Page 1

91xx pH/Electrolyte Analyzers

Service Manual

Page 2

COBAS

is a trademark of Roche.

©2007 Roche Diagnostics

Roche Diagnostics GmbH

D-68298 Mannheim

Germany

www.roche-diagnostics.com

Page 3

91xx pH/Electrolyte Analyzers

Version History

Edition notice

Manual Version Software Version Version date Changes

1.0 n/a July 2004 First edition

2.0 n/a April 2007 New template

Language Order Number

English 03077063001

e

For more information, see:

Software on page G-5

Service Manual on page G-6

91xx pH/Electrolyte Analyzers

Service Manual

This Service Manual is for the maintenance and repair of 91xx pH/Electrolyte

Analyzers (9110 pH Analyzers and 9120, 9130, 9140, 9180 and 9181 Electrolyte

Analyzers).

91xx pH/Electrolyte Analyzers Every effort has been made to ensure that all the information contained in this

manual is correct at the time of printing. However, Roche Diagnostics GmbH reserves

the right to make any changes necessary without notice as part of ongoing product

development.

Any customer modification to the instrument will render the warranty or service

agreement null and void.

Software updates are done by Roche Service representatives.

9180 Electrolyte Analyzers SN > 12001 are IVD compliant.

Intended use

This manual contains all of the information required for maintenance and repair of

91xx pH/Electrolyte Analyzers (9110 pH Analyzers and 9120, 9130, 9140, 9180 and

9181 Electrolyte Analyzers).

The user must be familiar with the function and operation of the instrument to fully

understand the processes described here.

e

For more information about 91xx pH/Electrolyte Analyzers, refer to corresponding

Instructions for Use.

Observe the service and repair procedures described in this manual and use only

genuine Roche replacement parts and Roche-approved materials to guarantee the full

functionality of the 91xx pH/Electrolyte Analyzers.

e

For the order numbers of replacement parts, refer to:

91xx pH/Electrolyte Analyzers Spare Part List

Roche Diagnostics April 2007

Service Manual · Version 2.0 3

Page 4

Copyrights

Trademarks

91xx pH/Electrolyte Analyzers

e

For an overview of possible revisions and available software versions, see:

Software on page G-5

Service Manual on page G-6

© 2007 Roche Diagnostics GmbH, All rights reserved.

The contents of this document may not be reproduced in any form or communicated

to any third party without the prior written consent of Roche Diagnostics. Every

effort is made to ensure its correctness. Subject to change without notice.

COBAS, LIFE NEEDS ANSWERS, ROCHE MICROSAMPLER, SNAPPAK, ISETROL

are trademarks of Roche.

Contact addresses

Manufacturer

All other trademarks are the property of their respective owners.

Roche Diagnostics GmbH

D-68298 Mannheim / Germany

www.roche.com

Roche Diagnostics April 2007

4 Service Manual · Version 2.0

Page 5

91xx pH/Electrolyte Analyzers

Contents

Ver s io n Hi s to r y 3

Edition notice 3

Intended use 3

Copyrights 4

Trademarks 4

Contact addresses 4

Contents 5

Preface 9

How to use this manual 9

Where to Find Information 9

Conventions used in this manual 10

System Description Part A

1 Safety information

Important information A-5

Operating safety information A-6

Important notes and warnings A-6

Disinfectants A-7

Deproteinizer A-7

Other disinfectants A-7

ESD protection measures A-8

Explanation of the phenomenon A-8

Influence of electrostatic charges on components A-8

Why is ESD protection so important today? A-9

How can ESD protection be guaranteed? A-9

Conclusion A-9

2 Specifications

Specifications A-13

Specifications A-13

Operating Parameters A-13

Classifications A-15

3 Interface specifications

Interface specifications A-19

Interface information A-19

Example data string information A-20

Data Link Information (9180/9181 only) A-20

System interconnect - 9110, 9120, 9130, 9140 A-42

SBC PCB - power supply - 9110, 9120, 9130, 9140

A-43

SBC PCB - valve drivers - 9110, 9120, 9130, 9140

A-44

SBC PCB - pump motor driver / door detect - 9110,

9120, 9130, 9140 A-45

SBC PCB - input amplifiers - 9110, 9120, 9130, 9140

A-46

SBC PCB - temperature circuit - 9110, 9120, 9130,

9140 A-47

SBC PCB - analog selector and A/D converter - 9110,

9120, 9130, 9140 A-48

SBC PCB - microprocessor - 9110, 9120, 9130, 9140

A-49

SBC PCB - printer display drivers - 9110, 9120, 9130,

9140 A-50

Printer daughter PCB - 9110, 9120, 9130, 9140, 9180,

9181 A-51

Lamp PCB - 9110, 9120, 9130, 9140 A-52

Display daughter PCB - 9110 A-53

Preheater PCB - 9110 A-54

Display daughter PCB - 9120, 9130, 9140 A-55

System interconnect - 9180, 9181 A-56

SBC PCB - power supply - 9180, 9181 A-57

SBC PCB - valve drivers - 9180, 9181 A-58

SBC PCB - pump motor driver/door detect - 9180,

9181 A-59

SBC PCB - input amplifier - 9180, 9181 A-60

SBC PCB - temperature circuit - 9180, 9181 A-61

SBC PCB - analog selector and A/D converter - 9180,

9181 A-62

SBC PCB - microprocessor - 9180, 9181 A-63

SBC PCB - microprocessor - 9180, 9181 A-64

SBC PCB - Fluid pack detector - 9180, 9181 A-65

Lamp PCB - 9180, 9181 A-66

Display daughter PCB - 9180 A-67

Software operation Part B

4 Description of modules

Description of modules A-23

Mechanical assemblies A-23

Fluidic Module A-27

Electronics A-33

6 Software operation 9110

Software operation 9110 B-5

Overview B-5

Overall program operation flow B-6

Main menu B-7

Measurement sequence B-8

5 Electronic diagrams

Electronic diagrams A-39

9110 analyzer block diagram A-39

9120, 9130, 9140, 9180 analyzer block diagram A-40

9181 analyzer block diagram A-41

Roche Diagnostics April 2007

Service manual · Version 2.0 5

Print functions menu B-9

QC sample menu B-10

Daily maintenance menu B-11

Operator functions menu B-12

Program instrument menu B-13

Page 6

91xx pH/Electrolyte Analyzers

Service functions menu B-14

Calibration sequence B-15

7 Software operation 9120, 9130, 9140

Software operation 9120, 9130, 9140 B-19

Overview B-19

Overall program operating flow B-20

Main menu B-21

Measurement sequence B-22

Print functions menu B-23

QC/standard/urine sample menu B-24

Daily maintenance menu B-25

Operator functions menu B-26

Program instrument menu B-27

Service functions menu B-28

Calibration sequence B-29

8 Software operation 9180

Software operation 9180 B-33

Overview B-33

Overall program operation flow B-34

Main menu B-35

Measurement sequence B-36

Print functions menu B-37

QC/standard/dialysate/urine sample menu B-38

Daily maintenance menu B-39

Operator functions menu B-40

Program instrument menu B-41

Service functions menu B-42

Calibration sequence (1) (Example Na/K/Li

calibration) B-43

Calibration sequence (2) (Example Na/K/Li

calibration) B-44

Power-up B-45

9 Software operation 9181

Software operation 9181 B-49

Overview B-49

Overall program operting flow B-50

Main menu B-51

Manual measurement sequence B-52

Automated measurement sequence B-53

Print functions menu B-54

QC/std/dialysate/urine sample menu B-55

Daily maintenance menu B-56

Operator functions menu B-57

Program instrument menu B-58

Service functions menu B-59

Calibration sequence (1) (example Na/K/Li

calibration) B-60

Calibration sequence (2) (example Na/K/Li

calibration) B-61

Power-up sequence B-62

10 Service functions

Service functions B-65

TEST ELECTRODES B-65

TEST SAMPLE SENSOR B-65

TEST SnapPak SENSOR (9180 and 9181 only) B-65

TEST LANGUAGE SWITCH (9180 and 9181 only)

B-65

TEST SAMPLE DOOR (except 9181) B-66

TEST PROBE (9181 only) B-66

TEST AUTOSAMPLER (9181 only) B-66

TEST PUMP B-66

TEST PINCH VALVES B-67

TEST INTERFACE B-67

TEST AMPLIFIER B-67

ENTER SERVICE CODE B-67

Miscellaneous functions B-69

Maintenance Part C

11 Adjustments

Adjustments C-5

Sample contacts adjustment (9110 only) C-5

Sample sensor adjustment (9120/9130/9140/9180/

9181 only) C-5

Temperature Adjustment (9110/9140/9180/9181

only) C-6

12 Maintenance

Maintenance C-9

Daily maintenance C-9

Weekly maintenance C-9

Monthly maintenance C-9

Six month maintenance C-9

Annual preventive maintenance C-9

Troubleshooting Part D

13 Troubleshooting

Error messages and troubleshooting D-5

Status-LEDs D-5

STATUS: NOT CALIBRATED D-5

STANDARD A NOT DETECTED D-5

STANDARD B NOT DETECTED, STANDARD C

NOT DETECTED (9180/9181 only) D-6

CHECK SAMPLE CONTACTS(9110), CHECK

SAMPLE SENSOR (9120/30/40/80/81) D-6

CHECK REFERENCE HOUSING D-7

PLEASE CLOSE SAMPLE DOOR (except 9181) D-7

NO SAMPLE D-8

CLEANING FLUID NOT DETECTED D-8

CONDITIONING FLUID NOT DETECTED (except

9110) D-8

INTERFACE ERROR D-9

Roche Diagnostics April 2007

6 Service manual · Version 2.0

Page 7

91xx pH/Electrolyte Analyzers

PAPER JAM OR PRINTER DEFECT D-9

CHECK ELECTRODES D-9

## NOT CAL’D D-9

CLOG IN SAMPLE PATH (9110 only), CLOG

CHECK FLUID PATH (except 9110) D-11

↑↑↑↑ ↓↓↓↓ (Out of range) D-11

↑ ↓ (Temparature out of range) D-11

ERR D-12

PERFORM DAILY MAINTENANCE (except 9110)

D-12

REPLACE FLUID PACK D-12

CHECK TEMPERATURE (9140/9180/9181 only)

D-12

VALVE OVERTEMP! CHECK VALVES D-13

ERROR: UPPER NEEDLE SENSOR D-13

ERROR: LOWER NEEDLE SENSOR D-13

WHEEL MISSING OR SAMPLER DEFECT D-13

SAMPLER JAMMED OR DEFECTIVE D-14

Glossary Part E

Glossary E-3

Index Part F

15 Index

Versions Part G

16 Versions

Software G-5

Service Manual G-6

Version 1.0 G-6

Version 2.0 G-6

Roche Diagnostics April 2007

Service manual · Version 2.0 7

Page 8

91xx pH/Electrolyte Analyzers

Roche Diagnostics April 2007

8 Service manual · Version 2.0

Page 9

91xx pH/Electrolyte Analyzers

Preface

This manual contains all of the information required for the maintenance and repair

of the 91xx pH/Electrolyte Analyzers.

