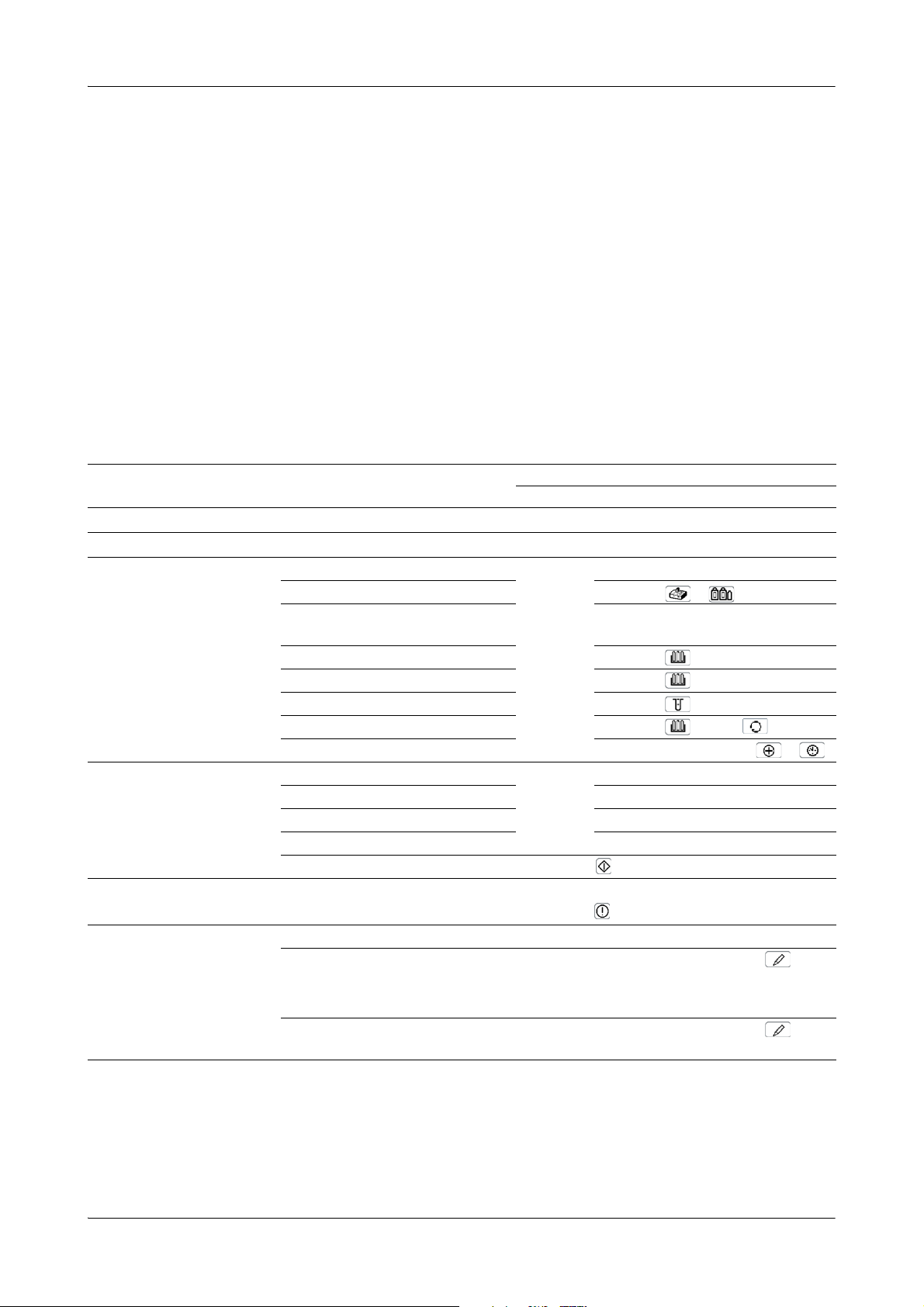

Task Steps Navigation

Starting the system 1. Switch on the system.

1

Logging on the system Overview > Logon

2

Preparing the system Start the Prepare wizard. Overview > Prepare

3

Defining orders Start the Orders wizard. Overview > Order (or Overview > STAT)

4

Monitoring the progress n/a Overview

5

With wizard As individual steps

1. Check the external fluid containers. Overview > >

2. Perform the maintenance actions

that are due.

3. Load the reagent disk. Overview >

4. Check the reagents. Overview >

5. Check the cuvettes. Overview >

6. Perform mixing Overview > > test >

7. Perform calibrations that are due. Wor k pl a ce > Calibrations > >

1. Identify the sample. n/a

2. Select the tests. n/a

3. Place the sample. n/a

4. Start the run.

Utilities > Maintenance

Validating results 1. View results. n/a Wo rk p l ac e > Result Review

6

2. Handle flagged results. n/a Wo r kp l ac e > Result Review >

... > Repeat

... > Rerun

3. Accept results. n/a Wo r k pl a ce > Result Review > >

Accept

Ta b le A -1 Overview of the daily operation tasks

Roche Diagnostics

A-22 Operator’s Manual · Version 3.0

Page 33

cobas c111 2 Introduction to the instrument

Daily operation

Task Steps Navigation

With wizard As individual steps

Performing calibrations

7

Performing individual

calibrations

Per form ing

all due calibrations

Performing controls

8

Per form ing

Default QC

Performing an individual

QC measurement

Performing all

due QC measurements

Ta b le A -1 Overview of the daily operation tasks

1. Start the wizard. Wo rk p l ac e > Calibrations >

2. Select the test. n/a

3. Prepare and place the calibrators. n/a

4. Start the calibration.

5. Validate the calibration results. Wo r kp l ac e > Calibrations >

6. Remove the calibrators.

1. Start the wizard. Wo rk p l ac e > Calibrations >

2. Select all tests with due calibrations.

or

Select all tests with calibration due

within the forecast period.

3. Prepare and place the calibrators. n/a

4. Start the calibration.

5. Validate the calibration results. Wo r kp l ac e > Calibrations >

6. Remove the calibrators.

1. Start the wizard. Overview > Order >

2. Select a control and place the tube.

Repeat until there are no controls left

on the screen.

3. Start the QC measurement.

4. Validate the QC results. Wo r kp l a ce > QC Status >

5. Remove the controls. n/a

1. Start the wizard. Wo rk p l ac e > QC Status >

2. Select a test. n/a

3. Select a control and place the tube.

Repeat until there are no controls left

on the screen.

4. Start the QC measurement.

5. Validate the QC results. Wo r kp l a ce > QC Status >

6. Remove the control.

1. Start the wizard. Overview > Order >

2. Select a control and place the tube.

Repeat until there are no controls left

on the screen.

3. Start the QC measurement.

4. Validate the QC results. Wo r kp l a ce > QC Status >

5. Remove the controls.

n/a

n/a

n/a

>

n/a

Roche Diagnostics

Operator’s Manual · Version 3.0 A-23

Page 34

2 Introduction to the instrument cobas c111

Daily operation

Task Steps Navigation

With wizard As individual steps

Finishing the shift 1. Check for unfinished orders. Wo rk p l ac e > Orders

9

Choose > Not Finished

2. Check for non-validated results. Wo r k pl a ce > Result Review

Choose > Not Accepted

3. Check for non-transmitted results.

(If working with a host system only.)

4. Start the End Shift wizard. Overview > End Shift

5. Perform the daily backup. Utilities > Export > Database

6. Export the full results. Utilities > Export > Results

7. Clean up the database. Wo r k pl a ce > Orders >

8. Perform the maintenance actions

that are due.

