Page 1

Operator’s Manual

SM-2001U & SM-2003U Single

Module Calibration Stations

Part Number: 71-0130RK

Revision: B

Released: 6/17/10

www.rkiinstruments.com

Page 2

Warranty

RKI Instruments, Inc., warrants gas alarm equipment sold by us to be

free from defects in materials and workmanship, and perf ormance for a

period of one year from date of shipment from RKI Instruments, Inc. Any

parts found de fective within that period will be repaired or replaced, at our

option, free of charge. This warranty does not apply to tho se items which

by their nature are subject to deterioration or consumption in normal

service, and which must be cleaned, repaired, or replaced on a routine

basis. Examples of such items are:

Absorbent cartridges Batteries

Pump diaphragms and

Filter elements

valves

Fuses

Warrant y is voi ded by abuse including mechanical damage, alteration,

rough handling, or repairs procedures not in accordance with the

instruction manual. This warranty indicates the full extent of our liability,

and we are not responsible for removal or replacement costs, local repair

costs, transportation costs, or contingent expenses incurred without our

prior approval.

HIS WARRANTY IS EXPRESSLY IN LIEU OF ANY AND ALL OTHER

T

WARRANTIES AND REPRESENTATIONS, EXPRESSED OR IMPLIED, AND

ALL OTHER OBLIGATIONS OR LIABILITIES ON THE PART OF RKI

NSTRUMENTS, INC., INCLUDING BUT NOT LIMITED TO THE WARRANTY

I

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. IN

NO EVENT SHALL RKI INSTRUMENTS, INC., BE LIABLE FOR INDIRECT,

INCIDENTAL, OR CONSEQUENTIAL LOSS OR DAMAGE OF ANY KIND

CONNECTED WITH THE USE OF ITS PRODUCTS OR FAILURE OF ITS

PRODUCTS TO FUNCTION OR OPERATE PROPERLY.

This warranty covers instruments and parts sold to users only by

authorized distributor s, dealers, and represen tatives as appoin ted by RKI

Instruments, Inc.

We do not assume indemnification for any accident or damage caused

by the operation of this gas monitor and our warranty is limited to

replacement of parts or our complete goods.

2 • Warranty

Page 3

Table of Contents

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Table of Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Chapter 1: Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About the SM-2001U & SM02003U. . . . . . . . . . . . . . . . . . . . . . . . . . 5

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

About This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 2: Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Back Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Control Panel, Status LEDs, and USB Port. . . . . . . . . . . . . . . . . . . .11

SM-2001U Instrument Connections. . . . . . . . . . . . . . . . . . . . . . . . . 13

SM-2003U Instrument Connections. . . . . . . . . . . . . . . . . . . . . . . . . 14

Chapter 3: Hardware Setup and Software Inst allation . . . . . . . . . . . . 16

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Hardware Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Installing the Single Module Data Viewer Software. . . . . . . . . . . . . 21

Chapter 4: Using the SM-2001 & SM02003. . . . . . . . . . . . . . . . . . . . . . 22

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Bump Testing Instruments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Calibrating Instruments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Bump Testing & Calibrating a GX-2003 with 100% Vol. Methane . . 28

Charging an Instrument in a Calibration Station . . . . . . . . . . . . . . . 31

Table of Contents • 3

Page 4

Calibration and Bump Test Records . . . . . . . . . . . . . . . . . . . . . . . . 33

Chapter 5: Single Module Data Viewer Software . . . . . . . . . . . . . . . . . 37

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Launching the Single Module Data Viewer Software. . . . . . . . . . . . 37

Using the Single Module Data Viewer Software . . . . . . . . . . . . . . . 38

Spare Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

CAUTION: Read and understand this manual before using the

SM-2001U or the SM-2003U. Also read and

understand the operator’s manual for the

instrument you will use, the GX-2001 or GX-2003,

with you calibration station.

4 • Table of Contents

Page 5

Chapter 1: Introduction

Overview

This chapter briefly describes the SM-2001U and SM-2003U Single

Module Calibration Stations and the Single Module Data View Software.

This chapter also describes the SM-2001U & SM-2003U Single Module

Calibration Stations Operator’s Manual (this document). Table 1 at the

end of this chapter lists the specifications for the calibration stations.

About the SM-2001U & SM-2003U

The SM-2001U and SM-2003U single module calibration stations are

advanced reliable systems that provide charging, calibration, bump

testing, and calibration and bump test records for the GX-2001 and GX2003 gas detectors. They are designed to save the records to a USB

flash drive. The Single Module Data Viewer Software can then be used

with a Windows-based personal computer to retrieve calibration and

bump test data files from the USB flash drive or from the computer’s hard

drive if the files have been transferred to the hard drive from the flash

drive.

The purpose of this manual is to explain how to set up and use the SM2001U and SM-2003U and the Single Module Data Vie wer Software. You

will learn how to:

• install and launch the software

• install the hardware

• perform a bump test

• perform a calibration

• save calibration and bump test records to a USB flash drive

• view, print, and export calibration and bump test reco rds

• use the SM-2001U and SM-2003U to charge an instrument

Overview • 5

Page 6

CAUTION: The GX-2001 and GX-2003 detect oxygen

deficiency and elevated levels of oxygen,

combustible gases, carbon monoxide, and

hydrogen sulfide, all of which can be dangerous or

life threatening. When using the GX-2001 and GX2003, you must follow the instructions and

warnings in the Operator’s Manual for each

instrument to assure proper and safe operation of

the unit and to minimize the risk of personal injury.

CAUTION: The operator of this instrument is advised that if t he

equipment is used in a manner not specified in this

manual, the protection provided by th e equipment

may be impaired.

System Requirements

To use the Single Module Data Viewer Sof tware, you r personal computer

must meet the following requirements:

• Operating Systems: Windows® 2000, Windows® XP.