The user must be familiar with the function and operation of the instrument to fully

understand the processes described here.

e

For more information about instructions, refer to:

9180 Electrolyte Analyzers Instructions for Use

Observe the service and repair procedures described in this manual and use only

genuine Roche replacement parts and Roche-approved materials to guarantee the full

functionality of the 91xx pH/Electrolyte Analyzers.

e

For the order numbers of replacement parts, refer to:

91xx pH/Electrolyte Analyzers Spare Part List

e

For an overview of possible revisions and available software versions, see:

Software on page G-5

Service Manual on page G-6

How to use this manual

o

Keep this Service manual in a safe place to ensure that it is not damaged and remains available

for use.

o

This Service manual should be easily accessible at all times.

To help finding information quickly, there is a table of contents at the beginning of

the book and each chapter. In addition, a complete index can be found at the end.

Where to Find Information

In addition to the Service manual, the following documents are also provided to assist

in finding desired information quickly:

o 91xx pH/Electrolyte Analyzers Instructions for Use

o 9180 Electrolyte Analyzer Short Instruction

o 91xx pH/Electrolyte Analyzers Service manual (PDF or iSDoc version in

GRIPS)

o 91xx pH/Electrolyte Analyzers Spare Part List (PDF or iSDoc version in

GRIPS)

Roche Diagnostics April 2007

Service manual · Version 2.0 9

Page 10

Conventions used in this manual

Visual cues are used to help locate and interpret information in this manual quickly.

This section explains formatting conventions used in this manual.

Symbols The following symbols are used:

Symbol Used for

a Start of procedure

o List item

e

h Call-up (software reference)

Cross-reference

Note

All sections or text locations marked with "NOTE" describe safe

procedures that are intended to provide the user with additional help.

Caution

All sections or text passages that are marked with this symbol describe

procedures or indicate conditions or dangers that could damage or

lead to malfunctions in the instrument, and which therefore should

never be attempted.

Warning

Sections marked with this symbol contain information that must be

observed for the prevention of personal injury (to patients, users or

third parties).

Risk of infection!

(according to the standard DIN EN 61010-2-101:2002) (Instrument)

91xx pH/Electrolyte Analyzers

Risk of infection!

(according to the standard DIN ISO 15223-1:2005) (Consumables)

High Voltage

Passages that are marked with this symbol warn of an immediate

danger in connection with electrical wiring or components.

ESD protection measures

All sections or passages that are marked with this symbol warn of

specific dangers in connection with static discharge. Packages that are

marked with this symbol must only be opened by trained technical

staff.

For more information about ESD protection measures, see ESD protection measures

on page A-8.

Roche Diagnostics April 2007

10 Service manual · Version 2.0

Page 11

91xx pH/Electrolyte Analyzers

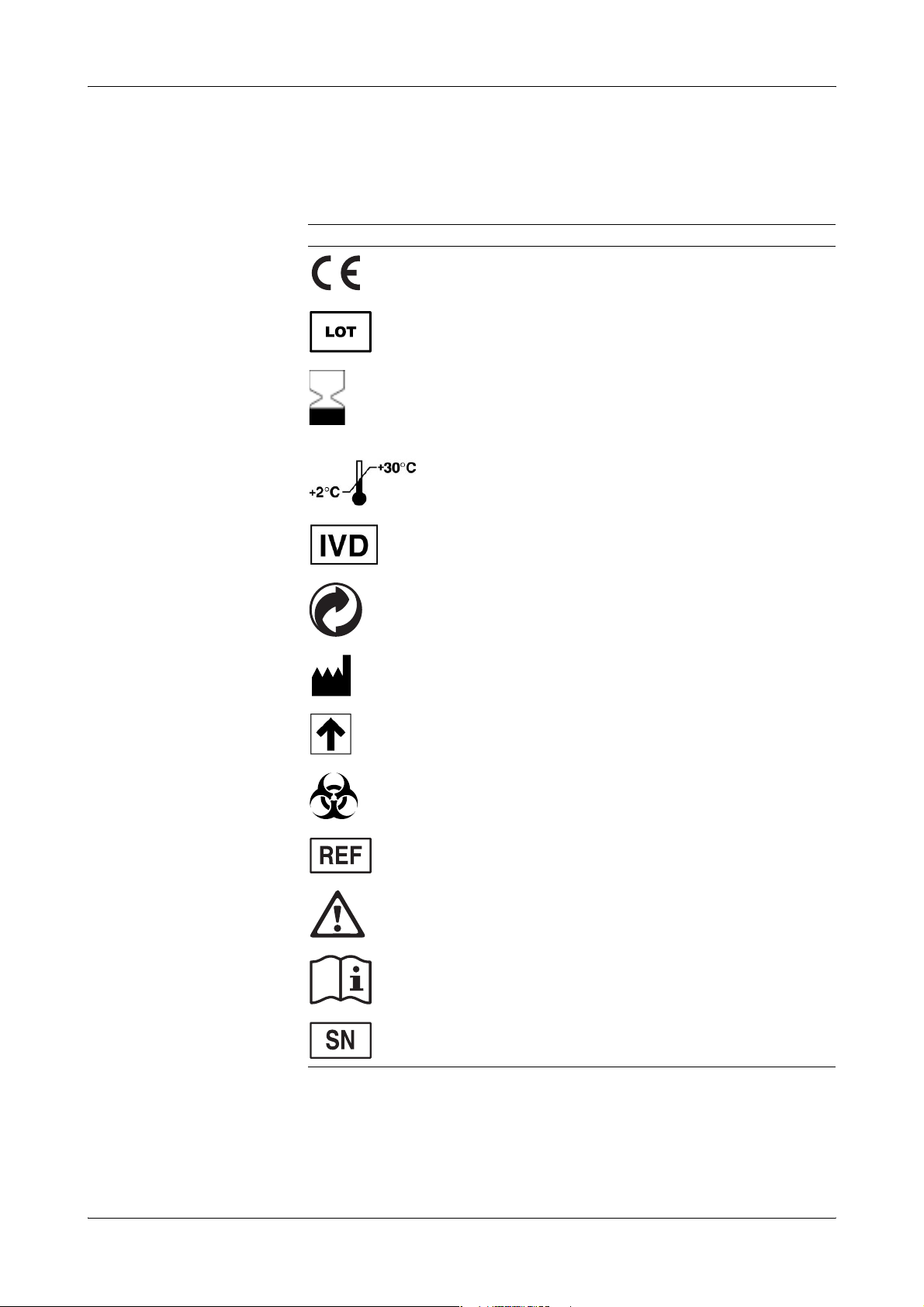

IVD symbols Instruments: applicable for 9180 Electrolyte Analyzers SN > 12001.

The IVD symbols are used in accordance with DIN EN 980:2003, ISO 15223:2000 (as

per the In Vitro Diagnostics Directive 98/79/EC), and DIN EN ISO 780:1997.

Symbol Description

This product complies with the requirements in the directive

98/79/EC on in vitro diagnostic medical devices.

Lot designation

Consumables: use by... (expiry date)

The consumables must be completely consumed by the indicated

date.

If a day is not indicated, apply the last day of the respective month.

Store at ...

The conditions necessary to preserve the product's shelf life before

opening.

For in vitro diagnostic use

"Grüner Punkt" (in Germany)

Manufacturer — according to directive 98/79/EC on in vitro

diagnostic medical devices

Store upright

Risk of infection!

(according to the standard DIN ISO 15223-1:2005) (Consumables)

Catalogue number

Caution (refer to accompanying documents). Please refer to safetyrelated notes in the manual, accompanying this instrument.

Please consult instructions for use

Serial number (model plate)

Roche Diagnostics April 2007

Service manual · Version 2.0 11

Page 12

91xx pH/Electrolyte Analyzers

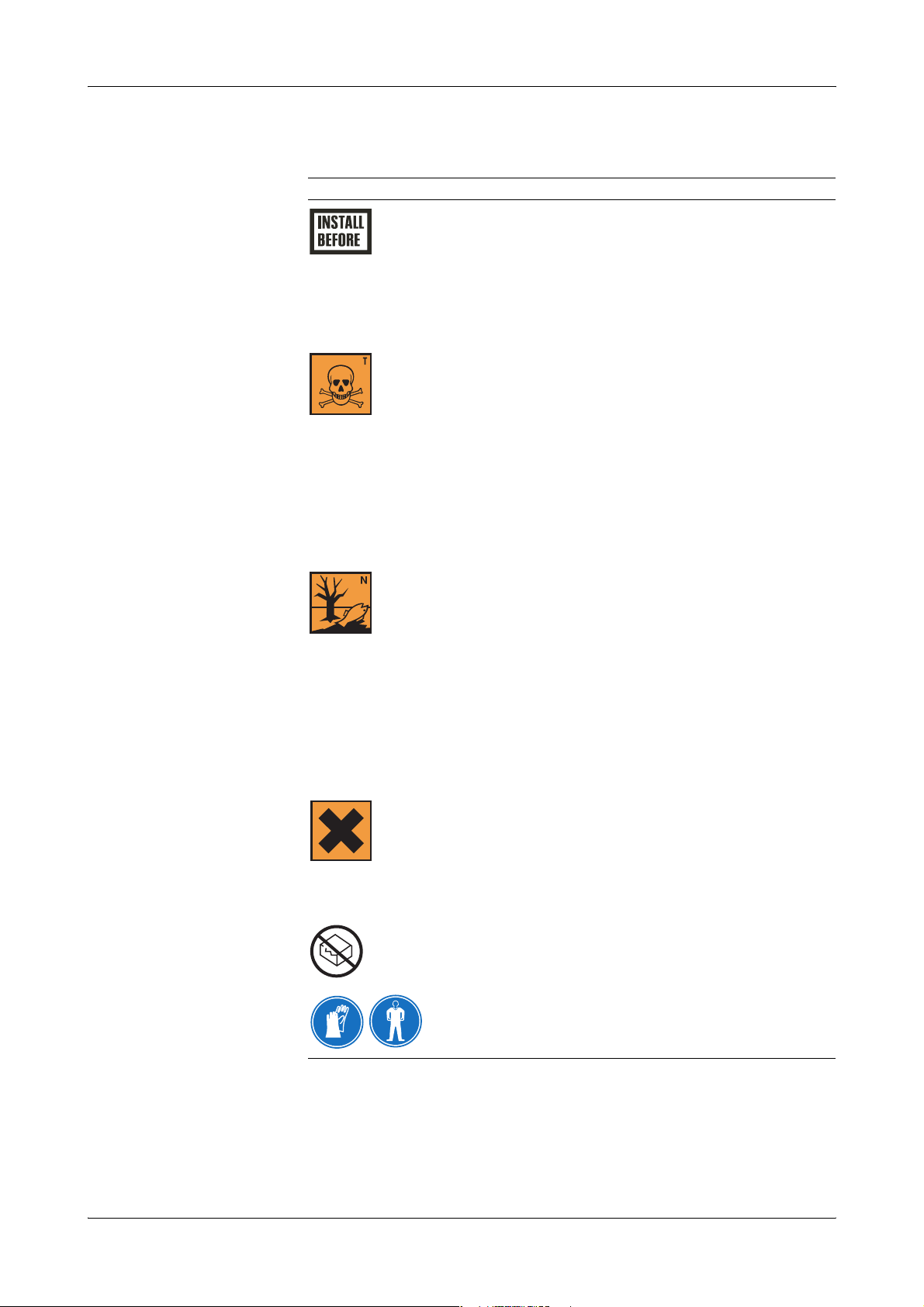

Other symbols The following symbols are listed as additional information:

Symbol Description

Electrodes:

This date indicates the limit of the maximum storage time of an

electrode. The electrode must be installed in the instrument no later

than the imprinted date.

