Rivera Primo Powerdrive 6 Transmission Shifter Cam User Manual

12450 Whittier Blvd. Whittier Ca. 90602

(562)907-2600 Fax: (562)907-2606

www.riveraprimoinc.com

INSTRUCTIONS

Disassembly

Shifter Cam Assembly

Shifter Forks

WARNING

To protect against accidental start-up of vehicle,

always disconnect the negative battery cable before

working on the motorcycle. Failure to disconnect the

battery cable could result in serious injury or death.

1. Remove battery negative cable (black) from battery

negative (-) terminal.

2. Remove exhaust system.

3. Remove the magnetic drain plug at the bottom right

side of the oil pan and drain the transmission uid.

Remove the ll plug/dipstick.

4. Remove connector from neutral safety switch.

5. Remove the ve socket head cap screws from the

transmission top cover. Remove the top cover from

the transmission case. Do not re-use the

top cover gasket .

6. Remove the four bolts and washers from the right

and left shifter cam support blocks. Raise the shifter

pawl and lift the shifter cam assembly from the

dowels on the transmission case.

7. If necessary, disassemble the shifter cam

assembly as follows:

a. Lift detent arm and slide right support block

o end of shifter cam. Remove pivot screw to release

detent arm,spring sleeve and spring. Remove

retaining ring (Do not re-use). If the needle bearing

is damaged, remove the bearing from the support

block by pressing it out and replace

with a new bearing.

b. Moving to opposite side, using a snap ring pliers

remove retaining ring from groove at left end of

shifter cam. Slide left support block o end of shifter

cam. DO NOT re-use retaining ring. If the needle

bearing is damaged, remove the bearing from the

support block by pressing it out and replace

with a new bearing.

WARNING

Always wear proper eye protection when removing

retaining rings. Failure to do so may result in eye injury.

