Page 1

SDM-2009 Docking Station

PC Controlled Configuration

Operator’s Manual

Part Number: 71-0262RK

Revision: F

Released: 12/12/17

www.rkiinstruments.com

Page 2

Warranty

RKI Instruments, Inc. warrants gas alarm equipment sold by us to be free from

defects in materials and workmanship, and performance for a period of one year from

date of shipment from RKI Instruments, Inc. Any parts found defective within that

period will be repaired or replaced, at our option, free of charge. This warranty does

not apply to those items which by their nature are subject to deterioration or

consumption in normal service, and which must be cleaned, repaired, or replaced on

a routine basis. Examples of such items are:

Absorbent cartridges Batteries

Pump diaphragms and valves Filter elements

Fuses

Warranty is voided by abuse including mechanical damage, alteration, rough

handling, or repairs procedures not in accordance with the instruction manual. This

warranty indicates the full extent of our liability, and we are not responsible for

removal or replacement costs, local repair costs, transportation costs, or contingent

expenses incurred without our prior approval.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ANY AND ALL OTHER

WARRANTIES AND REPRESENTATIONS, EXPRESSED OR IMPLIED, AND

ALL OTHER OBLIGATIONS OR LIABILITIES ON THE PART OF RKI

NSTRUMENTS, INC. INCLUDING BUT NOT LIMITED TO THE WARRANTY

I

OF MERCHANTABILITY OR FITNESS FOR A PARTIC ULAR PURPOSE. IN

NO EVENT SHALL RKI INSTRUMENTS, INC. BE LIABLE FOR INDIRECT,

INCIDENTAL, OR CONSEQUENTIAL LOSS OR DAMAGE OF ANY KIND

CONNECTED WITH THE USE OF ITS PRODUCTS OR FAILURE OF ITS

PRODUCTS TO FUNCTION OR OPERATE PROPERLY.

This warranty covers instruments and parts sold to users only by authorized

distributors, dealers, and representatives as appointed by RKI Instruments, Inc.

We do not assume indemnification for any accident or damage caused by the

operation of this gas monitor and our warranty is limited to replacement of parts or our

complete goods.

Warranty

Page 3

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

System Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

About This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Cautions & Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

AC Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Single-Port AC Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4-Port AC Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

USB Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Air Filter, Sample Tubing, and Check Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Instrument Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Back Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Power Jack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Sample Fittings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

PC Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

USB Hub Requirements for Multiple Station Systems. . . . . . . . . . . . . . . . . . . . . . . 11

Hardware Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Hardware Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Assembling a Manifold for Multiple SDM-2009 Units . . . . . . . . . . . . . . . . . . . . . 13

Exhaust Tubing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

GAS Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Connecting Calibration Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

EAGLE 2 and GX Type Instrument Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Installing the SDM-GX Docking Station PC Controller Program . . . . . . . . . . . . . . . 18

Launching the SDM-GX Docking Station PC Controller Program. . . . . . . . . . . . . . 23

Table of Contents

Page 4

Overview of the SDM-GX Docking Station PC Controller Program . . . . . . . . . . . . 24

PC Controller Program Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Main Program Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Control Buttons. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

SDM-2009/Instrument Display Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Program Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Fitting Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Setting Up the PC Controller Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Setting Up the Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Setting Up the SDM-2009 Display Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Cylinders Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Selecting a Cylinder from the Pre-Defined List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Defining New Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Connecting Instruments to the PC Controller Program. . . . . . . . . . . . . . . . . . . . . . 38

Icon View vs. Details View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Exporting an Instrument List from the Main Program Window . . . . . . . . . . . . . . 43

Automatic Bump Testing and Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Bump Testing a GX-2009. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Calibrating a GX-2009 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Charging an Instrument in an SDM-2009. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Recharging the Batteries After Performing a Bump Test or Calibration . . . . . . . 67

Recharging the Batteries Without Performing Any Operations . . . . . . . . . . . . . . 68

Batteries Too Drained for PC Controller Operation. . . . . . . . . . . . . . . . . . . . . . . 69

Logs Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Alarm Trend Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Calibration Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Event Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Interval Trend Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Memo Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Bump Test Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Table of Contents

Page 5

Deleting Data in the Logs Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Instrument Function Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Open Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Edit Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Parameter Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Sensor Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Download Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Clear Logs Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Power Off Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Config Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Parameter Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Database Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Password Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Spare Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

CAUTION: Read and understand this manual before using the SDM-2009. Also

read and understand the GX-2009 Operator’s Manual.

Table of Contents

Page 6

Introduction

This section briefly describes the SDM-2009 Docking Station, the Single Module Data

Viewer Program, and the SDM-GX Docking Station PC Controller Program. This

section also describes the SDM-2009 Docking Station PC Controlled Configuration

Operator’s Manual (this document). Table 1 at the end of this section lists the SDM-

2009’s specifications.

The SDM-2009 Docking Station is an advanced, reliable system that provides

charging, calibration, bump testing, and calibration and bump test records for the

GX-2009 portable gas monitor. It is designed to save the calibration and bump test

records to a USB flash drive (standalone functionality) or to be connected directly to a

computer (PC controlled functionality). If calibration and bump test records are stored

to a USB flash drive while operating in the standalone configuration, the Single

Module Data Viewer Program can then be used with a Windows-based personal

computer to retrieve calibration and bump test data files from the USB flash drive or

from the computer’s hard drive if the files have been transferred to the hard drive from

the flash drive. If you are using the PC Controller Program while operating in the PC

controlled configuration, you may retrieve instrument data, bump test, and calibrate

up to 10 units at once. Instrument information and data for each instrument can be

viewed directly using the PC Controller Program and can be printed from the PC

Controller Program. For instructions to use the SDM-2009 in the Standalone

configuration, see the SDM-2009 Docking Station Standalone Configuration

Operator’s Manual.

The purpose of this manual is to explain how to set up and use the SDM-2009 in PC

Controlled configuration. It also explains how to use the SDM-GX Docking Station PC

Controller Program. You will learn how to:

• install and launch the SDM-GX Docking Station PC Controller Program

• setup the SDM-GX Docking Station PC Controller Program for use with the

SDM-2009

• prepare the SDM-2009 for use

• bump test and calibrate up to 10 units using the PC controlled configuration

• use the SDM-2009 to charge a GX-2009

• view, print, and export calibration and bump test records

• view instrument information and data using the PC Controller Program

• update instrument parameters using the PC Controller Program

1 • Introduction

Page 7

CAUTION: The GX-2009 detect s oxygen deficien cy and elevated levels of oxygen,

combustible gases, carbon monoxide, and hydrogen sulfide, all of

which can be dange r ous or life threatening. When using the GX-2009,

you must follow the instructions and warnings in the GX-2009

Operator’s Manual to assure proper and safe operation of the unit and

to minimize the risk of personal injury.

CAUTION: The operator of this instr umen t is advised that if the equi pment is u sed

in a manner not specifie d in this manual, the protection pr ovided by the

equipment may be impaired.

System Requirements

To use the SDM-GX Docking Station PC Controller Software, your personal computer

must meet the following requirements:

• Operating Systems: Windows® XP, Windows® Vista, Windows® 7,

®

Windows

8, or Windows® 10.

• Processor: IBM

®

compatible PC running Pentium® 2 processor or equivalent

minimum

• Memory: 32 MB RAM minimum

• Hard Disk Space: 32 MB minimum

• One (for 4 or less SDM-2009s) or two (for 5 or more SDM-2009s) available

USB port(s), one or two USB hubs may also be needed depending on the

number of SDM-2009s in your system. See “USB Hub Requirements for

Multiple Station Systems” on page 11.

System Requirements • 2

Page 8

Specifications

Table 1: SDM-2009 Specifications

Input Power 12 VDC

NOTE: AC Adapter with 100 - 240 VAC, 50/60 Hz,

0.6A input and 12 VDC, 1.2A output provided as

standard.

Environmental Conditions • For Indoor Use Only

• -10° C to 40° C, below 80% Relative Humidity, NonCondensing

Applicable Instrument GX-2009

Memory Capacity 64 KB (Standalone configuration only)

Maximum Record Size 256 bytes (Standalone configuration only)

Maximum Number of

200 (Standalone configuration only)

Records Saved

Number of Calibration Gas

Cylinders

One calibration gas cylinder per bump test or

calibration

Standard Accessories • AC Adapter

• USB Flash Drive

• Single Module Data Viewer Program*

• SDM-GX Docking Station PC Controller

Program*

• Inlet Air Filter

• Instruction Manual

• 10 Foot Long 5/16 Inch Exhaust Tube

• One 3 Foot Long 3/16 Inch Tube for GAS

Fitting

• 10 Foot Long 3/16 Inch Tube for GAS Fitting

Manifolding

•2 T-Fittings

• Check Valve

• USB Cable, Type A to Type B

Not sent with SDM-2009. Download from www.rkiinstruments.com/sdm2009.

*

3 • Specifications

Page 9

NOTE: The bump test function of the GX-2009 is included in instruments with

firmware version 03955 or later installed. GX-2009 instruments

shipped after May 2011 include the bump test function. Instruments

that have a serial number starting with 04516 or later shipped from the

factory with the bump test function available. Instruments that have a

serial number starting with 04515 did not include the bump test

function when shipped from the factory. The factory setting for the

bump test function is off. Any GX-2009 can be bump tested using the

SDM-2009 and the PC Controller Program regardless of its firmware

version.

About this Manual

The SDM -2009 Docking Stati on PC Controlled Configuration Ope rator’s Manu al uses

the following conventions for notes, cautions, and warnings.

NOTE: Describes additional or critical information.

CAUTION: Describes potentia l dam a ge to equ i pm en t.

WARNING: Describes potential danger that can result in injury or death.

Cautions & Safety Information

• Use only polyurethane sample tubing with the SDM-2009. Consult RKI

Instruments, Inc. for other materials.

• Do not subject the SDM-2009 to infrared or intense light. This may cause

communication errors.

• Do not expose the SDM-2009 to water.

• Do not subject the SDM-2009 to any hard impact.

About this Manual • 4

Page 10

Description

To Power Jack

on SDM-2009

Back Panel

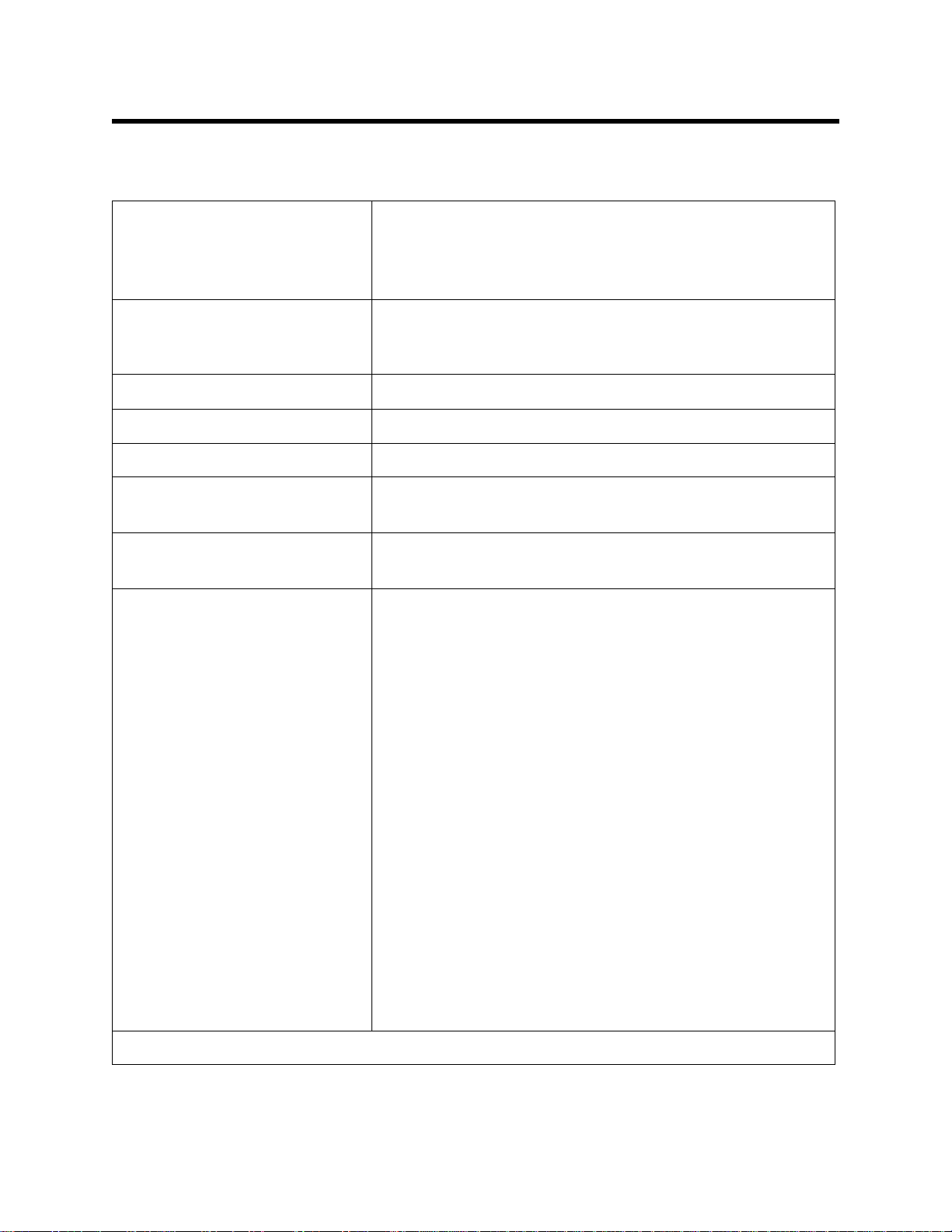

Figure 1: Single-Port AC Adapter

To Power Jack

on SDM-2009

Back Panels

Figure 2: 4-Port AC Adapter

This section describes the SDM-2009 docking station. It is designed to be used on a

table top and consists of the AC adaptor, Type A to Type B USB cable, air filter, check

valve, 3 plastic T-fittings, sample tubing, instrument panel, back panel, control panel,

status LEDs, and 2 USB ports.

