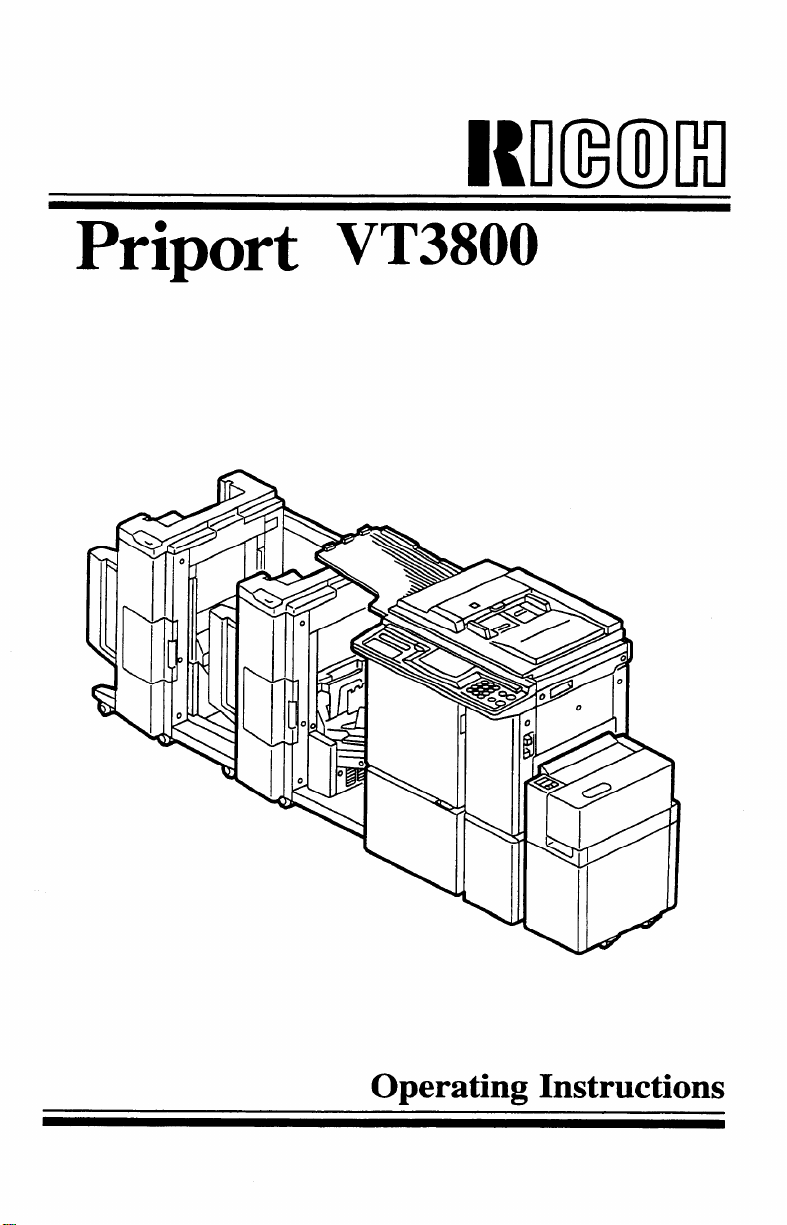

Priport VT3800

MIMI

Operating Instructions

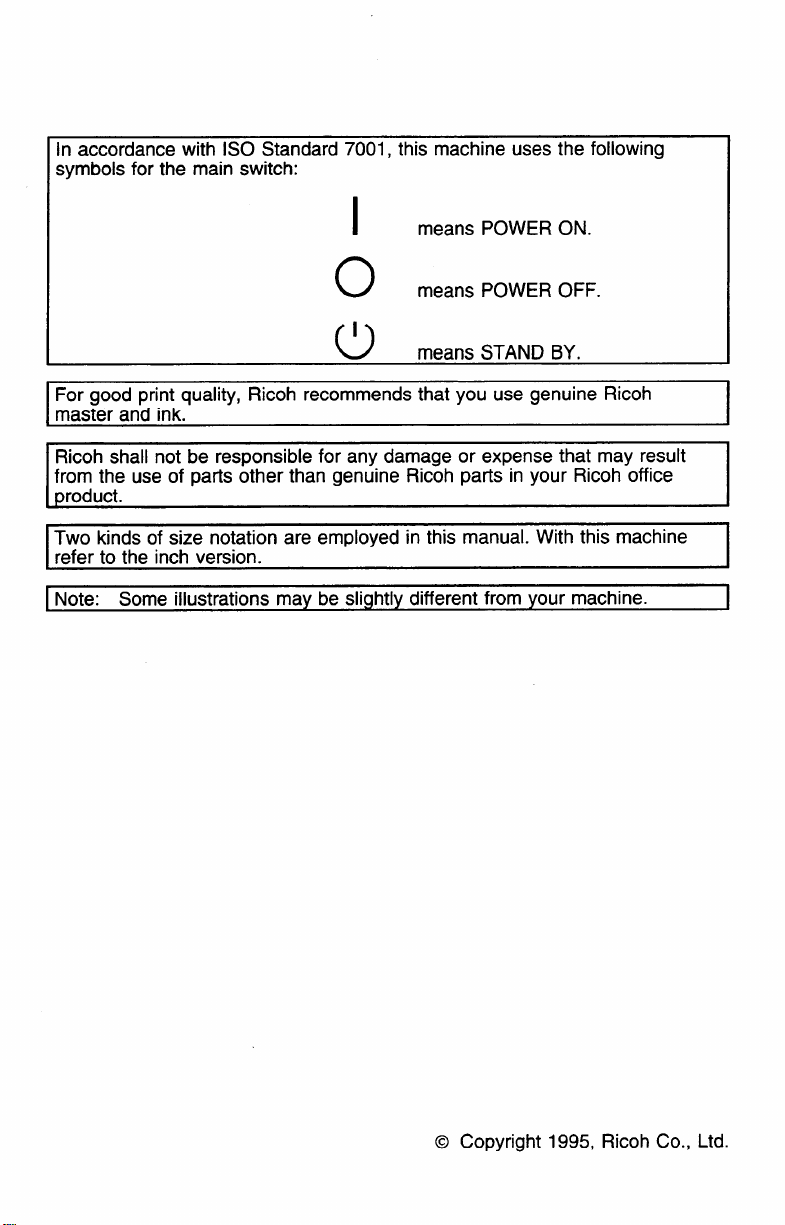

In accordance with ISO Standard 7001, this machine uses the following

symbols for the main switch:

I means POWER ON.

o

I

u means STAND BY.

For good print quality, Ricoh recommends that you use genuine Ricoh

master and ink.

Ricoh shall not be responsible for any damage or expense that may result

‘rem the use of parts other than genuine Ricoh parts in your Ricoh office

xoduct.

Two kinds of size notation are employed in this manual. With this machine

refer to the inch version.

\ Note: Some illustrations may be slightly different from your machine.

means POWER OFF.

@ Copyright 1995, Ricoh Co., Ltd.

INTRODUCTION

INTRODUCTION

This manual contains detailed instructions on the operation and care of

this machine. To get maximum versatility from this machine, all operators should read and follow the instructions in this manual. Please keep

this manual in a handy place near the machine.

SAFETY INFORMATION

When using your

ways be followed:

machine, the following safety precautions should al-

Safety During Operation

In this manual, all safety messages are identified by the words “WARNING” and “Caution”. These words mean the following:

~ WARN/NG:/rnPO~ant information to alert you

might cause serious

if instructions are not followed.

~caution:lmpoflantinformation on how to prevent damage to your equip-

ment, or how to avoid a situation that might cause minor injury.

WARNING -

-

Do not modify or replace any parts other than the ones specified in

this manual.

Since some parts of the machine are supplied with high voltage, touch

only the parts specified in this manual.

Do not operate the machine without covers. You might get your fingers

caught in the machine, or the machine might be damaged because, for

example, dust or the like might get inside it.

Since some parts of the machine are sharp and might cause injury,

touch only the parts specified in this manual.

injury and damage to your propetty

to a situation that

SAFETY INFORMATION

–

Caution –

D While printing, do not turn off the main switch.

n While printing, do not open the door or covers.

o While printing, do not unplug the power cord.

a While printing, do not move the machine.

n Keep corrosive liquids, such as acid, off the machine.

a Do not allow paper clips, staples, or other small objects to fall inside the

machine.

a Open and close the door and covers softly.

a Do not put anything except originals or command sheets on the machine.

n Do not spill liquid on the machine.

o When opening or closing the door or covers, keep hold of them so they don’t

full.

a If you clean rubber parts with benzine, wipe them with a dry cloth afterwards.

General Safety Information

D Always turn the machine off when you have finished printing for the day.

D When the machine will not be used for long periods, disconnect the power

cord.

D If the machine must be transported

by vehicle, please contact your service

representative.

ii

Section 7

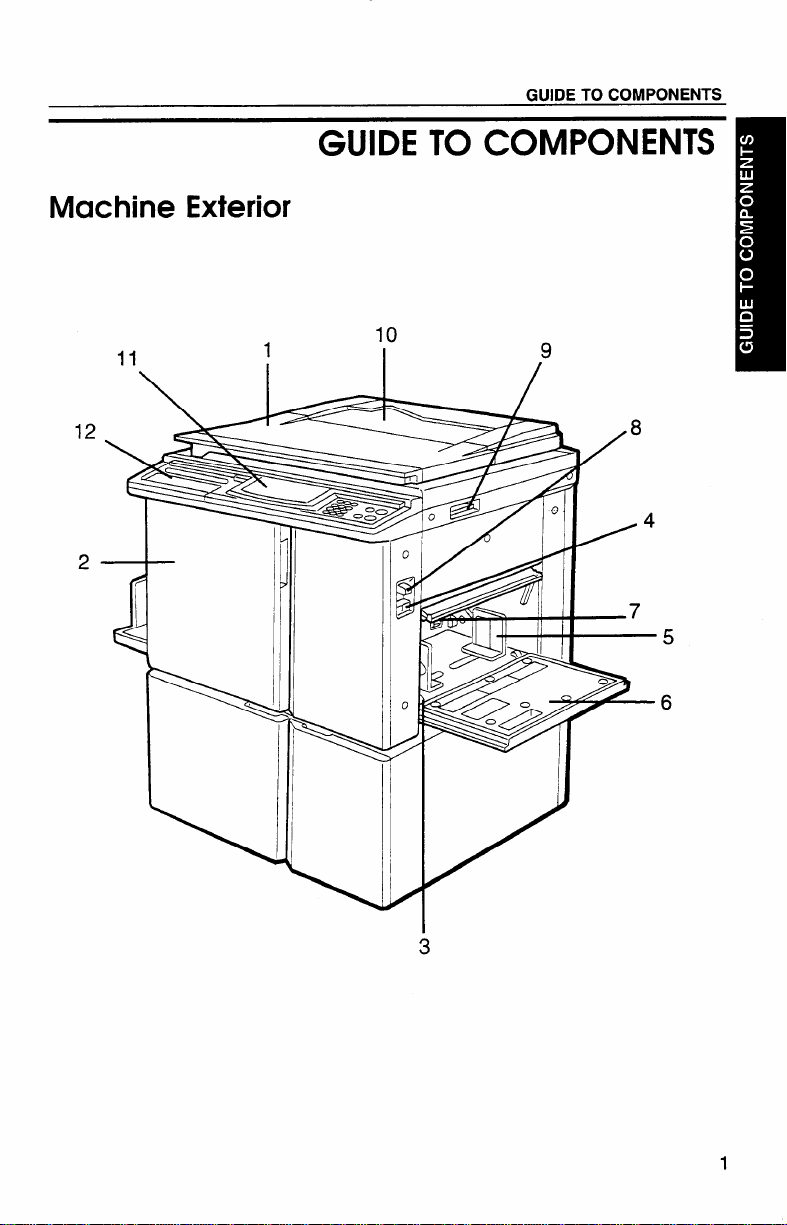

Machine Exterior

GUIDE TO COMPONENTS

GUIDE TO COMPONENTS

11

1

\/

10

I

,9

8

/

/4

—7

0

J

/

3

1

GUIDE TO COMPONENTS

Platen Cover

1.

2*

Front Door

Side Plate Fine

3.

Adjusting Dial

4.

Paper Feed Table

Down key

or

Change Paper key

Paper Feed Side

5.

Plates

Paper Feed Table

6.

7.

Separation Roller

Pressure Levers

Feed Roller

8.

Pressure Lever

9.

Original Table

Release Lever

10.

Original Holder

Lower this cover over an original before printing.

Open for access to the inside of the machine.

Use to shift the paper feed table sideways.

Press to lower the paper feed table.

When you have an optional large capacity tray,

this key is used to remove paper.

Use to prevent paper skew.

Set paper on this table for printing.

Use to adjust the separation roller pressure to

prevent double feed.

Use to adjust the contact pressure of the paper feed roller according to paper thickness.

Use to open the original table unit when installing the master.

Convenient place for holding originals while operating the machine.

11.

Operation Panel

12.

Behind Cover

2

Operator controls and indicators are located

here. = See page 6.

Open to access the CS Mode key and so on.

= See page 6.

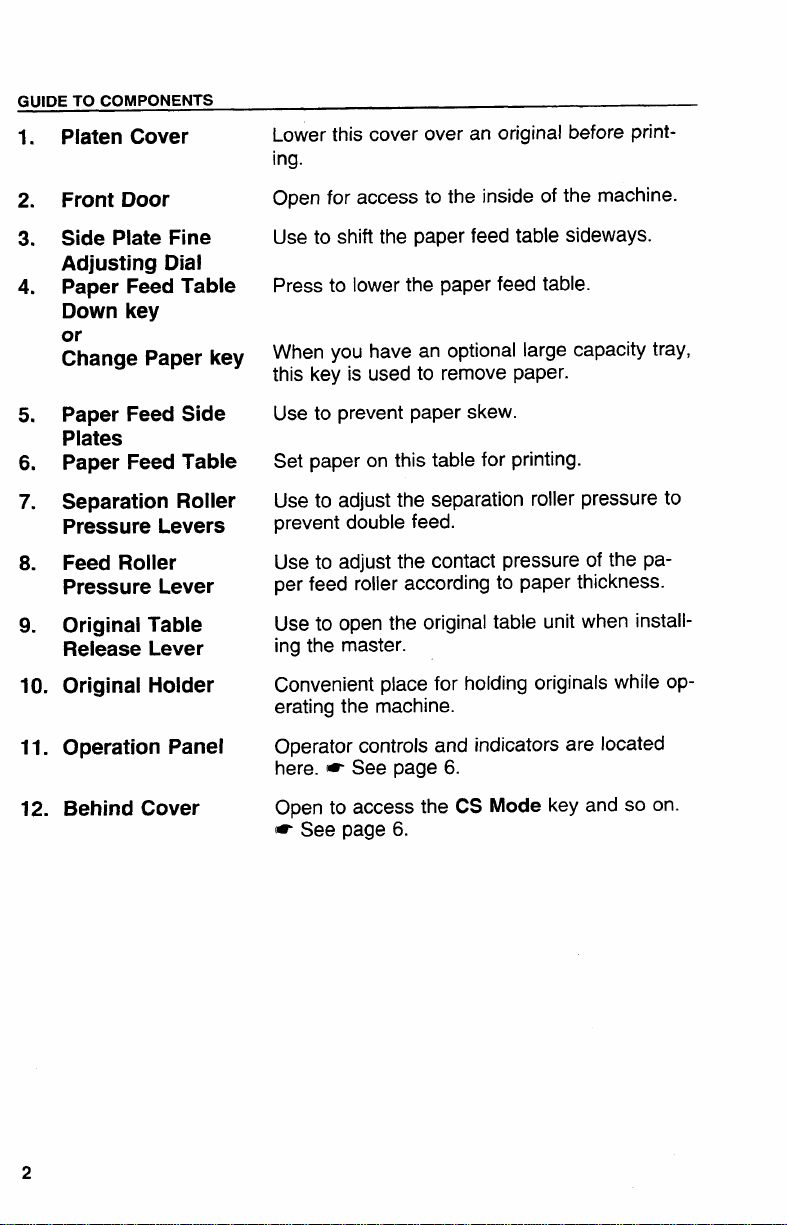

Machine Interior

GUIDE TO COMPONENTS

1

13

12

)

’10

‘9

1

7

3

GUIDE TO COMPONENTS

Main Switch

1.

Use to turn the power on or off.

Master Eject

2.

Container Cover

Paper Delivery Side Use to align the prints on the paper delivery ta-

3.

Plates

Paper Delivery End Use to align the leading edge of prints larger

4.

Plate

Small Size Paper

5.

Delivery End Plate

Paper Delivery Table Completed prints are delivered here.

6.

Ink Holder

7.

Drum Unit

8.

Drum Unit Lock

9.

Lever

Drum Rotation

o*

1

Button

Pressure Release

11.

Lever

Master Cut Button

12.

Master Eject Unit

13.

Open Button

Open when removing the master eject box.

ble.

than A4, 81/2” x 11”.

Use to align the leading edge of prints that are

A4, 81/2” x 11” or smaller.

Set the ink cartridge in this holder.

The master is wrapped around this unit.

Lift to unlock and pull out the drum unit.

Press to rotate the drum unit.

Use to install the master roll.

Press this button to cut the master leading

edge after installing a new master roll.

Press to remove misfed paper or a misfed mas-

ter.

4

GUIDE TO COMPONENTS

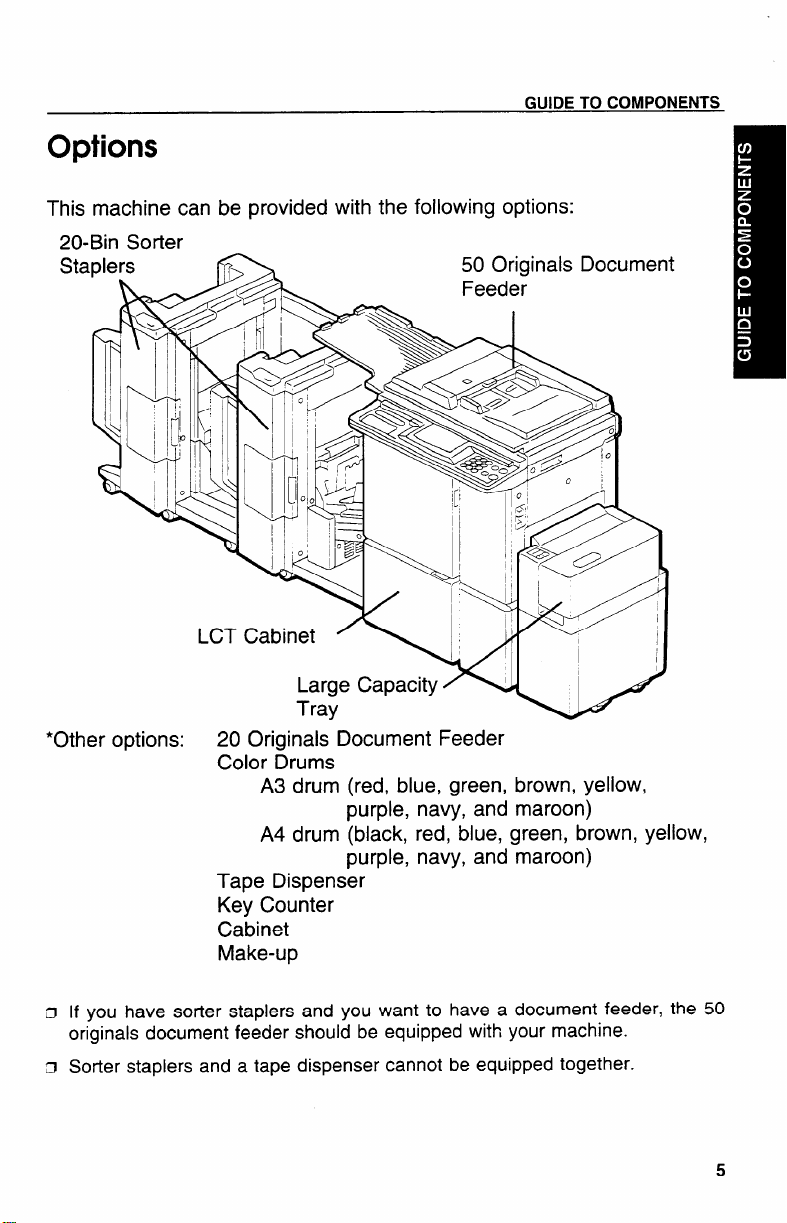

Options

This machine can be provided with the following options:

20-Bin Sorter

Sta

*Other options:

20 Originals Document Feeder

Color Drums

A3 drum (red, blue, green, brown, yellow,

purple,

A4 drum (black,

purple,

navy, and maroon)

red, blue, green, brown, yellow,

navy, and ‘maroon)

Tape Dispenser

Key Counter

Cabinet

Make-up

D If you have sorter staplers and you want to have a document feeder,

originals document feeder should be equipped with your machine.

