Page 1

Model GD-K11D

Operator’s Manual

Part Number: 71-0029RK

Edition: First

Released: August 1997

RKI Instruments, Inc. • 1855 Whipple Rd. • Hayward, CA 94544 • (510) 441-5656

Page 2

.

Warranty

RKI Instruments, Inc., warranties gas alarm equipment manufactured by RKI and sold by

RKI to be free from defects in materials and workmanship for a period of one year from

date of shipment from RKI Instruments, Inc. Any parts found defective within that period

will be repaired or replaced, at our option, fr ee of char ge. This warranty does not apply to

items that are subject to deterioration or consumption in normal service, and which must

be cleaned, repaired, or replaced routinely. Those items include, but are not limited to:

absorbent cartridges sensors

pump diaphragms and valves filter elements

lamp bulbs and fuses batteries

This warranty is voided by mechanical damage, misuse, alteration, rough handling, or

repairs not in accordance with the operator’s manual. This warranty indicates the full

extent of our liability. We ar e not responsible for r emoval or r eplacement costs, local repair

costs, transportation costs, or contingent expenses incurred without our prior approval.

T

HIS

WARRANTY

EXPRESSED

I

NSTRUMENTS

MERCHANTABILITY

I

NSTRUMENTS

DAMAGE

PRODUCTS

OF

OR

IMPLIED

, I

, I

ANY

TO

FUNCTION

IS

IN

NC

.,

INCLUDING

OR

NC

.,

BE

KIND

LIEU

OF

ANY

,

AND

ALL

FITNESS

CONNECTED

LIABLE

OR

OPERATE

FOR

FOR

OTHER

OTHER

BUT

A

INDIRECT

WITH

NOT

WARRANTIES

OBLIGATIONS

LIMITED

PARTICULAR

,

INCIDENTAL

THE

USE

PROPERLY

OR

TO

THE

PURPOSE

OF

ITS

AND

REPRESENTATIONS

LIABILITIES

WARRANTY

. I

N

NO

EVENT

,

OR

CONSEQUENTIAL

PRODUCTS

OR

ON

OF

THE

PART

SHALL

FAILURE

,

RKI

LOSS

OF

OF

ITS

RKI

OR

This warranty covers instruments and parts sold to end users by authorized distributors,

dealers, and representatives of RKI Instruments, Inc.

We do not assume indemnification for any accident or damage caused by the operation of

this gas monitor. Our warranty is limited to replacement of parts or our complete goods.

ii • Warranty Model GD-K11D Operator’s Manual

Page 3

Table of Contents

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Measuring Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Maintenance Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Flow System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Detection System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Mounting the Model GD-K11D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Connecting the Sample Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Wiring the Model GD-K11D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Introducing Incoming Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Setting the Zero Reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Displaying the Peak Reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Adjusting the Alarm Point. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Adjusting the Alarm Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Adjusting the Alarm Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Alarm Indications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Responding to Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Replacing Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Preparing for Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Setting the Zero Reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Setting the Response (Span) Reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Returning to Normal Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Model GD-K11D Operator’s Manual Table of Contents • iii

Page 4

iv Model GD-K11D Operator’s Manual

Page 5

Overview

The Model GD-K11D sample-draw transmitter is a single-point, fixed-instrument. It

continuously monitors for the target gas and alerts you to increasing gas levels with visual

alarms. Alarm contacts allow you to connect external alarms. The Model GD-K11D

includes a trouble alarm that alerts you to failure in the flow system and detection circuit.

The Model GD-K11D operates in two modes: measuring mode and maintenance mode.

Measuring Mode

Measuring mode is the mode in which the Model GD-K11D detects, measures, and

displays the target gas (normal operation).

Maintenance Mode

Maintenance mode allows you to perform maintenance tasks. These tasks include:

• adjusting the zero setting (see page 11)

• adjusting the K number when you replace a sensor (see page 18)

CAUTION: Maintenance mode includes five menus. Only menus 3 and 4 are for customer use.

To place the Model GD-K11D in maintenance mode, press the MODE button for

approximately 3 seconds. The SKIP light flashes until you exit maintenance mode.

Specifications

Table 1 lists specifications for the Model GD-K11D.

Power Source 115 VAC

Target Gas Various (see Table 2)

Area Classification Indoor, non-hazardous locations

Menus 1, 2, and 5 are for factory use only. The Model GD-K11D does not operate as

a gas detection device when you are in maintenance mode.

Table 1: Specifications

Sampling Method Sample-draw

Signal Output 4 to 20 mA

Response Time 90% in 60 seconds

Accuracy

Flow Rate (to sensor)

