Page 1

®

cobas

Operator’s Manual

Software Version 2.1 for cobas® 4800

CT/NG Test

4800 System

Page 2

cobas® 4800 System

CUS

®

CT/NG Test

Document information

Manual version Revision dates Main changes

1.1 May 2014 Change to error messages and reagent loading positions.

Table 1 Revision history

Edition notice Every effort has been made to ensure that the information contained in this manual is

accurate at the time of printing. Not all functionality described in this manual may be

available to all users. Roche reserves the right to make any further required changes

to software without prior notice. Such changes may not immediately be reflected in

this document.

The screenshots in this publication have been added exclusively for the purpose of

illustration. Configurable and variable data such as parameters, results, path names

etc. visible therein must not be used for laboratory purposes.

Intended use

This manual is for users of the cobas® 4800 CT/NG Test on the cobas

Before using the test, it is important that the operator reads the cobas

System Manual and this manual thoroughly.

U

For additional information, refer to the test-specific package insert.

Copyright © 2014 Roche Diagnostics International Ltd. All rights reserved.

Trademarks The following trademarks are acknowledged:

COBAS, COBAS X, COBAS Z, and LIFE NEEDS ANSWERS are trademarks of

Roche.

All other trademarks are the property of their respective owners.

Feedback Every effort has been made to ensure that this manual fulfils the intended purpose as

mentioned above. All feedback on any aspect of this manual is welcome and will be

considered during updates. Please contact your Roche representative, should you

have any such feedback.

Instrument approvals This manual meets the European Standard EN ISO 18113-3.

Compliance is demonstrated by the following marks:

Complies with the IVD directive 98/79/EC.

®

4800 System.

®

4800 System

Roche Diagnostics

2 cobas® 4800 System, Operator’s Manual · Version 1.1

Issued by Underwriters Laboratories, Inc. (UL) for Canada and the US.

Abbreviations The following abbreviations are used:

Abbreviation Definition

PC

Table 2 Abbreviations

PreservCyt

®

Page 3

cobas® 4800 System

CT/NG Test

Contact addresses

What is new in version 2.1

Workflow Recovery workflow run can be generated from a previously performed run within 24

hours. The PCR Only workflow has been renamed and improved to recovery

workflow.

Roche Molecular Systems, Inc.

1080 US Highway 202 South

Branchburg, NJ 08876

USA

Made in Switzerland

Roche Diagnostics GmbH

Sandhofer Strasse 116

68305 Mannheim

Germany

U

For details, see About workflows (p. 10)

Result view notifications Icons help you identify if a result failed, is invalid, or has a flag. The result view also

highlights cells with positive results.

For details, see Results (p. 55)

U

Work orders The work order editor is now integrated into the software (sample editor). Barcodes

are automatically scanned during loading and used to generate a work order.

For details, see Sample editor (p. 51)

U

LIS You can see the LIS availability status and the transfer status. There is a status

displayed of results sent to the LIS.

For details, refer to the cobas® 4800 System System Manual.

U

Reports Reports have been improved. For example, better formatting, positive results are

highlighted.

Reagent use optimization Allows multiples (up to 3) of 24 reagent kits for master mix reagent and Mn reagent

to be loaded into the system.

U

For details, see To load the reagent carrier (p. 33)

Unloading samples You have the option to automatically unload the samples after they are pipetted and

before the run is over.

U

For details, see To load samples (p. 23)

Tracking of used tip racks. To reduce tip waste, partially used tip racks can be used in next run on the same

system. You can reuse partially used tip racks as long as enough tips are loaded. The

software estimates how many tips are required for a run.

U

For details, see Loading the consumables (p. 27)

Roche Diagnostics

cobas® 4800 System, Operator’s Manual · Version 1.1 3

Page 4

cobas® 4800 System

CT/NG Test

Usability Improved test selection dialog and filtering options.

For details, see To start a new run (p. 22)

U

U For details, see Filtering and sorting runs and results (p. 58)

Test types CT/NG cytology and CT/NG non-cytology workflows can both be run by selecting

the CT/NG test.

Roche Diagnostics

4 cobas® 4800 System, Operator’s Manual · Version 1.1

Page 5

cobas® 4800 System

Table of contents

CT/NG Test

Overview..................................................................................................................................7

General safety information.............................................................................................7

Overview of the test .........................................................................................................7

About specimen types .....................................................................................................7

About workflow types .....................................................................................................8

About the test concept.....................................................................................................8

About subtests............................................................................................................8

About reagents .................................................................................................................9

Workflow ..............................................................................................................................10

About workflows............................................................................................................10

Overview of full workflow ............................................................................................11

Full workflow short guide.......................................................................................12

Overview of recovery workflow...................................................................................14

Recovery workflow short guide .............................................................................15

Operation ..............................................................................................................................18

Safety information .........................................................................................................18

Performing a full workflow run...................................................................................18

Performing startup procedures..............................................................................18

Performing maintenance........................................................................................21

Removing the samples and reagents from storage..............................................21

Starting a new run....................................................................................................22

Loading samples.......................................................................................................23

Confirming or creating a work order file.............................................................25

Loading the consumables .......................................................................................27

Loading the reagents ...............................................................................................28

Starting the sample preparation run .....................................................................34

Unloading the microwell plate...............................................................................36

Sealing the microwell plate.....................................................................................37

Removing used reagents, samples, and deepwell plate.......................................38

Starting amplification and detection run .............................................................38

Reviewing and accepting results............................................................................39

Sending results to LIS..............................................................................................40

Unloading the analyzer...........................................................................................41

Performing shutdown procedure ..........................................................................41

Performing a recovery workflow run..........................................................................42

Starting a recovery workflow run ..........................................................................43

Selecting the run to recover and adding new IDs ...............................................43

Printing the microwell plate layout.......................................................................44

Removing the deepwell plate .................................................................................45

Setting up microwell plate......................................................................................45

Performing manual PCR setup..............................................................................45

Sealing the microwell plate.....................................................................................46

Centrifuging the microwell plate...........................................................................47

Roche Diagnostics

cobas® 4800 System, Operator’s Manual · Version 1.1 5

Page 6

cobas® 4800 System

CT/NG Test

Starting amplification and detection run .............................................................47

Reviewing and accepting results............................................................................48

Sending results to LIS..............................................................................................49

Unloading the analyzer...........................................................................................50

Performing shutdown procedure ..........................................................................50

Sample editor..................................................................................................................51

About messages in the sample editor....................................................................51

Using the sample editor to create a work order file............................................52

Editing an existing work order file........................................................................54

Loading a work order file .......................................................................................55

Results..............................................................................................................................55

Reviewing results .....................................................................................................56

Grouping results ......................................................................................................57

Searching results ......................................................................................................57

Filtering and sorting runs and results...................................................................58

Accepting results......................................................................................................58

Printing results.........................................................................................................58

Creating result filters...............................................................................................60

Aborting a run................................................................................................................62

Configuration .......................................................................................................................63

Changing your password ..............................................................................................63

Troubleshooting...................................................................................................................64

List of error messages ....................................................................................................64

List of result flags ...........................................................................................................67

Revisions................................................................................................................................70

Roche Diagnostics

6 cobas® 4800 System, Operator’s Manual · Version 1.1

Page 7

cobas® 4800 System Overview

CT/NG Test General safety information

Overview

General safety information

Test-specific safety information is contained in this manual. For general safety

®

4800

Overview of the test

information (e.g. safety classifications, safety precautions), read the cobas

System System Manual.

The cobas® 4800 CT/NG Test is an in vitro nucleic acid amplification test for the

qualitative detection of Chlamydia trachomatis (CT) and/or Neisseria gonorrhoeae

(NG) in patient specimens.

The following sample carrier can be used for CT/NG testing:

o PreservCyt® carrier with PreservCyt

®

primary containers

o 24-position sample carrier with primary cobas® PCR Media tubes or secondary

tubes

U

For more information about the test (e.g. minimum sample volumes), refer to the testspecific package insert.

About specimen types

WARNING

The following specimen types are supported:

Test type Specimen type Abbreviation Carrier used

CT/NG Swab - 24-position sample carrier

Urine - 24-position sample carrier

PreservCyt® PC

o PreservCyt® carrier

(primary tubes)

o 24-position sample

carrier (secondary

tubes)

Table 3 Specimen types

Incorrect results due to use of non-approved specimen types

Supported specimen types may vary by region. Refer to the test-specific package insert for

your region for supported specimen types.

r Use only specimen types that are approved by Roche.

U For details about the types of secondary tubes you can use, refer to the test-specific

package insert.

Roche Diagnostics

cobas® 4800 System, Operator’s Manual · Version 1.1 7

Page 8

Overview cobas® 4800 System

About workflow types CT/NG Test

About workflow types

Two workflow types are supported. The workflow type has to be selected at the start

of a new run.

Full workflow The full workflow covers sample preparation on the cobas x 480 instrument and

amplification and detection on the cobas z 480 analyzer.

Recovery workflow The recovery workflow allows you to recover aborted runs which were pipetted

correctly into the deepwell plate or microwell plate. For example, you drop the

microwell plate while transferring it to the analyzer.

You manually pipette residual eluate from the deepwell plate into the new microwell

plate and add new master mix reagent and Mn reagent.

To recover a run, the following criteria must be fulfilled:

o Instrument and analyzer are turned on and maintenance has been performed.

o A full workflow run has been performed and the samples successfully prepared.

o A full workflow run has been performed in the last 24 hours.

o A full workflow run has been aborted by a user (M2 flag) or the analyzer (Z1 flag).

About the test concept

The recovery workflow run is only validated to work with extract from an

instrument.

U

For stability of eluates, refer to the test-specific package insert.

Figure 1 Workflow and test type selection at the start of a new run

Tests are run in batches.

For more details about batch sizes, throughput, or mixed batch runs, refer to the test-

U

specific package insert.

About subtests

The analyzer can simultaneously detect signal from one or more detection channels,

which makes it possible to obtain more information from a single reaction. This

provides multiple subtests for each test type.

Subtests can be ordered for each sample individually using the sample editor.

U

For information about the sample editor, see Sample editor (p. 51)

Roche Diagnostics

8 cobas® 4800 System, Operator’s Manual · Version 1.1

Page 9

cobas® 4800 System Overview

CT/NG Test About reagents

The following subtests are available:

Main test type Subtests Results

CT/NG CT and NG in combination CT/NG

CT only CT

NG only NG

Table 4 Subtests

About reagents

Reagent kit sizes Individual reagent kits are available for the following run sizes:

o 10 runs with 24 samples (up to 22 patient specimens plus 2 controls)

o 10 runs with 96 samples (up to 94 patient specimens plus 2 controls)

NOTICE

Kit size

o Make sure that the kit size corresponds to the intended run size. Although not an

optimal use of reagents, a 96 kit size can be used for a 24 run.

o For the most efficient reagent utilization, it is advisable to maximize the number of

patient specimens processed within a run. Remaining reagents cannot be used later

for another run.

Reagent handling Some reagents are poured into reagent reservoirs and then placed onto their

dedicated positions on the reagent reservoir carriers.

Other reagents are ready to use. They are decapped and then placed onto their

dedicated positions on the reagent carrier.

Reagent expiry time zone offset

The reagent expiry date is based on the Coordinated Universal Time (UTC). The local time

CAUTION

for reagent expiry could be offset by plus or minus 12 hours, depending on the local time

zone relative to UTC.

r Check the reagent expiry date and consider that it is based on UTC.

U For instructions on handling and storage of reagents, refer to the test-specific package

insert.

Controls Two external controls (positive control and negative control) are provided in a

control kit. Controls are always processed on position A1 and B1 respectively of the

deepwell and microwell plates.

All controls are homogeneous and do not require vortexing or shaking prior to

loading on the instrument.

U

For instructions on handling and storage of controls, refer to the test-specific package

insert.

Controls are loaded on the reagent carrier not the sample carrier.

Q

Roche Diagnostics

cobas® 4800 System, Operator’s Manual · Version 1.1 9

Page 10

Workflow cobas® 4800 System

About workflows CT/NG Test

Workflow

In this chapter the different workflows are described.

