Ricoh FAX2700L Technical Bulletin flx7

Technical Bulletin No. F/LX7 - 001

Page 1/1

SUBJECT: ADF Mylar

PREPARED BY: K. Misugi

CHECKED BY: S. Fujii

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

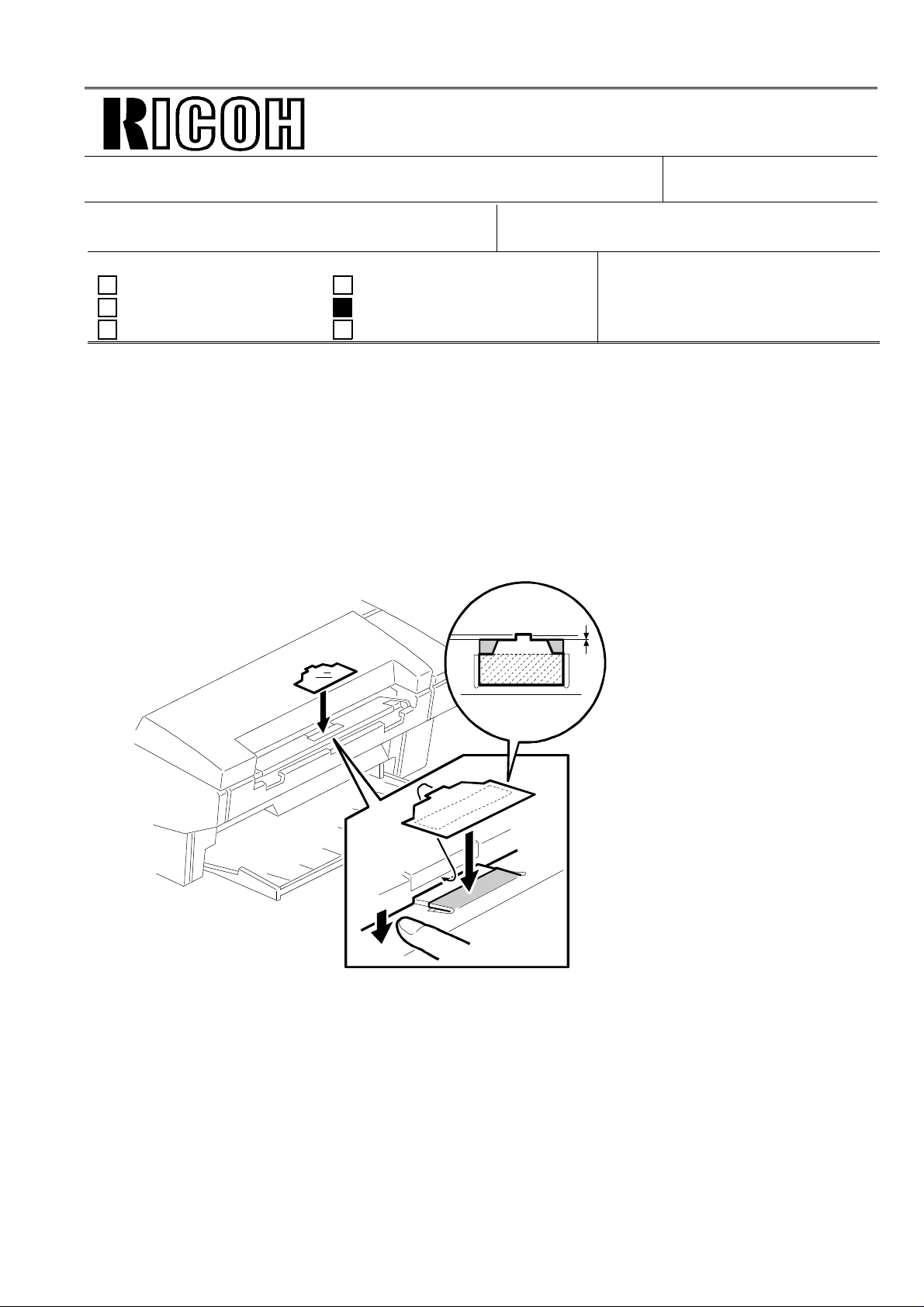

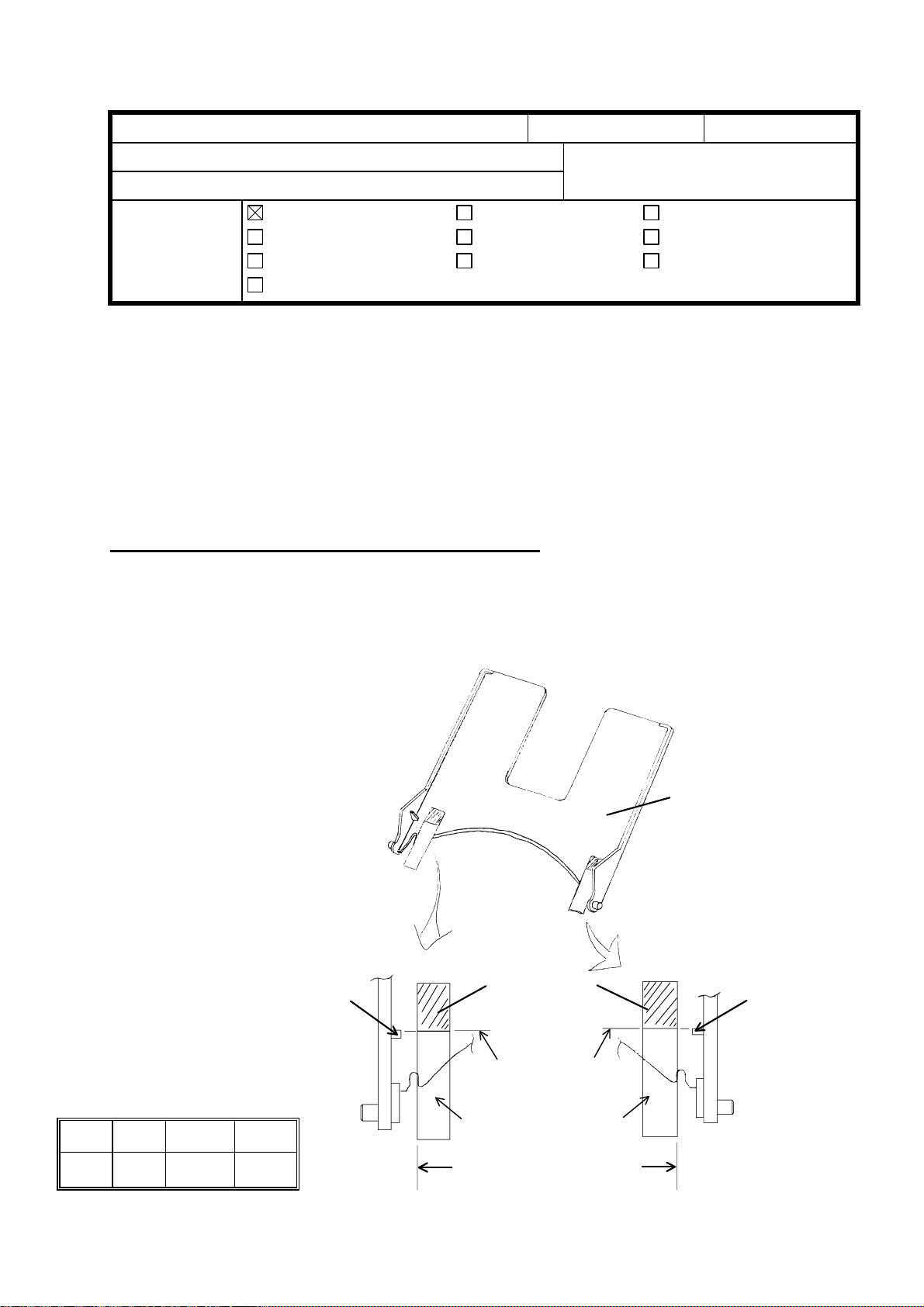

For customers who would like to use originals which contain silicone oil, place the mylar on the

Document Separation Pad as shown in the diagram below.

The ADF mylar will be available as a service part.

Part Number: H528 9500

FROM: 2nd Field Information Group,

MODEL: FX7

RICOH FAX1700L

NRG 9765, SAVIN FAX 3650

Infotec 3671

DATE:

1996. 10. 30.

QA Division

Page 1/1

Technical Bulletin No. F/LX7 - 003

SUBJECT: Print left margin from the optional paper feed unit

PREPARED BY: K.Moriizumi

CHECKED BY: S.Fujii

CLASSIFICATION:

Action Required Revision of service manual

Troubleshooting Information only

Retrofit Information Other

Symptom

The printed image shifts to left when printing from the optional paper feed unit.

The image is printed in the correct position when printing from the standard paper tray.

Cause

The initial value of the print left margin was fixed during the pre-mass-production.

However, the mechanical unit shifted the print left margin during the mass-production.

The print left margin for the standard paper tray was adjusted in the assembly line, but the

print left margin of the optional paper feed unit was not adjusted.

FROM: Quality Assurance Center

DATE:

15,Jan.1997

MODEL:FX7

RICOH FAX 1700L

NRG 9765,SAVIN FAX 3650

Infotec 3671

Countermeasure

The initial value of the print left margin for the standard paper tray and the optional paper

feed unit will be changed in order to match the mechanical unit. This change will be

implemented from the January production runs.

Action required

If the user makes a complaint about the print left margin from the optional paper feed unit,

adjust the print left margin for the optional paper feed unit by referring to the following

table.

