Page 1

Cedex HiRes Analyzer

Addendum 2 to

Operator’s Guide, Version 1.0

Software Version 2.2.1 August 2012

For life science research only.

Not for use in diagnostic procedures.

Page 2

Information regarding

the Cedex HiRes Analyzer

Dear Valued User of the Cedex HiRes Analyzer,

Roche Diagnostics Ltd. has merged into Roche Diagnostics International Ltd and therefore

the company name has changed to

Roche Diagnostics International Ltd

In order to harmonize and improve our support, the legal manufacturer changes as follows:

Roche Diagnostics GmbH

Sandhofer Strasse 116

68305 Mannheim

Germany

If you have any further questions regarding this matter, please do not hesitate to contact your

Roche Diagnostics representative. To call, write, fax, or email us, visit the Roche Applied Science

home page, http://www.roche-applied-science.com and select your home country.

Country-specific contact information will be displayed.

The address of the legal manufacturer in section

“Prologue/Contact Addresses” changes as follows:

Old adress New adress

Roche Diagnostics Ltd.

Forrenstrasse

CH-6343 Rotkreuz

Switzerland

Roche Diagnostics GmbH

Sandhofer Strasse 116

68305 Mannheim

Germany

CEDEX and INNOVATIS are trademarks of Roche.

06845932001 a 0 812

For life science research only. ©2012 Roche Diagnostics.

Not for use in diagnostic procedures. All rights reserved.

Page 3

Cedex HiRes Analyzer

Addendum 1 to Operator’s Guide, Version 1.0

Software Version 2.2.1

January 2012

For life science research only.

Not for use in diagnostic procedures.

Page 4

Information Regarding the

Cedex HiRes Analyzer Operator’s Guide

Please read the following information, which updates information given

in the Cedex HiRes Analyzer Operator’s Guide

Dear valued user of the Cedex HiRes Analyzer

This addendum includes:

c Updated information about the procedure for removal, reinstallation or replacement of the syringe.

If you have any further questions regarding this matter, please do not hesitate to contact

our Technical Services Department at your best convenience. To call, write, fax, or email

us, visit the Roche Applied Science home page, http://www.roche-applied-science.com

and select your home country. Country-specific contact information will be displayed.

Page 5

3

Maintenance and Care

E

E

Syringe Maintenance

Section E: Maintenance and Care

Chapter 5: Syringe Maintenance

Follow the syringe maintenance procedure described on pages 130 – 131 to remove, reinstall or replace the

syringe of the Cedex HiRes System. After removal, reinstallation or replacement of the syringe, a calibration

check of the Cedex HiRes System must also be performed. Use Cedex Density Reference Standard Beads to

check the calibration and confirm that the FlowFactor is correct. If necessary, adjust the FlowFactor.

To perform the Cedex HiRes System calibration check and FlowFactor adjustment, follow the instructions

described in the online Instructions for Use for the Density Reference Standard Beads, available for download

at:

https://www.roche-applied-science.com/PROD_INF/index.jsp?&id=iforu

Ordering Information

Product Pack Size Cat. No.

Density Reference Standard Beads 1× 10 ml Batch A 06 422 659 001

Density Reference Standard Beads 1× 10 ml Batch B 06 422 667 001

Page 6

Published by

Roche Diagnostics GmbH

Sandhofer Straße 116

683 05 Mannheim

Germany

© 2012 Roche Diagnostics.

All rights reserved.

www.roche-applied-science.com

066385 97001 0112

For life science research only.

Not for use in diagnostic procedures.

CE DEX and INNOVATIS are trademarks of Roche.

Page 7

Cedex HiRes Analyzer Operator’s Guide

Software Version 2.2.1

May 2011

For life science research only.

Not for use in diagnostic procedures.

Page 8

Page 9

3

Table of Contents

Prologue 9

I. Revision History ................................................................................................................................................................ 9

II. Contact Addresses .......................................................................................................................................................... 9

III. Declaration of Conformity .........................................................................................................................................10

IV. Warranty ..............................................................................................................................................................................10

V. Trademarks ........................................................................................................................................................................10

VI. Copyrights ..........................................................................................................................................................................10

VII. Intended Use .....................................................................................................................................................................10

VIII. Software License Agreement ..................................................................................................................................11

IX. Preamble .............................................................................................................................................................................14

X. Contents of this Operator’s Guide ........................................................................................................................ 14

XI. Conventions used in this Guide .............................................................................................................................14

XII. FCC Notifi cation ..............................................................................................................................................................15

XIII. Warnings and Precautions ........................................................................................................................................16

XIV. Disposal of the Analyzer ............................................................................................................................................ 17

A Overview 19

1 Description of the Cedex HiRes System ...........................................................................................................20

2 The Measurement Procedure ..................................................................................................................................21

3 Data Analysis .................................................................................................................................................................. 22

4 Technical Specifi cations of the Analyzer .......................................................................................................... 23

B System Description 25

1 Installing the Cedex HiRes System ...................................................................................................................... 25

2 Choosing a Suitable Location .................................................................................................................................26

2.1 Connecting or disconnecting the device ..................................................................................................................26

3 Connecting Hardware Components ....................................................................................................................27

3.1 Completing the Windows Mini-setup ........................................................................................................................27

4 Installing Cedex HiRes Software 2.2 or Updating to Cedex HiRes Software 2.2 ....................... 28

4.1 Installing the Cedex HiRes Software 2.2 .................................................................................................................. 28

4.1.1. Setting the Cedex Server to Autostart .......................................................................................................................32

4.2 Starting up the Software .................................................................................................................................................33

4.3 Updating Older Cedex HiRes Software version 2.x to Cedex HiRes Software 2.2 ..................................... 34

4.3.1. Overview ................................................................................................................................................................................34

4.3.2. Updating to Cedex HiRes Software 2.2 .....................................................................................................................34

4.3.3. Restoring a Cedex HiRes Software 2 Backup ......................................................................................................... 37

5 Starting the Cedex HiRes System after Installation ...................................................................................3 9

6 Securing Access Rights ..............................................................................................................................................40

6.1 Access Control at the Windows Operating System Level ...................................................................................40

6.2 Access Control at the Cedex HiRes System Software Level ..............................................................................40

Page 10

4

Cedex HiRes Analyzer Operator’s Guide

Table of Contents

C Operation 41

1 Overview of the Cedex Control Center ...............................................................................................................41

1.1 Menu Bar ..............................................................................................................................................................................41

1.2 System Menu .......................................................................................................................................................................41

1.3 Measurement Menu ......................................................................................................................................................... 42

1.4 Functions Menu ..................................................................................................................................................................42

1.5 Reports Menu .................................................................................................................................................................... 43

1.6 Master Data Menu ............................................................................................................................................................43

1.7 Setup Menu .........................................................................................................................................................................43

1.8 Help Menu ............................................................................................................................................................................ 44

1.9 Shortcut Area ......................................................................................................................................................................44

1.10 Tracking of Status of Events Carried out by the Analyzer ..................................................................................44

2 Preparing the Analyzer for Measurements ...................................................................................................... 45

2.1 Switching on ........................................................................................................................................................................45

2.2 Logging in at the Computer Operating System Level ..........................................................................................45

2.3 Starting the Cedex HiRes Software 2.2 ....................................................................................................................45

2.4 Performing a HW Startup and Prime ..........................................................................................................................46

2.5 Preparing the Reagent Kit ..............................................................................................................................................47

