M

INSTALLATION PROCEDURE for BRUTE IV EXTREME

T

MID-CONTROLS (PART NO. 2084-0504)

OTE: USE BLUE LOCTITE ON ALL FASTENERS

N

TORQUE 1/4” fasteners to 120 inch pounds . . . 5/16” fasteners to 30 foot pounds . . . 3/8” fasteners to 42 foot pounds

BRAKE SIDE ASSEMBLY (P/N 2084-0502) / INSTALLATION PROCEDURE

1. Remove the battery per O.E. manual.

2. Remove the exhaust system per O.E. manual.

3. Remove the stock forward brake controls & brake line per O.E. manual.

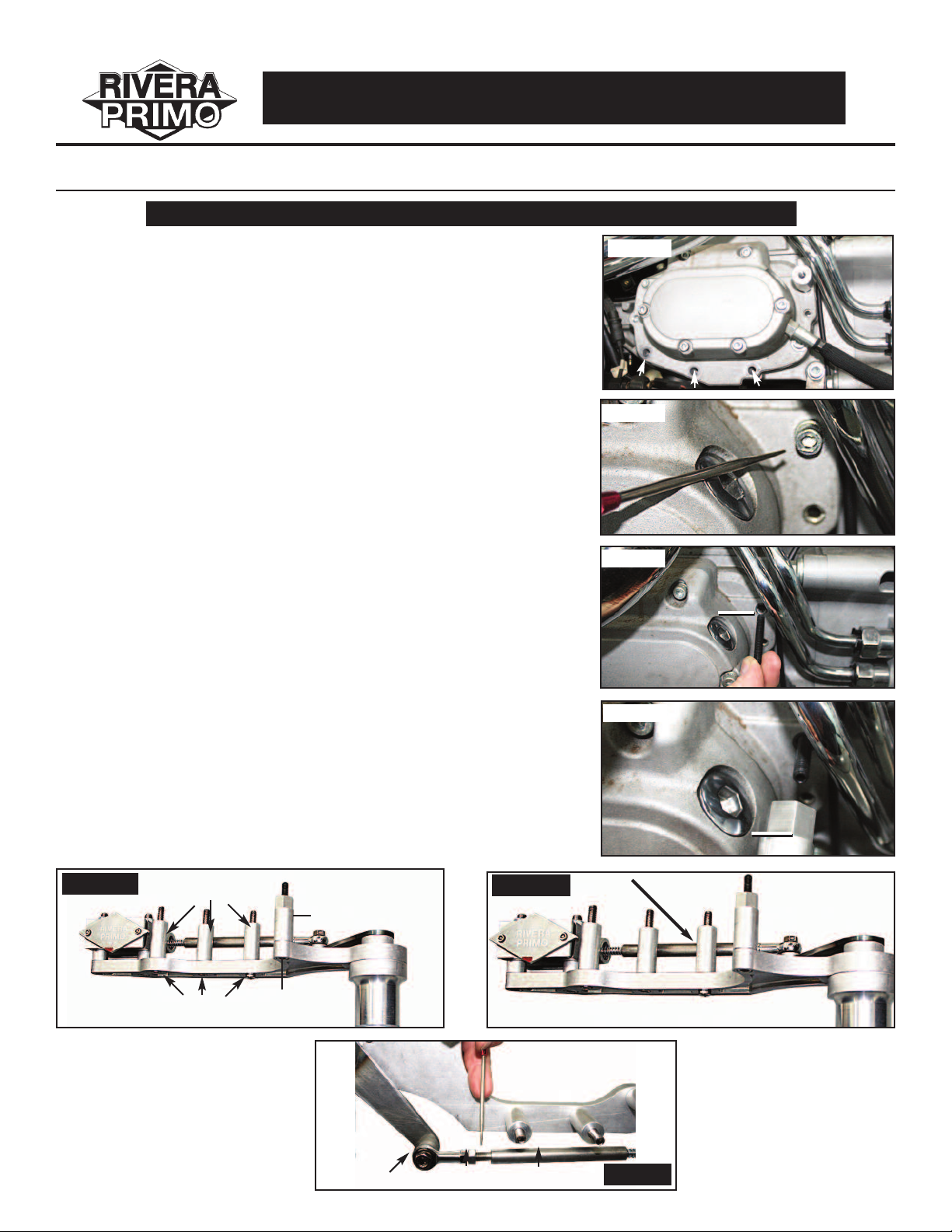

4. Remove the three(3) lower 5/16-18 socket head cap screws on the

bottom right side of the transmission. (Photo 1)