AC Adapter

Single-Port AC Adapter

The single-port AC adapter is a wall plug style adapter with a 5 foot cable. The end of

the cable has a plug that connects to the power jack on the SDM-2009’s back panel.

The AC adapter is rated 100 - 240 VAC input, 12 VDC 1.2 A output.

4-Port AC Adapter

The 4-port AC adapter is a wall plug style adapter with four 5-foot cables. The end of

each cable has a plug that connects to the power jack on the SDM-2009’s back

panel. The AC adapter is rated 100 - 240 VAC input, 12 VDC 2.0 A output.

5 • Description

Page 11

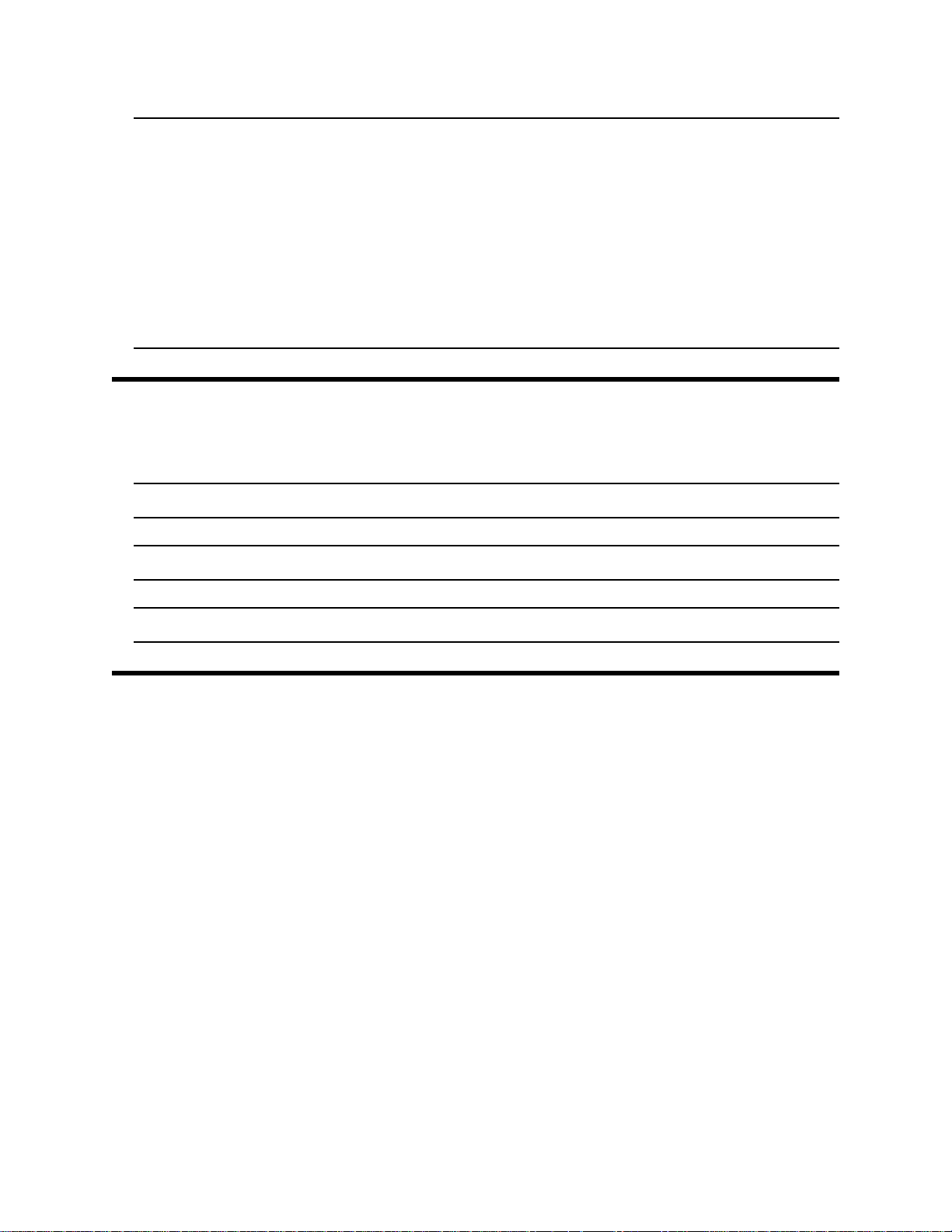

USB Cable

Type A, for

connection to

PC USB port

Type B, for connection

to USB port on the

SDM-2009's back panel

Exhaust Tubing, 5/16 Inch

ID,10 feet

Calibration Gas Sample Tubing, 3/16

Inch ID, 3 feet

Particle Filterfor Air Inlet

Manifold Tubing, 3/16 Inch

ID,10 feet

Figure 4: Air Filter & Sample Tubing

A Type A to Type B USB cable is provided with the docking station. It is used to

connect the USB port on the back of the SDM-2009 to a computer.

Figure 3: USB Cable

Air Filter, Sample Tubing, and Check Valve

A cylindrical particle filter with a short length of tubing is supplied with the SDM-2009

for installation to the AIR fitting on the back panel. The filter keeps particulate

contamination out of the docking station.

Three types of sample tubes are included with the docking station. One 3 foot length

of 3/16 inch ID polyurethane tubing is provided to connect the regulator on a

calibration cylinder to the GAS fitting on the back panel. One 10 foot length of 3/16

inch ID polyurethane tubing is provided for GAS fitting manifold construction (if

desired). In addition, a 10 foot length of 5/16 inch ID polyurethane tubing is provided

for connection to the exhaust fitting on the back panel to allow routing of the exhaust

to a location such as an open window where the exhaust can disperse.

WARNING: Do not use an exhaust tube that is longer than 10 feet. The increased flow

restriction caused by a longer tube may affect gas response and cause

inaccurate calibration and bump test results.

Description • 6

Page 12

A check valve is included with the SDM-2009. It is intended for use on the exhaust

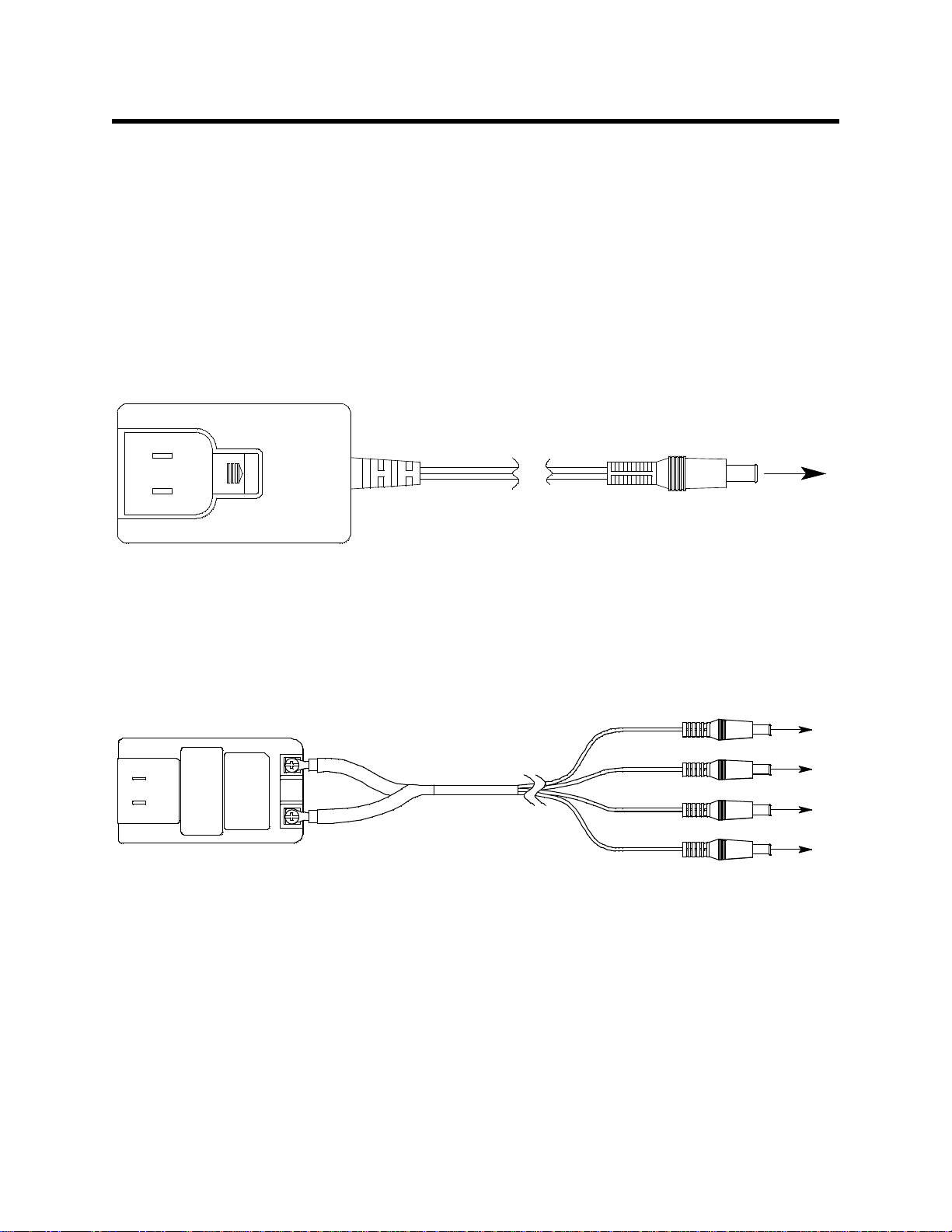

Figure 5: Check Valve

For Exhaust

Tubing

For GAS

Tubing

Figure 6: T-Fittings

fitting when manifolding multiple docking stations together. See “Assembling a

Manifold for Multiple SDM-2009 Units” on page 13 for manifolding instructions.

Two T-fittings are included with the SDM-2009. The larger fitting is for the exhaust

tubing manifold construction. The smaller fitting is for the GAS tubing manifold

construction.

7 • Description

Page 13

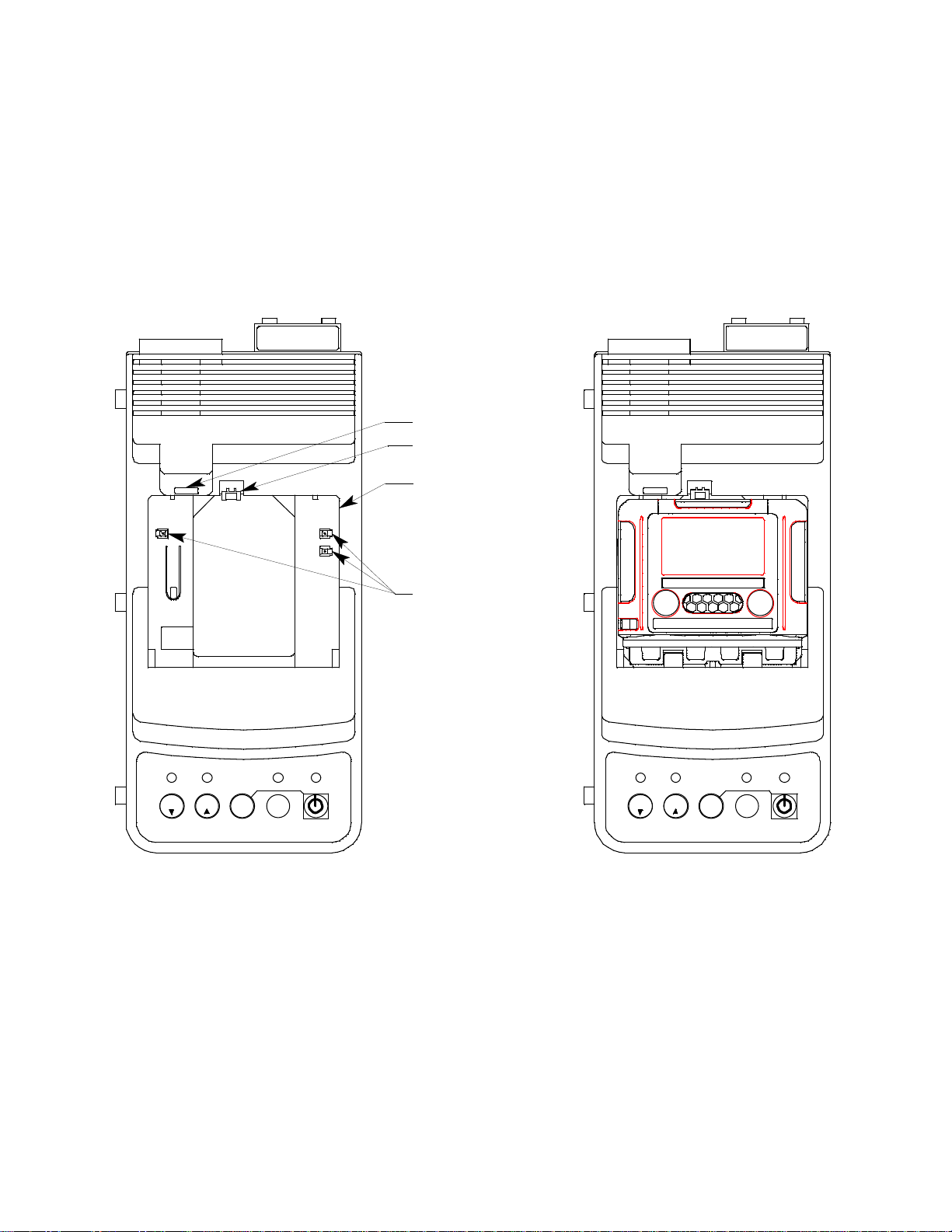

Instrument Cradle

EDIT

ENTER

CAL.

