Page 1

O

p

e

r

a

t

i

n

g

M

a

n

u

a

l

Operating Manual

Manual de funcionamiento

Manuel d’utilisation

Not for use in automotive

R-134a applications.

Model 25200B

Refrigerant Recovery Unit

Page 2

Model 25200B

Refrigerant Recovery Unit

Design Pressure: 336 psig — 435 psig

SAFETY DEFINITIONS: Follow all WARNING, CAUTION, IMPORTANT, and NOTE messages in this manual. These messages are

dened as follows: WARNING means you may risk serious personal injury or death; CAUTION means you may risk personal injury,

property damage, or unit damage; IMPORTANT means you may risk unit damage; and NOTEs and

ity and helpful information. These safety messages cover situations ROBINAIR is aware of. ROBINAIR cannot know, evaluate, and

advise you as to all possible hazards. You must verify that conditions and procedures do not jeopardize your personal safety.

DISCLAIMER: Information, illustrations, and specications contained in this manual are based on the latest information available

at the time of publication. The right is reserved to make changes at any time without obligation to notify any person or organization

of such revisions or changes. Further, ROBINAIR shall not be liable for errors contained herein or for incidental or consequential

damages (including lost prots) in connection with the furnishing, performance, or use of this material. If necessary, obtain additional

health and safety information from the appropriate government agencies and the vehicle, refrigerant, and lubricant manufacturers.

OPERATING TIPS provide clar-

WARNINGS

ALLOW ONLY QUALIFIED PERSONNEL TO OPERATE THE UNIT. Before operating the unit, read and follow

the instructions and warnings in this manual. The operator must be familiar with air conditioning and refrigeration

systems, refrigerants, and the dangers of pressurized components. If the operator cannot read this manual,

operating instructions and safety precautions must be read and discussed in the operator’s native language.

PRESSURIZED TANK CONTAINS LIQUID REFRIGERANT. Do not overll the internal storage vessel, because

overlling may cause explosion and personal injury or death. Do not recover refrigerants into nonrellable

containers; use only federally authorized rellable containers (DOT spec. 4BW or 4BA).

HOSES MAY CONTAIN LIQUID REFRIGERANT UNDER PRESSURE. Contact with refrigerant may cause per-

sonal injury. Wear protective equipment, including safety goggles. Disconnect hoses using extreme caution.

DO NOT BREATHE REFRIGERANT AND LUBRICANT VAPOR OR MIST. Exposure may cause personal

injury, especially to the eyes, nose, throat, and lungs. Use the unit in locations with mechanical ventilation that

provides at least four air changes per hour, or position the unit 18 inches above the oor. If accidental system

discharge occurs, ventilate the work area before resuming service.

DO NOT USE AN EXTENSION CORD. An extension cord may overheat and cause re. If you must use an

extension cord, use the shortest possible cord with a minimum size of 14 A

T

O REDUCE THE RISK OF FIRE, do not use the unit in the vicinity of spilled or open containers of gasoline

or other ammable substances.

DO NOT USE COMPRESSED AIR TO PRESSURE TEST OR LEAK TEST THE UNIT OR HVAC/R SYSTEM.

Some mixtures of air and refrigerant are combustible at elevated pressures. These mixtures are potentially

dangerous and may result in re or explosion causing personal injury or property damage.

USE THIS UNIT WITH ONLY THE FOLLOWING REFRIGERANTS: R-12, R-22, R-134a, R-401A, R-401B,

R-402A, R-402B, R-404A, R-407A, R-407B, R-407C, R-408A, R-409A, R-410A, R-500, R-502, R-507. The

unit is designed to only recover refrigerant. Do not attempt to adapt the unit for refrigerant that is not in this

list. Do not mix refrigerant types through a system or in the same container; mixing of refrigerants will cause

severe damage to the unit and the air conditioning system.

HIGH VOLTAGE ELECTRICITY INSIDE THE UNIT HAS A RISK OF ELECTRICAL SHOCK. Exposure may

cause personal injury. Disconnect the power before servicing the unit.

