Ricoh FAX2700L SPECIFICATIONS PIF130

PRINTER INTERFACE

PIF130

FIELD SERVICE MANUAL

1. OVERALL IN FORMATION

1.1. CONTROLLER SPECIFICATIONS

Item Specifications

Resolution 300 x 300 dpi

RAM Capacity 1.0 MB (Standard)

Upgradable to 2, 3, or 5 MB

Emul ation Standard:

HP LaserJet 4L

ESC/P

ESC/P

HP GL/2

Opti onal:

PostScrip t

Resident Fonts 21 scalable fonts and 3 bitmap fonts

(Refer to the Operator’s Manual for additional

information.)

Paper Size

Note: All the acceptable sizes

must be in portrait orientation.

Host Interface Standard:

A4

A5

B5

LT (Letter)

HLT (Half letter)

LGL (Legal )

GLT (Government letter)

GLG (Government legal)

EXE (Executive)

F4

MON (Monarch)

C10 (Commercial 10)

DL

C5

IB5 (International B5)

C6

Bi-Centronics

Optional:

LocalTalk

®

24-pin printer emulation (LQ ® mode)

®

9-pin printer emulation (LX ® mode)

TM

emulation (LJ4L mode)

TM

emulation (EPSON GL/2 ® mode)

TM

Level 2

TM

parallel interface x 1

TM

Interface x 1

1.2. ENGINE SPECIFICATIONS

Item Specifications

Resolution 300 x 300 dpi

Print Speed (Engine Speed) Up to 10 ppm (Letter or A4)

Warm-up Time 20 seconds or les s at normal temperatur e

Paper Size The available paper sizes are not the same as those

available with the controller. The selected paper size

depends on the machine’s hardware specifications.

Refer to the Operator’s Manual for addi tional

information.

PIF13 0 1-1 SM

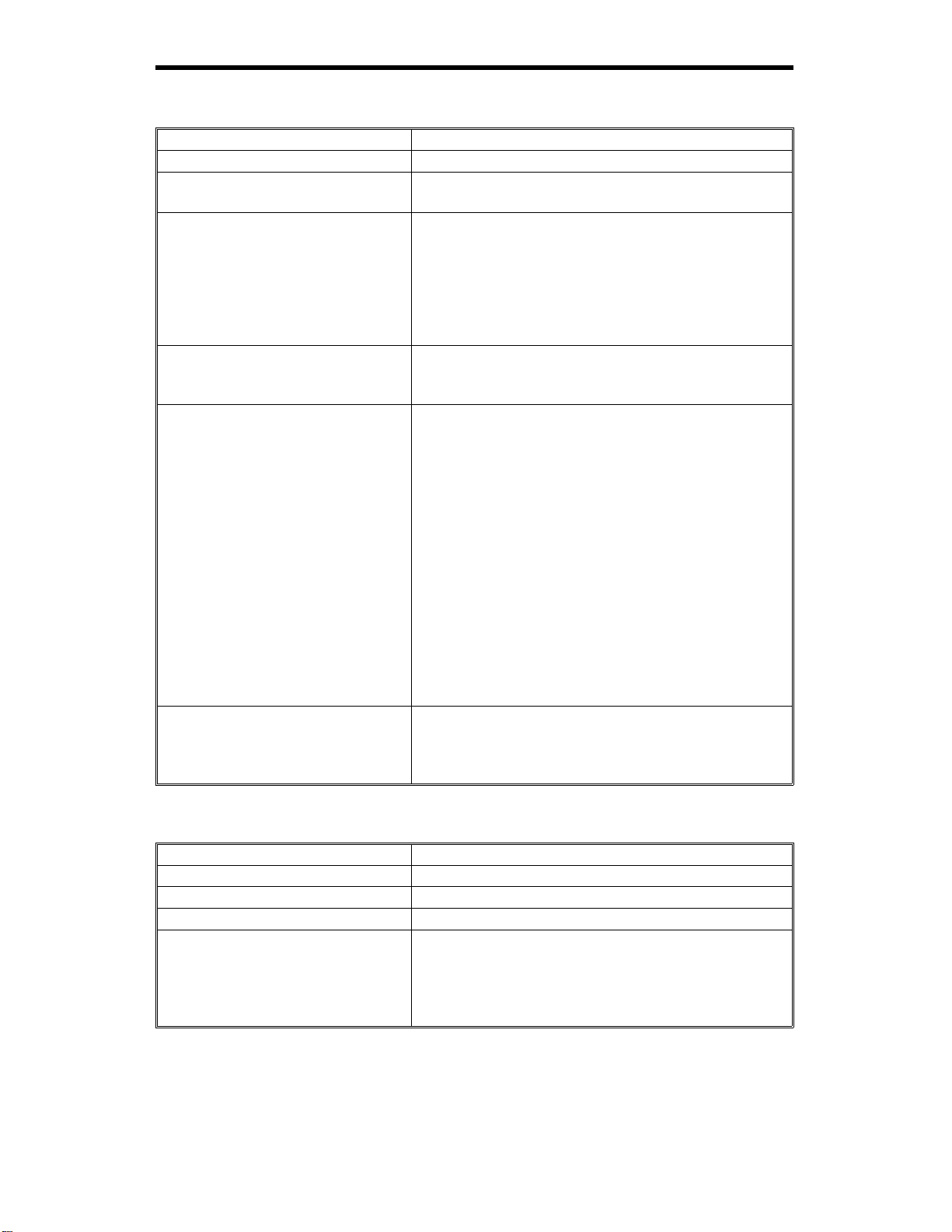

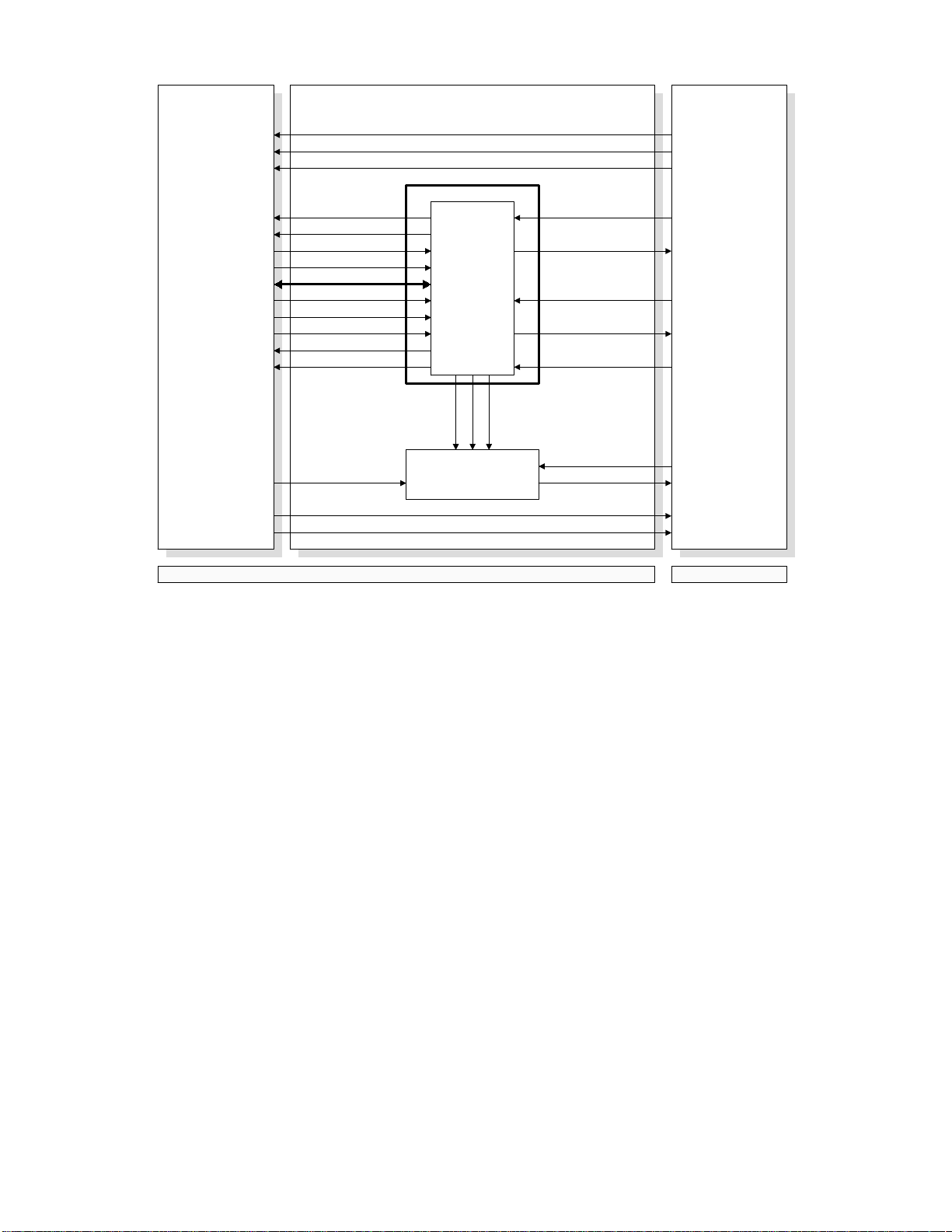

1.3. BLOCK DIAGRAM AND DATA PATH

The printer int erface u nit co nsists o f a contr oller board and an inter face board (PIF-L) .

FDU

FCE

Fax

Page

Memory

PSTN

Printer Interface

Controller PIF-L

Firmware

CPU CPU

NCU

Modem

Page

Memory

ADDRESS/DATA BUS

Cartridge

(Optional)

Font or PostScript

Compatible

Bi-Centronics I/F

PC-AT

(Optional)

LocalTalk I/F

Macintosh

Video/Command Interface

CPU

Laser Unit

H144V501.wmf

The Printer Inte rface Unit consists of two (2) logic boards ca lled the

Controller Board and the Interface Board (identified in the Service Manual as

the PIF-L Board).

The Controller Board contains a CPU chip, ROM for the firmware, Page

Memory, an optional Font or Postscript Interface Connector and two (2) Host

Interface Connectors ( a standard Bi-Centronic or an optional Local Talk).

Refer to the Controller Board Specifications for additional information.

The PIF-L Board also contains a CPU chip which is used to emulate the

commands fro m the Controller Board and to modify the displaye d message

in the display panel of the FAX machine. For example, if the FAX machine

can not use Legal size paper, the CPU chip on the PIF-L board will modify

the displayed message in the FAX machine to eliminate the displayed

selectio n of the Legal size paper. If the opti on of the legal size paper is not

displayed, the operator can not choose the legal size paper.

Data Path

The Controller’s CPU chip will inter pre t the print data from the host computer

and will write an imaginary page of data in the Page Me mory on the

Controller Board. After a page of prin t data has been stored in the Page

Memory, the Controller CPU chip will transfer the page of print data to the

CPU chip in the FA X machi ne will then pass the data direct ly to the Laser

Unit for printing.

SM 1-2 PIF130

The interface bet ween the CPU chips on the Controller board and the FAX

machine is known as "Video Interface". The function of the Video Interface is

to specify the handshaking pro cedure and the timing of the data transfer.

Dual Acce ss

Since the printer resources are shared, the FAX machine was designed to

perform multiple tasks.

If a FA X message is recei ved while the machine is busy printing data fro m

the computer, the F A X messa ge will be received an d the data will be

temporary stor ed in the S AF me mory of the FAX machine. At the co mpletion

of the computer print task, the machine will pr int the received FAX message

that was stored in the SAF Memory.

If the computer attempts to initiate a print task while the FAX machine is busy

receiving a FAX message or printing a report, the print data from the

computer will be received and stored in the Page Memory on the Controller

Board. At the complet ion of the FAX machin e t ask, the ma chine will swit ch

the printer resources of the Controller board to the computer printing task. If

the print data exceeds the Control ler’s me mory size, the print data will be

spooled in the co mputer (if the computer’s oper ati n g system or the

Application Program contains the Print Spooler Function).

The term "Spoole r" i s an acron y m for Simult aneous Print Operation On Line.

Print Spooler is a computer sof tware program that, when the printer is busy,

will intercept the print data tha t is on the way to the printer and will redire ct it

to a disk or memory. When the printer is no longer busy, the print data will

then be sent to the printer. An advantage of the Prin t Spooler feature is that

by diverting the entire print job to disk or memory and then coordinating it

with the printer, frees the user fro m waiti ng unti l the pri n t task is complet ed

before moving to another task.

1.4. POWER DISTRIBUTION

The required +24 volts and the +5 volts are supplied to the Printer Interface

from the FAX machine. The PIF-L board will then generate a different +5

volts for the CPU chips located on the PIF-L and Controller boar ds.

PIF13 0 1-3 SM

2. DETAILED S ECTION DE SCRIPTIONS

2.1. CONTROLLER

2.1.1. Bi-Centronics TM Interface

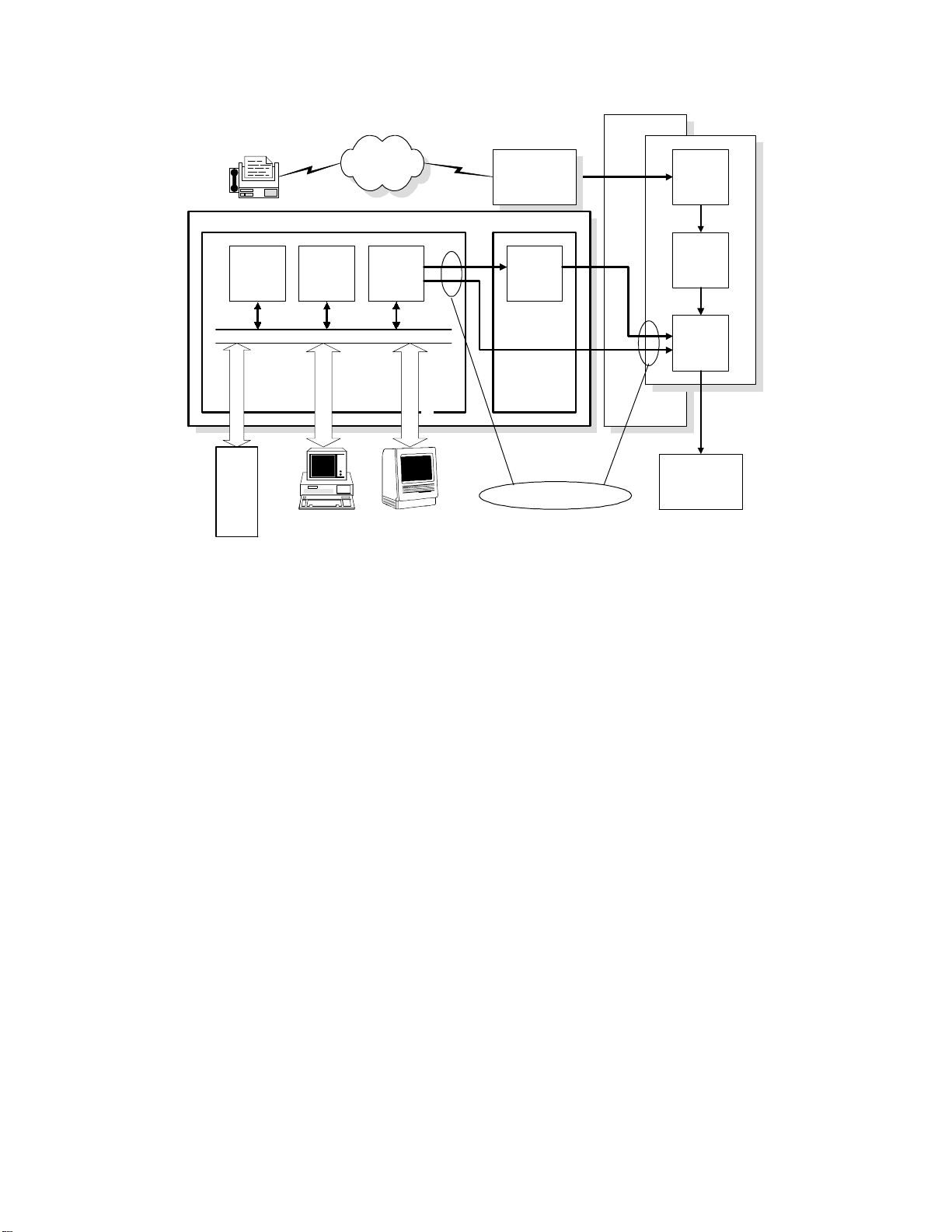

The parallel interface connector pin assignments and a description of the

interface signa ls are sho wn in the tabl e belo w.

Signal

Pin

10 28

11 29 BUSY OUT

12 30 PE OUT

13 — SLCT OUT

14 —

15 — NC — Not used

16 — GND —

17 —

18 — NC —

19~30 — GND — T wist ed-pai r return signal ground level.

31 — INIT IN

Return

Pin

119

2

3

4

5

6

7

8

9

20

21

22

23

24

25

26

27

CHASSIS

Signal Direction Description

STROBE pulse for readi ng data.

The

STROBE IN

DA TA1

DA TA2

DA TA3

DA TA4

DA TA5

DA TA6

DA TA7

DA TA8

ACKNLG OUT

AUTO IN

GND

IN

IN

IN

IN

IN

IN

IN

IN

—

The pulse width of the signal mu st be at

least 0 .5 µs at the receiving term inal .

The signals represent the parallel data

bits 1 to 8. Each signal is at the HIGH

level when the data is a logi c al 1 a nd

LOW when it is a logi cal 0.

About a 10 µs pulse width. A LOW

signal indicates that data ha s been

received and the printer is ready to

accept more data.

A HIGH signal indi cates that the pri nter

cannot receive data. The signal will go

HIGH in the following cases:

1. During printin g

2. When off line

3. During a printer-error stat e

A HIGH signal indi cates that the pri nter is

out of paper.

Availabl e onl y for bidirect i onal use.

Available only for bidirectional use.

A LOW signal enables an automatic line

feed upon receiving a CR signal. This

signal is only detected when the machine

has just been turned on, or when the

printer interface is initialized.

In ESC/P

operation in accordance with the

SelecT yp e

In HP

Logic ground level

Chassis ground, which is connected to

the signal ground.

Not used

When this signal goes LOW , the print er

controller will ignore the

®

mode, this signal effects a CR

TM

TM

setting.

mode, this signal will be ignored.

STROBE signal.

PIF13 0 2-1 SM

Signal

Pin

32 —

33 — GND —

34 — NC —

35 — +5V —

36 —

Return

Pin

Signal Direction Description

This signal will go LOW when the printer

is:

ERROR OUT

SLCTIN IN

1. Out of paper

2. In an error state

3. Off line

Same as for Pins 19~30

Not used

Pulled up to +5V through a 1KΩ resistor.

Availabl e onl y for bidirect i onal use.

Note: • All interface condi t ions are based on TTL levels. Both the rise and

fall times of each signal must be less than 0.2 microseconds.

• Data transfer is carried out by observing the ACKNLG or BUSY

signal.

(Data transfer to the printer interface can only be carried out after

the receipt of the ACKNLG signal or when the level of the B U SY

signal i s LOW.)

• The "Direction" column refers to the direction of signal flow as

viewed from the pri nt er interface.

• Return denotes the twisted-pair return to be connected at signal

ground level .

For the interface wiring, use a twisted-pair cable for each signal

and to complete the connection on the return side.

• The pulse width of the ACKNLG signal will vary.

SM 2-2 PIF130

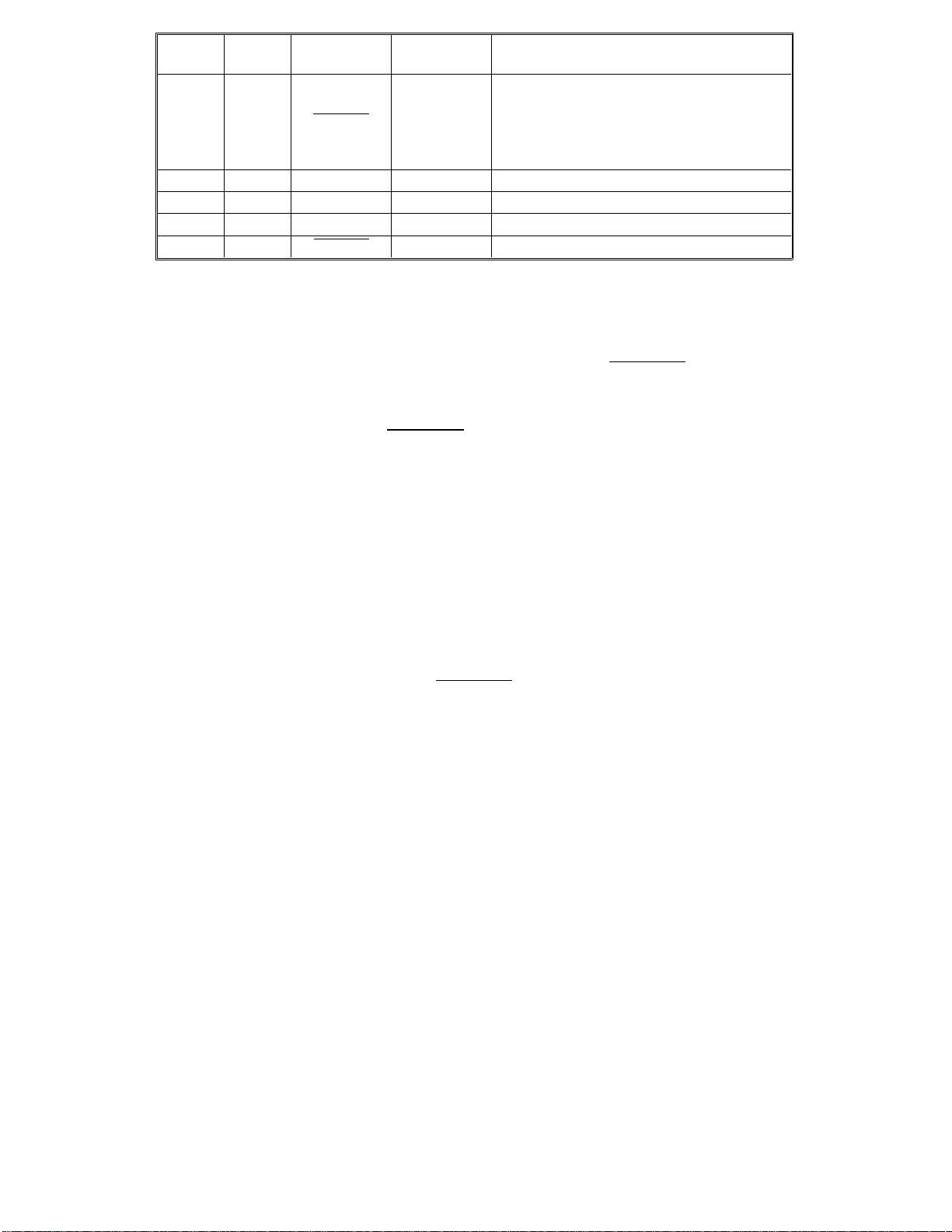

To enable bidirectional parallel interface communications between the printer

and computer, set the connector pin assignments as follows:

Printer Interface Computer

1

2

3

4

5

6

7

8

9

10

11

12

13

14

17

•

31

32

36

Chassis GND

• 16, 19—30, 33 connected to GND

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18—25

H144d501.wmf

2.1.2. LocalTalk TM Interface (Optional)

Specifications

Compatibility Phase 1 and phase 2

Baud rate 230.4 kbps

Topology Par al lel bus, lo w-re sistance transf orm er i solated, floati n g

ground.

Signaling standard EIA standard RS422, balanced vol tage

Signal encoding FMO (bi-phase) space

Frame format SDLC (Synchronous Data Link Control)

Node identification AppleTalk

action required.

Cabling AppleTalk

TM

logical address is self-configuring; no u ser

TM

8-pin mini DI N

PIF130 2-3 SM

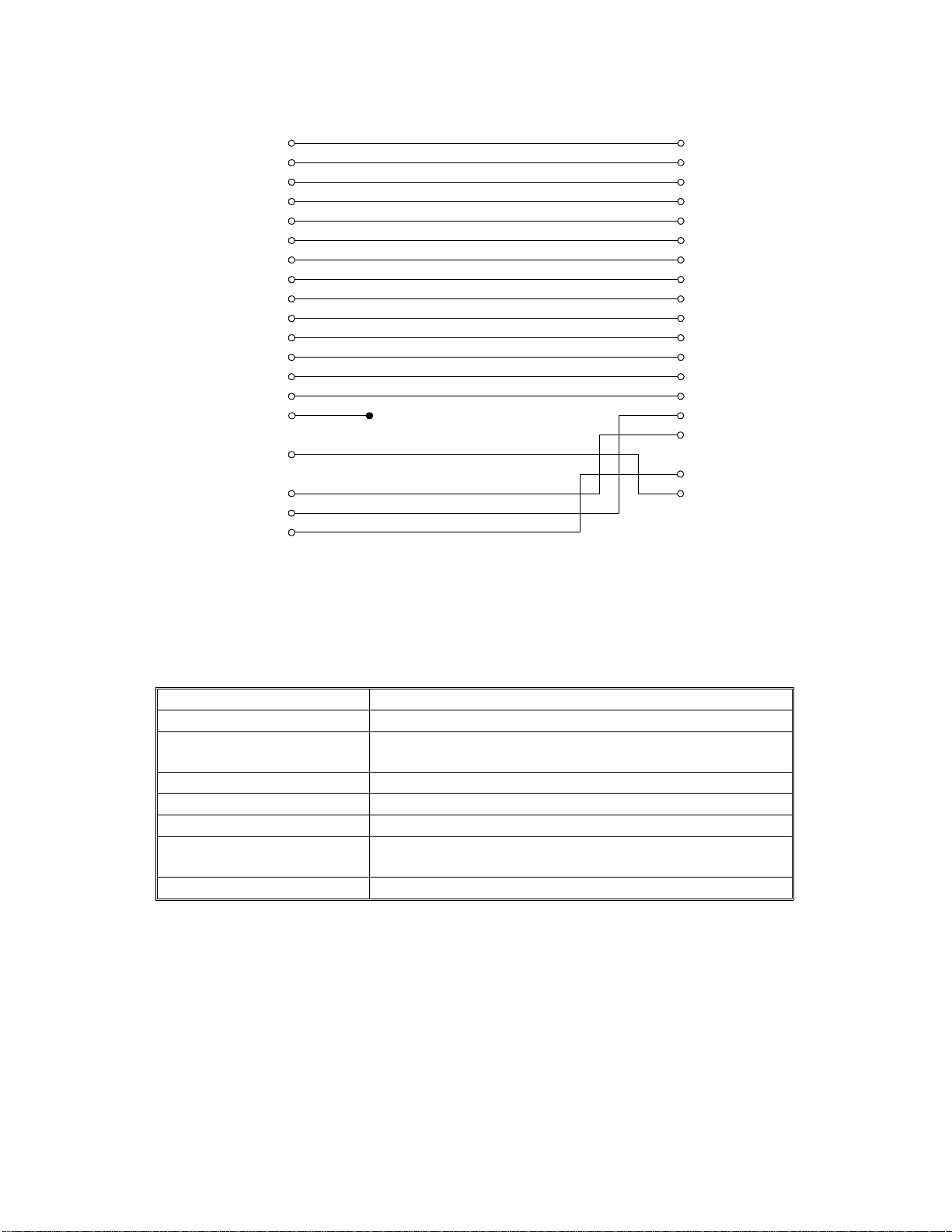

2.2. PIF

Controller PIF-L

5LSYNC

5VSYNC

5PRRDY

IC4

SWINT

PPRDY

RESET

CONNECT

LCD/KEY DATA

SERIAL CLOCK

CTBSY

COMMAND SERIAL DATA

STSBSY

STATUS

Print Density Adjustment

CPU

NORMAL

DARK

Circuit

5PRINT

5CPRDY

FDU/FCE

on the

Fax Machine

5PIFRESET

1INTPR

SERIAL CLOCK

SERIAL DATA

LIGHT

5LGATE

VIDEO SIGNALVIDEO SIGNAL

Printer Interface Unit

FAX

H144D502.wmf

The CPU on the PIF-L board acts as a interpreter (e mulator) between the

printer controller board and the FAX machine.

2.2.1. Command and Status Signals

The controller board will send various command signals to the FAX machine

through the CPU on the PIF-L board requesting hardware status (e.g.,

cassette paper size, jam, toner end) and for specifying a cassette for

printing. The FAX machine will respond to each command signal with a

status signal.

The CPU on the PIF-L board emulates the commands for FAX machine’s

hardware specifications (e.g, some models can have only one cassette).

SM 2-4 PIF130

2.2.2. Key/Display Emulation

When the operato r is using the prin ter function of the FA X machi ne, the FAX

machine’s keys and LCD panel are connected to the printer controller board.

through the CPU on the PIF-L board.

Because the capabilities of the contro ller and the FAX machine are not the

same (for exa mple, Mon arch paper is avail a ble with the controller, but not

with the FAX machine), the PIF-L board will emulate the user key operations

for the controller board and the display message to the FAX machine, so that

the user cannot select settings that the FAX machine is not capable of

performing.

2.2.3. Print Density Control

The controller controls the print density adjustment using the Level 2 menu.

Depending on the densi ty sett ing sent from the controller boa rd, th e PIF-L

board will adjust the pulse width of each pixel.

2.2.4. Printer Interface Reset

FDUPIF-LController

CPU

+5V

CN5-1,2

+5V +5V

+5V

CPU

RESET

DC/DC

Converter

5PIFRESET

Reset Circuit

+24V

+5V

CN1-20

CN1-2

FCE

CPU

H144D504.wmf

If the F AX mach ine’ s CPU chip activates the 5PIFRESET signal, the rese t

circuit on the PIF-L board will reset its CPU, and the DC/DC converter on the

will shut down the +5V supply to the Controller board.

The procedure for totally resetting the printer interface is described in

Section 4.

PIF130 2-5 SM

Loading...

Loading...