POWER

CHARGE

SDM-2009

1SEC ON

3SEC OFF

COPY

GX-200 9 OFF

BUMP

SDM-2009 Without GX-2009

H2SCO%LELO

2

RKI GX-2009

POWER

MODE

AIR

BUMP

GX-200 9 OFF

COPY

1SEC ON

3SEC OFF

SDM-2009

CHARGE

POWER

CAL.

EDIT

ENTER

Charging Contacts

SDM-2009 With GX-2009

IR Port

Inst rum ent Cradle

Instrument Retaining

Tab

Figure 7: Instrument Cradle

The instrument cradle is a recessed area on the top of the SM-2009 that is designed

to accept the GX-2009. Insert the GX-2009 in the instrument cradle when you

perform a bump test or calibration. The cradle has charging contacts on the bottom

that mate with the contacts on the back of the GX-2009. There are sample ports in

the front of the cradle that match up with the GX-2009’s sensors and route air and

calibration gas to the sensors during a bump test or calibration. An infrared (IR) port

at the back of the cradle lines up with the GX-2009’s IR port when it is inserted in the

cradle and is used to communicate with the GX-2009. A retaining tab that holds the

GX-2009 in the cradle is located to the right of the IR port.

Description • 8

Page 14

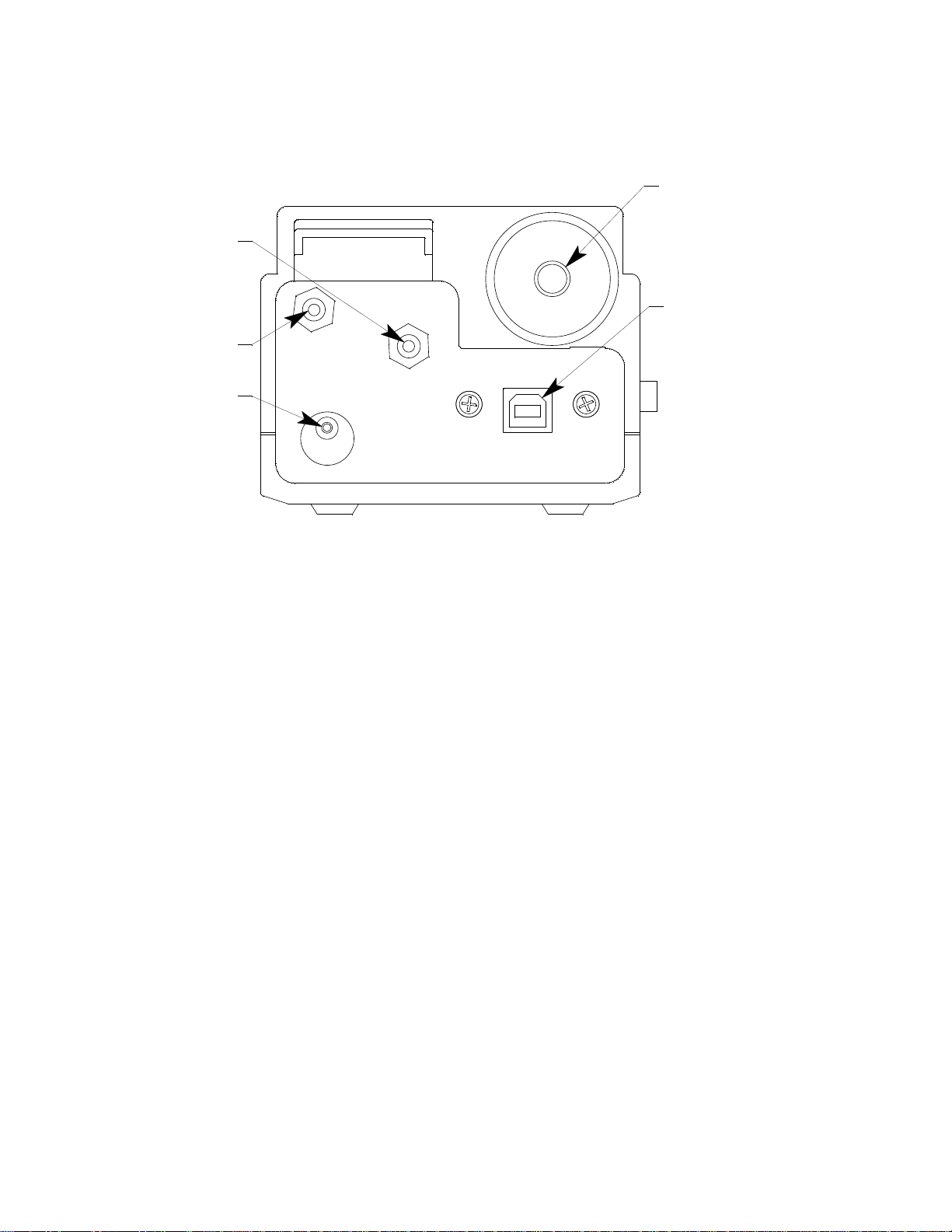

Back Panel

Gas Fitti ng

Exhaust Fitting

Back Panel USB

Port (Type B),

For Computer

Connection

Air Fitting

Power Jack

Figure 8: Back Panel

The back panel includes the power jack, sample fittings, and a USB PC connector.

Power Jack

The power jack is located in the bottom left corner of the back panel. The plug on the

end of the AC adapter cable mates to it.

Sample Fittings

Three sample fittings are located on the back of the SDM-2009. The AIR fitting is in

the upper left corner and draws air into the SDM-2009. The GAS fitting is to the right

of the AIR fitting and is used to connect the SDM-2009 to a calibration gas cylinder.

Both fittings accept 3/16 inch ID tubing.

An exhaust fitting is located in the upper right corner. It allows routing of the

exhausted calibration gas to a convenient location. This fitting accepts 5/16 inch ID

tubing. Even though the exhaust gas can be routed to an area to be safely dispersed,

the docking station should still be installed in a well ventilated area.

PC Connection

A type B USB connection is located beneath the exhaust fitting on the SDM-2009’s

back panel. It is used to connect the SDM-2009 to a PC.

9 • Description

Page 15

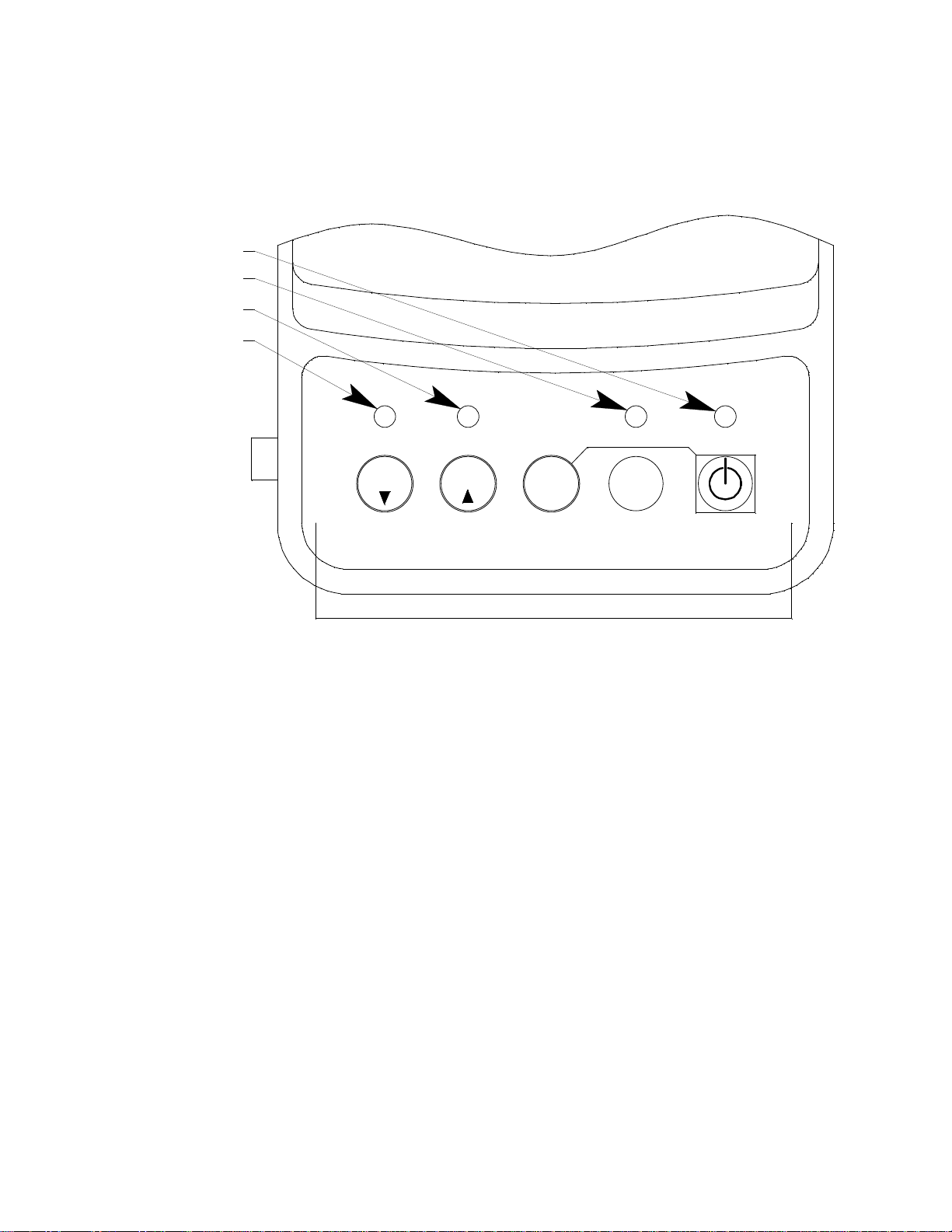

Control Panel

CHARGE

1SEC ON

3SEC OFF

COPY

GX-2009 OFF

POWER

SDM-2009

BUMP CAL.

Control Button s

EDIT

ENTER

BUMP LED

CHARGE LE D

COPY LED

CAL L ED

Figure 9: Control Panel

The control panel is used to setup and operate the docking station in the Standalone

configuration. It is located at the front of the docking station. It includes the control

buttons, the control button LEDs, and the CHARGE status LED.

Five control buttons are located on the control panel. From left to right they are BUMP

, CAL , EDIT ENTER, COPY, and POWER. The BUMP , CAL , EDIT

ENTER, and COPY control buttons are not used in the PC Controlled configuration of

the SDM-2009. The BUMP LED and CAL LEDs indicate the results of bump

tests and calibrations, respectively. The COPY LED does not indicate anything in the

PC Controlled configuration but will be on if the SDM-2009 was used in the

Standalone configuration and calibration and bump test records are still stored in the

SDM-2009’s memory. The CHARGE LED is located above the POWER button and

functions as a pilot LED, a system failure LED, and a charge indication LED.

The POWER button turns the SDM-2009 on and off.

Description • 10

Page 16

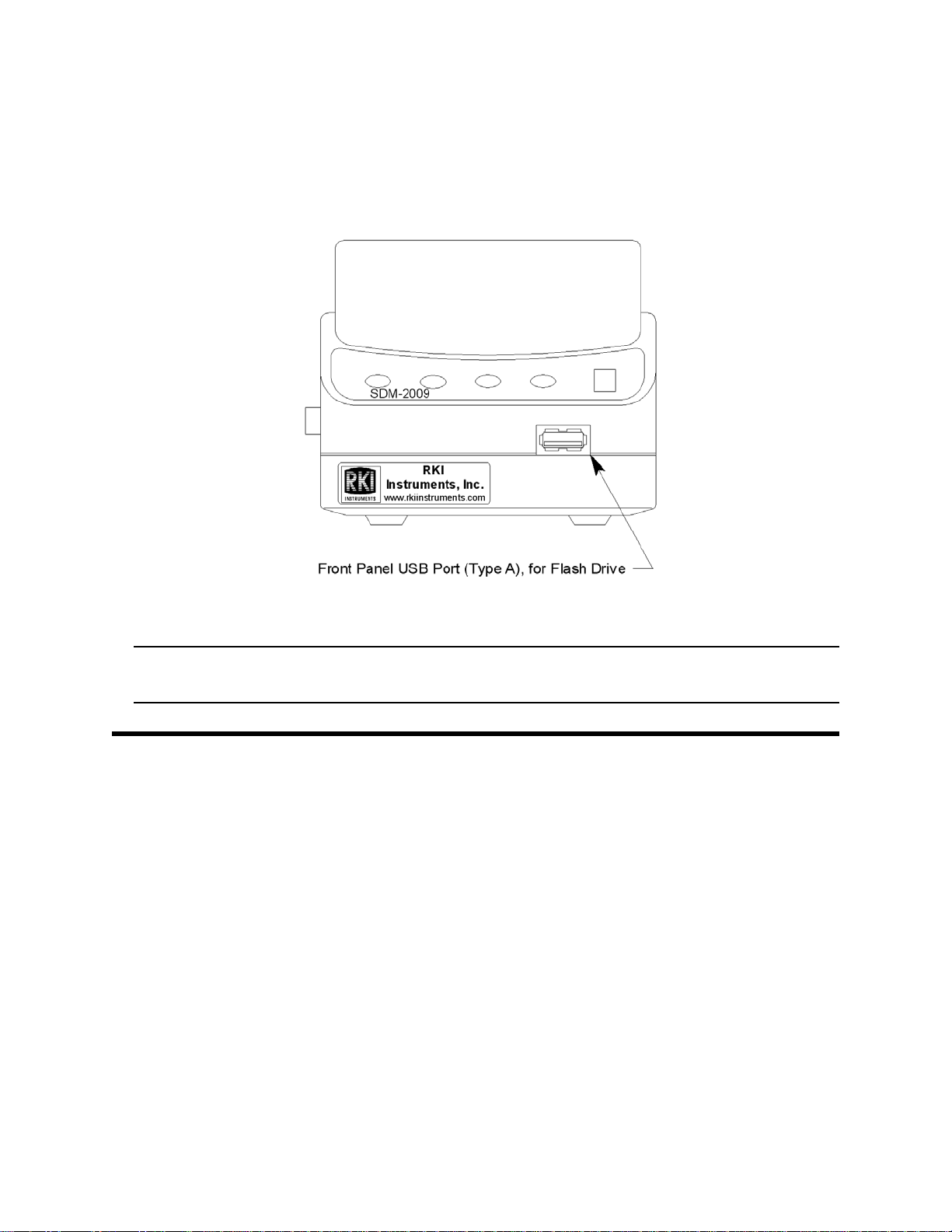

Front Panel

Figure 10: Front Panel

A type A USB port is located on the front of the docking station. This port can be used

to save calibration and bump test data to a USB flash drive. This USB port is for use

only in the Standalone configuration of the SDM-2009 and is not used in the PC

Controlled configuration.

