Page 1

Accu-Chek® Inform II

BLOOD GLUCOSE MONITORING SYSTEM

Operator’s Manual

Page 2

Revision History

Manual version Revision date Changes

Version 1.0 2008-01 New document

Version 2.0 2009-08 Update, new SW version 02.00

Version 3.0 2010-09 Update, new SW version 03.00

Version 4.0 2012-11 Update, new SW version 03.04 (OTS, OTE), revision

Cleaning/Disinfection section; misc. editorial revisions

Version 5.0 2013-09 Transition to new meter hardware: 2D barcode scan-

ner, modifications to wireless LAN option (separate

insertable RF card replaced by integrated WLAN component); new battery pack. Update to SW 04.00; misc.

editorial revisions.

2

Page 3

A

A

CCU-C

HEK

CCU-

HEK

Operator’s Manual

®

Inform II System

Version 5.0

0 4807839001 (05) 2013-09 EN

Page 4

© 2008-2013, Roche Diagnostics. All rights reserved.

The contents of this document, including all graphics, are the property of Roche Diagnostics. No part of this

document may be reproduced or transmitted in any form or by any means, electronic or mechanical, for any

purpose, without the express written permission of Roche Diagnostics. Roche Diagnostics has made every

reasonable effort to ensure that all the information contained in this manual is correct at the time of printing.

However, Roche Diagnostics reserves the right to make any changes necessary without notice as part of

ongoing product development.

Please send questions or comments about this manual to your local Roche representative.

ACCU-CHEK, ACCU-CHEK INFORM, ACCU-CHEK PERFORMA and COBAS are trademarks of Roche.

All other trademarks are the property of their respective owners.

The Wi-Fi CERTIFIED Logo is a certification mark of the Wi-Fi Alliance.

4

Page 5

On the packaging, on the identification plate of the meter, the battery pack, the base unit, or the code key

reader you may encounter the following symbols, shown here with their meaning:

Caution, consult accompanying documents. Refer to safety-related notes in the instructions

for use accompanying this product.

Temperature limitation (Store at)

Manufacturer

Catalog number

IVD

7.5V 1.7A

On meters with WLAN capability:

For other WLAN certifications, see label on bottom of battery compartment and list included in meter kit.

In vitro diagnostic medical device

This product fulfills the requirements of the European Directives 98/79/EC on in vitro

diagnostic medical devices and 1999/5/EC on radio and telecommunications terminal

equipment (R&TTE).

The system fulfills the Canadian and U.S. safety requirements (UL LISTED, in accordance

with UL 61010-1 and CAN/CSA-C22.2 No. 61010-1).

Power supply connection

This device complies with Part 15 of the FCC Rules and with RSS-210 of Industry Canada.

The compliance mark indicates that the product complies with the applicable standard and

establishes a traceable link between the equipment and the manufacturer, importer or their

agent responsible for compliance and for placing it on the Australian and New Zealand

market.

5

Page 6

This page intentionally left blank.

6

Page 7

1 Introduction 13

1.1 Before you start......................................................................................................................................... 13

Intended use ...................................................................................................................................... 13

Important information regarding use ....................................................................................... 13

If you need help................................................................................................................................ 14

Note on the use of “base unit” in this manual...................................................................... 14

Note on illustrations in this manual .......................................................................................... 14

What can the system do for you? .............................................................................................. 15

1.2 Important safety instructions and additional information......................................................... 16

Important information regarding safety................................................................................... 17

Disposal of the system ................................................................................................................... 18

Product safety.................................................................................................................................... 19

General care....................................................................................................................................... 19

Accessory box ................................................................................................................................... 19

Meter .................................................................................................................................................... 19

Automatic power-off....................................................................................................................... 19

Battery Pack ....................................................................................................................................... 20

Touchscreen....................................................................................................................................... 21

Electrostatic discharge (ESD)...................................................................................................... 21

Local Area Network: protection from unauthorized access ............................................ 22

Wired network connection ........................................................................................................... 22

Wireless connectivity ...................................................................................................................... 23

Radiofrequency radiation exposure information.................................................................. 24

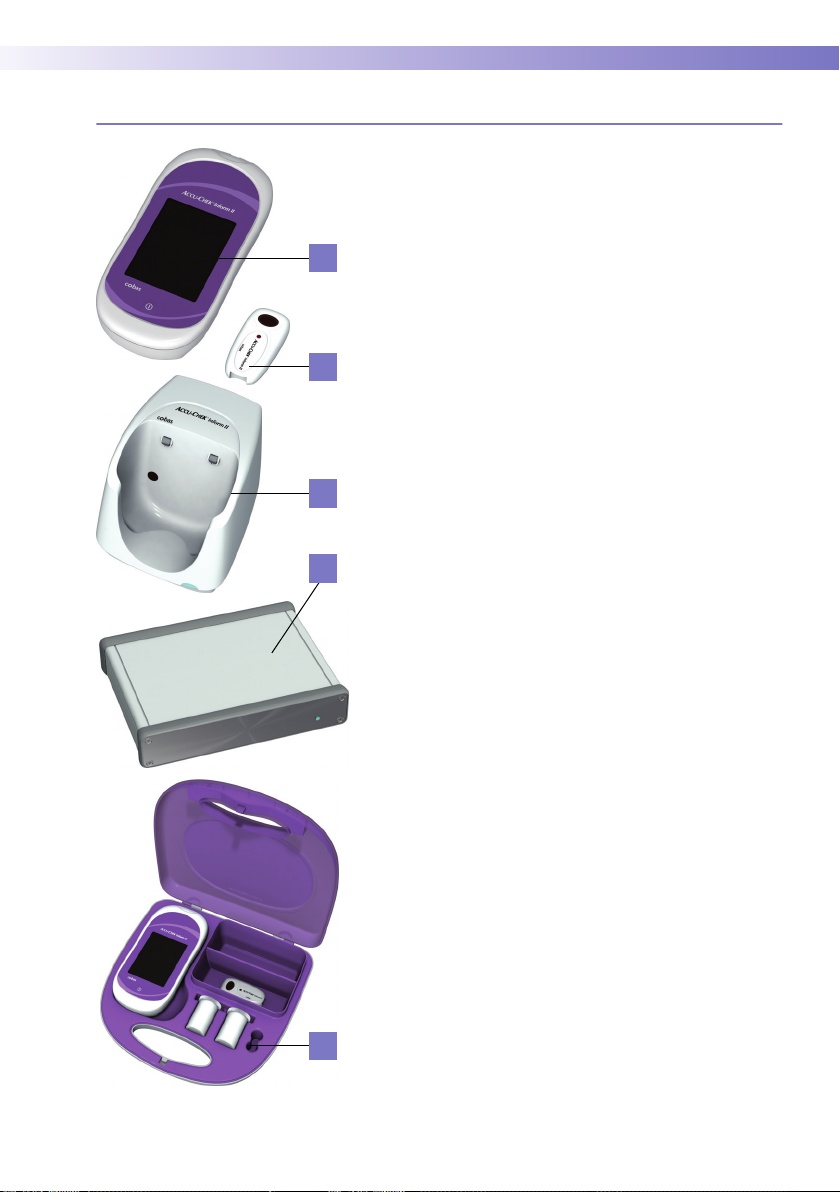

1.3 System components................................................................................................................................ 27

1.4 Overview of the meter ............................................................................................................................ 28

