Ricoh VT2100 S Service Manual 2250i

IMPORTANT SAFETY NOTICES

+

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the printer and peripherals,

make sure that the printer power cord is unplugged.

2. The wall outlet should be near the printer and easily accessible.

3. Note that some components of the printer are supplied with electrical

voltage even if the main switch is turned off.

4. If any adjustment or operation check has to be made with exterior

covers off or open while the main switch is turned on, keep hands away

from electrified or mechanically driven components.

HEALTH SAFETY CONDITIONS

1. If you get ink in your eyes by accident, try to remove it with eye drops or

flush with water as first aid. If unsuccessful, get medical attention.

2. If you ingest ink by accident, induce vomiting by sticking a finger down

your throat or by giving soapy or strong salty water to drink.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The printer and its peripherals must be installed and maintained by a

customer service representative who has completed the training course

on those models.

2. The RAM board has a lithium battery which can explode if handled

incorrectly. Replace only with the same type of RAM board. Do not

recharge or burn this battery. Used RAM boards must be handled in

accordance with local regulations.

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Dispose of replaced parts in accordance with local regulations.

2. Used ink and masters should be disposed of in an envionmentally safe

manner and in accordance with local regulations.

3. When keeping used lithium batteries (from the main control boards) in

order to dispose of them later, do not store more than 100 batteries

(from the main control boards) per sealed box. Storing larger numbers

or not sealing them apart may lead to chemical reactions and heat

build-up.

General Remarks

Each model code used in this manual represents the following models.

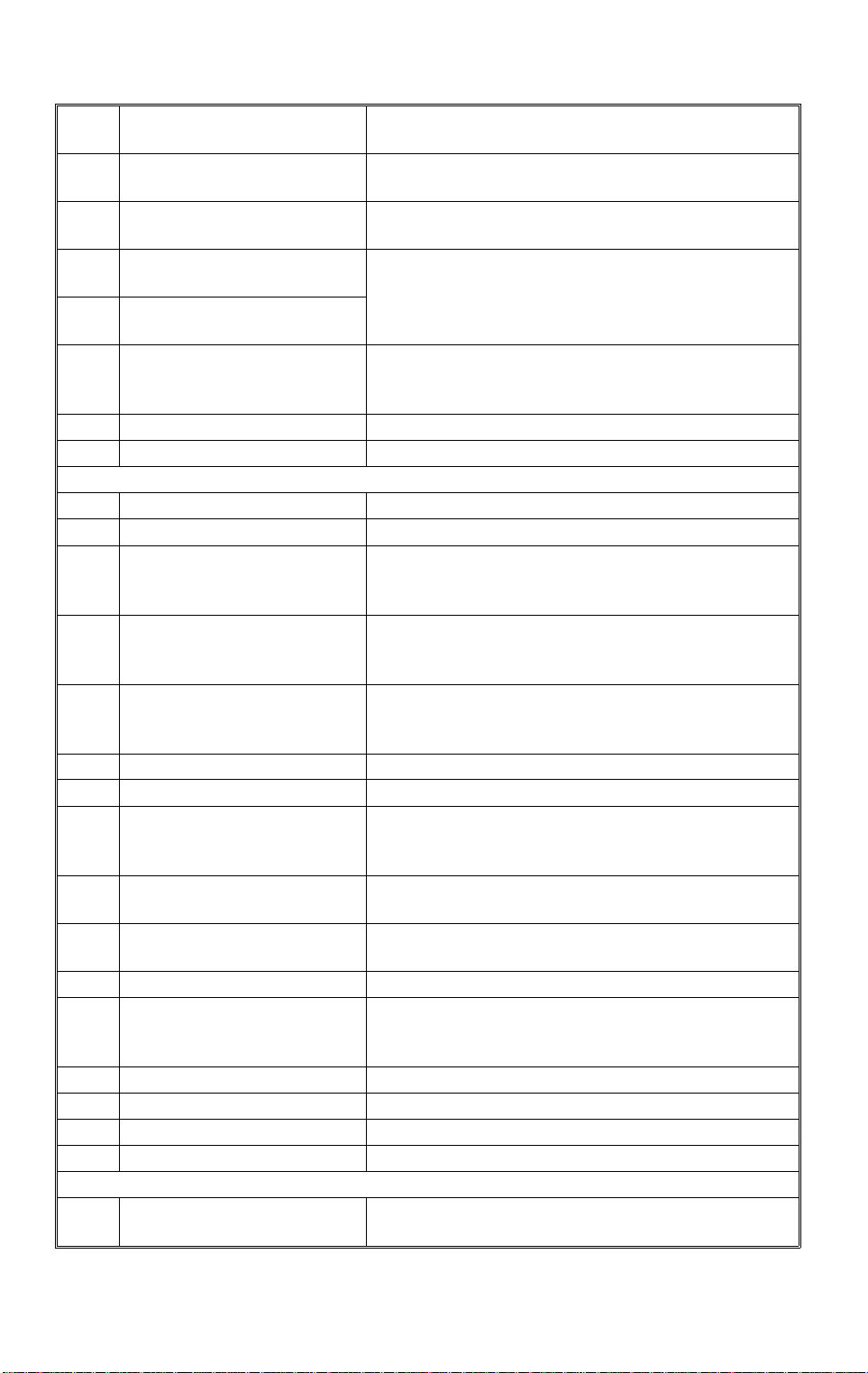

Model

Code

C215 VT2005 5323

C216 VT2105 CP325/1250/5325

C224 VT2200 CP327/1252/5327 6530 3200DNP

C226 VT2250/40 CP329(L)/1254(L)/5329(L) 6560 3250DNP

RICOH

Model

NRG Model A.B.Dick

Model

SAVIN

Model

SECTION 1

OVERALL MACHINE

INFORMATION

1 November 1996 SPECIFICATIONS

1. SPECIFICATIONS

Configuration: Desktop

Master processing: Digital

Printing process: Full automatic one-drum stencil system

Original type: Sheet/Book

Platen mode: Document Size:

Smaller than 257 x 364 mm [10.2" x 14.4"]

Thickness: Less than 30 mm

Weight: Less than 5 kg

ADF mode: Document Size

Length: 105 - 364 mm [4.1" - 16.5"]

Width: 148 - 364 mm [5.8" - 16.5"]

Thickness:

0.05 to 0.2 mm [2 to 8 mils]

2

(equivalent to 50 - 90 g/m

)

0.04 to 0.4 mm [1.6 to 16 mils],

manually assisted

(equivalent to 40 - 120 g/m

2

)

Overall

Information

Document Feed

Automatic feed, face up

ADF Capacity

30 sheets (using 20 lb paper)

Scanning method: Contact image sensor, with xenon lamp

Maximum scan width

256 mm [10.1"] ± 0.25%

1-1

SPECIFICATIONS 1 November 1996

Reproduction ratios: U.S.A. Version Other Versions

Full Size 100% 100%

Reduction 65% 71%

74% 82%

77% 87%

93% 93%

Enlargement 121% 115%

129% 122%

155% 141%

Image mode: Letter, Photo, Letter/Photo

Color printing: Drum unit replacement system

Master feed/eject: Roll master automatic feed/eject

Printing area: M aximum: 250 mm x 355 mm (9.8" x 14.0") at

20°C/ 65 % RH.

(210 mm x 288 mm for the A4 drum model)

Leading edge margin:

5 ± 3 mm at the "0" position

Print paper size: Minimum: 90 mm x 148 mm (3.6" x 5.9")

Maximum: 297 mm x 432 mm (11.6" x 17.0")

2

Print paper weight: 47.1 g/m

to 209.3 g/m2 (12.5 lb to 55.6 lb)

Printing speed: 60, 75, 90, 105, 120 sheets/minute (5 steps)

First copy time: Platen mode:

Less than 26 seconds (B4 paper)

Less than 25 seconds (A4 paper)

ADF mode:

Less than 29 seconds (B4 paper)

Less than 28 seconds (A4 paper)

Second copy time: Platen mode:

Less than 28 seconds (B4 paper)

Less than 27 seconds (A4 paper)

ADF mode:

Less than 32 seconds (B4 paper)

Less than 31 seconds (A4 paper)

Paper feed table

capacity:

Paper delivery table

capacity:

2

1000 sheets (66.3 g/m

1000 sheets (66.3 g/m

/17.6 lb)

2

/17.6 lb)

(800 sheets when the small guide plates are

used.)

1-2

1 November 1996 SPECIFICATIONS

Power source: 110/120 V, 60 Hz 4.5 A

220/240 V, 50/60 Hz 2.7 A

Maximum

power consumption:

110/120 V version: 325 W

220/240 V version: 340 W

Weight: 95 kg (209.4 lb)

Dimensions:

(W x D x H)

Trays closed: 685 mm x 625 mm x 620 mm

(27.0" x 24.6" x 24.4")

With ADF:

685 mm x 625 mm x 670 mm

(27.0" x 24.6" x 26.4")

Trays open: 1285 mm x 625 mm x 620 mm

(50.6" x 24.6" x 24.4")

With ADF:

(1285 mm x 625 mm x 670 mm

(50.6" x 24.6" x 26.4")

Pixel density: 300 dots/inch

Master eject box

capacity:

70 masters (Normal conditions)

60 masters (10°C/30%RH)

Paper feeding: Friction roller/center separation system

Overall

Information

Feed table side plate

88 mm to 330 mm (3.46" to 12.99")

width settings:

Paper feed roller

pressure:

Separation roller

pressure:

Side registration:

Vertical registration:

Normal position 300 g

Thick paper position 400 g

Normal position 180 g

Weak position 70 g

± 10 mm (manual)

± 20 mm (mechanical)

Ink supply: Automatic ink supply system

Press roller pressure:

10 ± 0.3 kg

Paper delivery: Air knife/vacuum delivery

1-3

SPECIFICATIONS 1 November 1996

Delivery side plate width

90 mm to 320 mm (3.54" to 12.6")

settings:

Print counter: 7 digits

Master counter: 6 digits (Option)

Supplies:

Master for B4 model

Thermal master 280 mm width

Master roll 257 masters/roll

Roll diameter 130 mm

Max run length 2,000 prints

Master for A4 model

Thermal master 240 mm width

Master roll 290 masters/roll

Roll diameter 130 mm

Max run length 2,000 prints

Ink colors:

(600 ml/pack)