NOTE: The SDM-2009 does not support connection of a computer to the front

USB port, only a USB flash drive.

USB Hub Requirements for Multiple Station Systems

If you have more docking stations than you have available USB ports, you will need a

USB hub. RKI provides both a 4-port hub and a 7-port hub. If you have more than 7

docking stations, you will need to purchase one of each hub. Do not connect one hub

to the other. Make sure that each USB hub has its own USB port on your computer.

You may also purchase your own USB hub of any port number from your local

electronics store but it must meet the following requirements:

•USB 2.0

®

• compatible with your Windows

An AC adapter comes with the USB hub(s) sold by RKI but does not need to be

plugged in for SDM-2009 operation. If the hub will be used to charge other devices,

the AC adapter needs to be plugged in.

operating system

11 • USB Hub Requirements for Multiple Station Systems

Page 17

Hardware Setup

Figure 11: SDM-2009 Arrangement

This section describes how to assemble the hardware that came with the SDM-2009,

assemble a manifold, and connect calibration gas.

Hardware Assembly

The hardware assembly consists of connecting the AC adapter(s), installing the air

filter(s), installing the check valve(s), connecting the sample tubing and connecting

the USB cable(s). The SDM-GX Docking Station PC Controller software can support

1-10 SDM-2009 docking stations connected at the same time. Perform the following

steps to complete the hardware assembly for each SDM-2009:

1. Place the SDM-2009(s) on a convenient table top near an AC wall socket or

power strip in a well ventilated area. A location near a window that can be

opened is best so that the exhaust can be routed to the window.

2. If you have more than one SDM-2009, arrange them side by side as shown in

Figure 11 below. Each docking station has three connection tabs on the left

side near the bottom of the station and three connection recesses on the right

side near the bottom of the station. The tabs from one docking station can be

pushed into the recesses on another station to mechanically connect the

docking stations.

3. Insert the round plug on the end of each AC adapter’s cable into the power

jack on the back of each SDM-2009.

NOTE: If you have multiple SDM-2009s and are using a 4-port AC adapter,

plug each of the round plugs on the end of the AC adapter into the

power jack on the back of 4 separate SDM-2009s.

4. Connect the AC adapter’s wall plug into a wall AC socket or power strip.

5. Install the air filter to the AIR fitting of each SDM-2009 so that the arrow on the

filter that indicates direction of flow is pointing towards the AIR fitting. Push the

open end of the flexible tube that is on one end of the filter onto the AIR fitting

on the back of the SDM-2009.

6. Install the 10 foot long 5/16 inch ID flexible tube that is included with each

Hardware Setup • 12

Page 18

SDM-2009 on the exhaust fitting of each SDM-2009. Route the tube to an area

where the exhaust can be safely dispersed, such as an open window. Exhaust

tubing from multiple units can be daisy chained together in a manifold for more

convenient operation. In this case, the check valves that are provided with the

docking stations need to be used. See "Assembling a Manifold for Multiple

SDM-2009 Units" below for instructions.

CAUTION: The maximum recomme nded le ngth for th e exha ust tube i s 10 feet. Do

not use more than 10 feet of tubing or tubing with an ID of less than

5/16 inch for the exhaust tube or the bump test and calibration

accuracy will be adversely affected. The exhaust tube that is shipped

with the SDM-2009 has an ID of 5/16 inch and is 10 feet long.

7. Install the 3 foot long 3/16 inch ID tube that is included with the SDM-2009 on

the GAS fitting. GAS tubing from multiple units can be daisy chained together

in a manifold for more convenient operation. See "Assembling a Manifold for

Multiple SDM-2009 Units" below for instructions.

8. Connect the provided USB cord from the type B USB port on the back of the

SDM-2009 to an available USB port on your computer or to a USB hub that is

connected to your computer. See “USB Hub Requirements for Multiple Station

Systems” on page 11 for more information about USB hubs.

Assembling a Manifold for Multiple SDM-2009 Units

Up to 10 SDM-2009s can be manifolded together. The GAS fitting can be manifolded

to allow the stations to draw from one calibration cylinder. The exhaust lines can also

be manifolded together and be routed away from the docking stations with only one

10 foot long 5/16 inch piece of tubing.

Each SDM-2009 is shipped with exhaust tubing, GAS tubing, T-fittings in two different

sizes, and a check valve.

Exhaust Tubing

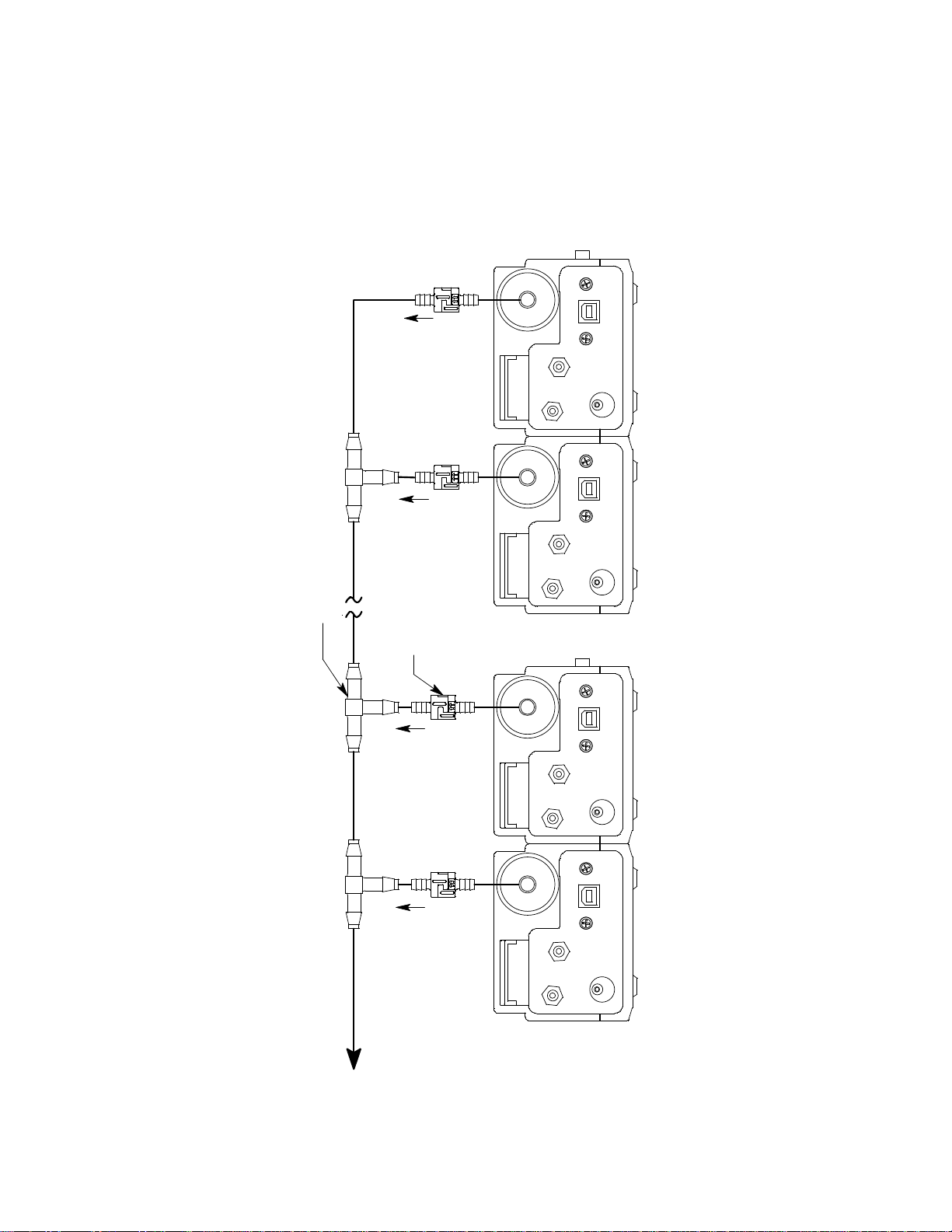

Reference Figure 12 for the instructions below.

1. Cut a 1-2” piece of 5/16 inch tubing for each SDM-2009 and connect it to each

unit’s exhaust fitting.

2. Connect the provided check valves to the short pieces of tubing already

installed at the exhaust fittings. Be sure that the arrows that appear on the

check valve are pointing away from the exhaust fitting.

3. Cut a 2-3” piece of 5/16 inch tubing for every SDM-2009 except the first one

and connect it to the other end of the check valve.

4. Insert the larger T-fittings into the tubing so that the remaining two ports on the

T-fitting are perpendicular to the exhaust tube and check valve.

5. For the first SDM-2009, cut a 9-10” piece of 5/16 inch tubing and connect it

from the check valve on the first SDM-2009 to the closest port on the second

SDM-2009’s exhaust T-fitting.

13 • Hardware Setup

Page 19

6. Use one of the provided 10 foot lengths of tubing and connect it to the T-fitting

7 inches

T-Fitting

10 Foot Max

Exhaust Tube

To Op en A rea

9 inc hes

AIR

GAS1

GAS1

Unit 2Unit 10

Check Valve

Unit 9

GAS1

AIR

AIR

GAS1

AIR

Unit 1

Figure 12: Exhaust Tubing Connections

on the last SDM-2009. The maximum recommended exhaust tube length is 10

feet.

7. For the remaining SDM-2009s, cut 6-7” pieces of 5/16 inch tubing and connect

the remaining T-fittings.

Hardware Setup • 14

Page 20

GAS Tubing

Reference Figure 13 for the instructions below.

1. Cut a 3-4” piece of 3/16 inch tubing for each GAS fitting on every SDM-2009

except the last one.

2. Connect the tubing to the GAS fitting on every SDM-2009 except the last one.

3. Insert the smaller T-fittings into the tubing so that the remaining two ports on

the T-fitting are perpendicular to the GAS fitting.

4. Cut 6-7” pieces of 3/16 inch tubing and connect the T-fittings.

5. Cut one more 6-7” piece of 3/16 inch tubing and connect the GAS fitting of the

last SDM-2009 to the T-fitting from the second to last SDM-2009.

6. Cut 1 piece of 3/16 inch tubing long enough for easy access to the calibration

cylinder and connect it to the T-fitting on the first SDM-2009.

15 • Hardware Setup

Page 21

Unit 1

Unit 10

Unit 2

Unit 9

GAS1

Unit 6

Unit 5

AIR

GAS1

GAS1

GAS1

AIR

GAS1

AIR AIR

GAS1

GAS1

AIR AIR

AIR

GAS1

GAS1

AIR

AIR

GAS1

AIR

Unit 7

Unit 4

Unit 8

Unit 3

Figure 13: Gas Manifold Connections

Hardware Setup • 16

Page 22

Connecting Calibration Gas

The GAS fitting on the back of the docking station is designed to be used with a

calibration gas cylinder that is fitted with a demand flow regulator. The AIR fitting may

be used with a demand flow regulator and a cylinder of zero emissions air, but this is

not normally necessary since the docking station will generally be in a fresh air area.

The type of calibration gas cylinder used depends on the gas sensors installed in the

instrument being used with the calibration station. A 4-gas mix, LEL/Oxygen/CO/H2S,

is used if the instrument being used with the calibration station is a 4-gas unit. If the

instrument does not have an H2S channel, then a 3-gas mix, LEL/Oxygen/CO, is

used. Although a 4-gas cylinder will work for an instrument of any gas combination, if

you have multiple instruments with various gas combinations, you may want to keep

a 4-gas cylinder and a 3-gas cylinder to help preserve the charcoal filter on the CO

sensor in instruments without an H2S channel. Use Table 2 below as a guide in

determining which calibration gas cylinder is appropriate for your system. See “Spare

Parts List” on page 112 for a list of available cylinder part numbers.

Table 2: Recommended Gas Cylinders

Typical Instrument Types

Recommended Calibration Gas

Cylinder(s)

LEL/Oxy/H2S/CO 4-gas mix with CH4/Oxy/H2S/CO

LEL/Oxy/CO 3-gas mix with CH4/Oxy/CO

LEL/Oxy/H2S 4-gas mix with CH4/Oxy/H2S/CO

LEL/Oxy 3-gas mix with LEL/Oxy/CO

Oxy/CO 3-gas mix with LEL/Oxy/CO

Oxy/H2S 4-gas mix with LEL/Oxy/H2S/CO

To connect calibration gas to the SDM-2009, do the following:

1. If the area around the docking station is not considered a fresh air area (an

area free of combustible and toxic gases and of normal oxygen content,

20.9%) install a tube not longer than 10 feet on the filter attached to the AIR

fitting on the back of the docking station and route it to a fresh air area or

connect a cylinder of zero air with a demand flow regulator to the AIR fitting.