5. Remove the top front 1/4-20 socket head cap screw on the right side of

the transmission. (Photo 2)

6. Install supplied 1/4-20 set screw into the top front hole (P/N 2100-0049)

on the right side of transmission. (Photo 3)

7. Install supplied threaded spacer (P/N 2084-0079) over stud with the hex

end towards the transmission and torque to 12 foot pounds. (Photo 4)

8. Install the brake assembly onto the transmission using three(3) each

5/16-18 x 3.00” socket head cap screws (P/N 2100-0001) with

spacers (P/N 2084-0069) and one(1) each 5/16-18 x 1.00” socket

head cap screw (P/N 2100-0047). (Photo 5A)

9. Check the working of the brake pedal up & down to make sure nothing

is rubbing or hitting any of the linkage or pedal (the plunger rod will stop

when it touches the front lower spacer and at this time the master cylinder

will be bottomed out). (Photo 5B)

10. Adjust the free play in the brake lever. You should have 1/8” up & down

free play. This can be adjusted with the plunger rod (P/N 2084-0065).

Loosen jam nuts then turn the plunger to add or take away free play.

When you have 1/8” of free play lock the jam nut (P/N RIV-201) to the

rod end (P/N 2018-0099). (Photo 6)

11. Now it’s time to measure for your rear brake line and light switch. Be

sure to run the brake line away from the exhaust system and any

moving parts. Once you’ve installed the brake line you can bleed the

brake system per the O.E. manual.

