Page 1

16600

Operating Manual — English

Refrigerant Leak Detector ..........................1

Manual de Operación — Spanish

Detector de Fugas de Refrigerante ............7

Manuel d’utilisation — French

Détecteur de fuites de frigorigène ..............13

Bedienungsanleitung — German

Kältemittel-Lecksuchegerät ........................19

Manuale dell’operatore — Italian

Sensore di perdite di refrigerante ...............25

Page 2

Table of Contents

Introduction ................................................................................ 1

Controls and Indicators............................................................... 2

Features....................................................................................... 3

Operation .................................................................................... 4

Maintenance ............................................................................... 5

Replacement Parts ...................................................................... 6

Specifications ............................................................................. 6

Introduction

The 16600 is an electronic leak detector used to detect refrigerant leaks in air

conditioning and refrigeration systems. It features a sensitivity selection switch

which allows it to be used with CFCs and HCFCs at one setting and HFCs at

the other. The unit is able to detect leaks smaller than 1/2 ounce per year.

Other features include audible and visual leak indicators, a volume control, a

threshold balancing control and a 16" gooseneck probe, which holds its

position for one-handed operations. When the unit is not being used, the probe

wraps into a retaining clip on the back of the case.

(2N08) Refrigerant Leak Detection Equipment Design Certified

by Underwriters Laboratories, Inc.® to meet SAE J-1627 (1993)

for R-12 and R-134a refrigerants.

16600 Refrigerant Leak Detector

1

Page 3

Description

Controls and Indicators

ON/OFF and BALANCE—The same control turns on the unit and gives you

infinite control for eliminating background contamination to find leaks fast.

VOLUME—Allows you to adjust the audible leak signal to the appropriate

volume for the working conditions.

SENSITIVITY LEVEL—The 16600 can be used for a wide range of

refrigerants, but because of different properties of the refrigerant, the correct

sensitivity level should be selected. Here are guidelines:

• Level 1—HFCs such as R-134a, HP 62, AC 9000, AZ 20, and AZ 50

(refrigerant blends made up primarily of HFCs)

• Level 2—CFCs and HCFCs such as R-12, R-22, R-500, and R-502

(refrigerant blends made up primarily of CFCs and HCFCs).

If you are not sure which refrigerant is in the system, start with Level 2 and

change to Level 1 if you have trouble pinpointing the leak after balancing the

leak detector several times.

VISUAL LEAK INDICATOR—The LEDs light up to show increasing levels

of concentration. One LED means a minimal amount of refrigerant is reaching

the sensor; when all LEDs are lit, there is a sizeable leak or concentration. The

LEDs illuminate in sequence from bottom to top.

LOW BATTERY INDICATOR—If only the top LED is lighted, the batteries

are low and should be replaced.

AUDIBLE LEAK INDICATOR—The normal operating sound is a steady

ticking. As you move the probe closer to a leak, the tone will change to a faster

ticking sound and then to an alarm sound (the loudness of this indicator can be

adjusted using the volume control).

2

1© 2000 Robinair, SPX Corporation

Page 4

Features

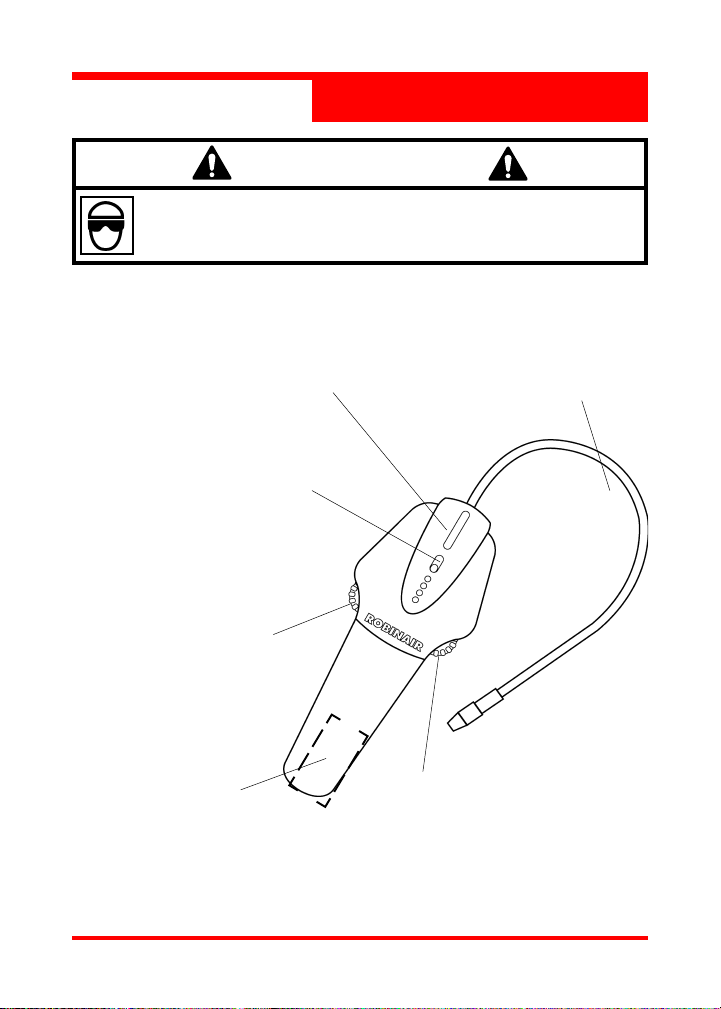

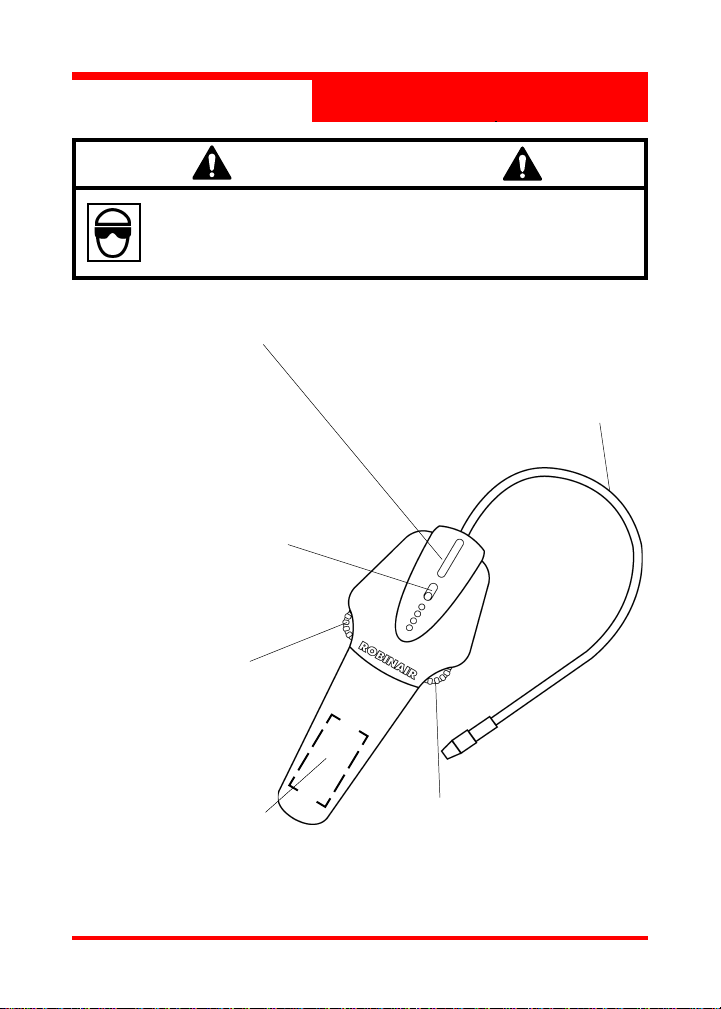

WARNING

Wear safety goggles when working with refrigerants.

Contact with refrigerants can cause eye injury.