C!JSorter staplers and a tape dispenser cannot be equipped together.

the 50

5

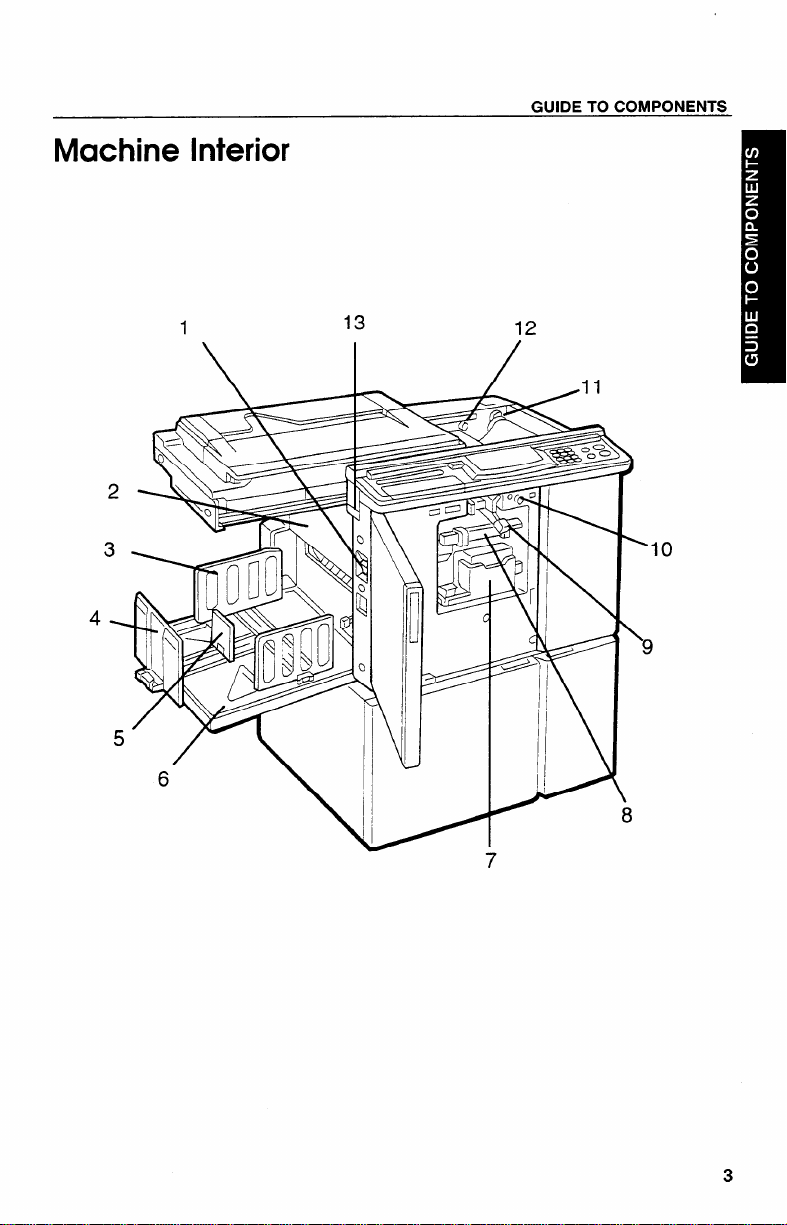

Operation Panel

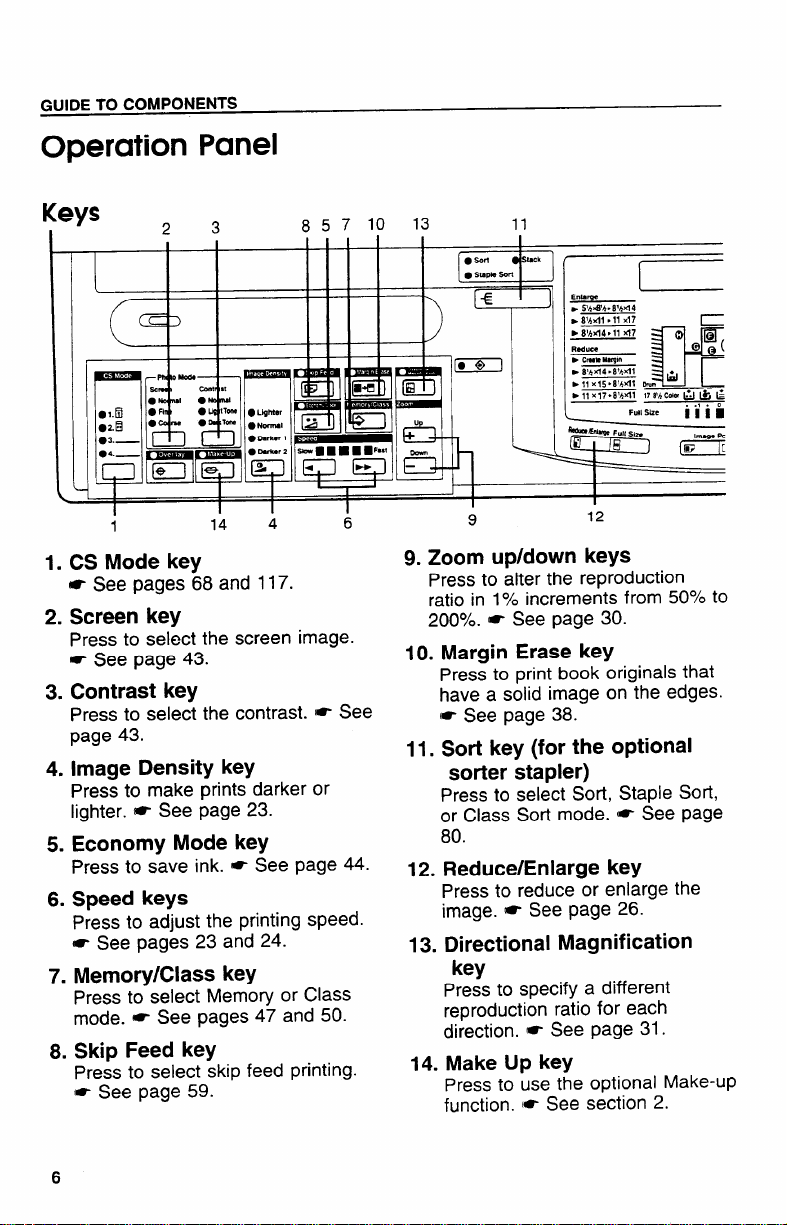

Keys

L

9 3

/

11(91

{

CS Mode key

1.

- See pages 68 and 117.

2.

Screen key

Press to select the screen image.

* See page 43.

Contrast key

3.

Press to select the contrast. ~ See

page 43.

Image Density key

4.

Press to make prints darker or

lighter. - See page 23.

Economy Mode key

5.

Press to save ink. * See page

Speed keys

6.

Press to adjust the printing speed.

e See pages 23 and 24.

Memory/Class key

7.

Press to select Memory or Class

mode. ~ See pages 47 and 50.

Skip Feed key

8.

Press to select skip feed printing.

[- See page 59.

Ii :

8571013

k

44.

11

I

tack

sod

.

staplesort

.

9

● s

1’

E“lm’w?

w 5’h&h. 81hM4

●

“8’hf14’” “7 = k

1

8’A41 .11 x17

12

9. Zoom up/down keys

Press to alter the reproduction

ratio in 1YOincrements from 50”/0 to

200%. I= See page 30.

10. Margin Erase key

Press to print book originals that

have a solid image on the edges.

{* See page 38.

11. Sort key (for the optional

sorter stapler)

Press to select Sort, Staple Sort,

or Class Sort mode. * See page

80.

12. Reduce/Enlarge key

Press to reduce or enlarge the

image. ~ See page 26.

13.

Directional Magnification

key

Press to specify a different

reproduction ratio for each

direction. * See page 31.

Make Up key

14.

Press to use the optional Make-up

function. * See section 2.

GUIDE TO COMPONENTS

,4 ., ,,,...

= =

19

~~ ), [ “;’‘) ‘+ ‘] ‘b l[@’ ]

rge

‘h@h.8’hX14

,..11

.11 .17 ~ n.., mm

E.KF%

Ia-. J2. II mm u 1

17.8VI*1 178’h c*&& a ti*Ba u

- Full SIZe

ID

Full Sm.

15

J

..! .0..1..2

II In II II

Image Posltl.an

[ml Im

1

1

1’6

1

Id “

)

u

.2 .4

M“nl COPY

=

17

IJlle

LMmmOlo

Pk.t.a

18

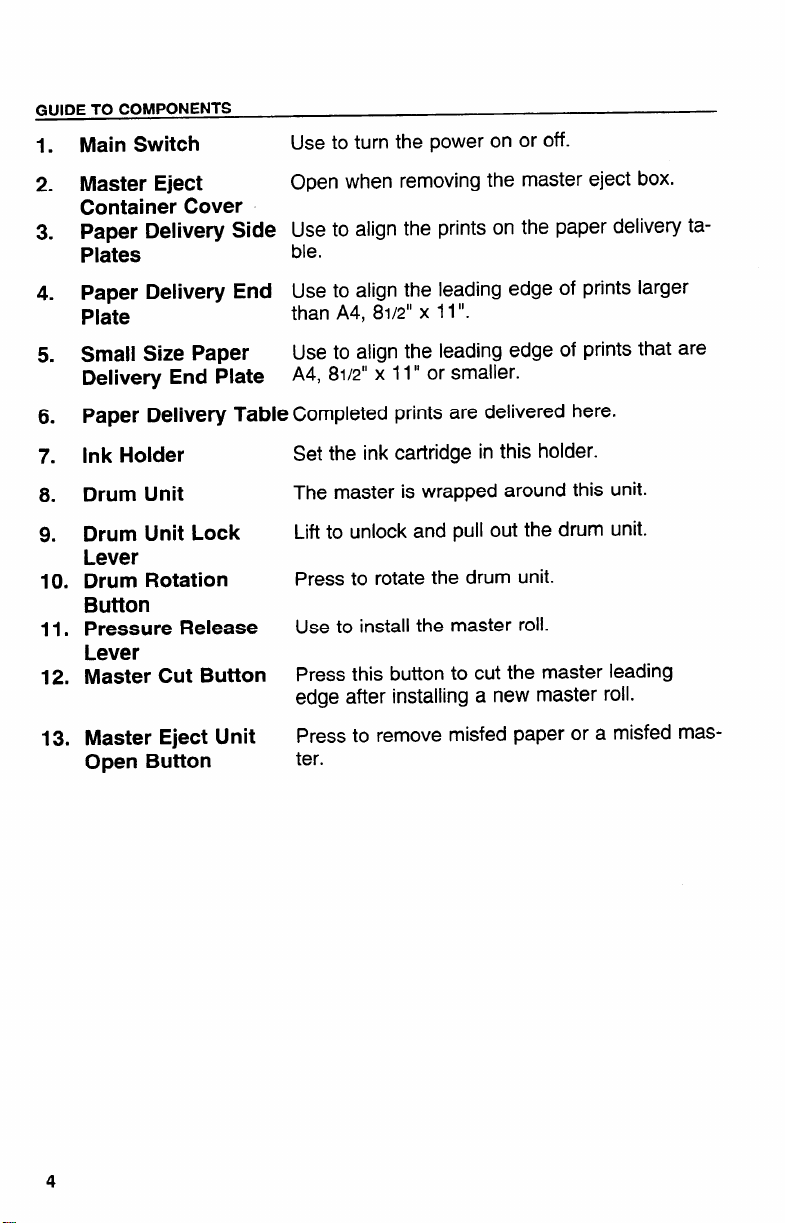

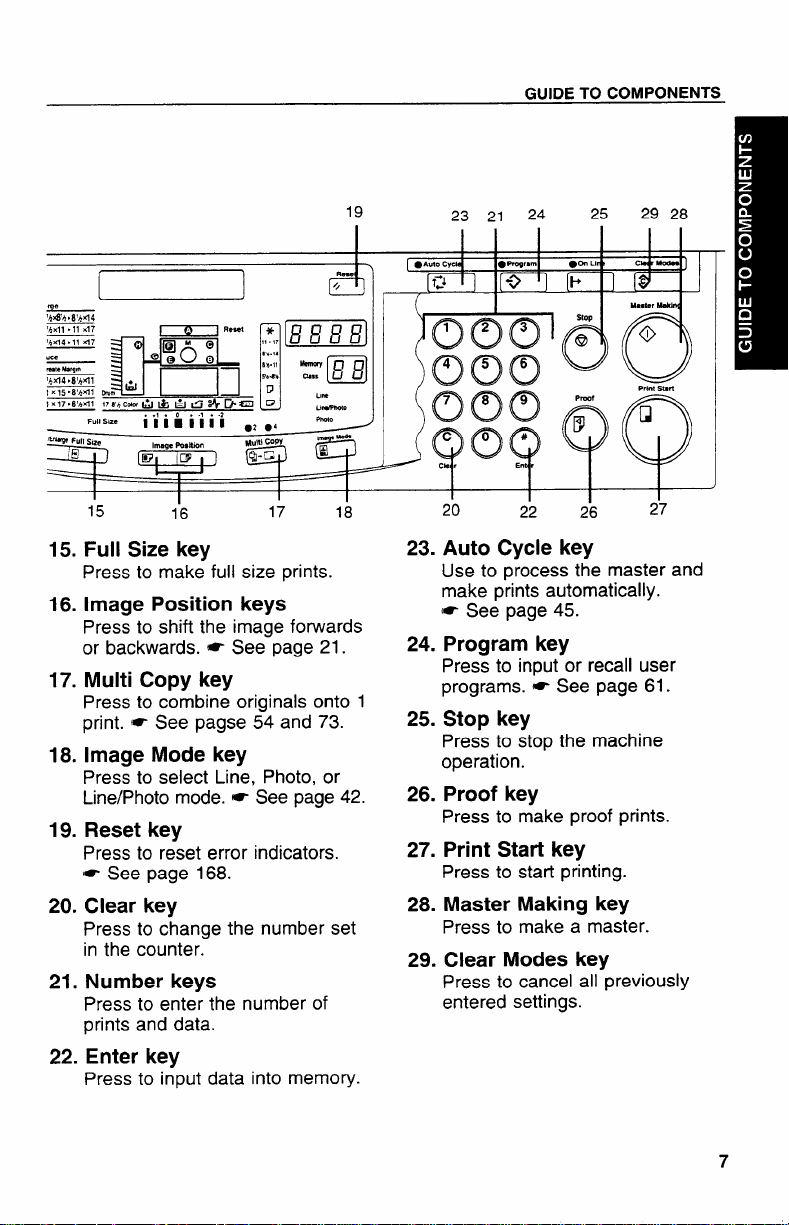

15. Full Size key

Press to make full size prints.

16. Image Position keys

23 21 24

● Aulo Cyc4e

Ooolfj

Cx5x3

● Progr.. ●On Lif+ CM r-

Cx!x3 f)

co#

00Q ,

CIWr

20

23.

Auto Cycle key

Use to process the master and

make prints automatically.

[- See page 45.

Ellt

22 26

Press to shift the image forwards

24.

or backwards. * See page 21.

17. Multi Copy key

Press to combine originals onto 1

print. * See pagse 54 and 73.

18. Image Mode key

Press to select Line, Photo, or

Line/Photo mode. = See page 42.

19. Reset key

Press to reset error indicators.

I* See page 168.

20. Clear key

Press to change the number set

in the counter.

21. Number keys

Press to enter the number of

Program key

Press to input or recall user

programs. * See page 61.

25.

Stop key

Press to stop the machine

operation.

26.

Proof key

Press to make proof prints.

Print Start key

27.

Press to start printing.

Master Making key

28.

Press to make a master.

29.

Clear Modes key

Press to cancel all previously

entered settings.

prints and data.

22. Enter key

Press to input data into memory.

25

!

o

29

Master MA

o

-.!-. e---

-,,.,,~..

27

28

r ,

7

GUIDE TO COMPONENTS

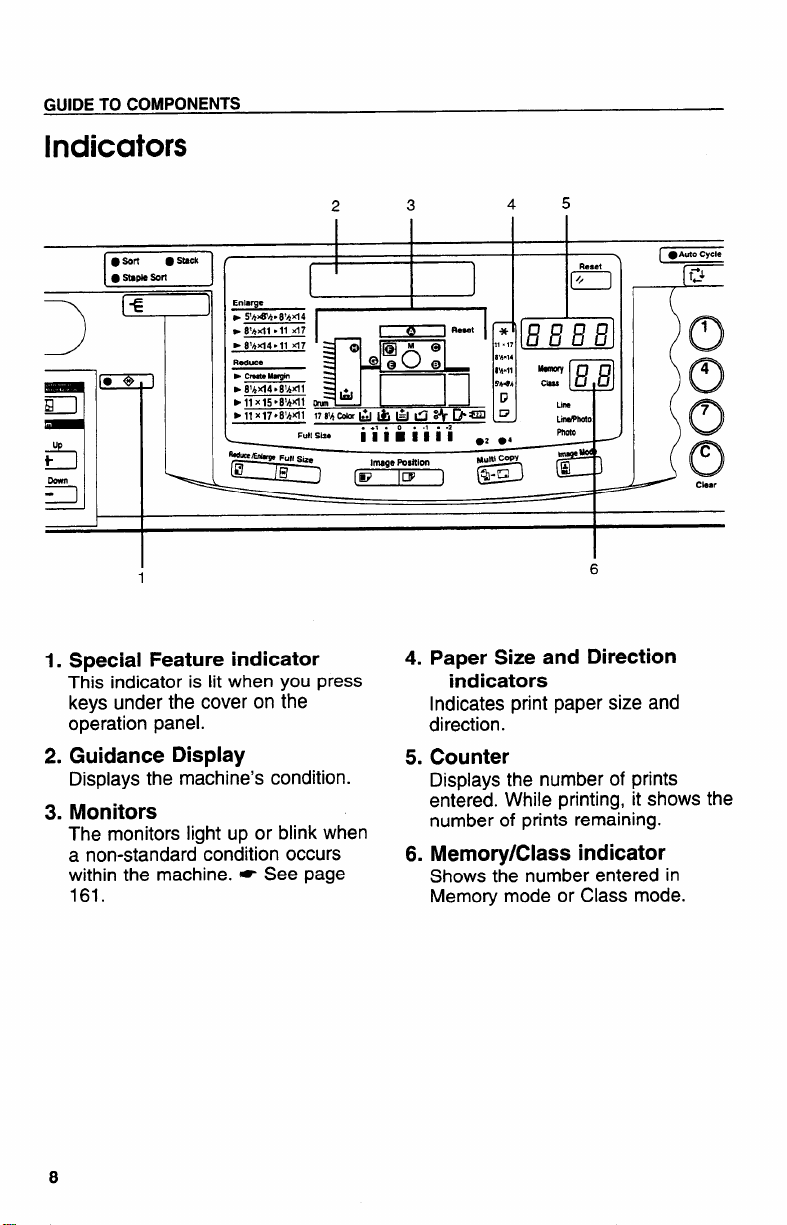

Indicators

I

5

2

3

4

+

L

Full Size

L

I. Special Feature indicator

This indicator is lit when you press

keys under the cover on the

operation panel.