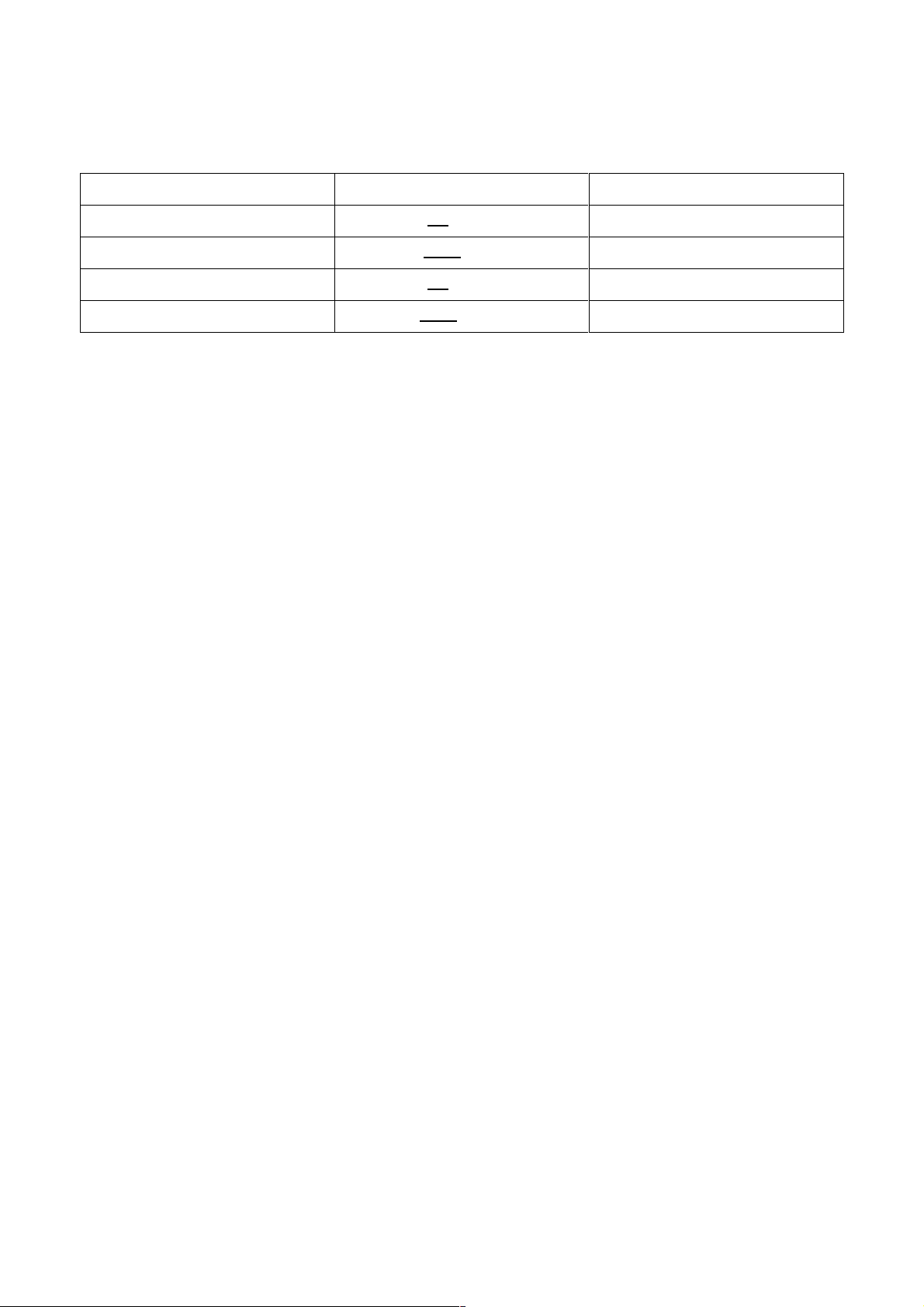

RAM address Value Function

8002C0 [H] 06 [H] Print left margin (Standard paper tray)

8002C1 [H] 06 [H] Print left margin (Optional paper feed unit)

RC RE ASIA

* * *

TECHNICAL BULLETIN

Model: F/X7 Date: 15-Feb-97

No: 002

Subject: FX7 Service Manual Correction Prepared by: K.Misugi

From: 2nd field Information Group, QA Division Checked by: S.Fujii

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Action required

Service manual revision

Retrofit information

Section 1. OVERALL MACHINE INFORMATION

1.1. Specifications

Paper Size and Capacity

Incorrect Correct Remarks

Paper Feed Unit (Optional):

A4, Letter, Legal, F4

Paper Feed Unit (Optional):

A4, Letter, Legal

F4 size cannot be used with

the optional paper feed unit.

1/

Section 2. DETAILED SECTION DESCRIPTIONS

2.2.1. Printing Process - Overview

Incorrect Correct Remarks

Document Blade - 550V Doctor Blade -550V Illustration: H528D545.wmf

Development Roller (Bias):

- 300V

Development Roller (Bias):

- 280V

Development Roller bias has

been changed.

2.2.5. Development

1. Overview

Incorrect Correct

“During printing, a bias voltage of -300V is

applied to the development roller.”

“During printing, a bias voltage of -280V is

applied to the development roller.”

2. Development Bias

Incorrect Correct Remarks

Development roller:

-300V [B]

Development roller:

-280V [B]

Same as above.

TECHNICAL BULLETIN

2.3.2. Automatic Service Calls

1. Service Call Conditions

Descriptions Incorrect Correct

Service Call Conditions Sub-code address

80033C(H)

Hexagonal mirror motor

error

Fan motor failure Sub-code 52 Sub-code 51

2. Excessive Jam Alarms

Incorrect Correct Remarks

Then, the alarm is disabled

until either bit 3 or bit 4 of

address 80033D(H) is reset

to zero.

4. PM Call

Incorrect Correct Remarks

Default setting: 60,000

sheets

Sub-code 32 Sub-code 31

Then, the alarm is disabled

until either bit 3 or bit 4 of

address 8002DD(H) is reset

to zero.

Default setting: 30,000

sheets

Sub-code address

8002F9(H)

The last sentence on the

descriptions of the

Excessive Jam Alarms. The

RAM address is incorrect.

Section 4. SERVICE TABLES AND PROCEDURES

4.1.17. Printer Test Patterns (Function 11)

Incorrect Correct Remarks

Press a key from 0 to 4. Press the 0 or 1 key. Only 0 or 1 are selectable.

4.2. Bit Switches

Bit Switch Incorrect Correct

System Switch 04: Bit 5

OPC replacement level

The drum replacement

interval is programmed at

addresses 8001E5 to

8001E7(H).

The drum replacement

interval is programmed at

addresses 8001EE to

8001F0(H).