2.5.1. Installing or Changing the Reagent Kit .................................................................................................................... 47

2.5.2. Refi lling Containers Individually ..................................................................................................................................48

2.6 Checking the Analyzer .....................................................................................................................................................49

3 Carrying out a Single Measurement ...................................................................................................................50

3.1 Opening the Measurement window and specifying the Operating Mode and Sample Data ..............51

3.2 Defi ning the Measurement and Analysis (Process) Parameters .....................................................................52

3.3 Preparing the Sample and Attaching it to the Multi Sample Tray or Sample Port ....................................53

3.3.1. Starting the Measurement .............................................................................................................................................53

3.3.2. End of Measurement ........................................................................................................................................................54

3.4 Interrupting a Measurement..........................................................................................................................................55

4 Working with the Multi Sampler ............................................................................................................................56

4.1 The Multi Sampler DefaultCup ..................................................................................................................................... 57

4.2 Preparing the Measurement .......................................................................................................................................... 58

4.2.1. Using the Multi Sample Tray ..........................................................................................................................................58

4.2.2. Ejecting the Multi Sample Tray ..................................................................................................................................... 58

4.2.3. Performing a Prime ............................................................................................................................................................59

4.3 Carrying out Measurements with the Multi Sampler ...........................................................................................59

4.3.1. The Multi Run Data Entry Window ..............................................................................................................................59

4.3.2. Preparing for Multiple Measurements in the Multi Run Window ................................................................... 59

4.3.3. Activating Sample Rows and Starting the Measurement .................................................................................60

4.3.4. Adding Measurements to the List while Measurements are Running .........................................................62

4.3.5. Modifying Data Entry, Changing Samples .............................................................................................................. 63

4.3.6. Non-Linear Measurements in a Sample Series ....................................................................................................63

4.4 Interrupting a Multi Run ..................................................................................................................................................63

4.5 Disruption of Measurements ......................................................................................................................................... 63

4.6 Results ...................................................................................................................................................................................64

4.6.1. The Multi Run Result List................................................................................................................................................64

5 Switching off the Cedex HiRes Analyzer...........................................................................................................65

5.1 Carrying out an LM Shutdown and HW Shutdown ..............................................................................................65

5.2 Logging out ..........................................................................................................................................................................66

5.3 Shutting down the Control Center ..............................................................................................................................66

Page 11

5

Table of Contents

D Software 67

1 Using the Measurement Results Window ........................................................................................................67

1.1 Result Data area .................................................................................................................................................................68

1.2 Sample Parameters and Processing Parameters areas .......................................................................................69

1.3 Image Area ...........................................................................................................................................................................70

1.3.1. Viewing Individual Cell Images ..................................................................................................................................... 70

1.3.2. Viewing a Cell Image Using the Image View Window ........................................................................................71

1.3.3. Excluding Images from the Evaluation Process/Including Excluded Images .............................................72

1.3.4. Viewing the Prescan Image ...........................................................................................................................................73

2 Using the Measurement List ....................................................................................................................................74

2.1 Viewing Analysis Results ................................................................................................................................................75

2.2 Searching for Measurements ........................................................................................................................................75

3 Editing Existing Analysis Results/Data Sets ................................................................................................... 76

3.1 The Reprocess Button ...................................................................................................................................................... 76

3.2 Effective Data Sets ............................................................................................................................................................77

4 Graphical Display of the Analysis Results........................................................................................................78

4.1 Enlarging the Histograms ...............................................................................................................................................78

4.2 Aggregate Histogram ....................................................................................................................................................... 79

4.3 Cell Diameter Histogram .................................................................................................................................................81

4.4 Object Diameter Histogram ...........................................................................................................................................82

4.5 Defi ning Diameter Intervals in the Diameter Histograms...................................................................................82

4.6 Compactness Histogram .................................................................................................................................................83

4.7 Measurement Statistics Histogram .............................................................................................................................84

5 Cultivation Time Chart .................................................................................................................................................85

5.1 Creating a CTC View ......................................................................................................................................................... 85

5.1.1. The View Area .....................................................................................................................................................................86

5.1.2. The Series of Measurements Belonging to Selected View Area .....................................................................86

5.1.3. Adding Measurements to a View ................................................................................................................................87

5.1.4. Editing Measurements in a View .................................................................................................................................88

5.1.5. Viewing List of Measurements in a Series ...............................................................................................................88

5.1.6. Deleting Views and Series .............................................................................................................................................. 89

5.1.7. Exporting a View ................................................................................................................................................................89

5.2 Creating a Cultivation Time Chart ...............................................................................................................................89

5.2.1. The Data Selection Area .................................................................................................................................................90

5.2.2. Fitting to the Lowest Common Value .........................................................................................................................91

5.2.3. Measurement Series Offset ...........................................................................................................................................91

5.2.4. Variable Axis Calibration .................................................................................................................................................91

5.2.5. The Exponential Regression Button ............................................................................................................................ 92

5.2.6. Printing out a Cultivation Time Chart ......................................................................................................................... 92

6 General Functions of the System ..........................................................................................................................93

6.1 Data Management ............................................................................................................................................................93

6.1.1. Printing Reports ..................................................................................................................................................................93

6.1.2. Export to fi le ......................................................................................................................................................................... 94

6.2 Data Exchange ....................................................................................................................................................................95

6.2.1. Export ....................................................................................................................................................................................95

6.2.2. Import ..................................................................................................................................................................................... 96

6.3 Viewing and Evaluating the Audit Trail File ..............................................................................................................96

6.4 User Preferences ................................................................................................................................................................ 97

6.4.1.

Adjusting Result Display in the Measurement List and Multi Run windows .............................................. 97

6.4.2. Specifying Default Measurement Parameters ........................................................................................................ 98

6.4.3. Specifying Other Default Parameters ......................................................................................................................... 98

6.4.4. Specifying the Workarea for the Analysis Data ......................................................................................................99

6.5 Changing own Password ................................................................................................................................................99

Page 12

6

Cedex HiRes Analyzer Operator’s Guide

Table of Contents

D Software Continued

7 Administrator Functions ...........................................................................................................................................100

7.1 Administration of User Accounts ...............................................................................................................................100

7.1.1. Creating User Accounts ...............................................................................................................................................100

7.1.2. Assigning Access Rights ............................................................................................................................................ 101

7.1.3. Creating user groups ......................................................................................................................................................102

7.1.4. Editing and Deleting User Accounts ........................................................................................................................102

7.1.5. Creating and Editing User roles .................................................................................................................................103

7.2 Password Management ................................................................................................................................................104

7.2.1. Specifying Password Characteristics ....................................................................................................................... 104

7.2.2. Assigning New Passwords ...........................................................................................................................................105

7.3 Assigning Work Areas ....................................................................................................................................................105

7.4 The System Options ....................................................................................................................................................... 106

7.4.1. Automatically Start the Hardware Management ................................................................................................ 106

7.4.2. Modifying the Standard Setting for the Multi Sampler DefaultCup .............................................................107

7.4.3. Turning off Automatic Incrementation of Sample Cup Position .....................................................................107

7.4.4. Turning off the Flow Chamber Prescan .................................................................................................................. 108

7.4.5. Error Level Displayed to Users ................................................................................................................................... 109

7.4.6. Liquid Container Confi guration ................................................................................................................................. 109

7.4.7. Disabling the Reagent Control ..................................................................................................................................109

