HOME OF PRIMO®BELT DRIVES

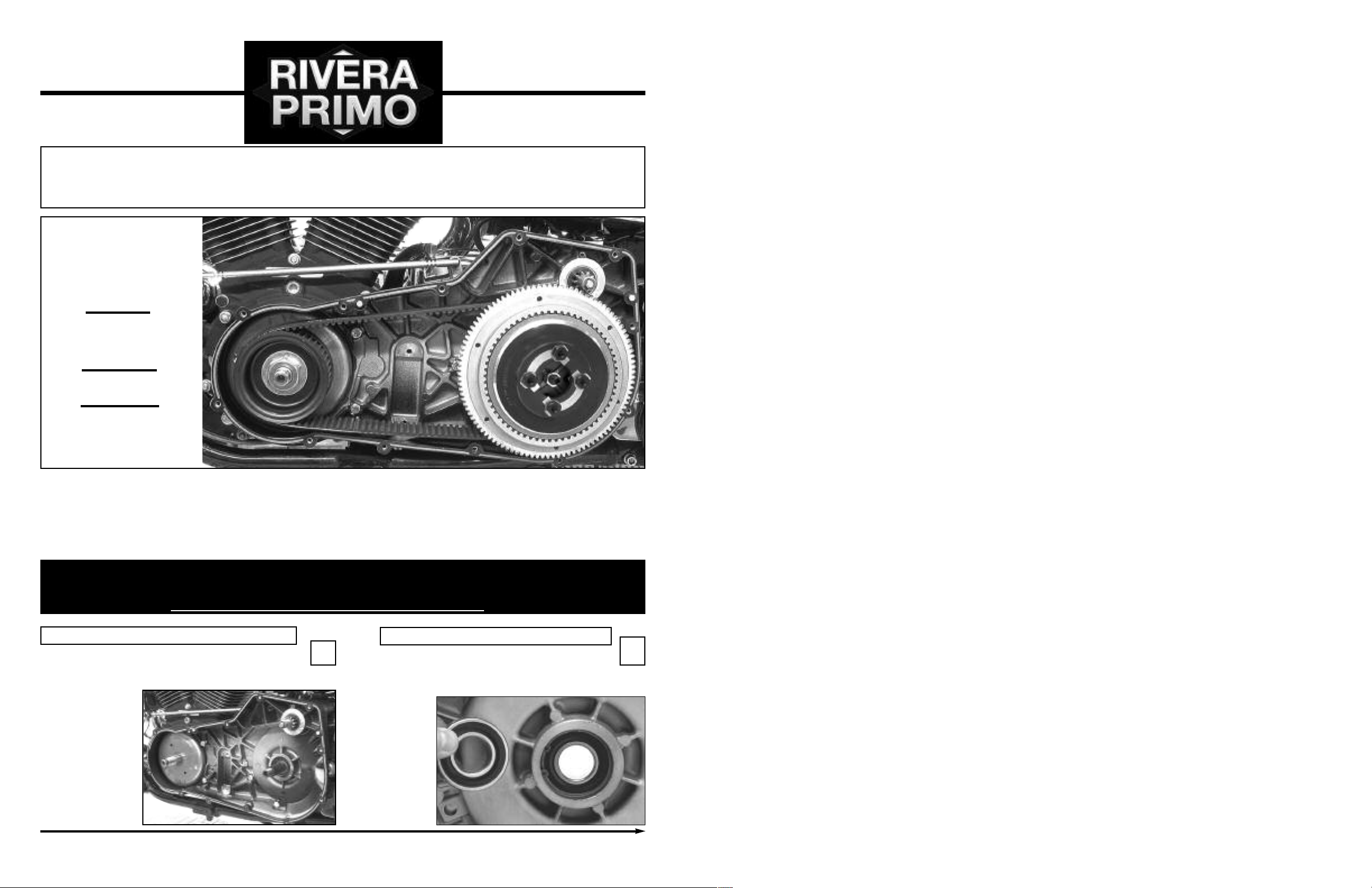

INSTALLATION INSTRUCTIONS FOR PRIMO’s

BRUTE III

8mm - 1-3/4” Wide

FITS:

1986-2000

FXR, FLT & FLH

1986-89 Softails

QUALITY & PERFORMANCE SINCE 1973

TM

BELT DRIVE

t is common knowledge that a belt drive primary provides advantages & service that a standard chain drive

I

primary cannot. For dependable, high-performance, long lasting service nothing beats a modern Primo®primary Belt Drive! A long standing tradition of ”Quality & Performance” has made Primo®Belt Drive systems

the most popular in the world! The wet clutch nightmare is over, no more leaky primary, no more draining the

primary for inspection or maintenance. Carefully read & follow these instructions for a quick, convenient installation. If you have any questions please call (562) 907-2600.

IMPORTANT SAFETY NOTICE....

When performi ng an y mot orcycle work such as inst all ing a b elt d rive, secure the motorc ycle in an u pright position with convenien t acces s to the primar y dr ive . If you are wor kin g wi th the moto rcycle on a lif t ma ke s ure it is

securely fastene d to preve nt it from falling .

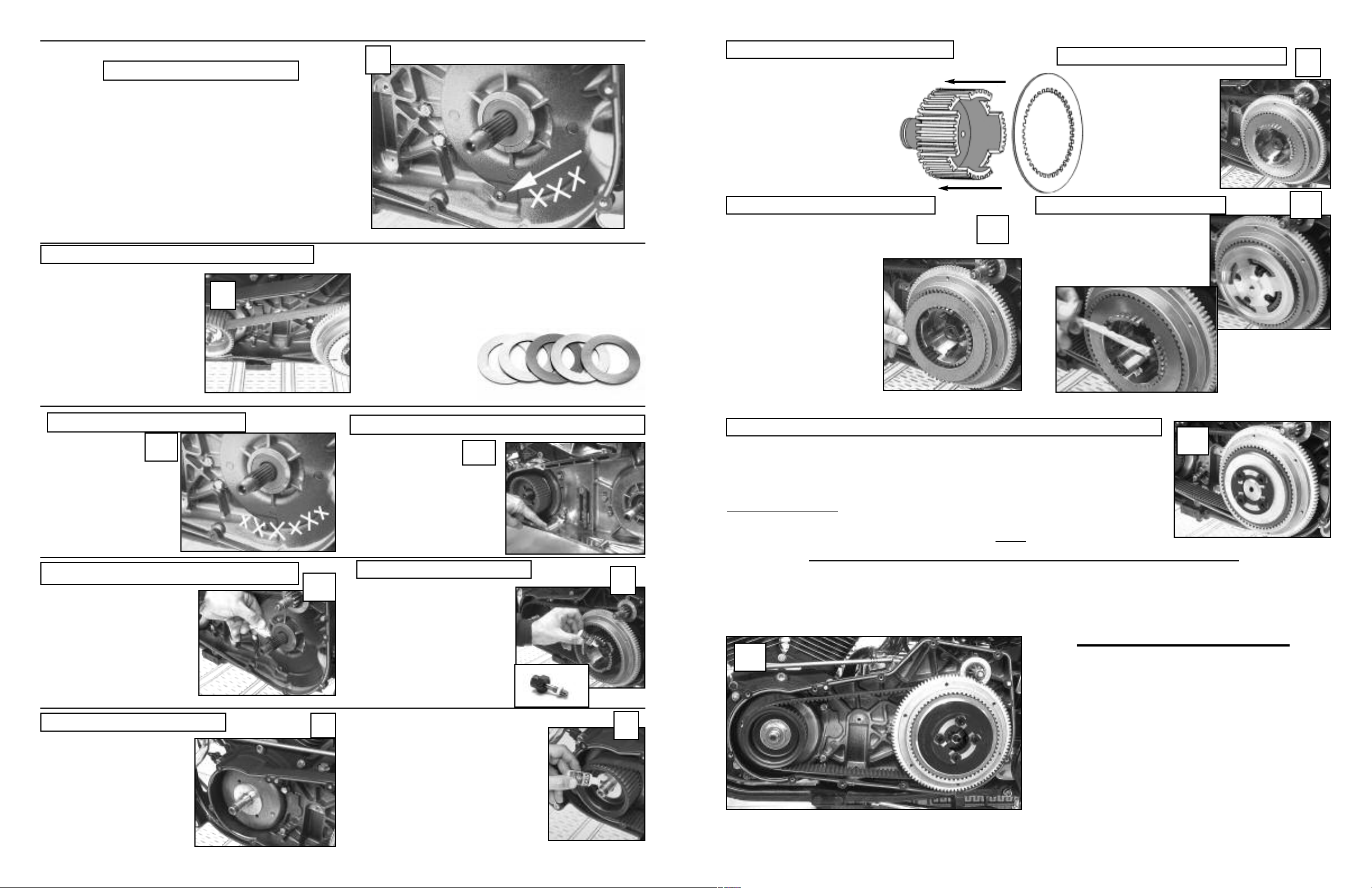

Strip the primary

Drain the primary case, remove both the inner & outer primary covers, & all OEM chain drive components from the

primary chaincase. Thoroughly clean the inner & outer

primary covers to

remove all traces

of primary fluid.

Pictured is a 1995

H arley -D a v i d s on

Dyna-Glide primary.

Remove the factory

bearing race from the

transmission mainshaft using the Jims

tool part # 34902-84.

®

Remove the battery prior to start ing the installation.

Install the sealed bearing (1018-0021)

1

Install Primo’s one-piece, sealed bearing included in the kit.

2

www.riveraprimoinc.com

1

2108-0001 Rev. 9/2014

nstall buttonhead Allen bolt

I

NOTE: Replace the OEM hex-head bolt (Dyna Glide only) with the