About workflows

The following workflow types are available.

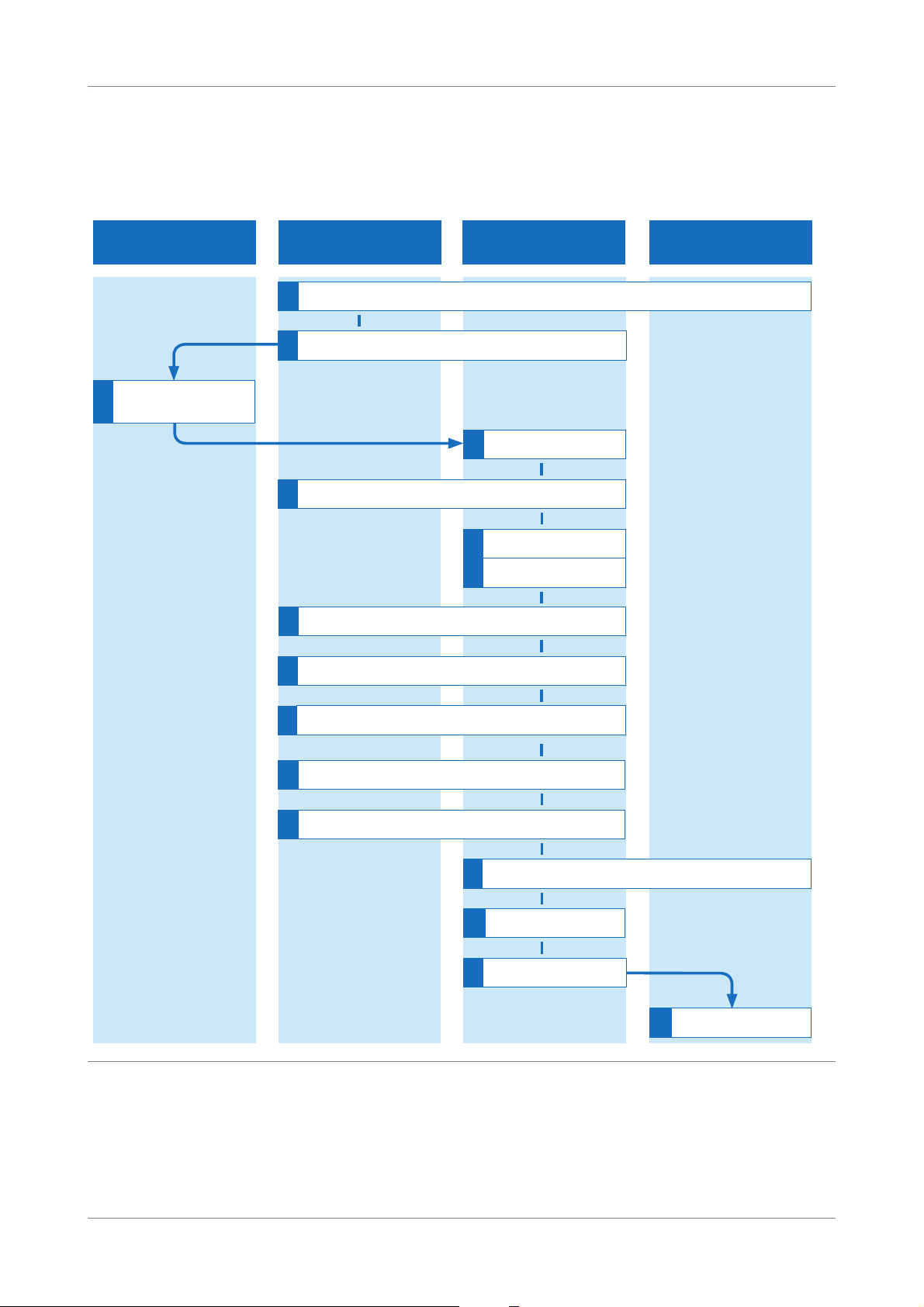

Workflow Description Ordering

Full workflow

(with or without LIS)

Recovery workflow

(with or without LIS)

Table 5 Workflow types

Sample preparation and

amplification and detection

Manual PCR setup and

amplification and detection

LIS or work order file

-

Roche Diagnostics

10 cobas® 4800 System, Operator’s Manual · Version 1.1

Page 11

cobas® 4800 System Workflow

$PSOLÀFDWLRQ'HWHFWLRQFREDV]

DQDO\]HU

6DPSOHSUHSDUDWLRQFREDV

[LQVWUXPHQW

6DPSOHDQGUHDJHQWKDQGOLQJDUHD FREDVVRIWZDUH

1

6WDUWXSWKHV\VWHP

2

3HUIRUPLQVWUXPHQWPDLQWHQDQFH

3

5HPRYHVDPSOHVDQG

UHDJHQWVIURPVWRUDJH

4

6WDUWQHZUXQ

5

/RDGVDPSOHV

7

/RDGFRQVXPDEOHVGHHSZHOOSODWHPLFURZHOOSODWHWLSUDFNV

8

/RDGUHDJHQWV

9

6WDUWVDPSOHSUHSDUDWLRQUXQ

10

8QORDGDQGVHDOPLFURZHOOSODWH

11

5HPRYHVDPSOHVXVHGUHDJHQWVGHHSZHOOSODWH

12

/RDGPLFURZHOOSODWHLQWRDQDO\]HU

13

5HYLHZUHVXOWV

14

:LWK/,6VHQGUHVXOWVWR/,6

15

8QORDGDQDO\]HU

:LWKRXW/,6FUHDWHZRUNRUGHU

6

:LWK/,6FRQÀUPZRUNRUGHU

CT/NG Test Overview of full workflow

Overview of full workflow

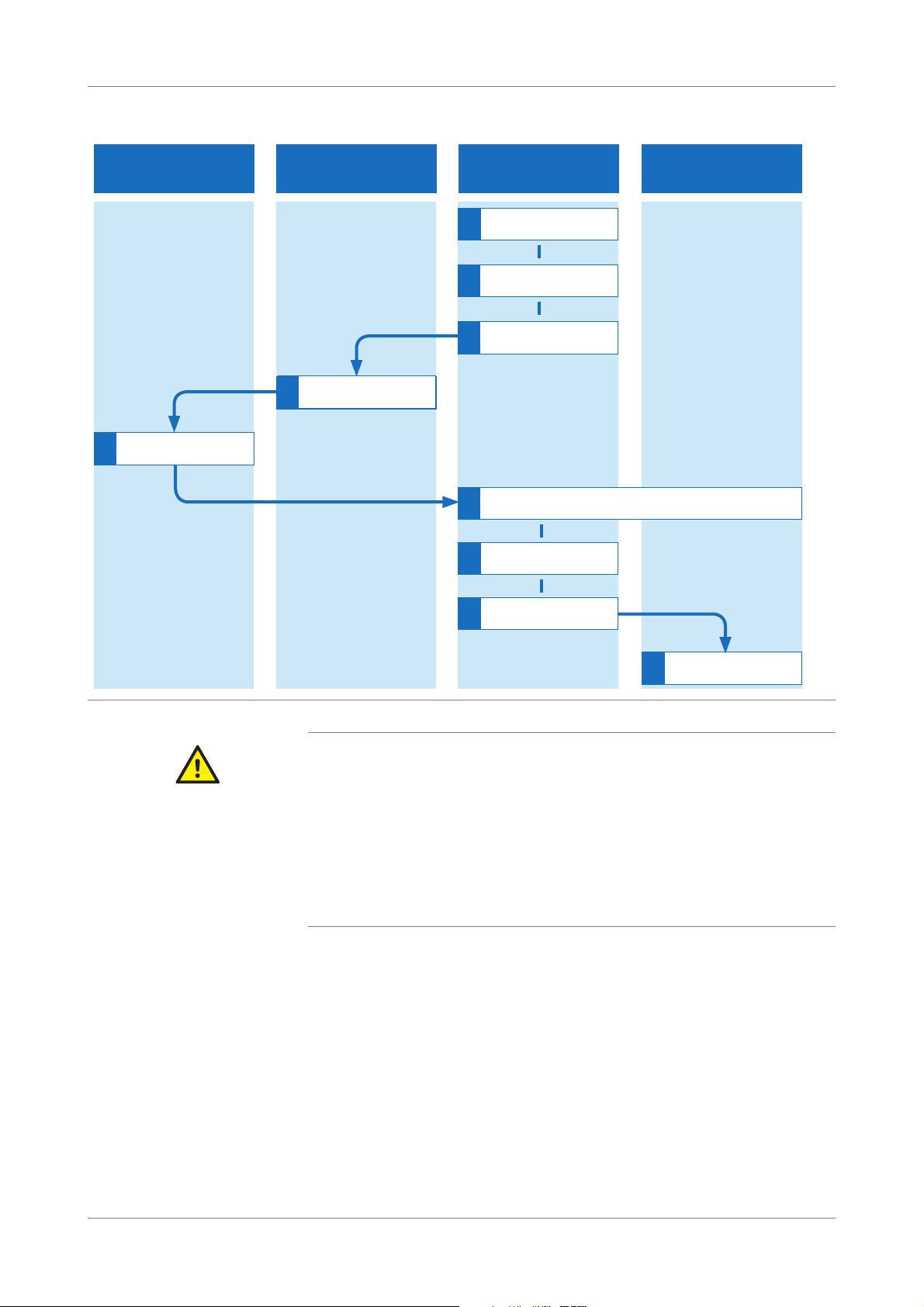

The full workflow with and without LIS is shown below.

Figure 2 Full workflow (with and without LIS)

Roche Diagnostics

cobas® 4800 System, Operator’s Manual · Version 1.1 11

Page 12

Workflow cobas® 4800 System

Overview of full workflow CT/NG Test

Infection by samples and associated materials due to inappropriate laboratory

practices

WARNING

Follow Good Laboratory Practices, especially when working with biohazardous material. If

Good Laboratory Practices are not followed, contact with biohazardous material may

occur, resulting in infection.

r Do not eat, drink, or smoke in laboratory work areas.

r Wear lab gloves and lab coats whenever preparing consumables, reagents, samples, or

when cleaning.

r Wear eye protection when handling samples. Wash hands thoroughly afterwards.

Full workflow short guide

The following short guide is a summary of the workflow without details.

For a complete and detailed description of the workflow, see Performing a full workflow

U

run (p. 18)

Step User action

1

Start up the system. Switch on the analyzer, heater/shaker unit, and

instrument

1. Switch on the analyzer.

2. Switch on heater/shaker unit.

3. Switch on the instrument.

Start up and log on to the software

1. Switch on the monitor and control unit.

2. Log on to the software.

2

Perform instrument

maintenance.

1. Choose Overview > System > cobas x 480 tab

and check maintenance status of the

instrument.

o If weekly maintenance is due, choose the

Perform weekly maintenance button.

o If daily maintenance is due, choose the Perform

daily maintenance button.

Follow the instructions displayed on the monitor.

3

Remove samples and reagents

from storage.

4

Start new run. 1. Choose (New run).

Table 6 Full workflow short guide (with or without LIS)

Roche Diagnostics

12 cobas® 4800 System, Operator’s Manual · Version 1.1

U For instructions on storage and handling of

reagents, samples and controls, refer to testspecific package insert.

2. Select the Full option.

3. Select the CT/NG check box.

4. Optionally, type a run name.

5. Choose the OK button.

Page 13

cobas® 4800 System Workflow

CT/NG Test Overview of full workflow

Step User action

5

Load samples. 1. Decap samples.

2. Place samples on corresponding carrier.

3. Insert sample carriers on autoload tray.

4. Choose the Load specimen button.

6

With LIS, confirm the work order

or

Without LIS, create the work

order.

7

Load consumables. 1. Place listed consumables on appropriate

With LIS:

1. Confirm the work order and choose the Next

button.

or

Without LIS:

1. Define the type of specimen.

2. Define the requested result.

3. Choose the Next button.

carriers.

2. Insert carriers on autoload tray.

3. Choose the Load consumables button.

8

Load reagents. 200 mL reagent reservoir carrier

1. Load wash buffer reagent 200 mL on reagent

reservoir carrier as indicated in the wizard

(scan-scan-pour-place principle).