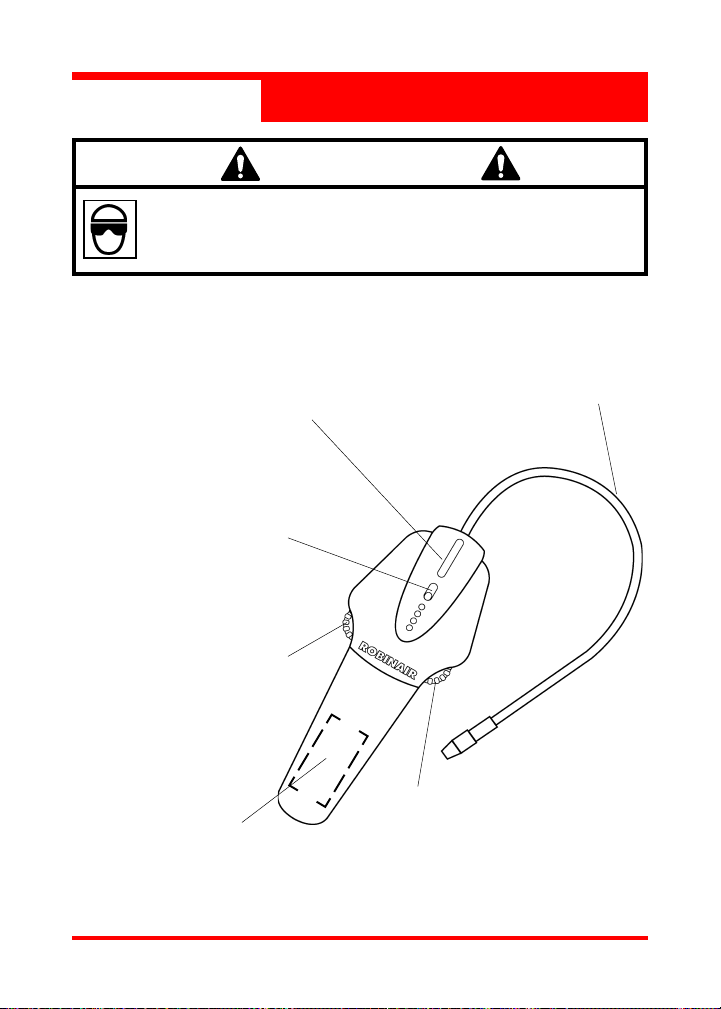

Audible and Visual Leak

Indicators—An alarm increases

in frequency as the tip nears a

high concentration of refrigerant.

LEDs light up to indicate a leak

and refrigerant concentration.

Sensing Selection Switch—

Slide the switch to Level 1 or

Level 2, depending on the

type of refrigerant in the

system.

Volume Control—Adjust

the audible signal to the

volume that’s right for the

background noise in the

shop or at the job site.

Battery Door—Located

on the back side of the

handle, the door is easy

to remove to change

batteries.

One-Hand Operation—

The 16" gooseneck probe

holds its position, so you

can operate the detector

with one hand.

Threshold Balancing

Control—Gives you infinite

control for eliminating

background contamination,

so you can zero in on the

leak site.

16600 Refrigerant Leak Detector

3

Page 5

Operation

The first time you use the 16600 leak detector, install the batteries before

turning on the unit. Four “AA” alkaline batteries are included (see

“Maintenance Instructions”).

1. Remove the gooseneck probe from the retaining clip on the back of the leak

detector case.

2. Turn the ON/OFF switch to ON.

3. Select the sensitivity level by sliding the switch to either the “1” setting or

the “2” setting.

4. Adjust the balance. Turn the BALANCE control up to a loud alarm sound,

then turn it down until you hear a slow, steady ticking.

5. Begin searching for the leak. The recommended scan rate is two (2) inches

per second with the sensing tip as close as possible to the area being

searched. Run the probe under tubing and check carefully around bends,

fittings, and other typical leak points.

TIP: Refrigerant is heavier than air, so check for leaks at the top of the system

first, working your way toward the bottom. In strong wind conditions, you may

need to shield the area before searching for leaks.

6. To pinpoint a leak, you may need to adjust the balance. When you are near a

concentration of refrigerant, the alarm tone will sound. Keep the probe in

the same position and turn the balance control down until you hear the

ticking sound. Then continue searching for the leak. You may need to

balance the unit several times if there is a large leak and refrigerant has

accumulated.

7. If you find more than one leak, or if you suspect more than one, repair the

larger leak(s) first so pinpointing the smaller leak is easier.

4

1© 2000 Robinair, SPX Corporation

Page 6

Maintenance

Maintenance

Cleaning/Replacing the Sensing

Tip

The sensing tip is the most critical component of the leak detector.

Periodically it may become clogged with dirt, grease, and oil. If the tip looks

dirty, and you have difficulty pinpointing a leak or experience constant false

alarms, the tip probably needs to be cleaned or replaced.

To Clean the Tip:

1. Turn the ON/OFF switch to OFF.

2. Unscrew the tip from the gooseneck probe.

3. The tip can be cleaned in most vaporizable solvents, such as denatured

alcohol. We recommend using a solvent, but if this is not possible, wash

the tip in warm, soapy water. Rinse thoroughly with clear water and allow

to air dry completely before reinstalling the tip on the probe.

IMPORTANT! Allow adequate time for the tip to air-dry before using

the leak detector. Moisture in the tip can trigger false alarms.

Be sure your hands are clean and dry. Be careful not to contaminate

the tip with perspiration, grease, hand cleaners, etc.

To Change the Tip:

An extra tip comes with the unit. You can also buy replacement tips. One extra

tip stores in a special slot inside the battery compartment. Follow the

instructions in “INSTALLING/REPLACING BATTERIES” to open the battery

compartment.

1. Turn the ON/OFF switch to OFF.

2. Unscrew the tip from the gooseneck probe.

3. Thread the new tip onto the probe until it’s finger-tight. Do not overtighten.

4. When the leak detector is not in use, wrap the gooseneck probe into the

retaining clip to protect it.

16600 Refrigerant Leak Detector

5

Page 7

Maintenance

Installing/Replacing Batteries

Your unit uses four (4) “AA” alkaline batteries. The batteries should be replaced

if the top LED (beside the words LOW BATTERY) lights up when the unit is

first turned on. The battery compartment is located on the back of the case.

1. Turn the ON/OFF switch to OFF.

2. Remove the screw holding the battery compartment door. If you are

replacing batteries, remove the old batteries.

3. Place the new batteries in the battery compartment, following polarity

indication.

4. Replace the battery compartment door, and secure the door with the screw.

Replacement Parts

16503 Replacement Sensing Tip

16604 Battery Compartment Door

Specifications

Power Supply .............................................................. 4 “AA” alkaline batteries

Sensitivity ..................................................................... Less than

Battery Life................................................................... Approximately 25 hours

Dimensions ........................................................................8

............................................................................... (21.59 cm x 8.26 cm x 5 cm)

Probe Length ...................................................................... 16 inches (40.6 CM)

Weight................................................................. 1.14 lbs. (.52 kg) with batteries

6

1© 2000 Robinair, SPX Corporation

1

/2 oz. per year

1

/2"L x 31/4"W x 2"D

Page 8

Contenido

Introducción................................................................................ 7

Controles e Indicadores .............................................................. 8

Características............................................................................. 9

Operación ................................................................................. 10

Mantenimiento ...........................................................................11

Partes de Repuesto.................................................................... 12

Especificaciones ....................................................................... 12

Introducción

El 16600 es un detector electrónico de fugas usado para detectar fugas de

refrigerante en sistemas de aire acondicionado y refrigeración. Tiene un

conmutador para seleccionar la sensibilidad lo que permite que en el un ajuste

sea usado con CFCs (CloroFúorCarbonados)y HCFCs y en el otro con HFCs.

La unidad es capaz de detectar fugas menores a 1/2 onza por año.