button-head Allen bolt provided in the kit. TORQUE THE BUTTON-

EAD BOLT TO 29 FOOT POUNDS.

H

Early FXR models may need to have some material removed from

the inner primary in the area indicated by the X’s. Check

pulley/belt clearance here before tightening clutch hub nut.

3

UPDATED CLUTCH HUB INFORMATION

rimo’s new clutch hub uses a .120” thick

P

teel plate at the back of the clutch pack

s

eplacing the permanently attached alu-

r

inum backing plate of the earlier model

m

lutch hub. See drawing.

c

Install the .120” thick steel plate at the

rear of the clutch pack as shown. The

clutch pack can then be installed.

.120” thick Steel Plate plate first.

After installing the .120”

steel drive plate, Install

the rest of the clutch pack

per steps 10 and 11.

9

Check pulley alignment with a straight-edge

Install front pulley. Install the

rear pulley without the belt &

check alignment as shown

(straight edge flush with rear of

ring-gear lines-up with outer

edge of front pulley). Remove

pulleys and proceed with installation. If alignment isn’t satisfactory see photo 8. The provided

.100” washer can be used to

space the front pulley outward

as needed, however it may be

nesecary to use less or more

shim.

4

Check for proper belt clearance

5

After ensuring proper pulley alignment, again

check the areas indicated

in the photo for belt and/or

pulley clearance. Always

check rear-pulley and belt

clearance here before

operating the motorcycle.

Shims are manufactured from high quality steel, precision

ground for parallel & flat surfaces to ensure perfect pulley

alignment. Correct pulley alignment & correct belt tracking

are a must for long belt life. These shims make pulley alignment easy. Shims are available in .020", .030", .050", .075" &

.100” thick dimensions, or sets of "one-of-each.”