2. Insert carrier on autoload tray.

3. Choose the Load reagents button.

50 mL reagent reservoir carrier

1. Load reagents on 50 mL reagent reservoir

carrier as indicated in the wizard (scan-scanpour-place principle).

2. Insert carrier on autoload tray.

3. Choose the Load reagents button.

Reagent carrier

1. Open reagent vials and load them on reagent

carrier as indicated in the wizard.

2. Insert carrier on autoload tray.

3. Choose the Load reagents button.

9

Start sample preparation run. 1. Choose the Start run button.

The sample preparation starts.

2. Check the timer in the wizard.

Table 6 Full workflow short guide (with or without LIS)

Roche Diagnostics

cobas® 4800 System, Operator’s Manual · Version 1.1 13

Page 14

Workflow cobas® 4800 System

Overview of recovery workflow CT/NG Test

Step User action

10

Unload and seal microwell plate. 1. To review the results of the sample preparation,

choose the Sample Preparation results button.

2. Choose the Unload button.

3. Seal the microwell plate as indicated on screen.

4. Choose the Next button.

11

Remove used reagents, samples,

and deepwell plate.

12

Load microwell plate on to the

analyzer.

1. Remove used reagents, samples, and deepwell

plate from the instrument.

1. Press the load button on the analyzer.

2. Place the sealed microwell plate into the

microwell plate loader.

3. Press the load button again.

The amplification and detection run starts

automatically.

4. Check the timer in the wizard.

13

Review result and accept results. 1. Choose the Show result button.

2. Review and accept results in Results work area.

3. Select results and choose (Print) to print

the results report, if required.

14

With LIS, send the results to LIS. Consider that depending on the configuration, all

results are transferred to LIS or only accepted

results are transferred to LIS. Control results are

always uploaded to LIS.

1. Select a result or group of results and choose the

Send results to LIS button.

15

Unload the microwell plate from

the analyzer.

Table 6 Full workflow short guide (with or without LIS)

1. Unload the microwell plate from the analyzer as

soon as is practical after the run has finished.

2. Discard the microwell plate according to the

appropriate local regulations.

Overview of recovery workflow

The recovery workflow allows you to recover failed runs where the sample has been

successfully prepared. A run can only be recovered one time.

The recovery workflow is shown below.

Roche Diagnostics

14 cobas® 4800 System, Operator’s Manual · Version 1.1

Page 15

cobas® 4800 System Workflow

Sample preparation cobas

x 480 instrument

Sample and reagent handling

area

cobas 4800 software

$PSOLÀFDWLRQ'HWHFWLRQ

cobas z 480 analyzer

1

Start recovery run

5

Remove deepewell plate

6

Load microwell plate into analyzer

2

6HOHFWUXQDQGDGG,'V

3

Print plate layout report

4

Get deepwell plate

5

Set up microwell plate

7

Review results

9

Unload analyzer

8

With LIS: send results

to LIS

CT/NG Test Overview of recovery workflow

Figure 3 Recovery workflow

Recovery workflow short guide

CAUTION

Infection by samples and associated materials due to inappropriate laboratory

practices

Follow Good Laboratory Practices, especially when working with biohazardous material. If

Good Laboratory Practices are not followed, contact with biohazardous material may

occur, resulting in infection.

r Do not eat, drink, or smoke in laboratory work areas.

r Wear lab gloves and lab coats whenever preparing consumables, reagents, samples, or

when cleaning.

r Wear eye protection when handling samples. Wash hands thoroughly afterwards.

The following short guide is a summary of the workflow without details.

For a complete and detailed description of the workflow, see Performing a recovery

U

workflow run (p. 42)

Roche Diagnostics

cobas® 4800 System, Operator’s Manual · Version 1.1 15

Page 16

Workflow cobas® 4800 System

Overview of recovery workflow CT/NG Test

Step User action

1

Start a recovery workflow run. 1. Choose (New run).

2. Select the Recovery option.

3. Select the CT/NG check box.

4. Optionally, type a run name.

5. Choose the OK button.

2

Select the run to recover and add

new IDs

3

Print the microwell plate layout. 1. To print the work order file for microwell plate

1. Choose the run to recover.

2. In the Microwell plate ID field, scan the

microwell plate barcode.

3. In the Master Mix ID field, scan the master mix

reagent barcode.

4. In the Mn Reagent ID field, scan the Mn

reagent barcode.

setup, choose (Print) from the global

navigation bar.

2. In the software, choose the Next button.

4

Get the deepwell plate.

1. Do one of the following:

o If the deepwell plate has been unloaded by

the instrument, remove it from the plate

carrier, or

o If the deepwell plate has been stored, get it

from storage, or

o If the deepwell plate has not been unloaded

by the instrument, unload the deepwell

plate manually.

U For details how to unload the instrument

manually, refer to the cobas

System Manual.

5

Set up the new microwell plate. 1. Pipette the reagents and prepared specimens

into the microwell plate in accordance with the

microwell plate layout and the description in

the test-specific package insert.

2. Seal the microwell plate.

3. If necessary, log back on to the software.

4. In the software, choose the Next button.

6

Load microwell plate into the

analyzer.

1. Press the load button on the analyzer.

2. Place the sealed microwell plate into the

microwell plate loader.

3. Press the load button again.

The amplification and detection run starts

automatically.

4. Check the timer in the wizard.

®

4800 System

Table 7 Recovery workflow short guide

Roche Diagnostics

16 cobas® 4800 System, Operator’s Manual · Version 1.1

Page 17

cobas® 4800 System Workflow

CT/NG Test

Step User action

7

Review and accept results. 1. Choose the Show result button.

2. Review and accept results in Results work area.

3. Select results and choose (Print) to print

the results report, if required.

8

With LIS, send the results to LIS. Consider that depending on the configuration, all

results are transferred to LIS or only accepted

results are transferred to LIS. Control results are

always uploaded to LIS.

1. Select a result or group of results and choose the

Send results to LIS button.

9

Unload the microwell plate from

the analyzer.

Table 7 Recovery workflow short guide

1. Unload the microwell plate from the analyzer as

soon as is practical after the run has finished.

2. Discard the microwell plate according to the

appropriate local regulations.

Roche Diagnostics

cobas® 4800 System, Operator’s Manual · Version 1.1 17

Page 18

Operation cobas® 4800 System

Safety information CT/NG Test

Operation

In this chapter the operation of the system is described.

Safety information

Considerations before operation

Make sure that you have read and understood the chapter General safety information in

the cobas®4800 System System Manual. The following safety messages in particular are

relevant:

r Warning messages:

o Loss of sight due to staring into the laser beam

o Infection by samples and associated materials

o Infection and injury due to sharp objects

o Infection by biohazardous waste

o Contamination of the environment by liquid waste and solid waste

r Caution messages:

o Personal injury due to contact with moving parts

o Skin inflammation or injury caused by reagents

o Personal injury due to hot surface

r Safety precautions:

o Operator qualification

r Observe the illustrated system safety labels from the cobas

Manual

®

4800 System System

Performing a full workflow run

The following procedures guide you through all required steps to perform a full

workflow run with sample preparation on the instrument and amplification and

detection on the analyzer. The procedures cover both working modes: with and

without LIS. Steps that only apply to one working mode are indicated accordingly.

Performing startup procedures

NOTICE

Roche Diagnostics

18 cobas® 4800 System, Operator’s Manual · Version 1.1

Instrument damage due to improper handling

To prevent hardware damage, follow the steps in the exact order outlined when starting up

the system.

To start up the system, it is important that you perform the following steps in this

exact order:

1. Switch on the analyzer.

2. Switch on the heater/shaker unit.

3. Switch on the instrument.

4. Start up the software.

Page 19

cobas® 4800 System Operation

A

A

CT/NG Test Performing a full workflow run

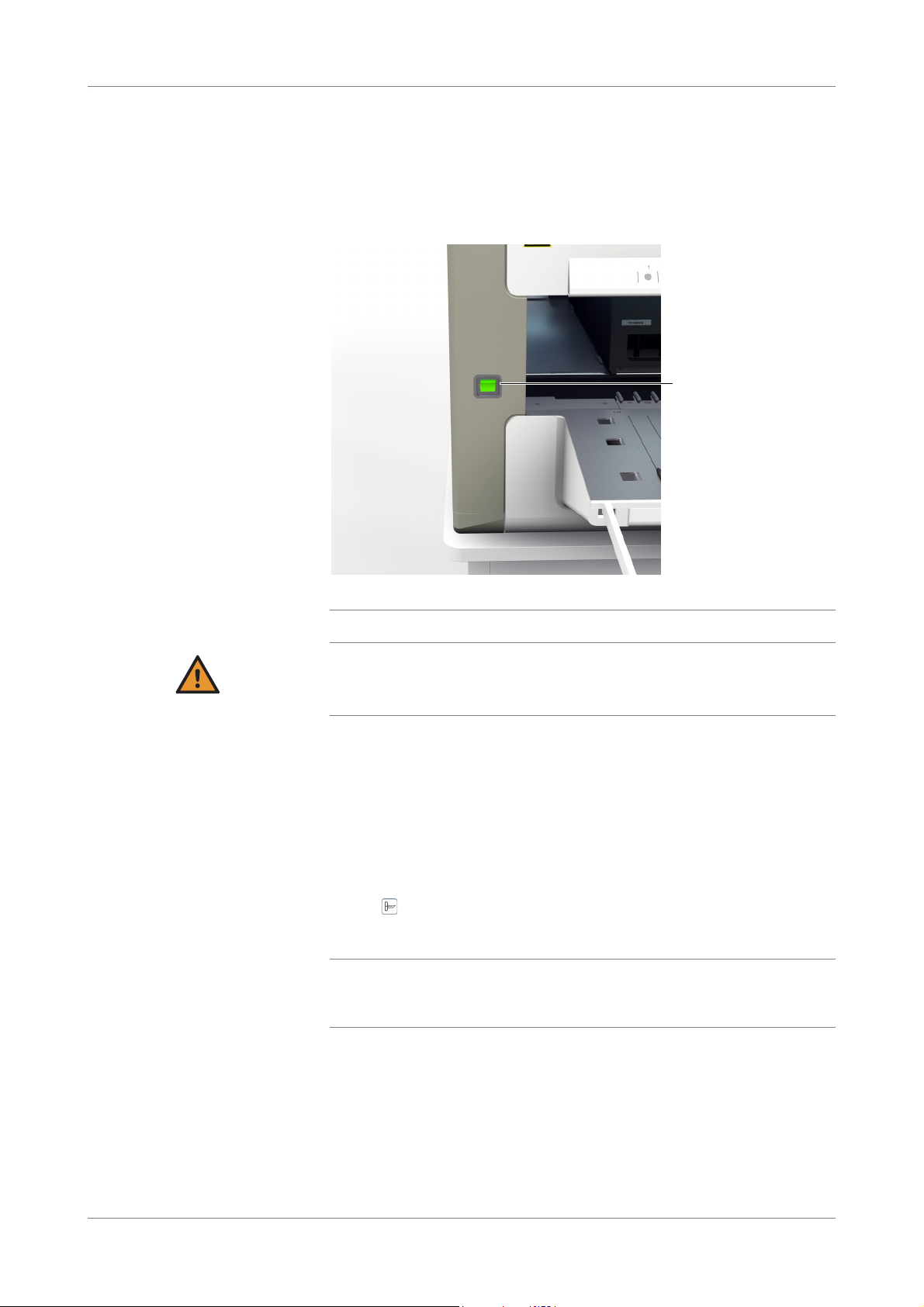

P To switch on the analyzer

1

Switch on the analyzer. The power switch is located at the back of the analyzer.

The analyzer is powered on and initializes.

A Power switch of the analyzer

Figure 4 Switching on the analyzer

S

P To switch on the heater/shaker unit

1

Switch on the heater/shaker unit. The switch is located at the front of the

heater/shaker controller box.