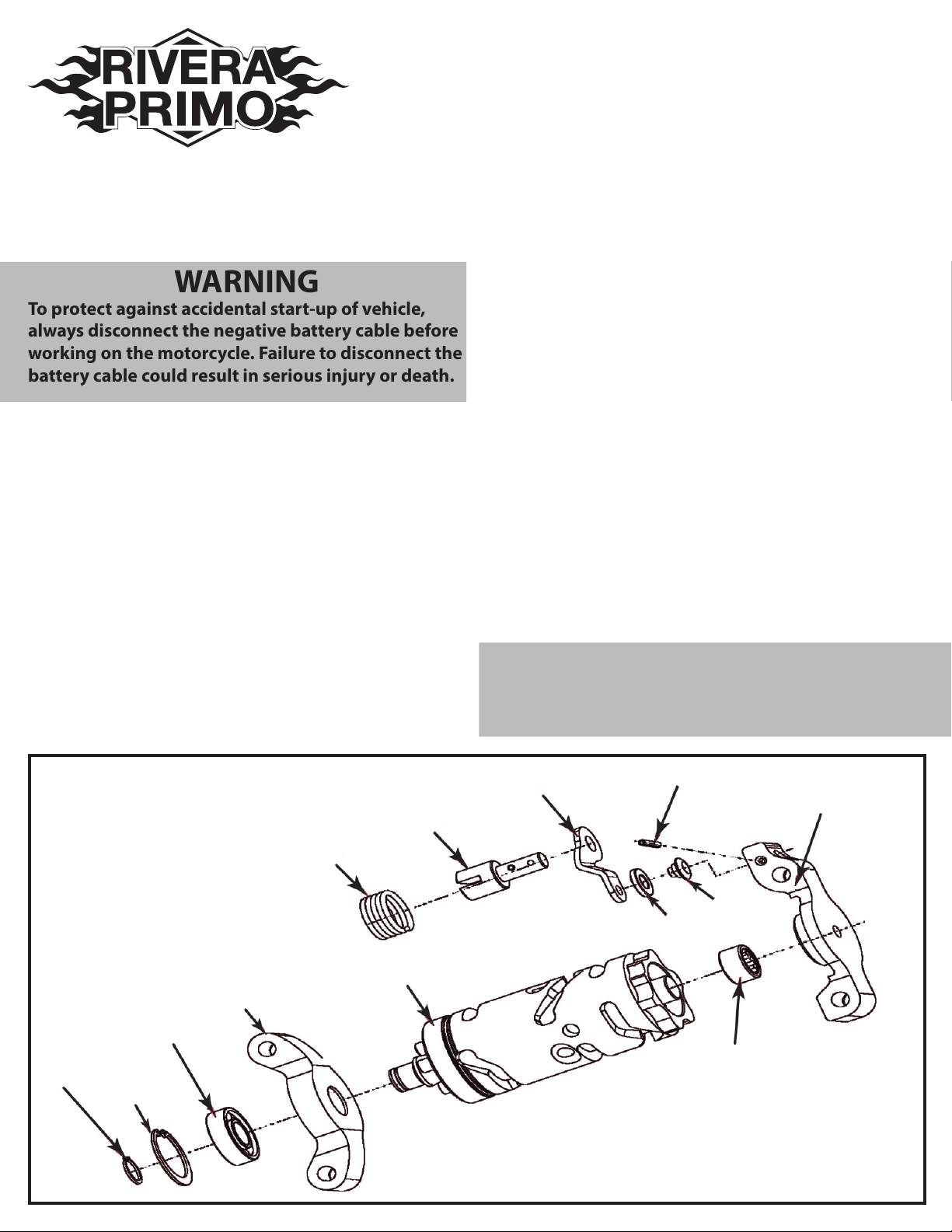

Shifter Cam Assembly

Exploded View

Support Tower (LH)

1217-0641

Cam Bearing

1018-0016

Retaining Ring

1101-0061

Retaining Ring

1101-0062

Coil Spring

1217-0645

Spring Hanger

1217-0640

Cam LSD

1217-0636

Cam Follower Arm

1217-0639

Roll Pin

1217-0647

Roller

1217-0646

Roller Shaft

1217-0644

Bearing

1018-0017

Support Tower (RH) LSD

1217-0642

Fig.1

8. Slide rubber boot o clutch cable adjuster. With a 1/2

inch wrench holding the cable adjuster, loosen jam

nut to get a signicant amount of free

play at hand lever.

9. Remove six socket head screws to remove clutch

release cover from the transmission side door.

DO not re-use the gasket.

10. Remove retaining ring from inner ramp, then lift inner

ramp out of clutch release cover. Turn the inner ramp

over so that ball pockets are facing outboard. Remove

hook of ramp from button on coupling. Remove the

coupling from clutch cable end.

11. Unscrew the cable from the clutch release cover. Remove the clutch cable.

12. Remove the mainshaft fork shaft from the hole on the

right side of the transmission case by sliding outward,

then remove the 1st gear fork shaft by rst removing

the threaded plug, then slide the shifter fork back

and forth until the shouldered head of the fork shaft

protrudes through the hole in the bearing housing.

Remove the shifter forks from the mainshaft and

countershaft grooves. (See Fig. 5 & 6)