9. Replace cuvettes. Overview >

10. Check the external fluid containers. Overview > >

11. Remove the reagent disk (if last shift). Overview > >

12. Log off the system. Overview > button with your user name

13. Switch off the system (if last shift). n/a n/a

Ta b le A -1 Overview of the daily operation tasks

Wo rk p l ac e > Result Review

Choose > Not Sent to Host

Wo rk p l ac e > Result Review>

Wo rk p l ac e > QC Status >

Wo rk p l ac e > QC History >

Wo rk p l ac e > Calibrations >

Utilities > Maintenance

Roche Diagnostics

A-24 Operator’s Manual · Version 3.0

Page 35

cobas c111 2 Introduction to the instrument

A

B C

Daily operation

Reagent and diluent handling

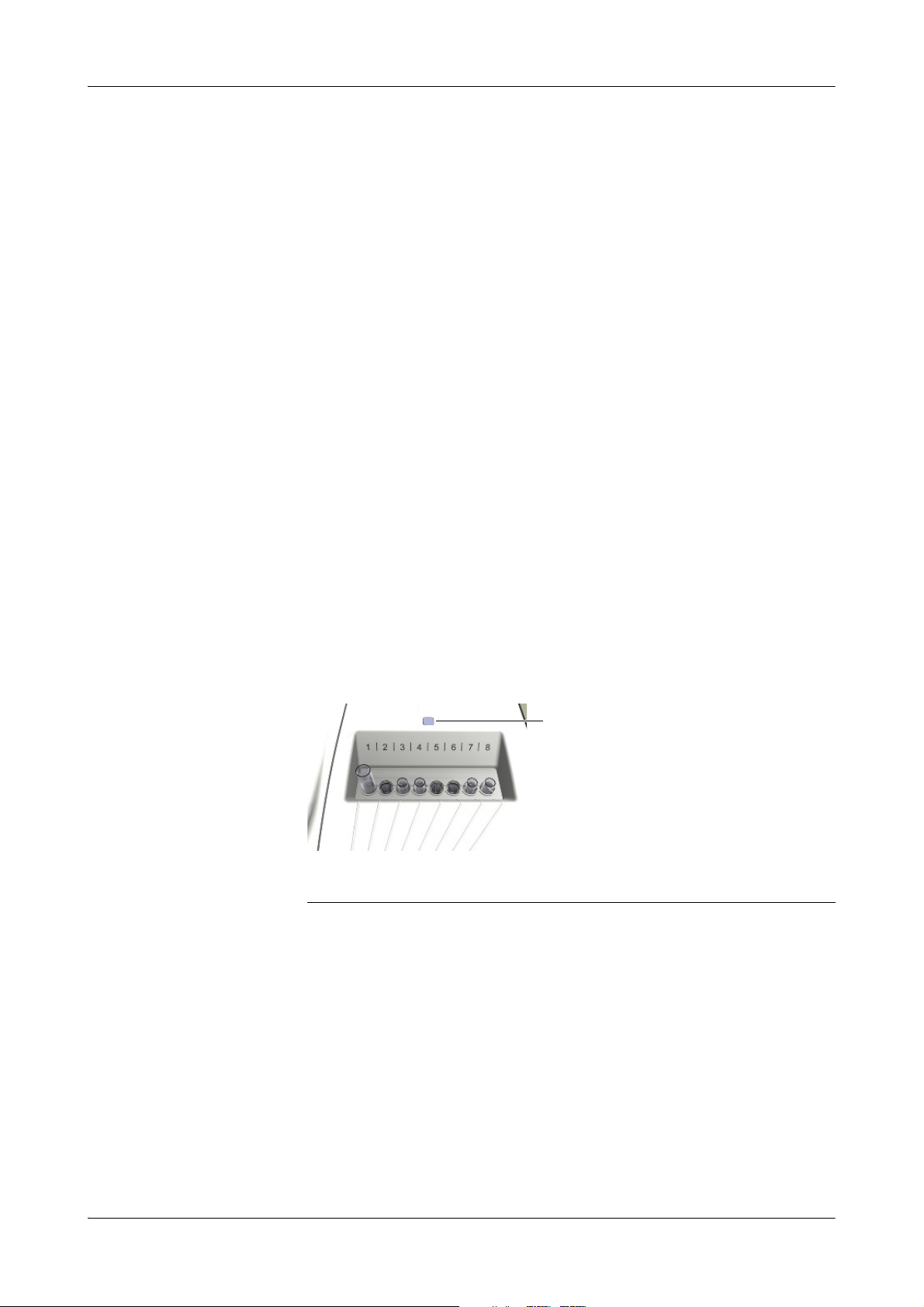

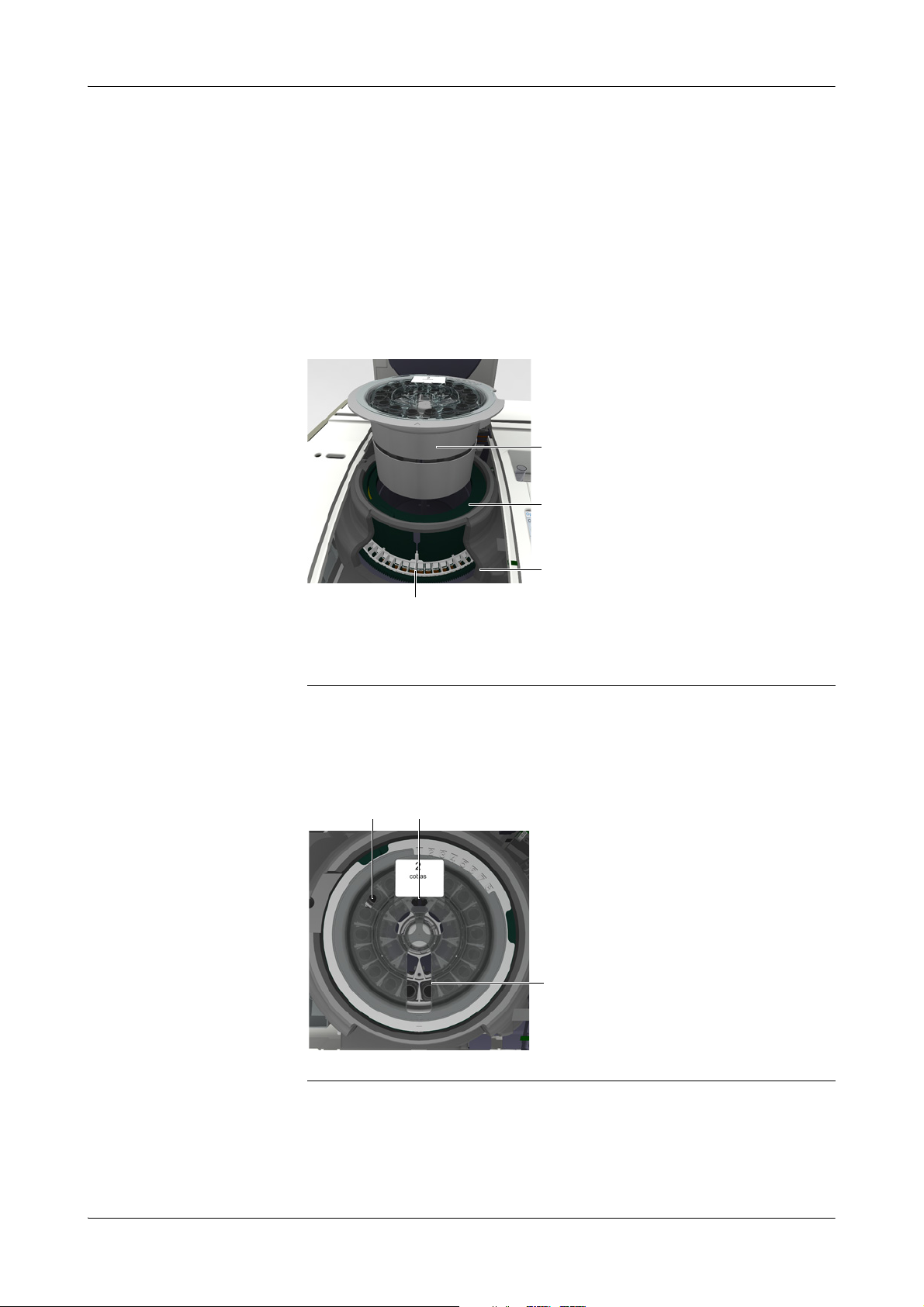

A Reagent disk

B Reagent bottle with barcode

C Chimney

Figure A-4 Equipment for reagent handling

Reagent disk On the instrument, the reagents are stored on a reagent disk. It provides space for 27

bottles, allowing up to 14 reagent sets to be installed on the disk, assuming that most

tests need two reagents. Extra diluents and cleaners are also loaded on the reagent

disk.

You can work with up to eight different reagent disks on one cobas c111 instrument.

You always load and remove bottles while the disk is on the instrument. (The system

needs to know exactly what is loaded on the disk.)

When you finished running tests, you can remove the whole reagent disk, place it in a

reagent disk container, and store it in a refrigerator.

Bottles cobas c 111 reagents, diluents and extra cleaners are provided in uniform bottles. They

are supplied with two dimensional barcodes and placed on the reagent disk with their

cap removed.

Chimneys Chimneys are bottle inserts that reduce evaporation. For reagents that are especially

sensitive to concentration changes, Roche recommend using chimneys on the reagent

bottles. (See the package inserts of the tests whether you should use chimneys or not.)

To generally reduce evaporation, you may use chimneys on all reagent bottles.

Reagent set Up to three reagents can be required to perform a certain test. These reagents are

handled in reagent sets. You can define more than one reagent set for a test, but only

one can be active.

A reagent set is defined as soon as its first bottle is loaded. From this moment on,

whenever you remove or replace a reagent, you do so for all reagents of the set.

Each diluent or cleaner bottle is treated as a separate reagent set.