2. Install the demand flow regulator on the calibration gas cylinder.

3. Connect the demand flow regulator to the GAS inlet fitting using the 3 foot

length of 3/16 inch ID sample tubing provided with the docking station.

17 • Hardware Setup

Page 23

EAGLE 2 and GX Type Instrument Connection

There are 2 different versions of the Docking Station PC Controller program. The

SDM-E2 Docking Station PC Controller program is intended for use with SDM-E2

docking stations and EAGLE 2 instruments. The SDM-GX Docking Station PC

Controller program is intended for use with GX type docking stations and GX type

instruments.

Bump tests and calibrations can be performed on multiple EAGLE 2s and GX type

instruments at the same time. The SDM-E2 Docking Station PC Controller program

controls the EAGLE 2 functions while the SDM-GX Docking Station PC Controller

program controls the GX type instrument functions. Both programs can be used

simultaneously on your PC. Follow all instructions in the SDM-E2 Docking Station PC

Controlled Configuration Operator’s Manual as well as the instructions in this manual.

Installing the SDM-GX Docking Station PC Controller Software

1. Launch Windows®.

2. Exit from all applications and open windows.

3. Go to www.rkiinstruments.com/sdm2009.

4. Click on the Download tab.

5. Click the PC Controlled Software link.

6. A .zip file will begin to download. Select whether you want to open or save the

.zip file.

7. Extract the contents of the .zip file.

8. Double click the setup.exe file.

9. The SDM-GX Docking Station PC Controller InstallShield Wizard comes up to

guide you through installation. Click Next to proceed to the License Agreement

window.

10. Read the license agreement and click the agreement acceptance selection

box, then click Next to proceed to the Customer Information window.

11. Enter a user name and organization and select if you want to install the

program for all users on the computer or just for your user account, then click

Next to proceed to the Destination Folder window.

12. The default installation folder (C:\Program Files\SDM-GX\) is displayed. If you

want to install the software in the default folder continue with step 13. If you

want to install the software in a different location, click Change and choose a

new installation folder and then continue with step 13.

13. Click Next to proceed to the Ready to Install the Program window.

EAGLE 2 and GX Type Instrument Connection • 18

Page 24

14. Review the installation settings. If they are OK, click Install and the installation

process will begin. If you want to change installation settings, click Back and

change them to the desired settings.

15. During software installation, the installation program may find newer versions

of Windows files on your computer than those in the downloaded .zip file. If

this happens, the installation software will ask you if you want to keep these

newer files. Click Yes to do so.

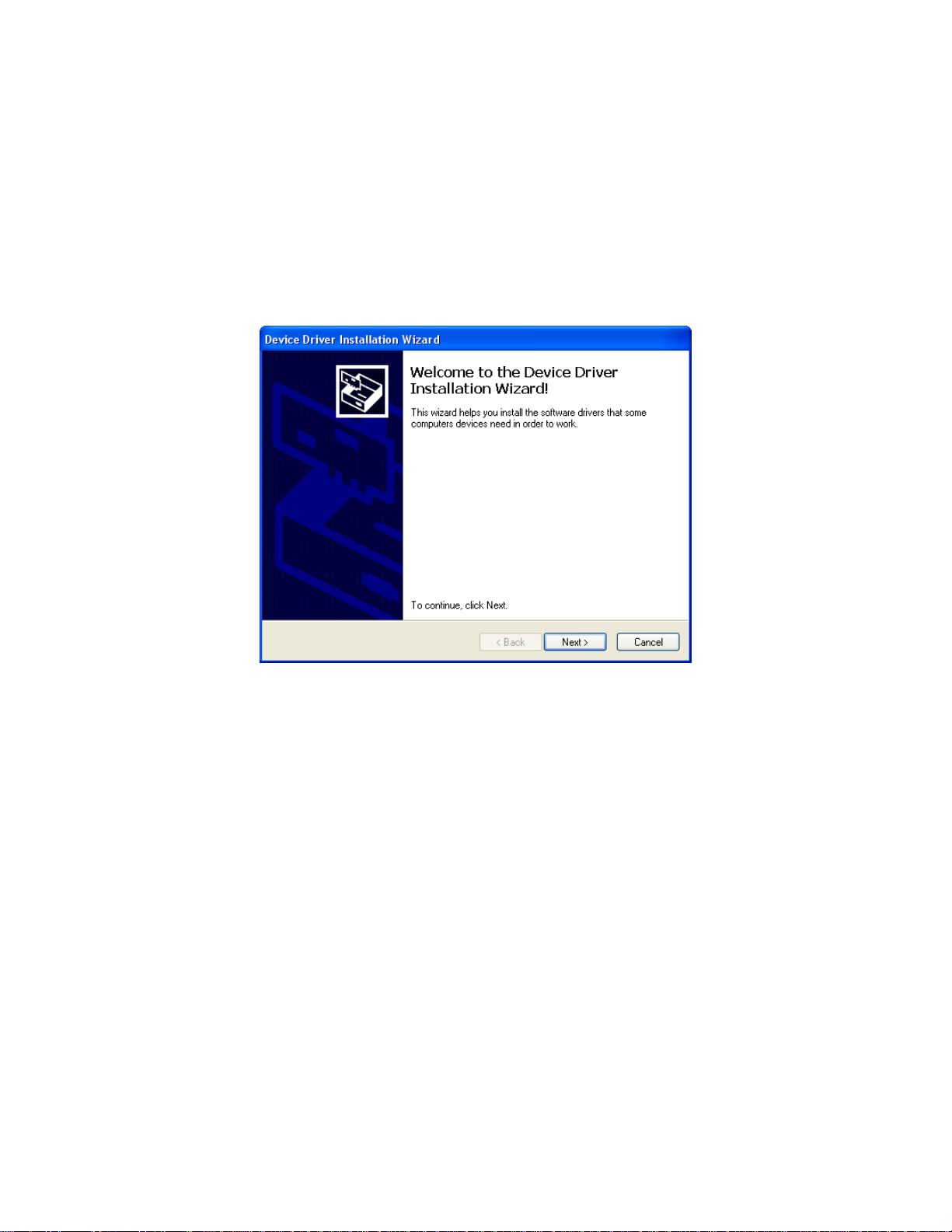

16. A Device Driver Window will appear prompting you to install necessary drivers.

You cannot continue the installation without installing the drivers.

Figure 14: Device Driver Installation

17. Click Next to install the drivers. The Wizard will find the appropriate drivers.

19 • Installing the SDM-GX Docking Station PC Controller Software

Page 25

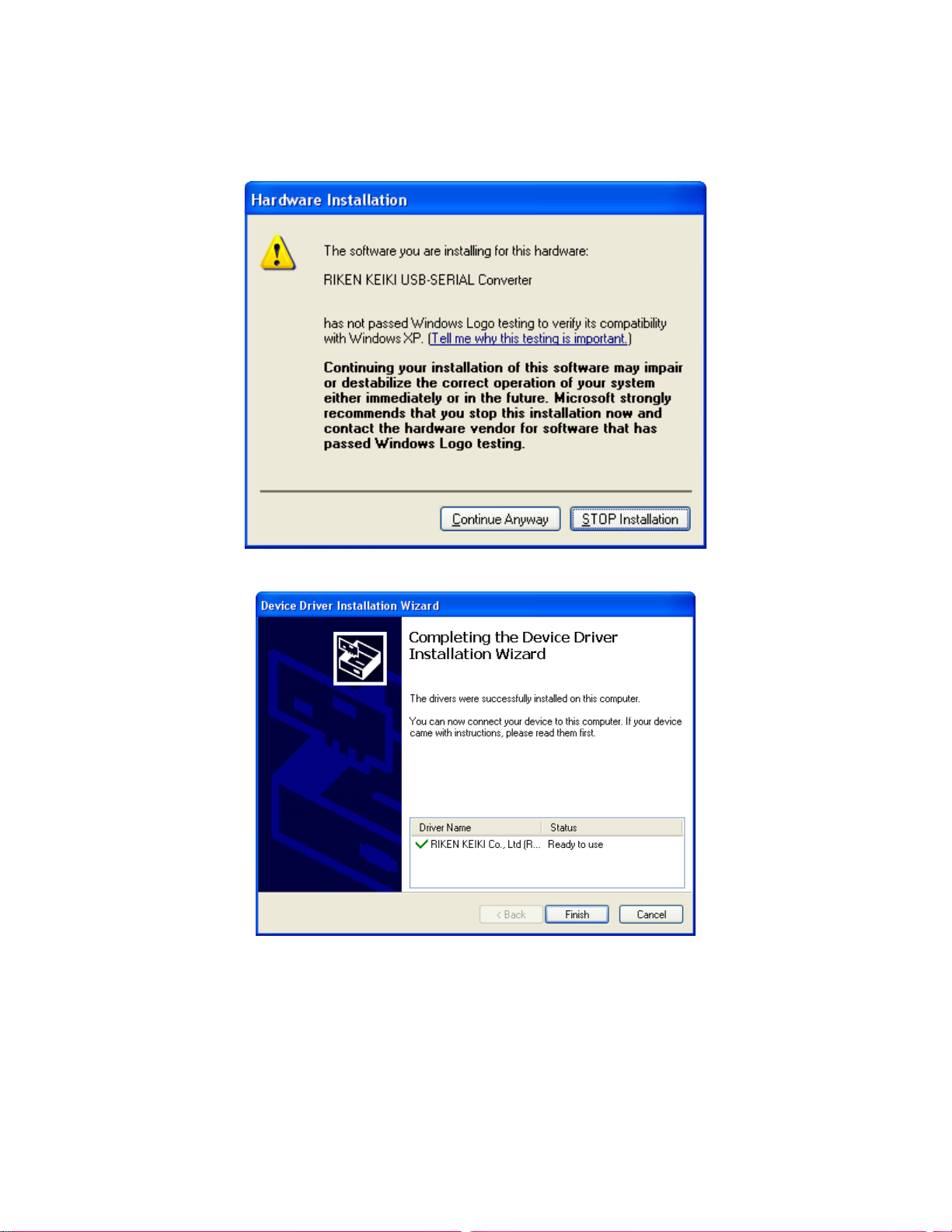

18. If this is the first time you are installing a PC Controller Program, a window will

appear saying that the file did not pass Windows logo testing. Click Continue

Anyway.

19. Click Finish once the drivers are successfully installed.

Figure 15: Finish Device Driver Installation

The installation will continue.

20. Follow the on-screen instructions to complete software installation.

21. To complete the driver installation, ensure that all of your docking stations are

connected to your computer.

Installing the SDM-GX Docking Station PC Controller Software • 20

Page 26

22. Turn on a docking station by pressing and holding the POWER button for at

least 1 second.

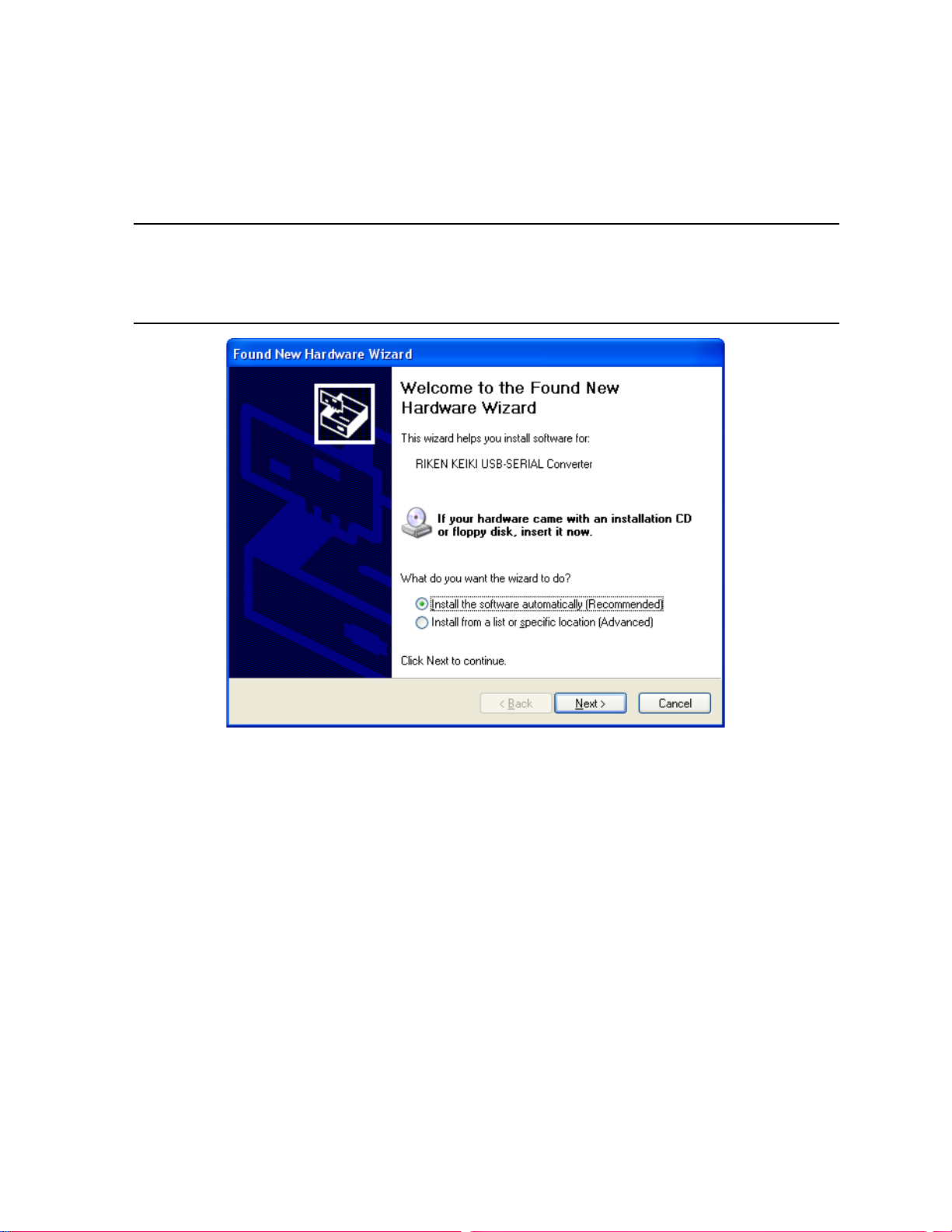

23. The first time an SDM-2009 is turned on after being connected to the

computer, a Found New Hardware window will appear.