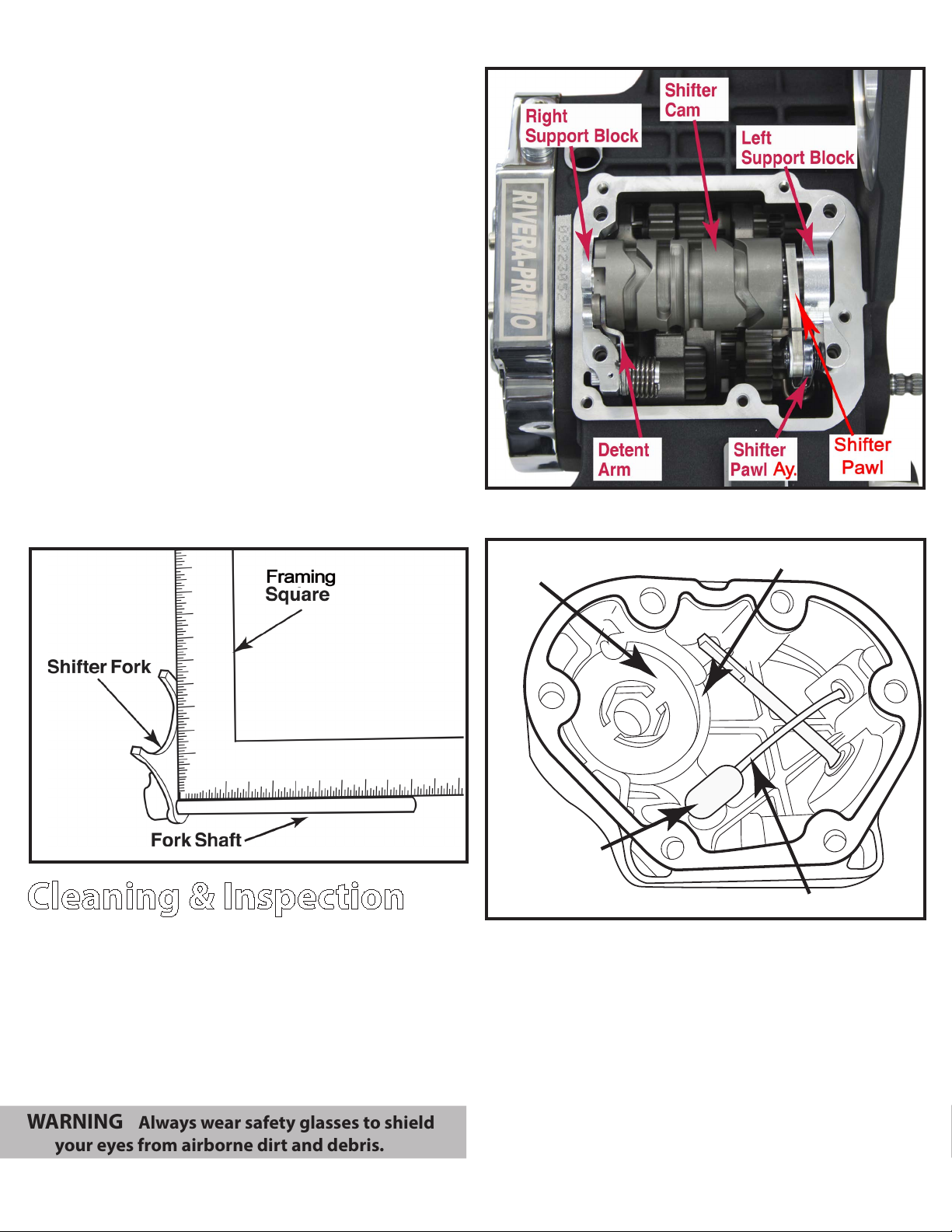

Check Shifter Forks for Squareness

Shifter Cam Assembly

Fig.2

Clutch Release Cover Assembly

Fig.3

Cleaning & Inspection

1. Clean all parts with solvent prior to installing any

bearings. Blow dry with low pressure air.

2. Inspect roller bearings make sure that bearings rotate freely without binding.

3. Inspect the shifter cam for cracks or wear. Inspect the

ends for grooves or pitting. Always install new roller

bearings whenever the shifter cam is replaced.

WARNING: Always wear safety glasses to shield

your eyes from airborne dirt and debris.

4. Inspect the shifter fork shaft and replace

if bent or damaged.

Retaining Ring

Inner Ramp

Coupling

Fig.4

5. Using a small framer’s square, verify that the shift-

er fork shafts are square. If a fork does not rest at

against the square, it is bent and must be replaced.

(See Fig. 3)

6. Inspect the shifter forks for wear. With a micrometer

or dial caliper, measure the width of the fork where

they contact the gear fork grooves. Replace any fork

that measures less than 0.170” (4.32 mm)

7. Inspect the neutral safety switch. Depress plunger

and observe the action. Plunger should pop back

without binding. The switch is not repairable and

must be replaced if inoperable.

Clutch Cable

Loading...

Loading...