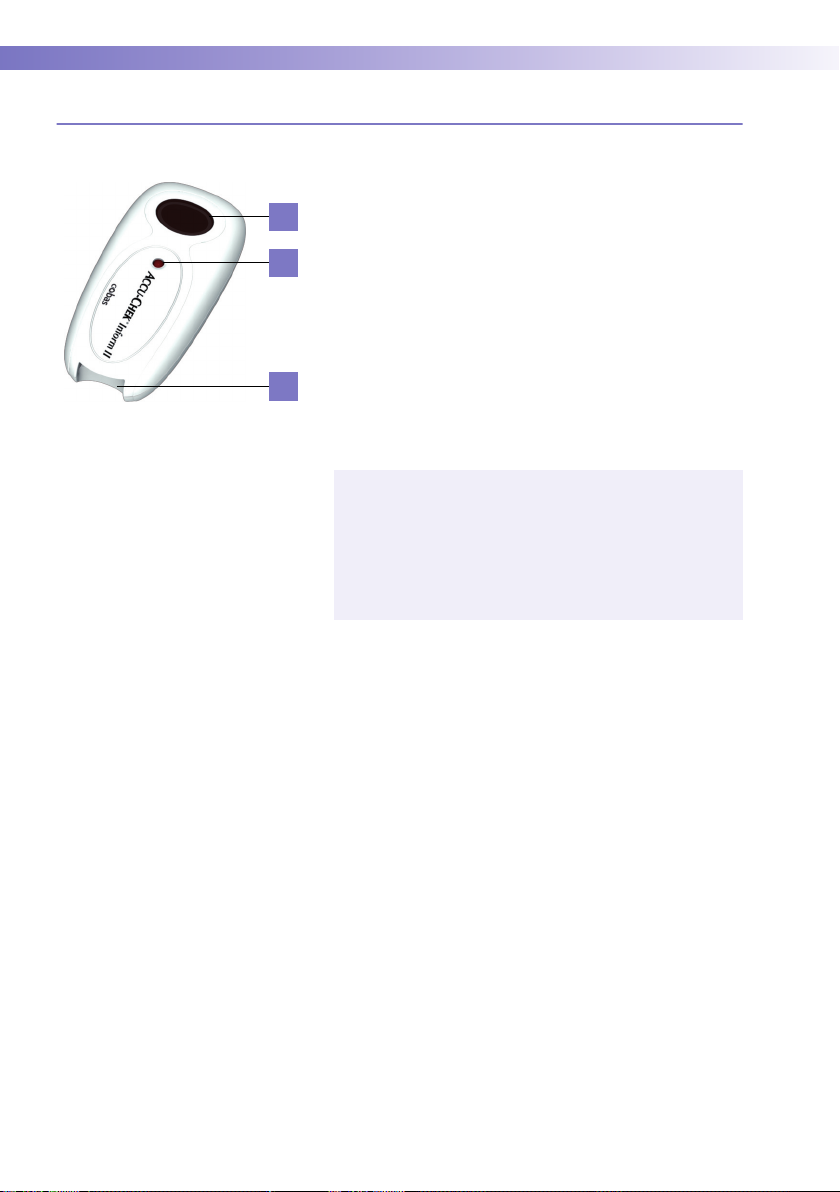

1.5 Overview of the code key reader ....................................................................................................... 30

1.6 Overview of the base unit ..................................................................................................................... 31

1.7 Overview of the Accu-Chek Inform II Base Unit Hub................................................................. 32

1.8 Overview of the accessory box ........................................................................................................... 33

1.9 Reagents and consumables................................................................................................................. 33

1.10 Instructions for initial setup.................................................................................................................. 34

2 Powering Up and Entering an Operator ID 35

2.1 Powering up the meter .......................................................................................................................... 35

Adjusting the display ...................................................................................................................... 36

Enabling/disabling wireless connectivity ................................................................................ 36

Closing startup.................................................................................................................................. 37

2.2 Entering the operator ID........................................................................................................................ 38

Entering an operator ID with barcode scanner .................................................................... 39

Entering the operator ID manually ............................................................................................ 40

Entering a password ....................................................................................................................... 40

7

Page 8

3 Patient Glucose Testing 41

3.1 Information regarding blood glucose testing ................................................................................ 41

Preparing to test ............................................................................................................................... 41

3.2 Performing a patient glucose test...................................................................................................... 42

Overview of test procedure .......................................................................................................... 42

Entering or selecting the patient ID .......................................................................................... 43

Entering the patient ID manually................................................................................................ 45

Selecting the patient ID from a list............................................................................................ 45

Entering a patient ID with barcode scanner .......................................................................... 46

Confirming or selecting the test strip lot................................................................................. 47

Inserting test strips .......................................................................................................................... 48

Obtaining a blood sample............................................................................................................. 49

Applying a blood sample............................................................................................................... 50

Results screen ................................................................................................................................... 51

Adding comments............................................................................................................................ 54

4 Glucose Control Testing 57

4.1 Information regarding glucose control tests.................................................................................. 57

Glucose control testing intervals................................................................................................ 58

Information stored during glucose control testing.............................................................. 59

Control solutions............................................................................................................................... 60

Preparing to run a glucose control test ................................................................................... 60

4.2 Performing glucose control tests ....................................................................................................... 61

Overview of test procedure .......................................................................................................... 61

Starting a glucose control test .................................................................................................... 62

Confirming or selecting the lot number for control solutions ......................................... 63

Confirming or selecting the test strip lot................................................................................. 64

Inserting test strips .......................................................................................................................... 65

Applying the control solution....................................................................................................... 66

Results screen ................................................................................................................................... 67

Performing a STAT test .................................................................................................................. 68

5 Review Results 69

5.1 Displaying test results from the memory ........................................................................................ 69

Information stored in data records for test results.............................................................. 69

List of results stored in the memory.......................................................................................... 70

6 Storing Test Strip, Control Solution, and Linearity Solution

Information in the Meter 73

6.1 Storing information about test strips ................................................................................................ 73

Transferring code key information to the meter................................................................... 74

Editing test strip data...................................................................................................................... 77

6.2 Storing control solution information ................................................................................................. 80

Entering the lot number of the control solution ................................................................... 80

Selecting a stored lot number as the current lot number................................................. 83

6.3 Storing linearity test information ........................................................................................................ 85

Entering the lot number of the linearity test .......................................................................... 85

Selecting a stored lot number as the current lot number................................................. 87

8

Page 9

7 Linearity Testing 89

7.1 Information regarding linearity tests................................................................................................. 89

Linearity testing intervals .............................................................................................................. 90

Information stored during linearity testing............................................................................. 90

Linearity test kit ................................................................................................................................ 91

Preparing to run a linearity test .................................................................................................. 91

7.2 Performing a linearity test..................................................................................................................... 92

Overview of test procedure .......................................................................................................... 92

Starting a linearity test ................................................................................................................... 92

Confirming or selecting the lot number for linearity test kits.......................................... 93

Confirming or selecting the test strip lot................................................................................. 93

Inserting test strips.......................................................................................................................... 94

Applying a linearity test sample ................................................................................................. 95

Results screen ................................................................................................................................... 96

8 Proficiency Testing 97

8.1 Information regarding proficiency tests .......................................................................................... 97

Information stored during proficiency testing....................................................................... 98

Preparing a proficiency test ......................................................................................................... 98

8.2 Performing a proficiency test............................................................................................................... 99

Overview of test procedure .......................................................................................................... 99

Starting a proficiency test............................................................................................................. 99

Entering the proficiency sample ID........................................................................................ 100

Confirming or selecting the test strip lot.............................................................................. 100

Inserting test strips....................................................................................................................... 101

Applying a proficiency sample................................................................................................. 102

Results screen ................................................................................................................................ 103

9 Initial Startup 105

9.1 Connecting the base unit ................................................................................................................. 105