NOTE: The following instructions apply only to computers running Windows

XP. If you have a newer operating system, the hardware driver will

automatically install and you will be notified that the USB device is

ready for use.

Figure 16: Found New Hardware Wizard

24. Select the “Install the software automatically” option and click Next.

21 • Installing the SDM-GX Docking Station PC Controller Software

Page 27

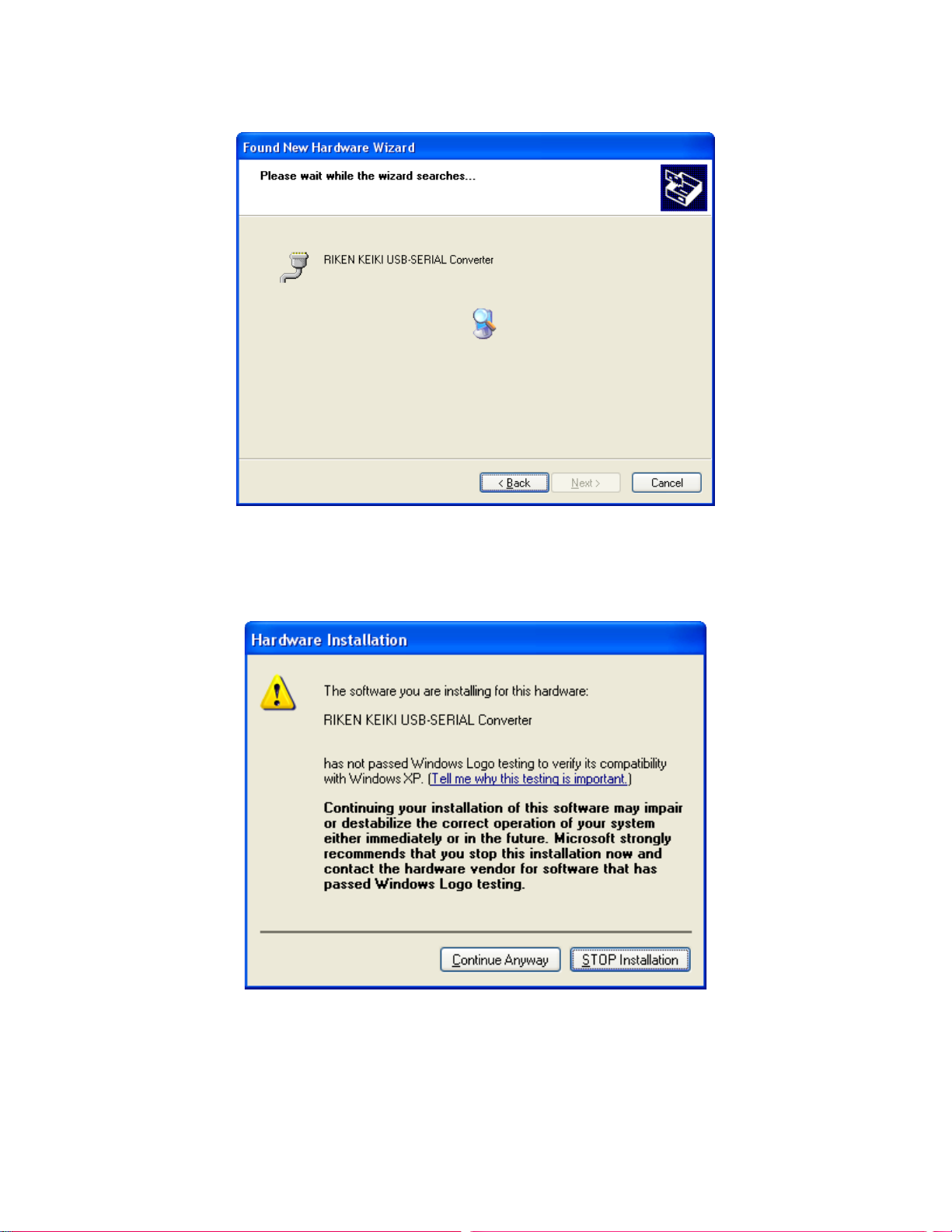

25. The wizard will search for the driver files.

Figure 17: Searching

26. Once the files have been found, a window will appear saying that the file did

not pass Windows logo testing. Click Continue Anyway.

Figure 18: Windows Logo Error

27. The installation will continue. Click Finish when the installation has completed.

28. Repeat steps 22 through 27 for every docking station in your system.

Installing the SDM-GX Docking Station PC Controller Software • 22

Page 28

Launching the SDM-GX Docking Station PC Controller Program

1. Click Start on the Windows Icon Tray, then select Programs/SDM-GX

Docking Station PC Controller. You may also double click the shortcut

created on your desktop. The SDM-GX Docking Station PC Controller

Program is launched and the main program window appears.

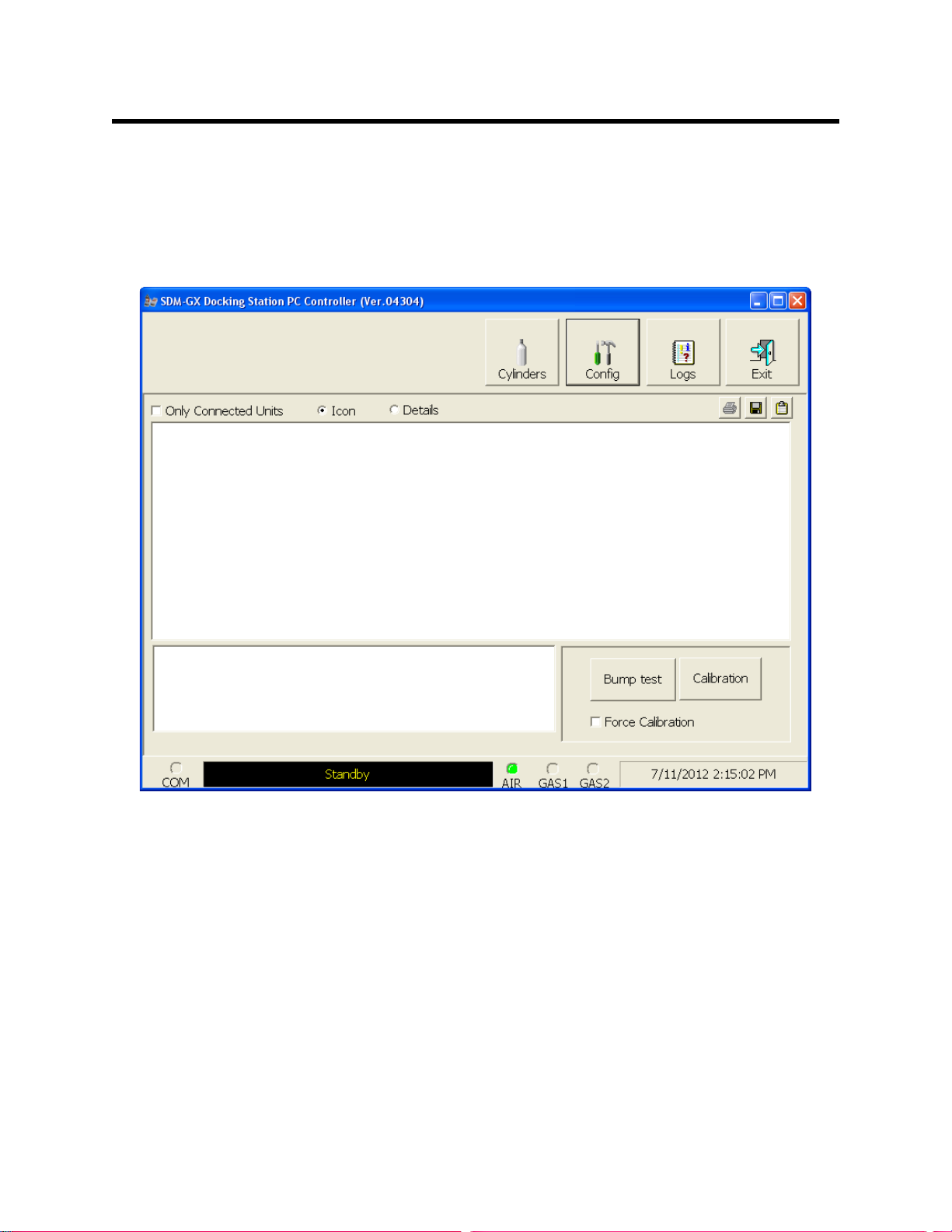

Figure 19: Main Program Window

2. If you are starting the software for the first time, a message window appears

informing you that a database has been created. Click OK in that window.

When starting the software for the first time, or if you wish to change the

software setup, proceed to the next section, "Overview of the SDM-GX

Docking Station PC Controller Program".

If you have already performed the software setup, proceed to “Connecting

Instruments to the PC Controller Program” on page 38.

23 • Launching the SDM-GX Docking Station PC Controller Program

Page 29

Overview of the SDM-GX Docking Station PC Controller Program

This section provides a brief overview of the program and a description of the main

program window. Instructions for using the program are given in other parts of this

manual. Use this section to become familiar with the main program window, but

before attempting to use the program, make sure to perform the program setup as

described in “Setting Up the PC Controller Program” on page 26.

The PC Controller Program is designed to provide manual or automated data

downloading, bump testing, and calibration of the GX-2009. It also provides the

capability to update instrument parameters such as alarm points. The program

compiles a database of the instruments that have been connected to the program

which consists of calibration and bump test history, logged data (if a unit’s data is

downloaded), and memos that record user entered information about an instrument

at a particular time.

The GX-2009 is a gas monitoring device for combustible gas, O2, H2S, and CO. It

stores logged data and calibration information in its internal memory. See the GX-

2009 Operator’s Manual for a complete description of the GX-2009.

PC Controller Program Functions

The PC Controller Program has the following basic functions accessed or controlled

by buttons in the main program screen.

• Gas cylinder setup accessed by the Cylinders control button

• Program and system configuration accessed by the Config control button (this

function is password protected)

• Data viewing accessed by the Logs control button

• Instrument bump testing controlled by the Bump test control button

• Instrument calibration controlled by the Calibration control button

Main Program Window

The main program window is where the current status of the program operation is

shown. Any SDM-2009s and instruments that are currently connected to it and any

instruments that have previously been but are not currently connected to it are also

shown. The program’s various functions are initiated or accessed from this screen.

The current date and time are always displayed in the lower right corner of the main

program window.

Overview of the SDM-GX Docking Station PC Controller Program • 24

Page 30

Message Area

SDM-2009/Instrument Display Area

Control Buttons

The Cylinders, Config, Logs, and Exit control buttons are located along the top

right of the window. The Bump test and Calibration control buttons are located in

the lower right of the window along with the Force Calibration selection box. The use

of these control buttons and the Force Calibration selection box is described in other

parts of this manual.

SDM-2009/Instrument Di spla y Area

The large middle portion of the main program window displays SDM-2009s and

instruments that are currently connected to the PC Controller Program and

instruments that are in the database. The SDM-2009s are identified by a number. The

instruments are identified by their serial number. By selecting either the Icon radio

button or the Details radio button, the SDM-2009s and instruments can be displayed

either as icons or in a table format that shows various instrument parameter details

such as station ID, user ID, the next scheduled bump test date, and the next

scheduled calibration date among others. If the Only Connected Units box is

25 • Overview of the SDM-GX Docking Station PC Controller Program

Figure 20: Parts of the Main Program Window

Page 31

checked, then only instruments that are currently connected to the PC Controller

Program will be shown.

Program Status

Three areas of the main program window indicate the program status. The smaller

area in the lower left below the SDM-2009/instrument display area is the message

area. It displays messages that indicate actions and status of the program.

Below this area is the communications port indicator which shows when the program

is communicating with the docking station(s).

To the right of the communications port indicator is the status field. It displays the

current status of the program. It can indicate if the software is in standby mode or if it

is downloading data among other indications.

Fitting Indicators

To the right of the status field are 3 round fitting indicators. They correspond to the

AIR and GAS fittings on the back of the SDM-2009. They indicate whether the

corresponding solenoid is activated so it can allow gas to flow through the fitting it

controls. When the indicator is green, the fitting is active. When the indicator is blank,

the fitting is not active.

NOTE: The SDM-2009 does not have a GAS 2 fitting. The GAS 2 indicator will

never be green while the PC Controller program is connected to an

SDM-2009.

Setting Up the PC Controller Program

Once the program is installed, you must set up the program for your system. Setting

up the PC Controller Program consists of the following tasks:

• setting up the parameter configuration

NOTE: Only the Parameter tab of the Configuration Window is discussed in

this section. See “Config Window” on page 109 for a description of the

other tabs in the Configuration Window.