Roche Diagnostics

Operator’s Manual · Version 3.0 A-25

Page 36

2 Introduction to the instrument cobas c111

Daily operation

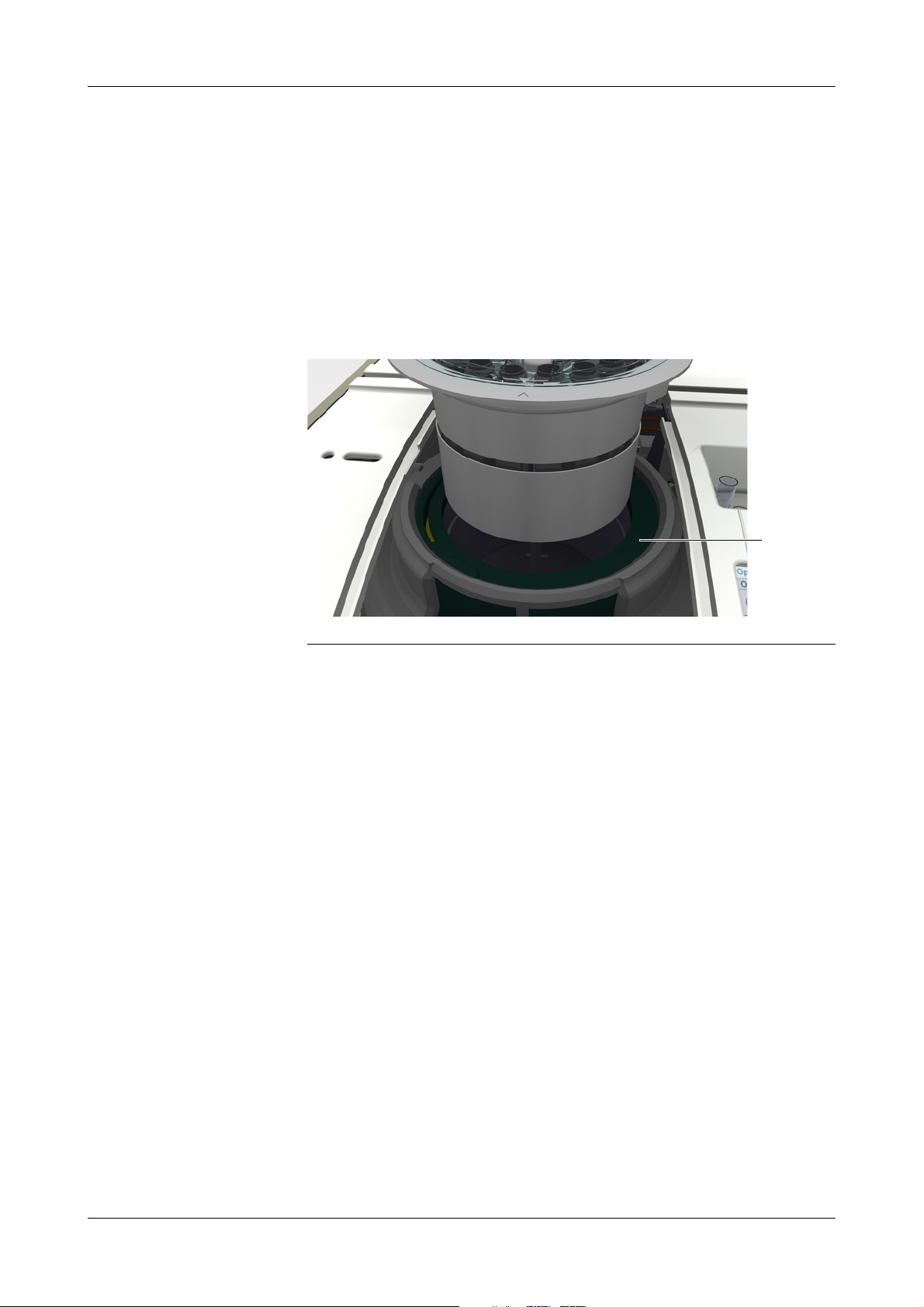

Volum e d et ec t io n For each reagent set, the number of available tests is continuously calculated.

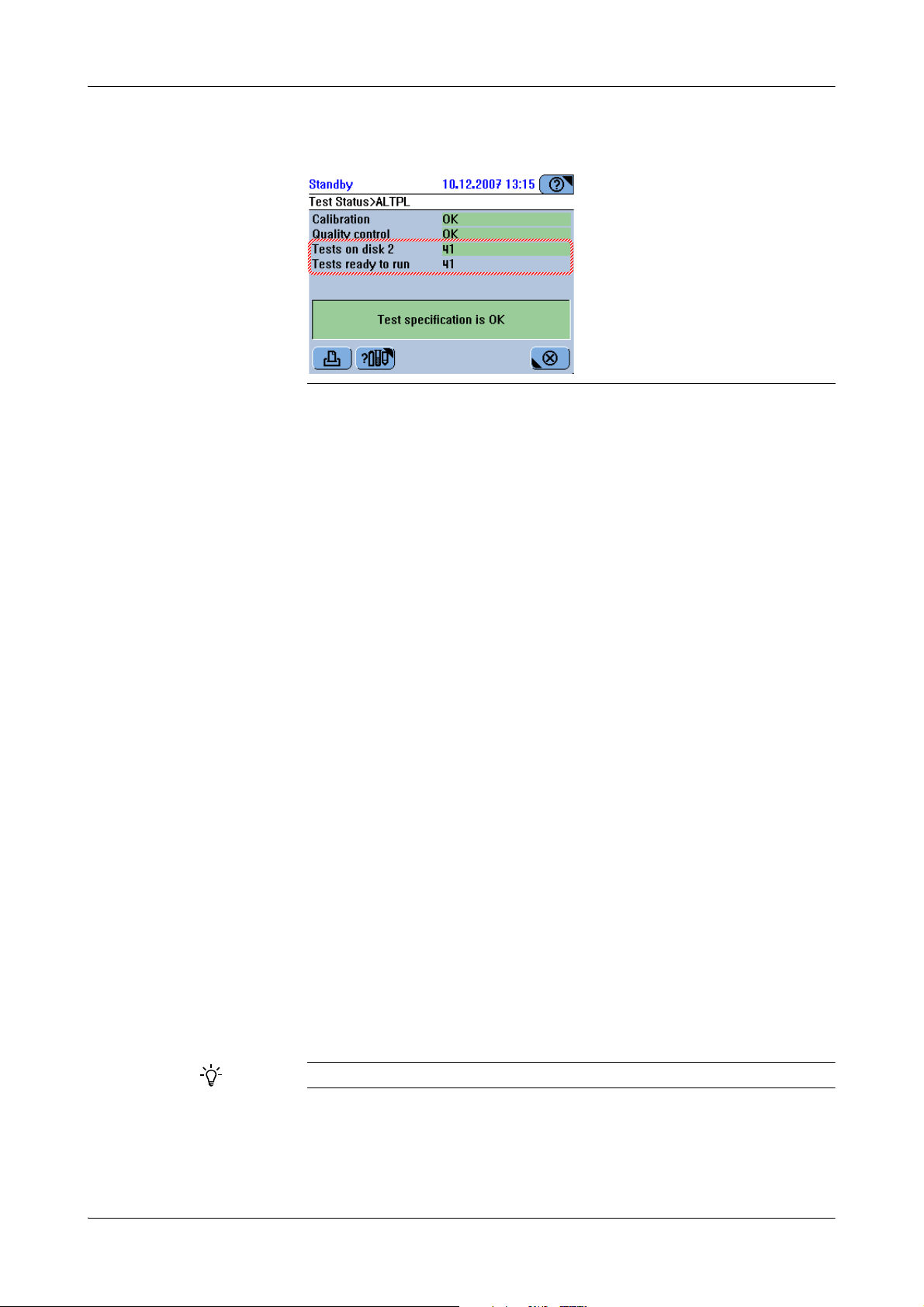

Figure A-5 Remaining tests indication

Periodic mixing Reagents may have a mixing interval defined. This interval is checked by the system

every 30 minutes, and mixing is performed without removing the reagent bottles

from the reagent disk.

For a reagent set that contains more than one reagent for which mixing is defined, the

shortest interval of all reagents of the set is used for all reagents.