9.2 Installing or replacing the battery pack ...................................................................................... 106

Removing the battery pack ....................................................................................................... 107

Installing the battery pack ......................................................................................................... 108

9.3 Docking the meter................................................................................................................................ 110

9.4 Initial setup on the meter................................................................................................................... 112

Menu overview............................................................................................................................... 113

9.5 Opening the Setup Menu .................................................................................................................. 116

9.6 Date and time format........................................................................................................................... 117

9.7 Display options and optional tests ................................................................................................. 118

9.8 Options for test strips .......................................................................................................................... 119

9.9 Options for glucose control tests.................................................................................................... 121

9.10 Value ranges (normal, critical, reportable).................................................................................. 123

9.11 Options for Operator ID Entry........................................................................................................... 124

9.12 Patient ID options.................................................................................................................................. 125

9.13 Creating a setup password................................................................................................................ 126

9.14 Setting the date and time................................................................................................................... 127

9.15 Beeper options....................................................................................................................................... 128

9

Page 10

10 Maintenance and Care 129

10.1 Conditions for storage and shipping ............................................................................................. 129

General operating conditions ................................................................................................... 129

Storage .............................................................................................................................................. 130

10.2 Cleaning/disinfecting the Accu-Chek Inform II system.......................................................... 130

Acceptable cleaning/disinfecting agents............................................................................. 131

Cleaning/disinfecting the meter .............................................................................................. 132

How to clean/disinfect ................................................................................................................ 134

Cleaning the barcode scanner window................................................................................ 136

Cleaning/disinfecting the base unit ....................................................................................... 136

Cleaning/disinfecting the accessory box ............................................................................. 137

Cleaning the code key reader .................................................................................................. 138

Cleaning the Accu-Chek Inform II Base Unit Hub............................................................ 138

10.3 Logging maintenance activities....................................................................................................... 139

10.4 Diagnostics view.................................................................................................................................... 140

10.5 Unlocking a Download Lockout ...................................................................................................... 142

10.6 Deleting patient data ........................................................................................................................... 144

11 Troubleshooting 145

Errors and unusual behavior without error messages .................................................... 145

Pop-up messages.......................................................................................................................... 149

Meter reset ...................................................................................................................................... 151

12 General Product Information 153

12.1 Technical data ....................................................................................................................................... 153

12.2 Further Information............................................................................................................................... 156

Ordering ........................................................................................................................................... 156

Accu-Chek Inform II Operator’s Manual and Quick Reference Guide..................... 157

Reagents and Solutions.............................................................................................................. 157

Information about software licenses...................................................................................... 158

Contact Roche................................................................................................................................ 159

A Appendix 161

A.1 Table of configuration options ......................................................................................................... 161

A.2 Example of barcode symbologies ................................................................................................... 173

B Appendix 175

B.1 Option: Wireless network (WLAN).................................................................................................. 175

Preliminary note............................................................................................................................. 175

Background ..................................................................................................................................... 175

Technical implementation.......................................................................................................... 176

RF specific functionalities and effective performance claims...................................... 178

10

Page 11

C Supplement for Other Test Entry 181

C.1 Before you start...................................................................................................................................... 181

Description ...................................................................................................................................... 181

C.2 Overview of Other Test Entry (OTE) ............................................................................................... 182

Introduction..................................................................................................................................... 182

C.3 Recording Other Patient Tests ......................................................................................................... 185

C.4 Recording Other Control Tests ........................................................................................................ 192

Introduction..................................................................................................................................... 192

Other Control Testing Intervals................................................................................................ 192

Stored Control Information........................................................................................................ 192

Warning messages ....................................................................................................................... 198

C.5 Reviewing Other Test Results........................................................................................................... 199

C.6 Other Test Entry Configuration Options ....................................................................................... 202

D Supplement for Observed Test Sequence 203

Observed Test Sequence (OTS)............................................................................................... 203

Using the OTS function............................................................................................................... 204

Index 207

11

Page 12

This page intentionally left blank.

12

Page 13

Introduction • 1

1 Introduction

1.1 Before you start

Intended use The Accu-Chek® Inform II system is intended for in vitro

diagnostic use in the quantitative determination of blood

glucose levels in venous, capillary, arterial, and neonatal

whole blood samples for monitoring blood glucose. The

system is indicated for use by healthcare professionals.

For healthcare professionals, the system is a bedside unit

that can help you provide quality patient care by measuring blood glucose and by automating the record keeping

associated with blood glucose and glucose control tests.

Important information regarding use

Read this operator's manual, as well as the package

inserts for all relevant consumables, before using the

system for the first test.

You must configure the Accu-Chek Inform II system

according to your needs before initial use. You can configure the system either directly on the meter or by using

a suitable data management system. Refer to Chapter 9

“Initial setup on the meter” for on-meter configuration.

Refer to Appendix A for configuration via a data management system.

Be sure to read the “Important safety instructions and

additional information” section in this chapter before

operating the system.

13

Page 14

1 • Introduction

If you need help Information about using the system, the screen menus and

performing a test can be found in this operator's manual.

Error messages that appear on screen include information or instructions on how to correct the error.

For all questions about the Accu-Chek Inform II system

that are not answered in this manual, contact your Roche

representative (see Chapter 12). In order to expedite

troubleshooting, please have ready your Accu-Chek

Inform II meter, its serial number, this manual, and all

related consumables when you call. If you suspect a communication error beyond the meter, also have your

Accu-Chek Inform II Base Unit serial number ready to

help assist our customer care group in troubleshooting.

Note on the use of “base unit” in this manual

Unless otherwise specified, the term “base unit” refers

to both the Accu-Chek Inform II Base Unit and the

Accu-Chek Inform II Base Unit Light.

