RIDGID 600-I, 690-I User Manual

Power Drives Manual

600-I/690-I

• Français – 15

• Castellano – pág. 31

600-I/690-I Power Drives

Table of Contents

Recording Form for Machine Serial Number..............................................................................................................1

Safety Symbols..............................................................................................................................................................2

General Power Tool Safety Warnings

Work Area Safety........................................................................................................................................................2

Electrical Safety ..........................................................................................................................................................2

Personal Safety ..........................................................................................................................................................3

Power Tool Use and Care ..........................................................................................................................................3

Service ........................................................................................................................................................................3

Specific Safety Information

Power Drive Safety ....................................................................................................................................................4

Description, Specifications and Standard Equipment

Description ..................................................................................................................................................................4

Specifications..............................................................................................................................................................5

Standard Equipment ..................................................................................................................................................5

Pre-Operation Inspection ............................................................................................................................................6

Set-Up and Operation ..................................................................................................................................................7

Installing Die Heads ....................................................................................................................................................7

Resisting Threading Forces ........................................................................................................................................8

Threading....................................................................................................................................................................9

Inspecting Threads ..................................................................................................................................................10

Maintenance Instructions

Cleaning....................................................................................................................................................................11

Changing Dies in 11-R Die Heads ............................................................................................................................11

Replacing Brushes in Motor......................................................................................................................................11

Accessories............................................................................................................................................................11-12

Machine Storage..........................................................................................................................................................12

Service and Repair......................................................................................................................................................12

Threading Oil ..............................................................................................................................................................12

Disposal ......................................................................................................................................................................12

Troubleshooting..........................................................................................................................................................13

EC Declaration of Conformity ..........................................................................................................Inside Back Cover

Lifetime Warranty ........................................................................................................................................Back Cover

*Original Instructions - English

ii

999-999-476.10_REV. D

Power Drives

600-I/690-I

WARNING!

Read this Operator’s Manual

carefully before using this

tool. Failure to understand

and follow the contents of

this manual may result in

electrical shock, fire and/or

serious personal injury.

600-I/690-I Power Drives

Record Serial Number below and retain product serial number which is located on nameplate.

Serial

No.

600-I/690-I Power Drives

Safety Symbols

In this operator’s manual and on the product, safety symbols and signal words are used to communicate important safety information. This section is provided to improve understanding of these signal words and symbols.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER

WARNING

CAUTION

NOTICE

NOTICE indicates information that relates to the protection of property.

This symbol means read the operator’s manual carefully before using the equipment. The operator’s manual contains

important information on the safe and proper operation of the equipment.

This symbol means always wear safety glasses with side shields or goggles when handling or using this equipment to reduce

the risk of eye injury.

This symbol indicates the risk of fingers, hands, clothes and other objects catching on or between gears or other rotating parts

and causing crushing injuries.

This symbol indicates the risk of electrical shock.

This symbol indicates the risk of machine tipping, causing striking or crushing injuries.

This symbol means do not wear gloves while operating this machine to reduce the risk of entanglement.

This symbol means use support device to resist the threading forces, improve control, and reduce the risk of striking, crushing, and/or other injuries.

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

General Power Tool Safety

Warnings

Read all safety warnings, instructions, illustrations

and specifications provided with this power tool.

Failure to follow all instructions listed below may

result in electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS

The term "power tool" in the warnings refers to your

mains-operated (corded) power tool or battery-operated

(cordless) power tool.

Work Area Safety

• Keep your work area clean and well lit. Cluttered or

dark areas invite accidents.

• Do not operate power tools in explosive atmo-

spheres, such as in the presence of flam mable

*

WARNING

FOR FUTURE REFERENCE!

liquids, gases, or dust. Power tools create sparks

which may ignite the dust or fumes.

• Keep children and bystanders away while operat-

ing a power tool. Distractions can cause you to lose

control.

Electrical Safety

• Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any adap ter plugs with earthed (grounded) power tools.

Un modified plugs and matching outlets will reduce

risk of electric shock.

• Avoid body contact with earthed or grounded sur-

faces such as pipes, radiators, ranges and refrigerators. There is an increased risk of electrical shock

if your body is earthed or grounded.

• Do not expose power tools to rain or wet condi-

tions. Water entering a power tool will increase the risk

of electrical shock.

* The text used in the General Power Tool Safety Warnings section of this manual is verbatim, as required, from the applicable EN 62841-1 standard. This sec-

tion contains general safety practices for many different types of power tools. Not every precaution applies to every tool, and some do not apply to this tool.

2

600-I/690-I Power Drives

• Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords increase

the risk of electric shock.

• When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a

cord suitable for outdoor use reduces the risk of electric shock.

• If operating a power tool in a damp location is

unavoidable, use a Ground Fault Circuit Interrupter

(GFCI) protected supply. Use of a GFCI reduces

the risk of electric shock.

Personal Safety

• Stay alert, watch what you are doing and use common sense when operating a power tool. Do not

use a power tool while you are tired or under the

influence of drugs, alcohol, or medication. A mo -

ment of inattention while operating power tools may

result in serious personal injury.

• Use personal protective equipment. Always wear

eye protection. Protective equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce

personal injuries.

• Prevent unintentional starting. Ensure the switch

is in the OFF-position before connecting to power

source and/or battery pack, picking up or carrying

the tool. Carrying power tools with your finger on the

switch or energizing power tools that have the switch

ON invites accidents.

• Remove any adjusting key or wrench before turn-

ing the power tool ON. A wrench or a key left

attached to a rotating part of the power tool may result

in personal injury.

• Do not overreach. Keep proper footing and bal-

ance at all times. This enables better control of the

power tool in unexpected situations.

• Dress properly. Do not wear loose clothing or

jewel ry. Keep your hair and clothing away from

moving parts. Loose clothes, jewelry, or long hair

can be caught in moving parts.

• If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used. Use of dust collection

can reduce dust-related hazards.

• Do not let familiarity gained from frequent use of

tools allow you to become complacent and ignore

tool safety principles. A careless action can cause

severe injury within a fraction of a second.

Power Tool Use and Care

• Do not force the power tool. Use the correct power

tool for your application. The correct power tool will

do the job better and safer at the rate for which it is

designed.

• Do not use power tool if the switch does not turn it

ON and OFF. Any power tool that cannot be controlled with the switch is dangerous and must be

repaired.

• Disconnect the plug from the power source and/or

remove the battery pack, if detachable, from the

power tool before making any adjustments, changing accessories, or storing power tools. Such pre-

ventive safety measures reduce the risk of starting

the power tool accidentally.

• Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the pow er tool or these instructions to operate the power

tool. Power tools are dangerous in the hands of

untrained users.

• Maintain power tools and accessories. Check for

misalignment or binding of moving parts, breakage

of parts and any other condition that may affect the

power tool’s op er ation. If damaged, have the power

tool repaired before use. Many accidents are caused

by poorly maintained power tools.

• Keep cutting tools sharp and clean. Properly main-

tained cutting tools with sharp cutting edges are less

likely to bind and are easier to control.

• Use the power tool, accessories and tool bits etc.

in accordance with these instructions, taking into

account the working conditions and the work to be

performed. Use of the power tool for operations dif-

ferent from those intended could result in a hazardous

situation.

• Keep handles and grasping surfaces dry, clean

and free from oil and grease. Slippery handles and

grasping surfaces do not allow for safe handling and

control of the tool in unexpected situations.

Service

• Have your power tool serviced by a qualified repair

person using only identical replacement parts.

This will ensure that the safety of the power tool is

maintained.

3

600-I/690-I Power Drives

Specific Safety Information

WARNING

This section contains important safety information

that is specific to this tool.

Read these precautions carefully before using the

power drives to reduce the risk of electrical shock

or serious personal injury.

SAVE THESE INSTRUCTIONS!

Keep this manual with the machine for use by the operator.

Power Drive Safety

• Always use the support device provided with the

tool. Loss of control during operation can result in

personal injury.

• Keep sleeves and jackets buttoned while operating

the tool. Do not reach across the tool or pipe.

Clothing can be caught by the pipe or the tool resulting

in entanglement.

• Only one person must control the work process

and tool operation. Additional people involved in the

process may result in unintended operation and personal injury.

• Keep floors dry and free of slippery materials

such as oil. Slippery floors invite accidents.

• Do not wear gloves while operating the tool. Do

not reach across the tool or pipe. Gloves can be

caught by the pipe or the tool resulting in entanglement.

• Always firmly hold the power drive when threading

or backing die head off the pipe to resist threading

forces, regardless of support device use. This will

reduce the risk of striking, crushing and other injuries.

• Follow instructions on proper use of this machine.

Do not use for other purposes such as drilling

holes or turning winches. Other uses or modifying

this machine for other applications may increase the

risk of serious injury.

• Do not use this power drive if ON/OFF switch is

broken. This switch is a safety device that lets you

shut off the motor by releasing the switch.

• Only use RIDGID die heads with RIDGID Power

Drives Other die heads may not fit correctly in the

power drive increasing the risk of equipment damage and personal injury.

If you have any question concerning this RIDGID®product:

– Contact your local RIDGID distributor.

– Visit RIDGID.com to find your local RIDGID con-

tact point.

– Contact Ridge Tool Technical Service Department at

rtctechservices@emerson.com, or in the U.S. and

Canada call (800) 519-3456.

Description, Specifications and

Standard Equipment

Description

The RIDGID®Model 600-I and 690-I Power Drives are

double insulated drives that provide power for threading

pipe and conduit. Forward and Reverse rotation can be

selected with a slide switch while ON/OFF is controlled by

a two-step momentary contact switch.

The 600-I Power Drive is designed to use RIDGID 11-R

Drop Head Die Heads (1/8" – 11/4" pipe). The 690-I Power

Drive is designed to use RIDGID 11-R Drop Head Die

Heads (1/8" – 2" pipe). An adapter is required for use of the

690-I Power Drive with the 1/8" – 11/4" sizes. The adapter

and the 11/2" – 2” sizes are held in the 690-I Power Drive

using a Retaining Mechanism.

Warning

Handle

Warning

Label (All)

Figure 1 – Model 600-I Power Drive

Label (120V)

Brush

Cap

Gear Housing

Fan Housing

Motor

F/R

Switch

ON/OFF Switch

Serial Plate

Brush Cap

Handle

Cord

• Do not use dull or damaged dies. Sharp cutting

tools require less torque and the power drive is easier

to control.

• Keep handles dry and clean; free from oil and

grease. Allows for better control of tool.

4

999-999-476.10_REV. D

600-I/690-I Power Drives

Warning

Label (All)

Drive

Ring

Handle

Warning

Label (120V)

Brush

Cap

Fan Housing

Gear Housing

F/R

Switch

Serial Plate

Brush Cap

Motor

Handle

Cord

ON/OFF

Switch

600-I Power Drive and 690-I Power Drive machine serial

number plate is located on the bottom of motor housing.

The last 4 digits of the serial number indicate the month

and year of the manufacture (MMYY).

Figure 4 – Machine Serial Number

Figure 2 – Model 690-I Power Drive

Standard Equipment

The Model 600-I/690-I Power Drives come with the following items:

• Power Drive

• 690-I Adapter (690-I only)

• Operator’s Manual

NOTICE

Selection of appropriate materials and installation, joining and forming methods is the responsibility of

the system designer and/or installer. Selection of improper materials and methods could cause system failure.