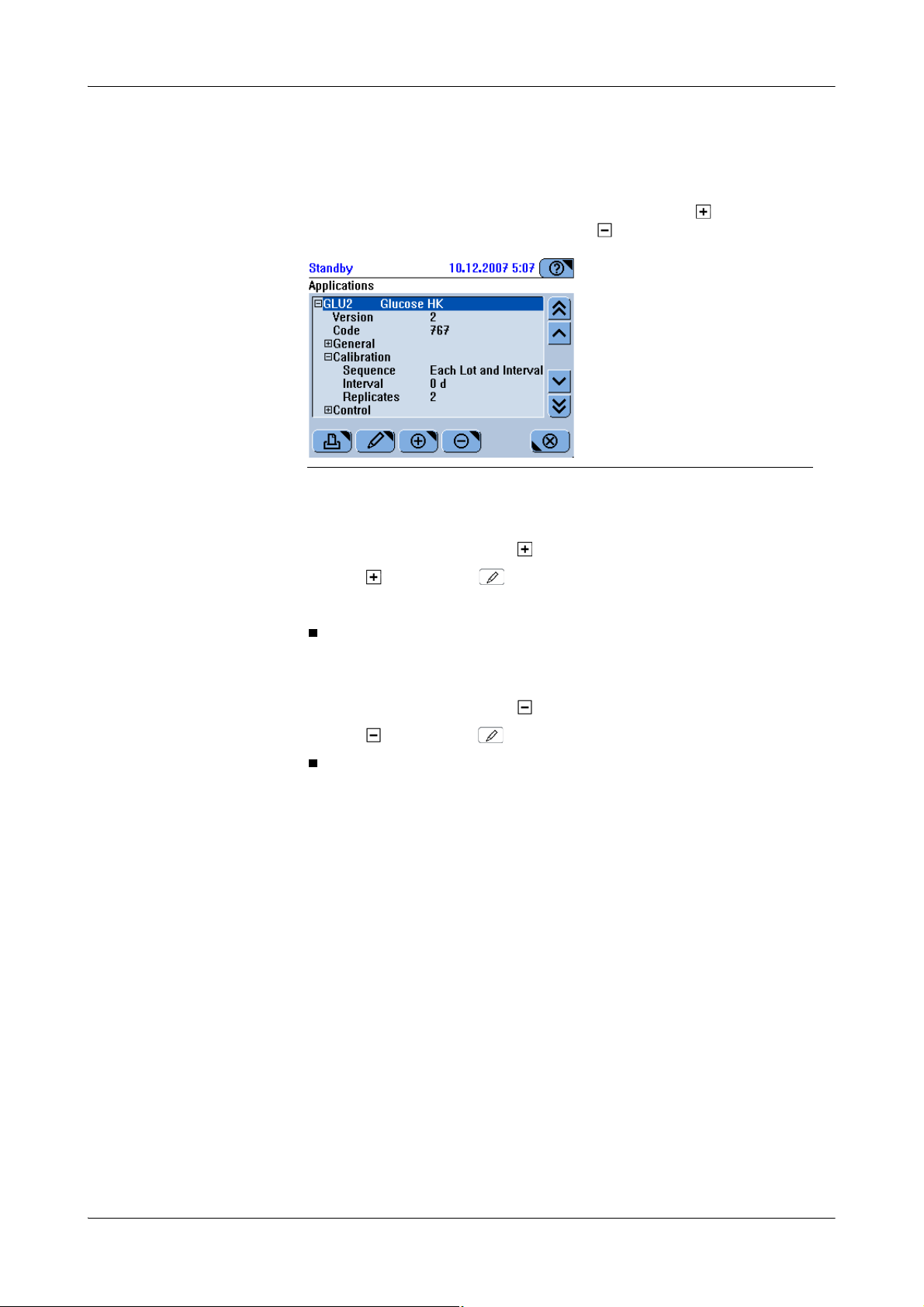

Calibration

Tests are blocked if any reagent they use requires mixing.

Diluents Both, system water and dedicated diluents are used. System water is kept in the

external water container, dedicated diluents are supplied in reagent bottles and placed

on the reagent disk.

Cleaners Both, a system cleaner and dedicated cleaners can be used. The system cleaner is kept

in the external cleaner bottle, dedicated cleaners are supplied in reagent bottles and

placed on the reagent disk.

Calibration is the process that establishes, under specified conditions, the relationship

between values indicated by the analytical instrument and the corresponding known

values of an analyte.

Periodic calibration is required because the concentration of reagents can change over

time.

Reagents are typically calibrated with a two-point calibration, measuring the

predefined value of a multicalibrator and of system water. Some reagents are

calibrated using a set of calibrators.

On the cobas c111 instrument, reagents are handled as sets of up to three reagents.

(You always load and unload all reagents of a set.) As a consequence, all reagents

(bottles) of a set are calibrated when performing calibration.

The system checks when calibration is due.

Each reagent set must have accepted calibration results to be available for use in tests.

When a calibration is due depends mainly on two definitions, the calibration type and

the calibration sequence.

Roche Diagnostics

A-26 Operator’s Manual · Version 3.0

Page 37

cobas c111 2 Introduction to the instrument

Daily operation

Calibration type

The calibration types Set and Lot define the manner in which the system determines

whether there is a valid calibration result for a particular reagent set.

Set calibration Set calibration results are valid for the calibrated set only. They can be generated from

any reagent set.

Lot calibration Lot calibration results are valid for the reagent set they were calibrated with and for all

subsequent reagent sets of the same lot. Usually, lot calibrations are generated by

calibrating the first reagent set of a new lot. There can only be one accepted lot

calibration result for the reagents of a given lot.

Let us suppose that you place the first reagent set of a new lot and calibrate it straight

away. Let us further assume that subsequent control measurements suggest that a new

calibration is required. Within the first 24 hours of placing a set on the system, you

can recalibrate it, and possibly existing lot calibration results of this set are

superseded. When this period has elapsed you can no longer change the lot

calibration results. (To generate new lot calibration results, you would have to delete

the existing results and then calibrate a new reagent set.)

Lot calibration is relevant if you work with the calibration sequence [Each Lot and Interval].

The following table illustrates the two calibration types in an example.

Assumptions:

o Sequence: Each Lot and Interval.

o Interval: 5 days.

(Note that the interval (re)starts when a set is calibrated as a result of the interval

expiring or a new lot being started.)

Day Trigger/Event Task Result used Set Cal. type Cal. Usage

1 NA 1. Place first reagent set of new lot.

2. Calibrate set L1/1.

2 Reagent empty. 1. Remove set L1/1.

2. Place new set L1/2.

Reagent empty. Replace set whenever it is empty. Result 1 Set Current

5 Interval expired. Calibrate current set L1/n. Result 2 L1/n

6 Reagent empty. Place new set L1/n+1. Result 1 L1/n+1

8 Reagent empty.

New lot.

Reagent empty. Place new set L2/2. Result 3 L2/2

10 Interval expired. Calibrate current set L2/n. Result 4 L2/n

11 Reagent empty. Place new set L2/n+1. Result 3 L2/n+1

Ta b le A -2 Example for set change and calibration types

1. Remove set L1/n+1.

2. Place new set, which is the first set of a new lot.

3. Calibrate set L2/1.

Result 1 L1/1 Lot Current

Result 1 L1/2

L1/1

L1/n-1

L1/n

Result 3 L2/1

L1/1

L1/n+1

L2/1

L2/n-1

L2/n

Set

Lot

Set

Set

Set

Set

Lot

Lot

Set

Set

Lot

Set

Set

Set

Set

Current

-

Current

Obsolete

Current

Obsolete

Current

Obsolete

Obsolete

Current

-

Current

Obsolete

Current

Obsolete

Roche Diagnostics

Operator’s Manual · Version 3.0 A-27

Page 38

2 Introduction to the instrument cobas c111

Daily operation

Calibration sequence

The calibration sequence is an application definition. It defines the manner in which

the system determines when a calibration is due.

Roche recommend not to change the calibration sequence.

The calibration interval defines the on-board stability of a reagent.

One of the following sequences applies to each reagent set:

No Interval You perform calibration whenever you think fit. Use this value if you are sure that the

reagent is stable until it is empty and you replace it with a new one. Calibration is due

whenever a new reagent set is loaded on the instrument.

Interval Only You perform calibration only when the interval has expired.

Each Lot and Interval You perform calibration whenever the fist reagent of a new lot is loaded and then each

time the interval has expired.

In this case, the interval is related to the date when the lot calibration was generated,

and it (re)starts whenever you calibrate a reagent set (as a result of interval expiry or

starting a new lot).

Each Set and Interval You perform calibration whenever a new reagent is loaded and when the interval has

Calibration status of a set

You can turn off the interval check by defining its duration as 0 (zero).

expired.

The interval starts again whenever you calibrate a reagent set because the interval had

expired or a new lot was started.

You can turn off the interval check by defining its duration as 0 (zero).

Each reagent set has one of the following calibration statuses:

CU (current) denotes that the set is on board and that its calibration results are currently

used.

OB (obsolete) denotes that the set’s calibration results are no longer used.

This status applies for example to the following situations:

o The set was removed and it is empty.

o The set was removed and it is not empty. It was removed more than 30 days ago.