Black, Red, Blue, Green, Brown

Yellow, Purple, Navy, Maroon, Orange, Teal

1-4

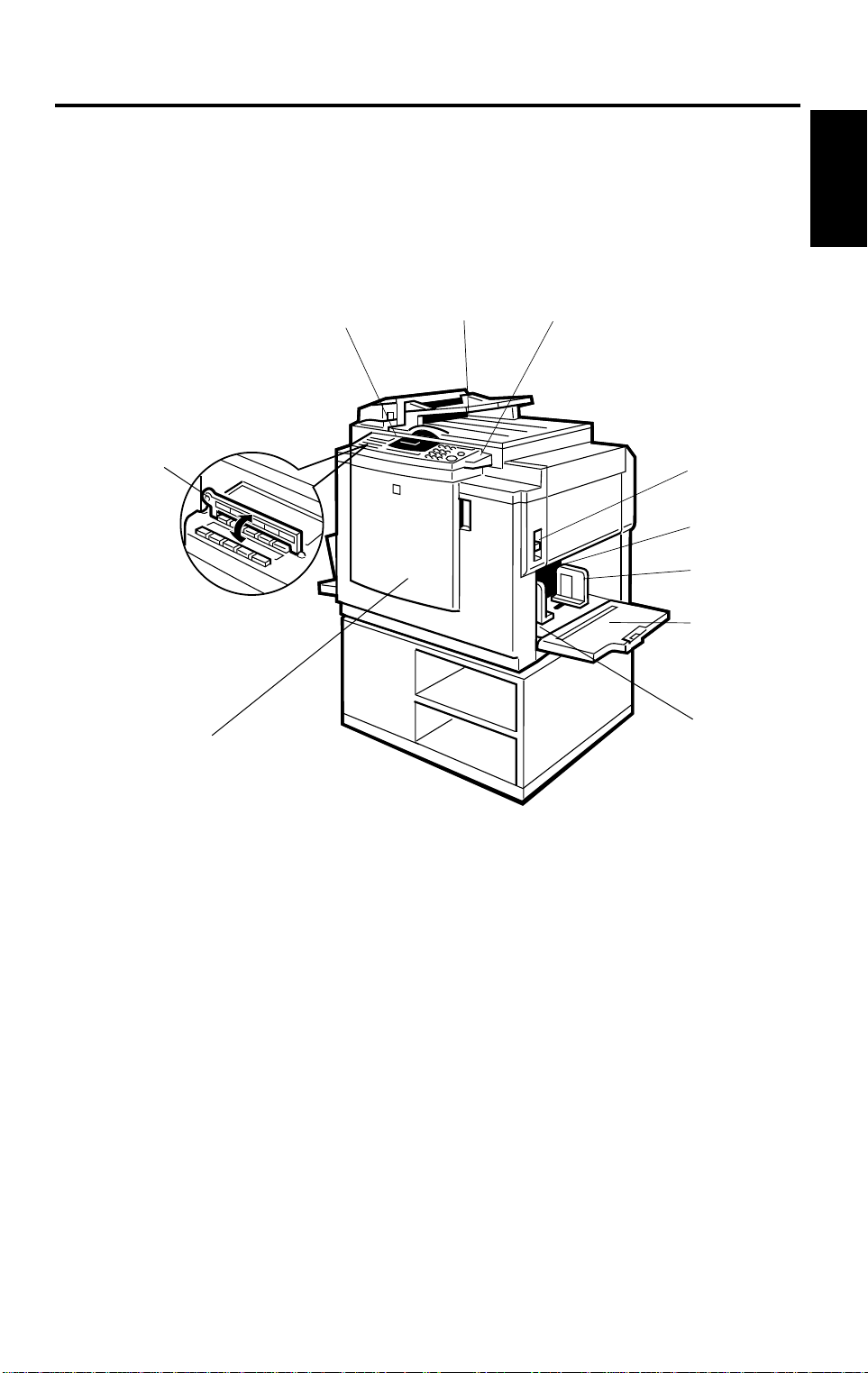

1 November 1996 GUIDE TO COMPONENTS AND THEIR FUNCTION

2. GUIDE TO COMPONENTS AND THEIR

FUNCTION

2.1 MACHINE EXTERIOR

1

10

9

Overall

Information

2

3

4

5

6

7

8

1-5

GUIDE TO COMPONENTS AND THEIR FUNCTION 1 November 1996

1. O peration panel

2. Platen cover

3. Original table

release lever

4. Feed roller

pressure leve r

5. Separation roller

pressure leve r

6. Paper feed side

plates

7. Paper feed table

8. Side plate fine

adjusting dial

9. Front cover

Operator control s and indicators ar e l ocated here.

Lower this cover over an original be fo re printing.

Use to open the original table unit when installing the master.

Use to adjust the contact pressure of th e paper feed roller

according to pa per thickness.

Use to adjust the separation roll er pressure to prevent

double feed.

Use to prevent paper skew.

Set paper on this table for printing.

Use to shift the paper feed table side w ays.

Open to access to the in si de of the machine .

10.Plate

Flip over when yo u use One Touch Clas s fu nct i on.

