Page 1

Portable Gas Leak Detec t or

SP-220 Series

TYPE F

Operating Manual

Part Number: 7 1-0421

Revision : P1

Released: 10/20/17

Page 2

- 2 -

Contents

Table of Contents

1. Outline of the Product ..................................................................................................................................... 3

Preface ............................................................................................................................................................ 3

Purpose of use ................................................................................................................................................ 3

Definition of DANGER, WARNING, CAUT IO N an d NO TE ............................................................................. 3

How to check the standards and explosion-proof specifications ................................................................... 4

2. Important Notices on Safety ........................................................................................................................... 5

2-1. Danger cases........................................................................................................................................... 5

2-2. Warning cases ......................................................................................................................................... 6

2-3. Precauti ons .............................................................................................................................................. 7

2-4. Safety infor mation (for ATEX/IECEx specifications) ................................................................................ 9

3. Product Components .................................................................................................................................... 10

3-1. Names and fu nc t i o ns for each part ....................................................................................................... 10

4. How to Use ................................................................................................................................................... 13

4-1. Before usi n g th e de tector ...................................................................................................................... 13

4-2. Preparation for start-up .......................................................................................................................... 13

4-3. How to replace the batteries .................................................................................................................. 13

4-4. How to start the detector ....................................................................................................................... 15

4-5. Basic opera ting procedures ................................................................................................................... 17

4-6. How to detect ......................................................................................................................................... 18

4-7. Changing the concentration measuring mode ...................................................................................... 19

4-8. Perform in g ai r c al ibr a t i on ...................................................................................................................... 22

4-9. Snap logger ........................................................................................................................................... 23

4-10. Peak hold function ............................................................................................................................... 24

4-11. Changing the alarm and operation sounds ......................................................................................... 24

4-12. How to turn on th e i l l umination lamp ................................................................................................... 25

4-13. Power-off ............................................................................................................................................. 25

5. Display Mode ................................................................................................................................................ 26

5-1. Entering the display mode ..................................................................................................................... 26

5-2. Measured g as reading setting ............................................................................................................... 29

5-3. Changing the measuring mode ............................................................................................................. 31

5-4. Log data display .................................................................................................................................... 32

6. User Mode .................................................................................................................................................... 33

6-1. Entering th e user mode ......................................................................................................................... 33

6-2. Date/time setting .................................................................................................................................... 35

6-3. Clock function ON/OFF setting .............................................................................................................. 36

7. Alarm Function .............................................................................................................................................. 37

7-1. Gas alarm activation .............................................................................................................................. 37

7-2. Fault alarm activation ............................................................................................................................ 37

8. Maintenance ................................................................................................................................................. 38

8-1. Maintena nce intervals and items ........................................................................................................... 38

8-2. How to clean .......................................................................................................................................... 40

8-3. Parts replacement ................................................................................................................................. 40

9. Calibration Mode .......................................................................................................................................... 43

9-1. Fresh Air Adjustment ............................................................................................................................. 43

9-2. Preparing for a Span Adjustment (Gas Ba g) ......................................................................................... 45

9-3. Preparing for a Span Adjustment (Deman d Flow Regulator) ................................................................ 46

9-4. Automatic Span Adjustment ................................................................................................................... 46

9-5. Manual Span Adjustment ....................................................................................................................... 49

9-6. Password ............................................................................................................................................... 51

10. Storage and Disposal ................................................................................................................................. 54

10-1. Procedures to store the detector or leave it for a long time ................................................................ 54

10-2. Procedures to use the detec tor again ................................................................................................. 54

10-3. Disposal of products ............................................................................................................................ 55

11. Troubleshooting .......................................................................................................................................... 56

12. Spare Parts List .......................................................................................................................................... 58

13. Product Specificat io ns ................................................................................................................................ 59

Page 3

- 3 -

1

1. Outline of the Product

Preface

Thank you for choosin g our portable gas leak det ec t or S P-220 TYPE F (hereinafter referred to as the

detector). Pl ease check that the m od el number of the product you purchased is include d i n th e

specifications on this manual.

This manual ex p la i ns how to use the detector and its specifications. It contains information required for

using the detector properly. First-time users and users who have already used the product m ust r ea d a nd

understand the o perating manual to en h ance the knowledg e a nd experience before using the detector.

Note that the contents of this manual are subject to change without notice for product improvement. It is

also prohibit ed to c o p y or reproduce this manu a l, in whole or in part, withou t permission.

Regardless of warranty period, we shall not make any indemnification for accidents and damage caused by

using the detec t or.

Make sure to read the warranty policy specified on the warranty.

Purpose of use

This detector is us e d to de tect fluorocarbons leaking out in air.

Detection results are not intended to guarantee life or safety in any way.

Definition of DANGER, WARNING, CAUTION and NOTE

Throughout this manual, the following indications are used to ensure safe and effective work.

DANGER

This message indicates that improper handling may cause serious

damage on life, health or assets.

WARNING

This message indicates that improper handling may cause serious

damage on health or assets.

CAUTION

This message indicates that improper handling may cause minor damage

on health or assets.

NOTE

This message indicates advice on handling.

Page 4

- 4 -

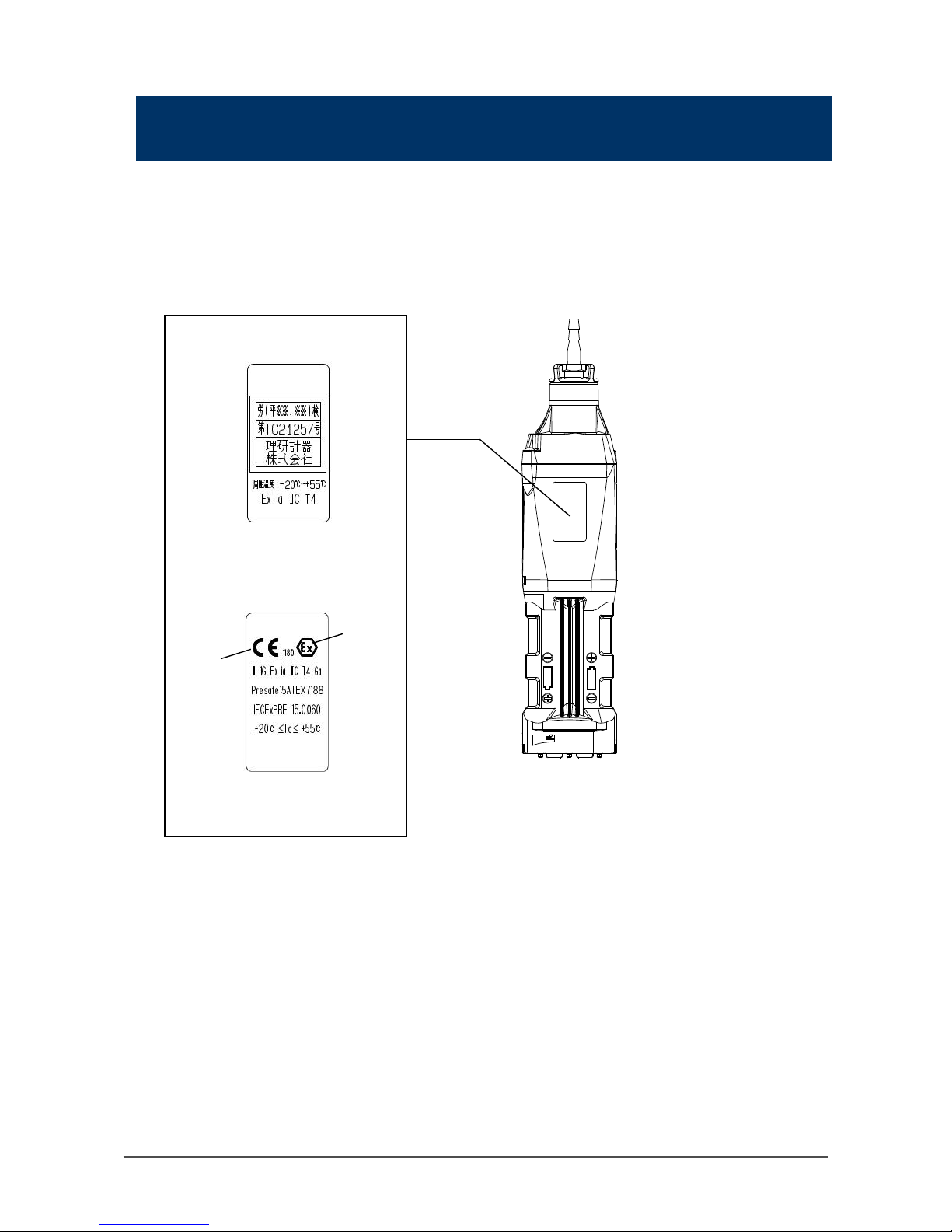

How to check the standards and explosion-proof

specifications

The detector has d ifferent specificati ons depending on the sta nd ards or explosion-proof certification type.

Check the specifications of the product you ha v e bef ore use. See the Declar ation of Conformity at the end

of this operating manual for CE marking specifications.

For the product specifications, check the nameplate attached to the product shown in the following figure.

(1) Nameplate exampl e of TIIS

specifications

(2) Nameplate exampl e of CE marking

specifications

* The above nameplate (1) or (2) is

attached depending on th e specified

explosion-proof spec i fications.

Ex mark

CE mark

Page 5

- 5 -

2

2. Important Notices on

Safety

To maintain the performance and use the det ec t or safely, observe the following instructions of DANGER,

WARNING, and CAUTION.

2-1. Danger cases

DANGER

About use

• While conducting measurement in a manhole or confined space, do not lean over or look into

the manhole or closed space. It may lead to dangers because oxygen-deficient air or other

gases may blow ou t.

• Oxygen-deficient air or oth er gases may be discharg e d f rom the gas exhaustin g ou t le t of the

detector. Never inhale t he air or gases.

• High-concentration (100% LEL or higher) gases may be discharged from the gas exhausting

outlet of the detector. Never use fire near it.

Page 6

- 6 -

2-2. Warning cases

WARNING

Sampling point pressure

• The concentration meter is designed to draw gases under the atmospheric pressure. If

excessive pres sure is applied to th e g as in l et an d ou t l et of t h e de t ec t or, measure d gases may

leak out from its inside and may cause dangerous conditions. Be sure that excessive pressure

is not applied to th e de t ec t or’s gas inlet or ou tl e t during use.

Air calibration in atmosphere

• Perform an air calibration in a fresh air environment. If interference gases or other gases exist,

the adjustmen t c an n ot be performed prop erly, thus leading to da ng er s wh e n gas is present.

Response to gas alarm

• A gas alarm is triggered by changes in temperature and humidity. In such a case, check the

atmosphere for freshness and perform air calibration again in the measured atmosphere.

Example) If th e de t ec t or is t ur n e d on in a ro om with a temperature of 20 ºC an d a humidity of

40% RH and taken outs id e ( a temperature of 30ºC a nd a humidity of 60% RH), an alar m is

triggered by humidity changes. In such a case, perform air calibration outside and measure.

The detector per f or ms air calibration a ut omatically when it is tur n e d on . E v en in s uch a case,

check the atmosphere for freshness and perform air calibration again in the measured

atmosphere.

WARNING

Battery level check

• Before use, check that there remains sufficient battery power . When the detector is not used for

a long period, the batteries may be exhausted. Never fail to replace them with new ones before

use.

• If a low battery voltage alarm is triggered, gas detection cannot be conducted. If the alarm is

triggered during use, turn off the power and promptly replace the batteries in a safe area.

Others

• Do not throw the detector into fire.

• Do not wash the detector in a washing machine or ultrasonic cleaner, etc.

• Do not block the buzzer sound opening. No alarm sound can be heard.

• Do not remove the battery while the power is on.

Page 7

- 7 -

2-3. Precautions

CAUTION

Do not use the detector where it is exposed to oil, chemicals, etc. Do not submerge the detector

under water on purpose.

• Do not use in a plac e wh ere the detector is exp osed to liquids such as o il an d c h emicals.