Model GD-K11D Operator’s Manual Overview • 1

±

5% of full scale

Approximately 0.5 liters/minute

Page 6

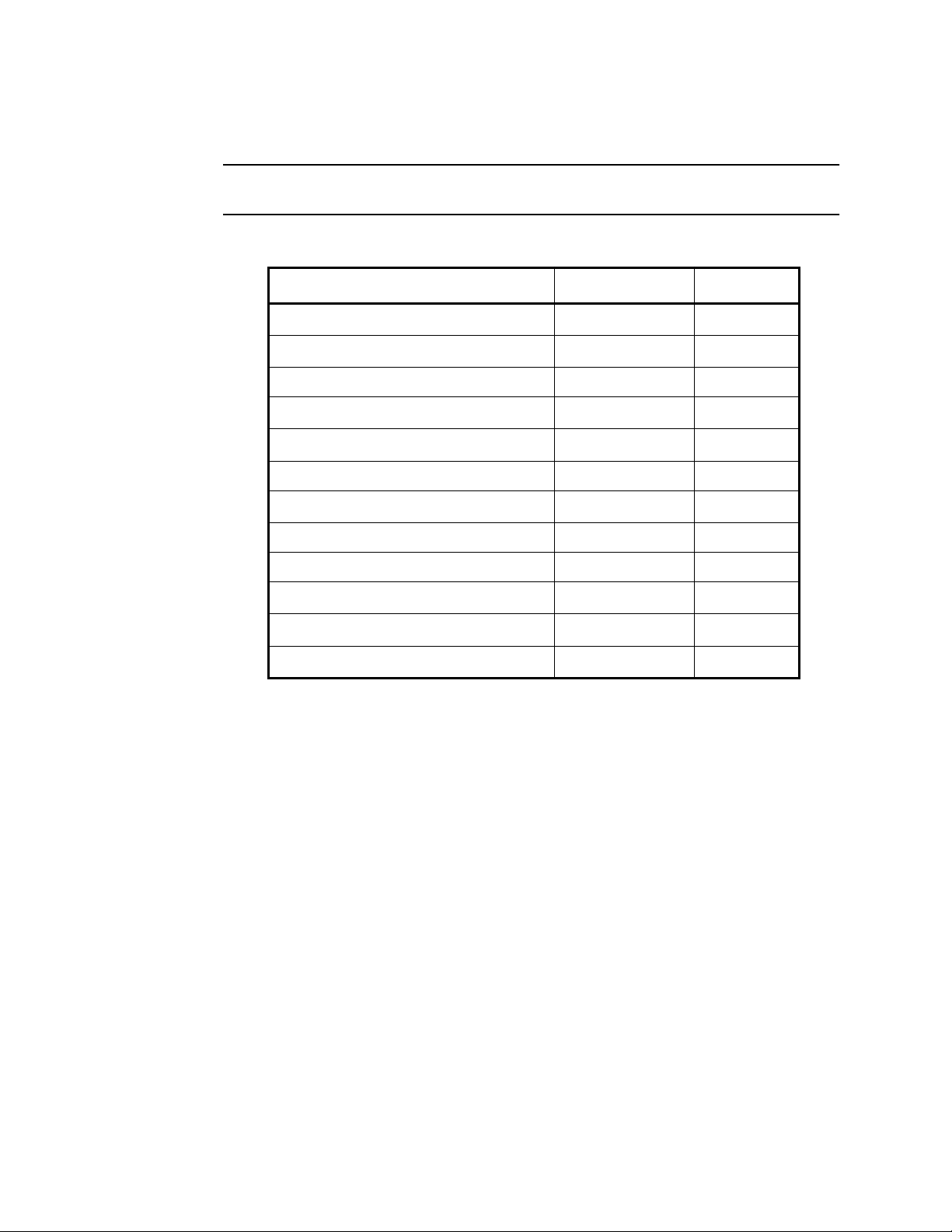

Table 2 lists the gases that the Model GD-K11D is capable of detecting. T able 2 also lists the

detection range, alarm point, and fail point for each target gas.

NOTE: Your Model GD-K11D is calibrated to only one of the gases listed below. A label

on the front of the instrument indicates the target gas of your Model GD-K11D.

