Ricoh FAX2700L SPECIFICATIONS PF100F

SERVICE MANUAL

Paper Feed Unit Type 140F

August 2nd, 1995

Subject to change

Table of Contents

1. OVERALL MACHINE INFORMATION

1.1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2. COMPONENT LAYOUT . . . . . . . . . . . . . . . . . . . . . . 1-2

2. DETAILED SECTION DESCRIPTIONS

2.1. PAPER PATH . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2. PAPER SIZE DETECTION . . . . . . . . . . . . . . . . . . . . . 2-4

2.3. PAPER END DETECTION . . . . . . . . . . . . . . . . . . . . . 2-5

2.4. CASSETTE LOCK . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.5. PAPER FEED . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.6. INTERFACE BOARD . . . . . . . . . . . . . . . . . . . . . . . . 2-7

3. INSTALLATION

3.1. INSTALLATION PROCEDURE . . . . . . . . . . . . . . . . . . 3-9

4. REPLACEMENT AND ADJUSTMENT

4.1. COVERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

4.2. PCB AND PAPER FEED MOTOR . . . . . . . . . . . . . . . . . 4-10

4.3. PAPER FEED ROLLER ASSE MBLY/P APE R FEED CLUT CH . . 4-11

4.4. SENSORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

August 2nd, 1995 OVERALL MACHINE INFORMATION

SPECIFICATIONS

1. OVERALL MACHINE INFORMATION

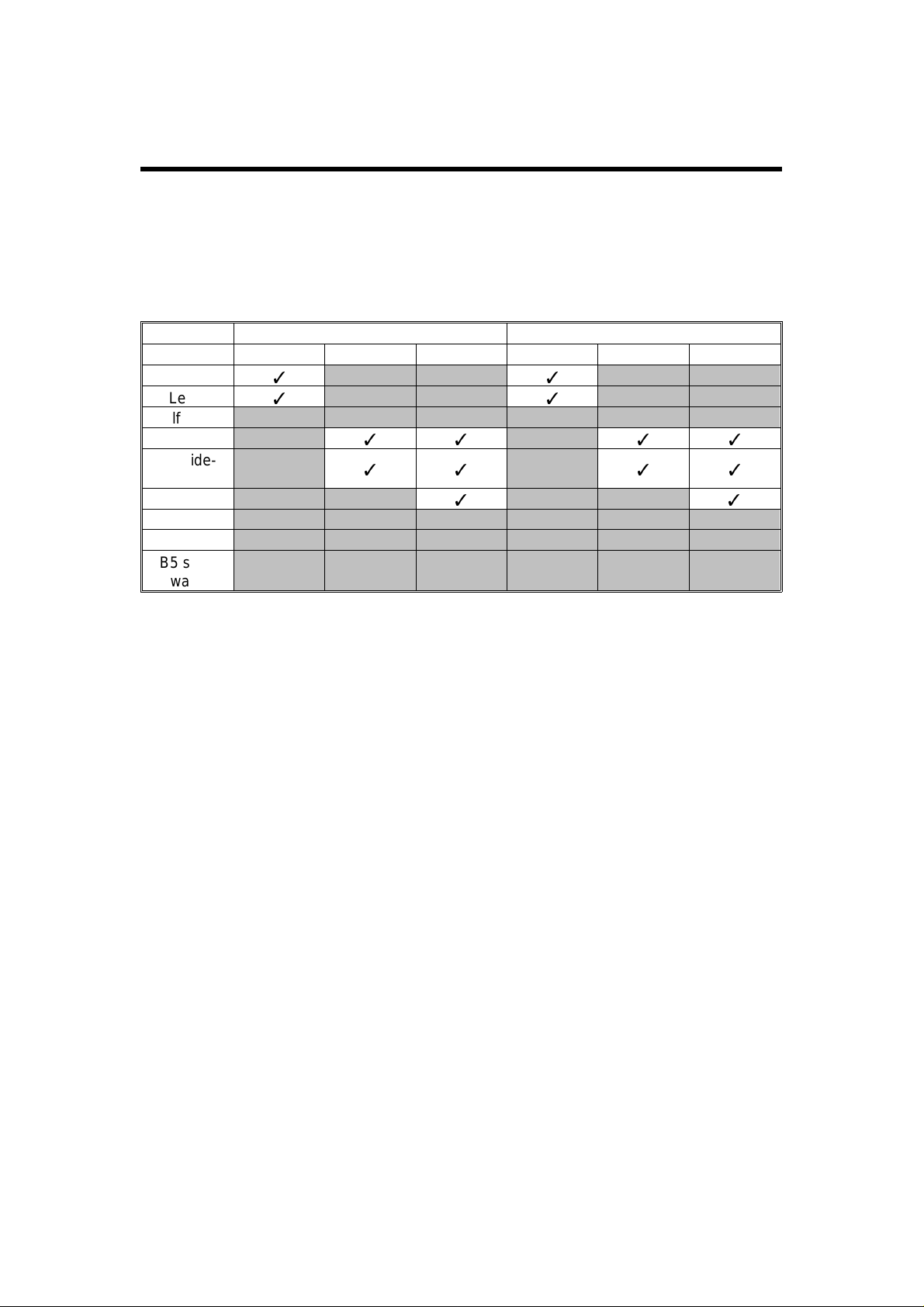

1.1. SPECIFICATIONS

Paper Capacity: 500 sheets

Acceptable Paper Sizes:

Model H526 H515

Paper Size US Europe Asia US Europe Asia

Letter

Legal

Half Letter

A4

A5 side-

ways

F/F4

B4

B5

B5 side-

ways

33

33

33 33

33 33

33

Note: The machine does not accep t a pa pe r size indicated by a shaded box.

Paper Weight: 60.0~90.0 g⁄

2

[16~24 lb.]

m

Dimensions (W x D x H): 427 x 54 9 x 153 mm [1 6.8 x 21.6 x 6.0 ins]

Weight: 7.5 kg [17 lbs]

1

OVERALL MACHINE INFORMATION August 2nd, 1995

COMPONENT LAYOUT

1.2. COMPONENT LAYOUT

1

2

7

3

4

Index Name Description

Paper End Sensor This sensor detects when the paper in the

1

Relay Sensor This sensor detects when the paper is at the

2

Paper Size Sensor This sensor detects the paper size installed in

3

LEDs The LEDs indicate whether a paper end or a

4

Paper Feed Clutch This clutch transfers drive from the paper feed

5

Paper Feed Motor This stepper motor drives the paper feed

6

Interface Board This board interfaces the control signals and

7

cassette has run out.

exit point of the paper feed unit.

the cassette. The user must install the correct

size actuator.

jam condition has been detected in the paper

feed unit.

motor to the paper feed roller.

mechanisms in the unit.

sensor outputs between the host fax machine

and the paper feed mechanisms in the unit.

It also relays the signals between the host fax

machine and another paper feed unit (if

installed).

5

6

H1 10D001.wmf

2

Loading...

Loading...