If the installation takes place on the imprinted date, it still falls within

the specifications. The calculation of the “Install before” date is based

on the production date of the elctrode.

Danger symbol: T: Toxic (on the packaging of the reference electrode)

Rating: Inhalation, swallowing or skin contact with even small

quantities can lead to serious health risks, including fatal risks.

T: R23/33/50-53

N: S45/60/61/7

Characteristics of this type of item are severe, possible irreversible

damage to health through repeated or prolonged contact, particular

with carcinogenic, genetic or reproductive (danger to reproductive

capabilities) effects.

Caution: Avoid any contact with the human body. If you feel unwell,

contact a doctor immediately. Any substances with carcinogenic,

genetic or reproductive dangers are indicated appropriately. Always

observe the regulations when handling such substances.

Danger symbol: N: Dangerous to the environment (on the packaging

of the reference electrode)

Rating: If released into aquatic and non aquatic environments, can

cause immediate or delayed damage to ecosystems through a change

in environmental conditions.

These substances or their by-products can cause simultaneous

damage to sensitive environmental areas.

Caution: Depending on the potential for damage, do not allow the

substance to enter sewers, soils or the environment. Observe the

specific disposal regulations.

Danger symbol: Xi: Irritant

Rating: Although not corrosive, momentary, longer-lasting, or

repeated contact with skin or mucous membrane may result in

inflammation. Danger of sensitization during contact with skin

XI: R36/37/38, S 26-37

(when classified with R 43).

Caution: Avoid contact with eyes and skin, do not inhale vapors.

Do not use content if the packaging is damaged

Protective gloves, protective goggles and suitable protective clothing

must be worn

Roche Diagnostics April 2007

12 Service manual · Version 2.0

Page 13

91xx pH/Electrolyte Analyzers

Abbreviations The following abbreviations are used:

Abbreviation Definition

A

ADC Analogue to digital converter

ANSI American National Standards Institute

C

CMOS Complementary Metal-Oxide Semiconductor

E

EEPROM Electrically erasable programmable read-only memory

e.g. exempli gratia – for example

EC European community

EN European standard

ESD Electrostatic Discharge

H

HIV Human Immunodeficiency Virus

HW Hardware

I

IEC International Electrical Commission

ISE Ion selective electrode

IVD In vitro Diagnostics

L

LCD Liquid Cristal Display

LED Light Emitting Diode

M

MC Measuring chamber

MOS Metal-Oxide Semiconductor

MSDS Material safety data sheet

P

PCB Printed Circuit Board

Q

QC Quality control

R

REF Reference solution

S

SBC board Mainboard of the instrument

SW Software

T

TTL Transisitor-Transistor Logic

Roche Diagnostics April 2007

Service manual · Version 2.0 13

Page 14

91xx pH/Electrolyte Analyzers

Roche Diagnostics April 2007

14 Service manual · Version 2.0

Page 15

System Description

1 Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-11

3 Interface specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-17

4 Description of modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-21

5 Electronic diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-37

A

April 2007

Page 16

Page 17

91xx pH/Electrolyte Analyzers 1 Safety information

Tab l e o f c onte nt s

Safety information

In this chapter

Important information ...............................................................................................A-5

Operating safety information .....................................................................................A-6

Important notes and warnings ...................................................................................A-6

Disinfectants ................................................................................................................A-7

Deproteinizer .........................................................................................................A-7

Other disinfectants ................................................................................................ A-7

ESD protection measures ............................................................................................ A-8

Explanation of the phenomenon .......................................................................... A-8

Influence of electrostatic charges on components ...............................................A-8

Why is ESD protection so important today? ........................................................A-8

How can ESD protection be guaranteed? .............................................................A-9

Conclusion .............................................................................................................A-9

Chapter

1

Roche Diagnostics April 2007

Service manual · Version 2.0 A-3

Page 18

1 Safety information 91xx pH/Electrolyte Analyzers

Tab l e o f c onte nt s

Roche Diagnostics April 2007

A-4 Service manual · Version 2.0

Page 19

91xx pH/Electrolyte Analyzers 1 Safety information

Important information

Important information

This Service Manual contains vital warning and safety information.

This instruments are intended to be used only for the specialized purpose described

in the instructions. The most important prerequisites for use, operation, and safety

are explained to ensure smooth operation. No warranty or liability claims will be

covered if the instrument is used in ways other than those described or if the

necessary prerequisites and safety measures are not observed.

The instrument may be operated only by persons whose qualifications enable them to

comply with the safety measures that are necessary during operation of the

instrument.

Suitable protective equipment, like laboratory clothing, protective gloves, protective

goggles and if necessary mouth protectors, must be worn to prevent direct contact

with biological working materials. In addition, a face mask is required if there is a

risk.

Adjustments and maintenance performed with removed covers and connected power

may be attempted only by a qualified technician who is aware of the associated

dangers.

Instrument repairs are to be performed only by the manufacturer or qualified service

personnel.

Only accessories and supplies either delivered by or approved by Roche are to be used

with the instrument. These items are manufactured especially for use with this

instrument and meet the highest quality requirements.

Operation of the instrument with solutions whose composition is not consistent with

that of the original solutions can negatively affect, above all, the long term

measurement accuracy. Deviations in the composition of the solutions can also

decrease the service life of the electrodes.

The quality control requirements must be completed at least once daily for safety

reasons. Because accurate measurement results depend not only on the proper

functioning of the instrument, but also on a number of other factors (such as

preanalytics), the results produced by the instrument should be examined by a

trained expert before subsequent decisions are reached that are based on the

measurement values.

Explanation:

"Caution, refer to accompanying documents“

Roche Diagnostics April 2007

Service manual · Version 2.0 A-5

Page 20

1 Safety information 91xx pH/Electrolyte Analyzers

Operating safety information

Operating safety information

The instrument has been constructed and tested according to the following European

Standards:

o IEC/EN 61010-1:2001

o IEC/EN 61010-2-101:2002 (valid for 9180 Electrolyte Analyzers SN > 12001 only)

o IEC/EN 61010-2-081:2002 + A1:2003

It was delivered from the factory in flawless condition with regards to safety features.

In order to preserve this condition and ensure safe operation, the user must respect

the notices and warnings that are contained in this Service Manual

o This instrument is classified under the protection class I according to

IEC/EN 61010-1.

o The instrument meets the conditions for overvoltage category II.

o The instrument meets the conditions for contamination level 2.

o Do not operate the instrument in an explosive environment or in the vicinity of

explosive anesthetic mixtures containing oxygen or nitrous oxide.

o If an object or liquid enters the internal areas of the instrument, remove the

instrument from its power supply and allow an expert to check it thoroughly

before using it again.

o The instrument is suitable for long-term operation indoors.

o

The power cord may be plugged into a grounded socket only. When using an extension cord,

make sure it is properly grounded.

o

Any rupture of the ground lead inside or outside the instrument or a loose ground connection

may result in hazardous operating conditions. Intentional disconnection of the grounding is not

permitted.

o

The instrument is not suitable for operation with a direct current power supply. Use only the

original mains plug delivered with the instrument.

Important notes and warnings

o

Never operate the analyzer in the vicinity of volatile or explosive gases

(e.g. anesthetic gases, etc.)!

o

The instrument must be connected to a 2-pin, grounded socket.

o

The power cable and the plug must be undamaged. Damaged power cables and plugs must be

replaced immediately.

o

Before opening the back panel switch off the instrument and disconnect the power cable.

o

Replace damaged fuses with the specified type of fuse.

Roche Diagnostics April 2007

A-6 Service manual · Version 2.0

Page 21

91xx pH/Electrolyte Analyzers 1 Safety information

Disinfectants

o

Service and repair work must be done only as specified in this manual. Unqualified service or

repair work may result in warranty claims not being granted.

o

Use only suitable tools and test instruments for service and repair work.

o

Do not allow fluids to enter the interior of the instrument, because this may damage the

electronics.

o

Use only slightly moistened cloths or cotton sticks to clean the instrument.

Disinfectants

Use only liquid disinfectant such as protein remover (Roche deproteinizer) or an alcohol-based

(about 70%) surface disinfectant.

Do not spray disinfectant directly onto the instrument because this could cause malfunctions in the

electronics.

Do not use any type of bleaching agent. Exception: Roche Deproteinizer.

Deproteinizer

Composition Aqueous NaOCl solution with active chlorine (≤ 2%)

Hazards identification Due to the basic and oxidizing character of the reagent ("Deproteinizer") local

First aid measures

Other disinfectants

Do not attempt to clean/decontaminate any part of the instrument before shutting it down and

unplugging it from the power source.

Before plugging in the instrument again and switching it on always wait for 15 minutes to allow the

disinfectant to evaporate.

irritations after contact with eyes, skin or mucous membranes cannot be excluded.

After inhalation:

After skin contact:

After eye contact:

After drinking:

breath fresh air, drink large amounts of water

wash with generous amounts of water, remove contaminated clothing

rinse eyes with generous amounts of water, contact an eye specialist

drink large amounts of water, avoid vomiting, contact a doctor

Use standard alcohol-based (70%) disinfectants to clean the surface of the

instrument. Read the product information first.

Never use standard disinfectant to clean the tubes and tubing paths under any circumstances!

Do not use any type of bleaching agent. Exception: Roche Deproteinizer.

Roche Diagnostics April 2007

Service manual · Version 2.0 A-7

Page 22

1 Safety information 91xx pH/Electrolyte Analyzers

ESD protection measures

ESD protection measures

ESD = Electrostatic Sensitive Device

Explanation of the phenomenon

The most frequent cause of electrostatic discharge is friction of various materials such

as plastic, synthetic fiber, hard rubber or paper.

It can also be caused by bending or applying pressure to a material.

Discharges that are dangerous to components occur when "charged" bodies or

components do not have a discharge connection (ground) to discharge the

electrostatic charge.

The discharges normally do not have a high capacity, but there are often voltage

differences in the range of several thousand volts. The discharges are perceived as

small shocks or visible sparks.

Examples: o Shoes with rubber soles:

Friction is caused by walking. A person develops an electrical charge different

from the ground. A discharge occurs when an object (e.g. door handle) is

contacted.

o Synthetic fiber clothing:

Discharge is audible and is visible in darkness.