Table 2: Model GD-K11D Target Gases, Detection Ranges, and Alarm Points

Target Gas Detection Range Alarm Point

Ammonia (NH

Arsine (AsH

)0 to 75.0 ppm 25.0 ppm

3

)0 to 1.00 ppm 0.30 ppm

3

Carbon monoxide (CO) 0 to 150 ppm 50 ppm

Chlorine (Cl

Chlorine trifluoride (ClF

)0 to 3.00 ppm 1.00 ppm

2

)0 to 1.00 ppm 0.30 ppm

3

Dichlorosilane (DCS) 0 to 15.0 ppm 5.0 ppm

Fluorine (F

)0 to 3.00 ppm 1.00 ppm

2

Hydrogen bromide (HBr) 0 to 9.00 ppm 3.00 ppm

Hydrogen chloride (HCl) 0 to 15.0 ppm 5.0 ppm

Phosphine (PH

Silane (SiH

Tungston hexafluoride (WF

)0 to 1.00 ppm 0.30 ppm

3

)0 to 15.0 ppm 5.0 ppm

4

)0 to 9.00 ppm 3.00 ppm

6

2 • Specifications Model GD-K11D Operator’s Manual

Page 7

Description

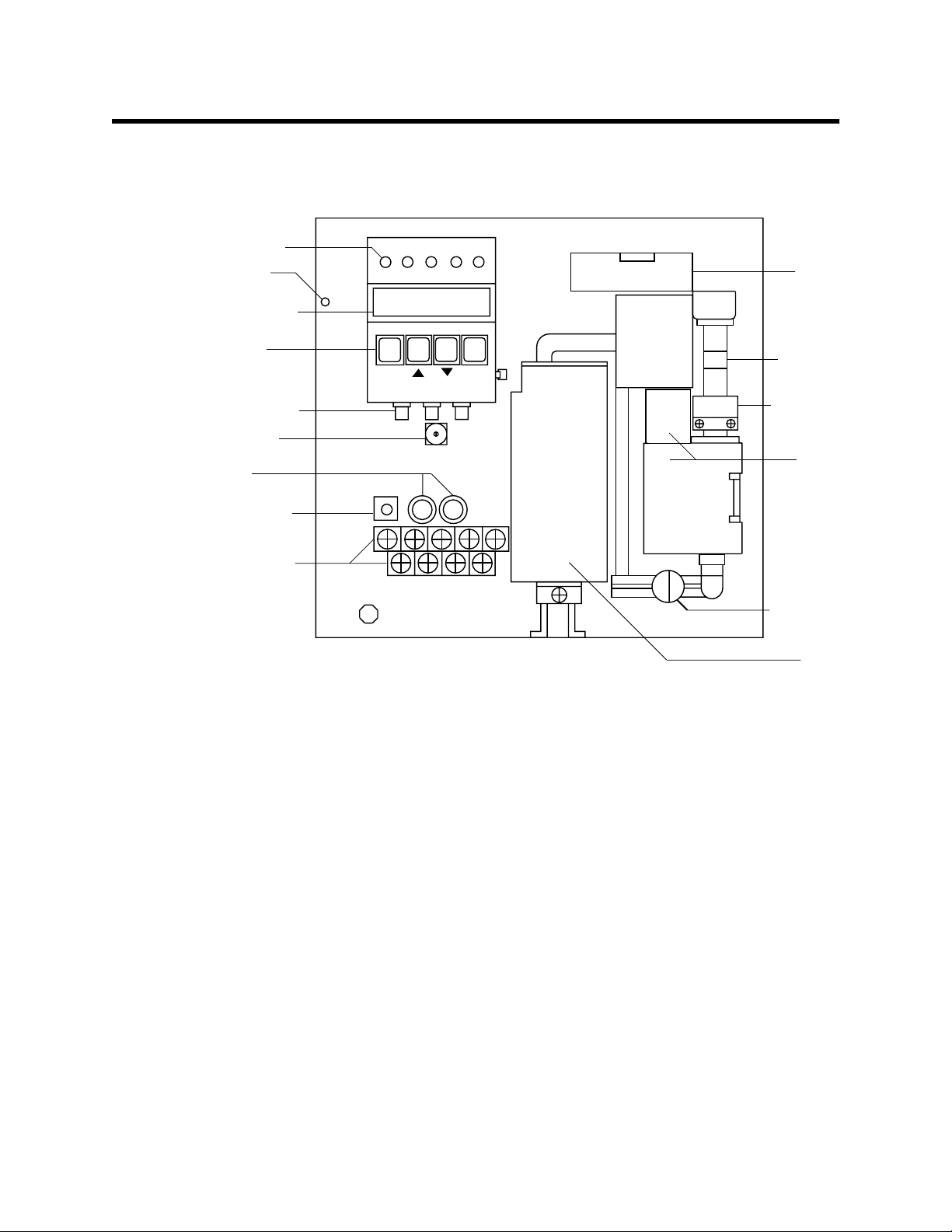

Status lights

Low flow

light

Display screen

Program

buttons

Potentiometers

INT switch

Fuses

This section describes the components of the Model GD-K11D. The Model GD-K11D

consists of the housing, electrical system, flow system, and detection system.

AL ZERO SPAN SKIP

PW/TR

(PEAK)

MODE

GAIN ZERO SPAN

(ALP)

Flowmeter

SET

Flow sensor

Battery

Sensor

Power switch

Terminal strip

E

Flow adjust

valve

Pump

Figure 1: Model GD-K11D Component Location

Housing

The Model GD-K11D’s steel housing is radio frequency (RF)-resistant. It is suitable for

installation in indoor areas where general purpose equipment is in use.

The housing cover is hinged on the front bottom edge and is secured by a thumbscrew on

the top of the housing. The flowmeter , display screen, and status lights ar e visible thr ough

windows in the housing cover. The cover also includes two labels that indicate the target

gas and detection range of the Model GD-K11D.

Three 3/8 in. cable fittings on the bottom of the housing allow you to make external

wiring connections. The gas out fitting to the right of the cable fittings allows the gas

sample to exit the Model GD-K11D after the sample passes through the sample system.

The gas in fitting above and to the right of the gas out fitting allows the gas sample to

enter the Model GD-K11D. The gas in and gas out fittings accept 6 mm OD x 4 mm ID

PTFE tubing.

Two mounting flanges are attached to the back of the housing. The top flange includes

two mounting slots; the bottom flange includes two mounting holes. The flanges allow

you to install the Model GD-K11D to a vertical surface at the monitoring site.

Model GD-K11D Operator’s Manual Description • 3

Page 8

Electrical System

The Model GD-K11D’s electrical system consists of the terminal strip, power switch, and

fuses (see Figure 1.)

Terminal strip

The terminal strip allows you make external wiring connections to the Model GD-K11D.

The nine-point terminal strip is divided into two rows. The upper (five-point) terminal

strip is for connection to a recorder or a controlling device, which accepts a 4 to 20 mA

signal. The lower (four-point) terminal strip is for connection to incoming power and

external alarms.

NOTE: See the “Installation” section on page 8 for all wiring procedures.

Power switch

The power switch turns power to the Model GD-K11D on and off. The power switch is

ON when the toggle switch is in the UP position.

Fuses

Two extractor-type fuses protect the AC line circuitry from short circuit or overload. The

fuses are rated at 1 amp.

Flow System

The Model GD-K11D’s flow system consists of the pump, flowmeter, flow adjust valve,

flow sensor, low flow light, gas in fitting, and gas out fitting (see Figure 1). The gas in and

gas out fittings were described earlier.

Pump

The pump pulls the test sample into the Model GD-K11D.

Flowmeter

The flowmeter measures the flow rate to the sensor. A ball in the flowmeter column

indicates the flow rate. Two horizontal lines on the flowmeter mark the acceptable flow

rate. Use the flow adjust valve to keep the flowmeter ball between the two lines.

Flow adjust valve

The flow adjust valve allows you to adjust the flow rate to the sensor.

Flow sensor

The flow sensor activates the low flow alarm if the flowmeter ball drops below the visible

part of the flowmeter.

Low flow light

The low flow light is near the top left corner of the main circuit board. The low flow light

is directly above the 50-pin connector. The main circuit board is behind the amplifier

circuit board. The low flow light turns on if the flowmeter ball drops below the visible part

of the flowmeter.

4 • Description Model GD-K11D Operator’s Manual

Page 9

Detection System

The Model GD-K11D’s detection system consists of the sensor, lithium battery, amplifier,

and display board (see Figure 1.)

Sensor

Through a series of electrical and chemical reactions, the sensor produces an electrical

current that is proportional to the detection range of the target gas.

Electrodes within the sensor housing are surrounded by liquid electrolyte. The electrical

and chemical reactions are facilitated by the electrolyte.

Battery

The 3.6-volt lithium battery maintains the bias voltage on the sensor when the

Model GD-K11D is not receiving incoming power.

Amplifier

The amplifier is the circuit board to which the display board is mounted. The power

switch, fuses, and terminal strip are also mounted to the amplifier circuit board.