ADDITIONAL HEALTH AND SAFETY INFORMATION MAY BE OBTAINED FROM THE REFRIGERANT

AND LUBRICANT MANUFACTURERS.

WG.

This equipment has been certied by ARI to meet the EPA minimum requirements for recovery equipment

intended for use with all HCFC applicances and other high pressure applicances.

OPERATING NOTE: At temperatures exceeding 120° F / 49° C, wait 10 minutes between recovery jobs.

Page 3

TABLE OF CONTENTS

Glossary of Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Operating Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . 2

Setup Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . 4

Recovery Procedure . . . . . . . . . . . . . . . . . . . . . . . . 4

Tank-to-Tank Transfer . . . . . . . . . . . . . . . . . . . . . . 5

High Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Self-Clearing Procedure . . . . . . . . . . . . . . . . . . . . . . 6

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . 7

Introduction

Troubleshooting Tips . . . . . . . . . . . . . . . . . . . . . . . . . 8

Flow Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Conversion Chart . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Warranty Statement . . . . . . . . . . . . . . . . . . . . . . . . 12

Safety Precautions . . . . . . . . . . . . . . . . . inside front cover

GLOSSARY OF TERMS

A/C-R Air conditioning or refrigeration.

A/C-R System The air conditioning or refrigeration system being serviced.

Unit The refrigerant recovery unit.

Tank Therellablerefrigeranttank.

552701 Rev. A April 7, 2009

1

Page 4

Setup Instructions

OPERATING GUIDELINES

• The voltage at the unit must be ±10% of the unit’s rated voltage.

• Extension cords must be a minimum of 14 AWG and kept as short as possible.

• To minimize mixing of refrigerants, the self-clearing procedure must be

performed after each recovery operation.

• The low-side gauge on the unit allows you to monitor system pressure and stop

recovery when a deep enough vacuum has been reached. The high-side gauge

allows you to monitor the rellable tank pressure.

• When changing from liquid to vapor, the unit may switch back and forth several

times before staying on vapor. You may notice the liquid light switching and

hear the solenoids opening and closing. This is normal and does not affect the

unit or its operation.