TECHNICAL BULLETIN

Scanner Switch 00:

Bits 2 and 3

Maximum transmittable

document length

4.5. Service RAM Addresses

RAM Address Incorrect Correct

8002F9(H):

Details of the service call

(hardware error)

80033D(H): Excessive jam

alarm

8003FD to 800404

Scanner Video Processing

Parameters

Bit 3 2 Setting

0 1 1200 mm

32(H): Mirror motor error 31(H): Mirror motor error

52(H): Fan motor error 51(H): Fan motor error

80033D(H) (address is

wrong)

8003FD to 800404(H)

(addresses are wrong)

Bit 3 2 Setting

0 1 1000 mm

8002DD(H)

800340 to 800347(H)

Section 5. PREVENTIVE MAINTENANCE

5.1. Special Tools and Lubricants

RAM Address Incorrect Correct

Flash/SRAM data copy tool

(P/N: A1939535)

Section 6. REPLACEMENT AND ADJUSTMENT

6.6. Image Adjustment

Incorrect Correct

"The RAM reset level 0 will reset all the

scan and print margin parameters to the

initial settings."

Flash/SRAM data copy tool

(P/N: A1939353)

"The RAM reset level 1 will reset all the

scan and print margin parameters to the

initial settings."

This information has already

been released.

TECHNICAL BULLETIN

Section 7. TROUBLESHOOTING

7.3. Service Call Conditions

Description Incorrect Correct

Mirror motor error Sub-code 32 Sub-code 31

SC Code 3-32 SC Code 3-31

Fusing unit fan motor error Sub-code 52 Sub-code 51

SC code 5-52 SC code 5-51

TECHNICAL BULLETIN

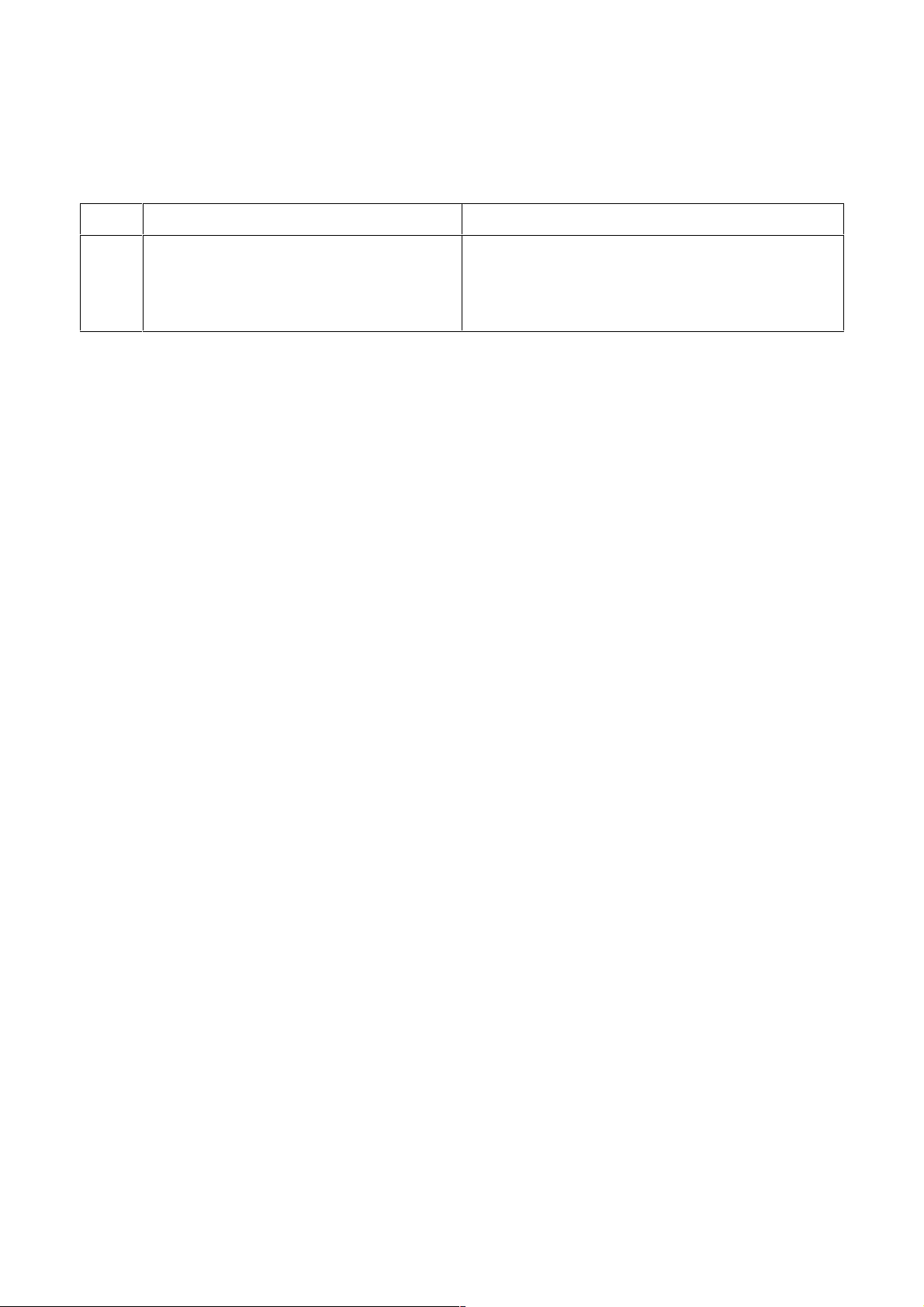

7.4. Error Codes

An error code has been added for an optional paper feed unit paper jam.

