Page 1

N810-II

SERVICE MANUAL

Page 2

INTRODUCTION

This manual explains only the features of the N810 -II (C225 model) that are

different compare d with the N810 (C217 model). So, please refer to the N810

service manual for the sections which are not described in this ma nual.

Page 3

SECTION 1

OVERALL MACHINE

INFORMATION

Page 4

5 September 1995 SPECIFICATIONS

1. SPECIFICATIONS

Configuration : Desk top

Master Making Process: Digital

Printing Process: Full automatic one-drum stencil system

Image Mode: Line/Phot o

Original Type: Sheet

Original Weight:

Original Size: Max: 216 mm x 356 mm (81/2" x 14")

Paper Size: Max: 216 mm x 356 mm (81/2" x 14")

Paper Weight:

Printing Area: LG drum: 210 mm x 349.6 mm

64 g/m2 ∼ 104.7 g/m2 (17.0 lb ∼ 27.9 lb)

(Legal Drum)

216 mm x 297 mm (81/2" x 11.7")

(A4 Drum)

Min: 90 mm x 140 mm (31/2" x 51/2")

(Legal Drum)

216 mm x 297 mm (81/2" x 11.7")

(A4 Drum)

Min: 90 mm x 140 mm (31/2" x 51/2")

52 g/m2 ∼ 150 g/m2 (13.8 lb ∼ 39.9 lb)

(8.3" x 13.8") or less

A4 drum: 210 mm x 291 mm

(8.3" x 11.5") or less

Printing Speed: 70/100/130 cpm (3 settings)

First Copy Time:

Second Copy Time:

Leading Edge Margin :

28 seconds ± 2 seconds (Legal Drum)

26 seconds ± 2 seconds (A4 Drum)

30 seconds ± 2 seconds (Legal Drum)

28 seconds ± 2 seconds (A4 Drum)

5 mm ± 3 mm (0.2" ± 0.12")

1-1

Page 5

SPECIFICATIONS 5 September 1995

Trailing Edge Margin:

1 mm ± 1 mm (0.04" ± 0.04")

Paper Feed Table Capacity: 500 sheets (80 g/m2, 20.0 lb)

Paper Delivery Table Capacity: 500 sheets (80 g/m2, 20.0 lb)

Master Eject Box Capacity: More than 25 masters

ADF Original Capacity: 6 sheets or a 0.6 mm height

Weight: 55 kg (122 lb)

Power Source: 120 V, 60 Hz, more than 3.6 A (for North

America)

220 V ∼ 240 V, 50/60 Hz, more than 2.1 A

(for Europe, Asia)

Power Consumption: Master Making: Less than 0.22 kW

Printing: Less than 0.22 kW

Dimensions:

(W x D x H)

[Tables stored]

692 mm x 612 mm x 440 mm

(26.2" x 24.1" x 17.3")

[Tables set up]

1050 mm x 612 mm x 440 mm

(41.3" x 24.1" x 17.3")

Pixel Density: 300 dpi

Print Counter: 7 digits

Master Counter: 6 digits

Noise Emission:

Printing Speed Operator position Bystander position

70 rpm less than 66 dB less than 64 dB

100 rpm less than 70 dB less than 68 dB

130 rpm less than 72 dB less than 71 dB

The measurements are to be made in accordance with ISO 7779.

1-2

Page 6

5 September 1995 SPECIFICATIONS

Optional Equipment: Key Counter, Tape Dispenser

Consumables:

Name Size Remarks

Thermal master Length: 125 m (410 ft)/roll

Width: 240 mm (9.5")

Ink 600 cc/pack Storage Conditions:

Tape for tape maker 35 m (114.8 ft)/roll

260 masters can be made per roll

with a Legal Drum.

304 masters can be made per roll

with an A4 Drum.

Storage Conditions:

–10 ∼ 40°C, 10 ∼ 90% RH

–5 ∼ 40°C, 10 ∼ 90% RH

1-3

Page 7

ESSENTIAL DIFFERENCES BETWEEN THE C217 AND THE C225 5 September 1995

2. ESSENTIAL DIFFERENCES BETWEEN THE

C217 AND THE C225

No. Item Remarks

1 Paper Delivery System The paper delivery system has been changed from a

delivery roller system to a vacuum transport system. Due

to this modification, 5 mm side margins are not required

for originals.

2 Paper Table Set Switch A magnetic switch has been added to detect whether or

not the paper table is in the paper feed position. Indicator

"B" lights when the paper table is in the low position.

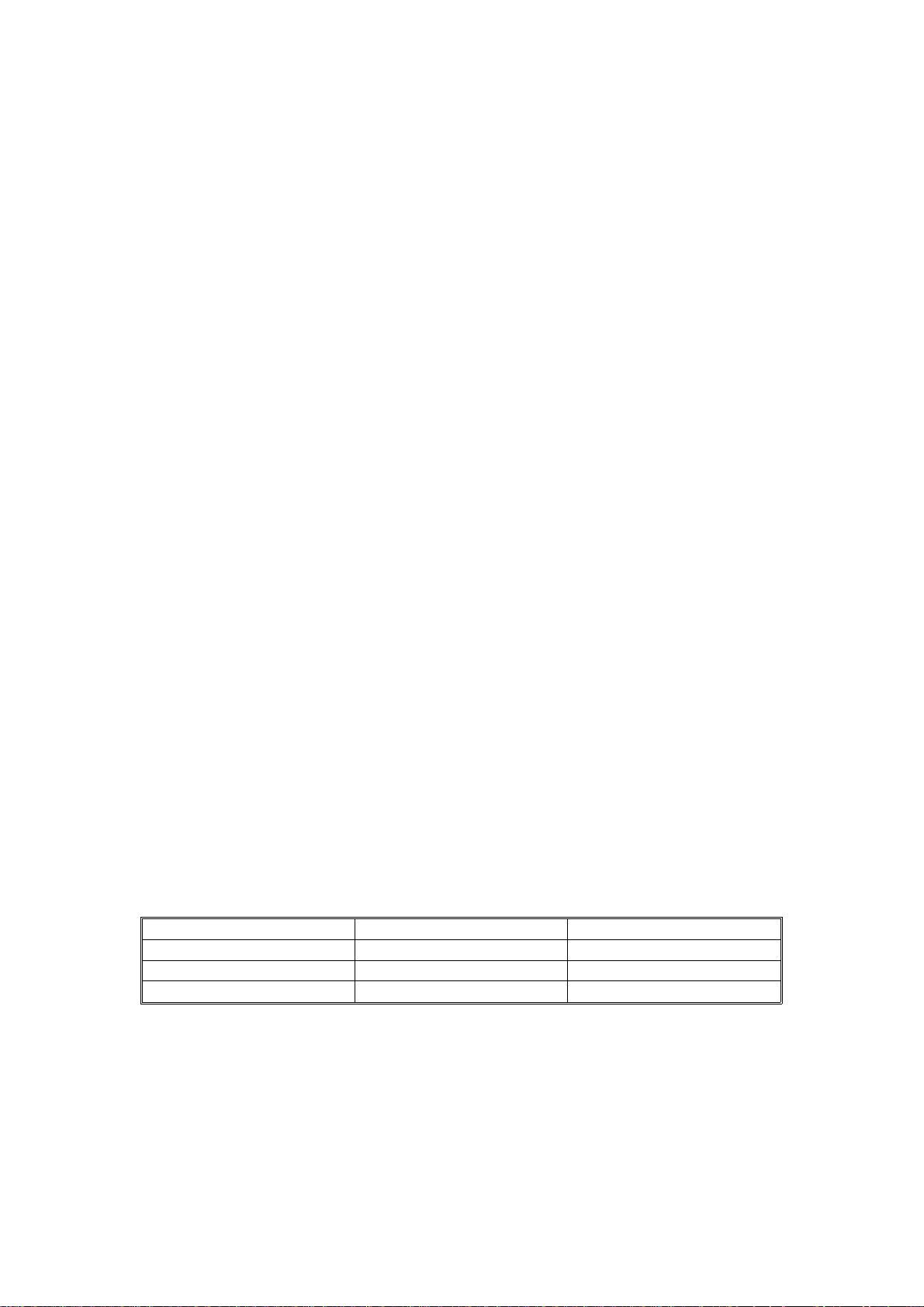

3 Thermal Head To minimize ink set-off, the shape of the thermal head

heating elements have been changed as shown below.