The amplifier converts the output of the sensor to a 4 to 20 mA signal (that is pr oportional

to the detection range of the Model GD-K11D) and converts the signal to a digital r eading

on the display screen.

CAUTION: The potentiometers on the amplifier circuit board are factory-set. Do not adjust them.

Display board

The display board includes the display screen, status lights, program buttons, and

adjustment potentiometers. The display board is mounted to the amplifier by standoffs.

NOTE: The display screen and status lights are visible through a window in the housing

cover.

Display screen

The display screen displays the current gas reading of the Model GD-K11D’s target gas.

The display screen also displays operational and error messages.

Model GD-K11D Operator’s Manual Description • 5

Page 10

Status lights

The display board includes five status lights. Table 3 lists each light and its function.

Table 3: Model GD-K11D Status Lights

Light Status

PW/TR

(power)

AL

(alarm)

ZERO • GD-K11D is prepared for adjustment of zero

SPAN • GD-K11D is prepared for adjustment of span

SKIP GD-11D is in maintenance mode (flashing light)

Program buttons

The display board includes five buttons. The MODE,

buttons are directly below the display screen. The TEST button is the red button near the

bottom right of the display board. Table 4 lists each button and its function.

Table 4: Model GD-K11D Program Buttons

Button Function

• live power is connected to GD-K11D and the

power switch is ON (solid light)

• fail condition (flashing light)

• gas alarm condition (solid light)

• over range condition (solid light)

setting (flashing light)

• GD-K11D accepted zero setting (solid light)

setting (flashing light)

• GD-K11D accepted span setting (solid light)

∆

(PEAK),

∇

, and SET (AL.P)

MODE Enters maintenance mode

∆

(PEAK)

∇

SET (AL.P) • Prepares a setting to be changed

TEST Enters alarm test mode

6 • Description Model GD-K11D Operator’s Manual

• Increases/changes the setting on the display

• Displays the peak reading

Decreases/changes the setting on the display

• Enters a new setting

• Displays the alarm point

Page 11

Adjustment potentiometers

The display board includes two potentiometers, which extend from the bottom of the

display board. Table 5 lists each potentiometer and its function.

Table 5: Model GD-K11D Adjustment Potentiometers

Potentiometer

1

Function

ZERO Adjusts the zero setting

2

SPAN

1

The GAIN potentiometer is for factory-use only. It is

for coarse span adjustments.

2

Only use the SPAN potentiometer if you cannot set

the span setting with the

Adjusts the span (response) setting

∆

and

∇

buttons.

INT switch

The INT switch is a 16-position rotary switch that allows you to perform particular tasks.

Use a small, flat-blade screwdriver to adjust the switch. The position that is at the top of

the switch is the currently selected position. If you are unsure which position is selected,

press the MODE button. If the switch is in any position other than 0, the position number

appears on the left side of the display screen.

Table 6 lists switch positions for common tasks. The table also references step-by-step

procedures for each task.

CAUTION: Switch positions not listed in this table are for factory use. Only use the switch

positions listed is this table and described later in this manual.

Switch position “0” is for normal operation (detection mode). If you adjust the INT

switch, always return it to the “0” position after you complete the task.

Table 6: Model GD-K11D INT switch positions

Position Task Refer to

0 Detection mode (normal operation) page 1

1 Calibration with gas sample page 22

2 Adjust the alarm point page 13

3 Adjust the alarm delay page 14

5Turn on/off peak reading feature page 13

7 Adjust the alarm type (high/low) page 15

Model GD-K11D Operator’s Manual Description • 7

Page 12

Installation

p

This section describes how to install the Model GD-K11D at the monitoring site. This

section includes procedures to mount the Model GD-K11D, connect sample lines to the

Model GD-K11D, and make power and other wiring connections to the Model GD-K11D.

Mounting the Model GD-K11D

CAUTION: The Model GD-K11D is suitable for installation in indoor areas where general

purpose equipment is in use.

1. Select a mounting site that is representative of the monitoring environment. Consider

the following when you select the mounting site.

• Select a site where the Model GD-K11D is not likely to be bumped or disturbed.

Make sure there is sufficient room to make wiring and sample line connections at

the bottom of the transmitter. Also make sure there is sufficient room to open the

housing cover and perform start-up, maintenance, and calibration procedures.

• Select a site near the sampling area.

NOTE: If your application does not require a specific mounting site, mount the

transmitter at approximately eye level.

8.2

1.2

0.3 dia.

(4 times)

9.8

.48

9.1

.45

GAS DETECTOR

7.3

MODEL

GD-K11D

7.3

8.4

Note 1: All measurements in inches.

Note 2: Model GD-K11D is 4.1 inches deep.

Note 3: Allow at least 2 feet in front of

Model GD-K11D to o

en housing door.

Figure 2: Mounting the Model GD-K11D

8 • Installation Model GD-K11D Operator’s Manual

Page 13

2. Use two screws through the slot cutouts at the top of the housing to secure the

housing to a vertical surface at the mounting site (see Figure 2.)

3. Use two screws through the mounting holes at the bottom of the housing to support

the installation of the Model GD-K11D (see Figure 2.)

Connecting the Sample Lines to the Model GD-K11D

1. Attach 4 x 6 mm PTFE teflon tubing to the gas in fitting. Place the opposite end of the

tubing at the sampling area.

CAUTION: Avoid loops or slumps in the incoming sample line. To reduce response time, keep the

incoming sample line as short as possible.

2. Attach 4 x 6 mm PTFE teflon tubing to the gas out fitting. Route the opposite end of

the tubing to an open area where the sample can safely disperse.

Wiring the Model GD-K11D

This section describes procedures to connect AC power to the Model GD-K11D. This

section also describes optional procedures to connect a controller or recorder and external

alarm device to the Model GD-K11D. Figure 3 illustrates wiring connections to the

Model GD-K11D.

WARNING: Always verify that the Model GD-K11D’s power switch is in the OFF

position before you make wiring connections to the Model GD-K11D.