Otras características incluyen indicadores de fugas sonoros y visuales, control

de volumen, control del balance de umbral, y una sonda exploradora cuello de

ganso de 16" al mantenerse en posición permite manipular la unidad con una

mano. Cuando no se usa la unidad, la sonda exploradora se la dobla y se la

asegura en la presilla de sujeción atrás en la caja.

UL (2N08) Diseño del Equipo Detector de Fugas de Refrigerante

Certificado por Laboratorios Underwriters, Inc. para que cumplan

con la norma SAE J-1627 (1993) para refrigerantes R-12 y R134a.

16600 Detector de Fugas de Refrigerante

7

Page 9

Descripcióne

Controles e Indicadores

ENCENDER/APAGAR y BALANCE—El mismo control enciende la unidad

y le da un control total para eliminar la contaminación de fondo y encontrar

rápidamente las fugas.

VOLUMEN—Le permite regular la señal sonora de la fuga al volumen

apropiado a las condiciones de trabajo.

NIVEL DE SENSIBILIDAD—El 16600 puede ser usado para una amplia

gama de refrigerantes, pero debido a las diferentes propiedades de los

refrigerantes, se deberá seleccionar el nivel correcto de sensibilidad. Aquí

algunas guías:

• Nivel 1—HFCs tales como R-134a, HP62, AC9000, AZ20, y AZ50

(Mezclas de refrigerante hechas principalmente con HFCs).

• Nivel 2—CFCs y HCFCs tales como R-12, R-22, R-500 y R-502 (mezclas

de refrigerantes hechas principalmente con CFCs y HCFCs).

Si Ud. no está seguro cual refrigerante está en el sistema, empiece con el nivel

2 y si luego de balancear varias veces el detector de fugas tiene problemas en

localizar con exactitud la fuga, cambie al Nivel 1.

INDICADOR VISUAL DE FUGAS—Los LEDs se iluminan para mostrar

niveles crecientes de concentración. Un LED iluminado significa que el sensor

detectó una cantidad mínima de refrigerante; cuando todos los LEDs están

iluminados hay una fuga o concentración considerable. Los LEDs se iluminan

en secuencia, desde abajo hacia arriba.

INDICADOR DE BATERÍA AGOTADA—Si solamente está iluminado el

LED superior, las baterías están agotadas y deberían ser cambiadas.

INDICADOR SONORO DE FUGAS—Un tictac uniforme es el sonido

normal de trabajo. A medida que la sonda exploradora se mueve más cerca de

una fuga, el tono cambia a un sonido tictac más rápido y luego a un sonido de

alarma (la intensidad sonora de este indicador puede ser regulada usando el

control de volumen).

8

1© 2000 Robinair, SPX Corporation

Page 10

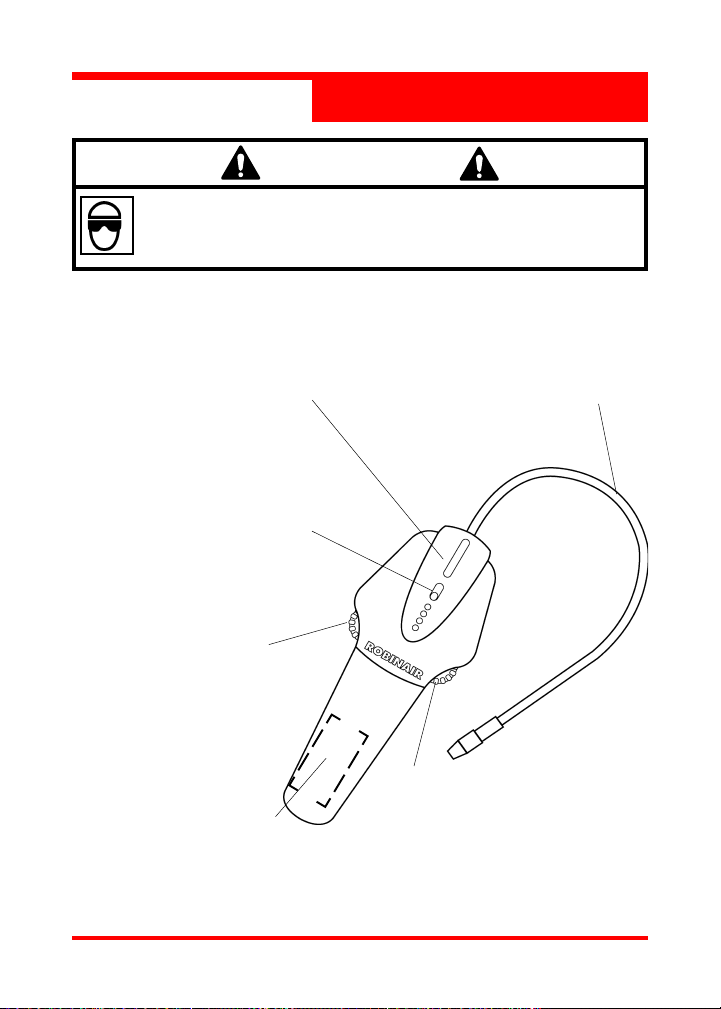

Características

¡ADVERTENCIA!

Use siempre gafas de seguridad cuando trabaje con

refrigerantes. El contacto con refrigerante puede

ocasionar lesión al ojo.

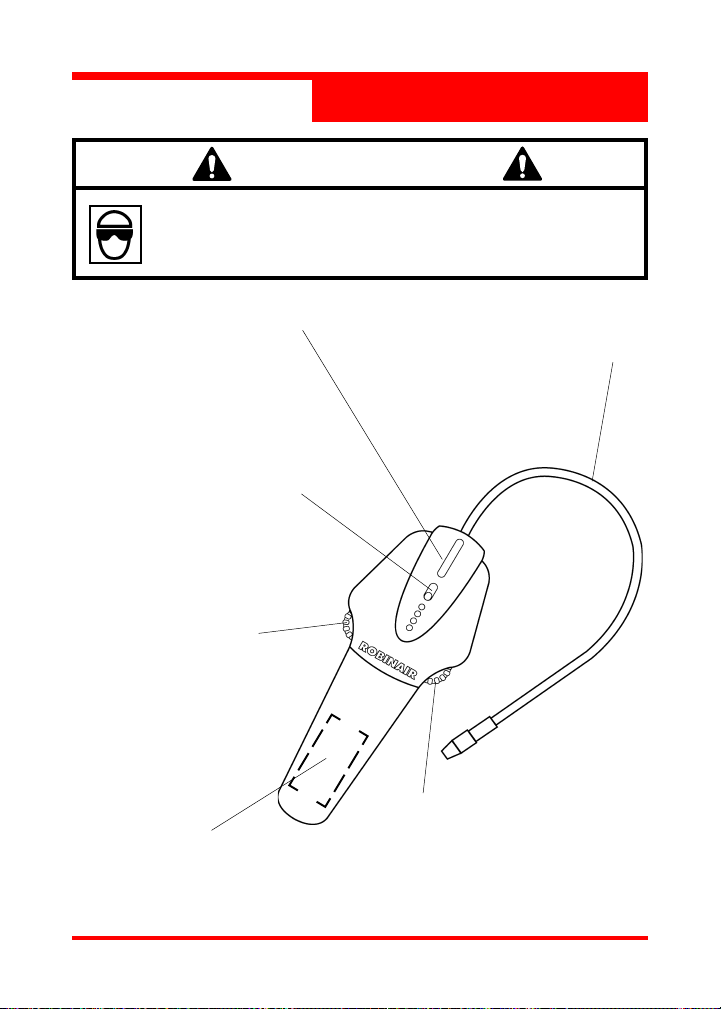

Indicadores de Fugas

Sonoros y Visuales—Una

alarma aumenta en

frecuencia a medida que la

punta se acerca a zonas de

mayor concentración de

refrigerante. Los LEDs se

iluminan para indicar la fuga y

la concentración de

refrigerante.

Selector de la Sensibilidad—

Deslice(mueva) el selector al

Nivel 1 o Nivel 2 dependiendo

del tipo de refrigerante del

Sistema.