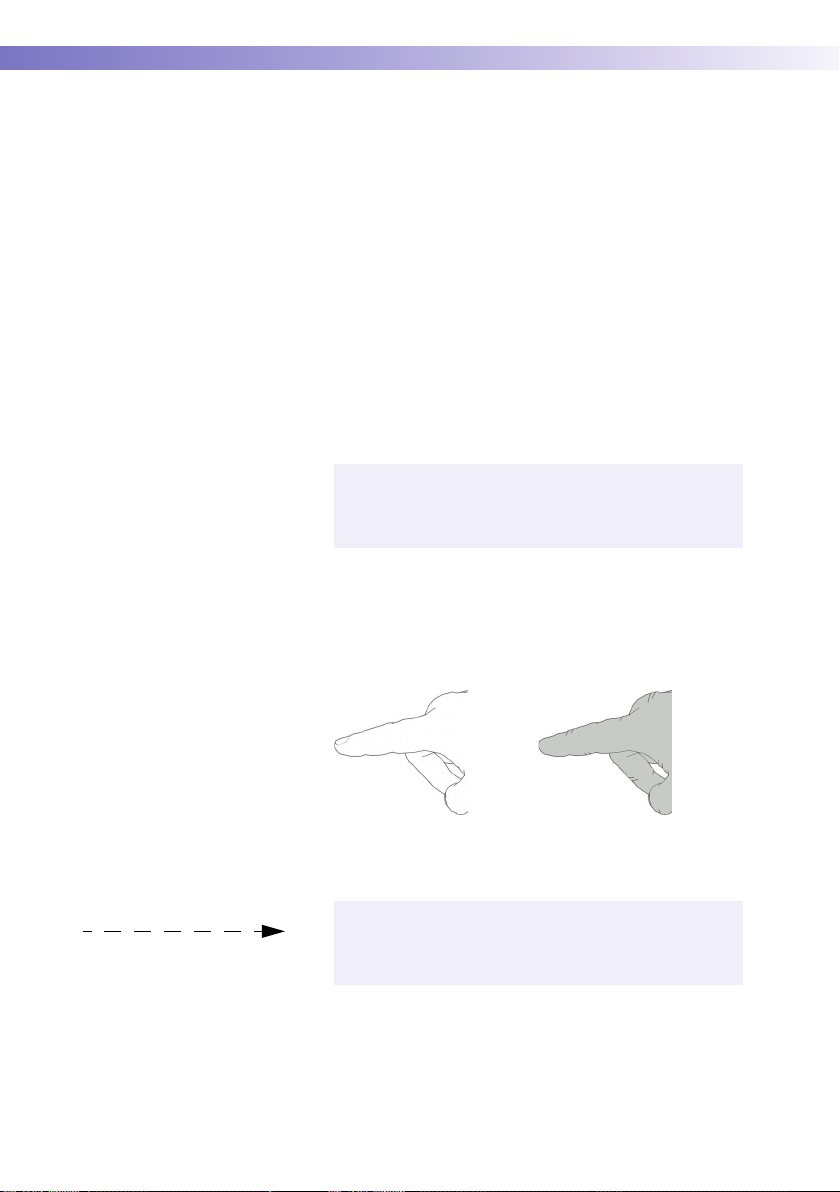

Note on illustrations in this manual

14

Illustrations in this manual show two different kinds of

hands:

Hand without glove Hand with glove

A dashed arrow between screen illustrations indicates

that some screens have been skipped in these

illustrations.

Page 15

Introduction • 1

What can the system do for you? The Accu-Chek Inform II system has the following

features and properties:

■ Perform patient blood glucose tests and glucose

control tests with control solution.

■ Automatically record all relevant data for the appli-

cation, which includes:

– Time and date of test

– IDs for operator, patient, and samples

– Information about control solutions, test strips, and

linearity

– Test results and comments

■ Record patient test results, quality control test

results and reagent information for certain offmeter manual tests.

■ For purposes of quality assurance, information on

the following areas can be collected, stored, and

transferred:

– Meters

– Test strips

– Glucose control solutions

– Linearity solutions

– Test results

15

Page 16

1 • Introduction

1.2 Important safety instructions and additional information

This section explains how safety-related messages and

information related to the proper handling of the system

are presented in the Accu-Chek Inform II manual. Please

read these passages carefully.

The safety alert symbol alone (without a signal word) promotes awareness to hazards which are generic or directs

the reader to related safety information.

WARNING

WARNING

CAUTION

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

16

NOTICE

NOTICE

Indicates a hazardous situation which, if not avoided,

may result in damage to the system.

Important information that is not safety relevant is

presented against a colored background (without a

symbol). Here you will find additional information on

correct use of the meter or useful tips.

Page 17

Important information regarding safety

WARNING

Introduction • 1

Operator qualification

Only trained healthcare professionals may operate the

Accu-Chek Inform II system. Operators must also have

received comprehensive instruction in the operation,

quality control, and care of the Accu-Chek Inform II

system.

Protection against infection and blood-borne

pathogens

Healthcare professionals using the Accu-Chek Inform II

system to perform tests on more than one patient must

be aware that any object coming into contact with

human blood is a potential source of infection. Operators

need to adhere to Standard Precautions when handling

or using the Accu-Chek Inform II system. All parts of this

system should be considered potentially infectious and

are capable of transmitting blood-borne pathogens

between patients and healthcare professionals.

■ Use gloves. Wear a new pair of clean gloves for

testing each patient.

■ Wash hands thoroughly with soap and water

before putting on a new pair of gloves and performing the next patient test.

■ Use an auto-disabling single-use lancing device

for each patient.

■ Dispose of used lancets in a sturdy sharps con-

tainer with lid.

■ Dispose of used test strips from patient and

proficiency tests according to your institution’s

infection control policy.

■ Follow all health and safety regulations in force

locally.

17

Page 18

1 • Introduction

CAUTION

Disposal of the system

WARNING

Allergy or injury caused by reagents and other

working solutions

Direct contact with reagents, detergents, cleaning/disinfection solutions, or other working solutions may cause

skin irritation or inflammation.

■ Always use protective gloves.

■ Observe the cautions given in the package inserts of

the reagents and cleaning/disinfection solutions.

■ If a reagent, control, linearity, or cleaning/disinfection

solution comes into contact with your skin, wash it off

immediately with water.

■ Follow all health and safety regulations in force

locally.

Infection by a potentially biohazardous instrument

The Accu-Chek Inform II system or its components must

be treated as potentially biohazardous waste. Decontamination (i.e., a combination of processes including cleaning, disinfection and/or sterilization) is required before

reuse, recycling, or disposal.

18

Dispose of the system or its components according to

the appropriate local regulations or you may return it to

Roche. For more information, contact your Roche

representative.

Page 19

Introduction • 1

Product safety Observe the following information to ensure product

safety:

■ The system is suitable for continuous operation.

NOTICE

General care

NOTICE

Accessory box

NOTICE

Meter

Automatic power-off

The system is not protected against the harmful ingress

of fluids (IP X0 rating according to IEC 60529).

Clean the system only with the solutions recommended.

Using other solutions may result in incorrect operation

and possible failure of the system. Make sure that the

meter and base unit are thoroughly dried after cleaning

and disinfecting.

Carry the accessory box carefully by the handle for easy

transport. Dropping or hitting the box may damage it.

■ Dispose of the meter in accordance with applicable

laws and regulations. See “Disposal of the system”

on page 18.

■ Unless otherwise configured, the system automati-

cally powers off after 5 minutes of inactivity (e.g., no

screen touches, strip insertions).

■ In measurement mode only: If you are performing a

test (patient, control, proficiency, or linearity), the

meter will power off after 10 minutes of inactivity

(no screen touches), independently of configured

automatic power-off time. If a result is already

present, the meter will emit three warning beeps

every minute after 5 minutes of inactivity and will

save the result before powering off after 10 minutes

of inactivity.

19

Page 20

1 • Introduction

Battery Pack The meter contains a rechargeable battery pack that

begins charging as soon as it is placed in an active base

unit (i.e., one connected to a power supply).

NOTICE

Use only the specially designed battery pack provided by

Roche Diagnostics. Using any other type of battery may

damage the system.

Observe the following general safety instructions for

handling batteries:

Disposal of used batteries

Do not dispose of the batteries with normal domestic

waste. Dispose of used batteries in accordance with

applicable local regulations and directives and your

facility’s guidelines on the disposal of electronic waste

equipment.

■ When storing or disposing of the battery pack, use

the manufacturer's original packaging.

Save or download data from the meter prior to replacing the battery pack to prevent loss of data (see

Chapter 9).

■ Always power off the meter before removing the

battery pack.

■ When the Battery Low warning is displayed, the

meter must be returned as soon as possible to

the base unit for recharging.

20

■ The Battery Critically Low warning indicates that

the meter must be returned immediately to the

base unit for recharging.

Page 21

Touchscreen

Introduction • 1

NOTICE

Use only your finger to touch the screen elements.

■

Using a sharp-edged object (e.g., tip of a pen) can

damage the touchscreen.

■ Do not use the system in direct sunlight. Direct

sunlight may reduce the life expectancy and functionality of the display, as well as the integrity of

test strips.