12. Install your footpeg and brake pedal peg (not supplied).

13. Reinstall your exhaust system & check for clearance.

Photo 1

Photo 2

Photo 3

2100-0049

2100-0049

Photo 4

2084-0079

2084-0079

Photo 5A

OE=Original Equipment

SHCS=Socket Head Cap Screw

SFHCS=Socket Flat Head Cap Screw

2084-0069

2100-0001

2100-0047

2084-0079

2018-0099

RIV-201

Photo 5B

2084-0065

Photo 6

1108-0046 / 6-08

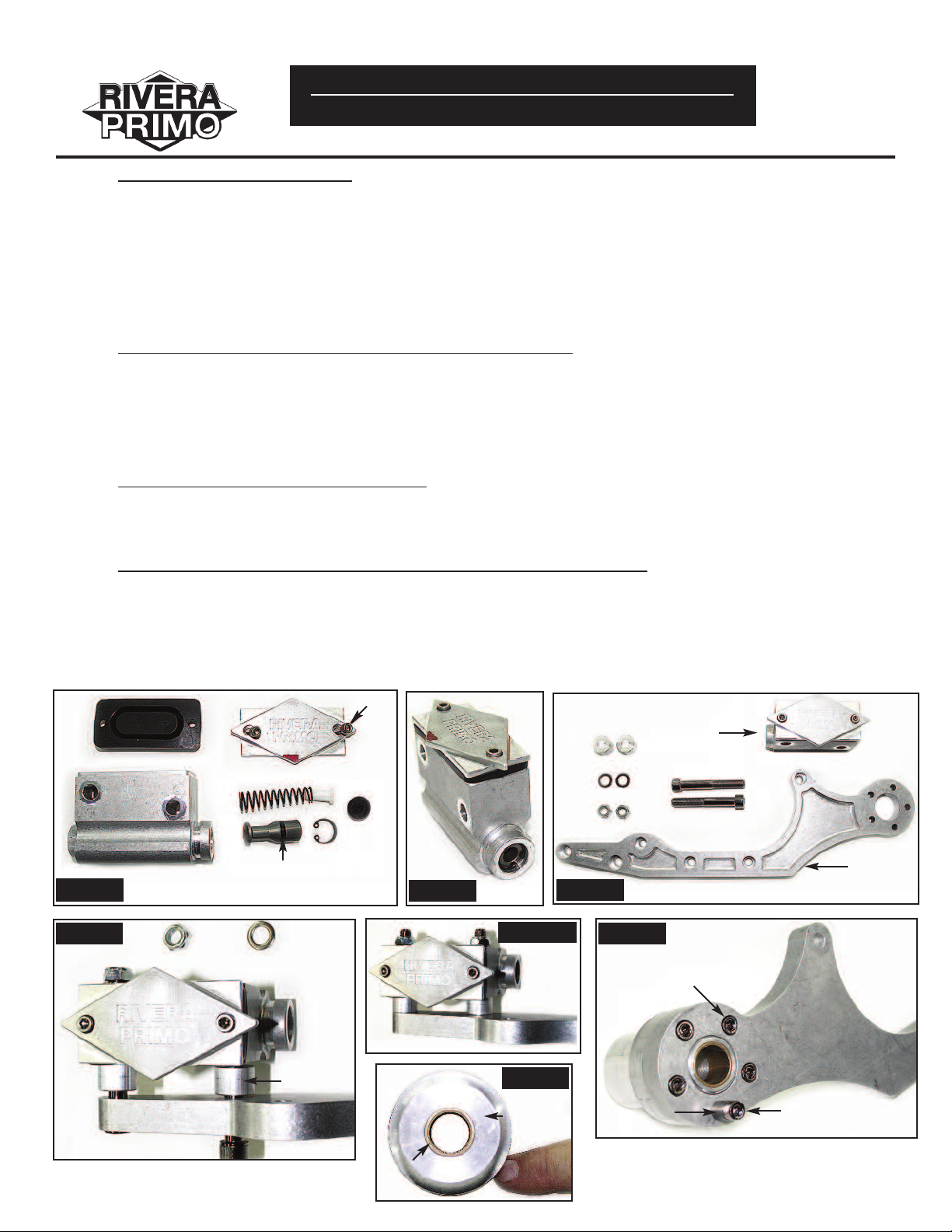

BRAKE SIDE ASSEMBLY. . . P/N 2084-0502

ITEMIZATION OF PARTS

* NOTE: USE BLUE LOCTITE ON ALL FASTENERS

Master Cylinder Assembly

Qty Part Number Description

1 2034-0051 Polished Master Cylinder Body Photo 1 & 2

1 2037-0001 Master Cylinder Rebuild Kit Photo 1

1 2034-0056 Polished Master Cylinder Top Cover Photo 1

1 2094-0001 Master Cylinder Top Cover Gasket Photo 1

2 2100-0112 10-24 x .500” Top Cover Screws Photo 1

1 2084-0412 Master Cylinder Assembly Photo 2

Master Cylinder Assembly to Brake Mounting Plate

Qty Part Number Description

1 2084-0063 Polished Brake Mounting Plate Photo 3

2 2100-0045 3/8-24 x 2.75” SHCS Photo 3

2 2084-0076 Spacers (Master Cylinder) Photo 4

2 RIV-318 3/8” Flat Washers Photo 4

2 3/8-24 Locknuts Photo 5A

Brake Pedal Ext. Spacer Assembly

Qty Part Number Description

1 2084-0066 Brake Pedal Ext. Spacer Photo 6

2 2084-0048 Bronze Bushings Photo 6

2094-0001

Photo 1

Photo 4

Brake Pedal Ext. Spacer Assembly to Brake Mounting Plate

Qty Part Number Description

4 2100-0113 1/4-20 x 1.00” SHCS Photo 7

1 2100-0042 1/4-20 x 1.375” SHCS Photo 7

1 2084-0071 Chrome Spacer for P/N 2100-0042 Photo 7

1 2084-0409 Brake Pedal Ext. Spacer Assembly Photo 7

2034-0051

O-Ring

2037-0001

RIV-318

2100-0112

2034-0056

Rubber

Cup Seal

Photo 2

2084-0412

Photo 5A

2084-0076

RIV-318

Photo 3

M/Cylinder

Assembly

2100-0045

Photo 7

2100-0113

2084-0063

2084-0063

2084-0076

2084-0048

Photo 6

2084-0066

2084-0071

2100-0042

Brake Side Assembly & Brake Linkage Assembly

Qty Part Number Description

1 Welded Brake Linkage Photo 8

3

1 2084-0075 Brake Shaft Spacer Photo 8 & 10

1

1 1101-0020 Thrust Washer (Small) Photo 10

1 1101-0022 Thrust Washer (Large) Photo 11

2101-0008 .125” x .750” Dowell Pins Photo 8 & 9

1100-0018 Curved Disc Spring Washer Photo 10

Master Cylinder Plunger Rod Assembly

Qty Part Number Description

1 2018-0099 Rod End 5/16-24 Female Photo 12

1 2084-0065 Plunger Rod Photo 12 & 13

1 RIV-201 Jam Nut for Rod End on Plunger Rod Photo 13

1 1101-0023 Return Spring Photo 13

1 2100-0043 5/16-24 x 1.25” SFHCS Photo 12 & 13

1 2084-0073 Spacer (Rod End) Photo 12 & 13

1 2100-0044 5/16-24 Center Locknut Photo 12 & 13

Photo 12

1101-0023

2084-0075

2084-0093

1100-0018

2084-0073

1101-0020

Photo 8

