Page 1

03 Series:

OX-03, CO-03, HS-03

Versions

Operator’s Manual

Part Number: 71-0304

Revision: C

Released: 9/26/18

www.rkiinstruments.com

Page 2

WARNING

Read and understand this instruction manual before operating

instrument. Improper use of the gas monitor could result in

bodily harm or death.

Periodic calibration and maintenance of the gas monitor is essen-

tial for proper operation and correct readings. Please calibrate

and maintain this instrument regularly! Frequency of calibration

depends upon the type of use you have and the sensor types.

Typical calibration frequencies for most applications are between

1 and 3 months, but can be required more often or less often

based on your usage.

03 Series Operator’s Manual

Page 3

Warranty

RKI Instruments, Inc. warrants the OX-03 Single Gas Monitor sold by us to

be free from defects in materials, workmanship, and performance for a

period of two (2) years from the date of shipment from RKI Instruments,

Inc. and warrants the CO-03 and HS-03 Single Gas Monitors sold by us for

three (3) years from the date of shipment from RKI Instruments, Inc. This

includes the instrument and the original sensor. Replacement parts are

warranted for one (1) year from the date of their shipment from RKI

Instruments, Inc. Replacement sensors are warranted for two (2) years

from the date of their shipment from RKI Instruments, Inc. Any parts found

defective within their warranty period will be repaired or replaced, at our

option, free of charge. This warranty does not apply to those items, which

by their nature, are subject to deterioration or consumption in normal

service, and which must be cleaned, repaired, or replaced on a routine

basis. Examples of such items are as follows:

Absorbent cartridges

Filter elements, disks, or sheets

Pump diaphragms and valves

Warranty is voided by abuse including mechanical damage, alteration,

rough handling, or repair procedures not in accordance with the instruction

manual. This warranty indicates the full extent of our liability, and we are

not responsible for removal or replacement costs, local repair costs,

transportation costs, or contingent expenses incurred without our prior

approval.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ANY AND ALL OTHER WARRANTIES

AND REPRESENTATIONS, EXPRESSED OR IMPLIED, AND ALL OTHER

OBLIGATIONS OR LIABILITIES ON THE PA RT OF RKI INSTRUMENTS, INC.

INCLUDING BUT NOT LIMITED TO THE WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. IN NO EVENT SHALL RKI

NSTRUMENTS, INC. BE LIABLE FOR INDIRECT, INCIDENTAL, OR

I

CONSEQUENTIAL LOSS OR DAMAGE OF ANY KIND CONNECTED WITH THE USE

OF ITS PRODUCTS OR FAILURE OF ITS PRODUCTS TO FUNCTION OR OPERATE

PROPERLY.

This warranty covers instruments and parts sold to users only by

authorized distributors, dealers, and representatives as appointed by RKI

Instruments, Inc.

We do not assume indemnification for any accident or damage caused by

the operation of this gas monitor and our warranty is limited to replacement

of parts or our complete goods.

03 Series Operator’s Manual Warranty

Page 4

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Sensor Gasket, Sensor Membrane, and Charcoal Filter . . . . . . . . . . . . . . . . . . 10

Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

LCD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Control Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Alarm LED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Buzzer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Vibrator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

IrDA Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Printed Circuit Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Protective Rubber Boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Alligator & Belt Clips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Start Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Start-up Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Performing a Fresh Air Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Turning Off the 03 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Measuring Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Adjusting the Buzzer Volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Display Mode, CO-03 and HS-03 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Display Mode, OX-03 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Data Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

03 Series User Setup Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Calibration Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Calibration Frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Using Calibration Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Setting the Date and Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Performing a Fresh Air Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table of Contents 03 Series Operator’s Manual

Page 5

Performing an Automatic Span Adjustment

(Zero Adjustment for OX-03) in A--CAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Performing an Easy Span Adjustment (Zero Adjustment for OX-03) in E--CAL.. 44

Performing a Manual Span Adjustment (Zero Adjustment for OX-03) in M--CAL 50

Performing a Bump Test in BUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Viewing the Instrument’s Firmware Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Setup Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Using Setup Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Setting the Date and Time in DATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Performing a Fresh Air Adjustment in AIR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Performing an Automatic Span Adjustment

(Zero Adjustment for OX-03) in A--CAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Performing an Easy Span Adjustment (Zero Adjustment for OX-03) in E--CAL.. 62

Performing a Manual Span Adjustment (Zero Adjustment for OX-03) in M--CAL 63

Setting the Alarm Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Adjusting the Bump Test Limit Check Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Setting the Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Replacing the Batteries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Replacing the Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Replacing the Sensor Membrane and Charcoal Filter . . . . . . . . . . . . . . . . . . . . 74

Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

WARNING: Understand this manual before operating the 03 Series.

Substitution of components may impair intrinsic safety.

To prevent ignition of a hazardous atmosphere, batteries

must only be changed in an area known to be

nonhazardous. This unit has not been tested in an

oxygen enrich ed atmosphere (above 21%).

03 Series Operator’s Manual Table of Contents

Page 6

Introduction

Using an advanced microprocessor controlled detection system, the 03

Series Personal Single Channel Gas Monitor detects the presence of either

carbon monoxide (CO), hydrogen sulfide (H2S), or oxygen (O2). The 03

Series’ compact size and easy-to-use design make it ideally suited for a

wide range of applications, including sewage treatment plants, tunnels,

hazardous waste sites, petrochemical facilities, oil fields, mines, and

chemical plants. The 03 Series is even small enough to be placed

conveniently in a pocket. The 03 Series offers the following features:

• Compact design

• Fast, accurate response with backlit digital liquid crystal display (LCD)

• Visual, audible, and vibration alarms

• Microprocessor control for reliability, ease of use, and advanced

• Resistance to RF (radio frequency) interference

capabilities

• Datalogging including interval trend data and alarm trend data

• Peak, STEL, and TWA indication for CO-03 & HS-03

• Minimum and maximum indication for OX-03

• Over range alarm

• Gas, battery, sensor failure, and system failure alarms

• Over 3,000 hours operation on one set of alkaline batteries

• Rotatable alligator clip for “hands free” gas monitoring, belt clip optional

• CSA certification for intrinsic safety in Class I, Division I, Groups A, B,

C, and D hazardous atmospheres

WARNING: The 03 Series detects oxygen deficiency and elevated

levels of oxygen, carbon monoxide, and hydrogen

sulfide, all of which can be dangerous or life threatening.

When using the 03 Series, you must follow the

instructions and warnings in this manual to assure

proper and safe operation of the unit and to minimize the

risk of personal injury. Be sure to maintain and

periodically calibrate the 03 Series as described in this

manual.

6 • Introduction 03 Series Operator’s Manual

Page 7

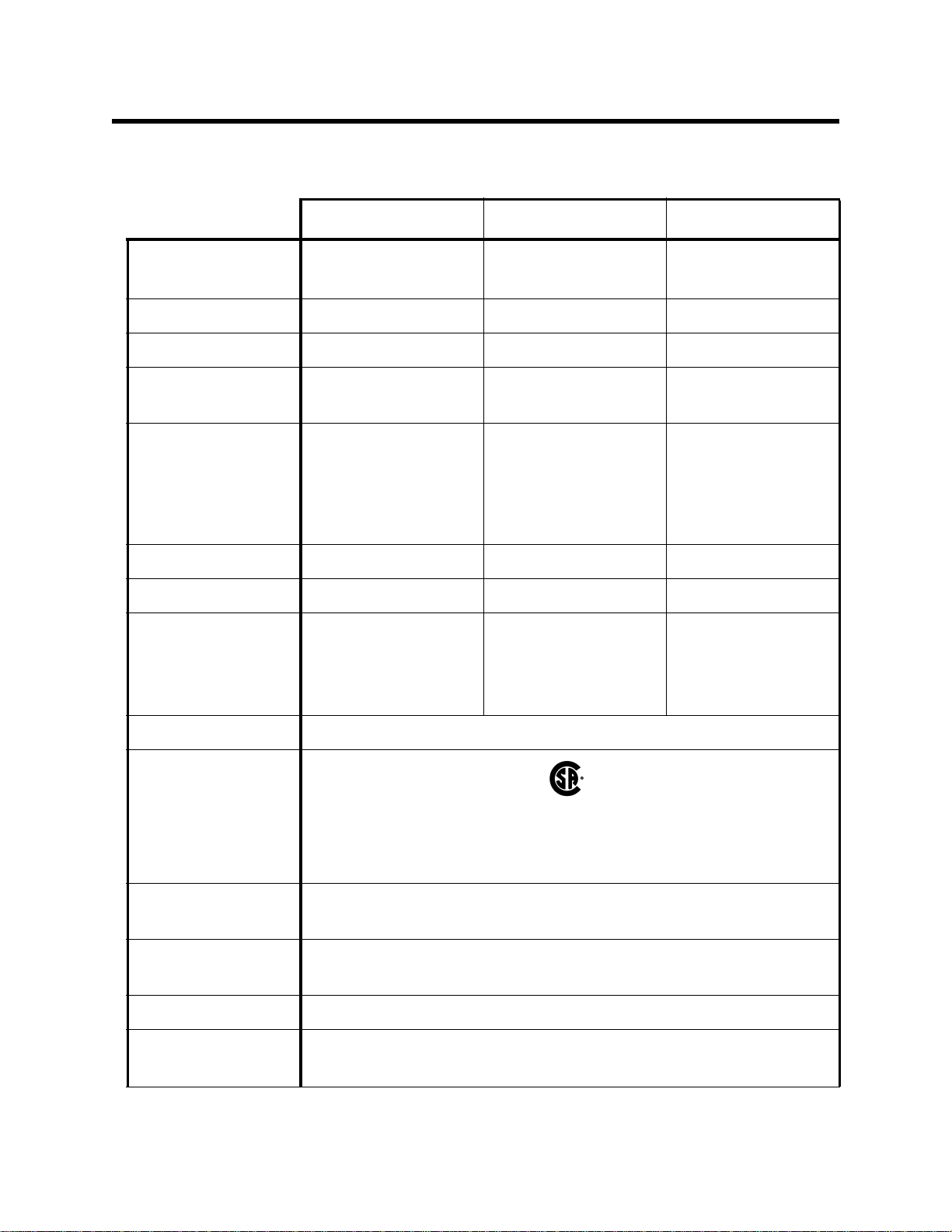

Specifications

Table 1: 03 Series Specifications

CO-03 HS-03 OX-03

Target Gas Carbon Monoxide

(CO)

Hydrogen Sulfide

(H2S)

Oxygen

(O2)

Detection Range 0 to 500 ppm 0 to 100.0 ppm 0 to 40.0% vol.

