Page 1

17607 Universal a/C FlUsh Fitting Kit

WARNING

Wear protective equipment, including

•

safety goggles, when working with

refrigerants and solvents. Refrigerants

and solvents can cause injuries.

Do not use any solvent containing alcohol, lacquer

•

thinner, brake cleaner, or any other non-approved

solvent.

Do not look into the component to observe air ow

•

- injury may result!

Equipment must be operated by qualied personnel.

•

Operator must be familiar with air conditioning and

refrigeration systems, solvents, and the dangers of

pressurized components.

The operator is responsible for complying with any

•

and all applicable laws and regulations governing

the use of this equipment, as well as the disposal

of used solvents, oil, equipment, and components.

These instructions are intended as guidelines for general

operation of the Universal Flush Fitting Kit. Follow

the vehicle manufacturer’s instructions for ushing

A/C systems.

The clamp assemblies and support plates included in

this kit can be installed on most A/C line or tube ends

for attachment of the ushing apparatus being used.

Installation of the Sealing Cone:

1. After selecting the correct support plate to t

the tube or line tting, tighten the clamp screw

until the cone is seated tightly against the end of

the tube or line tting on the A/C component.

2. While holding the clamp screw by hand, rotate

the forcing nut an additional 1/8 to 1/4 turn. This

provides a leak-tight seal for the ushing operation.

To remove the clamp assembly, hold the clamp screw

and back off the forcing nut to free up the sealing cone

without damaging the end of the cone.

When using adapters on a tube or tting that is too

small for the sealing cone to enter, replace the cone-

shaped seal with the concave seal.

To replace the sealing cone, hold the forcing nut and

back out the clamp screw until the cone is pulled out

the end of the clamp screw. Insert the desired sealing

cone into the end of the clamp screw, and tighten the

screw until the cone bottoms in the screw, using the

non-slotted support plate against the end of the cone.

CAUTION : Do NOT use pliers or other tools to twist

the sealing cone out of the clamp screw, because it

could damage the sealing cone.

The support plates are slotted to allow for different size

tubes or line nuts to be supported against the lower

end of the sealing clamp. The chamfered area on the

support plates allow the ared end of the tubes to sit

level. This way the sealing cone can be seated without

slipping or damaging the end of the tube.

Seating of the sealing cone into the ttings or tube

ends does not require the use of wrenches or other

tools. Sealing cones damaged by tools must be replaced.

Included in this Kit:

(2) Clamp Assembly

(2) Support Plate (1/2" OD tube)

(2) Support Plate (5/8" OD tube)

(2) Support Plate (3/4" OD tube)

(2) Support Plate (7/8" OD tube)

(2) Support Plate (No slot)

Toll-free Technical Support Line:

1-800-822-5561

%

In all other locations, contact your local distributor.

Because of ongoing product improvements, we reserve the right

to change design, specications, and materials without notice.

in the U.S. and Canada

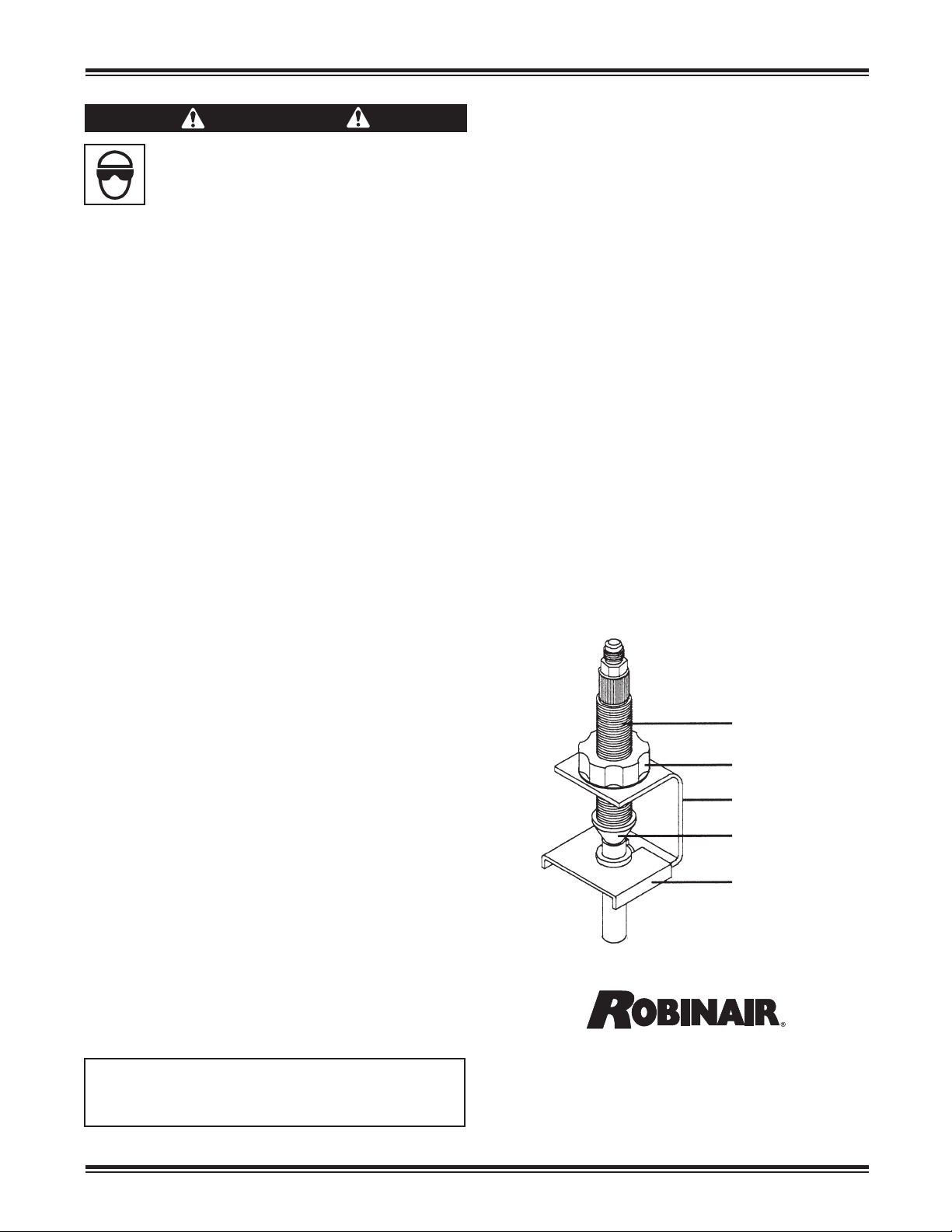

Clamp Screw

Forcing Nut

Clamp Assembly

Sealing Cone

Support Plate

655 Eisenhower Drive

Owatonna MN 55060

Customer Service: 1-800-533-6127

Fax : 1-800-322-2890

Technical Service : 1-800-822-5561

Fax : 1-866-259-1241

www.robinair.com

119366 (Rev. C, April 11, 2014) © Bosch Automotive Service Solutions LLC

Loading...

Loading...