A Power switch of heater/shaker controller box

Figure 5 Switching on the heater/shaker unit

S

Roche Diagnostics

cobas® 4800 System, Operator’s Manual · Version 1.1 19

Page 20

Operation cobas® 4800 System

A

Performing a full workflow run CT/NG Test

P To switch on the instrument

1

Switch on the instrument. The power switch is located at the front of the

instrument.

The instrument is powered on and initializes.

WARNING

A Power switch of the instrument

Figure 6 Switching on the instrument

Delay of results due to improper handling

Turning the power of the instrument off during a run can lead to a sample rerun.

r Do not turn off the instrument power during a run.

S

P To start up and log on to the software

1

Switch on the monitor and control unit.

After the Windows operating system starts, double-click the cobas 4800 v2.1

desktop icon to open the software.

The software displays the System overview tab.

2

Choose (Log on) to log on and enter your assigned user ID and password.

3

Choose the OK button.

Q

o The user ID is not case-sensitive.

o The password is case-sensitive. The password displays as asterisks when typed to

maintain security.

S

Roche Diagnostics

20 cobas® 4800 System, Operator’s Manual · Version 1.1

Page 21

cobas® 4800 System Operation

CT/NG Test Performing a full workflow run

Performing maintenance

Periodic maintenance needs to be performed in order to ensure safe and reliable

operation of the instrument.

NOTICE

Periodic maintenance

o Performing daily and weekly maintenance is mandatory. A sample preparation run can

only be started when maintenance is done.

o If any parts of the instrument or carriers have become contaminated, the weekly

maintenance procedure must be performed.

o Counters are reset to twenty-four hours when daily maintenance is performed. If

weekly maintenance is being performed, daily maintenance is not required on that day.

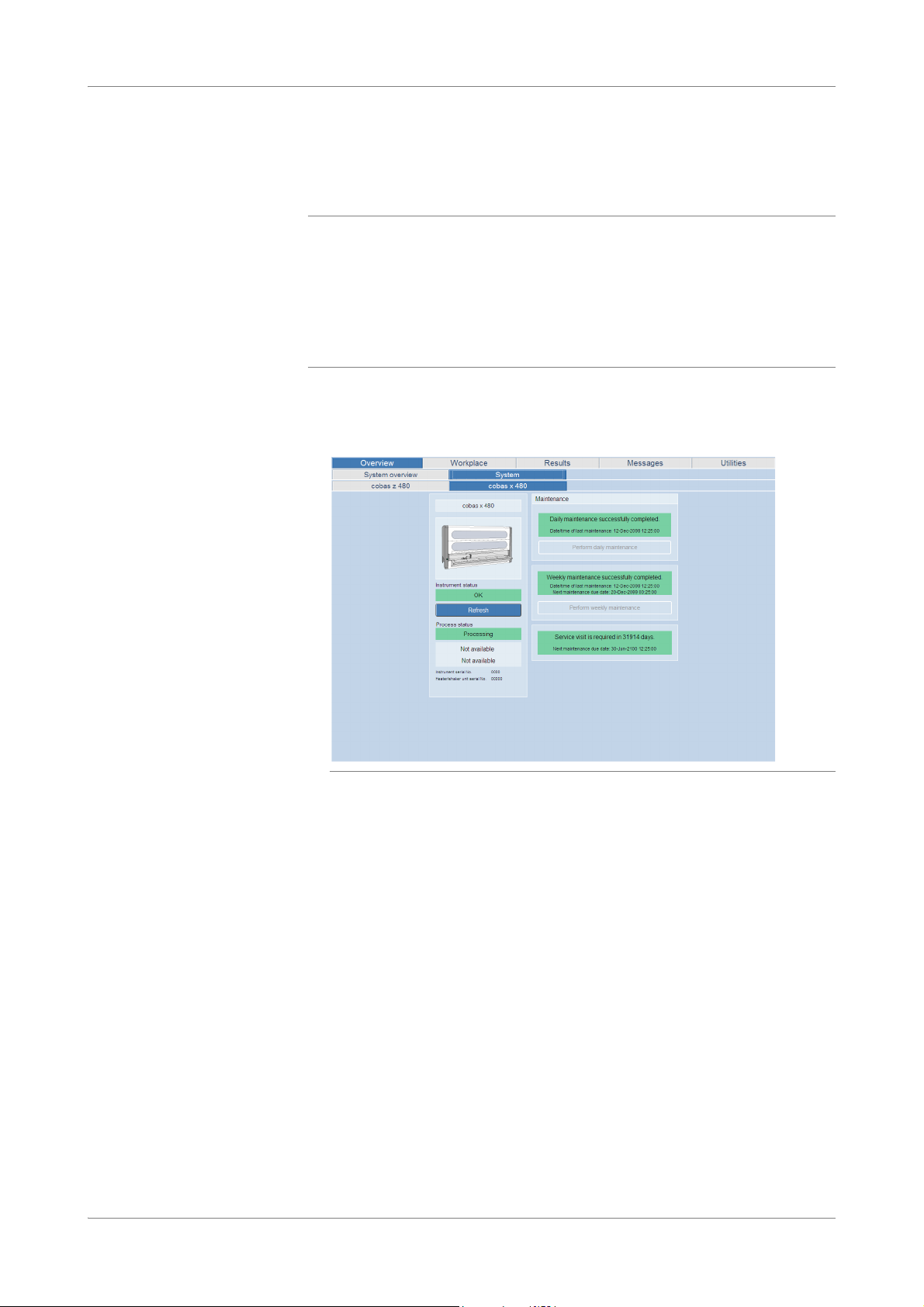

P To perform daily or weekly maintenance on the instrument

1

To check the maintenance status, choose Overview > System > cobas x 480 tab.

Figure 7 Checking the maintenance status

2

Do one of the following:

o If the weekly maintenance is due, choose the Perform weekly maintenance

button and follow the instructions displayed on the monitor.

U

For more details about weekly maintenance, refer to the cobas®4800 System System

Manual.

o If the daily maintenance is due, choose the Perform daily maintenance

button and follow the instructions displayed on the monitor.

For more details about daily maintenance, refer to the cobas®4800 System System

U

Manual.

S

Removing the samples and reagents from storage

The reagents that you need to perform the run depends on the run size.

U

For instructions on storage and handling of reagents, samples and controls, refer to testspecific package insert.

Roche Diagnostics

cobas® 4800 System, Operator’s Manual · Version 1.1 21

Page 22

Operation cobas® 4800 System

B

C

A

D

Performing a full workflow run CT/NG Test

Starting a new run

A wizard guides you through the entire run, from sample preparation on the

instrument to amplification and detection on the analyzer.

Loss of reagents, samples, or consumables

Inappropriate user actions can cause loss of reagents, samples, or consumables.

r Do not disconnect the USB cable during a run. The run will be aborted immediately

r It is not possible to go back to a previous step in a run. To avoid losing reagents,

samples, or consumables, follow the guidelines outlined in this manual.

r If the instrument is installed on a bench top, a small solid waste bag is used. This solid

waste bag has a capacity for tips up to one full workflow run. Exchange the small solid

waste bag each time before starting a new run to avoid overfilling of the tip waste.

r You can use the sample editor to prepare one or more work order files before starting

a run, or to prepare a work order file for the next run while a run is still in progress.

U For details about replacing the small solid waste bag, refer to the cobas

System Manual.

Before starting a run, check the Overview > System > cobas z 480 tab if the Xenon

Q

lamp needs replacement. Replace the Xenon lamp, if required.

U For details about Xenon lamp replacement, refer to the cobas

Manual.