Electrostatic discharge (ESD) The Accu-Chek Inform II system complies with both the

electromagnetic immunity requirements and radio interference immunity requirements at the frequency and test

levels according to EN ISO 15197 Annex A. The system also

complies with the electrostatic discharge (ESD) immunity

requirements as specified in IEC 61000-4-2 and complies

with applicable electromagnetic emissions requirements

according to EN 61326-1 and EN 61326-2-6. The system’s

emissions of the energy used are low and not likely to

cause interference in nearby electronically driven

equipment.

21

Page 22

1 • Introduction

Electrostatic discharge (ESD) is an electrical charge at

rest, most commonly known as static electricity. If the

Accu-Chek Inform II meter experiences a form of ESD

before or after running a blood glucose test, the test

result will be stored in the meter memory and transmitted

when the meter is docked in a connected base unit or

when a wireless connection is established. If the meter

experiences ESD during a blood glucose test, an error

message is displayed and no blood glucose result is displayed by the meter or stored in the meter’s memory. The

blood glucose test will need to be repeated.

To avoid ESD, do not use the meter in a very dry environment, particularly one in which synthetic materials (e.g.,

carpets) are present that might cause damaging static

discharges, or near electronic equipment that is a source

of electromagnetic radiation.

Local Area Network: protection from unauthorized access

Wired network connection If connected to a local area network, the Accu-Chek

If this product is connected to a local area network, this

network must be protected against unauthorized access.

In particular, it must not be linked directly to any other

network or the Internet. Customers are responsible for

the security of their local area network, especially in protecting it against malicious software and attacks. This

protection might include measures, such as a firewall, to

separate the device from uncontrolled networks as well

as measures that ensure that the connected network is

free of malicious code.

Inform II Base Unit or Accu-Chek Inform II Base Unit Hub

must be protected against unauthorized access by means

of a strong password management. Observe your own

facility guidelines on password management where available, or apply the following rules:

22

Page 23

Introduction • 1

Characteristics of strong passwords

■ Passwords must not contain the user’s account

name or parts of the user’s full name that exceed

two consecutive characters.

■ Passwords must be at least eight characters in

length.

■ Passwords must contain characters from at least

three of the following four categories:

– English uppercase alphabetic characters

(A through Z)

– English lowercase alphabetic characters

(a through z)

– Numeric characters (0 through 9)

– Non-alphabetic characters (for example, !, $, #, %)

Examples of weak passwords

■ uhxwze11 contains no upper case letter.

■ UHXW13SF contains no lower case letter.

■ uxxxxx7F contains the same character more than

four times.

■ x12useridF contains a substring of the user ID

longer than four characters.

Wireless connectivity If the meter is equipped with WLAN functionality:

Wireless connectivity allows the meter to send data (test

results, patient IDs, operator IDs, etc.) to the data management system without the need to return the meter to

the base unit. This feature must be configured by the

system administrator. Observe the guidelines of your

facility for using wireless local area network connections.

For information about how to temporarily enable or disable this function, see page 36. For a description of the

Accu-Chek Inform II meter’s ability to connect to Wireless

Local Area Networks (WLAN, Wi-Fi), see appendix B.

23

Page 24

1 • Introduction

Radiofrequency radiation exposure information

Glossary:

■ “FCC” stands for “Federal Communications

Commission” (USA).

■ “RF” stands for “radio frequency”

■ “RSS” stands for “Radio Standards Specification”

(Canada).

■ “WLAN” stands for “Wireless Local Area

Network”

The Industrial, Scientific and Medical (ISM) radio

frequencies may contain emissions from microwave

ovens, heaters, and other noncommunication devices.

While these types of devices usually pose no threat of

interference as they are low-powered devices, the possibility exists that some industrial high power systems may

wipe out any attempted communication use of a WLAN.

Therefore, perform a site survey and interference analysis

with a spectrum analyzer to view the entire spectrum,

looking for signals that might not only be within the frequency range of the intended WLAN but also could be

near or at the same frequency and cause interference.

24

Page 25

Introduction • 1

Roche supports industry wireless standards and recommends using products that have Wi-Fi certification. This

certification tests products to the 802.11 industry standards for basic connectivity, security, authentication, Quality of Service (QoS), interoperability and reliability. The

Wi-Fi CERTIFIED logo is an assurance that the Wi-Fi Alliance has tested a product in numerous configurations

and with a diverse sampling of other devices to ensure

compatibility with other Wi-Fi CERTIFIED equipment that

operates in the same frequency band. The Wi-Fi Alliance

network of independent test labs conducts interoperability testing programs to ensure that wireless devices work

together and support secure connections.

The Accu-Chek Inform II system complies with FCC radiation exposure limits set forth for an uncontrolled environment. This equipment should be installed and

operated with minimum distance of 20 cm (8 inches)

between the radiator and your body.

This transmitter must not be co-located or operated in

conjunction with any other antenna or transmitter.

Changes or modifications made to this equipment not

expressly approved by Roche Diagnostics may void the

FCC authorization to operate this equipment.

This device complies with Part 15 of the FCC Rules and

with RSS-210 of Industry Canada. Operation is subject to

the following two conditions:

(1) this device may not cause harmful interference,

and

(2) this device must accept any interference received,

including interference that may cause undesired operation.

25

Page 26

1 • Introduction

The Accu-Chek Inform II system complies with the

emission and immunity requirements described in

EN 61326-2-6. It has been designed and tested to

CISPR 11 Class B.

This equipment has been tested and found to comply

with the limits for a Class B digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if

not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment

does cause harmful interference to radio or television

reception, which can be determined by powering the

equipment off and on, the user is encouraged to try to

correct the interference by one or more of the following

measures:

■ Reorient or relocate the receiving antenna.

■ Increase the separation between the equipment

and receiver.

26

■ Connect the equipment into an outlet on a circuit

different from that to which the receiver is connected.

■ Consult the dealer or an experienced radio/TV

technician for help.

This Class B digital apparatus complies with Canadian

ICES-003.

Page 27

1.3 System components

A

B

C

D

Introduction • 1

The Accu-Chek Inform II system includes the following

components and accessories:

A Meter

B Code key reader

C Base unit (power supply not shown)

D Accu-Chek Inform II Base Unit Hub (power supply

not shown)

E Accessory box (shown with consumables, not

included)

The meter can be configured by two different methods:

1 Configuration via the Setup function on the meter

(see Chapter 9)

2 Configuration via data management system

Note: Not all options can be configured using the Setup

function on the meter.

The meter performs the following tasks within the system:

■ Serves as the primary operator interface through

the touchscreen and on/off button

■ Performs glucose tests

■ Scans barcodes

1

(test strip lots, controls, patient

and operator IDs) in a variety of supported formats

■ Displays test results from patient tests and control

tests

■ Transfers stored data to the data management

system via wireless communication (WLAN,

optional) or the base unit (LAN)

E

1. Barcodes on control solutions may not be available in all

countries. A list of supported barcode symbologies can be

found in Appendix A.2.

27

Page 28

1 • Introduction

1.4 Overview of the meter

1

2

3

4

The meter has the following elements:

1 Test strip port

Insert the test strip here.

2 Touchscreen

(touch-sensitive display)

This screen allows you to perform patient tests, perform controls tests, and review results. To select

any of these functions, simply touch the button on

the screen.

3 On/Off button

Press this button to power the meter on or off.

4 Barcode scanner

The integrated barcode scanner can be used to

read operator and patient IDs.

5 Battery compartment cover

Remove to insert the battery pack.

6 Charging contacts

These contacts are used to charge the battery pack

when the meter is in the base unit.

28

7 Infrared window

5

6

7

Facilitates data communication with code key

reader and base unit.

Page 29

8

9

10

11

Introduction • 1

8 Battery pack

Powers the device.