Control del Volumen—

Regula la señal sonora hasta

el nivel de volumen correcto

según el ruido de fondo del

taller o del sitio de trabajo.

Compuerta de las baterías—

Ubicada en la parte posterior

de la agarradera, esta

compuerta facilita el retiro de

las baterías para su cambio.

Operación con una Mano—

La sonda exploradora de 16"

tipo cuello de ganso mantiene

su posición de modo que Ud.

pueda hacer funcionar al

detector sólo con una mano.

Control del Balance de

Umbral—Le da a Ud. un

control total para eliminar la

contaminación de fondo de

modo que Ud. pueda en el

de trabajo ponerlo en cero.

sitio

16600 Detector de Fugas de Refrigerante

9

Page 11

Operación

La primera vez que use el detector de fugas 16600 y antes de encender la

unidad, instale las baterías. Vienen incluidas cuatro baterías alcalinas “AA”

(vea “Instrucciones de Mantenimiento”).

1. Retire la sonda exploradora cuello de ganso de la presilla de sujeción atrás

de la caja del detector de fugas.

2. Gire el interruptor ENCENDER/APAGAR a ENCENDER.

3. Seleccione el nivel de sensibilidad moviendo el selector sea al ajuste “1” ó

al ajuste “2”.

4. Regule el balance. Suba el control del BALANCE a un sonido fuerte de la

alarma, bájelo luego hasta que Ud. oiga un tictac lento y uniforme.

5. Empiece buscando las fugas. La velocidad de rastreo recomendada es dos

(2) pulgadas por segundo con la punta detectora tan cerca como sea posible

del área a ser investigada. Lleve la sonda exploradora por debajo de las

tuberías y revise cuidadosamente alrededor de las curvas, acoples y otros

puntos de fuga típicos.

SUGERENCIA: El refrigerante es más pesado que el aire, de modo que

primero revise las fugas en la parte superior del sistema, de la forma que la

hace hacia la parte inferior. Bajo condiciones de fuerte viento, pueda que sea

necesario proteger el área antes de buscar las fugas.

6. Para localizar con exactitud la fuga, puede que Ud. necesite regular el

balance. Cuando Ud. esté cerca de una concentración de refrigerante, sonará

el tono de alarma. Mantenga la sonda exploradora en la misma posición y

baje el control de balance hasta que Ud. oiga el sonido de tictac. Continúe

luego buscando la fuga. Si hay una fuga grande y el refrigerante se ha

acumulado, pueda que Ud. necesite balancear varias veces la unidad.

7. Si Ud. halla más de una fuga, o si sospecha que hay más de una, repare

primero la(s) fuga(s) mayores de forma que sea más fácil la localización

exacta de las menores.

10

1© 2000 Robinair, SPX Corporation

Page 12

Mantenimiento

Limpieza/Reemplazo de la Punta

Maintenance

Detectora

La punta detectora es el componente más crítico del detector de fugas. Puede

taponarse periódicamente con suciedad, grasa y aceite. Si la punta se muestra

sucia y Ud. tiene dificultad en la localización exacta de la fuga o experimenta

falsas alarmas constantes, probablemente la punta necesita ser limpiada o

reemplazada.

Para Limpiar la Punta:

1. Ponga el interruptor ENCENDER/APAGAR en APAGAR.

2. Desenrosque la punta de la sonda exploradora cuello de ganso.

3. El extremo de la punta puede ser limpiado usando la mayoría de solventes

evaporables, tales como alcohol desnaturalizado. Recomendamos usar un

solvente, pero si esto no es posible, Ud. puede lavar la punta con agua

caliente jabonosa. Enjuáguela completamente con agua limpia y deje que se

seque íntegramente al aire antes de instalarla en la sonda.

¡PRECAUCIÓN! Deje para que la punta se seque al aire el tiempo que

sea necesario antes de usar el detector de fugas. La humedad en la

punta puede activar falsas alarmas.

Asegúrese que sus manos estén limpias y secas. Asegúrese de no

contaminar la punta con sudor, grasa, limpiadores de manos, etc.

Para Cambiar la Punta:

Con la unidad viene una punta extra. Ud. puede también comprar puntas de

repuesto. Una punta extra se guarda en una ranura especial dentro del

compartimento de las baterías. Siga las instrucciones en “INSTALACIÓN/

REEMPLAZO DE BATERÍAS” para abrir el compartimento de las baterías.

1. Ponga el interruptor ENCEDER/APAGAR en APAGAR.

2. Desenrosque la punta de la sonda exploradora cuello de ganso.

3. Enrosque la nueva punta en la sonda hasta que ajuste con la mano. No ajuste

excesivamente.

4. Cuando no se use el detector de fugas, doble la sonda exploradora cuello de

ganso y asegúrela en la presilla de sujeción para protegerla.

16600 Detector de Fugas de Refrigerante

11

Page 13

Mantenimiento

Instalación/Reemplazo de las

Baterías

Su unidad usa cuatro(4) baterías alcalinas “AA”. Las baterías deberían ser

reemplazadas si al encender por primera vez el LED superior (el que va junto a

las palabras BATERÍA DESCARGADA) se prende. El compartimento de las

baterías está ubicado en la parte posterior de la caja.

1. Ponga el interruptor ENCENDER/APAGAR en APAGAR.

2. Retire el tornillo que sostiene la compuerta del compartimento de las

baterías. Si va a cambiar las baterías, retire las baterías viejas.

3. Coloque las nuevas baterías en el compartimento de las baterías, tomando en

cuenta la indicación de polaridad.

4. Vuelva a colocar la compuerta del compartimento de las baterías y asegúrela

con un tornillo.

Partes de Repuesto

16503 Punta Detectora de Repuesto

16604 Compuerta del Compartimento de las Baterías

Especificaciones

Fuente de alimentación .............................................. 4 baterías alcalinas “AA”

Sensibilidad .............................................................. Menos de 1/2 onza por año

Vida de las baterías ................................................... aproximadamente 25 horas

Dimensione ..................................................... 8 1/2" Largo x 3 1/4" Ancho x 2"

Espesor .................................................................. (21,59 cm x 8,26 cm x 5 cm)

Longitud de la Sonda Exploradora .................................. 16 pulgadas (40,6 cm)

Peso ................................................................... 1,14 lbs. (0,52 Kg) con baterías

12

1© 2000 Robinair, SPX Corporation

Page 14

Table des matières

Introduction .............................................................................. 13

Commandes et indicateurs........................................................ 14

Caractéristiques ........................................................................ 15

Mode d’emploi ......................................................................... 16

Entretien ................................................................................... 17

Pièces de rechange.................................................................... 18

Spécifications ........................................................................... 18

Introduction

Le modèle 16600 est un détecteur de fuites électronique utilisé pour détecter les

fuites de frigorigène des systèmes de climatisation et de réfrigération. Il est

équipé d’un commutateur sélecteur de sensibilité qui permet de l’employer

avec les chlorofluorocarbones (CFC) et hydrochlorofluorocarbones (HCFC) sur

un réglage et les hydrofluorocarbones (HFC) sur l’autre. L’appareil peut

détecter des fuites inférieures à 1,5 cl (1/2 once) par an.

Les autres caractéristiques consistent en indicateurs de fuites (sonore et visuel),

un contrôle du volume, un discrimateur d’équilibre et une sonde à col de cygne

de 40,6 cm (16 pouces) qui maintient sa position, permettant son utilisation

d’une seule main. Lorsque l’appareil n’est pas utilisé, la sonde s’enroule dans

un étrier de retenue à l’arrière du boîtier.

(2N08) Conception d’appareil de détection des fuites de frigorigène

homologuée par Underwriters Laboratories, Inc.®, conforme à la

norme SAE J-1627 (1993) relative aux frigorigènes R-12 et R-134a.