• The detector is not water-pressure-resistant. Do not use the detector where a high water pressure is

applied to it (under a faucet, shower, etc.) or submerge it under water for a long time. The detector

is water-proof only in fresh wa ter and running water, and not in hot wat er, salt wat er, detergen t,

chemicals, human sweat, etc.

• The gas inlet and outlet are not water-proof. Be careful not to let water such as rainwater, etc. get

into these parts. Because this may cause trouble and gas cannot be detected.

• Do not place the de tector where water or d irt gets accumulated. The detector placed at such a

location may cause malfunction due to water or di rt that gets into the buzzer opening, etc.

• Note that dra win g i n d irty water, dust, metallic powder, etc. will si gn if icantly deterior at e th e s e ns or

sensitivities. Be careful when t he de tector is used in an environment where thes e el ements exist.

Do not use the detector in a place where the temperature drops below -20ºC or rises over 55ºC.

• The operating temperature of the detector is -20 to +55ºC. Do not use the detector at higher

temperatures, humidities and pressures or at lower temperatures than the operating range.

• Avoid long-term use of the detector in a place where it is exposed to direct sunlight.

• Do not store the detector in a sun-heated car.

• Avoid a sudden humidity or temperature change.

• Do not leave the de tector in a place with hi g h temperature and hum i di ty for a long time. The

performance of the unit m ay de t eriorate.

Observe the operating restrictions to prevent condensation inside the concentration meter or gas

sampling hose.

• Condensation formed on the detector or taper nozzle causes clogging, gas adsorption, etc., which

may disturb accurate gas detection. Thus, condensation must be avoided. In addition to the

installati on envir onment, c areful ly monitor the temperature/humidity of the sampling point to prevent

condensati on , etc. on the detector or tape r no zzl e . P l e as e observe the operatin g r estrictions.

Do not use a transceiver near the detector.

• Radio wave from a transceiver or other device near the detector may disturb readings. If a

transceiver or ot h er r ad i o w a ve trans mitting device is us ed , it m us t be us e d in a pl ace w her e it

disturbs nothing.

• Do not use the det ec t or near a device that em its str on g e lectromagnetic wa v es ( h ig h-frequency or

high-voltage devices).

Verify that the flow check display is rotating before using the detector.

• If the flow check display is not rotating , th e g as de tector is not operati n g pr o p erly. Check whether

the flow rate is lost.

Never fail to perfor m a regular maintenance.

• Since this is a precision device , a regular maintenance must be performed. Continuing to use the

detector without performing maintenance will compromise the sensitivity of the sensor, thus

resulting in inaccurate gas detection.

Page 8

- 8 -

CAUTION

Others

• After a gas continuously comes into contact or a highly-concentrated gas comes into contact,

the detector may stay in alarm. In such a case, draw fresh air for more than five minutes

(recommended) and perform air calibration again.

• Pressing buttons unnecessarily may change the settings, preventing alarms from activating

correctly. Operate the detector using only the procedures described in this operating manual.

• Do not drop or gi ve shoc k to the detector. The accuracy of th e de tector may be deter i ora te d.

• Do not jab the buzzer opening with a sharp-pointed item. Doing so may cause a failure or

damage.

• Do not remove the panel sheet on the display. The water-proof and dus t-proof performances

will be deteriorated.

• Do not affix a label or the like on the infrared port. Infrared communications can no longer be

conducted.

• The operating environment may include gases that have harmful effects on the sensor of the

detector. The detector cannot be used in the presence of the following gases:

(1) High-concentration sulfides (such as H2S, SO2, etc.)(2) Halogen gases (such as chloride

compounds, etc.)(3) Silicone (Si compounds)(4) High-concentration solvent gasesDo not use

the detector in th e pr esence of the above (1) , ( 2), and (3) gases (such as h ig h-concentration

sulfides, halo gen gases, silicone, etc.), which may shorten the sensor life significantly or cause

malfunctions such as inaccurate readings.

In case the detector is used for detection in the presence of silicone, etc., be sure to check the

gas sensitiv it i es before using it again.

If the above (4) gas (high-concentration solvent gas) is exposed, a crack may occur in the unit.

Thus, do not use high-concentration solvent gases.

About battery replacement

• Never fail to tur n off the po wer of the detector before replacing the b atteries.

• Replace both of the two batteries with new ones at one time.

• Pay attention to the polarities of the bat te r i es.

Usage

• In a low-temperature environment, the operating time is shortened due to the battery

performance property.

• At low temperat ures, the responses of the LCD display may slow down.

• Perform air calibration under pressure and temperature/humidity conditions close to those in

the operating en v iro nment and in fresh air.

• Perform air calibr ation after the readi ng is stabilized.

• If there is a sudden temperature change of 15ºC or more between the storage and operational

locations, tur n on t h e p o we r of th e de tector, let it stand for more than 5 minutes in a similar

environment to the operational location, and perform air calibration in fresh air before using it.

• When cleaning the de te cto r, do not splash water over it o r use o r gani c solv en ts such as alcohol

and benzine on i t. The sur f ac e of th e d etector may be disco lored or damaged.

• If the detector is not used for a long time, turn on the power at least once every six months and

check that the pump draws in air (about three minutes). The detector, when not activated for a

long time, ma y ce as e to wo r k because of hardenin g of th e gr e ase in the pump motor.

• If the detector is not used for a long time, store it after removin g t he batteries. Battery leaks

may result in fire, injury, etc.

• When the detect or is us ed again after a long-period storage, never fail to perform air

calibration. For information on readjustment including air calibration, please contact RKI.

Page 9

- 9 -

2-4. Safety information (for ATEX/IECEx specifications)

Portable gas leak detector S P-2 2 0 is a g as detector to continuously detect combustible gases.

The detector draws gases with the internal micro pump.

Use only two TOSHIBA AA alkaline batteries (LR6T) connected in series for power supply.

Do not replace the dry batteries in a hazardous location.

Explosion-proof specifications

・ Ex ia IIC T4 Ga

・ Operating temperature range: -20 to +55°C

Electrical sp e cif ications

・ Only TOSHIBA AA alkaline batteries (LR6T) can be used.

Certificate Number

・ IECEx: IECEx PRE 15.0060

・ ATEX: Presafe15 A TEX7188

Applied standards

・ IEC 60079-0:2011 ・ EN60079-0:2012

・ IEC 60079-11:2011 ・ EN60079-11:2012

Precautions

・ Do not replac e t he battery unit in a hazar dous location.

・ Do not replac e t he dry batteries in a ha zardous location.

・ Do not disassemble/modify the unit.

・ Use only TOSHIBA AA alkaline batteries (LR6T) for the dry battery unit.

INST. No. 0 0 0 0 0 0 0 0 0 0 0

A B C D E

A: Manufacturing year (0-9)

B: Manufacturing month (1-9, XYZ for Oct.-Dec.)

C: Manufacturing lot

D: Serial number

E: Factory code

Manufacturer

RIKEN KEIKI CO., LTD.

2-7-6 Azusawa, Itabashi-ku, T okyo, 174-8744 Japan

Web site: http://www.rikenkeiki.co.jp/

NOTE

TOSHIBA AA alkaline batteries (LR6) can be used for TIIS specifications.