C225V500.img

4 Paper Table Side

Fences

5 Master Eject Box To prevent the used master from drooping when the

6 Paper Delivery Table The delivery end fence and the side fences can be folded

7 Master Eject Box

Capacity

8 Economy Mode If Economy mode is selected, the thermal head energy is

For easy side fence positioning, a rack and pinion

mechanism has been installed. The left and right side

fences move together.

customer takes out the master eject box, a master holder

has been added to the master eject box.

for storing in the delivery table.

The pressure for compacting the master in the master

eject box has been increased. The master eject box

capacity has been increased from 15 to 25 masters.

reduced by 15% (this is done by changing the pulse

width). The image density will be slightly lighter, and ink

consumption will be less than normal.

1-4

Page 8

5 September 1995 ESSENTIAL DIFFERENCES BETWEEN THE C217 AND THE C225

No. Item Remarks

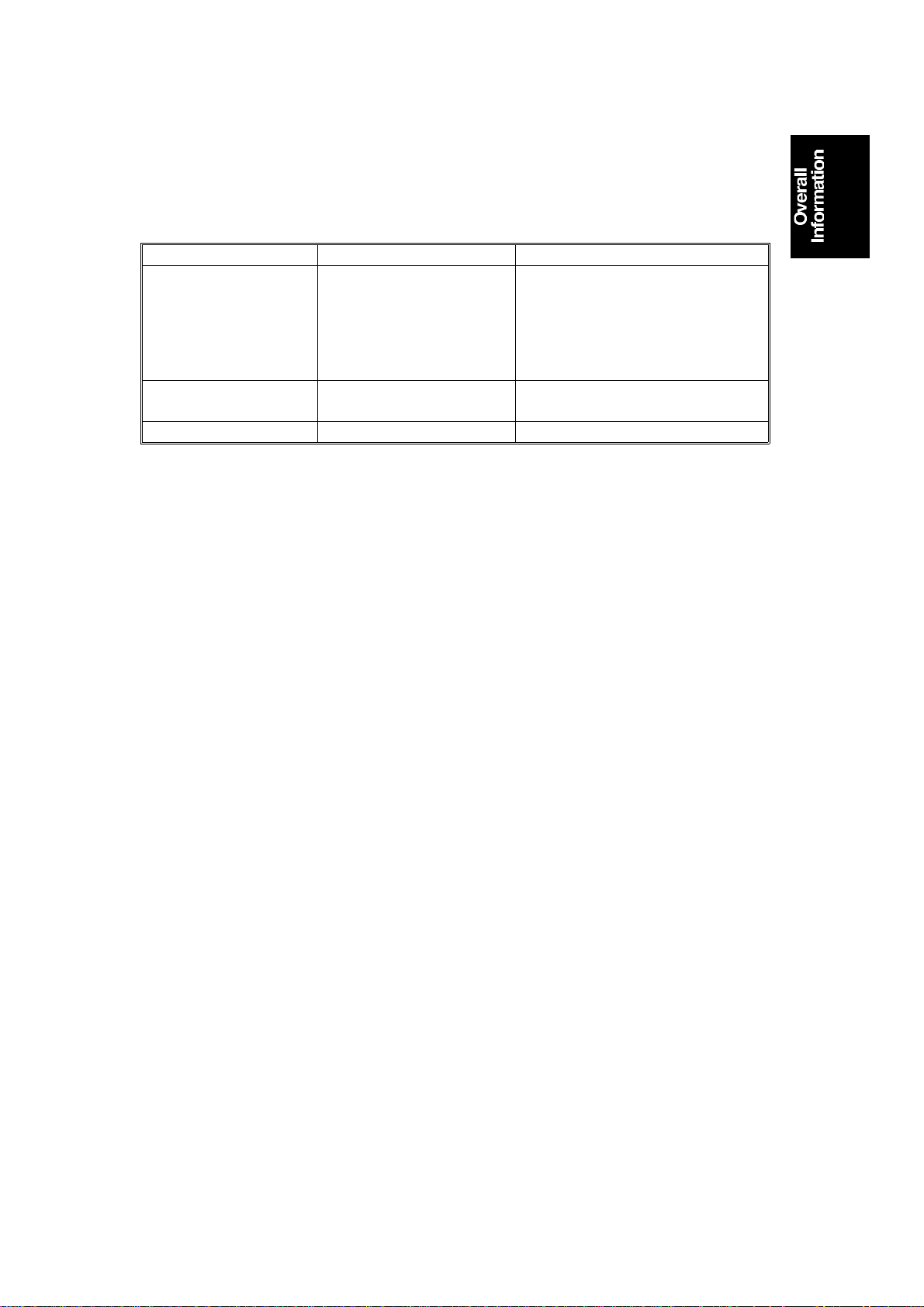

9 Exposure Glass Bracket To prevent the scanned original from being pushed out by

the next original, the shape of the exposure glass bracket

has been changed as shown below.

H225V501.wmf

10 Original Feed Spring

Plate

To ensure proper feeding of thin paper, the angle of the

original feed spring plate has been changed.

11 Paper Feed Timing To reduce noise which occurs when the paper hits the

2nd feed roller, the first paper feed length has been

reduced. (The buckle between the 1st and 2nd paper

feed rollers has been shortened.)

12 Skip Feed A user can select from 2 to 9 rotations of the drum while

one sheet of paper is fed.

13 A4 Size Drum (Only A4

machines)

To minimize master consumption, the screen mesh length

and the master cut length of the Europe/Asia machines

has been shortened. (The master consumption of the

LT/LG machines is the same as for the C217.)

14 Quality Start The first print tends to be light. To increase the image

density of the first print, Quality Start mode can be

selected. In this mode, the first print is made at 30 rpm.

15 Image Processing in

the "Darker 2" setting

In the C217 model, only the A/D conversion parameters

are changed when the image density setting is changed.

This does not change the density of solid black areas.

In the C225 model, if "Darker 2" is selected on the

operation panel, the thermal head energy is increased to

115% of the normal setting. The solid black areas will

become darker.

1-5

Page 9

PRINTING PROCESS 5 September 1995

3. PRINTING PROCESS

2

1

3

5

6

4

C225V502.img

1. Master Ejecting: The machine ejects the used master

wrapped around the dru m into the master

eject box.

2. Scanning: The machine scans the original using the

CCD, through the mirror and the lens,

while feeding the original.

3. Master Feeding: The machine converts the signa l from th e

CCD into digital signals and sen ds th em to

the thermal head to ma ke holes in the

master. The master then wraps aro un d

the drum.

4. Paper Feeding: The machine sends paper separat ely to

the drum.

5. Printing: The ma chin e presses the paper fed from

the paper feed section against the drum.

This transfers the ink to the pap er through

the drum screen and the master.

6. Paper Delivering: The machine peels off the printed paper

with the exit pawls and air knife, and

ejects the paper onto th e pa pe r delivery

table.