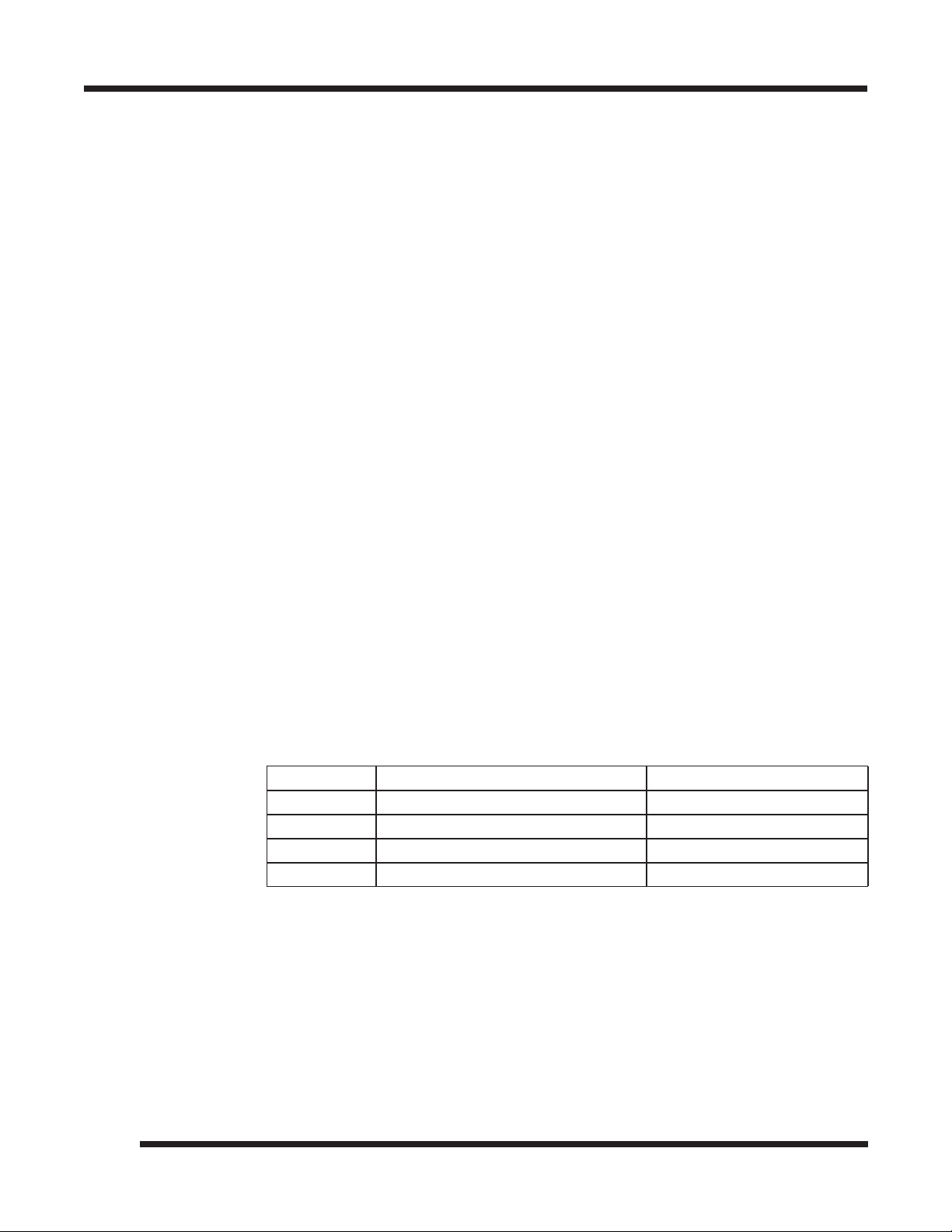

SET-UP INSTRUCTIONS

The unit comes with four 60-inch Enviro-Guard hoses with ball valves. Either

blue hose may be used where blue hose connections are called for, and either red

hose may be used for red hose connections.

CAUTION: To prevent personal injury, all valves on hoses must be in

the closed position before making connections.

1. Connect the hoses as follows:

Hose Connect Standard End To: Connect Ball Valve End To:

Blue Hose TANK LIQUID tting on unit LIQUID port on tank

Red Hose TANK VAPOR tting on unit VAPOR port on tank

Blue Hose SYSTEM VAPOR tting on unit SYSTEM VAPOR port

Red Hose SYSTEM LIQUID tting on unit SYSTEM LIQUID port

2. Plug the unit into a correct voltage electrical outlet. The fan starts running

immediately and the unit is ready for operation.

2

Page 5

Setup Instructions

Liquid

Valve

Vapor

Valve

TYPICAL

A/C-R SYSTEM

Vapor

Liquid

TANK LIQUID

TANK VAPOR

SYSTEM VAPOR

SYSTEM LIQUID

Liquid Indicator

System Pressure

High Pressure Indicator

Tank Pressure

Circuit Breaker

Recover / Power / Clear

Switch

Front View of Unit

552701 Rev. A April 7, 2009

Hose Connections

3

Page 6

Operating Instructions

RECOVERY PROCEDURE

To prevent personal injury,

Read and follow all warnings at the beginning of this manual

before operating the unit. Wear safety goggles when working with

refrigerants. Use only authorized rellable refrigerant tanks.

Disconnect hoses using extreme caution. All hoses may contain

refrigerant under pressure.

1. Connect hoses as described in the Setup Instructions.

2. Open the LIQUID and VAPOR valves on the recovery tank. Open the ball

valves on all four hoses.

NOTE: To prevent overlling, monitor the tank capacity/weight during recovery.

During liquid recovery, refrigerant transfers rapidly. Monitor tank weight using the

appropriate weight scale.

WARNING

3. Look at the system pressure gauge on the unit to conrm there is refrigerant

pressure in the system. If there is no pressure, there is no refrigerant to be

recovered.