2. Guidance Display

Displays the machine’s condition.

3. Monitors

The monitors light up or blink when

a non-standard condition occurs

within the machine. * See page

161.

... .0..1. .2

Ilimllll

4. Paper Size and Direction

Indicates print paper size and

direction.

5.Counter

Displays the number of prints

entered. While printing, it shows the

number of prints remaining.

6. Memory/Class indicator

Shows the number entered in

Memory mode or Class mode.

● *

.2

indicators

I

6

8

INSTALLATION REQUIREMENTS

INSTALLATION REQUIREMENTS

The machine’s location should be carefully chosen because environ-

mental conditions can affect its performance.

Optimum Environmental Conditions

J

Temperature:

a Humidity: 20- 90?40RH

rJ A strong and level base (a sturdy desk and cabinet etc.).

D The machine must be level within 5 mm, 13/64” both front to rear and left to

right.

n Make sure to locate this machine in a large well ventilated room that has an

air turnover of more than 30 m3/hr/person.

10 – 30”C, 50- 86°F

Environments To Avoid

Direct sunlight or strong light (more than 1500 Iux).

Locations directly exposed to cool air from an air conditioner or heated air

from a heater. (Sudden temperature changes from low to high or vice versa

may cause condensation within the machine.)

!J

Dusty areas.

Access To The Machine

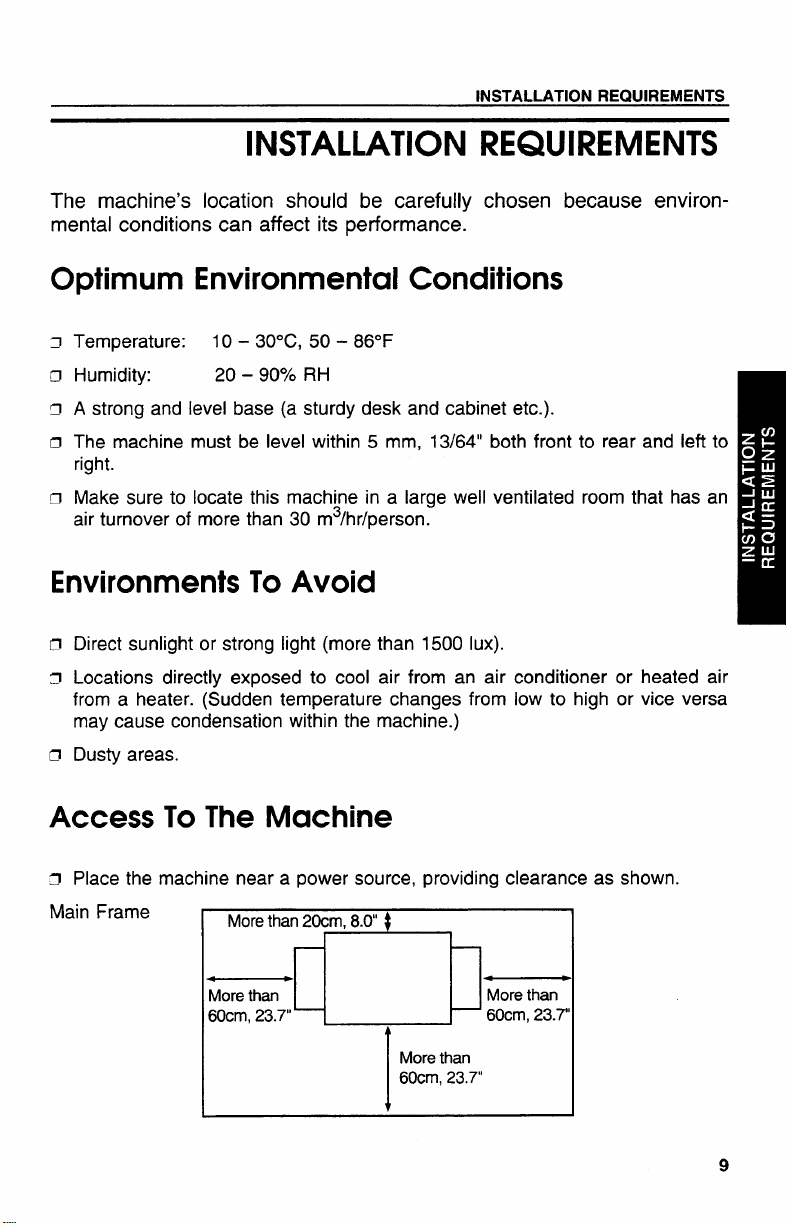

CJPlace the machine near a power source, providing clearance as shown.

Main Frame

Morethan20cm,8.0$

1

I

Morethan

d-k%

t

More than

60cm,23.7”

9

INSTALLATION REQUIREMENTS

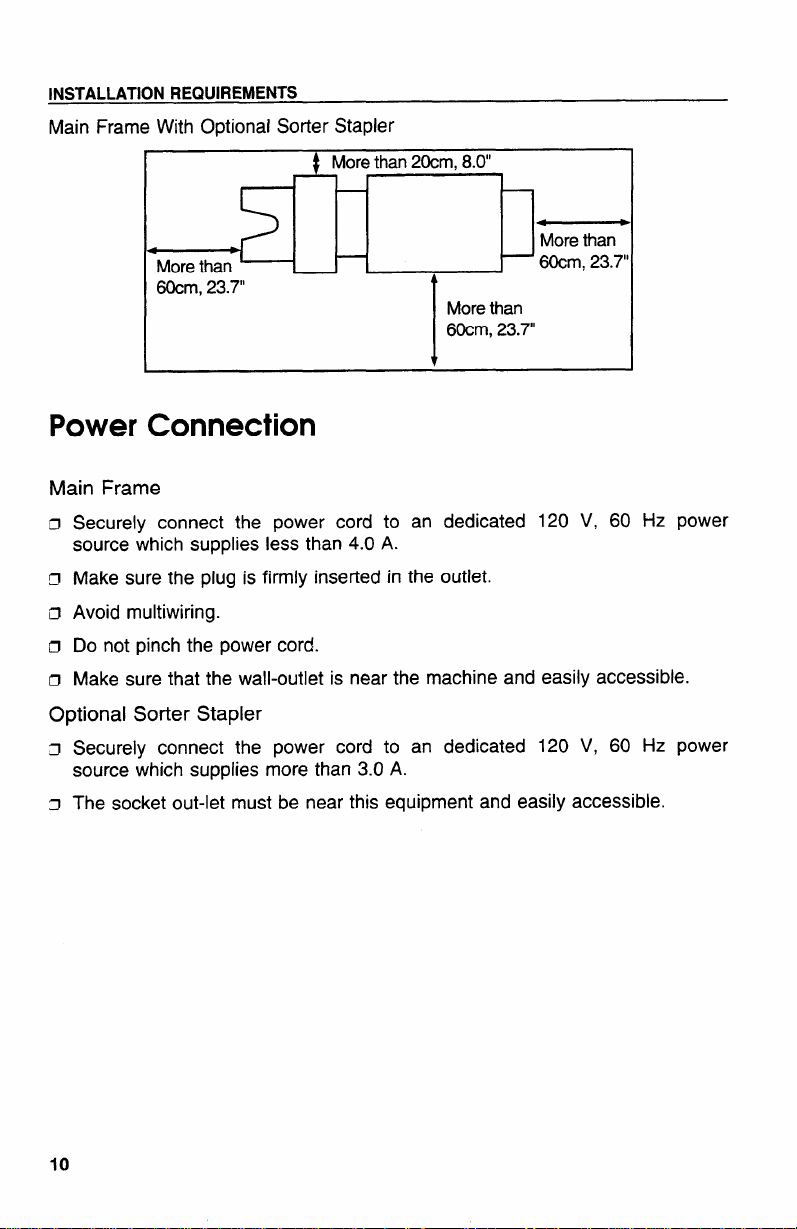

Main Frame With Optional Sorter Stapler

Morethan 20cm,8.0”

r-k

D

4

Morethan

60cm,23.7”

4

Morethan

—60cm, 23.7’

Morethan

60cm,23.7”

I

Power Connection

Main Frame

Securely connect the power cord to an dedicated 120 V, 60 Hz power

rI

source which supplies less than 4.0 A.

~ Make sure the plug is firmly inserted in the outlet.

n Avoid multiwiring.

a Do not pinch the power cord.

D Make sure that the wall-outlet is near the machine and easily accessible.

Optional Sorter Stapler

CI Securely connect the power cord to an dedicated 120 V, 60 Hz power

source which supplies more than 3.0 A.

~ The socket out-let must be near this equipment and easily accessible.

10

OPERATION

OPERATION

Printing Paper

The following types of print paper are not recommended for this machine.

. Paper smaller than 90 mm x 148 mm, 3.6” x 5.9”

. Paper larger than 297 mm x 432 mm, 11.6” x 17.0”

. Paper heavier than 209.3 g/m2, 55.6 lb

. Paper lighter than 47.1 g/m2, 12.5 lb

. Roughly-cut paper

. Paper of different thickness in the same stack

. Buckled or curled paper

. Short grain paper

. Low stiffness paper

A3 (297 x 420 mm), 11” x 17“, originals or printing paper can be used but

the maximum print area is 290 x 415 mm, 11.4” x 16.3”. Select Reduce

mode when you want to print the entire image of an A3, 11” x 17“ original.

Correct curls in the paper before setting it in the machine. When you cannot

correct the paper curl, stack the paper with the curl face down. Otherwise

the paper might wrap around the drum or stains might appear.

Store paper where it will not curl or absorb moisture. Use paper soon after it

is unpacked.

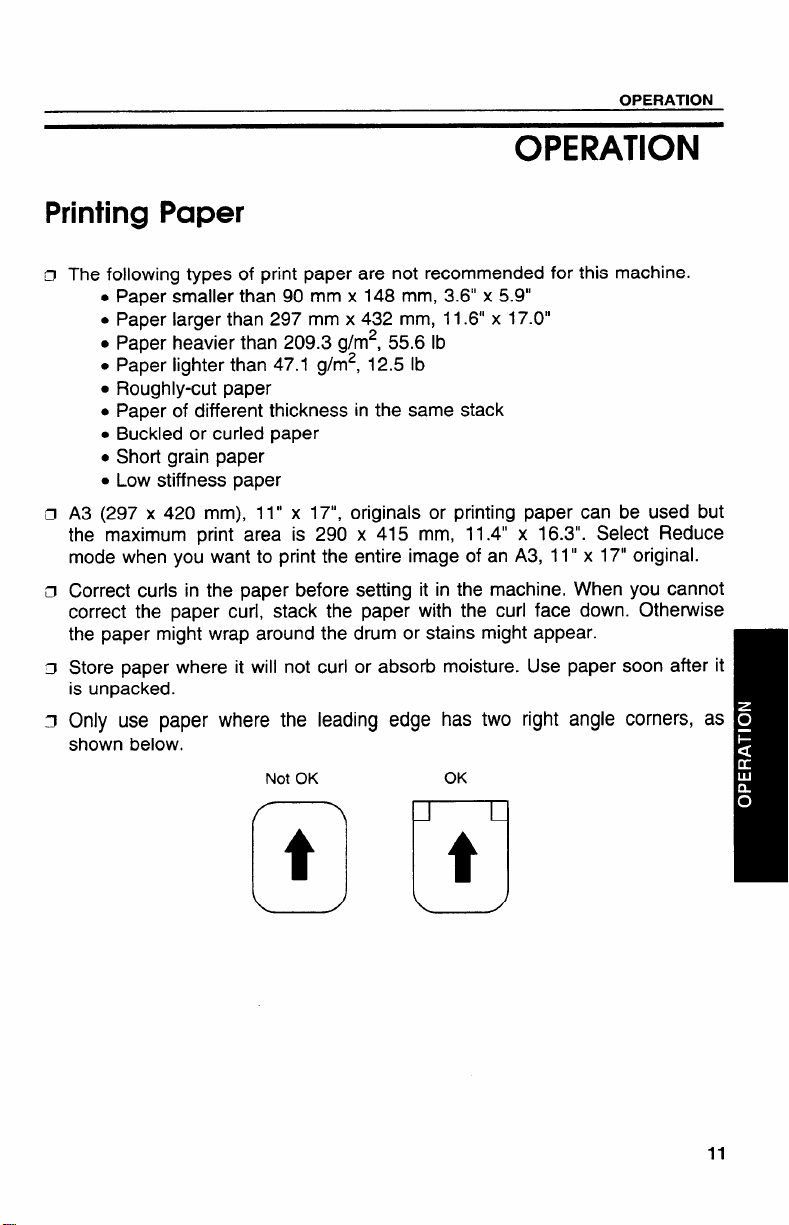

Only use paper where the leading edge has two right angle corners, as

shown below.

Not OK

(t] ~1

11

OPERATION

Originals

Under the following conditions, the machine might not detect the original on

the exposure glass. If you press the Master Making key again, the machine

will start making a master anyway.

. When you set a dark original on the exposure glass.

. When the original is not centered according to the size marks on the left

scale.

. If you do not open the platen cover at an angle of more than 25 degrees

with the exposure glass when you replace originals.

The maximum original size you can set on the exposure glass is 307 x 432

mm, 12” x 17”.

If you use paste-up originals, make sure the pasted parts hold firmly to the

base sheet. If the thickness of the paste-up original is more than 0.2 mm,

2/250” and the space between the pasted parts is less than 2 mm, 2/25”, a

shadow might appear on the prints.

If you use originals that have bold letters or solid images at the leading

edges, you might get prints with dirty edges. In this case, insert the widest

margin first, or raise the printing speed.

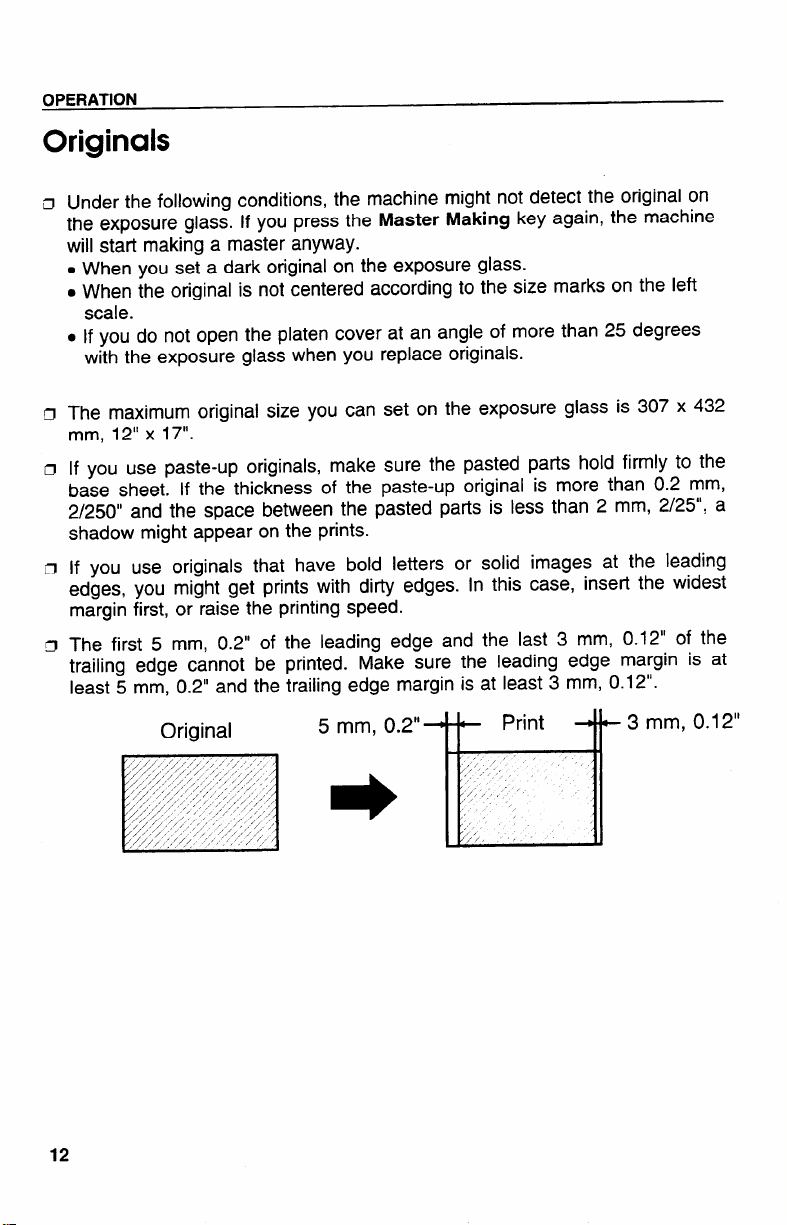

The first 5 mm, 0.2” of the leading edge and the last 3 mm, 0.12“ of the

trailing edge cannot be printed. Make sure the leading edge margin is at

least 5 mm, 0.2” and the trailing edge margin is at least 3 mm, 0.12”.

Original

5 mm, 0.2”++ Print

.-3 mm, 0.12”

-1

12

OPERATION

Preparation For Printing

CI * Seepage 95 when you Ioadpaper in the optional Iarge capacity tray.

o ~ See page 101 when you load paper in the optional paper cassette for

LCT.

