Robin EC02 Service Manual

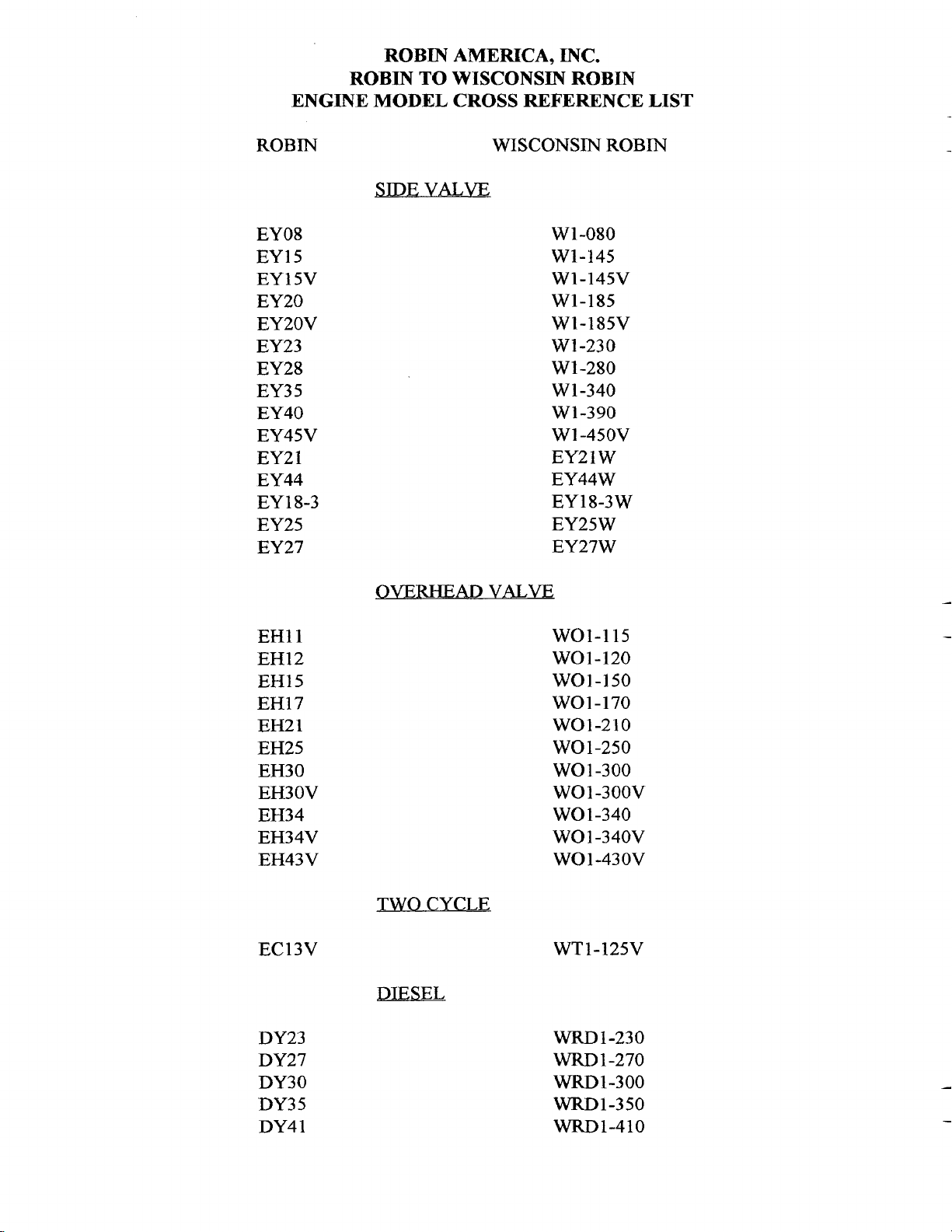

ROBIN

AMERICA,

INC.