CONTROLLER/

RECORDER

+

output

4-20

mA

E

AC POWER

115V, 60 HZ.

GROUND

NEUTRAL

HOT

POWER

SOURCE

ALARM

DEVICE

CAUTION: If the alarm device draws more than 1 amp, use the

alarm contacts to control a relay with an appropriate contact rating.

Figure 3: Wiring the Model GD-K11D

Model GD-K11D Operator’s Manual Installation • 9

Page 14

Connecting AC power

1. Loosen the thumbscrew at the top of the housing.

2. Rotate the housing cover toward the bottom of the housing to gain access to the

terminal strip.

3. Verify that the Model GD-K11D’s power switch is in the OFF position.

4. Unscrew and remove the two screws that secure the terminal strip’s protective cover,

then remove the protective cover.

5. Guide the AC power cord through an unused conduit fitting at the bottom of the

housing.

6. Connect the AC line to the lower row of the terminal strip as shown in Figure 3.

7. Connect the AC line’s ground wire to the ground screw as shown in Figure 3. The

ground screw is below and to the left of the terminal strip.

8. If you do not plan to make any more wiring connections to the terminal strip, position

the protective cover over the terminal strip, then secure the cover with the two screws

you removed in step 4.

Connecting the Model GD-K11D to a controller or recorder

Perform the following procedure to connect a controller or recording device to the Model

GD-K11D. The output at the Model GD-K11D’s terminal strip is a 4 to 20 mA signal that is

proportional to the detection range.

1. Guide the wiring from the controller or recording device through an unused conduit

fitting at the bottom of the housing.

CAUTION: Do not route wiring from the AC power source and the controller or recorder

through the same conduit fitting. The power cable may disrupt the transmission of

the 4 to 20 mA signal to the controller or recorder.

2. Connect the leads to the upper row of the terminal strip as shown in Figure 3.

Connecting the Model GD-K11D to an external alarm device

CAUTION: The maximum current rating of the normally-open, dry contacts is 1 amp. If the

alarm device exceeds this rating, use the alarm contacts to control a relay with an

appropriate current rating.

1. Guide the wiring of the external alarm through an unused conduit fitting at the bottom

of the housing.

CAUTION: If the external alarm device is powered by AC current, do not route wiring from the

external alarm and the controller or recorder (if applicable) through the same conduit

fitting. The power wiring may disrupt the transmission of the 4 to 20 mA signal to

the controller or recorder.

2. Connect the leads to the lower row of the terminal strip as shown in Figure 3.

10 • Installation Model GD-K11D Operator’s Manual

Page 15

Start Up

This section describes procedures to start up the Model GD-K11D and place the Model

GD-K11D into normal operation.

Introducing Incoming Power

1. Complete the installation procedures described earlier in this manual.

2. Verify that the power wiring is correct and secure (see the “Installation” section on

page 8.)

3. Turn on or plug in the incoming power at the power source end, then place the Model

GD-K11D’s power switch in the ON position.

4. Verify that the PW/TR (power) light is on.

5. Verify that the flowmeter ball is between the two lines on the flowmeter. If necessary,

use the flow adjust valve to adjust the flow rate to the sensor, so the flowmeter ball is

between the two lines.

6. Verify that the incoming sample line is not leaking. To test the sample line, plug the

open end of the sample line with your thumb. If the flowmeter ball drops to the

bottom of the flowmeter, the incoming sample line is not leaking.

CAUTION: Allow the Model GD-K11D to warm up for 30 minutes (2 hours for ammonia

transmitters) before you continue with the next section. If the sensor keeper batteries

are dead and the Model GD-K1 1D has been off power for an extended period of time,

allow the Model GD-K11D to warm up overnight.

Setting the Zero Reading

CAUTION: If you suspect the presence of toxic gas in the monitoring environment, use the

calibration kit and the zero air calibration cylinder to introduce “fresh air” to the

sensor and verify an accurate zero setting.

1. Verify that the Model GD-K11D is in a fresh air environment (environment known to

be free of toxic gas.)

2. Press and hold down the MODE button until 1. appears on the display screen

(approximately 3 seconds).

The SKIP light flashes.

3. Press the

4. Press the SET button.

The ZERO light flashes, and the gas reading appears on the display screen. The Model

GD-K11D is prepared to adjust the zero reading.

5. Use the ZERO potentiometer to adjust the display reading to zero.

∆

button twice to display 3.

Model GD-K11D Operator’s Manual Start Up • 11

Page 16

6. Press the MODE button.

The ZERO light turns off, and 3. appears on the display screen.

NOTE: The purpose of this procedure is to set the zero r eading only. It is not necessary to

set the span (response) reading at this time.

7. Press the MODE button for approximately 3 seconds to exit maintenance mode and

return to the normal screen.

8. Rotate the housing cover up to its original position, then tighten the thumbscrew at

the top of the housing to secure the cover to the housing.

12 • Start Up Model GD-K11D Operator’s Manual

Page 17

Operation

This section describes procedures to display the peak reading, and to adjust the alarm

point, alarm delay, and alarm type.

Displaying the Peak Reading

The Model GD-K11D defines the peak reading as the highest reading above the alarm point

since the last time the peak reading was reset. A reading must remain above the alarm

point for a period longer than the alarm delay (default is 3 seconds) before the Model

GD-K11D compares the gas reading to the current peak reading.

You must also “turn on” the peak reading feature in order for the Model GD-K11D to

recognize and save peak readings.

To turn on the peak reading feature:

1. Adjust the INT switch to the “5” position. The INT switch is the rotary switch located

on the amplifier circuit board (see Figure 1, Model GD-K11D Component Location.)

The SKIP light flashes. If 1 appears on the display screen, the peak hold feature is

turned on. If not, continue with step 2.

2. Press the MODE button, and make sure 5 appears on the left side of the display

screen.

3. Press the ∆ button to display 1 on the screen.

4. Press the SET button.

The SPAN light turns on.