The dryer the air the greater the risk of electrical discharge caused by friction.

Eectrostatic charges are less likely to build up in humid air, particularly when saturated with water

vapor.

The probability of ESD phenomena is therefore particularly great in a northern hemisphere winter

in centrally heated rooms where the humidity is low.

Influence of electrostatic charges on components

If a person with an electrostatic charge touches a component, a discharge over a

connection of an IC or semiconductor element may occur. The resulting voltages may

damage the component.

Critical situations can occur while repairing or testing components if they are lying

on a more or less conductive surface (e.g. table top) and a person with an electrostatic

charge touches them. A discharge through a critical component connection can also

occur in this case.

Roche Diagnostics April 2007

A-8 Service manual · Version 2.0

Page 23

91xx pH/Electrolyte Analyzers 1 Safety information

ESD protection measures

Why is ESD protection so important today?

Formerly, current controlling semiconductors were mostly used (TTL, normal

transistors, etc.).

Today the principle of current logic is virtually the only technology in use in MOS

and CMOS components.

Currents generated by an electrostatic discharge (as much as several kV!) destroy the

sensitive component inputs or cause hidden damage. This damage is generally not

immediately detectable.

Another effect is that the clearances inside the ICs continuously become smaller. The

internal wires become thinner and thinner, the allowable maximum input voltages

become smaller and the effects of any discharges become more and more critical.

How can ESD protection be guaranteed?

A continuous discharge is required when working on an electronic assembly. Do this

as follows:

o Use ESD wrist bands (special wrist bands connected to a protective ground).

o Repairs and tests on assemblies must only be conducted on tables with ESD mats

connected to grounds or ESD wrist bands.

o Always pick up components at the edge (e.g. like a photo).

o Components must always be transported in ESD packages or appropriate storage

or shipping containers (use original packaging!).

o Shoes with rubber soles or clothing of synthetic fibers must not be worn in

workshops where electronic components are repaired.

o Use a humidifier if necessary to maintain optimum humidity in the work area.

o Do not touch assemblies or components with the hand after testing.

o Always transport and ship assemblies or components for repair in ESD protective

packaging only. This will prevent further damage that may result in

misinterpretation of the original cause of the fault.

The ESD mat consists of materials that have a very low, defined conductivity (1012 ohms).

The following materials prevent charges caused by friction from building up and protect the

component from damage.

o

ESD mats

o

ESD packages

o

Shipping containers

Conclusion

Of course, not all circuit boards and electronic assemblies require such careful

handling. An electrical board that only carries simple plug connectors does not

require ESD packaging.

In cases of doubt always use ESD packaging.

Roche Diagnostics April 2007

Service manual · Version 2.0 A-9

Page 24

1 Safety information 91xx pH/Electrolyte Analyzers

ESD protection measures

Roche Diagnostics April 2007

A-10 Service manual · Version 2.0

Page 25

91xx pH/Electrolyte Analyzers 2 Specifications

Tab l e o f c onte nt s

Specifications

In this chapter

Specifications .............................................................................................................A-13

Specifications .......................................................................................................A-13

9110 ................................................................................................................A-13

9120/9130/9140/9180/9181 ...........................................................................A-13

Operating Parameters .........................................................................................A-13

9110 ................................................................................................................A-13

9120/9130/9140/9180/9181 ...........................................................................A-14

Common operating parameter .....................................................................A-14

Classifications ......................................................................................................A-15

Product data ...................................................................................................A-15

Approvals .......................................................................................................A-15

Chapter

2

Roche Diagnostics April 2007

Service manual · Version 2.0 A-11

Page 26

2 Specifications 91xx pH/Electrolyte Analyzers

Tab l e o f c onte nt s

Roche Diagnostics April 2007

A-12 Service manual · Version 2.0

Page 27

91xx pH/Electrolyte Analyzers 2 Specifications

Specifications

Specifications

Specifications

9110

Sample types Whole blood, Serum, Plasma, QC solutions

Reported parameters Measuring range Resolution

pH 6.00 - 8.00 0.001 pH units

Ta b le A -1 9110 reported parameters

9120/9130/9140/9180/9181

Sample types Whole blood, Serum, Plasma

Reported parameters Measuring range Resolution

Sodium (Na+) 40 - 205 mmol/L 0.1 mmol/L

Potassium (K

Chloride (Cl

Calcium (Ca

Lithium (Li

Ta b le A -2 9120, 9130, 9140, 9180, 9181 reported parameters (1)

Sample type Urine

Reported parameters Measuring range Resolution

Sodium (Na+) 1 - 300 mmol/L 1.0 mmol/L

Potassium (K

Chloride (Cl

Ta b le A -3 9120, 9130, 9140, 9180, 9181 reported parameters (2)

Calcium and Lithium are not measured in urine samples.

Lithium is not measured in dialysate samples.

+

) 1.5 - 15 mmol/L

(0.8 - 15 mmol/L dialysate)

–

) 50 - 200 mmol/L 0.1 mmol/L

2+

) 0.2 - 5.0 mmol/L 0.01 mmol/L

+

) 0.1 - 6.0 mmol/L 0.001 mmol/L

+

) 4.5 - 120 mmol/L

(60 - 120 mmol/L

with add. dilution)

–

) 1 - 300 mmol/L 1.0 mmol/L

0.01 mmol/L

0.1 mmol/L

Operating Parameters

9110

Sample types Whole blood, serum, plasma, aqueous and QC solutions

Sample device Syringe, sample cup, capillary, Roche MICROSAMPLER

Roche Diagnostics April 2007

Service manual · Version 2.0 A-13

Page 28

2 Specifications 91xx pH/Electrolyte Analyzers

Specifications

Sample size 25 μL

Analysis time 70 seconds

Sample rate o 40 per hour with printout

o 50 per hour without printout

pH Sensor pH sensitive flow-through glass capillary electrode in transparent acrylic plastic

Reference System Open liquid junction, flow-through electrode

Calibration o Fully automatic

o 1 point with each sample

o 2 point every 3 hours

Warm-up t ime 10 minutes

9120/9130/9140/9180/9181

Sample types Whole blood, serum, plasma, urine, dialysate (acetate or bicarbonate)

Sample device Syringe, sample cup, capillary, Roche MICROSAMPLER

Sample size 95 μL

Analysis time 50 seconds

Sample rate o 45 per hour with printout

o 60 per hour without printout

Sodium (Na

Potassium (K

Chloride (Cl

Calcium (Ca

Lithium (Li

+

) sensor Ion-selective, flow-through, glass capillary electrode

+

) sensor Ion-selective, flow-through, liquide membrane electrode

–

) sensor Ion-selective, flow-through, liquide membrane electrode

2+

) sensor Ion-selective, flow-through, liquide membrane electrode

+

) sensor Ion-selective, flow-through, liquide membrane electrode

Reference system Open liquid junction, flow-through electrode

Calibration o Fully automatic

o 1 point with each sample

o 2 point every 3 hours (9180/9181 every 4 hours)

Warm-up t ime 10 minutes

Common operating parameter

Standby mode Suspends calibrations

Te mp e ra t ur e Room temperature, 15 - 32°C, 60 - 90 °F

Roche Diagnostics April 2007

A-14 Service manual · Version 2.0

Page 29

91xx pH/Electrolyte Analyzers 2 Specifications

Specifications

Humidity maximum 85 % relative humidity, non-condensing

Data management Quality control memory storage, 3 levels, 35 values; calculation of mean, standard

deviation and coefficien of variation (CV)

Diganostic programs user-controlled diagnostics, YES/NO operation via the display

Electronics Microprocessor-controlled

Display LCD dot-matrix, 2 lines, 16 characters per line

Printer Integral thermal printer, 16 characters width

Autosampler (9181 only) Integral turntable, 18 positions, 2 mL or 0.25 mL sample cups

Interface RS232C serial port

DataLink Data link to COMAPCT 2/3 (9180/9181)

Electrical requirements 100 - 240 VAC, 50/60 Hz (90 - 250 VAC for 9110), self adjusting

Nominal power consumption 50 W

Dimensions

Classifications

Product data

Safety category I

Device type B (according to ÖVE-MG/EN 60601-1,

Mode of operation continuous operation

Protection classification IP 20

Height 335 mm (12.2")

Width 315 mm (12.4")

Depth 295 mm (12.0")

Weight approx. 6 kg (13 lbs)

Ta b le A -4 Instrument dimensions

IEC 601-1)

Explosion protection the device is not designed for operation in explosive environments.

Approvals

CSA, CE, FCC Class B

CLIA Complexity Category: Moderate

Test System Code: 04739

Roche Diagnostics April 2007

Service manual · Version 2.0 A-15

Page 30

2 Specifications 91xx pH/Electrolyte Analyzers

Specifications

FDA 510(k) numbers: K932642 (9110)

K961458 (9180)

K972673 (9181)

Analyte Codes: Na

Special requirements for IVD

products

+

: 5805

+

: 4910

K

–

Cl

: 1018

2+

Ca

: 1004

+

Li

: 3712

EN 61010-2: 2001-12

EN 61010-2: 2002-01

(9180 SN > 12001 only)

Data subject to change without notice. Technical information is supplied for general informational

purposes only!

Roche Diagnostics April 2007

A-16 Service manual · Version 2.0

Page 31

91xx pH/Electrolyte Analyzers 3 Interface specifications

Tab l e o f c onte nt s

Interface specifications

In this chapter

Interface specifications ..............................................................................................A-19

Interface information ..........................................................................................A-19

Software .........................................................................................................A-19

Example data string information .......................................................................A-20

Automatic Calibration Report ......................................................................A-20

Serum sample report ..................................................................................... A-20

Data Link Information (9180/9181 only) .......................................................... A-20

Chapter

3

Roche Diagnostics April 2007

Service manual · Version 2.0 A-17

Page 32

3 Interface specifications 91xx pH/Electrolyte Analyzers

Tab l e o f c onte nt s

Roche Diagnostics April 2007

A-18 Service manual · Version 2.0

Page 33

91xx pH/Electrolyte Analyzers 3 Interface specifications

Interface specifications

Interface specifications

Interface information

The 9110, 9120, 9130, 9140, 9180 and 9181 analyzers are equipped with a standard

serial interface output. This interface output is intended to be used with standard

commercially available computer systems.

The data transmitted through the serial interface port employs the ASCII code.

The serial interface is terminated on the rear cover with a 9-pin male DB-9 connector.

The signal levels are as follows:

o Binary 1 = -12 V to -3 V

o Binary 0 = +3 V to +12 V

Two stop bits follow the eight data bits to complete the 10 bit word.

The baud rate is set at 9600 Baud fixed.

The maximal recommended cable length is 40 feet.

Software

The pin assignment is as follows:

o pin 1...sample ground...GND

o pin 2...receive data....RxD

o pin 3...send data.......TxD

o pin 4...NC

o pin 5...signal ground...GND

o pin 6...NC

o pin 7...RTS (not used)

o pin 8...CTS(not used)

o pin 9...NC

(NC=Not Connected)

Higher discharge current

A higher discharge current can be expected when using the serial interface. This must be checked by

suitably qualified personnel, depending on the local regulations.