Code Meaning Suggested Cause/Action

9-50 Paper non-feed or jam at the paper

entrance

(With the paper feed unit.)

If the problem persists, replace the FCU.

Cross reference

Paper non-feed - Section 7-2-2

Jam at the paper entrance - Section 7-2-2

RICOH Technical Bulletin

Model: F/LX7 Date: 28-Feb-97

Subject: Scanner bottom margin Prepared by: K.Moriizumi

From: 2nd Technical Support Section Checked by: S. Fujii

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

No: 004

Action required

Service manual revision

Retrofit information

Symptom

The scanner bottom margin is wider by a few millimeters.

Cause

A sheet has been added to the scanner cover to accurately reset the document exit

sensor starting from the November 1996 production run.

(H5291156:Sheet - Scanner Cover)

As a result, the document exit sensor resets accurately and quickly.

It may cause a wider blank space at the bottom of the scanned pages and the

omission of the trailing edges of the scanned pages.

1/1

Countermeasure

If the scanner bottom margin is too wide, please change the following RAM data.

Address Value

800298 10 → 16 (Copy Mode 100%)

804D67 00 → 07 (Memory Tx STD)

804D69 0B → 11 (Copy Mode 75%)

804D6B 0D → 13 (Copy Mode 85%)

804D6D 0F → 15 (Copy Mode 95%)

804D6F 13 → 17 (Copy Mode 125%)

804D71 17 → 1C (Copy Mode 150%)

804D73 1F → 1E (Memory Tx SSF)

804D75 07 → 00 (Memory Tx STD)

Note: Do not change the above RAM values on the machines in which the Scanner

Cover Sheet was not added.

RC RE ASIA

* * *

RICOH Technical Bulletin

Model: F/LX7 Date: 28-Feb-97

Subject: TTI on the System Parameter List Prepared by: K.Moriizumi

From: QAC 2nd Field Information Dept. Checked by: S. Fujii

Classification:

The programmed TTI is not printed in the middle of the system parameter list but at the

upper right corner because of the limited ROM capacity.

Troubleshooting

Mechanical

Paper path

Other (Information Only )

Part information

Electrical

Transmit/receive

No: 005

Action required

Service manual revision

Retrofit information

1/1

Technical Bulletin PAGE: 1/1

Model: FX7,LX7 Date: 15-Mar-97

Subject: ADF Solenoid control Prepared by: Y.Tamaoka

From: QAC 2nd Field Information Dept. Checked by: S. Fujii

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Action required

Service manual revision

Retrofit information

No: 007

SYMPTOM

The Document Pick-up Solenoid stays on even after document is fed out and this

causes overheating . This may result in warping of the operation panel cover and

damage to transistor Q4 on the FCU.

CAUSE

There is no software protection for the above condition.

This may happen if an original is fed in too far between the Document Pick-up

Roller and Separation Pad, but it is rare.

SOLUTION

1) Software Update

H5287120E for FX7, H5297120C for LX7

2) Adding a decal informing users not to forcibly insert documents (Under

preparation :The decal should be expectedly available at the beginning of March

1997)