1-6

1 November 1996 GUIDE TO COMPONENTS AND THEIR FUNCTION

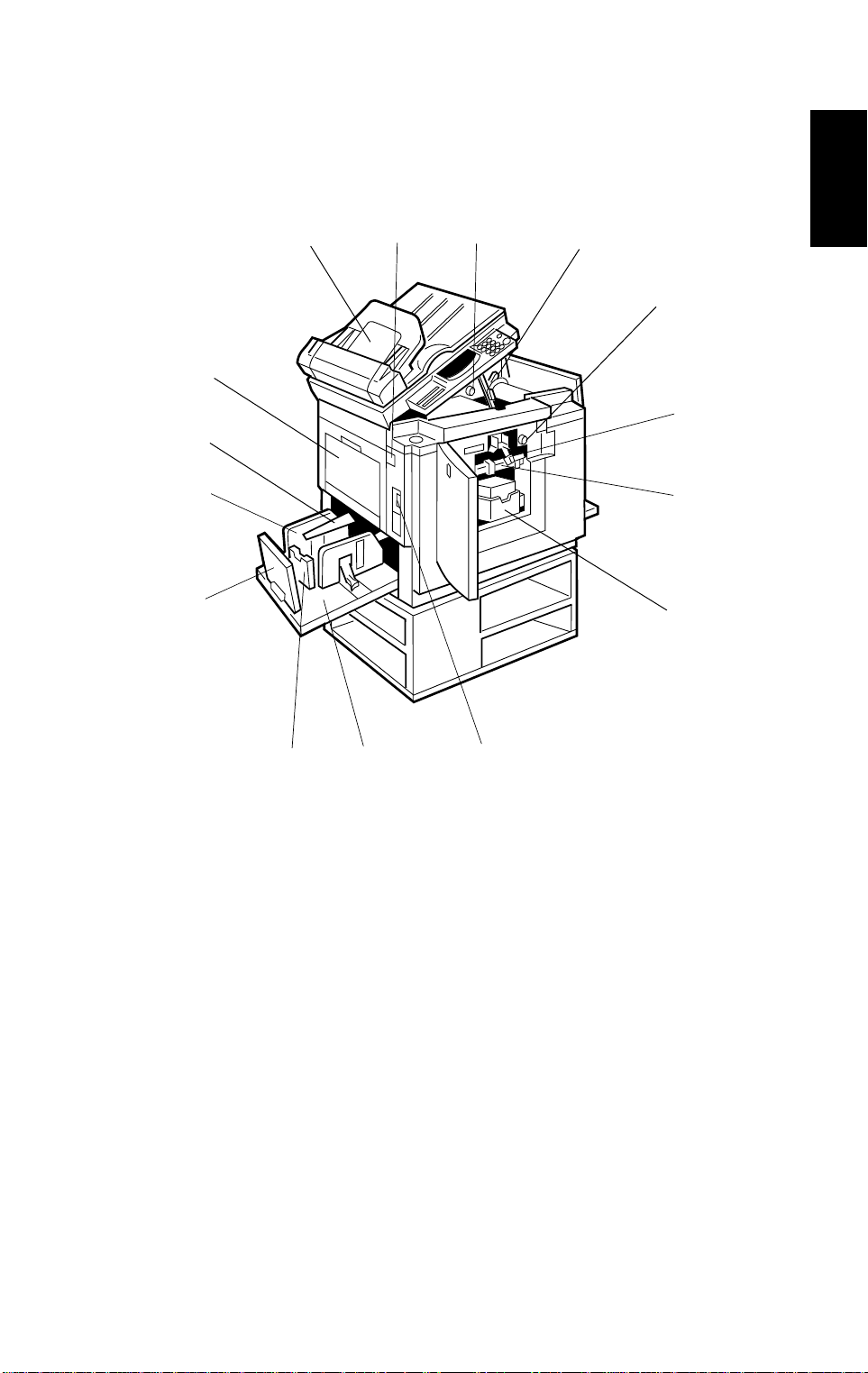

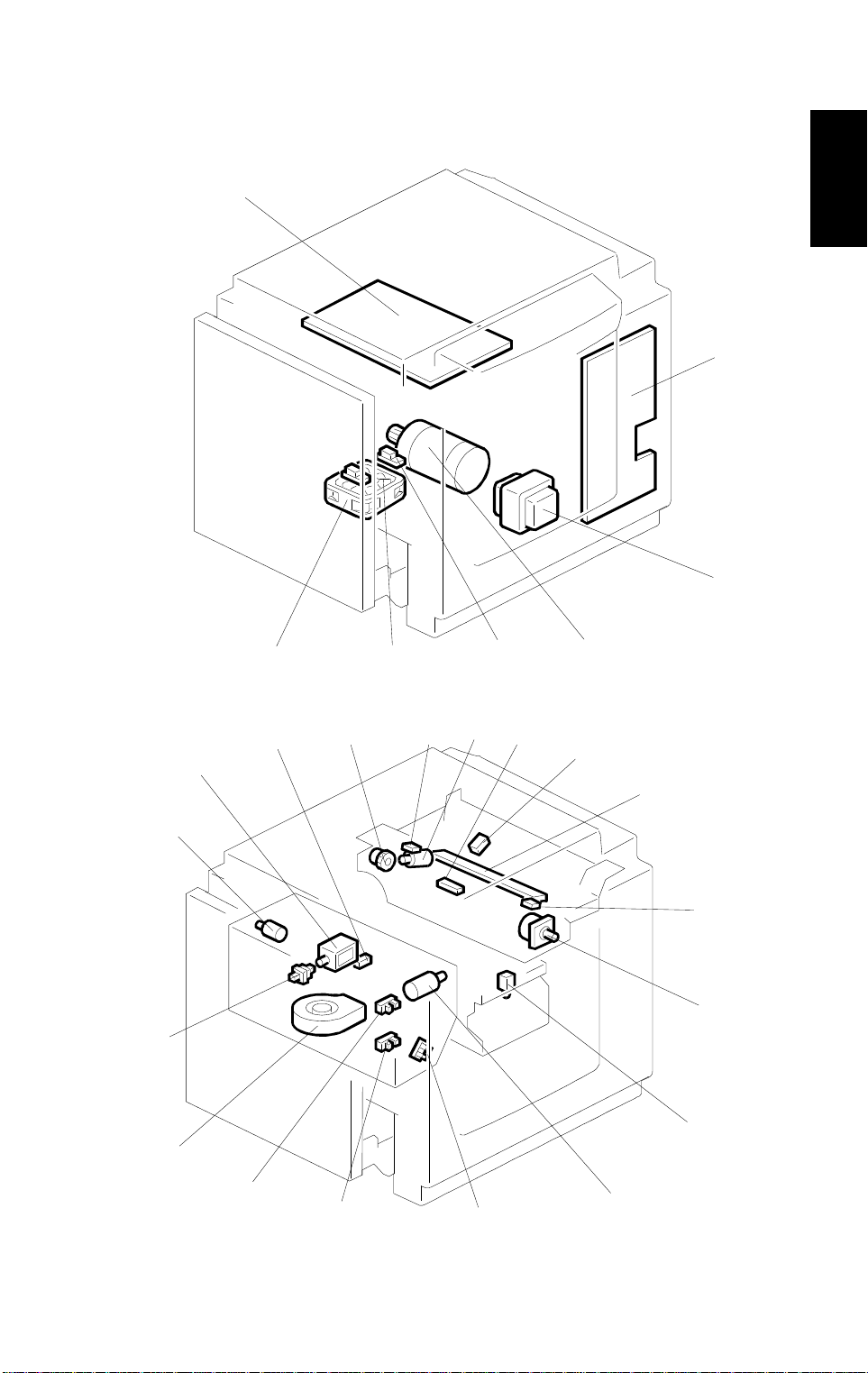

2.2 MACHINE INTERIOR

1

15

14

23

4

5

6

Overall

Information

13

12

11

10

7

8

9

1-7

GUIDE TO COMPONENTS AND THEIR FUNCTION 1 November 1996

1. Document feeder

(Option)

2. Master eject unit

open button

3. Master cut button

4. Pressure release

lever

5. Drum rotatio n

button

6. Drum unit lock

lever

7. Drum unit

8. Ink holder

9. Main switch

10.Paper delivery ta bl e

11.Small size paper

delivery end plate

Original ins er ted into the document feeder are indivi dually

and automatically fed onto and re m oved from the exposur e

glass.

Press to remove misfed paper or a misf ed master.

Press this button to cu t t he m aster leading edge after

installing a new master roll.

Use to install the master roll.

Press to r otate th e drum unit.

Lift to unlock and pul l out the drum unit.

The master is wrapped around this unit.

Set the ink cartridge in this holder.

Use to turn the power on or off.

Completed pr i nt s ar e del i vered here.

Use to align the le adi ng edge of prints tha t ar e A4, 8

1/2

" x 11"

or smaller.

12.Paper delivery end

plate

13.Paper delivery side

plate

14.Wing guides

15.Master eject

container cov er

Use to align the le adi ng edge of prints la rger than A4, 8

1/2

11".

Use to align the prints on the paper delivery table.

When printing o n th i n or small size pape r, li ft these guides.

Open when removing the master eject box.

" x

1-8

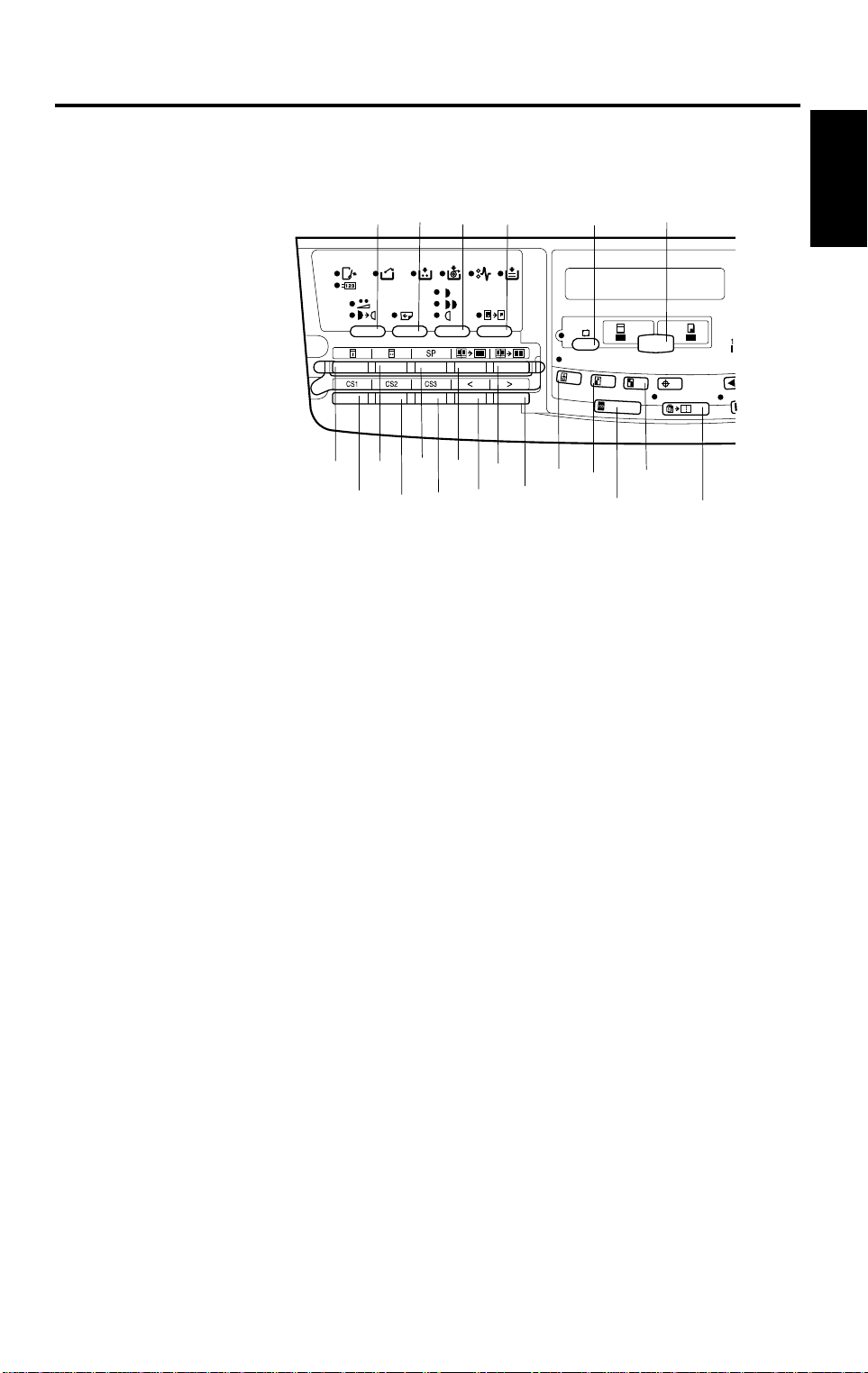

1 November 1996 OPERATION PANEL

3. OPERATION PANEL

3.1 KEYS

1

2

4

3

5

6

Overall

Information

7

1. Economy/Tint key

2. Skip Feed key

3. Image Density key

4. Paste Shadow Erase key

5. Auto Cycle key

6. Master Makin g/ Prin t key

Press to select Master Making or Print

mode.

7. Security key

8. Quality Start key

9. SP mode key

10. Edge Erase key

12

8

13 14

9

10 11

15

11. Edge Erase/Center Era se key

12. 13. 14. CS mode ke ys

15. 16. Scroll keys

Press to select size and direction

of paper or original in Edge

Erase/Center Erase and Edge

Erase function.

Press to select the mode in

Service Program mode.