SB (standby) indicates that the set’s calibration results are not currently used.

This status applies for example to the following situations:

o A new set was loaded and calibrated while an identical set was still in use (pre-

calibration).

o The set was removed not more than 30 days ago and it is not empty.

Calibration result storage

The current and up to five obsolete calibration results are stored on the system. If

there are more than five obsolete calibration results, the oldest obsolete calibration

results are automatically deleted as part of the daily end of shift activities.

Roche Diagnostics

A-28 Operator’s Manual · Version 3.0

Page 39

cobas c111 2 Introduction to the instrument

<xyz>

Daily operation

Validating calibration results

Applications define checks for ranges and limits. If these are exceeded, the results are

flagged.

Each new calibration result has to be validated. If flags were generated, you must

determine their cause and decide whether to accept the result, rerun the calibration or

continue using the old calibration results.

You can automatically accept unflagged results and results with flags that are

contained in a specific list of flags that should be ignored.

e

See Editing the acceptable flags list on page B-162.

Calibration procedures

There are three basic procedures for performing calibration:

o Calibrating all reagent sets that need calibrating

o Calibrating all reagent sets that will need calibrating during the forecast period

o Calibrating individual reagent sets

Forecast per iod The forecast period is a configurable period of time. Calibrations that fall due within

this period will be performed collectively.

e

See Calibration on page B-167.

Typically you would set this period to fit your shift length, for example 8 hours. This

would enable you to prepare the instrument before the work shift starts and so avoid

having to interrupt sample processing for performing calibrations.

Precalibration At any given time, there is only one accepted calibration result for each test. You can,

however, install and precalibrate one reserve reagent set. This is done, for example, to

ensure continuous sample processing.

Roche Diagnostics

Operator’s Manual · Version 3.0 A-29

Page 40

2 Introduction to the instrument cobas c111

Daily operation

Quality control (QC)

QC is performed at regular intervals to check the integrity of the whole measuring

system. For each test, up to three controls are defined. The results are compared

against predefined ranges or values and then interpreted accordingly.

Control A control is a sample that has been measured using all tests it is associated with, in

order to define the ranges and values that determine the correct functioning of the

instrument. This is typically done both for the normal and the pathological analyte

concentration.

When QC is due With regards to when it needs to be performed, QC is divided in the following types:

o QC After Cal

The QC measurement is due after calibration of the test.

o Interval QC

QC is due whenever its interval has expired. QC measurements of this type are

performed in a batch, typically once or twice a day.

o Default QC

QC is performed at certain times during routine operation. This is done to fit in

with laboratory processes and procedures.

Ways of performing QC With regards to how QC is performed, the following methods are provided:

o Default QC

Default QC is an automated process for performing multiple QC measurements

at the time when you define the QC orders. This is the ideal method if you want to

perform QC at certain times and days.

This method only applies to tests whose controls are defined to be performed as

part of Default QC. Therefore, if you intend to work with the Default QC

function, you need to configure the tests accordingly.

Default QC follows a streamlined procedure where the necessary QC orders are

automatically defined as soon as you identify a control. An order is defined for

each test for which this control is defined, provided the test is currently active on

the system. A wizard helps you select the controls, and a placement list supports

you in preparing and loading the controls.

o Interval QC

This method applies to tests whose controls have an interval defined.

Interval QC is a process that is suitable both for performing a single QC

measurement and for performing all QC measurements that are due. You can

select all tests that require QC simply by pressing a button. (This selection also

reflects QC of the type QC After Cal.) A wizard helps you select the controls, and

a placement list supports you in preparing and loading them.

Roche Diagnostics

A-30 Operator’s Manual · Version 3.0

Page 41

cobas c111 2 Introduction to the instrument

A

WARNING

Daily operation

Validating QC results Each new QC result has to be validated. If flags were generated, you must determine

their cause and decide whether to accept or ignore the result.

You can automatically accept unflagged results and results with flags that are

contained in a specific list of flags that should be ignored.

e

See Editing the acceptable flags list on page B-162.

If you ignore a QC result you exclude the result from further QC result calculations

such as QC History statistics.