5. Return the INT switch to the “0” position to return to normal operation.

The SPAN and SKIP lights turns off.

To display the peak reading:

1. From the normal screen, press the ∆ (PEAK) button.

The peak reading displays.

2. To reset the peak reading, press and hold down the ∆ (PEAK) and SET buttons until

the peak reading is cleared from the display screen.

Adjusting the Alarm Point

The factory-set alarm point is one-third of the fullscale value. Alarm points for the Model

GD-K11D’s target gases are listed in Table 2, Model GD-K11D Target Gases, Detection

Ranges, and Alarm Points. The range of acceptable alarm points is 10% to 100% of the

fullscale value.

To display the current alarm point, from the normal screen press and hold down the SET

button until the alarm point appears on the display screen. Release the SET button to

return to the normal screen.

To adjust the alarm point:

1. Loosen the thumbscrew at the top of the housing.

2. Rotate the housing cover toward the bottom of the housing to gain access to the

interior of the Model GD-K11D.

Model GD-K11D Operator’s Manual Operation • 13

Page 18

3. Adjust the INT switch to the “2” position.

The current alarm point appears on the display screen, and the SKIP light flashes.

4. Press the MODE button, and make sure 2 appears on the left side of the display

screen.

5. Use the ∆ and ∇ buttons to adjust the alarm point to the setting you want.

6. Press the SET button to confirm the new alarm point.

The SPAN light turns on indicating that the Model GD-K11D accepted the new

setting.

7. Return the INT switch to the “0” position to return to normal operation.

The SPAN and SKIP lights turns of.

8. Rotate the housing cover up to its original position, then secure the cover to the

housing with the thumbscrew.

Adjusting the Alarm Delay

The factory-set alarm delay is 3 seconds. The range of acceptable alarm delay settings is

0.5 to 60 seconds.

1. Loosen the thumbscrew at the top of the housing.

2. Rotate the housing cover toward the bottom of the housing to gain access to the

interior of the Model GD-K11D.

3. Adjust the INT switch to the “3” position.

The current alarm delay appears on the display screen, and the SKIP light flashes.

4. Press the MODE button, and make sure 3 appears on the left side of the display

screen.

5. Use the ∆ and ∇ buttons to adjust the alarm delay to the setting you want.

6. Press the SET button to confirm the new alarm delay.

The SPAN light turns on indicating that the Model GD-K11D accepted the new

setting.

7. Return the INT switch to the “0” position to return to normal operation.

The SPAN and SKIP lights turns of.

8. Rotate the housing cover up to its original position, then secure the cover to the

housing with the thumbscrew.

14 • Operation Model GD-K11D Operator’s Manual

Page 19

Adjusting the Alarm Type

You can program the Model GD-K11D’s alarm to activate on increasing readings or

decreasing readings. The factory-set alarm type is increasing.

1. Loosen the thumbscrew at the top of the housing.

2. Rotate the housing cover toward the bottom of the housing to gain access to the

interior of the Model GD-K11D.

3. Adjust the INT switch to the “7” position.

The current alarm type displays, and the SKIP light flashes. H (“high”) indicates an

increasing setting; L (“low”) indicates a decreasing setting.

4. Press the MODE button, and make sure 7 appears on the left side of the display

screen.

5. Use the ∆ or ∇ button to display the alternate alarm type.

6. Press the SET button to confirm the new alarm type.

The SPAN light turns on indicating that the Model GD-K11D accepted the new

setting.

7. Return the INT switch to the “0” position to return to normal operation.

The SPAN and SKIP lights turns of.

8. Rotate the housing cover up to its original position, then secure the cover to the

housing with the thumbscrew.

Model GD-K11D Operator’s Manual Operation • 15

Page 20

Alarms

This section describes the Model GD-K11D’s visual indications for normal, alarm, and fail

conditions. This section also suggests response to these conditions.

Alarm Indications

Table 5 lists the indications for normal, alarm and fail conditions.

The Model GD-K11D includes an alarm delay feature. The alarm indications listed below

are delayed by 3 seconds once the Model GD-K11D recognizes an alarm or fail condition.

Table 7: Model GD-K11D Alarm Indications

Condition Cause(s) Indications Alarm Contacts

Normal • Start up complete

• No gas or fail alarms

Gas

Alarm

Fail

Alarm

Low Flow

Alarm

1

The PW/TR (power) light flashes.

Increasing gas reading at

or above alarm point

Disconnected sensor • E-01 on screen

Low flow rate • E-05 on screen

PW/TR light De-energized

AL light Energized

• PW/TR light

• AL light

• 0.5 mA output

• PW/TR light

• Low flow (red) light

on main board

• 0.5 mA output

Responding to Alarms

This section suggests response to gas and fail alarms.

Responding to gas alarms

De-energized

1

De-energized

1

1. Follow your established procedure for an increasing toxic gas condition.

2. When the display reading falls below the alarm point, the alarm circuit automatically

resets itself. The AL (alarm) light turns off.

Responding to fail alarms

1. Set the correct flow rate with the flow adjust valve.

2. If you cannot set the correct flow rate, check the sample lines for obstructions or kinks.

3. Calibrate the Model GD-K11D as described on page 21.

4. If the fail condition continues, replace the sensor as described on page 18.

5. If the fail condition continues, contact RKI Instruments, Inc., for further instruction.

16 • Alarms Model GD-K11D Operator’s Manual

Page 21

Maintenance

This section describes maintenance procedures for the Model GD-K11D. It includes

preventive maintenance and troubleshooting procedures.

Preventive Maintenance

This section describes a preventive maintenance schedule to ensure the optimum

performance of the Model GD-K11D. It includes daily, quarterly, and biannual

procedures.

Daily

1. Verify that the PW/TR (power) light is on. If the power light is not on, see the

2. Verify that the flowmeter ball is between the two lines on the flowmeter. If necessary,

3. Verify a display reading of 0 PPM. Investigate significant changes in the reading.

Quarterly

If you are not in a sensor exchange program, set the sensor’s K number as described on

page 19, then calibrate the Model GD-K11D as described on page 21.

troubleshooting guide in this manual.

use the flow adjust valve to adjust the flow rate, so the flowmeter ball is between the

two lines.

Biannually

If you are in a sensor exchange program, replace the sensor as described on page 18.

As required

This procedure describes a test to verify that the alarm circuit is operating properly.

NOTE: This test duplicates an alarm condition. Any external alarms wired to the Model

GD-K11D will activate during this test.

1. Loosen the thumbscrew at the top of the housing.

2. Rotate the housing cover toward the bottom of the housing to gain access to the

interior of the Model GD-K11D.

3. Press and hold down the TEST button. The TEST button is the red button on the right

side of the display panel.

The SKIP light turns on indicating that the Model GD-K11D is in alarm test mode.

4. While pressing the TEST button, press the ∆ button until the display reading is greater

than the alarm point.

After the alarm delay, the AL (alarm) light turns on and the relay contacts on the

terminal strip energize. Any external alarm devices wir ed to the r elay contact activate

when the relays contacts energize.

5. Release the TEST button to return to measuring mode (normal operation).

The display reading decreases to the normal level, and the alarm circuit automatically

resets itself.

6. Rotate the housing cover up to its original position, then tighten the thumbscrew at

the top of the housing to secure the cover to the housing.

Model GD-K11D Operator’s Manual Maintenance • 17

Page 22

Troubleshooting

The troubleshooting table describes error messages, symptoms, probable causes, and

recommended action for problems you may encounter with the Model GD-K11D.

Table 8: Troubleshooting the Model GD-K11D

Symptoms Probable Causes Recommended Action

• E-00 on display screen • Memory error 1. Contact RKI Instruments, Inc.

• E-01 on display screen

• PW/TR light is flashing

• Output is 0.5 mA

• E-05 on display screen

• PW/TR light is flashing

• Output is 0.5 mA

• Low flow light is on

• Flowmeter indicates low

flow rate

• E-06 on display screen • Communication error 1. Verify that wiring to the 4-20mA output

• Unable to zero or span

reading during

calibration

• Display screen does not

indicate gas reading

• Sensor is disconnected 1. Verify that the sensor connector is

• Sample line is

obstructed

• Pump is disconnected

• Pump is failing

• Calibration cylinder is

low, out-dated, or

defective

• Sample line is

obstructed

• Model GD-K11D is in

maintenance mode

securely connected to the sensor.

2. Calibrate the sensor.

3. If difficulties continue, contact RKI.

1. Set the correct flow rate with the flow

adjust valve.

2. Check the sample line for obstructions or

kinks.

3. Verify that the pump connector is

plugged into the pump socket (PUMP).

4. If difficulties continue, contact RKI.

terminales is correct.

2. If difficulties continue, contact RKI.

1. Verify that the calibration cylinder

contains an adequate supply of a fresh

calibration sample.

2. If necessary, set the correct flow rate with

the flow adjust valve.

3. If you cannot set the correct flow rate,

check the calibration tubing for

obstructions or kinks.

4. If difficulties continue, contact RKI.

1. Verify that the INT switch is in the “0”

position. Adjust the switch if necessary.

2. Press the MODE button until the normal

screen appears.

• on display screen • Abnormal indication

• LCD (display) not

working

1. Set the sensor’s zero reading as described

on page 11.

2. If difficulties continue, contact RKI.

Replacing Components

The section includes procedures to replace the sensor, pump, and fuse.

Replacing the sensor

This section includes procedures to remove the sensor, install the replacement sensor,

enter the new K number, and set the zero reading.

Removing the sensor

1. Loosen the thumbscrew at the top of the housing.

2. Rotate the housing cover toward the bottom of the housing to gain access to the

interior of the Model GD-K11D.

3. Place the power switch in the OFF position.

18 • Maintenance Model GD-K11D Operator’s Manual

Page 23

4. Pull the metal restraining bracket that secures the sensor in the housing away from

the sensor, then rotate the bracket to the right.

5. Slide the sensor to the left (toward the pump), then remove the sensor from the flow

chamber.

6. Disconnect the connector from the sensor, then remove the sensor from the housing.

Installing the replacement sensor

1. Connect the connector to the replacement sensor, then install the sensor in the same

position as the original sensor.

2. Place the metal restraining bracket in its original position to secure the sensor within

the housing.

3. Place the power switch in the ON position.

4. Allow the sensor to warm up for 30 minutes (2 hours for ammonia sensors) before

you continue with this procedure.

Entering the new K number

Each sensor is shipped with a K number written on the label. The K number is established

at the factory at the time of calibration. The K number allows the Model GD-K11D to

automatically set the span setting without introducing calibrating gas.

CAUTION: The K number is only valid for 3 months after shipment from the factory. If you

suspect the replacement sensor is beyond this 3-month limit, calibrate the

replacement sensor (see page 21) after you enter the K number.

1. Press the MODE button until the SKIP light begins flashing and 1. appears on the

display screen.

2. Press the ∆ button three times to display 4. on the screen.

3. Press the SET button to display the K number of the previous sensor.

4. Use the ∆ and ∇ buttons to adjust the value on the display screen to the K number of

the replacement sensor.

5. Press the SET button to enter the new K number.

The SPAN light is on steady (instead of flashing) to indicate the new K number is

entered.

6. Press the MODE button to display 4.

Setting the zero reading

CAUTION: If you suspect the presence of toxic gas in the monitoring environment, use the

calibration kit and the zero air calibration cylinder to introduce “fresh air” to the

sensor and verify an accurate zero setting.

1. Verify that the Model GD-K11D is in a fresh air environment (environment known to

be free of toxic gas.)

2. Press the

∇ button to display 3.

3. Press the SET button.

The ZERO light flashes, and the gas reading appears on the display screen. The Model

GD-K11D is prepared to adjust the zero reading.