RICOH Technical Bulletin PAGE: 1/1

Model: FX7 Date: 31-Mar-97

No: 006

Subject: SC Code Coreection Prepared by: Y.Tamaoka

From: QAC 2nd Field Information Dept. Checked by: S. Fujii

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Action required

Service manual revision

Retrofit information

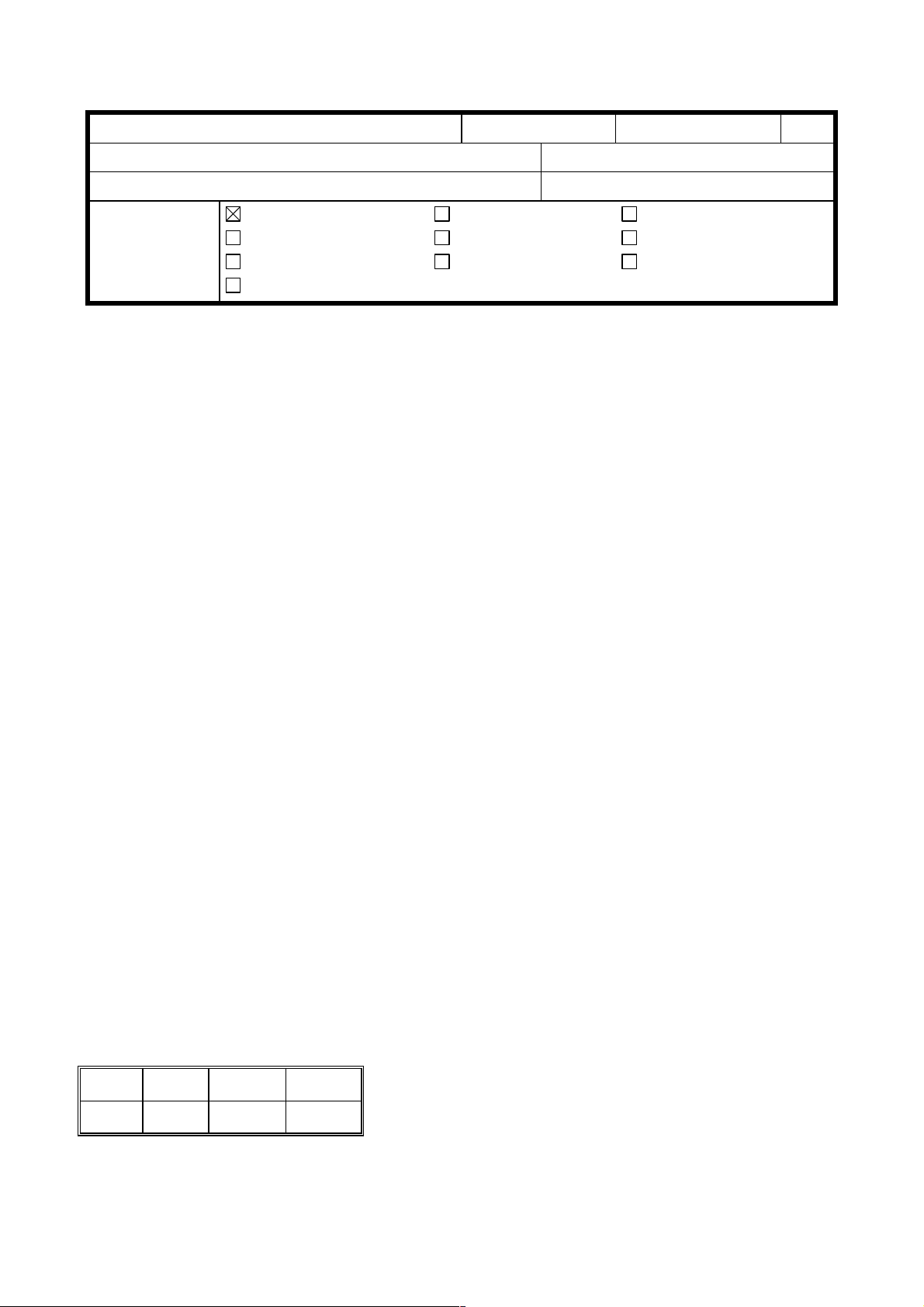

Page 7-22

7.3 SERVICE CALL CONDITIONS

Current

Symptom Error Code Sub-code SC Code

Mirror motor error 9-23 32 3-32

Corrected to

Symptom Error Code

Mirror motor error 9-23

RC RE ASIA

* * *

Sub-code SC Code

31 3-31

T

H

echnical

B

ulletin

RTB Correction

Reissue date: 30-Sep-97

The items in bold italic have been corrected or added.

PAGE: 1/1

Model:

Subject:

From:

Classification:

Modification

Schedule

FX7

Drum Cartridge

QAC 2nd Field Information Dept.

Troubleshooting

Mechanical

Paper path

Other ( )

Date:

Prepared by:

Part information

Electrical

Transmit/receive

31-May-97

No:

K.Moriizumi

Action required

Service manual revision

Retrofit information

008

A

SYMPTOM

When the drum cartridge is replaced, if the top cover is not opened fully, paper jams will

occur.

CAUSE

The drum cartridge gear comes off if the top cover is not opened fully.

SOLUTION

Instruct the customer to repair the drum cartridge gears in the following manner

1. Remove drum cartridge gear-1 from the drum cartridge.

2. Snap on drum cartridge gear-1 in the correct position.

3. Instruct the customer to open the top cover fully when installing the drum

cartridge.

We will prepare the drum cartridge gear as a service part. If the customer breaks the drum

cartridge gear by mistake, use a new one.

Drum Cartridge

RC RE ASIA

∗ ∗ ∗

Drum Cartridge Gear – 1

H5289500

5289501

WIINl

ModeI: FX7

Technical

Bulletin

Date:

31-May-97

No:

PAGE: 1/2

009

Subject:

From:

Classification:

Document Sensor

QAC 2nd Field Information Dept.

❑

Troubleshooting

❑

Mechanical

❑

Paper path

❑

Part information

❑

Electrical

❑

Transmit/receive

Prepared by:

K.

Moriizumi

❑

Action required

❑

Service manual revision

❑

Retrofit information

❑ Other ( )