Sample handling

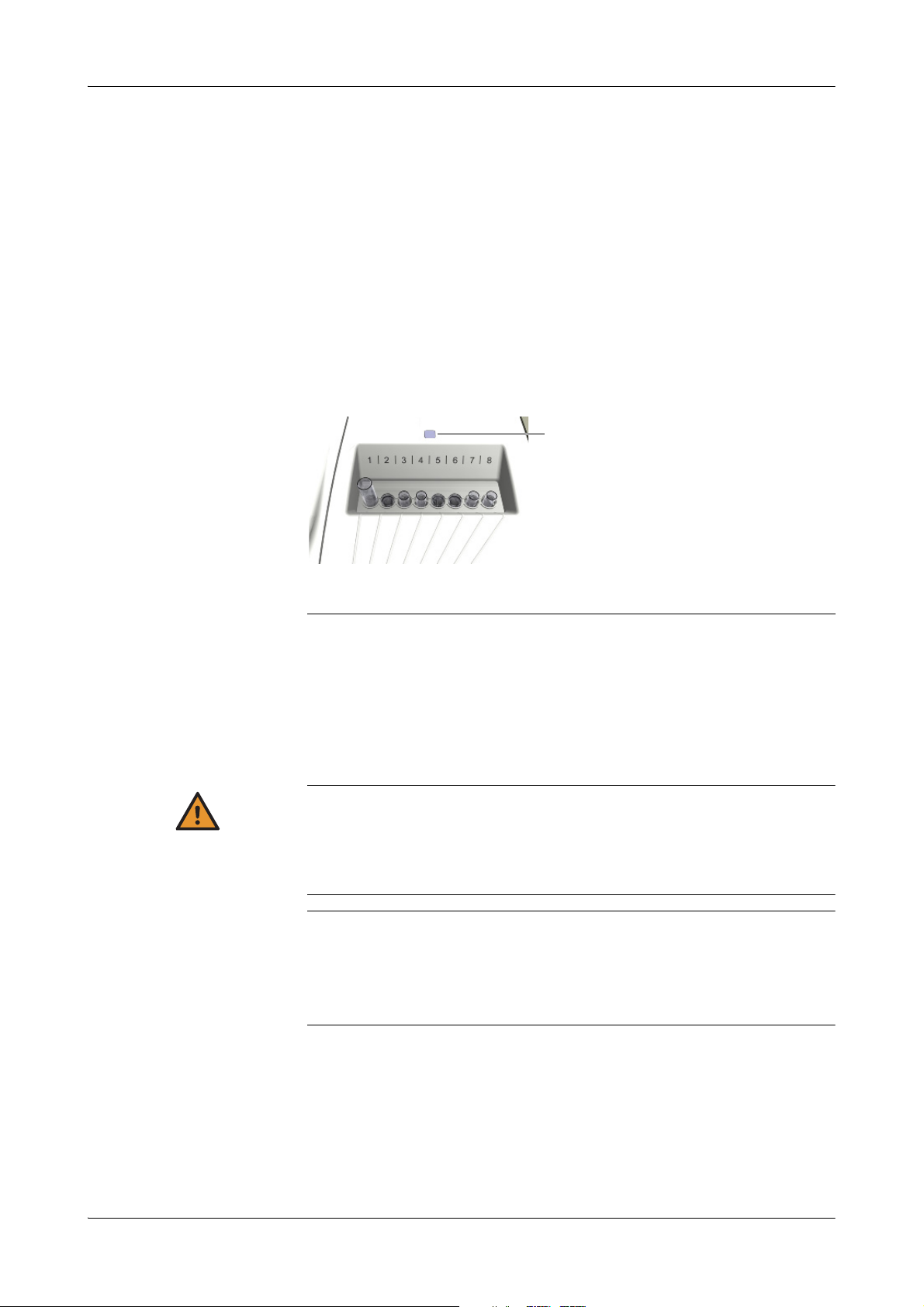

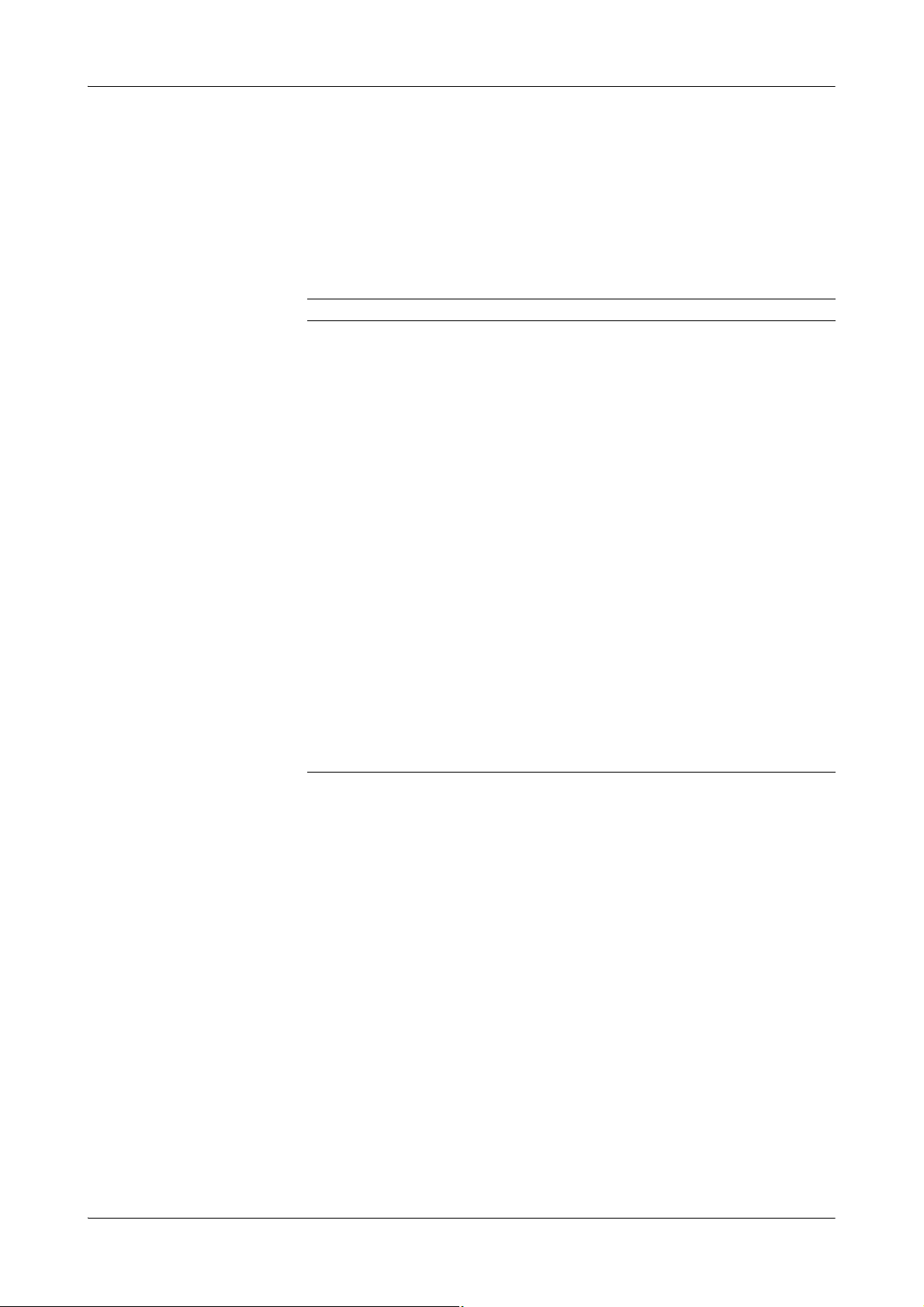

You can place up to eight sample tubes on the sample area.

A Sample area LED. A green LED indicates that you should place a tube, a blinking yellow LED

that you should keep clear of the sample area.

Figure A-6 Sample area with sample tubes

Sample types The cobas c111 instrument can process the following sample fluids:

o Serum

o Plasma

o Urine

o Whole blood for HbA1c

Incorrect results due to inadequate sample preparation

Specimen containing clots may obstruct the probe. Specimen containing bubbles or foam

may cause level detection errors and air pipetting. Consequently, incorrect results may be

generated.

Take adequate care when preparing the samples.

Incorrect results due to insufficient fluid

Insufficient fluid may lead to inaccurate pipetting and consequently to incorrect results.

Always fill the tubes with enough fluid that at least the defined dead volume of fluid is left

when pipetting is complete.

e

See Tubes on page A-54.

Roche Diagnostics

Operator’s Manual · Version 3.0 A-31

Page 42

2 Introduction to the instrument cobas c111

NOTICE

Daily operation

Sample tubes The cobas c111 instrument can use both primary and secondary tubes (cups).

You can use any type of primary tube, as long as their dimensions lay within

prescribed limits. Roche recommend using approved cups only.

e

See Tubes on page A-54.

Probe damage due to not removing primary tube caps

The probe is not designed to pierce tube caps. It can get damaged when trying to pierce

tube caps.

Always remove the caps of primary tubes before placing them on the instrument.

Sample ID The sample ID is an identifier of up to 23 alphanumeric characters that is unique

within a whole organization, for example the hospital. It identifies the sample and is

also used for host communication.

Sample IDs are defined either by scanning a barcode or by typing them manually.

Because there is limited space when displaying lists on screens, Roche recommend to

limit the ID to 13 characters.

Sample barcode You can use sample tubes with or without barcode.

Removing sample tubes You can remove sample tubes as soon as pipetting is complete.

Order handling

Order Mode The order mode reflects the way in which you organize the tests on the test selection

Dilution Pre-dilution is used when performing calibration.

Post-dilution is used when measuring samples.

(The dilution factor is part of the application definition and therefore does not need

to be defined by the operator.)

screen.

Choose Easy if the reagents fit on one or two reagent disks and you work with one test

panel on the screen (You can fit up to 25 tests and profiles on this panel).

Choose Full if you distribute the reagents across several (up to eight) reagent disks

and if you predominantly work with specific groups of tests, for example for

emergency situations or for testing diabetes. You can assign up to 20 tests and profiles

to each panel (tab).

Order ID The order ID is an identifier of up to 23 alphanumeric characters that is unique

within the laboratory. The order ID identifies the order and links it to the sample.

Order and sample IDs are often identical. Using separate IDs makes sense when

working with a host system.

Order IDs are defined either by scanning a barcode or by typing them manually.

Because there is limited space when displaying lists on screens, Roche recommend to

limit the ID to 13 characters.

Patient demographics The cobas c111 software does not support the handling of patient demographic data.

Roche Diagnostics

A-32 Operator’s Manual · Version 3.0

Page 43

cobas c111 2 Introduction to the instrument

Daily operation

Host connectivity The cobas c111 instrument can be connected to an external laboratory information

system (LIS), a host computer for downloading order information and uploading

results, or a cobas c 111 Printer Tool.

If the instrument is connected to a host system, the following setups can be

configured:

o Downloading order information

When you identify a sample using the barcode scanner, the appropriate order

information is automatically assigned to the order on the system. (The order

information was downloaded previously.)

o Performing host queries

When you identify a sample using the barcode scanner, a query is sent to the host,

asking for the order information of the sample in question. This information is

then downloaded to the cobas c111 instrument and automatically assigned to the

sample on the system.

o Transmitting results

You can have results automatically transmitted to the host as soon as they are

accepted.

e

For the setup when connecting to a cobas c111 Printer Tool, see the cobas c111 Printer

Tool Operator’s Manual.

Routine orders Routine orders are normally defined on the Overview tab. The software guides you

through the process of assigning the tests to the sample and placing the sample tube

on the instrument.

STAT orders STAT (short turn around time) orders are handled in the same way as routine orders,

except that their tests are processed next, irrespective of the scheduling of routine

order tests.

Defining orders There must be at least one free sample tube position when defining an order. You are

guided by the software when ordering the tests and placing the samples.

There can be only one order for each test and sample.

Modifying orders The process for changing an order is similar to that of defining it. You first identify the

sample and then change the tests. You can change an order as long as its processing

has not yet started.

It is always possible to add a further test to an existing order.

Deleting orders At the end of a shift, you should delete all orders that are defined on the system. This

is to free storage space for the next shift. Deleting the orders is an integral part of the

End Shift wizard. (Deleting an order also deletes the corresponding sample results.)

You can export the data to a USB stick and store them on a computer.

Controlling the run Controlling the execution of test runs is done via the global action buttons.

Press to start the run.

Press to stop the run.

Roche Diagnostics

Operator’s Manual · Version 3.0 A-33

Page 44

2 Introduction to the instrument cobas c111

Maintenance

Results

You can check the results on the screen as soon as they are calculated.

Units Results are normally given in your lab units. The units can be configured.

Flags Result flags are test-specific. They indicate that the limit of an internal check was

exceeded or not reached.

System flags point to the status of the result within the process of analysis; for

example, they tell you that the result has not been accepted or that is has not been

transmitted to the host successfully.

Printing results You can print all or selected results on the built-in printer.

Val idating results All results need to be validated (result accepted, test rerun or repeated).

Result flags help you identify critical results and point to possible actions that need to

be taken.

Each test must have accepted calibration results; tests whose associated calibration

results are not accepted cannot be performed.