・

II 1 G Ex ia IIC T4 Ga

Page 10

- 10 -

3

3. Product Components

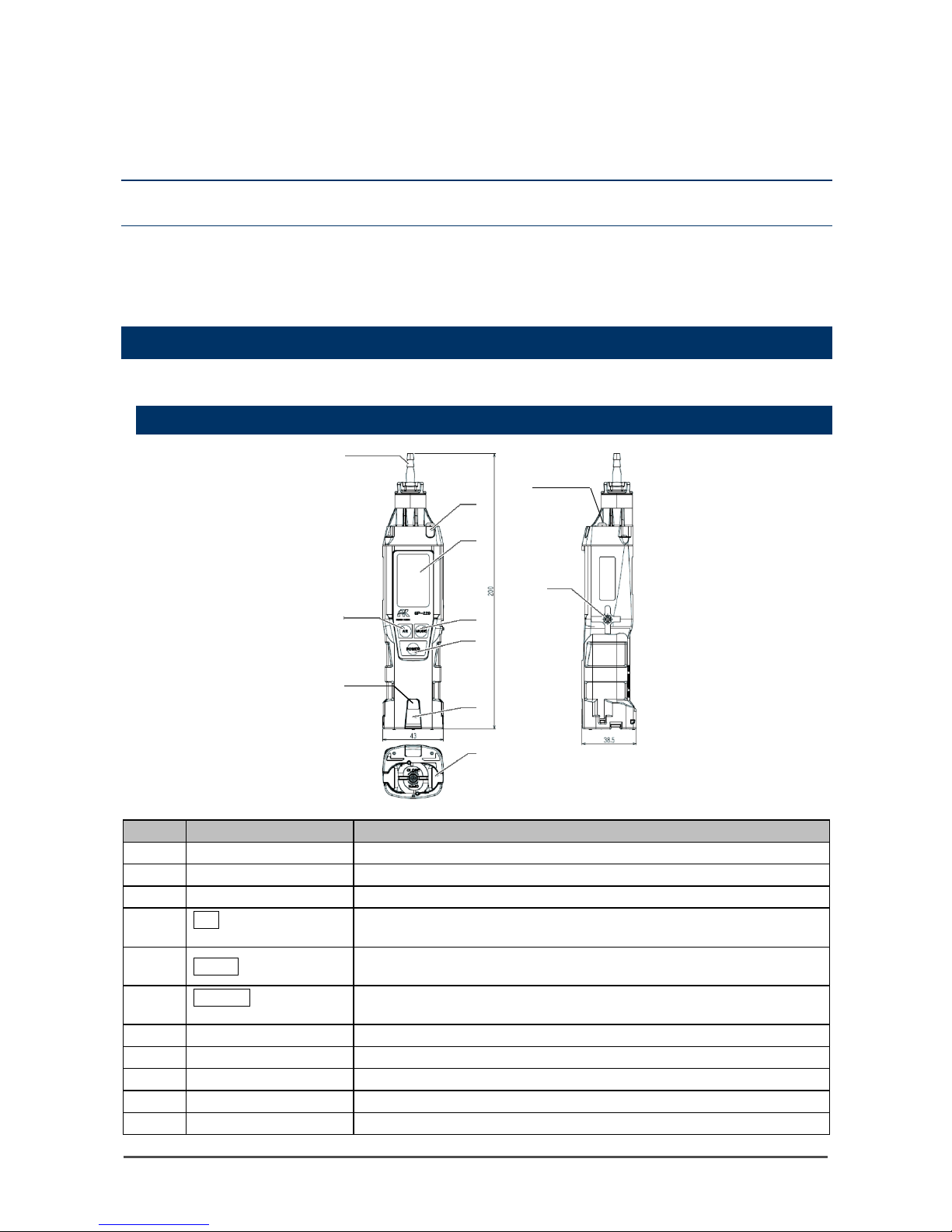

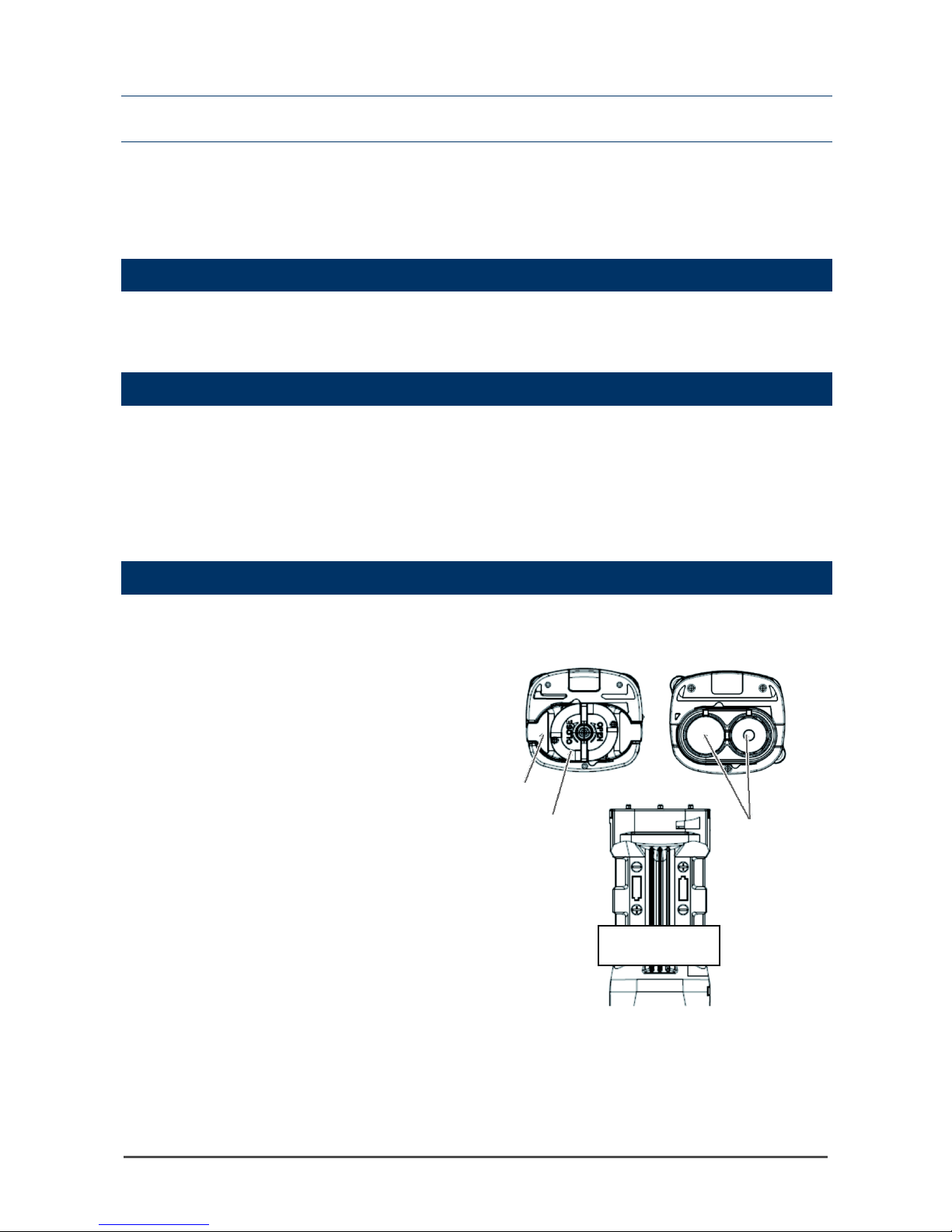

3-1. Names and functions for each part

This section describes names and functions of main unit, the battery unit parts, and the LCD display.

Main unit

No.

Name

Function

(1)

Gas inlet

Collects gas es.

(2)

Alarm LED arrays

Blinks or lights up in response to an alarm.

(3)

LCD display

Displays gas concentrations, measured gas name, alarms, etc.

(4)

AIR button

Keep this switch pressed to perform air calibration. Used to change the

screen and decrease numerical values in the setting mode.

(5)

MODE button

Press this switch to change between display modes. Used to change

the screen and increase numerical values in the setting mode.

(6)

POWER button

Turns the power ON or OFF . Used to change the screen and confirm

values in the setting mode.

(7)

Gas outlet

Exhausts the gas dr a wn in t o the detector. (Do not block it.)

(8)

Alarm LED arrays

Blinks or lights up in response to an alarm.

(9)

Infrared port

Used during inf ra r e d c om m un ications.

(10)

Battery cover

Protects the battery. Remove it to replace the batteries.

(11)

LED light

Provides you light for work.

(10)

(11)

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

Page 11

- 11 -

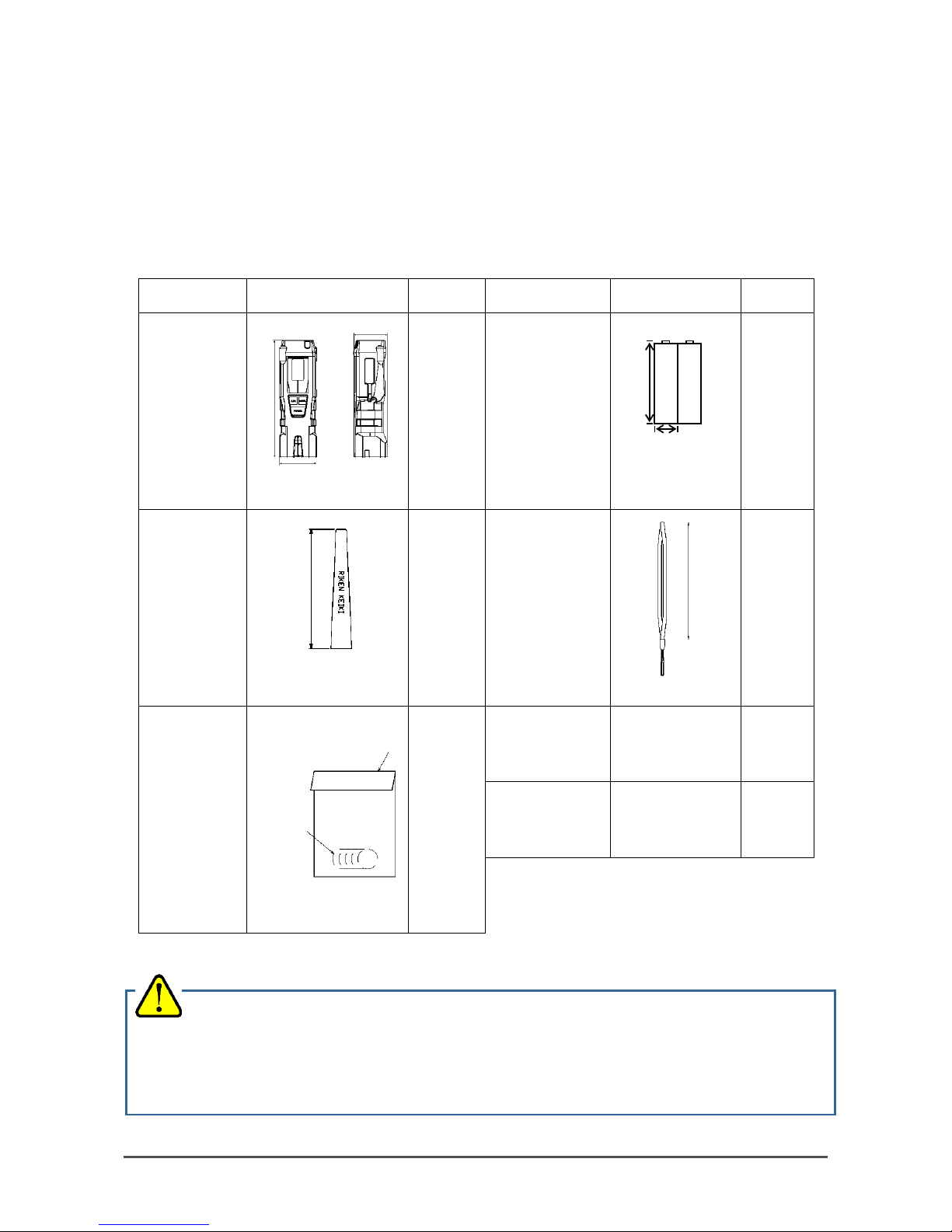

Standard accessories

Unpack and check the main unit and accessories.

• AA alkaline battery (2 pcs) ( ins tal l ed)

• Taper nozzle (1 pc)

• Rubber protec tion cover (1 pc) (Protect the detector from shocks by being hit, etc.)

• Hand strap (1 pc)

• Replacement hydrophobic filters (5 pcs)

• Product warra n t y ( 1 pc)

• Operating manual (1 pc)

Name

Appearance/

weight

Quantity Name

Appearance/

weight

Quantity

Rubber

protection

cover

1 pc

(attached)

AA

alkaline batt ery

2 pcs

(installed)

Taper nozzle

1 pc Hand strap

1 pc

Replacement

hydrophobic

filters

1 bag

(5 pcs

included)

Operating

manual

-

1 pc

Product

warranty

-

1 pc

If there is anything missing, contact RKI.

Approx. 9 g

Approx. 70 mm

Approx. 2 g

Approx. 150 mm

CAUTION

• Do not remove the panel sheet on the display. The water-proof and dus t-proof performances will

be deteriorated.

• Do not affix a label or the like on the infrared port. Infrared communications can no longer be

conducted.

Approx.

42 g

Approx. 44 g

Approx. 14.5 mm

Approx.

47mm

Approx. 42.5 mm

Approx. 149 mm

Approx. 50 mm

Approx. 1g

Approx.

φ16 mm

Plastic bag

Page 12

- 12 -

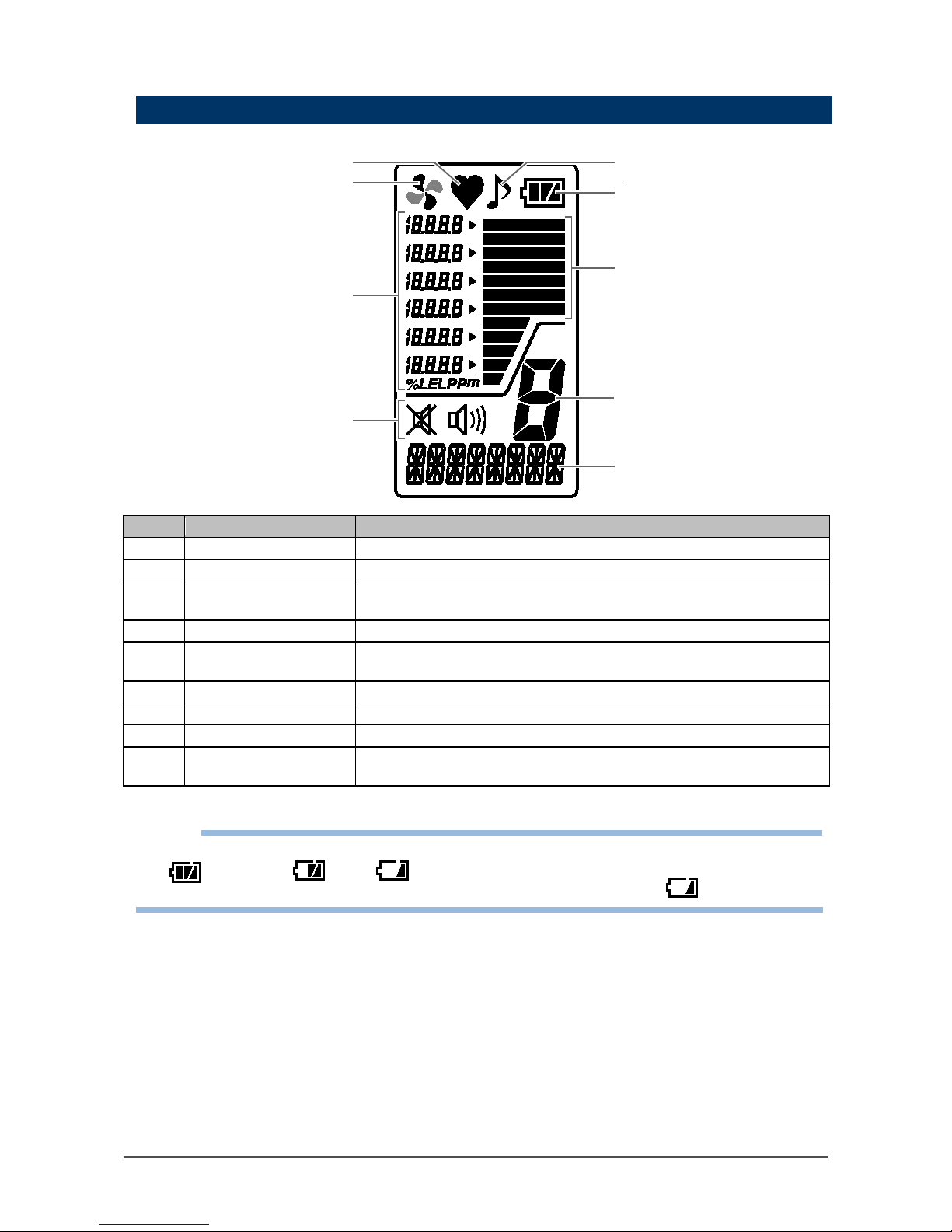

LCD display

No.