17. Type of Original key

18. Reduce key

19. Enlarge key

16

17

18

20

19

21

1-9

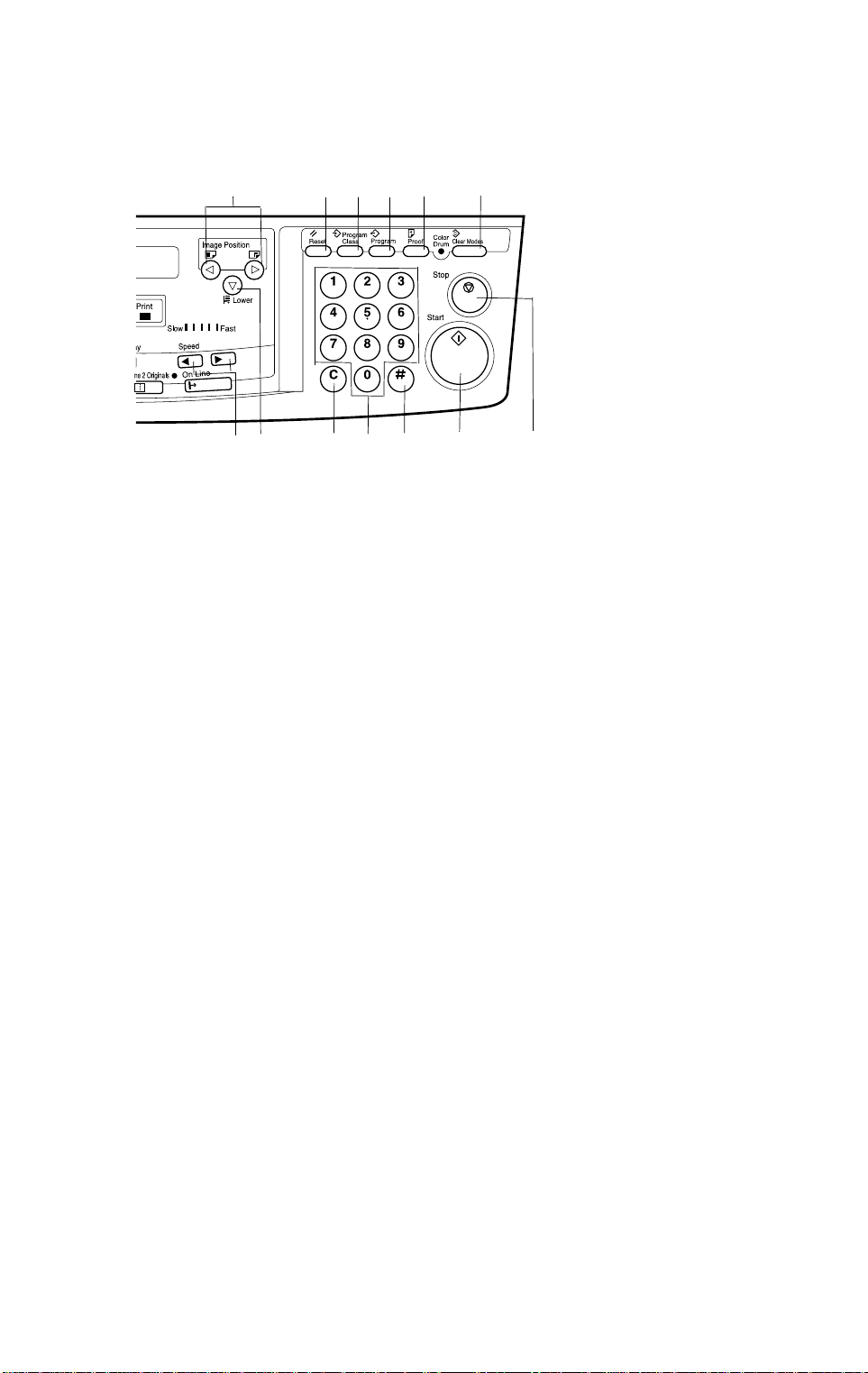

OPERATION PANEL 1 November 1996

22

28

29

20. Full Size key

Press to make full size prints.

21. Combine 2 Originals key

22. Image Positio n keys

23. Reset key

Press to reset the error indicators.

24. Program Class key

25. Program key

26. Proof key

Press to make proof prints.

27. Clear Modes key

Press to cancel all previously

entered settings.

28. Speed keys

23

30

2425

31

27

26

32

33

29. Lower key

30. Clear key

31. Number keys

32. Enter key

33. Start key

34. Stop key

34

Press to lower the paper feed

table.

Press to change t he number set.

Press to enter the number of

prints and data.

Press to input dat a in t o m emory.

Press to start making of a mast er

or printing .

Press to stop the machine

operation.

1-10

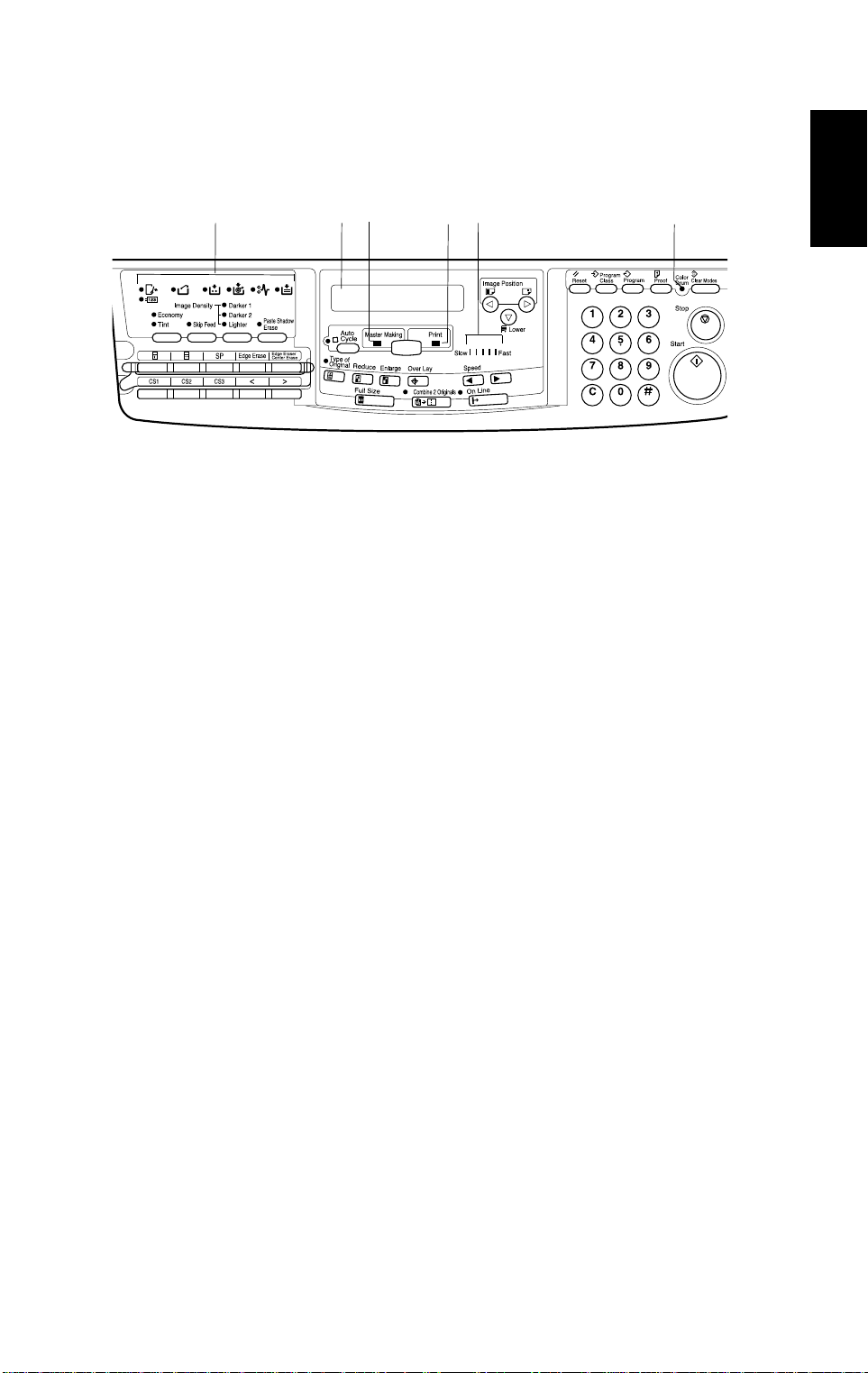

1 November 1996 OPERATION PANEL

3.2 INDICATORS

1

1. Error indicators

These indicators are lit when a

non-standar d condition occurs

within the mac hi ne.

2. Guidance Display

Press to stop the machine

operation.

3. Master Making indicator

This indicator is lit when Master

Making mod e i s selected.

2

3

5

4

4. Print indicator

This indicator is lit when Print

mode is selected.

5. Speed indicators

These indicators show the

printing speed that is selected.

6. Color Drum indicator

This indicator is lit when the

option al color drum unit is set.

6

Overall

Information

1-11

PRINTING PROCESS 1 November 1996

4. PRINTING PROCESS

2

1

6

4

5

1. Master Ejecting: Eject the used master wrapped around the

drum into the master eject box.

2. Scanning: Scan the original image by Contact Image

Sensor while feeding the original.

3

3. Master Feeding: Convert the image signal into the digital signal

and send it to the thermal head to make holes

on the surface of the master and then, set the

master around the drum.

4. Paper Feeding: Send paper to the drum section by using center

separation system consisting of the separation

plate and separation roller.

5. Printing: Press the paper fed from the paper feed section

to the drum to transfer the ink through drum

screen and the master.

6. Paper Delivering: Peel the printed paper with the Exit Pawl and

Air knife and eject the paper onto the paper

delivery table.