• Processor: IBM

equivalent minimum

• Memory: 32 MB RAM minimum

• Hard Disk Space: 32 MB minimum

• CD-ROM Drive

• Available USB port

®

compatible PC running Pentium® 2 processor or

6 • System Requirements

Page 7

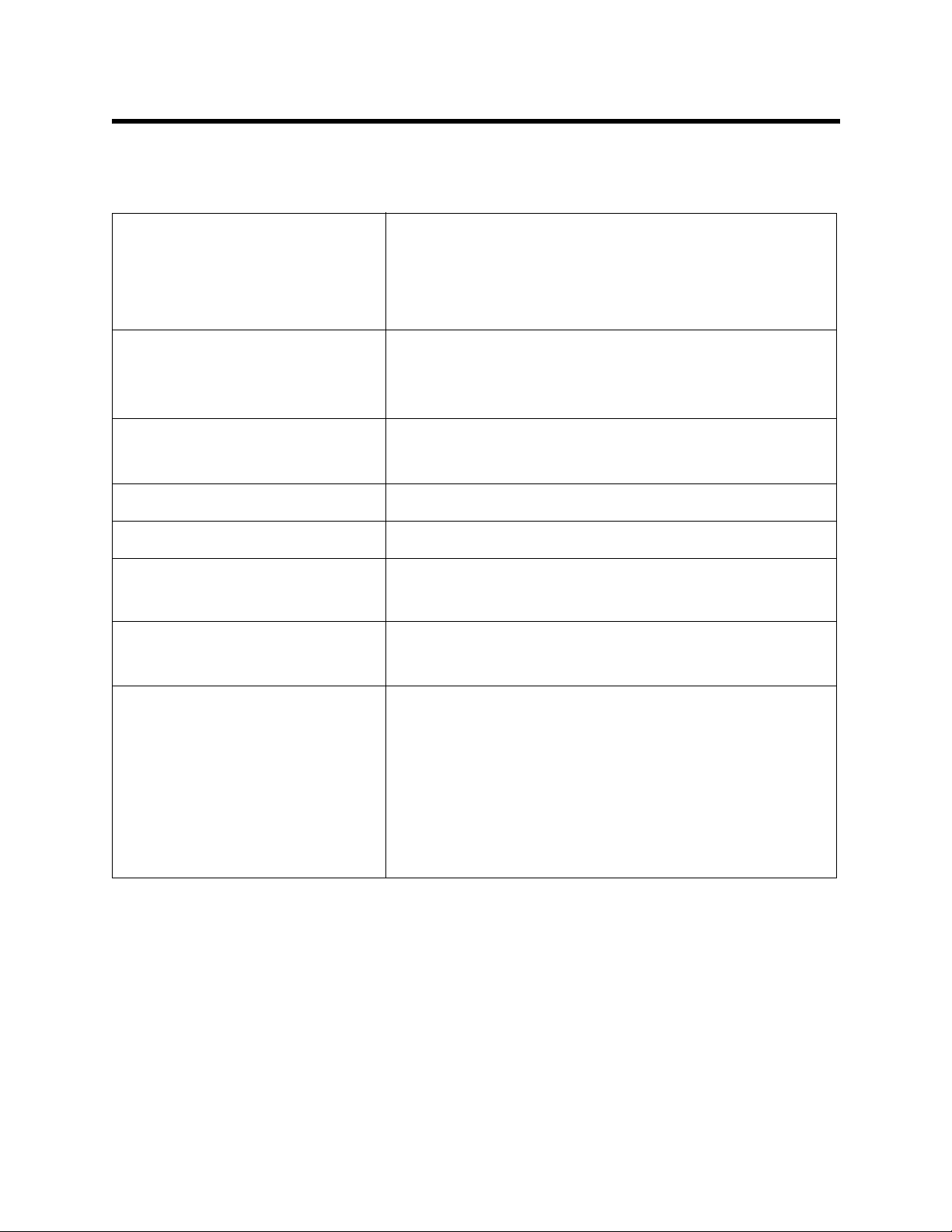

Specifications

Table 1: SM-2001U & SM-2003U Specifications

Input Power 100 VAC - 240 VAC, 50/60 Hz, 10 VA

NOTE: The power cable supplied with the

SM-2001U and SM-2003U as standard is for 115 V AC power.

Environmental Conditions • For Indoor Use Only

• -10° C to 40° C, below 80% Relative

Humidity, Non-Condensing

Applicable Instruments • SM-2001U: GX-2001

• SM-2003U: GX-2003

Memory Capacity 64 KB

Maximum Record Size 256 bytes

Maximum Number of

200

Records Saved

Number of Calibration

One cylinder per bump test or calibration

Gas Cylinders

Standard Accessories • AC Power Cord

• USB Flash Drive

• Single Module Data Viewer Software

• Inlet Air Filter

• Instruction Manual

Specifications • 7

Page 8

About this Manual

The SM-2001U & SM-2003U Single Module Calibration Stations

Operator’s Manual uses the following conventions for notes, cautions,

and warnings.

NOTE: Describes additional or critical information.

CAUTION: Describes potential damage to equipment.

WARNING: Describes potential danger that can result in

injury or death.

8 • About this Manual

Page 9

Chapter 2: Description

Overview

This section describes the SM-2001U and SM-2003U single module

calibration stations. They are designed to be used on a table top and

consist of the back panel, control panel, status LEDs, USB port, and

instrument connections.

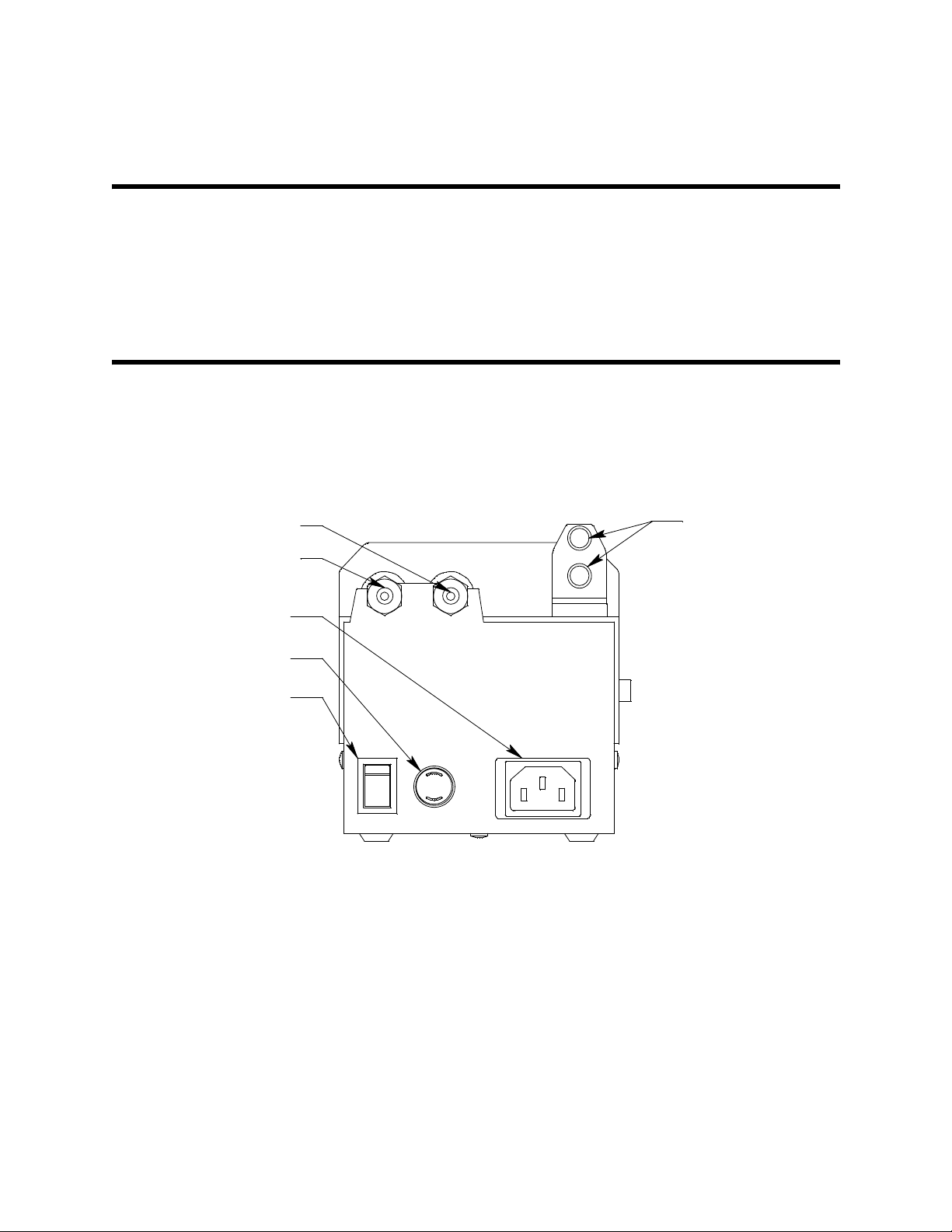

Back Panel

The back panels of both types of calibration stations are identical. The

back panel is shown in Figur e 1 below. It includes the power switch, fuse,

power cord plug, sample fittings, and air filter.

CAL. GAS Fitting

AIR Fitting

AC Power Cord Plug

Fuse

Power Switch

2A

l

O

Exhaust Fittings

Figure 1: SM-2001U & SM-2003U back panel

Power Switch

The power switch is a rocker switch lo cated in t he lower left corner of the

back panel. The calibration station is on when the upper half of the

switch, the “1” position”, is pressed in, and off when the lower half of the

switch, the “0” position, is pressed in.

Overview • 9

Page 10

Fuse & Power Cord Plug

A fuse holder is located to the right of the power switch. The fuse holder

consists of a panel mounting socket and a quarter turn fuse holder. The

fuse is a 2 amp, 5 mm x 20 mm fuse. A recessed 3-pin plug for the 115

VAC power cord is located to the right of the fuse holder.

NOTE: Although the SM-2001U and SM-2003U can operate

from 100 VAC - 240 VAC, the power cord supplied with

the calibration stations is a 115 VAC power cord. If you

wish to power a calibration station from 220 VAC, you

will need to provide an appropriate plug-in power cord.

Gas Sample Fittings/Air filter/Exhaust Tube

Four sample fittings are located on the back of each calibra tion station.

The AIR fitting is in upper left corner and draws air into the station. A

particle filter with a short length of tubing is supplied with each calibration

station for installation to the AIR fitting to keep particu l ate contamination

out of the calibration station. The CAL. GAS fitting is next to the AIR

fitting and is used to connect the st ation to a calibration gas cylinder . Both

the AIR and CAL. GAS fittings accept 3/16” ID tubing.

NOTE: The SM-2001U and SM-2003U are originally shipped

with a cylindrical air filter. If a replacement filter is

needed, the 33-0165RK disk filter is recommended.

A two port exhaust fitting is located in the upper right corner of the back

panel. It allows routing of the exhausted calibration gas to a convenient

exhaust location. The bottom port is plugged with a push-on plug th at is

supplied with the calibration station and the top port is used for tubing

connection. This port accepts 5/16” ID tubing. A 10 foot long 5/16” ID

tube is included with the calibration st ation for routing of the exhaust.