• setting up the SDM-2009 display order

• defining which calibration gas cylinders will be used

Setting Up the Configuration

1. Launch the program as described in “Launching the SDM-GX Docking Station

PC Controller Program” on page 23.

NOTE: It is not necessary to turn on the SDM-2009 docking stations if you are

only performing configuration setup.

Setting Up the PC Controller Program • 26

Page 32

2. The configuration parameters are located in the Configuration Window of the

SDM-GX Docking Station PC Controller program. To access the Configuration

Window, click the Config button along the top of the main program window.

3. You will be prompted to enter a password. The factory set password is

ABCDE. Enter the password and click OK keeping in mind that the password

is case sensitive. You may change the password using the Password Tab once

you have entered the Configuration Window. See “Password Tab” on page 111

for instructions to change the password.

4. The Parameter Tab of the Configuration Window will be displayed.

Figure 21: Config Window Parameter Tab

27 • Setting Up the PC Controller Program

Page 33

5. Select the Instrument Information options.

• Change Parameter

If Change Parameter is selected (factory setting), the Edit function is active

in the Instrument Function Menu allowing you to change various

parameters in connected instruments. See “Edit Function” on page 99 for a

complete description of the Edit function. If it is not selected, the Edit

function is not active. Select or deselect the Change Parameter box.

• Auto Power OFF Time

This is the length of time that will pass after the last operation is finished

before the program will automatically shut off the instrument. If a

successful bump test or calibration is performed, the program will

automatically shut off the instrument in 20 seconds regardless of the Auto

Power OFF Time setting. Use the arrows to the right of the current setting

to change the value or highlight the current setting and type in the desired

value. It is defined in seconds with a maximum setting of 3600 seconds (1

hour). The factory setting is 3600 seconds.

6. Select the Data Logger options.

• Down Load Data Logger

The Down Load Data Logger selection allows you to have saved data

automatically downloaded from the instrument once it is connected to the

PC Controller program. The data will automatically be downloaded based

on the frequency set in the Down Load Interval option. The factory setting

is deselected. Select or deselect the Down Load Data Logger box.

• Clear After Down Load

The Clear After Down Load selection allows you to automatically clear the

instrument data logger after an automatic download. The factory setting is

deselected. Select or deselect the Clear After Down Load box. If Down

Load Data Logger is not selected, selecting Clear After Download has no

effect.

• Down Load Interval

The Down Load Interval is the length of time, in days, that will pass before

the PC Controller program will automatically download data from an

instrument if Down Load Data Logger is selected. If the instrument is

connected to the program before the interval has passed, a data download

will not automatically occur. The Down Load Interval can be set anywhere

from 1 to 60 days. The factory setting is 1 day. Use the arrows to the right

of the current setting to change the interval or highlight the current setting

and type in the desired value.

7. SDM Selection

If you select the Initialize Display Order selection box, the PC Controller

Setting Up the PC Controller Program • 28

Page 34

program will reset the numbers it has assigned to specific docking stations and

reassign them as you turn SDM-2009 docking stations on and connect them to

the program. See “Setting Up the SDM-2009 Display Order” on page 33 for

instructions to use this feature.

8. Select the Waiting Time for Auto Process

The Waiting Time for Auto Process parameter defines the time delay of an

automatic calibration or automatic bump test after an instrument is connected

to the SDM-2009. You can set the delay from 0 seconds to 3600 seconds.

9. Select the Calibration options.

If Manual Calibration is selected, you are able to manually select an instrument

or instruments in the main program window and click Calibration in the lower

right corner of the window in order to perform a calibration.

If Auto Calibration is selected and Every Time is not, if an instrument is due for

calibration, a calibration will automatically begin in the time defined by the

Waiting Time for Auto Process parameter after that instrument successfully

connects to the program and its instrument parameters are retrieved by the

program. When you select Auto Calibration, a window pops up indicating that

only sensors tested with GAS 1 and one sensor tested with GAS 2 will be

calibrated in auto calibration.

This screen does not have any meaning for the GX-2009 and is only

applicable to the GX-2012 and Gas Tracer instruments.

If Auto Calibration and Every Time are selected, a calibration will automatically

begin in the time defined by the Waiting Time for Auto Process parameter after

that instrument successfully connects to the program and its instrument

parameters are retrieved by the program regardless of whether a calibration is

due.

If neither Manual Calibration nor Auto Calibration box is selected, you will not

be able to perform a calibration. The factory setting is Manual Calibration

selected and Auto Calibration deselected. Select the box for the desired

operation.

The Auto Calibration selection also has a Standard GAS and an All GAS

selection. The GX-2009 does not have any non-standard sensors so this

setting does not have any effect on the automatic calibration of a GX-2009.

The Interval (for CX-II) parameter sets the calibration interval but is only used

for CX-II instruments. It does not have any effect on the SDM-GX program

29 • Setting Up the PC Controller Program

Page 35

when used with GX-2009 instruments.

10. Select the Bump Test options.

The Bump Test section of the Parameters Tab allows you to make selections

related to the bump test functionality of the SDM-2009.

• Manual Bump Test/Auto Bump Test

You can select Manual Bump Test or Auto Bump Test.

If Manual Bump Test is selected, you have to manually select an instrument

or instruments in the main program window and click Bump Test in the

lower right corner of the window in order to perform a bump test.

If Auto Bump Test is selected, and an instrument is due for bump testing, a

bump test will automatically begin in the time defined by the Waiting Time

for Auto Process parameter after that instrument successfully connects to

the program and its instrument parameters are retrieved by the program.

NOTE: If the instrument’s Bump Test Function is set to On, the GX-2009’s

instrument information is used to determine if a bump test is needed.

If the instrument’s Bump Test Function is set to Off, the SDM-GX PC

Program’s Bump Test Interval parameter and last successful bump test

date are used to determine if a bump test is needed. If a bump test has

never been done using the SDM-GX Program, an auto bump will be

initiated.

When you select Auto Bump Test, a window pops up indicating that only

sensors tested with GAS 1 and one sensor tested with GAS 2 will be bump

tested in auto bump test.

This screen does not have any meaning for the GX-2009 and is only

applicable to the GX-2012 and Gas Tracer instruments.

If neither box is selected, you will not be able to perform a bump test. The

factory setting is Manual Bump Test selected and Auto Bump Test

deselected. Select the box for the desired operation.

The Auto Bump Test selection also has a Standard GAS and an All GAS

selection. The GX-2009 does not have any non-standard sensors so this

setting does not have any effect on the automatic bump testing of a

GX-2009.

Setting Up the PC Controller Program • 30

Page 36

• Fast Bump

If Fast Bump is not selected, the gas application during a bump test will

continue for the time period defined by the Gas Exposure Time bump test

parameter regardless of the sensor reading(s).

If Fast Bump is selected and the gas reading for the sensor(s) being tested

is above the lower tolerance and below the upper tolerance within 10

seconds, the sensor(s) pass bump testing, the gas application will be

stopped, and the test will move on to the next sensor(s) or to the fresh air

purge. If the gas reading on any of the tested channels is below the lower

tolerance or above the upper tolerance within 10 seconds, the gas

application will continue for the time period defined by the Gas Exposure

Time bump test parameter, and the pass/fail status of the sensor(s) will be

determined at that point. Turning Fast Bump on allows calibration gas to be

saved when the tested sensors respond quickly and accurately.

Consider the following scenario as an example.

•50% LEL methane used for bump testing the combustible gas channel

•GAS bump test parameter set to 20 seconds

•Tolera nce set to ± 50% LEL, which means that the acceptable reading

range is 25% LEL - 75% LEL

•Fast selected

The table below shows possible readings at 10 seconds and the effect on

the gas application.

Table 3: Example Fast Bump Scenarios

Gas Reading 10 Seconds

Into Fast Bump

Outcome

15% LEL (-70% of 50% LEL) • Gas application continues for the full 20 seconds

• Pass/fail determined at end of 20 seconds

30% LEL (-40% of 50% LEL) • Gas application stops

• Sensor passes bump testing

60% LEL (+20% of 50% LEL) • Gas application stops

• Sensor passes bump testing

80% LEL (+60% of 50% LEL) • Gas application continues for the full 20 seconds

• Pass/fail determined at end of 20 seconds

• Interval

The Interval can be set anywhere between 1 and 30 days and is the length

of time that can pass before the program will prompt you to perform a bump

test. The factory setting is 30 days.

31 • Setting Up the PC Controller Program

Page 37

Use the arrows to the right of the current interval or highlight the current

setting and type in the desired value. The value you type in must be valid

(between 1 and 30 days).

NOTE: This parameter only affects the operation of the SDM-GX PC Program

when used with GX-2009s whose Bump Test Function is set to Off. If

the GX-2009’s Bump Test Function is set to On, the instrument’s bump

test interval is used to determine if a bump test is due.

• Gas Exposure Time

The Gas Exposure Time can be set to 30 (factory setting), 45, 60, 90, 120

seconds or Auto and is the length of time that gas is applied to the

instrument. If you select Auto, the PC Controller program will apply gas for

the appropriate amount of time based on your instrument sensor

configurations.

To change the Gas Exposure Time, click on the current setting. A drop

down menu will appear. Select the desired time.

• Tolerance

The Tolerance can be set between 10% and 50%. The factory setting is

50%. It determines how close the instrument gas reading must be to the

calibration gas concentration for each channel during a bump test in order

to pass the bump test. It is defined as a percentage of the calibration gas

concentration.The amount that the instrument gas reading differs from the

calibration gas concentration must be equal to or less than this percentage

of the calibration gas concentration. For example, if the tolerance is set to

50%, and the %LEL calibration gas concentration is 50% LEL, then the

bump test gas reading for the LEL channel on the instrument must be 50

%LEL ± 25 %LEL.

To change the Tolerance, use the arrows to the right of the current setting

or highlight the current setting and type in the desired value. The value you

type in must be valid (between 10 and 50%).

11. When you are finished making changes, click OK. If you want to save the

changes, click Yes in the window that comes up. If you do not want to save the

changes, click No in the window that comes up. To return to the Configuration

Window, click Cancel.

To exit the Configuration Window and return to the main program window

without saving any changes, click Cancel in the Configuration Window and

click OK in the confirmation screen that comes up.

Setting Up the PC Controller Program • 32

Page 38

Setting Up the SDM-2009 Display Order

Setting up the display order for your SDM-2009s ensures that the docking stations

will appear in the PC Controller program in the same order that they are laid out in

your calibration area.

Before performing this operation, make sure your SDM-2009s are arranged on the

table top or other surface as desired and that they are connected to the computer.

See “Hardware Setup” on page 12. Also be sure that you have performed the driver

installations as described in “Installing the SDM-GX Docking Station PC Controller

Software” on page 18.

1. Click the Config button along the top of the screen to access the Configuration

Window.

2. You will be prompted to enter a password. The factory set password is

ABCDE. Enter the password and click OK keeping in mind that the password

is case sensitive. You may change the password using the Password Tab once

you have entered the Configuration Window. See “Password Tab” on page 111

for instructions to change the password.

3. The Parameter Tab of the Configuration Window will be displayed.

Figure 22: Config Window Parameter Tab

33 • Setting Up the PC Controller Program

Page 39

4. Click the box next to Initialize Display Order in the SDM portion of the

Parameter tab.

5. Click OK.

6. The program will ask if you want to save the changes. Click Yes .

7. A window will appear informing you that you need to turn off all SDMs and

restart the program. Click OK.

8. Click the Exit button in the upper right corner of the main program window to

exit the program.

9. Turn off all of the SDM-2009s if they are on.

10. Open the SDM-GX Docking Station PC Controller program again.

11. Turn on your SDM-2009s in the order that you wish for them to appear on the

main program window. Typically the order in which the docking stations appear

on the screen corresponds to their left to right arrangement on the tabletop.

12. Your SDM-2009 docking stations should all appear on the screen in numerical

order. The program will remember each SDM-2009’s number. If fewer than all

of the docking stations are turned on, the stations will still appear in numerical

order on the Main Program Window, but the stations which are off will not be

shown.

13. If you need to reorder the docking stations, repeat steps 1 through 12.

Setting Up the PC Controller Program • 34

Page 40

Cylinders Window

The Cylinders Window allows you to keep track of cylinders that are in use and the

expiration date for those cylinders. If a cylinder’s expiration date has passed, the PC

Controller program will alert you in the message area of the main program window as

soon as the program is started. The Cylinders window comes with a list of predefined

cylinders that are fairly common. If a cylinder that you need to use is not on this list, it

can be added at the bottom of the cylinder list. You may add as many custom

cylinders as necessary.

Figure 23: Cylinders Window

The Cylinders window has the cylinder list number, the cylinder name, the part

number, the expiration date, and the status of the cylinder.

35 • Setting Up the PC Controller Program

Page 41

Selecting a Cylinder from the Predefined List

The Cylinders Window comes with several predefined cylinders that you can choose

from.

1. To access the Cylinders Window, click the Cylinders button along the top of the

main program window.

2. Click in a Name field, click on the drop down menu that appears, and select a

predefined cylinder.

Figure 24: Predefined List of Cylinders

3. Set the expiration date by clicking in the Expiration field and clicking the drop

down menu that appears. Use the calendar to choose an expiration date. The

expiration date box will be highlighted in orange if the expiration date of the

cylinder is less than 10 days away. The expiration date box will be highlighted

in red if the expiration date has passed.

4. Select or deselect the Active box for each cylinder. If the cylinder is active, the

PC Controller program will alert you at start up if the cylinder has passed its

expiration date. If it is not active, the program will not alert you.

5. To return to the main program window without saving any changes, click

Setting Up the PC Controller Program • 36

Page 42

Cancel in the Cylinders Window. A window will appear notifying you that

changes will not be saved. To continue to the main program window, click OK.