1101-0022

2101-0008

2100-0043

Photo 9

2084-0065

Photo 10

2100-0044

1101-0022

2084-0075

1100-0018

1101-0020

Photo 11

2018-0099

RIV-201

Photo 13

1101-0023

2100-0043

2100-0044

2084-0073

Brake Lever Assembly

Qty Part Number Description

1 2084-0055 Brake Lever Mounting Block Photo 14

1 2084-0053 Brake Lever Photo 14

1 2084-0073 Brake Lever Retainer Photo 15A

7 2100-0048 10-24 x 1.125” SHCS Photo 15B

1

2100-0047 5/16-18 x 1.00” SHCS Photo 15B

Installing Brake Lever Assembly to Brake Mounting Plate

Qty Part Number Description

1 Brake Mounting Plate Assembly Photo 16A/B

1 Brake Lever Assembly Photo 16A/B

Installing Spacers onto Brake Mounting Plate

Qty Part Number Description

3 2100-0001 5/16-18 x 3.00” SHCS Photo 17/18

1 2100-0047 5/16-18 x 1.00” SHCS Photo 17/18

3 2084-0069 Spacers Photo 17/18

1 2084-0079 Spacer Photo 17/18

1 2100-0049 1/4-20 x 1.50” SSS Photo 17/18

Photo 14

2084-0073

2084-0053

Photo 16A

1101-0022

Photo 18

Line-up Hole

2084-0055

2084-0069

2100-0048

2100-0049

Photo 14

Retainer

Retaining

Block

Top Front

Photo 16B

2100-0047

2084-0079

Photo 15A/B

Photo 17

2100-0001

2084-0069

2084-0079

2100-0047

2100-0049

2100-0001

COMPONENT ASSEMBLY / BRAKE SIDE

1. Master cylinder rebuild kit (P/N 2037-0001). Lubricate rubber

cup seal & o-ring on piston with DOT 5 BRAKE FLUID.

(Photo 1A)

2. Install large end of spring into the master cylinder (P/N 2034-

0051) bore with nylon pin inserted into small end of spring

followed by rubber cup seal (flat side of rubber cup seal faces

outward). (Photo 1A)

3 Spread a small amount of brake fluid in master cylinder base.

Install aluminum piston with the o-ring end facing outward and

push aluminum piston into the master cylinder bore and install

snap ring. (Photo 1B)

4. Install master cylinder top cover rubber gasket (P/N 2094-

0001) with master cylinder top cover (P/N 2034-0056) using

two(2) each 10-24 x .500” SHCS (P/N 2100-0112) and hand

tighten. (Photo 1C)

2094-0001

O-Ring

2

034-0056

2100-0112

ubber Cup

R

Seal

Photo 1A

084-0412

2

2034-0051

2084-0076

RIV-318

M/Cylinder Assy

2100-0045

1. Install two(2) each 3/8-24 x 2.75” SHCS

(P/N 2100-0045) thru the two counterbored

holes at end of brake mounting plate (P/N

2084-0063) followed by two(2) each spacers

(P/N 2084-0076). (Photo 3 & 4)

2. Now slide master cylinder onto 3/8-24 x 2.75”

SHCS followed by two(2) each washers

2084-0063

Photo 3 Photo 4

(P/N RIV-318). (Photo 4)

1. Press two(2) each bushings (P/N 2084-0048) into each end of brake pedal

ext. spacer (P/N 2084-0066). (Photo 6)

NOTE: TRY INSTALLING WELDED BRAKE LINKAGE INTO BRAKE PEDAL

EXT. SPACER. THIS WILL LET YOU KNOW IF THE BUSHINGS

NEED TO BE REAMED.