The patient sample data is sent at the end of each measurement, the calibration report

is sent at the end of each calibration.

The interface is always on, independent of the printer settings; the data is always sent.

Note

The arrow up (e.g. out of normal range) is sent as HEX 18 (↑), the arrow down as HEX19 (↓) and

the ° (degree) is sent as HEX1A (→).

Roche Diagnostics April 2007

Service manual · Version 2.0 A-19

Page 34

3 Interface specifications 91xx pH/Electrolyte Analyzers

Interface specifications

Example data string information

Automatic Calibration Report

<sx>* AVL 9130*<cr><crlf>ELECTROLYTE ISE<cr><crlf> 03JAN92

10:51crcrlf*CALIBR REPORT*<cr><crlf><cr><crlf>

DailyMaintenance<cr><crlf>Performed Last: <cr><crlf> 02JAN92 10:35

<cr><crlf><cr><crlf> Standard A<cr><crlf>Na = -112mV (3)<cr><crlf>

K = -1392mV (3)<cr><crlf>Cl = -106mV (3)<cr><crlf><cr><crlf>

Difference A-B<cr><crlf>Na = 1402mV ( )<cr><crlf>K = 1032mV ( )

<cr><crlf>Cl = -1006mV ( ) <cr><crlf><cr><crlf>Fluid Pack:<cr><crlf>

68% Remaining<cr><crlf><cr><crlf><ex>

Serum sample report

<sx>* AVL 9130*<cr><crlf>ELECTROLYTE ISE<cr><crlf> 03JAN92

10:59<cr><crlf><cr><crlf> Name: ..........<cr><crlf> ..........

<cr><crlf>Sample: SERUM<cr><crlf><cr><crlf> Sample No.13

<cr><crlf><cr><crlf>Na= 159soh mmol/L<cr><crlf>K = 5.4 mmol/L

<cr><crlf>Cl= 122soh mmol/L<cr><crlf><cr><crlf>*PERFORM DAILY *

<cr><crlf>*MAINTENANCE ! *<cr><crlf><cr><crlf><ex>

Data Link Information (9180/9181 only)

The data link with the COMPACT 2/3 blood gas analyzer allows to combine ISE

results with pH/blood gas results on one printout. If Ca

9181, a pH-corrected Ca

sample report.

For connection of the 9180/9181 analyzer to the COMPACT 2/3 analyzer, the optional

Interface Kit is required. To install the kit, first turn both instruments off. Connect the

interface filter provided in the kit to the RS232 port on the 9180/9181. Then connect

one end of the cable to the interface filter, the other end to the COM 2 port on the

COMPACT 2/3. On the COMPACT 2/3, select 9180 under the COM 2 interface

options.

e

See COMPACT 2/3 Operator's Manual for details.

2+

2+

value will be calculated and printed on the combined

is activated on the 9180/

Roche Diagnostics April 2007

A-20 Service manual · Version 2.0

Page 35

91xx pH/Electrolyte Analyzers 4 Description of modules

Tab l e o f c onte nt s

Description of modules

Insert introducing text here.

In this chapter

Description of modules ............................................................................................ A-23

Mechanical assemblies ........................................................................................A-23

Front door assembly ...................................................................................... A-23

Needle unit assembly .....................................................................................A-23

Electrode holder assembly ............................................................................A-24

Peristaltic pump assembly .............................................................................A-24

Solenoid assembly .........................................................................................A-25

Printer assembly ............................................................................................A-25

Rear panel assembly ......................................................................................A-25

SBC board ...................................................................................................... A-26

Lamp board ....................................................................................................A-27

Display board ................................................................................................. A-27

Fluidic Module ....................................................................................................A-27

Standard A ....................................................................................................A-27

Standard B .....................................................................................................A-27

Standard C (not on 9110) ............................................................................. A-27

Cleaning solution (9110 only) ...................................................................... A-28

Reference solution .........................................................................................A-28

Waste liquids .................................................................................................. A-28

Main tube set (all models)/ Intake tube set (9110 only) ............................. A-28

Sample Contacts (9110 only) ........................................................................ A-29

Electronics ............................................................................................................A-33

ISE SBC card ..................................................................................................A-33

Lamp board ....................................................................................................A-34

Display board ................................................................................................. A-35

Chapter

4

Roche Diagnostics April 2007

Service manual · Version 2.0 A-21

Page 36

4 Description of modules 91xx pH/Electrolyte Analyzers

Tab l e o f c onte nt s

Roche Diagnostics April 2007

A-22 Service manual · Version 2.0

Page 37

91xx pH/Electrolyte Analyzers 4 Description of modules

Description of modules

Description of modules

After changing any part of the analyzer always perform a calibration of the analyzer as well as a full

QC measurement. QC measurements must be performed in their entirety (i.e., all three QC levels

must be measured). Omitting QC measurements or ignoring QC measurement results may lead to

incorrect patient measurements, which may result in incorrect clinical decisions, possibly

endangering the patient's health.

Mechanical assemblies

Front door assembly

For the 9110, 20, 30, 40 and 80 analyzers, the front door can be removed by moving

the analyzer to the edge of a work surface so the analyzer door, when opened, will

extend past the edge of the work surface. With one hand, hold the analyzer door near

the right side hinge pin and, with the other hand, gently apply pressure to the middle

rear area of the door. This will allow the right hinge pin to clear the retaining hole in

the main chassis. The door can then be removed from the analyzer.

Needle unit assembly

The 9181 front panel can be removed by tilting it slightly away from the analyzer and

lifting it straight up. The plastic window can also be replaced in the field by gently

pressing from the rear of the window and snapping the plastic window out toward the

front of the analyzer door. The door magnets cannot be replaced in the field as they

are glued in place with conductive adhesive.

Due to the update of the 9180 Electrolyte Analyzer according to IVDD compliance a new shielded

front door "FRONT DOOR 9180" is available and compatible with any 9180 Electrolyte Analyzer

(old type SN < 11999 and new type SN > 12001) and with 9120, 30, 40 Electrolyte Analyzers.

Further information: see the 91xx Spare Parts List.

e

See the 91xx Spare Parts List for a detailed reference of the parts of this assembly.

To remove the 9110 fill port for replacement or cleaning, grasp the white tab on the

fill port and rotate the bayonet-style connector counter-clockwise. Gently pull the fill

port forward to remove. Replacement can be accomplished in the reverse order.

During removal, be careful not to bend the needle.

The 9110 fill port assembly is desinged for easy removal without the use of tools, for

cleaning, changing tubing or replacement. First, disconnect the sample intake tube on

the left side of the fill port assembly from the sample preheater. Grasp the fill port

assembly and pull it forward carefully. Disconnect the wire from the needle arm. To

reassemble, reconnect the wire, press the fill port assembly into place and reconnect

the tubing.

The 9110 wash port located on the underside of the flap can be removed by appying

pressure to one side to overcome the snap fit. To reinsert, align wash port and apply

pressure to snap into place.

The 9120, 30, 40, 80 and 81 sample needle and fill port are both designed for easy

replacement by the user. To remove the fill port assembly for replacement, pull the fill

Roche Diagnostics April 2007

Service manual · Version 2.0 A-23

Page 38

4 Description of modules 91xx pH/Electrolyte Analyzers

Description of modules

port holder towards the front for easy access. Then, press the two plastic tabs on the

fill port to allow removal of the fill port from the fill port holder. The sample needle

can also be removed and is supplied as a one-piece assembly including the intake

tubing.

To remove the 9120, 30, 40, 80 and 81 sample needle, grasp the needle near the white

holder block and pull up to unsnap the sample needle from its position. To replace

the assembly, align a replacement sample needle and press the replacement assembly

into place.

Two (9110) or three screws (9120, 30, 40, 80, 81) located on the left side of the

assembly hold the needle unit assembly in place. To access the two rear screws, turn

power off and remove the rear panel. The rear panel can be moved away from the unit

for easier access by unplugging the wire harness from the power supply. The SBC

board can now be removed by removing the screws which secure the SBC board and

disconnecting the cables on the SBC board.

Disconnect the connector to the lamp board which supplies the Door Open signal.

The two rear screws which secure the needle unit can now be removed using a Philips

screwdriver (9110) or an Allen wrench (9120, 30, 40, 80, 81). Then, remove the front

securing screw (n./a. on the 9110), the sample intake tubing and the reagent supply

tubing (red tag) from the fill port. The needle unit can now be removed from the

front of the analyzer for replacement.

Electrode holder assembly

Peristaltic pump assembly

e

See the 91xx Spare Parts List for a detailed reference of the parts of the needle unit.

To remove the electrode holder assembly from the analyzer, first unplug the sample

intake tubing on the right side of the module, then the preheater cable (9110 only) or

the sample sensor cable (9120, 30, 40, 80 and 81), then remove the reference solution

tubing connector and last, take out the waste tube (green tag) at the left side of the

electrode holder. The electrode holder can now be removed by pressing the two

plastic tabs (right and left side of the module) and sliding the module forward. Press

the plastic tabs again to release the second detent and completely remove the module

from the analyzer. The sample preheater or the sample sensor and/or the left side

electrode holder can be removed and replaced by removing the screws on the under

side of this module.

e

See the 91xx Spare Parts List for a detailed reference of the parts of this assembly.

Replacement of the roller assembly of the peristaltic pump can be accomplished by

removing the pump tubing and firmly pulling the roller assembly toward the front. To

replace the roller assembly, align the roller and the flat on the motor shaft and press

the replacement roller into position.

To remove the motor, first remove the rear panel assembly and SBC Board.

e

For details, see Rear panel assembly on page A-25, SBC board on page A-26.

Now, the electrical connector on the lamp board can be accessed to unplug the motor

connector. The motor can now be removed by removing four screws located on the

front of the housing near the peristaltic pump.

Roche Diagnostics April 2007

A-24 Service manual · Version 2.0

Page 39

91xx pH/Electrolyte Analyzers 4 Description of modules

Description of modules

Solenoid assembly

Removal of each solenoid is identical. Each solenoid valve has a removable pressure

piece which is held in place by a solenoid cap. To remove the pressure piece, locate the

arrow on the solenoid cap and remove the solenoid cap by sliding it off the solenoid

shaft in the direction of the arrow. This exposes the pressure piece which can now be

removed from the solenoid shaft. To replace pressure piece and cap, energize the

solenoid as described in TEST PINCH VALVES on page B-67. This extends the

solenoid shaft to the outermost position for ease in replacing pressure piece and cap.

Removal of the pressure piece and cap is required prior to removing the solenoid and

allows for easier replacement of the tubing under each solenoid.

To remove the solenoid assembly, the rear panel and the SBC Board (described in

Rear panel assembly on page A-25 and SBC board on page A-26) must be removed

first.

e

For details, see Rear panel assembly on page A-25, SBC board on page A-26.

Each solenoid has an electrical connection to the lamp board which must be

unplugged prior to removal of the solenoid. At this point, remove the two screws on

the front panel to remove the solenoid assembly.