®

4800 System System

®

4800 System

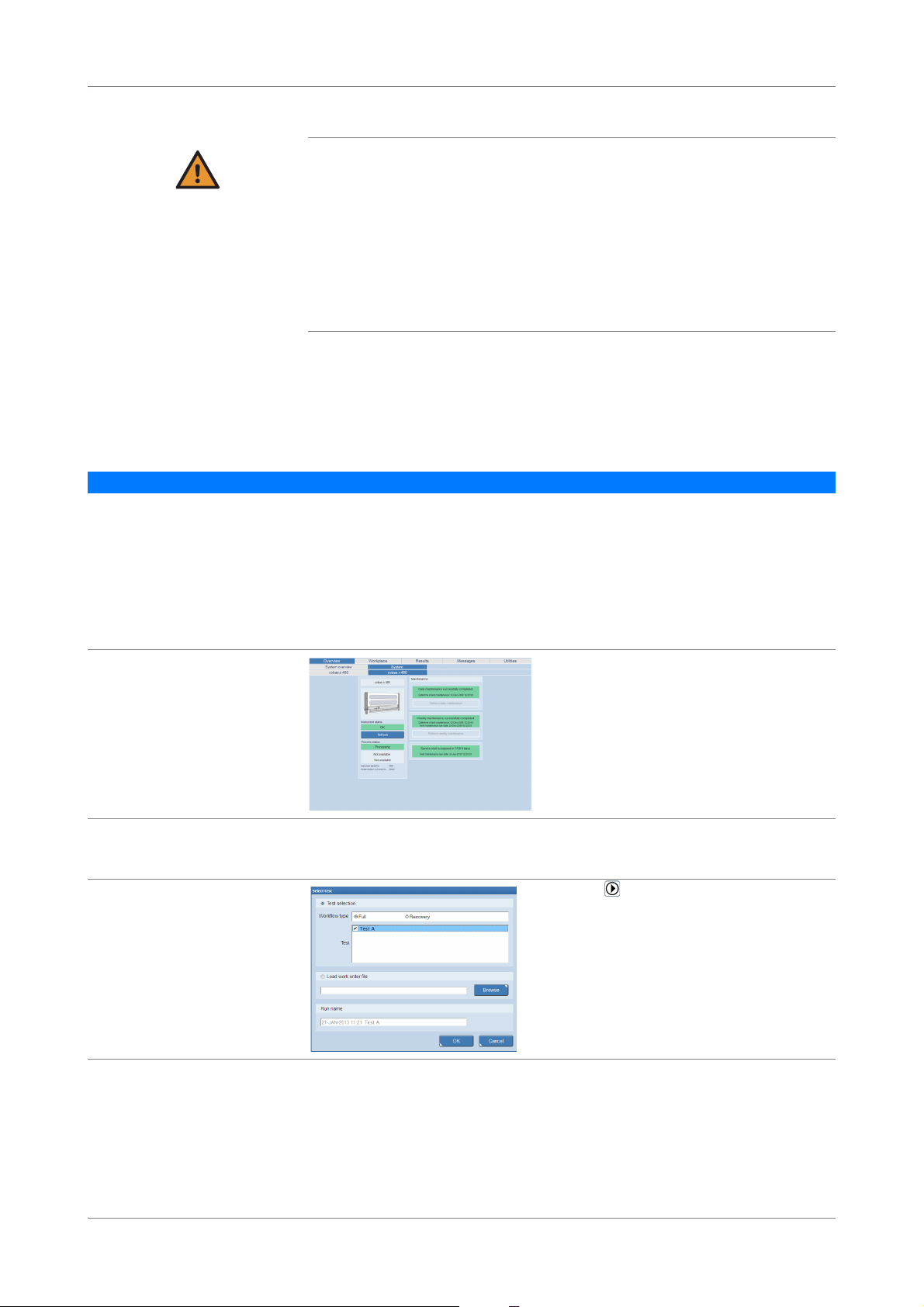

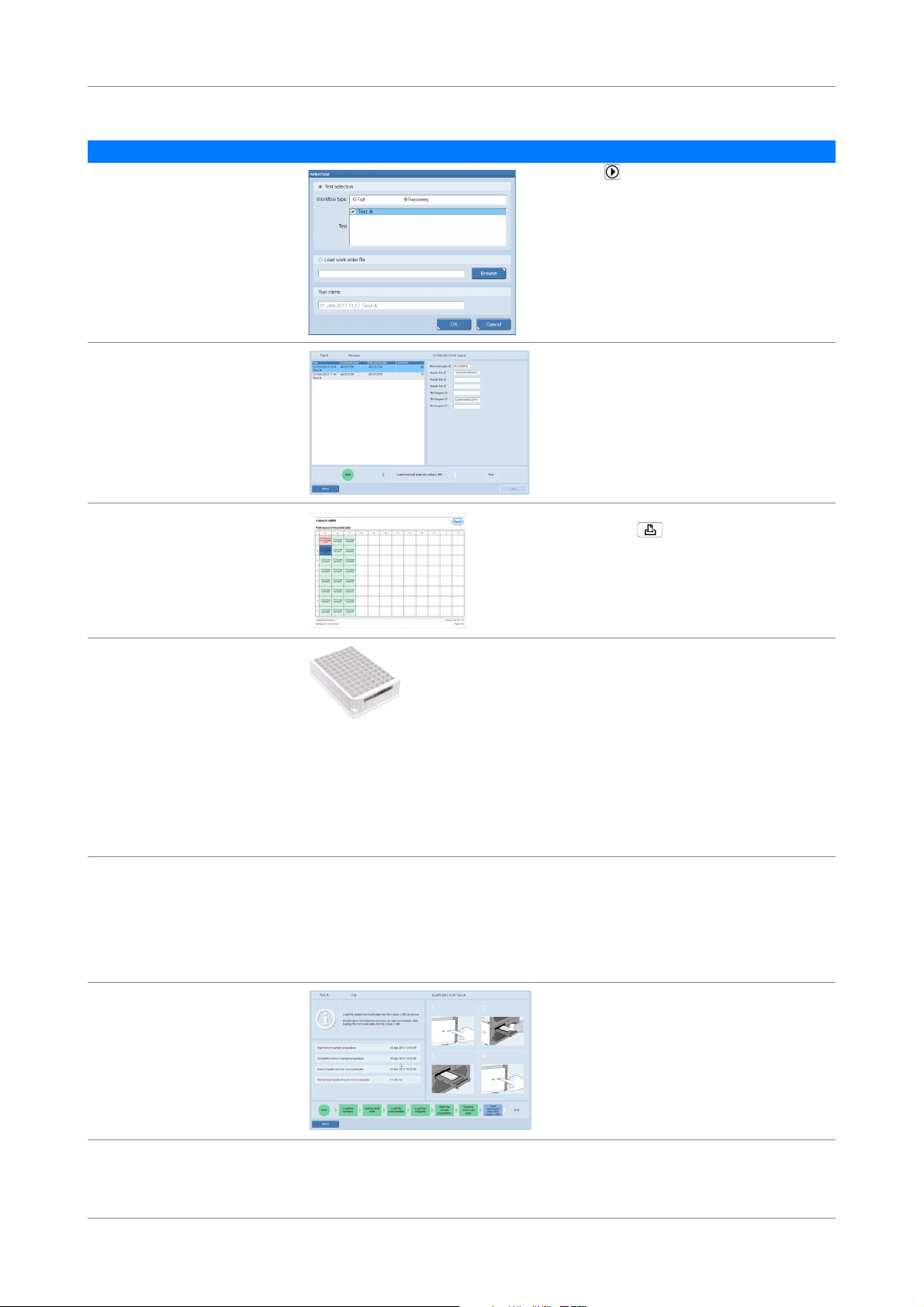

P To start a new run

1

Choose (New run).

The Select test dialog box is displayed.

A Load a work order file. C Choose a test.

B Choose a Full workflow. D Browse for a work order file.

Figure 8 Select test dialog box

2

Select the Full option.

3

Select the CT/NG check box.

4

Optionally, enter a name for the run in the Run name field.

If you leave the field empty, the system generates a generic run name with the

date, time, and test name (e.g. "28-May-2013 11:57 AM Test A"). If you enter a

name for the run, the system adds a time stamp to the name.

Roche Diagnostics

22 cobas® 4800 System, Operator’s Manual · Version 1.1

Page 23

cobas® 4800 System Operation

CT/NG Test Performing a full workflow run

5

Choose the OK button.

The Workplace tab is displayed showing the wizard for the new run. The

instrument initializes. This can take some time.

S

Loading samples

Samples can be loaded in barcoded primary or secondary tubes.

Up to 94 patient specimens can be loaded for a single test run. Two positions on the

plates are reserved for controls. Controls are not loaded together with samples. They

are loaded onto the reagent carrier during reagent loading.

U

For a list of sample types, refer to the test-specific package insert.

U For more details about sample carriers, see About specimen types (p. 7)

o The sample editor and work order files are only used when the system is not connected

Q

to an LIS or if the LIS is not working.

o If an LIS is used, order information is loaded automatically from the LIS after samples

are loaded onto the instrument.

o If more specimens are loaded than requested in the work order file, you can define the

ordering for these samples in the sample editor.

o If a work order file and the loaded samples do not match, both the work order file and

the samples must be reloaded. It is not possible to choose another work order file and

leave the samples loaded.

o Samples can be loaded in any order as long as they match the set of samples listed in

the work order file.

o If you unload samples to correct a work order mismatch error, all carriers are unloaded.

If you unload samples to correct another type of error (e.g. barcode reading), only the

carrier with the error is unloaded.

o Do not load empty or capped sample tubes. If a hardware error occurs, manually

remove all carriers, and then restart the system.

o You cannot mix specimen type PreservCyt

the same run.

®

with specimen types Urine and/or Swab in

U For more information about barcodes and barcode character lengths, refer to the

cobas®4800 System System Manual.

Spillage and contamination due to overfilling sample tubes

Do not overfill sample tubes to avoid spillage and contamination during loading.

WARNING

r The maximum sample volume in the secondary tubes is 10 mL.

P To load samples

1

Decap the sample tubes or containers and place the samples on the appropriate

carrier. The sample barcodes must face to the right of the carrier.

Q

Roche Diagnostics

cobas® 4800 System, Operator’s Manual · Version 1.1 23

Make sure that the sample tubes or containers are seated correctly in the sample

carrier.

U For details about sample placement, refer to the cobas

®

4800 System System Manual.

Page 24

Operation cobas® 4800 System

C

BA

Performing a full workflow run CT/NG Test

2

Insert all sample carriers into their designated track positions on the autoload

tray. The correct loading position is indicated by blinking LEDs on the LED bar

above the autoload tray.

U

For details about carrier loading, refer to the cobas®4800 System System Manual.

A Sample carrier C Sample barcodes facing to the right

B Tracks 17 through 34 are reserved for

sample carriers

Figure 9 Loading samples

3

When you have placed all sample carriers on the indicated track positions on the

autoload tray, choose the Load specimen button.

Check that all sample carriers are placed correctly before loading the samples.

Q

Sample carriers i.e. samples, are automatically unloaded when pipetting is finished. If

you do not want this, clear the Unload sample carriers after samples were

transferred to deepwell plate check box.

Roche Diagnostics

24 cobas® 4800 System, Operator’s Manual · Version 1.1

Page 25

cobas® 4800 System Operation

A

A

B

CT/NG Test Performing a full workflow run

A When sample carriers are ready for loading, choose the Load specimen button.

Figure 10 Wizard > Load the samples

The sample carriers are loaded automatically onto the instrument. During

loading, the barcode reader scans the carrier barcode and the sample barcodes.

The scanned sample barcodes are displayed in the Sample ID column.

If the instrument is connected to an LIS, the orders are downloaded automatically

from the LIS after the samples are loaded.

4

Follow the instructions displayed on the monitor in case a sample barcode cannot

be read.

For details about barcode error handling, refer to cobas®4800 System System Manual.

U

S

Confirming or creating a work order file

Tips In the same run, you can select specimen types Swab and Urine. You cannot mix

samples of specimen type PreservCyt

To select a range of adjacent samples, use the Shift key.

To select several nonadjacent samples, use the Ctrl key.

A Defining multiple samples B Defining individual samples

Figure 11 Defining multiple or individual samples

®

with samples of a different specimen type.

Roche Diagnostics

cobas® 4800 System, Operator’s Manual · Version 1.1 25

Page 26

Operation cobas® 4800 System

B C D EA

F

Performing a full workflow run CT/NG Test

P To confirm or define the work order file

1

Do one of the following:

o If the instrument receives work orders from an LIS, check that the work order

is correct

or,

o If the instrument does not receive work orders from an LIS, define the type of

specimen and the requested result.

A Select one or more samples. D Displays the ID of the scanned sample.

B Defining the type of specimen. E If you are using LIS or you have loaded a

work order file, the sample IDs are displayed

under Received ID.

C Defining the result. F Confirm the work order.

Figure 12 Confirming or creating a work order file

2

Choose the Next button.

The work order file information is cross-checked against the loaded samples. Run

and test types, number of samples, sample types, and barcode IDs must match.

3

In case the work order file and the loaded samples do not match, follow the

instructions displayed on the monitor.

S

Roche Diagnostics

26 cobas® 4800 System, Operator’s Manual · Version 1.1

Page 27

cobas® 4800 System Operation

CT/NG Test Performing a full workflow run

Loading the consumables

One deepwell plate (1.6 mL), one microwell plate, and two tip rack carriers are used

for each run.

Delay of results due to insufficient pipetting tips/tip rack carriers

The total number of pipetting tips per run varies and depends on several criteria (test type,

WARNING

specimen type, run size, etc.) The instrument tracks tip usage from run to run. The

instrument checks if enough pipetting tips have been loaded to perform the run. If there

are not enough, a message is displayed. Partially used tip racks can be used in next run.

r To perform a run, you must load all the required tip rack carriers with enough tips into

the instrument. If you unload samples to correct a work order mismatch error, all

carriers are unloaded. If you unload samples to correct another type of error (e.g.

barcode reading), only the carrier with the error is unloaded.

Incorrect results due to improper loading of the microwell plate or deepwell plate

If the microwell plate or deepwell plate are sealed when placed on the instrument, the seal

WARNING

could be pierced during the run resulting in carryover.

r Do not seal the microwell plate or deepwell plate before loading the plate into the

instrument.

All consumables are barcoded and designed to be used only once. The software tracks the

Q

use of the consumables and rejects already used consumables.

P To load the consumables

1

Place the listed consumables (e.g. 1 mL pipetting tips) on the appropriate carrier.

The barcodes must face to the right of the carrier.

For details about carrier loading, refer to the cobas®4800 System System Manual.

U

2

Load all carriers into their designated track positions on the autoload tray. The

correct loading position is indicated by blinking LEDs on the LED bar above the

autoload tray.

Use the following tracks:

o Plate carrier: tracks 1 through 6

o Left tip rack carrier: tracks 11 through 16

o Right tip rack carrier: tracks 35 through 40

Roche Diagnostics

cobas® 4800 System, Operator’s Manual · Version 1.1 27

Page 28

Operation cobas® 4800 System

Performing a full workflow run CT/NG Test

3

When you have placed all carriers on the indicated track positions on the

autoload tray, choose the Load consumables button.

Check that all carriers are placed correctly before loading the consumables.

Figure 13 Loading consumables

The carriers are loaded automatically onto the instrument. During and after

loading, the barcode reader scans the carrier barcodes and the consumable

barcodes.

4

In case a consumables barcode cannot be read or a consumable is recognized as

already used, follow the instructions.

For details about barcode handling and inventory errors, refer to the cobas®4800

U

System System Manual.

After successful loading of consumables, the wizard asks for loading the reagents.

S

Loading the reagents

The reagent reservoirs are barcoded and need to be filled manually by the operator

(scan-scan-pour-place principle) for each run.

The reagent carrier holds the test-specific reagents for sample processing and PCR

setup.

The required reagents and controls are manually decapped and then placed onto

their dedicated positions on the reagent carrier. The reagent barcodes must face to

the right of the carrier.

Scan-scan-pour-place principle To minimize handling errors the reagent reservoirs are filled and placed using the

scan-scan-pour-place principle:

1. Scan the barcode of the required reagent using the hand-held barcode reader.

2. Scan the barcode of an unused reagent reservoir using the hand-held barcode

reader.

3. Pour the reagent in the scanned reagent reservoir.

4. Place the filled reagent reservoir onto the required position of the reagent

reservoir carrier as indicated in the wizard.

The reagent reservoirs are available in two sizes: 200 mL and 50 mL. The reagent

reservoir barcodes must face to the right of the carrier.