To return to the Cylinders Window to save your changes, click Cancel.

6. If you want to save any changes made, click OK. A window will appear asking

if you want to save the changes you made. To return to the main program

window and save your changes, click Yes. To return to the main program

window without saving changes, click No. To return to the Cylinders Window,

click Cancel.

Defining New Cylinders

If your instrument configuration requires the use of a cylinder that is not in the

predefined list, you can add that cylinder by either typing in the information for the

cylinder or by editing the information for an existing cylinder.

1. To access the Cylinders Window, click the Cylinders button along the top of the

main program window.

2. Click in any blank cylinder name field and click again to bring the cursor up or

use the drop down menu to select a cylinder name that is close to the one you

want and click the name to bring the cursor up.

Figure 25: New Cylinder

37 • Setting Up the PC Controller Program

Page 43

3. Type in the name of your new cylinder (ie. gas name and concentration).

4. Click in the Part No field once to select it and once more to bring the cursor up.

Type in the part number for your new cylinder (typically the RKI part number).

5. Click in the Expiration field and click on the drop down menu that appears. Use

the calendar to select an expiration date. The expiration date box will be

highlighted in orange if the expiration date of the cylinder is less than 10 days

away. The expiration date box will be highlighted in red if the expiration date

has passed.

6. Select the Active box if you want the PC Controller program to alert you when

the cylinder’s expiration date has passed. If you do not want the program to

alert you, leave the box deselected.

7. To enter any more cylinders, repeat step 3 through step 6.

8. To return to the main program window without saving any changes, click

Cancel in the Cylinders Window. A window will appear notifying you that

changes will not be saved. To continue to the main program window, click OK.

To return to the Cylinders Window to save your changes, click Cancel.

9. If you want to save any changes made, click OK. A window will appear asking

if you want to save the changes you made. To return to the main program

window and save your changes, click Yes. To return to the main program

window without saving changes, click No. To return to the Cylinders Window,

click Cancel.

Connecting Instruments to the PC Controller Program

NOTE: Be sure to set up the display order for the SDM-2009s as described in

“Setting Up the SDM-2009 Display Order” on page 33, before

continuing.

Do the following to turn on the SDM-2009s and establish a connection with the

instruments in your system:

1. If necessary, verify that the SDM-2009(s) are arranged on the work surface as

desired, all plumbing is installed, and all hardware and cables are installed.

See “Hardware Setup” on page 12.

2. Launch the SDM-GX Docking Station PC Controller Software as described in

“Launching the SDM-GX Docking Station PC Controller Program” on page 23.

Connecting Instruments to the PC Controller Program • 38

Page 44

3. Install a GX-2009 in the instrument cradle.

NOTE: If the GX-2009 is left in the SDM-2009 after bump testing or calibration,

the pump will run for 12 seconds every 2 minutes in order to keep

hydrogen generated from charging of the NiMH batteries from affecting

the CO sensor.

4. Turn on each SDM-2009 by pressing and holding the SDM-2009’s POWER

button. When the control panel LEDs turn on, release the POWER button.

5. The BUMP and CAL LEDs will turn off and the COPY LED will be

steadily on or off. It will be on if the SDM-2009 was used in Standalone

Configuration and calibration and bump test records are still stored in the

SDM-2009’s memory (see the SDM-2009 Docking Station Standalone

Configuration Manual for more information). The CHARGE LED will be

blinking green if the SDM-2009 is operating properly or solid red if there is a

system failure.

6. When a connection has been established between the SDM-GX Docking

Station PC Controller Program and all of the SDM-2009s, the main program

window will appear as shown below.

Figure 26: SDM-2009 Connection

7. Press and hold the POWER MODE button on the instrument until you hear a

beep, then release it. The instrument will begin its power up sequence (see

39 • Connecting Instruments to the PC Controller Program

Page 45

exceptions below in step 8). If a successful connection between the instrument

50 12.0

TRANSMIT

CO ppm H2S ppm

CH4 %LEL OXY vol%

50 25.0

FAIL

C-LIMIT

CAL

C--LIMIT

and the SDM-2009 occurs, the home screen will appear on the instrument

display at the end of the startup sequence. The auto calibration values for all

installed sensors will be displayed.

NOTE: The screen shown above applies to a 4-channel GX-2009. If your GX-

2009 has less than 4 channels, the inactive channels will not appear in

the above screen or in any screens where channels are displayed. All

screens in this manual assume a 4-channel GX-2009.

8. There are two exceptions to the sequence described in step 7 above. See the

GX-2009 User Setup Program Operator’s Manual for a description of the Cal

Limit Display and Cal Limit Check instrument parameters.

• When Cal Limit Display is set to On and Cal. Limit Check is set to Can’t

Use, if the GX-2009 is due for calibration the instrument will show a

calibration expired failure screen and the buzzer and LED arrays will pulse

for a few seconds.

The instrument will then connect to the SDM-2009 and display the home

screen shown above in step 7. The CHARGE LED will begin to blink green.

• When Cal Limit Display is set to On and Cal. Limit Check is set to

Confirm to use, if the GX-2009 is due for calibration the unit will show the

following screen and beep and flash the LED arrays for a few seconds

indicating that calibration is due.

When the beeping and flashing stops, press and release the POWER

MODE button on the GX-2009 to continue. The unit will now connect to the

SDM-2009, the home screen shown in step 7 above will be displayed, and

the CHARGE LED will begin to blink green.

9. For each instrument, the SDM-GX Docking Station PC Controller Program will

indicate that an instrument was found and it will download the instrument’s

Connecting Instruments to the PC Controller Program • 40

Page 46

parameters. The BUMP and CAL LEDs will flash amber while the data is

being downloaded. Once the parameter download is complete, the BUMP

and CAL LEDs will be solid amber. When all instruments have been turned

on, connected, and downloaded, the main program window will appear as

shown below. When the instrument is connected to the PC Controller Program,

the date and time of the instrument are automatically updated to the current

date and time on the PC Controller Program’s screen.

NOTE: Turn each instrument on 10-15 seconds after the previous instrument

to minimize the possibility of the instrument not connecting to the PC

Controller Program. If an instrument does not connect, use the

instrument’s POWER MODE button to turn it off and turn it back on

again.

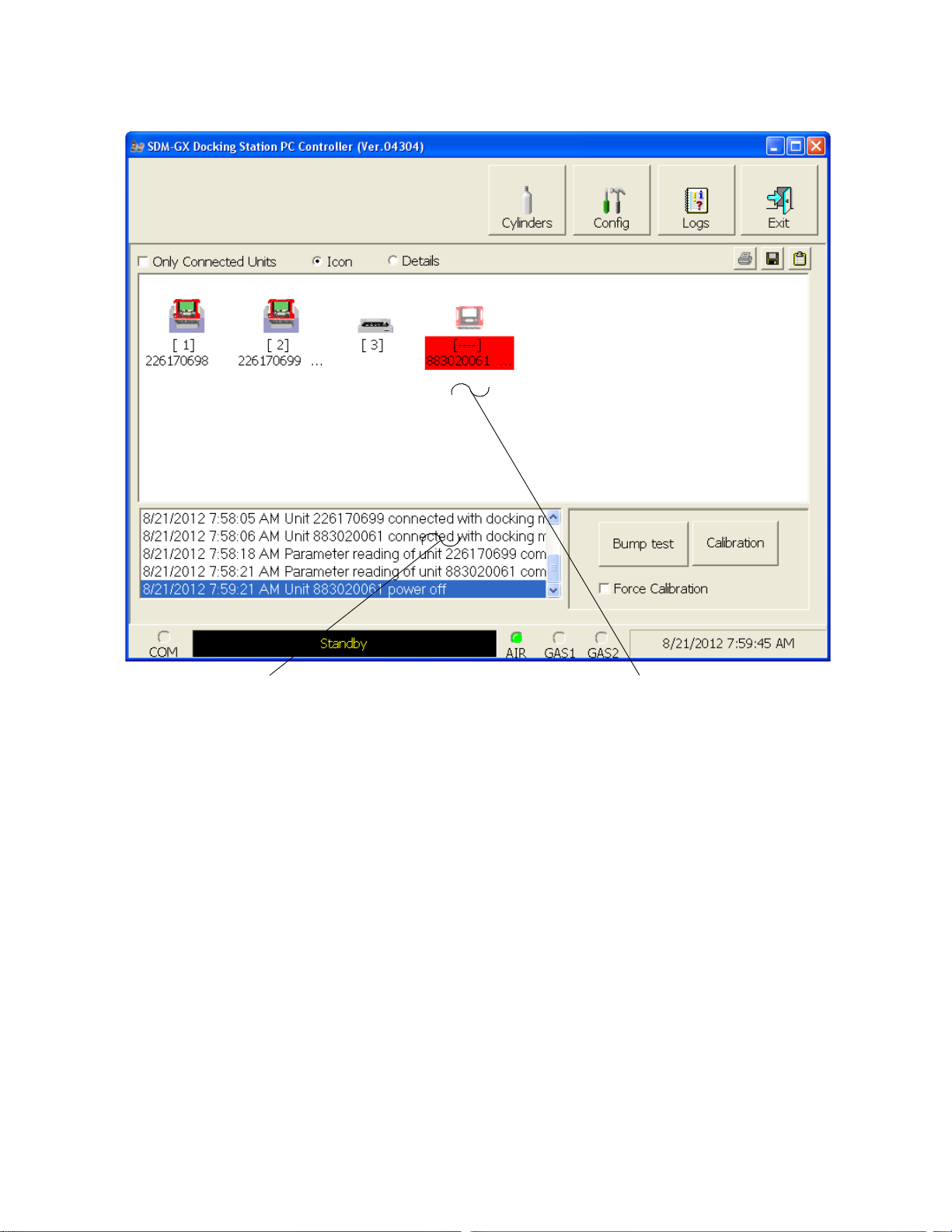

Figure 27: Instruments Connected and Downloaded

If an instrument is due for calibration, the docking station number and

instrument serial number will be highlighted in red.

If an instrument is due for calibration in the next 10 days, the docking station

and instrument serial number will be highlighted in orange.

If an instrument’s parameters could not be downloaded properly, a red triangle

will appear over the instrument and SDM-2009 picture.

41 • Connecting Instruments to the PC Controller Program

Page 47

Icon View vs. Details View

Instruments that are currently connected or have been previously connected can be

viewed in either Icon View or Details View. Choose Icon or Details View by clicking

the Icon or Details radio button below the control buttons. Icon View allows you to

view connected instruments and previously connected instruments in an icon

configuration. Connected instruments are shown as an instrument inserted in an

SDM-2009 icon. Previously connected instruments are shown as instrument icons.

Right clicking an instrument causes the Instrument Function Menu to appear.

Details View allows you to view connected instruments and previously connected

instruments in a table format. Scrolling to the right in Details View allows you to view

existing instrument parameters. For a description of these parameters and

instructions to change them, see “Edit Function” on page 99.

Figure 28: Main Program Window, Details View

Unless otherwise noted, all following figures that show the main program window in

this manual are shown in Icon View.

Connecting Instruments to the PC Controller Program • 42

Page 48

Printing and Exporting an Instrument List from the Main Program Window

You can print, save, or add to clipboard the instrument list in the main program

window. You can only print the list if it is viewed in Details format. The list cannot be

printed when viewed in Icon format.

To print the instrument list:

1. Ensure that the main program window is being viewed in Details format.

Figure 29: Main Program Window, Details View

The print icon will not be active if the main program window is viewed in Icon

format.

2. Click the Print icon located just below the Exit button.

3. A print confirmation screen will appear.

43 • Connecting Instruments to the PC Controller Program

Page 49

To print the instrument list, click OK.

To cancel the print job, click Cancel.

To save the instrument list as a .csv file:

1. Click the Save icon located just below the Exit button.

2. Choose a file path and enter a file name and click Save.

To save the instrument list to the clipboard:

1. Click the Clipboard button located just below the Exit button. The serial

number, model, station ID, user ID, next bump test date, next calibration date,

the calibration interval, and the data logging interval time for each instrument

in the main program window will be saved to the clipboard in a table format.

2. Open a spreadsheet program such as Excel or a word processing program

such as Word and paste the clipboard data into it.

Automatic Bump Testing and Calibration

The PC Controller Program will automatically perform a bump test or calibration on a

connected instrument if Auto Bump Test or Auto Calibration is selected in the

Configuration Window and if the bump test or calibration is due. The use of these

features allows the user to launch the PC Controller Program, turn on the

instrument(s) and walk away. No oversight of the bump test or calibration is needed.

For this reason, the calibration cylinder needs to already be in place before an

instrument is connected to the program.

NOTE: The Standard GAS or All GAS settings in the Configuration Window do

not affect the automatic testing of a GX-2009.

Automatic Bump Testing and Calibration • 44

Page 50

To automatically bump test or calibrate an instrument or instruments:

1. Be sure that Auto Bump Test or Auto Calibration are selected in the

Configuration Window. See “Setting Up the PC Controller Program” on

page 26 for instructions.

2. Verify that all of the bump test and/or calibration parameters are set correctly.

See “Setting Up the Configuration” on page 26 for instructions.

3. Verify that the appropriate calibration gas cylinder is connected to each

SDM-2009 or to the manifold line.

4. Establish a connection between the SDM-2009, instrument, and the PC

Controller program as described in “Connecting Instruments to the PC

Controller Program” on page 38.

5. The bump test or calibration will begin 1 minute after the last connected

instrument’s instrument information download is complete.

6. During an automatic bump test, if the bump test fails, a calibration is

immediately performed.

7. If Auto Bump Test and Auto Calibration are both selected, the calibration will

begin 1 minute after the bump test has finished.