Optional pulley shims kit

Part # 2100-0066

Includes one each of

.020”, .030”, .040”,

.050” and .100”

Check primary belt clearance here

5A

This inner primary (Early

Ev o) ha s had a tab

re moved to allow belt

clearance in the area indica ted. Most insta ll ations

require some grinding on

the outer primary webbing.

Friction Plate plate second...

Friction plate 2nd, then alternate

steel, friction, steel, friction. The

clutch plates should be installed in

the same order as delivered.

The clutch pack height is preset prior to shipment, &

should not be altered without

consulting a Primo technician.

10

Install the pressure plate

nstall the pressure plate as shown.

I

pply a generous dab of high

A

quality anti-seize to each of the

Pro-Clutch studs (as shown).

Install the locking tabs & retainer, & adjust the clutch.

Inst a ll t h e di a phra g m sp ring , spr i ng r e tain e r (b e vele d si d e in w ard agai n st

the spr i n g) lock i n g t abs, and sho u lder e d n u ts as s hown . T IGH T E N T HE

NUTS EQU A LLY U NTILTH E Y B O TTO M , & T HEN TIGH T EN T O 3 0 INC H PO U N DS

OF TOR Q UE. B end a ta b o v er e ach nu t t o k e ep i t t ight ! S p ring ad just m ent

(and c lutc h pack h eigh t ) is e s t abl i s hed p r ior t o ship p ing.

Clut c h adju s tmen t : Run th e c l utch c a b le all th e w a y out unt i l t he clu t c h

leve r touc h es th e hand l ebar g rip. T hen r u n the c ente r adju s ting s crew i n

unti l it to u ches t he pu s hrod , b ack i t out 1 / 4 tur n and t i ghte n t he j a m nut.

Adju s t the cl utch c a b le fo r 1 /8” fr e e pla y. No te: B r aid e d c lutc h c able s

requ i re li t tle o r no fr e e pla y.

11

12

Apply grease to the main-shaft splines

Apply a thin coat of grease to

the splines of the transmission

main-shaft to act as both a corrosion inhibitor, & lubricant.

The grease also acts as a cushion for the splines on the transmission main-shaft during

operation.

Install washer as needed.

A .100” washer may be

needed behind the front

pulley on some Dyna-Glide

& Softail applications.

5B

7

Install rear pulley & belt.

Install the rear pulley (clutch basket) & belt. Apply 2 drops of blue

thread-lock to the main-shaft

threads as shown. INSTALL THE

CLUTCH HUB NUT (WITH SEAL),

& TIGHTEN TO 70-80 FOOT

POUNDS OF TORQUE. The center adjustment screw/sealed nut

combination prevents transmission oil from leaking thru the

main-shaft into the clutch pack.

Install front pulley, washer & inner/outer

guides. Use 1-2 drops of blue threadlock on the threads of the motor shaft.

INSTALL & TIGHTEN NUT TO FACTORY

SPECS (150-165 FOOT POUNDS) using

a quality torque wrench or air impact

driver.

2

6

8

Belt s houl d h ave 3 / 4”-t o -1” o f u p & do w n play w hen the d r ive t r a in is co l d. Re - i nst a l l the o u ter p r imar y

cove r an d che c k b e l t c l eara n ce. I nsta l l a louv e red o r v ent e d de r by o r in s pect i on c o ver, a n d yo u ’re read y

to ride . C h eck be l t t e nsio n a f ter th e driv e t r ain re a ches no r mal op e rati n g t empe r atur e . T h e b elt sh o uld

feel s nug b u t not e xces s ivel y t igh t !

AT T EN T I ON!

13

BELT SHOULD HAVE

1/2” - TO - 1” UP & DOWN

PLAY WHEN THE DRIVE

TRAIN IS COLD!

Always check the clearance between the OUTER PRIMARY

COVER, & the belt drive assembly PRIOR TO OPERATING THE

MOTORCYCLE with a new belt drive, particularly with 95 and

later motorcycles.

3

WEAR COMPENSATION ADJUSTMENTS

Pro-Clutch clutch-pack requires no immediate adjustment, the clutch pack height having been set at the factory.