9 Wireless LAN label

If the meter supports wireless connectivity: This

label displays registration numbers that are specific

to the meter RF hardware.

10 Interface

(For manufacturer’s use only.)

11 Battery pack connector socket

Connect battery pack here.

8

29

Page 30

1 • Introduction

1.5 Overview of the code key reader

Test strip vials include a code key.1 This code key is read

by the code key reader and the data is sent to the meter.

14

For additional information about the code key reader, see

Chapter 6.

13

12

The code key reader has the following elements:

12 Code key slot

13 LED (green) for displaying status

14 Infrared window for transmitting the code file to the

meter

Do not replace code keys while the code key reader is

still flashing. If the green LED status light is still flashing, the code key reader will continue to transmit the

previously loaded code file and ignore the code file on

the newly inserted code key. You may get an error

message on the meter.

30

1. The code key is also frequently referred to as a code chip.

The terms are synonymous.

Page 31

1.6 Overview of the base unit

Introduction • 1

To provide flexibility in line with customer requirements,

two versions of the base unit are available.

20 21 18

15

16

17

19

■ The Accu-Chek Inform II Base Unit

■ The Accu-Chek Inform II Base Unit Light

Both versions of the base unit can:

■ charge the meter battery pack.

In addition, the Accu-Chek Inform II Base Unit also

supports:

■ communication with a data management system.

■ communication with a computer.

1

Both versions of the base unit have the following elements:

15 Charging contacts

16 Infrared window for communication with the meter

17 Status LED (lights up when power is connected):

– Lights up red: Power supply is connected, applica-

tion is starting up (Accu-Chek Inform II Base Unit

only)

– Lights up green: Ready

– Flashes red: Error

– Lights up blue: Configuration mode (Accu-Chek

Inform II Base Unit only)

17

18 Jack for the power supply unit provided

19 Removable mount for wall installation

The Accu-Chek Inform II Base Unit has the following

additional elements:

20 Network connection — LAN, Ethernet (RJ45)

21 USB connection

1. The Accu-Chek Inform II Base Unit Light can support

communication with a data management system only

when used together with the Accu-Chek Inform II Base

Unit Hub.

31

Page 32

1 • Introduction

Electrical connections are located on the back of the base

unit (for a better view the removable wall mount is shown

as transparent).

For instructions on connecting the base unit, see

Chapter 9.

1.7 Overview of the Accu-Chek Inform II Base Unit Hub

The Accu-Chek Inform II Base Unit Hub is able to connect up to 4 Accu-Chek Inform II Base Units Light (RJ25)

and supports communication to a data management

system via Ethernet (RJ45).

The hub also provides power for the Accu-Chek Inform II

Base Unit Light. When connected to a hub an Accu-Chek

Inform II Base Unit Light does not require a separate

power supply. The LED colors of the hub are the same as

17

for the Accu-Chek Inform II Base Unit Light.

17 Status LED (lights up when power is connected)

18 Jack for the power supply unit provided

20 Network connection — LAN, Ethernet (RJ45)

32

20 18

2221

21 USB connection

22 Connections for up to 4 Accu-Chek Inform II Base

Units Light (RJ25, data transfer, and power)

Page 33

1.8 Overview of the accessory box

The accessory box provides an area for storing and transporting consumables needed for performing point-ofcare blood glucose tests.

1.9 Reagents and consumables

You need the following reagents to perform patient tests

and glucose control tests:

Introduction • 1

■ Accu-Chek Inform II Test Strips

■ Accu-Chek Performa Control Solutions

■ Accu-Chek Linearity Kit (if required by your facility

guidelines)

Your facility provides additional consumables such as

blood collection supplies. Observe the current rules and

safety guidelines for collecting and handling blood

samples.

33

Page 34

1 • Introduction

1.10 Instructions for initial setup

The meter must be configured prior to initial use. During

this setup, the following parameters are configured:

■ Date and time format

■ Input mode for Patient ID

■ Input mode for Operator ID

■ Glucose controls: Type and schedule

■ Results screen for glucose control

■ Comments for entry after a test

■ Settings for data transfer

You can perform these settings on a limited basis directly

in the Setup Menu of the meter. For more information

about configuration using the Setup Menu, see

Chapter 9, as well as Appendix A. In addition to this

option, the meter can be configured using a data management system. Suitable data management systems

provide a range of functions for configuring the meter

that go beyond what is possible with the meter-based

configuration feature.

34

For questions about using data management systems,

contact your Roche representative (see Chapter 12).

To ensure standardized configuration within a facility,

the meter-based Setup Menu may be disabled.

Page 35

Powering Up and Entering an Operator ID • 2

2 Powering Up and Entering an Operator ID

2.1 Powering up the meter

1 Press and release the On/Off button . The meter

is now on.

2 The Power Up screen appears.

3 Check in the Power Up screen whether the date

(lower left) and time (upper right) are displayed

correctly. If necessary, refer to the instructions for

updating these settings in Chapter 9.

Power Up 12:48 pm

Performing self-checks...

Contrast

09/18/13

■ If during self-check an error is detected, the appro-

priate error message appears on screen.

■ If the QC Lockout feature is enabled and glucose

control is required, a corresponding message is

displayed.

■ The battery icon shows the current battery level.

A completely filled icon indicates a fully

charged battery, and a partial charge is displayed

as a partially filled battery icon . If the battery

is nearly empty, the battery icon turns red .

35

Page 36

2 • Powering Up and Entering an Operator ID

Adjusting the display Using the Display options, you can adjust the display con-

trast to the ambient light conditions.

Display

Lighter Darker

09/18/13

12:48 pm

Enabling/disabling wireless connectivity

WARNING

1 In the Power Up screen, touch Contrast. The Display

screen appears.

2 Touch or to make the display lighter or

darker.

3 Touch to confirm the setting.

After 30 seconds without any activity (e.g., without a

screen touch) the meter automatically dims the display backlight to conserve energy (“Low Power

Mode”).

If the meter supports wireless connectivity, you can temporarily enable or disable this functionality as required.

Wireless connectivity is automatically reactivated the next

time you power on the meter. You can then disable it

again temporarily, if required.

If you suspect that the RF emissions of wireless communication are harming the patient or affecting other

devices, you should carefully reassess the appropriateness of continued use of the WLAN functionality of the

Accu-Chek Inform II system using the guidelines of your

facility.

36

Page 37

Powering Up and Entering an Operator ID • 2

Power Up 12:48 pm

Contrast

09/18/13

Power Up 12:48 pm

Contrast

09/18/13

If wireless connectivity is activated, the (RF OFF)

icon is displayed as a button in the Power Up screen.

■ To temporarily disable the wireless network con-

nection, touch (RF OFF) in the Power Up

screen. The icon then changes to (RF ON).

■ To temporarily enable the wireless network con-

nection, touch (RF ON) in the Power Up

screen. The icon then changes to (RF OFF).

The RF ON/RF OFF button always displays the option you

currently have. The current communication status is displayed in the status bar (bottom line) of the display in all

menus and screens.

■ The icon is displayed, if wireless connectivity is

enabled.

■ The icon is displayed if the last attempt to com-

municate with the data management system was

successful and was terminated according to the

communication protocol.

■ The icon is displayed if the last attempt to

communicate with the data management system

was not successful or was unintentionally terminated. If this icon persists, contact your system

administrator. Ignoring this information may lead to

a Download Lockout (if configured, see page 41).

Closing startup Once you have completed all the necessary changes,

■ touch to proceed to the screen used to enter

the operator ID, or

■ wait 5 seconds and the meter automatically pro-

ceeds to the screen used to enter the operator ID.