Display Increment 1 ppm 0.5 ppm 0.1% vol.

Detection

Electro Chemical Electro Chemical Galvanic Cell

Principle

Alarm Points Low

High

TWA

STEL

25 ppm

50 ppm

25 ppm

200 ppm

Low

High

TWA

STEL

5.0 ppm

30.0 ppm

1.0 ppm

5.0 ppm

Low 19.5% vol.

(decreasing)

High 23.5% vol.

(increasing)

Sampling Method Diffusion Diffusion Diffusion

Response Time T90 in 30 seconds T90 in 30 seconds T90 in 20 seconds

Accuracy ± 5% of reading or

± 5 ppm CO

(whichever is

greater)

± 5% of reading or

± 2 ppm H2S

(whichever is

greater)

± 0.5% O

2

Indication Digital LCD

Safety/Regulatory

C US

186718

CSA classified, “C/US”, as Intrinsically Safe. Exia. Class I,

Groups A, B, C, & D. Temperature Code T3C.

Power Two AAA size alkaline batteries standard, Duracell MN2400 or

PC2400

Continuous

At 25 °C: Over 3,000 hours, no alarms or backlighting

Operating Hours

Case High-impact plastic, dust and weather proof

Standard

Accessories

• Rubber protective boot

• Alligator clip

03 Series Operator’s Manual Specifications • 7

Page 8

Table 1: 03 Series Specifications

CO-03 HS-03 OX-03

Optional

Accessories

Dimensions and

Weight

Operating Temp. &

Humidity

• Calibration adapter

• Calibration kit

•Belt clip

• Wrist strap

• IrDA/USB cable for downloading data to computer

• Product CD, includes 03 Series Datalogging Program and

03 Series User Setup Program

2.2” (54mm) W x 2.6” (67mm) H x 0.9” (24mm) D;

2.8 oz. (80 g)

-20°C to +50°C, 16 - 95% RH

(non condensing)

-20°C to +50°C,

0 - 95% RH (non

condensing)

8 • Specifications 03 Series Operator’s Manual

Page 9

Description

Bat tery Cover Screw

Battery Cover

CO

AIR

CO-03

LCD

Buzzer Opening

IrDA Port

Control Buttons

Wrist St r ap

Connection

POWER

MODE

Dif f usion Port

Alarm LED

Figure 1: Components of the 03 Series

This section describes the components of the 03 Series.

Case

The 03 Series’ sturdy, high-impact plastic case is blue and consists of a

front and rear case. The case is suitable for use in many environmental

conditions, indoors and out. The unit is dust proof and weather resistant.

The front case has an LCD (liquid crystal display) that shows various

indications. Below the LCD are two black control buttons. The left button is

labeled “AIR” and the right button is labeled “POWER MODE”.

The buzzer opening is located in the top left corner of the front case. To the

right of the buzzer is the diffusion port for the sensor.

The alarm LED lens is located at the top of the front case.

The battery compartment is located in the rear case. Access to the

compartment is accomplished by turning the captive battery cover screw

counterclockwise and by removing the battery cover.

There are two spring bars on the rear case. One is on the left and one is on

the right. They are the same type of spring bar that is used to retain a

watch band and are used to mount the alligator clip or optional belt clip.

A feature in the lower left corner of the rear case is used to install the

optional wrist strap.

03 Series Operator’s Manual Description • 9

Page 10

Sensor Gasket, Sensor Membrane, and Charcoal Filter

The sensor membrane is a paper-like filter disk that is held in place by the

sensor gasket and fits into a recessed area on the inside of the front case.

The sensor membrane covers the diffusion port and protects the sensor

from dirt and moisture. The sensor membrane should be inspected

periodically and replaced if contaminated by dirt or moisture. See

“Replacing the Sensor Membrane and Charcoal Filter” on page 74 for

sensor membrane replacement instructions.

The CO-03 includes a charcoal filter disk which is located in the sensor

gasket. The charcoal filter disk removes gases from the sampled air that

will cause a response on the CO sensor such as H2S and certain

hydrocarbons. If false or elevated CO readings are noticed, especially in

the presence of H2S, change the charcoal filter disk. See “Replacing the

Sensor Membrane and Charcoal Filter” on page 74 for replacement

instructions.

Sensor

The 03 Series uses either an oxygen, CO, or H2S sensor. The sensor is

protected by the white sensor membrane which is held in place by the

sensor gasket. The sensor membrane allows ambient air to diffuse past it

to the sensor. The three sensors used in the three 03 Series models use

different detection principles as described below.

Oxygen Sensor

The oxygen sensor is a galvanic type of sensor. A membrane covers the

cell and allows gas to diffuse into the cell at a rate proportional to the partial

pressure of oxygen. The oxygen reacts in the cell and produces a voltage

proportional to the concentration of oxygen. The voltage is measured by

the 03 Series’ circuitry, converted to a measurement of gas concentration,

and displayed on the LCD.

CO and H

The CO and H2S sensors are electrochemical sensors that consist of two

precious metal electrodes in an acid electrolyte. A gas permeable

membrane covers the sensor face and allows gas to diffuse into the

electrolyte. The gas reacts in the sensor and produces a current

proportional to the concentration of the target gas. The current is amplified

by the 03 Series’ circuitry, converted to a measurement of gas

concentration, and displayed on the LCD.

S Sensors

2

LCD

The LCD is visible through the front case. When the 03 Series is in

Measuring Mode, the target gas concentration, battery condition, and

alarm indications are displayed on the LCD. Various other items are

10 • Description 03 Series Operator’s Manual

Page 11

displayed when the LCD is in other modes, such as Calibration Mode.

When either of the two control buttons are pressed, the LCD backlight

comes on for 20 seconds.

Control Buttons

Below the LCD are two control buttons: POWER MODE and AIR. The

POWER MODE button turns the 03 Series on and off. The functions

performed by the control buttons are summarized in the following table:

Table 2: 03 Series Control Buttons

Button Function

• Turns the unit on and off.

• Turns the LCD back light on.

POWER MODE

• Resets the alarm circuit (gas alarms).

• Enters Display Mode.

• Enters Calibration Mode with the AIR button.

• Enters Setup Mode with the AIR button.

• Turns the LCD back light on.

• Adjusts LCD reading when the fresh air

adjustment is performed.

• Enters Calibration Mode with the POWER MODE

AIR

button.

• Enters Setup Mode with the POWER MODE

button.

• Increases or decreases settings when the unit is in

Calibration Mode or Setup Mode.

Alarm LED

The 03 Series has one red alarm LED. It alerts you to gas, low battery, and

sensor failure alarms. The alarm LED is located at the top of the front case

beneath a clear plastic lens.

Buzzer

A solid-state electronic buzzer is mounted inside the 03 Series. An opening

in the top left corner of the front case allows the buzzer’s sound to emanate

from the case. The buzzer sounds for gas alarms, unit malfunctions, and

the dead battery alarm. It also serves as an indicator during normal use of

the various LCD display options.

Vibrator

A vibrating motor (vibrator) is mounted inside the 03 Series. The vibrator

vibrates momentarily during the power-up sequence and for gas alarms.

03 Series Operator’s Manual Description • 11

Page 12

IrDA Port

An infrared (IR) communications port is located just to the left of the alarm

LED at the top of the front case beneath the clear lens. The data

transmitted through the port is in standard IrDA protocol. A computer’s

infrared port or an IrDA/USB cable connected to a computer’s USB port

can be used to download data saved by the 03 Series to a computer using

the 03 Series Data Logger Management Program. See the 03 Series Data

Logger Management Program operator’s manual for data logging and

downloading instructions.

Printed Circuit Board

The primary function of the 03 Series’ printed circuit board is to amplify the

signal sent to it from the sensor, convert the signal to a meaningful

measurement of gas concentration, display the gas concentration on the

LCD, store STEL, TWA, and peak gas readings, and activate the alarm

circuit if an alarm point has been reached. It monitors battery level, battery

failure, and sensor failure. It also controls various operating modes of the

unit.

NOTE: The printed circuit board contains no user serviceable parts.

Batteries

Two AAA-size alkaline batteries run the 03 Series. At 25°C the alkaline

batteries last at least 3,000 hours. The battery icon on the LCD shows

remaining battery life.

When the 03 Series detects low battery voltage, a low battery warning is

activated. When battery voltage is too low for normal operation, the 03

Series sounds a dead battery alarm.

The alkaline batteries can be replaced by removing the battery cover on

the rear case. Turn the captive battery cover screw counterclockwise to

release the door. See “Replacing the Batteries” on page 70 for detailed

battery changing instructions.