After significant mileage, some adjustment may be necessary due to normal wear. Use procedures outlined

below when adjustment is required. For best all around performance the spring should be compressed to within

.010” of being flat! This will provide best clutch lever action at the handlebar, & normal spring pressure to the

clutch pack. Slightly more clutch pressure can be gained with the diaphragm spring with .030” of spring height

(outward bow), but this will increase slightly the hand effort needed to operate the clutch. This spring configuration can be obtained by placing a small diameter washer on each of the clutch hub studs, as shown in photo B!

Three clutch spring strengths are available: A stock equivalent spring (black), a medium spring for street performance applications (silver ), & a competition spring (gold) for drag race only applications.

BRUTE III CLUTCH PACK HEIGHT = 1.715”-1.745”

If when installed the diaphragm spring is not compressed

to within .010”-to.020” of being flat (as measured at the

outer edge of the spring) optimum clutch function will not

be available. To increase compression a special .028”

washer can be installed on each shoulder nut as shown.

When adjusted correctly a typical diaphragm spring will

provide more than twice the spring pressure of it’s coil

spring counterpart. Rivera offers three different

diaphragm springs. Stock, medium, and heavy for any

street or competition applications

If when installed diaphragm spring is completely flat, or

the center of the spring is pushed past the point of being

flat, (excessive compression) correct spring function will

not be available. To reduce diaphragm spring compression, a special .022” flat washer can be installed on each

of the clutch hub studs as shown at right. Always check

the compression or curvature of the spring with a quality

straight edge.

correct

incorrect

IMPORTANT INFORMATION

LIMITED WARRANTY:

All pulleys are warranted to be free from defects in material and workmanship under normal use for a period of one year from

actual date of purchase. Seller’s liability shall be limited to repair or replacement of any materials found to be defective, free

of charge at it’s plant or authorized service depots, of specific manufactures components. It is further warranted that products

that were designed for a specific purpose, shall perform for that purpose when installed exactly as defined in the Installation

Instructions accompanying the unit. In no event shall Rivera Primo Inc. or seller be liable for consequential or special damages asserted to be attributed to malfunction of our product, for any reason including, but not limited to, damage asserted to

be from improper installation of our purchased Primary Belt Drive components.

This warranty shall not apply to any products which have been subjected to abuse, neglect or accident, nor shall it apply to

any product which has been repaired or modified by any person not specifically authorized in writing by the manufacturer.

THERE IS NO WARRANTY ON BELTS.

and used, Gates Rubber Company will not warranty any belt for length of service. Regardless of belt type, keeping your

system free of debris and other objects is most important. Remember too, improper handling of the belt can shorten service

life. Do not crimp the belt. Do not twist the belt. Do not pry the belt onto the application. If you’re shipping or storing, try to

eliminate forward and back-bending of the belt.

LIMITATION OF LIABILITY:

THERE ARE NO IMPLIED WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE OF ANY SHIPMENT AND THERE IS NO IMPLIED WARRANTY OF MERCHANTABILITY AND FITNESS EXCEPT THAT THE MATERIAL

SOLD HEREUNDER SHALL BE OF SELLER’S STANDARD QUALITY, and buyer assumes all risk and liability for all loss,

damage or injury to person or property resulting from the use of said material in manufacturing processes or in combination

with other substances, or otherwise. Except as otherwise provided herein quality shall be in accordance with seller’s specifications. Final determination of the suitability of the material for the use contemplated by buyer is the sole responsibility of

buyer, and seller shall have no responsibility in connection with such suitability.

Due to the differing conditions and circumstances under which all belts are installed

RIV E R A P RIMO I n c .

12450 Whittier Blvd, WHITTIER, CA 90602

(562) 907-2600 FAX (562) 907-2606 E-mail: info1@riveraprimoinc.com

www.riveraprimoinc.com

4

Loading...

Loading...