Name

Function

(1)

Operating state display

Displays the operating status in the detection mode. Normal: Blinking

(2)

Flow check display

Displays the drawing status. Normal: Rotating

(3)

Gas concentration

display

Displays gas concentration and units (ppm).

(4)

Alarm sound display

Displays the setting status of the alarm sound.

(5)

Operation sound

display

Displays the setting status of the operation sound.

(6)

Battery level icon

Displays a reference of the battery level.

(7)

Bar meter display

Displays the level of gas concentration in the form of a bar meter.

(8)

Mode display

Displays the measuring mode status.

(9)

Gas name and

message display

Displays the gas name and a message according to the function.

NOTE

• The meanings of bat tery level icons are as follows:

: Sufficient/ : Low/ : Needs replacement

If the batter y lev e l further drops, the insid e of the battery icon starts to bl i nk ( ).

(7)

(1)

(2)

(3)

(4)

(5)

(6)

(8)

(9)

Page 13

- 13 -

4

4. How to Use

4-1. Before using the detector

First-time users and user s wh o ha v e a lr ea dy used the detector must follow the operating precautions.

Ignoring the pr ec autions may damage t h e u n it, res u lt i ng in in ac curate gas measurement.

4-2. Preparation for start-up

Before use, read and understand the following precautions. Ignoring these may cause inaccurate gas

detection.

・ The batteries are installed (with sufficient battery level).

・ Check that the taper nozzle and filter are not contaminated.

・ Check that the taper nozzle is not bent or has no hole.

・ Check that the nipple to which the taper nozzle is attached is not loose.

4-3. How to replace the batteries

When the detector is used for the firs t t ime, or when the battery level is low, attach two new AA alkaline

batteries according to the following procedures.

1 Check that the power of the

detector is turned off.

Turn off the power if it is turned on.

2

Turn the lock plate

counterclockwise and open

the battery cover.

3

Remove old batteries and

then put new batteries

while observing the correct

polarity.

4

Close the battery cover and

tur n t he lock plate

clockwise to lock.

Battery cover

Lock plate

Dry batteries

Displaying batte ry

polarity

Page 14

- 14 -

CAUTION

• Never fail to turn off the power of the detector bef ore replacing the batteries.

• Replace the batteries in a safe plac e.

• Replace both of the two batteries with new ones at one time.

• Pay attention to the polarities during replacement. Replace while checking the battery polarities

stamped on the body.

• If the batter y cov er is not completel y locked, the dry batter ies m a y become dislodged or wa ter

may get in through the clearan ce. Wa ter may also get in if a minute forei gn sub stan ce is caugh t

between the detector and battery cover.

Page 15

- 15 -

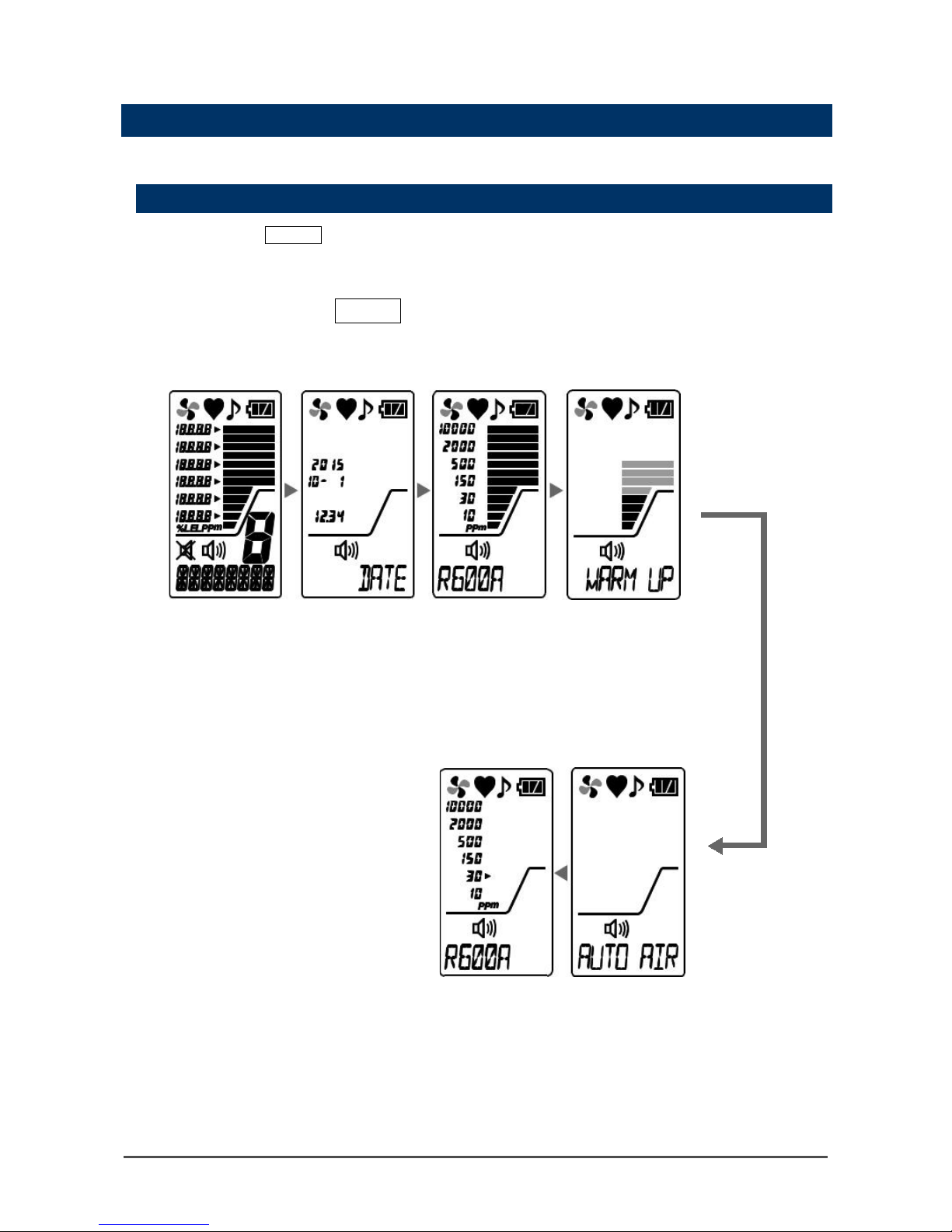

4-4. How to start the detector

When the power is t ur n ed on , a s e lf -diagnostic starts, and then the detector enters the detection mode.

Power-on

Press and hold th e POWER button until the buzzer blips (one second or longer) to turn o n th e po w e r.

When the power is t ur n ed on , th e LCD display chang es au tomatically as sho wn be l o w, and the detec t or

enters the detection mode.

1

Press and hold t he POWER button for one second or longer.

Hold it down until all the LCDs and alarm lamp light up and the buz zer bl ips.

All LCDs light

up

Date/time

display *

Gas name/

full scale display

Warm-up time

Display exam pl e:

Thursday,

October 01, 20 1 5

12:34

(Display for city

gases)

Detection mode

Automatic air

calibration

display

The buzzer blips

once and the

detection mode is

displayed.

* The date/time di s play i s d isp lay ed o nly when the clock fun cti on i s en abl ed . It i s no t displayed because the

clock function is disabled by default.

To enable the clock function, see "6-3. Clock function ON/OFF setting" on page 36.

Page 16

- 16 -

NOTE

• When powering on after leaving the detector for more than five minutes with the batteries removed,

such as when powering on for the first time, replacing the batteries, et c., or powering on with the

batteries inserted with incorrect polarities, a clock abnormality (FAIL CLOCK) may be triggered.

When it is reset using the MODE butto n, the detector moves to th e da t e /t ime setting screen. S ee

"6-2. Date/time setting" on page 35 and set the date/t ime.

• Warm-up time (WARM UP) is different depending on the stability status of the sensor.

• If the detector is not used for a long peri o d, war m-up time may be long er or a s en s or ab n or mality

(FAIL SENSOR) may be displayed. In such a case, restar t the detector.

• The detector performs air c al i br at io n a utomatically duri ng start-up. If an envir o nment where the

detector is tur ne d o n is d iffere nt from the atmosph ere being measured, perform air calibration again

in the measured atmosphere.

About LCD backlight

• Pressing the AIR, MODE or POWER button turns on the LCD backl i gh t. The LCD bac klight goes off

after 30 seconds of no operation.

When an alarm is tr ig g ered, the LCD backlig h t l ig hts up automatically.

Page 17

- 17 -

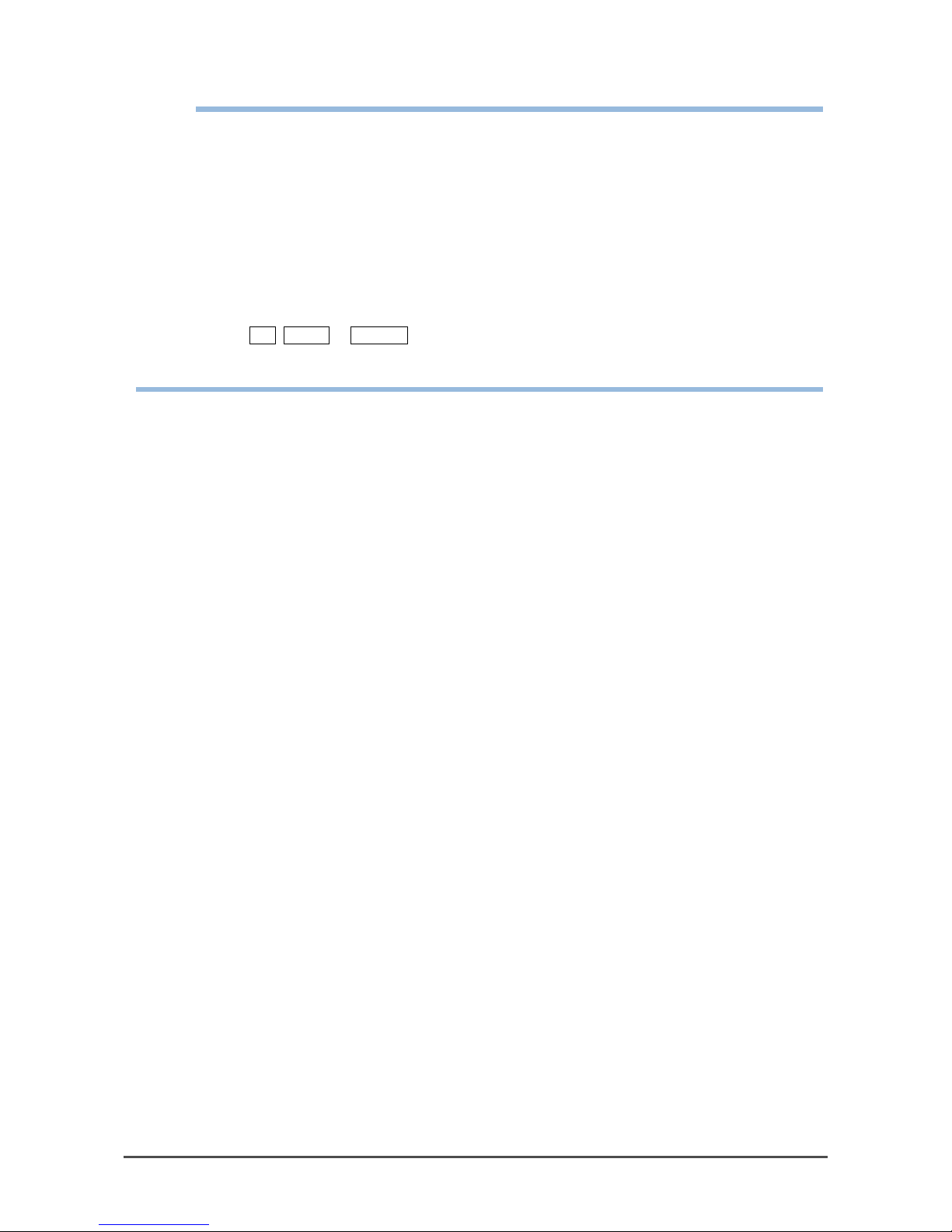

4-5. Basic operating procedures

The detectio n m od e is used after power-on. Gas is detected i n th e ppm range.

buttons

Hold down for

3 secs

Illumination

lamp lights

up

button

Hold down for

1 sec

Hold down for

3 secs

button

buttons

buttons

Hold down for 3 secs

<AIR calibration>

<Alarm setpoint change>

<Snap logger record>

<Operation/alarm sound ON/OFF>

<Peak clear> <Peak hold ON/OFF> <Display mode>

* Displayed only when the clock

function is enabled

See "6-3. Clock function ON/OFF

setting" on page 36.