1-6

Page 10

10

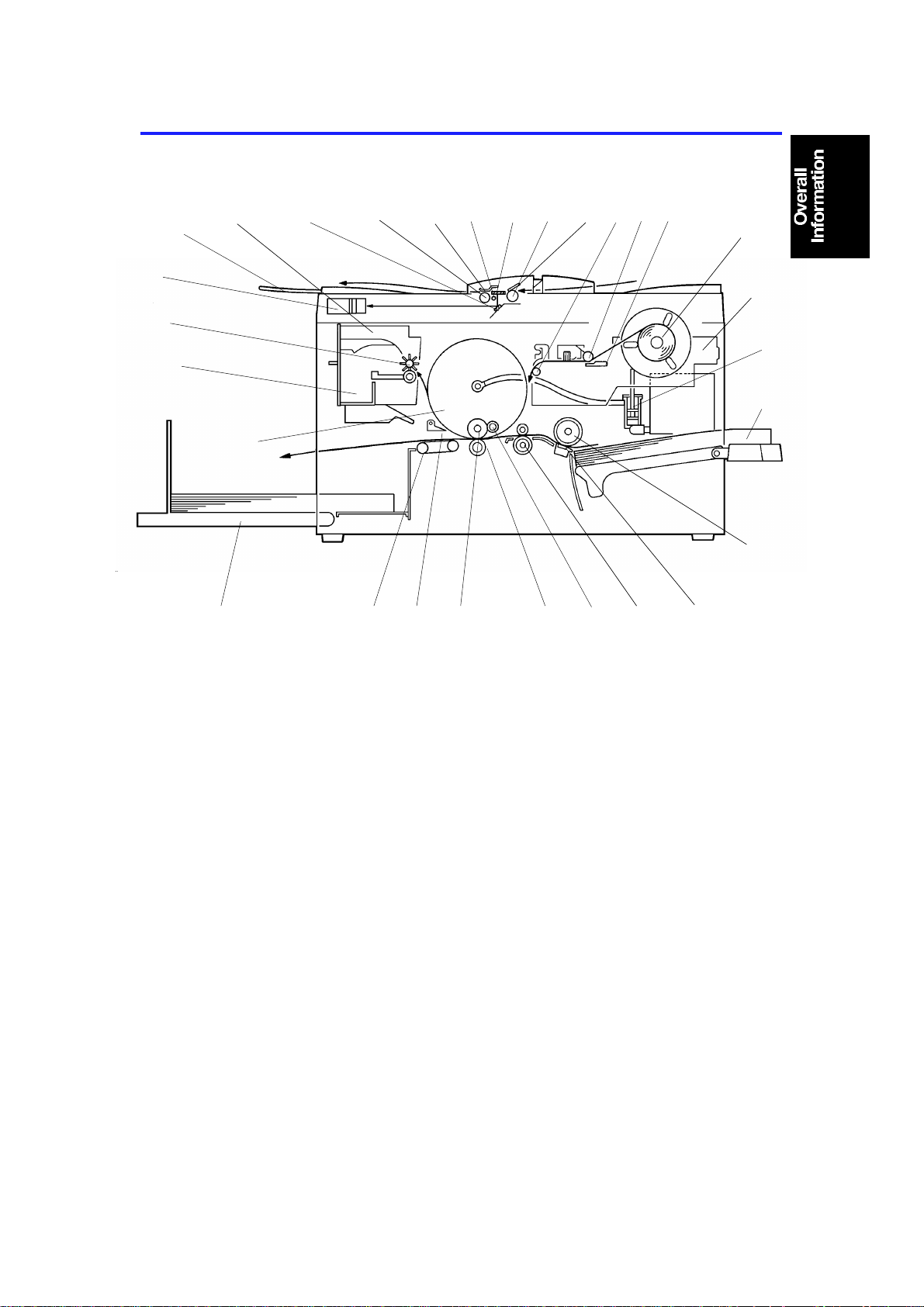

5 September 1995 MECHANICAL COMPONENT LAYOUT

4. MECHANICAL COMPONENT LAYOUT

27

26

28

25

29

24

1234

5

6789

11

12

13

14

15

1617181920212223

1. Mirror

2. Original Feed Roller

3. Original Pressure Plate

4. Exposure Lamp

5. Exposure Glass

6. Original Pick-up Roller

7. Original Friction Pad

8. Master Tension Roller

9. Platen Roller

10. Thermal Head

11. Master Roll

12. Platter Unit

13. Ink Pump

14. Paper Table

15. Paper Feed Roller

C225V502-2.img

16. Friction Pad

17. 2nd Feed Roller

18. Doctor Roller

19. Press Roller

20. Ink Roller

21. Exit Pawl

22. Transport Unit

23. Paper Delivery Table

24. Drum

25. Master Eject Box

26. Master Eject Roller

27. CCD Unit

28. Original Exit Tray

29. Master Eject Unit

1-7

Page 11

14

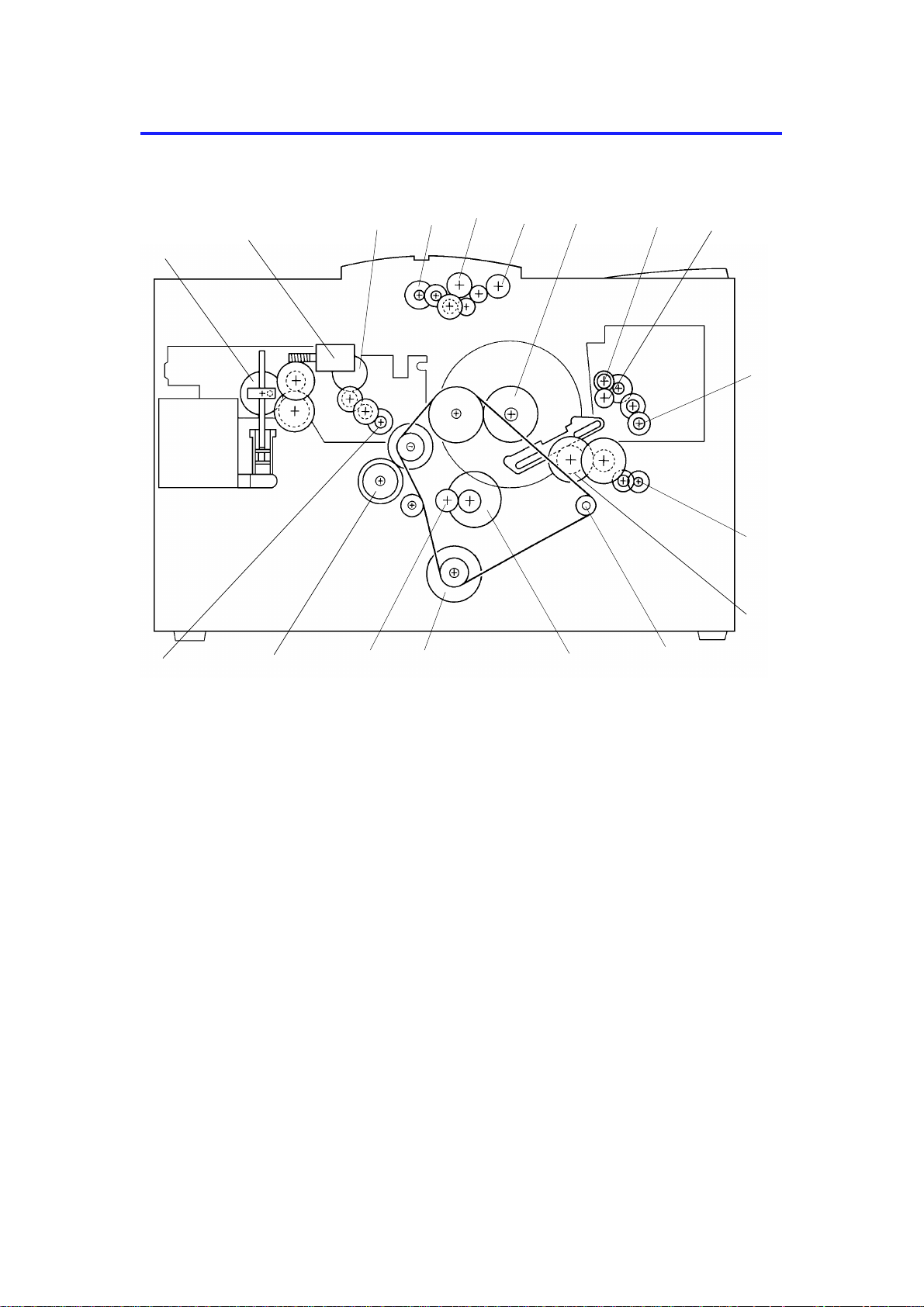

DRIVE LAYOUT 5 September 1995

5. DRIVE LAYOUT

2

3

5

4

6

7

8

9

1

10

11

12

18

17

16

15

1. Pump Drive Gear

2. Ink Supply Motor

3. Platen Roller Gear

4. Original Feed Motor

5. Original Pick-up Roller

6. Original Feed Roller

7. Drum Drive Gear

8. Upper Master Eject Roller Gear

9. Lower Master Eject Roller Gear

13

C225V503.img

10. Master Eject Motor

11. Master Clamper Motor

12. Master Clamper Drive Gear

13. Transport Unit Drive Pulley

14. 2nd Feed M otor

15. Main Motor

16. 2nd Feed Roller Gear

17. Paper Feed Roller Gear

18. Master Feed Motor

1-8

Page 12

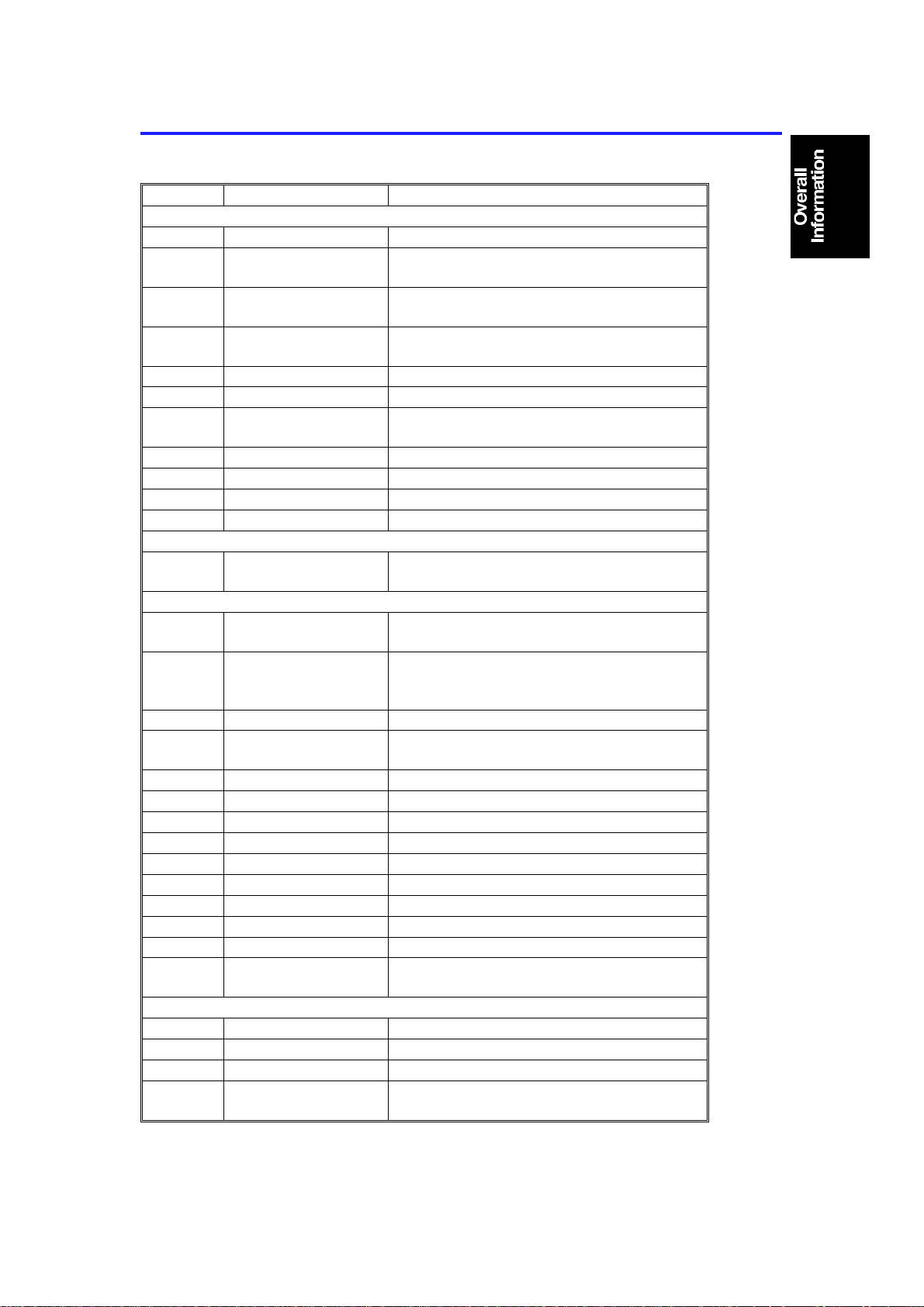

5 September 1995 ELECTRICAL COMPONENT DESCRIPTION

6. ELECTRICAL COMPONENT DESCRIPTION

Index No. Name Function

Motors

11 Master Feed Feeds the master to the drum.

25 Master Eject Sends the used master into the master eject

box.

28 Main Drives the paper feed, drum, printing and

paper delivery unit components.

29 Vacuum Provides suction so paper is held firmly on

the transport belt.

32 2nd Feed Drives the 2nd feed roller.

35 Master Clamper Open and closes the master clamper.

38 Air Knife Rotates the fan which generates the air knife

to separate the paper from the drum.

40 Pressure Plate Drives the pressure plate.

45 Original Feed Transports the original for scanning.

46 Master Cutter Cuts the master.

49 Ink Supply Drives the ink pump to supply ink.

Solenoid

31 Pressure Release

Solenoid

