Page 1

High Performance Vacuum Pump

Model 15401/15601/15603/15605/15607

Operating Manual .........................................2

Bombas de Vacío de Alto Rendimiento

Modelo 15401/15601/15603

Manuel del Operador....................................8

Pompe à Vide à Haut Rendement

Modèle 15401/15601/15603

Manuel d’utilisation .....................................16

Hochleistungs-Vakuumpumpe

Modelle 15401/15601/15603

Bedienungsanleitung ..................................24

Page 2

T able of contents

○○○○○○○○○○○○○○

CoolTech® high performance

vacuum pumps ................................................... 2

Pump components .............................................. 3

Warnings............................................................. 3

Before using your vacuum pump ....................... 4

To use the gas ballast feature ............................ 5

To shut down your pump after use .................... 5

To maintain your high vacuum pump ................. 5

Vacuum pump oil ........................................... 5

Oil change procedure .................................... 5

Cleaning your pump....................................... 5

Motor Lubrication ........................................... 5

Troubleshooting guide ........................................ 6

Failure to start..................................................... 6

Oil leakage ..................................................... 6

Failure to pull a good vacuum ....................... 6

®

CoolTech

Replacement parts ............................................. 7

Warranty coverage ............................................. 7

Out of warranty .............................................. 7

pump specifications .......................... 6

For use on A/C-R systems

using CFCs, HCFCs and HFCs

in conjunction with mineral oil,

ester oil, alkylbenzene oil and

PAG oil as lubricants. Not for

use with ammonia or lithium

bromide systems. Not for use

with flammable refrigerants.

Operating Manual

CoolTech® high performance

vacuum pumps

○○○○○○○○○○○○○

Congratulations on purchasing one of Robinair’s

top quality CoolTech

has been engineered specifically for air conditioning and refrigeration service, and is built with

Robinair’s proven offset rotary vane for fast,

thorough evacuation.

You’ll appreciate these key features...

Iso-Valve

Allows the pump to be shut off while still connected to the A/C-R system, which is handy for

checking rate of rise. With the valve handle in the

“Open” position, the pump is open to the system

being evacuated. In the “Close” position, the

pump is isolated from the system. This minimizes

pump oil pulled into the pumping module, making

start-up easier and reducing wear and tear on the

pump components.

High vacuum rating

The two-stage, offset rotary vane design provides

powerful, quiet high vacuum capability and

assures moisture removal, while the high

pumping capacity reduces evacuation time.

Lifetime Filtration

The intake filter prevents foreign matter from

entering the pumping chamber, and an internal

exhaust filter separates oil vapor from the

exhaust flow.

Directed exhaust

The exhaust is expelled through the handle to

direct it away from the service technician.

Gas ballast

A precise amount of atmospheric air is introduced

into the pump, preventing condensation of

moisture vapor and helping maintain the purity of

the pump oil. By using the gas ballast, the pump

operates more efficiently and pump life is

extended.

Sure-grip handle

The one-piece, molded handle makes it easy to

carry the pump to and from job sites, and the

handle stays cool to the touch during operation.

Compact design

Your pump measures approximately 40 cm long,

while aluminum housing and offset rotary vanes

keep the pump weight low, making it easy to

carry.

TM

®

vacuum pumps. Your pump

2

Page 3

Operating Manual

Pump components

1. Intake Fitting

2. Gas Ballast Valve (located

beside handle base)

3. Oil Fill Port

4. Sight Glass

5. Die-Cast Aluminum Housing

6. Oil Drain

7. Molded Polycarbonate Base

8. Iso-Valve

from the system

9. Powerful, High Torque Motor

10. Power Switch

11. Through-The-Handle Exhaust

12. Sure-Grip Handle

TM

— Isolates the pump

Warnings

○○○○○○○○

When working with refrigerants, goggles should

always be worn. Contact with refrigerants may

cause injury.

Improper use or connections may cause

electrical shock hazards. Read and follow the

instructions carefully and take precautions to

avoid electrical shock hazards. Be sure that all

associated devices are properly grounded before

energizing circuits.

The normal operating temperature will cause

certain external portions of the pump to be hot to

the touch. Do not touch the pump housing or

motor during operation.

NOTICE: Airborne Noise Emissions

This equipment has been tested for airborne noise emission per

the Council Directive for Machinery (89/392/EEC) Section 1.7.4

Instructions — Essential Health and Safety Requirements.

Sound levels do not exceed 80dB(A) actual value.

3

Page 4

Before using your vacuum pump

○○○○○○○○○○○○○○○○○○○○○○○○○○○○

In all cases, motors are designed for operating

voltages plus or minus 10% of the normal rating

(see SPECIFICATIONS).

1. Check to make certain the voltage and

frequency at the outlet match the specifications on the pump motor decal. Check the

ON-OFF switch to be sure it is in the OFF

position before you plug the pump into an

outlet. Check to be certain the gas ballast

valve is closed. Remove and discard the

exhaust plug from the end of the pump’s

handle.

2. The pump is shipped without oil in the

reservoir. Before starting the pump, fill with

oil. Remove the OIL FILL cap (black plastic

plug directly in front of the handle) and add

oil until oil just shows in the bottom of the

sight glass. The approximate oil capacity of

the pump is 375 milliliters.

3. Replace the OIL FILL cap and remove the

cap from one of the inlet ports. Turn the IsoValve to OPEN. Turn the motor switch to

ON. When the pump runs smoothly, turn the

Iso-Valve to CLOSED and replace the cap

on the inlet port. This may take from two to

30 seconds depending on the ambient

temperature. After the pump runs for

approximately one minute, check the sight

glass for proper oil level — oil should be

even with the sight glass OIL LEVEL line.

Add oil if necessary.

When the pump is running, the oil level should be

even with the line on the sight glass. Underfilling

will result in poor vacuum performance. Overfilling can result in oil blowing from the exhaust.

Your pump is now ready to evacuate air conditioning and refrigeration systems. Follow normal

service procedures and the A/C-R manufacturer’s

instructions for connections to the system.

Operating Manual

CAUTION! Before connecting your vacuum pump

to an A/C-R system, remove refrigerant from the

system in an accepted manner. Damage to the

pump may occur if evacuation is started while

the system is under high pressure. Robinair

recommends use of our Refrigerant Recovery

and Recycling equipment.

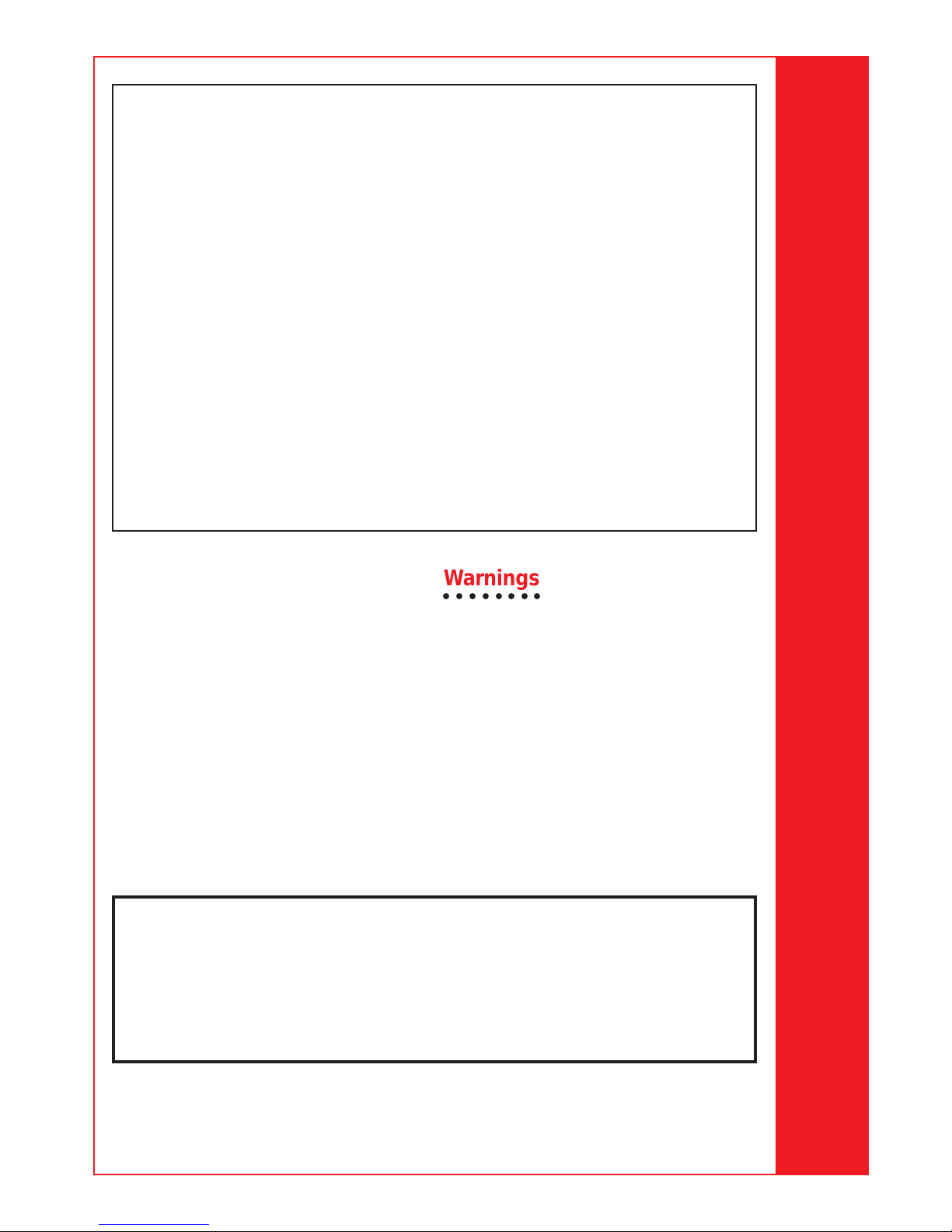

Wiring Instructions:

The CoolTech vacuum pump features dual

voltage ranges. Before operating the pump, read

and follow these rewiring instructions (if necessary) to be sure your pump is wired for the

appropriate voltage.