Photo 1B Photo 1C

RIV-318

M/Cylinder Assy

2084-0076

2084-0063

Photo 6

2084-0066

2084-0048

1 Install brake pedal ext. into the machined and pocketed side of brake

mounting plate. (Photo 7)

2. Install four(4) each 1/4-20 x 1.00” SHCS (P/N 2100-0113) into counterbored

holes and then slide spacer (P/N 2084-0071) onto 1/4-20 x 1.375” SHCS

(P/N 2100-0042) and torque these to 12 foot pounds. (Photo 7)

2100-0113

2084-0071

Photo 7

2100-0042

1. Install three(3) each pins (P/N 2101-0008) into the three holes on the threaed

end of welded brake linkage. Using a hammer tap the three pins until they

bottom out. (Photo 8 & 9)

2084-0075

100-0018

1

hoto 8

P

101-0022

1

hoto 9

P

2. Install spacer (P/N 2084-0075) onto welded brake linkage (flat side facing out).

Now install curved disc spring washer (P/N 1100-0018) followed by small

thrust washer (P/N 1101-0020). (Photo 10)

100-0020

1

3. Install welded brake linkage (Photo 10) onto brake mounting plate with brake

pedal ext. and master cylinder from the master cylinder side. Now slide the

large thrust washer (P/N 1101-0022) onto welded brake linkage from the

outside. (Photo 11)

2101-0008

084-0075

2

1100-0018

Photo 11

NOTE: NOTCH ON WELDED BRAKE

LINKAGE GOES BEHIND SHCS

(P/N 2100-0042) & SPACER

(P/N 2084-0071) ON BRAKE

MOUNTING PLATE. (Photo 7)

Photo 7

Photo 10

100-0020

1

1100-0022

1. Install jam nut (P/N RIV-201) onto threaded end of of plunger rod (P/N 2084-0065) followed by rod end (P/N 2018-0099). (Photo 12)

2. Install 5/16-24 x 1.25” SFHCS (P/N 2100-0043) into welded brake linkage. On the other side install spacer (P/N 2084-0073).

(Photo 13)

3. Now install spring (P/N 1101-0023) on machined end of plunger rod (P/N 2084-0065). Guide the plunger rod & spring into the

master cylinder and install rod end onto P/N 2100-0043 followed by center locknut (P/N 2100-0044). (Photo 13)

4. Torque to 30 foot pounds.

Photo 12

2084-0073

100-0043 2100-0044

2

2100-0044

2018-0099

1101-0023

1101-0023

2084-0065

RIV-201

2018-0099

Photo 13

1. Holding brake lever mounting block (P/N 2084-0055) so top front

is facing you, install brake lever (P/N 2084-0053) onto brake

mounting block lining up the top two mounting screw holes

Retainer

(NOTE: THE BRAKE LEVER WILL POINT TO YOUR RIGHT).

(Photo 14)

2. Now install brake lever retainer (P/N 2084-0073) with counter-

bored holes facing outward. Start by installing 10-24 x1

(P/N 2100-0048) in top hole and now install 10-24 x 1-

-1/8” SHCS

1

/

” SHCS

8

Retaining

Block

Top Front

in every other hole going downwards and tighten. (Photo 15A/B)

1. Install brake lever with mounting block assembly onto welded brake linkage shaft that is installed

in brake mounting plate. The top hole on the brake mounting block will go in the top pin on brake

linkage shaft with thrust washer between the two.

2. Now tap the brake lever mounting block onto the welded brake linkage with a rubber hammer.

(Photo 16A)

3. Now install

5

/

-18 x 1” SHCS (P/N 2100-0047) thru center hole in brake lever mounting block

16

and thread onto welded brake linkage. (Photo 16B)

NOTE: YOU WILL USE THE

4. Now that the unit is complete remove

5

/

-18 x 1” SHCS TO PULL THE TWO UNITS TOGETHER

16

5

/

-18 x 1” SHCS and put one(1) drop of blue loctite

16

onto threads and torque to 30 foot pounds.