7.4.8. Default Settings ............................................................................................................................................................... 109

7.5 Adjustment of the Image Analysis using the Live Operator ..................................................................................110

7.5.1. Description of the Cell Type List and Live Operator ...........................................................................................111

7.5.2. The Cell Type List Window ............................................................................................................................................111

7.5.3. Creating a New Cell Type..............................................................................................................................................112

7.5.4. Editing an Existing Cell Type ........................................................................................................................................113

7.5.5. Viewing an Existing Cell Type ......................................................................................................................................113

7.5.6. Deleting an existing Cell Type .....................................................................................................................................114

7.5.7. Working with the Live Operator..................................................................................................................................115

7.5.8. Description of the Individual Operator Parameters ............................................................................................117

7.6 Archiving Data .................................................................................................................................................................119

7.6.1. Archive .................................................................................................................................................................................119

7.6.2. Restore .................................................................................................................................................................................120

7.6.3. Deleting Archived Data .................................................................................................................................................120

Page 13

7

E Maintenance and Care 121

1 Cleaning and Maintenance Check List ............................................................................................................121

2 Scheduling Automatic Cleaning Routines .....................................................................................................122

3

Daily and Manual Maintenance and Cleaning Routines .......................................................................... 123

3.1 Checking the Reagent Containers when Manually Refi lling .........................................................................123

3.2 Cleaning Routines Carried out by the Liquid Management ............................................................................124

3.2.1. Cleaning Options .............................................................................................................................................................124

3.2.2. The Hardware Management Window ......................................................................................................................126

3.2.3. Carrying out a Cleaning Routine ................................................................................................................................126

3.2.4. Interrupting/Terminating a Cleaning Routine ........................................................................................................126

3.3 Scanning the Chamber to Verify the Effectiveness of Cleaning Routines ................................................126

4 Automatic Adjustment and Alignment Verifi cation ..................................................................................128

5 Syringe Maintenance ................................................................................................................................................ 130

5.1 Removing the Syringe ................................................................................................................................................... 130

5.2 Assembling and Installing the Syringe ................................................................................................................... 131

5.3 Maintenance of the Syringe Guide and Spindle ..................................................................................................132

6 Maintenance of the Flow chamber, 8-Way Valve and the remaining Hardware

Components .................................................................................................................................................................133

7 Operational Data ..........................................................................................................................................................133

8 The System Suitability Test (SST) ..................................................................................................................... 134

8.1 Creating SST Checkpoints........................................................................................................................................... 134

8.1.1. Creating SST Checkpoints With and Without Measurements ....................................................................... 134

8.1.2. Running a Water Blank ............................................................................................................................................... 136

8.1.3. Setting up the SSTFailureReaction in the System Options Menu ................................................................ 136

8.2 Performing an SST ...........................................................................................................................................................137

8.2.1. Performing an SST with Measurements .................................................................................................................137

8.2.2. Performing an SST without Measurements .......................................................................................................... 138

8.3 Tracking Trends in SST Results over Time ............................................................................................................. 139

8.3.1. Tracking Trends in SST Checkpoints with Measurements .............................................................................. 139

8.3.2. Tracking SST Checkpoints without Measurements .......................................................................................... 141

8.4 Locking – Unlocking the System ................................................................................................................................142

F Troubleshooting 143

1 Diagnosis of the Cedex HiRes Analyzer ..........................................................................................................143

2 Trace and Logging ....................................................................................................................................................... 144

3 The System Audit Trail File ..................................................................................................................................... 144

G Appendix 145

1 System Options und User Preferences ............................................................................................................145

Table of Contents

Page 14

8

Cedex HiRes Analyzer Operator’s Guide

Page 15

9

Prologue

Prologue

I. Revision History

Version Revision Date

1.0 May 2011

© Copyright 2011, Roche Diagnostics GmbH, all rights reserved.

Information in this document is subject to change without notice. No part of this document may be reproduced

or transmitted in any form or by any means, electronic or mechanical, for any purpose, without the express

written permission of Roche Diagnostics GmbH.

Questions or comments regarding the contents of this Operator’s Guide can be directed to your local Roche

Diagnostics representative.

Every effort has been made to ensure that all the information contained in the Cedex HiRes System Operator’s

Guide is correct at the time of printing.

However, Roche Diagnostics GmbH reserves the right to make any changes necessary without notice as part of

ongoing product development.

II. Contact Addresses

Manufacturer Roche Diagnostics Ltd.

Forrenstrasse

CH-6343 Rotkreuz

Switzerland

Distribution Roche Diagnostics GmbH

Sandhofer Straße 116

D-68305 Mannheim

Germany

Distribution in USA Roche Diagnostics

9115 Hague Road

PO Box 50457

Indianapolis, IN 46250

USA

Revision History

Page 16

10

Cedex HiRes Analyzer Operator’s Guide

III. Declaration of Conformity

The instrument meets the requirements laid down in Council Directive 2004/108/ EC relating

to “Electromagnetic Compatibility” and Council Directive 2006/95/EC relating to “Low Voltage

Equipment”. The following standards were applied: IEC/EN 61326-1 (EMC) and IEC/EN 61010-1

(Safety).

UL 61010-1 Electrical Equipment for Measurement, Control and Laboratory Use; Part 1:

General Requirements CAN/CSA-C22.2 No. 61010-1 (Second Edition) — Safety Requirements

for Electrical Equipment

IV. Warranty

The warranty conditions are specifi ed in the sales contract. Contact your Roche Diagnostics representative for

further information.

Any unauthorized modifi cation of the Cedex HiRes Analyzer and/or the Cedex HiRes Software will result in

invalidity of the guarantee and service contract.

V. Trademarks

CEDEX and INNOVATIS are trademarks of Roche.

Other brands or product names are trademarks of their respective holders.

VI. Copyrights

Cedex HiRes Analyzer Operator’s Guide. Copyright© 2011 Roche Diagnostics GmbH, all rights reserved.

Operating instructions and manuals are protected by copyright. No part of this document may be reproduced,

edited or translated without prior written consent of Roche Diagnostics GmbH except as permitted under the

terms of the copyright.

VII. Intended Use

The Cedex HiRes Analyzer automatically determines the cell concentration and viability of cell suspensions for

the purpose of life science research only.

The Cedex HiRes Analyzer is for life science research only. Not for use in diagnostic procedures.

It was neither developed nor validated by the manufacturer for any kind of in vitro diagnostic application.

Declaration of Conformity

Page 17

11

Prologue

VIII. Software License Agreement

Read the following terms and conditions of this Software License Agreement (“Agreement”) carefully before

installing the Cedex 2 Software, hereinafter referred to as (“Software”). Proceeding with the installation of the

Software will constitute acceptance of the terms and conditions of this Agreement. By accepting the terms and

conditions of this Agreement, the end user (“Licensee”) assumes all responsibility and liability for the selection

of this Software to achieve the intended results, and for its installation and subsequent use. If Licensee is not

willing to be bound by the terms and conditions of this Agreement, the Software package must be promptly

returned to Roche (“Supplier”) with a copy of the receipt against refunding of the purchase price for this

Software.

1. Programm License Agreement

Licensee assumes all responsibility and liability for the selection of this Software to achieve the intended results,

and for its installation and subsequent use. The Software is protected by copyright.