Ratio results The user can manually define ratios. Ratio results are handled like any other sample

result, with the exception that they cannot be accepted by the user. They are

automatically accepted if all their constituent results are accepted.

Repeating and rerunning tests If a result is flagged, you may decide to run a test again. You can either perform

exactly the same test (Repeat) or perform it with a different predefined dilution

(Rerun).

Storing results The cobas c111 instrument is designed to hold the sample results of one day’s

analyzing. Therefore, you need to back up the data regularly to an external medium.

(Backing up results is an integral part of the End Shift wizard.)

The QC results of the previous and the current months are stored on the system.

Up to five calibration results are stored on the system for each test.

Maintenance

Completing maintenance actions correctly and on time helps to ensure smooth and

uninterrupted operation of your instrument.

Maintenance scheduling The cobas c111 instrument facilitates performing the maintenance actions in bundles

at the times that suit your laboratory work processes. To that purpose, you can define

in the configuration settings one day of the week as your maintenance day.

e

For information on scheduling maintenance actions, see Scheduling maintenance actions

on page B-158.

All maintenance actions can be performed any time.

Roche Diagnostics

A-34 Operator’s Manual · Version 3.0

Page 45

cobas c111 2 Introduction to the instrument

System status

Interval For most maintenance actions a fixed maintenance interval is defined. (You cannot

change this interval.) This is the basis upon which the system calculates the date when

the actions need to be performed.

The interval timers and counters are reset whenever you confirm that the

maintenance action has been performed.

Maintenance actions without predefined intervals are performed whenever necessary,

or they are triggered by another maintenance action.

Due date The due date is the last possible maintenance day. This is the date you see when you

check the status of maintenance actions.

Ensuring smooth operation Performing all due maintenance actions during the daily Prepare or End Shift phase

ensures that routine operation does not have to be interrupted for performing

maintenance actions.

System status

The cobas c111 instrument provides several means of indicating the status of the

various parts and processes:

o Color coded LEDs on the instrument inform you when and when not to open

covers or place sample tubes.

e

See Color interpretation for LEDs on page A-122.

o The colors of buttons inform you whether you need to intervene.

e

See Color concept on page A-74.