ROBIN

TO WISCONSIN

ROBIN

ENGINE

MODEL CROSS

REFERENCE

LIST

ROBTN

EY 08

EY15

EY

15V

EY20

EY20V

EY23

EY28

EY35

EY40

EY45V

EY2

I

EY44

EY25

EY27

EY 18-3

EH11

EH12

EH15

EH17

EH21

EH25

EH3

0

EH30V

EH34

EH34V

EH43V

EC13V

DY23

DY27

DY30

DY35

DY4 1

WISCONSIN

ROBIN

-

W 1-080

W1-145

W1-145V

W1-185

W1-185V

W1-230

Wl-280

W 1-340

W 1-390

W1-450V

EY2

1

W

EY44W

EY25W

EY27W

EY18-3W

v

WOI-115

wo1-120

WO1-150

WO1-170

wo1-210

WO1-250

WO

1

-300

WO1-340

WO1-300V

WO

1

-340V

WO 1-43

OV

TWO CYCLE

WT1-125V

DIESEL

WRD

1-230

WRD

1-270

-1-300

WRD1-350

WRD1-410

CONTENTS

.

.

Section

Title

Page

1

.

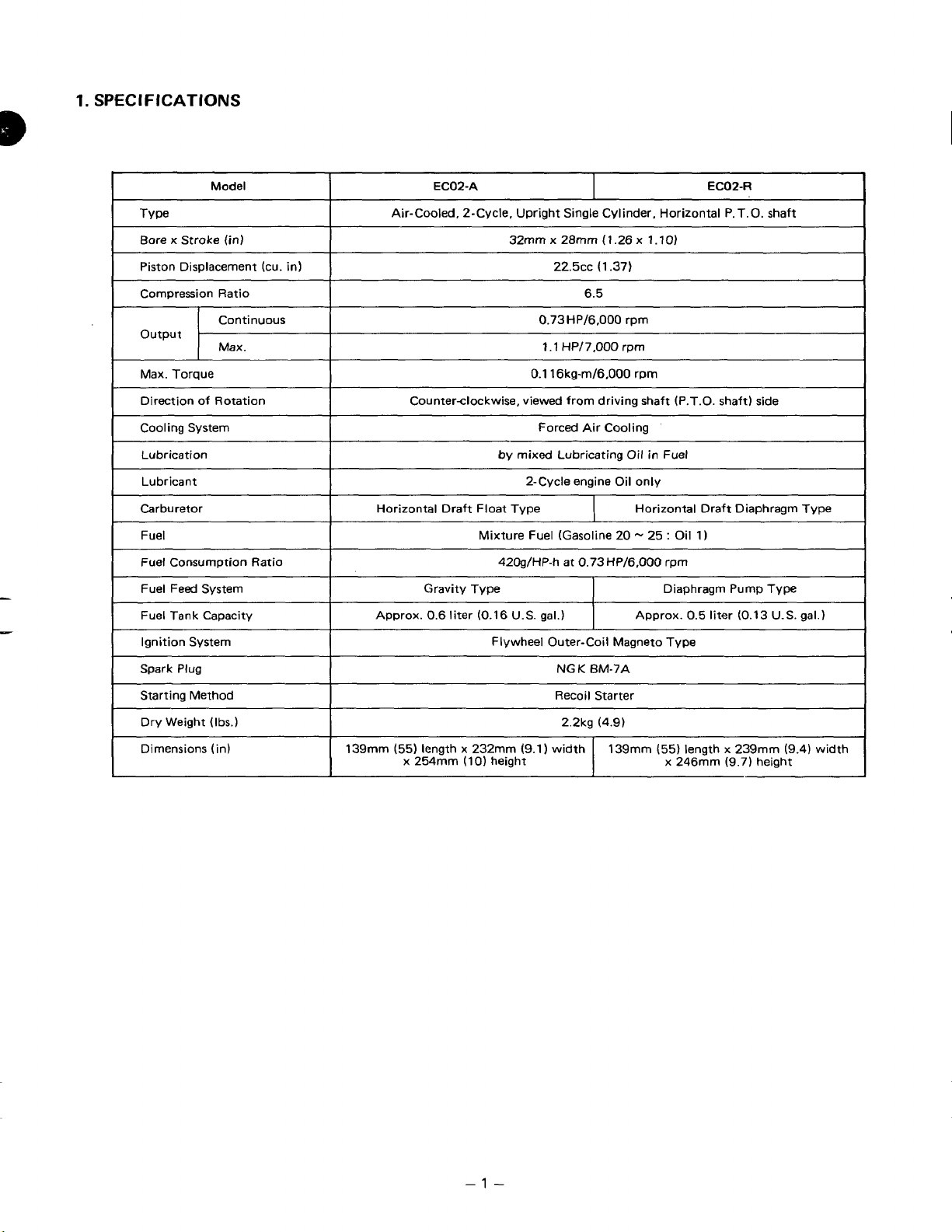

SPECIFICATIONS ........................................... 1

2

.

PERFORMANCE ............................................ 2

2.1

.

Maximum Output

......................................

2

2.2 . Continuous Rated Output

................................

2

2.3

.

Maximum Torque and Fuel Consumption Ratio and

Max

. Output

......

2

3

.

FEATURES

...............................................

3

4

.

DISASSEMBLY and REASSEMBLY ...............................

4

4.1

. Preparation and Suggestions ...............................

4

4.2

.

Special

Tools

.........................................

4

4.3.

Disassembly Procedures

..................................

5

4.4

. Reassembly Procedures

..................................

6

5

. BREAKER POINT ADJUSTMENT PROCEDURES

.....................

9

6

.

CARBURETOR ADJUSTMENT

..................................

10

7

. OPERATION

OF

FLOAT DIAPHRAGM CARBURETOR

................

11

8

.

TROUBLE SHOOTING

........................................

13

9

.

CHECKS and CORRECTIONS

...................................

16

10

.

MAINTENANCE and STORING

...................................

19

10-

1

.

Daily Checks and Maintenance

.............................

19

10.2

. Every 50 Hours Checks and Maintenance

......................

19

10.3

. Every 150 Hours Checks and Maintenance

......................

19

10.4

.

Yearly Checks and Maintenance

............................