Figure 3 – 602/692 Support Arms

Stainless steel and other corrosion resistant materials

can be contaminated during installation, joining and form-

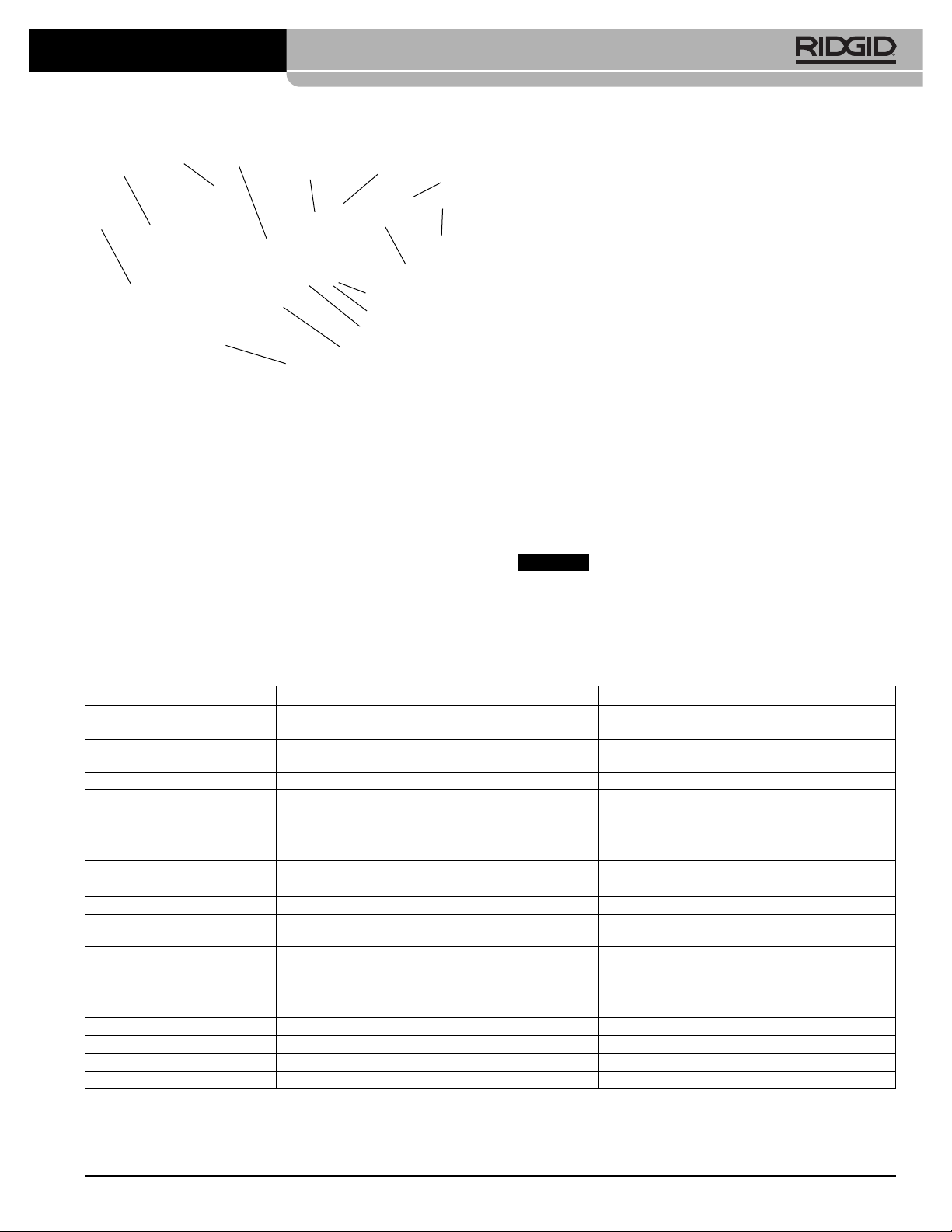

Specifications

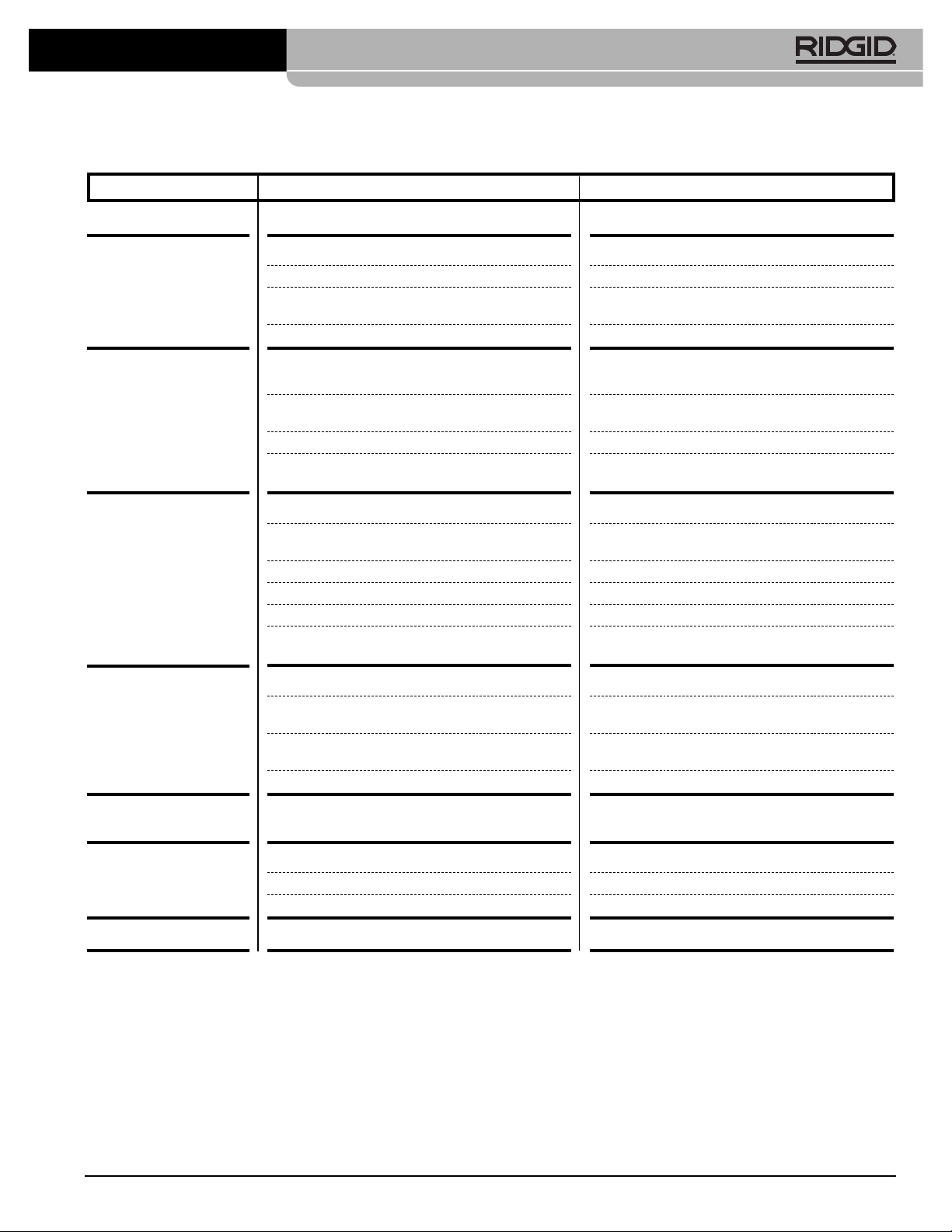

Parameter 600-I Power Drive 690-I Power Drive

Pipe Threading Capacity

Die Head Holding Ring Spring Retaining Mechanism (1

LH Threads Yes Yes

Support Arm No. 602, No. 601 No. 692, No. 691

Adapter Not Required. Used with

Motor Type Universal Motor, Single Phase Universal Motor, Single Phase

Watts 1270 (120V), 1020 (220-240V) 1270 (120V), 1020 (220-240V)