Photo 14

Photo 15A/B

2084-0065

2084-0073

2100-0043

Photo 16A

1101-0022

2100-0047

Photo 16B

1. Install three(3) each 5/

-18 x 3” SHCS (P/N 2100-0001) thru brake

16

mounting plate. Then slide three(3) each spacers (P/N 2084-0069)

5

/

onto

-18 x 3” SHCS.

16

2. Install one(1) each 5/16-18 x1” SHCS (P/N 2100-0047) into top hole

and thread round end of spacer (P/N 2084-0079) onto SHCS.

Thread 1/4-20 x 1.50” SSS into hex end of spacer (P/N 2100-0049).

2100-0049

2084-0069

2100-0001

2084-0079

Photo 18

2100-0047

M

INSTALLATION PROCEDURE for BRUTE IV EXTREME

T

MID-CONTROLS (PART NO. 2084-0504)

NOTE: USE BLUE LOCTITE ON ALL FASTENERS

TORQUE 1/4” fasteners to 120 inch pounds . . . 5/16” fasteners to 30 foot pounds . . . 3/8” fasteners to 42 foot pounds

SHIFT SIDE ASSEMBLY (P/N 2084-0500) / INSTALLATION PROCEDURE

1. Remove primary covers and primary drive per O.E. manual.

2. Remove the shifter and shifter mounting plate per O.E. manual.

3. Remove block-off plug from motor plate & install supplied shifter crossover tube(P/N 2084-0050) (Photo 7A, 7B, 7C)

Photo 7A

Photo 7C

2084-0050

4. Install spring washer (P/N 1101-0018) onto shifter shaft &

then thrust washer (P/N 1101-0022). Install shifter shaft

into shifter crossover tube. (Photo 8)

5. Install motor plate onto motorcycle per your BRUTE IV

TM

EXTREME

instructions.

6. Install belt drive and clutch per your BRUTE IV EXTREME

instructions.

Photo 7B

TM

Welded

Shifter

Linkage

1101-0018

Photo 8

1101-0022

7. Install the shifter rod to the shifter linkage

and shifter arm on transmission using

two(2) each 5/16-24 x 1.00” socket head

cap screws (P/N 1100-0017) & one(1) each

5/16-24 lock nut (P/N 2100-0044). (Photo 9)

Photo 9

2100-0044

1101-0017

Shifter Rod Assy

1101-0017

. Remove block-off cap from outer belt guard. (Photo 10A & 10B)

8

f your outer belt guard does not have a block-off cap

I

you will have to finish machining the shifter crossover

tube hole. (Photo 10C)

hoto 10A

P

Photo 10B

M

9. Install the outer belt guard per BRUTE IV EXTREME

T

instructions.

10. Install thrust washer (P/N 1101-0022) over shifter shaft.

(Photo 11)

Photo 10C

Photo 11

1101-0022

11. Install shifter yoke onto shifter shaft aligning the

three(3) each dowel pins on the shaft to the yoke

using one(1) each 5/16-18 x 1.00” socket head cap

screw to pull the yoke onto the shifter shaft and torque.

(Photo 12)