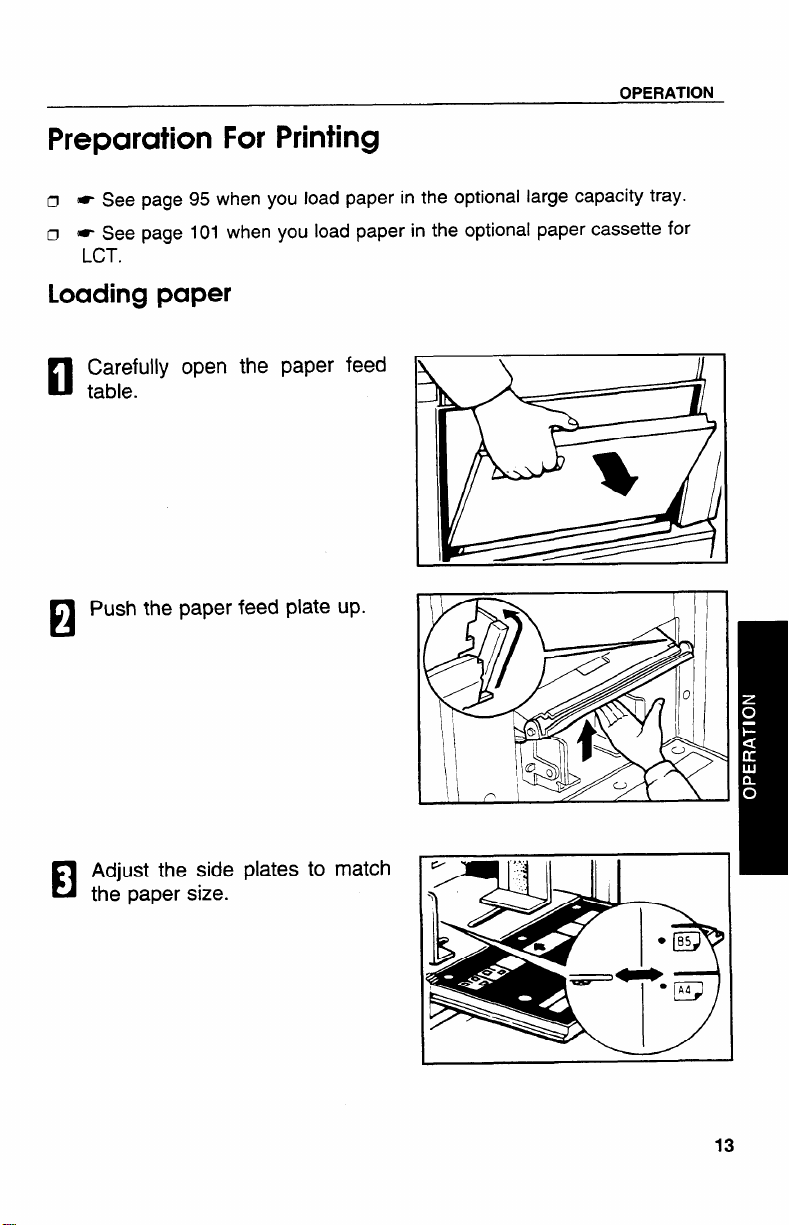

Loading paper

Carefully

El

table.

Push the paper feed plate up.

open the

El

Adjust the side plates to match

El

the paper size.

paper

w

13

OPERATION

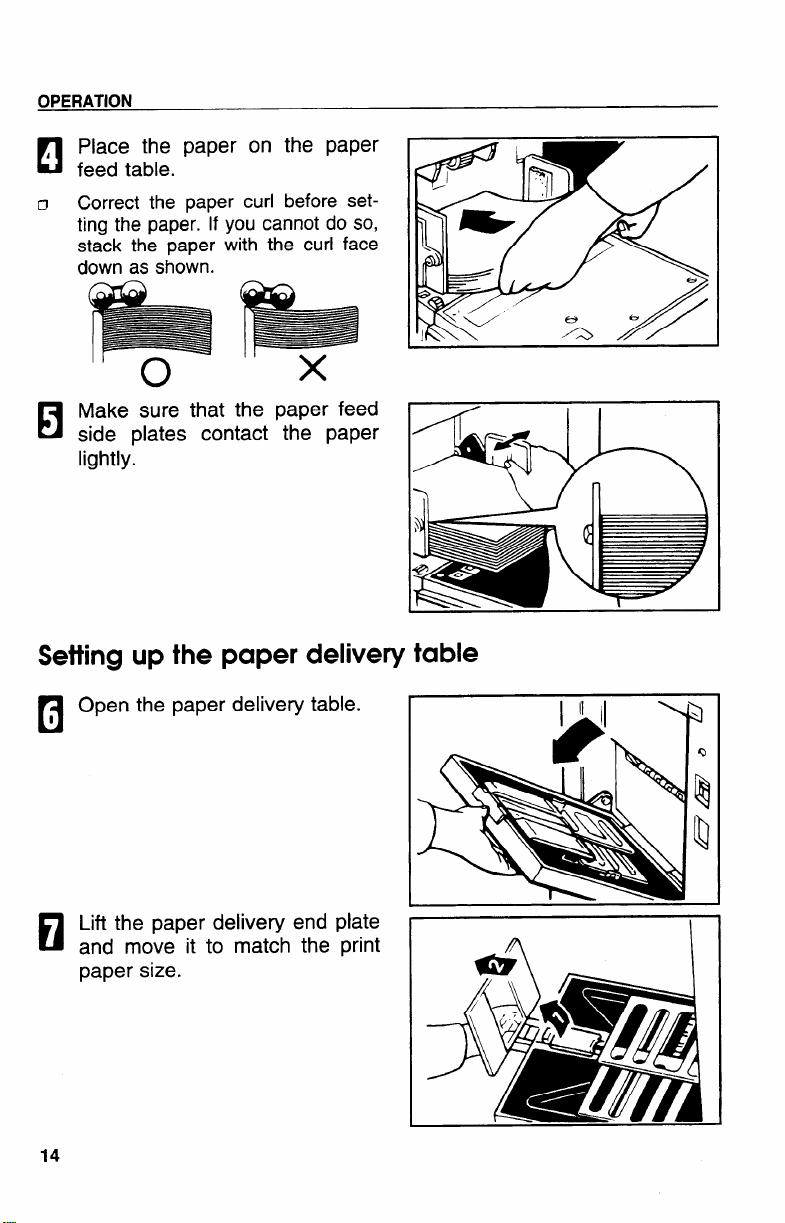

Place the paper on the paper

feed table.

Correct the paper curl before set.:

——AL ---- -“1s

ung me pdper.

stack the paper

down as shown.

you cannot do so,

II

with the curl face

.

mlb

—

II

II

o

Make sure that the paper feed

side plates contact the paper

lightly.

Setting up

the paper delivery table

paper delivery table.

I

x

I II II

Lift the paper delivery end plate

and move- it to match the print

paper size.

14

I

OPERATION

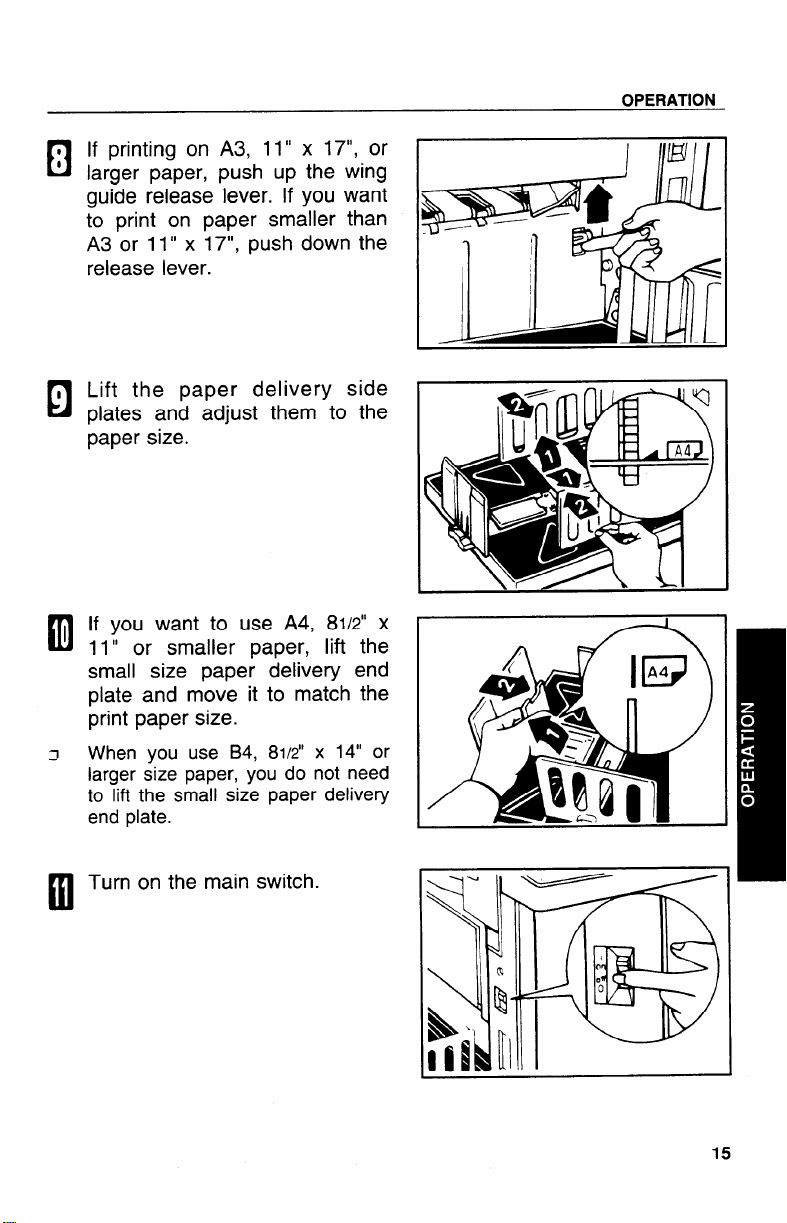

If printing on A3, 11” x 17“, or

larger paper, push up the wing

guide release lever. If you want

to print on paper smaller than

A3 or 11” x 17“, push down the

release lever.

Lift the paper delivery side

plates and adjust them to the

paper size.

If you want to use A4, 81/2” x

11” or smaller paper, lift the

small size paper delivery end

plate and move it to match the

print paper size.

When you use B4, 8112”x 14“ or

larger size paper, you do not need

to lift the small size paper delivery

end plate.

I WI

I

Turn on the main switch.

m

15

OPERATION

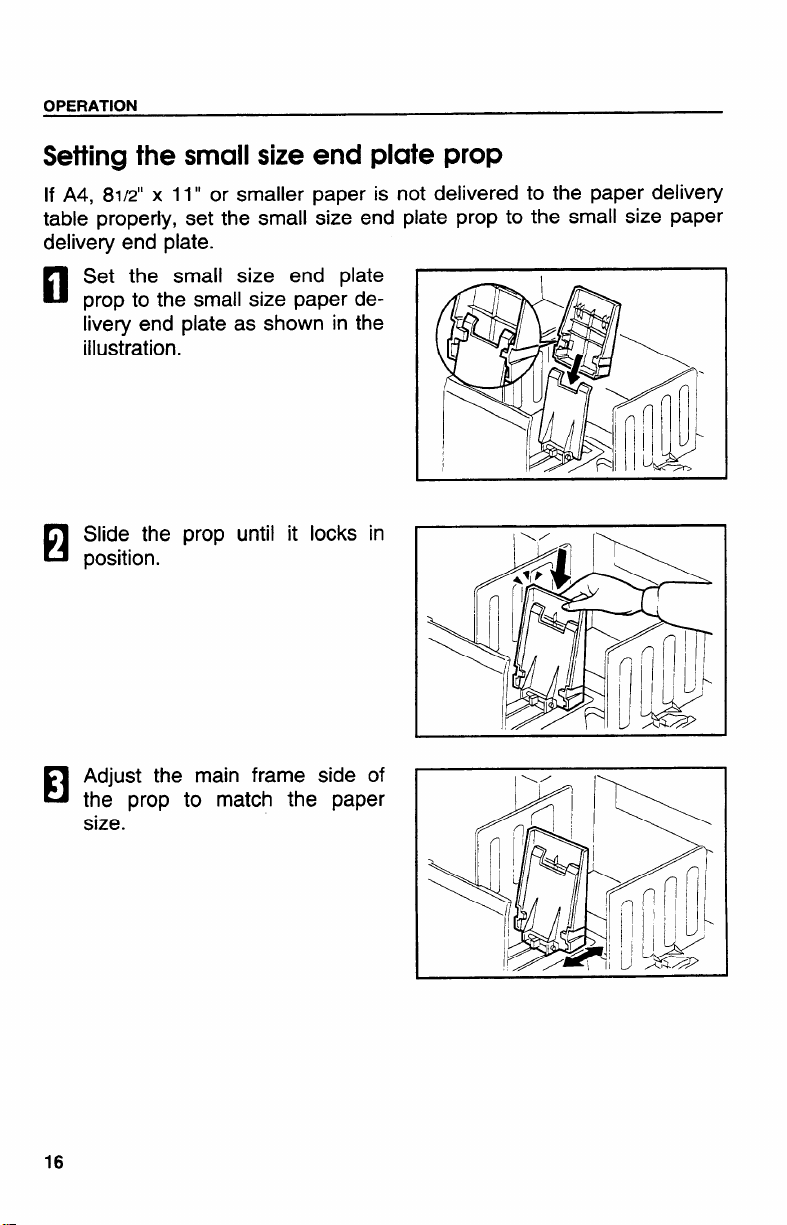

Setting the small size end plate prop

If A4, 81/2” x 11” or smaller paper is not delivered to the paper delivery

table properly, set the small ‘size end plate prop to the small size paper

delivery

d

El

end plate.

the small size end plate

Set

prop to the small size paper delivery end plate as shown in the

illustration.

Slide the prop until it locks in

position.

Adjust the main frame side of

El

the prop to match the paper

size.

16

Standard Printing

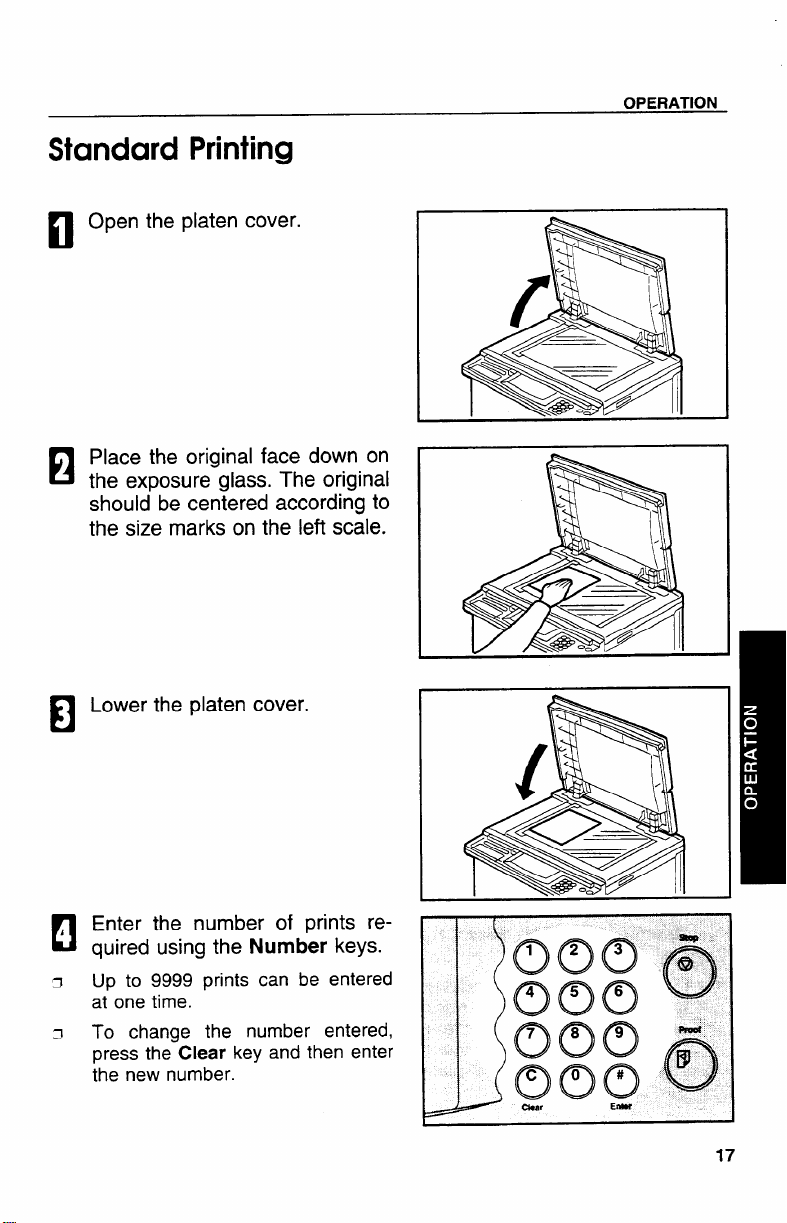

Open the platen cover.

El

Place the original face down on

El

the exposure glass. The original

should be centered according to

the size marks on the left scale.

OPERATION

Lower the platen cover.

El

Enter the number of prints required using the

Up to 9999 prints can be entered

at one time.

To change the number entered,

press the Clear key and then enter

the new number.

Number keys.

17

OPERATION

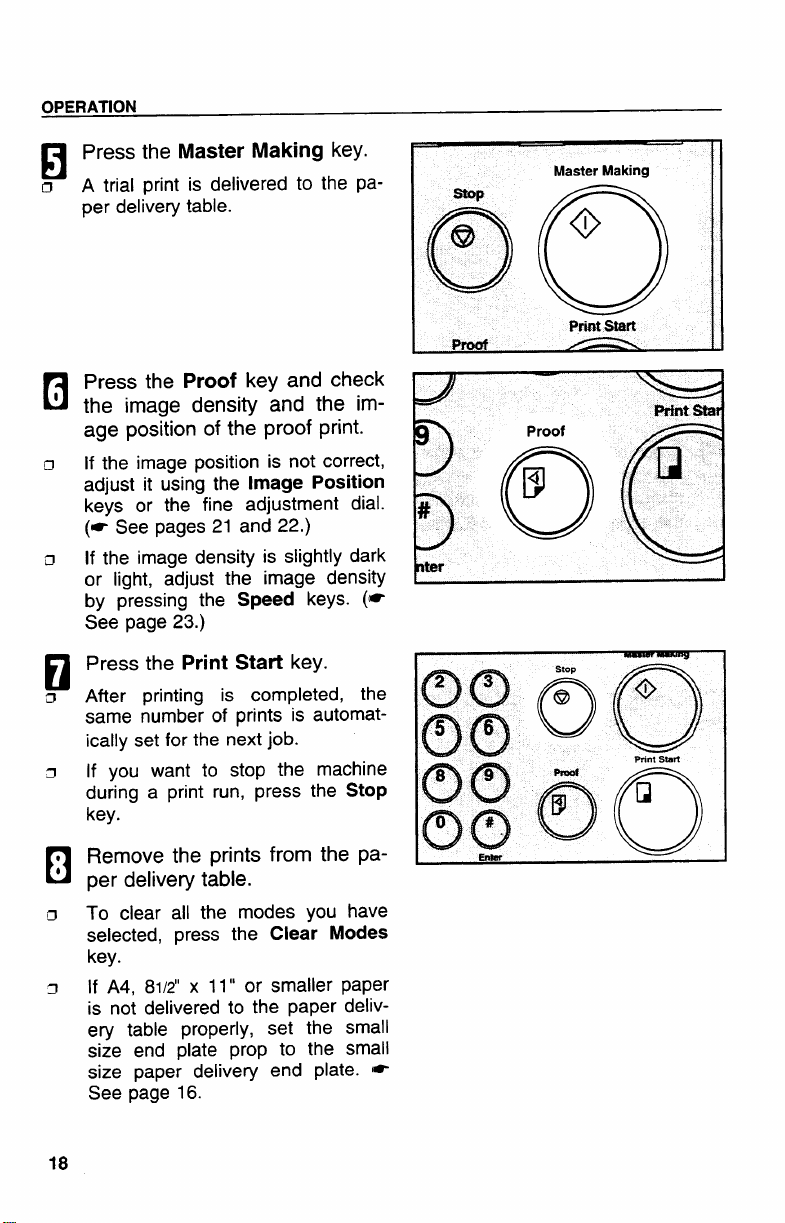

Press the Master Making key.

H

A trial print is delivered to the pa-

c1

per delivery table.

Press the Proof key and check

the image density and the image position of the proof print.

If the image position is not correct,

adjust it using the Image Position

keys or the fine adjustment dial.