WARNING: To prevent ignition of a hazardous atmosphere, batteries

must only be changed in an area known to be

nonhazardous.

AVERTISSEMENT:Pour éviter l’inflammation d’une atmosphère

dangereuse, les batteries doivent uniquement être

modifiés ou facturés dans une zone connue comme non

dangereuse.

12 • Description 03 Series Operator’s Manual

Page 13

NOTE: Use of batteries not specified by RKI Instruments, Inc. will void the

Side Front

Open

Alligator Clip

Closed

CSA classification and may void the warranty. See “Replacing the

Batteries” on page 70.

Protective Rubber Boot

A protective rubber boot is installed over the 03 Series.

Figure 2: Rubber Boot

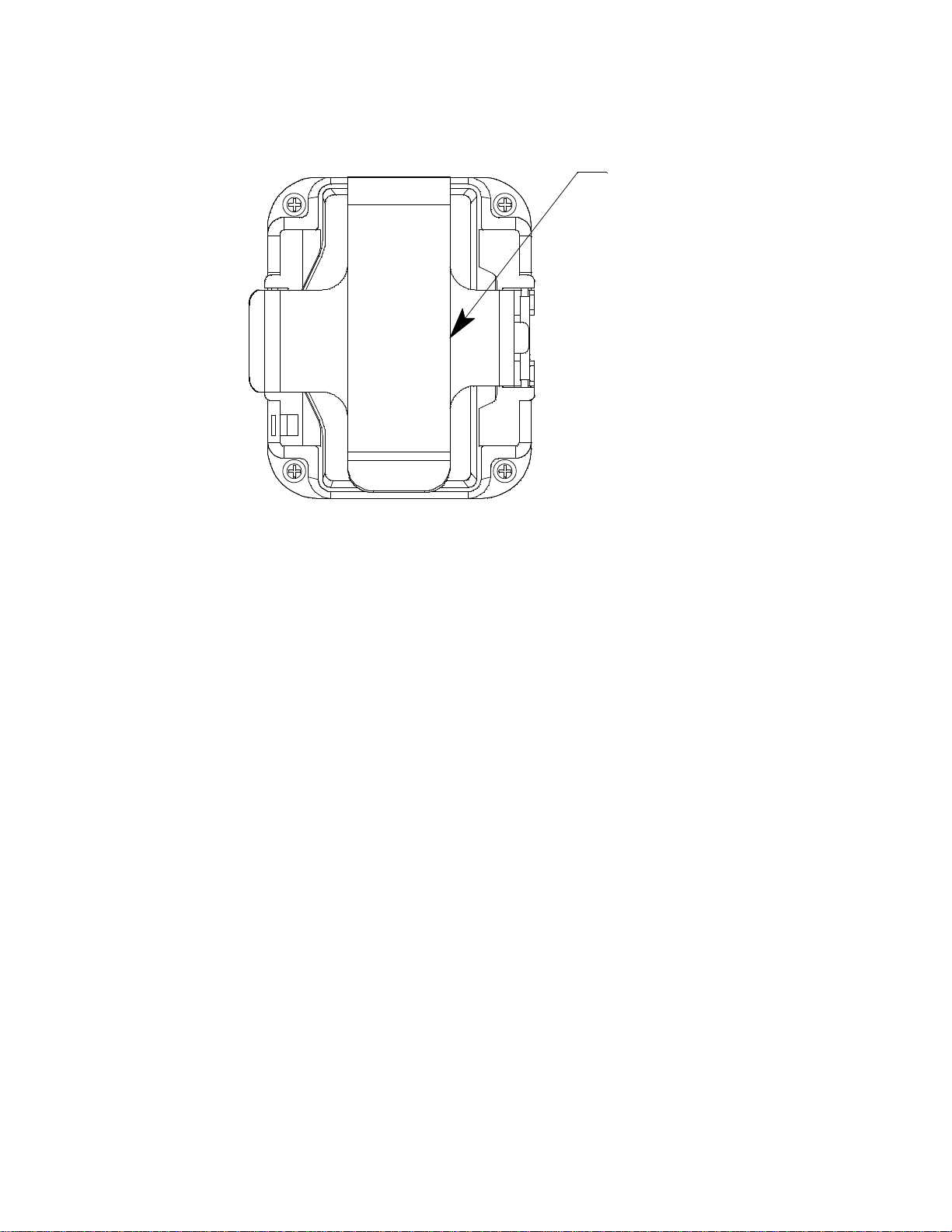

Alligator and Belt Clips

The 03 Series is available with two types of clips: the alligator clip

(standard) and the belt clip (optional). The alligator clip is shown in Figure 3

below. The alligator clip can be used to attach the 03 Series to clothing or a

belt. Teeth in the clip’s jaws prevent the unit from slipping off. The clip can

be rotated in 45 degree turns if necessary.

03 Series Operator’s Manual Description • 13

Figure 3: Alligator Clip

Page 14

The belt clip is shown in Figure 4 below and is used to easily clip the 03

Belt Clip

Series on a belt.

Figure 4: Belt Clip

14 • Description 03 Series Operator’s Manual

Page 15

Start Up

C.AL

FAIL

This section explains how to start up the 03 Series and to get it ready for

operation.

NOTE: The screens shown in this section are for a CO-03. If you are

using a different version of the 03 Series, your instrument screen

will vary slightly from those shown below.

Start-up Procedure

1. Press and briefly hold down the POWER MODE button. The backlight

will turn on and all the display segments will turn on. Release the button

when you hear a beep.

2. The vibrator vibrates and the alarm light flashes momentarily.

3. The initial startup screen depends on how Bump Fail Behavior is set.

This parameter along with the Cal. Limit Display and Cal. Limit Check

parameters mentioned in Step 5 and the Auto Zero Adjustment

parameter mentioned in Step 12 below cannot be set using the 03

Series’ instrument menus, but are set using the 03 Series User Setup

Program. See the 03 Series User Setup Program Operator’s Manual for

information regarding changing various instrument parameters that are

not available for adjustment in the instrument’s operating modes.

•If Bump Fail Behavior is set to None (factory setting) or if it is set to

Can Not Use and the most recently performed bump test passed,

proceed to Step 5.

•If Bump Fail Behavior is set to Can Not Use and the most recently

performed bump test failed, the following screen will appear.

The instrument cannot be used until a successful bump test or

calibration is performed. See “Calibration Mode” on page 36 for

instructions.

4. If Cal. Limit Display is set to Off, proceed to Step 6.

03 Series Operator’s Manual Start Up • 15

Page 16

5. If Cal. Limit Display is set to On (factory setting), the screen that

MODE

C.LIMIT

CAL

YES

C.LIMIT

CAL

AIR

C.LIMIT

CAL

NO

C.LIMIT

CAL

C.LIMIT

CAL

C.LIMIT

CAL

appears next depends on how Cal. Limit Check is set.

• If the unit is due for calibration and Cal. Limit Check is set to

Confirm to use (factory setting), then the following screen sequence

will occur.

The alarm LED and buzzer will pulse several times.

To continue the startup sequence without performing a calibration,

press and release the AIR button. Continue to Step 6.

To perform a calibration, press and release the POWER MODE

button. Depending on the value entered into the One Touch Cal

Time parameter using the 03 Series User Setup Program, the

instrument will display either the A--CAL menu item or the E--CAL

menu item in Calibration Mode. See “Calibration Mode” on page 36

for instructions.

WARNING: You must press either the POWER MODE or AIR button to

continue. If you do not press a button, the buzzer will

continue to beep and the LED will continue to flash for 6

seconds every 5 seconds.

16 • Start Up 03 Series Operator’s Manual

Page 17

• If the unit is due for calibration and Cal. Limit Check is set to Can’t

MODE

C.LIMIT

FAIL

YES

C.LIMIT

FAIL

C.LIMIT

FAIL

MODE

C.LIMIT

YES

C.LIMIT

C.LIMIT

0d 0d

0d

use, then the following screen sequence will occur.

The alarm LED and buzzer will pulse several times. Press and

release the POWER MODE button. Depending on the value entered

into the One Touch Cal Time parameter using the 03 Series User

Setup Program, the instrument will display either the A--CAL menu

item or the E--CAL menu item in Calibration Mode. The above

screen will remain on the display until the unit is either turned off or

Calibration Mode is entered. The 03 Series cannot be used until a

complete calibration has been performed either by selecting A-CAL, E--CAL, or M--CAL in the Calibration Mode menu. See

“Performing an Automatic Span Adjustment (Zero Adjustment for

OX-03) in A--CAL” on page 39, “Performing an Easy Span

Adjustment (Zero Adjustment for OX-03) in E--CAL” on page 44, or

“Performing a Manual Span Adjustment (Zero Adjustment for OX-

03) in M--CAL” on page 50 for calibration instructions.

WARNING: You must perform a successful calibration in order to

continue to normal operation. If you do not perform a

successful calibration, the screen sequence will

continue, the buzzer will continue to beep, and the LED

will continue to flash for 6 seconds every 5 seconds and

the unit will not enter normal operation.

• If a calibration is due and Cal. Limit Check is set to None, the

sequence below will occur twice.

03 Series Operator’s Manual Start Up • 17

Page 18

Press and release the POWER MODE button during this time to go

CAL.

14. 2.17

180d

NEXT

14. 2.17

180d

BUMP

teSt

YES

NOW

teSt

MODE

BUMP

teSt

NOW

teSt

NO

BUMP

teSt

AIR

NOW

teSt

to the A--CAL or E--CAL menu item in Calibration Mode depending

on the value entered into the One Touch Cal Time parameter of the

03 Series User Setup Program. If no button is pressed, the

instrument will continue with the warmup sequence in Step 6 once

the sequence shown above has finished.