Printer assembly

Note

The 9110 R-solenoid incorporates two heat sinks and is not interchangeable with the other

solenoids.

The printer assembly is designed to allow for easy removal by the user which can be

accomplished without removal of the electrical power to the analyzer. Slide the paper

tray forward to allow access to the printer, tear the paper roll and completely remove

it together with the paper tray. Slide fingers under the printer assembly and pull the

printer forward. This will disengage the printer from the interconnector and enable

removal of the assembly from the front of the analyzer. Removal of the printer should

be performed for replacement and for removal of a paper jam.

To replace the printer, locate the printer slide and insert the printer assembly. Press

firmly into place to ensure electrical connection of the printer.

Note

Never attempt to dislodge paper from the printer with a paper clip or similar object to avoid

damage to the print head or printer platen.

Due to the update of the 9180 Electrolyte Analyzer according to IVDD compliance a new printer

assembly "PRINTER MODULE, ISE" is available and compatible with 9110 pH Analyzers and

with any 9120, 30, 40, 80 and 81 Electrolyte Analyzer.

e

Further information: see the 91xx Spare Parts List.

Rear panel assembly

To remove the rear panel assembly, ensure that the power cord has been disconnected

from the analyzer. Remove the four corner screws to expose the rear panel. The power

supply module located on the rear panel assembly can now be removed by removing

the three screws securing the circuit board and by disconnecting the wiring

Roche Diagnostics April 2007

Service manual · Version 2.0 A-25

Page 40

4 Description of modules 91xx pH/Electrolyte Analyzers

Description of modules

interconnections. The main power receptacle can also be replaced by removing the

two screws holding this assembly.

Due to the update of the 9180 Electrolyte Analyzer according to IVDD compliance a new power

supply module "POWER SUPPLY 9180 >SN 12001" is available and compatible with 9180

Electrolyte Analyzers serial number > 12001 only.

The former power supply "MODULE POWER SUPPLY, ISE" is still available and has to be used

for 9180 Electrolyte Analyzers SN < 11999, for 9110 pH Analyzers and for 9120, 30, 40 and 81

Electrolyte Analyzers.

e

Further information: see the 91xx Spare Parts List.

After changing the main board or the power supply always perform a measurement of protective

ground resistance to ensure a safe connection of the system ground. Always measure with the power

cord attached to the analyzer. The resistance measurement has to be done between the ground pin

of the power plug and several ground connectors placed on each of the analyzer's electronic

components such as power supply or main board and shielding. The total resistance should not

exceed 0.5 ohms. Be sure to consider the resistance of the ohmmeter's connecting cables.

SBC board

After the rear panel has been removed, the SBC Board is accessible for removal. This

circuit board can be removed by removing the seven screws securing the board to the

housing and by disconnecting electrical connectors from the power supply module,

display board and lamp board.

e

For details, see Rear panel assembly on page A-25.

The electrode push pins can now be replaced by simply pulling the connecting pin

from its socket. When installing the board, make sure to place the plastic washers

under the screw heads.

Due to the update of the 9180 Electrolyte Analyzer according to IVDD compliance a new SBC

board "MAINBOARD 9180 >SN 12001" is available and compatible with 9180 Electrolyte

Analyzers serial number > 12001 only. The former SBC board "MAINBOARD 9180 <SN 11999"

is still available and has to be used for 9180 Electrolyte Analyzers SN < 11999.

Further information: see the 91xx Spare Parts List.

After changing the main board or the power supply always perform a measurement of protective

ground resistance to ensure a safe connection of the system ground. Always measure with the power

cord attached to the analyzer. The resistance measurement has to be done between the ground pin

of the power plug and several ground connectors placed on each of the analyzer's electronic

components such as power supply or main board and shielding. The total resistance should not

exceed 0.5 ohms. Be sure to consider the resistance of the ohmmeter's connecting cables.

Note

Due to the update of the 9180 Electrolyte Analyzer according to IVDD compliance the printouts,

display messages and data links sequences of the 9180 Electrolyte Analyzers serial number > 12001

will show "Roche" instead of "AVL". This also applies to 9180 Electrolyte Analyzers serial number

< 11999 in case of replacing the main board "MAINBOARD 9180 >SN 12001" or the program set

"PROGRAM SET 9180".

Roche Diagnostics April 2007

A-26 Service manual · Version 2.0

Page 41

91xx pH/Electrolyte Analyzers 4 Description of modules

Description of modules

Lamp board

The rear panel and SBC board must be removed to gain access to the lamp board.

Remove one screw and washer which hold the board in place and remove the

electrical connectors to remove this board.

Display board

The rear panel and SBC board must be removed to gain access to the display board.

Remove three screws and 50 degree spacers and unplug the preheater or sample

sensor cable from the front and the ribbon cable to the SBC board to remove the

display board.

Fluidic Module

Standard A

Standard A is drawn to the electrode module by vacuum provided by the peristaltic

pump.

9110 pH Analyzers: When Standard A is to be aspirated into the electrode module, solenoid valve A and R

9120, 30, 40, 80, 81 Electrolyte

Analyzers:

Standard B

are opened. Standard A is then drawn from the ISE SnapPak

TM

until Sample Contact

1 detects Standard A bridging the T-piece and Sample Contact 1. At this point,

solenoid valve V is opened and solenoid valve A is closed. The standard is pumped up

the tubing, through the wash portand into the sample needle until Sample Contact 2

detects the standard. The peristaltic pump slows down and the standard moves into

the electrode module until detected by Sample Contact 3 (bridge between sample

preheater tube and reference electrode). Then, the pump stops.

When Standard A is to be aspirated into the electrode module, solenoid valve A is

opened and solenoid valves B, V and R are closed. Standard A is then drawn from the

ISE SnapPak

TM

, to the fill port, through the sample needle and is sensed by the

sample sensor. At this point, solenoid valve V is opened and solenoid valve A is closed

as the peristaltic pump continues to pump Standard A into the electrode module. As

the trailing edge of the Standard A sample is sensed by the sample sensor, the

peristaltic pump stops.

During the time Standard A is aspirated into the electrode module, the reference

housing is pressurized due to the peristaltic pump providing pressure to the reference

solution line and solenoid valve R being closed. An amount of reference solution is

forced out through the reference junction to provide contact to the sample.

The process for Standard B is identical to that of Standard A with the exception of the

operation of solenoid valve B. This solenoid valve is operated in reverse order of

Standard A aspiration.

Standard C (not on 9110)

The process for Standard C is identical to that of Standard A with the exception of the

operation of solenoid valve C. This solenoid valve is operated in reverse order of

Standard A aspiration.

Roche Diagnostics April 2007

Service manual · Version 2.0 A-27

Page 42

4 Description of modules 91xx pH/Electrolyte Analyzers

Description of modules

Cleaning solution (9110 only)

The cleaning routine within the 9110 pH Analyzer is automatic with cleaning solution

being aspirated through the system every 40th sample or every 24 hours. Automatic

operator-initiated cleaning can also be performed, by selecting ELECTRODE

CLEANING from the main menu. The cleaning routine is very similar to the

aspiration of Standard A or B with solenoid valve C being opened to allow cleaning

solution to be aspirated through the fluidic path. The timing of the cleaning solution

routine allows for a larger volume of cleaning solution to be aspirated than the

Standard A or B cycles to ensure that cleaning solution covers the electrodes, wash

port, fill port, sample needle and preheater during the cleaning cycle.

Reference solution

The reference housing is filled automatically using the second winding of the

peristaltic pump and solenoid valve R. The reference solution connector allows for

the reference housing tubing to be plugged into the reference solution circuit. As the

peristaltic pump aspirates reference solution, solenoid valve R is opened to allow

excess solution to be pumped into the reference return line of the ISE SnapPak

TM

.

A check valve is placed in the return line to ensure that the KCl output is constant

(9110 only).

Waste liquids

Calibration standard and sample waste are pumped out of the left side of the

electrode module (green-banded tubing) through the peristaltic pump to the waste

line of the ISE SnapPak

line of each ISE SnapPak

SnapPak

TM

.

TM

. An internal one-way valve is incorporated into the waste

TM

Main tube set (all models)/ Intake tube set (9110 only)

The main tube set is supplied as a pre-cut tubing harness with the fluidic

interconnections preassembled. Replacement of the tube set should be performed

annually. For removal of the tubing, first remove the ISE SnapPak

compartment. This will allow access for removal of the white TPR block which is the

main interconnection between the ISE SnapPak

removed by grasping the front surface and pulling forward. Next, remove tubing from

each solenoid valve. Follow the procedure outlined in Section 4.1.5 for disassembly of

the solenoid valves to enable fluidic tubing to be easily removed at each solenoid.

e

For details, see Rear panel assembly on page A-25, SBC board on page A-26.

Pull the two pump windings at the peristaltic pump tube set off the pump roller and

remove the white reference solution tube connector. Remove the white TPR reference

solution block by grasping the front of the block and pulling forward. The three tube

connections are labeled with green, blue and red tags. All remaining tubes can now be

removed and the entire tubing harness can be discarded.

to prevent any waste products from leaking out of the ISE

TM

from the reagent

TM

and the tubing. This block can be

Fit the replacement tubing harness and assemble in reverse order as disassembly.

Reference the Tube Diagram on the next page for correct tube locations.

Intake Tube Set (9110 only) The intake tube set comprises three pieces of tubing. A short piece (red tag) fits

between the white T-piece and the standard contact. The long piece can be positioned

between the standard contact and the wash port. The remaining tube can be fitted

between the sample needle and the preheater tube.