(~ See pages 21 and 22.)

If the image density is slightly dark

c1

or light, adjust the image density

by pressing the Speed keys. (*

See page 23.)

Press the Print

After printing is completed, the

same number of prints is automat-

ically set for the next job.

if you want to stop the machine

during a print run, press the Stop

key.

Start key.

#l

;o~

nter

o~”

Stop

@

Master Making

o

Print SWt

m

Proof

4

Q

I

:

PrFl%tSW

c1

*

Remove the prints from the pa-

b

fl

per delivery table.

To clear all the modes you have

c1

selected, press the Clear Modes

key.

If A4, 81/2” x 11” or smaller paper

is not delivered to the paper delivery table properly, set the small

size end plate prop to the small

size paper delivery end plate. *

See page 16.

Restoring Paper Feed And Paper Delivery

OPERATION

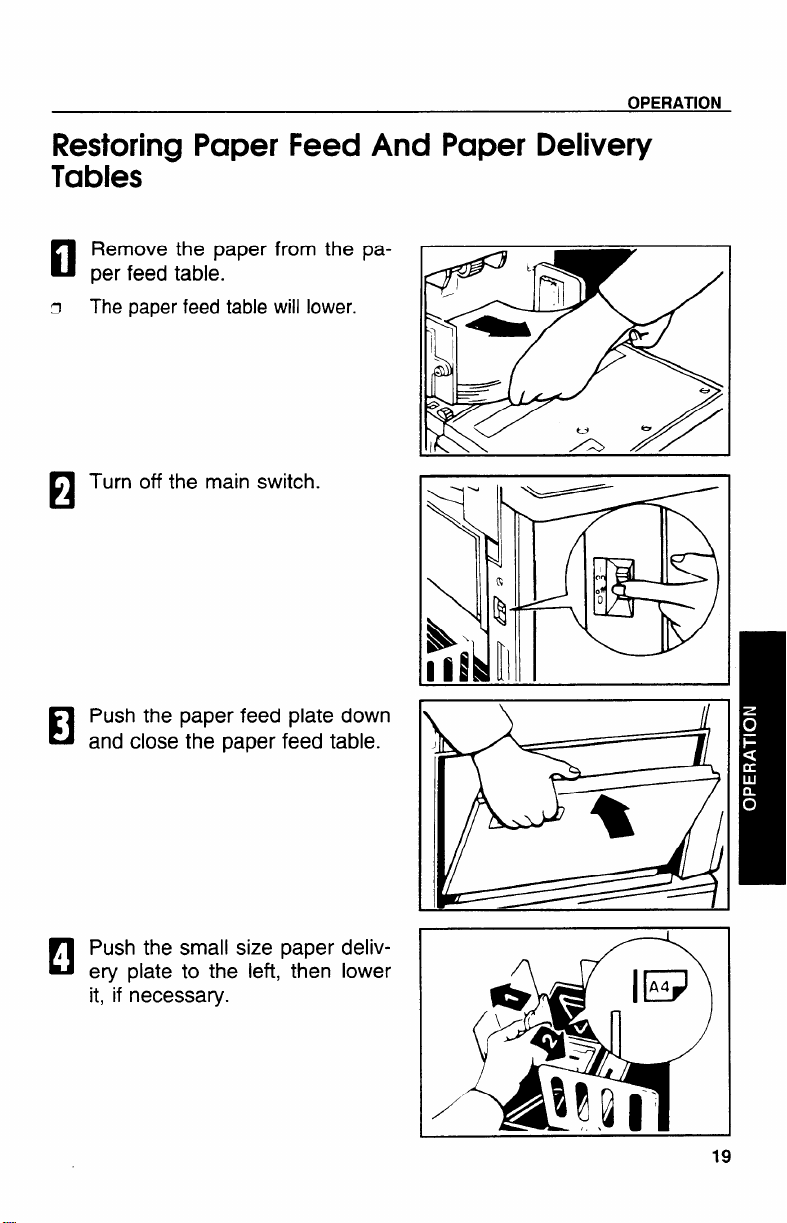

Remove the paper from the

per feed table.

The paper feed table will lower.

Turn off the main switch.

EI

Push the paper feed plate down

El

and close the paper feed table.

pa-

Push the small size paper deliv-

A

El

ery plate to the left, then lower

it, if necessary.

19

OPERATION

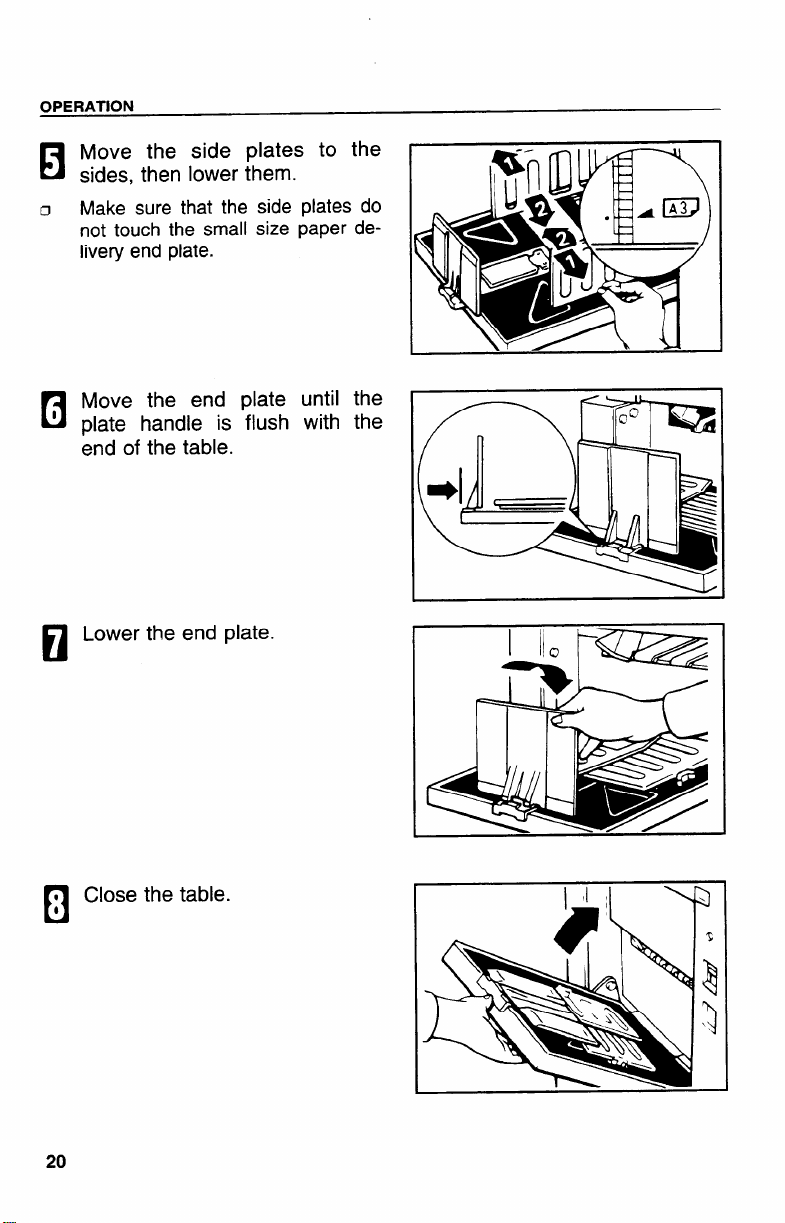

Move the side plates to the

la

sides, then lower them.

Make sure that the side plates do

IJ

not touch the small size paper delivery end plate.

Move the end plate until the

plate handle is flush with the

end of the table.

Lower the end plate.

El

I

0 Close the table.

b

o

20

OPERATION

Adjusting The Image Position

Shifting the image position forward or backward

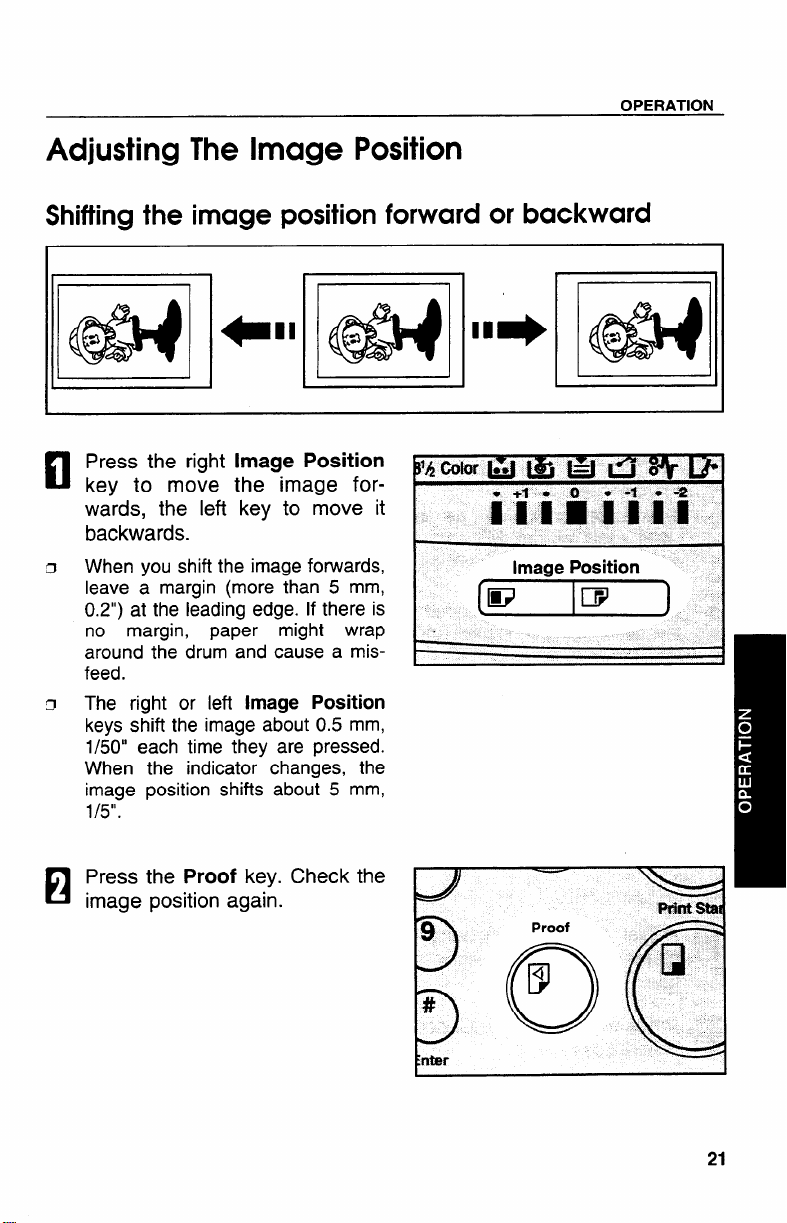

Press the right Image Position

key to move the image for-

wards, the left key to move it

backwards.

When you shift the image forwards,

leave a margin (more than 5 mm,

0.2”) at the leading edge. If there is

no margin, paper might wrap

around the drum and cause a mis-

feed.

The right or left Image Position

keys shift the image about 0.5 mm,

1/50” each time they are pressed.

When the indicator changes, the

image position shifts about 5 mm,

1/5”.

Press the Proof key.

image position again.

21

OPERATION

Shifting the image to the right or left

If your machine is equipped with the optional large capacity tray, = see

@

page 106.

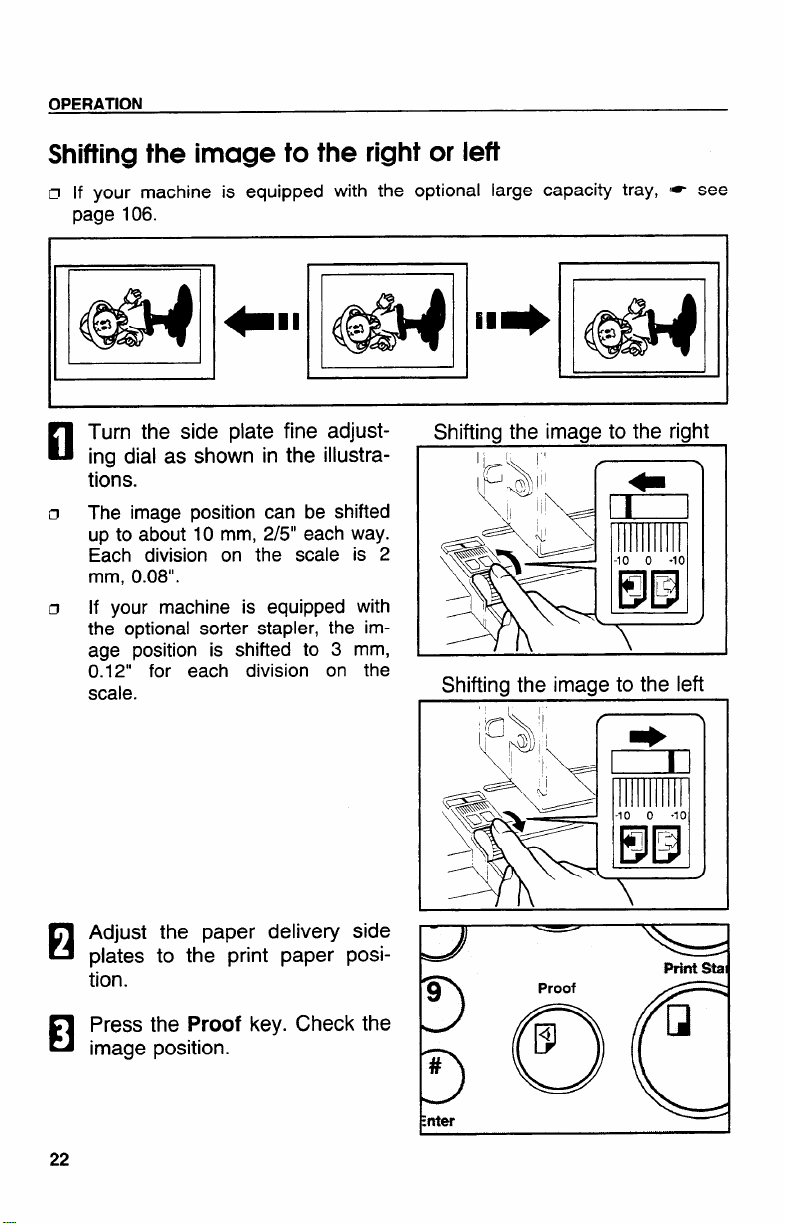

Turn the side plate fine adjust-

K1

ing dial as shown in the illustra-

tions.

The image position can be shifted

Cl

up to about 10 mm, 2/5” each way.

Each division on the scale is 2

mm, 0.08”.

If your machine is equipped with

c1

the optional sorter stapler,

age position is shifted to

0.12” for each division

scale.

Adjust the paper delivery

El

plates to the print paper

tion.

the im-

3 mm,

on the

side

posi-

Shifting the image to the right

I

I

I It

Shifting the image to the left

I

Press the

El

image position.

22

Proof

key. Check the

Adjusting The Image Density

Before making a master

OPERATION

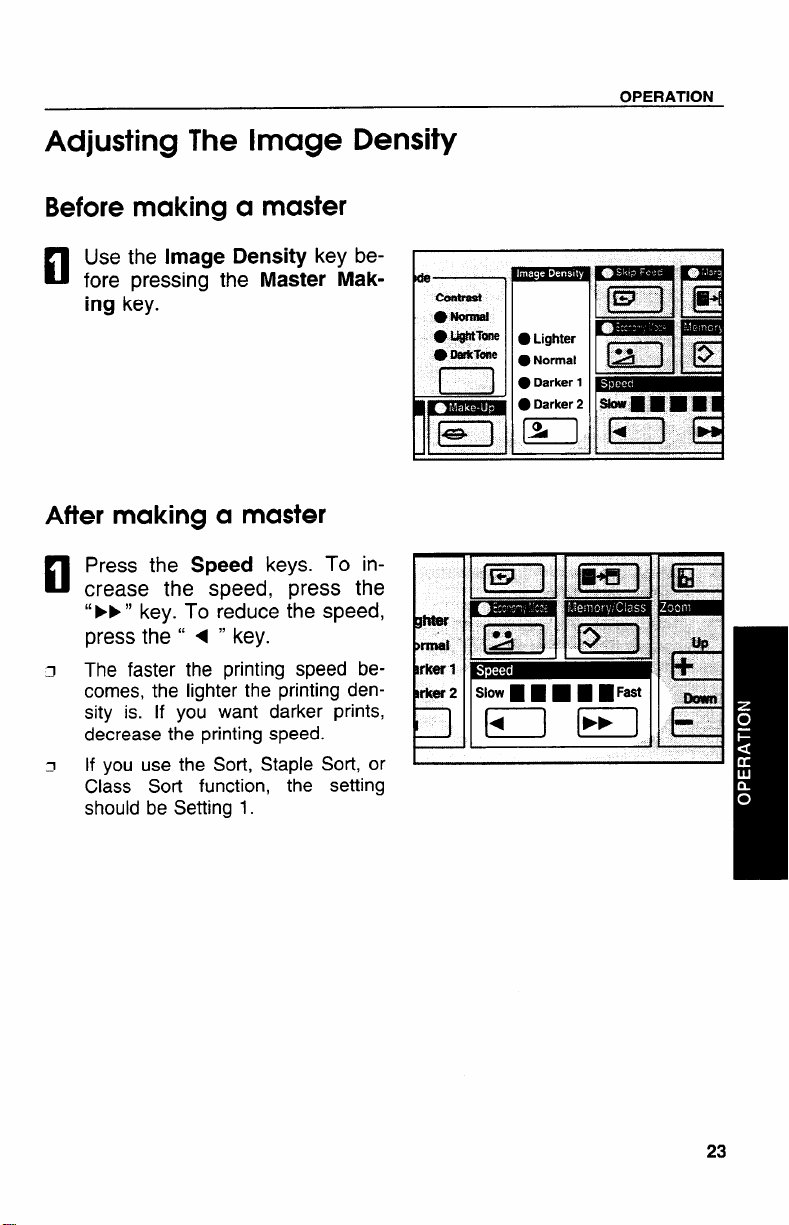

Use the Image Density key be-

n

fore pressing the

key.

ing

After making a master

Press the Speed keys. To in-

n

crease the speed, press the

“F*” key. To reduce the speed,

press the “ < “ key.

The faster the printing speed be-

comes, the lighter the printing den-

sity is. if you want darker prints,

decrease the printing speed.

If you use the Sort, Staple Sort, or

Class Sort function, the setting

should be Setting 1.

Master Mak-

.0

.0.