NOTE: By taking the ambient temperature and using a pressure/temperature chart,

you can use this pressure to determine the type of refrigerant in the system.

4. Turn the switch to RECOVER. The light on the switch illuminates and you

will hear the compressor start.

A oat chamber monitors the refrigerant being recovered and automatically adjusts

the unit to handle either liquid or vapor refrigerant. This provides for the most

efcient recovery. The amber light on the control panel indicates when liquid is

entering the unit.

5. The blue gauge labeled SYSTEM PRESSURE shows the current system

pressure throughout the recovery process. When the system pressure reaches

an adequate vacuum level, turn the RECOVERY switch OFF.

The recovery process is complete, but the unit must be cleared before disconnecting

all hoses. (Refer to the Self-Clearing Procedure.)

TANK CAPACITY CHART

Refrigerants 30 lb. Tank 50 lb. Tank

R-12 22 lbs. 40 lbs.

R-22 22 lbs. 40 lbs.

R-134a 22 lbs. 41 lbs.

R-407C 21 lbs. 39 lbs.

R-410A 19 lbs. 36 lbs.

4

Page 7

Operating Instructions

WARNING

The refrigerant level in the tank must not exceed 80% of the tank

volume. Failure to monitor the level could result in excessive

hydrostatic pressures, causing physical injury or death.

TANK-TO-TANK TRANSFER

When recovering refrigerant from one rellable tank into another, the color of the

hoses used for SYSTEM LIQUID and SYSTEM VAPOR may not match the color

of the liquid and vapor valves on the tank you are pulling the refrigerant from.

Conrm the hose for SYSTEM LIQUID is connected to the liquid valve of the tank,

and the hose for SYSTEM VAPOR is connected to the vapor valve of the tank.

1. Connect the hoses in the following manner.

Standard End connects to: Ball Valve End connects to:

TANK LIQUID tting on unit LIQUID port on tank refrigerant

is being transferred into

TANK VAPOR tting on unit VAPOR port on tank refrigerant

is being transferred into

SYSTEM VAPOR tting on unit VAPOR port on tank refrigerant

is being transferred from

SYSTEM LIQUID tting on unit LIQUID port on tank refrigerant

is being transferred from

2. Follow Steps 1 through 5 in the Recovery Procedure on the previous page.

NOTE: Remember to monitor tank weight.

HIGH PRESSURE

If, during the recovery or self-clearing process, the HIGH PRESSURE light comes

on, verify all appropriate valves are open. If the valves are open and the light is

still on, there is an excessive amount of air or the tank is full. Follow these steps:

1. Press the COMPRESSOR switch to OFF.

2. Close both valves on the rellable tank, and close both valves on the red and

blue hoses connected to the tank.

3. Disconnect the red hose and the blue hose from the rellable tank.

4. Replace this tank with an empty rellable tank.

5. Reconnect the hoses as described in the Setup Instructions. Then follow the

steps in either the Recovery Procedure or the Self-Clearing Procedure.

If, after completing the above steps, either light is still on, call the Technical

Support Line at (800) 822-5561.

552701 Rev. A April 7, 2009

5

Page 8

Operating Instructions

SELF-CLEARING PROCEDURE

CAUTION! Do not mix refrigerant types. Always perform the selfclearing procedure after each recovery. Beginning each job with a

“clean” unit will help eliminate mixing of different refrigerant types.

1. Close the ball valves on the red and blue hoses connected to the A/C-R

system. Disconnect these hoses from the system’s access ports.

2. Close the blue LIQUID valve on the tank and the ball valve on the blue

TANK LIQUID hose. Disconnect the TANK LIQUID hose from the tank.

3. Verify the red TANK VAPOR hose is still connected to the red VAPOR tting

on the tank. Both the tank’s red VAPOR valve and the ball valve on the red

TANK VAPOR hose should be open.

4. Press the switch to SELF-CLEAR. You will hear the compressor start and the

switch will illuminate.

5. Let the compressor run until the system pressure gauge reaches the

appropriate vacuum level. The system pressure gauge will return to

VACUUM. Press the COMPRESSOR switch to OFF. Unplug the unit from

the electrical source.