37

Page 38

2 • Powering Up and Entering an Operator ID

2.2 Entering the operator ID

How and when an operator ID is entered and if a password is required, depends on the configuration of the

system. It is also, for example, possible to require the

operator ID only when starting control tests. In general,

the system can manage and check operator IDs as well

as make additional functions ID-dependent.

Main Menu

Maria S.

09/18/13

12:48 pm

Patient Test

Control Test

Review Results

If an operator name matching the entered operator ID is

available on the meter, this name will be displayed in the

Main Menu (shown here as “Maria S.”).

There are a number of options for entering operator IDs

and these depend on the configuration of the system:

■ Via barcode scanner

■ Manually or optionally via barcode scanner

1

only

Operator IDs can consist of up to 20 alphanumeric

characters.

Alphanumeric characters are any combination of

A - Z and 0 - 9, additionally “.” (period), or “-”

(hyphen) may be used. See also page 40.

Barcode masking can be used to eliminate any characters not belonging to the Operator ID. See information on “Operator and patient ID barcode masks” on

page 172.

38

1. A list of supported barcode symbologies can be found in

Appendix A.2.

Page 39

Powering Up and Entering an Operator ID • 2

Entering an operator ID with barcode scanner

Operator ID

123

456

789

09/18/13

12:48 pm

A-O0

When the screen for entering the operator ID is

displayed:

1 Press and release . The button now appears

with a black background (during the scan).

2 Hold the meter so that the window of the barcode

scanner is approx. 10-20 cm (4-8 in) above the barcode you wish to read.

The meter beeps once the barcode has been read successfully. The barcode information appears in the operator ID field. The barcode scanner turns off after 10

seconds, if a barcode is not scanned.

39

Page 40

2 • Powering Up and Entering an Operator ID

Entering the operator ID manually

Operator ID

123

456

789

09/18/13

12:48 pm

A-O0

When the screen for entering the operator ID is

displayed:

Operator ID

MARIA

ABCDE

FGHI J

KLMNO

09/18/13

12:48 pm

P-Z123

Operator ID

MARIA S.

PQRST

UVWXY

Z.

123 A-O

09/18/13

12:48 pm

-

1 Touch the letters or numbers to enter the ID.

2 Use the following buttons to toggle between ranges

of characters:

A-O

– for letters A-O

P-Z

– for letters P-Z

123

– for numbers 0-9

3 Touch to backspace and delete a character

entered incorrectly. Touch to delete the whole

entry. Touch to enter a space.

4 Touch to confirm.

If the operator ID you have entered is not valid (or the

operator is not stored in the meter), an error message is

displayed. Confirming the message allows you to enter

the ID again.

Entering a password Once the operator ID has been entered correctly, a

screen for entering a password may appear (if configured). Enter the password in the same manner as

described above for the operator ID.

Once all entries are complete, the Main Menu appears.

40

Page 41

Patient Glucose Testing • 3

3 Patient Glucose Testing

3.1 Information regarding blood glucose testing

Preparing to test The following requirements must be met before you can

perform a test:

Power Up

QC Due: Immediately

Contrast

09/18/13

12:48 pm

■ The Accu-Chek Inform II test strips are available.

■ The code file for the test strip lot in use must be

stored in the meter (see Chapter 6).

■ An operator ID must be entered (with password, if

required), if the meter is configured for login.

■ Glucose control tests specified in the system con-

figuration must be run and completed successfully

before running patient tests. Information whether

glucose control tests are necessary is displayed in

the Power Up screen.

■ If configured, the meter may require downloading

stored data to the data management system within

defined time intervals. If such a download (either

via WLAN or by docking the meter in a base unit)

does not happen within the specified time, the

meter is locked (Download Lockout) and cannot be

used for testing.

41

Page 42

3 • Patient Glucose Testing

If a glucose control test is shown as required, patient glucose testing cannot be performed until the controls are

run successfully.

Depending on how your meter is configured (see

page 121), QC Lockout occurs when

■ patient testing is attempted and controls have not

been run in the time interval or frequency established by your facility.

■ controls have been run but the control values

were not in range.

■ a test strip lot other than the “current” lot is

selected.

■ new software has been installed.

For emergencies, STAT (Short TurnAround Time) tests

can be configured in the meter. This option allows the

meter to perform a limited number of patient glucose

tests, if circumstances require, despite the meter being in

QC Lockout or Download Lockout (see page 68).

■ Observe the applicable regulations and directives

for hygiene and safety when collecting blood

samples.

■ Observe the applicable regulations and directives

for disposing of potentially infectious samples and

materials.

3.2 Performing a patient glucose test

Overview of test procedure A patient glucose test comprises the following steps:

■ Enter the patient ID. This can be done either man-

ually or by using the barcode scanner.

■ Confirm that the test strip lot matches the test strips

in use (if configured).

■ Perform the test.

■ Optionally a test may be categorized as an

Observed Test Sequence (see page 203).

42

Page 43

Patient Glucose Testing • 3

As mentioned previously, the following steps must be

completed already:

1 The meter is switched on.

2 You have entered your operator ID.

3 You have completed login by selecting and

the Main Menu screen is displayed.

Entering or selecting the patient IDAfter preparing the meter as described, you can proceed

to the steps directly related to testing:

Main Menu

09/18/13

12:48 pm

Patient Test

Control Test

Review Results

Patient ID

123

456

789

09/18/13

12:48 pm

A-O0

Patient ID

123456789

Patient Confi rmation

ABCDE

D-503: Patient ID:

123456789

F GHI J

Name:

Mary-Jane Miller

DOB: 12/03/56

KLMNO

Is this correct?

P-Z 123

09/18/13

1 From the Main Menu screen touch Patient Test.

2 Enter or select the Patient ID as described on the

following pages.

3 If the function Patient Confirmation is enabled,

verify and confirm the displayed patient information, after you entered or selected the ID.

12:48 pm

43

Page 44

3 • Patient Glucose Testing

You now have three different options, depending on

setup, for assigning the subsequent test to a patient.

The patient ID function can be configured by your

system administrator to:

■ Enter any combination of up to 20 alphanumeric

characters, with specified minimum and maxi-

mum lengths.

Alphanumeric characters are any combination of

A - Z and 0 - 9, additionally “.” (period), or “-”

(hyphen) may be used.

■ Enter patient ID via barcode scanner.

■ Select a patient from a list.

2

1

The following options are available for validating

patient IDs:

■ Manual entries can be validated based on an

downloaded list.

■ Confirmation of patient name, date of birth, and ID

can be required.

■ Barcode masking can be used to eliminate any

2

characters not belonging to the Patient ID. See

information on “Operator and patient ID barcode

masks” on page 172.

44

1. A list of supported barcode symbologies can be found in

Appendix A.2.

2. Depending on the meter configuration, this feature may

be disabled.

Page 45

Patient Glucose Testing • 3

Entering the patient ID manually Use the displayed keypad to enter the patient ID. You can

select characters in the same manner as when entering

an operator ID.

Patient ID

ABCDE

FGHI J

KLMNO

09/18/13

12:48 pm

P-Z123

Selecting the patient ID from a list

Patient ID

Keyboard

Name: James Doe

ID: 2222222222

Name: Jane Doe

ID: 3333333333

Name: Jenny Doe

ID: 4444444444

Name: John Doe

ID: 5555555555

12:48 pm

1 Touch the letters or numbers to enter the ID.

2 Use the following buttons to toggle between ranges

of characters:

A-O

– for letters A-O

P-Z

– for letters P-Z

123

– for numbers 0-9

3 Touch to backspace and delete a character

entered incorrectly. Touch to delete the whole

entry. Touch to enter a space.