Roche Diagnostics

28 cobas® 4800 System, Operator’s Manual · Version 1.1

Page 29

cobas® 4800 System Operation

CT/NG Test Performing a full workflow run

Incorrect results or delay of results due to wrong placement of reagents

Each reagent has a specific position assigned to it on the carriers. Even though each

WARNING

reagent is uniquely identified by barcodes, it must be placed at the correct location,

otherwise an error message will be generated, and loading will not proceed.

There is a limited time (60 minutes) between scanning the reagents and initiating the

instrument run. The timer starts when the wash buffer reagent vial is scanned. The system

checks if the reagent onboard stability time is elapsed when the run is started.

All controls are homogeneous and do not require vortexing or shaking prior to loading on

the instrument.

r Always place the reagent reservoirs and the reagent vials in the indicated positions on

the carriers before starting a run.

U For instructions on handling and storage of reagents and controls, refer to test-specific

package insert.

Considerations before loading the reagents

r Consider the following:

o All reagents and reagent reservoirs are barcoded and designed to be used only

once. The software tracks the use of the reagents and reagent reservoirs and

rejects partially used reagents or previously used reagent reservoirs.

o An acoustic signal is issued and an error message is displayed in the alarm area

when the system does not accept a scanned reagent barcode.

o To minimize the risk of contamination, it is highly recommended to change lab

gloves between handling patient samples and loading reagents onto instrument.

o Make sure that the reagent kit size corresponds to the intended run size. Although

not an optimal use of reagents, a 96 kit size can be used for a run size of 72 or less.

o For the most efficient reagent utilization it is advisable to maximize the number of

patient specimens processed within a run. Remaining reagents cannot be used

later on in another run.

o The reagent inventory marks a reagent as used as soon as it is assigned to a

reservoir. From this time point on the reagent is dedicated to this run and cannot

be used later on another run even if the reagent is not used during the run.

U For instructions on storage and handling of reagents and controls, refer to the test-

specific package insert.

The following table shows an example of the reagent positions on the different

carriers. For the exact placement of reagents, refer to the color coded picture

displayed in the software.

Example of reagent loading for

Swab and Urine

Roche Diagnostics

cobas® 4800 System, Operator’s Manual · Version 1.1 29

Carrier type Position Reagents

200 mL reagent

reservoir carrier

50 mL reagent

reservoir carrier

Reagent carrier 1 through 14 Not used

Table 8 Placement of reagents (example for 24/96 batch size)

1 through 3 Not used

4 Wash buffer

1 through 3 Not used

4MGP

5Elution buffer

15 Internal control

16 Positive control

Page 30

Operation cobas® 4800 System

Performing a full workflow run CT/NG Test

Carrier type Position Reagents

17 Negative control

18 Control diluent

19 through 21 Not used

22 Master mix reagent (for 96-sample runs only)

23 Master mix reagent

24 Mn reagent

Table 8 Placement of reagents (example for 24/96 batch size)

Example of reagent loading for PC

Carrier type Position Reagents

200 mL reagent

reservoir carrier

50 mL reagent

reservoir carrier

Reagent carrier 1 through 12 Not used

Table 9 Placement of reagents (example for 24/96 batch size)

1 through 3 Not used

4 Wash buffer

1Not used

2SDS reagent

3 Lysis buffer

4MGP

5Elution buffer

13 Proteinase K reagent (for 96-sample runs only)

14 Proteinase K reagent

15 Internal control

16 Positive control

17 Negative control

18 through 21 Not used

22 Master mix reagent (for 96-sample runs only)

23 Master mix reagent

24 Mn reagent

P To load the reagents on the 200 mL reagent reservoir carrier

1

Scan the barcode of the wash buffer using the hand-held barcode reader.

The reagent in the list is highlighted in light green.

Scanning the barcode of the wash buffer starts the reagent onboard stability timer

in the software. The run must be started within 60 minutes.

2

Scan the barcode of an unused 200 mL reagent reservoir using the hand-held

barcode reader.

The reagent in the list is checked and highlighted in dark green.

Roche Diagnostics

30 cobas® 4800 System, Operator’s Manual · Version 1.1

Page 31

cobas® 4800 System Operation

A

CT/NG Test Performing a full workflow run

3

Pour the entire reagent vial in the scanned reagent reservoir.

Q

o It is advisable to pour the reagent into the reservoir in a lengthwise movement to

minimize the risk of splashing and resulting reagent loss.

o Do not pour reagents into reservoirs that are already placed onto a reagent rack.

Always follow the scan-scan-pour-place principle.

o Do not fill reagent reservoirs above the maximal fill height. A line within the reagent

reservoir indicates the maximal fill height.

o Handle filled reservoirs with particular care to avoid splashes and tipping over.

4

Place the filled reagent reservoir onto position 4 of the 200 mL reagent reservoir

carrier as indicated.

5

Insert the 200 mL reagent reservoir carrier into its designated track positions on

the autoload tray. The correct loading position is indicated by blinking LEDs on

the LED bar above the autoload tray.

Use the following tracks:

o 200 mL reagent reservoir carrier: tracks 48 through 49

6

When you have placed the 200 mL reagent reservoir carrier on the indicated track

positions on the autoload tray, choose the Load reagents button.

Check that the 200 mL reagent reservoir carrier is placed correctly before loading

it.

A When the carrier is ready for loading, choose the Load reagents button.

Figure 14 Load reagents

The 200 mL reagent reservoir carrier is loaded automatically onto the instrument.

During loading, the barcode reader scans the carrier barcode and the reagent

reservoir barcode.

Roche Diagnostics

cobas® 4800 System, Operator’s Manual · Version 1.1 31

Page 32

Operation cobas® 4800 System

Performing a full workflow run CT/NG Test

7

In case a barcode cannot be read or a reagent is recognized as already used, follow

the instructions displayed on the monitor.

For details about barcode handling and inventory errors, refer to the cobas®4800

U

System System Manual.

After successful loading, the wizard asks for loading the reagents for the 50 mL

reagent reservoirs.

S

P To load the reagents on the 50 mL reagent reservoir carrier

1

Scan the barcode of one of the reagents in the list using the hand-held barcode

reader.

The reagent in the list is highlighted in light green.

2

Scan the barcode of an unused 50 mL reagent reservoir using the hand-held

barcode reader.

The reagent in the list is checked and highlighted in dark green.

3

Pour the entire reagent vial in the scanned reagent reservoir.

Q

o It is advisable to pour the reagent into the reservoir in a lengthwise movement to

minimize the risk of splashing and resulting reagent loss.

o Do not pour reagents into reservoirs that are already placed onto a reagent rack.

Always follow the scan-scan-pour-place principle.

o Do not fill reagent reservoirs above the maximal fill height. A line within the reagent

reservoir indicates the maximal fill height.

o Handle filled reservoirs with particular care to avoid splashes and tipping over.

4

Place the filled reagent reservoir into the indicated position of the 50 mL reagent

reservoir carrier.

5

Repeat step 1 to 4 for all reagents in the list.

Roche Diagnostics

32 cobas® 4800 System, Operator’s Manual · Version 1.1

Page 33

cobas® 4800 System Operation

CT/NG Test Performing a full workflow run

6

Insert the 50 mL reagent reservoir carrier into its designated track position on the

autoload tray. The correct loading position is indicated by a blinking LED on the

LED bar above the autoload tray.

Use the following track:

o 50 mL reagent reservoir carrier: track 50

7

When you have placed the 50 mL reagent reservoir carrier on the indicated track

position on the autoload tray, choose the Load reagents button.

Check that the 50 mL reagent reservoir carrier is placed correctly before loading

it.

Figure 15 Loading reagents on the 50 mL reagent reservoir carrier

The 50 mL reagent reservoir carrier is loaded automatically onto the instrument.

During loading, the barcode reader scans the carrier barcode and the reagent

reservoir barcodes.

8

Follow the instructions in case a barcode cannot be read or a reagent is recognized

as already used.

For details about barcode handling and inventory errors, refer to the cobas®4800

U

System System Manual.

After successful loading, the wizard asks for loading the reagents for the reagent

carrier.

S

P To load the reagent carrier

1

Open the listed reagent vials and place them onto the indicated positions on the

reagent carrier.

To minimize reagent waste, the software displays the optimal reagent kit size

usage for the run. If the suggested kit size is not available, you can use the Change

kit size for function. Consider that using a larger kit size than required is not an

optimal use of reagents.

The reagent barcode must face to the right of the carrier.

Q

Roche Diagnostics

cobas® 4800 System, Operator’s Manual · Version 1.1 33

Open the reagent vials before placing them onto the reagent carrier to minimize the

risk of contamination.

Page 34

Operation cobas® 4800 System

Performing a full workflow run CT/NG Test

2

Insert the reagent carrier into its designated track on the autoload tray. The

correct track is indicated by a blinking LED on the LED bar above the autoload

tray.

Use the following track:

o reagent carrier: track 51

3

When you have placed the reagent carrier on the indicated track on the autoload

tray, choose the Load reagents button.

Check that the reagent carrier is placed correctly before loading it.

Q

The colors on reagent vials match the colors displayed on the software.

Figure 16 Loading reagents on the reagent carrier

The reagent carrier is loaded automatically onto the instrument. During loading,

the barcode reader scans the carrier barcode and the reagent vial barcodes.

4

In case a barcode cannot be read or a reagent is recognized as already used, follow

the instructions displayed on the monitor.

For details about barcode handling and inventory errors, refer to the cobas®4800

U

System System Manual.

After successful loading, the wizard shows the instrument deck. Loaded samples,

reagents and consumables are highlighted in green. The sample preparation

process is now ready to be started.

S

Starting the sample preparation run

The loading is now complete and the sample preparation is ready to be started. The

loaded instrument deck is shown with all loaded samples, reagents, and consumables

highlighted in green.

o The loaded reagents have limited onboard stability. Sample preparation should be

Q

started as soon as practical. This is especially important when maximum system

throughput is desired. The reagent onboard stability time is indicated on screen.

o Do not touch any carrier or remove a carrier after a run has started.

Roche Diagnostics

34 cobas® 4800 System, Operator’s Manual · Version 1.1

Page 35

cobas® 4800 System Operation

B

A

CT/NG Test Performing a full workflow run

Moving parts

r Never attempt to start and/or operate the instrument with the front cover open. Keep

hands away from all moving parts while the instrument is in use.