6. Close the red VAPOR valve on the tank and the ball valve on the red TANK

VAPOR hose. Disconnect the TANK VAPOR hose from the tank.

WARNING

To prevent personal injury, disconnect hoses using extreme

caution. All hoses may contain refrigerant under pressure.

7. While the hoses are still connected to the unit, slowly open the ball valve

on each hose to relieve any pressure in the hose. Close the ball valves, then

disconnect the hoses from the unit.

6

Page 9

Maintenance

This unit has been designed for minimal maintenance. The compressor should be

evaluated for wear after 2,500 hours of use. Call Robinair’s Technical Support

Line, (800) 822-5561, for the location of an authorized Robinair service center

near you.

REPLACEMENT PARTS

System Pressure Gauge 551196

Tank Pressure Gauge 551197

Switch—Compressor 19813

High Pressure Cut-Out 19720

Ball Valve Hose—60” Red 65360

Ball Valve Hose—60” Blue 65260

Compressor 19652

Indicator Light, Red 111029

Indicator Light, Amber 111030

Fan 109820

Float Chamber 19685

CAUTION!

Use only standard

soap and water

to clean the

shroud and/or

base. Industrial

solvents found in

most cleaners and

degreasers can

cause the plastic

to crystallize and

become brittle.

Relay Board 19699

Case Bottom 121840

Case Back 121839

Case Front 121838

552701 Rev. A April 7, 2009

7

Page 10

Troubleshooting Tips

Compressor does not start

Problem: Compressor circuit breaker has tripped.

Solution: Depress the circuit breaker switch.

Problem: HIGH PRESSURE light is ON.

Solution: The high side pressure switch has tripped; verify the tank and

hose ball valves are open. Check tank and verify it is not full.

Problem: COMPRESSOR switch is not ON.

Solution: Press the COMPRESSOR switch to ON.

Compressor runs but does not move refrigerant

Problem: The ball valves on the hoses are not open.

Solution: Open the ball valves.

Problem: The tank valves are not open.

Solution: Open the valves.

During recovery, unit shuts off on high pressure

Problem: The rellable tank valves are not open.

Solution: Open the tank valves.

Problem: Valves on hoses are shut.

Solution: Open valves.

Unit will not pull down to appropriate vacuum level

Problem: There is a leak in the A/C system.

Solution: Fix the leak.

8

Problem: Trapped pockets of refrigerant.

Solution: Allow system to stabilize then heat with a heat gun.

Page 11

Flow Diagram

552701 Rev. A April 7, 2009

9

Page 12

Wiring Diagram

10

Page 13

CONVERSION

TABLE

OZ. LBS.

0.5 0.03

1.0 0.06

1.5 0.09

2.0 0.13

2.5 0.16

3.0 0.19

3.5 0.22

4.0 0.25

4.5 0.28

5.0 0.31

5.5 0.34

6.0 0.38

6.5 0.41

7.0 0.44

7.5 0.47

8.0 0.50

8.5 0.53

9.0 0.56

9.5 0.59

10.0 0.63

10.5 0.66

11.0 0.69

11.5 0.72

12.0 0.75

12.5 0.78

13.0 0.81

13.5 0.84

14.0 0.88

14.5 0.91

15.0 0.94

15.5 0.97

16.0 1 lb.

Conversion Table

552701 Rev. A April 7, 2009

11

Page 14

Warranty

Robinair

Limited Warranty Statement

Rev. November 1, 2005

This product is warranted to be free from defects in workmanship, materials, and components for a period of one year from

date of purchase. All parts and labor required to repair defective products covered under the warranty will be at no charge. The

following restrictions apply:

1. The limited warranty applies to the original purchaser only.

2. The warranty applies to the product in normal usage situations only, as described in the Operating Manual. The product

must be serviced and maintained as specied.

3. If the product fails, it will be repaired or replaced at the option of the manufacturer.

4. Transportation charges for warranty service will be reimbursed by the factory upon verication of the warranty claim and

submission of a freight bill for normal ground service. Approval from the manufacturer must be obtained prior to shipping

to an authorized service center.