12. Install footpeg and shifter peg.

13. Reinstall the battery.

Photo 12

Shifter Lever Assy

SSHIFT SIDE ASSEMBLY. . . P/N 2084-0500

ITEMIZATION OF PARTS

* NOTE: USE BLUE LOCTITE ON ALL FASTENERS

Shifter Support Tube Assembly

Qty Part Number Description

1

2 2084-0048 Bronze Bushings Photo 13

Shifter Lever Assembly

Qty Part Number Description Photo 14

1 2084-0055 Shifter Lever Mounting Block Photo 15A

1 2084-0053 Shifter Lever Photo 15B

1 2084-0073 Shifter Lever Retainer

7 2100-0048 10-24 x 1.125” SHCS

Shifter Linkage Assembly

Qty Part Number Description Photo 25

1 Welded Shifter Linkage Photo 20

3 2101-0008 .125” x .750” Dowell Pins Photo 21

1 1101-0018 Curved Disc Spring Washer Photo 22

1 1101-0020 Thrust Washer (Small) Photo 23

1 1101-0022 Thrust Washer (Large) Photo 24

1 2100-0047 5/16-18 x 1.00” SHCS

2084-0050 Shifter Support Tube Photo 13

Shifter Rod End Assembly

Qty Part Number Description Photo 26

2 2018-0099 Rod Ends 5-16-24 Female

1 2084-0080 Rod 5/16-24 Male Each End

2 1100-0017 5/16-24 x 1.00” SHCS

1 2100-0044 5/16-24 Center Locknut

Photo 13

2084-0048

Photo 15A

2084-0050

Top Front

Photo 14

2084-0073

2100-0048

2084-0053

Line-up Hole

Photo 15B

2084-0055

Line-up Hole

2101-0008

Photo 20 Photo 21

1101-0018

1101-0020

Welded Shifter Linkage

2084-0050

2084-0091

1101-0022

2100-0047

Photo 23

Photo 22

1101-0018

1101-0020

Welded Shifter Linkage

Photo 26

2018-0099

1101-0022

2084-0081

Photo 24

2018-0099

Photo 25

Shifter Linkage

Assembly

COMPONENT ASSEMBLY / SHIFT SIDE

1. Press two(2) each bushings (P/N 2084-0048) into shifter support tube (P/N 2084-0050)

NOTE: TRY INSTALLING WELDED SHIFT LINKAGE INTO SHIFTER SUPPORT TUBE.

THIS WILL LET YOU KNOW IF THE BUSHINGS NEED TO BE REAMED.

084-0050

084-0048

2

NOTE: ASSEMBLY OF SHIFT LEVER IS THE SAME AS BRAKE LEVER ASSEMBLY, EXCEPT SHIFTER POINTS TO YOUR LEFT

1. Holding shift lever mounting block (P/N 2084-0054) top front install shift

lever (P/N 2084-0053) onto mounting block lining up the top two

mounting screw holes (NOTE: THE SHIFT LEVER WILL POINT TO

YOUR LEFT). Photo 15A

2084-0072

2. Now install the shift lever retainer (P/N 2084-0072) with counterbored

holes facing outward. Start by installing 10-24 x 1.125” SHCS

(P/N 2100-0048) in top hole and now 10-24 x 1.125” install SHCS in

every other hole going downwards and tighten. Photo 15B

Photo 15A

2

100-0048

2

Top Front

Photo 15B

1. Install three(3) each pins (P/N 2101-0008) into the threaded end of

welded shifter shaft. Using a HAMMER tap the three (3) each pins until

they bottom out. Photo 21

2. Install the curved disc washer (P/N 1101-0018) onto the welded shifter

shaft, then slide on the thrust washer (P/N 1101-0020). Photo 22

3. Install the welded shifter linkage into the shifter support tube. Photo 23

4. Install thrust washer (P/N 1101-0022) onto the shaft & line-up the pin on

the welded shift linkage with the top hole on the shifter lever assembly.

Photo 24

5. Using a NO BOUNCE HAMMER give one light tap and start 5/16-18 x1.00”

SHCS (P/N 2100-0047).

Photo 21 Photo 22

1101-0020

1101-0018

2084-0050

2084-0053

Line-up Hole

2084-0054

Line-up Hole

2101-0008

1101-0018

1101-0020

Welded Shifter Linkage

Photo 23 Photo 24

1101-0022

2100-0047

1101-0022

Welded Shifter Linkage

2084-0081

2018-0099

1. Thread rod ends (P/N 2018-0099) onto the threaded rod (P/N 2084-0081) using blue loctite. When tightening the rod ends they

should both face the same way.

BRINGIN’ OUT THE BEAST !

BRINGIN’ OUT THE BEAST !

Performance upgrades are

often obscured in such a way

that you really never get what

you’re looking for. After you

peel-off all the fancy trimmings

you’re basically left with about

what you started with.

2018-0099

Rivera Primo®delivers performance, plain & simple. Every go-fast

item has been tried & tested. We

work real hard at making sure your

buck will get you somethin’!

So, join us & the thousands worldwide who’ve made it a habit of

upgrading with the best . . . you

won’t be disappointed !

Start by gettin’ your hands on a Rivera Primo®parts catalog. It’s filled with the

goods that serious riders want, products that do perform. If you don’t have one

simply call us and ask for your copy of “BRINGIN’ OUT THE BEAST”.

RIVERA PRIMO INC. 12450 WHITTIER BLVD. WHITTIER, CALIFORNIA 90602

TEL: 562-907-2600 FAX : 562-907-2606 ORDERS: 800-872-1515

www.riveraprimoinc.com

Loading...

Loading...