16600 Détecteur de fuites de frigorigène

13

Page 15

Description

Commandes et indicateurs

MARCHE/ARRÊT et ÉQUILIBRE—La même commande met l’appareil en

marche et donne le contrôle illimité d’élimination de toute contamination

secondaire permettant de localiser rapidement les fuites.

VOLUME—Permet de régler le signal de fuite sonore au volume qui convient

aux conditions de travail.

NIVEAU DE SENSIBILITÉ—Le 16600 peut être employé avec une gamme

importante de frigorigènes mais, par suite des propriétés différentes de ces

produits, le niveau de sensibilité correct doit être sélectionné. Voici quelles sont

les recommandations :

• Niveau 1—HFC tels que R-134a, HP 62, AC 9000, AZ 20 et AZ 50

(préparations de frigorigènes comprenant principalement des

hydrofluorocarbones).

• Niveau 2—CFC et HCFC tels que R-12, R-22, R-500 et R-502 (solutions de

frigorigènes comprenant principalement des chlorofluocarbones et

hydrochlorofluocarbones).

Si vous n’êtes pas certain du type de frigorigène contenu dans le système,

commencez par le niveau 2 et passez au niveau 1 si vous avez des problèmes à

localiser la fuite après avoir équilibré le détecteur de fuites plusieurs fois.

INDICATEUR DE FUITES VISUEL—Les voyants à diode électroluminescente

s’allument pour indiquer des niveaux croissants de concentration. Un voyant

signifie qu’une quantité minime de frigorigène atteint le détecteur ; lorsque tous

les voyants sont allumés, cela signifie la présence d’une fuite de concentration

mesurable. Les voyants s’allument en séquence de bas en haut.

INDICATEUR DE PILES DÉCHARGÉES—Si seul le voyant du haut est

allumé, les piles sont déchargées et doivent être remplacées.

INDICATEUR DE FUITES SONORE—Le son de fonctionnement normal

est un tic-tac régulier. Alors que la sonde se rapproche d’une fuite, la fréquence

du tic-tac s’accélère jusqu’à devenir un son d’alarme (la puissance sonore de

cet indicateur peut être réglée à l’aide du contrôle du volume).

14

1© 2000 Robinair, SPX Corporation

Page 16

Caractéristiques

AVERTISSEMENT

Portez toujours des lunettes de protection lorsque vos

travaillez avec du frigorigène. Un contact avec du

frigorigène peut provoquer des blessures aux yeux.

Indicateurs de fuites sonore

et visuel—La fréquence de

l’alarme augmente lorsque la

pointe de la sonde

s’approche d’une haute

concentration de frigorigène.

Les voyants s’allument pour

indiquer une fuite et une

concentration de frigorigène.

Commutateur sélecteur de

détection—Faites coulisser

le commutateur sur Level 1

(Niveau 1) ou Level 2

(Niveau 2) selon le type de

frigorigène dans le système.

Contrôle du volume—

Réglez le signal sonore au

volume qui convient au

bruit ambiant de l’atelier

ou de l’endroit où le travail

est accompli.

Porte du compartiment

à piles—Située à l’arrière

de la poignée, la porte

s’enlève facilement pour

changer les piles.

Manœuvre d’une seule

main—La sonde à col de

cygne de 40,6 cm (16

pouces) maintient sa

position de sorte que vous

pouvez vous en servir

d’une seule main.

Discriminateur d’équilibre—

Cette fonction vous donne le

contrôle illimité d’élimination

de toute contamination

secondaire de sorte que vous

pouvez localiser en toute

certitude le site de la fuite.

16600 Détecteur de fuites de frigorigène

15

Page 17

Mode d’emploi

Lors de la première utilisation du détecteur de fuites 16600, installez les piles

avant de mettre l’appareil en marche. Quatres piles alcalines « AA » sont

comprises (voir la section « Entretien »).

1. Dégagez la sonde à col de cygne de l’étrier de retenue à l’arrière du boîtier

du détecteur de fuites.

2. Placez le commutateur MARCHE/ARRÊT sur MARCHE

3. Sélectionnez le niveau de sensibilité en faisant coulisser le commutateur sur

le réglage « 1 » ou sur le réglage « 2 ».

4. Réglez l’équilibre. Tournez le contrôle de l’équilibre, BALANCE, jusqu’à

l’obtention d’une alarme bruyante, puis dans l’autre sens jusqu’à n’entendre

qu’un tic-tac lent et régulier.

5. Commencez la recherche de la fuite. La vitesse de balayage recommandée

est de 5 cm (2 pouces) par seconde en maintenant la pointe de détection

aussi près que possible de la zone objet de la recherche. Faites passer la

sonde sous les conduits et vérifiez soigneusement autour des plis, des

raccords et autres endroits typiques de fuites.

CONSEIL : Le frigorigène est plus lourd que l’air. Commencez donc à

chercher par le haut du système en continuant vers le bas. Dans des conditions

de vents forts, un écran peut être nécessaire afin d’abriter l’endroit avant de

rechercher les fuites.

6. Pour localiser une fuite, un réglage de l’équilibre peut devenir nécessaire.

Lorsque vous vous rapprochez d’une concentration de frigorigène, la

tonalité d’alarme se fait entendre. Maintenez la sonde dans la même position

et tournez le contrôle d’équilibre pour réduire le son jusqu’à n’entendre que

le tic-tac. Continuez ensuite à chercher la fuite. Plusieurs réglages de

l’équilibre de l’appareil peuvent s’avérer nécessaires en présence d’une fuite

importante et d’accumulation de frigorigène.

7. Si vous trouvez plusieurs fuites, ou si vous pensez qu’il y en a plusieurs,

réparez la ou les fuites les plus importantes d’abord de façon à faciliter la

localisation des fuites moins importantes.

16

1© 2000 Robinair, SPX Corporation

Page 18

Entretien

Nettoyage/réparation de la pointe

de détection

La pointe de détection constitue l’élément le plus délicat du détecteur de fuites.

Il peut se trouver périodiquement obstrué par de la crasse, de la graisse et de

l’huile. Si la pointe semble sale et si vous avez des difficultés à localiser une

fuite ou si de fausses alarmes se déclenchent constamment, la pointe a sans

doute besoin d’être nettoyée ou remplacée.

Pour nettoyer la pointe :

1. Tournez le commutateur MARCHE/ARRÊT sur ARRÊT.

2. Dévissez la pointe de la sonde à col de cygne.

3. La pointe peut être nettoyée avec la plupart des solvants par vaporisation,

tels qu’un alcool dénaturé. Nous recommandons l’emploi d’un solvant, mais

si c’est impossible, vous pouvez laver la pointe à l’eau chaude savonneuse

tiède. Rincez ensuite vigoureusement à l’eau propre et laissez sécher à l’air

complètement avant de réinstaller la pointe.

ATTENTION ! Donnez à la pointe le temps de sécher suffisamment à l’air

avant d’utiliser le détecteur de fuites. La présence d’humidité dans la

pointe peut déclencher de fausses alarmes.

Assurez-vous d’avoir les mains propres et sèches. Faites attention de ne

pas contaminer la pointe par de la transpiration, de la graisse, des

nettoyants pour les mains, etc.

Pour changer la pointe :

Une pointe supplémentaire est livrée avec l’appareil. Vous pouvez également

acheter des pointes de rechange. Une pointe supplémentaire est rangée dans un

logement spécial à l’intérieur du compartiment à piles. Suivez les instructions

de la section « INSTALLATION/REMPLACEMENT DES PILES » pour ouvrir

le compartiment à piles.

1. Tournez le commutateur MARCHE/ARRÊT sur ARRÊT.

2. Dévissez la pointe de la sonde à col de cygne.

3. Vissez la pointe neuve sur la sonde jusqu’à ce qu’elle soit bien serrée à la

main. Ne serrez pas à l’excès.

4. Lorsque le détecteur de fuites n’est pas utilisé, enroulez la sonde à col de

cygne dans l’étrier de retenue pour la protéger.