1-12

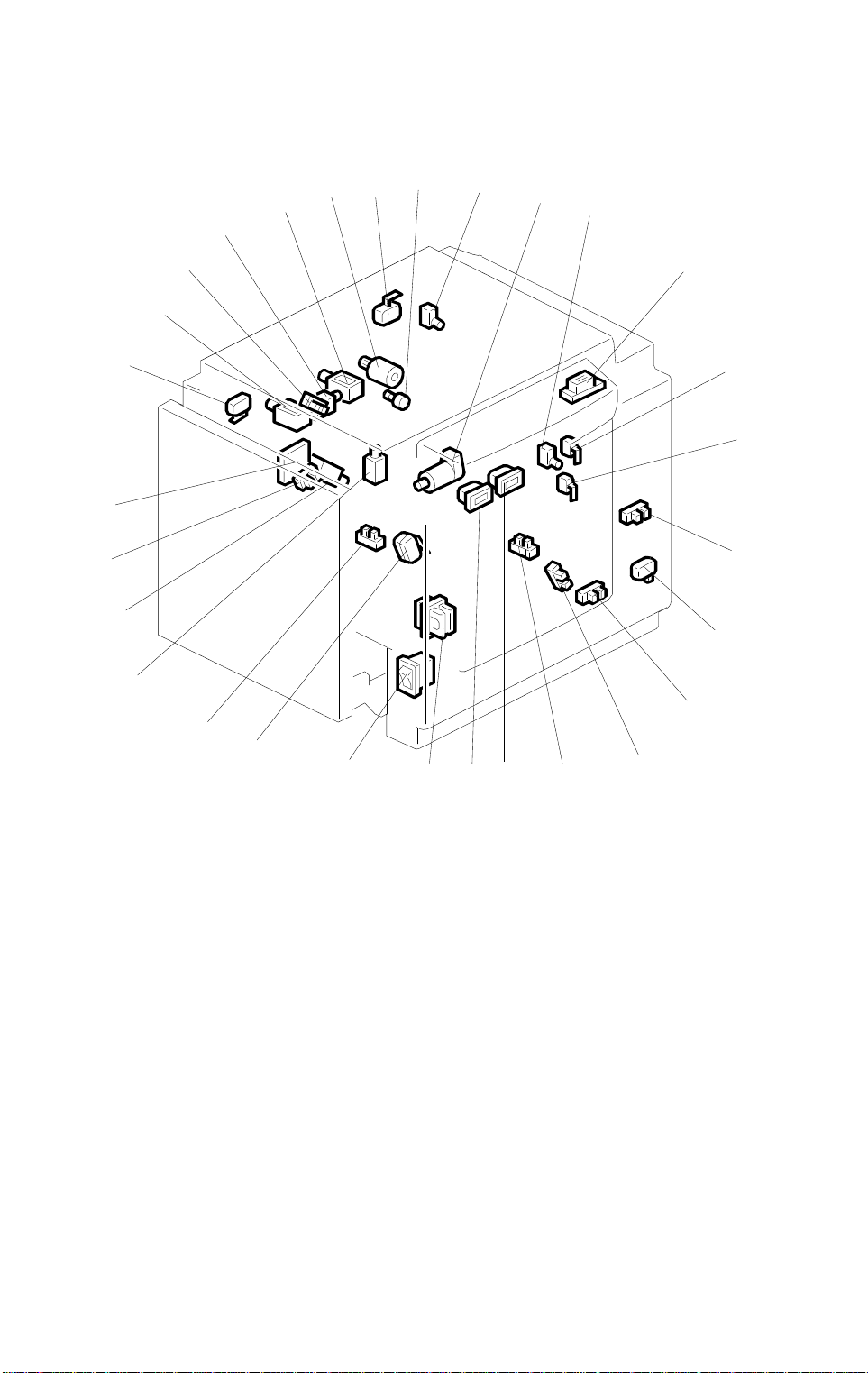

1 November 1996 ELECTRICAL COMPONENTS LAYOUT

5. ELECTRICAL COMPONENTS LAYOUT

5.1 ADF AND SCANER

4

1

6

9

Overall

Information

17

19

20

13

21

22

25

28

1-13

ELECTRICAL COMPONENTS LAYOUT 1 November 1996

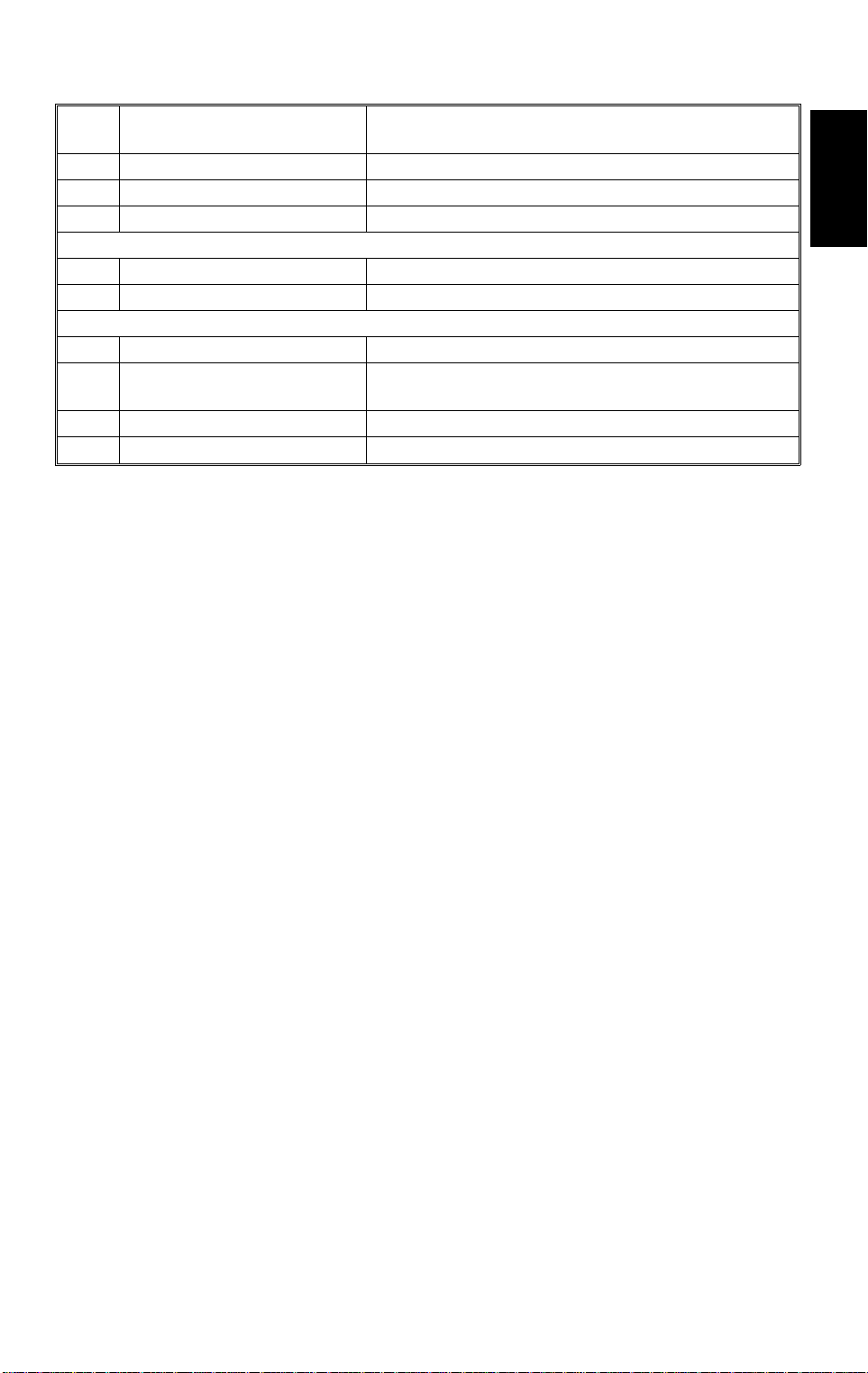

Table

INDEX

NO.

Printed Circuit Board

1 OPU (Operati on Panel Unit) This board co nt rols the operation panel.

Contact Imag e Sensor and

Xenon Lamp

9

Motors

6 ADF Motor This stepper motor dri ves the scanner.

4 Scanner Motor This stepper mot or drives the book scanner.

Sensors and Switc hes

Document Sen sor This detects the pr esence of a document i n th e

17

Scan Line Senso r This detects when a page is approaching the auto

19

20 Not used

ADF Cover Switch This detects whether the ADF cover is open or

21

Scanner Home Posi t i on

28

Sensor

Platen Cover Sens or This detects whe ther the platen cover i s open or

25

22 ADF Swi t ch This detects whet her the ADF unit is ope n or closed.

NAME FUNCTION

This sensor rea ds and converts the li ght re flected

from the docume nt into an analog video si gnal. It

uses an RMLA (Roof Mirror Lens Array) sensor unit.

The xenon lamp which illuminates the document is

contai ned in thi s unit.

feeder.

shading positi on.

closed.

This detects when the image sensor is at home

position.

closed.

Others

13 Lamp Stabilizer This supplies power to the xenon lamp.

1-14

1 November 1996 ELECTRICAL COMPONENTS LAYOUT

5.2 MAIN BODY

39

63

Overall

Information

28

27

29

5

30

31

2

1

33

3

34

4

32

35

36

19

20

26

25

24

21

22

23

1-15

ELECTRICAL COMPONENTS LAYOUT 1 November 1996

59

60

14

62

64

65

61

58

54

53

55

52

51

56

57

50

49

48

47

46

45 44

18

37

38

40

41

42

43

1-16

1 November 1996 ELECTRICAL COMPONENTS LAYOUT

Table

INDEX

No.

Motors

Main Motor Drives paper feed, drum, printing and paper delivery

1

Vacuum Motor Provides suction so that paper is h el d f i rml y on the

4

20 Master Fe ed Motor Feeds the master to the drum.

22 Pressure Pl at e M otor Raises and low er s the pressure plate.

Air Knife Motor Rotates the fan to provide air to se par at e t he paper

26

28 Master Eject Motor Sends used masters into t he master eject box.

33 Cutter Motor Cuts the master.

Image Shift Mot or Changes the timing betw een the paper feed roll er

60

64 Paper Table Drive Motor Raises and lowers the paper table.

Solenoids

Ink Supply Solenoi d Releases the spring clutch to acti vat e the ink supply

21

29 Master Eject Solenoid Opens the master cl am p to eject the mast er.

Paper Feed Solenoid Releases the paper feed sector gear to rotate the

51

52 Printing Pr essure Solenoid Moves the press roller against the drum.

Master Eject Clamper

56

Solenoid

Drum Lock Solen oi d Prevents rem oval of the drum unit when the drum is

58

Master Feed Clam per

59

Solenoid

NAME FUNCTION

unit component s.

transport belt.

leading edge fro m the drum.

and the drum to ad j ust the vertical imag e position.

pump.

paper feed roll er.

Opens the master cl am p to eject the mast er.

not at the home posi t i on.

Opens the master cl am p to eject the mast er.

Overall

Information

Switches

Scanner Unit Safety Switch Check whether the scanner unit is set c or rectly or

14

Plotter Cover Saf et y Sw i tc h Check whether the cover on the plotter uni t i s cl osed

18

19 Left Cutter Switch Detects when the cutter position is at the far left.

Master Eject Box Switch Checks whether the master eject box is installed

27

32 Right Cutter Switch Detects when the cutter position is at the far right.

37 Front Doo r Safety Switch Checks whether the front doo r is set correctly or not.

38 Drum Safety Switch Checks whether the drum unit is set correctly or not.

Paper Table Safety Switch Checks whether the paper table is opened or not.

41

not.

correctly or not.

correctly or not.

1-17

ELECTRICAL COMPONENTS LAYOUT 1 November 1996

INDEX

No.

Test Switch Releases the cover safety functions. (NOTE:)

47

Main Switch Turns the power on or off.

48

Master Eject Unit Safety

49

Switch (220V machines only)

Master Eject Unit Safety

55

Switch (115V machines only)

Master Cutter Switch Informs the CPU to cut the master paper leading

62

65 Drum Rotation Switch Informs the CPU to rotate the main motor at 10 rpm.

Sensors

3 1st Paper Exit Sensor Detects misfeeds.

5 2nd Paper Exit Sens or Detects misfee ds.

Lower Pressure Plate Sensor Informs the CPU if the pressure plate is at the lower

23

Full Master Box Sensor Informs the CPU if the master eject box is full of

24

NAME FUNCTION

Checks whether the master eject unit i s cl osed

correctly or not. Cuts the ac power.

edge.

limit position.

used masters.