19

10.5

. Preparation for Long Abeyance ............................. 19

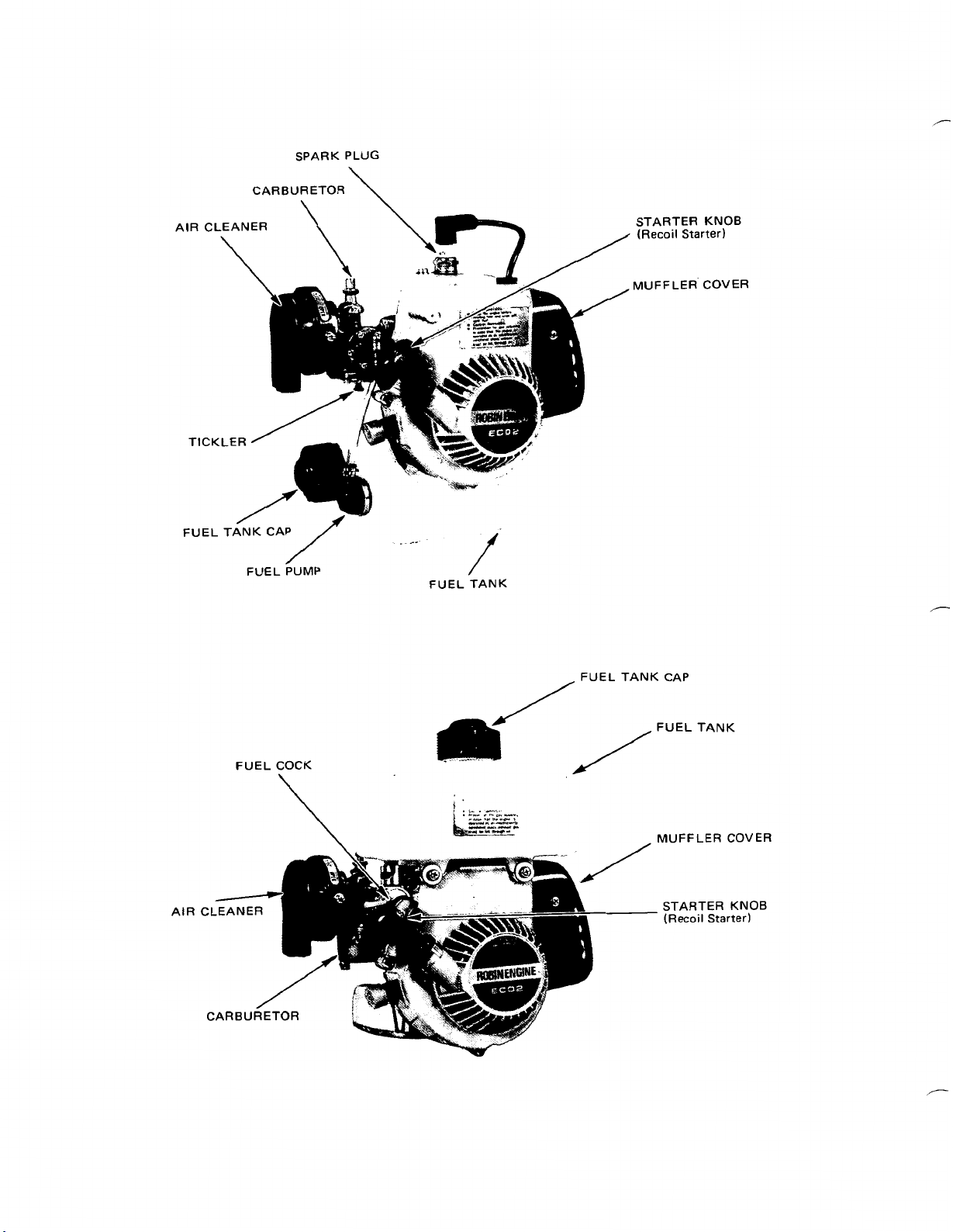

SPARK PLUG

CARBURETOR

\

AIR CLEANER

\

\-

\

/

TICKL

STARTER KNOB

(Recoil

Starter)

MUFFLER.COVER

/

FUEL

TANK

CAP

,FUEL

TANK

FUEL COCK

.

MUFFLER COVER

1.

SPEC1

FlCATlONS

-1-

2.