Voltage/Phase Available 120V/1PH, 220-240V/1PH 120V/1PH, 220-240V/1PH

Amps 12A (120V), 5A (220-240V) 12A (120V), 5A (220-240V)

Operating Speed (RPM) 36 (120V), 32 (220-240V) 36 (120V), 32 (220-240V)

Controls Forward/Reverse Slide Switch Forward/Reverse Slide Switch

Gear Head Die Cast Aluminum Permanently Greased Die Cast Aluminum Permanently Greased

Length 20 inch (508 mm) 24.13 inch (613 mm)

Width 3.75 inch (95 mm) 4.75 inch (121 mm)

Height 7.5 inch (191 mm) 8 inch (203 mm)

Weight 12.65 lbs (5.7 kg) 21.15 lbs (9.6 kg)

Sound Pressure (L

Sound Power (L

PA

)* 83 dB(A), K=3 83 dB(A), K=3

WA

)* 94 dB(A), K=3 94 dB(A), K=3

Vibration* < 2.5 m/s

* Sound and Vibration measurements are measured in accordance with a standardized test per Standard EN 62481-1.

- Vibration levels may be used for comparison with other tools and for preliminary assessment of exposure.

- Sound and vibration emissions may vary due to your location and specific use of these tools.

- Daily exposure levels for sound and vibration need to be evaluated for each application and appropriate safety measures taken when needed. Evaluation of exposure

levels should consider the time a tool is switched off and not in use. This may significantly reduce the exposure level over the total working period.

1

/8to 11/4inch

1

/8to 2 inch

(3 to 32 mm) (3 to 50 mm)

1

Ring Spring (

1

1

/8– 11/4inch)

/8" through 11/4" Die Heads.

/2– 2 inch)

ON/OFF two-step momentary contact switch ON/OFF two-step momentary contact switch

2

, K=1.5 < 2.5 m/s2, K=1.5

999-999-476.10_REV. D

5

600-I/690-I Power Drives

ing. This contamination could cause corrosion and premature failure. Careful evaluation of materials and meth ods

for the specific service conditions, including chemical and

temperature, should be completed before any installation

is attempted.

Pre-Operation Inspection

WARNING

Before each use, inspect power drive and correct

any problems to reduce the risk of serious injury

from electric shock, crushing injuries and other

causes and prevent power drive damage.

1. Make sure that the power drive is unplugged.

2. Clean any oil, grease or dirt from the power drive and

support device, including the handles and controls.

This aids inspection and helps prevent the machine or

control from slipping from your grip.

3. Inspect the power drive and support arm for the following:

• Damage or modification to the cord and plug.

• Proper assembly, maintenance and completeness.

• Damaged, misaligned or binding parts.

• Proper operation of two-step momentary contact

ON/OFF switch (Figure 5).

• Support arm gripping teeth are clean and in good

condition. Teeth can be cleaned with a wire brush.

• Presence and readability of the warning label.

• Any other condition which may prevent safe and nor-

mal operation.

If any problems are found, do not use the power

drive or support device until the problems have been

repaired.

2. Pull Up

ON

Figure 5B – Two Step Momentary Contact ON/OFF Switch

4. Inspect the cutting edges of the dies for wear, deformation, chips or other issues. Dull or damaged cutting

tools increase the amount of force required, produce

poor quality threads and increase the risk of injury.

5. Inspect and maintain any other equipment being

used per its instructions to make sure it is functioning

properly.

6. Following the Set Up and Operation instructions,

check the power drive for proper operation.

• Move the F/R (Forward/Reverse) switch to the F

position. Depress and release the ON/OFF switch

(Figure 5). Confirm that the power drive rotates in

the clockwise direction (see Figure 6) and stops

when releasing the switch.

• Repeat the process for the REVERSE (counter-

clockwise) operation. If the power drive does not

rotate in the correct direction, or the ON/OFF switch

does not control the machine operation, do not use

the machine until it has been repaired.

NOTICE

Change position of the F/R slide switch only

when the ON/OFF trigger switch is released. Allow the

power drive to come to a complete stop before reversing

the direction with the F/R slide switch. This will reduce the

risk of power drive damage.

• Depress and hold the ON/OFF switch. Inspect the

moving parts for misalignment, binding, odd noises

or any other unusual conditions. Release the ON/OFF

switch. If any unusual conditions are found, do not

use the machine until it has been repaired.

1. Push Forward

OFF

Figure 5A – Two Step Momentary Contact ON/OFF Switch

6

Figure 6A – F (FORWARD) (Clockwise) Switch Position

999-999-476.10_REV. D

Figure 6B – R (REVERSE) (Counter-Clockwise) Switch

Position

7. Release the ON/OFF switch and with dry hands

unplug the machine.

Set-Up and Operation

600-I/690-I Power Drives

• Clear, level, stable, dry location for all equipment

and operator.

• Good ventilation. Do not use extensively in small,

enclosed areas.

• Properly wired electrical outlet of the correct voltage.

If in doubt, have outlet inspected by a licensed electrician.

• Clear path to electrical outlet that does not contain

any potential sources of damage for the power cord.

2. Inspect the pipe to be threaded and associated fittings

and confirm that the selected power drive is a correct

tool for the job. See Specifications. Do not use to

thread anything other than straight stock.

WARNING

Set up and operate the power drive according to

these procedures to reduce the risk of injury from

electric shock, entanglement, striking, crushing and

other causes, and to help prevent power drive damage.

Use an appropriate support device per these instructions. Sup port devices im prove control and reduce

the risk of striking, crushing, and/or other injuries.

When using a support device other than the supplied

support arm, the support device must react against

the gear housing or fan housing. Support devices

contacting the motor housing or handle may damage

these parts or increase the risk of injury.

Always firmly hold the power drive when threading

or backing die head off the pipe to resist use forces,

regardless of support device use. This will reduce

the risk of striking, crushing and other injuries.

Do not wear gloves or loose clothing. Keep sleeves

and jackets buttoned. Loose clothing can become

entangled in rotating parts and cause crushing and

striking injuries.

Properly support pipe. This will reduce the risk of

falling pipe, tipping and serious injury.

Do not use a power drive without a properly operating ON/OFF switch and F/R slide switch.

One person must control both the work process

and the ON/OFF switch. Do not operate with more

than one person. In case of entanglement, the operator must be in control of the ON/OFF switch.

1. Check work area for:

• Adequate lighting.

• Flammable liquids, vapors or dust that may ignite.

If present, do not work in area until sources have

been identified and corrected. The power drives are

not explosion proof and can cause sparks.

Equipment for other applications can be found in the

Ridge Tool catalog, online at www.RIDGID.com or by

calling Ridge Tool Technical Service in the U.S. and

Canada at (800) 519-3456.

3. Make sure equipment to be used has been properly

inspected.

4. Properly prepare the pipe as needed. Make sure the

pipe is squarely cut and deburred. Pipe cut at an

angle can damage the dies while threading or cause

difficulty engaging the die head.

Installing Die Heads

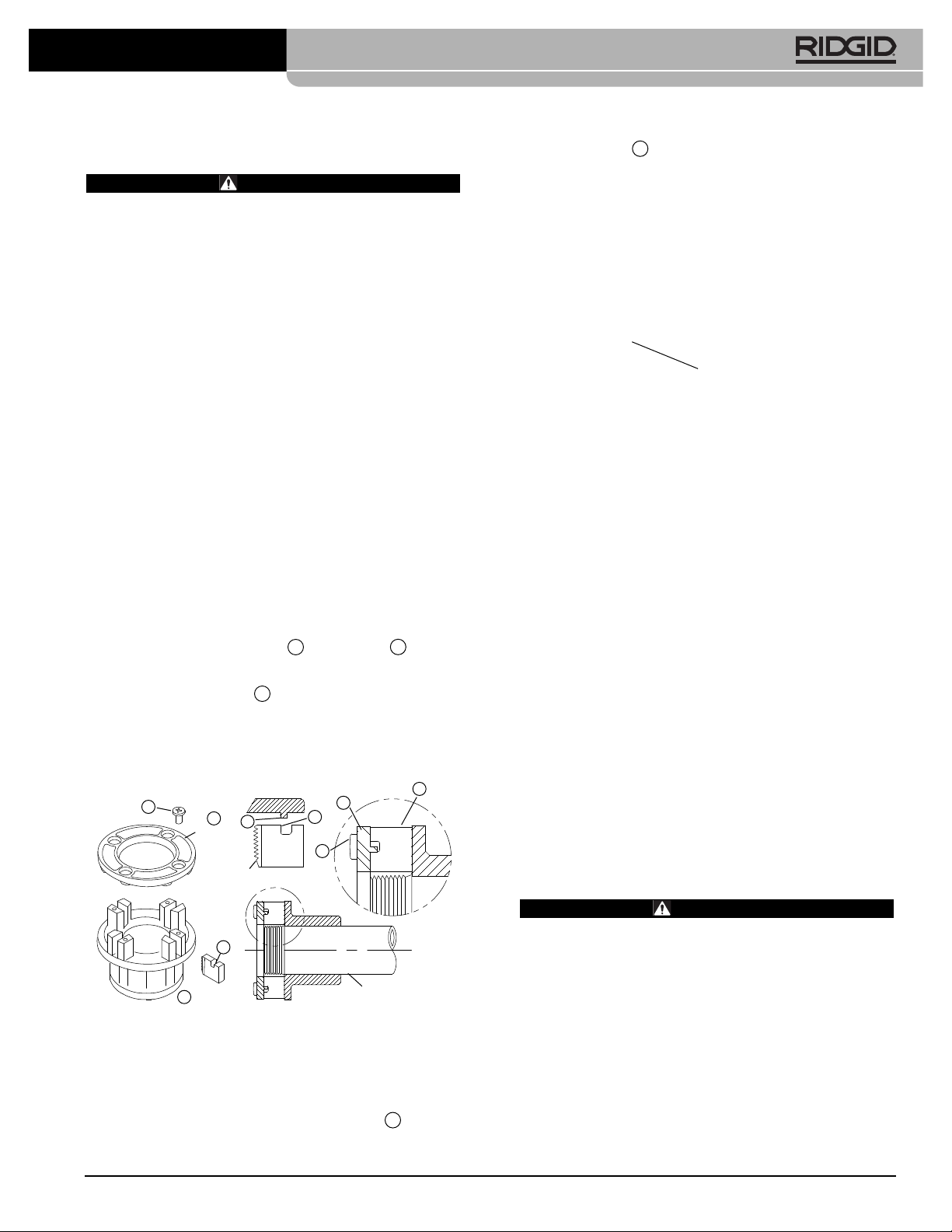

5. Installing 11/2" or 2" Die Head or Adapter in 690-I:

a. Make sure ON/OFF switch is released and power

drive is unplugged.

b. Rotate the drive ring counter-clockwise to open

the retaining mechanism. Fully insert the die head

or adapter (if required) spline end into the power

drive (Figure 7).

c. Release the drive ring and confirm that the die

head/adapter is secure.

d. Reverse process to remove.

OPEN

Closed

Open

Drive

Ring

Figure 7 – Retaining Mechanism, Drive Ring in the

Open/Closed Position

999-999-476.10_REV. D

7

OPEN

600-I/690-I Power Drives

Figure 8 – Installing Adapter Into 690-I

6. Installing 11/4" and smaller Die Heads:

a. Make sure the ON/OFF switch is released and

power drive unplugged from the outlet.

b. If needed install the adapter in the 690-I (Figure 8).

c. Squarely insert the octagonal end of the 11-R Die

Head into the power drive until secured by the

spring ring. On the 600-I, the die head can be

inserted into either side of the power drive. With the

690-I, die heads can only be inserted from the

adapter side.

d. To remove, pull die head from power drive. If

needed, use a soft face hammer or a block of

wood to tap the die head out. Do not pound on the

die head, this can damage the tool.

Spring Ring

600-I

Only

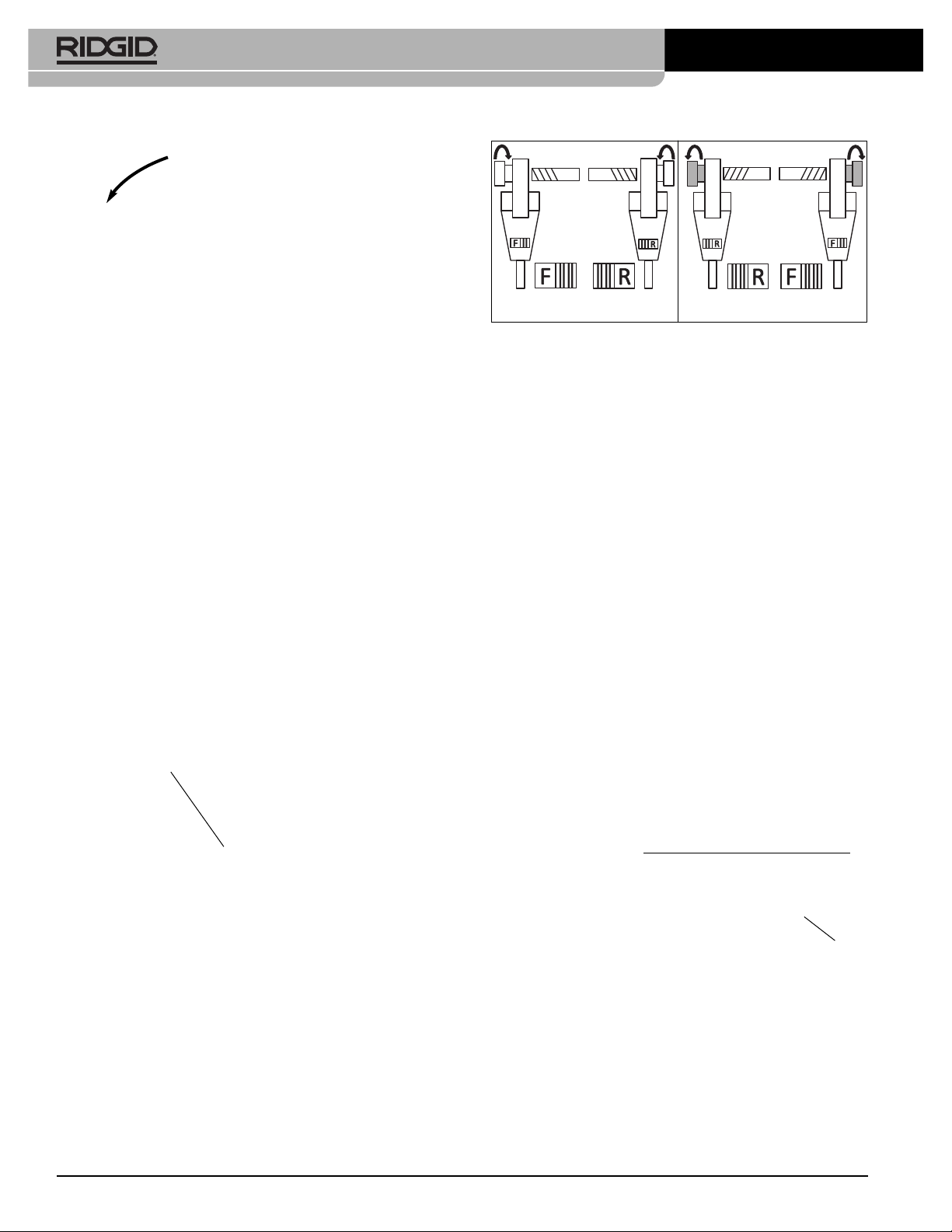

RH RH LH LH

Right Hand Thread

Figure 10 – Slide Switch/Die Head Orientation

Left Hand Thread

600-I

Only

8. Make sure that pipe to be threaded is stable and

secured to prevent tipping during use. Use appropriate pipe stands to support pipe length.

9. Check the level of RIDGID Thread Cutting Oil in the

RIDGID 418 oiler. Remove the chip tray and confirm

that the filter screen is clean and fully submerged in

oil. Replace or add oil if necessary. Place the 418

Oiler bucket under the pipe end to be threaded.

Resisting Threading Forces

Using the supplied support arm:

a. Always use the supplied support arm (601 or 602

support arm for 600-I, 691 or 692 support arm for

690-I) unless it can’t be used because of space or

other constraints. The support arm clamps to the

pipe and helps to resist the threading forces.

b. Position the support arm on pipe, so end of support

arm aligns with end of pipe and top of support

arm is horizontal (Figure 11). This properly places

the support arm for threading and prevents threading oil from entering the motor (Figure 12).

c. Make sure that the support arm jaws are squarely

aligned with the pipe and securely tighten the support arm.

Horizontal

Figure 9 – Installing Die Heads into 600-I Power Drive

7. Position the power drive F/R Slide Switch for the

desired right or left hand thread. See Figure 10.

8

Support

Arm

Figure 11A – Positioning the Support Arm

999-999-476.10_REV. D

600-I/690-I Power Drives

Aligned

Support

Arm

Figure 11B – Positioning the Support Arm

Figure 12 – Proper Orientation of the Power Drive

c. Do not place the power drive motor or handle

against adjacent structural members to react

threading forces, as this may cause power drive

damage.

d. Keep power drive against the structural member

and do not place fingers or hands between the

power drive and the structural member. When

backing die head off thread, always firmly hold

the power drive to resist forces from breaking the

thread chips. These steps will reduce the risk of

striking, crushing and other injuries. The ON/OFF

switch can be released at any time to shut OFF the

power drive.

Always firmly hold the power drive when threading or

backing die head off pipe to resist forces, regardless

of support device use. This will reduce the risk of

striking, crushing and other injuries. The ON/OFF

switch can be released at any time to shut off the

power drive.

Threading

10. With dry hands, plug in the power drive.

11. Position the die head over the pipe end and support the power drive as directed in the Resisting

Threading Forces Section.

When support arm can’t be used:

When threading pipe in place or similar application, the

support arm may not be able to be used because of

space constraints.

a. If possible remove the pipe and thread in a vise. If

this cannot be done, other support devices must be

used to help resist threading forces, such as placing the power drive gear or fan housing against an

adjacent structural member (examples include

walls, beams and joists). This requires that the

pipe and surroundings be able to withstand the

weight of the tool and the threading forces. It may

be necessary to add temporary or permanent pipe

supports or structural elements.

b. For right hand threads, die head will rotate clock-

wise (looking at the face of the Die Head). Forces

developed by the threading torque will be in the

opposite or counter-clockwise direction. Rotation

and force will be reversed for left hand threads.

Make sure that the support device is set up to

properly absorb the threading force.

Figure 13 – Starting the Thread

12. Simultaneously actuate the ON/OFF switch and push

against the Die Head cover plate with the palm of free

hand to start the thread. Do not wear gloves, jewelry

or use a rag while pushing on the cover plate – this

increases the risk of entanglement and injury. Once

the dies engage the pipe, threads will be cut as the

dies pull themselves onto the end of the pipe.

Always firmly hold the power drive handle to resist the

handle forces. Support devices can slip and allow the

999-999-476.10_REV. D

9

600-I/690-I Power Drives

power drive to move. The ON/OFF switch can be

released at any time to shut off the power drive.

13. Stop pushing on cover plate and use oiler to apply a

generous quantity of RIDGID Thread Cutting Oil to the

area being threaded. This will lower threading torque,

improve thread quality and increase die life.

Figure 14 – Threading Pipe

14. Depress ON/OFF switch until end of the pipe is even

with edge of the dies and release the switch. Let the

power drive come to a complete stop.

16. Release the switch and remove the power drive and

Die Head from the pipe.

17. With dry hands unplug the power drive.

18. Wipe oil and debris off the threads and out of the die

head, taking care not to cut yourself on sharp debris

or edges. Clean up any oil spills in the work area.

Inspecting Threads

1. Remove any oil, chips or debris from the thread.

2. Visually inspect thread. Threads should be smooth

and complete, with good form. If issues such as

thread tearing, thin threads, or pipe out-of-roundness are observed, the thread may not seal when

made up. Refer to the “Troubleshooting” chart for

help in diagnosing these issues.

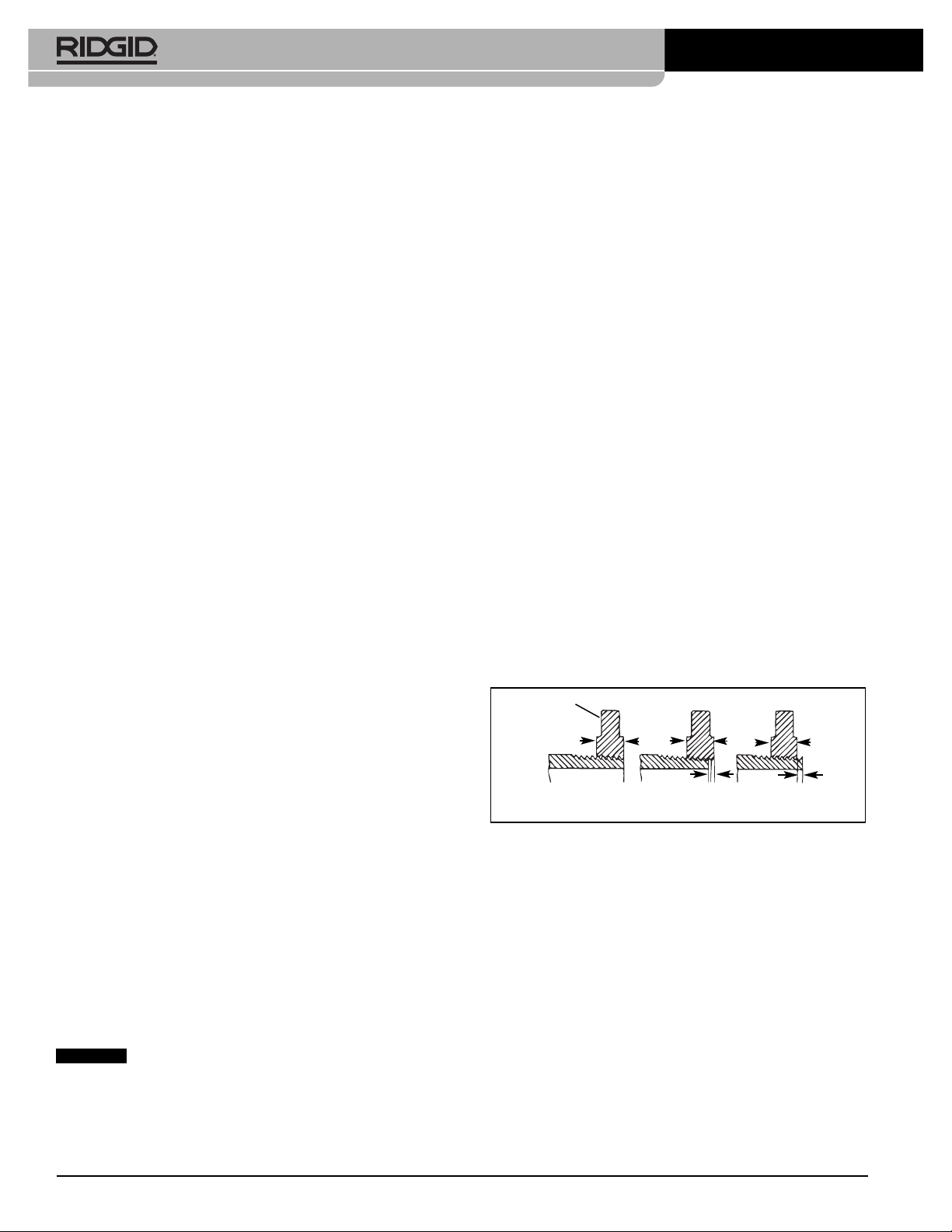

3. Inspect the size of the thread. The preferred method

of checking thread size is with a ring gauge. There are

various styles of ring gauges, and their usage may differ from that shown in Figure 16.

• Screw ring gauge onto the thread hand tight.

• Look at how far the pipe end extends through the ring

gage. The end of the pipe should be flush with the

side of the gauge plus or minus one turn. If thread

does not gauge properly, cut off the thread, adjust the

die head and cut another thread. Using a thread

that does not gauge properly can cause leaks.

Figure 15 – Pipe Even with Edge of Dies

15. Reverse the F/R slide switch and actuate the ON/OFF

switch to remove Die Head from the threaded pipe.

Hold onto the power drive handle firmly to resist the

handle forces developed while backing off the Die

Head.

NOTICE

Change position of the F/R slide switch only

when the ON/OFF switch is re leased. Allow the power

drive to come to a complete stop before reversing the

direction with the F/R slide switch. This will reduce the risk

of power drive damage.

Thin Ring

Gauge

D

Flush

(Basic Size)

Checking Threads With Ring Gauge

Figure 16 – Checking Thread Size

One Turn Large

(Maximum Size)

D

One Turn Small

(Minimum Size)

D

• If a ring gauge is not available to inspect thread

size, it is possible to use a new clean fitting representative of those used on the job to gauge thread

size. For 2" and under NPT threads, the threads

should be cut to obtain 4 to 5 turns to hand tight

engagement with the fitting and for 2" and under

BSPT threads it should be 3 turns.

10

999-999-476.10_REV. D

600-I/690-I Power Drives

Maintenance Instructions

WARNING

Make sure that the ON/OFF switch is released and

the machine is unplugged before performing any

maintenance or making any adjustments.

Maintain tool according to these procedures to

reduce the risk of injury from electrical shock,

entanglement and other causes.

Cleaning

1. After each use, empty the threading chips from the

418 Oiler chip tray and wipe out any oil residue.

2. Wipe off any oil, grease, chips or dirt from the power

drive, including the handles and controls. Clean the

690-I retaining mechanism.

3. Wipe off any oil, grease or dirt from the support arm.

If required, clean the support arm jaws with a wire

brush.

4. Remove chips and dirt from die heads.

Changing Dies in 11-R Die Heads

A variety of dies are available for installation in RIDGID

11-R Die Heads. See catalog for availability.

1. Remove the four screws from cover and re -

4

move the cover plate.

2. Remove the old dies from the die head.

3

3. Insert new dies into slots – numbered edge up.

Numbers on the dies must correspond with those

on the die head slots. Always replace dies as a set.

Screws

Figure 17 – Installing Dies In Die Head

Up

4

2

A

Cover

(Throat in Down Position)

Dies

3

1

Die Head

2

B

4

2

3

Threaded Pipe

against lugs on cover plate and properly sets the

A

size.

6. Tighten the four screws securely. Remove the threaded pipe and make a test cut.

Replacing Brushes in Motor

Check motor brushes every 6 months. Replace when

worn to less than 5/16" (8 mm).

Brush

Figure 18 – Brush Installation

1. Unplug the machine from power source.

2. Unscrew brush caps (Figures 1 and 2). Remove

and inspect brushes. Replace when worn to less

than 5/16" (8 mm). Inspect the commutator for wear. If

excessively worn, have tool serviced.

3. Re-install brushes/install new brushes and securely

tighten the brush caps.

4. It is best practice to run the unit at idle for 15 minutes

in the forward direction followed by 15 minutes in

the reverse direction to seat the brushes to the commutator before use.

Accessories

WARNING

To reduce the risk of serious injury, only use accessories specifically designed and recommended for

use with the 600-I and 690-I Power Drives such as

those listed below. Other Accessories suitable for

use with other tools may be hazardous when used

with the 600-I and 690-I Power Drives.

4. Replace the cover plate and tighten the four screws

lightly.

5. Place die head on already threaded pipe until dies

begin to thread. This forces stop on dies outward

999-999-476.10_REV. D

B

11

600-I/690-I Power Drives

600-I and 690-I Power Drive Accessories

Catalog

No. Description

45923 602 Support Arm

45928 692 Support Arm

46668 600-I Carrying Case

46673 690-I Carrying Case

10883 418 Oiler with 1 Gallon Nu-Clear Oil

16703 425

36273 460-6

1

/8" - 21/2" TRISTAND Vise

1

/8" - 6" TRISTAND Vise

Further information on accessories specific to the tool

can be found in the RIDGID Catalog and online at

RIDGID.com

Machine Storage

WARNING

well covered in rainy weather. Store the machine in a

locked area that is out of reach of children and people

unfamiliar with the machines. These machines can cause

serious injury in the hands of untrained users.

Power Drives must be kept indoors or

Service and Repair

WARNING

Improper service or repair can make machine

unsafe to operate.

Threading Oil

For information concerning RIDGID®Thread Cutting Oil

use and handling, refer to the labels on the container

and Material Safety Data Sheet (MSDS). MSDS is available at RIDGID.com or by contacting Ridge Tool Techni cal Service Department at (800) 519-3456 in U.S. and

Canada or rtctechservices@emerson.com.

Disposal

Parts of the Power Drives contain valuable materials and

can be recycled. There are companies that specialize in

recycling that may be found locally. Dispose of the components in compliance with all applicable regulations.

Contact your local waste management authority for more

information.

For EC Countries: Do not dispose of electrical equipment with household waste!

According to the European Guideline 2012/19/ EU for Waste Electrical and Electronic Equip ment and its implemen tation into national

legislation, electrical equipment that is no

longer usable must be collected separately

and disposed of in an environmentally correct manner.

The “Maintenance Instructions” will take care of most of

the service needs of this machine. Any problems not

addressed by this section should only be handled by an

authorized RIDGID service technician.

Tool should be taken to a RIDGID Independent Service

Center or returned to the factory.

For information on your nearest RIDGID Independent

Service Center or any service or repair questions:

• Contact your local RIDGID

®

distributor.

• Visit RIDGID.com to find your local RIDGID contact

point.

• Contact Ridge Tool Technical Service Department at

rtctechservices@emerson.com or in the U.S. and

Canada call (800) 519-3456.

12

999-999-476.10_REV. D

600-I/690-I Power Drives

Troubleshooting

SYMPTOM POSSIBLE REASONS SOLUTION

Machine will not run.

Machine not able to

thread.

Sparks forming at motor

commutator.

Die head does not start

threading.

Brushes do not touch armature.

Dull dies.

Overload due to torn or out-of-round threads.

Poor quality or insufficient thread cutting oil.

Insufficient line voltage.

Insufficient contact between brushes and commutator.

Brushes do not touch commutator properly.

Brushes of different manufacture.

New brushes.

Die head not square with end of pipe.

Engagement force not properly applied to the die

head.

Pipe end not squarely cut.

Dull or broken dies.

Machine running in wrong direction.

Dies set improperly in the die head.

Check brushes, replace if worn.

Replace dies.

See possible reasons below.

Use RIDGID

®

Thread Cutting Oil in adequate

quantity.

Check power supply voltage.

Tighten the brush caps to make sure brushes are

pressed firmly onto commutator.

Replace worn brushes and or armature.

Only use RIDGID®brushes.

Seat the brushes by running the unit at idle for 15

minutes in Forward and Reverse.

Push against die head cover plate to start thread.

Apply engagement force through the center line

of the pipe.

Cut the pipe end squarely.

Replace dies.

Check position of the F/R Slide Switch.

Ensure chasers are set outward against the cover

plate lugs.

Torn threads.

Out-of-round or crushed

threads.

Support device turns

while threading.

Thin Threads.

Damaged, chipped or worn out dies.

Improper or insufficient thread cutting oil.

Incorrect type of die for material.

Poor pipe material/quality.

Pipe wall thickness too thin.

Support arm jaws dirty.

Support arm not aligned properly.

Support arm not tight.

Dies not placed in proper order.

Replace dies.

Only use RIDGID

®

Thread Cutting Oil in adequate

quantity.

Select high-speed, stainless steel , or alloy dies

that are suitable for the application.

Use higher quality pipe.

Use schedule 40 or heavier wall thickness.

Clean with wire brush.

Align support arm squarely with the pipe.

Tighten feedscrew.

Place dies in proper die head slot.

999-999-476.10_REV. D

13

600-I/690-I Power Drives

14

999-999-476.10_REV. D

Loading...

Loading...