5. Warranty service claims are subject to authorized inspection for product defect(s).

6. The manufacturer shall not be responsible for any additional costs associated with a product failure including, but not

limited to, loss of work time, loss of refrigerant, cross-contamination of refrigerant, and unauthorized shipping and/or labor

charges.

7. All warranty service claims must be made within the specied warranty period. Proof-of-purchase date must be supplied to

the manufacturer.

8. Use of recovery/recycling equipment with unauthorized refrigerants or sealants will void warranty.

• Authorized refrigerants are listed on the equipment or are available through the Technical Service Department.

• The manufacturer prohibits the use of the recovery/recycling equipment on air conditioning (A/C) systems containing leak

sealants, either of a seal-swelling or aerobic nature.

This Limited Warranty does NOT apply if:

• The product, or product part, is broken by accident.

• The product is misused, tampered with, or modied.

• The product is used for recovering or recycling any substance other than the specied refrigerant type. This includes, but is

not limited to, materials and chemicals used to seal leaks in A/C systems.

12

Page 15

Visit our web site at www.robinair.com or call our toll-free

Technical Support Line at 800-822-5561

in the continental U.S. or Canada.

In all other locations, contact your local distributor. To help us serve you better, please be prepared to provide the model

number, serial number, and date of purchase of your unit. To validate your warranty, complete the warranty card attached

to the unit, and return it within ten days from date of purchase.

NATIONWIDE NETWORK OF AUTHORIZED SERVICE CENTERS

If your unit needs repair or replacement parts, contact the service center in your area. For help in locating a service center,

call the toll-free technical support line or visit www.robinair.com.

Visite nuestro sitio web en www.robinair.com o llame sin costo a

la línea de Asistencia técnica al 800-822-5561

en EE.UU. continental o Canadá.

En todas las demás ubicaciones, comuníquese con su distribuidor local. Para ayudarnos a servirle mejor, tenga a mano el número de

modelo, número de serie y fecha de compra de su unidad. Para validar la garantía, complete la tarjeta de garantía anexa a su unidad y

enviela dentro de los diez días siguientes a la fecha de compra.

RED NACIONAL DE CENTROS DE SERVICIO AUTORIZADOS

Si su unidad necesita reparaciones o partes de reemplazo, comuníquese con el centro de servicio de su área. Para obtener ayuda para

ubicar un centro de servicio, llame sin costo a la línea de asistencia técnica o visite www.robinair.com.

Visitez notre site Web à www.robinair.com ou appelez sans frais

le soutien technique au 800-822-5561

sur le territoire continental des États-Unis ou au Canada.

Pour tout autre endroit, contactez votre distributeur local. An de nous aider à mieux vous servir, soyez prêt à nous donner le numéro

de modèle, le numéro de série et la date d’achat de votre unité. An de valider votre garantie, remplissez la carte de garantie jointe à

votre système et renvoyez-la dans les dix jours suivant la date d’achat.

RÉSEAU NATIONAL DES CENTRES DE SERVICE AUTORISÉS

Si votre unité doit être réparée ou à besoin de pièces de remplacement, contactez le centre de service de votre région. Pour vous aider

à localiser un centre de service, appelez sans frais la ligne de soutien technique ou visitez www.robinair.com.

Due to ongoing product improvements, we reserve the right to change design, specications, and materials without notice.

En raison des améliorations constantes apportées à nos produits, nous nous réservons le droit de changer de concept, de spécications et de matériaux sans préavis.

Debido a las constantes mejoras del producto, nos reservamos el derecho de cambiar diseño, especicaciones y materiales sin aviso.

Page 16

owaton na, Mn 55060-0995 Usa

655 EisEnhowE r DrivE

TECH SE RVICES 800 822 5561

CUSTOMER SERVICE 800 533 6127

FAX 412 690 2001

FAX 800 322 2890

www.robinair.com

552701 (Rev. A, April 7, 2009) © 2009 SPX

Loading...

Loading...