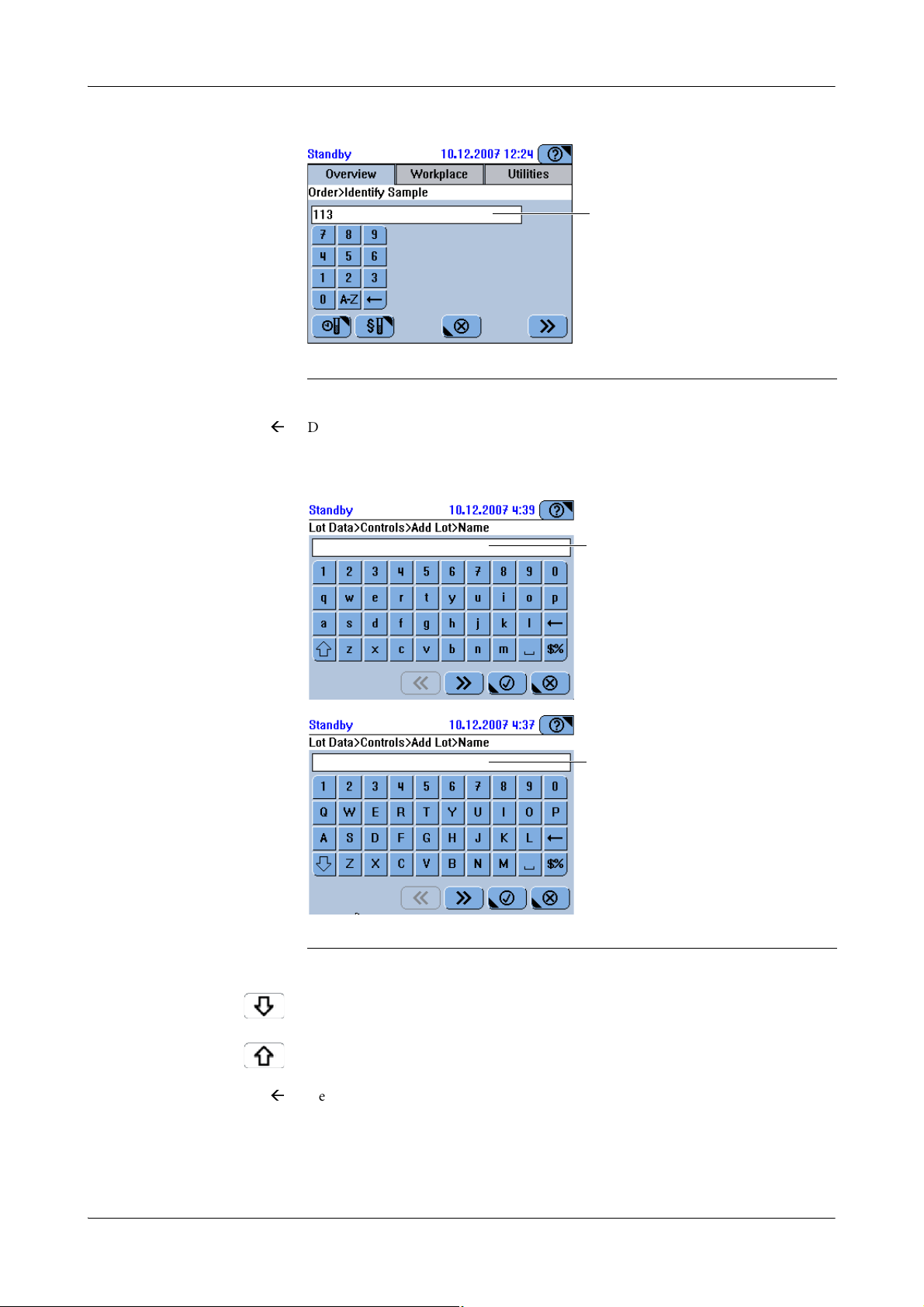

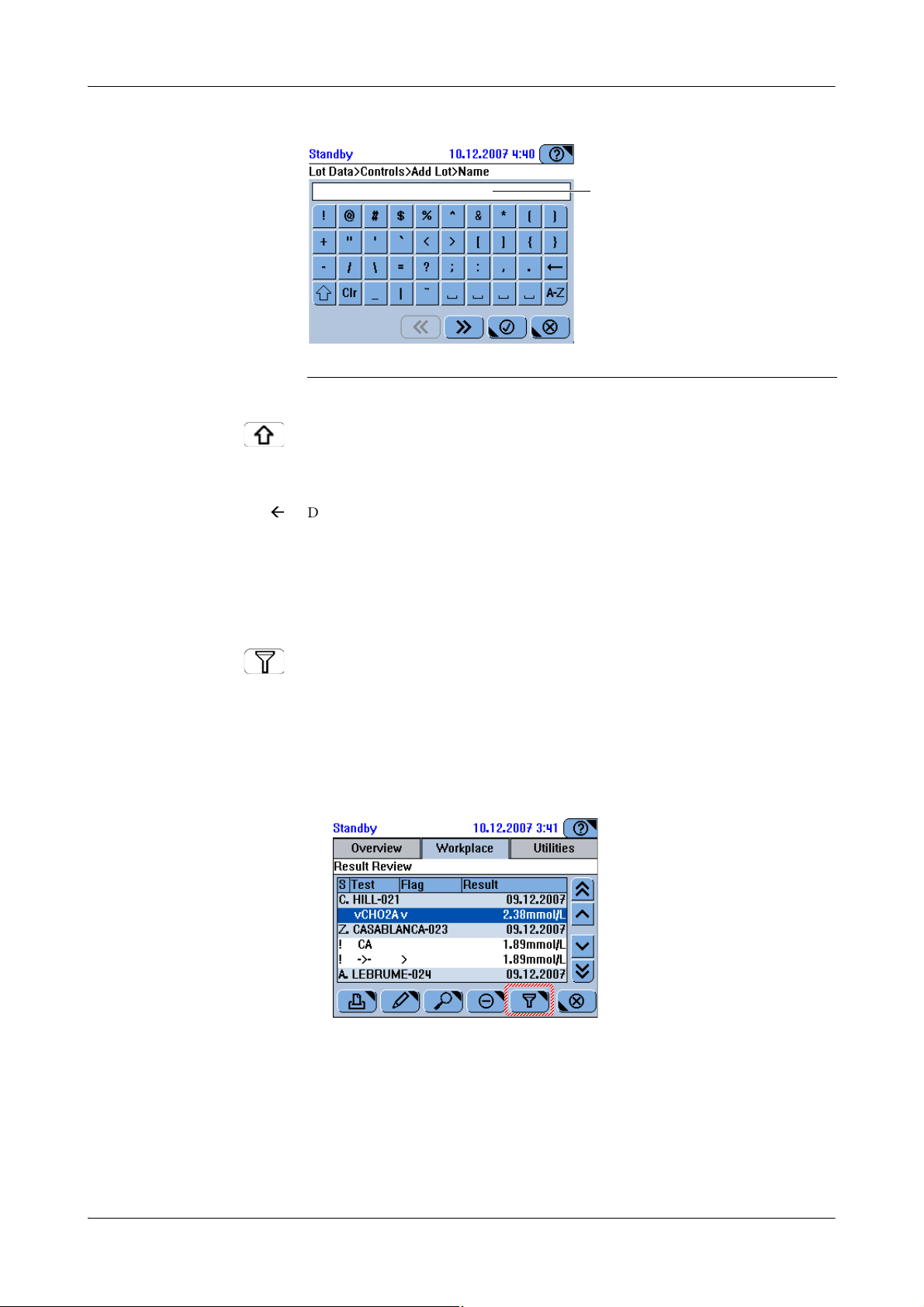

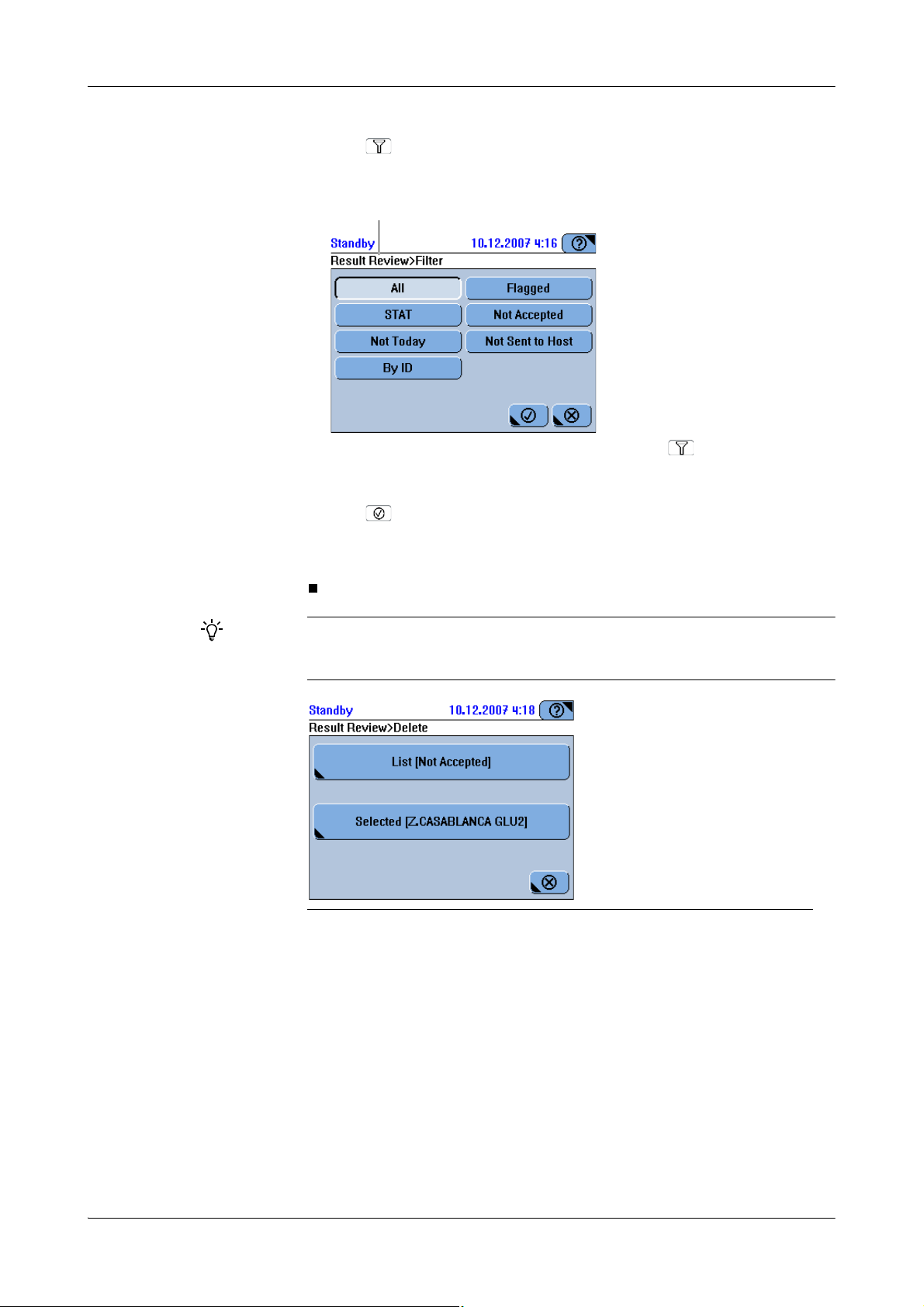

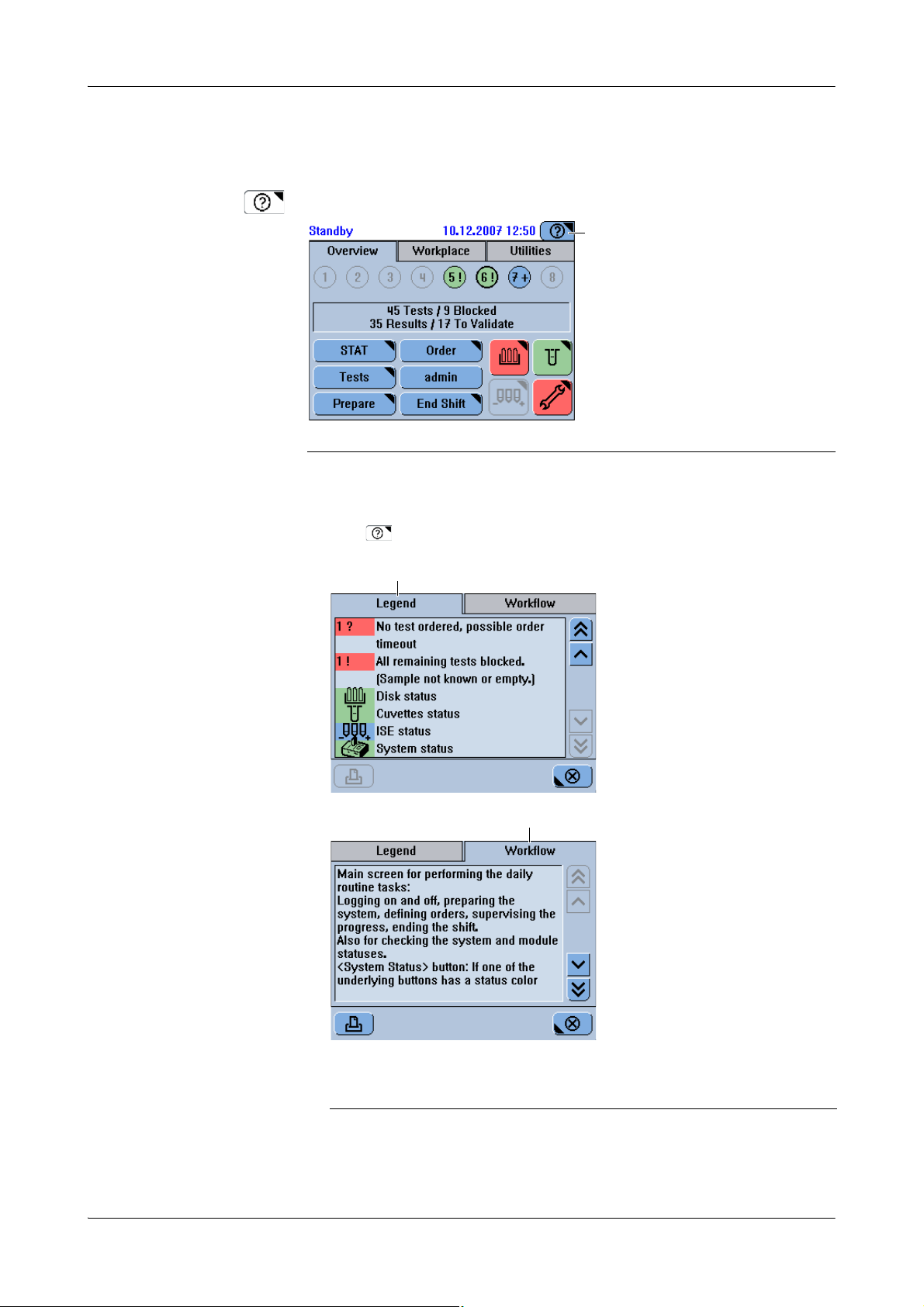

You can check the meaning of a button using the online Help .