CAUTION! Unplug the unit before beginning

any service work. Improper use or connections can cause electrical shock. Only

qualified personnel should perform service

work.

The CoolTech vacuum pump is factory wired for a

high voltage range of 220 to 250 volts. To wire

the switch for a low voltage range of 110 volts to

115 volts, follow these steps.

1. Disconnect the unit from the AC power

source before proceeding.

2. Loosen the screws on the plate at the rear of

the motor, and carefully move the plate aside

to clear the opening.

3. Disconnect the leads and reconnect for low

voltage, following the diagram and chart.

(High voltage connections are also shown

if you want to rewire at some time.)

4. Check to see that all connections are

secure and that there are no short circuits.

Be sure the grounding connector is properly

connected.

5. Re-install the plate on the rear of motor with

the screws which were loosened in Step 2.

IMPORTANT: Check for short circuits using a

continuity tester before reconnecting to the AC

power source.

4

NOTE: EXTERNAL POWER LEADS ARE ALWAYS

3

2

5

6

1

4

CONNECTED TO TERMINALS 1 AND 4.

- EMERSON -

INTERNAL VOLTAGE CONNECTION

MOTOR

LEAD VOLTAGE

WHITE 4 3

LOW HIGH

3BROWN 6

VOLTAGE

INST0350

Emerson MotorsGeneral Electric Motors

Page 5

To use the gas

ballast feature

○○○○○○○○○○○○

To maintain your high

vacuum pump

○○○○○○○○○○○○

Moisture from the A/C-R system that is carried

into the pump as a vapor tends to condense into a

liquid and combine with the vacuum pump oil.

When moisture contaminates the pump oil, it

reduces the pump’s ability to reach its ultimate

deep vacuum level.

The gas ballast valve purges a small amount of

atmospheric air through the exhaust chamber.

This extra volume of air mixes with the vapor from

the refrigerant system to prevent condensation

and to help exhaust moisture in the form of vapor

from the pump.

To use the gas ballast, start the pump and open

the gas ballast valve until the system has reached

approximately 1000-3000 microns. Close the

valve to allow the pump to pull down to its

ultimate vacuum level. The gas ballast valve is

located beside the handle, opposite the inlet

fitting.

The gas ballast valve may be opened or closed at

any time during pump operation. It is fully open at

two turns counterclockwise.

NOTE:

Robinair recommends the use of a

thermistor vacuum gauge to most accurately

measure vacuum levels.

To shut down your

pump after use

○○○○○○○○○○○○○

To help prolong pump life and promote easy

starting, follow these procedures for shutdown:

1. Close the manifold valve between the pump

and the system.

2. Turn the Iso-Valve to the CLOSED position.

3. Remove the hose from the pump inlet.

4. Turn the pump power switch to OFF, then

return the Iso-Valve to the OPEN position for

a few seconds to relieve any vacuum inside

the pump.

5. Cap the inlet port to prevent any contamination or loose particles from entering the port.

For maximum performance, Robinair recommends

changing vacuum pump oil after each use.

Vacuum pump oil

The condition and type of oil used in any high

vacuum pump are extremely important in determining the ultimate attainable vacuum. Robinair recommends the use of our Premium High Vacuum Pump

Oil. This oil has been specifically blended to maintain

maximum viscosity at normal running temperatures

and to improve cold weather starts.

Robinair Premium High Vacuum Pump Oil is

available in handy quart containers or in convenient gallon containers. Order by part number:

13203 — Quart (shipped 12 quarts per case)

13204 — Gallon (shipped 4 gallons per case)

Oil change procedure

1. Be sure the pump is warmed up.

2. Remove the OIL DRAIN cap. Drain contaminated oil into a suitable container and dispose

of properly. Oil can be forced from the pump

by opening the inlet and partially blocking the

exhaust with a cloth while the pump is

running. Do not operate the pump for more

than 20 seconds using this method.

3. When the flow of oil has stopped, tilt the

pump forward to drain residual oil.

4. Replace the OIL DRAIN cap. Remove the OIL

FILL cap and fill the reservoir with new

vacuum pump oil until the oil just shows at the

bottom of the sight glass. The approximate oil

capacity of the pump is 375 milliliters.

5. Be sure the inlet ports are capped, then turn

ON the pump. Allow it to run for one minute,

then check the oil level. If the oil is below the

sight glass OIL LEVEL line, add oil slowly

(with the pump running) until the oil reaches

the OIL LEVEL line. Replace the OIL FILL

cap, making sure the inlet is capped and the

drain cap is tight.

6. If the oil is badly contaminated, you may need

to flush your pump. To flush, remove the

pump drain cap and start the pump. Slowly

pour a small quantity of new pump oil through

the oil fill inlet.

Repeat this procedure as required until the

contamination is removed. Replace the OIL

DRAIN cap and refill the reservoir to the proper

level with fresh pump oil (see Step 4).

Cleaning your pump

Clean the pump with soap and water only. Do not

use commercial cleaners that contain degreasing

agents that can damage polycarbonates. The

pump handle and base are made of Lexan, one of

the toughest polycarbonate plastics available.

However, it is sensitive to degreasing agents.

*Lexan is a registered trademark of General Electric

Motor Lubrication

After three years of normal service or one year of

heavy-duty service, add oil annually. Use electric

motor oil or SAE 10 oil.

Operating Manual

5

Page 6

T roubleshooting guide

○○○○○○○○○○○○○○○○○○○

Your CoolTech pump has been designed for

dependable use and long life. If something should

go wrong, however, the following guide will help

you get the pump back into service as quickly as

possible.

If disassembly of the pump is required, please

check your warranty. The warranty may be

voided by misuse or customer tampering which

results in the pump being inoperable.

Failure to start

Check the line voltage. Robinair pumps are

designed to start at

o

C. At extremes, however, switching between

0

the start and run windings may occur. When

starting the pump in cold temperatures, be sure

the Iso-Valve and inlet port are open to free air.

Oil leakage

1. Be sure the oil is not a residual accumulation

from spillage, etc.

2. If leakage exists, the module cover gasket or

the shaft seal may need replacing. Follow the

instructions supplied with the seal replacement kit, part number 15367. If leakage

exists in the area of the drain plug, you may

need to reseal the plug using a commercial

pipe thread sealer.

Failure to pull a good vacuum

1. Be sure the Iso-Valve on the pump is in the

OPEN position and the gas ballast knob is

tightly sealed.

2. Be sure the vacuum gauge and all connections are in good conditon and leak-free.

You can confirm leakage by monitoring the

vacuum with a thermistor gauge while

applying vacuum pump oil at connections or

suspected leak points. The vacuum will

improve briefly while the oil is sealing the

leak.

3. Be sure the pump oil is clean. A badly

Operating Manual

contaminated pump may require several oil

flushes. See OIL CHANGE PROCEDURE.

4. Be sure the oil is at the proper level. For

maximum pump operation, the oil must be

even with the OIL LEVEL line on the sight

glass when the pump is running. See OIL

CHANGE PROCEDURE. Do not overfill —

operating temperatures will cause the oil to

expand so it will appear at a higher level than

when the pump is not running. To check the

oil level, start the pump with the inlet capped.

Check the oil level in the sight glass. Add oil

if necessary.

+10% line voltage (loaded) at

U.S Patents 4,523,897; 5,209.653. Other U.S.

and Foreign Patents Pending.

6

CoolTech ® pump

specifications

○○○○○○○○○○○○

Frequency Range ................................... 50-60 Hz

Free Air Displacement ....................... 4 cfm/60 Hz

................................................. 94 l/m @50 Hz

............................................... 113 l/m @60 Hz

Stages................................................................. 2

Motor Speed ............................1425 rpm @50 Hz

............................................1725 rpm @60 Hz

Voltage Range .......................................110-115V

..........................................................220-250V

Factory Micron Rating .........................20 microns

Approximate Oil Capacity ........................... 400 ml

Weight...........................................................15 kg

Width ...................................................... 14.29 cm

Height ....................................................... 24.6 cm

Length .......................................................... 40 cm

Intake ..................................

Min. Starting Temp. (at 90% Voltage)............. 0oC

Motor Size ...........0.25kW (

Operating Temp. ............................................ 68oC

Frequency Range ................................... 50-60 Hz

Free Air Displacement ....................... 6 cfm/60 Hz

............................................... 142 l/m @50 Hz

............................................... 170 l/m @60 Hz

Stages................................................................. 2

Motor Speed ............................1425 rpm @50 Hz

............................................1725 rpm @60 Hz

Voltage Range .......................................110-115V

..........................................................220-250V

Factory Micron Rating .........................20 microns

Approximate Oil Capacity ........................... 400 ml

Weight....................................................... 15.2 kg

Width ...................................................... 14.29 cm

Height ....................................................... 24.6 cm

Length .......................................................... 42 cm

Intake ..................................

Min. Starting Temp. (at 90% Voltage)............. 0oC

Motor Size....... 0.375 kW (1/2 HP) Capacitor Start

Operating Temp. ............................................ 68

Note:

1. All motors are internally protected (automatic

reset).