4 Touch to confirm, or touch to cancel this

procedure and return to the Main Menu.

If the patient ID you have entered is not valid (or the

patient is not found in the downloaded list), an error message is displayed. Confirming the message allows you to

enter the ID again.

Choose the patient ID from a list

1

, if a list has been down-

loaded to the meter (from the data management system).

1 Touch or to scroll up or down in the list.

If one of the buttons is hidden, you have reached the top

or bottom of the list.

2 Touch the desired entry to select a patient, or touch

to cancel this procedure and return to the

Main Menu.

09/18/13

1. Depending on the meter configuration, this feature may

be disabled.

45

Page 46

3 • Patient Glucose Testing

Entering a patient ID with barcode scanner

Patient ID

ABCDE

FGHI J

KLMNO

09/18/13

12:48 pm

Patient ID

Keyboard

Name: James Doe

ID: 2222222222

P-Z123

Name: Jane Doe

ID: 3333333333

Name: Jenny Doe

ID: 4444444444

Name: John Doe

ID: 5555555555

09/18/13

When the screen for entering the patient ID is displayed:

12:48 pm

1 Press and release . The button now appears

with a black background (during the scan).

2 Hold the meter so that the window of the barcode

scanner is approx. 10-20 cm (4-8 in) above the barcode you wish to read.

The meter beeps once the barcode has been read successfully. The barcode information appears in the patient

ID field. The barcode scanner turns off after 10 seconds, if

a barcode is not scanned.

46

Page 47

Patient Glucose Testing • 3

Confirming or selecting the test strip lot

Patient Test

Patient 123456789

Use Strip Lot

123456?

09/18/13

Strip Lots

09/18/13

12:48 pm

12:48 pm

545794

344789

545777

344654

Once you have entered and confirmed the patient ID, you

are asked to choose the lot number for the test strips.

Compare the number displayed by the meter to the

number on the label of the test strip vial.

1 Select the lot number as follows:

■ If you want to use the preselected lot number dis-

played by the meter, touch to confirm.

■ To use a different lot number than the one dis-

played, touch to display a list of stored lot

numbers. Select the desired lot number from the

list.

■ To read the lot number from the test strip vial via

barcode scanner, press and release . Follow

the instructions for scanning IDs (see note below).

2 Touch to confirm the selected or scanned lot

number.

The meter can be configured so that manual

confirmation is not necessary. In this setup, only the

lot number is displayed. Additional options are not

available.

The meter can be configured so that lot numbers are

entered via barcode scanner only (see note below).

For additional information about storing lot numbers for

test strips, see page 73.

Note: Barcodes on control solutions may not be available in all countries. In this case either

■ manually enter the lot number each time

(recommended),

■ pick a previously entered lot number from the list,

or

■ configure the meter to only display the lot number

(without confirmation by the operator).

47

Page 48

3 • Patient Glucose Testing

Inserting test strips After confirming the test strip lot, a flashing green arrow

appears on screen and prompts you to insert the test

strip.

Patient Test

Patient 123456789

ot 545794

Strip L

09/18/13

Patient Test

Patient 123456789

ot 545794

Strip L

09/18/13

12:48 pm

12:48 pm

1 Remove the test strip from the test strip vial and

close the vial with the cap.

2 Hold the test strip so the lettering “ACCU-CHEK” is

facing upward.

3 Slide the test strip into the test strip port as far as it

goes in the direction indicated by the arrows on the

test strip.

The meter beeps. The hourglass icon appears and indicates that the meter is checking the test strip. Do not

apply blood while it is displayed.

48

Page 49

Patient Glucose Testing • 3

Obtaining a blood sample Prepare the selected blood collection site and obtain

blood from the patient per facility policy.

Recommendations for the collection of capillary

blood

If no facility policy exists for obtaining capillary blood, the

patient's hands (or heel in the case of small children)

should be washed with warm water and soap, and then

dried thoroughly. If you are using alcohol wipes or other

disinfectants when obtaining capillary blood, the patient's

skin must be completely dry before you lance the site to

obtain blood.

We recommend obtaining the capillary blood sample

from the side of the fingertip as this part is the least

sensitive to pain.

Potential risk of incorrect results due to residues on

skin

WARNING

■ Traces of food on the fingers or fatty residues from

hand cremes or soap products may contaminate

the sample and lead to incorrect results. Wash the

puncture site thoroughly and rinse with plenty of

water.

■ Residues of water or disinfectant on the skin can

dilute the drop of blood and lead to incorrect

results. After you have washed and disinfected the

site, ensure that the patient's skin is completely dry

before lancing the site to obtain a capillary blood

sample.

Use an auto-disabling single-use lancing device for each

patient. The lancing device must be intended for use by

healthcare professionals in a multiple patient setting.

Follow the manufacturer's instructions for use.

49

Page 50

3 • Patient Glucose Testing

Applying a blood sample Once the meter has checked the test strip, the hourglass

icon disappears and you are prompted to apply a blood

sample.

Patient Test

Patient 123456789

ot 545794

Strip L

09/18/13

12:48 pm

When applying the sample, position the meter so that

the test strip port is always higher or on the same level

as the blood drop. This prevents any excess blood

from flowing down the strip and entering the meter.

50

1 Wait until the flashing drop appears in the display

before applying the blood. The meter beeps.

2 Apply the drop of blood to the front edge (yellow

dosing area) of the test strip. Blood is pulled into

the test strip by capillary action.

Do not apply the blood to the top of the strip. Blood

on top of the test strip is not available for testing

because it will not be pulled into the strip.

Once a sufficient blood sample has been detected, the

meter beeps and the measurement begins.

Page 51

Patient Glucose Testing • 3

Results screen The hourglass icon indicates the test is running. When

the test is completed and the result is ready, the meter

beeps again.

Patient Test

Patient 123456789

ot 545794

Strip L

09/18/13

12:48 pm

Patient Test

Patient 123456789

Date 09/18/13 12:48 pm

mmol/L

8.3

Range

09/18/13

12:48 pm

Patient Test

Patient 123456789

te 09/18/13 12:48 pm

Da

150

I-502:

3.9-11.1 mmol/L

Critical Range:

2.2-16.7 mmol/L

Repor

table Range:

0.6-33.3 mmol/L

09/18/13

12:48 pm

Range

Normal Range:

L22

When the result is displayed, a message or warning may

also appear (depending on system configuration) notifying you if the result exceeds the specified limit values.

Additionally, a red flashing arrow next to the test result

indicates that a result is out of range.

: the value is above the normal/critical upper range.

: the value is below the normal/critical lower range.

These limit values define ranges that can either be configured individually by the system administrator in line

with facility guidelines, or are the (technical) limits of the

system. The characteristics of these ranges are explained

on the following page.

The results screen contains a button that changes its

name based on the result (Range or Out of ... Range).

Touch this button to display the configured limit values.

51

Page 52

3 • Patient Glucose Testing

Patient Test

Patient 123456789

Date 09/18/13 12:48 pm

12.2

Out of Normal Range

09/18/13

mmol/L

12:48 pm

Patient Test

Patient 123456789

Date 09/18/13 12:48 pm

mmol/L

1.9

Out of Critical Range

Patient Test

Patient 123456789

Date 09/18/13 12:48 pm

09/18/13

CR LO

Out of Critical Range

09/18/13

■ The System Measurement Range refers to the

12:48 pm

12:48 pm

Patient Test

Patient 123456789

Date 09/18/13 12:48 pm

RR HI

Out of Reportable Range

09/18/13

12:48 pm

Patient Test

Patient 123456789