Page 18

- 18 -

4-6. How to detect

While the detector is ope rati ng in det e ction mode , put th e tip o f the ta pe r nozz le clo se to the det e cti on area

and draw sample.

The detector measures gas in the ppm range. If a gas is drawn, the detected gas concentration is

displayed with the bar meter on the LCD display.

CAUTION

• Before performing gas detection , at tac h th e ta p er no z z le pro v i de d wi t h th e detector to preve nt

disturbances by air dust.

DANGER

• While conducting measurement in a manhole or confined space, do not lean over or look into

the manhole or closed space. It may lead to dangers because oxygen-deficient air or other

gases may blow ou t.

• Oxygen-deficient air or oth er gases may be discharg e d f rom the gas exhaustin g ou t le t of the

detector. Never inhale t he air or gases.

• High-concentration (100% LEL or higher) combustible gases may be discharged from the gas

exhausting o ut l et of th e de tector. Never use fire near it.

WARNING

• The detector is designed to draw gases around it under the atmospheric pressure. If excessive

pressure is applied to the gas inlet and outlet of the detector, detected gases may leak out from

its inside and may cause dangerous conditions. Be sure that excessive pressure is not applied

to the detector while used.

• When performing an air calibrati o n, v erify that you are in a fr es h a ir en v ir onment before

starting. If interference gases or other gases exist, the adjustment cannot be performed

properly, thus leading to dangers when the gas leaks.

• Issuance of a gas alarm indicates t ha t th er e are ex tr e me dangers. Take proper acti ons based

on your judgment.

• Before use, check that there remains sufficient battery power . When the detector is not used for

a long period, the batteries may be exhausted. Never fail to replace them with new ones before

use.

• If a low battery alarm is triggered, gas detection cannot be conducted. If the alarm is triggered

during use, turn off the power and promptl y replace the batteries i n a safe area.

• Do not block the buzzer sound opening. No alarm sound can be heard.

• If the main unit is dropped or given a shock, the reading may rise and it may remain so. In such

a case, perform air calibration in a place where the surrounding air is fresh.

Page 19

- 19 -

4-7. Changing the concentration measuring mode

In the detector, the detection gas type is factory set to R600a (Isobutane) and the alarm setpoint is factory

set to 30 ppm.

The detector has 5 preset alarm setpoints that the user can cycle through (10 ppm, 30 ppm, 150 ppm, 500

ppm, and 20 0 0 ppm).

For the measuring mode, the concentration measuring mode or differential measuring mode can be

selected.

<Concentration measuring mode>

Perform air calibration in the atmosphere.

Then, the mode monitors chang e s to the air value , showin g the co rrelation between a leakage amount and

the bar display.

(If the measured atmosphere changes, perform air calibration again.)

<Differential measuring mode>

Perform automatic air calibration at regular intervals in the atmosphere of measurement environment. This

is a high sensitivity mode that ena ble s detection of ultralow amounts of leaking gas in the air by eliminating

the environmental effects (other gases, temperature and humidity). Since it can detect a slight amount of

increase in gas concentration even in th e en vironment where a gas is l eaking already, this measuring

mode is effective to identify a leakin g po i nt .

In the differential measuring mode, "LOW MODE"(low sensitivity) and "HIGH MODE"(high sensitivity) can

be switched. When the detector cannot detect gas leakage in “LOW MODE”, switching to “HIGH MODE”

will allow detection of an ultralow gas leak.

Gas alarm setpoint for concentration measuring mode

1

In the detection m ode, press the AIR and MODE buttons at the same time.

The alarm setpoint is changed to the next pre-defined setpoint every time the AIR and MODE buttons

are pressed. There are 5 setpoints t otal , a ll in the ppm range.

NOTE

• The alarm setpoint cannot be set to 10000 ppm.

Page 20

- 20 -

Gas alarm setpoint for differential measuring mode

1

In the detection mode, press the AIR and MODE buttons at t he same time.

The alarm setpoint is chan ge d to the next pre-defined setpoint every time the AIR and MODE buttons

are pressed. There are 6 setpoints t otal .

Changing the gas alarm sensitivity for differential measuring

mode

1

In the detection mode, press the AIR button.

The alarm sensitivity changes from LOW MODE to HIGH MODE every time the AIR butt on is pr es sed.

Page 21

- 21 -

NOTE

• For switching to the differential measuring mode, see "Change of the measuring mode" in the display

mode on page 31.

CAUTION

• Performing an air c a libration in the prese nc e of gas will decrease th e bar meter.

• For excessiv e temperature/hum id ity changes, the bar meter may increase.

• When the mode is switched from the differential mode to the concentration measuring mode,

check the atmosphere for freshness and perform air calibration again in the measured

atmosphere.

• The gas concentrati on is displayed in six levels (without a unit).

• Air calibration is performed automatically and it cannot be performed manually.

Page 22

- 22 -

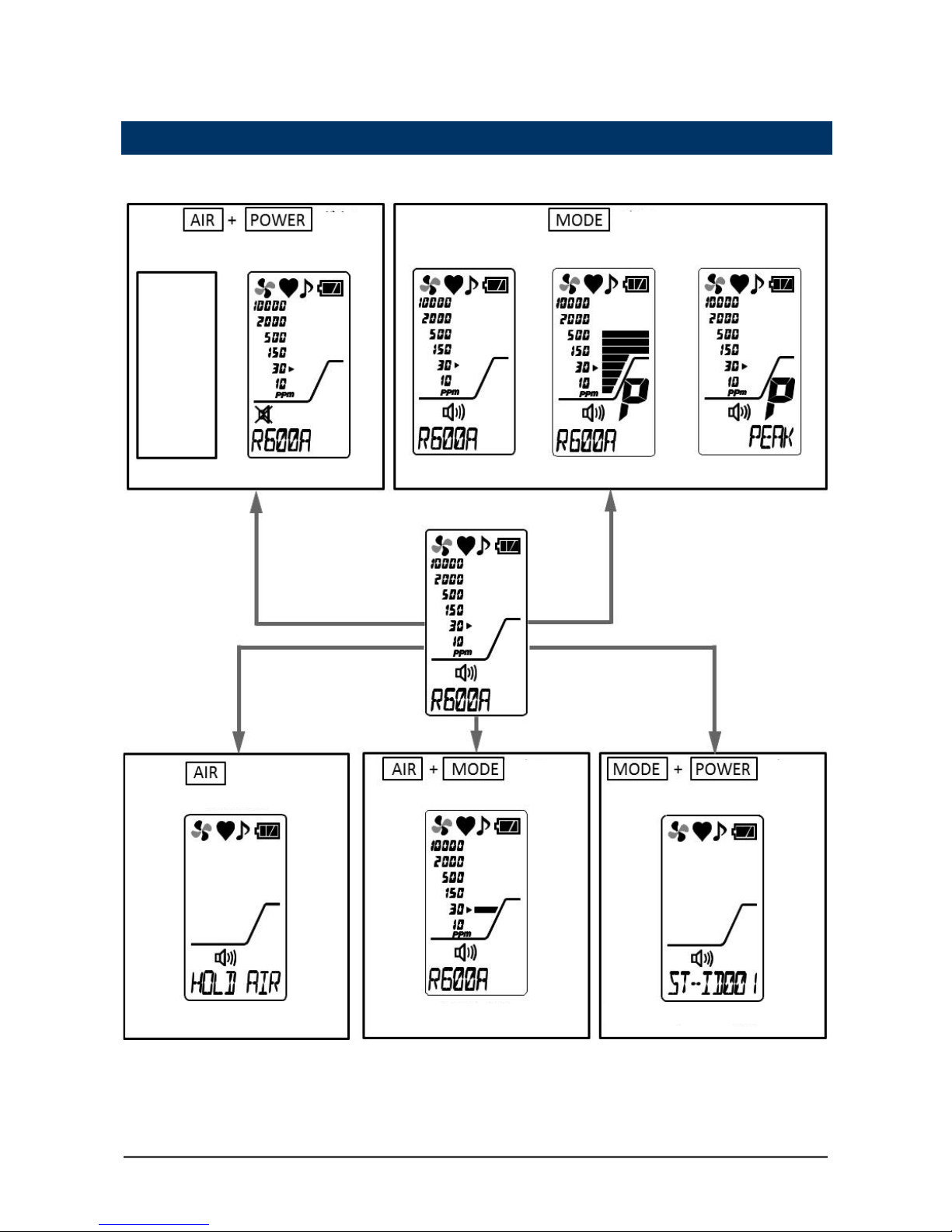

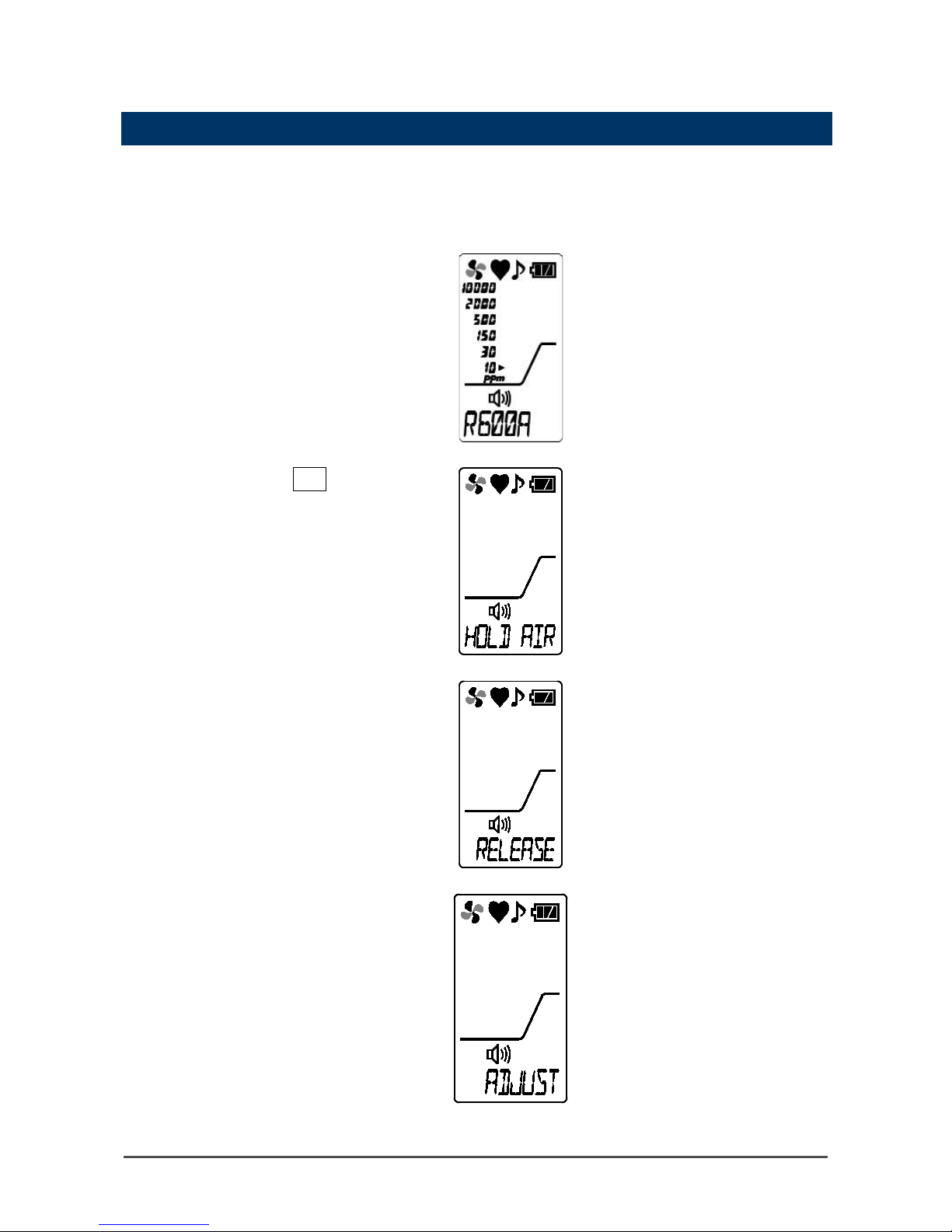

4-8. Performing air calibration

After a high-concentration gas is detected or an alarm is triggered by temperature/humidity changes,

perform air calibration in the measured atmosphere.