Contreai

● ramal

● WTWW ● Lighter

● mwkwne ●Normal

n

nnlF

● Darker 1

● Darker2 Skw19

H

m

m

[’~ ~

n

23

OPERATION

Changing The Printing Speed

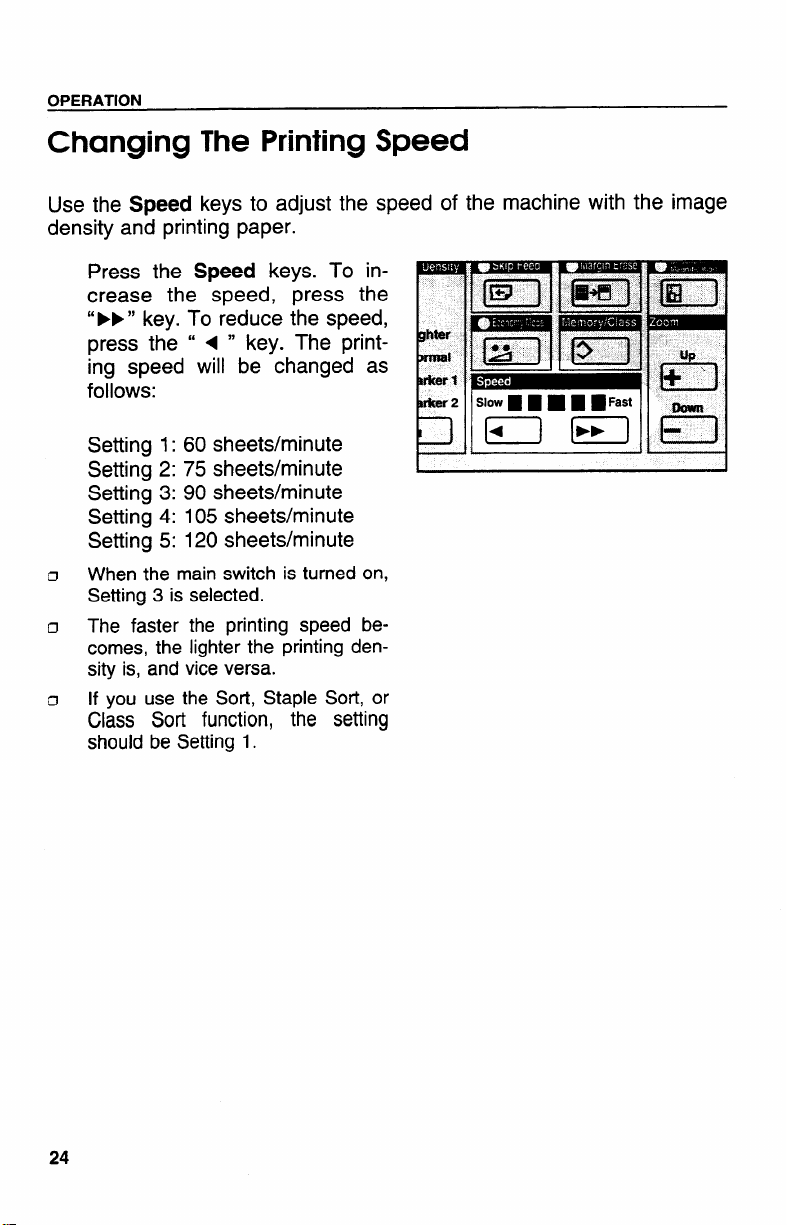

Use the Speed keys to adjust the speed of the machine with the image

density and printing paper.

Press the

Speed keys. To in-

crease the speed, press the

“ FF” key. To reduce the speed,

press the “ 4 “ key. T

ing speed will be cha

follows:

Setting 1:60 sheets/minute

Setting 2:75 sheets/minute

Setting 3:90 sheets/minute

Setting 4:105 sheets/minute

Setting 5:120 sheets/minute

When the main switch is turned on,

o

Setting 3 is selected.

0

The faster the printing speed becomes, the lighter the printing density is, and vice versa.

If you use the Sort, Staple

0

Class Sort function, the

should be Setting 1.

le printlged as

Sott, or

setting

24

OPERATION

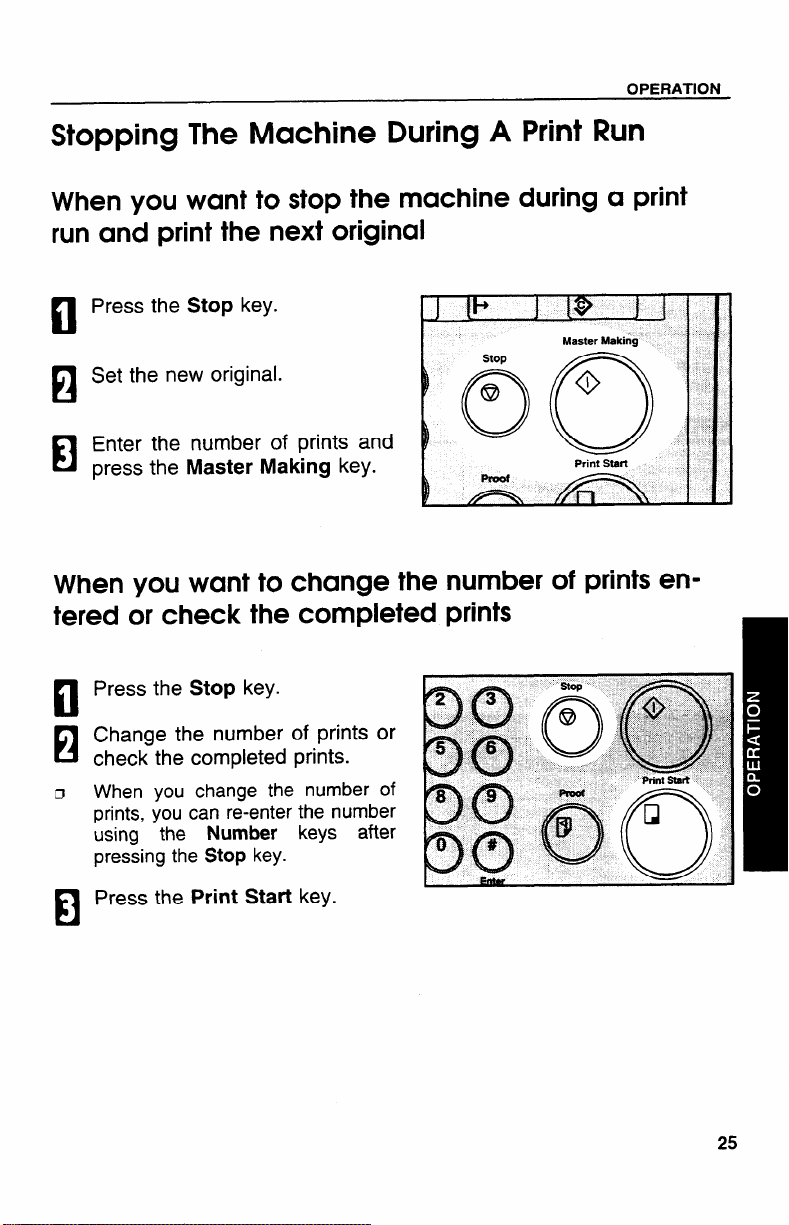

Stopping The Machine During A Print Run

When you want to stop the machine during a print

run and print the next original

Press the Stop key.

n

Set the new original.

~

u

Enter the

El

press the

When you

tered or check the completed prints

Press the Stop key.

number of prints and

Master Making key.

want to change the number of prints en-

n

Change the number of prints or

H

check the completed prints.

When you change the number of

D

prints, you can re-enter the number

using the Number keys after

pressing the Stop key.

Press the Print

H

Start key.

25

OPERATION

Reduction/Enlargement Printing

Original

, Prjnt

Paper

Feed

Dwection

c’

L

~Constant

D The center and the leading edge of the print image do not shift when a print

image is made with this function.

Reduction

Prints can be reduced in size by using the Reduce/Enlarge key.

— Metric version —

93 ?40

*

1,

87 Yo

l--f?++

82 ?40

B4

B5

A3 , A4

?40

71

A4 A5

B4

* Select this ratio when you make prints with a lot of edge margins.

26

A4

A5

B5

65

0/0

~

OPERATION

Select the desired reduction ra-

n

tio using the

Make sure that the original and

n

the nrint DaDer are the correct

size:

Set your original on the expo-

sure glass or in the optional

document feeder.

Press the

Check the

trial or proof print.

If the image position is not correct,

adjust it using the Image Position

keys (- see page 21) or the side

plate fine adjusting dial (* see

page 22).

Reduce/Enlarge

11

Master Making key.

image position of the

bjlx~q

H-—

%..

.al Ld4 *V aft 4

Make your prints.

27

OPERATION

Enlargement

‘ii

!ii!i

Prints can be enlarged by using the Reduce/Enlarge key.

— Metric version —

A4 A3*

141 Yo

122%

115%

*

Some part of the image on the trailing edge might not appear. To

print the entire image: adjust the enlargement ratio with the

up/down

A5

B5

B6

A4

A5 B5

B4

1

B5

II

keys.

A4

B4

B5

B4

A3*

A4

II

155 ?40

II51@’ ~ 81/2” II 81,+2” ~ 14”

Zoom

28

Select the desired enlargement

El

ratio using the

key.

Make sure that the original and

El

the print paper are the correct

size.

Set your original on the expo-

H

sure glass or in the optional

document feeder.

Reduce/Enlarge

OPERATION

Press the

A

c1

Check the image position of the

trial or proof print.

o

If the image position is not correct,

adjust it using the Image Position

keys (* see page 21) or the side

plate fine adjusting dial (* see

page 22)0

Make your prints.

Master Making key.

H

29

OPERATION

Zoom

In this mode, the reproduction ratio can be changed from 50 YO to 200

70 in 1 70 steps.

Press the Zoom down (-) key

c1

repeatedly to reduce the ratio in

1 ?40steps.

or, press the

repeatedly to increase the ratio

0/0 steps.

in 1

Make sure that

El

the print paper

size.

Set your originals

El

sure glass or in

document feeder.

, Press the Master Making key.

rl

Check the image position of the

trial or proof print.

If the image position is not correct,

J

adjust it

keys (= see page

plate fine adjusting dial (~ see

page 22).

Make your prints.

Zoom Up (+) key

the original and

are the correct

on the expo-

the optional

using the Image Position

21) or the side

El

Print Start

30

OPERATION

Directional Magnification Printing

L

You can select independent ratios for vertical and horizontal directions.

D If you do not know the proper reproduction ratios, you can use SP mode to

enter the size of the original and print paper (- See page 133). The machine will then select the proper reproduction ratios and you can make prints.

When you enter the reproduction ratios

Press the Directional

n

cation key.

Enter the desired reproduction

El

ratio for the vertical direction using the

Press the Enter key.

Number keys.

El

Magnifi-

31

OPERATION

Enter the desired reproduction

A

n

ratio for the horizontal direction

using the

Number keys.

Press the

Enter key.

El

Make sure that the original and

I

B

the print paper are the correct

size.

Set your original on the expo-

a

sure glass or in the optional

document feeder.

; Press the Master Making key.

El

Check the image position of the

trial or proof print.

0 If the image position is not correct,

adjust it using the Image Position

keys (~ see page 21) or the side

plate fine adjusting dial (~ see

page 22).

*

Stup

@

o~!

,

\ *

Master Making

I

o

SM

Print

I

, Make your prints.

D

32

OPERATION

Entering the lengths of the original and print paper

Press the Directional

El

cation key.

Enter the vertical length of the

El

original using the

and press the Enter key.

Enter the horizontal length of

El

the original using the Number

keys and press the

Number keys

Enter key.

, Enter the vertical length of the

c1

print paper using the

keys and press the Enter key.

Enter the horizontal length of

El

the print paper using the Number keys and press the

key.

The machine will select proper re-

D

production ratios for vertical and

horizontal directions.

Number

Enter

33

OPERATION

Make sure that the original and

n

1 the print paper are the correct

size.

Set your original on the expo-

El

sure glass or in the optional

document feeder.

o Press the Master Making key.

n

‘ Check the image position of the

trial or proof print.

If the image position is not correct,

rl

adjust it using the Image Position

keys (= see page 21) or the side

plate fine adjusting dial (= see

page 22).

~ Make your prints.

a

34

OPERATION

Erasing Center And Edge Margins

When printing from thick books, or similar originals, the binding margin

at the center and the edges might appear on prints. To prevent this,

follow the steps on the next page.

The 1 mm,

width of the margins will change depending on the reduction ratios.

Shadows near the book edge might not be erased completely.

If the shapes of the originals are as below, shadows might appear on the

prints. In this case, make a master with the platen cover closed.

If there is a line or solid image on the margin and you erase the center and

the edges, the image might be erased

the function described on page 38.

0.02” margins on all four sides of the original will be erased. The

Shadow

Scanningdirection

as shown below. In this case, use

—

—

1 I

v

9–

—

i

Scanning direction

OPERATION

n If you do not press hard on the book while it is scanned, the margin at the

center might not be erased completely.

D If the machine is installed under a strong light, such as a fluorescent light, a

shadow might appear on the prints. In this case, close the platen cover a lit-

tle to block the light or move the machine.

a If you set the original on the exposure glass as shown below, the screened

image below may not be printed. Lines or solid images that run from the

screened image below onto the original may also not be printed.

154mm, 6.1”

L

Set the book on the exposure

glass.

Keep the platen cover at an an-

of at

least 25 dea

gle

exposure glass.

the

Press the Master Making key.

El

Press hard on the book with

your hand while it is scanned.

36

rees with

1

Master Making

stop

@

3

Print Staft

OPERATION

Check

A

n

trial or

3

If the image position is not correct,

adjust it using the Image Position

keys

plate

page

Make your prints.

the image position of the

proof print.

(= see page 21) or the side

fine adjusting dial (~ see

22).

El

I

I # I

Image Position

[w Im

J

I

37

OPERATION

Erasing Margins

If you want to erase edge margins of a book original, follow the steps

below.

Set the original on the exposure

n

glass.

Enter the number of prints re-

El

quired using the

Number keys.

Press the

H

, The following message will ap-

c1

pear on the guidance display.

The paper size and direction

will be changed by pressing the

Zoom up/down keys.

SCROLL BY ZOOM KEY

38

Margin Erase key.

(YYY x XXX MM)

When you reach the desired

H

paper size and direction, press

the Enter key.

Press the Master Making key.

Check the image position of the

trial or proof print.

image position is not correct,

If the

c1

adjust it using the Image Position

keys (- see page 21) or the side

plate fine adjusting dial (~ see

page 22).

Make your prints.

El

OPERATION

39

OPERATION

Printing On Thick Or Thin Paper

When you make prints on thick (127.9 to 209.3 g/m2, 34 to 55.6 lb) or

thin (47.1 to 81.4 g/m

steps.

Printing on thick paper

2, 12.5 to 21.6 lb) paper, perform the following

When you

El

than 127.9

lighter than

position the pressure lever (A)

to the Thick paper position.

When you use paper heavier than

o

64 g/m2, 17 lb and lighter than

157.0 g/m2, 41.7 lb, position the

pressure lever (A) to the standard

position.

0

In the case of paper smaller

B5, 51@’ x 81/2” and heavier

81.4 g/m2 (21.6 lb), move the

roller pressure lever to the Thin

per position.

Push the pressure levers

El

down.

There are two pressure levers

o

Make sure that both levers

down.

If dog-eared or wrinkled prints

0

delivered, push the levers up.

use paper

g/m2, 34.0

209.3 g/m2,

heavier

lb and

55.6 lb,

than

than

feed

pa-

(B)

(B).

are

are

Printing on thin paper

OPERATION

Set the

H

side pad

posite).

Position the pressure lever

H

to the Thin paper position.

Push the pressure levers

H

down.

o If dog-eared or wrinkled prints

delivered, push the levers up.

11 There are two pressure levers

Make sure that both levers

down.

side pads (move

levers to as shown

the

op-

(A)

(B)

are

(B).

are

41

OPERATION

Photo Mode Printing

Original

When printing

CI Moire patterns may occur when screened originals are printed.

D When using Photo mode to print originals with both text and photographs,

the text will appear lighter. To avoid this, select Line/Photo mode with the

Image Mode key. Alternatively, use the optional Make-up function to specify

Line mode for text areas and Photo mode for photograph areas.

Press the Image Mode key to

c1

select Photo mode.

Press the Image Density key

El

to adjust the image density.

Photo mode

a photograph or

Line mode

a color original, select

I

Line/Photo

Photo mode.

mode

42

tll~

Ilr

If necessary, adjust the screen

El

image by pressing the

key in Photo or Line/Photo

mode.

If necessary, adjust the contrast

by pressing the

Photo mode.

, Set your original on the expo-

n

sure glass or in the optional

document feeder.

Press the Master Making key.

H

Check the image position of the

trial or proof print.

If the image position is not correct,

c1

adjust it using the Image Position

keys (~ see page 21) or the side

plate fine adjusting dial (- see

page 22).

Contrast key in

Screen

OPERATION

● *-

Screen

-

1.EI

2.IEI

3

.—

4

.—

r‘h”’”””dezzilr

. Normal

● Fine ● LightTone

● Coarae

00

l-l

S*

62

● Normal

.

Dark Tone

Master Making

I

o

O(-J ,

PrintStart

I

Make your prints.

I

I

43

OPERATION

Ink Saving (Economy Mode)

When

n The

a When you

you want to save ink, select

printing density may be light in

set Tint mode and press the Economy Start key, Tint mode is

canceled.

Press the Economy Mode key.

c1

Set your original on the expo-

El

sure glass or in the optional

document

Press the

El

Check the image position of the

trial or proof print.

If the image position is not correct,

o

adjust it using the Image Position

keys (~ see page 21) or the side

plate fine adjusting dial (- see

page 22).

feeder.

Master Making key.

Economy mode.

this mode.

Print

start

, Make your prints.

c1

44

OPERATION

Printing From Several Originals At Once

Use the Auto Cycle key to process masters and make prints at one

stroke.

n When you use the optional document feeder, it is not necessary to place

originals one by one. All originals are fed and prints are completed after you

press the Print Start key.

CI If you use the optional tape dispenser, the tape dispenser drops a strip of

paper onto the top of the paper stack after the last page of each printing set

is fed out to the paper delivery table. This marks the end of each printing

group.

Set the original face down on

El

the exposure glass or in the optional document feeder.

o

You can

the optional 20 originals document

feeder.

You can set up to 50 originals into

n

the optional 50 originals document

feeder.

set up to 20 originals into

Enter the number of prints re-

El

quired using the

Press the Master Making key.

El

Check the image position of the

trial or proof print.

image position is not correct,

If the

c1

adjust it using the Image Position

keys (= see page 21) or the side

plate fine adjusting dial (* see

page 22).

Number keys.

45

Press the

i

El

If you press the Auto Cycle key,

o

you cannot make proof prints by

pressing the Proof key.

If you use the optional tape dis-

El

penser, turn on the power

switch of the tape dispenser.

Auto Cycle key.

Press the Print

I

D

If you set originals into the optional

c1

document feeder, originals are fed

and prints are completed automatically.

Repeat steps 1 through 3 until

El

all originals are printed when

you set originals on the expo-

sure glass.

o

After the last page of each set is

fed out to the paper delivery table,

the optional tape dispenser drops a

strip of paper on the top of the pa~er stack. The next cvcle begins.

,

46

Start key.

.,

~

PrQof

4

P

Print Start

Q

o

b

OPERATION

Group Printing From The Same Original (Class

Mode)

Use the Memory/Class key to make sets of prints from the same

original. The same number of prints is made for each set.

D The optional tape dispenser automatically feeds out strips of paper which

separate the printing groups on the paper delivery table.

a Up to 99

sets of prints can be selected for one original.

Press the

light the Class indicator.

Set the original face down on

the exposure glass or in the optional document feeder.

Memory/Class key to

47

With the Number keys, enter

El

the number of prints for each

set to be made from the original.

, Press the Enter key.

n

With the

the desired number of sets.

The maximum number of sets that

can be made is 99.

Turn on

optional

48

Number keys, enter

the power switch

tape dispenser.

of the

Press the Master Making key.

Check the image position of the

trial or proof print.

image position is not correct,

If the

adjust it using the Image Position

keys (~ See page 21) or the side

plate fine adjusting dial (~ See

page 22).

Make your prints.