2. Operating temperatures are typical for

normal operating conditions.

3. Model 15603 has a bipolar side grounded plug.

4. 15405 & 15605 have an Australian plug.

Because of ongoing product improvements, we reserve the right to

change design, specifications, or materials without notice.

Model 15401

1

/2” and 1/4” SAE MFL

1

/3 HP) Capacitor Start

Model 15601/15603/15605

1

/2” and 1/4” SAE MFL

o

C

Page 7

12

13

14

11

9

8

10

7

6

5

4

15

3

Operating Manual

16

INST0026

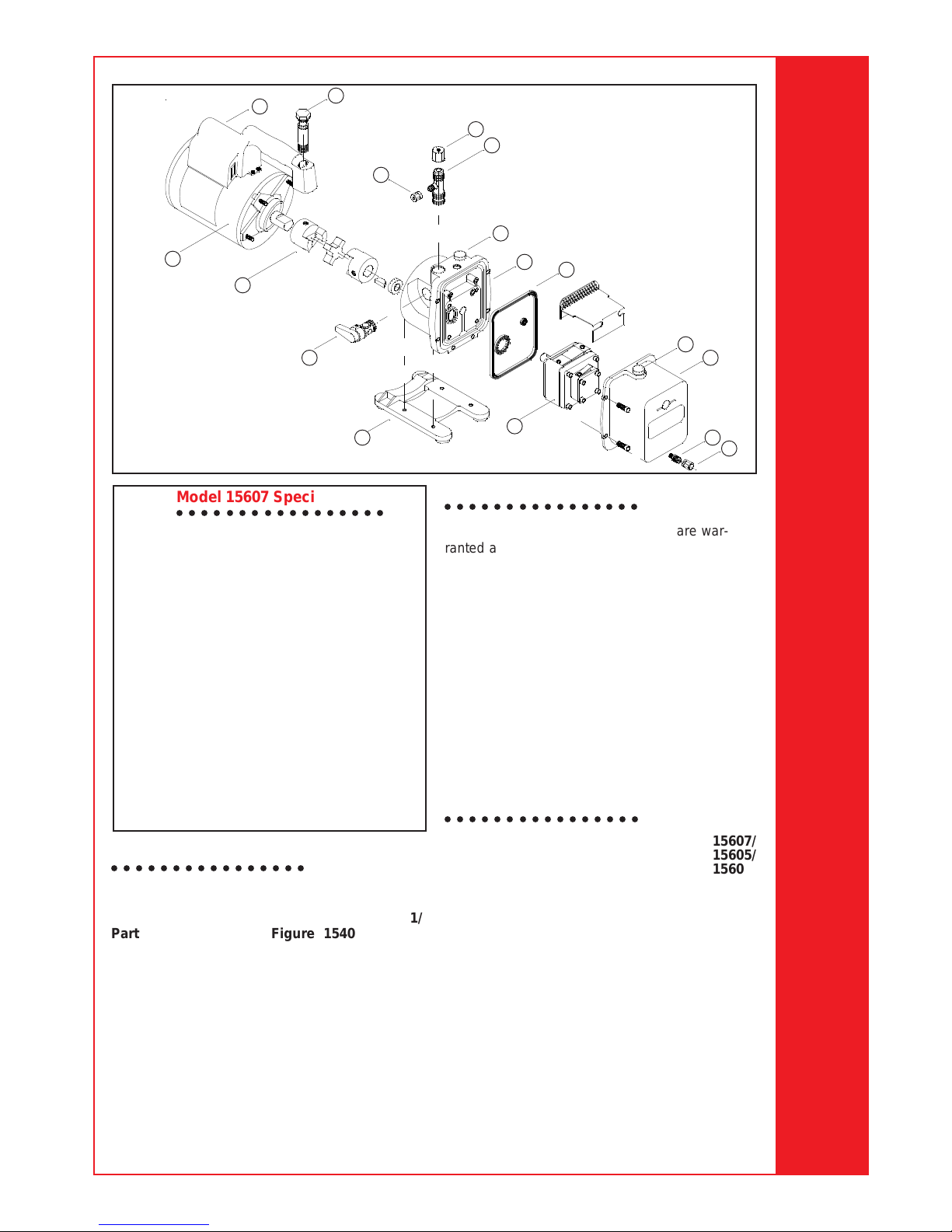

Model 15607 Specifications

○○○○○○○○○○○○○○○○○

Voltage Range 220V

Frequency Range 50 Hz.

Free Air Replacement 142 l/m

Stages 2

Motor Speed 1425 rpm

Factory Micron Rating 20 microns

Approximate Oil Capacity 400 ml

Weight 15 kg.

Width 14.29 cm.

Height 24.6 cm.

Length 42 cm.

Intake 1/2"and 1/4"

SAE MFL

Min. Starting Temp. at 90% Voltage 0oC

Motor Size .37kW (1/2 hp)

Capacitor Start

Operating Temperature 68oC

Replacement parts

○○○○○○○○○○○○○○○○

15607/

15605/

15601/

Part Figure 15401 15603

Oil Drain Cap (6) 1 40572 40572

Oil Drain Kit

(includes No. 1) 2 48116 48116

Module Cover Kit

(includes No. 2, 4 and 5) 3 15337 15337

Oil Fill Cap

(includes No. 7) 4 15371 15371

Intake Fitting

(includes No. 9 and 10) 8 15364 15364

Intake Cap (2),

1

/2” SAE MFL 9 41135 41135

17

INST0026

Warranty co verage

○○○○○○○○○○○○○○○○

2

1

Robinair CoolTech® vacuum pumps are warranted against defects in material and workmanship for one year of normal use from the date of

purchase. See your distributor for warranty

details.

Out of warranty

A pump which is no longer covered by the oneyear warranty period and which fails to operate

properly should be returned to the distributor with

a full written explanation of the problem. The

distributor may suggest returning the pump to the

factory. Before returning an out-of-warranty

pump, review all maintenance procedures to

avoid an unnecessary return. Replacement parts

are available for doing your own service.

Replacement parts

○○○○○○○○○○○○○○○○

15607/

15605/

15601/

Part Figure 15401 15603

Intake Cap (6),

1

/4” SAE MFL 10 41139 41139

Vent Bolt

(includes O-rings) 11 15338 15338

Handle, Power Cord

and Switch Assembly 12 15466 15466

Motor 13 15465 15665

Coupling 14 48103 48103

TM

Iso-Valve

Assembly 15 15368 15368

Base and Foot Assembly 16 15369 15369

Pump Assembly, less motor

(includes No. 3 and 6) 17 15547 15548

Seal Replacement Kit

(not shown) -- 15367 15367

7

Page 8

Contenido

○○○○○○○○○

Bombas de vacío de alto rendimiento CoolTech®8

Componentes de la bomba ................................ 9

Advertencias ....................................................... 9

Antes de utilizar su bomba de vacío ................ 1 0

Para utilizar el balasto de gas .......................... 11

Para apagar la bomba después de utilizarla.... 1 1

Para mantener su bomba de alto vacío ........... 12

Aceite de la bomba de vacío ....................... 1 2

Procedimiento para cambios de aceite ....... 12

Limpieza de la bomba.................................. 12

Lubricación de motor ................................... 12

Guía para la resolución de problemas ............. 1 3

Fallas de arranque ....................................... 13

Fugas de aceite ........................................... 13

Vacío deficiente ........................................... 13

Repuestos......................................................... 14

Cobertura de la garantía .................................. 14

Período de garantía ..................................... 14

Especificaciones de las bombas

CoolTech

®

......................................................... 15

Para los sistemas A/C-R que

utilizan los CFC, HCFC, y HFC

en combinación con aceite

mineral, aceite de éster, aceite

aiquilbenceno y aceite PAG

como lubricantes. No para uso

con sistemas de amoníaco o

bromuro de litio. No para uso

con refrigerantes combus-

tibles.

Manual del Operador

Bombas de vacío de alto

rendimiento CoolT ech

○○○○○○○○○○○○○○○○○○○

Felicitaciones por su compra de una bomba

de vacío CoolTech

Robinair. Su bomba ha sido diseñada específicamente para servicios de aire acondicionado

y refrigeración y está construida con el álabe

rotatorio compensado de la Robinair para tener

una comprobada evacuación rápida y completa.

Ud. va a apreciar estas características...

Iso-Valve

Permite que la bomba se cierre mientras está

conectada todavía al sistema de A/C-R, lo cual

es conveniente para controlar el ritmo de

aumento. Con el mango de la válvula en la

posición “Open,” la bomba está abierta al sistema

que está siendo evacuado. En la posición

“Close,” la bomba está aislada del sistema. Esto

minimiza la cantidad de aceite de la bomba

llevado al módulo de bombeo, facilitando el

arranque de la bomba y disminuyendo el

desgaste de sus componentes.

Alto vacío nominal

El diseño del álabe rotatorio compensado de dos

etapas ofrece una capacidad de alto vacío

poderosa, pero silenciosa, y asegura la

eliminación de la humedad, mientras que la

fuerte capacidad de bombeo reduce el tiempo de

evacuación.

Filtración durante la Vida Util

El filtro de entrada evita que materias extrañas

entren a la cámara de bombeo, y un filtro interno

de escape separa el vapor de aceite del flujo de

escape.

Escape dirigido

El escape se expulsa a través del mango para

dirigirlo en sentido contrario al técnico de

servicio.

Balasto de gas

Una cantidad precisa de aire atmosférico se

introduce en la bomba, previniendo la condensación del vapor de humedad y ayudando a mantener la pureza del aceite de la bomba. Al utilizar

el balasto de gas, la bomba opera con mayor

eficiencia y se extiende la vida de la bomba.