16600 Détecteur de fuites de frigorigène

17

Page 19

Entretien

Installation/remplacement des

piles

Cet appareil emploie quatre (4) piles alcalines « AA ». Les piles doivent être

remplacées si le voyant du haut (sous les mots - PILES DÉCHARGÉES)

s’allume lorsque l’appareil est mis en marche pour un premier emploi. Le

compartiment à piles se trouve à l’arrière du boîtier.

1. Tournez le commutateur MARCHE/ARRÊT sur ARRÊT.

2. Enlevez la vis qui retient la porte du compartiment à piles. Si vous devez

remplacez les piles, retirez les piles usagées.

3. Placez les piles neuves dans le compartiment et respectant les indications de

polarité.

4. Replacez la porte du compartiment à piles et fixez-la à l’aide de la vis.

Pièces de rechange

16503 Pointe de détection de rechange

16604 Porte du compartiment à piles

Spécifications

Alimentation ...................................................... 4 piles alcalines « AA »

Sensibilité ........................................... Moins de 1,5 cl (1/2 once) par an

Durée de vie des piles ................................................. Environ 25 heures

Dimensions ..............21,59 cm de longueur x 8,26 cm de largeur x 5 cm

d’épaisseur ................................................... (8,1/2 po x 3,1/4 po x 2 po)

Longueur de la sonde............................................... 40,6 cm (16 pouces)

Poids ..............................................520 grammes (1,14 lb) avec les piles

18

1© 2000 Robinair, SPX Corporation

Page 20

Inhaltsverzeichnis

Einführung .............................................................................19

Regler und Anzeigen ............................................................. 20

Funktionsmerkmale ............................................................... 21

Anweisungen zum Betrieb .................................................... 22

Anweisungen zur Wartung .................................................... 23

Ersatzteilliste ......................................................................... 24

Technische Daten ................................................................... 24

Einführung

Das Modell 16600 ist ein elektronisches Lecksuchegerät für Kältemittel, das in

Klima- und Kälteanlagen eingesetzt wird. Es ist mit einem Schalter zum

Einstellen der Empfindlichkeit ausgestattet. Der Schalter hat eine Stellung für

CFC und HCFC und eine Stellung nur für HFC. Das Gerät registriert Lecks

kleiner als 14 g pro Jahr.

Weitere Einrichtungen sind akustische und visuelle Leckanzeigen,

Lautstärkenregler, Ansprechsgrenzenregler und eine 40 cm lange

Schwanenhalssonde, die ihre jeweilige Position hält und somit die Bedienung

mit einer Hand ermöglicht. Wenn das Gerät nicht verwendet wird, kann die

Sonde eingerollt und in die Halteklemme an der Rückseite des Gehäuses

geklemmt werden.

(2N08) Kältemittel-Lecksuchegeräteausführung zertifiziert durch

Underwriters Laboratories, Inc.®, erfüllt SAE J-1627 (1993) für die

Kältemittel R-12 und R-134a.

16600 Kältemittel-Lecksuchegerät

19

Page 21

Beschreibung

Regler und Anzeigen

EIN/AUS und ANSPRECHGRENZE—Dieser Regler dient zum Ein- und

Ausschalten des Gerätes und bietet zugleich eine stufenlose Einstellung zur

Eliminierung von Nebengeräuschen für die exakte Auffindung der Leckstelle.

LAUTSTÄRKENREGLER—Zum Einstellen des Leckwarntons auf die für

das jeweilige Arbeitsumfeld geeignete Lautstärke.

EMPFINDLICHKEITSPEGEL—Das 16600 kann für viele verschiedene

Kältemittel verwendet werden. Aufgrund der unterschiedlichen Merkmale der

Kältemittel sollte jedoch immer der richtige Empfindlichkeitspegel gewählt

werden. Dabei gelten folgende Richtlinien:

• Pegel 1—nur HFC, wie z.B. R-134a, HP 62, AC 9000, AZ 20 und AZ 50

(Kältemittelmischungen, die hauptsächlich aus HFC bestehen).

• Pegel 2—CFC und HCFC, wie z.B. R-12, R-22, R-500 und R-502

(Kältemittelmischungen, die hauptsächlich aus CFC und HCFC bestehen).

Wenn nicht genau bekannt ist, welches Kältemittel im System verwendet

wird, sollte mit Pegel 2 begonnen werden. Wenn nach mehrmaliger Justierung

der Ansprechgrenze das Leck nicht gefunden wird, sollte Pegel 1 verwendet

werden.

VISUELLE LECKANZEIGE—Die LED-Anzeigen leuchten auf, um

ansteigende Konzentrationen anzuzeigen. Wenn eine LED leuchtet, erreicht

eine minimale Menge Kältemittel den Sensor. Wenn alle LED aufleuchten,

liegt ein großes Leck bzw. eine hohe Konzentration vor. Die LED-Anzeigen

leuchten der Reihe nach von unten nach oben auf.

ANZEIGE FÜR SCHWACHE BATTERIE—Wenn nur die oberste LED

leuchtet, sind die Batterien schwach und sollten ausgewechselt werden.

AKUSTISCHE LECKANZEIGE—Bei normalem Betrieb ertönt ein

gleichmäßiges Ticken. Wird die Sonde näher an ein Leck bewegt,

beschleunigt sich das Ticken bis schließlich der Alarmton ertönt (die

Lautstärke des Alarmtons kann am Lautstärkenregler eingestellt werden).

20

1© 2000 Robinair, SPX Corporation

Page 22

Funktionsmerkmale

WARNUNG

Bei der Arbeit mit Kältemittel immer eine Schutzbrille

tragen. Ein Kontakt mit dem Kältemittel kann

Augenverletzungen zur Folge haben.

Akustische und sichtbare

Leckanzeigen—Das Alarmsignal

ertönt mit zunehmender

Frequenz, wenn sich die

Sondenspitze einer hohen

Kältemittelkonzentration nähert.

Die LED-Anzeigen leuchten von

unten nach oben auf, wenn eine

Kältemittelkonzentration

registriert wird.

Empfindlichkeitsschalter—

Den Schalter je nach Art des

im System verwendeten

Kältemittels auf Level 1 oder

Level 2 einstellen.

Lautstärkenregler—Zur

Einstellung der Lautstärke des

Alarmtons, so dass der Ton bei

Nebengeräuschen in der

Werkstatt oder auf der Baustelle

immer gut zu hören

Batteriefachtür—Befindet

sich an der Rückseite des

Handstücks und ist leicht zu

öffnen.

ist.

Bedienung mit einer Hand—

Die 40 cm lange

Schwanenhalssonde hält ihre

Position, so dass zur

Bedienung des Gerätes nur

eine Hand gebraucht wird.

Ansprechsgrenzenregler—

Ermöglicht die stufenlose

Regelung der Ansprechsgrenze

zur Eliminierung von

Nebengeräuschen für die exakte

Auffindung der Leckstelle.

16600 Kältemittel-Lecksuchegerät

21

Page 23

Anweisungen zum Betrieb

Vor dem ersten Gebrauch des 16600-Lecksuchegerätes müssen Batterien

installiert werden. Vier Mignonzellen sind im Lieferumfang enthalten (siehe

„Anweisungen zur Wartung“).

1. Die Schwanenhalssonde aus der Halteklemme an der Geräterückseite

herausnehmen.

2. Den EIN/AUS-Schalter einschalten (ON).

3. Den Empfindlichkeitspegel einstellen. Dazu den Gleitschalter auf „1‘ oder

„2“ schieben.

4. Die Ansprechgrenze einstellen. Dazu den BALANCE-Regler aufdrehen,

bis ein lauter Alarmton ertönt. Dann zurückstellen, bis ein langsames,

gleichmäßiges Ticken zu hören ist.

5. Die Lecksuche beginnen. Die empfohlene Abtastrate ist 54 mm pro

Sekunde, wobei die Sondenspitze so nahe wie möglich an die abgesuchte

Fläche gehalten werden sollte. Die Sonde unter Rohren vorbeiführen und

sorgfältige alle Biegungen, Verschraubungen und andere typische

Leckstellen abtasten.