After the last page of each printing

set is fed out to the paper delivery

table, the tape dispenser drops a

strip of paper on the top of the pa-

per stack.

If the power switch of the optional

tape dispenser is turned off or the

tape dispenser is not installed in

your machine, the group printing

cycle stops after each set is delivered. Remove the set of prints

from the paper delivery table and

press the Print Start key to start

the next group printing cycle.

OPERATION

49

OPERATION

Group Printing From Different Originals

(Memory Mode)

Use the Memory/Class key to make sets of prints from different origi-

nals.

rl

With the optional document feeder, you can set several originals and make

prints of all of them at once. I= See page 75.

c1

The optional tape dispenser automatically feeds out strips of paper which

separate the printing groups on the paper delivery table.

Press the Memory/Class key to

light the Memory indicator.

With the Number

the desired number

the first original.

keys, enter

of prints for

Press the Enter key. This

El

stores the number of prints to

be made for the first original in

memory 1.

When the number of prints in each

5

set is the same, it is not necessary

to input the number of prints for

each group in memory. Simply select Auto Cycle mode and enter the

desired number of prints once.

With the Number keys, enter

A

n

the number of prints for the

second original.

OPERATION

Press the

H

stores the number of prints to

be made for the second original

in memory 2.

Repeat steps 4 and 5 for each

I

H

original.

u

The number of prints for up to 25

originals can be stored.

Press the Enter key again. The

El

memory returns to memory 1.

If you store the number of prints for

7

25 originals, the memory number

returns to 1. It

press the Enter key.

Enter key. This

is not necessary to

51

OPERATION

t

Set the first original face down

b

n

on the exposure glass.

o

Set originals one sheet at a time in

the same order that you stored

them in memory.

Press the

9

El

Check the image position of the

trial or proof print.

If the image position is not correct,

0

adjust it using the Image Position

keys (~ see page 21) or the side

plate fine adjusting dial (~ see

page 22).

, Turn on the power switch of the

m

optional tape dispenser.

Press the Auto Cycle key.

Master Making key.

M

If you press the Auto Cycle key,

o

you cannot make proof prints by

pressing the Proof key.

Press the Print Start key.

After the first set is fed to the pa-

per delivery table, the optional tape

dispenser drops a strip of paper on

the top of the paper stack.

After the first set is completed,

set the second original on the

exposure glass and press the

Master Making key.

Repeat step 13 until you have

finished printing.

OPERATION

53

OPERATION

Multi Copy

Combine 2 originals

D+B “*!!IH

~+~lq!Qj3q

You can print 2 separate originals on a single sheet of paper. The

following tables list the combinations that can be used when combining

two originals.

— Metric version —

% CYialnal Sizell

,afj& 1 ““

“‘5Q 1‘5D ‘“ “D

1------II

I

I

I

I

— Inch version —

A

I

I

54

A3 Q

B4D

A4 D

85 w

Paper Size

11’’ X17” C3

8112” x 14 D

8112”x 11“ D

51/2” x 8112”w

II

II

II

II

10070 115940 ~ 141% 1630/o 200’XO

650/o

I

i

1

I

173%

1410/0

122?io

100940

87%

710/0

6170

5070

II

II

100?40

I

820/o

I

7170

I

5770

I

81/2” x 11” D

100?40

770/0

650/o

50°A

I

i

I

I

122%

1000/0

87%

71%

I

I

1

I

51/2” x 81/2” Q

I

I

1410/0

1150/0

1000/0

82!X0

1290/o

1000/0

1000/0

I

I

OPERATION

Combined print

You can print 4 original images on a single sheet of paper using 2

originals. The images are positioned on the print as shown above. The

following tables list the combinations that can be used when combining

originals.

— Metric version —

Paper Size

A3 v 50%

B4 w —

A4 G — —

B5 G — — —

A5 D — — — —

— Inch version —

Paper Size

11’’ X17”W

8112°x 14” G II

81/2” x 11“ Q II

A3 G B4w

58%

50?40

II” X17NC?

I I

500/0

II

—

—

A4 G

71?lo 82%

61%

50’XO

I

65%

50?40

B5 GI

71‘/0 87%

580/0

500/0

A5 v B6E7 A6 w

100% 115% 141?40

7170 82% 10070

61’%0

50%

65?40

50?40

50%

I

100$?0 122940

71’%0 87?40

58?40

I

1

I

I

7070

10070

770/0

7770

50?40

55

OPERATION

Notes for multi copy mode

If originals are longer than the maximum length for combined prints, images

~

do n~t completely ‘appear on prints. The following table gives the maximum

combined original length for each print paper size.

B4

A4 D

B5 w

A5 D

11” x 17”

8112”x 14”

8112”x 11“ D

X 8112;’ D

51/2”

Any image closer than 5 mm, 0.2” to the leading edge of the first original will

IJ

not be printed. Also, any image closer than 4 mm, 0.16“ to the leading edge

of the second original will not be Printed. When the image is too close to the

leading edge, us~ copies of the “originals with the image

mm, 0.2” for the first original (4 mm, 0.16“ for the second

leading edge.

You can select different kinds of image settings for the

c1

original.

Cl

When you use the optional document feeder with this function, c see page

73.

Cl

Make sure that the paper feed side plates contact the paper lightly when you

use Multi Copy. Otherwise, the two original images will not appear at the

proper position on the prints.

II

!

Maximum original length = actual original

length x magnification ratio

182 mm

148 mm

128 mm

105 mm

216 mm, 8.5”

178 mm, 7.0”

140 mm, 5.5”

108 mm, 4.3”

shifted at least 5

original) from the

first and second

56

How to make prints in multi copy mode

Set the first original face down

and with the top toward the operating side.

The first original will be printed on

the leading part of the print.

Enter the number of prints us-

ing the Number keys.

Check the print paper size and

the reproduction ratio.

OPERATION

Then press the Multi Copy key

either:

Once to select the Combine 2

Originals function.

;wice to select the Combined

Print function.

57

OPERATION

Press the

The beeper sounds after the

first original is on the master.

Set the second original face

down and with the top toward

the operating side.

Press the

Check the image position of the

trial or proof print.

If the image position is not correct,

adjust it using the Image Position

keys (~ See page 21) or the side

pIate fine adjusting dial. (- See

page 22.)

Master Making key.

Master Making key.

stop

@

o~

Proof

step

@

3~

Proof ~

Master Making

I

o

Print start

Master Making

I

o

PrintStart

.

58

Make your

prints.

OPERATION

Skip Feed Printing (Skip Feed Mode)

If the backs of prints are dirty, you can increase the time between two

prints using the Skip Feed key. In the default setting, when one sheet of

paper is fed the drum rotates once. However, you can select the

number of rotations of the drum. This gives you the chance to remove

prints one by one from the paper delivery table or insert one sheet of

paper between two prints. If you use this function, you can also use

paper longer than 447 mm, 17.5” in spite of the maximum length

limitations of paper.

a The maximum length of paper in Skip Feed mode is 590 mm, 23.2”.

CI When you use paper longer than 447 mm, 17.5”, completed prints will not be

delivered to the paper delivery table properly, so receive them by hand.

Set your original on the exposure glass or in the optional

document feeder.

While pressing the Skip Feed

key, select the number of rotations of the drum while one

sheet of paper is fed, using the

Number key.

You can select from 1 to 9 rota-

tions.

The beeper sounds after you set

the number of rotations.

Release the

El

enter the number of prints using

the Number keys.

Skip Feed key and

OPERATION

Press the

A

c1

2heck

:rial or

If the image position is not correct,

n

adjust it using the Image Position

keys (* see page 21) or the side

plate fine adjusting dial (- see

page 22).

Make your prints.

Master Making key.

the image position of the

proof print.

El

60

OPERATION

User Programs

This User Program function allows you to store and recall up to 8

frequently used job setups.

IJ The stored programs are not cleared when you turn off the main switch.

How to input a user program

Select and enter the job set-

tings you want to store in mem-

ory.

Press the Program key.

Numbers already containing a program are displayed on the guidance display.

Enter “O” using the Number

key.

Press the

The program numbers (1 to 8) will

be displayed in the guidance display.

If a user program has been pro-

tected, that program number will

not appear in the display. For

changing a protected

gram, ~ see page 65.

If all the user programs

protected, the machine

the ready condition.

Enter key.

user pro-

have been

returns to

61

OPERATION

Enter one of the program num-

El

bers displayed on the guidance

display using the

Make sure that the previous job

D

settings

program

, Press the Enter key.

stored under the selected

Number keys.

B

62

How to access a user program

Press the Program key.

Numbers already containing a pro-

gram are displayed on the guidance display.

Using the Number keys, enter

El

the number of the program that

you want to access.

OPERATION

Press the Enter key.

All stored job settings are recalled.

63

OPERATION

Set your originals on the expo-

i

n

sure glass or in the optional

document feeder.

Press the Master Making key.

H

64

How to protect a program

OPERATION

If you want to prevent someone from

following procedure.

While pressing the Reset key

II

and Stop key

press the Prograrr

Enter

n

key.

Press the Enter key.

The numbers of the programs

J

which are not protected will

played in the guidance display.

“1” using the Number

simultaneously,

key.

be dis-

writing over your program, do the

65

OPERATION

Using the Number keys, enter

c1

‘ the number of the program that

you wish to protect.

Press the Enter key.

B

How to remove user program protection

While pressing the Reset key

n

Stop key simultaneously,

and

press the Program key.

OPERATION

Enter

El

key.

Press the Enter key.

H

If no program number is

rl

the machine

condition.

A

c1

the number of the program that

you wish to remove protection

from.

11~11

using the

to the ready

Number

protected,

enterUsing the Number keys,

Press the Enter key.

u

OPERATION

Printing Of Secret Documents (Security Mode)

This function prevents others from making prints of secret documents

from the master. For example, if you want to print some documents with

sensitive information, use this function after making your prints so that

nobody can access that aster again.

Make your prints.

While pressing the CS Mode

key, press

ber key.

If you press the Proof key or the

Print Start key after finishing one

print job, the beeper sounds and

you cannot make prints.

You cannot cancel Security mode

even if you turn off the

switch.

If you make the next master,

rity mode is canceled.

“1” using the Num-

68

OPTIONALFUNCTIONS

OPTIONAL FUNCTIONS

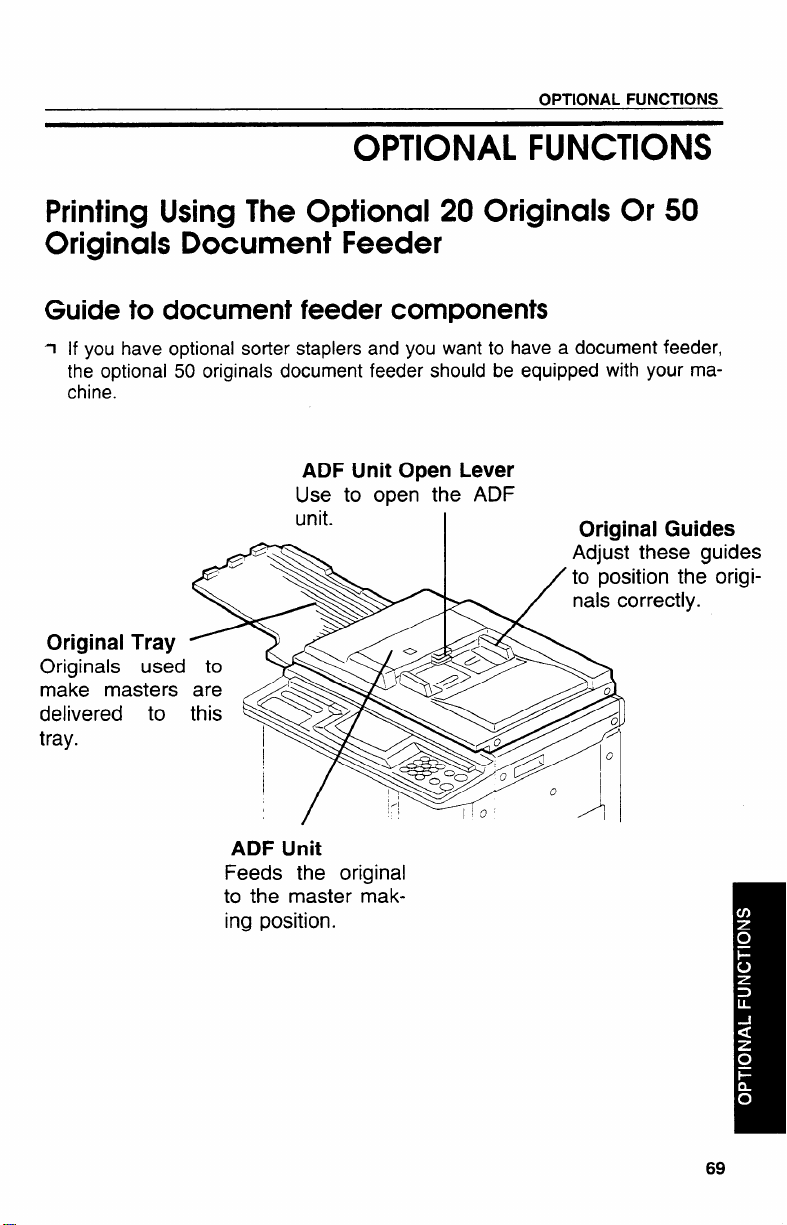

Printing Using The Optional 20 Originals Or 50 Originals Document Feeder

Guide to document feeder components

1

If you have optional sorter staplers and you want to have a document feeder,

the optional 50 originals document feeder should be equipped with your machine.

ADF Unit Open Lever

Use to open the ADF

unit.

Original Tray

Originals used

make masters

delivered to

tray.

Original Guides

Adjust these guides

to position the origi-

nals correctly.

ADF Unit

Feeds the original

to the master mak-

ing position.

69

OPTIONALFUNCTIONS

Originals

CI The following types of originals are not recommended for use with the op-

tional document feeder. Set these types of originals on the exposure glass.

. Originals heavier than 127.9 g/m2, 34 lb

. Originals lighter than 40.7 g/m2, 10.8 lb

. Carbon coated originals

. Damaged originals

. Originals with glue on them

. Originals perforated for ring binders

. Book originals

. Originals written with a pencil or ball-point pen

. Originals smaller than 90 mm x 140 mm, 3.6” x 5.6”

. Originals larger than 307 mm x 432 mm, 12.0” x 17.0”

. Folded, curled, creased originals

. Bound, stapled, or clipped originals

a If you use paste-up originals, make sure the pasted parts hold firmly to the

base sheet. If the thickness of the paste-up original is more than 0.2 mm,

1/125” and the space between the pasted parts is less than 2 mm, 2/25”, a

shadow might appear on the prints.

CI The first 5 mm, 0.2”, of the leading edge and the last 3 mm, 0.12”, of the

trailing edge cannot be printed. Make sure the leading edge margin is at

Ieast 5 mm, 0.2”, and the trailing edge margin is at least 3 mm, 0.12“.

Original

5 mm, 0.2”

*

-tl-

Print

-’tt-

3 mm, 0.12”

OPTIONAL FUNCTIONS

Setting originals into the document feeder

If you set one original into the document feeder while another original is still

o

on the exposure glass, the original set into the document feeder will be

Set the original tray.

U

Adjust the

H

size of the

Insert the originals face

El

the document feeder

stops.

Do not insert different size originals

ill

at the same time.

Approximately 20 originals can be

5

inserted at one time in the 20 originals document feeder. The first

(bottom) original will be fed first.

Approximately 50 originals can be

c1

inserted at one time in the 50 originals document feeder. The last

(top) original will be fed first.

The guides must fit snugly against

c1

both sides of the stack.

original guides to

down in

until it

71

OPTIONALFUNCTIONS

Set the required image settings

i

rl

and press the Master Making

key.

Make your prints.

El

MasterMaking

I

0

If the next original has been set in

o

the document feeder before the

machine stops, that original is fed

automatically and a trial print is delivered to the paper delivery table

after the print of the first original is

completed. Check the image position of the trial print of the next

original. If necessary, make proof

prints using the Proof key to check

the image position again.

When you set originals in the 50

c1

originals document feeder, the last

original (original set on the top of

the original stack in the document

feeder) will be delivered to the

original tray first and the first original (original set at the bottom of

the original stack in the document

feeder) will be delivered to the

original tray last. So, the order of

originals is inverted as shown in

the illustration. Reset the order of

originals.

o

PrintStart

~

72

Multi copy with the document feeder

OPTIONALFUNCTIONS

D I= see

c1

!7

c1

El

page w for details about the Multi Copy function.

Select Combine 2 Originals

mode and insert the 2 originals

face down, tops pointing to-

wards the operation side.

or

Select Combined Print mode

and insert the 2 originals face

down, tops towards the paper

delivery table.

When you use the optional 20

originals document feeder, the bottom original will be printed on the

leading part of print.

When you use the optional 50

originals document feeder, the top

original will be printed on the leading part of print.

Enter the number of prints us-

ing the Number keys.

n’!

\~

a

.,---.,

. . ....

\

,.

.-.

,,

,.

s

,..:,

;...,;

2.

J,

,..

Check the print paper size and

El

the reproduction ratio.

73

OPTIONALFUNCTIONS

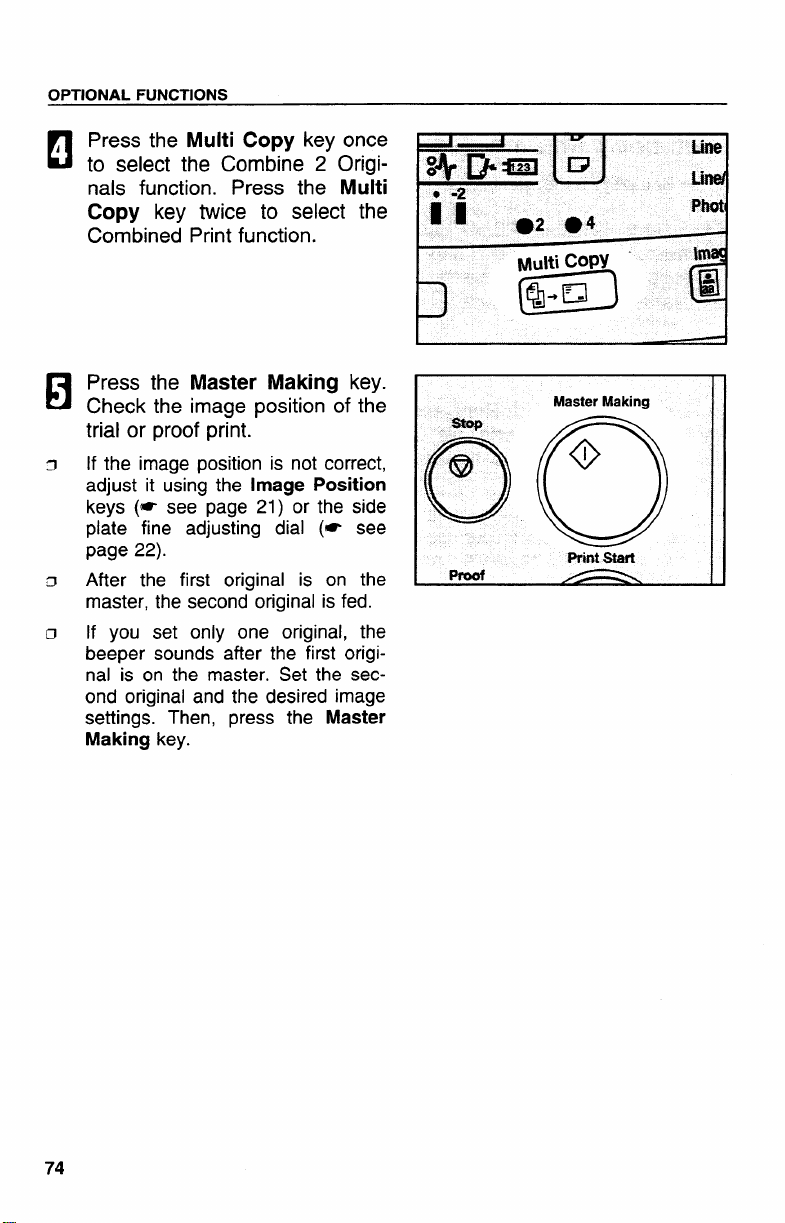

Press the Multi

to select the Combine 2 Originals function. Press the Multi

Copy key

Combined

Press the

Check the

trial or proof print.