Even though the exhaust gas can be routed to an area to be safely

dispersed, the docking station should still be installed in a well ventilated

area.

10 • Back Panel

Page 11

Control Panel, Status LEDs & USB Port

The control panel and status LEDs are the same for both types of

calibration stations. The control panel is used to setup and operate the

calibration stations. It is located at the front of the calibration stations. It

includes the MODE rotary switch, control buttons, and the control button

LEDs. The CAL. and CHARGE status LEDs are located on the top front

of the calibration stations.

CAL.

Status

LED

CAL. CHARGE

CHARGE

Status

LED

Control

Mode

LEDs

Switch

MODE

0

9

8

7

6

5

1

2

3

4

BUMP CAL. VOL. COPY

OFF

CLEAR

Control

Buttons

Figure 2: Control Panel & Status LEDs

MODE Rotary Switch

The MODE rotary switch is located on the left end of the control panel. It

is a 10 position rotary switch whose positions are labelled 0 -9. Each

position defines the value of various bump test parameters. See “Setting

the MODE Switch” on page 18 for a complete description of the

parameters and settings.

Control Panel, Status LEDs & USB Port • 11

Page 12

Control Buttons & LEDs

Four control buttons are located to the right of the MODE switch. From

left to right they are BUMP, CAL., VOL., and COPY. Above each button is

a control button LED that indicates the status of the function controll ed by

the button.

.

Table 2: Control Button Functions

Control

Control Button Function(s)

Button

BUMP • Initiates a bump test

• Cancels a bump test

• Turns instrument off (when

used with VOL. button

CAL. • Initiates a calibration

• Cancels a calibration

• Clears data from station

memory (when used with

COPY button)

VOL. • Functional only in the SM-

2003U

• Toggles bump test and

calibration functions between

%volume methane only and

all other active channels

Control Button LED

Function(s)

Indicates status of a

bump test in progress

Indicates status of a

calibration in progress

Indicates whether %volume

only operation is activated

• Turns off instrument (when

used with BUMP button)

COPY • Copies data to USB flash

drive.

• Clears data from station

memory (when used with CAL

button)

12 • Control Panel, Status LEDs & USB Port

• Indicates amount of

calibration station memory

used

• Indicates status of copying

function

• Indicates the result of a

copy operation

Page 13

Status LEDs

Two status LEDs are located on the top front of the calibration stations.

The CAL. status LED is on the left side of the station and indicates the

status and result of a bump test or calibration. The CHARGE status LED

is on the right side of the station and functio ns as a pi lot LED, a system

failure LED, and a charge indication LED.

USB Port

A USB port is located on the fro nt right of the calibr ation statio n below the

COPY button. The port can be used to save calibration and bump test

data to a USB flash drive.

NOTE: The SM-2001U & SM2003U do not support connection

of a computer to the USB port, only a USB flash drive.

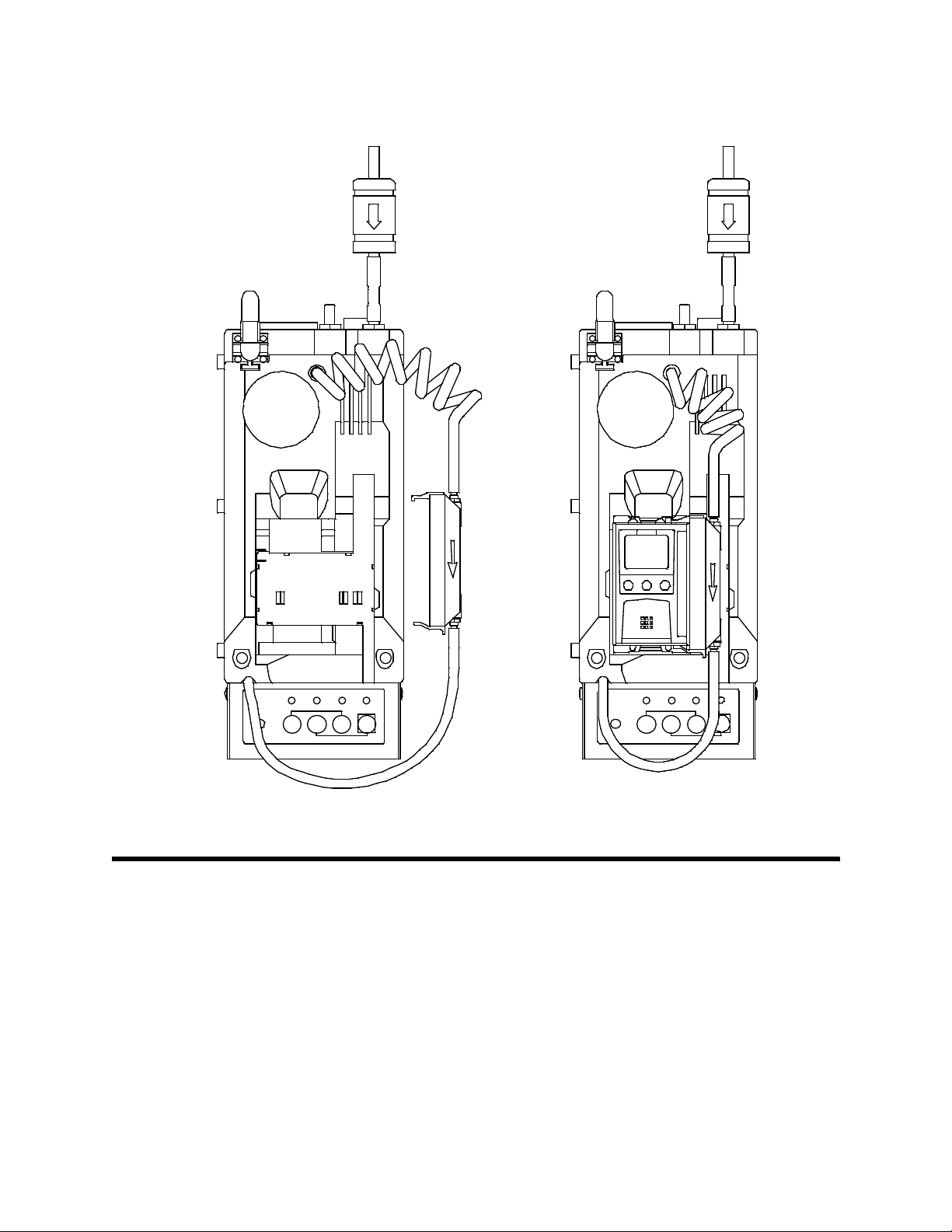

SM-2001U Instrument Connections

The GX-2001 fits into the SM-2001U as shown in Figure 3 below. The

calibration station includes a sn ap-on sample adapter for the GX-2001.

The exhaust port of the adapter is connected to a port on the front left of

the module by a short tube and the adapter’s inlet port is connected to a

port on the top rear of the module by a coiled tube. The sample adapter

snaps onto the sensor side of the GX-2001 before the GX-2001 is

installed into the calibration stat ion.

NOTE: The SM-2001U is shipped with the sample adapter

disassembled from the calibration station. See “Parts

Assembly” on page 16 for installation instructions.

SM-2001U Instrument Connections • 1 3

Page 14

O2

Flow

HC

CO

H2S

SM-2001U

MODE

OFF

COPYBUMP CAL.

VOL.

CLEAR

RKI

GX-2001

MODE DISP AIR

POWER

SM-2001U

MODE

BUMP CAL. OPY

2

O

O2

Flow

HC

HC

CO

CO

H2S

H2S

OFF

VOL.