Model GD-K11D Operator’s Manual Maintenance • 19

Page 24

4. Use the ZERO potentiometer to adjust the display reading to zero.

5. Press the MODE button.

The ZERO light turns off, and 3. appears on the display screen.

6. Press the MODE button for approximately 3 seconds to exit maintenance mode and

return to the normal screen (measuring mode).

7. Rotate the housing cover up to its original position, then tighten the thumbscrew at

the top of the housing to secure the cover to the housing.

Replacing the pump

1. Loosen the thumbscrew at the top of the housing.

2. Rotate the housing cover toward the bottom of the housing to gain access to the

interior of the Model GD-K11D.

3. Place the power switch in the OFF position.

4. Disconnect the pump connector from the socket on the amplifier circuit board. The

socket is marked PUMP and is to the right of the fuses.

5. Loosen the captive screw at the bottom of the pump cover, then rotate the cover

toward the top of the housing.

6. Remove the pump.

7. Place the replacement pump in the same position as the original pump.

8. Rotate the pump cover down to its original position, then secure the cover with the

captive screw.

9. Connect the pump connector to the socket marked PUMP on the amplifier circuit

board.

10. Place the power switch in the ON position.

11. Rotate the housing cover up to its normal position, then secure the cover to the

housing with the thumbscrew.

Replacing the fuses

1. Loosen the thumbscrew at the top of the housing.

2. Rotate the housing cover toward the bottom of the housing to gain access to the

interior of the Model GD-K11D.

3. Place the power switch in the OFF position.

4. Use a screwdriver to slightly push the fuse holder down, then rotate the holder to the

left.

5. Remove the fuse holder from the Model GD-K11D, then remove the fuse from the

holder.

6. Install the replacement fuse in the fuse holder, then insert the fuse holder into its

original position.

7. Use a screwdriver to slightly push the fuse holder down, then rotate the holder to the

right.

8. Place the power switch in the ON position.

9. Rotate the housing cover up to its normal position, then secure the cover to the

housing with the thumbscrew.

20 • Maintenance Model GD-K11D Operator’s Manual

Page 25

Calibration

This section describes how to calibrate the Model GD-K11D. It includes procedures to

prepare for calibration, set the zero r eading, set the r esponse (span) r eading, and r eturn to

normal operation.

WARNING: The Model GD-K11D is not an active gas monitoring device during the

calibration procedure.

Preparing for Calibration

NOTE: This procedure describes calibration using the RKI calibration kit that includes a

“demand flow” regulator. A calibration kit that uses a gas collection bag is also

available. Contact RKI Instruments, Inc., for more information concerning the

gas collection bag accessory.

1. Screw the regulator into the zero air calibration cylinder.

2. Disconnect the incoming sample line from the Model GD-K11D’s gas in fitting, then

connect the calibration kit sample tubing to the gas in fitting.

NOTE: Do not connect the tubing from the gas in fitting to the regulator at this time.

3. Loosen the thumbscrew on the top of the housing, then rotate the housing cover

toward the bottom of the housing.

Setting the Zero Reading

1. Press and hold down the MODE button until 1. appears on the display screen

(approximately 3 seconds).

The SKIP light flashes.

2. Press the ∆ button twice to display 3.

3. Press the SET button.

The ZERO light flashes, and the gas reading appears on the display screen.

4. Connect the tubing from the Model GD-K11D’s gas in fitting to the regulator. The

Model GD-K11D’s pump automatically begins pulling the calibrating sample fr om the

zero air calibration cylinder when you connect the tubing to the regulator.

5. When the display reading stabilizes, use the ZERO potentiometer to adjust the

display reading to zero.

6. Press the MODE button.

The ZERO light turns off, and 3. appears on the display screen.

7. Disconnect the sample tubing from the regulator, then unscrew the regulator from the

zero air calibration cylinder. Leave the tubing connected to the Model GD-K11D.

8. Press the MODE button for approximately 3 seconds to exit maintenance mode and

return to the normal screen.

Model GD-K11D Operator’s Manual Calibration • 21

Page 26

Setting the Response (Span) Reading

1. Adjust the INT switch to the “1” position. The INT switch is the rotary switch located

on the amplifier circuit board (see Figure 1, Model GD-K11D Component Location).

The display reading, SPAN light, and SKIP light flash.

2. Press the MODE button, and make sure 1 appears on the left side of the display

screen.

3. Screw the regulator into the calibration cylinder.

4. Connect the tubing from the Model GD-K11D’s gas in fitting to the regulator. The

pump begins pull the sample from the calibration cylinder.

The display reading increases as the sensor begins to sample the calibrating gas.

When the display reading reaches 20% of fullscale, the reading stops flashing.

NOTE: The reading must be at least 20% of fullscale before the Model GD-K11D will

allow adjustment of the span setting.

5. When the display reading stabilizes, use the ∆ and ∇ buttons to adjust the display

reading to match the concentration of the calibration cylinder.

NOTE: If you cannot adjust the display reading to the concentration of the calibration

cylinder with the ∆ and ∇ buttons, adjust the reading to be in the middle of the

adjustment range, then adjust the reading with the span potentiometer.

6. Press the SET button to set the response (span) reading.

The SPAN light is on steady indicating that the Model GD-K11D accepted the span

setting.

7. Disconnect the sample tubing from the regulator, then disconnect the opposite end of

the sample tubing from the Model GD-K11D’s gas in fitting.

8. Reattach the sample line to the gas in fitting.

Returning to Normal Operation

1. Unscrew the regulator from the calibration cylinder.

NOTE: If the display reading is above the alarm point when you return to the normal

screen, the Model GD-K11D will initiate an alarm condition.

2. Return the INT switch to the “0” position to return to normal operation.

The SPAN and SKIP lights turn off.

3. Rotate the housing cover up to its normal position, then secure the cover to the

housing with the thumbscrew.

4. Store the components of the calibration kit in a safe and convenient place.

5. Verify that the display reading decreases and stabilizes at zero.

22 • Calibration Model GD-K11D Operator’s Manual

Loading...

Loading...