Upper Pressure Plate Sensor Informs the CPU if the pressure plate is at the upper

25

30 Master Ejec t Sen sor Detects mas ter eject jams.

34 Master Buc kl e Sensor Detect s m aster buckling.

Master End Sensor Informs the CPU when the plotter unit runs out of

35

Paper Table He i ght Sensor Detects when the paper table reaches t he paper

40

Paper Ta ble Lower Li m it

42

Sensor

43 Printing Pressure Sensor Informs the CPU w hen printing pressur e is applied.

Paper End Sensor Informs the CPU when the paper table runs out of

44

50 Drum Rot at i on Sensor Supplies timi ng pulses to the main boar d.

53 2nd Drum Posi t i on Sensor Checks the posit i on of th e dr um.

57 1st Drum Position Sensor Checks the position of the dr um.

Printed Circuit Board

Main Control PCB Controls all machine functions both directly and

39

limit position.

master roll.

feed position.

Detects when the paper table reach es t he l ow est

position.

paper.

through other boards.

1-18

1 November 1996 ELECTRICAL COMPONENTS LAYOUT

INDEX

No.

54 Ink Detection PCB Checks if the ink is present in the drum.

63 Power Supply PCB Rectifies 100 V ac input an d supplies dc voltage.

Counters

45 Copy Coun ter Keeps track of the total number of copies m ade.

46 Master Counter Keeps track of the total number of ma sters made.

Others

2 Transforme r Steps down the wal l vol t age.

Reverse Roller Clutch Transfers master feed motor rotation to the reverse

31

36 Thermal H ead Burns the image onto the maste r.

61 Encoder Converts 16 image positions to 4 bit data.

NOTE:

1) The Master Eject Unit Safety Switch in the 220 V machines cannot

NAME FUNCTION

roller at proper timing.

be disabled by this test switch.

2) When you use this test switch, be sure to return it to home position

after servicing in order to recover the cover safety functions.

Overall

Information

1-19

MECHANICAL COMPONENT LAYOUT 1 November 1996

6. MECHANICAL COMPONENT LAYOUT

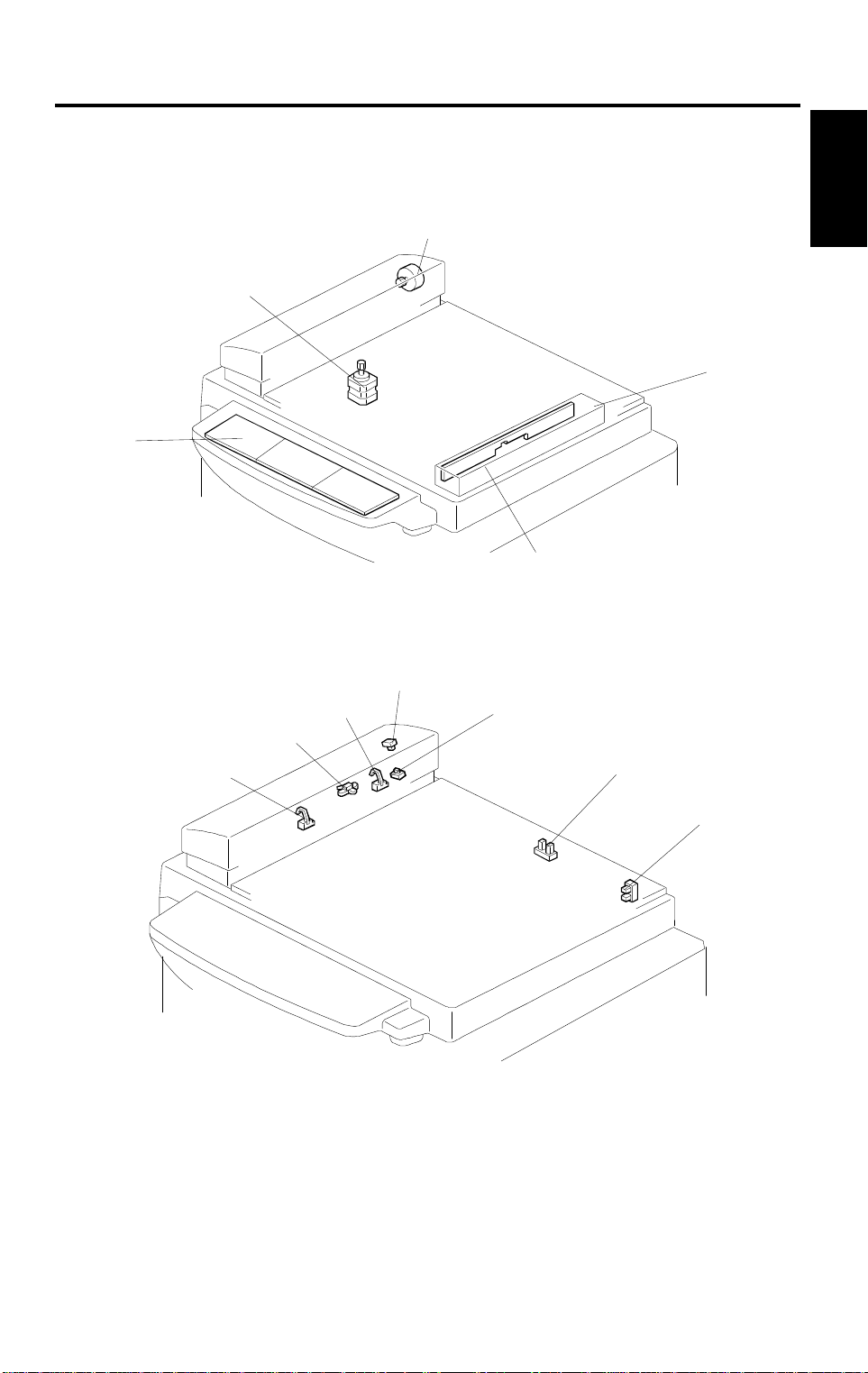

6.1 ADF AND SCANNER

43

6

5

7

8

9

2

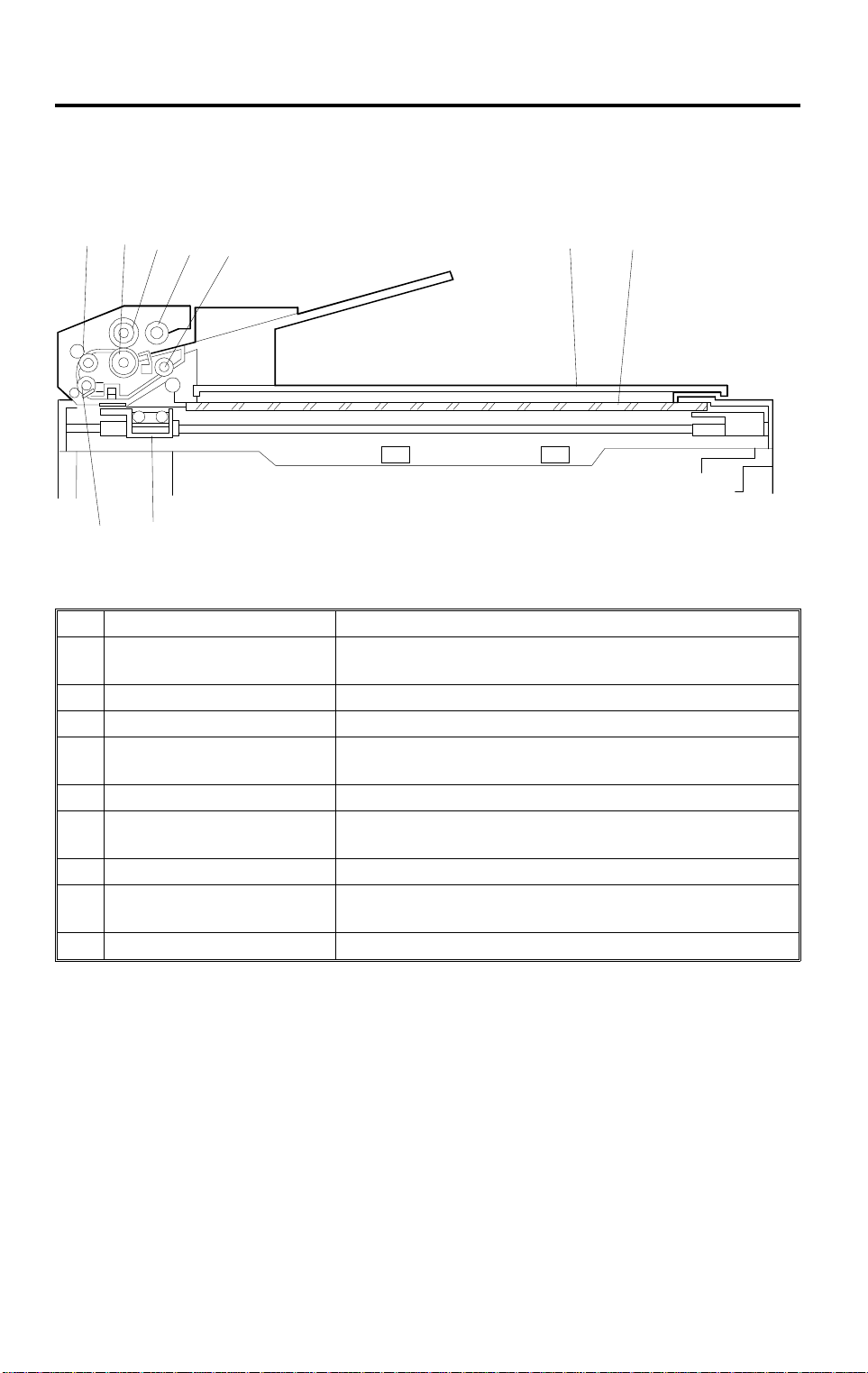

No. Name Description

1

2 R1 Roller Feeds the document through the scanner.

3 R0 Roller Feeds the document into the scanner.

4

5 Document Feed R ol l er Feeds th e document into the sc anner.

6

7 R2 Roller Feeds the document through the scanner.

8

9 Exposure Glas s Book scanner rea ds t he or i gi nal on it.

1

Scanner Contains a contact image sensor and a xenon lamp

driver.

Separation rol l er Prevents more than one sheet from feed i ng i nt o t he

scanner.

Pick-up Roller Picks up page s of the document from the document

table one at a time.

Platen Cover This covers the origin al w hi ch was placed on the

exposure glass.