Sensors

1 Master End Detects if the plotter unit has run out of

3 Original Registration

(Upper: light receiver,

Lower: light emitter)

14 Feed Jam Timing Determines the paper misfeed check timing.

15 Paper End Detects if there is any paper on the paper

16 Registration Detects paper misfeeds.

17 Feed Start Timing Determines the paper feed start timing.

18 Exit Jam Timing Determines the master misfeed check timing.

19 Master Eject Position Detects the master eject position of the drum.

26 Drum Master Detects if there is a master on the drum.

30 Exit Detects paper misfeeds.

33 Master Eject Detects used master misfeeds.

37 Full Master Detects if the master eject box is full.

39 Pressure Plate H.P. Detects the pressure plate home position.

48 Original Set Detects if there is an original on the original

Switches

5 ADF Open Checks if the ADF is open.

6 Left Cutter Determines the left limit position of the cutter.

9 Master Cut Starts the cutter motor to cut the master.

13 Paper Table Set Detects if the paper table is in the paper feed

Releases the press roller to apply printing

pressure.

master roll.

Informs the CPU of the original position.

Also, detects original misfeed.

table.

table.

position.

1-9

Page 13

ELECTRICAL COMPONENT DESCRIPTION 5 September 1995

Index No. Name Function

21 Scanner Unit Open Checks if the scanner unit is open.

22 Delivery Cover Open Checks if the delivery cover is open.

23 Main Turns the power on or off.

27 Master Eject Box Checks if the master eject box is set

correctly.

36 Master Clamper Detects the master clamper open/close

position.

47 Right Cutter Determines the right limit position of the

cutter.

Printed Circuit Board

4 Lamp Control Controls the power to the exposure lamp.

8 Operation Panel Interfaces the CPU with the operator.

12 Main Controls all machine functions.

20 Power Supply Provides power for all dc components.

24 Main Motor Control Controls the main motor speed.

34 Noise Filter Filters out electrical noise on the ac power

input lines.

41 CCD Converts light intensity into an electrical

signal.

42 A/D Conversion Converts the analog signals into digital

signals.

Counters

7 Print Keeps track of the total number of prints

made.

10 Master Keeps track of the total number of masters

made.

Others

2 Thermal Head Makes the master using heat.

43 Paper Feed Clutch Transmits main motor drive to the paper feed

roller at the appropriate time.

44 Exposure Lamp Illuminates the original for exposure.

1-10

Page 14

SECTION 2

DETAILED SECTION

DESCRIPTIONS

Page 15

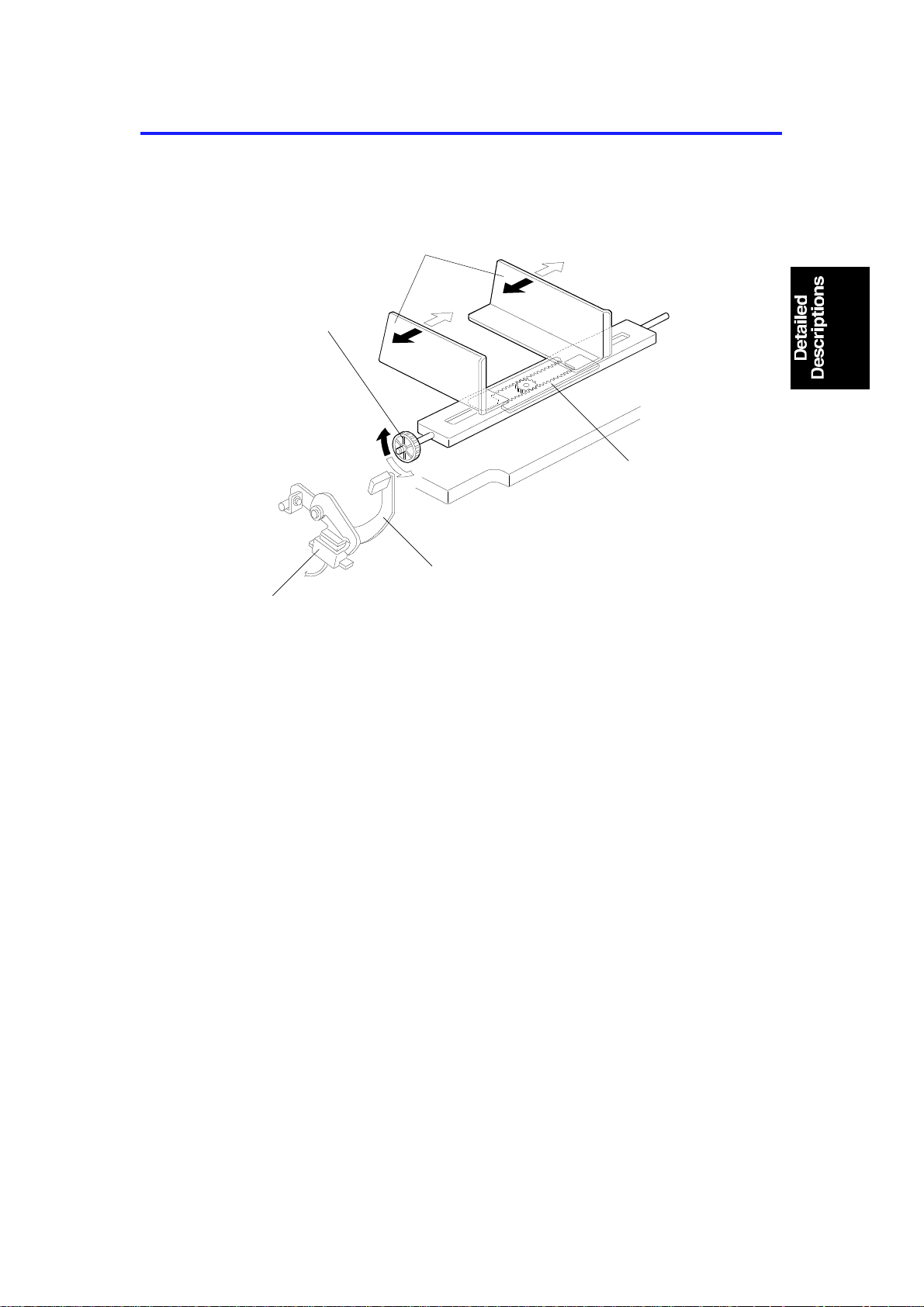

5 September 1995 PAPER FEED

1. PAPER FEED

1.1 PAPER TABLE

[C]

[E]

[A]

[B]

[D]

C225D506.wmf

The paper table side fen ces [A ] should be adjusted depending on the pap er

size. The left and right side fences move together because of the rack a nd

pinion [B], to ensure correct pap er positioning on the tray. If the dial [C] is

turned, the side fen ces move together, changing the paper po sitio n on the

table.

When the lever [D] is lowered and the paper table is in the no-paper feed

position, the magnetic switch [E] is de-act ivat ed . In this con dit ion, the Print

Start key is disabled.

2-1

Page 16

[C]

PAPER DELIVERY SECTION 5 September 1995

2. PAPER DELIVERY SECTION

2.1 OVERALL

[B]

[A]

[D]

C225D505.img

The exit pawl [A] and the air knife [B] sep ara te the paper fro m t he drum. Th e

paper is transported to the delivery table by the transport unit [C].

There is a reflective photosensor [D] to detect paper jams.

2-2

Page 17

[A]

[D]

5 September 1995 PAPER DELIVERY SECTION

2.2 VACUUM UNIT DRIVE MECHANISM

[B]

[C]

C225D507.wmf

The vacuum fan [A] holds the paper against the transport be lts [B ] to deliver

the paper to the delivery t ab le. The transport belts are driven by the main

motor through gears [C] .

The exit sensor (reflective photo sen sor) [D] located on the vacuum unit

detects paper jams.

2-3

Page 18

IMAGE PROCESSING 5 September 1995

3. IMAGE PROCESSING

3.1 IMAGE DENSITY SETTING

The A/D conversion paramet ers (refer to page 2-43 of the C217 model

service manual) and thermal head energy change depending on the image

density selected on the operat ion panel.

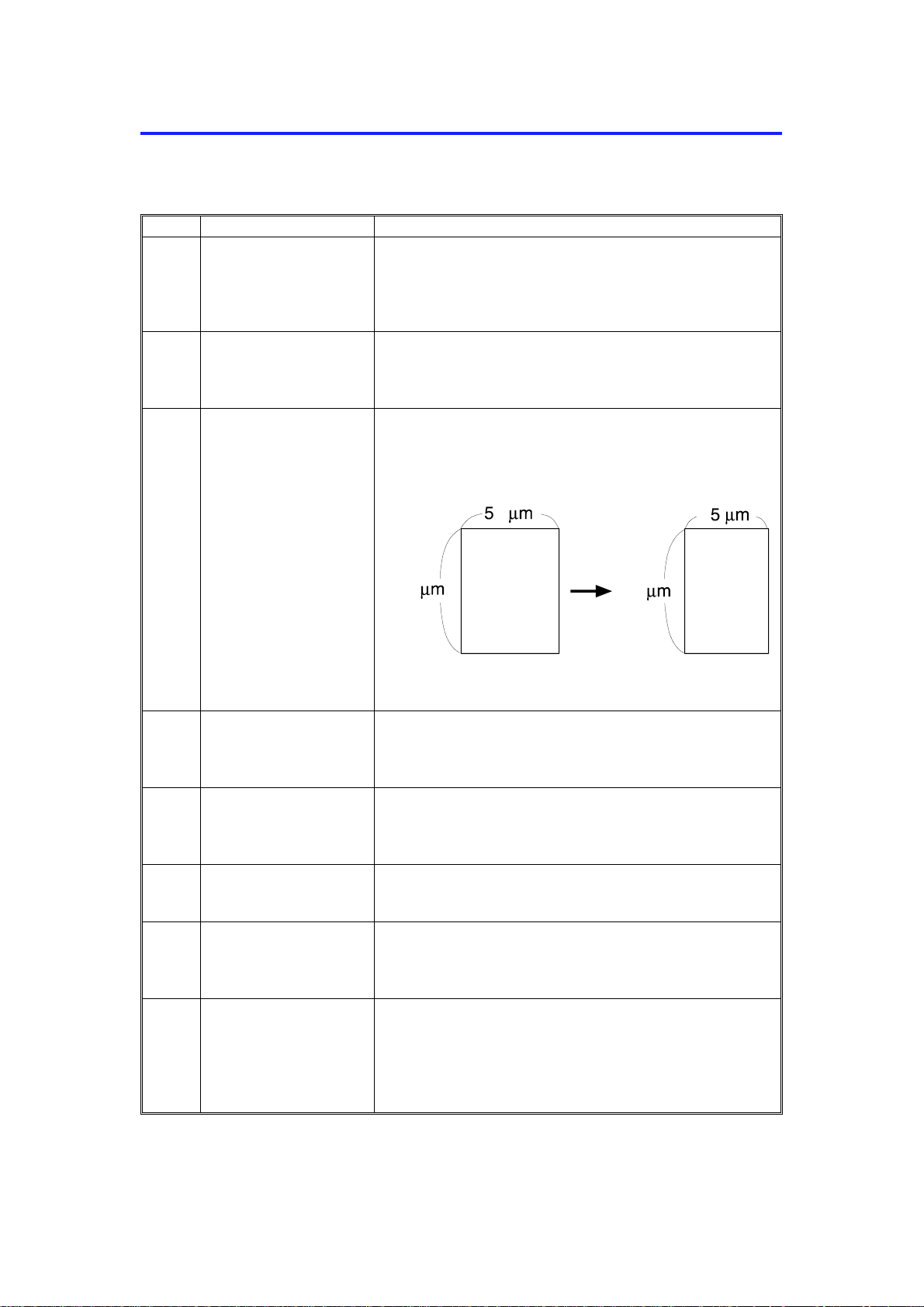

The table below shows th e relationships between the image mode s,

parameters, and the thermal head energy.

VH (%) M1 (%) M2 (%) M3 (%) VL (%) T/H

Energy

(%)

Shading Distortion Memory 100 86.5 73.0 59.5 46.0

Image

Setting

Line Mode Lighter 74.0 57.0 40.0 23.0 6.0 100

Normal 100 76.5 53.0 29.5 6.0 100

Darker 1 100 79.8 59.5 39.3 19.0 100

Darker 2 100 79.8 59.5 39.3 19.0 115

Photo

Mode

Lighter 70.0 36.6 19.6 11.4 7.0 100

Normal 80.0 43.4 24.8 15.8 11.0 100

Darker 1 85.0 47.9 29.0 19.9 15.0 100

Darker 2 85.0 47.9 29.0 19.9 15.0 115

In the C217 model, the the rmal head energy is always the same regardless

of the image density setting. Only the A/D conversion parame te rs ch an ge

depending on the selected image density. Using this method , the imag e

density of solid black areas does not change even if a darker setting is

selected. This is because all the pixel data will be the same (evenly black)

after the binary processing, if the area is purely bla ck.

In the C225 model, when Darker 2 is selected , th e A/ D conve rsion

parameters are the same as those of Darker 1, but the thermal hea d energy

increases to 115% of the norma l the rmal head energy. (Th is is done by

changing the pulse width.) As a result, the densit y of solid black are as will

become darker.

2-4

Page 19

5 September 1995 MASTER PLOTTING AND PRINTING AREA

4. MASTER PLOTTING AND PRINTING AREA

1. Length (Legal Drum)

Original

Master

Screen

Paper

(Shift : 0 mm)

Paper

(Shift : 15 mm)

Paper

(Shift : –15 mm)

2-5

C225D502.wmf

Page 20

Original

Screen

MASTER PLOTTING AND PRINTING AREA 5 September 1995

(A4 Drum)

Master

Paper

(Shift : 0 mm)

Paper

(Shift : 15 mm)

Paper

(Shift : –15 mm)

C225D503.wmf

2-6

Page 21

5 September 1995 MASTER PLOTTING AND PRINTING AREA

2. Width (Legal and A4 Drum)

Original

Master

Screen

Paper

C225D504.wmf

2-7

Page 22

TIMING CHART 3 (Master Cut/Trial Print) is identical to that of C217 model.

TIMING CHART 5 September 1995

5. TIMING CHART

5.1 MASTER EJECT (TIMI NG CHART 1)

2-8

C225D500.wmf

Page 23

5 September 1995 TIMING CHART

5.2 ORIGINAL FEED/PLOTTING (TIMING CHART 2)

2-9

C225D501.wmf

Page 24

SECTION 3

INSTALLATION

Page 25

5 September 1995 INSTALLATION REQUIREMENTS

1. INSTALLATION REQUIREMENTS

The installation loca tion should be carefully chosen becau se the

environmental con dit ions greatly affect the performan ce of the machine.

1.1 OPTIMUM ENVIRONMENTAL CONDITIONS

C225I500.img

Temperature — 10 to 30°C

(50 to 86°F)

Humidity — 20 to 90 % RH

C225I501.img

On a strong and level base.

The machine must be level within

5 mm (13/64") both front to rear

and left to right.

3-1

Page 26

INSTALLATION REQUIREMENTS 5 September 1995

1.2 ENVIRONMENTS TO AVOID

C225I502.img

Locations exposed to direct

Dusty areas.

C225I503.img

sunlight or strong light (more than

1,500 lux).

C225I504.img

C225I505.img

Areas with corrosive gases. Locations directly expo sed to cool air

from an air conditioner or reflected

heat from a space heater. (Sudden

temperature changes from low to

high or vice versa may cause

condensation within the machine.)

3-2

Page 27

5 September 1995 INSTALLATION REQUIREMENTS

1.3 POWER CONNECTION

C225I506.img

Securely connect the power cord

to a power source.

Make sure that the wall outlet is

near the machine and easily

accessible.

Make sure the plug is firmly

inserted in the outlet.

C225I507.img

Voltage must not fluctuate more

than 10%.

C225I508.img

C225I509.img

Avoid multiwiring. Do not pinch the power cord.

3-3

Page 28

More than

(24.0")

(27.6")

INSTALLATION REQUIREMENTS 5 September 1995

1.4 ACCESS TO THE MACHINE

Place the machine near a power sou rce, provid ing cle ara nce as shown belo w.

10 cm (4.0")

Paper

Delivery

Table

More than

60 cm

(23.7")

105 cm (41.3")

Paper

Feed

Table

More than

60 cm

(23.7")

61 cm

70 cm

C225I510.wmf

3-4

Page 29

5 September 1995 INSTALLATION PROCEDURE

2. INSTALLATION PROCEDURE

1. Make sure that you have all the accessories listed below.

(1) Master Spool............ .. .. .. .. .. .. .... .. .. .. .. .. .. .... .. .. .. .2

(2) Paper Feed Side Pad...................................... 2

(3) Operating Instructions - English............... .. .... .1

(4) NECR (Ricoh version only) ........................ ..... 1

(5) Brand Stickers

(OEM version only).......................................... 1 set

(6) Model Name Plates

(OEM version only).......................................... 1 set

3-5

Page 30

INSTALLATION PROCEDURE 5 September 1995

[A]

C225I511.wmf

2. Mount the machine on a strong and level base.

NOTE: Use a sturdy desk, or someth ing similar. The machine must be

level within 5 mm (0.2") both front to rea r and left to righ t.

3. Remove the tape and string securing the covers and units as shown

above.

4. Open the paper feed tray. Then remove the cush ions [A] supporting the

paper feed table and scan ne r co ver.

5. Firmly insert the plug in the wall outlet.

NOTE: Make sure that the wall o ut let is near th e machine and easily

accessible.

6. Turn on the main switch.

3-6

Page 31

5 September 1995 INSTALLATION PROCEDURE

7. Load paper as follows:

a. Open the paper feed table.

b. Press down the feed roller

pressure lever.

C225I512.img

c. Place the paper on the

paper feed table.

d. Adjust the paper feed side

plates to match the paper size.

e. Lift the feed roller pressure

lever.

f. Make sure that the paper

feed side plates contact the

paper lightly.

C225I513.img

C225I514.img

3-7

Page 32

INSTALLATION PROCEDURE 5 September 1995

8. Open the paper delivery table.

9. Move the paper delivery end

and side plates to mat ch the

print paper size.

C225I516.img

10. Install the master roll as follows:

a. Insert both spools int o th e

new master roll.

b. Open the top cover.

c. Position the master roll.

d. Lift the pressure re lea se

lever to release the platen

roller pressure.

C225I517.img

C225I518.img

3-8

Page 33

5 September 1995 INSTALLATION PROCEDURE

e. Insert the leading edge of

the master roll under the

platen roller. Then rotate the

master roll clockwise a little.

f. Return the pressure release

lever to its original position.

g. Turn on the main switch.

C225I519.img

h. Press the master cut button to cut

the leading edge of th e master

roll.

i. Remove the cut-off portion of the

master roll.

j. Close the top cover.

C225I520.img

C225I521.img

3-9

Page 34

INSTALLATION PROCEDURE 5 September 1995

11. Install the ink cartridge as follows:

a. Open the ink cover.

b. Press down the release

lever (green tab [A]).

Then pull out the ink

cartridge holder.

c. Open the ink cap and insta ll the

ink cartridge as shown in the

illustration.

C225I522.img

d. Slide in the ink cartridge holder.

Then press the setting lever

(green tab) until it clicks in

position.

e. Close the ink cover.

12. Make some test prints as follows:

a. Adjust the original guides to

match the original size.

b. Place an original face down.

c. Input the desired number of

prints with the number keys

and press the Master Making

key.

d. After one sheet of paper is

delivered, press the Print Start

key to make prints at the lowest

print speed until the print image

density stabilizes. Use a test

chart to check for changes in the

image density.

C225I523.img

e. Check the copy image after the

image is stabilized.

C225I524.img

3-10

Page 35

5 September 1995 INSTALLATION PROCEDURE

30 mm

18

mm

BRAND DECAL AND NAME PLATE INSTRUCTIONS

This procedure is for the OEM version machines only.

1. Peel off the backing film of the brand decal (accessory).

2. Adhere the brand decal to the operation pan el as sho wn.

3. Peel off the backing film of the model name plate (accessory).

4. Adhere the model name plate in the recess on th e fro nt cover.

3-11

C225I525.img

Page 36

SECTION 4

SERVICE TABLES

Page 37

5 September 1995 MAINTENANCE TABLE

1. MAINTENANCE TABLE

The following items should be maint ained periodically. There are two sets of

intervals - one based on time and the other base d on print coun t. For

maintenance items with entrie s in both of them , use whiche ver comes first.

C: Clean R: Replace L: Lubricate A: Adjust

Interval

Item

Scanner/Optics

Exposure Lamp C C C Dry Cloth

Original Pick-up Roller R

Mirror/Reflector C C C Soft Cloth

Exposure Glass C C C Dry Cloth

Original Registration

Sensor

Original Friction Pad R R R

Master Feed

Platen Roller

Master Eject Rollers C C C Alcohol

Drum Master Sensor C Dry Cloth

Paper Feed

Paper Feed Roller R R R R R R R R R

Friction Pad C C C C R R Damp Cloth

Press Roller R R

Paper Feed Roller

One-way Clutch

Paper Feed Clutch R

Feed Roller Bushing

Feed Roller Drive Gears

Registration/Exit Sensors C C C C Dry Cloth

2nd Feed Roller C C C C Dry Cloth

Transport Unit Drive Gear

Bearing

Transport Unit Gears

Drum and Ink Supply

Cloth Screen R R

Drum Drive Gears and

Cam

Drum Flange Bushing

Inside/Outside of the

Drum

Ink Pump Nozzle C C C Alcohol

Time Print Counter

6M 1Y 2Y 3Y 300K 600K 1M 1.2M 2M

CCC

RRR

RR

LLL

LLL

LLL

LLL

LLL

LLL

CCC

EM NOTE

Dry Cloth

Expected life

is 6K masters.

Motor Oil

(SAE #20)

Grease

(Albania #2)

Motor Oil (SAE

#20)

Grease

(Albania #2)

Grease

(Albania #2)

Motor Oil

(SAE #20)

Alcohol

4-1

Page 38

MAINTENANCE TABLE 5 September 1995

Interval

Item

Others

Timing Belt Tension A

Press Roller Lock Lever

Position

Time Print Counter

6M 1Y 2Y 3Y 300K 600K 1M 1.2M 2M

EM NOTE

A

4-2

Page 39

5 September 1995 LUBRICATION POINTS

2. LUBRICATION POINTS

2.1 FEED ROLLER BUSHING

Lubricant: Motor Oil

C225M500.img

4-3

Page 40

LUBRICATION POINTS 5 September 1995

2.2 TRANSPORT UNIT DRIVE GEAR BEARING

Lubricant: Motor Oil

C225M504.wmf

2.3 TRANSPORT UNIT GEARS

Lubricant: Grease (Alban ia #2 )

C225M505.wmf

4-4

Page 41

5 September 1995 LUBRICATION POINTS

2.4 FEED ROLLER DRIVE GEARS

Lubricant: Grease (Alban ia #2 )

C225M501.img

2.5 DRUM DRIVE GEARS AND CAM

Lubricant: Grease (Alban ia #2 )

C225M502.img

4-5

Page 42

LUBRICATION POINTS 5 September 1995

2.6 DRUM FLANGE BUSHING

Lubricant: Motor Oil

C225M503.img

4-6

Page 43

5 September 1995 SPECIAL OPERATION MODES

3. SPECIAL OPERATION MODES

3.1 SKIP FEED MODE

Customers can select the number of rota tions of the drum for one print by the

following key operation.

• While pressing the Clear key and Stop key, select the numb er of rotations

of the drum while one sheet of paper is fed using the Number keys (1 to 9

can be selected.).

To cancel the skip feed mode, follow one of the procedures belo w.

• While pressing the Clear key and Stop key, select 1 using the Nu mbe r

key.

• While pressing the Reset key, press the Clea r ke y.

• Turn the main switch off and on.

3.2 ECONOMY MODE

Customers can select this mod e by the following key operation. If th is mo de

is selected, the thermal head energy (pulse width) is reduced by 15%. The

image will be lighter and ink consumption will be reduced.

• While pressing the Clear key and Image Den sity key, press th e Image

Mode key.

To cancel the economy mod e, follo w o ne of the procedures below.

• While pressing the Reset key, press the Clea r ke y.

• Turn the main switch off and on.

3.3 QUALITY START MODE

This mode increases the image de nsit y of th e 1st print. Normally, the first

print after the proof print is made at the selected copy speed (70, 100 or

130 rpm). If the Quality Start mo de is selected by the following key operation,

the 1st print is made at 30 rpm.

• While pressing the Clear key, press the < and > keys.

To cancel the quality start mode, follo w one of the pro cedures below.

• While pressing the Reset key, press the Clea r ke y.

• Turn the main switch off and on.

4-7

Page 44

INPUT/OUTPUT CHECK MODE 5 September 1995

4. INPUT/OUTPUT CHECK MODE

The electrical component s can be checke d with this program. The input

check mode can check if the sensors or switch es function correctly. The

output check mode can manually activa te the elect rical devices, such as

motors and solenoids.

4.1 ACCESS PROCEDURE

1. Turn on the main switch while holding down the Print Start, Stop, and

Clear keys at the same time.

2. The memory indicator displays "01", which indicates th at the Inp ut Check

mode is selected.

3. To select the Output Check mode, press the Memory/Class key. The

memory indicator displays "00".

4.2 DRUM FREE RUN MODE

1. Select either the Input or Output Check mode.

2. Select the Photo mode by pressing the Im ag e Mode key.

3. To start the free run, press the Image Density key. Operation depends on

the Image Density selectio n as fo llows:

Image Density Selection Drum Speed

Lighter 30 rpm

Normal Stop

Darker 30 rpm

Darkest 70/100/130 rpm (see Note)

NOTE: The drum speed can be change d with the Spe ed key.

4-8

Page 45

5 September 1995 INPUT/OUTPUT CHECK MODE

4.3 INPUT CHECK MODE

By entering a number list ed belo w aft er accessing the input check mode, the

input level from each electrical device can be checked. Depending on th e

electrical device’s condition , th e be eper sounds and the machine status

indicators light.

No. Device Conditions when the beeper sounds

1 Feed Start Timing Sensor The sensor is actuated

2 Feed Jam Timing Sensor The sensor is actuated

3 Exit Jam Timing Sensor The sensor is actuated

Master Eject Position

4

Sensor

5 Drum Master Sensor The sensor detects a master on the drum

6 Cover Safety The scanner unit is open

7 Master End Sensor The sensor detects no master

8 Master Cut Switch The switch is pressed

9 Right Cutter Switch The switch is actuated

10 Left Cutter Switch The switch is actuated

11 Paper End Sensor The sensor detects no paper

12 Registration Sensor The sensor detects paper

13 Exit Sensor The sensor detects paper

Master Clamper Switch

14

(Open)

Master Clamper Switch

15

(Close)

16 Original Set Sensor The sensor detects an original

Original Registration

17

Sensor

18 ADF Open Switch The ADF is closed

19 Master Eject Sensor The sensor is actuated

20 Pressure Plate H.P. Sensor The sensor is actuated

21 Full Master Sensor The sensor is actuated

22 Paper Table Set Switch The switch is on

23 DIP SW 103-1 The switch is on

24 DIP SW 103-2 The switch is on

25 DIP SW 103-3 The switch is on

26 DIP SW 103-4 The switch is on

27 DIP SW 103-5 The switch is on

28 DIP SW 103-6 The switch is on

29 DIP SW 103-7 The switch is on

30 DIP SW 103-8 The switch is on

The sensor is actuated

The clamper is open

The clamper is closed

The sensor detects an original

4-9

Page 46

INPUT/OUTPUT CHECK MODE 5 September 1995

4.4 OUTPUT CHECK MODE

You can turn on each electrical device listed below individually. The

procedure is as follows:

1. Select the output check mode.

2. Enter the number of the device which you would like to turn on.

3. Press the Print key to turn on the device.

4. To turn off the device, press the Clear key.

NOTE: Some of these are devices are turned on only while the Print key

is pressed (marked with *).

CAUTION:

I

1. Do not turn the drum manually nor by using the output mode when

the clamper is opened with the output mode.

2. Do not open the clamper when the drum is not at the master fee d

or eject positions. Use the drum stop functions (No. 15 or 16)

before opening the clamper.

No. Device/Function Note

Thermal Head Power is applied to the thermal head for 30 seconds

1

2 Paper Feed Clutch *

3 Pressure Release Solenoid *

4 Master Eject Motor *

5 Ink Supply Motor *

Master Cutter Motor The motor stops when one of the cutter time

6

Print Counter The counter is increased by one each time the Print

7

Master Counter The counter is increased by one each time the Print

8

9 Exposure Lamp

Master Clamper Motor (Open) * The motor stops when the master clamper switch

10

Master Clamper Motor (Close) * The motor stops when the master clamper switch

11

12 Master Feed Motor

13 Original Feed Motor

14 Shading Distortion Correction The shading distortion memory is rewritten.

Drum Stop (Master Exit) The drum turns and stops at the master eject

15

Drum Stop (Master Feed) The drum turns and stops at the master feed

16

after the Print key is pressed. While the power is

applied to the thermal head, the beeper sounds.

sensors is activated.

key is pressed.

key is pressed.

detects the clamper open condition.

detects the clamper closed condition.

position automatically.

position automatically.

4-10

Page 47

5 September 1995 INPUT/OUTPUT CHECK MODE

No. Device/Function Note

Pressure Plate Motor *

17

(To Home Position)

Pressure Plate Motor *

18

(To the Compression Position)

19 Air Knife Motor *

20 Vacuum Motor

21 Operation Panel Indicators Turns on all the indicators on the operation panel.

The motor moves pressure plate towards to the

home position. The motor stops when the pressure

plate H.P. sensor is actuated.

The motor moves the pressure plate towards to the

master compression position. The motor stops

when the full master box sensor is actuated.

4-11

Page 48

SERVICE TABLES 5 September 1995

5. SERVICE TABLES

5.1 TEST POINT TABLE

Main PCB

No Usage

TP101

TP102

TP103

TP104

TP105

TP106

TP107

TP108

TP109

TP110

TP111

A/D Conversion PCB

–12 V

Ink Level (Standard Pulse)

Ink Level (Detection Pulse)

GND–b

+12 V

+24 V

4MHz Clock

+38 V

+5 V

GND–a

Original Registration Sensor

No Usage

TP201

TP202

TP203

TP204

OS Signal (CCD Output)

VS Signal (Inverted and Amplified CCD Output)

GND

Scan Line Trigger

5.2 VARIABLE RESISTOR TABLE

Main PCB

No Usage

VR101

VR102

A/D Conversion PCB

No Usage

VR201 White Level Adjustment

Power Supply PCB

No Usage

VR301

VR401

Ink Detection Adjustment

Original Registration Sensor Adjustment

Factory Use Only (+5V Adjustment)

Thermal Head Voltage Adjustment

4-12

Page 49

5 September 1995 SERVICE TABLES

5.3 DIP SWITCH TABLE

Main PCB

DPS 101 OFF ON

1 Outputs a Test Pattern 2 Dither Matrix (Screw Pattern) 3 Dither Matrix (Bayer Pattern) 4 Dither Matrix (8 x 8 Pattern) 5 Dither Matrix (6 x 6 Pattern) Dither Matrix (4 x 4 Pattern)

6 Normal Edge Emphasis in Photo Mode

7 Normal Enable Data Noise Filter

8 Production Use Only Must be ON

Factory Setting

DPS 101

1ON

2ON

3ON

4ON

DPS 101

5ON

6OFF

7OFF

8ON

If two or more of DPS 101-2 ∼ 6 are OFF, the image will not be produced.

DPS 102

1 Not Used

DPS 102

2 3 4 Leading Edge Registration Adjustment

OFF

OFF

OFF

OFF

ON

ON

ON

ON

OFF

OFF

ON

ON

ON

ON

OFF

OFF

OFF

ON

OFF

ON

ON

OFF

ON

OFF

+2.4 mm

+1.6

+0.8

0 (Standard)

–0.8

–1.6

–2.4

–3.2

4-13

Page 50

SERVICE TABLES 5 September 1995

DPS 103

1 2 3 Vertical Magnification

OFF

OFF

OFF

OFF

ON

ON

ON

ON

DPS103 Description

45Trailing Edge Erase Margin Adjustment

OFF

OFF

ON

ON

DPS 103 OFF ON

6

7

8

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

ON

OFF

ON

Normal

LG version

Normal

OFF

ON

OFF

ON

OFF

ON

OFF

ON

+1mm

+2 mm

+3 mm

–1mm

+1.75%

+1.25

+0.75

0 (Standard)

–0.75

–1.25

–1.75

–2.25

Enable Key Counter Operation

A4 version

Print and master counters do not change.

5.4 LED TABLE

Main PCB

LED # OFF ON

101

102

Insufficient Ink

–

Sufficient Ink

During Paper Feed

5.5 FUSE TABLE

Main PCB

FUSE #

101 630 mA 24 V

102 4 A 38 V Air Knife Motor

Rated

Current

Voltage Device

Master Cutter, Master Clamper, and Pressure Plate

Motors

Protect

4-14

Loading...

Loading...