PERFORMANCE

2-1

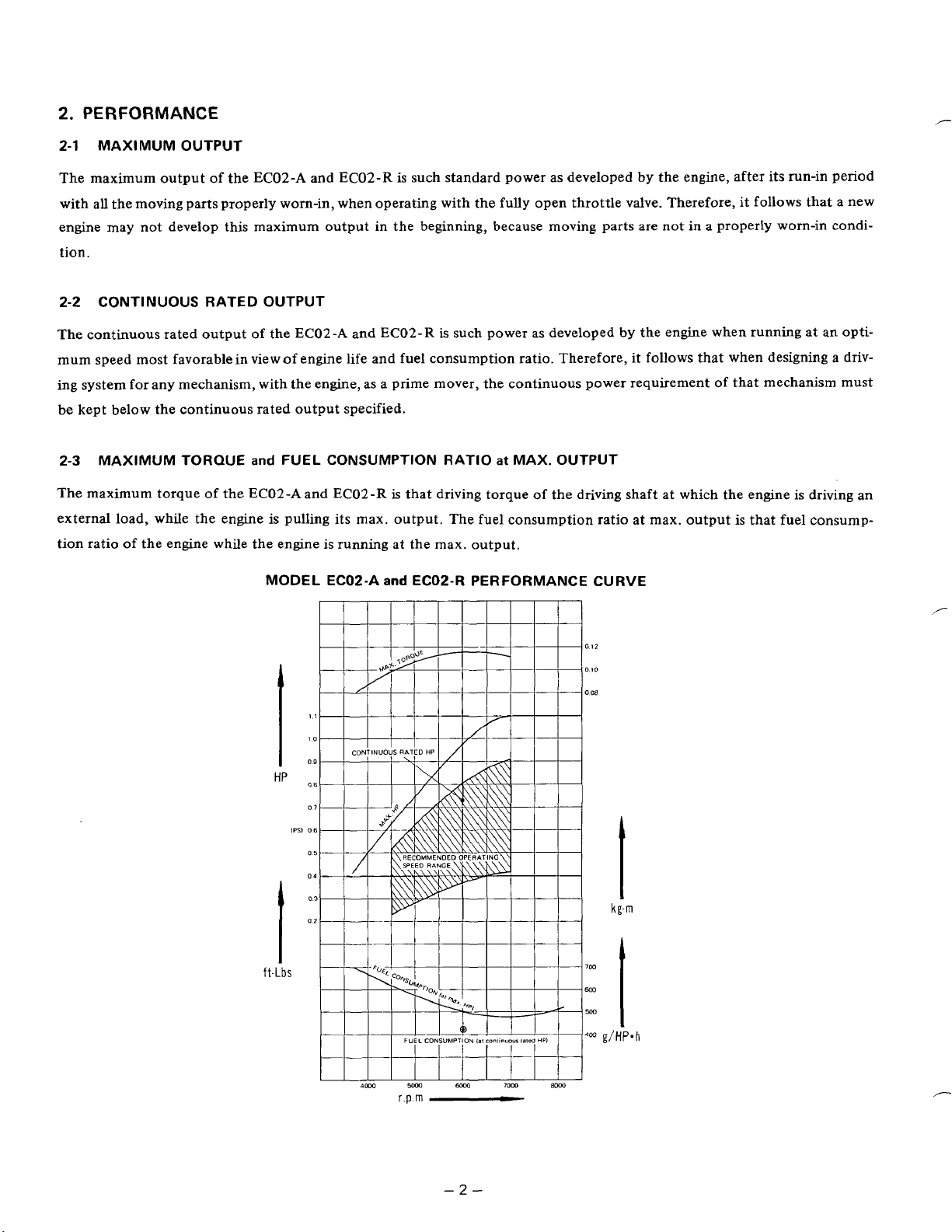

MAXIMUM OUTPUT

The maximum output of the EC02-A and ECOZ-R is such standard power as developed by the engine, after its run-in period

with all the moving parts properly worn-in, when operating with the fully open throttle valve. Therefore, it follows that a new

engine may not develop this maximum output in the beginning, because moving parts are not

in

a properly worn-in condi-

tion.

,"

2-2 CONTINUOUS RATED OUTPUT

The continuous rated output

of

the EC02-A and EC02-R

is

such power as developed by the engine when running at

an

opti-

mum speed most favorable in view

of

engine

life

and fuel consumption ratio. Therefore,

it

follows that when designing a driv-

ing system

for

any mechanism, with the engine, as a prime mover, the continuous power requirement of that mechanism must

be kept below the continuous rated output specified.

2-3

MAXIMUM

TORQUE

and

FUEL CONSUMPTION RATIO at MAX. OUTPUT

The maximum torque

of

the EC02-Aand EC02-R

is

that driving torque

of

the driving shaft at which the engine is driving an

external load, while the engine

is

pulling its rnax. output. The fuel consumption ratio at max. output

is

that fuel consump-

tion ratio

of

the engine while the engine is running at the max. output.

MODEL ECO2-A

and

ECOP-R PERFORMANCE CURVE

ft-LbS

HP

-2-

3.

FEATURES

1.

COMPACT, LIGHT WEIGHT, HIGH PERFORMANCE and LOW FUEL CONSUMPTION

2.

TROUBLE FREE because of simple design and easy

to

handle

3.

HIGH DURABILITY engine withstand long severe operation

4.

TILTED OPERATION AVAILABLE

Be

able to operate at any position due to diaphragm carburetor.

5.

EASY STARTING with recoil starter

6.

Forged steel Crankshaft

7.

Ball main bearings at both ends

8.

Forged steel connecting

rod.

9.

With CHROME PLATED CYLINDER, HEAT CONDUCTIVITY and WEAR

PROOF

are quite excellent.

-3-

Loading...

Loading...