1-20

1 November 1996 MECHANICAL COMPONENT LAYOUT

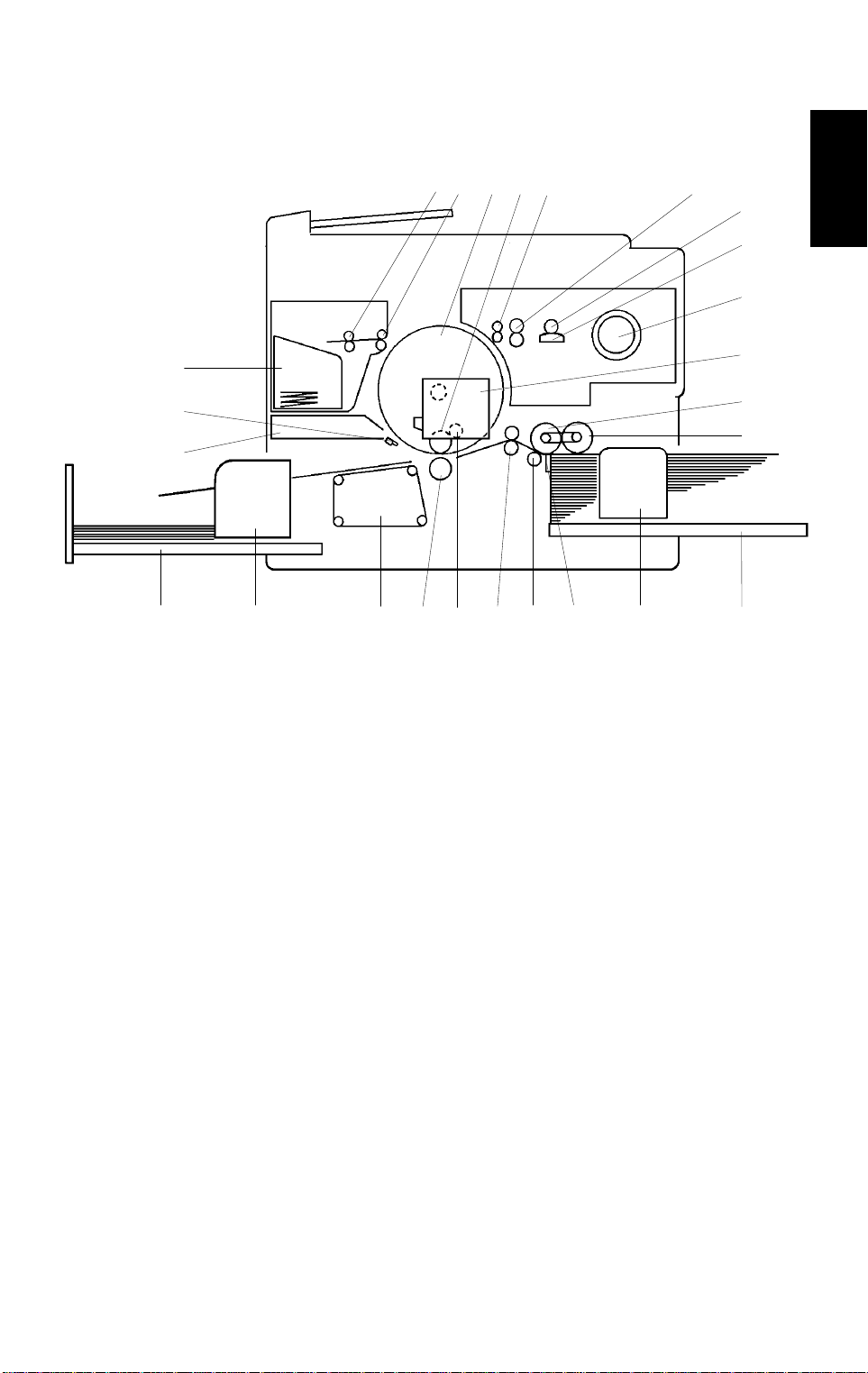

6.2 MECHANICAL COMPONENT LAYOUT

10 9 8 7 6

3

2

Overall

Information

1

38

22

23

37

36

35

24

333231302928272625

34

1. Thermal Head

2. Platen Roller

3. Master Feed Roller

6. Reverse Roller

7. Ink Roller

8. Drum Unit

9. 1st Eject Roller

10. 2nd Eject Roller

22. Master Eject Box

23. Exit Pawl

24. Air Knife

25. Delivery Table

26. Delivery Guide Plate

27. Vacuum Unit

28. Press Roller

29. Doctor Roller

30. 2nd Feed Roller

31. Lower Separation Roller

32. Separation Plate

33. Paper Feed Side Plate

34. Paper Feed Table

35. Paper Feed Roller

36. Upper Separation Roller

37. Ink Holder

38. Master Spool

1-21

DIFFERENCES BETWEEN MODELS 1 November 1996

7. DIFFERENCES BETWEEN MODELS

7.1 C226 AND C224

No. Item Remarks

These units are commonly used in our facsimile products.

The C226 model uses a book type scanner. The C224

model does not have this feature. The contact image

sensor remove s the necessity of complicated adju st m ent s

1.

ADF, Scanner, and

Operation Pan e l

needed for a CCD scanner.

A half-tone proce ssor is used for image processing. This

processor is similar to those in higher level models. It

produces bette r copy quality half- to ne i m ages in Photo

and Letter/Photo modes.

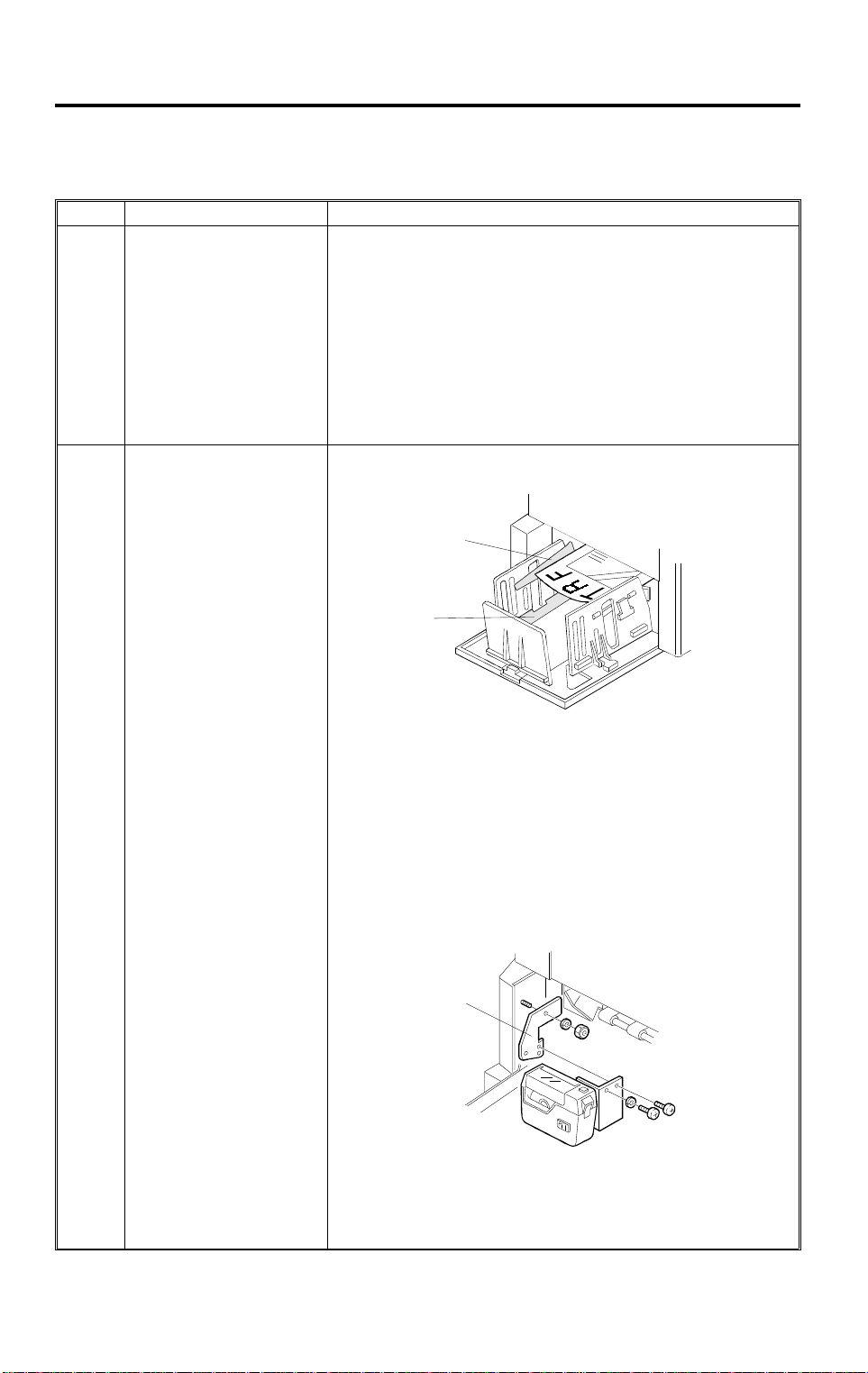

[A]

2. Paper Delivery Table

[B]

The C226 model uses a new paper deliv er y table. This

table has newly added small guide plates [A] on each

front and rear side f ence. The guide pla tes stack the

prints more eve nl y. The small guide plates [B], on the

bottom of each si de f ence keep the prints al i gned in the

center of the table w hi l e the copies are stacked.

Also, the paper sta ck capacity has been in creased from

500 sheets to 1000 sheets.

[C]

Due to the the new paper delivery table design, a new

auxiliary bracket [C] has been added for optional TAPE

MAKER installation. For details, refer to the "Tape Maker

Installation" section.

1-22

1 November 1996 DIFFERENCES BETWEEN MODELS

No. Item Remarks

NOTE:

1) The small upper guide platesare needed

2

when thin or normal paper (80g/m

or 20 lb.

and thinner paper) is used. The guide plate is

not needed for thicker paper. If the paper is too

thick, it may be caught by the upper guide

plates. (Thick paper can be stacked evenly

without the upper guide plates.)

2) When the small upper guide plates are used,

the paper delivery table’s stack capacity

reduces to about 750 sheets (depending on

paper type). Close the guide plates to achieve

the maximum paper stack capacity.

3) The optional TAPE MAKER works with up to

500 sheets (depending on paper type).

Overall

Information

3. Main Control PCB

The C224 model’s A/ D Co nversion PCB is not used. T he

function is now included in the Main Control PCB, which

is located beneat h t he scanner unit. Sinc e the Main

Control PCB was moved from the operat i onal side, the

Power Supply PCB was also moved from th e

non-operation side of the machi ne t o w her e t he Main

Control PCB was located in the C224 model.