Roche Diagnostics April 2007

A-28 Service manual · Version 2.0

Page 43

91xx pH/Electrolyte Analyzers 4 Description of modules

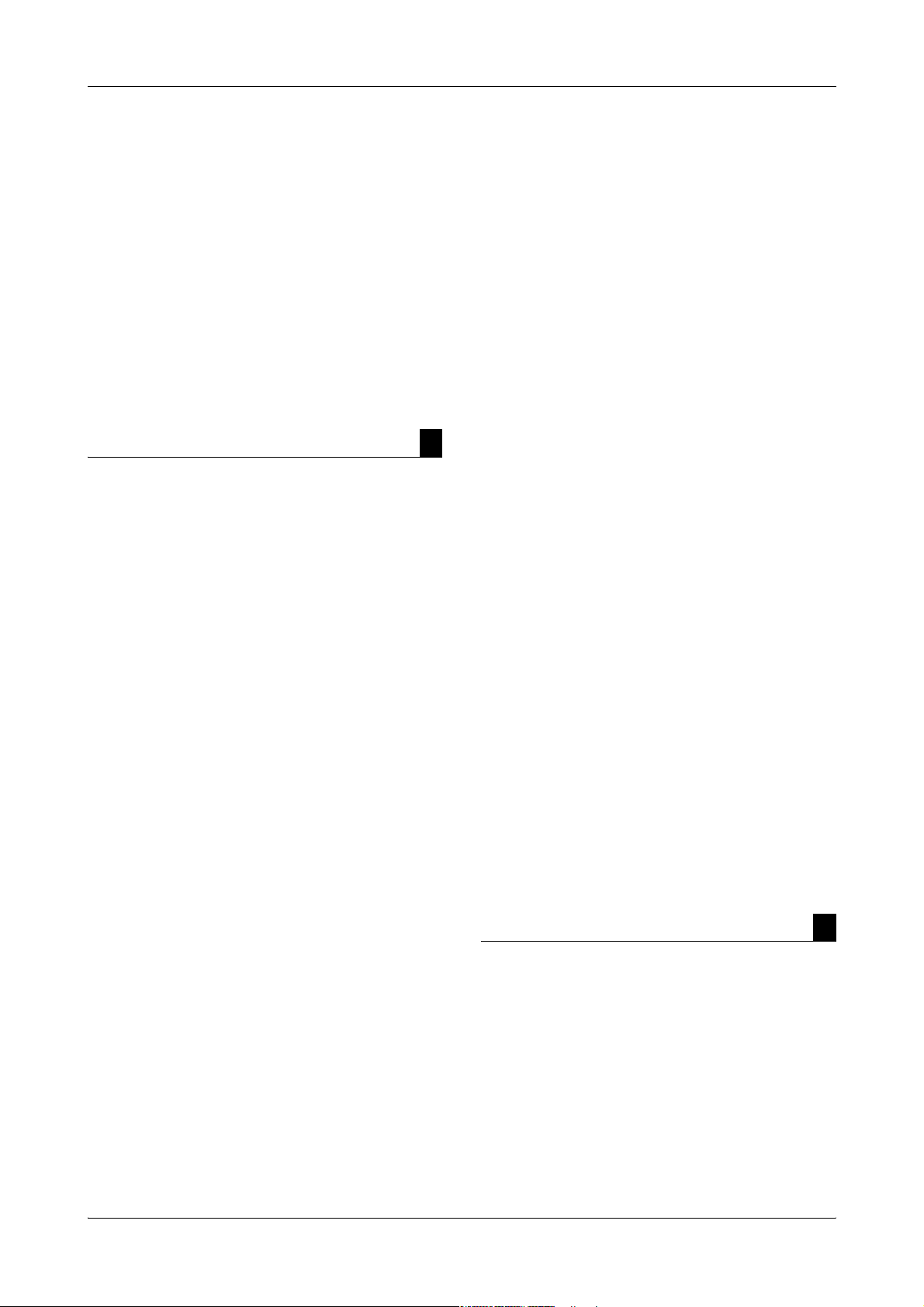

Description of modules

Sample Contacts (9110 only)

The 9110 fluid detection is based on the principle of measuring the impedance in a

sample contact path. There are three sample contacts in the 9110 pH Analyzer.

Sample Contact 1 senses standard solution draws.

Roche Diagnostics April 2007

Service manual · Version 2.0 A-29

Page 44

4 Description of modules 91xx pH/Electrolyte Analyzers

Description of modules

SAMPLE

SAMPLE PROBE

ASSEMBLY

PROBE

FILLPORT

RED

BLUE

LENOID V

SO

AIR VENT

R

PRE

HEATE

YELLOW DOT

pH

REF

GREEN

ELECTRODE ASSY

PERI PUMP

SOLENOID C

OID B

SOLEN

SOLENOID A

FLUID

CONNECTOR

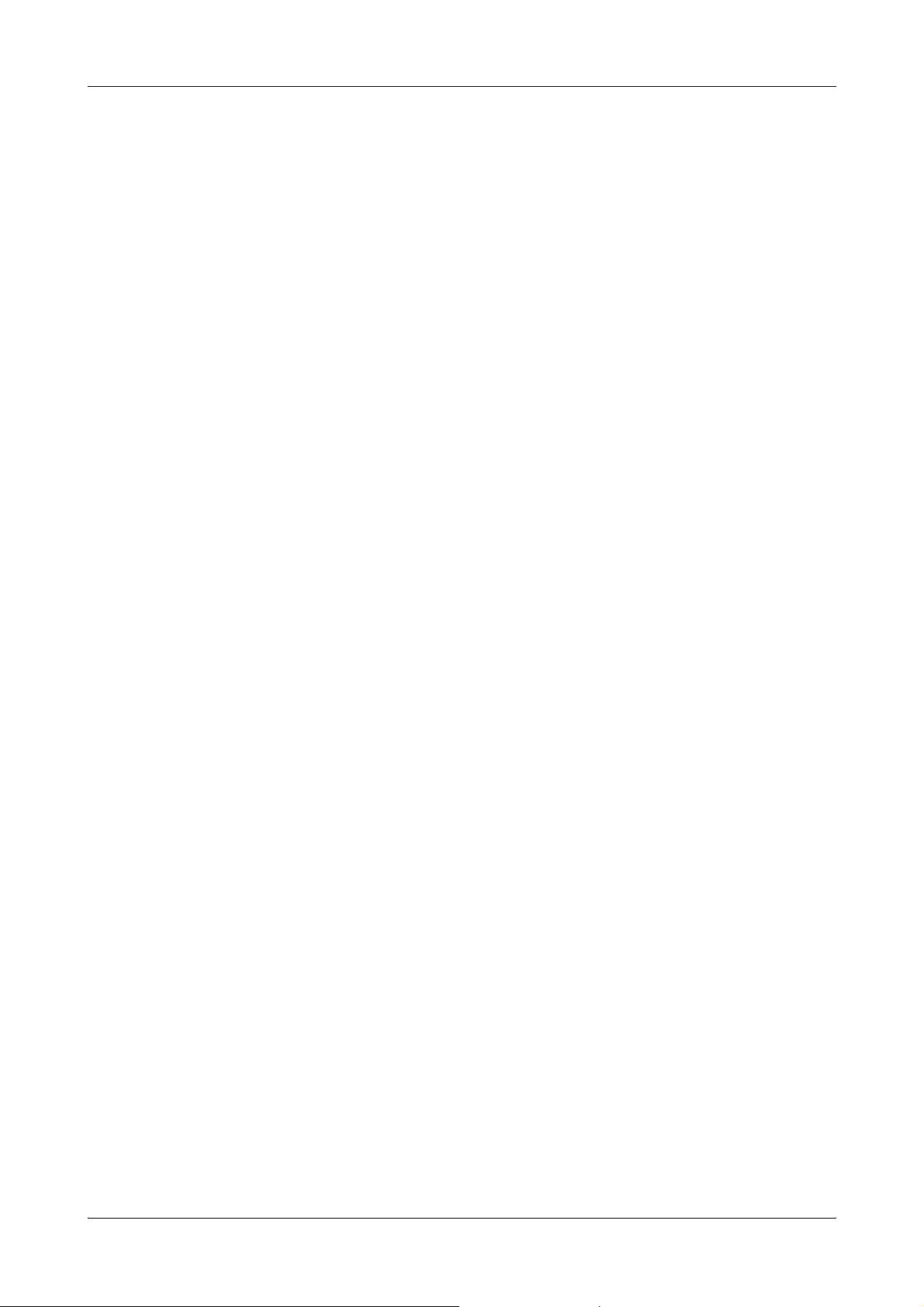

9110 FLUIDIC DIAGRAM

OID R

YELLOW DOT

REFERENCE

CONNECTOR

Figure A-1 9110 fluidic diagram

Roche Diagnostics April 2007

A-30 Service manual · Version 2.0

SOLEN

LVE

REF

WASTE

CHECK VA

CLEANING

REF. RETURN

A

B

FLUID PACK

Page 45

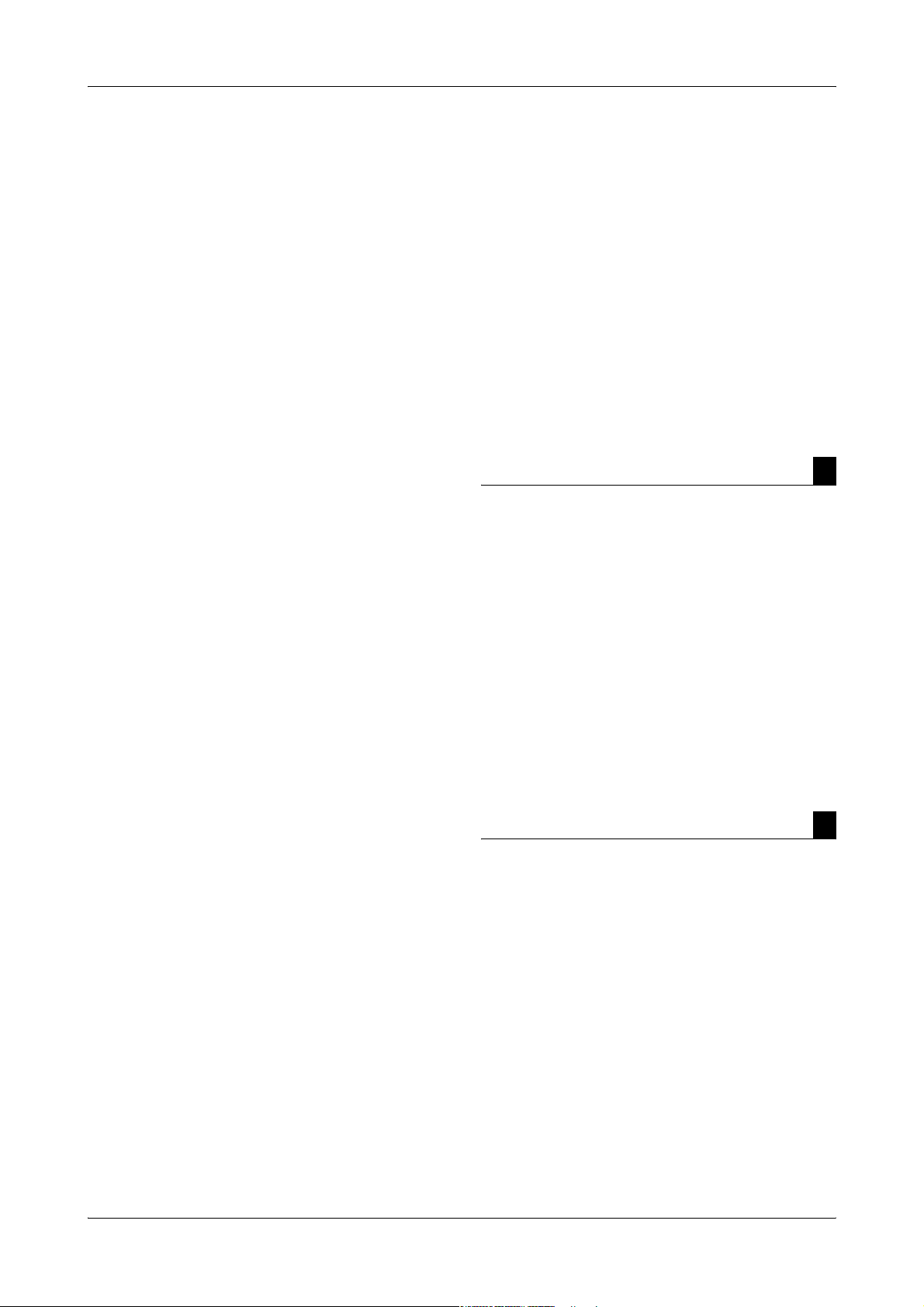

91xx pH/Electrolyte Analyzers 4 Description of modules

Description of modules

SAMPLE

SAMPLE PROBE

ASSEMBLY

PROBE

FILLPORT

RED

BLUE

LENOID V

SO

AIR VENT

Cl

Ca

K

YELLOW DOT

Na

REF

GREEN

ELECTRODE ASSY

PERI PUMP

LENOID B

SO

LENOID A

SO

FLUID

CONNECTOR

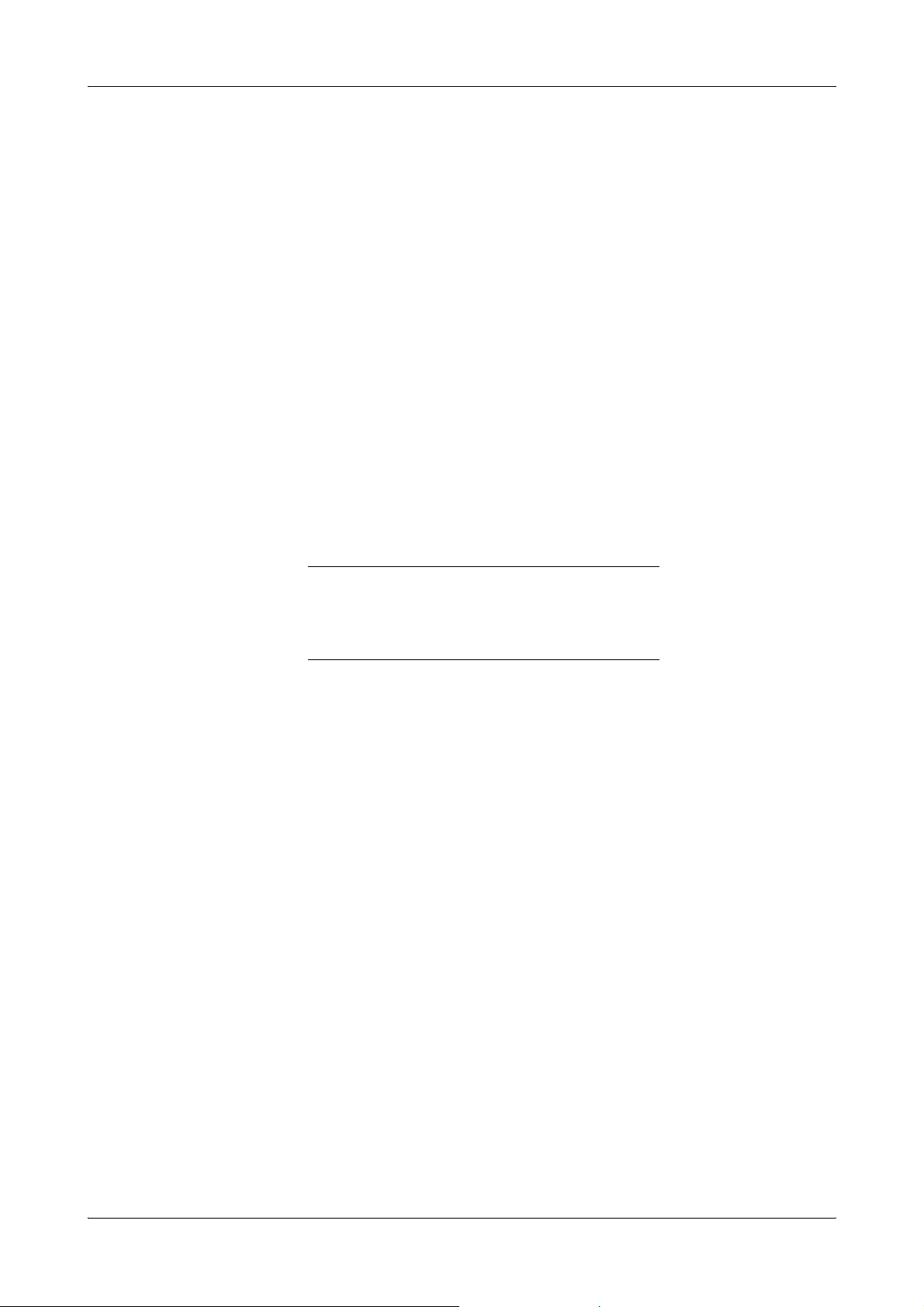

9120, 9130, 9140 FLUIDIC DIAGRAM

A

OID R

YELLOW DOT

REFERENCE

CONNECTOR

Figure A-2 9120, 9130, 9140 fluidic diagram

Roche Diagnostics April 2007

Service manual · Version 2.0 A-31

SOLEN

REF

WASTE

REF. RETURN

B

NOT USED C

FLUID PACK

Page 46

4 Description of modules 91xx pH/Electrolyte Analyzers

Description of modules

SAMPLE

SAMPLE PROBE

ASSEMBLY

PROBE

FILLPORT

RED

9180/9181 FLUIDIC DIAGRAM

BLUE

SOLENOID V

AIR VENT

LiClCa

K

YELLOW DOT

Na

REF

GREEN

ELECTRODE ASSY

PERI PUMP

LENOID B

SO

ID A

SOLENO

SOLENOID C

FLUID

CONNECTOR

A

B

OID R

YELLOW DOT

REFERENCE

CONNECTOR

SOLEN

REF

WAS TE

REF. RETURN

C

FLUID PACK

Figure A-3 9180, 9181 fluidic diagram

Roche Diagnostics April 2007

A-32 Service manual · Version 2.0

Page 47

91xx pH/Electrolyte Analyzers 4 Description of modules

Description of modules

Electronics

ISE SBC card

Power circuits Power is supplied to this circuit board through connector JP3 from the power supply

assembly. Test points are provided to measure supply voltages, and light emitting

diodes D1 through D5 are turned on to indicate each supply voltage present on the

card. Since each LED is connected in series after the fuse, a blown fuse results in the

respective LED turned off.

Four additional voltage regulator circuits are mounted on the ISE SBC II Card.

IC U2 and IC U3 provide -8 VDC and +8 VDC (9180/9181: -5 VDC and

+5 VDC) and are used to provide the supply voltages for the analog circuitry. IC U1

develops the supply voltage used to operate the peristaltic pump and provide either

+10 VDC or +22 VDC. The +22 VDC is supplied only for the FAST speed and

+10 VDC is used for all other pump speeds. Signal FAST/SLOW determines which

supply voltage is selected.

U5 switches the voltage between 22 VDC and 12.5 VDC (16 VDC on the 9110) which

supplies the solenoids. When a solenoid is turned on, the voltage switches to 22 VDC

for 0.5 sec, then it returns to 12.5 VDC (16 VDC on the 9110).

The circuit which includes Q7 and R5 provides necessary switching for the measuring

chamber illuminator LEDs.

The following list identifies the test points, fuses and LEDs for each respective DC

supply voltage:

Test point Voltage Fuse Rating LED

TP1 +24 VDC F3 1.25 AT D3

TP2 +5 VDC F1/F2 2.0 AT/1.6 AT D1/D2

TP3 -12 VDC F4 0.3 AT D4

TP4 +12 VDC F5 0.3 AT D5

TP5 Ground

Ta b le A -5 Voltage test points, LEDs

Test point Voltage

TP6 -8 VDC (9180/9181: -5 VDC)

TP7 +22/12 VDC

TP8 +8 VDC (9180/9181: +5 VDC)

+

TP9 Na

TP10 K

TP11 Ca

TP12 Temperature

TP13 +10.000 V ref. voltage

TP14 -2.500 V ref.voltage (-2.500 V on the 9110)

TP15 Sample sensor (sample contact voltage on the 9110)

TP16 +22/12.5 VDC (+22/+16 VDC on the 9110)

Ta b le A -6 Voltage test points

channel (pH channel on the 9110)

+

channel (not used on the 9110)

2+

/Cl– channel (Li+ 9180/9181 only; not used on the 9110)

Roche Diagnostics April 2007

Service manual · Version 2.0 A-33

Page 48

4 Description of modules 91xx pH/Electrolyte Analyzers

Description of modules

Valve d r iv e rs The solenoids are activated by transistors Q9 - Q13. To open the solenoid, a 0.5-

second pulse of 22 V is applied, then the voltage drops down to 12.5 V (16 V on the

9110) to hold the solenoid open.

Pump motor driver/cover sensor The pump driver circuit IC U9 and IC U10 provide the drive and control for the

peristaltic pump. Signals PUMPEN, Pump Enable and PUMPSTEP, Pump Step Pulses

enable IC U10 to provide the necessary control to driver IC U9 which supplies pump

drive signals PHASE A through PHASE D to control peristaltic pump operation.

IC U11 operates with signal DCLOSED from the sample door light gate to provide

signal DOOR which detects the status of the sample door (open or closed).

Input amplifiers IC U13, U14 and U15 (9110/9180/9181: U13 only) provide high to low input

impedance matching for each Electrode input. Offset generator IC U12D and

amplifiers IC U12A, U12B and U12C provide the necessary gain and offset for each

electrode channel. TP9, TP10 and TP11 provide test points for the Na

the 9110), K

+

and Cl–/Ca2+/Li+ channels respectively.

+

(TP9: pH on

9110 only: IC U300 is used as the input amplifier for the reference electrode, IC U12A

is used for the subtraction of the reference electrode signal from the pH electrode

signal. For sample detection, the reference electrode is switched to ground (relay

K300) during aspiration.

Temperature sensor This circuit is used in the 9110 pH Analyzer to amplify the signal of the temperature

Analog channel selector and A/D

converter

Microprocessor Microprocessor IC U31, EPROM IC U25 (9180/9181: U40) and MOSTEK Real Time

SnapPak Sensor (9180/9181

only)

sensor in the preheater. This is an optional circuit which is used in the 9140, 9180 and

9181.

The circuit creates a temperature-dependent voltage which is converted by software to

degrees Celsius. R54 can be adjusted for correct temperature display.

Analog inputs from the input amplifiers are selected via signals ADSEL0 through

ADSEL2 and are multiplexed by IC U19. This multiplexed signal is then fed to the A/

D Converter IC U20. IC U21 supplies the necessary reference voltage (2500mV) for

the A/D Converter and can be measured at TP14.

Clock/RAM IC U22 form the components of the central processing system. IC U23

Address Demultiplexer, IC U24 Programmable Array Logic (PAL) and IC U28

provide serial data buses (9180/9181: U23, U24 and U28 not present). IC U34

through IC U38 convert serial data to parallel data and provide printer data, display

data, solenoid valve control and peristaltic pump control (9110: U34 not present).

This fashion of serial to parallel data conversion is used to prevent analyzer lock-up by