• If calibration is not due, then the following screen appears for a few

seconds indicating when the next calibration is due. “NEXT” and

“CAL” alternate on the bottom of the screen.

NOTE: The following screens in Step 6 only appear if Bump Test Limit

Display is set to On using the 03 Series User Setup Program. The

standard factory setting for this function is Off.

6. If Bump Test Limit Display is set to Off (factory setting), proceed to

Step 8.

7. If Bump Test Limit Display is set to On using the 03 Series User Setup

Program, the next screen will depend on how Bump Test Limit Check

is set in Setup Mode or using the 03 Series User Setup Program.

• If the unit is due for bump testing and Bump Test Limit Check is set

to Confirm to use (factory setting), then the following screen

sequence will occur.

18 • Start Up 03 Series Operator’s Manual

Page 19

The alarm LED and buzzer will pulse several times.

BUMP

FAIL

YES

NOW

FAIL

MODE

BUMP

FAIL

NOW

FAIL

To continue the startup sequence without performing a bump test,

press and release the AIR button. Continue to Step 8.

To perform a bump test, press and release the POWER MODE

button. The instrument will display the BUMP menu item in

Calibration Mode. See “Performing a Bump Test in BUMP” on

page 53 for instructions.

WARNING:You must press either the POWER MODE or AIR button to

continue. If you do not press a button, the screen

sequence will continue, the buzzer will continue to beep

and the LED will continue to flash for 6 seconds every 5

seconds.

• If the unit is due for bump testing and Bump Test Limit Check is set

to Can’t use, then the following screen sequence will occur.

The alarm LED and buzzer will pulse several times. Press and

release the POWER MODE button to go to the BUMP menu item in

Calibration Mode. The above screens will remain on the display until

the unit is either turned off or Calibration Mode is entered. The 03

WARNING:You must perform a successful bump test in order to

03 Series Operator’s Manual Start Up • 19

Series cannot be used until a bump test has been performed. See

“Performing a Bump Test in BUMP” on page 53 for bump test

instructions.

continue to normal operation. If you do not perform a

successful bump test, the buzzer will continue t o beep and

the LED will continue to flash for 6 seconds every 5

seconds and the unit will not enter normal operation.

Page 20

• If a bump test is due and Bump Test Limit Check is set to None,

MODE

BUMP

YES

BUMP

BUMP

0d 0d

0d

BUMP

14. 2.17

180d

NEXT

14. 2.17

180d

8:20

2014

1.31

bAtt

3.0

V

the sequence below will occur twice.

Press and release the POWER MODE button during this time to go

to the BUMP menu item in Calibration Mode. If no button is pressed,

the instrument will continue with the warmup sequence in Step 8

once the sequence shown above has finished.

NOTE: If a successful calibration is performed, the next bump test date is

reset and starts over even though a bump test was not performed.

• If bump testing is not due, then the following screen appears for a

few seconds indicating when the next bump test is due. “NEXT” and

“BUMP” alternate on the bottom of the screen.

8. The Date/Time Screen appears for a few seconds.

This screen displays the current date and time.

9. The Battery Voltage Screen appears for a few seconds.

20 • Start Up 03 Series Operator’s Manual

Page 21

The screen displays the current battery voltage.

SENSOR

FAIL

ZERO

AUTO

- - - -

CAUTION: If the unit gives a low batt ery warning or dead battery alarm,

change the alkaline batteries before using the unit.

10.The display then indicates the following items for about a second each:

• Full scale value

• Warning setpoint (low gas alarm)

• Alarm setpoint (high gas alarm)

• STEL alarm setpoint (CO and H2S only)

• TWA alarm setpoint (CO and H2S only)

11. If the 03 Series experiences a sensor failure during start up, the

following screen will appear.

The instrument cannot be used if a sensor failure occurs. Replace the

failed sensor.

12. If Auto Zero Adjustment is set to On (factory setting is Off), then the

03 Series will perform an automatic fresh air adjustment.

If the fresh air adjustment is successful, the unit will proceed to Normal

Mode. If the sensor fails the air adjustment, the screen will indicate the

failure. If a failure occurs, press and release the POWER MODE button

to proceed to Normal Mode. Replace the failed sensor as soon as

possible.

03 Series Operator’s Manual Start Up • 21

Page 22

WARNING: If the Auto Zero Adjustment feature is turned on, mak e

CO

ppm

0

AIR

HOLD

- - - -

sure that you start-up the 03 Series in a known fresh air

environment, an environment free of combustible or toxic

gasses and of normal oxygen content, 20.9%. If you do

not start-up the unit in a fresh air environment, the fresh

air adjustment will not be accurate.

13.The 03 Series is now operating in Measuring Mode and monitoring for

gas. The Normal Operation Screen appears and the instrument beeps

once.

The gas concentration of the target gas is displayed along with the

battery charge level in the lower left corner. The heart symbol displayed

in the upper right corner flashes while the instrument is functioning

properly. If it disappears or is steadily on, the unit is experiencing a

microprocessor error. The backlight turns off after 20 seconds.

Performing a Fresh Air Adjustment

Before using the 03 Series, set the fresh air reading. Performing this

adjustment ensures accurate gas readings in the monitoring environment.

1. Find a fresh air environment of normal oxygen content (20.9%) that is

free of toxic or combustible gases.

2. With the unit on and in Measuring Mode, press and hold the AIR button.

The LCD displays “hold” prompting you to hold the AIR button.

22 • Start Up 03 Series Operator’s Manual

Page 23

3. Release the AIR button when the following screen appears. The unit

ADJ

- - - -

will set the reading to 0 ppm (20.9% for the OX-03) and return to

Measuring Mode.

Turning Off the 03 Series

1. Press and hold the POWER MODE button for about five seconds to

turn off the unit. The buzzer will pulse while the POWER MODE button

is being pressed before the unit turns off.

2. Release the button when the LCD is blank. The unit is off.

NOTE: If Power Off Password Protection is turned On (factory setting is

Off) using the 03 Series User Setup Program, a password is

required to turn the 03 Series off. When the password screen

appears, adjust each digit with the AIR button and press and

release the POWER MODE button to move on to the next digit.

Once the password has been entered, the instrument will shut off

and the LCD will be blank.

03 Series Operator’s Manual Start Up • 23

Page 24

Operation

CO

ppm

0

This section describes Measuring Mode, setting the buzzer volume,

Display Mode, and alarm indications.

NOTE: The screens shown in this section are for a CO-03. If you are

using a different version of the 03 Series, your instrument screen

will vary slightly from those shown below.

Measuring Mode

In Measuring Mode, the battery level and target gas concentration are

displayed on the LCD. The battery icon has three bars visible when the

batteries have a full charge. As the battery charge decreases, the bars will

gradually disappear, one by one. The heart symbol displayed in the upper

right corner flashes while the instrument is functioning properly. If it

disappears or is steadily on, the unit is experiencing a microprocessor

error.

The target gas concentration is displayed in the middle of the LCD. On the

CO-03, CO is displayed in parts per million (ppm). On the HS-03, H2S is

displayed in ppm. On the OX-03, oxygen is displayed as volume percent.

Adjusting the Buzzer Volume

The buzzer volume on the 03 Series can be adjusted while in Measuring

Mode if Buzzer Volume Selection is set to On (factory setting is Off). The

Buzzer Volume Selection setting can be adjusted using the 03 Series

User Setup Program. The default buzzer volume setting is HI. If it is

changed to LO, the setting will revert back to HI the next time the

instrument is turned on.

1. Make sure the 03 Series is in the Measuring Mode Normal Operation

screen.

2. Press and hold the POWER MODE and AIR buttons simultaneously.

NOTE: To avoid entering Display Mode, press the AIR button slightly

sooner than pressing the POWER MODE button.

Release both buttons when the instrument starts simulating an alarm

24 • Operation 03 Series Operator’s Manual

Page 25

condition after the second beep. The current setting for the buzzer will

BEEP

b - HI

B--LO

CO

ppm

0

be displayed and the current volume will be emanating from the buzzer.

3. Use the AIR button to select LO or HI. The buzzer volume during the

simulated alarm condition will change as you select a different volume.

4. Press and release the POWER MODE button to save the setting and

return to Normal Operation.

5. If LO was selected, “B--LO“ will appear at the bottom of the Normal

Operation screen.