CLEAR

Figure 3: SM-2001U Instrument Connections

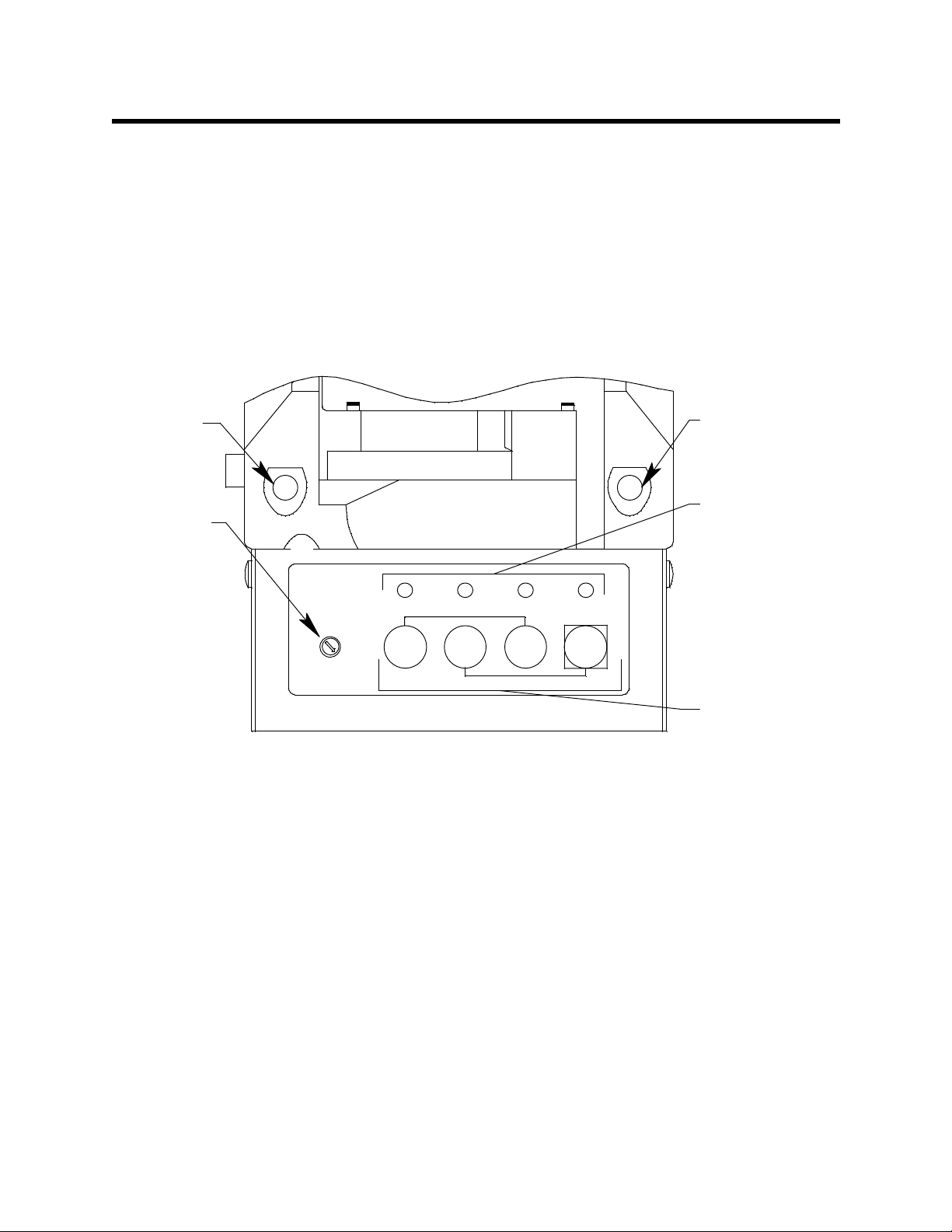

SM-2003U Instrument Connections

The GX-2003 fits into the SM-2003U as shown in Figure 4 below. A

coiled black tube with a plastic push-on fitting resides in a recess in the

left rear cor ner of the top of the module. The coiled tube ro utes gas to the

GX-2003 and extends to connect to the GX-2003’s inlet fitting. A straight

green tube comes out of the top of the module to the right of the coiled

tube and also has a plastic push-on fitting on its end. The fitting on this

tube is pushed onto the GX-2003 exhaust fitting and routes gas away

from the GX-2003.

14 • SM-2003U Instrument Connections

Page 15

NOTE: The SM-2003U is shipped with the green tube

disassembled from the calibration station. See “Parts

Assembly” on page 16 for assembly instructions.

AIR

DISPLAY

POWER

(ADJ)

ENTER

(SHIFT)

SM-20 03U

SM-20 03U

BUMP CAL.

OFF

VOL.2COPY

CLEAR

MO DE

0

1

9

8

7

3

6

4

5

Figure 4: SM-2003U Instrument Connections

RESET

SILENCE

SM-2003U Instrument Connections • 1 5

Page 16

Chapter 3: Hardware Setup and Software Installation

Overview

There are two parts t o preparing the SM-2001U and SM-2003U for use:

hardware setup and software installation. This chapter describes how to

setup the SM-2001U and SM-2003U hardware. It also describes how to

install the Single Module Data Viewer Software on a Windows based

personal computer.

Hardware Setup

The hardware setup consists of some parts assembly, connecting

calibration gas, and setting the MODE switch to the position that

corresponds the desired bump test parameter settings.

Parts Assembly

Some assembly is required before the SM-2001U or SM-2003U can be

used. Perform the following assembly before attempting to use a

calibration station.

1. If you have an SM-2001U, install the instrument sample adapter.

Push the coiled end of the tubing onto the onto the recessed stub

located at the rear top of t he calibration st atio n and the straight end

of the tubing onto the recessed stub located on the upper left front

of the calibration station.

If you have an SM-2003U, install the green tube with the plastic

push-on fitting. Push the open end of the tube onto the recessed

stub located on the top rear of the calibration station.

2. Install the air filter. Push the open end of the tube on the filter onto

the AIR fitting on the back of the calibration station.

3. If it is not already installed, install the exhaust plug on the bottom

exhaust port. It is a black rubber plug that fits over the port.

4. Plug the power cord into the power cord connector on the back of

the calibration station.

16 • Overview

Page 17

Connecting an Exhaust Tube

The top exhaust fitting port is used to route exhaust away from the

calibration station. Install the 5/16” ID flexible tube that is included with

the calibration stati on on the top exhaust fit ting port and route the tube to

an area where the calibration gas can be safely exhausted.

CAUTION: The maximum recommended length for the

exhaust tube is 10 feet. Do not use more than 10

feet of tubing or tubi ng with an ID of less than 5/1 6”

for the exhaust tube or the bump test and

calibration accuracy will be adversely affected. The

tube that is shipped with the Docking station has an

ID of 5/16” and is 10 feet long.

Connecting Calibration Gas

The CAL. GAS fitting on the back of the calibration station is designed to

be used with a calibration gas cylinder that is fitted with a demand flow

regulator. The AIR fitting may be used with a demand flow regulator and

a cylinder of zero emissions air, but this is not normally necessary since

the calibration station will generally be in a fresh air area.

The type of calibration gas cylinder used depends on the gas sensors

installed in the GX-2001 or GX-2003 being used with the calibration

station. Typically a 4-gas mix will be used if the instrument being used

with the calibration station is a 4-gas unit. If a GX-2003 t hat is a 5-sensor

unit is being used, a 100% volume methane cylinder will also be needed.

Use Table 3 below as a guide in determining which and how many

calibration gas cylinders are appropriate for your syste m.

Table 3: Recommended Gas Cylinders

Recommended Calibration Gas

Typical Instrument Types

Cylinder(s)

GX-2001

4-gas mix with CH4/Oxy/H2S/CO

LEL/Oxy/H2S/CO

GX-2001

LEL/Oxy/CO

3-gas mix with CH4/Oxy/CO

Hardware Setup • 1 7

Page 18

Table 3: Recommended Gas Cylinders

Typical Instrument Types

GX-2001

LEL/Oxy/H2S

GX-2003

GX-2003: LEL/Oxy H2S/CO

GX-2003

%V ol CH4/LEL CH4/Oxy/H2S/

CO

GX-2003

%V ol CH4/LEL CH4/Oxy/CO

GX-2003

LEL/Oxy/CO

GX-2003

LEL/Oxy/H2S

Recommended Calibration Gas

Cylinder(s)

4-gas mix with CH4/Oxy/H2S/CO

4-gas mix with CH4/Oxy/H2S/CO

• 4-gas mix with CH4/Oxy/H2 S/CO

• 100% Volume CH4

• 3-gas mix with CH4/Oxy/CO

• 100% Volume CH4

3-gas mix with CH4/Oxy/CO

4-gas mix with CH4/Oxy/H2S/CO

To connect calibration gas to the SM-2001U or SM-2003U do the

following:

1. If the area around the calibration station is not considered a fresh

air area (an area free of combusti ble and toxic gases and of normal

oxygen content, 20.9%) install a t ube not longer than 10 feet on t he

filter attached to the AIR fitting on the back of the docking station

and route it to a fresh air area or connect a cylinder of zero air to

the fitting using a demand flow regulator.

2. Install the demand flow regulator on the calibration gas cylinder.

3. Connect the demand flow regulator to the CAL. GAS port using

sample tubing.