TIPP: Kältemittel ist schwerer als Luft. Deshalb sollte die Suche an der

Oberseite des Systems begonnen und dann nach unten fortgesetzt werden. Bei

starkem Wind sollte der Bereich eventuell vor Beginn der Lecksuche

abgeschirmt werden.

6. Zur Auffindung der exakten Leckstelle muss eventuell die Ansprechgrenze

justiert werden. Wenn sich die Sonde in der Nähe einer

Kältemittelkonzentration befindet, ertönt der Alarmton. Bei Ertönen des

Alarmtons die Sonde in ihrer Position halten und den Balance-Regler

nach unten drehen, bis ein Ticken zu hören ist. Dann die Lecksuche

fortsetzen. Wenn ein großes Leck bzw. eine hohe

Kältemittelkonzentration vorliegt, muss die Ansprechgrenze eventuell

mehrmals justiert werden.

7. Wenn mehrere Lecks gefunden oder vermutet werden, sollten zuerst die

größeren Lecks repariert werden, damit die kleineren Lecks leichter zu

finden sind.

22

1© 2000 Robinair, SPX Corporation

Page 24

Anweisungen zur Wartung

Reinigen/Auswechseln derSondenspitze

Die Sondenspitze ist die wichtigste Komponente des Lecksuchegeräts. Sie kann

nach einiger Zeit durch Schmutz, Schmierfett und Öl verstopft werden. Wenn

die Spitze verschmutzt aussieht, das Auffinden eines Lecks schwierig ist oder

laufend falsche Alarme ausgegeben werden, muss die Spitze wahrscheinlich

gereinigt oder ersetzt werden.

Reinigen der Spitze:

1. Den EIN/AUS-Schalter ausschalten (OFF).

2. Die Spitze von der Schwanenhalssonde abschrauben.

3. Zum Reinigen der Spitze eignen sich die meisten verdampfbaren

Lösungsmittel, wie z.B. Spiritus. Die Verwendung eines Lösungsmittels wird

empfohlen. Wenn kein Lösungsmittel zur Verfügung steht, kann auch warmes

Seifenwasser verwendet werden. Die Spitze nach der Reinigung gründlich

mit sauberem Wasser abspülen und vor der Installation in die Sonde

vollständig an der Luft trocknen lassen.

VORSICHT! Ausreichend Zeit zum Trocknen der Spitze vorsehen.

Feuchtigkeit in der Sondenspitze kann falsche Alarme auslösen.

Vor der Handhabung der Spitze immer die Hände gründlich waschen

und trocknen. Die Spitze darf nicht durch Schweiß, Fett, Handreiniger

usw. verunreinigt werden.

Auswechseln der Spitze:

Im Lieferumfang des Gerätes ist eine extra Sondenspitze enthalten. Zusätzliche

Ersatzsondenspitzen können gekauft werden. Die extra Sondenspitze befindet sich

in einem Schlitz im Batteriefach. Zum Öffnen des Batteriefachs die Anweisungen

unter „INSTALLIEREN/WECHSELN DER BATTERIEN“ befolgen.

1. Den EIN/AUS-Schalter ausschalten (OFF).

2. Die Spitze von der Schwanenhalssonde abschrauben.

3. Die neue Spitze handfest auf die Sonde schrauben. Nicht zu fest anziehen.

4. Wenn das Lecksuchegerät nicht verwendet wird, sollte die Schwanenhalssonde

zum Schutz aufgerollt und in die Halteklemme geklemmt werden.

16600 Kältemittel-Lecksuchegerät

23

Page 25

Anweisungen zur Wartung

Installieren/Wechseln der Batterien

Dieses Gerät verwendet vier (4) Mignonzellen. Die Batterien sollten ersetzt

werden, wenn die oberste LED (neben den Worten LOW BATTERY) bei

eingeschaltetem Gerät aufleuchtet. Das Batteriefach befindet sich auf der

Rückseite des Gehäuses.

1. Den EIN/AUS-Schalter ausschalten (OFF).

2. Die Befestigungsschraube der Batteriefachtür entfernen. Die alten Batterien

herausnehmen.

3. Die neuen Batterien einsetzen und dabei auf die richtige Polarität achten.

4. Die Batteriefachtür wieder anbringen und mit der Schraube befestigen.

Ersatzteilliste

16503 Ersatzsondenspitze

16604 Batteriefachtür

Technische Daten

Stromversorgung ........................................................................ 4 Mignonzellen

Empfindlichkeit ........................................................... weniger als 14 g pro Jahr

Batterielebenszeit ......................................................................... ca. 25 Stunden

Abmessungen .......................................................... 21,59 cm x 8,26 cm x 5 cm

Sondenlänge ............................................................................................ 40,6 cm

Gewicht ............................................................................. 0,52 kg mit Batterien

24

1© 2000 Robinair, SPX Corporation

Page 26

Indice

Introduzione.............................................................................. 25

Comandi e indicatori ................................................................ 26

Funzioni .................................................................................... 27

Funzionamento ......................................................................... 28

Manutenzione ........................................................................... 29

Ricambi..................................................................................... 30

Specifiche ................................................................................. 30

Introduzione

Il 16600 è un sensore di perdite elettronico, usato per rilevare le perdite di

refrigerante nei sistemi di aria condizionata e di refrigerazione. Esso è

caratterizzato da un interruttore di selezione della sensibilità che può essere

usato con refrigeranti CFC e HCFC ad una impostazione e con refrigeranti

HFC all’altra. L’apparecchio è capace di rilevare perdite più piccole di 1/2

oncia per anno.

Altre funzioni includono indicatori di perdite visivi e acustici, controllo del

volume, controllo della soglia di bilanciamento ed una sonda a collo d’oca

di 16", che tiene la sua posizione con una operazione ad una mano sola.

Quando l’unità non è usata, la sonda viene avvolta in un fermaglio di

ritegno sul retro della scatola.

(2N08) Modello di rilevamento di perdite di refrigerante

Certificato dalla Underwriters Laboratories, Inc.Ò come conforme

a SAE J-1627 (1993) per refrigeranti R-12 ed R134a.

16600 Sensore di perdite di refrigerante

25

Page 27

Descrizione

Comandi e indicatori

ACCESO/SPENTO E BILANCIAMENTO—Lo stesso comando fa girare

l’unità e assicura un controllo assoluto per la eliminazione della

contaminazione di base in vista di trovare rapidamente le perdite.

VOLUME—Consente di regolare il segnale acustico di perdite al volume

appropriato per le condizioni di lavoro.

LIVELLO DI SENSIBILITÀ—Il 16600 può essere usato per un’ampia

gamma di refrigeranti, ma, a causa della diversità di questi ultimi, si deve

selezionare il livello corretto di sensibilità. Queste sono le linee direttive:

• Livello 1—i refrigeranti con HFC – quali R-134a, HP 62, AC 9000, AZ 20 e

AZ 50 (miscele di refrigeranti prodotte principalmente con HFC).

• Livello 2—Per i refrigeranti con CFC e HCFC quali R-12, R-22, R500 e

R502 (miscele refrigeranti prodotte principalmente con CFC e HCFC).

Se non si è sicuri di quale refrigerante si trova nel sistema, avviare con il

Livello 2 e cambiare al livello 1, se si ha difficoltà a localizzare le perdite dopo

aver bilanciato diverse volte il sensore di perdite.

INDICATORE VISIVO DI PERDITE – La spia LED si accende per mostrare

l’aumento di livelli di concentrazione. Un LED significa che una quantità

minima di refrigerante sta raggiungendo il sensore; quando tutti i LED sono

accesi, significa che vi è dimensione notevole di perdite e di concentrazione. I

LED si accendono in sequenza dal basso verso l’alto.

INDICATORE DI PERDITE ACUSTICO – il suono operativo normale è un

ticchettio regolare. Come la sonda si avvicina alla perdita, il tono cambia in un

ticchettio più rapido e quindi verso un suono d’allarme (il livello sonoro di

questo indicatore può essere regolato usando il comando del volume).