Mango de agarre seguro

El mango moldeado de una sola pieza hace que

sea fácil de transportar la bomba a diferentes

lugares de trabajo, y no se calienta durante la

operación.

Diseño compacto

Su bomba mide aproximadamente 40 cm de

largo, y la caja de aluminio y álabes rotatorios

compensados aligeran el peso de la bomba,

haciéndola fácil de llevar.

TM

®

de óptima calidad de

®

8

Page 9

Manual del Operador

Componentes de la bomba

1. Conectador de la Entrada

2. Válvula de Balasto de Gas (ubicada al lado

de la base del mango)

3. Puerto para el Llenado de Aceite

4. Tubo Indicador

5. Caja Moldeada de Aluminio

6. Drenaje de Aceite

7. Base Moldeada de Policarbonatos

8. Iso-Valve

9. Potente Motor de Alto Torque

10. Interruptor Eléctrico

11. Escape por el Mango

12. Mango de Agarre Seguro

TM

— aísla la bomba del sistema

Advertencias

○○○○○○○○○○○

Cuando se trabaja con refrigerantes, siempre se

debe usar gafas protectoras. El contacto con

refrigerantes puede causar daños a su persona.

El uso o conexiones inadecuados pueden crear

situaciones de peligro de shock eléctrico. Lea y

siga las instrucciones cuidadosamente y tome

precauciones para evitar estos peligros.

Asegúrese de que todos los dispositivos

asociados estén adecuadamente conectados a

tierra antes de pasar energía a los circuitos.

La temperatura normal de operación hará que

ciertas porciones externas de la bomba se

calienten. No toque la caja de la bomba o el motor

durante su operación.

NOTICIA: Emisiones Aerotransportadas de Ruido

Este equipo ha sido probado para emisiones aerotransportadas

de ruido según la Directiva del Consejo para Maquinaria (89/392/

EEC), Sección 1.7.4 Instrucciones — Requisitos Esenciales de

Salud y Seguridad. El nivel de ruido no sobrepasa el valor

actual de 88dB(A).

9

Page 10

Antes de utilizar su bomba de vacío

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

En todos los casos, los motores están diseñados

para voltajes de trabajo con una variación del

+10% del valor nominal (ver ESPECIFICACIONES).

1. Asegúrese de que el voltaje y la frecuencia

en la salida se conformen con las especificaciones en la calcomanía del motor de la

bomba. Revise el interruptor (ON-OFF) para

asegurar que está en la posición de OFF

antes de enchufar la bomba. Verifique que la

válvula de balasto de gas esté cerrada.

Saque y bote el tapón de escape del mango.

2. La bomba se envía sin aceite en el

reservorio; antes de arrancarla, hay que

llenarlo de aceite. Saque la tapa OIL FILL

(un tapón hecho de plástico negro que está

directamente al frente al mango) y agregue

aceite justamente hasta que aparezca en el

fondo del tubo indicador. La bomba tiene una

capacidad aproximada de aceite de 375 ml.

3. Reemplace la tapa de LLENADO DE ACEITE

(Oil Fill), y remueva la tapa de uno de los

puertos de entrada. Ponga la Iso-válvula en

la posición ABIERTO (Open). Gire el

interruptor de motor a ENCENDIDO (On).

Cuando la bomba funcione suavemente,

ponga la Iso-válvula en la posición

CERRADO (Closed) y reemplace la tapa del

puerto de entrada. Esto puede requerir de

dos a 30 segundos dependiendo de la

temperatura ambiente. Después de que la

bomba funcione por aproximadamente un

minuto, verifique el nivel adecuado del aceite

en el cristal visor — el aceite debe estar

nivelado con la línea de NIVEL DE ACEITE

(Oil level) del cristal visor. Añada más aceite

si es necesario.

Cuando la bomba está funcionando, el aceite

debe estar al nivel de la línea del tubo indicador.

Una cantidad demasiado baja resultará en un

vacío deficiente. Una cantidad demasiado grande

resultará en la salida de aceite por el escape.

Manual del Operador

Ahora su bomba está lista para evacuar sistemas

de aire acondicionado y refrigeración. Para

conectar la bomba al sistema, siga los

procedimientos normales de servicio y las

instrucciones del fabricante.

CUIDADO! Antes de conectar la bomba de

vacío al sistema de A/C-R, elimine el

refrigerante del sistema de una manera

aceptable. Pueden producirse daños en la

bomba si se inicia la evacuación mientras el

sistema está bajo mucha presión. La Robinair

recomienda el uso de nuestros equipos de

Recuperación y Reciclaje de Refrigerantes.

Instrucciones para la instalación

alámbrica del interruptor:

Los bombas de vacío CoolTechofrecen rangos

duales de voltaje. Antes de operar la bomba, lea

y siga estas instrucciones para cambios de

alambrado (si esto fuera necesario) para

asegurar que su bomba esté preparada para el

voltaje apropiado.

CUIDADO! Desenchufe la unidad antes de

iniciar cualquier trabajo de servicio. El uso o

conexiones inadecuados pueden causar

shock eléctrico. Solamente personal

calificado debe realizar trabajos de servicio.

Los bombas de vacío CoolTech vienen de la

fábrica listos para un rango de alto voltaje de 200

a 250 voltios. Para cambiar el alambrado a un

rango de bajo voltaje de 100 a 115 voltios, siga

estos pasos:

1. Desconecte la unidad de la fuente de poder

de corriente alterna (AC) antes de proceder.

2. Afloje los tornillos de la placa en el lado

posterior del motor y coloque cuidadosamente a un lado la placa para despejar la

entrada.

3. Desconecte los avances y reconecte para el

bajo voltaje, siguiendo el diagrama y el

cuadro en la siguiente página. (Las

conexiones de alto voltaje también están

indicadas por si acaso quisiera volver a la

configuración original alguna vez.)

4. Verifique que las todas las conexiones estén

bien sujetadas y que no haya cortocircuitos.

También de que la conexión a tierra esté

bien hecha.

5. Reinstale la placa en el lado posterior del

motor con los tornillos que se aflojaron en el

paso 2.

IMPORTANTE: Antes de volver a conectar con

la fuente de poder, revise para ver si hay

cortocircuitos utilizando un medidor de

continuidad.

10

Page 11

1

2

4

3

5 6 7

8

9

La bomba de General Electric

À Tornillo Para La

Puesta A Tierra

Á

Nota:

Las conexiones

eléctricas externas siempre

se conectan con las terminales

1 y 2.

Avances Eléctricos

Para utilizar el

balasto de gas

○○○○○○○○○○○○

La humedad que la bomba se lleva del sistema

A/C-R, en forma de vapor, tiende a condensarse

y este líquido se une al aceite de la bomba de

vacío. Cuando el aceite de la bomba se

contamina de humedad, esto reduce la capacidad

de la bomba de alcanzar su máximo nivel de alto

vacío.

La válvula del balasto de gas purga una pequeña

cantidad de aire atmosférico a través de la

cámara de escape. Este volumen adicional de

aire se mezcla con el vapor del sistema de

refrigerante para evitar la condensación y facilitar

la salida de humedad de la bomba en forma de

vapor.

Para utilizar el balasto de gas, arranque la bomba

y abra la válvula de balasto de gas hasta que el

sistema haya llegado a aproximadamente

1000-3000 (mil) micrones. Cierre la válvula para

permitir que la bomba llegue a su máximo nivel de

vacío. La válvula del balasto de gas está ubicada

al lado del mango, frente al conectador de la

entrada.

La válvula del balasto de gas puede estar abierta

o cerrada en cualquier momento durante la

operación de la bomba. Está totalmente abierta

con dos vueltas en la dirección contraria al

movimiento de las manecillas del reloj.

NOTA:

La Robinair recomienda el uso de un

manómetro de vacío tipo termistor para medir los

niveles de vacío de la manera más precisa.

La bomba de Emerson

à Conexión Interna De

Voltaje

Ä Avance Del Motor

Å Bajo Voltaje

Æ Alto Voltaje

Ç Marrón

È Blanco

É Púrpura

Para apagar la

bomba después de utilizarla

○○○○○○○○○○○○○○○○○○○○○○○○

Para ayudar a prolongar la vida útil de la bomba y

facilitar el arranque, siga estos procedimientos

para apagarla.

1. Cierre la válvula del múltiple entre la bomba y

el sistema.

2. Ponga la Iso-válvula en la posición

CERRADO (Closed).

3. Remueva la manguera de la entrada de la

bomba.

4. Ponga el interruptor de energía para la

bomba en la posición PARADO (Off), luego

ponga la Iso-válvula en la posición ABIERTO

(Open) de nuevo, por unos segundos para

eliminar el vacío del interior de la bomba.

5. Tape el puerto de entrada para prevenir

cualquier contaminación o entrada de

partículas flojas en el puerto.

Manual del Operador

11

Page 12

Para mantener su bomba de alto vacío

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Para un máximo rendimiento, Robinair

recomienda que se cambie el aceite de la bomba

de vacío después de cada uso.

Aceite de la bomba de vacío

La condición y el tipo de aceite utilizado en

cualquier bomba de alto vacío son sumamente

importantes en la determinación del máximo vacío

alcanzable. Robinair recomienda el uso de

nuestro Aceite Premium para Bombas de Alto

Vacío. Este aceite ha sido mezclado

específicamente para mantener la viscosidad

máxima a temperaturas normales de trabajo y

para mejorar los arranques en temporadas frías.

Se dispone del Aceite Premium para Bombas de

Alto Vacío Robinair en recipientes convenientes

de un galón o cuarto de galón. Haga los pedidos

por los números de repuesto:

13203 — Cuartos (enviados 12 cuartos por caja)

13204 — Galón (enviados 4 galones por caja)

Procedimiento para cambios de aceite

1. Asegúrese de calentar la bomba.

2. Saque la tapa OIL DRAIN. Drene el aceite

contaminado en un recipiente apropiado y

disponga del mismo adecuadamente. El

aceite puede ser forzado a salir de la bomba

al abrir la entrada y bloquear parcialmente el

escape con una tela mientras la bomba está

funcionando. No opere la bomba por más de

20 segundos utilizando este método.

3. Cuando se haya detenido el flujo de aceite,

incline la bomba hacia adelante para drenar

el aceite residual.

4. Vuelva a colocar la tapa OIL DRAIN. Saque

la tapa OIL FILL y llene el reservorio con el

nuevo aceite para bombas de vacío

justamente hasta que aparezca en el fondo

del tubo indicador. La bomba tiene una

capacidad aproximada de aceite de 375 ml.

5. Asegúrese de que estén tapados los puertos

de entrada y luego encienda la bomba

(póngala en ON). Permita que funcione

durante un minuto y luego revise el nivel del

aceite. Si el aceite está por debajo de la línea

OIL LEVEL, agregue más aceite lentamente

(mientras funciona la bomba) hasta que

alcance la línea. Vuelva a poner la tapa OIL

FILL, asegurándose de que la entrada esté

tapada y que la tapa del drenaje esté bien

ajustada.

6. Si el aceite está muy contaminado, puede ser

necesario enjuagar la bomba. Para hacerlo,

saque la tapa del drenaje de la bomba y

arranque la bomba. Lentamente vierta una

pequeña cantidad de nuevo aceite para

bombas por el puerto para el llenado de

aceite.

Repita este procedimiento las veces que sean

necesarias hasta que se elimine la contaminación. Vuelva a colocar la tapa OIL DRAIN y vuelva

a llenar el reservorio con aceite fresco para

bombas hasta el nivel apropiado (ver el paso 4).

Limpieza de la bomba

Limpie la bomba con agua y jabón. No utilice los

limpiadores comerciales que contienen agentes

desengrasadores que pueden dañar los

policarbonatos. La manilla y la base de la bomba

son construidas de Lexan, uno de los plásticos

policarbonatos más duros. Sin embargo es

sensible a los agentes desengrasadores.

*Lexan es una marca registrada de General Electric

Lubricación de motor

Después de tres años de servicio normal o un año

de servicio pesado, añada aceite anualmente.

Use aceite de motor eléctrico o aceite SAE 10.

Manual del Operador

12

Page 13

Guía para la resolución de problemas

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Su bomba CoolTech ha sido diseñada para

ofrecer un servicio confiable y una larga vida útil.

Sin embargo, si hubiera una falla, la siguiente

guía le ayudará a tener la bomba funcionando de

nuevo lo más rápidamente posible.

Si se requiere desmontar la bomba, favor de

revisar su garantía. La garantía puede ser

anulada por la mala utilización o por trabajos

realizados por personas no autorizadas,

incluyendo al cliente, cuando estos resultan en la

inoperabilidad de la bomba.

Fallas de arranque

Revise el voltaje de la línea eléctrica. Las

bombas Robinair están diseñadas para arrancar

o

C a un voltaje de línea (cargada) con una

a 0

variación de

condiciones extremas, pueden producirse

conmutación entre los bobinados de arranque y

de operación. Cuando encienda la bomba en

bajas temperaturas, asegúrese de que la Isoválvula y el puerto de entrada estén expuestos al

aire libre.

Fugas de aceite

1. Asegúrese de que el aceite no sea residuos

de un derrame, etc.

2. Si existe una fuga, puede ser necesario

reemplazar el empaque de la tapa del

módulo o el sello del eje. Siga las

instrucciones suministradas con el juego de

repuesto del sello, repuesto número 15367.

Si existe una fuga en el área del tapón de

drenaje, puede ser necesario volver a

sellarlo utilizando un sellador comercial para

la rosca de la tubería.

+10%. Sin embargo, bajo

Vacío deficiente

1. Asegúrese de que la Iso-Valve de la bomba

esté en la posición abierta (OPEN) y que la

manilla de balasto de gas esté

completamente sellada.

2. Asegúrese de que el manómetro de vacío y

todas las conexiones estén en buen estado y

libre de fugas. Se puede confirmar una fuga

a través de un manómetro tipo termistor

mientras se vaya aplicando aceite para

bombas de vacío en las conexiones o los

puntos en donde se sospecha que pueda

presentarse una fuga.

3. Asegúrese de que el aceite de la bomba esté

limpio. Una bomba muy contaminada puede

requerir varios enjuagues de aceite. Ver el

PROCEDIMIENTO PARA CAMBIOS DE

ACEITE.

4. Asegúrese de que el aceite esté en el nivel

apropiado. Para el máximo rendimiento de la

bomba, el aceite tiene que estar en el nivel

de la línea OIL LEVEL en el tubo indicador

cuando la bomba está funcionando. Ver el

PROCEDIMIENTO PARA CAMBIOS DE

ACEITE. No cargue la bomba con

demasiado aceite — las temperaturas de

trabajo causarán la expansión del aceite, el

cual aparecerá en un nivel más alto que

cuando la bomba no está funcionando. Para

revisar el nivel del aceite, arranque la bomba

con la entrada tapada. Agregue aceite si es

necesario.

Manual del Operador

13

Page 14

12

13

14

11

9

8

10

7

6

5

4

15

3

16

INST0026

Repuestos

○○○○○○○○○

15601/

Repuesto Figura 15401 15603

Tapa para Drenaje

de Aceite (6) 1 40572 40572

Juego de Drenaje de

Aceite (incluye #1) 2 48116 48116

Juego de Cubierta de

Módulo (incluye #2, #4, #5) 3 15337 15337

Tapa para Llenado de

Aceite (incluye #7) 4 15371 15371

Conectador de Entrada

(incluye #9 y #10) 8 15364 15364

Tapa de Entrada (2),

1

/2" SAE MFL 9 41135 41135

Tapa de Entrada (6),

1

/4" SAE MFL 10 41139 41139

Cobertura de la garantía

○○○○○○○○○○○○○○○○○○○○

Las bombas de vacío CoolTech de Robinair

están garantizadas contra defectos de materiales

y fabricación durante un año de uso normal

desde la fecha de adquisición. Para los detalles

de la garantía, comuníquese con el distribuidor.

Período de garantía

Una bomba que ya no esté cubierta por el

período de garantía de un año que deje de

funcionar adecuadamente debe ser devuelta al

distribuidor con una explicación completa del

problema por escrito. Antes de devolver una

bomba sin garantía, revise todos los

procedimientos de mantenimiento para evitar la

devolución innecesaria. Están disponibles

repuestos para que usted realice su propio

servicio de mantenimiento.

17

INST0026

Tuerca de Ventilación

(incluye juntas tóricas) 11 15338 15338

Manual del Operador

Conjunto Mango-Cable

Eléctrico-Interruptor 12 15466 15466

Motor 13 15465 15665

Acople 14 48103 48103

Conjunto de Válvula

TM

(Iso-Valve

) 15 15368 15368

Conjunto Base-Pie 16 15369 15369

Conjunto de Bomba, no motor

(incluye #3 y #6) 17 15547 15548

Juego de Reemplazo

del Sello (no ilustrado) -- 15367 15367

2

1

14

Page 15

Especificaciones de las bombas CoolT ech

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

®

Modelo 15401

Rango de Frecuencia.............................. 50-60 Hz

Desplazamiento Libre de Aire ............ 4 cfm/60 Hz

..................................................94 l/m @50 Hz

................................................113 l/m @60 Hz

Etapas ..................................................................2

Velocidad de Motor ................. 1.425 rpm @50 Hz

........................................... 1.725 rpm @60 Hz

Rango de Voltaje ................................... 110-115V

.......................................................... 220-250V

Valor Nominal de la Fábrica............... 20 micrones

Capacidad Aprox. de Aceite .......................375 ml

Peso .............................................................. 15 kg

Anchura...................................................14,29 cm

Altura.........................................................24,6 cm

Longitud .......................................................40 cm

1

Entrada ....................................

Temp. Mínima de Arranque

(a voltaje de 90%) ............................................0

Tamaño del Motor ........................................1/3 HP

Temp. de Trabajo...........................................68

/2” y 1/4” SAE MFL

o

Arranque por Capacitor

o

Modelo 15601/15603

Rango de Frecuencia.............................. 50-60 Hz

Desplazamiento Libre de Aire ............ 6 cfm/60 Hz

................................................142 l/m @50 Hz

................................................170 l/m @60 Hz

Etapas ..................................................................2

Velocidad de Motor ................. 1.425 rpm @50 Hz

........................................... 1.725 rpm @60 Hz

Rango de Voltaje ................................... 110-115V

.......................................................... 220-250V

Valor Nominal de la Fábrica............... 20 micrones

Capacidad Aprox. de Aceite .......................375 ml

Peso ........................................................... 15,2 kg

Anchura...................................................14,29 cm

Altura.........................................................24,6 cm

Longitud .......................................................42 cm

1

Entrada ....................................

Temp. Mínima de Arranque

(a voltaje de 90%) ............................................0

C

Tamaño del Motor ........................................1/2 HP

C

Temp. de Trabajo...........................................68

/2” y 1/4” SAE MFL

Arranque por Capacitor

Nota:

1. Todos los motores llevan protección interna

(con reactivación automática).

2. Las temperaturas de trabajo son típicas para

condiciones normales de operación.

3. El Modelo 15603 tiene un enchufe lateral

bipolar puesto a tierra.

Patentes EE.UU. 4.523.897; 5,209.653. Otras

patentes pendientes en los Estados Unidos y

otros países.

Debido al continuo mejoramiento de los

productos, nos reservamos el derecho de

cambiar diseños, especificaciones y

materiales sin previo aviso.

Manual del Operador

o

C

o

C

15

Page 16

Sommaire

○○○○○○○○○

Pompes à vide CoolTech

à haut rendement ............................................. 16

Composants de la pompe ................................ 17

Avertissements ................................................. 17

Avant d’utiliser la pompe à vide........................ 18

Utilisation du dispositif de lest de gaz .............. 19

Arrêt de la pompe après usage........................ 19

Entretien de la pompe à vide

à haut rendement ............................................. 20

Huile de la pompe à vide ............................. 20

Instructions pour le changement d’huile...... 2 0

Nettoyage de la pompe ............................... 20

Lubrification de moteur ................................ 20

Guide de détection des pannes ........................ 21

La pompe ne démarre pas ............................... 21

Il y a une fuite d’huile ................................... 21

Il est impossible d’obtenir

un haut niveau de vide................................. 21

Pièces de rechange .......................................... 22

Garantie ............................................................ 22

Hors garantie ............................................... 22

Spécifications de la pompe CoolTech

®

®

............. 23

Pour les systèmes A/C-R,

utilisant les CFC, HCFC et HFC

en conjonction avec de l’huile

minérale, de l‘huile ester, de

l’huile de benzène d’alkyle et

de l’huile PAG comme

lubrifiants. Ne pas utiliser sur

les systèmes à ammoniaque

ou bromure de lithium. Ne pas

Manuel d’utilisation

utiliser avec des réfrigérants

inflammables.

Pompes à vide CoolTech

à haut rendement

○○○○○○○○○○○○○○○

Nous vous félicitons d’avoir opté pour un modèle

de pompes à vide CoolTech

Cette pompe a été spécifiquement conçue pour

entretenir les installations de climatisation et de

réfrigération et comporte un dispositif à ailettes

rotatives Robinair qui a fait ses preuves et qui

assure une évacuation rapide et complète.

Ces qualités sont là pour vous servir au mieux...

Soupape Iso-Valve

Elle permet d’arrêter la pompe tout en la laissant

branchée sur le système A/C-R, ce qui est

commode pour vérifier les niveaux. Lorsque la

manette de soupape est en position “Open,” la

pompe s’ouvre au système en cours

d’évacuation. Lorsqu’elle est en position “Close,”

elle est isolée du système. Ce dispositif permet

de limiter la quantité d’huile injectée dans le

module de pompage, facilite le démarrage et

réduit l’usure des composants de la pompe.

Régime nominal de vide poussé

Sa conception à deux étages et à deux ailettes

rotatives donne à la pompe une capacité de vide

puissante et silencieuse ainsi que la possibilité de

prélever l’humidité; cette forte capacité de

pompage réduit le temps d’évacuation.

Filtration et durée de vie

Le filtre d’aspiration retient toute matière

étrangère à l’entrée de la chambre de pompage

et un filtre d’échappement interne sépare la

vapeur d’huile du flux d’échappement.

Echappement dirigé

L’échappement s’effectue par la poignée et est

expulsé loin du technicien de maintenance.

Lest de gaz

Un volume précis d’air est introduit dans la

pompe, ce qui empêche la condensation de la

vapeur d’humidité et aide à maintenir la pureté de

l’huile. En utilisant le lest de gaz, la pompe opère

plus efficacement et sa durée de vie est

rallongée.

Poignée de prise sûre

Cette poignée moulée, faite d’une seule pièce,

facilite le transport de la pompe de chantier en

chantier. Elle reste froide lorsque la pompe

fonctionne.

Conception compacte

La pompe, qui mesure environ 40 cm de long, est

légère grâce à son boîtier en aluminium et ses

ailettes rotatives, et dès lors facile à transporter.

TM

®

®

de haute gamme.

16

Page 17

Manuel d’utilisation

Composants de la pompe

1. Raccord d’aspiration

2. Soupape de lest de gaz (située près du socle

de la poignée)

3. Orifice de remplissage d’huile

4. Hublot de regard

5. Boîtier en aluminium moulé

6. Orifice de vidange d’huile

7. Socle en polycarbonate moulé

8. Soupape Iso-Valve

pompe du système

9. Moteur puissant à fort couple

10. Interrupteur d’alimentation

11. Echappement par la poignée

12. Poignée à prise sûre

TM

— permet d’isoler la

Avertissements

○○○○○○○○○○○○○

Pour travailler avec des réfrigérants, le port de

lunettes protectrices est obligatoire car le contact

avec les réfrigérants peut occasionner des

blessures.

Une utilisation inappropriée ou des connexions mal

faites peuvent être sources de chocs électriques.

Lire soigneusement les instructions et prendre

toutes les précautions nécessaires pour éviter les

chocs électriques. S’assurer que tous les appareils

associés à la pompe sont correctement mis à la

masse avant de mettre les circuits sous tension.

La température normale de fonctionnement

provoquera le réchauffement de certaines parties

extérieures de la pompe. Ne pas toucher le boîtier

de la pompe ou le moteur pendant que la pompe

fonctionne.

NOTICE: Emissions de Bruits Aériens

Cet équipment a été testé pour les émissions de bruits aériens

selon la Directive du Conseil pour la Machinerie (89/392/EEC),

Section 1.7.4 Instructions — Prescriptions Essentielles de Santé

de Sécurité. Les niveaux sonores ne doivent pas excéder

88dB(A) en valeur effective.

17

Page 18

Avant d’utiliser la pompe à vide

○○○○○○○○○○○○○○○○○○○○○○○○○○

Dans tous les cas, les moteurs sont conçus pour

fonctionner avec des tensions de fonctionnement

de plus ou moins 10% de la tension nominale (cf.

SPECIFICATIONS).

1. Vérifier que les spécifications de tension et

de fréquence mentionnées sur la plaque

d’identification du moteur correspondent bien

à celles de la prise de courant. Faire attention que l’interrupteur ON-OFF soit en

position OFF avant de brancher la pompe

dans une prise. Vérifier que la soupape de

lest de gaz est fermée. Enlever et mettre de

côté le bouchon de l’échappement situé à

l’extrémité de la poignée de la pompe.

2. La pompe est livrée sans huile dans le

réservoir. Avant de démarrer la pompe, il

faut remplir le réservoir d’huile. Retirer le

bouchon de l’orifice de remplissage d’huile

(bouchon noir en plastique situé devant la

poignée) et ajouter de l’huile jusqu’à ce qu’on

la voit apparaître au fond du hublot de

regard. La capacité de la pompe en huile est

d’environ 375 millilitres.

3. Remettre le bouchon de remplissage d’huile

(OIL FILL) et enlever le bouchon de l’un des

orifices d’admission. Mettre la soupape Isovalve en position ouverte (OPEN). Placer le

commutateur moteur sur ON. Une fois la

pompe mise en route, mettre la soupape Isovalve en position fermée (CLOSED) et

replacer le capuchon sur l’orifice

d’admission. L’opération dure entre 2 et 30

secondes suivant la température ambiante.

Après avoir laissé la pompe fonctionner

pendant une minute environ, vérifier le

niveau d’huile dans le hublot de regard :

l’huile doit atteindre la ligne OIL LEVEL.

Ajouter de l’huile si nécessaire.

Lorsque la pompe fonctionne, le niveau d’huile

doit arriver au trait du hublot de regard. Si le

niveau est inférieur, le rendement sera moindre

en termes de vide réalisé. Si le niveau est

Manuel d’utilisation

supérieur, de l’huile s’échappera éventuellement

de l’orifice d’échappement.

La pompe est maintenant prête à évacuer les

systèmes de climatisation et de réfrigération.

Suivre les procédures normales d’entretien et les

instructions du fabricant de systèmes A/C-R

concernant le branchement de la pompe au

système.

ATTENTION! Avant de brancher la pompe à

vide sur un système A/C-R, retirer le réfrigérant

du système en suivant la méthode habituelle.

Si l’évacuation commence alors que le système

est sous haute pression, la pompe encourt des

dommages. Robinair recommande l’utilisation

de son équipement de récupération et de

recyclage du réfrigérant.

Instructions relatives au cablâge :

La pompe à vide CoolTech® est disponible en

bitension. Avant d’utiliser la pompe, lire et suivre

les instructions de recâblage (si nécessaire) afin

que la pompe soit réglée sur la tension appropriée.

ATTENTION! Débrancher la pompe avant

d’entreprendre tout travail d’entretien. Une

utilisation ou des connexions inappropriées

peuvent causer des chocs électriques. Seul un

personnel qualifié doit réaliser le travail de

maintenance.

La pompe à vide CoolTech est câblée en usine

pour une haute tension de 220 á 240 volts. Pour

brancher le commutateur qui permet de se régler

sur une basse tension de 110 á 115 volts, il

convient d’adopter la procédure suivante:

1. Avant de procéder, débrancher l’appareil de la

source de courant.

2. Desserrer les vis du plateau à l’arrière du

moteur et déplacer avec précaution le plateau

sur le côté pour dégager l’ouverture.

3. Débrancher les conducteurs principaux et les

rebrancher pour une basse tension, suivant le

schéma et le tableau de la page opposée (les

connexions de haute tension sont aussi

indiquées pour le cas où l’on veuille recâbler).

4. S’assurer que toutes les connexions sont

sures et qu’il n’y a pas de court-circuits.

S’assurer que la prise de terre est bien

branchée.

5. Réinstaller le plateau à l’arrière du moteur

avec les vis qui ont été desserrées à l’étape 2.

IMPORTANT : Vérifier l’absence de court-circuits

à l’aide d’un testeur de continuité avant de

rebrancher l’appareil à la source de courant.

18

Page 19

1

2

4

3

5 6 7

8

9

La pompe à vide General Electric

À Vis De Mise A La Terre

Á

Remarque :

d’alimentation externe sont

toujours connectés aux

terminaux 1 et 2.

Les conducteurs

Conducteurs Principaux

à Connexion de Tension Interne

Utilisation du dispositif

de lest de gaz

○○○○○○○○○○○○

L’humidité du système A/C-R qui arrive dans la

pompe sous forme de vapeur tend à se condenser

en liquide et à se combiner avec l’huile de la

pompe. Lorsque l’humidité contamine l’huile de la

pompe, la capacité de la pompe à atteindre son

niveau optimal de vide profond est réduite.

La soupape de lest de gaz laisse passer une

petite quantité d’air par la chambre

d’échappement. Ce volume supplémentaire d’air

se mélange avec la vapeur du système de

réfrigérant pour prévenir la condensation et aider

à expulser l’humidité de la pompe sous forme de

vapeur.

Pour utiliser la soupape de lest de gaz, démarrer

la pompe et ouvrir la soupape de lest de gaz

jusqu’à ce que le système atteigne un vide

d’environ 1000-3000 microns. Fermer la soupape

pour que la pompe puisse descendre à son

niveau optimal de vide. La soupape de lest de gaz

est située à côté de la poignée, en face du

raccord d’aspiration.

La soupape de lest de gaz peut être ouverte ou

fermée à n’importe quel moment du

fonctionnement de la pompe. Elle est

complètement ouverte lorsqu’on lui fait faire deux

tours dans le sens des aiguilles d’une montre.

REMARQUE :

d’un manomètre à thermistor pour mesurer le plus

précisément possible les niveaux de vide.

Robinair recommande l’utilisation

La pompe à vide Emerson

Ä Conducteur Principal De

Moteur

Å Basse Tension

Æ Haute Tension

Ç Marron

È Blanc

É Violet

Arrêt de la pompe

après usage

○○○○○○○○○○

Afin de prolonger la vie de la pompe et d’en

faciliter le démarrage, arrêter la pompe en suivant

les instructions ci-après.

1. Fermer le manifold entre la pompe et le

système.

2. Mettre la soupape Iso-valve en position

fermée (CLOSED).

3. Sortir le tuyau à l’entrée de la pompe.

4. Mettre l’interrupteur de la pompe sur OFF;

remettre ensuite la soupape Iso-valve en

position ouverte (OPEN) pendant quelques

secondes pour dégager tout vide se trouvant

dans la pompe.

5. Boucher l’orifice d’admission pour empêcher

toute contamination ou l’entrée dans l’orifice

de particules isolées.

Manuel d’utilisation

19

Page 20

Entretien de la pompe à vide à haut rendement

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Pour assurer un rendement maximal, Robinair

recommande de changer l’huile de la pompe

après chaque utilisation.

Huile de la pompe à vide

Le type d’huile utilisé pour chaque pompe à vide à

haut rendement et son état, sont deux facteurs

extrêmement importants pour déterminer le vide

maximum possible. Robinair recommande

l’utilisation de son huile pour pompe à vide à haut

rendement, de qualité supérieure. Cette huile a

été spécifiquement mélangée pour maintenir une

viscosité maximale à des températures normales

de fonctionnement et pour améliorer les

démarrages en conditions hivernales.

L’huile de qualité supérieure Robinair pour pompe

à vide à haut rendement est disponible en

conteneurs d’un quart (0,95 l) ou en conteneurs

d’un gallon (3,8 l).

Pour les commander, indiquer le numéro de

référence:

13203 — Quart (livré par caisse de 12 quarts)

13204 — Gallon (livré par caisse de 4 gallons)

Instructions pour le changement d’huile

1. S’assurer que la pompe est chaude.

2. Enlever le bouchon de l’orifice de vidange

d’huile. Verser l’huile contaminée dans un

conteneur approprié et l’éliminer de manière

propre. Il est possible d’extirper l’huile de la

pompe en ouvrant la bouche d’aspiration et

en bloquant l’échappement avec un tissu

alors que la pompe fonctionne. Si l’on utilise

cette méthode, ne pas faire marcher la

pompe plus de 20 secondes.

3. Lorsque l’écoulement d’huile s’arrête,

pencher la pompe vers l’avant pour vider

l’huile qui reste.

Manuel d’utilisation

4. Replacer le bouchon de vidange d’huile.

Enlever le bouchon de remplissage d’huile et

remplir le réservoir avec de l’huile neuve

jusqu’à ce que l’on aperçoive l’huile au fond

du hublot de regard. La capacité de la pompe

en huile est d’environ 375 millilitres.

5. S’assurer que les orifices d’aspiration sont

bouchés puis mettre la pompe sous tension.

La faire tourner pendant une minute puis

vérifier le niveau d’huile. Si l’huile est en

dessous du repère de niveau dans le hublot

de regard, en rajouter lentement (en continuant de faire tourner la pompe) jusqu’à ce

qu’elle atteigne le niveau souhaité. Replacer

le bouchon de remplissage d’huile en

s’assurant que l’aspiration est bouchée et que

le bouchon de vidange est bien serré.

6. Si l’huile est très contaminée, il faudra peutêtre laver la pompe à l’huile. Pour cela, il faut

enlever le bouchon de l’orifice de vidange et

démarrer la pompe. Verser lentement une

petite quantité d’huile nouvelle par l’orifice de

remplissage.

Répéter la procédure comme indiqué jusqu’à ce

que les contaminants aient disparu. Replacer le

bouchon de l’orifice de vidange d’huile et remplir

le réservoir avec de l’huile propre jusqu’au niveau

adéquat (cf. Etape 4).

Nettoyage de la pompe

Ne nettoyer la pompe qu’avec de l’eau et du

savon. Ne pas utiliser de détergents vendus dans

le commerce contenant des agents dégraissants

qui pourraient endommager les polycarbonates.

La poignée et le socle de la pompe sont fabriqués

en Lexan, un des plastiques polycarbonates les

plus résistants. Les agents dégraissants

pourraient toutefois les abîmer.

*Lexan est une marque déposée de General Electric

Lubrification de moteur

Aprés trois ans de service normal ou un an de

service à haut rendement, ajouter de l’huile

annuellement. Utiliser de l’huile pour moteur

électrique ou de l’huile SAE 10.

20

Page 21

Guide de détection des pannes

○○○○○○○○○○○○○○○○○○○○○○○○○

La conception de la pompe CoolTech est telle

qu’elle garantit une utilisation fiable et durable.

Si toutefois quelque chose ne fonctionne pas, le

présent guide des anomalies permettra de

remettre la pompe en service aussi rapidement

que possible.

Si le démontage de la pompe s’avère nécessaire,

consulter la garantie. Elle peut ne pas s’appliquer

lorsque la pompe est devenue inopérable à la

suite d’une mauvaise utilisation ou d’une

altération par l’utilisateur.

La pompe ne démarre pas

Vérifier la tension de la ligne électrique. Les

pompes Robinair sont conçues pour démarrer

+10% de la tension de la ligne (chargée) à 0oC.

à

Aux extrêmes toutefois, un transfert entre les

enroulements de démarrage et d’allure normale

peut se produire. Lorsque l’on démarre la pompe

à de basses températures, s’assurer que la

soupape Iso-valve et l’orifice d’admission sont

ouverts pour laisser s’échapper l’air.

Il y a une fuite d’huile

1. S’assurer que l’huile ne provient pas d’une

accumulation due à un débordement, etc.

2. Si la fuite existe, il faut peut-être remplacer le

joint de couvercle du module ou le joint

d’arbre. Suivre les instructions fournies avec

le kit de remplacement de joint, pièce

N°15367. Si une fuite existe autour du

bouchon de l’orifice de vidange,

il faudra éventuellement resceller le bouchon

à l’aide d’un dégrippant commercial.

Il est impossible d’obtenir un haut

niveau de vide

1. S’assurer que la soupape Iso-valve est en

position OPEN et le bouton de lest de gaz

est fermé hermétiquement.

2. S’assurer que le manomètre et toutes les

connexions sont en bon état et qu’ils ne

présentent pas de fuites. On peut confirmer

la présence d’une fuite en contrôlant le vide

à l’aide d’un manomètre à thermistor et en

appliquant de l’huile aux jointures ou aux

points de fuite qu’on a identifiés. Le vide

s’améliorera rapidement dès que l’huile aura

remédié à la fuite.

3. S’assurer que l’huile de la pompe est propre.

Si la pompe est gravement contaminée, il

faudra éventuellement lui faire subir plusieurs

lavages d’huile. Cf. la section INSTRUCTIONS POUR LE CHANGEMENT D’HUILE.

4. S’assurer que l’huile est au niveau souhaité.

Pour que la pompe fonctionne de manière

optimale, il faut, lorsqu’elle marche, que

l’huile atteigne la ligne de niveau du hublot

de regard. Cf. INSTRUCTIONS POUR LE

CHANGEMENT D’HUILE. Ne pas remplir de

trop le réservoir car la température de la

pompe en marche provoque une expansion

de l’huile qui apparaît à un niveau plus haut

que lorsque la pompe ne fonctionne pas.

Pour vérifier le niveau d’huile, démarrer la

pompe avec la bouche d’aspiration fermée.

Vérifier le niveau d’huile dans le hublot.

Ajouter de l’huile si nécessaire.

Manuel d’utilisation

21

Page 22

12

13

14

11

9

8

10

7

6

5

4

15

3

16

INST0026

Pièces de rechange

○○○○○○○○○○○○○○○○

15601/

Pièce N° 15401 15603

Capuchon (6) d’orifice

de vidange d’huile 1 40572 40572

Orifice de vidange d’huile

(comprend N° 1) 2 48116 48116

Kit de couvercle de Module

(comprend N° 2, 4 et 5) 3 15337 15337

Bouchon de l’orifice de

remplissage d’huile

(comprend N° 7) 4 15371 15371

Raccord d’aspiration

(comprend N° 9 et 10) 8 15364 15364

Bouchon (2) d’aspiration

1

13mm (

/2” SAE MFL) 9 41135 41135

Bouchon (6) d’aspiration

1

6 mm (

Manuel d’utilisation

Boulon d’évent

/4” SAE MFL) 10 41139 41139

(comprend bagues) 11 15338 15338

Garantie

○○○○○○○

Les pompes CoolTech® de Robinair sont

garanties contre les défauts de matériel et de

fabrication pendant une durée normale

d’utilisation d’un an à partir de la date d’achat.

Prendre contact avec le distributeur pour obtenir

les détails concernant l’application de cette

garantie.

Hors garantie

Toute pompe dont la période de garantie d’un an

est révolue et qui ne fonctionne plus correctement doit être retournée au distributeur,

accompagnée d’une lettre expliquant en quoi

consiste le problème. Le distributeur peut alors

suggérer le renvoi de la pompe à l’usine.

Toutefois, avant de renvoyer une pompe qui n’est

plus couverte par la garantie, revoir toutes les

procédures d’entretien afin d’éviter un retour

inutile. Des pièces de rechange sont disponibles

pour l’utilisateur désireux d’effectuer l’entretien

lui-même.

17

INST0026

Manette, fil électrique et

ensemble interrupteur 12 15466 15466

Moteur 13 15465 15665

Raccord 14 48103 48103

Ensemble soupape

(Iso-ValveTM) 15 15368 15368

Ensemble socle et pied 16 15369 15369

Ensemble le Pompe, ne moteur

(comprend N° 3 et 6) 17 15547 15548

Kit de remplacement de

joint (non illustré) -- 15367 15367

2

1

22

Page 23

Spécifications de la pompe CoolT ech

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

®

Modèle 15401

Gamme de fréquence ............................. 50-60 Hz

Déplacement libre d’air ...................... 4 cfm/60 Hz

..................................................94 l/m @50 Hz

................................................113 l/m @60 Hz

Etages ..................................................................2

Vitesse du moteur .................... 1425 rpm @50 Hz

............................................ 1725 rpm @60 Hz

Gamme de tension................................ 110/115 V

......................................................... 220/250 V

Niveau micronique de fabrication......... 20 microns

Capacité d’huile approx ..............................375 ml

Poids .............................................................15 kg

Largeur....................................................14,29 cm

Hauteur .....................................................24,6 cm

Longueur ...................................................... 40 cm

1

Raccord...................................

Température de départ

minimum (à 90% de tension) ........................... 0

Capacité du moteur....................1/3 HP Démarreur

Température opérationnelle ........................... 68oC

/2” et 1/4” SAE MFL

o

Modèle 15601/15603

Gamme de fréquence ............................. 50-60 Hz

Déplacement libre d’air ...................... 6 cfm/60 Hz

................................................142 l/m @50 Hz

................................................170 l/m @60 Hz

Etages ..................................................................2

Vitesse du moteur .................... 1425 rpm @50 Hz

............................................ 1725 rpm @60 Hz

Gamme de tension................................ 110/115 V

......................................................... 220/250 V

Niveau micronique de fabrication......... 20 microns

Capacité d’huile approx ..............................375 ml

Poids ..........................................................15,2 kg

Largeur....................................................14,29 cm

Hauteur ..................................................... 24,6 cm

Longueur ...................................................... 42 cm

1

Raccord...................................

Température de départ

minimum (à 90% de tension) ........................... 0

C

Capacité du moteur....................1/2 HP Démarreur

Température opérationnelle ........................... 68oC

/2” et 1/4” SAE MFL

Remarque :

1. Tous les moteurs sont protégés à l’intérieur

(remise à zéro automatique).

2. Les températures opérationnelles reflètent

des conditions normales d’opération.

3. Le Modèle 15603 a une fiche latérale

bipolaire munie d’un fil de terre.

Brevets U.S 4.523,897; 5,209.653. Autres brevets

U.S. et étrangers en instance.

En raison des améliorations continues

apportées au produit, nous nous réservons le

droit de modifier, sans notification préalable,

la conception, les spécifications et les

matériaux s’y rapportant.

Manuel d’utilisation

o

C

23

Page 24

Inhaltsverzeichnis

○○○○○○○○○○○○○○○

CoolTech® Hochleistungs-Vakuumpumpen ..... 24

Pumpenbestandteile ......................................... 25

Warnung ........................................................... 25

Bevor Sie Ihre Vakuumpumpe

in Betrieb nehmen ............................................ 26

Benutzung der Gasballastventile ...................... 27

Abschalten der Pumpe nach Gebrauch ........... 2 7

Instandhaltung Ihrer Hochvakuumpumpe ........ 28

Vakuumpumpenöl ........................................ 28

Ölwechselvorgang ....................................... 28

Reinigen ihrer Pumpe .................................. 2 8

Motor Schmierung ....................................... 28

Störungssuch-Hinweise .................................... 29

Springt nicht an ............................................ 29

Öl läuft aus................................................... 2 9

Zieht kein gutes Vakuum ............................. 29

Ersatzteile ......................................................... 30

Garantie ............................................................ 30

Garantieablauf ............................................. 30

®

Technische Daten der CoolTech

31

Vakuumpumpe

Für Gebrauch an A/C-R

Systemen mit CFCs, HCFCs,

und HFCs in Verbindung mit

Mineralöl, Esteröl, Alkylben-

zenöl und PAG-Öl als

Schmiermittel. Nicht für den

Gebrauch mit Ammoniak oder

Lithiumbromid Systemen.

Nicht für den Gebrauch mit

brennbaren Kühlmitteln.

Bedienungsanleitung

CoolTech® HochleistungsVakuumpumpen

○○○○○○○○○○○○○○

Wir gratulieren Ihnen zum Kauf einer

Hochqualitäts Robinair CoolTech

pumpe. Ihre Pumpe wurde speziell für den

Service an Klima- und Kühlanlagen hergestellt

und sie ist mit Robinairs bewährtem Offsetrotationsflügel für schnelle, sorgfältige Evakuierung

ausgestattet.

Sie werden diese wesentlichen Eigenshaften

schätzen...

Iso-Valve

Ermöglicht das Ausschalten der Pumpe während

sie noch an dem Klima- Kühlanlagensystem

angeschlossen ist, was praktisch zur Überprüfung

der Anstiegsgeschwindigkeit ist. Indem der

Ventilgriff in der “Offen” Position ist, steht die

Pumpe zu dem System das evakuiert wird offen.

In der “Zu” Position ist die Pumpe vom System

isoliert. Damit wird das Einziehen des Pumpenöls

in den Pumpenelement vermindert, das Anlassen

geht einfacher und Verschleiß der Pumpenbestandteile wird ebenfalls vermindert.

Hoher Vakuumnennwert

Der zweistufige Offsett-Rotationsflügelentwurf

erzeugt kraftvolle, geräuscharme, hohe

Vakuumleistung und versichert die Entfernung

von Feuchtigkeit, während die HochpumpenKapazität die Evakuierungszeit vermindert.

Filtrierung auf Lebenszeit

Der Einlaßfilter verhindert den Eindrang von

Fremdstoffen in die Pumpenkammer und ein

interner Ablaßfilter scheidet Öldampf von den

Ablaßgasen ab.

Abgeleitete Abgase

Die Abgase werden durch den Griff abgegeben,

um sie von dem Service Techniker wegzuleiten.

Gasballast

Ein genau angegebener Anteil atmosphärischer

Luft wird in die Pumpe eingezogen, um

Kondensation von Wasserdampf zu verhindern

und um die Reinheit des Pumpenöls zu erhalten.

Die Benutzung des Gasballasts ermöglicht, daß

die Pumpe leistungsfähiger arbeitet und die

Lebenszeit der Pumpe verlängert wird.

Rutschsicherer Griff

Ein einzelteiliger, geformter Griff vereinfacht den

Transport der Pumpe zu und von der

Arbeitsstelle und der Griff bleibt zum Anfassen

während des Betriebs kühl.

Kompakter Entwurf

Ihre Pumpe ist nur ungefähr 40 cm lang, wobei

ein Gehäuse aus Aluminium und OffsetrotationsFlügel das Pumpengewicht niedrig halten und

damit den Transport vereinfachen.

TM

®

Vakuum-

24

Page 25

Bedienungsanleitung

Pumpenbestandteile

1. Einlaßanschluß

2. Gasballastventil (befindet sich neben der

Griffbasis)

3. Ölfülleingang

4. Sichtglas

5. Druckgußgehäuse aus Aluminium

6. Ölablaß

7. Basis aus geformten Polykarbonat

8. Iso-Valve

System

9. Kraftvoller Motor mit hohem Drehmoment