Setting the MODE Switch

The MODE switch can be used to lengthen or short en the bump test time

by shortening or lengthening the calibration gas application time. It can

also be used to set the calibration station to aut omatically perform a

calibration if the instrument fails a bump test. Since shortening the time

18 • Hardware Setup

Page 19

that calibration gas is applied during a bump test, the shorter the bump

test time, the larger bump test tolerance used to determine whether a

bump test failed or passed. The MODE switch sets the value of the

following bump test parameters:

• Air Purge Time

This is the length of time that a calibration station will draw air

through the AIR fitting on the back of t he station to an instrument

installed in it. Air is d rawn during a bump te st or calibration bef ore an

air adjust operation and to purge calibration gas from the system

after calibratio n ga s has b een drawn thr ough th e CAL GA S fi tting on

the back of the station. This parameter is fixed at 30 seconds for all

switch settings

• Gas Exposure Time

This is the length of time that a calibration station will draw

calibration gas through the CAL GAS fitt ing on the back of the station

during a bump test or calibration.

• Bump Te st Tol e r a nce

The bump test tolerance determines how close the instrument gas

reading must be to the calibration gas concentration for each

channel during a bump test in order to pass the bump test. It is

defined as a percentage of the calibration gas concentration.The

amount that the instrument gas reading differs from the calibration

gas concentration must be equal to or less than this percentage of

the calibration gas concentration. For example, if the toler ance is set

to 50%, and the %LEL calibration gas concentration is 50% LEL,

then the bump test gas reading for the LEL channel on the

instrument must be 50 %LEL ± 25 %LEL.

• Automatic Calibration

This parameter is set to on or off. If it is set to on, then the calibrat ion

station will automatically perform a calibration if a bump test fails.

Hardware Setup • 1 9

Page 20

The parameter settings for each MODE switch position are shown in

Table 4 below.

Table 4: MODE Switch Parameter Settings

Switch

Position

0

1

2 ± 30%

Air Purge

Time

Gas Exposure

Time

Tolerance Auto. Cal.

30 seconds ± 50%

± 20%

45 Seconds

Off

3 ± 50%

30

4 90 seconds ± 10%

seconds

5 30 seconds ± 50%

6

7 ± 30%

45 seconds

± 20%

On

8 90 seconds ± 10%

9 60 seconds ± 20%

Set the MODE switch to the position that corresponds to the desired

parameter settings using a small flat blade screwdriver.

20 • Hardware Setup

Page 21

Installing the Single Module Data

Viewer Software

1. Launch Windows®.

2. Exit from all applications and open windows.

3. Insert the Single Module Data Viewer Software Installation CD into

your computer’s CD-ROM drive.

4. The Single Module Data Viewer InstallShield Wizard comes up to

guide you through installation. Click Next to pr oceed to the License

Agreement window.

5. Read the license agreement and click the agreement acceptance

selection box, then click Next to proceed to the Customer

Information window.

6. Enter a user name and organization and select if you want to inst all

the program for all users on the computer or just for your user

account, then click Next to proceed to the Destination Folder

window.

7. The default installation folder (C:\Program Files\Single Module

Data Viewer\) is displayed. If you want to install the software in the

default folder continue with step 8. If you want to install t he software

in a different location, click Change and choose a new installation

folder now and then continue with step 8.

8. Click Next to proceed to the Ready to Insta ll the Program window.

9. Review the installation settings. If they are Ok, click Install and the

installation process will begin. If you want to change installation

settings, click Back and change them to the desired settings.

10. During software installation, the installation program may find

newer versions of Windows files on your computer than those in

the Installation CD. If this happens, t he insta llation soft ware will ask

you if you want keep these newer files. Click Yes to do so.

11. Follow the on-screen instructions to complete software installation.

Installing the Single Module Data Viewer Software • 21

Page 22

Chapter 4: Using the SM-2001U & SM-2003U

Overview

The SM-2001U and SM-2003U calibration stations are capable of

performing bump tests and calibrations on instruments and charging

rechargeable battery packs in instruments. This chapter describes

procedures for using the calibration stations to bump test, calibrate, and

recharge GX-2001 and GX-2003 instruments. It also describes the

information that is saved in a calibration st ation’s memory and how to

save that information to a USB flash drive.

Bump Testing Instruments

When a bump test is performed, the calibration st ation performs an air

adjust operation on an instrument and then applies calibration gas to th e

instrument. The calibration station analyzes the response results based

on criteria defined by the MODE switch position and determines if the

instrument passed the bump test. The criteria set by the MODE switch is

defined in Table 4 on page 20.

To perform a bump test on an instrument:

1. Ver i fy that the appropriate calibration gas cylinder is connected to

the CAL. GAS fitting on the back of the calibration station.

2. Ver i fy that the MODE switch is in the position that defines the

desired bump test pass criteria. See Table 4 on page 20.

3. If the calibration station is off, turn it on using the power switch on

the back of the station. The CHARGE st atus LED will begin to blink

green.

4. Put the instrument to be bump tested into the calibration station. A

GX-2001 is placed into an SM-2001U and a GX-2003 is placed into

an SM-2003U.

• For a GX-2001, attach th e flow adapter cup to the sensor side of

the instrument before inserting it into the SM-2001U.

• For the GX-2003, place the instrument into the SM-2003U,

connect the plastic fitting on the end of the coiled black tube to

22 • Overview

Page 23

the inlet fitting, and then connect the pl astic fitting on the end of

the straight green tube to the exhaust fitt ing.

If you take more than a few seconds before continuing, the

CHARGE LED may begin blinking yellow indicating that the

calibration station is charging the battery pack in the instrument if

the instrument has a battery pack whose charge is low enough.

5. Turn on the instrument.

• A GX-2003 will begin its normal startup sequence and after a

few seconds, the pump will turn of f and the display will indicate it

is ready to communicate with the calibration station:

PC

TRANSMIT

STAND BY

OK

21:09

If LB Mode is activated on a GX-2003, press the POWER

ENTER button as soon as the unit turns on to avoid waiting 20

seconds for the unit to time out of the Mode Select screen to

begin its startu p sequence.

• A GX-2001 will begin its normal startup sequence and after a

second or two the display will indicate the following:

Conn

6. The CHARGE status LED will start blinking green and the

calibration station will take several seconds to connect to the

instrument. During this time, the CAL. status LED will blink yellow.

7. When the connection is complete, the CAL. status LED will become

solid yellow indicating that you can continue with the next step.

8. Press and hold the BUMP button for at least one second, then

release it. The bump test begins. During the bump test, the BUMP

control LED will flash green and the CAL. status LED will flash

yellow indicating that a bump test is in progress. The calibration

station will perform the following functions:

Bump Testing Instruments • 23

Page 24

• Apply fresh air to the instrument for 30 seconds.

• Perform a zero operation on the instrument.

NOTE: If one or more of the sensors fails the zero operation,

then the calibration station will abort the bump test and

will not apply calibration gas. If this happens, the CAL.

status LED will blink red indicating a failure and the

BUMP control LED will stop blinking and be on steadily

green.

• Apply calibration gas to the instrument for the time defined by

the MODE Switch setting.

• Purge the system with fresh air for 30 seconds.

9. After the system is purged, the BUMP control LED will stop blinking

and be on steadily green and the CAL. status LED will be on

steadily green if the bump test passed or steadily red if the bump

test failed.

10. If the bump test failed and the MODE switch is set to position 5, 6,

7, 8, or 9, the calibration station will calibrate the instrument.

11. The results of the bump test will be stored in the calibration

station’s memory and will be available to cop y to a USB flash drive.

See “Copying Calibration and Bump Test Records to a USB Flash

Drive” on page 34 for instructions to copy the saved bump test and

calibration records to a USB flash drive.

12. If you want to perform a bump test on a GX-2003 with 100%

volume methane, See “Bump Testing and Calibrating a GX-2003

with 100% Volume Methane” on page 28 for instructions.

13. Turn off the instrument by pressing and holding the BUMP and

VOL. control buttons simultaneously for at least one second and

then releasing them. If no control buttons are pressed for 10

minutes, the calibration station will automatically turn off the

instrument.

24 • Bump Testing Instruments

Page 25

CAUTION: When using the GX-2001 with the SM-2001U or the

GX-2003 with the SM-2003U, do not turn off the

instrument using the instrument power switch. Use

the BUMP and VOL. control buttons on the

calibration station to turn off the instrument.

14. Remove the instrument from the calibrat ion station.

Calibrating Instruments

The SM-2001U and SM-2003U calibration stations are capable of

performing a calibration on an instrument that is connected to it. When a

calibration is performed, the calibration station performs an air adjust

operation on an instrument and then applies calibration gas to the

instrument. The calibration station analyzes the calibration results and

determines if the instrument passed the calibration.

To perform a calibration on an instrument:

1. Ver i fy that the appropriate calibration gas cylinder is connected to

the CAL. GAS fitting on the back of the calibration station.

2. If the calibration station is off, turn it on using the power switch on

the back of the station. The CHARGE st atus LED will begin to blink

green.

3. Put the instrument to be calibrated into the calibration station. A

GX-2001 is placed into an SM-2001U and a GX-2003 is placed into

an SM-2003U.

• For a GX-2001, attach th e flow adapter cup to the sensor side of

the instrument before inserting it into the SM-2001U.

• For the GX-2003, place the instrument into the SM-2003U,

connect the plastic fitting on the end of the coiled black tube to

the inlet fitting, and then connect the pl astic fitting on the end of

the straight green tube to the exhaust fitt ing.

If you take more than a few seconds before continuing, the

CHARGE LED may begin blinking yellow indicating that the

calibration station is charging the battery pack in the instrument if

the instrument has a battery pack whose charge is low enough.

Calibrating Instruments • 25

Page 26

4. Turn on the instrument.

• A GX-2003 will begin its normal startup sequence and after a

few seconds, the pump will turn of f and the display will indicate it

is ready to communicate with the calibration station:

PC

TRANSMIT

STAND BY

OK

21:09

If LB Mode is activated on a GX-2003, press the POWER

ENTER button as soon as the unit turns on to avoid waiting 20

seconds for the unit to time out of the Mode Select screen to

begin its startu p sequence.

• A GX-2001 will begin its normal startup sequence and after a

second or two the display will indicate the following:

Conn

5. The CHARGE status LED will start blinking green and the

calibration station will take several seconds to connect to the

instrument. During this time, the CAL. status LED will blink yellow.

6. When the connection is complete, the CAL. status LED will become

solid yellow indicating that you can continue with the next step.

7. Press and hold the CAL. button for at least one second, then

release it. The calibration begins. During the calibration, the CAL.

control LED will flash green and the CAL. status LED will flash

yellow indicating that a calibration is in progress. The ca libration

station will perform the following functions:

• Apply fresh air to the instrument for 30 seconds.

• Perform a zero operation on the instrument.

26 • Calibrating Instruments

Page 27

NOTE: If one or more of the sensors fails the zero operation,

then the calibration station will abort the calibration and

will not apply calibration gas. If this happens, the CAL.

status LED will blink red indicating a failure and the

CAL. control LED will stop blinking and be on steadily

green.

• Apply calibration gas to the instrument for 90 seconds.

• Purge the system with fresh air for 30 seconds.

8. After the system is purged, the CAL. control LED will stop blinking

and be on steadily green and the CAL. status LED will be on

steadily green if the calibration passed or steadily red if the

calibration failed.

9. The results of the calibration will be stored in the calibration

station’s memory and will be available to cop y to a USB flash drive.

See “Copying Calibration and Bump Test Records to a USB Flash

Drive” on page 34 for instructions to copy the saved bump test and

calibration data to a USB flash drive.

10. If you want to perform a calibration on a GX-2003 with 100%

volume methane, see “Bump Testing and Calibrating a GX-2003

with 100% Volume Methane” on page 28 for instructions.

11. Turn off the instrument by pressing and holding the BUMP and

VOL. control buttons simultaneously for at least one second and

then releasing them. If no control buttons are pressed for 10

minutes, the calibration station will automatically turn off the

instrument.

CAUTION: When using the GX-2001 with the SM-2001U or the

GX-2003 with the SM-2003U, do not turn off the

instrument using the instrument power switch. Use

the BUMP and VOL. control buttons on the

calibration station to turn off the instrument.

12. Remove the instrument from the calibrat ion station.

Calibrating Instruments • 27

Page 28

Bump Testing and Calibrating a GX-2003

with 100% Volume Methane

The GX-2003 can have a %volume methane detector installed. This

detector cannot be bump tested or calibrated using the typical gas mix

that is used for the other detectors. To accommodate this special need,

the SM-2003U includes the VOL. control button. Thi s button activates the

%volume gas function. When this function is active, the SM-2003U will

bump test or calibrate only the %volume detector in a GX-2003 when a

bump test or calibration is performed. If an instrument does not have an

active %volume detector, then the VOL. button does not function.

NOTE: The SM-2001U also includes a VOL. control button, b ut

it does not function on an SM-2001U since the GX-2001

does not have %volume methane capability.

To bump test or calibrate the %volume detector in a GX-2003, do the

following:

NOTE: If you have performed a bump test or calibration on a

GX-2003 and then wish to perform a bump test or

calibration on the %volume detector, begin with

instruction 8 below.

WARNING: Use only 100% volume methane when bump

testing or calibrating a GX-2003 %volume

detector. Use of a different concentration will

result in an inaccurate bump test or calibration.

1. Ver ify that the 100% volume methane gas cylinder is connected to

the CAL. GAS fitting on the back of the SM-2003U.

2. If performing a bump test, verify that the MODE rotary switch is in

the position that defines the desired bump test pass criteria. See

Table 4 on page 20.

If performing a calibration, skip this step

3. If the calibration station is off, turn it on using the power switch on

28 • Bump Testing and Calibrating a GX-2003 with 100% Volume Methane

Page 29

the back of the station. The CHARGE st atus LED will begin to blink

green.

4. Put the GX-2003 to be bump tested or calibrated into the SM2003U, connect the plastic fitting on the end of the coiled black

tube to the inlet fitting, and then connect the plastic fitting on the

end of the straight green tube to the exhaust fitting.

If you take more than a few seconds before continuing, the

CHARGE LED may begin blinking yellow indicating that the

calibration station is charging the battery pack in the instrument if

the instrument has a battery pack whose charge is low enough.

5. Turn on the GX-2003. It will begin i ts normal startup sequence and

after a few seconds, the pump will turn off and the display will

indicate it is ready to communicate with the SM-2003U:

PC

TRANSMIT

STAND BY

OK

21:09

If LB Mode is activated on a GX-2003, press the POWER ENTER

button as soon as the unit turns on to avoid waiting 20 seconds for

the unit to time out of the Mode Select Screen to begin its startup

sequence.

6. The CHARGE status LED will start blinking green and the

calibration station will take several seconds to connect to the

instrument. During this time, the CAL. status LED will blink yellow.

7. When the connection is complete, the CAL. status LED will become

solid yellow indicating that you can continue with the next step.

8. Press and hold the VOL. button until the VOL. LED turns on, then

release it. It will remain on as long as the %volume gas function is

active.

9. Press and hold the BUMP or CAL. button for at least one second,

then release it. The bump test or calibration begins. During the

bump test, the BUMP or CAL. control LED will flash green and the

CAL. status LED will flash yellow indicating that a bump test or

calibration is in progress. The calibration station will perform the

Bump Testing and Calibrating a GX-2003 with 100% Volume Methane • 29

Page 30

following functions:

• It will apply fresh air to the instrument for 30 seconds.

• It will perform a zero operation on the GX-2003.

NOTE: If the %volume methane detector fails the zero

operation, then the calibration station will abort the

bump test or calibration and will not apply calibration

gas. If this happens, the CAL. status LED will blink red

indicating a failure and the CAL. control LED will stop

blinking and be on steadily green.

• It will apply calibration gas to the GX-2003 for the time defined

by the MODE Switch setting if a bump test is being pe rformed or

for 90 seconds if a calibration is being performed.

• Purge the system with fresh air for 30 seconds.

10. After the system is purged, the BUMP or CAL. control LED will stop

blinking and be on steadily green and the CAL. status LED will be

on steadily green if the bump test or calibration passed or steadily

red if the bump test or calibration failed.

11. if a bump test failed and the MODE switch was set to 5, 6, 7, 8, or

9, the calibration will calibrate the GX-2003.

12. The results of the bump test or calib ration will be stored in the

calibration station’ s memory and will be available to copy to a USB

flash drive. See See “Copying Calibration and Bump Test Records

to a USB Flash Drive” on page 34 for instructions to copy the saved

bump test and calibration data to a USB flash drive.

13. If you wish to disable the %volume calibration function, press and

hold the VOL. button until the VOL. LED turns off.

14. Turn off the instrument by pressing and holding the BUMP and

VOL. control buttons simultaneously for at least one second and

then releasing them. If no control buttons are pressed for 10

minutes, the calibration station will automatically turn off the

instrument.

30 • Bump Testing and Calibrating a GX-2003 with 100% Volume Methane

Page 31

CAUTION: When using the GX-2001 with the SM-2001U or the

GX-2003 with the SM-2003U, do not turn off the

instrument using the instrument power switch. Use

the BUMP and VOL. control buttons on the

calibration station to turn off the instrument.

15. Remove the instrument from the SM-2003U.

Charging an Instrument in a

Calibration Station

The SM-2001U and SM-2003U calibration stations can be used to

charge the rechargeable battery pack in a GX-2001 or GX-2003. A

calibration station will not recharge the batteries in an alkaline version of

the GX-2003. To maximize the battery pack run time and the battery p ack

life, make sure the battery pack’s charge is as low as possible before

recharging it.

To recharge the battery pack in an instrument af ter performing a bump

test or calibration:

1. Perform a bump test or calibration on an instrument as described

in “Bump Testing Instruments” on page 22 or “Calibrating

Instruments” on page 25 or “Bump Testing and Calibrating a GX2003 with 100% Volume Methane” on page 28.

2. After the bump test or calibration has been completed, turn off the

instrument by pressing and holding the BUMP and VOL. control

buttons simultaneously for at least one second and then releasing

them. If no control buttons are pressed for 10 minutes, the

calibration station will automatically turn off the instrument.

3. After a few seconds, the CHARGE status LED on the right front of

the calibration station will start blinking yellow. The CAL. status

LED on the front left of the calibration station will continue to be

either green or red depending on the result of the bump test or

calibration.

Charging an Instrument in a Calibration Station • 31

Page 32

4. If the battery pack is fully charged, then the CHARGE status LED

will turn solid green in a few minutes.

If the battery pack is drained enough for the calibration station to

charge it, the CHARGE status LED will continue to blink yellow

while charging is taking place. Both the GX-2001 and GX-2003 will

take approximately 90 minutes to fully charge.

5. When the charge is complete, the CHARGE status LED will turn

solid green.

To recharge the batteries in an instrument without performing any other

operations:

1. Place the instrument in the calibration station. If no bump test or

calibration will be performed , it is not necessary to make any tubing

connections to the instrument.

2. Turn on the calibration st ation using the power switch on the back.

3. The CHARGE st atus LED on the right front of the calibration st ation

will begin to blink green for a few seconds, then bli nk yellow.

4. If the battery pack is fully charged, then the blinking yellow LED will

turn solid green in a few minutes.

If the battery pack is drained enough for t he mo dule to charge it,

the CHARGE status LED will continue to blink yellow while

charging is taking place. Both the GX-2001 and GX-2003 will take

approximately 90 minutes to fully charge.

5. When the charge is complete, the CHARGE status LED will turn

solid green.

32 • Charging an Instrument in a Calibration Station

Page 33

Calibration and Bump Test Records

The SM-2001U and SM-2003U save a record of each bump test and

calibration performed. The calibration stations are capable of saving up

to 200 such records. When a calibration station’s memory becomes full,

the oldest record is overwritten when a new record is saved. These

saved records can be saved to a USB flash drive using the USB port.

Available Memory in the Calibration Station

The COPY function LED above the copy button indicates how much of

the calibration station’s memory has been used. The table below

describes the various indications.

Table 5: COPY LED Indications

COPY LED Indication Memory Used

Off None. No records are saved

Solid Green Less than 80% of the calibrat ion sta-

tion’s memory has been used.

Solid Yellow More than 80% of the calibration sta-

tion’s memory has been used.

Solid Red The calibration station’s memory is

full. A newly saved record will overwrite the oldest one.

The calibration station’s memory can be cleared by simultaneously

pressing and holding the CAL. and COPY control buttons for five

seconds.

Calibration and Bump Test Records • 3 3

Page 34

Copying Calibration and Bump Test Records to a USB

Flash Drive

The calibration station will only perform a copy operation if there is at

least one record saved in it’s memory. If there are no records saved in the

station’ s memory, the COPY LED will be off and the COPY button will not

function. Do the following to save calibrati on and bump test records in the

calibration station’s memory to a USB flash drive.

1. If the calibration station is off, turn it on using the power switch on

the back of the station.

NOTE: The USB port on the front of the calibration station

cannot be used to connect the SM-2001U or the SM2003U to a computer, only to save calibration and bump

test records to a USB flash drive.

2. Install a USB flash drive into the USB port on the front of the

calibration station. The calibration st ation will t ake a few seconds to

determine how much memory is available in the flash drive.

• If the flash drive’s available memory it is not enough for the

contents of the calibration station’s memory, the COPY LED will

alternate between green and red. Enough memory will have to

be cleared in the flash drive for the records in the calibration

station’s memory.

• If there is enough available memory in the flash drive for the

contents of the calibration station’s memory, the COPY LED will

begin flashing in the same color that it was before installing the

flash drive.

3. Press and release the COPY button. The COPY LED will become

solid red while the records in the calibration station’s memory are

copied to the flash drive.

34 • Calibration and Bump Test Records

Page 35

4. Wait until the flash drive’s LED stops blinking, then remove the

flash drive from the USB port.

NOTE: If you pull out the flash drive while it’s LED is still

blinking, the file saved in the flash drive with the

calibration an d bu m p test records may be incomplete.

5. If the flash drive has not already been used with a calibration

station, a folder named DAT will be created on the flash drive and a

file with all the saved calibration and bump test records will be

saved to this folder.

If the flash drive has b een used before wit h a calibration st ation, the

file will be saved to the existing DAT folder.

6. The files on the flash drive can now be either transferred to a

computer or kept on the flash drive for use with the Single Module

Data Viewer Software. See the next section, "Bump Test and

Calibration Record Files", for a discussion of these files and how t o

use them.

Bump Test and Calibration Record Files

Each time a copy function is performed, a file is sa ved to the fl ash drive in

the DAT folder. The f ile name will begin with either “SM-200 1SAMPLE” or

“SM-2003SAMPLE” depending on whether the records came from an

SM-2001U or SM-2003U and the remainder of the file name will depend

on the date of the most recent bump test or calibration performed on the

calibration station. So i t is possible to have multiple files in th e DAT folder

from the SM-2001U or SM-2003U.

The files that a calibration station saves to a USB flash drive are

structured so that they can be impor ted into a da t abase cont rolled by t he

Single Module Data Viewer software. See “Importing Files Into the

Database” on page 39 for instructions to add files to the database.

Calibration and Bump Test Records • 3 5

Page 36

Bump Testing or Calibrating and Saving Files To a Flash

Drive Multiple Times In One Day

The SM-2001U and SM-2003U assign file names to calibration and

bump test record files based on the day of the most recent calibration or

bump test record saved in the calibration station’s memory. If a copy

operation is performed, additional bump tests or calibrations are

performed, and another copy operatio n is performed with the same flash

drive all on the same day, the existing file on the flash drive from the first

copy operation will be overwritten by the file from the second copy

operation because it’s name will be the same as the new file. In this case,

no information is lost since the second file saved to the flash drive

includes all the records that were in the first file.

However, if a copy operation is performed, the calibration station

memory is cleared, addit ional bump t ests or calibrati ons are performed,

and another copy operation is per formed with the same flash drive all on

the same day, this will result in the information in the file from the first

copy operation being lost. This is because the fi le saved to the f lash drive

in the second copy operation only includes records since the memory

was cleared and when it overwrites the file from the first copy operation,

all the information in the first file is lost.

CAUTION: If copying a calibration station’s memory to a flash

drive multiple times during the same day, transfer

the calibration/bump test record files from the flash

drive to a computer hard drive or some other

memory device if the calibration station memory is

cleared to avoid possible loss of informati on during

subsequent copy operations.

36 • Calibration and Bump Test Records

Page 37

Chapter 5: Single Module Data Viewer Software

Overview

The Single Module Data Viewer Software is used to view, organize, and

print bump test and calibration records that were created by the SM2001U and SM-2003U. It can also be used to export these records from

it’s database for use in other programs. This chapter describes how to

use the Single Module Data Vie we r Software.

Launching the Single Module Data

Viewer Software

1. Click Start on the Windows® Icon Tray, then select Programs/

Single Module Data Viewer.

NOTE: If you are starting the software for the first time, a

message window appears informing you that a

database has been created. If this occurs, click OK.

2. The Single Module Data Viewer program is launch ed and the data

viewing window appears.

Figure 5: Single Module Data Viewer Window

Overview • 3 7

Page 38

NOTE: When you start the Single Module Dat a V iewer program

Control Buttons

for the first time, there will be no data in the left part of

the data viewing window since no data has been

imported into the database yet.

Using the Single Module Data Viewer Software

Data Viewing Window

Data Folders

Viewed in Thi s

Area

All of the operations that can be performed in the Single Module Dat a

Viewer Program can be executed from the data viewing window. There

are function buttons along the top of the window and one in the lower

right that initiate the vari ous operations. The upper lef t side of the window

displays the contents of the database. The lower left corner of the

window has selection boxes that allow you to organize the data. The

Data Folders and Files

Figure 6: Data Viewing Window

Viewed in This Area

File Content Details

Viewed in This Area

38 • Using the Single Module Data Viewer Software

Page 39

upper right side of the window shows t he co nte nt s of t he ite m selecte d in

the upper left side, and the lower right side indi cates the contents of the

item selected in the area above it. In the example above, the data is

organized by date.

You can do the following in the data viewing window:

• Import files into the database that were created by an SM-2001U or

SM-2003U

• View the bump test and calibration data saved in the database.

• Delete data.

• Print bump test or calibration results (pass or fail indication only).

• Copy bump test or calibration records to the clipboard or to a

particular location on your computer or network.

• Print a bump test or calibrati on report that includes the result s and all

gas readings.

Importing Files Into the Database

The files generated by the SM-2001U and SM-2003U are structured to

be imported into the Single Module Data Viewer Software database. To

import data files into the database, do the following:

1. While in the Data Viewing Window, click the Import button. The

Import Window will appear.

Figure 7: Import Window

Using the Single Module Data Viewer Software • 39

Page 40

2. Navigate to the location of the files that you want to import into the

database and select them.

3. Click the Apply button. A window will appear for a few seconds

indicating that the file or files are being imported.

4. The files are now added to the database.

Viewing the Data

When viewing the data, it can be organized in two ways:

1. Base View Format

In base view format, neither of the Serial No, Station ID, or User ID

selection boxes in the lower left of the window are select ed and th e

Base box appears next to these selection boxes. The data can be

organized by either the data type (bump test and calibration data)

or by the month and year. The example below shows the data

organized by type.

Figure 8: Data in Base Viewing Format

40 • Using the Single Module Data Viewer Software

Page 41

2. ID View Format

In ID view format, the data can be organized by one or more of the

following items depending on which selection box or boxes in the

lower left corner of the data viewing window are selected:

• Serial Number

• Station ID

• User ID

If any of these boxes is selected, the Base box disappears. The

example below shows the data organized by serial number.

Figure 9: Data in ID Viewing Format

The data is organized in folders. A data folder is represented as an icon

in the left side of the data viewing window. If it there is a (+) or a (-)

symbol to its left, then it contains another folder. There are various folder

icons which are used depending on how the data is organized.

Using the Single Module Data Viewer Software • 41

Page 42

Once you have selected how you want to organize the data:

1. Click the expanded view symbol (+) next to a folder in the left side

of the data viewing window or double click the folder to view the

contents below it. Single click on the folder to view the contents in

the right side of the wi ndow. If a folder is expanded and you want to

close it, click the (-) symbol next to the folder or double click it.

2. When an item no longer has a (+) or (-) symbol next to it, single

click it and the contents of the item will be shown on the right side

of the window.

3. If you are viewing data in base view format with the dat a or ganized

by type, expand the data folder you wish to view, bump test or

calibration data. Folders organized by year/month will appear

below the folder. Click on the folder whose contents you wish to

see. The bump test or calibration files in the folder will be shown in

the upper right side of the data view window.

Figure 10: Calibration/Bump Test Files in Base View Format

If you organize the data by date, then folders organized by year/

Using the Single Module Data Viewer Software • 42

Page 43

month appear in the left side of the window. Expand the folder you

want to see and click on the calibration or bump test folder. The

calibration or bump test files will appear in the upper right side of

the window.

If you are viewing data in ID view format, expand the folders in the

left side of the window until the bump test or calibration folder you

wish to view is visible. Expand the folder. Folders organized by

year/month will be listed below the calibration or bump test folder.

Click the folder whose contents you want to view and the

calibration or bump test files in it will be shown in the upper right

side of the data view window. The example below is organized by

serial number.

Figure 11: Calibration/Bump Test Files in ID View Format

4. Files that record a failed calibration or bump test on all channels

are highlighted in red. Files that record a calibration or bump test

where not all channels passed are highlighted in oran ge.

5. To view the file contents, click on the file in the upper right part of

Using the Single Module Data Viewer Software • 43

Page 44

the data view window t hat you wish t o view. The contents in the file

will appear in the lower right part of the window. The contents

include the instrument’s serial number, station ID, user ID, bump

test or calibration time, test gas, and gas readings during the

operation.

6. To print the files as they appear in the upper right part of the data

view window, click the print button in the upper left corner of the

window. A dialog box will appear confirming if you want to print.

Click OK.

7. To print the contents of all files in the upper right window, click the

Bump test & Calibration Report button above the files. A dialog

box will appear showing the selected printer and confirming if you

want to print. Verify that the selected printer is correct and click OK.

8. To print the contents of one of the files in the upper right part of the

data view window, click on one of the files to select it and then click

the print button that appears above the file det ails in the lower right.

A dialog box will appear showing the selected printer and

confirming if you want to print. Verify that the selected printer is

correct and click OK.

9. To save files as they appear in the upper right p a rt of the dat a view

window , cli ck the Save To File button to the right of the print butt on

in the upper left corner of the window. The Save T o File button has

a floppy disk icon in it. A “Save As” dial og box will a ppear for you to

specify the filename, file location, and f ile type. Select the T ext files

(*.csv) choice to save t he information as a comma sep ar ated value

file that may be opened with a spreadsheet program such as

Microsoft Excel.

10. To save files to the clipboard as they appear in the upper right part

of the data view window, click the Copy To Clipboard button. The

Copy T o Clipboard button has a clipboard icon in it. The file will be

saved to the clipboard. It can then be pasted int o a document by

using the Paste command in an application.

Deleting Data

You can delete an instrument, bump test data, or calibration dat a in the

data view window. The delete function is password protected to avoid

Using the Single Module Data Viewer Software • 44

Page 45

accidental deletion of instrument s or data. To delete an instrument or

data, perform the following:

1. Find the item you wish to delete and right click it. A window will

appear that says “Delete(D) Change Password(C)”.

2. Click on “Delete(D)”. A password entry window will appear.

3. Enter the password and click OK. The default password is

“ABCDE” and is case sensitive. A confirmation window will appear.

4. Click OK to complete the deletion of the selected item.

Changing the Password

The default password is “ABCDE” and is case sensit ive. You can change

the password in the data view window. To change the password perform

the following:

1. Right click in the upper right or upper left part of the data view

window. A window will appear that says “Delete(D) Change

Password(C)”.

2. Click on “Change Password(C)”. A window will appear prompting

you for the current password.

3. Enter the current password and click the Current Password

button. A window will appear prompting you for the new password.

4. Enter the new password and click the New Password button. A

confirmation window will appear prompting you for the new

password again.

5. Enter the new password again and click the Confirm New

Password button. A window will appear indicating that the

password has been changed.

6. Click OK to complete the password update.

Exiting the Program

To exit the Single Module Data View program, do the following:

1. Click the Exit button in the upper right corner of the data view

window. A confirmation window will appear.

Using the Single Module Data Viewer Software • 45

Page 46

2. Click the OK button to exit the program or the Cancel button to

return to the program.

Spare Parts List

Table 6: Spare Parts List

Part Number Description

06-0201RK Exhaust fitting plug, DataCal 2000 module

06-1248RK Polyurethane tubing, 5/16-inch OD x 3/16-inch ID, for

connecting calibration cylinder to calibrati on station

06-1254RK Polyurethane tubing, 7/16-inch OD x 5/16-inch ID, for

exhaust tube, 10 feet maximum

33-0165RK Particle air filter replacement

43-4155RK Fuse, 5 x 20 mm, 2A, 250V

47-1013RK Power cord, for 115 VAC

71-0130RK Operator’s Manual SM-2001U & SM-2003U Single

Module Calibration Stations (this document)

81-0016RK-05 Cylinder, methane, 100% volume, 58 liter steel

81-0090RK-03 Three-gas calibration cylinder, 50% LEL CH

/12% O2/

4

50 ppm CO, 103 liter steel

81-0154RK-02 Four-gas calibration cylinder , 50% LEL CH

ppm CO/25 ppm H

S, 58 liter aluminum

2

/12% O2/50

4

81-1054RK Demand flow regulator, 50/103 liter

81-SM2001U Single Module Calibration Station for GX-2001

81-SM2003U Single Module Calibration Station for GX-2003

83-0009RK Single Mode Data Viewer software

Spare Parts List • 46

Loading...

Loading...