* Before performing air calibration, verify a fresh air enviro nment.

1

In the detection m ode,

hold down the AIR button.

2

Release the AIR button

when the display

changes from "HOLD

AIR" to "RELEASE".

(Buzzer sound: Three times <blip,

blip, blip>)

▼

▼

The air calibra t io n is d on e an d th e

detector returns to detection

mode.

(Buzzer sound: Once < blip>)

If air calibration fails, "FAIL AIR

CAL" is displayed.

Perform air calibration aga i n i n

fresh surrounding air.

Page 23

- 23 -

NOTE

• Perform air calibration under pressure and temperature/humidity conditions close to those in the

operating environment and in fresh air.

• Perform air calibr ation after the readi ng is stabilized.

• If there is a sudden temperature change between the storage and operational locations, turn on the

power of the detector, let it stand for five minutes or more in a similar environment to the operational

location, and perform air calibration in fresh air before using it.

4-9. Snap logger

Any peak value during measurement can be recorded.

Up to 256 points of data can be recorded. When the number of recorded data points reaches the maximum,

recorded data will be overwritten, starting from the oldest data.

This function is enabled when the clock function is enabled. Since the clock function is disabled by default,

enable it before using the snap logger function (See "6-3. Clock function ON/OFF setting" on page 36).

1

In the detection m ode,

press the MODE and

POWER buttons at the

same time.

The detector enters the station ID

selection screen.

2

Use the MODE or AIR

button to select the

station ID and pres s the

POWER button.

The peak value is d is pl ayed.

To stop recording, press the

AIR and MODE buttons at the

same time. The detector

returns to the detection mode.

3

Press the POWER button.

The date/time and peak value are

recorded.

To continue recording the log,

repeat steps 2 to 3.

To stop recording the log, press

the AIR and MODE buttons at

the same time. The detector

returns to the detection mode.

NOTE

• The recorded data c an be r ea d o ut by the "Data Logger Mana gement Program" (o pt i on a l) . S e e th e

operating manual of "Data Logger Management Program" for more information.

Page 24

- 24 -

4-10. Peak hold function

When the peak hold function is enabled, the latest peak value is always displayed with the bar meter.

1

In the detection

mode, hold down the

MODE button (for

three seconds or

longer).

The peak hold function is

enabled. While the peak

hold function is enabled, "P"

is displayed on the LCD

display.

To disable the peak hold

function, hol d do wn the

MODE button for three

seconds or longer.

NOTE

• To clear a retained peak value, hold down the MODE button (for one second) in the detection mode.

4-11. Changing the alarm and operation sounds

Turn the alarm and operation sounds ON or OFF.

1

In the detection mode, press the AIR and POWER buttons at the same time.

The settings for the alarm and operation sounds are switched every time the AIR and POWER buttons

are pressed.

Alarm sound ON

Operation sound ON

Alarm sound OFF

Operation sound ON

Alarm sound OFF

Operation sound OF F

Alarm sound ON

Operation sound OF F

Page 25

- 25 -

4-12. How to turn on the illumination lamp

The illumination lamp can be turned on, if necessary.

1

Hold down the AIR and POWER buttons at the same time (for three

seconds or longer).

The illuminat i on lamp lights up. The illumination lamp will aut omatically go off two minutes after it

lights up.

To turn off the illumination lamp, hold down the AIR and POWER buttons at the same time (for three

seconds or longer).

4-13. Power-off

Press and hold the POWER button (at least three seconds) until the buzzer blips three times ("TURN OFF"

disappears) to turn off the power.

CAUTION

• If a gas remains in the detector, it enters the automatic exhaust mode (for a maximum of 30

seconds). How e v e r, the detector is t ur n ed off after t he au tomatic exhaust m ode . The mode

counts down from automatic exhaust start (PURGE 30). The detector switches to the "TURN

OFF" display when the gas exhaust is completed and is turned off.

Automatic exhaust start (PURGE 30)

Page 26

- 26 -

5

5. Display Mode

5-1. Enteri ng the displ ay mode

This mode allows users to view and change various display settings and perform other operation.

(Display example: For city gases)

1

In the detection m ode, press the

MODE button.

The detector enters the peak value display in the

display mode.

2

Next, press the MODE butto n to

display the appropriate menu.

The setting screen for the display mode is

switched every time the button is pr ess e d.

Holding down the button also switches the

setting screen. When the detector returns to the

detection mode, the setting screen stops being

switched.

3

Select the setting item and press

the POWER button.

For setting items, see "Display mode overview"

on page 27.

NOTE

• The detector automatically returns to the detection mode in about 20 seconds if the detector is left

unoperated.

• Gas detection is continued in the display mode and an al arm can be activated.

Page 27

- 27 -

Display mode overview

Item

LCD display

Details

Peak display

Displays the maximum concentration

detected dur in g th e p eriod from power-on

to the point of checking.

* To clear the peak display, hold down the

AIR button until "PEAK CLR" is

displayed.

Measured gas reading

setting

By changing the setting to the

pre-registe re d gas in the detector, the

converted concentration from the

detection targe t g as wi l l b e dis p layed.

(P. 29)

Measuring mode setting

Changes (in small measure) the pump

suction volume by mode changing the

measuring mode (in the differential

measuring mode the pump suction

volume is up).

(P. 31)

* NORMAL (Concentration measuring

mode)

DIFF (Differential measuring mode)

Log data display

Displays the data recorded by the snap

logger. (P. 32)

* Displayed only when the clock function

is enabled

See "6-3. Clock function ON/OFF

setting" on page 36.

Page 28

- 28 -

Entering user mode

Enters the user mode.

(P. 33)

Detection mode

Returns to the detection mode.

Page 29

- 29 -

5-2. Measured gas reading setting

Normally, the concentration display of the detector is "Isobutane (R600a)" depending on the specification;

however, a pre-registered gas can be read instead to detect its concentration.

1

On the "GAS LIST"

screen in the display

mode, press the POWER

button.

The detector enters the gas

reading setting.

▼

The currently set gas name is

displayed.

2

Press the MODE or AIR

button to select a gas

name to be read

instead.

The gas name switches to

another every time the button is

pressed.

3

When the target gas

name is displayed,

press the POWER

button.

"END" is displayed, returning to

the display mode.

Page 30

- 30 -

Note

・ To perform the concentration displayed gas reading setting, see the "Gas list" in the following page.

Gas list

Gas name

(standard name)

Display

Grid 1

(ppm)

Grid 2

(ppm)

Grid 3

(ppm)

Grid 4

(ppm)

Grid 5

(ppm)

Grid 6

(ppm)

Unit

conversion

【

Only as a guide】

(g/year)

R600a(Isobutane) R600A 10 30 150 500 2000 10000 Approx.2.7

R290(Propane) R290 10 50 200 500 2000 10000 Approx.2.1

R123 R123 20 100 500 2000 5000 10000 Approx.14.4

R134a R134A 20 100 500 2000 5000 10000 Approx.9.58

R142b R142B 10 50 100 200 500 1000 Approx.4.7

R22 R22 10 50 200 1000 3000 10000 Approx.4.1

R32 R32 10 50 200 500 2000 10000 Approx.2.4

R23 R23 10 50 200 500 2000 5000 Approx.3.3

R407C R407C 10 50 200 500 2000 10000 Approx.4.0

R410A R410A 10 50 200 500 2000 10000 Approx.3.4

R404A R404A 10 50 200 500 2000 5000 Approx.4.6

2,3,3,3-Tetrafluoro

propene

(HFO-1234yf)

R1234YF 10 50 200 500 1000 2000 Approx.5.3

R507A R507A 10 50 200 500 1000 2000 Approx.4.6

R407A R407A 10 50 200 500 2000 5000 Approx.4.2

Alarm setting can be changed in five levels among grid 1 to 5.

Note

• Unit conversi o n is estimated value wh e n it ass umed as pump flow rate is approx. 20m l/min and

steady and measured by “Grid 1”.

The actual conversion value is affected by the age of the pump and varies from pump to pump.

• High-concentration or continuous contact with a chloride or sulfur compound will shorten the sensor

life or cause larger errors.

• If a Si compound is detected, the sensitivity will decrease.

• If a high-concentration so lv en t gas is drawn, the rubb e r se a l us e d i n th e d et ec t or wi l l deteriorate.

Page 31

- 31 -

5-3. Changing the me asu r ing mode

The measuring mode of the detector (for fumigation gases) can be switched from "concentration measuring

mode" to "differential measuring mode", where lower concentration detection can be conducted.

1

On the "MODE CHG"

screen in the display mode,

press the POWER button.

The detector enters the setting

to switch the measuring mode.

2

Press the MODE or AIR

button to select the

measuring mode.

The measuring mode switches

to the other every time the

button is press e d.

<Concentration measuring

mode>

<Differential

measuring mode>

3

In the appropriate

measuring mode, press the

POWER button.

"END" is displayed, returning to

the display mode.

Page 32

- 32 -

5-4. Log data display

The data recorded by the snap logger can be viewed.

The "REC DATA" screen is displayed only when the clock function is enabled (See "6-3. Clock function

ON/OFF setting" on page 36).

1

On the "REC DATA"

screen in the display

mode, press the POWER

button.

The detector enters the log data

display.

The recorded date/time is

displayed and the station ID and

memory number are displayed

alternately. If there is no

recorded data, "NO DATA" is

displayed.

* When there is no r ec or d ed data

2

Press the MODE or AIR

button to select log

data to be displayed.

The recorded content switches

to the other every time the

button is press e d.

<Station ID> <Memory number>

3

When the target log

data is displayed, press

the POWER button.

The gas name and peak value

of the selected memory are

displayed alternately.

4

To exit the display,

press the MODE and

AIR buttons at the same

time.

The detector returns to the

display mode.

Page 33

- 33 -

6

6. User Mode

6-1. Enteri ng the user mode

The maintenance including internal clock correction, etc. can be performed.

1

In the detection m ode, press the

MODE button a few times to display

"USER" and then press the POWER

button.

The detector enters the date/time setting in the

user mode.

2

Next, press the MODE or AIR button

to display the appropriate menu.

The setting screen for the user mode switches to

another every time the button is pres s ed.

3

Select the setting item and press

the POWER button.

For setting items, see "User mode overview" on

page 34.

CAUTION

• Return to the detection mode after use.

Page 34

- 34 -

User mode overview

Item

LCD display

Details

Date/time setting

Set the date/time of the internal clock.

(P. 35)

* When the clock function is disabled, the

date/time setting screen is not

displayed.

Clock function ON/OFF

setting

Enable or disable the clock function.

ROM/SUM display

Displays the program number and SUM

value of the detector.

* This is not typical ly used by the user.

Entering detection mode

To exit the user mode, press the POWER

button to enter th e d et ec t i o n m od e.

Page 35

- 35 -

6-2. Date/time setting

Set the date/time of the internal clock.

The date/time setting screen is displayed only when the clock function is enabled. Enable the clock function

in "6-3. Clock function ON/OFF setting" on page 36 before setting the date/time.

1

On the "DATE" screen in th e user

mode, press the POWER button.

The detector enters the date/time setting.

2

Press the MODE or AIR button, s et

the date/time and press the POWER

button.

3

Set year -> month -> day -> ho ur ->

minute in this order.