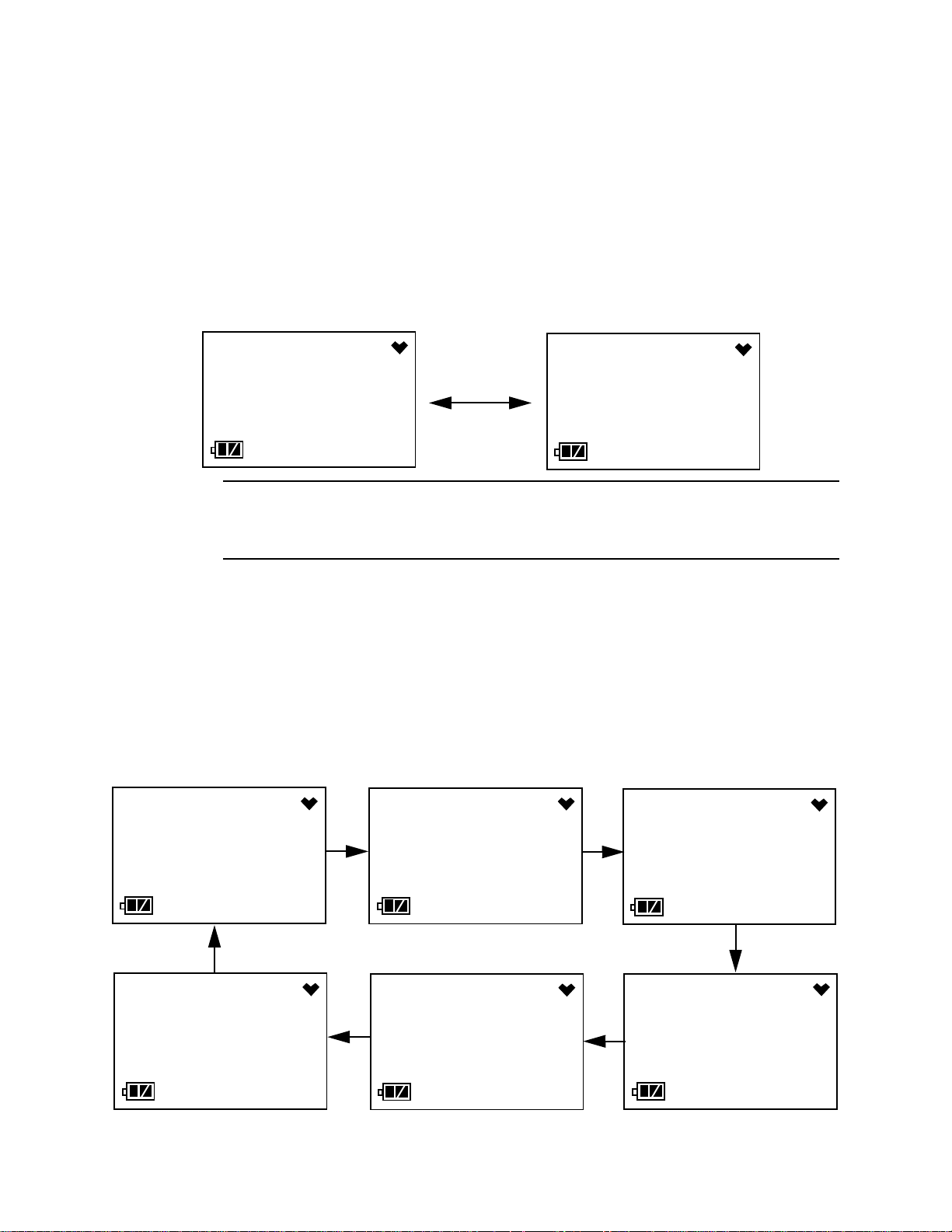

Display Mode, CO-03 and HS-03

This section describes Display Mode for CO-03 and HS-03 instruments

only. See “Display Mode, OX-03” on page 27 for a description of the OX03’s Display Mode.

You can access Display Mode while in Measuring Mode by using the

POWER MODE button. In Display Mode you can view and reset the peak

readings, view the TWA and STEL values, view the detection range full

scale, and view the date and time.

STEL is an acronym for short-term exposure limit, and it is the average

reading of the target gas during the last 15 minutes. TWA is an acronym for

time-weighted average, and it is the average reading for the target gas

during the last eight (8) hours. If eight (8) hours has not elapsed since the

unit was turned on, the TWA is still calculated over eight hours, with the

missing time assigned a zero (0) value for the readings. Similarly, if the unit

has not been on for 15 minutes, the missing time is assigned a 0 value and

the STEL is calculated over 15 minutes. The peak readings, STEL values,

and TWA values are cleared when the unit is turned off.

To enter Display Mode, do the following:

1. Make sure the 03 Series is in the Measuring Mode Normal Operation

screen. The 03 Series must be in the Normal Operation Screen for you

to access Display Mode.

03 Series Operator’s Manual Operation • 25

Page 26

2. Press and release the POWER MODE button to enter Display Mode.

PEAK

ppm

15

HOLD

CLEAR

- - - -

CLEAR

- - - -

STEL

ppm

5

The backlight will turn on and the PEAK Screen will appear.

The peak reading since the 03 Series was turned on is displayed.

3. If you do not want to clear the peak reading, continue to the next step.

If you want to clear the peak reading, press and hold the AIR button.

After a couple of seconds, the LCD will prompt you to hold the AIR

button with the following screen.

Hold the AIR button until the following screen appears, then release it.

The peak reading will be cleared and the unit will return to the PEAK

Screen.

4. Press and release the POWER MODE button again to proceed to the

STEL Screen. The STEL reading will be displayed.

26 • Operation 03 Series Operator’s Manual

Page 27

5. Press and release the POWER MODE button again to proceed to the

TWA

ppm

10

F. S.

ppm

L

500

8:20

2014

1.31

TWA Screen. The TWA reading will be displayed.

6. Press and release the POWER MODE button again to proceed to the

Full Scale Screen. The detection range full scale value is displayed. An

“L” or an “A” will appear under the full scale value to indicate whether

the alarms are set to latching (L) or auto-resetting (A). This setting can

be adjusted using the 03 Series User Setup Program.

7. Press and release the POWER MODE button again to proceed to the

Date/Time Screen. The date and time of the instrument is displayed.

8. Press and release the POWER MODE button once again to return the

unit to Measuring Mode.

NOTE: If you do not press a button for 20 seconds while in Display Mode,

the unit will return to Measuring Mode automatically and the

backlight will turn off.

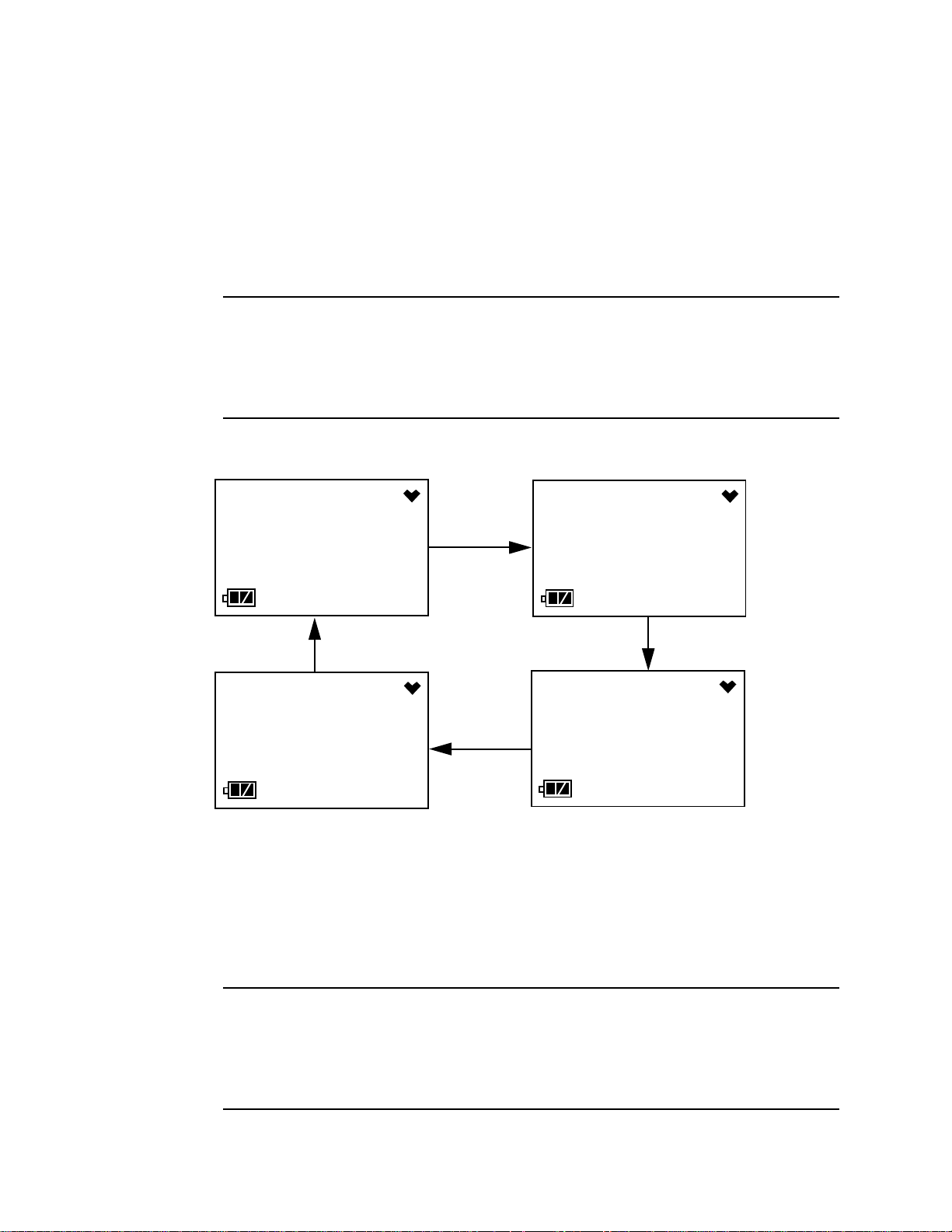

Display Mode, OX-03

This section describes Display Mode for the OX-03 only. See “Display

Mode, CO-03 and HS-03” on page 25 for a description of the CO-03 and

HS-03 instruments’ Display Mode.

You can access Display Mode while in Measuring Mode by using the

POWER MODE button. In Display Mode you can view and reset the

minimum and maximum readings, view the detection range full scale, and

view the date and time.

03 Series Operator’s Manual Operation • 27

Page 28

To enter Display Mode and view items or reset the peak readings, do the

MIN.

%

20.1

HOLD

CLEAR

- - - -

CLEAR

- - - -

following:

1. Make sure the 03 Series is in the Measuring Mode Normal Operation

screen. The 03 Series must be in the Normal Operation Screen for you

to access Display Mode.

2. Press and release the POWER MODE button to enter Display Mode.

The backlight will turn on.

3. The Min. Screen will be displayed. This is the minimum oxygen reading

taken since the instrument was turned on.

4. If you do not want to clear the minimum reading, continue to the next

step.

If you want to clear the minimum reading, press and hold the AIR

button. After a couple of seconds, the LCD will prompt you to hold the

AIR button with the following screen.

Hold the AIR button until the following screen appears, then release it.

The minimum reading will be cleared and the unit will return to the Min.

Screen.

28 • Operation 03 Series Operator’s Manual

Page 29

5. Press and release the POWER MODE button to display the Max.

MAX.

%

21.2

HOLD

CLEAR

- - - -

CLEAR

- - - -

F. S.

%

L

40.0

Screen. This is the maximum oxygen reading taken since the

instrument was turned on.

6. If you do not want to clear the maximum reading, continue to the next

step.

If you want to clear the maximum reading, press and hold the AIR

button. After a couple of seconds, the LCD will prompt you to hold the

AIR button with the following screen.

Hold the AIR button until the following screen appears, then release it.

The maximum reading will be cleared and the unit will return to the Max.

Screen.

7. Press and release the POWER MODE button again to proceed to the

Full Scale Screen. The detection range full scale value is displayed. An

“L” or an “A” will appear under the full scale value to indicate whether

the alarms are set to latching (L) or auto-resetting (A). This setting can

be adjusted using the 03 Series User Setup Program.

03 Series Operator’s Manual Operation • 29

Page 30

8. Press and release the POWER MODE button again to proceed to the

8:20

2014

1.31

Date/Time Screen. The date and time of the instrument is displayed.

9. Press and release the POWER MODE button once again to return the

unit to Measuring Mode.

NOTE: If you do not press a button for 20 seconds while in Display Mode,

the unit will return to Measuring Mode automatically and the

backlight will turn off.

Alarms

This section covers alarm indications. It also tells you how to reset the 03

Series after an alarm has occurred and how to respond to an alarm

condition.

Alarm Indications

The 03 Series will sound the buzzer, flash its alarm LED, and vibrate when

the target gas concentration rises above (falls below for oxygen) the

warning level. The 03 Series also sounds the buzzer, flashes its alarm

LED, and vibrates when the alarm level is reached. In addition, the 03

Series has a low battery warning, a dead battery alarm, an over range

alarm, a sensor failure alarm, a system failure alarm, and a clock failure

alarm. See Table 3 below for a description of each alarm indication.

Table 3: Alarm Types and Indications

Alarm Type Visual Indications Other Indications

Warning

Concentration of gas

rises above (falls

below for OX-03) the

warning level.

• Gas reading

flashes.

• WARN appears

below the gas

reading.

• Back light turns on.

• Alarm LED flashes.

• Buzzer sounds

alternating between

a low and high

pitch.

• Vibrator pulses.

30 • Operation 03 Series Operator’s Manual

Page 31

Table 3: Alarm Types and Indications

Alarm Type Visual Indications Other Indications

Alarm

Concentration of gas

rises above the alarm

level.

TWA or STEL

(CO-03 & HS-03 Only)

Concentration of CO

or H2S rises above the

TWA or STEL alarm

point.

• Gas reading

flashes.

• ALRM appears

below the gas

reading.

• Back light turns on.

• Alarm LED flashes

faster than warning

indication.

• Back light turns on.

• Gas reading

flashes.

• TWA or STEL

appears below the

gas reading.

• If the unit is in both

TWA alarm and

STEL alarm, only

STEL will be

displayed.

• Alarm LED flashes.

• Buzzer sounds

alternating between

low and high pitch

faster than warning

indication.

• Vibrator pulses

faster than warning

indication.

• Buzzer sounds

alternating between

a low and high pitch

at same rate as

warning indication.

• Vibrator pulses at

same rate as

warning indication.

Over Range

Concentration of gas

rises above the

• Gas reading

replaced by blinking

brackets.

measuring limit of the

03 Series. (Or there

could be a problem

with the unit.)

• Back light turns on.

• ALRM appears

below gas reading.

Low Battery Warning • Last remaining bar

on the right in

battery icon

flashes.

Dead Battery Alarm • Gas reading

replaced by FAIL.

• Battery icon

flashes.

• Buzzer sounds

alternating between

low and high pitch

at the same rate as

alarm indication.

• Vibrator pulses at

same rate as alarm

indication.

•None

• Double pulsing tone

(two pulses in quick

succession) occurs

once a second.

03 Series Operator’s Manual Operation • 31

Page 32

Table 3: Alarm Types and Indications

Alarm Type Visual Indications Other Indications

Sensor Failure • Gas name replaced

by SENSOR.

• Gas reading

replaced by FAIL.

• Double pulsing tone

(two pulses in quick

succession) once a

second.

• Alarm LED flashes.

System Failure • Gas name replaced

by SYSTEM.

• Gas reading

replaced by FAIL.

• Double pulsing tone

(two pulses in quick

succession) once a

second.

• Failure code

displays below

FAIL.

Clock Failure • Gas name replaced

by FAIL.

• Gas reading

replaced by FAIL.

• Double pulsing tone

(two pulses in quick

succession) once a

second.

Resetting Gas Alarms

If the alarms are latching (factory setting), then an alarm indication will

continue even if the gas reading causing the alarm decreases below the

alarm setpoint (increases above for oxygen Warning) and will continue until

the alarm is reset. The gas reading that caused the alarm must decrease

below the alarm setpoint (increase above for oxygen Warning) before that

alarm can be reset. To reset latching alarms, press and release the

POWER MODE button after the gas reading falls below the alarm setpoint

(rises above for oxygen Warning).

If the alarms are self-resetting, then an alarm condition will automatically

reset when the gas reading that caused the alarm decreases below the

alarm setpoint (increases above for oxygen Warning).

Responding to Alarms

This section describes response to gas, over range, battery, sensor failure,

and system failure alarms.

Responding to Gas Alarms

1. Follow your established procedure for an increasing gas condition or a

decreasing oxygen condition.

2. If your unit is set for latching alarms, reset the alarm using the POWER

MODE button once the alarm condition has been cleared.

32 • Operation 03 Series Operator’s Manual

Page 33

Responding to an Over Range Alarm

WARNING: An over range condition may indicate an extreme toxic

gas or oxygen concentration. Confirm the gas

concentration with a different 03 Series or with another

gas detecting device.

1. Follow your established procedure for an increasing gas condition.

2. Reset the alarm by pressing and releasing the POWER MODE button

after the alarm condition has cleared.

3. Calibrate the 03 Series as described in “Calibration Mode” on page 36.

4. If the over range condition continues, replace the sensor as described

in “Replacing the Sensor” on page 72.

5. If the over range condition continues after you have replaced the

sensor, contact RKI Instruments, Inc. for further instructions.

Responding to Battery Alarms

WARNING: The 03 Series is not operational as a gas monitoring

device during a dead battery alarm. Take the 03 Series to

a non-hazardous area and change the alkaline batteries

as described in “Replacing the Batteries” on page 70.

The 03 Series is fully functional in a low battery warning condition.

However, only a couple of days of operation may remain depending on

certain conditions such as alarm occurrences and how often the backlight

comes on.

NOTE: Alarms and the back light feature consume battery power and

reduce the amount of operating time remaining.

When a low battery warning occurs, change the batteries as soon as

possible. Refer to the instructions in “Replacing the Batteries” on page 70

for more information.

Responding to a Sensor Failure Alarm

1. Try calibrating the 03 Series as described in “Calibration Mode” on

page 36.

2. If the sensor failure continues, replace the sensor as described in

“Replacing the Sensor” on page 72.

3. If the gas sensor failure condition continues after you have replaced the

gas sensor, contact RKI Instruments, Inc. for further instructions.

03 Series Operator’s Manual Operation • 33

Page 34

Responding to a System Failure Alarm

SYSTEM

FAIL

021

1. If a system failure occurs, the system failure screen will display an error

code as shown below:

2. The error code meanings are shown below:

Table 4: Error Code Explanation

Error Code Explanation

000 MPU failure

010 RAM failure

021 EEPROM failure

3. The instrument cannot be used if a system failure occurs. Contact RKI

Instruments, Inc. as soon as possible.

Responding to a Clock Failure Alarm

This alarm occurs if the internal unit date has been changed to something

unreasonable like 15/34 (month/day).

1. Press and release the POWER MODE button to continue into normal

operation.

CAUTION: There will be no datalog ging function if you operate the

instrument after a clock failure.

2. Attempt to change the date using the DATE menu item in Calibration

Mode. See “Setting the Date and Time” on page 38.

3. If the date cannot be set correctly, contact RKI Instruments, Inc. as

soon as possible.

34 • Operation 03 Series Operator’s Manual

Page 35

Data Logging

The 03 Series features the ability to log data to its internal memory and

download it to a computer via the IrDA port on the top of the case. It logs

normal operation gas readings, alarm data, calibration data, and bump test

data.

To utilize the 03 Series’ downloading capability, you will need the 03 Series

Data Logger Management Program and a computer with an infrared port

that conforms to IrDA 1.1 protocol or a USB port that runs one of the

following operating systems: Windows 7, Windows 8, or Windows 10. If

your computer has an infrared port that conforms to IrDA 1.1 protocol, then

no additional accessories are needed to download data from the 03 Series.

If your computer does not have an infrared port but does have a USB port,

a USB/IrDA adapter cable can be used to download data from the 03

Series using the USB port. The 03 Series Data Logger Management

Program is available at www.rkiinstruments.com/03series. The USB/IrDA

adapter cable is also available from RKI.

See the 03 Series Data Logger Management Program Operator’s Manual

for a complete description of the 03 Series Data Logger Management

Program and procedures for downloading data to a computer.

03 Series User Setup Program

There are some instrument operating parameters that are not accessible in

either Calibration Mode or Setup Mode such as the calibration frequency,

auto zero function, and the alarm logic (latching or self resetting). Many of

these parameters either do not typically need to be accessed once the 03

Series is shipped from the factory or may only need to be accessed once

because of operator preferences. These parameters can be accessed and

updated if necessary using the 03 Series User Setup Program, a computer

with the same requirements described above in “Data Logging”, and a

USB/IrDA cable if necessary. The 03 Series User Setup Program is

available at www.rkiinstruments.com/03series. The USB/IrDA adapter

cable is also available from RKI. See the 03 Series User Setup Program

Operator’s Manual for a complete description of the 03 Series User Setup

Program and procedures for accessing and updating instrument operating

parameters.

03 Series Operator’s Manual Data Logging • 35

Page 36

Calibration Mode

This section describes the 03 Series in Calibration Mode. In Calibration

Mode, you can move through a menu of screens to do the following:

• Set the date and time

• Perform a fresh air adjustment (part of a calibration)

• Perform an automatic span adjustment (part of a calibration)

• Perform an easy span adjustment (part of a calibration)

• Perform a manual span adjustment (part of a calibration)

• Perform a bump test (if Bump Test Function is set to On using the

03 Series User Setup Program)

• View the instrument’s firmware version and firmware checksum

NOTE: You can set the 03 Series to alert you during the startup sequence

when calibration or bump testing is due with the 03 Series User

Setup Program. See the 03 Series User Setup Program

Operator’s Manual for information on setting the Cal. Limit

Display and Bump Test Limit Display parameters.

Calibration Frequency

The optimum frequency of calibration depends heavily on how the 03

Series is used. For example, instruments used daily may need to be

calibrated weekly or monthly, while instruments that are used only a few

times a year may need to be calibrated before each use. Typical calibration

frequencies range from monthly to quarterly. Make sure to develop a

calibration schedule tailored to your application.

Using Calibration Mode

WARNING: The 03 Series is not in operation as a gas detector while

in Calibration Mode. Although it will respond to gas in

parts of AIR CAL, A--CAL., M--CAL., and BUMP, there are

no gas alarm indications.

1. Take the 03 Series to a non-hazardous area and turn it off if it is on.

36 • Calibrat ion Mode 03 Series Operator’s Manual

Page 37

2. Press and hold the AIR button, then press and hold the POWER MODE

DATE

START

button. When you hear a beep release the buttons. The DATE Screen is

displayed.

3. Use the AIR button to move forward through Calibration Mode. When

you get to the last menu item, the START menu item, continuing will

take you back to the beginning of the menu.

4. When you arrive at the item you wish to enter, press and release the

POWER MODE button to enter that item.

5. When you need to adjust the numerical value of a parameter, increase it

or decrease it, use the AIR button to change the value. When adjusting

a numerical parameter value, it is possible to reverse the direction of

adjustment. To switch from increasing to decreasing a value or

decreasing to increasing a value, do the following:

• with the parameter flashing on the screen, press and hold the AIR

button

• immediately press the POWER MODE button and then release both

buttons

• the direction of adjustment when you press the AIR button is now

reversed

6. When you are done using the menu items in Calibration Mode, use the

AIR button to scroll through the menu items to the START item.

7. At the START screen, press and release the POWER MODE button.

The 03 Series will begin its start-up sequence.

The Calibration Mode menu items are described below in the order in

which they appear while moving through Calibration Mode.

03 Series Operator’s Manual Calibration Mode • 37

Page 38

Setting the Date and Time

DATE

2014

2.11

3:05

AIR

Entering the DATE menu item allows you to set the date and time.

1. When the DATE Screen is displayed, press and release the POWER

MODE button. A screen appears with the year flashing in the upper left,

the month and day in the middle, and the time in the lower right.

2. Use the AIR button to display the desired year.

3. Press and release the POWER MODE button to save the setting. The

month setting flashes.

4. Repeat steps 2 and 3 to enter the month, day, hour and minute setting.

When you save the minute setting, END is displayed before the

instrument returns to the DATE Screen.

Performing a Fresh Air Adjustment

Entering the AIR menu item allows you to perform a fresh air adjustment.

Perform a fresh air adjustment in Calibration Mode when you are

performing a calibration before proceeding either to the A--CAL or M--CAL

menu item to perform a span adjustment (zero adjustment for OX-03). A

fresh air adjustment performed in Calibration Mode is the same as a fresh

air adjustment in Normal Mode. The AIR menu item is available in

Calibration Mode for convenience when performing a complete calibration.

WARNING: Calibrate the 03 Series in a non-hazardous environment.

38 • Calibrat ion Mode 03 Series Operator’s Manual

Page 39

1. Find a fresh air environment, an environment of normal oxygen content

AIR

ppm

0

CO

AIR

HOLD

- - - -

ADJ

- - - -

(20.9%) that is free of toxic and combustible gasses.

2. When the AIR screen is displayed, press and release the POWER

MODE button. A screen appears that displays the current gas reading.

If you want to cancel the fresh air adjustment, press and release the

AIR button to return to the AIR screen. To continue with the fresh air

adjustment, proceed to Step 3.

3. Press and hold the AIR button. The LCD prompts you to continue to

hold the AIR button.

4. Release the AIR button when the following screen appears.

5. The unit will take a few seconds to adjust the fresh air reading, then

indicate “END” in the upper left corner and return to the AIR Screen.

Performing an Automatic Span Adjustment (Zero Adjustment for OX-03) in A--CAL

The A--CAL menu item only appears in Calibration Mode if the One Touch

Cal Time parameter in the 03 Series User Setup Program is set to 0

(factory setting). If One Touch Cal Time is set to anything other than 0, E--

CAL will replace A--CAL.

03 Series Operator’s Manual Calibration Mode • 39

Page 40

Entering the A--CAL menu item allows you to perform an automatic span

A--CAL.

adjustment (zero adjustment for OX-03).

Perform a span adjustment (zero adjustment for OX-03) as part of a

calibration after performing a fresh air adjustment. Performing a span

adjustment (zero adjustment for OX-03) requires the use of a calibration

kit. A calibration kit is available from RKI Instruments, Inc. for each 03

Series model (see “Parts List” on page 76). You will need:

• A gas cylinder with an appropriate concentration of the target gas for

the CO-03 or HS-03, or a cylinder of 100% nitrogen for the OX-03.

NOTE: On the OX-03, instead of 100% nitrogen (0% oxygen), it is

allowable to use higher than 0% oxygen to set the zero level. RKI

Instruments, Inc. recommends 18% oxygen or lower.

• a fixed-flow regulator with a flow rate of 0.5 LPM (liters per minute)

WARNING: Use a 0.5 LPM (liters per minute) fixed flow regulator

when calibrating. Using a different flow rate may

adversely affect the accuracy of the calibration.

• non-absorbent tubing

• calibration adapter that will fit over the 03 Series’ sensor

WARNING: Calibrate the 03 Series in a non-hazardous environment.

1. Before performing a span adjustment (zero adjustment for OX-03),

perform a fresh air adjustment as described in “Performing a Fresh Air

Adjustment” on page 38.

40 • Calibrat ion Mode 03 Series Operator’s Manual

Page 41

2. At the A--CAL screen, press and release the POWER MODE button. A

CO

A--CAL.

ppm

50

A--CAL.

ppm

50

CO

A--CAL.

ppm

50

screen appears that displays the calibration gas concentration that the

03 Series expects you to use.

If the displayed concentration matches the calibration cylinder

concentration, continue with Step 4.

If the displayed concentration does not match the calibration cylinder

concentration, do the following:

• Press and hold the AIR button, then press and momentarily hold the

POWER MODE button.

• Release both buttons as soon as you hear the buzzer sound a beep.

The following screen will display and the gas concentration will be

flashing.

• Use the AIR button to adjust the calibration gas value to the desired

value. See Step 5 on page 37 for instructions to increase or

decrease the value.

• Press and release the POWER MODE button to accept the

displayed value. The previous screen will return.

03 Series Operator’s Manual Calibration Mode • 41

Page 42

3. Press and release the POWER MODE button. The LCD will display the

CO

A--CAL.

ppm

0

To Fixed Flow

Regulator

Calibration

Adapter

Calibration Tubing

current gas readings and “A--CAL.” will flash.

If you want to cancel the calibration, press and hold the AIR key for 2

seconds. The instrument will return to the A--CAL. Screen. If you hold

the AIR key down longer than 2 seconds, the instrument will start

scrolling through the Calibration Mode items.

4. Use the sample tubing to connect the calibration adapter to the

regulator. Attach the tubing to the calibration adapter on the inlet side as

shown below in Figure 5.

Figure 5: Calibration Kit Assembly

42 • Calibrat ion Mode 03 Series Operator’s Manual

5. Confirm that the regulator on/off knob is turned all the way clockwise

(closed) and screw the calibration gas cylinder onto the regulator.

Page 43

6. Push the calibration adapter onto the 03 Series’ sensor face as shown

POWER

MODE

CO-03

Calibration

Adapter

AIR

PASS

in Figure 6. The calibration adapter secures itself to the instrument by

latching on to two recesses in the instrument’s rear case. The rubber

boot (if installed) does not need to be removed to install the adapter.

Figure 6: Installing the Calibration Adapter

7. Turn the regulator on/off knob counterclockwise to open it. Calibration

gas will begin to flow.

8. Allow the gas to flow for two minutes.

9. Press and release the POWER MODE button.

10. The 03 Series will attempt to make a span adjustment (zero adjustment

for OX-03).

11. If the span adjustment (zero adjustment for OX-03) is successful, the

LCD will show the following screen before returning to the A--CAL

screen.

If the Maximum Span setting is turned On (factory setting is Off) using

the 03 Series User Setup Program, the LCD will show the maximum

reading the sensor could have been calibrated to before returning to the

03 Series Operator’s Manual Calibration Mode • 43

Page 44

A--CAL screen.

C--MAX

ppm

75

FAIL

CO

ppm

A--CAL.

12.If the span adjustment (zero adjustment for OX-03) fails, the LCD will

show the following screen, the alarm LED will flash, and the buzzer will

sound a double pulsing tone.

Press and release the POWER MODE button to clear the failure

indication and return to the A--CAL. screen.

See “Troubleshooting” on page 68 to investigate the cause of the failure

and replace the failed sensor if necessary.

13.Turn the regulator on/off knob clockwise to close it.

14.Remove the calibration adapter from the instrument.

15.Remove the regulator from the calibration gas cylinder.

16.Leave the regulator connected to the calibration adapter for

convenience.

17.Store the components of the calibration kit in a safe and convenient

place.

Performing an Easy Span Adjustment (Zero Adjustment for OX-03) in E--CAL

The E--CAL menu item only appears in Calibration Mode if the One Touch

Cal Time parameter in the 03 Series User Setup Program is set to anything

other than 0 (factory setting). When One Touch Cal Time is set to 0, A--

CAL will replace E--CAL. The value entered into the One Touch Cal Time

field is the amount of time that the instrument will allow gas to be applied

44 • Calibrat ion Mode 03 Series Operator’s Manual

Page 45

before attempting to perform a span adjustment.

E--CAL.

Entering the E--CAL menu item allows you to perform an easy span

adjustment (zero adjustment for OX-03). In an easy span adjustment, the

instrument will automatically count down in the E--CAL gas exposure

screen when gas is applied and perform a span adjustment when the

countdown is over.

Perform a span adjustment (zero adjustment for OX-03) as part of a

calibration after performing a fresh air adjustment. Performing a span

adjustment (zero adjustment for OX-03) requires the use of a calibration

kit. A calibration kit is available from RKI Instruments, Inc. for each 03

Series model (see “Parts List” on page 76). You will need:

• A gas cylinder with an appropriate concentration of the target gas for

the CO-03 or HS-03, or a cylinder of 100% nitrogen for the OX-03.

NOTE: On the OX-03, instead of 100% nitrogen (0% oxygen), it is

allowable to use higher than 0% oxygen to set the zero level. RKI

Instruments, Inc. recommends 18% oxygen or lower.

• a fixed-flow regulator with a flow rate of 0.5 LPM (liters per minute)

WARNING: Use a 0.5 LPM (liters per minute) fixed flow regulator

when calibrating. Using a different flow rate may

adversely affect the accuracy of the calibration.

• non-absorbent tubing

• calibration adapter that will fit over the 03 Series’ sensor

WARNING: Calibrate the 03 Series in a non-hazardous environment.

1. Before performing a span adjustment (zero adjustment for OX-03),

perform a fresh air adjustment as described in “Performing a Fresh Air

Adjustment” on page 38.

03 Series Operator’s Manual Calibration Mode • 45

Page 46

2. At the E--CAL screen, press and release the POWER MODE button. A

CO

E--CAL.

ppm

50

E--CAL.

ppm

50

CO

E--CAL.

ppm

50

screen appears that displays the calibration gas concentration that the

03 Series expects you to use.

If the displayed concentration matches the calibration cylinder

concentration, continue with Step 3.

If the displayed concentration does not match the calibration cylinder

concentration, do the following:

• Press and hold the AIR button, then press and momentarily hold the

POWER MODE button.

• Release both buttons as soon as you hear the buzzer sound a beep.

The following screen will display and the gas concentration will be

flashing.

• Use the AIR button to adjust the calibration gas value to the desired

value. See Step 5 on page 37 for instructions to increase or

decrease the value.

• Press and release the POWER MODE button to accept the

displayed value. The previous screen will return.

46 • Calibrat ion Mode 03 Series Operator’s Manual

Page 47

3. Press and release the POWER MODE button. The LCD will display the

G--IN

E--CAL.

ppm

0

To Fixed Flow

Regulator

Calibration

Adapter

Calibration Tubing

current gas readings and “E--CAL.” will flash.

If you want to cancel the calibration, press and hold the AIR key for 2

seconds. The instrument will return to the E--CAL. Screen. If you hold

the AIR key down longer than 2 seconds, the instrument will start

scrolling through the Calibration Mode items.

4. Use the sample tubing to connect the calibration adapter to the

regulator. Attach the tubing to the calibration adapter on the inlet side as

shown below in Figure 7.

Figure 7: Calibration Kit Assembly

03 Series Operator’s Manual Calibration Mode • 47

5. Confirm that the regulator on/off knob is turned all the way clockwise

(closed) and screw the calibration gas cylinder onto the regulator.

Page 48

6. Push the calibration adapter onto the 03 Series’ sensor face as shown

POWER

MODE

CO-03

Calibration

Adapter

AIR

E--CAL.

ppm

60

10

in Figure 8. The calibration adapter secures itself to the instrument by

latching on to two recesses in the instrument’s rear case. The rubber

boot (if installed) does not need to be removed to install the adapter.

Figure 8: Installing the Calibration Adapter

7. Turn the regulator on/off knob counterclockwise to open it. Calibration

gas will begin to flow.

8. Once the gas reading reaches 10% of the calibration gas value (HS-03

and CO-03 units) or 18.9% (OX-03 units), “E--CAL” will begin to flash

and a countdown will begin. The countdown’s duration is defined by the

value of the One Touch Cal Time parameter accessed in the 03 Series

User Setup Program.

If the gas reading never reaches 10% of the calibration gas value (HS03 and CO-03 units) or 18.9% (OX-03 units), the countdown will never

start and the instrument will remain in the G--IN screen shown in Step 3.

Press and hold the AIR button for 2 seconds to cancel the calibration

then continue with Step 12. See “Troubleshooting” on page 68 to

investigate the cause of the issue.

9. At the end of the countdown, the 03 Series will attempt to make a span

48 • Calibrat ion Mode 03 Series Operator’s Manual

Page 49

adjustment (zero adjustment for OX-03).

PASS

C--MAX

ppm

75

FAIL

CO

ppm

E--CAL.

10.If the span adjustment (zero adjustment for OX-03) is successful, the

LCD will show the following screen before returning to the E--CAL

screen.

If the Maximum Span setting is turned On (factory setting is Off) using

the 03 Series User Setup Program, the LCD will show the maximum

reading the sensor could have been calibrated to before returning to the

E--CAL screen.

11. If the span adjustment (zero adjustment for OX-03) fails, the LCD will

show the following screen, the alarm LED will flash, and the buzzer will

sound a double pulsing tone.

Press and release the POWER MODE button to clear the failure

indication and return to the E--CAL. screen.

See “Troubleshooting” on page 68 to investigate the cause of the failure

and replace the failed sensor if necessary.

12.Turn the regulator on/off knob clockwise to close it.

13.Remove the calibration adapter from the instrument.

03 Series Operator’s Manual Calibration Mode • 49

Page 50

14.Remove the regulator from the calibration gas cylinder.

M--CAL.

15.Leave the regulator connected to the calibration adapter for

convenience.

16.Store the components of the calibration kit in a safe and convenient

place.

Performing a Manual Span Adjustment (Zero Adjustment for OX-03) in M--CAL

Entering the M--CAL menu item allows you to perform a manual span

adjustment (zero adjustment for OX-03).

Perform a span adjustment (zero adjustment for OX-03) as part of a

calibration after performing a fresh air adjustment. Performing a span

adjustment (zero adjustment for OX-03) requires the use of a calibration

kit. A calibration kit is available from RKI Instruments, Inc. for each 03

Series model (see “Parts List” on page 76). The procedure below describes

a span adjustment (zero adjustment for OX-03). You will need:

• A gas cylinder with an appropriate concentration of the target gas for

the CO-03 or HS-03, or a cylinder of 100% nitrogen for the OX-03.

NOTE: On the OX-03, instead of 100% nitrogen (0% oxygen), it is

allowable to use higher than 0% oxygen to set the zero level. RKI

Instruments, Inc. recommends 18% oxygen or lower.

• a fixed-flow regulator with a flow rate of 0.5 LPM (liters per minute)

WARNING: Use a 0.5 LPM (liters per minute) fixed flow regulator

when calibrating. Using a different flow rate may

adversely affect the accuracy of the calibration.

• non-absorbent tubing

• calibration adapter that will fit over the 03 Series’ sensor

WARNING: Calibrate the 03 Series in a non-hazardous environment.

1. Before performing a span adjustment (zero adjustment for OX-03),

perform a fresh air adjustment as described in “Performing a Fresh Air

50 • Calibrat ion Mode 03 Series Operator’s Manual

Page 51

Adjustment” on page 38.

M--CAL.

ppm

0

To Fixed Flow

Regulator

Calibration

Adapter

Calibrat ion T u bing

2. At the M--CAL screen, press and release the POWER MODE button.

The current gas reading will be shown and it will be flashing. The