2. Grant of Software License

Supplier is entitled to grant to Licensee subject to continuous compliance with all the provisions hereinafter, a

non exclusive, single use license to use the Software upon the terms and conditions contained in this Agreement.

Licensee may:

a. Use the Software on workstations which have to be owned, leased or otherwise controlled by Licensee,

whether in a network or other confi guration.

b. Transfer the Software by assigning the rights under this Agreement to another party, provided that the other

party agrees in writing to accept the terms and conditions of this Agreement. In addition, Licensee must

ensure that the copyright notice is maintained on the Software transferred.

Licensee may not:

a. Use the Software, in whole or in part, except as expressly provided in this Agreement.

b. Use the Software on more than one workstation at a time.

c. Copy, sell, or otherwise transfer the Software or assign its rights under this Agreement, in whole or in part,

to another party, except as expressly provided in this Agreement.

d. Rent, distribute, license or sublicense the Software.

e. Create derivative works based on Software.

f. Modify, adapt, translate, reverse engineer, decompile or disassemble the Software.

Supplier reserves all rights not expressly granted herein, including, but not limited to, the rights to market the

Software either directly or through affi liates, distributors and/or third parties.

For further information, please contact your local Roche Applied Science support organization. You will fi nd

the contact information on the following webpage:

www.roche applied science.com.

3. Limited Warranty

The Software is provided “as is” without warranty of any kind, either expressed or implied, including, but not

limited to the implied warranties of merchantability and fi tness for a particular purpose. The entire risk as to

the quality and performance of the Software is with Licensee, should the Software prove to be defective. Licensee

assumes the entire costs of all necessary servicing, repair, or correction. However, Supplier warrants that the

program media on which the Software is furnished is free from defects in materials and workmanship under

normal use for a period of ninety (90) days from the date of delivery as evidenced by a copy of your receipt.

SUPPLIER MAKES NO FURTHER WARRANTIES OR GUARANTEES NOR EXPLICIT NOR IMPLIED

Software License Agreement

Page 18

12

Cedex HiRes Analyzer Operator’s Guide

4. Disclaimer of Warranties

AS FAR AS PERMITTED UNDER THE GOVERNING LAW AS SET FORTH UNDER SECTION 11 OF THIS

AGREEMENT THE WARRANTY SET FORTH IN THE PREVIOUS PARAGRAPH, IS IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, ARISING BY LAW, FROM A COURSE OF PERFORMANCE,

A COURSE OF DEALING, TRADE USAGE, OR OTHERWISE. AS FAR AS PERMITTED UNDER THE

GOVERNING LAW AS SET FORTH UNDER SECTION 11 OF THIS AGREEMENT SUPPLIER AND ANY

ENTITY CONTROLLING, CONTROLLED BY OR UNDER COMMON CONTROL WITH SUPPLIER

(“SUPPLIER’S AFFILIATE”) SPECIFICALLY DISCLAIM, WITHOUT LIMITATION, ALL WARRANTIES

OF ANY KIND, WHETHER EXPRESS OR IMPLIED, INCLUDING, WITHOUT LIMITATION, THE

IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, AND

NON INFRINGEMENT. SUPPLIER AND SUPPLIER’S AFFILIATES MAKE NO REPRESENTATION OR

WARRANTY AS TO THE SOFTWARE OR AS TO THE RESULTS TO BE ATTAINED BY LICENSEE OR ANY

THIRD PARTY FROM THE SOFTWARE. LICENSEE ACKNOWLEDGES THAT IT HAS NOT RELIED UPON

ANY REPRESENTATIONS OR WARRANTIES MADE BY SUPPLIER OR A SUPPLIER’S AFFILIATE EXCEPT

FOR THOSE EXPRESSLY AND SPECIFICALLY SET FORTH IN THIS AGREEMENT.

5. Limitations of Remedies

Supplier’s sole liability and Licensee’s sole remedy shall be:

a. The replacement of the program media not meeting Supplier’s limited warranty and which is returned to

Supplier with a copy of Licensee’s receipt;

b. If Supplier is unable to deliver replacement of program media which is free of defects in material and

workmanship, Licensee may terminate this Agreement by returning the Software and a copy of Licensee’s

receipt to Supplier, and Licensee’s money will be refunded.

IN NO EVENT WILL SUPPLIER OR ANY OF SUPPLIER’S AFFILIATES (OR THEIR RESPECTIVE OFFICERS,

EMPLOYEES, CONSULTANTS, ATTORNEYS OR AGENTS), BE LIABLE FOR ANY SPECIAL, INDIRECT,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT LIMITED TO, LOST PROFITS,

LOST DATA OR INFORMATION, LOSS OF USE OF THE SOFTWARE, BUSINESS INTERRUPTION, LOSS

OF BUSINESS REPUTATION OR GOODWILL, OR DOWNTIME COSTS) WHICH THE LICENSEE OR

THIRD PARTIES MAY INCUR OR EXPERIENCE, DIRECTLY OR INDIRECTLY ARISING OUT OF OR

RELATING TO THE SOFTWARE, THIS AGREEMENT, OR THE TERMINATION OF THIS AGREEMENT,

EVEN IF SUPPLIER OR A SUPPLIER’S AFFILIATE HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH

DAMAGES AND NOTWITHSTANDING ANY FAILURE OF ESSENTIAL PURPOSE. THE AGGREGATE

LIABILITY, ON A COMBINED BASIS, OF SUPPLIER AND SUPPLIER’S AFFILIATES (AND THEIR

RESPECTIVE OFFICERS, EMPLOYEES CONSULTANTS, ATTORNEYS, AND AGENTS) FOR DAMAGES

FOR ANY CAUSE WHATSOEVER DIRECTLY OR INDIRECTLY RELATING TO OR ARISING OUT OF

THIS AGREEMENT OR THE SOFTWARE, AND REGARDLESS OF THE FORM OF ACTION, SHALL BE

LIMITED TO, AT SUPPLIER’S OPTION, REPLACEMENT OF THE SOFTWARE OR REFUND OF THE

FEES RECEIVED BY SUPPLIER OR A SUPPLIER’S AFFILIATE FROM LICENSEE WITH RESPECT TO THE

SOFTWARE.

6. General Information

Licensee may not sublicense, assign or transfer the license or the Software, in whole or in part, except as expressly

provided in this Agreement. Any attempt otherwise to sublicense, assign or transfer any of the rights, duties or

obligations hereunder is void.

Software License Agreement

Page 19

13

Prologue

7. Intellectual Property Rights

Licensee shall only hold those rights to the Software that are expressly described in Section 2 of this Agreement.

Any other rights with regard to the Software, including without limitation, ownership rights and patent,

copyright, trademark, trade secret and other intellectual property rights, shall remain the sole property

of Supplier. Licensee will not remove from the Software any references to copyrights, trademarks or other

ownership rights, or cover up or alter any such references. Licensee will take all reasonable steps to prevent any

unauthorized use, reproduction, sale, or publication of the Software or the unauthorized provision of access

thereto. Licensee will indemnify and hold harmless Supplier from any losses, damages, claims and expenses

(including, without limitation, reasonable legal expenses) relating to any infringement of the rights of Supplier

caused by Licensee, Licensee’s breach of this Agreement or Licensee’s use of the Software in a manner not

authorized under this Agreement.

8. Duration and Termination

The Agreement is effective until terminated. Licensee may terminate this Agreement at any time by destroying the

Software and documentation relating to the Software in any form. The Agreement will terminate automatically

and without notice from Supplier, if Licensee fails to comply with any term or condition of this Agreement.

Licensee agrees to destroy the Software upon termination of this Agreement by Supplier. On any termination of

this Agreement, all rights of use of the Software held by Licensee shall expire.

9. Import, Export and Use of the Software

Licensee shall be exclusively responsible for ensuring compliance with the relevant legislation relating to its

rights to import, export or use the Software.

10. Miscellaneous

Should any part of this Agreement be declared void or unenforceable by a court of competent jurisdiction, the

remaining terms shall remain in full force and effect.

Failure of Supplier to enforce any of its rights in this Agreement shall not be considered a waiver of its rights,

including but not limited to its rights to respond to subsequent breaches.

By opening and using this Software Licensee acknowledges that he has read this Agreement, understands it,

and agrees to be bound by its terms and conditions. Licensee further agrees that this Agreement is the complete

and exclusive statement of the Agreement between Licensee and Supplier and supersedes any proposal or prior

agreement, oral or written, any other communications between Licensee and Supplier relating to the subject

matter of this Agreement.

The headings of the several Sections of this Agreement are intended for convenience of reference only and are

not intended to be a part of or to affect the meaning or interpretation of this Agreement.

11. Governing Law and Place of Jurisdiction

This Agreement shall be governed by and construed in accordance with the laws of Germany, without giving

effect to any choice of law principles thereof. The parties agree that the United Nations Convention on Contracts

for the International Sale of Goods (1980) is specifi cally excluded from application to this Agreement.

The parties agree that courts of Mannheim, Germany, shall have exclusive jurisdiction over any dispute arising

out of or in connection with this Agreement.

Software License Agreement

Page 20

14

Cedex HiRes Analyzer Operator’s Guide

IX. Preamble

Before setting up operation of the Cedex HiRes Analyzer, it is important to read this Operator’s Guide thoroughly

and completely. Non-observance of the instructions contained herein or performing an operation not stated in

this Operator’s Guide could involve safety hazards.

X. Contents of this Operator’s Guide

This Operator’s Guide describes the operation of the Cedex HiRes Analyzer. It contains the following chapters:

Chapter A Overview presents the specifi cations of the Cedex HiRes Analyzer.

Chapter B System Description contains the installation requirements of the Cedex HiRes Analyzer and a

description of the system’s components. This chapter also gives a short overview of the basic functions and

operation of the system.

Chapter C Operation describes the operating procedures for the Cedex HiRes Analyzer, including the correct

placement of the reagents and disposables and instructions for carrying out single and multiple measurements

of cell samples.

Chapter D Software provides a detailed description of the Cedex HiRes Analyzer software functions and

features.

Chapter E Maintenance and Care describes the maintenance and care procedures that are required for the

Cedex HiRes Analyzer.

Chapter F Troubleshooting contains troubleshooting information for the Cedex HiRes Analyzer.

Chapter G Appendix contains a detailed list of System Options and User Preferences, and an index.

XI. Conventions used in this Guide

Text Conventions

To present information consistently and memorably the following text conventions are used in this Operator’s

Guide:

Numbered list:

Steps in a procedure that must be performed in the order listed.

Italic type:

Used for operating instructions for the Cedex HiRes Software. In addition,

important notes and information notes are shown in italic type.

Blue italic type:

Refers to a different section in this Operator’s Guide, which should be consulted.

Preamble

Page 21

15

Prologue

Symbols

In this Operator’s Guide the following symbols are used as visual signals:

Symbol Heading Description

WARNING This symbol is used to indicate that non-compliance with instructions or

procedures could lead to physical injury or even death or could cause

damage to the system.

IMPORTANT NOTE Information critical to the success of the procedure or use of the product.

INFORMATION NOTE Additional information about the current topic or procedure.

Procedure continued on next page.

■

End of procedure.

The following symbols appear on the analyzer

Symbol Heading Description

CE MARK The CE mark on the analyzer type plate indicates conformity with

requirements of the directives relevant for this analyzer.

XII. FCC Notifi cation

Changes or modifi cations to this unit not expressly approved by the party responsible for compliance may

void the user‘s authority to operate the equipment.

Note: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates, uses

and can radiate frequency energy and, if not installed and used in accordance with the instruction manual, may

cause harmful interference to radio communications. Operating this equipment in a residential area is likely to

cause harmful interference, in which case the user will be required to correct the interference at his own expense.

FCC Notifi cation

Page 22

16

Cedex HiRes Analyzer Operator’s Guide

XIII. Warnings and Precautions

Moving parts may cause hand injuries. Never use the Cedex HiRes Analyzer without the protective cover

on the Multi Sampler and Syringe Module.

It is important that the following safety instructions and guidelines be observed in order to ensure safe and

reliable operation of Cedex HiRes Analyzer:

Place the device on a dry and sturdy surface, free of vibrations.

Avoid transporting the device as much as possible once it has been assembled.

Prevent the device from getting wet.

Protect the device from dust and smoke.

Do not expose the device to direct sunlight.

Ensure there is suffi cient air circulation around the Cedex HiRes Analyzer during operation (particularly

around the computer and monitor).

Operate within a constant temperature range of 50°F – 100°F (10°C – 40°C).

For best performance it is recommended to keep the analyzer permanently on and only shut down the

software application on a regular basis.

The Cedex HiRes Analyzer should only be used with the supplied or specifi ed devices (Cedex HiRes

Analyzer, Cedex HiRes Software, monitor, computer, Multi Sampler, Reagent Tray).

Do not install any additional software on the corresponding computer.

Only trained personnel in a controlled laboratory environment should operate the Cedex HiRes Analyzer.

All services and repairs should be performed only by authorized service technicians.

Always ensure that there are suffi cient reagents in the reagent containers.

Clean the containers before reusing them.

Always observe the safety regulations when handling Trypan Blue, Detergent, Cleaning Solution or acids

and bases.

Waste contaminated with tissue or cells, e.g. Cedex Sample Cups, pipette tips, etc., must be disposed of

according to the recommended rules for handling biohazard materials.

Any leaks in the Liquid Management system must be repaired immediately. Contact your distributor or

authorized service technician.

Always ensure that there is a Cedex Sample Cup attached to the single sample port or placed in the Default-

Cup position on the Multi Sample tray.

Only use Cedex Detergent for the cleaning process in the Liquid Management system.

Only use Cedex Sample Cups from Roche Diagnostics GmbH for the conveyance of cell samples to the

sample port.

Other sample cups can cause irreparable damage to the Cedex HiRes Analyzer!

Always wear protective clothing, particularly gloves, when handling samples.

To prevent damage to the fl ow chamber, no particles larger than 80 µm should enter the measurement

system.

Particles ( especially microcarriers) larger than 90 µm should not gain access into the analyzer because they

cause irreparable damage and render the device non-functional.

Dirt or dust particles should not gain access into the device.

Ensure that all equipment required for sample preparation, e.g. Cedex Sample Cups, pipette tips, etc., are

stored in a dust-free environment since coarse dust particles can impair the fl ow chamber’s functionality.

Check that the Cedex Sample Cup is free of contamination before use. Only clean Cedex Sample Cups can

guarantee optimal functioning of the Cedex HiRes Analyzer.

Warnings and Precautions

Page 23

17

Prologue

Ensure that the Trypan Blue solution is free of contamination, otherwise fi lter prior to use. Roche Diagnostics

GmbH recommends the use of the Cedex HiRes Reagent Kit.

Secure your measurement data.

If the system has been upgraded from some previous version to Software version 2.2, it is possible that some

default settings in the System Options may have slightly different values than those described in this manual.

The settings described in this manual apply to systems on which Software version 2.2 has been installed as

the original software.

The software and hardware of your Cedex HiRes System can differ from the information described here, but

this should not make a difference to the operational functions in general.

The manufacturer is not responsible or liable for any damages resulting from improper use or failure to

comply with the regulations in the Operating Instructions.

Electrical Safety

The Cedex HiRes Analyzer is designed in accordance with Protection Class I

(IEC). The chassis/

housing of the instrument is grounded to protection earth

(PE) by means of a cord. For protection

against electrical shock hazards, the instrument must be directly connected to an approved

power source

such as a three-wire grounded receptacle for the 110 V or 230 V line. Do not use

an ungrounded receptacle; have a qualifi ed electrician replace the ungrounded receptacle with

a properly (PE) grounded receptacle in accordance with the local electrical code. Do not use an

extension. Any break in the electrical ground path, whether inside or outside the instrument,

could be hazardous.

Under no circumstances should the user attempt to modify or deliberately

defeat the safety

features of this instrument. If the power cord becomes

cracked, frayed, broken, or otherwise

damaged, replace it immediately with the equivalent part from Roche Diagnostics.

XIV. Disposal of the Analyzer

Disposal Recommendations

All electrical and electronic products should be disposed of separately from the municipal waste system. Proper

disposal of your old appliance prevents potential negative consequences for the environment and human health.

The analyzer must be treated as biologically contaminated hazardous

waste.

Decontamination (i.e.,

a combination of processes, including cleaning, disinfection

and/or sterilization) is required before

reuse, recycling or disposal.

Dispose of the analyzeraccording to local and/or laboratory regulations.

For more information contact your local Roche Support personnel.

Components of your control unit such as the computer, monitor, keyboard, etc. which are marked

with the crossed-out wheeled bin symbol are covered by the European Directive 2002/96/EC on

waste electrical and electronic equipment (WEEE) of the European Parliament and the Council of

January 27, 2003.

These items must be disposed of via designated collection facilities appointed by government or

local authorities.

For more information about disposal of your old product, please contact your city offi ce, waste

disposal service or local Roche Support personnel.

Disposal Recommendations

It is left to the responsible laboratory organization to determine whether control unit components are

contaminated or not. If contaminated, treat in the same way as the analyzer.

Disposal of the Analyzer

Page 24

18

Cedex HiRes Analyzer Operator’s Guide

Page 25

19

Overview

A

A

A Overview

The Cedex HiRes Analyzer automatically determines the cell concentration and viability of cell suspensions.

The analysis is based on the Trypan Blue Exclusion Method whereby cell suspensions are stained and analyzed.

The data obtained allows for the evaluation of the overall state of the cell culture, including the specifi c growth

rate and doubling time of a cell population, as well as the documentation of the cultivation process.

The evaluation of the samples is based on automatically obtained digital images that are analyzed using analysis

software on a separate computer (Cedex HiRes Control Unit). All the necessary steps – from the staining of

the samples to the recording and evaluation of the image data – are automatically performed by the analyzer.

Recognition and differentiation of cells as either viable or dead is done under standardized conditions, which

provides very precise and objective results.

A variety of parameters, including Viable Concentration, Total Concentration, Viability, Total Object Count,

Average Compactness and Average Diameter are analyzed using result data from single images, as well as from

all of the selected images of a sample. Standard deviation (Std. Dev.) of the number of cells from image to image is also calculated. In addition, the Aggregate Rate, which shows the percentage of the total number of cells

that appear in aggregates (clusters), is determined for both single images and all of the images. The use of a Live

Operator makes it possible to directly observe the effects on the analysis of a sample when the image analysis

software ( Operator) is adjusted.

Graphical representations of the measurement results can be viewed in the Measurement Statistics Histogram,

Diameter Histogram, Compactness Histogram, Aggregate Histogram and Cultivation Time Chart. In the

Measurement Statistics histogram, individual images can be compared to give a better overview of the distribution of the cells in the images. The Cell Diameter Histogram shows the diameter distribution of living cells.

The Object Diameter Histogram shows the diameter distribution of all objects detected such as cells, debris,

air bubbles and viable and dead cell aggregates. The deviation of the shape of living cells from that of an ideal

sphere is represented in the Compactness Histogram. The Aggregate Histogram provides an overview of the

amount and size of aggregation found in the cell culture.

The Cultivation Time Chart displays growth curves and cultivation parameters in a time- dependent manner.

The results of the Cultivation Time Chart can be separately printed out. For further processing of the results in

other programs, data export in formats such as Excel-compatible formats and CSV (Comma Separated Values,

generally applicable) is possible. The Cultivation Time Chart includes calculations for the doubling time [T]

and specifi c growth-rate [µ].

The Cedex HiRes Software 2.2 can be operated on Windows® XP Professional. Secure data handling, as well as a

carefully designed user management system, guarantee compatibility with 21 CFR, Part 11. Access security for

the Cedex HiRes System has been stepped up. Access is only allowed for authorized persons. The workstation

can be automatically blocked after a certain number of consecutive entries of a false password via the Systems

Options. A warning message will appear before the last allowed attempt.

Page 26

20

Cedex HiRes Analyzer Operator’s Guide

A

A

1 Description of the Cedex HiRes System

The Cedex HiRes System consists of two functional units, the Analyzer (see Figure 1) and the Control Unit

(computer equipped with Cedex HiRes Software 2.2).

Preparation and processing of the samples takes place in the analyzer. The analysis software is installed on a

computer and controls the analyzer, as well as the analysis and evaluation of the images obtained.

Multi Sampler tray with

Cedex Sample Cups

Syringe module with 8-way valve

Tray with the Cedex Reagent Kit

ON/OFF Switch

Figure 1: The Cedex HiRes Analyzer

The analyzer consists of two main components, the hardware for image capturing (scanner) and the Liquid

Management system.

The fl ow chamber is specially developed to allow for the analysis of a defi ned volume of cell suspension. The

Liquid Management system is responsible for staining the sample as well as for fi lling and cleaning the fl ow

chamber and liquid feed system.

The volumes of sample and dye, as well as specifi c cleaning solutions required for each cleaning routine, are

precisely controlled via the syringe module with the 8-way distribution valve. The individual components of the

Liquid Management system are easily accessible to allow for trouble-free maintenance and control.

Description of the Cedex HiRes System

Page 27

21

Overview

A

A

2 The Measurement Procedure

The determination of the number of viable cells (cells/ml) and viability of cell suspensions (the percentage

of viable cells from the total cell sample) is a fully automated, standardized procedure based on the manual

Trypan Blue Exclusion Method. A defi ned volume of Trypan Blue is added by the syringe to the Cedex Sample

Cup containing the cell suspension. The cell suspension and dye are optimally mixed between the syringe and

Cedex Sample Cup by controlled pump actions and then incubated for exactly the same amount of time for

each measurement. This minimizes effects on the viability measurements that might be caused by the toxicity

of the Trypan Blue.

After the incubation period, the stained cell suspension in the syringe is then transported in one portion via

the capillary tubes and the 8-way valve into the precision fl ow chamber, an image of which is scanned with the

scanner. The scanned image of the fl ow chamber is then cut up into smaller images for evaluation.

Once the measurement procedure is completed, a cleaning routine is automatically per formed by the Liquid

Management system. It is only possible to begin a new measurement after the cleaning routine has fi nished.

The Trypan Blue Exclusion Method

The Trypan Blue Exclusion Method is based on the principle that viable cells will not take up the dye, while

dead or dying cells have a compromised membrane that allows for the up take of the dye. Thus, dead cells will

appear darkly stained.

Trypan Blue has a greater affi nity for serum proteins than cellular proteins. If the image has a dark

background due to high quantities of stained serum proteins, centrifuge the cell sample and resuspended it in

a protein-free medium or physiological saline solution prior to counting.

The Measurement Procedure

Page 28

22

Cedex HiRes Analyzer Operator’s Guide

A

A

3 Data Analysis

The analysis software and its graphical user interface ( GUI), known as the Cedex Control Center, enables

the user to work with Cedex HiRes Analyzer. The image analysis software (Operator) recognizes structures

and identifi es particles, thus differentiating cells from cell debris and dirt particles. Live and dead cells are

differentiated according to their degree of Trypan Blue staining.

The image processing is integrated in the Cedex Control Center in such a way that the user or Administrator

can check on its function in the system. The analysis process cannot be altered during data recording in order

to allow for consistent and objective measurement results.

Data Analysis

Page 29

23

Overview

A

A

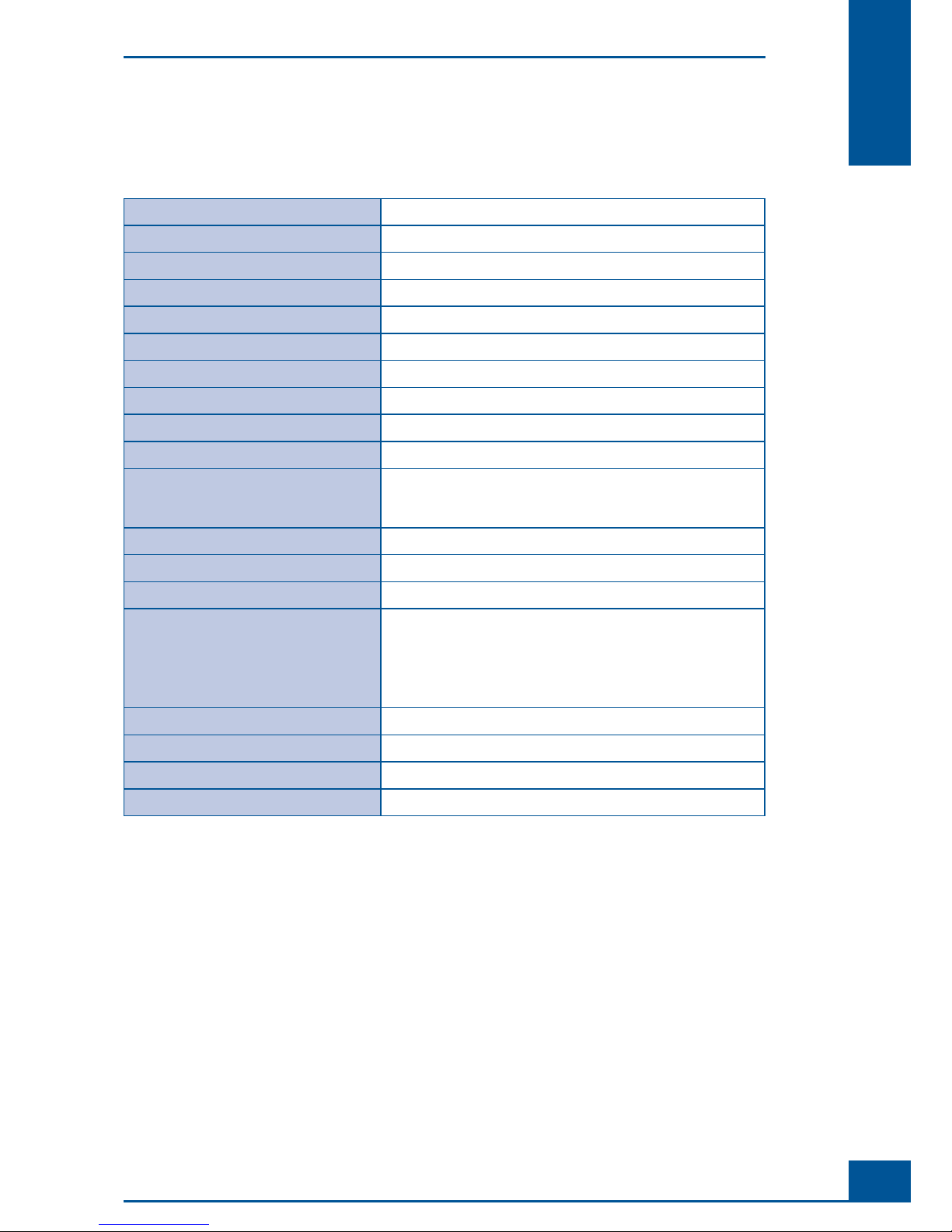

4 Technical Specifi cations of the Analyzer

Cedex HiRes Analyzer

Method of measurement

Digital image and pattern recognition

Viable/dead cell differentiation

Trypan Blue Exclusion Method

Detectable cell concentration range

5 × 10

4

– 1 × 107 cells per ml

Detectable cell diameter range

2 µm – 40 µm

Detectable object diameter range

1 µm – 90 µm

Required sample volume

300 µl

Average measurement period

< 4.0 min

Geometric resolution

0.8 µm/Pixel

Chamber height

100 µm

Material and diameter of the capillaries

Te fl on, 765 µm

Operating temperature

(Optimal image quality is achieved

between 20°C and 30°C)

+10 to +40°C

Maximum temperature change

5°C per hour

Maximum humidity deviation

5% per hour

Operating Humidity

20% – 80% relative humidity (non-condensing)

Dimensions

Height: 470 mm

Width: 405 mm

Depth: 505 mm

Weight with Multi Sampler: 28.9 kg

Weight without Multi Sampler: 26.9 kg

Energy requirements

100 – 250 VAC, 50 – 60 Hz

Energy consumption

24 VDC 2.0 A

Pollution Degree

2 (according to IEC 61010-1)

Installation Category

II (according to IEC 61010-1)