When the "minute" value is confirmed, "END" is

displayed an d t he n th e d et ec t or returns to the

user mode menu.

Page 36

- 36 -

6-3. Clock function ON/OFF setting

Enable or disable the clock function.

The clock function is disabled by default. If the date/time needs to be displayed on start-up or the snap logger

function is used, enable the clock function.

1

On the "CLOCK" screen in the user

mode, press the POWER button.

2

Press the MODE or AIR button to

display the desired setting (ON/OFF)

and press the POWER button to

confirm it.

3

Setting completed

After the clock function ON/OFF setting is

completed, "END" is displayed and then the

detector returns to the user mode menu.

NOTE

• When the clock function is changed from disabled to enabled, a clock abnormality (FAIL CLOCK)

may be triggered if the date/time is inaccurate. When the failure condition is rese t usi n g the MODE

button, the detector moves to the date/time setting screen. Set the dat e/ time in acc ordance with

"6-2. Date/time setting" on page 31.

• When the clock function is changed from disabled to enabled for the

first time, powered on after leaving the detector for more than five minutes

with the batteries removed, or po wered on with the batter i es ins er t e d wi th

incorrect polarities, a clock abnormality (FAIL CLOCK) may be triggered.

Page 37

- 37 -

7

7. Alarm Function

7-1. Gas alarm activation

When the conce ntration of detected g as r eac hes or exceeds the ala r m setpoint values, a "g as a larm" is

triggered in the detector. The alarm lamp blinks, the buzzer sounds, and the bar meter display indicates an

alarm condition. (Auto-res e t op er a t io n)

Blinking alarm lamp and buzzer sound operation for gas alarms have different intervals depending on the

detected concentration.

7-2. Fault alarm activation

"Fault alarm" i s tri gge red using a buz z er so und and bl in king alarm lamp when an abnormality is detected in

the detector. (Self-latching)

When an alarm is trigge red, one of the following fault details is displayed on the LCD.

- System

abnormalities

: FAIL SYSTEM

- Battery voltage

low

: FAIL BATTERY

- Calibration

abnormalities

: FAIL AIR CAL

- Clock

abnormalities

: FAIL CLOCK

- Low flow rate

: FAIL LOW FLOW

- Pump

abnormalities

: FAIL PUMP

- Sensor

abnormalities

: FAIL SENSOR

Alarm lamp

Repeatedly blinks at about one-second intervals.

Buzzer

Repeatedly sounds intermittent bee ps at ab out

one-second intervals.

Blip-blip, blip-blip

LCD display

Display example of low flow rate (LOW FLOW)

If a fault alarm is triggered, refer to trouble shooting and take appropriate action.

If the unit has problems and is repeatedly malfunctioning, contact RKI immediate l y.

NOTE

• The low flow rate alarm (FAIL LOW FLOW), calibration abnormalities (AIL AIR CL) and clock

abnormalities (FAIL CLOCK) can be reset by pressing the MODE button.

• For informati o n on m alf u nc t io ns (er ror messages), see "Troubleshooting" on page 45.

Page 38

- 38 -

8

8. Maintenance

The detector is a precision d e v ice.

To maintain the performance of the detector and improve the reliability of detecting leak ag e, perform a

regular maintenance.

8-1. Maintenance interva ls and item s

Perform the following maintenance regularly before use.

・ Daily maint e na nc e : P er f o r m maintenance befor e commencing each wor k.

・ Monthly maintenance: Perform alarm test once a month.

・ Regular maintenance: Perform maintenance once or more for one year to maintain the performance as a

unit.

Maintenance

item

Maintenance content

Daily

maintenance

Monthly

maintenance

Regular

maintenance

Battery level

check

Check that the battery level is

sufficient.

○ ○ ○

Concentration

display check

Make the detector draw in fresh air

and check that the concentration

display valu e is ze r o . When the

reading is incorrect, perform zero

adjustment by air calibration after

ensuring that no other gases exist

around it.

○ ○ ○

Flow rate

check

Check the flow check display to find

abnormalities.

○ ○ ○

Filter check

Check the dust filter for dust or

clogging.

○ ○ ○

Gas alarm

calibration

Check the gas al arm using a

calibration g as .

- - ○

Page 39

- 39 -

About maintenance services

We provide services on regular maintenance including span adjustment, other a dj ustments and

maintenance.

Our qualified ser v ice engineers have ex p ertise, knowledge an d other informatio n on th e d edicated tools

used for services, along with other products. To maintain the safety operation of the unit, pl ease use our

maintenance service.

The followings are typical maintenance services. For details, contact RKI.

<Main Services>

Item

Services

Battery level

check

Checks the battery level.

Concentration

display check

Verifies that the concentration display value is zero by using the zero gas.

Performs the air calibration if the reading is incorrect.

Flow rate check

Checks the flow rate indicator to find abnormalities.

Checks the flow rate by using an external flow meter to verify the correctness of the

flow rate indicator on the detector. If the flow rate is incorrect, performs the flow rate

adjustment.

Filter check

Checks the dust filter for dust or clogging.

Replaces a dirty or clogged dust filter.

Span

adjustment

Performs span adjustment using a ca li bration gas.

Cleaning and

repair of the unit

(visual

diagnosis)

Checks dust or damage on the surface of the unit, cleans and repairs such parts.

Replaces parts whic h ar e cr ac ked or damaged.

Unit operation

check

Operates the buttons to check the operation of functi o ns an d par ameters, etc.

Replacement of

consumable

parts

Replaces consumable parts, such as a sensor, filter, pump, etc.

Page 40

- 40 -

8-2. How to clean

Clean the detec t or if i t becomes extreme l y dirty. The detector must be turned off while clean i n g it . Us e a

waste cloth or the like to remove dust. Do not use water or organic solvent for cleaning because they may

cause malfunctions.

Because an extremely contaminated inside of the taper nozzle may disturb the gas detection, it must be

cleaned with dry air, etc.

NOTE

• When the detector gets wet, water may remain in the buzzer sound opening or grooves. Drain water

as follows:

(1) Wipe away moisture on the detector thoroughly using a dry towel, cloth, etc.

(2) While holding the detector firmly, shake it about ten times with the buzzer sound opening facing

downward.

(3) Wipe away moisture coming out from the inside thoroughly using a towel, cloth, etc.

(4) Place the det ec t or o n a dry towel, cloth, etc. an d let it stand at normal tem peratures.

8-3. Parts replacement

Hydrophobic filter replacement procedure

Continuing to use the detector may cause the hydrophobic filter to be contaminated or clogged.

Replace the hydrophobic filter if it becomes extremely dirty.

Also, replace the hydrophobic filte r wh en it has absorb ed water or has a lower flow r at e.

1

Turn the cap co unterclockwise and

remove it.

2

Remove the rubber seal from the cap.

The hydrophobic filter is instal led in

the rub ber seal.

CAUTION

• When cleanin g t he det ec t or, do not splas h water over it or use org an ic s o l ve nts su c h as

alcohol, benzene, etc. on it. Otherwise, it may cause discoloration or damage to the surface of

the detector or a sensor failure.

Cap

Rubber seal

Page 41

- 41 -

3

Replace the hydrophobic filter with a

new one. Make sure it’s seated in the

rubber seal correctly.

4

Attach the rubber seal, with the filter

installed, to the cap.

Make sure the rubber seal’s rib has been firmly

inserted into t h e cap’s groove.

5

Attach the cap, with the rubber seal

attached, to the main unit.

Hydrophobic

Filter

Rubber seal

Rib

Groove

Page 42

- 42 -

Sensor replacement

The sensor comes with a 1-year warr an t y. It has a typical life of 2-3 years, depen di n g on th e op erating

environment. The sensor life has expired if, for example, the reading fluctuates or does not respon d during

calibration. Contact RKI for sensor replacement.

Battery replacement

For battery re p lac ement, see "How to rep lac e the batteries" on page 13.

Page 43

- 43 -

9

9. Calibr ation Mode

This section describes how to perform a fresh air adjustment, an automatic span adjustment, and a manual

span adjustmen t on the SP-220. It also describes how to turn on the Calibration Mode password function.

9-1. Fresh Air Adjustment

RKI Instrumen ts, I nc . r ec ommends that the fr es h air a dj us tment be performed in a fresh air area (area

known to be free of t ox ic a nd combustible gases an d of nor mal oxygen conten t, 20 .9 % ). If a fresh air

environment is not available, a cylinder of zero air can be used as long as the gas is applied through a

humidifier tube. Calibration kits for the SP-220 do not normally include zero a ir or a humidifier tube.

1

Be sure the SP-220

has been running in

Detection Mode for

at least 10 minutes

before continui ng.

2

With the ins t rument

running i n Detection

Mode, press and hold

the AIR and MODE

buttons for 3

seconds.

3

If the Calibration

Mode password

parameter ha s been

set to on (factory

setting is off), you

will be prompt ed for

a password.

Use the AIR and

MODE buttons to

adjust each

character and press

the POWER button to

move to the next

character.

Page 44

- 44 -

4

The AIR C AL menu

item will be

displayed.

5

Press and release

the POWER button.

6

Make sure you are in

a fresh air area (area

known to be free of

toxic and

combustible gases

and of normal

oxygen content,

20.9%).

7

Press and hold t he

AIR button. Release

the AIR button whe n

the screen says

“RELEASE”.

8

The instrument will

perform a f resh air

adjustment and will

return to the AIR

CAL menu item.

Page 45

- 45 -

9

See the following

sections for span

adjustment

descriptions.

To return to

Detection Mode

without performing a

span adjustment,

scroll to the

MEASURE menu

item and press and

release the POWER

button.

To turn the

instrument off, press

and hold the POWER.

9-2. Preparing for a Span Adjustment (Gas Bag)

This section describes how to prepare for calibration if you are using a calibration kit that includes:

• Gas bag with a tub in g clamp

• Fixed flow regulator

• Calibration cylinder

1. Empty the gas bag.

2. Connect the bag’s tubing to the fixed flow regulator’s hose barb fitting.

3. Screw the fixed flow regulator onto the calibration cylinder.

4. If your regulator has a knob, turn the knob counterc l ockwise to start the flo w of ga s into t h e g as ba g.

5. Allow the gas to dispense until the gas bag is a little over half full.

6. If your regulator has a knob, turn the knob clockwise to stop the flow of gas.

7. Clamp the gas bag tubing shut.

8. Remove the tubing from the fixed flow regulator’s hose barb fitting.

9. Remove the fixed flow regulator from the calibration cylinder.

Page 46

- 46 -

9-3. Preparing for a Span Adjustment (Demand Flow

Regulator)

This section describes how to prepare for calibration if you are using a calibration kit that includes:

• Demand flow regulator

• Calibration tubing

• Calibration cylinder

1. Screw the demand flow regulator onto the calibration cylinder.

2. Connect the tubing to the demand flow regulator’s hose barb fitting.

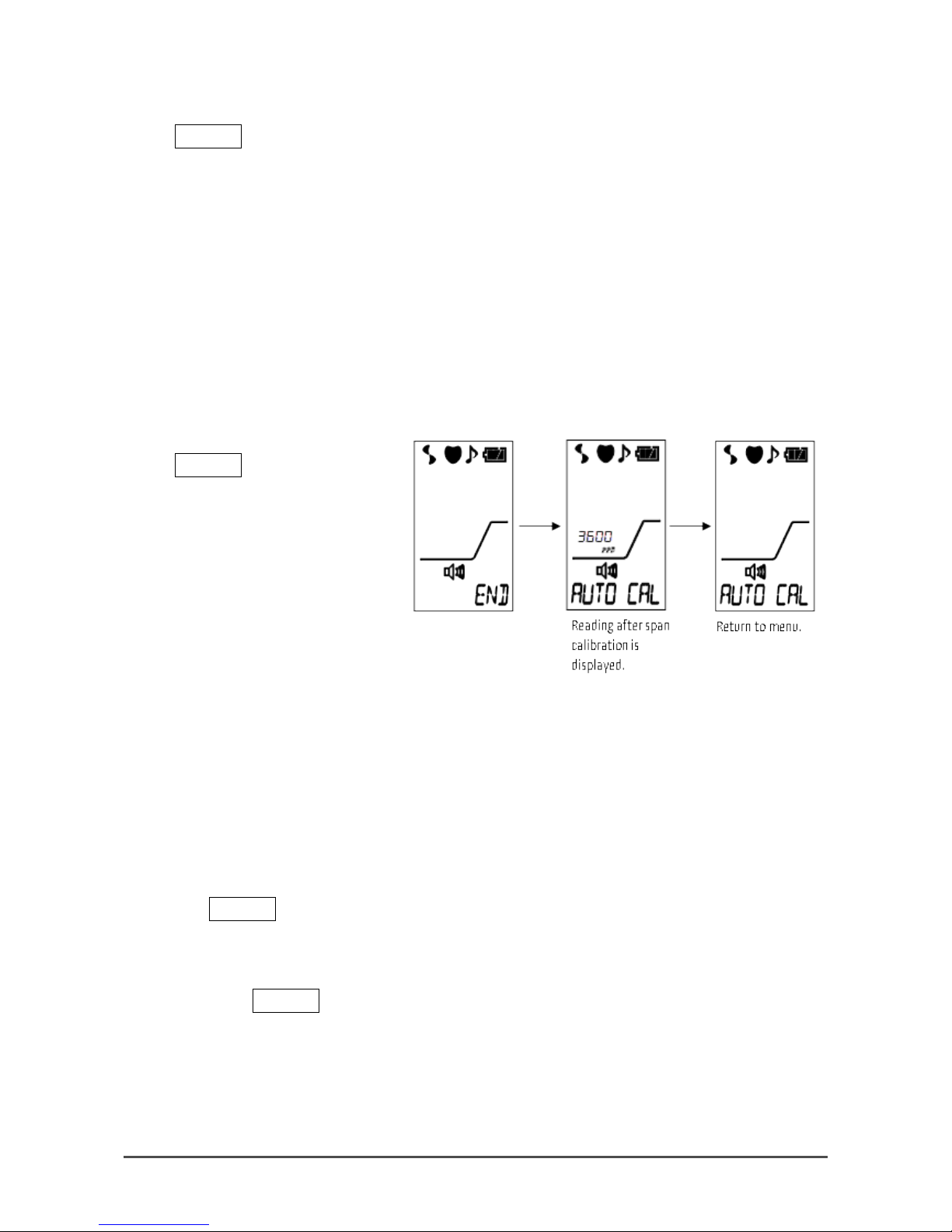

9-4. Automatic Span Adjustment

These instructions describe an automatic calibration of the SP-220. Be sure you have performed a fresh air

adjustment and prepared for calibration as described in the previous sections before continuing.

1

If you have just

perform ed a fresh air

adjustment and the

instrument is still

running i n Calibration

Mode, continue to step

5.

If your i ns t rument is not

currently running in

Calibration Mode,

continue to step 2.

2 With t he instrument

running i n Detection

Mode, press an d hold

the AIR and MODE

buttons for 3 seconds .

3

If the Calibration Mode

password parameter

has been set to on

(factory setting is off),

you will be prompted for

a password.

Page 47

- 47 -

Use the AIR and MODE

buttons to adjust each

character and press the

POWER button to move

to the next character.

4

The AIR C AL menu item

will be displayed.

5

Use the AIR or MODE

button to scrol l to the

AUTO CAL menu item.

6

Press and release the

POWER button. The auto

cal value will be

displayed.

7

To adjust the aut o cal

value:

a. Press and hold the

MODE button then

press and hold the

POWER button. The

auto cal value will

begin to flash.

b. Use the AIR and

MODE buttons to

adjust the value.

c. Press t he POWER

button to confirm the

change.

Page 48

- 48 -

8

Press and release the

POWER butt on. T h e gas

reading will begin to

flash.

9

Apply calibration gas for

1 minute.

Depending on your calibration

kit, you will need to either:

a. Connect the gas bag

tubing to the

instrument’s inlet or

b. Connect the tubing

from the demand flow

regulator to the

instrument’s inlet.

10

Press and release the

POWER butt on. T h e

instrument will perform

a gas adjustment and

will return to the AUTO

CAL menu item.

11

Disconnect the

calibration gas source

from the instrument’s

inlet fitting.

12

To enter Detection

Mode, scroll t o the

MEASURE menu item

and press and release

the POWER button.

To turn off the

instrument, press and

hold the POWER button.

Page 49

- 49 -

9-5. Manual Span Adjustment

These instructions describe a manual calibration of the SP-220. B e s ur e you h a ve per f or med a fresh air

adjustment and prepared for calibration as described in the previous sections before continuing.

1

If you have just

perform ed a fresh air

adjustment and the

instrument is still

running i n Calibration

Mode, continue to step

5.

If your i ns t rument is

not currently running in

Calibration Mode,

continue to step 2.

2

With the ins t rument

running i n Detection

Mode, press an d hold

the AIR and MODE

buttons for 3 seconds .

3

If the Calibration Mode

password parameter

has been set to on

(factory setting is off),

you will be prompted

for a password.

Use the AIR and MODE

buttons to adjust each

character and press the

POWER button to move

to the next character.

4 The AIR CAL menu item

will be displayed.

Page 50

- 50 -

5

Use the AIR or MODE

button to scrol l to the

MANU_CAL menu item.

6

Press and release the

POWER button. The gas

reading will begin to

flash.

7

Apply calibration gas

for 1 minute.

Depending on your

calibration kit, you wil l need

to either:

a. Connect the gas bag

tubing to the

instrument’s inlet or

b. Connect the tubing

from the demand flow

regulator to the

instrument’s inlet.

8

Use the AIR and MODE

buttons to adjust the

gas reading t o m atch

the value listed on the

calibration cylinder.

9

Press and release the

POWER butt on. T h e

instrument will perform

a gas adjustment and

will return to the

MANU_CAL menu item.

Page 51

- 51 -

10

Disconnect the

calibration gas source

from the instrument’s

inlet fitting.

11 To enter Detection

Mode, scroll t o the

MEASURE menu item

and press and release

the POWER button.

To turn off the

instrument, press and

hold the POWER button.

9-6. Password

These instructions describe how to turn the Calibration Mode password on or off and how to set the

password.

1

If your i ns t rument is

still running in

Calibration Mode,

continue to step 4.

If your i ns t rument is

not currently running in

Calibration Mode,

continue to step 2.

2

With the ins t rument

running i n Detection

Mode, press an d hold

the AIR and MODE

buttons for 3 seconds .

Page 52

- 52 -

3

The AIR CAL menu item

will be displayed.

4

Use the AIR or MODE

button to scrol l to the

PASSWORD menu item.

5

Press and release the

POWER butt on. T h e

current setting will be

displayed.

6

Use the AIR or MODE

button to adjust the

on/off setting. If the

password is set to on, a

user-defined password

will be required to enter

Calibration Mode.

7

Press and release the

POWER button.

If you set the password

function to off,

continue to step 9.

If you set t he password

function to on, continue

to step 8.

8

Use the AIR or MODE

button to adjust the

first number in the

desired password.

Press and release the

POWER button to move

on to the next

character and the n

save the password.

Page 53

- 53 -

9

To enter Detection

Mode, scroll t o the

MEASURE menu item

and press and release

the POWER button.

To turn off the

instrument, press and

hold the POWER button.

Page 54

- 54 -

10

9. Storage and Disposal

10-1. Procedures to store the detector or leave it for a

long time

The detector must be stored under the following environmental conditions.

• In a dark place under the normal temperature and humidity away from direct sunlight

• In a place where g as es, solvents, vapors, e tc . are not present

Store the detector in a shi p pi n g car t on , if any, in which the pro duct was delivered.

Store the detector away from dust, etc. if the sh ip p i ng c arton is not availabl e.

10-2. Procedures to use the detector again

CAUTION

• When the detector is used again after a l on g-period storage, never fail to perform a calibration.

• Contact RKI for inf or mation on readjus tment including cal i bra tion.

CAUTION

• If the detector is not used for a long time, store it after removing the batteries. Leaks from dry

batteries may result in fire or injury.

• The detector, when not ac tiv at ed for a long time, ma y cease to work because of h ar d e ni n g of

the grease in th e pump motor.

Page 55

- 55 -

10-3. Disposal of products

When the detect or is d is po s ed of, it m us t b e tr e at e d properly as an indus trial waste in accorda nce with the

local regulations, etc.

<Disposal in EU Member States>

When disposing of the detector in EU member states, sort the batteries as specified. Handle the removed

batteries according to the classified refuse collection system and recycling system based on the

regulations of EU member states.

Removing batteries

For battery removal, see "4-3. How to replace the batteries" on page 13.

NOTE

Crossed-out recycle dustbin mark

This symbol mark is indicated on the products which contain the batteries which

fall under EU Battery Directive 2006/66/EC. Such batteries need to be di spo sed o f

as specified by the latest Directive. This symbol mark indicates that the batteries

need to be separated from the ordinary waste and disposed of appropriately.

WARNING

• Dispose of dry batteries in accor da nce with procedure sp ec ified by the local authority.

Page 56

- 56 -

11

10. Troubleshooting

The Troubleshooting does not expla in the ca uses of all the malfunctions which occ ur on the detector. This

simply helps to fi nd the ca u s es of m alf unctions which may frequently occur.

If the detector shows a symptom which is not explained in this manual, or still has malfunctions e ve n

though remedial actions are taken, please contact RKI.

<Abnormalities on Unit>

Symptoms

Causes

Actions

The power cannot be

turned on.

The batter y leve l is too lo w.

Replace both of the two batteries with new

ones.

The POWER button was

released quickly.

For power-on, keep the POWER button

pressed until a bl i p is h eard.

Dry batteries ar e n ot

installed properly.

Check that the batteries are properly

installed to the main unit.

Abnormal operations

Disturbances by sudden

static elec tricity noise, etc .

Turn off the power once and t h en turn it on

again (restart).

Cannot operate the

detector.

Disturbances by sudden

static electric ity noise, etc.

Remove the bat teries in a safe place. Then

reinstall them and turn on the power to

perform operations.

System abnormalities

FAIL SYSTEM

A circuit abnormality

occurred.

Contact RKI for repair.

Sensor abnormalities

FAIL SENSOR

A sensor has failed.

Remove the bat teries in fresh air. Then

reinstall them and turn on the power to

perform operations. Restart the detector a

few times. If the p roblem still persists,

contact RKI to re p lace the sensor.

A low battery voltage

alarm is displayed.

FAIL BATTERY

The batter y leve l is lo w.

Turn off the power and replace the dry

batteries wit h n e w on es in a s af e ar e a .

A low flow rate alarm is

displayed.

FAIL LOW FLOW

Water, oil or the like is

drawn.

Check the taper no z zle for any damage or

mark of drawn water, oil, etc.

The taper nozz le i s clogge d.

Check the taper nozzle for connection

condition, clogging, torsion, etc.

The detector w as powered

on at a low temperature or

has not been used for a

long time.

Cycle the power a fe w times. The pump

may start operating. If the problem still

persists, con tac t RK I to replace the pump.

The pump has det eriorated.

Contact RKI to replace the pump.

Page 57

- 57 -

Symptoms

Causes

Actions

Air calibration

impossible

FAIL AIR CAL

Fresh air is not s up p l ie d

around the detector.

Supply fresh a ir an d th e n p er f orm air

calibration in the measured atmosphere.

Clock abnormalities

FAIL CLOCK

Abnormalities of the internal

clock

Make a settin g of da te / t ime.

If such a symptom is observed repeatedly,

the built-in clock is seemingly

malfunctioning. Thus, it must be replaced.

Contact RKI for repair.

Pump abnormalities

FAIL PUMP

Abnormalities of the pump Contact RKI for repair.

Page 58

- 58 -

12

10. Spare Parts List

Part Number

Description

06-1248RK-03

Calibration tubing, 3 feet

81-0021RK-01

Calibration cylinder, 3600 ppm isobutane in air, 34 liter steel

81-1001RK

Dispensing val v e, wi t ho ut knob, for 17 liter an d 34 l it er s te el cylinders (cylin ders with

external thre ads )

81-1054RK