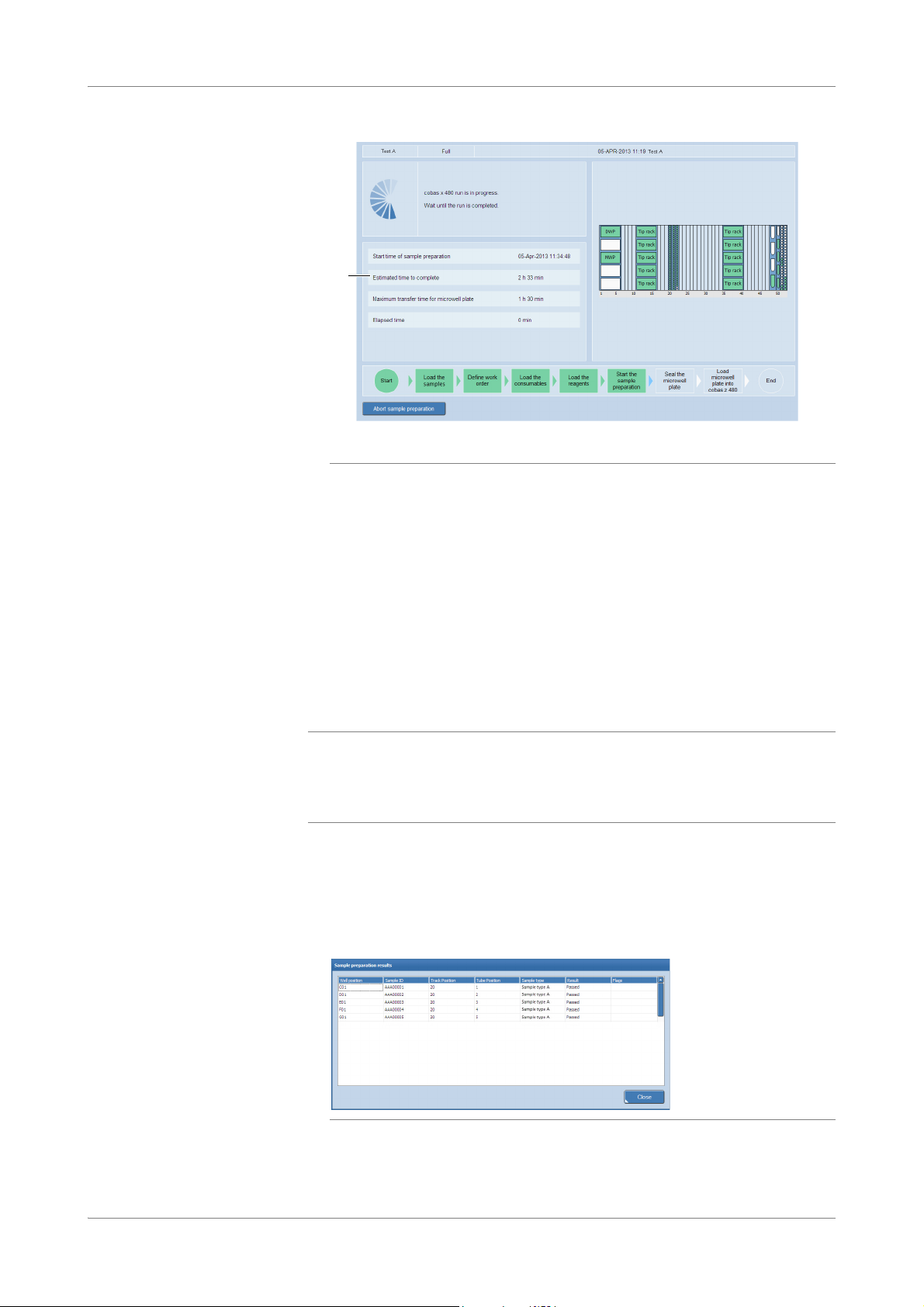

P To start the sample preparation run

1

Choose the Start run button.

The sample preparation is started. After starting the run, the estimated

completion time is indicated on the screen.

2

Check the timer in the wizard.

If the Unload sample carriers after samples were transferred to deepwell plate

check box was selected, the specimens will be unloaded after being pipetted into

the deepwell plate.

Q

o The indicated completion time is only an estimate.

o After sample preparation is completed, there is a limited time (90 minutes) before

the amplification and detection process must be started. A timer is displayed in the

Workplace tab.

A Onboard reagent expiry time B Start the run

Figure 17 Ready to start the run

After you start the run, an estimated time to complete the run is displayed.

Roche Diagnostics

cobas® 4800 System, Operator’s Manual · Version 1.1 35

Page 36

Operation cobas® 4800 System

A

Performing a full workflow run CT/NG Test

A Estimated completion time

Figure 18 Run in progress

S

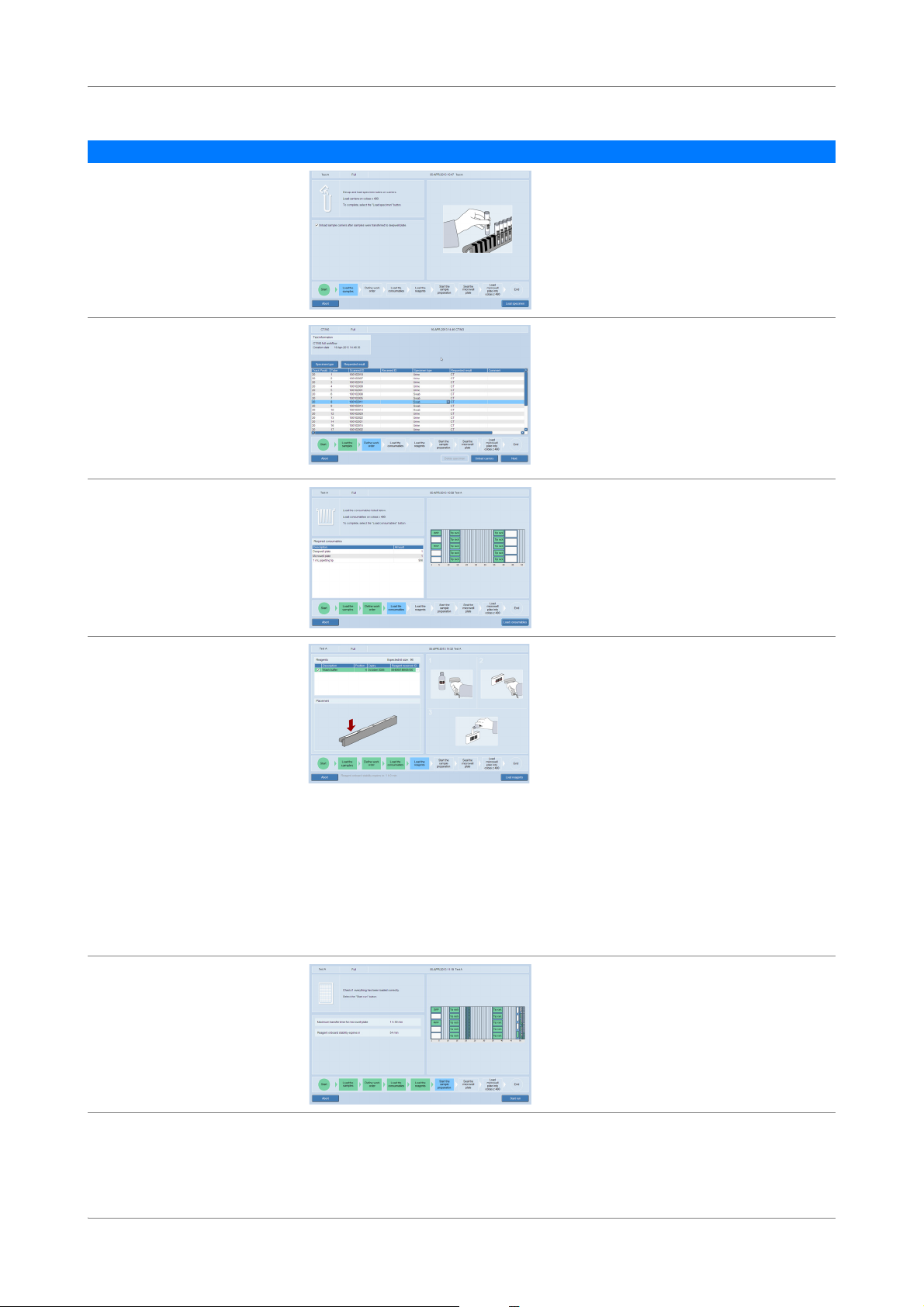

Unloading the microwell plate

NOTICE

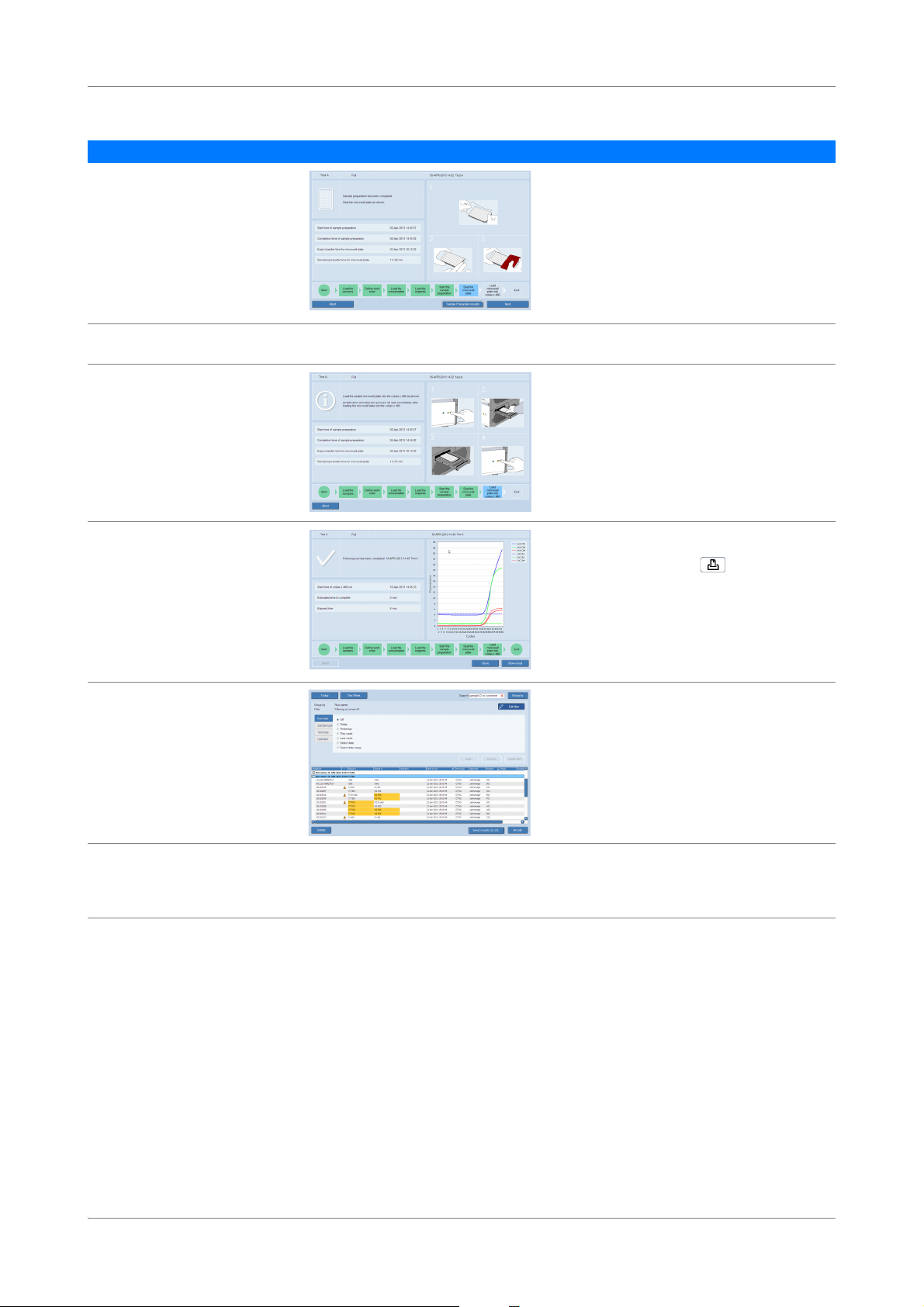

P To review the sample preparation results

After a successful sample preparation run, the Sample Preparation results button

and the Unload button become available.

After completion of the sample preparation the microwell plate is transported back to

the plate carrier. After unloading, the microwell plate must be sealed and then

manually transferred to the analyzer for amplification and detection.

The results of the prepared samples can be reviewed in the Sample preparation

results dialog box.

Failed sample due to pipetting error

If there is an error during pipetting, a sample can be skipped. This sample will be marked

as failed.

r Rerun the failed sample.

1

To review the results of the sample preparation, choose the Sample Preparation

results button.

The Sample preparation results dialog box is displayed.

Figure 19 Viewing the sample preparation results

Sample preparation results are printable intermediate results. They cannot be

saved or transmitted to the LIS.

Roche Diagnostics

36 cobas® 4800 System, Operator’s Manual · Version 1.1

Page 37

cobas® 4800 System Operation

CT/NG Test Performing a full workflow run

U For flagged sample preparation results, see List of result flags (p. 67)

2

To close the Sample preparation results dialog box, choose the Close button.

3

To print the results, close the Sample preparation results dialog box and choose

(Print).

4

To unload the plate carrier, choose the Unload button.

Sealing the microwell plate

CAUTION

Q

o Allow the instrument to unload all the carriers. Do not pull them out manually. This

would interrupt the unload process and crash the instrument.

o If the instrument encounters a problem during unloading an error message is

displayed. Confirm the error message.

o In some cases the instrument must be unloaded manually. After unloading, seal the

microwell plate and start the amplification and detection run on the analyzer. The

results will be flagged (X9 flag).

Q

The prepared samples with working master mix reagent have a limited stability. You

have 90 minutes between completion of the sample preparation and the start of the

amplification and detection run. The expiry time is indicated on the screen.

S

On the plate carrier seal the microwell plate properly with a sealing film. Sealing the

microwell plate is crucial to eliminate evaporation at high temperatures.

Incorrect results due to evaporation or contamination of samples and controls

r Make sure that microwell plate and sealing film are not expired.

r Follow the outlined procedure to seal the microwell plate to prevent leakage of the

sealing film or contamination of samples. Plate leakage can contaminate the analyzer.

If contamination is suspected, contact Roche Service.

r Examine the microwell plate after amplification and detection to ensure that no

leakage has occurred.

P To seal the microwell plate

1

Remove the protection layer from the sealing film.

Do not touch the film on the adhesive side and handle the film only at the sides.

2

Cover the microwell plate with the adhesive side of the sealing film.

3

Firmly press the sealing film to the plate surface using the sealing film applicator.

Q

Roche Diagnostics

cobas® 4800 System, Operator’s Manual · Version 1.1 37

To ensure a strong seal, use the provided sealing film applicator.

Page 38

Operation cobas® 4800 System

Performing a full workflow run CT/NG Test

4

Remove both ends of the sealing film alongside the perforation.

Do not lift the sealing film from the plate while tearing off the ends of the foil.

Figure 20 Sealing the microwell plate

5

In the software, choose the Next button.

The screen for loading the microwell plate onto the analyzer is displayed.

S

Removing used reagents, samples, and deepwell plate

To optimize throughput used reagents, samples and the deepwell plate can be

removed and the instrument can be prepared for the next run as soon as the

amplification and detection run on the analyzer has been started.

Starting amplification and detection run

The sealed microwell plate has to be manually transferred to the analyzer for

amplification and detection.

The amplification and detection will start immediately after loading.

o The prepared samples with working master mix reagent have a limited stability.

Q

Therefore, be sure not to wait too long before starting the amplification and detection

run. You have 90 minutes between completion of the sample preparation and the start

of the amplification and detection run. The expiry time is indicated on the screen.

o After starting amplification and detection on the analyzer the instrument is ready for

the next sample preparation run.

Roche Diagnostics

38 cobas® 4800 System, Operator’s Manual · Version 1.1

Page 39

cobas® 4800 System Operation

B

A

CT/NG Test Performing a full workflow run

P To load the prepared microwell plate into the analyzer

1

Press the load button on the analyzer.

A Load button B Microwell plate loader

Figure 21 Loading prepared microwell plate

The microwell plate loader opens.

2

Place the sealed microwell plate into the loading frame of the microwell plate

loader.

3

WARNING

4

Reviewing and accepting results

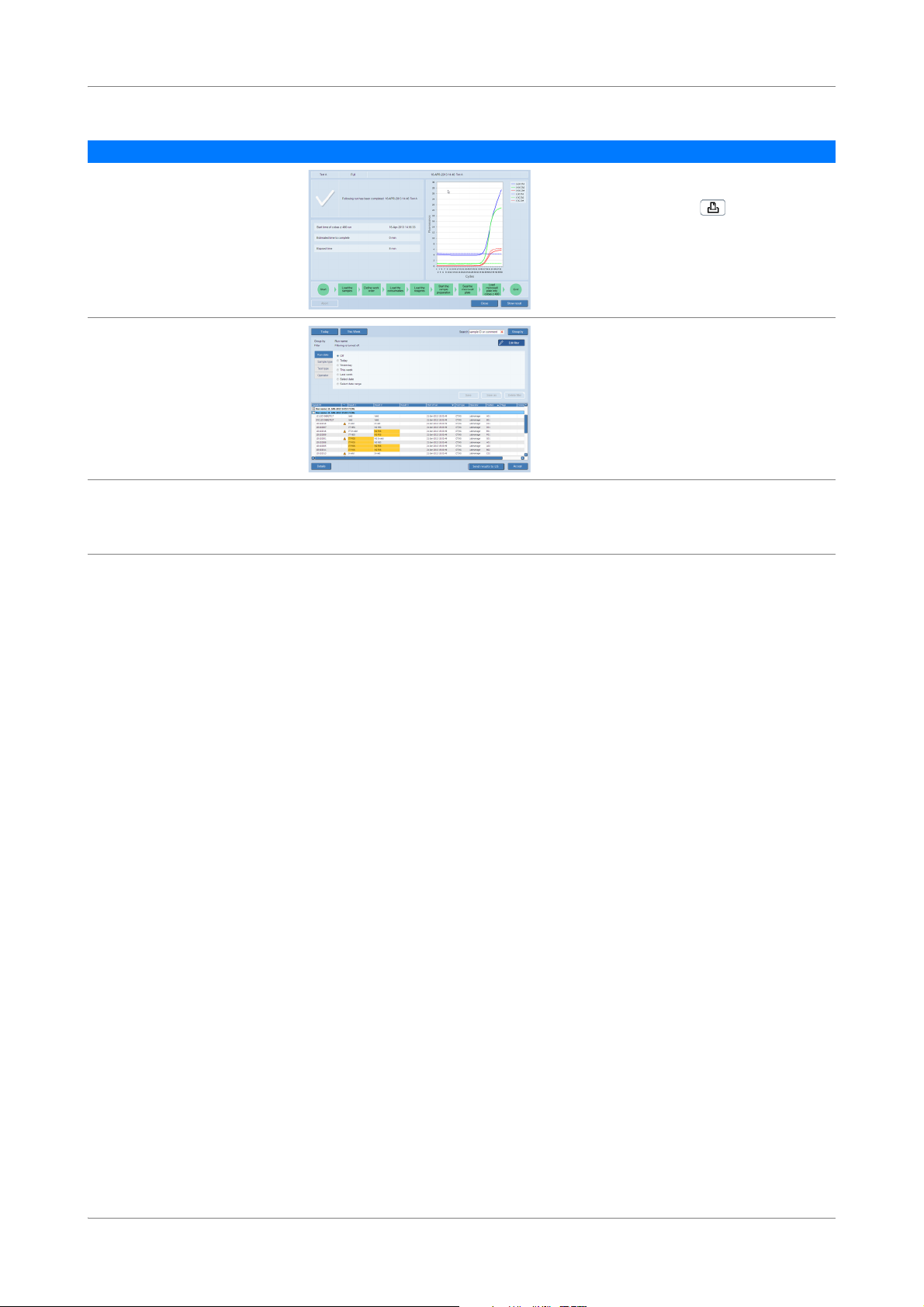

Test results are displayed in the Results work area as soon as the analyzer has finished

amplification and detection.

Press the load button again to close the microwell plate loader.

The microwell plate loader is retracted. The run starts immediately.

Delay of results due to improper handling

Turning the power of the analyzer off during a run can lead to a sample rerun.

r Do not turn off the analyzer power during a run.

Check the timer in the wizard.

When the run is finished, in the software, the Show result button becomes

available.

S

Roche Diagnostics

cobas® 4800 System, Operator’s Manual · Version 1.1 39

Page 40

Operation cobas® 4800 System

A

B

Performing a full workflow run CT/NG Test

P To review and accept results

1

In the Workplace work area, choose the Show result button.

Sending results to LIS

A Fluorescence growth curves of the positive

(+) and negative (-) controls of all channels

Figure 22 Displaying results

BShow result button

The Results work area is displayed.

2

Review and accept results in the Results work area.

For details, see Accepting results (p. 58)

U

3

To print the results report, select results and choose (Print).

For details, see Printing results (p. 58)

U

S

After review, test results can be sent to the LIS.

o This step can be skipped if working without LIS.

Q

o Depending on the configuration, all results are transferred to LIS or only accepted

results are transferred to LIS. Control results are always uploaded to LIS.

o Unless the system is configured to send only accepted results to LIS, all results of the

run will be sent even if you only select one result in the run.

o If necessary, the displayed runs can be filtered and sorted.

o To select several nonadjacent results, use the Ctrl key. To select a range of adjacent

results, use the Shift key.

P To send results to the LIS

1

Choose the Results tab to display the Results work area.

2

If required, accept the results you want to send.

3

To send a complete run, select the run header of the run.

Roche Diagnostics

40 cobas® 4800 System, Operator’s Manual · Version 1.1

Page 41

cobas® 4800 System Operation

B

A

D

C

CT/NG Test Performing a full workflow run

4

Choose the Send results to LIS button.

After successfully sending results to the LIS, a status is displayed in the Result

sent column.

Unloading the analyzer

CAUTION

AResult sent column (must be selected in

the Column Chooser).

BConfirmed means that run was successfully

sent to LIS and LIS confirmed the result. This

will only be displayed if a certain protocol is

used by LIS.

Figure 23 Confirmation from LIS

Q

o Results sent to LIS are kept in the Results work area. They are not deleted from the

results database.

CSent means that LIS has not acknowledged

the results.

D Failed that the sending of results to LIS

failed.

S

Unload the microwell plate as soon as practical after the run has finished to prevent

plate leakage and contamination of the analyzer.

Risk of burns due to hot surfaces

r Before removing the microwell plate from the plate loader, wait for an appropriate time

to allow the plate loader and microwell plate to cool down. Be aware that the microwell

plate may have a temperature of 60 °C to 80 °C even if you have allowed the analyzer to

cool down after the run. Otherwise, there is a risk of burns when touching the plate

loader or microwell plate.

P To unload the analyzer

1

When the run has finished, open the microwell plate loader to remove the

microwell plate.

2

Examine the microwell plate after amplification and detection.

Incorrect results due to evaporation of samples or sample contamination

Plate leakage can lead to incorrect results or can contaminate the analyzer. If

CAUTION

contamination is suspected, contact Roche Service.

r Unload the microwell plate as soon as practical after the run has finished and

check the microwell plate for indications of leakage.

3

Discard the plate according to the appropriate local regulations.

S

Performing shutdown procedure

To shut down the system, the following steps need to be performed.

Roche Diagnostics

cobas® 4800 System, Operator’s Manual · Version 1.1 41

Page 42

Operation cobas® 4800 System

Performing a recovery workflow run CT/NG Test

P To shut down the system

1

Check that there are no remaining pipetting tips or teaching needles on the

pipetting head of the instrument. If there are pipetting tips or teaching needles on

the pipetting head, perform daily maintenance.

U

For details on daily maintenance, refer to the cobas®4800 System System Manual.

2

Shut down the system in the following order:

o Log off the software and switch off the control unit.

o Switch off the heater/shaker unit.

o Switch off the instrument.

o Switch off the analyzer.

S

Performing a recovery workflow run

The following procedures guide you through all required steps to perform a recovery

workflow run with amplification and detection on the analyzer.

The recovery workflow is intended for repeat amplification from the remaining

eluate in the deepwell plate.

For the recovery workflow, the microwell plate is manually prepared with working

master mix reagent, Mn reagent, and residual eluate from the deepwell plate.

Only specimens successfully processed on the instrument can be amplified/detected

using the recovery workflow.

The recovery workflow is valid for all specimen types.

Q

Pre-conditions o Instrument and analyzer are turned on and maintenance has been performed.

o A full workflow run has been performed and the samples successfully prepared.

o A full workflow run has been performed in the last 24 hours.

o A full workflow run has been aborted by a user (M2 flag) or the analyzer (Z1 flag).

Roche Diagnostics

42 cobas® 4800 System, Operator’s Manual · Version 1.1

Page 43

cobas® 4800 System Operation

A

B

CT/NG Test Performing a recovery workflow run

Starting a recovery workflow run

P To start a recovery workflow run

1

Choose (New run).

The Select test dialog box is displayed.

A Select the test. B Select the recovery workflow.

Figure 24 Select test dialog box

2

Select the Recovery option.

3

Select the CT/NG check box.

4

Optionally, type a run name.

5

Choose the OK button.

S

Selecting the run to recover and adding new IDs

The software displays all failed runs that were aborted by the user or analyzer within