Technical Specifi cations of the Analyzer

Page 30

24

Cedex HiRes Analyzer Operator’s Guide

A

A

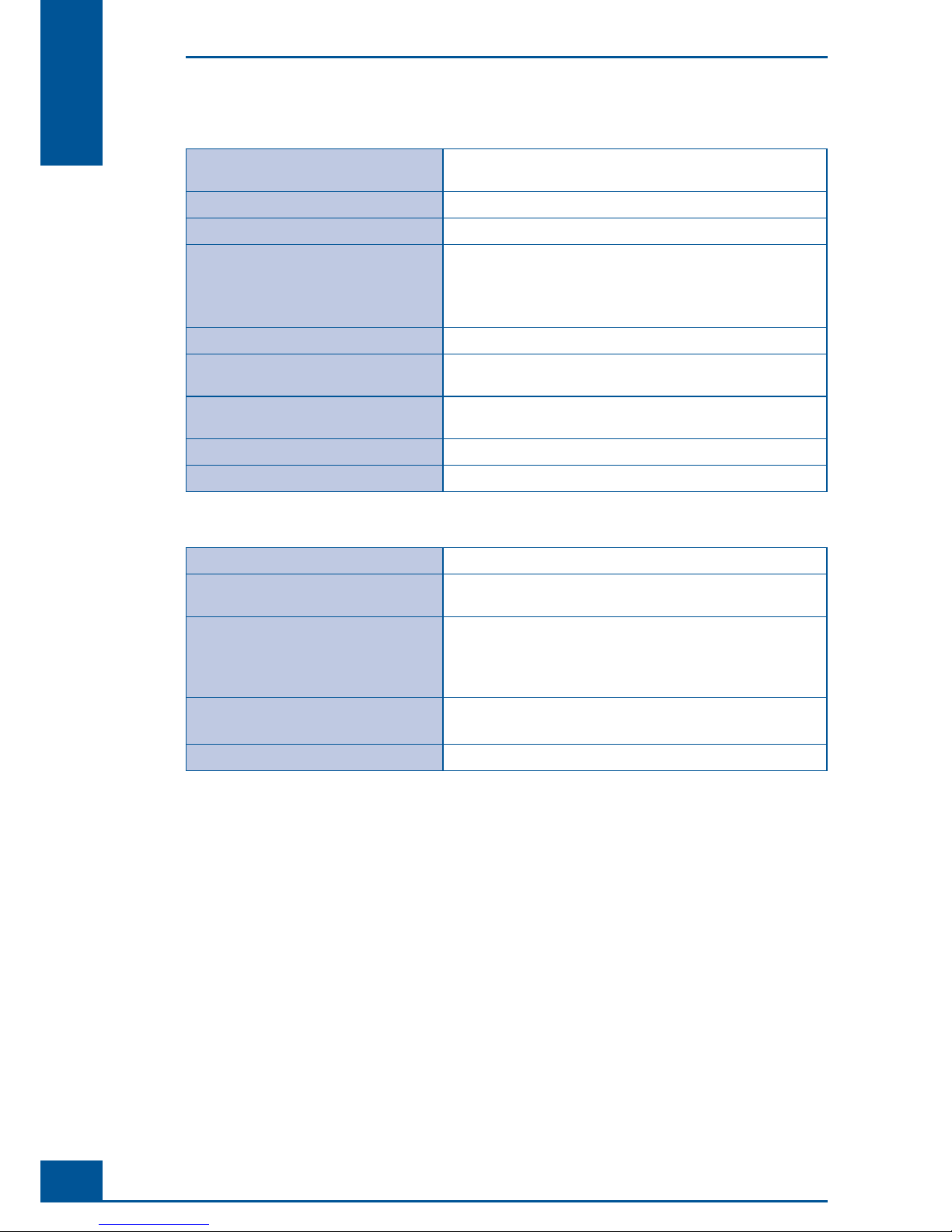

Hardware Requirements for the Cedex HiRes Control Unit

Computer x86-Architecture, Intel Pentium IV

minimum 2 GHz required, 3 GHz recommended

Operating system Windows® XP Professional

RAM Minimum 1 GB RAM

Hard-disk storage 100 MB free hard-disk storage for installation of application.

Minimum 20 GB free hard-disk storage for data storage of

approx. 1000 measurements

Recommended 80 GB

USB 2 free ports

Firewire 1 free port

(400 Mbps, with 4 or 6 contacts)

CD/DVD burner Minimum CD burner required, DVD burner recommended if

computer will not be connected to a server

Graphic card Resolution: 1024 × 768 Pixel, 24-bit color

Monitor (color monitor or -TFT) 1024 × 768 Pixel, 24-bit color

Multi Sampler

Number of samples 1 – 20

Average measurement period for

20 samples < 90 min

Dimensions Height: 170 mm

Width: 190 mm

Depth: 260 mm

completely integrated into the Cedex HiRes Analyzer

Energy requirements 24 VDC, 2,0 A

derived from internal supply

Energy consumption max. 10 W

Technical Specifi cations of the Analyzer

Page 31

25

System Description

B

B

B System Description

1 Installing the Cedex HiRes System

The Cedex HiRes System comprises the Cell Analyzer and the Control Unit (PC equipped with the Cedex

HiRes Software 2.2). The Cell Analyzer and Control Unit are delivered and assembled by a service technician

authorized by Roche Diagnostics GmbH. The service technician assembles the Cell Analyzer. He/she controls

the installation, activates the security settings, runs the focus adjustments and ensures that the Cedex HiRes

System is operational. Finally, he/she will create a report on the installation and current status of the device.

We recommend choosing your local IT specialist as the system administrator for the general administration of

the Windows operations. This person controls the confi gurations that regulate system access at the level of the

operating system.

Installation of the Cedex HiRes System is done in the following steps:

The system administrator should set up net access and/or printer installation, if desired, before the service

technician assembles the Cedex HiRes System.

The Cedex HiRes System is assembled by a service technician authorized by Roche Diagnostics GmbH.

The service technician installs the analyzer and checks the security settings in the software.

The service technician will check the software information, perform a focus adjustment and ensure that the

Cedex HiRes System is ready to use. Finally, he/she will create a current status report of the device.

The system administrator is responsible for setting up the user accounts for the operating system. The

system administrator is also responsible for ensuring data safety and security of the system.

The Administrator for the Cedex HiRes System then sets up Cedex HiRes System user accounts and assigns

them the required rights (see “Administration of User Accounts”).

Please be aware that the correct operation of the analyzer and software can only be guaranteed if no other

software has been loaded on to the computer.

The software and hardware of your Cedex HiRes Analyzer may differ from the information described here,

but this should not make a difference to the operational functions in general.

Installing the Cedex HiRes System

Page 32

26

Cedex HiRes Analyzer Operator’s Guide

B

B

2 Choosing a Suitable Location

The Cedex HiRes Analyzer is highly sensitive and consists of top-quality electronic and optical components.

To guarantee optimal and reliable performance of the Cedex HiRes Analyzer, select the appropriate location in

accordance with the safety regulations described in the Prologue.

Avoid further transportation of Cedex HiRes Analyzer after the professional installation.

The transportation locks for the scanner must be attached to the inside of the casing before the Cedex

HiRes Analyzer is transported once again. Please contact a Roche Diagnostics GmbH authorized service

technician in such a case. Vibrations or shaking must also be avoided when transporting the analyzer over

short distances and when operating the system. Focus adjustment must be done after transportation (see

“Automatic Adjustment and Alignment Verifi cation”).

Injury from heavy loads

The Cedex HiRes Analyzer weight is 29 kg. (63.8 lbs). No attempt should be made by the user to remove or

set up the instrument alone. You may injury your hands, fi ngers, or back when putting the analyzer in place.

2.1 Connecting or disconnecting the device

First connect the device using the power cord to the external power supply. On the power supply is a power

switch. When turned to ON, it is illuminated indicating the power supply is alive. A blue power switch is located

on the front panel of the Cedex HiRes System. When the switch is turned to ON it illuminates, indicating that

the device is alive. In case of problems, turned the device switch to OFF and then switch the power supply to

OFF.

In case of emergency, remove the power line from the Cedex HiRes System immediately.

ON/OFF Switch

Figure 2: The ON/OFF switch for the Cedex HiRes Analyzer

Choosing a Suitable Location

Connecting or disconnecting the device

Page 33

27