26

1© 2000 Robinair, SPX Corporation

Page 28

Funzioni

AVVERTENZA

Indossare sempre occhiali di sicurezza quando si lavora

con il refrigerante. Il contatto con refrigerante può

causare lesioni agli occhi.

Indicatori sonori e visivi—Un

allarme aumenta di frequenza

man mano che la punta si

avvicina ad un’alta

concentrazione di refrigerante. Il

LED si accende per indicare

l’esistenza di una perdita e di una

concentrazione di refrigerante

Interruttore di selezione della

sensibilità—Far scivolare

l’interruttore al livello 1 o al livello

2 a seconda del tipo di

refrigerante nel sistema.

Controllo del volume—

regolare il segnale acustico al

volume che più si adatta al

rumore di fondo nell’officina o

nel sito di lavoro.

Porta della batteria—situata

sul retro del manico, la porta

si rimuove facilmente per

cambiare le batterie.

Funzionamento a una mano—

La sonda a collo d’oca di 16”

tiene la sua posizione in modo

che si può far funzionare il

sensore con una mano.

Controllo della soglia di

bilanciamento—Assicura un

controllo assoluto per eliminare la

contaminazione di base, in modo

che si può azzerarla sul sito della

perdita

16600 Sensore di perdite di refrigerante

27

Page 29

Funzionamento

La prima volta che si usa il sensore di perdite 16600, installare le batterie prima

di accendere l’unità. Quattro batterie alcaline “AA” sono incluse (vedere

“Istruzioni di manutenzione”).

1. Rimuovere la sonda a collo d’oca nel fermaglio di ritegno sul retro

dell’involucro del sensore.

2. Girare l’interruttore ON/OFF su ON (acceso).

3. Selezionare il livello di sensibilità facendo scivolare l’interruttore

sull’impostazione “1” o sull’impostazione “2”.

4. Regolare il bilanciamento. Girare il comando BALANCE fino ad avvertire

l’allarme acustico ad alto volume, quindi abbassare il volume fino ad

avvertire un ticchettio basso e continuo.

5. Iniziare la ricerca della perdita. Il tasso di scansione raccomandato è di due

(2) pollici al secondo con la punta del sensore più vicina possibile all’area in

cui si esegue la ricerca. Far passare la sonda sotto la tubazione e controllare

attentamente intorno alle pieghe, ai raccordi ed agli altri punti dove

generalmente si possono formare delle perdite.

SUGGERIMENTO: Il refrigerante è più pesante dell’aria, per cui conviene

cercare le perdite prima sulla parte superiore del sistema e poi scendere fino al

fondo. In condizioni di forte vento può essere necessario schermare la zona

prima di cercare le perdite.

6. Per localizzare una perdita può essere necessario regolare il bilanciamento.

Quando si è nei pressi di una concentrazione di refrigerante, l’allarme emette

un segnale acustico. Tenere la sonda nella stessa posizione e girare il comando

del bilanciamento verso il basso fino a che si avverte il ticchettio. Quindi

continuare a cercare la perdita. Si può aver bisogno di bilanciare l’unità

numerose volte se vi è una grande perdita e il refrigerante si è accumulato.

7. Se si cerca più di una perdita o se si ha il sospetto che ve ne sia più di una,

riparare prima la perdita più grande, in modo sarà più facile localizzare la

perdita più piccola.

28

1© 2000 Robinair, SPX Corporation

Page 30

Manuntenzione

Maintenance

Pulizia/Sostituzione della punta del

sensore

La punta è il componente più importante del sensore di perdite. Periodicamente si

intasa con sporcizia, grasso e olio. Se la punta sembra sporca e si ha difficoltà a

localizzare una perdita o si verificano frequenti falsi allarmi, è probabile che la

punta deve essere pulita o sostituita.

Per pulire la punta:

1. Girare l’interruttore ON/OFF in posizione OFF (spento).

2. Svitare la punta dalla sonda a collo d’oca.

3. La punta può essere pulita nella maggior parte dei solventi che evaporano,

quali l’alcol denaturato. Si raccomanda l’uso di solventi, ma se non è

possibile, si può lavare la punta in una soluzione calda di acqua e vapore.

Sciacquare accuratamente con acqua pulita e lasciar asciugare completamente

all’aria prima di reinstallare la punta sulla sonda.

ATTENZIONE! Lasciar passare un adeguato periodo di tempo all’aria prima di

usare il rilevatore di perdite. L’umidità nella punta può determinare falsi allarmi.

Assicurarsi che le proprie mani siano pulite e asciutte. Fare attenzione a non

contaminare la punta con sudore, grasso, detergente per le mani, ecc.

Per cambiare la punta:

Una punta di ricambio viene fornita con l’unità. Le punte di ricambio sono anche

acquistabili in commercio. La punta di ricambio è conservata in una speciale

fessura all’interno del compartimento batteria. Per aprire il compartimento

batteria, seguire le istruzioni nel capitolo “INSTALLAZIONE/SOSTITUZIONE

DELLE BATTERIE”.

1. Girare l’interruttore “ON/OFF” su “OFF” (spento).

2. Svitare la punta dalla sonda a collo d’oca.

3. Avvitare manualmente la nuova punta nella sonda. Non avvitare

eccessivamente.

4. Quando il rilevatore di perdite non è in uso, avvolgere la sonda a collo d’oca

nel fermaglio di ritegno per proteggerla.

16600 Sensore di perdite di refrigerante

29

Page 31

Manuntenzione

Installazione/Sostituzione delle

batterie

L’unità funziona con quattro (4) batterie alcaline. Le batterie devono essere

sostituite se il LED superiore (oltre alle parole LOW BATTERY) si accende

quando l’apparecchio è acceso per la prima volta. Il compartimento batteria è

situato sul retro dell’involucro.

1. Girare l’interruttore “ON/OFF” su “OFF” (spento).

2. Rimuovere la vite che tiene lo sportello del compartimento batteria. Se si

sostituiscono le batterie, rimuovere le vecchie batterie.

3. Porre le nuove batterie nel compartimento batteria, seguendo le indicazioni

della polarità.

4. Rimontare lo sportello del compartimento batteria e assicurarlo con la vite.

Ricambi

16503 Punta di ricambio del sensore

16604 Sportello del compartimento batteria

Specifiche

Alimentazione .............................................................. 4 batterie alcaline “AA”

Sensibilità ................................................................. Meno di 1/2 oncia all’anno

Durata della batteria ........................................................................ Circa 25 ore

Dimensioni ............................................................. Lu 8 1/2" x La 3 1/4" x P 2"

............................................................................... (21,59 cm x 8,26 cm x 5 cm)

Lunghezza della sonda ........................................................ 16 pollici (40,6 cm)

Peso ................................................................... 1,14 lb (0,52 kg) con le batterie

30

1© 2000 Robinair, SPX Corporation

Page 32

The 16600 Leak Detector is covered by Robinair’s exclusive No Hassle

Over-the-Counter Exchange Warranty for a period of one year from the

date of sale. For details, see your local distributor or visit our web site.

Visit our web site at

www.robinair.com

☎

call our Toll-Free Technical Support Line at:

or

1-800-822-5561

in the co

In all other locations, call your local distributor.

ntinental U.S. and Canada.

NATIONWIDE NETWORK OF AUTHORIZED

SERVICE CENTERS

If your unit needs replacement parts, contact the service center

in your area. For help in locating a service center, call the TollFree Technical Support Line or visit our web site.

SPX Corporation

655 Eisenhower Drive

Owatonna, MN 55060-0995 USA

Technical Services: 1-800-822-5561

Fax: 1-800-822-7805

Customer Service: 1-800-533-6127

Fax: 1-800-322-2890

Web Site: www.robinair. com

123264 (Rev. B, 10/15/03) 16600 Refrigerant Leak Detector © SPX Corporation

Loading...

Loading...