1-23

DIFFERENCES BETWEEN MODELS 1 November 1996

No. Item Remarks

The following f unctions were not us ed i n t he C 224 model:

– CS Mode

– SP Mode (User Accessible)

– Paste Shadow Erase Mod e (Unique to the C226

model)

– One Touch Class Mode (Unique to the C 226 model)

– Tint Mode (Unique to the C226 model)

– Program Mode

– Letter/Photo Mode (In addition to the Letter and

Photo modes.)

– Quality Start Mode: See NOTE 1

– Edge Erase Mode: See NOTE 2

– Edge Erase / Center Erase Mod e: See N OTE 2

4.

New Functions in

Operation

NOTE:

1) In the Quality Start mode, after the master

making process, one extra print (this can be set

by the operator from 0 to 3 prints) is made at

the lowest printing speed (20 cpm). The trial

print is made in the same way as other models.

As the default setting, two extra prints are made

in the Quality Start mode. The Quality Start

mode is also used in some other models,

however, this method is unique to the C226

model.

1-24

SECTION 2

SECTIONAL DESCRIPTION

1 November 1996 ORIGINAL FEED SECTION

1. ORIGINAL FEED SECTION

1.1 BOOK SCANNER OVERVIEW

[C]

[A]

[D]

[E]

[I]

[H]

Detailed

Descriptions

[B]

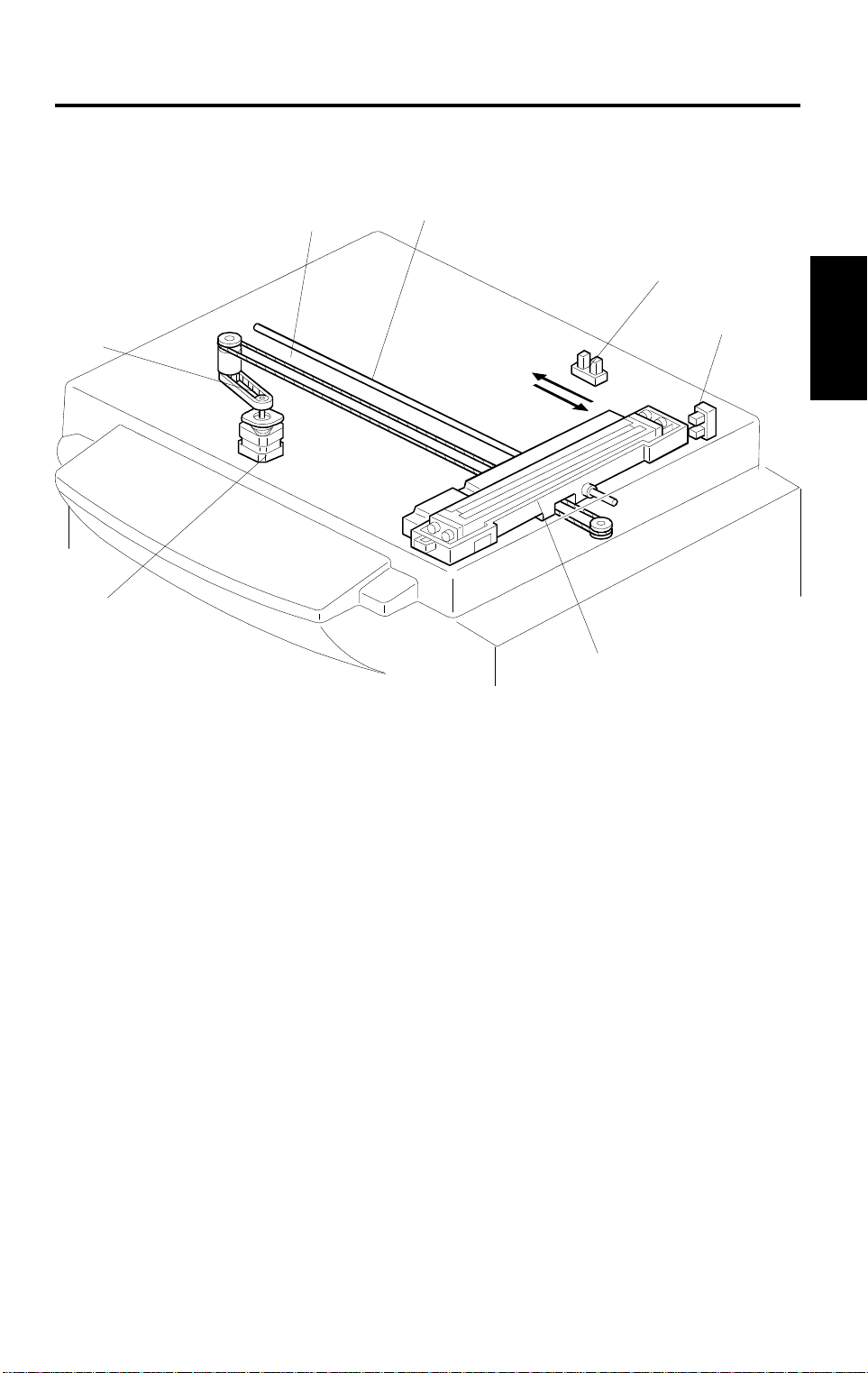

The scanner motor [A] drives the scanner [B] through the timing belt [C] and

drive wire [D]. The shaft [E] guides scanner movement in the sub-scan

direction. Inside the scanner [B] are a contact image sensor (containing a

sensor element and xenon lamp) and a xenon lamp driver.

The scanner [B] consists of a contact image sensor and a xenon lamp driver.

The scanner home position sensor [H] allows the scanner return to the same

position after scanning.

The platen cover switch [I] detects if the cover is opened or not.

2-1

ORIGINAL FEED SECTION 1 November 1996

1.2 ADF OVERVIEW

[D]

[E]

[C]

[H]

[B]

[G]

[A]

[F]

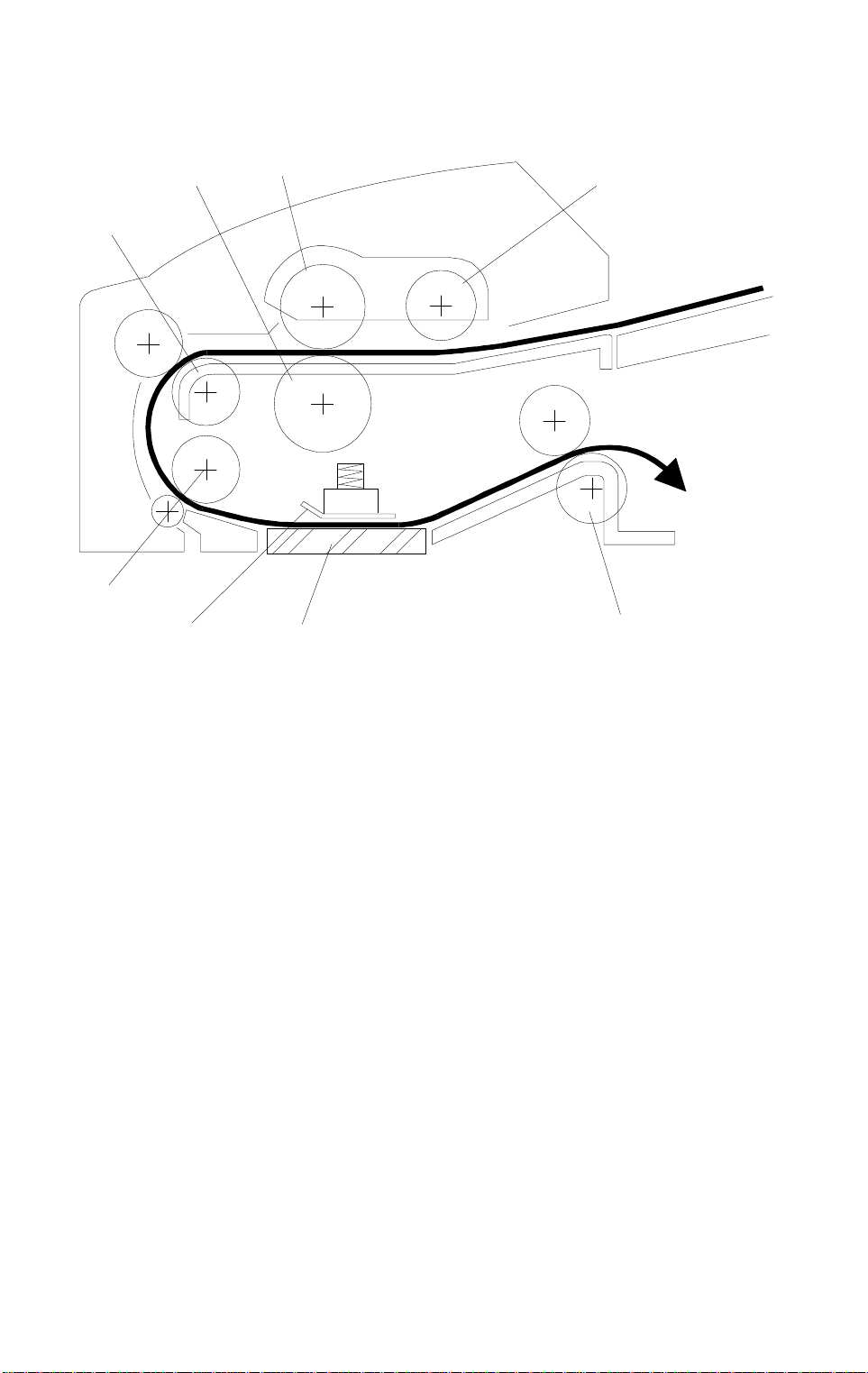

The sheet through type ADF feeds the document from the top page of the

document stack on the table.

The pick-up [A] and feed roller [B] feed the original into the scanner, and the

separation roller [C] helps to feed one sheet at a time. Then, the R0 [D], R1

[E], and R2 [F] rollers feed the document through the scanner.

At the time of scanning the document, the scanner moves down to the

scanning position under the exposure glass [G]. The shading plate [H]

pushes the document to the exposure glass at the scan line, so that the

document is within the image sensor’s range of focus.

After scanning, the ADF feeds out the document onto the platen cover, and

the scanner moves back to its home position at the right end of the scanner.

2-2

Loading...

Loading...