Page 1

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Operating

M

anual

Automatic A/C Charging Station

For Refrigerant R-134a Systems Only!

Page 2

Safety

Precautions

This equipment is intended for professional use only. The service technician should be familiar

with proper servicing of air conditioning systems as well as the dangers and use of refrigerants and

pressurized components before using the equipment.

!

▲ WARNING ▲

Always wear safety goggles when working with refrigerants. Contact with refrigerants can cause

injury.

Connecting hoses to the wrong ports may cause personal injury or may damage the equipment. Check the operating manual for your air conditioning system for the correct hookup.

Disconnect hoses with extreme caution! All hoses may contain liquid refrigerant under pressure.

Contact with refrigerant can cause injury. Wear proper, personal protective equipment, including safety

goggles. Point the disconnected end of a hose away from you and anyone who is nearby.

Use only with refrigerant type R-134a! Cross-contamination with other refrigerant types will cause

severe damage to the A/C system and to service tools and equipment. Do not mix refrigerant types

through a system or in the same container!

Avoid breathing A/C refrigerant and lubricant vapor or mist. Exposure may irritate eyes, nose

and throat. To remove R-134a from the A/C system, use service equipment certified to meet the

requirements of SAE J2210 (R-134a recycling equipment). If accidental system discharge occurs,

ventilate work area before resuming service.

HFC-134a service equipment or vehicle A/C systems should not be pressure tested or leak

tested with compressed air. Some mixtures of air/HFC-134a have been shown to be combustible at

elevated pressures. These mixtures are potentially dangerous and may result in fire or explosion

causing injury or property damage. Additional health and safety information may be obtained from

refrigerant and lubricant manufacturers.

Improper use or connections may cause electrical shock hazards. Read and follow these

instructions carefully and take all necessary precautions to avoid electrical shock hazards. Before

energizing circuits, be sure that all associated devices are properly grounded. Unplug the station from

the power source before removing the control box.

!

Limited

Warranty

This product is warranted to be free from

defects in workmanship, materials, and components for a period of one year from date of

purchase. All parts and service center labor

required to repair defective products covered

under the warranty will be at no charge. The

following restrictions apply:

1. The limited warranty applies to the original

purchaser only.

2. The warranty applies to the product in

normal usage situations only, as described

in the Operating Manual. The product

must also be serviced and maintained as

specified.

3. If the product fails, it will be repaired or

replaced at the option of the manufacturer.

4. Transportation charges for warranty service

will be reimbursed by the factory upon

verification of the warranty claim and

submission of a freight bill for normal

ground service. Approval from Robinair

must be obtained prior to shipping to either

an authorized service center or the factory.

5. Warranty service claims are subject to

factory inspection for product defect(s).

6. Robinair shall not be responsible for any

additional costs associated with a product

failure including, but not limited to, loss of

work time, loss of refrigerant, and nonauthorized shipping and/or labor charges.

7. All warranty service claims must be made

within the specified warranty period. Proofof-purchase date must be supplied to the

manufacturer.

8. Use of Robinair charging equipment with

non-authorized refrigerants will void our

warranty. Authorized refrigerants are listed

on the equipment or are available through

our Technical Service Department.

This Limited Warranty does not apply if:

• The product, or product part, is broken by

accident.

• The product is misused, tampered with, or

modified.

• The product is used for recharging any

substance other than the specified refrigerant type.

Page 3

Introduction ................................................................................................................... 2

Set Up Instructions ....................................................................................................... 2

Preparing the Vacuum Pump .................................................................................. 2

Diagram of Vacuum Pump Components ................................................................. 2

Installing a Refrigerant Tank .................................................................................. 3

Diagram of Disposable Tank Installation............................................................... 3

Diagram of Refillable Tank Installation ................................................................. 4

Removing an Empty Tank........................................................................................ 4

Using the Heater Blanket ........................................................................................ 4

Operating Procedures ................................................................................................... 5

Summary Chart of Operating Procedures ............................................................... 5

To Attach Hoses to the System ................................................................................ 5

To Diagnose System Problems ................................................................................. 5

To Add Refrigerant to Partially Charged Systems ................................................. 5

To Recover Refrigerant............................................................................................. 6

To Program Vacuum/Charging Cycle...................................................................... 6

To Use Automatic Vacuum/Charging Cycle............................................................ 6

To Check Final System Operation........................................................................... 7

To Disconnect the System ........................................................................................ 7

Maintenance Instructions ............................................................................................. 7

Storing the Station.................................................................................................... 7

Maintaining the Vacuum Pump ............................................................................... 7

Checking the Scale Accuracy ................................................................................... 7

Calibrating the Scale ................................................................................................ 8

Using Manual Diagnostics ....................................................................................... 8

Additional Operating Guidelines ................................................................................. 9

How to Use the Controls........................................................................................... 9

Diagram of Control Components ............................................................................. 9

Using the Keypad...................................................................................................... 10

Diagram of Keypad ................................................................................................... 10

Using the Display Panel ........................................................................................... 10

Quick Reference Chart .............................................................................................. 11

Diagram of Display Panel ........................................................................................ 11

Table of

Contents

Replacement Parts List................................................................................................. 12

Troubleshooting Tips ..................................................................................................... 13

Temperature/Pressure Relation Chart ........................................................................ 14

Conversion Chart .......................................................................................................... 14

A/C Air conditioning

System The A/C system being serviced

Tank The refrigerant supply tank

Station The automatic A/C charging station

U.S. Patent Nos.: 4,523,897; 5,005,375; 4,688,388 RE: 33,212

Other U.S. and Foreign Patents Pending

R-134a Smart Cart® Automatic A/C Charging Station

Glossary of

Terms

1

Page 4

Introduction

This automatic A/C charging station is

designed with you in mind. It is accurate,

easy to program, and simple to use.

Before using the station, read and

understand all instructions and warnings

in this operating manual.

The 220V 50Hz models have some

operating exceptions, which are noted in

this operating manual.

In addition, all measurements are metric

and the manifold is equipped with kPa/

bar gauges showing temperature in

degrees Celsius.

Before operating the 220V 50Hz model,

plug the short power cord from the upper

control box into the outlet on the lower

power box. Plug the main power cord

into a 220V 50Hz power source that is

free of transients and electrical noise.

Set Up

Instructions

To set up the station for operation, you

need to prepare the vacuum pump and

install the refrigerant tank.

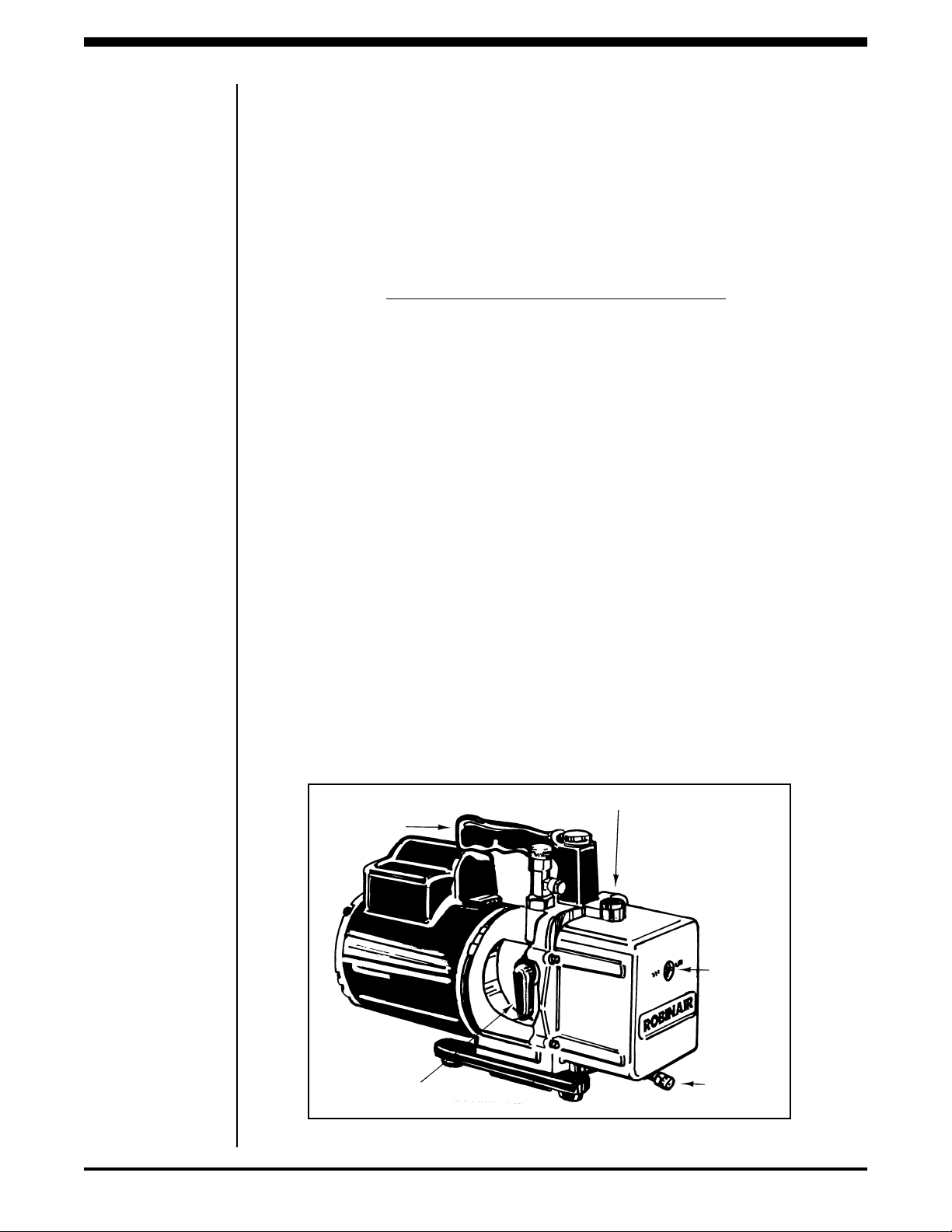

PREPARING THE VACUUM PUMP

The VacuMaster® vacuum pump is

shipped without oil in the reservoir.

Before starting the station, you must

fill the pump with oil and remove the

exhaust plug from the end of the

pump’s handle.

Note: The Iso-ValveTM isolation valve on

the side of the pump must remain open

(the position shown in the illustration)

for the station to operate.

CAUTION! Do not attempt to run the

vacuum pump when the manifold gauge

set shows pressure readings above 5 psi.

In the vacuum mode, positive pressure

will:

• High pressure — not allow the

vacuum solenoids to open.

• Low pressure — blow oil out of the

pump handle when the vacuum

solenoids do open.

Running the vacuum pump with positive

pressure locks high pressure between the

two solenoids and prevents operation of

the pump.

Follow these procedures to prepare the

vacuum pump for use with the charging

station.

1. Remove and discard the exhaust plug

from the end of the pump’s handle.

2. Remove and retain the black plug on

the oil fill port.

3. Pour vacuum pump oil into the oil fill

port until oil appears in the sight

glass on the reservoir. The approximate oil capacity of the pump is 13

ounces (384 milliliters).

4. Close both the high side and low side

valves on the station’s manifold.

2

EXHAUST PLUG

ISO-VALVEˇ

OIL FILL PORT

SIGHT

GLASS

OIL

DRAIN

VALVE

Diagram of Vacuum Pump Components

© 1991 Robinair Division, SPX Corporation

Page 5

5. Plug the station into the proper

voltage outlet, and turn on the MAIN

POWER switch.

6. Simultaneously press the ENTER

and zero keys on the keypad to access

the manual diagnostic mode.

7. Press “1” on the keypad to start the

pump.

8. While the pump is running, add

enough vacuum pump oil so that the

oil level is even with the line on the

reservoir’s sight glass.

9. Press “1” or the RESET CYCLE key

on the keypad to stop the pump.

10. Replace the black plug on the oil fill

port.

IMPORTANT! For maximum performance, change the vacuum pump oil

frequently (approximately after every

four hours of running time). We recommend using our Premium High Vacuum

Pump Oil; it is specifically blended to

maintain maximum viscosity at normal

running temperatures and to improve

cold weather starts (see the “Replacement Parts List”).

Read and follow the detailed instructions

in the Vacu-Master

®

Vacuum Pump

Operating Manual. You do not need to

return the warranty registration card

contained in the Vacu-Master® Vacuum

Pump Operating Manual — return only

the warranty registration card attached

to the station to validate your warranty.

INSTALLING A REFRIGERANT TANK

Follow these steps to install a refrigerant

tank on the charging station.

▲ WARNING ▲

! !

Always wear safety goggles when

working with refrigerants. Read and

follow all warnings at the beginning of

this manual before operating the unit.

Connecting hoses to the wrong ports

may cause personal injury or may

damage the equipment. Read and follow

all warnings at the beginning of this

manual before operating the unit.

Use only with refrigerant type R-134a!

Cross-contamination with other refrigerant types will cause severe damage to the

station and to tools and equipment.

Do not mix refrigerant types through a

system or in the same container!

1. Attach the station’s yellow charging

hose to a full refrigerant tank, as

follows:

•Disposable tanks — Connect the

yellow hose, open the tank’s valve,

and place the inverted tank (with its

valve down) on the scale platform.

Be sure to center the tank over the

stud welding point. Use only tanks

designed for use with R-134a, including Acme threads on the fittings.

(Continued)

Set Up

Instructions

Dual Purpose

Hold-Down

Bracket

Bulk Refrigerant Tank

Diagram of Disposable Tank Installation

R-134a Smart Cart® Automatic A/C Charging Station

(Not Included)

Valve Handle

Yellow Hose To

Refrigerant

Solenoid

Valve

Tank

Ball

3

Page 6

Set Up

Instructions

•Refillable tanks — Leave the tank

upright, attach the yellow charging

hose to the blue LIQUID valve on the

tank, and open the blue valve.

2. Open the ball valve on the yellow

charging hose (the open position runs

parallel to the hose).

Note: Use a maximum tank size of 50

pounds (23 kilograms) with this charging

station.

3. Fasten the tank securely with the

tank hold-down bracket. Place the

heater blanket around the center of

the tank, and fasten it securely (see

“Using the Heater Blanket”).

4. Secure the retaining strap around

the tank.

Note: Adjust the strap so that it comes in

contact with the tank, but is not tight

around the tank .

5. If the tank was changed after pressing the HOLD key to interrupt the

cycle, press the CONT key or RESET

CYCLE key, depending on the

operation you require next.

REMOVING AN EMPTY TANK

Follow these steps to remove an empty

refrigerant tank from the charging

station.

1. If the station is operating, press the

HOLD key. You do not need to turn

off the MAIN POWER switch.

▲ WARNING ▲

! !

Disconnect hoses with extreme caution!

All hoses may contain liquid refrigerant

under pressure. Read and follow all

warnings at the beginning of this manual

before operating the unit.

2. Disconnect the hose from the tank.

3. Release the retaining strap buckle.

4. Loosen the wing nut on the holddown bracket and remove the empty

tank from the platform.

USING THE HEATER BLANKET

A heater blanket speeds the transfer of

refrigerant and assures a complete

charge by raising the pressure within the

refrigerant tank.

1. Wrap the heater blanket around the

refrigerant tank, secure it with the

®

Velcro

strap, and plug its power cord

into the heater outlet on the bottom

of the control box (right receptacle).

2. Turn on the MAIN POWER switch

on the front of the station.

The heater blanket is on whenever the

station’s MAIN POWER switch is on,

eliminating the need for manual control.

You can extend the life of the heater

blanket by unplugging the heater when

it’s not being used or turning off the

MAIN POWER switch.

4

Blue LIQUID Valve

Ball Valve

Yellow

Hose To

Refrigerant

Solenoid

Bulk

Refrigerant

Tank

(Not Included)

Platform

Mount

Diagram of Refillable Tank Installation

© 1991 Robinair Division, SPX Corporation

Ring

Page 7

Before operating the 220V 50Hz model,

plug the short power cord from the upper

control box into the outlet on the lower

power box. Plug the main power cord

into a 220V 50Hz power source that is

free from transients and electrical noise.

The chart below summarizes the steps in

each of the following sections.

TO ATTACH HOSES TO THE SYSTEM

1. Be sure all valves on the manifold are

closed.

▲ WARNING ▲

Connecting hoses to the wrong ports

may cause personal injury or may

damage the equipment. Check your A/C

system operating manual for the correct

hook-up.

Use only with refrigerant type R-134a!

Cross-contamination with other refrigerant types will cause severe damage to the

station and to tools and equipment.

Do not mix refrigerant types through a

system or in the same container!

! !

TO DIAGNOSE SYSTEM PROBLEMS

1. Start the A/C system and watch the

gauge pressures (refer to the

manufacturer’s specifications for

proper operating pressures).

2. Perform any other visual and diagnostic inspections recommended by

the manufacturer.

3. If the A/C system is operating properly, disconnect the hose couplers

from the A/C system. To recharge or

make necessary repairs, see the

appropriate sections that follow.

TO ADD REFRIGERANT TO PARTIALLY

CHARGED SYSTEMS

1. In the program mode, press ADD .2

lbs. REFRIG. The messages “AUTOMATIC” and “REFRIGERANT”

appear on the display.

2. Open the low side valve. The station

dispenses .2 pounds (.1 kilograms) of

refrigerant, then displays the message “CPL.” Close the low side valve.

Operating

Procedures

2. Attach the red high side hose’s

coupler to the high side of the A/C

system.

3. Attach the blue low side hose’s

coupler to the low side of the A/C

system.

Note: The manifold is ported so that the

gauges indicate pressure whether or not

the valves are open.

SUMMARY

1. Attach hoses to the A/C system.

2. Start the A/C system and compare operating pressures to

manufacturer’s specifications.

3. Add a partial charge, if necessary.

4. Discharge the A/C system, if required.

3. Monitor the A/C system operating

pressures. Correct any low charge

indications by pressing RESET

CYCLE; repeat Step 1 as necessary.

Note: There are other A/C system problems which cause symptoms similar to a

low refrigerant charge — refer to your

operator’s manual or a reliable A/C

troubleshooting chart. If adding one

pound of refrigerant does not correct the

low charge symptoms, you may need to

recover and/or recharge refrigerant, as

described next.

5. Program the vacuum/recharge cycles.

6. Start the A/C system and perform final operating check.

7. Disconnect the hoses from the A/C system.

Summary Chart of Operating Procedures

R-134a Smart Cart® Automatic A/C Charging Station

5

Page 8

Operating

Procedures

TO RECOVER REFRIGERANT

IMPORTANT! Use a recovery unit. Do

not vent refrigerant to the atmosphere.

1. Be sure the A/C system is turned off,

then connect the yellow hose from

the manifold’s center port to your

recovery unit’s inlet port.

2. Open the manifold’s red high side

valve, blue low side valve, and center

valve, and start the recovery unit.

Follow the recovery unit’s instructions to recover refrigerant.

TO PROGRAM VACUUM/

CHARGING CYCLE

Vacuum is programmed in minutes and

refrigerant is programmed by weight. If

no quantity for any particular category is

required, enter zeros.

1. If the message “PROGRAM” is not

displayed, press RESET CYCLE.

2. The message “VACUUM” should

appear on the display. If it does not,

press the REVIEW PROGRAM key

repeatedly until it does.

Note: Follow the A/C system manufacturer’s recommendations for the proper

vacuum and refrigerant requirements.

3. Press the appropriate number keys

until the desired vacuum time

appears on the display. Enter

vacuum time in whole minutes.

Note: Use the convenient conversion

chart on the back cover of this manual if

you need help converting ounces to

hundredths of a pound.

TO USE AUTOMATIC VACUUM/

CHARGING CYCLE

IMPORTANT! Before starting the

vacuum pump, be sure that all A/C

system pressure is discharged.

1. Close the SYSTEM DISCHARGE

valve, and open the appropriate high

side and/or low side valves on the

station.

2. Press the START key on the keypad.

The display shows the message

“AUTOMATIC” followed by the

message “VACUUM.”

3. After a slight delay the vacuum

pump starts. The display shows the

amount of time programmed and

begins a countdown to zero.

4. At the end of the automatic vacuum

cycle, the display shows the message

“HOLD.” Close the high and low side

valves and make sure the A/C system

holds a vacuum (if it doesn’t, perform

any necessary repairs). Then open

the high and low side valves, and

press CONT to continue charging.

Note: Consult your A/C system service

guide for the proper charging

procedure.

6

For example, to program 20 minutes,

press two and zero — the display

shows “20.00.” Press ENTER and the

display flashes once indicating the

programmed data is accepted.

4. Press the REVIEW PROGRAM key.

The message “REFRIGERANT”

appears on the display. Enter the

amount of refrigerant to be recharged

to hundredths of a pound.

For example, to program 2

press two, seven, five and ENTER.

The display shows “2.75” and flashes

once, indicating the programmed

data is accepted. To program 21/

pounds, press two, five, zero and

ENTER — be sure to add the last

zero.

3

/4 pounds,

2

5. During the charging cycle, the

message “REFRIGERANT” appears

on the display. The display shows the

programmed amount of refrigerant,

counts down to zero as the charging

process proceeds, and indicates the

end of the charging process by

showing the message “CPL.”

6. If the refrigerant transfer is too slow,

the station emits an audible signal,

the display countdown stops, and the

message “CHECK REFRIGERANT”

appears on the display. Press the

HOLD key and close the high side

valve, but leave the low side valve

open. Start the A/C system, and press

the CONT key to pull the remainder

of the charge into the low side of the

A/C system.

© 1991 Robinair Division, SPX Corporation

Page 9

If the signal continues and the

display does not count down, press

the HOLD key and replace the tank

as described in “Installing a Refrigerant Tank.” Press the CONT key to

complete the automatic cycle, or

press RESET to access the program

mode.

2. Compare the gauge pressure readings to the system manufacturer’s

specifications.

3. Check the cool air vent discharge

temperature to be sure that the

system cooling is acceptable.

TO DISCONNECT THE SYSTEM

Operating

Procedures

7. When the automatic cycle is completed, the station beeps once, and

the message “CPL” appears on the

display, followed by the “HOLD”

message. Press any key to access the

program mode.

TO CHECK FINAL SYSTEM OPERATION

Before disconnecting the A/C system

from the station, you should check that it

is operating properly.

CAUTION! Before starting the A/C

system, be sure both valves on the

station’s manifold are closed.

1. Run the A/C system until the gauge

readings stabilize.

Follow these instructions to properly

maintain your automatic A/C charging

station. Be sure to wipe up any spills

immediately and keep the station clean.

1. Turn off the A/C system.

▲ WARNING ▲

!

Disconnect hoses with extreme caution!

All hoses may contain liquid refrigerant

under pressure. Read and follow all

warnings at the beginning of this manual

before operating the unit.

2. Disconnect the blue and red hose

couplers from the A/C system.

3. Replace the caps on all fittings. Store

the hoses on the cart, and store the

couplers by connecting them to the

coupler rack.

2. For maximum efficiency and longer

pump life, change the vacuum pump

oil frequently (approximately after

every four hours of running time).

!

Maintenance

Instructions

STORING THE STATION

1. Turn off the MAIN POWER switch,

and unplug the station.

2. Store the hoses on the cart, and store

the couplers by connecting them to

the coupler rack.

3. Close all valves when the station is

not in use.

MAINTAINING THE VACUUM PUMP

1. Check the vacuum pump oil daily,

and add oil as necessary. The proper

level is at the midpoint of the sight

glass when the vacuum pump is

running and the A/C system is under

vacuum.

Note: Use only our Premium High

Vacuum Pump Oil (see “Replacement

Parts List”).

Read and follow the detailed instructions

in the vacuum pump operating manual

to change oil.

CHECKING THE SCALE ACCURACY

You should routinely check the accuracy

of the scale platform and calibrate the

scale, if necessary, to assure that the unit

charges accurately.

1. While in the PROGRAM mode,

simultaneously press the ENTER and

zero keys on the keypad to clear the

display.

2. Press the “6” key on the keypad to

display the approximate scale

platform weight.

3. Remove the tank from the scale

platform. The empty platform weight

displayed should range from + two

pounds. If it does not, contact the

factory.

R-134a Smart Cart® Automatic A/C Charging Station

7

Page 10

Maintenance

Instructions

CALIBRATING THE SCALE

You should also routinely calibrate the

scale, if necessary, to assure that the

compressor shuts off when the tank is

full. You can automatically calibrate the

scale through the keypad.

▲ WARNING ▲

Proper operation of the scale is essential to safety features built into the

station. If you have any questions about

scale accuracy, call the factory.

1. Press ENTER and the zero key on

the keypad to access the diagnostic

mode, then press 8-7-8-7. The display

will show “A1.”

! !

USING MANUAL DIAGNOSTICS

The station has internal and manual

diagnostic modes. The internal or selfdiagnostic mode checks for entries or

pressures outside of normal limits and

for certain electrical conditions. The

manual diagnostic mode allows you to

check major components for proper

operation.

The station’s safety features include a

check valve which prevents high side

pressure from entering the refrigerant

tank. Also, any operating problems

resulting in an error message on the

display prevent operation until the

problem is corrected.

Note: If you press any other key before

the 8-7-8-7 sequence, you cannot enter

the automatic calibration routine.

2. Be sure the scale is empty of all

weight (e.g. tank). Press “0” and then

press ENTER on the keypad. The

display shows “0.00” and then

changes to the message “A2.”

3. Place a known weight (between 10

and 80 pounds) in the center of the

scale platform. Enter that weight on

the display using the keypad, then

press ENTER. The display returns to

the VACUUM mode.

4. To re-enter the diagnostics mode and

verify the calibration, simultaneously

press ENTER and the zero key on the

keypad. Then press “6.” The display

shows the known weight on the scale

platform.

5. Remove the known weight, and the

display returns to “0.00.”

▲ WARNING ▲

Be sure to discharge any system pressure before performing any manual

diagnostics.

1. If the message “PROGRAM” is not

displayed, press the RESET CYCLE

key.

2. Simultaneously press the ENTER

and zero keys. The display should be

blank except for the decimal point.

3. Press the following keys to perform

these functions:

Press “1” — The VACUUM display

segment comes on, the vacuum

solenoid opens, and the pump starts.

Press “1” again to turn off.

Press “3” — The REFRIGERANT

display segment comes on and the

solenoid opens. This is a momentary

contact switch which turns off when

released. Close the high and low side

valves to perform this test.

! !

8

Press “5” — All display segments

light up. Press “5” again to turn off.

Press “6” — The display shows the

approximate weight on the scale. See

“Checking the Scale Accuracy” for

diagnostic procedures.

4. Press the RESET CYCLE key to

return to the program mode.

© 1991 Robinair Division, SPX Corporation

Page 11

HOW TO USE THE CONTROLS

The charging station has various components that control its operating functions.

CAUTION! Do not operate the station

until you have filled the vacuum pump

with oil and removed the exhaust plug

from the pump’s handle, as outlined in

“Preparing the Vacuum Pump.”

1. SYSTEM DISCHARGE Valve — Lets

you depressurize the A/C system.

Connect to a refrigerant recovery

unit — do not vent refrigerant to the

atmosphere.

2. LOW Side Valve — When closed,

isolates the low side of the A/C

system from the station controls.

Note: The manifold is ported so that the

gauges indicate pressure whether or not

the valves are open.

3. LOW Side Compound Gauge — When

connected to the low side of an A/C

system, indicates the system’s low

side pressure.

9. ACCESSORY Outlet — Provides an

electrical outlet for accessory equipment, such as a thermistor vacuum

gauge. This outlet is energized when

the station is plugged in, and it is

located on the side of the control box.

Note: There is no accessory outlet on the

220V 50Hz model.

10.HEATER Outlet — Provides an

electrical outlet for the refrigerant

tank’s heater blanket. This outlet is

controlled by the MAIN POWER

switch and is energized when the

power is on.

11.PUMP Outlet — Provides an electri-

cal outlet for the vacuum pump. This

outlet is controlled by the logic board.

Additional

Operating

Guidelines

4. HIGH Side Valve — When closed,

isolates the high side of the A/C

system from the station controls.

5. HIGH Side Pressure Gauge — When

connected to the high side of an A/C

system, indicates the system’s high

side pressure.

6. Display — Shows the time programmed for vacuum, the weight of

refrigerant programmed for charging, the control status, and the cycle

of operation. Detailed instructions for

programming the display follow the

next section.

7. Keypad — Accomplishes specific

operating functions, as described in

the next section.

8. MAIN POWER Switch — Supplies

electrical power to the control panel.

Diagram of Control Components

R-134a Smart Cart® Automatic A/C Charging Station

9

Page 12

Additional

Operating

Guidelines

USING THE KEYPAD

The charging station also has a unique

keypad for data entry. It uses only six

keys for sequence control, and the LCD

display indicates the operating mode.

CAUTION! Do not operate the station

until you have filled the vacuum pump

with oil and removed the exhaust plug

from the pump’s handle, as outlined in

“Preparing the Vacuum Pump.”

START — Press to begin the automatic

cycle after the charging station is programmed.

CONT — Press to resume (or continue)

operations after pressing the HOLD key

(described below).

HOLD — Press to interrupt the

automatic cycle.

REVIEW PROGRAM — Press to review

the existing programmed data.

ENTER — Press to enter program data

into the computer’s memory.

RESET CYCLE — Press to access

program mode.

USING THE DISPLAY PANEL

The charging station also displays

various messages on the display panel.

CAUTION! Do not operate the station

until you have filled the vacuum pump

with oil and removed the exhaust plug

from the pump’s handle, as outlined in

“Preparing the Vacuum Pump.”

Segment A — Indicates in which mode

the station is operating:

PROGRAM — The station is in the

programming mode, which allows

you to program vacuum time and

refrigerant weight or to review the

existing program.

HOLD — The evacuation process is

complete and the vacuum pump is

off, or no refrigerant is being

charged; also HOLD is used while

changing a refrigerant tank or to

interrupt the vacuum/charging

cycles.

AUTOMATIC — Either the vacuum

or refrigerant charging cycle is in

process.

ADD .2 LB. REFRIG. — Press to partially

charge the A/C system.

Diagram of Keypad

Segment B — Indicates the station is

either evacuating the A/C system or

charging refrigerant or the station is

ready to be programmed for one of these

two functions:

VACUUM

• With PROGRAM, indicates the

station is ready to be programmed for

evacuation.

• With AUTOMATIC, indicates the

vacuum pump is running; the number displayed counts down in seconds, showing the amount of time

remaining for evacuation.

• With HOLD, indicates the vacuum

cycle is complete (if the display shows

“0.00”), or if you pressed the HOLD

key to interrupt the vacuum cycle,

indicates the remaining time the

pump runs when you press the

CONT key.

10

© 1991 Robinair Division, SPX Corporation

Page 13

Segment B Messages

Additional

VACUUM + PROGRAM = Program station for vacuum

VACUUM + AUTOMATIC = Vacuum pump is running

VACUUM + HOLD = Evacuation complete or

interrupted vacuum cycle

REFRIGERANT + PROGRAM = Program station for charge

REFRIGERANT + AUTOMATIC = Station is charging A/C system

REFRIGERANT + HOLD = Interrupted charging cycle

Quick Reference Chart

REFRIGERANT (POUNDS)

• With PROGRAM, indicates the

station is ready to be programmed

for the amount of refrigerant to be

charged into the A/C system;

on the keypad enter the charge in

pounds (or kilograms, depending on

the model you have).

• With AUTOMATIC, indicates the

station is charging refrigerant into

the A/C system; the number shown

on the display counts down, showing

the remaining amount of refrigerant

to be dispensed.

• With HOLD, indicates the HOLD key

was pressed to interrupt the charging

cycle; the number shown on the

display is the amount of refrigerant

remaining to be charged into the

system. To continue charging, press

CONT.

Use the quick reference chart above to

interpret Segment B messages.

Segment C — Shows a number or a

coded error message on the display that

indicates the station’s operating status or

any specific problems.

NUMBER

Indicates the vacuum time in minutes or the refrigerant weight in

pounds (or kilograms, depending on

the model you have).

MESSAGE CODES

• CPL — Indicates the refrigerant

charging cycle is complete.

• ERR5 — Indicates an overloaded or

broken scale.

Segment D — Indicates the transfer of

refrigerant is slow or has stopped.

•If the disposable tank is empty or

the refillable tank is low , replace

the tank following the instructions in

“Installing a Refrigerant Tank.” A

small amount of refrigerant always

remains in a refillable tank.

•If there is adequate refrigerant in

the tank , you need to pull the

remainder of the programmed charge

into the low side of the A/C system,

as outlined in Step 7 of “To Use

Automatic Vacuum/Charging Cycles.”

Operating

Guidelines

Diagram of Display Panel

R-134a Smart Cart® Automatic A/C Charging Station

11

Page 14

Replacement

Parts List

The following is a list of replacement

parts you may need to service or maintain your automatic charging station.

Because of ongoing product improvements, we

reserve the right to change design, specifications,

or materials without notice.

Description 115V 60 Hz 220V 50 Hz

Handle (Red) 40448 40448

Handle (Blue) 40447 40447

Gauge, Blue Low Side Compound 11741 11726

Gauge, Red High Side Pressure 11742 11727

High Side Coupler 18191 18191

Low Side Coupler 18190 18190

Vacuum Pump RA15427 RA15428

120” Blue Hose 62120 62120

120” Red Hose 63120 63120

60” Yellow Hose 37160 37160

9” Blue Hose 37059 37059

Tank Hose 37024 37024

Black Vacuum Hose 40586 40586

Main Power Switch RA40994 RA40994

Scale Assembly RA19008 RA19008

Tank Platform RA14967 RA14967

Heater Blanket 10994 45605

Vacuum Solenoid Assembly RA19020 RA19020

Refrigerant Solenoid RA19006 RA19006

Main Board RA18761 RA19092

Keypad RA18751 RA18751

Check Valve RA17112 RA17112

Tank Strap RA19056 RA19056

Cover 17495 17495

Wheel & Nut RA10751 RA10751

Transformer N/A RA19091

High Vacuum Grease 13033 13033

Our Premium High Vacuum Pump Oil is

also available in handy quart containers

or in convenient gallon containers:

Quart (shipped 12 quarts per case) 13203

Gallon (shipped 4 gallons per case) 13204

This oil has been specifically blended to

maintain maximum viscosity and to

improve cold weather starts.

12

© 1991 Robinair Division, SPX Corporation

Page 15

Symptom Cause Cure

Trouble-

No power when

POWER switch is on —

no display showing

Vacuum pump does not

start

Audible tone sounds

and “CHECK REFRIGERANT” message

displays during

refrigerant transfer

Refrigerant doesn’t flow

or “REFRIGERANT”

message doesn’t

display

• Station unplugged • Plug station into power

source

• No power at wall outlet • Locate problem with outlet or

change outlets

• Vacuum pump unplugged • Plug pump into power source

• Vacuum time not entered • Program required vacuum

time

• Defective vacuum pump • Remove and replace pump

• Faulty components • Call factory

• Transfer stopped or • Start A/C system and pull

too slow rest of refrigerant into system

(Step 6 in “To Use Automatic

Vacuum/Charge Cycle”)

• Tank safety strap too tight • Loosen the safety strap

• Refrigerant supply empty • Replace the refrigerant tank

or call factory

• Refrigerant supply empty • Replace the refrigerant tank

Shooting

Tips

Vacuum pump runs, but

low side gauge does not

register an appropriate

vacuum

ERR5

• Discharge valve open • Close discharge valve

• Low side valve closed • Open low side valve

• Pump oil contaminated • Flush and change pump oil

• Hose gasket damaged • Replace gasket or hose

• Charging line loose • Check connections

• Manifold leaking • Check connections

• Pump’s Iso-valve closed • Open Iso-valve

• Overloaded or broken • Check tank weight, recali-

scale brate if necessary, or call

factory

R-134a Smart Cart® Automatic A/C Charging Station

13

Page 16

Temperature — Pressure Relation

R-134a Refrigerant

Conversion Chart

Ounces to Hundredths of a Pound

PSI

(oF) R-34a

-20 -1.8

-15 0

-10 2.0

-5 4.1

0 6.5

5 9.1

10 12.0

15 15.1

20 18.4

25 22.1

30 26.1

35 30.4

40 35.0

45 40.1

50 45.4

55 51.3

60 57.4

65 64.0

70 71.1

75 78.5

80 86.7

85 95.3

90 104.3

95 113.9

100 124.1

105 134.9

110 146.3

115 158.4

120 171.1

125 184.5

130 198.7

135 213.5

140 229.2

Note

: Gauge pressures are approximations

rounded to the nearest 1/20 PSI.

Ounce Pound

1 .06

2 .12

3 .19

4 .25

5 .31

6 .38

7 .44

8 .50

9 .56

10 .62

11 .69

12 .75

13 .81

14 .88

15 .94

16 1.00

☎

For assistance in servicing or using the

Automatic A/C Charging Station, call the

toll-free Service Line, 800-822-5561, inside

the continental U.S. In Canada, call 419485-5561, Ext. 300. In all other locations,

contact your local distributor. To help us

serve you better, please be prepared to

provide the model number, serial number,

and date of purchase.

To validate your warranty, you must complete the warranty card attached to your

station and return it within ten days from

date of purchase.

x

SP

ROBINAIR

Robinair Division

SPX Corporation

Robinair Way

Montpelier, OH 43543-0193 USA

Phone 419-485-5561

FAX 419-485-8300

© 1993 Robinair Division, SPX Corporation34100/10324 Smart Cart Charging Station

Printed In USA111615 (Rev. 1/94)

Loading...

Loading...