If the image position is not correct,

adjust it using the

keys (~ see page 21) or the side

plate fine adjusting dial (* see

page 22).

After the first original is on the

master, the second original is fed.

If you set only one original, the

beeper sounds after the first original is on the master. Set the second original and the desired image

settings. Then, press the

Making

key.

Copy key once

twice to select the

Print function.

Master Making key.

image position of the

Image Position

Master

o~

S?op

63

Proof

MasterMaking

I

0

PrintSt8rt

74

OPTIONALFUNCTIONS

Group printing from different originals with the document feeder (Memory mode)

To prevent original misfeeds, do not set originals of different sizes.

3

~ Do not set more than 20 originals at one time in the optional 20 originals

document feeder.

Follow steps 1 to 7 on pages

50 and 51.

Set the originals face down into

the document feeder.

When you use the optional 20

originals document feeder, the

originals are fed from the bottom of

the stack. Make sure that the originals are set in the correct sequence with the first original on the

bottom.

When you use the optional 50

originals

originals

stack. Make sure that the originals

are set in the correct sequence

with the first original on top.

document feeder, the

are fed from the top of the

Press the Master Making key.

Check the image position of the

trial or proof print.

image position is not correct,

If the

adjust it using the Image Position

keys (= see page 21) or the side

plate fine adjusting dial (~ see

page 22).

o~

S!op

@

Proof

MasterMaking

I

o

PrintStart

-

75

4

●

.

1

OPTIONALFUNCTIONS

Turn on the power switch of the

optional tape dispenser.

Press the Auto Cycle key.

El

In Auto Cycle mode, printing starts

c1

automatically after a trial print is

delivered.

Press the Print Start key.

I

n

After the last page of each set is

c1

fed out to the paper delivery table,

the tape dispenser drops a strip of

paper on the top of the paper

stack. The next cycle begins.

OPTIONAL FUNCTIONS

Printing Using The Optional Sorter Stapler

Guide to 20-bin sorter stapler components

c1

Up to 2 sorter staplers can be equipped with your machine.

o

If you have optional sorter staplers and you want to have a document feeder,

the optional 50 originals document feeder should be equipped with your machine.

rl

Sorter staplers and a tape dispenser cannot be equipped together.

c1

When you use the Sott, Staple Sort or Class Sort function, set the speed to

Setting- 1.

Non-sort Tray

Staple Key

Press to set or

cancel Staple

mode.

If you do not select

Sort, Staple Sort or

Class Sort mode,

prints are delivered

here.

When a misfeed occurs, open to remove

misfed paper.

I

Stapler

Open to

staples.

\

77

OPTIONAL FUNCTIONS

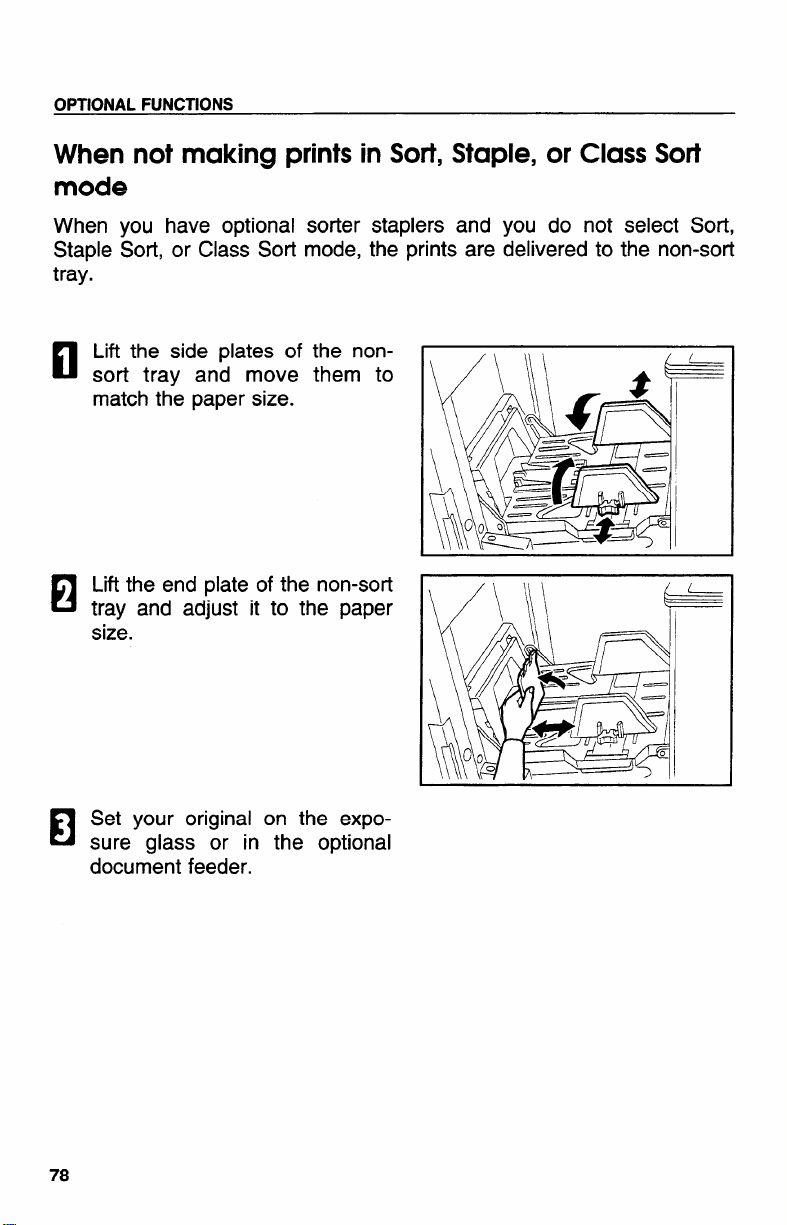

When not making prints in Sort, Staple, or Class Sort

mode

When you have optional

Staple Sort, or Class Sort

tray.

Lift the side plates of the non-

D

sort tray and move them to

match the paper size.

Lift the end plate of the non-sort

El

tray and adjust it to the paper

size.

sorter

mode,

staplers and

the prints are

you do not

delivered to

select Sort,

the non-sort

Set your original on the expo-

El

sure glass or in the optional

document feeder.

, Press the Master Making key.

n

Than mcika \Im Ir nrintc

I 11=11, Illul\u ywul pIIll LQ.

OPTIONAL FUNCTIONS

MasterMakina

stop

I

@

o

c)’~

Proof

PrintStart

Sorting into sets (123, 123, 123) (Sort mode)

P 1

w

I

One print of each original is delivered to each bin and prints are collated

into sets.

CI For Sorting, the following limitations apply:

lWL1l W Vulwlwma.

Paper size

Paper weight

Maximum

capacity of bins A3 and paper sizes other than the SiZeSdescribed above:

Maximum

number of sets

Paper that

cannot be used I

Paper sizes described above with exception of A3:

50 sheets

25 sheets

D Roughly-cut paper

,u Paper of different thickness in the same stack

a Buckled or curled paper

,5 Short grain paper

t 1 I

I I

L

A3 G, B4 GI,A4 b, B5 D, A5 D.

64-82 g/m2

20 sets (per sorter stapler)

1 t

I

I

I I

I

OPTIONALFUNCTIONS

IV. , .V. w.v, ,.

Paper size

Paper

weight

Maximum so ~heets

capacity of

bins

Maximum

number of

sets

Paper that

cannot be

used

IJ Print sets over the maximum number of sets are delivered to the non-sort

When you set originals on the exposure glass:

11’’ X17”D

Paper sizes described above with exception of 11” x 17“:

11” x 17“ and paper sizes other than the sizes described

above: 25 sheets

a Roughly-cut paper

CI Paper of different thickness in the same stack

D Buckled or curled paper

rJ Short grain paper

, 8112”x 14” G, 81/2” x 11” ~ u, 51@’x 81/2” G.

17.1 -21.8 lb

20 sets (per sorter stapler)

Press the Sorter

c1

the Sort indicator.

Set the speed to Setting 1.

El

you do not set the speed to Set-

If

o

ting 1, the Speed function Setting 1

indicator and the Special Feature

indicator blink.

key to light

Set the last original on the ex-

El

posure glass.

Make sure that the last original is

o

set first. Otherwise, prints are delivered to the bins in the wrong order.

Enter the number of sets re-

A

c1

quired using the Number keys.

For the maximum number of

!J

* see page 79 or 80.

H

trial or proof print.

‘3

If the image position is not correct,

adjust it using the

keys (~ see page 21) or the side

plate fine adjusting dial (- see

page 22).

c1

The trial and proof prints are delivered to the non-sort tray.

image position of the

Image Position

OPTIONAL FUNCTIONS

sets,

key.

Make your prints.

t

n

c1

Each print is delivered to each bin

of the sorter stapler.

81

OPTIONAL FUNCTIONS

Set the second to last original

on the exposure glass.

Press the Master Making key.

Check

trial or

o Make your prints.

the image position of the

proof print.

El

, Repeat steps 7 through 9 until

m

you have finished printing.

00

Stq)

@

l%oof

MasterMaking

I

o

start

Print

When you set originals in the optional 50 originals document feeder:

Follow steps 1 and 2 on page

K1

80.

Set your originals in the op-

El

tional document feeder.

Enter the number of sets re-

El

quired using the Number keys.

cl

For the maximum number of sets,

e see page

79 or 80.

OPTIONAL FUNCTIONS

Press the

i

c1

Check the

trial or proof print.

If the image position is not correct,

o

adjust it using the

keys (= see page 21) or the side

plate fine adjusting dial (* see

page 22).

The trial and proof prints are deliv-

0

ered to the non-sort tray.

D

If you press the Auto Cycle key,

all sets of prints are delivered to

the bins automatically after pressing the

case, you cannot make proof prints

for each original.

Make your prints.

Master Making key.

image position of the

Image Position

Print Start key. In this

la

c1

Each print is delivered to each bin

of the sorter stapler. Then, the next

original is fed and the machine

makes its master automatically.

O(y

@

Proof

MasterMaking .

I

o

PrintStart

Repeat step 5 until you have

B

1 finished printing.

83

OPTIONAL FUNCTIONS

Stapling prints (Staple Sort mode)

L

After prints are sorted into sets, they are stapled automatically.

The original set direction and the

o

staple

shown

position of the prints are as

in the illustration.

~ For Stapling, the following

IGU Iv VGI=IUI 1.

Paper size

Paper weight

Stapler capacity

Maximum number

of sets

Paper that cannot

be used

limitations apply:

A3D, B4D, A4QD, B5D.

64-82 g/m2

64 g/m2:

75 g/m2:

80 g/m2:

20 sets (per sorter stapler)

D Roughly-cut paper

o Paper of different thickness in the same

D Buckled or curled paper

fl Short grain paper

2-50 sheets

2-42 sheets

2-40 sheets

Ich version:

Paper size

Paper weight

Stapler capacity

Maximum number

of sets

Paper that cannot

be used

OPTIONAL FUNCTIONS

11” x 17”D , 8112” x 14”D , 8112”x 11” Q D.

17.1 -21.8 lb

17.1 lb:

20.0 lb: 2-42 sheets

21.8 lb: 2-40 sheets

20 sets (per sorter stapler)

CI Roughly-cut paper

o Paper of different thickness in the same stack

a Buckled or curled paper

n Short grain paper

2-50 sheets

n Print

Setting stapling before

CI This function can be

c1

sets over the maximum number of sets are delivered to the non-sort

tray.

printing (Auto Staple mode)

used only when your machine is equipped with the

optional 50 originals document feeder.

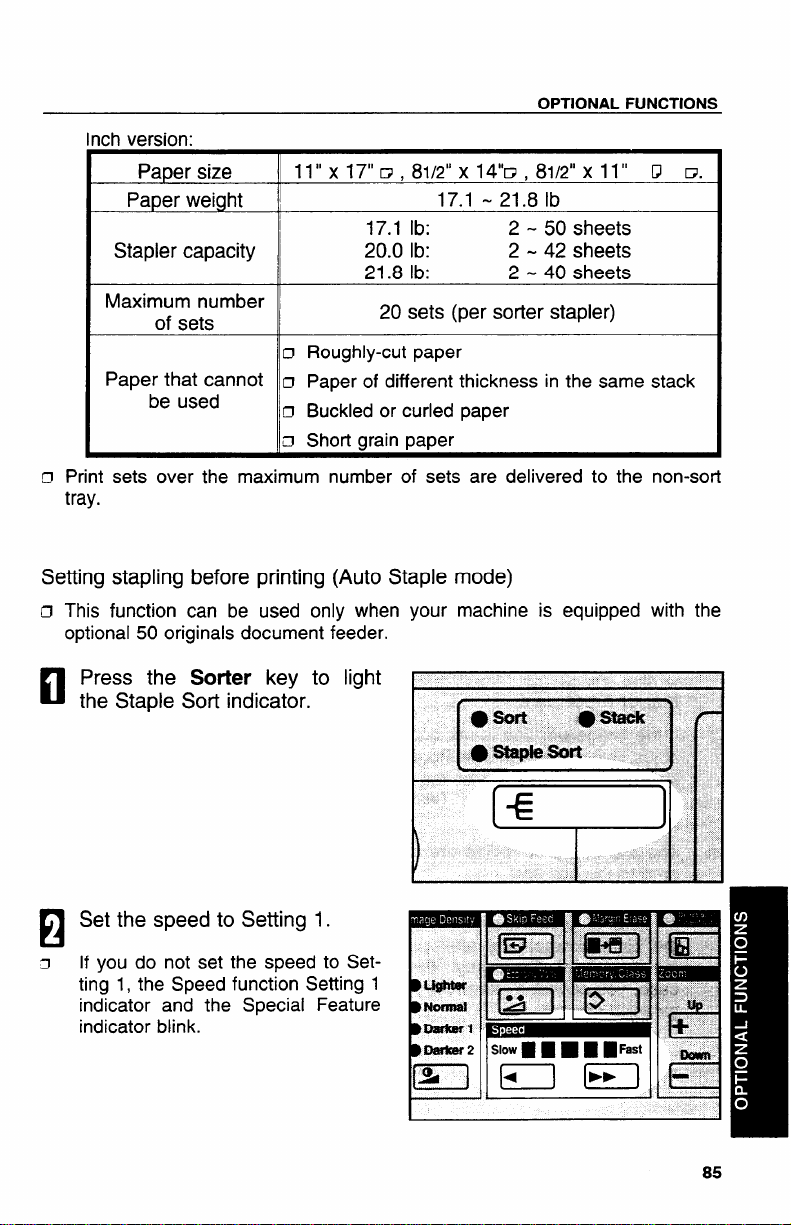

Press the Sorter key to light

the Staple Sort indicator.

Set the speed to Setting 1.

la

If you do not set the speed to Set-

5

ting 1, the Speed function Setting 1

indicator and the Special Feature

indicator blink.

85

OPTIONAL FUNCTIONS

Set your originals in the op-

El

tional 50 originals document

feeder.

Enter

A

n

quired

Press the

H

Check the

trial or proof print.

o

If the image position is not correct,

adjust it using the Image

keys (* see page 21) or the side

plate fine adjusting dial (~ see

page 22).

The trial and proof prints are deliv-

0

ered to the non-sort tray.

If you press the

0

all sets of prints are delivered to

the bins automatically after press-

ing the

case, you cannot make proof prints

for each original.

the number of sets re-

Number keys.

Master

image position of the

Auto Cycle key,

Print Start key. In this

Position

Pror3f ~

PrintStart

Make your prints.

1

n

c1 Each print is delivered to each bin

of the softer stapler. Then, the next

original is fed and the machine

makes its master automatically.

Repeat step 6 until you have

El

finished printing.

OPTIONAL FUNCTIONS

~Caution: ‘0 not insert your hands

After all prints are delivered to the

0

bins, the machine stark stapling.

To cancel Staple Sort mode, press

o

the

pler.

again, the machine starts stapling

prints again.

m the bins during printing

or stapling.

Staple key on the sorter sta-

If you press the Staple key

87

OPTIONAL FUNCTIONS

Setting stapling after printing (Manual Staple Mode)

When you set originals on the

El

exposure glass, follow the steps

1 through 10 on pages 80, 81

and 82.

When you set originals in the

optional document feeder, follow steps 1 through 6 on pages

82 and 83.

When you use 2 or more origi-

u

nals, the Staple key on the

sorter stapler will be lit. Press

the Staple key.

~Caution:

To cancel Staple Sort mode while

Cl

stapling, press the

again. If you want to restart sta-

pling, press the Staple key once

again.

Do not insert your hands

in the bhs during printing

or stapling.

Staple key

88

Bypass Feed Stapling

OPTIONAL FUNCTIONS

You can staple

stapler.

D Before

of the bins.

c1 For stapler capacity, I= see page 84 or 85.

El

n

o

setting

Set the stack of paper you want

to staple on the first bin.

Make sure that the

the sorter stapler is lit.

The paper stack must make con-

tact the front cover and the fence

inside of the bins.

Press the Staple key.

a stack of paper that is set on the first bin of the sorter

paper on the first bin, make sure that no prints remain on any

Staple key on

El

ACaution:

Do not insert your hands

in the bin during stapling.

89

OPTIONAL FUNCTIONS

Group printing from the same original with the sorter

stapler (Class Sort mode)

I

Use this function to make sets of prints from the same original. The

same number of prints is made for each set. They are delivered to the

each bin of the sorter stapler.

n For Class Sorting, the following limitations apply:

Mlln+rip \/nrc2inn.

IVlwbllw Vws”, ”m, .

Paper size

Paper weight

Capacity of

bins

Maximum

number of sets

Paper that

cannot be used

Paper sizes described above with exception of A3:

50 sheets

A3 and paper sizes other than the sizes described above:

25 sheets

n Roughly-cut paper

n Paper of different thickness in the same stack

n Buckled or curled paper

D Short grain paper

A3G, B4G, A4u G, B5Qu , A5n.

64-82 g/m2

18 sets (When you have 1 sorter stapler)

38 sets (When you have 2 sorter staplers)

OPTIONAL FUNCTIONS

lch version:

—. -.

Paper Size 11’’ XI7”D , 8112”x 14” u, 8112”x 11“ ~ G , 5w” x 8112”Q

Paper

Weight

Capacity of 50 sheets

bins

Maximum

number of

sets

Paper that

cannot be

used

Press the Sorter key to light

El

the Stack indicator.

Paper sizes described

11” x 17“ and paper sizes other than the sizes described

above: 25 sheets

18 sets (When you have 1 sorter stapler)

38 sets (When you have 2 sorter staplers)

D Roughly-cut paper

a Paper of different thickness in the same stack

D Buckled or curled paper

D Short grain paper

17.1 -21.8 lb

above with exception of 11” x 17“: