Page 1

SDM-2012 Docking Station

PC Controlled Configuration

Operator’s Manual

Part Number: 71-0256RK

Revision: C

Released: 8/12/13

www.rkiinstruments.com

Page 2

Warranty

RKI Instruments, Inc. warrants gas alarm equipment sold by us to be free from

defects in materia ls and workmans hip, and perform ance for a perio d of one year from

date of shipment from RKI Instruments, Inc. Any parts found defective within that

period will be repair e d or repl ace d, at our optio n, fre e of char ge . This w arra nty do es

not apply to those items which by their nature are subject to deterioration or

consumption in normal service, and which must be cle aned, repaired, or replac ed o n

a routine basis. Examples of such items are:

Absorbent cartridges Batteries

Pump diaphragms and valves Filter elements

Fuses

Warranty is voided by abuse including mechanical damage, alteration, rough

handling, or repairs procedures not in accordance with the instruction manual. This

warranty indicates the full extent of our liability, and we are not responsible for

removal or replacement costs, local repair costs, transportation costs, or contingent

expenses incurred without our prior approval.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ANY AND ALL OTHER

WARRANTIES AND REPRESENTATIONS, EXPRESSED OR IMPLIED, AND

ALL OTHER OBLIGATIONS OR LIABILITIES ON THE PART OF RKI

NSTRUMENTS, INC. INCLUDING BUT NOT LIMITED TO THE WARRANTY

I

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. IN

NO EVENT SHALL RKI INSTRUMENTS, INC. BE LIABLE FOR INDIRECT,

INCIDENTAL, OR CONSEQUENTIAL LOSS OR DAMAGE OF ANY KIND

CONNECTED WITH THE USE OF ITS PRODUCTS OR FAILURE OF ITS

PRODUCTS TO FUNCTION OR OPERATE PROPERLY.

This warranty covers instruments and parts sold to users only by authorized

distributors, dealers, and representatives as appointed by RKI Instruments, Inc.

We do not assume indemnification for any accident or damage caused by th e

operation of th is gas mo nitor an d our war ranty is li mited to r eplacement of par ts or our

complete goods.

Warranty

Page 3

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

About This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Cautions & Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

AC Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Single-Port AC Adapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3-Port AC Adapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

USB Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Air Filter, Sample Tubing, and Check Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Instrument Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Back Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Power Jack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Sample Fittings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

PC Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

USB Hub Requirements for Multiple Station Systems. . . . . . . . . . . . . . . . . . . . . . . 12

Hardware Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Hardware Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Assembling a Manifold for Multiple SDM-2012 Units . . . . . . . . . . . . . . . . . . . . . 15

Exhaust Tubing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

GAS 1 and GAS 2 Tubing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Connecting Calibration Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

EAGLE 2 and GX Type Instrument Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Installing the SDM-GX Docking Station PC Controller Program . . . . . . . . . . . . . . . 24

Launching the SDM-GX Docking Station PC Controller Program. . . . . . . . . . . . . . 29

Table of Contents

Page 4

Overview of the SDM-GX Docking Station PC Controller Program. . . . . . . . . . . . . 30

PC Controller Program Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Main Program Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Control Buttons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

SDM-2012/Instrument Display Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Program Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Fitting Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Setting Up the PC Controller Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Setting Up the Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Setting Up the SDM-2012 Display Orde r . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Cylinders Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Selecting a Cylinder from the Pre-Defined List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Defining New Cylinders. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Connecting Instruments to the PC Controller Program. . . . . . . . . . . . . . . . . . . . . . 43

Icon View vs. Details View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Exporting an Instrument List from the Main Program Window . . . . . . . . . . . . . . 50

Automatic Bump Testing and Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Bump Testing a GX-2012. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Calibrating a GX-2012 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Bump Testing a Gas Tracer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Calibrating a Gas Tracer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Charging an Instrument in an SDM-2012. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Recharging a Battery Pack After Performing a Bump Test or Calibration. . . . . 113

Recharging a Battery Pack Without Performing Any Operations . . . . . . . . . . . 115

Battery Pack Too Drained for PC Controller Operation. . . . . . . . . . . . . . . . . . . 116

Logs Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Alarm Trend Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Calibration Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Event Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Interval Trend Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Table of Contents

Page 5

Memo Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Bump Test Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .138

Barhole Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Normal Operation Snap Log Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Leak Check Mode Snap Log Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Deleting Data in the Logs Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Instrument Function Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Open Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Edit Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Parameter Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Sensor Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Station & User Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Download Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Clear Logs Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Power Off Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Config Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Parameter Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Database Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Password Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Spare Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Appendix A: Multiple Instrument Configurations. . . . . . . . . . . . . . . . . . . . . . . . . . 178

Bump Testing GX-2012s and Gas Tracers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Calibrating GX-2012s and Gas Tracers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

CAUTION: Read and understand this manual before using the SDM-2012. Also

read and understand the GX-2012 Operator’s Manual and/or Gas

Tracer Operator’s Manual.

Table of Contents

Page 6

Introduction

This section briefl y describes the S DM-2012 D ocking S t ation, the Single Modul e Data

Viewer Program, and the SDM-GX Docking Station PC Controller Program. This

section also describes the SDM-2012 Docking Station PC Controlled Configuration

Operator’s Manual (this document). Table 1 at the end of this section lists the SDM2012’s specifications.

The SDM-2012 Docking Station is an advanced, reliable system that provides

charging, calibratio n, bump test in g, and cali brati on and bu mp test r ecords for the GX2012 and Gas T r acer port able g as monitor s. It is de signed to s ave the calibrati on and

bump test reco rds to a USB flash drive (standalone functionality) or to be connected

directly to a computer (PC controlled functionality). If calibration and bump test

records are stored to a USB flash drive while operating in the standalone

configuration, the Single Module Data Viewer Program can then be used with a

Windows-based personal computer to retrieve calibration and bump test data files

from the USB flash drive or from the computer’s hard drive if the files have been

transferred to the hard drive from the flash drive. If you are using the PC Controller

Program while operating in the PC controlled configuration, you may retrieve

instrument data, bump test, and calibrate up to 10 units at once. Instrument

information and data for each instrument can be viewed directly using the PC

Controller Program and can be printed from the PC Controller Program. For

instructions to use the SDM-2012 in th e S tan dalone config uration, see th e SDM-2012

Docking Station Standalone Configuration Operator’s Manual.

The purpose of this manual is to explain how to set up and use the SDM-2012 in PC

Controlled config uratio n. It also explai ns how to use the SD M-GX Doc king S t ation PC

Controller Program. You will learn how to:

• install and launch the SDM-GX Docking Station PC Controller Program

• setup the SDM-GX Docking Station PC Controller Program for use with the

SDM-2012

• prepare the SDM-2012 for use

• bump test and calibrate up to 10 units using the PC controlled configuration

• use the SDM-2012 to charge a GX-2012 or Gas Tracer

• view, print, and export calibr ation and bump test records

• view instrumen t inf or m ati on and data using the PC Controller Program

• update instrument parameters using the PC Controller Program

1 • Introduction

Page 7

CAUTION: The GX-2012 and Gas Tracer detect oxygen deficiency and elevated

levels of oxygen, combustible gases, carbon monoxide, and hydrogen

sulfide (GX-2012 only), all of which can be dangerous or life

threatening. When using the GX-2012 or Gas Tracer, you must follow

the instructions and warnings in the GX-2012 Operator’s Manual or

Gas Tracer Operator’s Manual to assure proper and safe operation of

the unit and to minimize the risk of personal injury.

CAUTION: The operator of this instr umen t is advised that if the equi pment is u sed

in a manner not specifie d in this manual, the protection pr ovided by the

equipment may be impaired.

System Requirements

To use the SDM-GX Docking St atio n PC Controll er Softw are, your perso nal computer

must meet the following requirements:

• Operating System s: Windows® XP, Windows® Vista, Windows® 7.

• Processor: IBM® compatible PC running Pentium® 2 processor or equivalent

minimum

• Memory: 3 2 MB RAM minimum

• Hard Disk Space: 32 MB minimum

• CD-RO M Drive

• One (for 4 or less SDM-2012s) or two (for 5 or more SD M-2012s) available

USB port(s), one or two USB hubs may also be needed depending on the

number of SDM-2012s in your system. See “USB Hub Requirements for

Multiple Station Systems” on page 12.

System Requirements • 2

Page 8

Specifications

Table 1: SDM-2012 Specifications

Input Power 12 VDC

NOTE: AC Adapter with 100 - 240 VAC, 50/60 Hz,

0.6A input and 1 2 VDC, 1.2A output provided as

standard.

Environmental Conditions • For Indoor Use Only

• -10° C to 40° C, below 80% Relative Humidity, NonCondensing

Applicable Instruments GX-2012 and G as Tracer

Memory Capaci ty 64 KB (S tandalone configuration only)

Maximum Record Size 256 bytes (Standalone configuration only)

Maximum Number of

Records Saved

Number of Calibration Gas

Cylinders

Standard Accessories • AC Adapter

200 (Standalone configuration only)

Up to two calibration gas cylinders per bump test or

calibration at a time

• USB Flash Drive

• Single Module Data Viewer Software

• SDM-GX Docking Station PC Controller

Software

• Inlet Air Filter

• Instruction Manual

• 10 Foot Long 5/16 Inch Exhaust Tube

• Two 3 Foot Long 3/16 Inch Tubes for GAS 1

and GAS 2 Fittings

• 10 Foot Long 3/16 Inch Tube for GAS 1 and

GAS 2 Manifolding

3 • Specifications

• 3 T-Fittings

• Check Valve

• USB Cable, Type A to Type B

Page 9

About this Manual

The SD M-2012 D ocking S ta tion PC Controll ed Config uration O perator’s Man ual uses

the following conventions for notes, cautions, and warnings.

NOTE: Describes additional or critical information.

CAUTION: Describes potentia l damage to equipm en t.

WARNING: Describes potential danger that can result in injury or death.

Cautions & Safety Information

• Use only polyurethane sample tubing with the SDM-2012. Consult RKI

Instruments, Inc. for other materials.

• Do not subject the SDM-2012 to infrared or intense light. This may cause

communication errors.

• Do not expose the SD M-2012 to water.

• Do not subject the SDM-2012 to any hard impact.

About this Manual • 4

Page 10

Description

To Power Jack

on SDM-2012

Back Panel

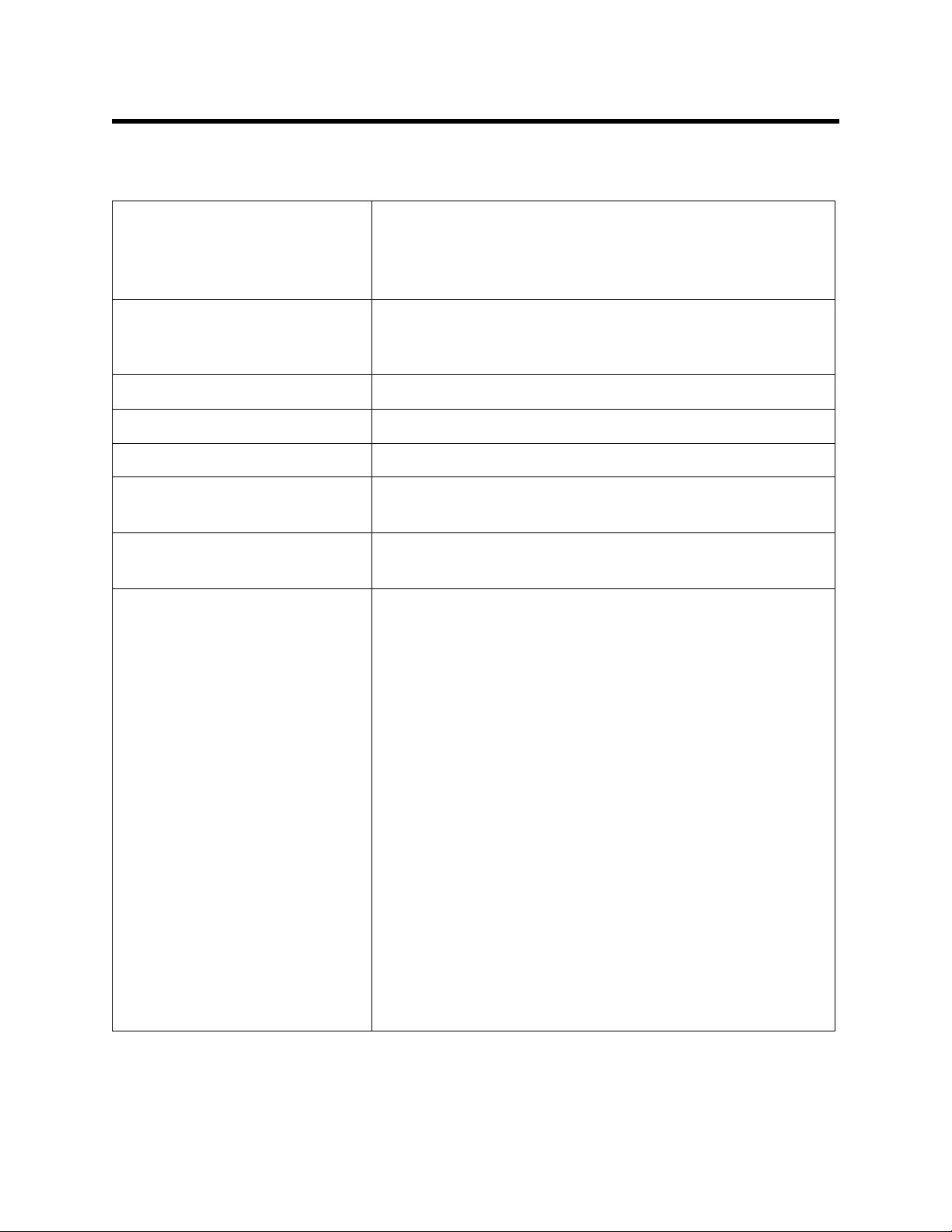

Figure 1: Single-Port AC Adapter

To Power Jack

on SDM-2012

Back Panels

Figure 2: 3-Port AC Adapter

This section describes the SDM-2012 docking station. It is designed to be used on a

table top and cons ists of the AC ad aptor , T ype A to T y pe B USB cable, air filte r , check

valve, 3 plasti c T-fittings, sample tubing, instrument panel, back panel, control panel,

status LEDs, and 2 USB ports.

AC Adapter

Single-Port AC Adapter

The single-port AC ada pt er is a w all plug style ada pter w ith a 5 f oot cable. The en d of

the cable has a plug that connects to the power jack on the SDM-2012’s back panel.

The AC adapter is rated 100 - 240 VAC input, 12 VDC 1.2 A output.

3-Port AC Adapter

The 3-port AC adapter is a wall plug style adapter with three 5-foot cables. The end of

each cable has a plug that connects to t he power jack on the SDM-2012’s back

panel. The AC adapter is rated 100 - 240 VAC input, 12 VDC 2.0 A output.

5 • Description

Page 11

USB Cable

Type A, for

connection to

PC USB port

Type B, for connection

to USB port on the

SDM-2012's back panel

Exhaust Tubing, 5/16 Inch

ID,10 feet

Particle Filter for Air Inlet

Calibration Gas Sample Tubing, 3/16

Inch ID, 3 feet, 2 Tubes Included

Manifold Tubing, 3/16 I nch

ID,10 feet

Figure 4: Air Filter & Sample Tubing

A Type A to Type B USB cable is provided with the docking station. It is used to

connect the USB port on the back of the SDM-2012 to a computer.

Figure 3: USB Cable

Air Filter, Sample Tubing, and Chec k Valve

A cylindrical particle filter with a short length of tubing is supplied with the SDM-2012

for installation to the AIR fitting on the back panel. The filter keeps particulate

contamination out of the docking station.

Three types of sampl e tubes are i nclude d with the docking st atio n. Two 3 foot lengths

of 3/16 inch ID p olyurethane tubing are provided to connect the regulator on a

calibration cylinder to the GAS 1 and GAS 2 fittings on the back panel. One 10 foot

length of 3/16 inch ID polyurethane tubing is provided for GAS 1 and GAS 2 manifold

construction (if desired). In addition, a 10 foot length of 5/16 inch ID polyurethane

tubing is provided for connection to the exhaust fitting on the back panel to allow

routing of the exhaust to a location su ch as an open window where the exhaust can

disperse.

WARNING: Do not use an exhaust tube that is longer than 10 feet. The increased flow

restriction caused by a longer tube may affect gas response and cause

inaccurate calibration and bump test results.

Description • 6

Page 12

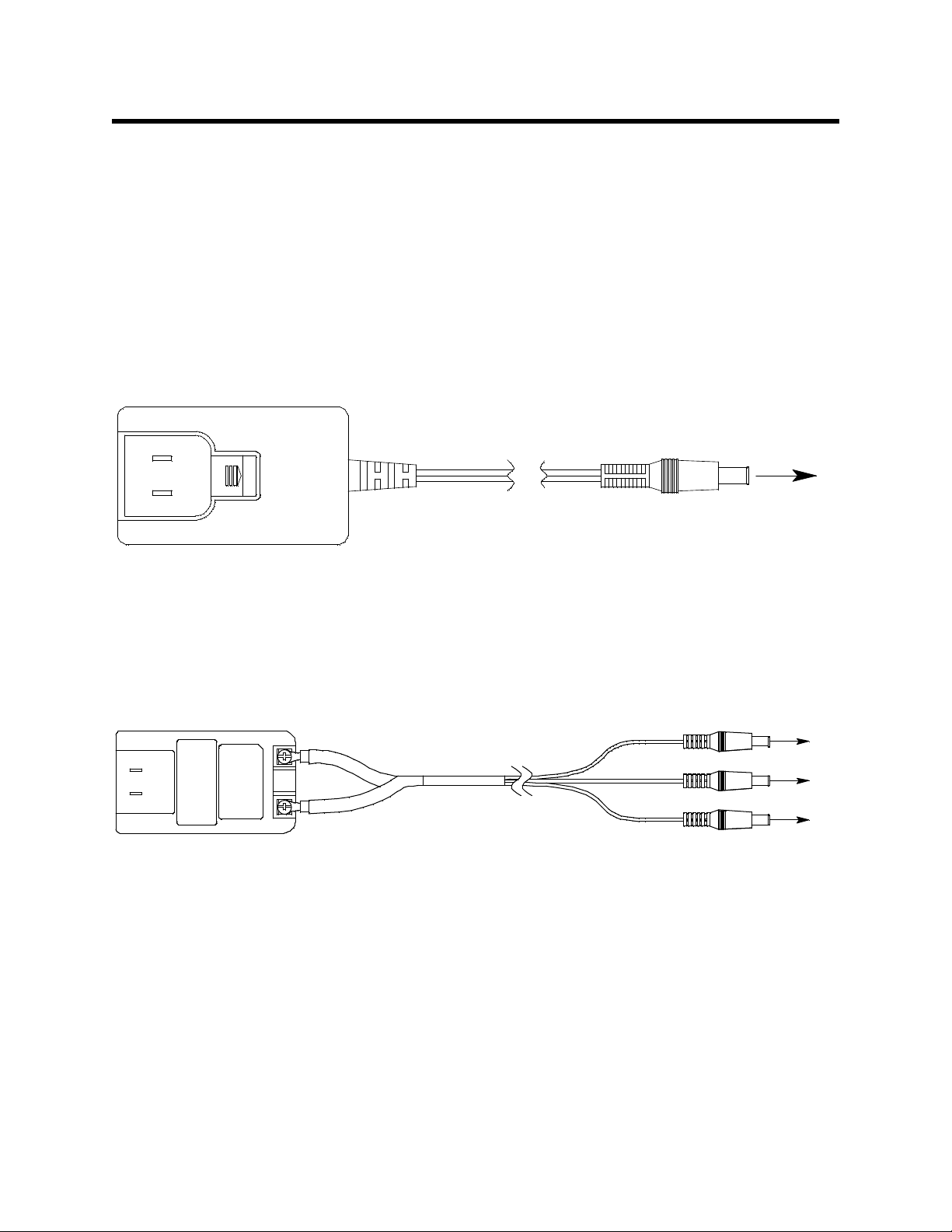

A check valve is included with the SDM-2012. It is intended for use on the exhaust

Figure 5: Check Valve

For Exhaust

Tubing

For GAS

Tubing

Figure 6: T- Fittings

fitting when manifolding multiple docking stations together. See “Assembling a

Manifold for Multiple SDM-201 2 Units” on page 15 for manifolding instructions.

Three T-fittings are included with the SDM-2012. The larger fitting is for the exhaust

tubing manifold constr uction. The two sma ller fittings a re for GAS 1 and G AS 2 tubing

manifold construction.

7 • Description

Page 13

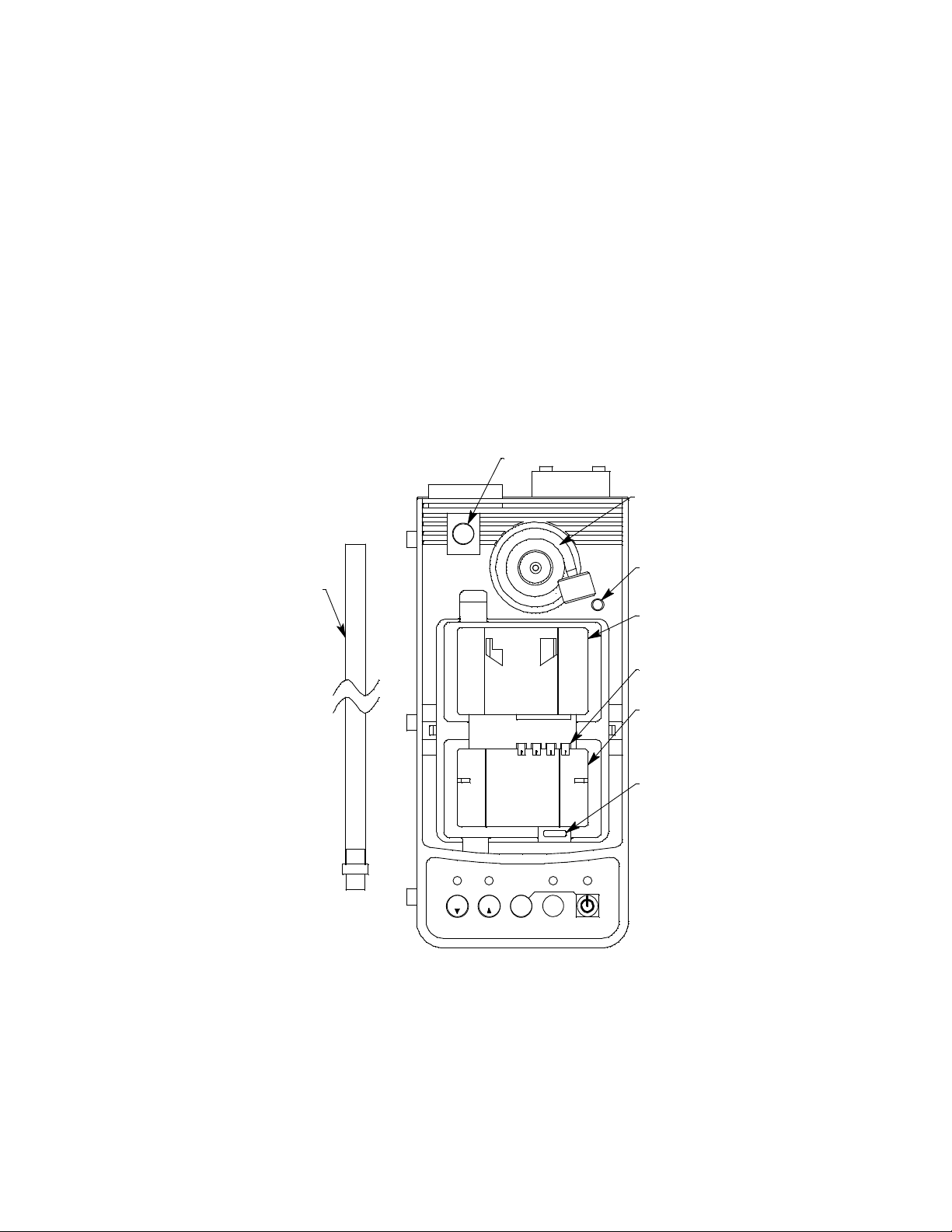

Instrument Panel

Exhaust Line

StorageFitting

GasOut to

Instrument Line

Alkaline Battery

Pack Cradle

Charging Contacts

GX-2012OFF

COPY

CHARGE

POWER

1SECON

3SECOFF

IR Port

Exhaust Line (Must Be

Installed by User)

SDM-2012

CAL.BUMP

Lithium Ion Battery

Pack Cradle

Exhaust Line Connection Fitting

EDIT

ENTER

Figure 7: Instrument Panel (Shown Without Recess Cover Flap)

The instrument panel is on the top of the SDM-2012 and includes the instrument

cradle, the IR port, the charging contacts, the exhaust line connection fitting, and the

gas out to instrument line . The in strum en t cra dl e con si st s of two r ecesse d ar ea s and

is designed to accept the instrument. The recess at the front of the instrument panel

is for instruments that have a Li-ion battery pack installed. Charging contacts are

located at the back of this recess. The recess behind the Li-ion batter y pa ck cradle i s

for instruments that have an alkaline battery pack installed. A plastic flap covers the

recess that is not in use. Insert the instrument into the appropriate instrument cradle

recess when you perform a bump test, calibrat e, or charge an instrumen t. An infrared

(IR) port in the fron t rece ss lines up w ith the in strumen t’ s IR por t when it is inse rted in

either recess and is used to communicate with the instrument. The exhaust line

connection fitting is in the upper left corner of the instrument panel. The exhaust line

is not factory installed and must be installed by the user. An exhaust line storage

fitting is located along the right side of the instrument panel and accepts the fitting at

the end of the exhaust line for storage. The gas out to instrument line is coiled and

stored in a recess in the upper middle portion of the instrument panel.

Description • 8

Page 14

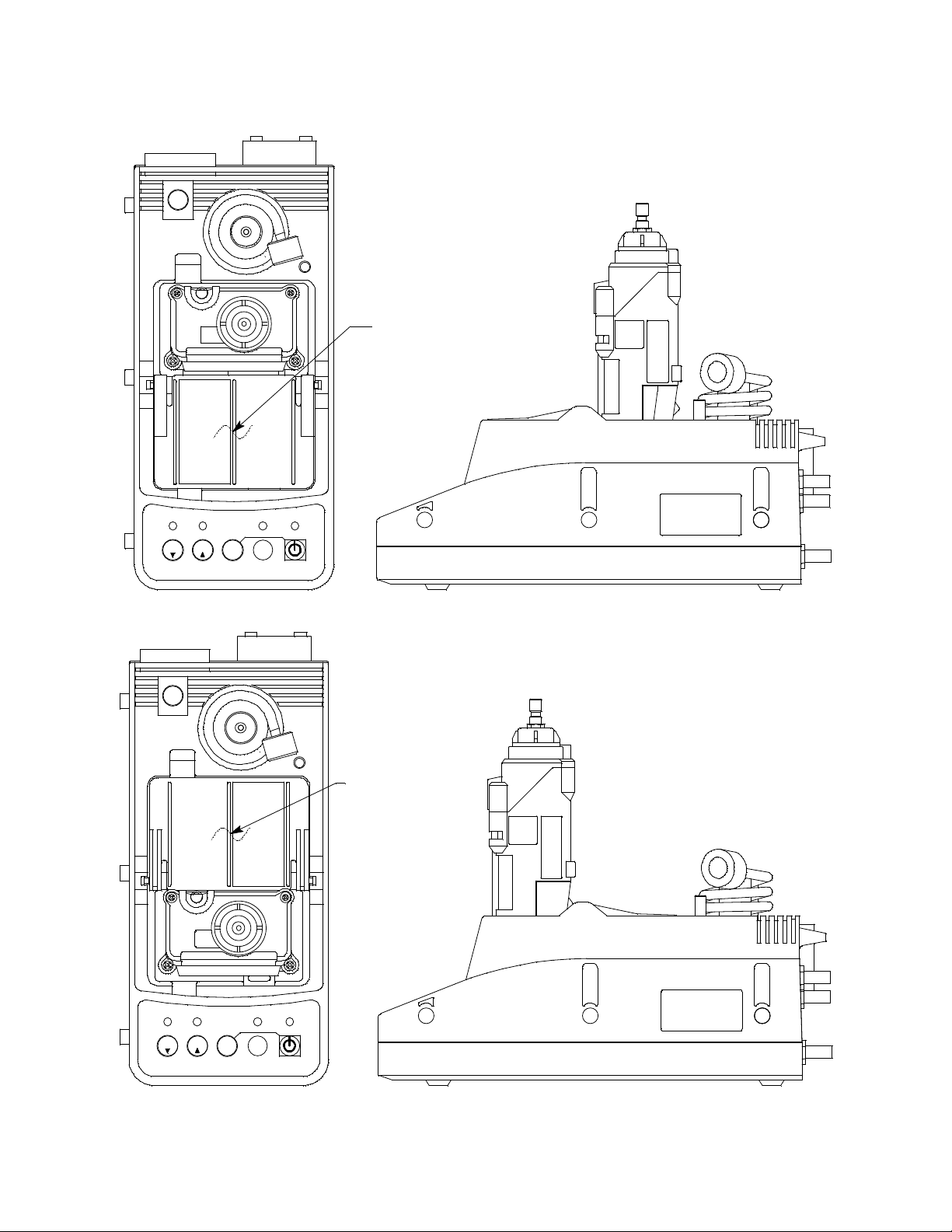

SDM-2012

BUMP CAL.

EDIT

ENTER

GX-2012 OFF

COPY

CHARGE

POWER

1SEC ON

3SEC OFF

Recess Cover Flap

Figure 8: Instrument Panel with Alkaline Instrument Installed

EDIT

ENTER

CAL.

SDM-2012

BUMP

GX-2012 OFF

COPY

POWER

1SEC ON

3SEC OFF

CHA RGE

Recess Cover F lap

Figure 9: Instrument Panel with Lithium Ion Instrument Installed

9 • Description

Page 15

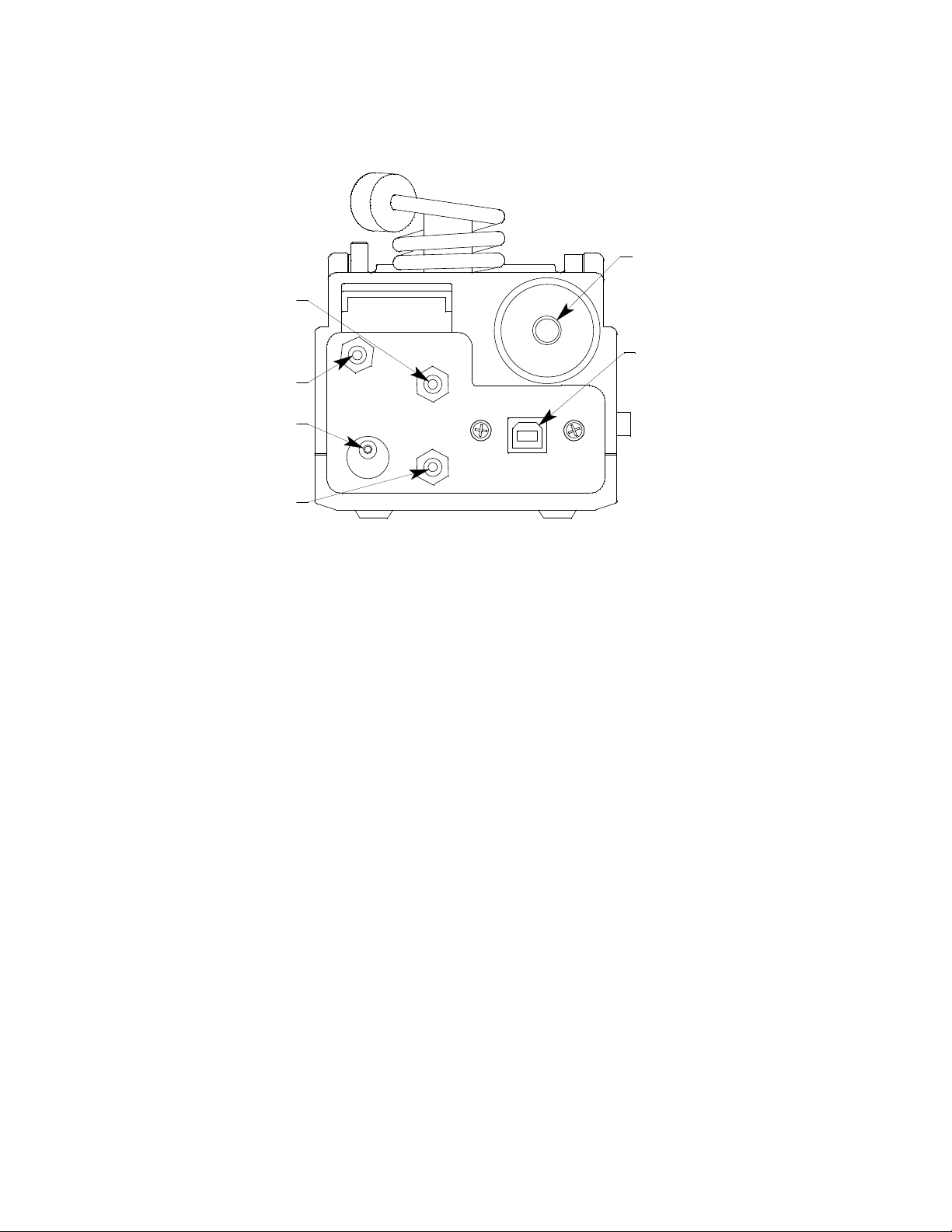

Back Panel

Gas 2 Fitting

Power Jack

Air Fitting

Gas 1 Fitting

Back Panel USB

Port (Type B),

For Computer

Connection

Exhaust Fitting

Figure 10: Back Panel

The back panel includes the power jack, sample fittings, and a USB PC connector.

Power Jack

The power jack is located in the bottom left corner of the back panel. The plug on the

end of the AC adapter cable mates to it.

Sample Fittings

Four sample fittings are located on the back o f the SDM-2012. The AIR fitting is in the

upper left corner and draws air into the SDM-2012. The two GAS fittings are in the

center of the back panel and are used to connect the SDM-2012 to calibration gas

cylinders. The GAS 1 fitting is above the GAS 2 fitting. All three fittings accept 3/16

inch ID tubing.

An exhaust fitting is located in the upper right corner. It allows routing of the

exhausted calibration gas to a convenient location. This fitting accepts 5/16 inch ID

tubing. Even though the exhau st gas can be r outed to an area to b e safely disp ersed,

the docking station should still be installed in a well ventilated a rea.

PC Connection

A type B USB connection is located beneath the exhaust fitting on the SDM-2012’s

back panel. It is used to connect the SDM-2012 to a PC.

Description • 1 0

Page 16

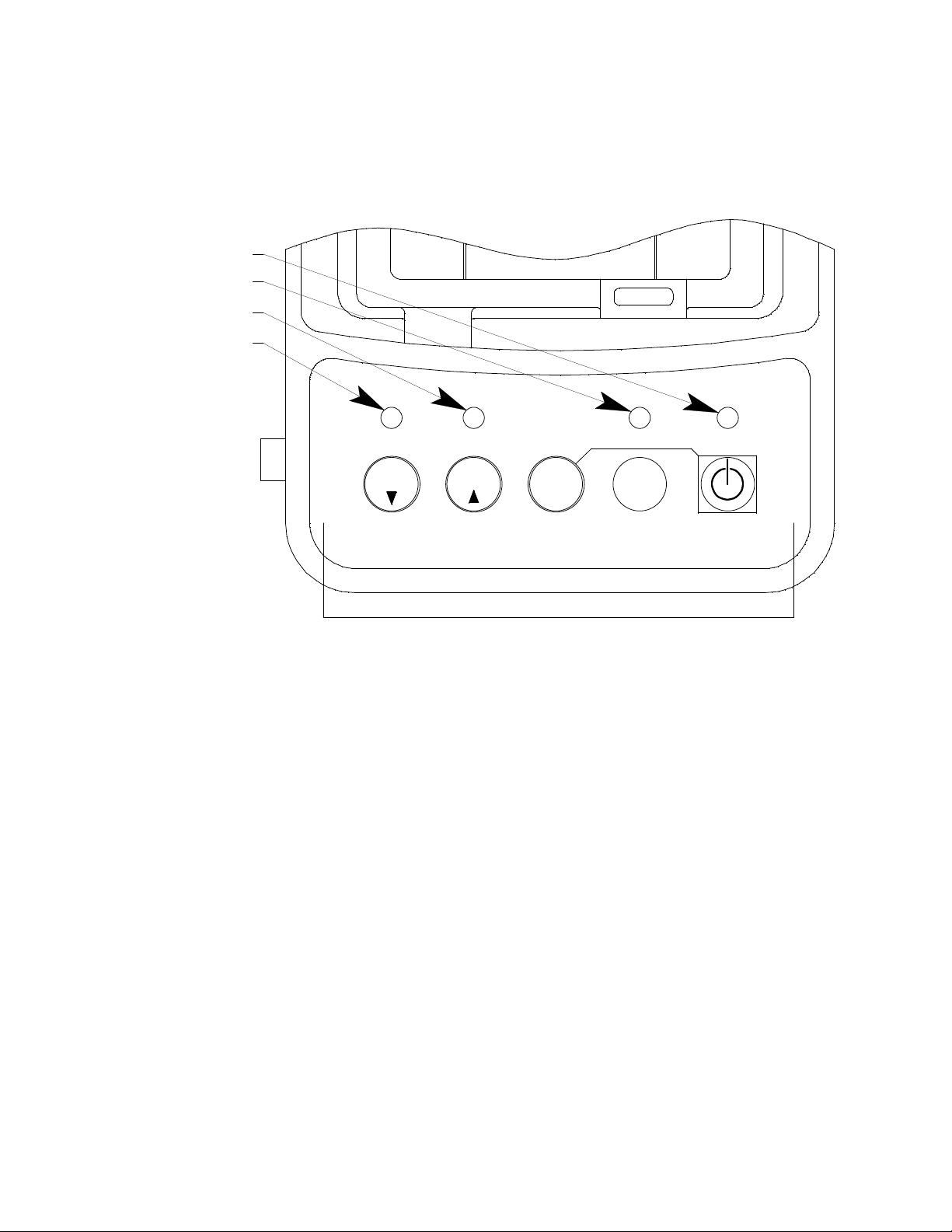

Control Panel

COPY

1SEC ON

3SEC OFF

CHARGE

POWER

GX-2012 O FF

BUMP

SDM-20 12

CAL.

Control Buttons

EDIT

ENTER

BUMP LED

CHARGE LED

COPY LED

CAL LED

Figure 11: Control Panel

The control panel is us ed to setup and operate the docking station in the Standalone

configuration. It is located at the front of the docking station. It includes the control

buttons, the control button LEDs, and the CHARGE status LED.

Five control butto ns are located on the control p anel. From lef t to right the y are BUMP

T , CAL S , EDIT ENTER, COPY, and POWER. The BUMP T , CAL S , EDIT

ENTER, and COPY control buttons are not used in the PC Controlled configuration of

the SDM-2012. The BUMP T LED and CAL S LEDs indicate the results of bump

tests and calibrations, respectively. The COPY LED does not indicate anything in the

PC Controlled configuration but will be on if the SDM-2012 was used in the

Standalone configuration and calibration and bump test records are still stored in the

SDM-2012’s memory. The CHARGE LED is located above the POWER button and

functions as a pilot LED, a system failure LED, and a charge indication LED.

The POWER button turns the SDM-2012 on and off.

11 • Description

Page 17

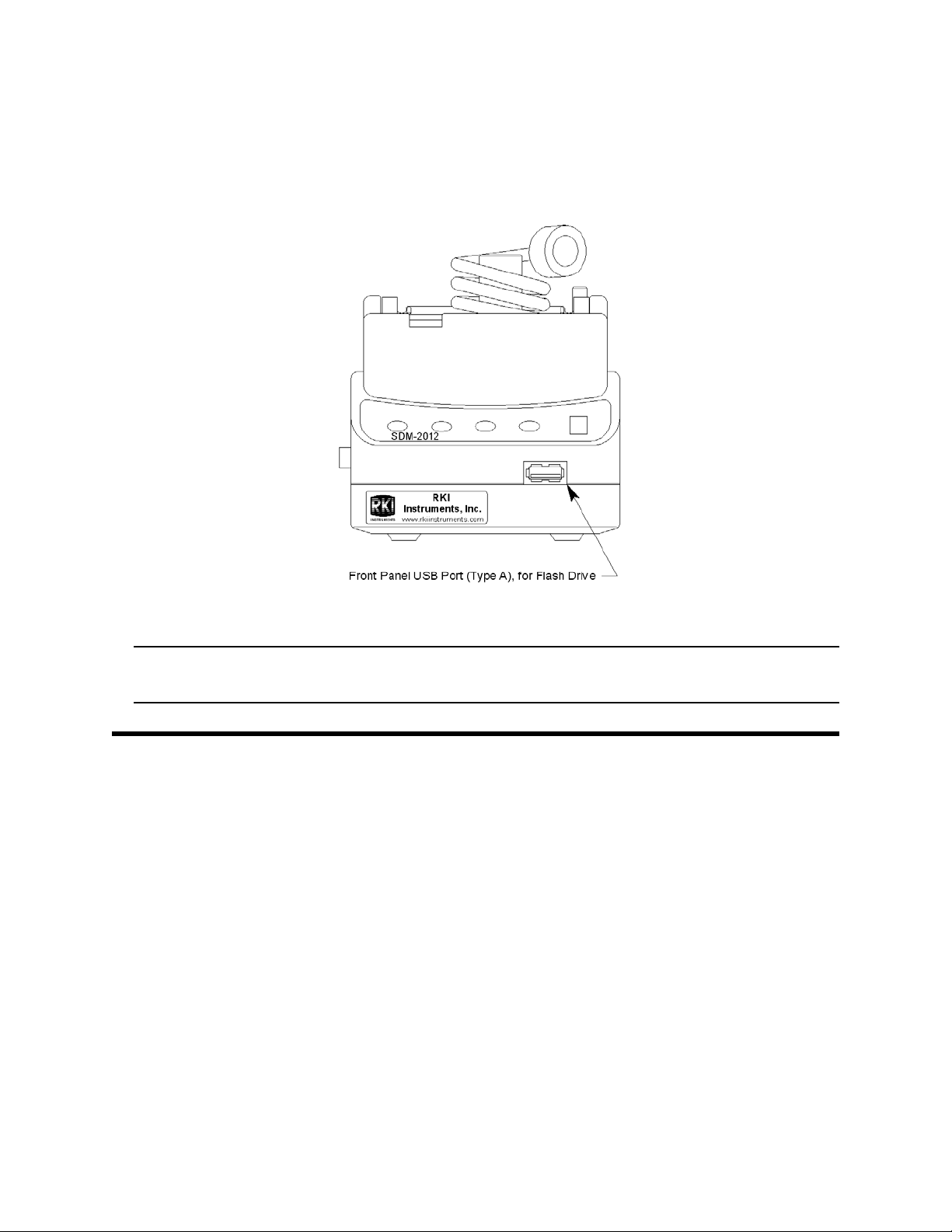

Front Panel

Figure 12: Front Panel

A type A USB port is located on the front of the docking station. This port can be used

to save calibration and bump test data to a USB flash drive. This USB port is for use

only in the Standalone configuration of the SDM-2012 and is not used in the PC

Controlled configuration.

NOTE: The SDM-2012 does not support connection of a computer to the front

USB port, only a USB flash drive.

USB Hub Requirements for Multiple

Station Systems

If you have more docking stations than you have available USB ports, you will need a

USB hub. RKI provides both a 4-port hub and a 7-port hub. If you have more than 7

docking stations, you will need to purchase one of each hub. Do not connect one hub

to the other. Make sure that each USB hub has its own USB port on your computer.

You may also purchase your own USB hub of any port number from your local

electronics store but it must meet the following requirements:

•USB 2.0

®

• compatible with your Windows

An AC adapter comes with the USB hub(s) sold by RKI but does not need to be

plugged in for SDM-2012 operation. If the hub will be used to charge other devices,

the AC adapter needs to be plugged in.

operating system

USB Hub Requirements for Multiple Station Systems • 12

Page 18

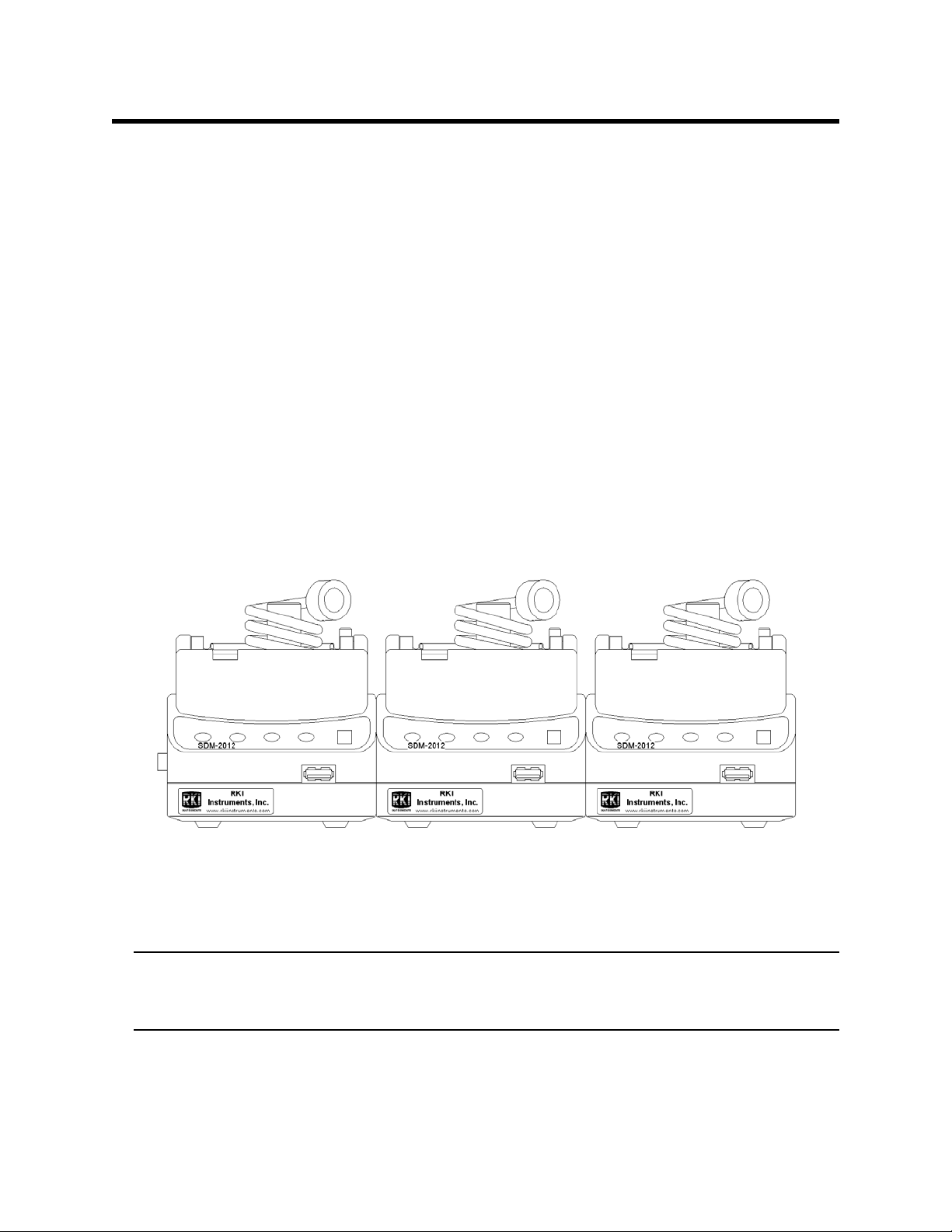

Hardware Setup

Figure 13: SDM-2012 Arrangement

This section describes how to assemble the hardware that came with the SDM-2012,

assemble a manifold, and connect calibration gas.

Hardware Assembly

The hardware assembly consists of connecting the AC adapter(s), installing the air

filter(s), installing the check valve(s), connecting the sample tubing and connecting

the USB cable(s). The SDM-GX Docking Station PC Controller software can support

1-10 SDM-2012 docking stations connected at the same time. Perform the following

steps to complete the hardware assembly for each SDM-2012:

1. Place the SDM-2012(s) on a convenient table top near an AC wall socket or

power strip in a well ventilated area. A location near a window that can be

opened is best so that the exhaust can be routed to the window.

2. If you have more than one SDM-2012, arrange them side by side as shown in

Figure 13 below. Each docking station has three connection tabs on the left

side near the bottom of the station and three connection recesses on the right

side near th e bottom of the station. The tabs from one docking statio n can be

pushed into the recesses on another station to mechanically connect the

docking stations.

3. Insert the round plug on the end of each AC adapter’s cable into the power

jack on the back of each SDM-2012.

NOTE: If you have multiple SDM-2012s and are using a 3-port AC adapter,

plug each of the round plugs on the end of the AC adapter into the

power jack on th e back of 3 separate SDM-2012s.

4. Connect the AC adapter’s wall plug into a wall AC socket or power strip.

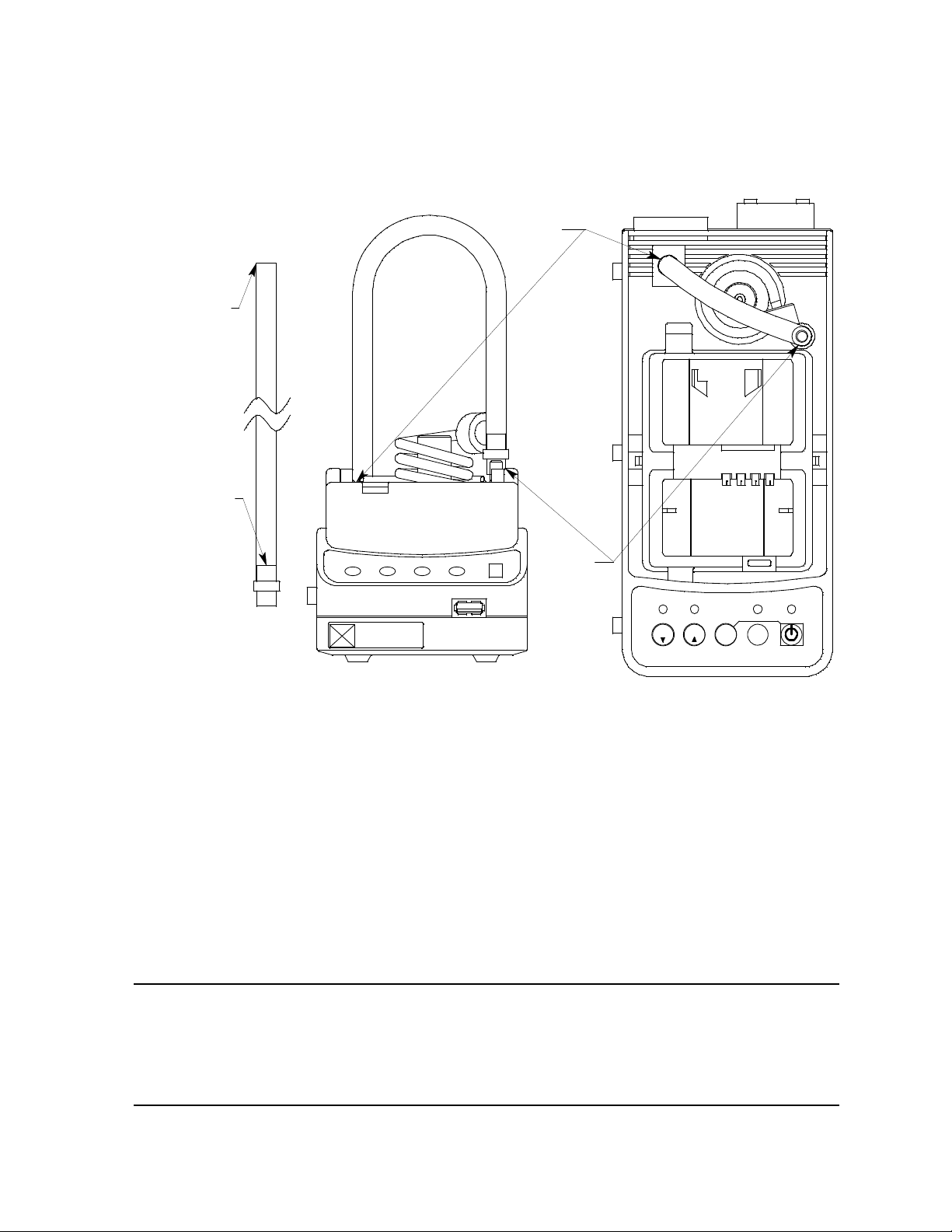

5. Install the exhaust line, a clear 12 inch long tube with a black plastic push-on

13 • Hardware Setup

Page 19

fitting, by pushing the open end of the exhaust tube onto the exhaust line

Open En d

BUMP

GX-2012 O FF

COPY

1SEC ON

3SEC OFF

SDM-2012

POWER

CAL.

EDIT

ENTER

CHA RGE

SDM-2012

RKI

Instru men ts, I nc .

www.rkiins truments.com

Blac k Push On Fitti n g

Step 2:

Black Push

On Fitting

Step 1:

Ope n End

Figure 14: Installing the Exhaust Line

connection fitting located in the upper left corner of the instrument panel. You

may then push the black push on fitting of the exhaust line onto the exhaust

line storag e fitting on the other side of the instrument panel.

6. Install th e air filter to the AI R fitting of ea ch SD M-2012 so that th e ar row on the

filter that in dicates dir ection of fl ow is poin ting toward s t he AI R fitt ing. Push the

open end of the flexible tube that is on one end of the filter onto the AIR fitting

on the back of the SDM-2012.

7. Install the 10 foot long 5/16 inch ID flexible tube that is included with each

SDM-2012 on the exh aust fitting of e ach SDM-2012 . Route the t ube to an area

where the exhaust can b e safe ly d isperse d, such as an ope n w indow. Exhaust

tubing from multiple units can be daisy chained together in a manifold for more

convenient operation. In this case, the check valves that are provided with th e

docking stations need to be used. See "Assembling a Manifold for Multiple

SDM-2012 Units" below for instructions.

CAUTION: The maximum recomme nded le ngth for th e exha ust tube is 10 feet. Do

not use more than 10 feet of tubing or tubing with an ID of less than

5/16 inch for the exhaust tube or the bump test and calibration

accuracy will be adversely affected. The exhaust tube that is shipped

with the SDM-2012 has an ID of 5/16 inch and is 10 feet long.

Hardware Setup • 1 4

Page 20

8. Install the 3 foot long 3/16 inch ID tubes that are included with the SDM-2012

on the GAS 1 and GAS 2 fittings. GAS 1 and GAS 2 tubing from multiple units

can be daisy chained together in a manifold for more convenient operation.

See "Assembling a Manifold for Multiple SDM-2012 Units" below for

instructions.

9. Connect the provided USB cord from the type B USB port on the bac k of the

SDM-2012 to an available USB port on your computer or to a USB hub that is

connected to your computer. See “USB Hub Requirements for Multiple Station

Systems” on page 12 for more information about USB hubs.

Assembling a Manifold for Multiple SDM-2012 Units

Up to 10 SDM-2012 s can be manifolded together and draw from one gas cylinder. If

you only have standard 4-gas GX-2012s, you only need to create a manifold for the

GAS 1 fitting. If you have a st andar d 4-gas GX -201 2 plu s a %volu me sens or, you will

need to create one manifold for the GAS 1 fitting and another manifold for the GAS 2

fitting. If you have a Gas Tracer of any configuration, you will need to create one

manifold for the GAS 1 fitting and ano ther ma nifold for the GAS 2 fitting. Th e exhau st

lines can also be manifolded together and be routed away from the docking stations

with only one 10 foot long 5/16 inch piece of tubing.

Each SDM-2012 is shipped with exhaust tubing, GAS 1 and GAS 2 tubing, T-fittings

in two different sizes, and a check valve.

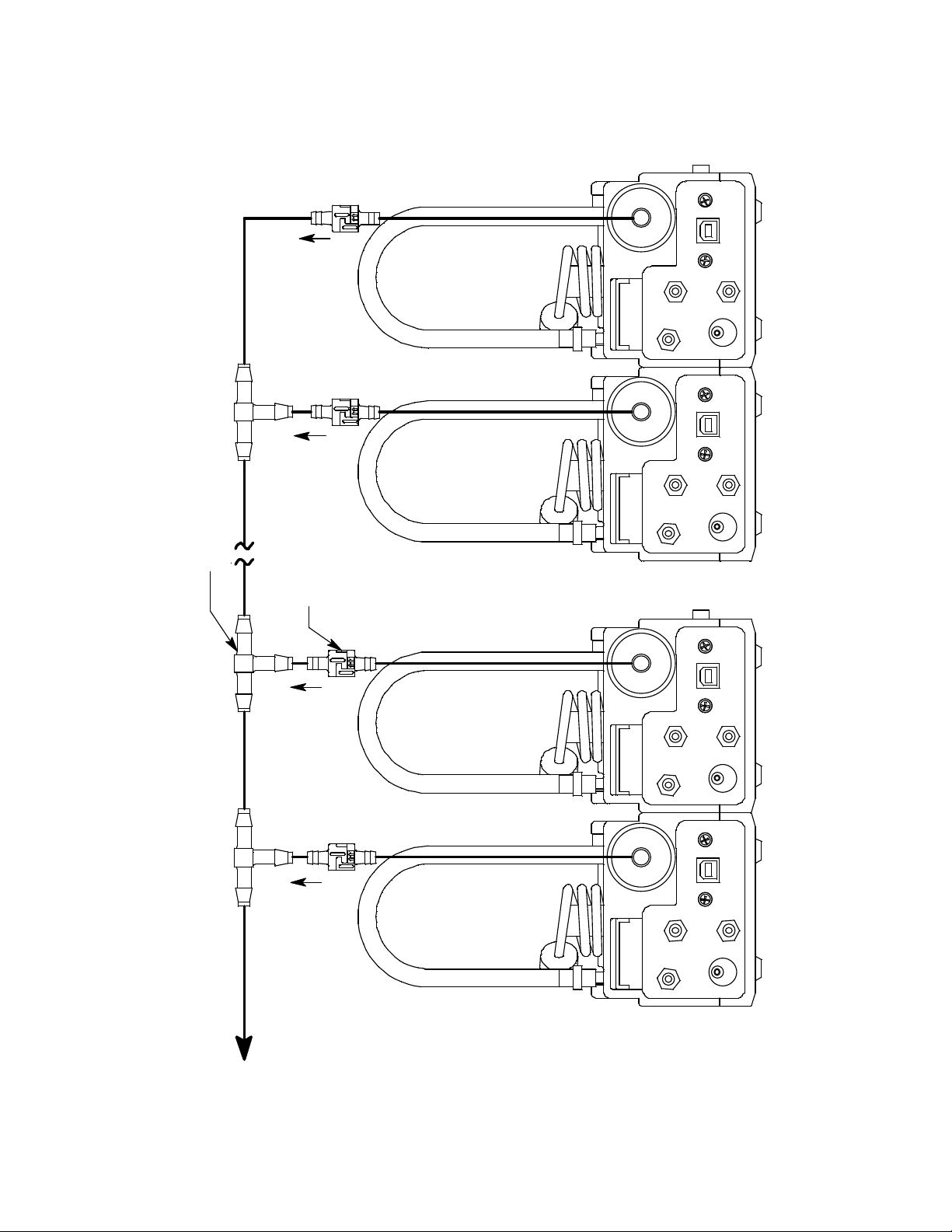

Exhaust Tubing

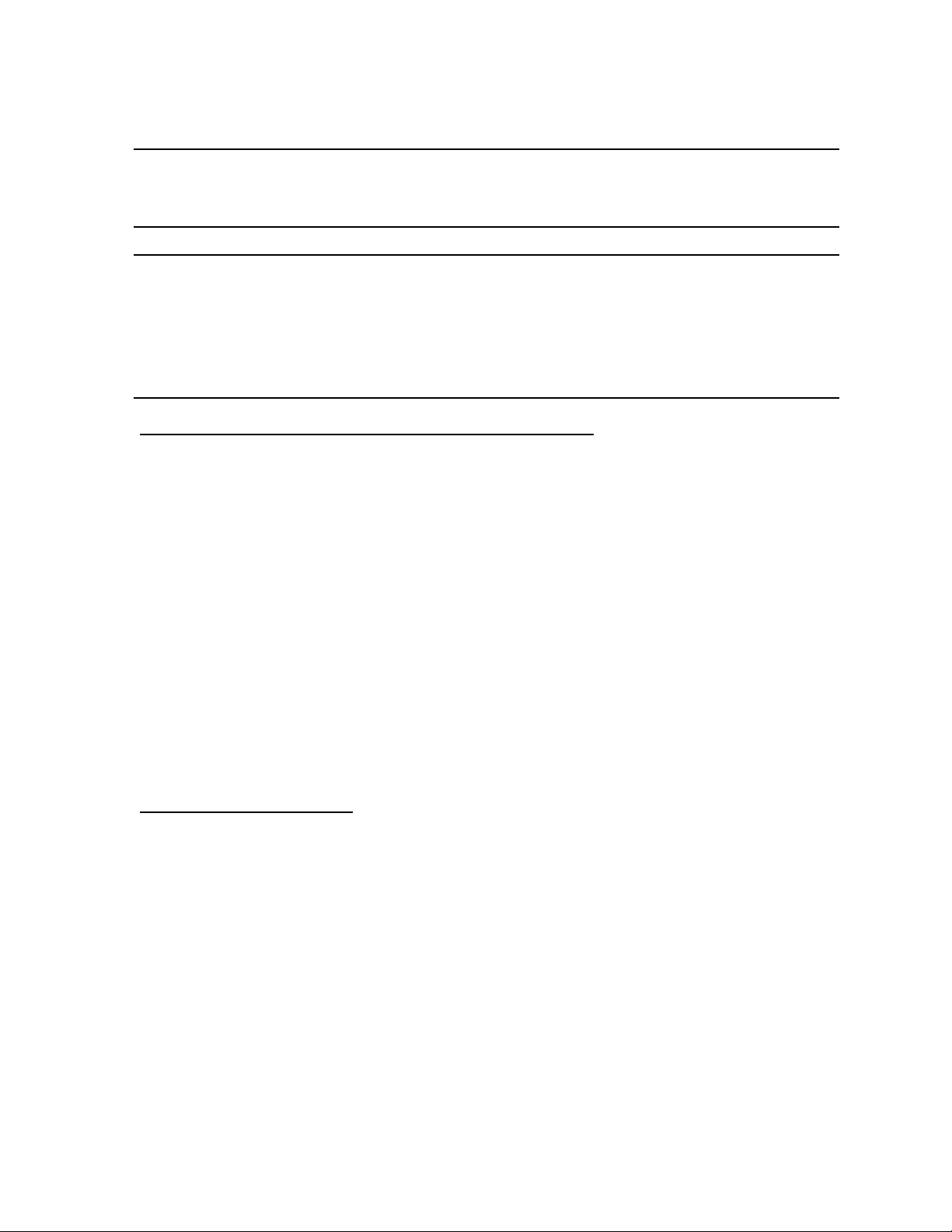

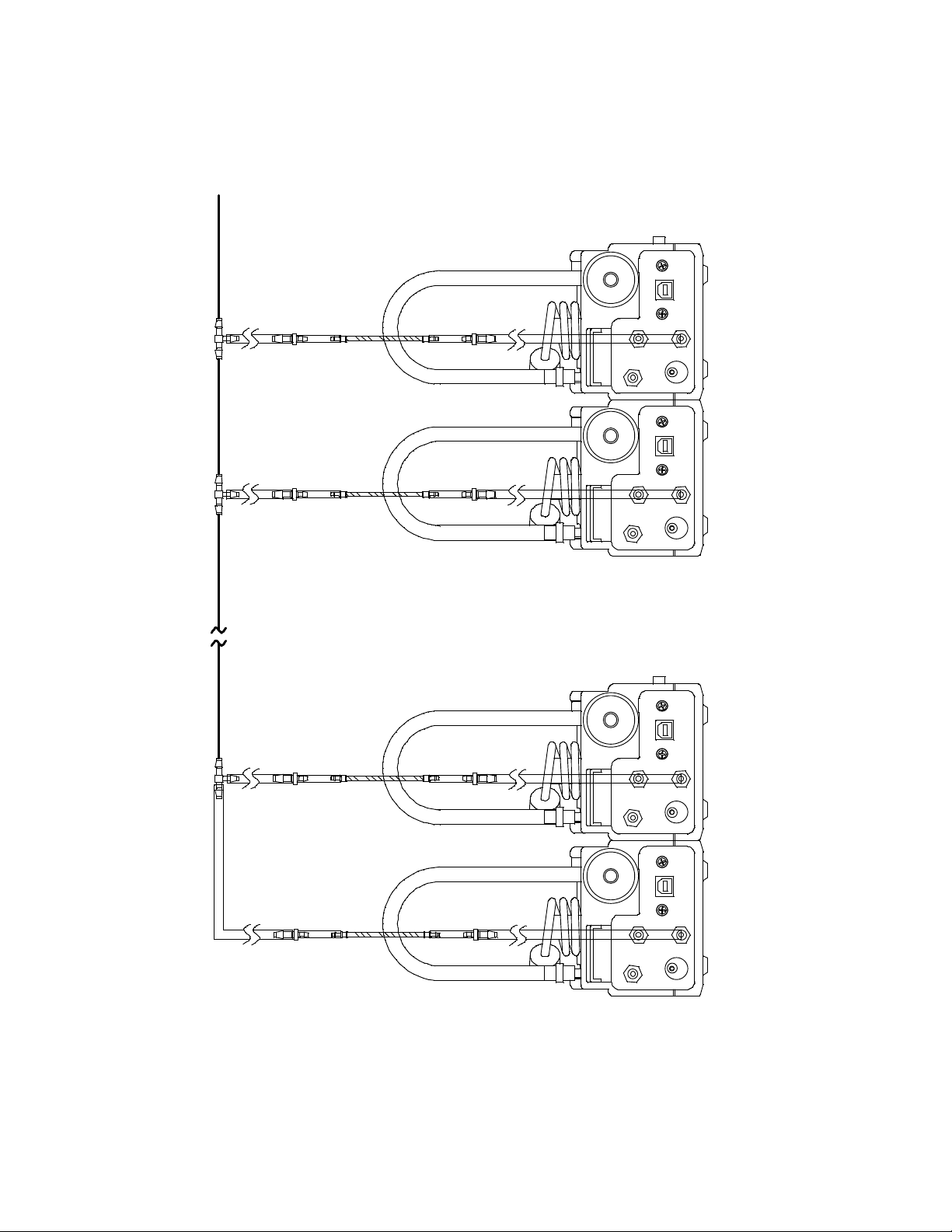

Reference Figure 15 for the in structions below.

1. Cut a 1- 2” pi ece o f 5/ 16 in ch tubi ng fo r each SDM- 2012 a nd con ne ct it to each

unit’s exhaust fi tting.

2. Connect the provided check valves to the short pieces of tubing already

installed at the exhaust fittings. Be sure that the arrows that appear on the

check valve are pointing away fr om the exhaust fitting.

3. Cut a 2-3” piece of 5/16 inch tubing for every SDM-2012 except the first one

and connect it to the other end of the check valve.

4. Insert the larger T-fittings into the tubing so that the remaining two ports on the

T-fitting are perpendicular to the exhaust tube and check valve.

5. For the first SDM-2012, cut a 9-10” piece of 5/16 inch tubing and connect it

from the check valve on the first SDM-2012 to the closest port on the second

SDM-2012’s exhaust T-fitting.

6. Use one of the provided 10 foot lengths of tubing and connect it to the T-fitting

on the last SDM-2012 . The maxim um recomm ended e xhaust tub e lengt h is 10

feet.

7. For the r emaini ng SDM- 2012s, cut 6-7” pi eces of 5/16 inch tubing and con nect

the remaining T-fittings.

15 • Hardware Setup

Page 21

7 inches

T-Fitting

10 Foot Max

Exhaust Tube

To O penArea

Check Valve

9 inches

Uni t 1

GAS2

GAS1

AIR

GAS2

GAS1

AIR

AIR

GAS1

GAS2

AIR

GAS1

GAS2

Uni t 1 0 Uni t 9 Uni t 2

Figure 15: Exhaust Tubing Connections

Hardware Setup • 1 6

Page 22

GAS 1 and GAS 2 Tubing

NOTE: If you have only standard 4-gas GX-2012s, you do not need to

assemble a GAS 2 manifold. For ever y othe r instr um e nt con fi gura t ion,

a GAS 2 manifold does need to be assembled.

NOTE: If you are planning to bump test or calibrate GX-2012s and Gas

Tracers at the same time, create one manifold for the SDM-2012s that

will test the GX-2012s and a separate manifold for the SDM-2012s that

will test the Gas Tracers. See “Appendix A: Multiple Instrument

Configurations” on page 178 for instructions to bump test or calibrate

GX-2012s and Gas Tracers at once.

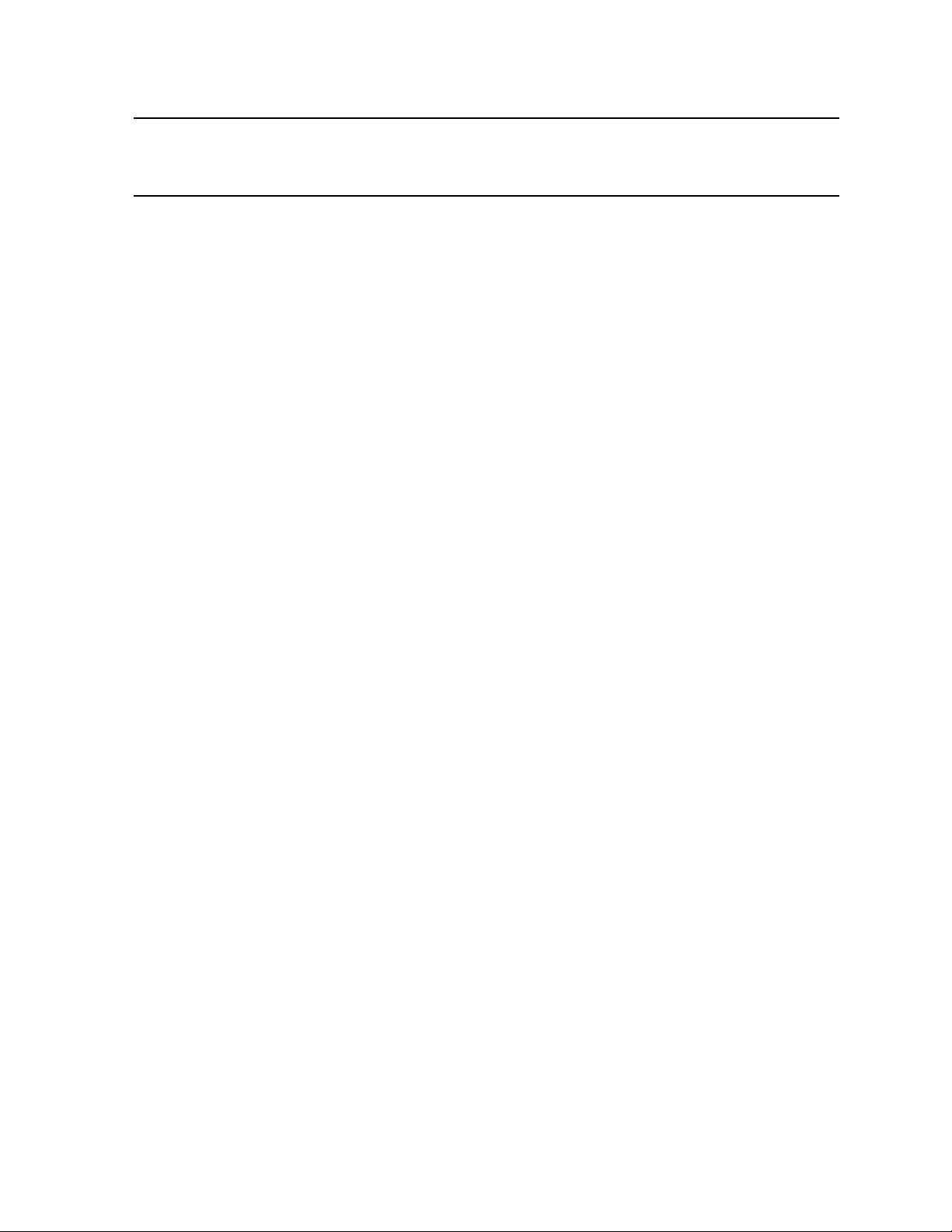

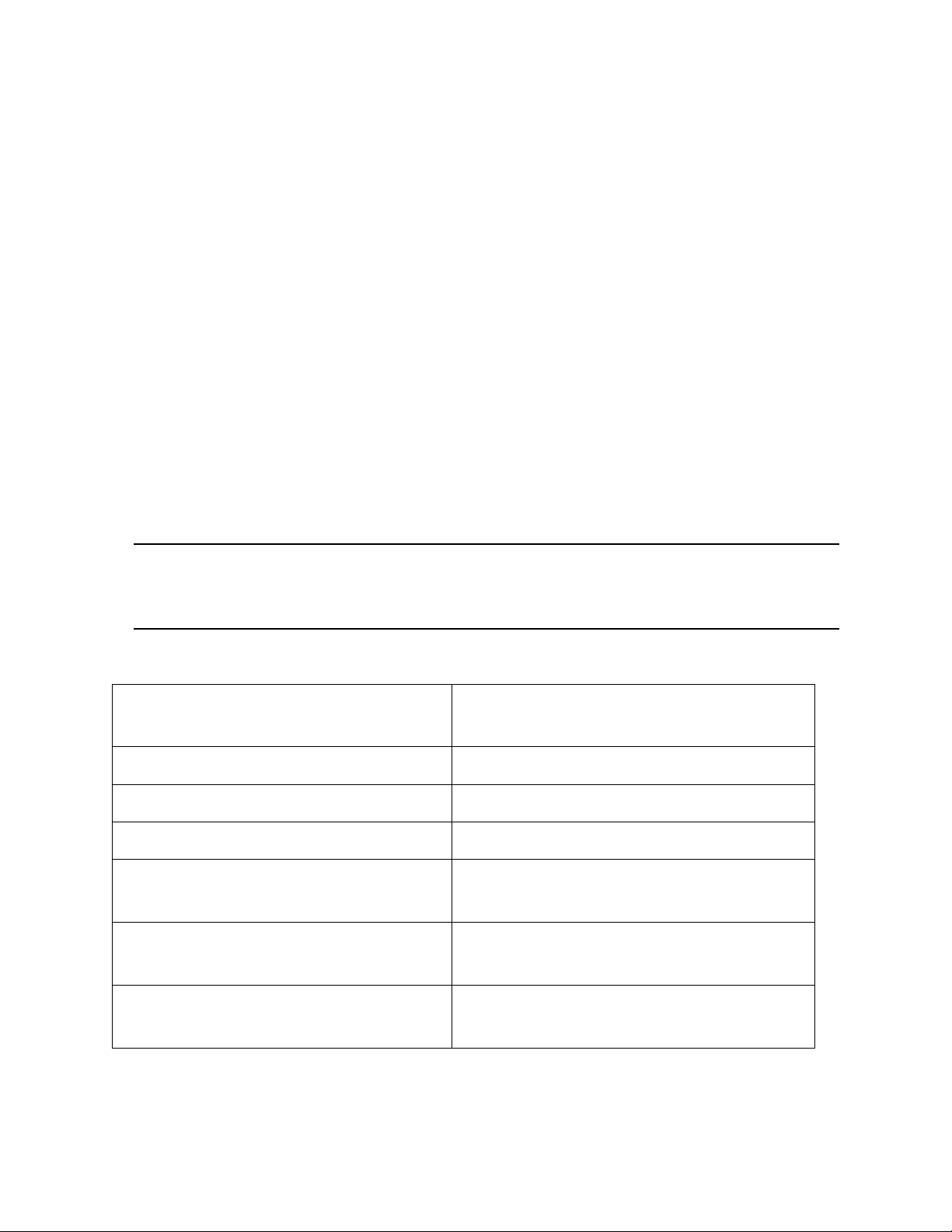

GX-2012 GAS 1, GAS 2 and Gas Tracer GAS 1 Tubing

Reference Figure 16 and Figure 17 for the instructions below.

1. Cut a 3-4” piece of 3/16 inch tubing for each GAS 1 and GAS 2 fitting on every

SDM-2012 except the last one.

2. Connect the tubing to the GAS 1 and GAS 2 fittings on every SDM-2012

except the last one.

3. Insert the smaller T-fittings into the tubing so that the remaining two ports on

the T-fitting are perpendicular to the GAS fitting.

4. Cut 6-7” pieces of 3/16 inch tubing and connect the T-fittings.

5. Cut two more 6-7” pieces of 3/16 inch tubing and connect the GAS 1 and GAS

2 fittings of the last SDM-2012 to the appropriate T-fittings from the second to

last SDM-201 2.

6. Cut 2 pieces of 3/1 6 inch tubi ng long enou gh for easy access to the calibrati on

cylinders and connect them to the T-fittings on the first SDM-2012.

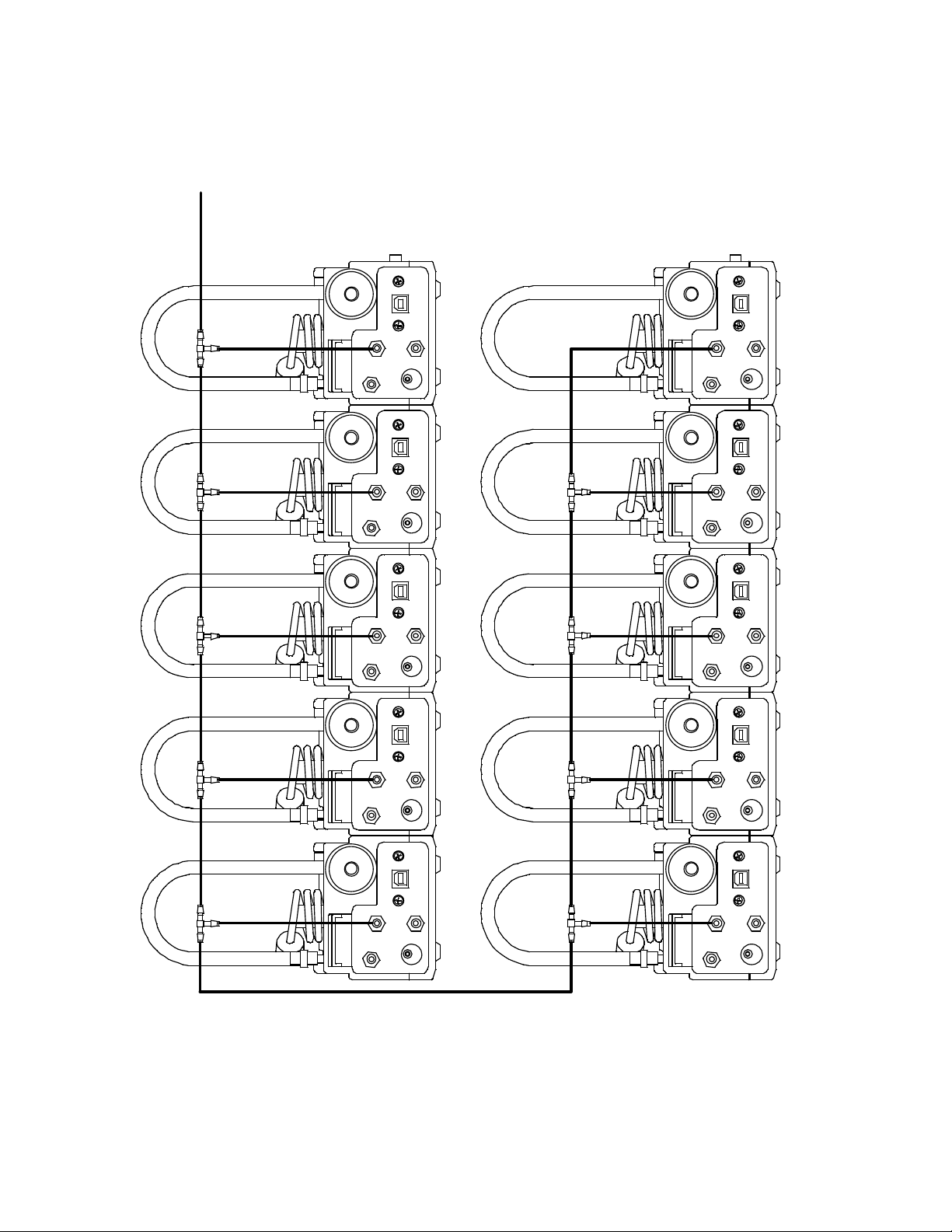

Gas Tracer GAS 2 Tubing

You must use a 6 inch humidifier during calibration of th e ppm combustible gas

sensor. There are 3 options for calibration:

• use one calibration cylinder, one demand flow regulator, and one 6 inch

humidifier per SDM-2012

• have one calibration cylinder, one demand flow regul ator, and one 6 inch

humidifier and calibrate all Gas Tracers one at a time using one SDM-2012

• use one calibrat io n cylinder, one demand flow regulator, an d a manifold of up to

ten 6 inch humidifiers

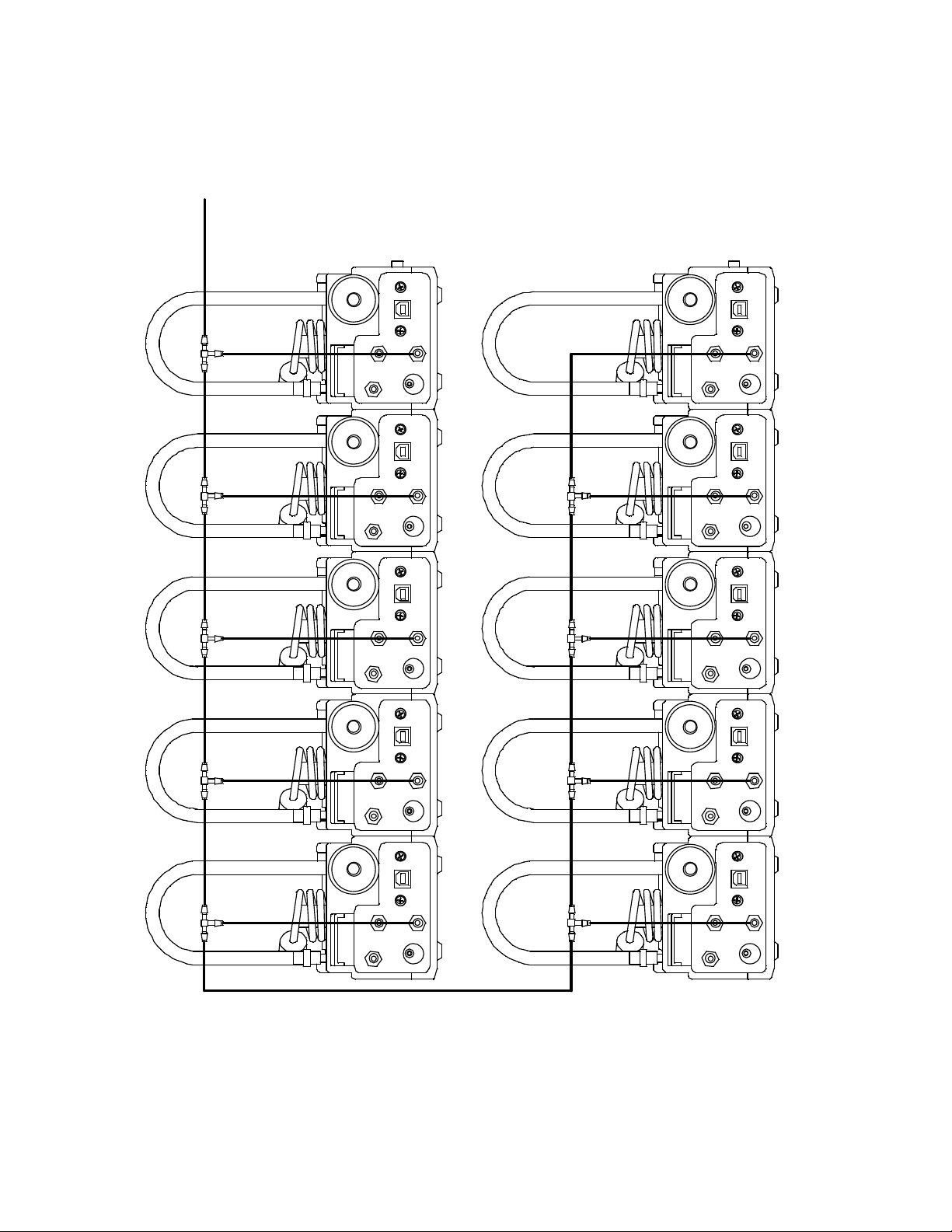

If you choose to manifold the humidifiers together, complete the following manifold

assembly instruct ions, and reference Figure 18.

17 • Hardware Setup

Page 23

NOTE: The following instructions can also be applied to the AIR fitting if you

are using a zero air cylinder and a humidifier tube to perform a WET air

adjustment.

1. Connect a 6 inch humidifier tube to the GAS 2 fitting on the back of each

SDM-2012.

2. Insert the smaller T-fittings into the open end of every humidifier tube except

the last one so that the remaining two ports on the T -fitting are perpendicular to

the GAS fitting.

3. Connect the last humidifier tube directly to the last T-fitting.

4. Cut 6-7” pieces of 3/16 inch tubing and connect the remaining T-fittings.

5. Cut a piece of 3/16 inch tubing long enough for easy access to the calibration

cylinders and connect them to the T-fitting on the first SDM-2012.

Hardware Setup • 1 8

Page 24

Unit 9 Unit 10

GAS2

GAS1

AIR

AIR

GAS1

GAS2

AIR

GAS1

GAS2

GAS2

GAS1

AIR

GAS2

GAS1

AIR

GAS2

GAS1

AIR

AIR

GAS1

GAS2

AIR

GAS1

GAS2

GAS2

GAS1

AIR

GAS2

GAS1

AIR

Unit 5

Unit 1Unit 2

Unit 3Unit 4

Unit 6 Unit 7 Unit 8

Figure 16: Gas 1 Manifold Connections

19 • Hardware Setup

Page 25

GAS2

GAS1

AIR

GAS2

GAS1

AIR

AIR

GAS1

GAS2

AIR

GAS1

GAS2

GAS2

GAS1

AIR

GAS2

GAS1

AIR

AIR

GAS1

GAS2

AIR

GAS1

GAS2

Unit 10Unit 9

Unit 8Unit 7Unit 6

Unit 4 Unit 3

Unit 2 Unit 1

Unit 5

GAS2

GAS1

AIR

GAS2

GAS1

AIR

Figure 17: Gas 2 Manifold Connections

Hardware Setup • 2 0

Page 26

GAS2

GAS1

AIR

Unit 2 Unit 1

AIR

GAS1

GAS2

Unit 9

GAS2

GAS1

AIR

Unit 10

AIR

GAS1

GAS2

Figure 18: Gas Tracer Humidifier Manifold

21 • Hardware Setup

Page 27

Connecting Calibration Gas

The GAS 1 and GAS 2 fittings on the back of the docking station are designed to be

used with a calibration gas cylinder that is fitted with a demand flow regulator. The

AIR fitting may be used with a demand flow regulator and a cylinder of zero

emissions air, but this is not normally necessary since the docking station will

generally be in a fresh air area.

The type of calibratio n g as cyli nd er u s ed de pen ds on the gas sensors installed in the

instrument being used w ith the cal ibration st ation. Typically a 4-gas m ix will be used if

the instrument being used with the calibration station is a 4-gas GX-2012 . If a 5sensor GX-2012 is being used, a 100% volume methane cylinder will also be needed.

If a Gas Tr acer is being used, a 1000 p pm me thane cylinde r and a 3-g as cylinde r are

needed. If a Gas Tracer with a %volume sensor is being used, a 1000 ppm methane

cylinder, a 3-gas cylinder, and a 100% volume methane cylinder are needed. The

1000 ppm methane cylinder should be connected to the GAS 2 fitting first. The

docking station will begin every bump test or calibration with the ppm sensor. The

user will need to ch ange th e GAS 2 cylinder to the 100% volu me m ethane cylin der (i f

%volume sensor installed) when prompted to do so by the PC Controller Program

during bump testing an d calib ra ti on .

Use Table 2 below as a guide in determ ining which and how many calibration gas

cylinders are appropriate for your system.

NOTE: Do not use a 4-gas cylinder or any cylinder that includes H2S when

bump testing or calibrating a Gas Tracer. H2S adversely affects the

ppm combustible sensor.

Table 2: Recommended Gas Cylinders

Typical Instrument Types

Recommended Calibration Gas

Cylinder(s)

LEL/Oxy/H2S/CO (GX-2012) 4-gas mix with CH4/Oxy/H2S/CO

LEL/Oxy/CO (GX- 2012) 3-gas mix with CH

/Oxy/CO

4

LEL/Oxy/H2S (GX-2012) 4-gas mix with CH4/Oxy/H2S/CO

%V o l CH4/LEL CH4/Oxy/H2S/CO

(GX-2012)

%V o l CH4/LEL CH4/Oxy/CO

(GX-2012)

ppm CH4/LEL CH4/Oxy/CO

(Gas Tracer)

• 4-gas mix with CH4/Oxy/H2S/CO

• 100% Volume CH

4

• 3-gas mix with CH4/Oxy/CO

• 100% Volume CH

4

• 3-gas mix with CH4/Oxy/CO

• 1000 ppm CH

4

Hardware Setup • 2 2

Page 28

Table 2: Recommended Gas Cylinders

Typical Instrument Types

ppm CH

/LEL CH4/%vol CH4/Oxy/CO

4

(Gas Tracer)

Recommended Calibration Gas

Cylinder(s)

• 3-gas mix with CH4/Oxy/CO

• 1000 ppm CH

• 100% volume CH

4

4

To connect calibration gas to the SDM-2012, do the following:

1. If the area around the docking station is not considered a fresh air area (an

area free of combustible and toxic gases and of normal oxygen content,

20.9%) install a tube not longer than 10 feet on the filter attached to the AIR

fitting on the back of the docking station and route it to a fresh air area or

connect a cylinder of zero air with a demand flow regulator to the AIR fitting.

2. Install the demand flow regulat or on the calibration gas cylin der(s).

3. Connect the demand flow regulator to the GAS 1 or GAS 2 inlet fitting using

the 3 foot length of 3/16 inch ID sample tubing provided with the docking

station.

For a 3- or 4-gas mix, connect the regulator to the GAS 1 inlet.

For a special calibration cylinder (ppm or %volume), connect the regulator to

the GAS 2 inlet.

NOTE: If you have set up a ma nifold for ca librati ng instr ume nt s, the r egula tors

can be connected to tubing leading to the manifold inlet in stead of

connected directly to the GAS 1 or GAS 2 inlet fitting.

EAGLE 2 and GX Type Instrument Connection

There are 2 different versions of the Docking Station PC Controller program. The

SDM-E2 Docking Station PC Controller program is intended for use with SDM-E2

docking stations and EAGLE 2 instruments. The SDM-GX Docking Station PC

Controller program is intended for use with GX t ype docking stations and GX type

instruments.

Bump tests and calibrations can be performed on multiple EAGLE 2s and GX type

instruments at the same time. The SDM-E2 Docking Station PC Controller program

controls the EAGLE 2 functions while the SDM-GX Docking Station PC Controller

program controls the GX type instrument functions. Both programs can be used

simultaneousl y on your PC. Fo llow all i nstructions i n the SDM- E2 Docking Station PC

Controlled Conf iguration Op erator’s Manual as well as th e instructions in thi s manual.

23 • EAGLE 2 and GX Type Instrument Connection

Page 29

Installing the SDM-GX Docking Station

PC Controller Software

1. Launch Windows®.

2. Exit from all applications and open windows.

3. There are two ways to install the SDM-GX Docking Station PC Controller

Software: by using the SDM-2012 product CD or by using the SDM-GX

Docking Station PC Controller Software Installation CD.

• If you are using the SDM-2012 Product CD, i nsert the Produ ct CD into your

computer’s CD-ROM drive. The CD will automatically open revealing

several folders. Open the S DM-GX Docking S tation PC Controller Software

folder, double click on setup.exe and continue with step 4.

• If you are using the SDM-GX Docking Station PC Controller Software

Installation CD, it will automatically begin the installation process. Insert it

in your computer’s CD-ROM drive, then continue with step 4.

4. The SDM-GX Docking Station PC Controller InstallShield Wizard comes up to

guide you through installation. Click Next to proceed to the License Agreement

window.

5. Read the license agreement and click the agreement acceptance selection

box, then click Next to proceed to the Customer Information window.

6. Enter a user name and organization and select if you want to install the

program for all users on the computer or just for your user account, then click

Next to proceed to the Destination Folder window.

7. The default installation folder (C:\Program Files\SDM-GX\) is displayed. If you

want to install the software in the default folder continue with step 8. If you

want to install the software in a different location, click Change and choose a

new installation folder and then continue with step 8.

8. Click Next to proceed t o the Ready to Install the Program window.

9. Review the installation settings. If they are OK, click Install and the installation

process will begin. If you want to change installation settings, click Back and

change them to the desired settings.

10. During software installation, the installation program may find newer versions

of Windows files on your computer than those in the Installation CD. If this

happens, the installation software will ask you if you want to keep these newer

files. Click Yes to do so.

Installing the SDM-GX Docking Station PC Controller Software • 24

Page 30

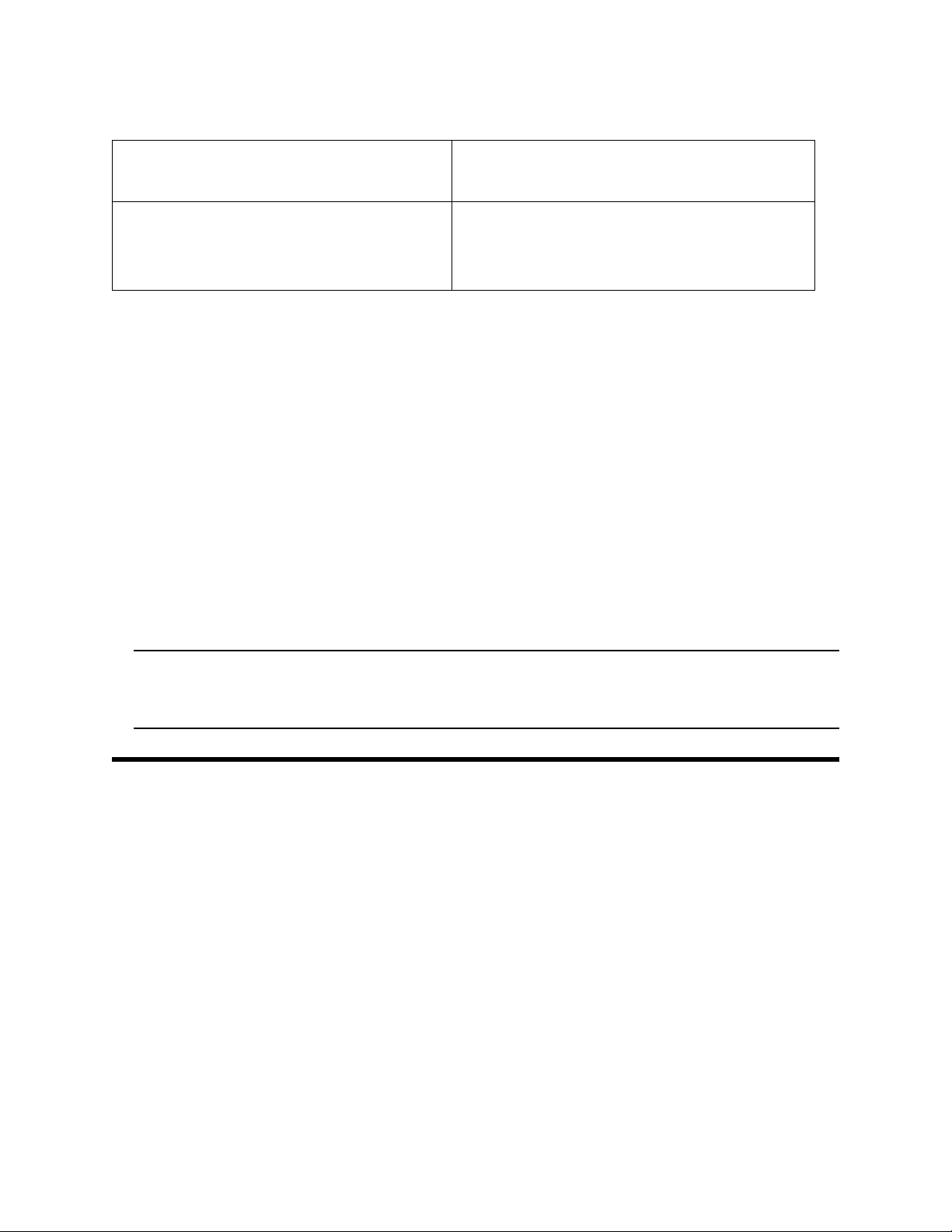

11. A Device Driver Window will appear prompting you to install necessary drivers.

You cannot continue the installation without installing the drivers.

Figure 19: Device Driver Installation

12. Click Next to install the drivers. The Wizard will find the appropriate drivers.

13. If this is the first time you are installing a PC Controller Program, a window will

appear saying that the file did not pass Windows logo testing. Click Continue

Anyway.

25 • Installing the SDM-GX Docking Station PC Controller Software

Page 31

14. Click Finish once the drivers are successfully installed.

Figure 20: Finish Device Driver Installation

The installation will continue.

15. Follow the on-screen instructions to complete software installation.

16. To complete the driver installation, ensure that all of your docking stations are

connected to your computer.

17. Turn on a docking station by pressing and holding the POWER button for at

least 1 second.

Installing the SDM-GX Docking Station PC Controller Software • 26

Page 32

18. The first time an SDM-2012 is turned on after being connected to the

computer, a Found New Hardware window will appear.

NOTE: The following instructions do not apply to computers running Windows

Vista or Windows 7. The hardware driver will automatically in stall and

you will be notified that the USB device is ready for use.

Figure 21: Found New Hardware Wizard

19. Select the “Install the software automatically” option and click Next.

27 • Installing the SDM-GX Docking Station PC Controller Software

Page 33

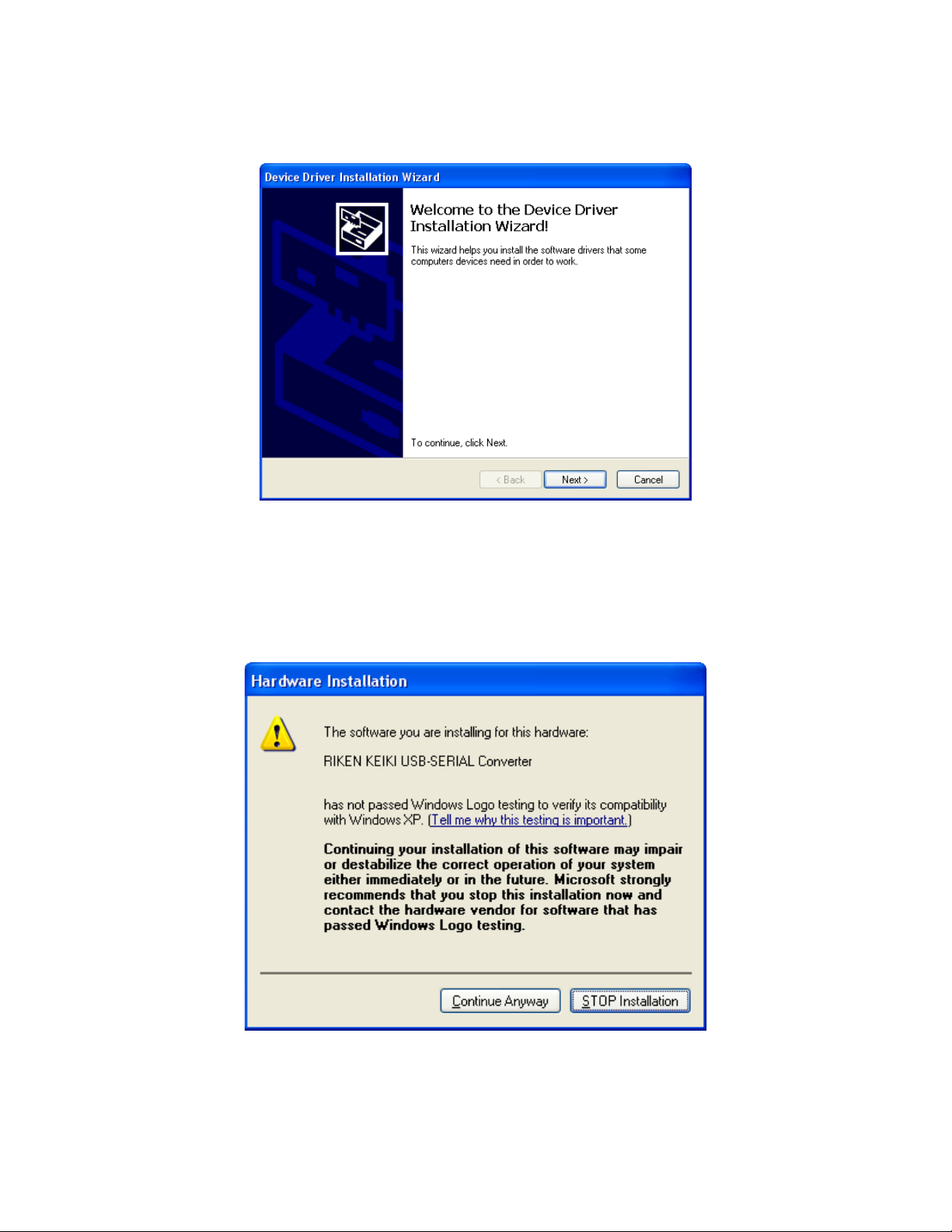

20. The wizard will search for the driver files.

Figure 22: Searching

21. Once the files have been found, a window will appear saying that the file did

not pass Windows logo testing. Click Continue Anyway.

Figure 23: Windows Logo Error

22. The installation will continue. Click Finish when the installation has comple ted.

23. Repeat steps 17 through 22 for every docking station in your system.

Installing the SDM-GX Docking Station PC Controller Software • 28

Page 34

Launching the SDM-GX Docking Station

PC Controller Program

1. Click Start on the Windows Icon Tray, then select Programs/SDM-GX

Docking Station PC Controller. You may also double click the shortcut

created on yo ur desktop. The SDM-GX Docking Station PC Controller

Program is launched and the main program window appears.

Figure 24: Main Program Window

2. If you are starting the software for the first time, a message window appears

informing you that a database has been created. Click OK in that window.

When starting the software for the first time, or if you wish to change the

software setup, proceed to the next section, "Overview of the SDM-GX

Docking Station PC Controller Program".

If you have al ready performed the software setup, proceed to “Connecting

Instruments to the PC Controller Program” on page 43.

29 • Launching the SDM-GX Docking Station PC Controller Program

Page 35

Overview of the SDM-GX Docking Station PC

Controller Program

This section pr ovides a brief overview of the program and a description of the main

program window. Instructions for using the program are given in other parts of this

manual. Use this section to become familiar with the main program window, but

before attempting to use the program, make sure to perform the program setup as

described in “Setting Up the PC Controller Program” on page 32.

The PC Controller Program is designed to provide manual or automated data

downloading, bump testing, and calibr ation of the GX-2012 and Gas Tracer. It also

provides the capability to update instrument parameters such as alarm points. The

program compiles a database of the instruments that have been connected to the

program which consists of calibration and bump test history, logged data (if a unit’s

data is downloaded), and memos that record user entered information about an

instrument at a particular time.

The GX-2012 and Gas Tracer are gas monitoring devices for combustible gas, O2,

H2S, and CO. They store logged data and calibration information in their internal

memory. See the GX-2012 Opera tor’s Manual or Gas T race r Operator’s Man ual for a

complete description of the GX-2012 or Gas Tracer.

PC Controller Program Functions

The PC Controller Program has the following basic functions accessed or controlled

by buttons in the main program screen.

• Gas cylinder setup accessed by the Cylinders control button

• Program and system configuration accessed by the Config control button (this

function is password protected)

• Data viewing accessed by the Logs control button

• Instrument bump testing controlled by the Bump test control button

• Instrument calibration controlled by th e Calibration control button

Overview of the SDM-G X Docking Station PC Controller Program • 30

Page 36

Main Program Window

Message Area

SDM-2012/Instrument

Display Area

The main program window is where the current status of the program operation is

shown. Any SDM-2012s and instruments that are currently connected to it and any

instruments that have previously been but are not currently connected to it are also

shown. The program’s various functions are initiated or accessed from this screen.

The current date and time are always displayed in the lower right corner of the main

program window.

Control Buttons

The Cylinders, Config, Logs, and Exit control buttons are located along the top

right of the window. The Bump test and Calibration control buttons are located in

the lower right of the window along with the Force Calibration selecti o n box. The use

of these control buttons and the Force Calibration selection box is described in other

parts of this manual.

SDM-2012/Instrument Displa y Are a

The large middle portion of the main program window displays SDM-2012s and

instruments that are currently connected to the PC Controller Program and

31 • Overview of the SDM-GX Docking Station PC Controller Program

Figure 25: Parts of the Main Program Window

Page 37

instruments t hat are i n the dat abase. The SDM-2012s are iden tified by a number. The

instruments are identified by their serial number. By selecting either the Icon radio

button or the Details radio button, the SDM-2012s and instruments can be displayed

either as icons or in a table format that shows various instrument parameter details

such as station ID, user ID, the next scheduled bump test date, and the next

scheduled calibration date among others. If the Only Connected Units box is

checked, then only instruments that are currently connected to the PC Controller

Program will be shown.

Program Status

Three areas of the main program window indicate the program status. The smaller

area in the lower left below the SDM-2012/instrument display area is the message

area. It displays messages that indicate actions and status of the program.

Below this area is t he com mu nic a ti ons por t in di cato r wh i ch sh ow s when the program

is communicating with the docking station(s).

To the right of the communications port indicator is the status field. It displays the

current status of the program. It can indicate if the software is in standby mode or if it

is downloading data among other indications.

Fitting Indicators

To the right of the status field are 3 round fitting indicators. They correspond to the

AIR and GAS fittings on the back of the SDM-2012. They indicate whether the

corresponding solenoid is activated so it can allow gas to flow through the fitting it

controls. When th e i ndicator is gree n, the fitt ing is act ive. When the i ndicat or i s bl ank,

the fitting is not active.

Setting Up the PC Controller Program

Once the program is installed, you must set up the program for your system. Setting

up the PC Controller Program consists of the following tasks:

• setting up the parameter configuration

NOTE: Only the Parameter tab of the Configuration Window is discussed in

this section. See “Config Window” on page 173 for a description of the

other tabs in the Configuration Window.

• setting up the SDM-2012 display order

• defining which calibration gas cylinders wil l be used

Setting Up the Configuration

1. Launch the program as described in “Launching the SDM-GX Docking Station

PC Controller Program” on page 29.

NOTE: It is not necessary to turn on the SDM-2012 docking st a ti on s i f you ar e

only performing confi guration setup.

Setting Up the PC Controller Program • 32

Page 38

2. The configuration parameters are located in the Configuration Window of the

SDM-GX Docking Station PC Controller program. To access the Configuration

Window, click the Config button along the top of the main program window.

3. You will be prompted to enter a password. The factory set password is

ABCDE. Enter the password and click OK keeping in mind that the password

is case sensitive. You may change the passwo rd using the Password Tab once

you have entered the Configuration Window. See “Password T ab” on page 175

for instructions to change the password.

4. The Parameter Tab of the Configura tion Window will be displayed.

Figure 26: Config Window Parameter Tab

33 • Setting Up the PC Controller Program

Page 39

5. Select the Instrument Information options.

• Change Parameter

If Change Parameter is selected (facto ry setting), the Edit function is a ctive

in the Instrument Function Menu allowing you to change various

parameters i n co nne cte d instr u me nts. See “Edit Function” on page 155 for

a complete description of the Edit function. If it is not selected, the Edit

function is not active. Select or deselect the Change Parameter box.

• Auto Pow er OFF Time

This is the length of time that wi ll pass after the last operation is finished

before the program will automatica lly shut off the instrument. If a

successful bump test or calibration is performed, the program will

automatically shut off the instrument in 20 seconds regardless of the Auto

Power OFF Time setting. Use the arrows to the right of the current setti ng

to change the value or highlight the current setting and type in the desired

value. It is defined in seconds with a maxi mum setting of 3600 seconds (1

hour). The factory setting is 3600 second s.

6. Select the Data Logger options.

• Down Load Data Logg er

The Down Load Data Logger selection allows you to have saved data

automatically downloaded from the instrument once it is connected to the

PC Controller program. The data will automatically be downloaded based

on the frequency set in the Down Load Interval option. The factory setting

is deselected. Select or deselect the Down Load Data Logger box.

• Clear After Down Load

The Clear After Down Load selection allows you to automatically clear the

instrument data logger after an automatic download. The factory setting is

deselected. Select or deselect the Clear After Down Load box. If Down

Load Data Logger is not selected, selecting Clear After Download has no

effect.

• Down Load Interval

The Down Load Interval is the length of time, in days, that will pass before

the PC Controller program will automatically download data from an

instrument if Down Load Data Logger is selected. If the instrument is

connected to the program before the inter val h as p assed, a data download

will not automatically occur. The Down Load Interval can be set anywhere

from 1 to 60 days. The factory setting is 1 day. Use the arrows to the right

of the current setting to change the interval or highlight the current setting

and type in the desired value.

7. SDM Selection

If you select the Initialize Display Order selection box, the PC Controller

Setting Up the PC Controller Program • 34

Page 40

program will reset the numbers it has assigned to specific docking stations and

reassign them as you turn SDM-20 12 docking sta tions on and connect them to

the program. See “Setting Up the SDM-2012 Display Order” on page 38 for

instructions to use this feature.

8. Select the Calibration options.

In the Calibrati on section of the Parameter Ta b, you can select Manual

Calibration or Auto Calibration.

If Manual Calibration is selected, you have to manually select an instrument or

instruments in the main program window and click Calibration in the lower right

corner of the window in order to perform a calibration.

If Auto Calibration is selected, and an instrument is due for calibration, a

calibration will automatically begin 1 minute after that instrument successfully

connects to the program and its instrument parameters are retrieved by the

program. When you select Auto Calibration, a window pops up indicating that

only sensors tested with GAS 1 and one sensor tested with GAS 2 will be

calibrated in auto calibration.

Every instrument configuration except a Gas Tracer with a %volume

combustible gas sen sor inst alled can be fully calib rated usin g Auto Cal ibration .

If you have a Gas Tracer with a %volume combustible sensor installed, only

the standard 3 sensor s (catalyti c LEL, O

, and CO) will be calibr ated. You must

2

perform a manual calibration in order to perform a complete calibration that

includes the ppm combustible sensor and the %volume sensor.

If neither box is selected, you will not be able to perform a calibration. The

factory setting is Manual Calibration selected and Auto Calibration deselected.

Select the box for the desired operation.

The Auto Calibration selection also has a Standard GAS and an All GAS

selection. If Standard GAS is selected, only the standa rd sensors (catalytic

LEL, O

, CO, and H2S [GX-2012 only]) will be calibrated during an au tomatic

2

calibration. If All GAS is selected, all installed sensors will be calibrated during

an automatic calibration for every instrument configuration except for a Gas

Tracer with a %volume sen sor inst alled . Only the st anda rd 3 sensor s (cat alytic

LEL, O2, and CO) will be calibrated in a Gas Tracer with a %volume s ensor

installed.

9. Select the Bump Test options.

The Bump Test section of the Parameters Tab allows you to make selections

35 • Setting Up the PC Controller Program

Page 41

related to the bump test functionality of the SDM-2012.

• Manual Bump Test/Auto Bump Test

You can select Manual Bump Test or Auto Bump Test.

If Manual Bump Test is selected, you have to man ually select an instrument

or instruments in the main program window and click Bump Test in the

lower right corner of the window in order to perform a bump test.

If Auto Bump Test is selected, and an instrument is du e for bump testin g, a

bump test will automatically begin 1 minute after that instrument

successfully connects to the program and its instrument parameters are

retrieved by the program. When you select Auto Bump T est, a window pops

up indicating that only sensors tested with GAS 1 and one sensor tested

with GAS 2 will be bump tested in auto bump test.

Every instrument configuration except a Gas Tracer with a %volume

combustible ga s sensor installed can be fully bump tested using Auto

Bump Test. If you have a Gas Tracer with a %volume combustible sensor

installed, only the standard 3 sensors (catalytic LEL, O2, and CO) will be

bump tested. You must perform a manual bump test in order to perform a

complete bump test that includes the ppm combustible sensor and the

%volume sensor.

If neither box is selected, you will not be able to perform a bump test. The

factory setting is Manual Bump Test selected and Auto Bump Test

deselected. Select the box for the desired operation.

The Auto Bump Test selection also has a Standard GAS and an All GAS

selection. If S t anda rd GAS is selecte d, only the st andard se nsors (cat alytic

LEL, O

, CO, and H2S [GX-2012 only]) will be bump tested during an

2

automatic bump test. If All GAS is selected, all installed sensors will be

bump tested during an automatic bump test for every instrument

configuration except for a Gas Tracer with a %volume sensor installed.

Only the standard 3 sensors (catalytic LEL, O2, and CO) will be bump

tested in a Gas Tracer with a %volume sensor installed.

• Interval

The Interval can be set an ywhe re be tween 1 and 30 days an d is th e lengt h

of time that can pass before the program will prompt you to perform a bump

test. The factory setting is 30 days.

Use the arrows to the right of the curren t interval or highlight t he current

Setting Up the PC Controller Program • 36

Page 42

setting and type in the desired value. The value you type in must be valid

(between 1 and 30 ).

• Gas Exposure Time

The Gas Exposure Time can be set to 30 (factory setting), 45, 60, 90, 120

seconds or Auto and is the length of time that gas is applied to the

instrument. If you select Auto, the PC Controller program will apply gas for

the appropriate amount of time based on your instrument sensor

configurations.

To change the Gas Exposure Time, click on the current setting. A drop

down menu will appear. Select the desired time.

• Tolerance

The Tolerance can be set between 10% and 50%. The factory setting is

50%. It determines how close the instrume nt gas reading must be to th e

calibration gas concentration for each channel during a bump test in order

to pass the bump test. It is defined as a percentage of the calibration gas

concentration.The amount that the instrument gas reading differs from the

calibration gas conce ntra tion mu st be equ al to or less th an thi s perce nt age

of the calibration gas concentration. For example, if the tolerance is set to

50%, and the %LEL calibration gas concentration is 50% LEL, then the

bump test gas reading for the LEL channel on the instrument must be 50

%LEL ± 25 %LEL.

To change the Tole rance, use the arrows to the right of the current setting

or highlight the curren t setting an d type in the de sired value . The valu e you

type in must be valid (between 10 and 50%).

10. When you are finished making changes, click OK. If you want to save the

changes, click Yes in the window that comes up. If you do not wa nt to save the

changes, click No in the window that comes up. To return to the Configuration

Window, click Cancel.

To exit the Configuration Window and return to the main program windo w

without savi ng any changes, click Cancel in the Configuration Wind ow and

click OK in the confirmation screen that comes up.

37 • Setting Up the PC Controller Program

Page 43

Setting Up the SDM-2012 Display Order

Setting up the display order for your SDM-2012s ensures that the docking stations

will appear in the PC Controller program in the same order that they are laid out in

your calibration area.

Before performing this operation, make sure your SDM-2012s are arranged on the

table top or other surface as desired and that they are connected to the computer.

See “Hardware Setup” on page 13. Also be sure that you have performed the driver

installations as described in “Installing the SDM-GX Docking Station PC Controller

Software” on page 24.

1. Click the Config button along the top of the screen to access the Configuration

Window.

2. You will be prompted to enter a password. The factory set password is

ABCDE. Enter the password and click OK keeping in mind that the password

is case sensitive. You may change the passwo rd using the Password Tab once

you have entered the Configuration Window. See “Password T ab” on page 175

for instructions to change the password.

3. The Parameter Tab of the Configura tion Window will be displayed.

Figure 27: Config Window Parameter Tab

Setting Up the PC Controller Program • 38

Page 44

4. Click the box next to Initialize Display Order in the SDM portion of the

Parameter tab.

5. Click OK.

6. The program will ask if you want to save the changes. Click Yes.

7. A window will appear infor ming you that you need to turn off all SDMs and

restart the program. Click OK.

8. Click the Ex it button in the upper right corner of the main program window to

exit the program.

9. Turn off all of the SDM-2012s if they are on.

10. Open the SDM-GX Docking Station PC Controller program again.

11. Turn on your SDM-2012s in the order that you wis h for them to appear on the

main program window . T ypically the order in which the docking stations appear

on the screen corresponds to their left to right arrangement on the tabletop.

12. Your SDM-2012 docking stations should all appear on the scr ee n in nu m er ical

order. The program will remember each SDM-2012’s number. If fewer than all

of the docking stations are turned on, the stations will still ap pear in numerical

order on the Main Program Window, but the stations which are off will not be

shown.

13. If you need to reorder the docking stations, repeat steps 1 through 12.

39 • Setting Up the PC Controller Program

Page 45

Cylinders Window

The Cylinders Window allows you to keep track of cylinders that are in use and the

expiration date for those cylinde rs. If a cylinder’s expiration date has passed, the PC

Controller program will alert you in the message area of the main program window as

soon as the progr am is st arte d. The Cyli nde rs win dow com es wi th a lis t of pre def ined

cylinders that are fair ly comm on. If a cyli nder th at you ne ed to u se is no t on thi s list, i t

can be added at the bottom of the cylinder list. You may add as many custom

cylinders as necessary.

Figure 28: Cylinders Window

The Cylinders window has the cylinder list number, the cylinder name, the part

number, the expiration date, and the status of the cylinder.

Selecting a Cylinder from the Predefined List

The Cylinders Window comes with several predefin ed cylinders that you can choo se

from.

1. To access the Cylinders Window, click the Cylinders button along the top of the

main program window.

Setting Up the PC Controller Program • 40

Page 46

2. Click in a Name field, click on the drop down menu that appears, and select a

predefined cylinder.

Figure 29: Predefined List of Cylinders

3. Set the expiration date by clicking in the Expiration field and clicking the drop

down menu that appears. Use the calendar to choose an expiration date. The

expiration date box will be h i ghlighted in orange if the expiration date of the

cylinder is less than 10 days away. The expiration date box will be highlighted

in red if the expiration date has passed.

4. Select or deselect the Active box for each cylinder. If the cylinder is active, the

PC Controller program will alert you at start up if the cylinder has passed its

expiration date. If it is not active, the program will not alert you.

5. To return to the main program window without saving any changes, click

Cancel in the Cylinders Window. A window will appear notifying you that

changes will not be saved. To continue to the main program window, click OK.

To return to the Cylinders Window to save your changes, click Cancel.

6. If you want to save any changes made, click OK. A window will appear asking

if you want to save the changes you made. To return to the main program

window and save your changes, click Yes. To return to the main program

window without saving changes, click No. To return to the Cylinders Window,

click Cancel.

41 • Setting Up the PC Controller Program

Page 47

Defining New Cylinders

If your instrument configuration requires the use of a cylinder that is not in the

predefined list, you can add that cylinder by either typing in the information for the

cylinder or by editing the information for an existing cylinder.

1. To access the Cylinders Window, click the Cylinders button along the top of the

main program window.

2. Click in any blank cylinder name field and click again to bring the cursor up or

use the drop down menu to sele ct a cylinde r name tha t is clo se to the one you

want and click the name to bring the cursor up.

Figure 30: New Cylinder

3. Type in the name of your new cylinder (ie. gas name and concentration).

4. Click in the Part No fiel d once to select it and once mo re to b ring the cursor up.

Type in the part number for your new cylinder (typically the RKI part number).

5. Click in the Expiration field and cli ck on the drop do wn menu that appears. Us e

the calendar to select an expiration date. The expiration date box will be

highlighted in orange if the expiration date of the cylinder is less than 10 days

away. The expiration date box will be highlighted in red if the expiration date

has passed.

Setting Up the PC Controller Program • 42

Page 48

6. Select the Active box if you want the PC Controller program to alert you when

the cylinder’s expiration date has passed. If you do not want the program to

alert you, leave the box deselected.

7. To enter any more cylinders, repeat step 3 through step 6.

8. To return to the main program window without saving any changes, click

Cancel in the Cylinders Window. A window will appear notifying you that

changes will not be saved. To continue to the main program window, click OK.

To return to the Cylinders Window to save your changes, click Cancel.

9. If you want to save any changes made, click OK. A window will appear asking

if you want to save the changes you made. To return to the main program

window and save your changes, click Yes. To return to the main program

window without saving changes, click No. To return to the Cylinders Window,

click Cancel.

Connecting Instruments to the

PC Controller Program

NOTE: Be sure to set up the display order for the SDM-2012s as described in

“Setting Up the SD M-2012 Display Order” on page 38, before

continuing.

Do the following to turn on the SDM-2012s and establish a connection with the

instruments in your system:

1. If necessary, verify that the SDM-20 12( s) a re a r ra ng ed on the work surface as

desired, all plumbing is installed, and all hardware and cables are installed.

See “Hardware Setup” on page 13.

2. Launch the SDM-GX Docking Station PC Controller Software as described in

“Launching the SD M -GX Do ckin g Station PC Co ntr ol ler P ro gr am” o n page 29.

43 • Connecting Instruments to the PC Controller Program

Page 49

3. Install an instrument in the appropriate recess of the instrument cradle. The

GX-2012 or Gas

Tracer with Alkaline

Battery P ack

GX-2012 or Gas

Tracer wi th Li-Ion

Battery P ack

plastic flap should be cove ring the recess not in use. Flip th e plastic fla p over if

it is covering the recess you need to use.

NOTE: If you are only chargi ng an instrumen t or viewing or editi ng parame ters,

you do not need to connect the gas out to instrument line or the

exhaust line to the instrument.

Figure 31: Inserting the Instrument

Connecting Instruments to the PC Controller Program • 44

Page 50

4. Turn on each SDM-2012 by pressing and holding the SDM-2012’s POWER

button. When the control panel LEDs turn on, release the POWER button.

5. The BUMP T and CAL S LEDs will turn off and the COPY LED will be

steadily on or off. It will be on if the SDM-2012 was used in Standalone

Configuration and calibration and bump test records are still stored in the

SDM-2012’s memory (see the SDM-2012 Docking Station Standalone

Configuration Manual for more information). The CHARGE LED will be

blinking green if the SDM-2012 is operating properly or solid red if there is a

system failure.

6. When a connection has been established between the SDM-GX Docking

Station PC Controller Program and all of the SDM-2012s, the main program

window will appear as shown below.

Figure 32: SDM-2012 Connection

7. Connect the gas out to instrument line of each SDM-2012 to the inlet of each

instrument.

45 • Connecting Instruments to the PC Controller Program

Page 51

8. Turn on each instrument by pressing and holding the POWER ENTER button

50

12.0

50

25.0

%

ppm

ppm

CH4

O2

CO

H2S

TRANSMIT

%LEL

12.0

50

25.0

%

ppm

ppm

CH4

O2

CO

H2S

TRANSMIT

ppm

12.0

50

25.0

%

ppm

ppm

CH4

O2

CO

H2S

TRANSMIT

vol%

%LEL

12.0

50

25.0

%

ppm

ppm

CH4

O2

CO

H2S

TRANSMIT

ppm

Standard 4-Gas GX-2012 %Volume GX-2012

Standard Gas Tracer %Volume Gas Tracer

vol%

%LEL

%LEL

0

20.9

0

0.0

vol%

%LEL

%

ppm

ppm

CH4

O2

NORMAL ?

CO

H2S

on each instrument until you hear a beep, then rel ea s e it. The instrument will

begin its power up sequence (see exceptions below in step 9). If a successful

connection between the instrument and the SDM-2012 occurs, the home

screen will appear on the instrument display at the end of the start up

sequence. The heart symbol will be flashing and the instrument display will

appear as shown below depe ndin g on the connect ed in strum ent. If th e charge

LED was amber, it will begin to blink green and the battery charging will stop

until the instrument is turned off.

9. There are three exceptions to the seq uen ce described above in step 8 above.

See the GX-2012 Operator’s Manual or the Gas Tracer Operator’s Manual for