Modification

Schedule

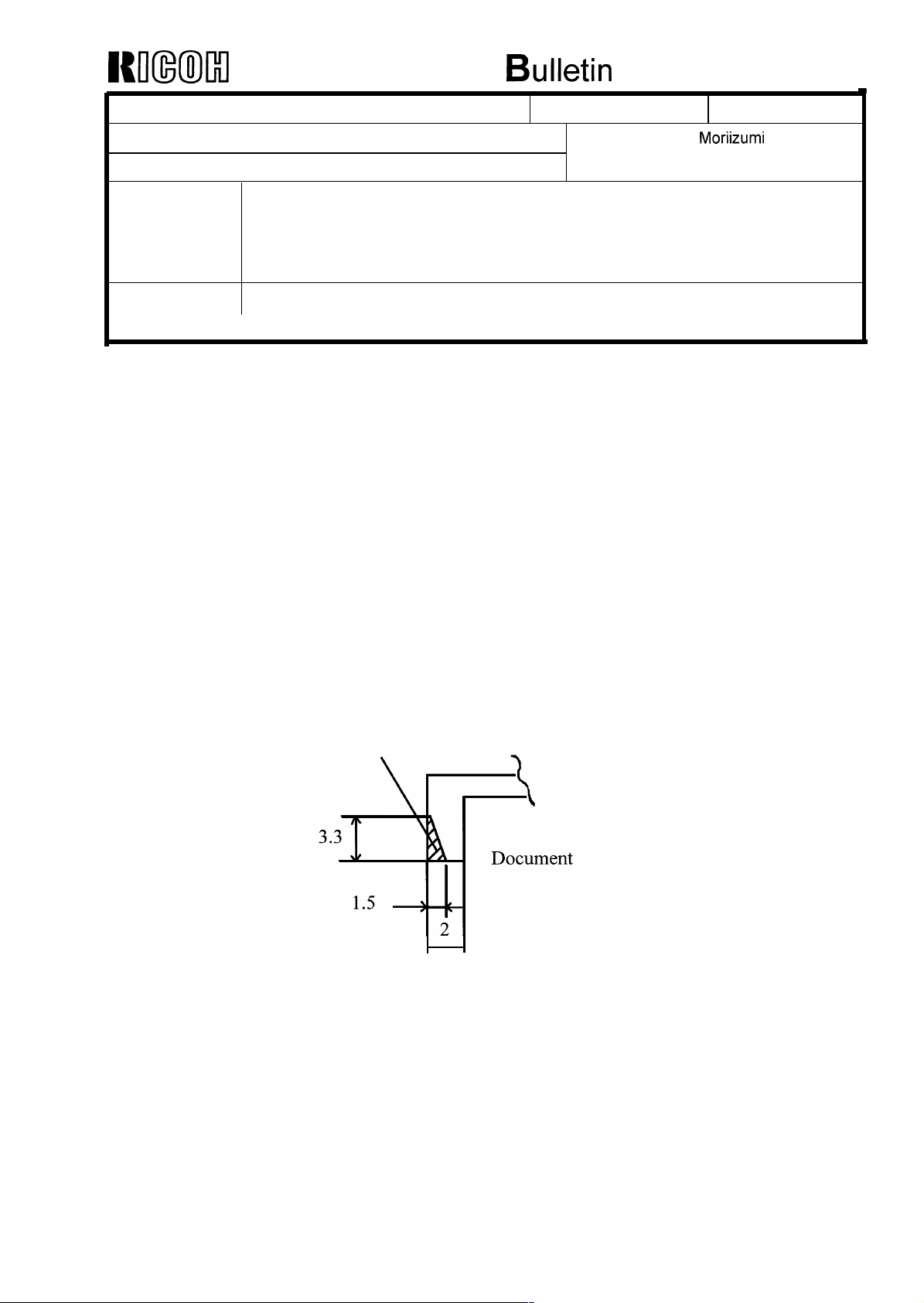

SYMPTOM

A document jam error occurs even though there are no documents in the ADF. This is

because the Document Sensor is stuck.

CAUSE

The actuator of the document sensor touches the sensor unit on the Scanner Sensor

Board.

I

From September, the scanner sensor board was shifted to the left during assembly,

However, the board might be shifted due to vibration during transportation.

From December, the document sensor actuator was changed to prevent contact with

the sensor.

Cut here

Sensor

Actuator

Kmml

Model:FX7

Technical

Bulletin

Date: 31-May-97

No:

PAGE: 2/2

009

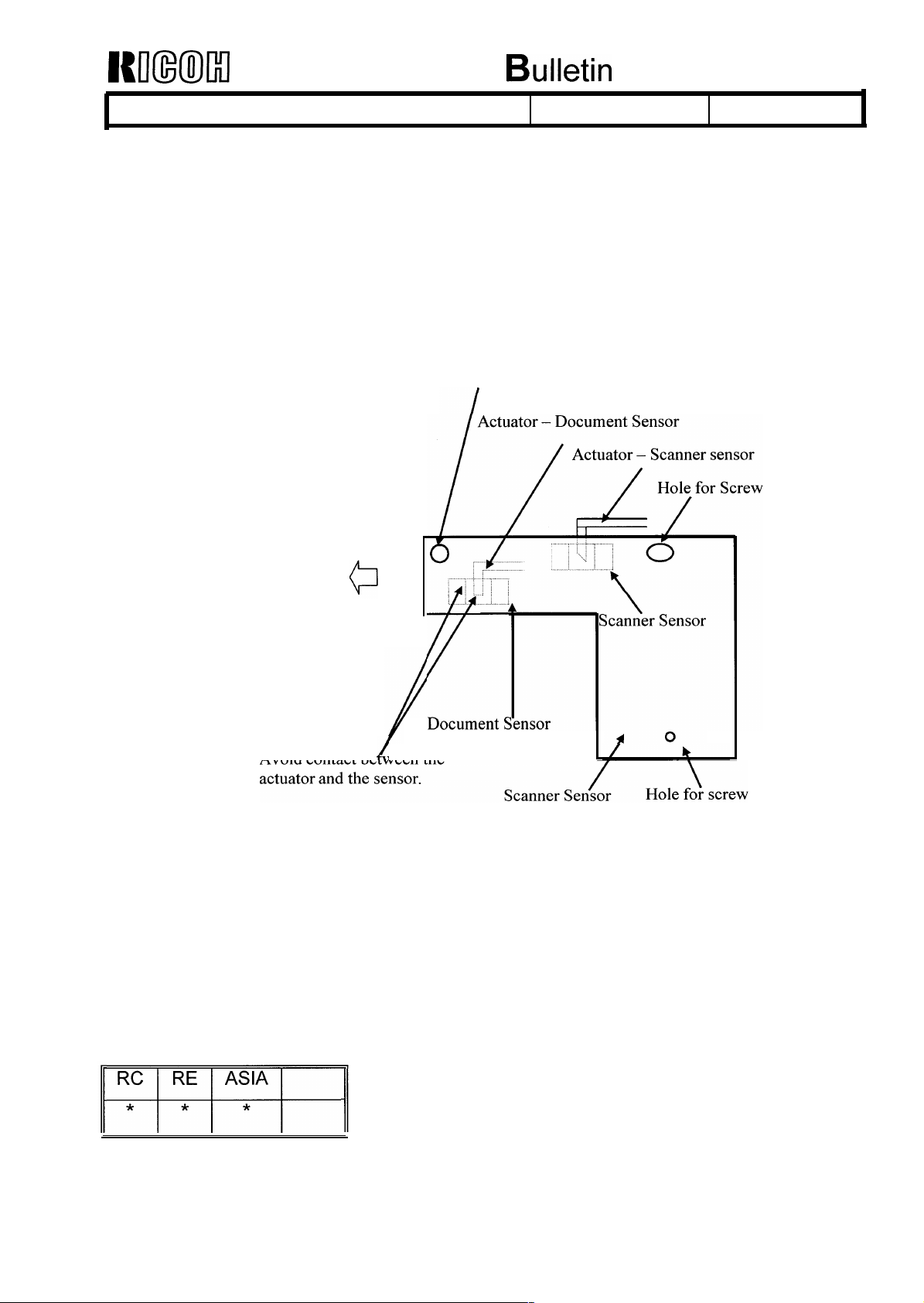

SOLUTION

If the document sensor does not return to the initial position, please do the following.

Temporary Countermeasure

1. Loosen the screws of the Scanner Sensor Board.

2. Push the Scanner Sensor Board to the left side.

3. Tighten the screws.

Hole for Screw

Push the Scanner Sensor Board to the left.

(It can be moved only about 0.3 mm.)

Avoid contact be ween the

Permanent Countermeasure

1. Replace the Document Sensor Actuator.

The new part number is:

H5291160: Actuator – Document Sensor

RICOH Technical Bulletin PAGE: 1/1

Right rib

Two –side

Line A

H5293168

Model: F/LX7 Date: 15-Jun-97

Subject: Paper Tray Prepared by: K.Moriizumi

From: QAC 2nd Field Information Dept.

Classification:

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Action required

Service manual revision

Retrofit information

No: 010

SYMPTOM

A paper jam occurs because the paper tray is in the wrong position.

SOLUTION

Sheets have been added to the paper tray as a countermeasure to prevent the paper tray

from being set in the wrong position. Please refer to the following installation procedure.

P/N : H5293168 (Sheet – Paper Tray)

Sheet – Paper Tray Installation Procedure

1. Put two-sided adhesive tape on the underside of the paper tray near the hinges along

the Line A and B and Line B and C as shown below.

2. Press down on the adhesive tape after application to remove any air bubbles.

Paper Tray Under Side

Left rib

adhesive tape

Line C

Line C

RC RE ASIA

* * *

Sheet-Paper Tray

Line B

RICOH Technical Bulletin PAGE: 1/2

Model: F/LX7 Date: 31-Jul-97

Subject: History of Software Changes Prepared by: K.Moriizumi

From: QAC 2nd Field Information Dept.

Classification:

# Reason/Problem H5287120 H5297120

1 The rotation time of the document exit roller has a

limited margin. So, the document exit roller might hold

the end of the last page of the document.

2 If the size of paper in the Optional Paper Feed Unit is

different from the setting , a paper size error for the

Standard Tray occurred instead of for the Optional

Paper Feed Unit.

3 Spelling correction. D A

Troubleshooting

Mechanical

Paper path

Other (Software History)

Part information

Electrical

Transmit/receive

Action required

Service manual revision

Retrofit information

(Suffix)

No: 011

D

(Suffix)

D A

A

4 Correction for Spain and Switzerland to meet

regulations.

5 Garbage data is inserted in the first ECM frame

occasionally. But, the garbage data is not inserted in the

frame that is transferred again.

6 The printed image shifts to the left when printing from

the Optional Paper Feed Unit. (See RTB No. F/LX7-003)

7 The received page is printed out twice for non–ECM and

direct reception mode if a communication error has

occurred.

8 The engine version is always printed as “00” on the

System Parameter Report.

9 The Distinctive Ring function is printed on the User

Parameter List (Europe/Asia).

10 The scanner bottom margin is a few millimeters wider

(See RTB No. F/LX7-004).

11 The DIS frame description is always printed as

“V17 14. 4K W: A4 OMS (1/1 1/1)” on the protocol dump

list for PC Fax reception (Class 1) mode. The DIS Hex

Code dump is correct.

D A

D A

D A

D A

D A

D A

D B

– B

12 Correction for Spain to meet regulations. (The default

value for polarity change detection was changed so that

it is now enabled.)

RC RE ASIA

E C

RICOH Technical Bulletin PAGE: 2/2

Model: F/LX7 Date: 31-Jul-97

13 Document Pick-up Solenoid problem

(See RTB No. F/LX7-007)

14 It is impossible to send the document after the machine

detected a ringing signal if the Distinctive Ring function

is enabled.

15 The AI Short Protocol function is disabled after redialing. E C

FX7:

H5287120

Suffix D January, 1997 1B27/BEEF/5C38

Suffix E February, 1997 42B3/BEEF/83C4

Implementation Check Sum

(Total/Boot/Main)

No: 011

E C

E C

LX7:

H5297120

Suffix A November, 1996 8412/BEEF/C523

Suffix B January, 1997 8ABE/BEEF/CBCF

Suffix C February, 1997 96A7/BEEF/D7B8

Implementation Check Sum

(Total/Boot/Main)

RICOH Technical Bulletin PAGE: 1/1

Model: F/LX7 Date: 31-Jul-97

Subject: Tapping Screws Prepared by: K.Moriizumi

From: QAC 2nd Field Information Dept.

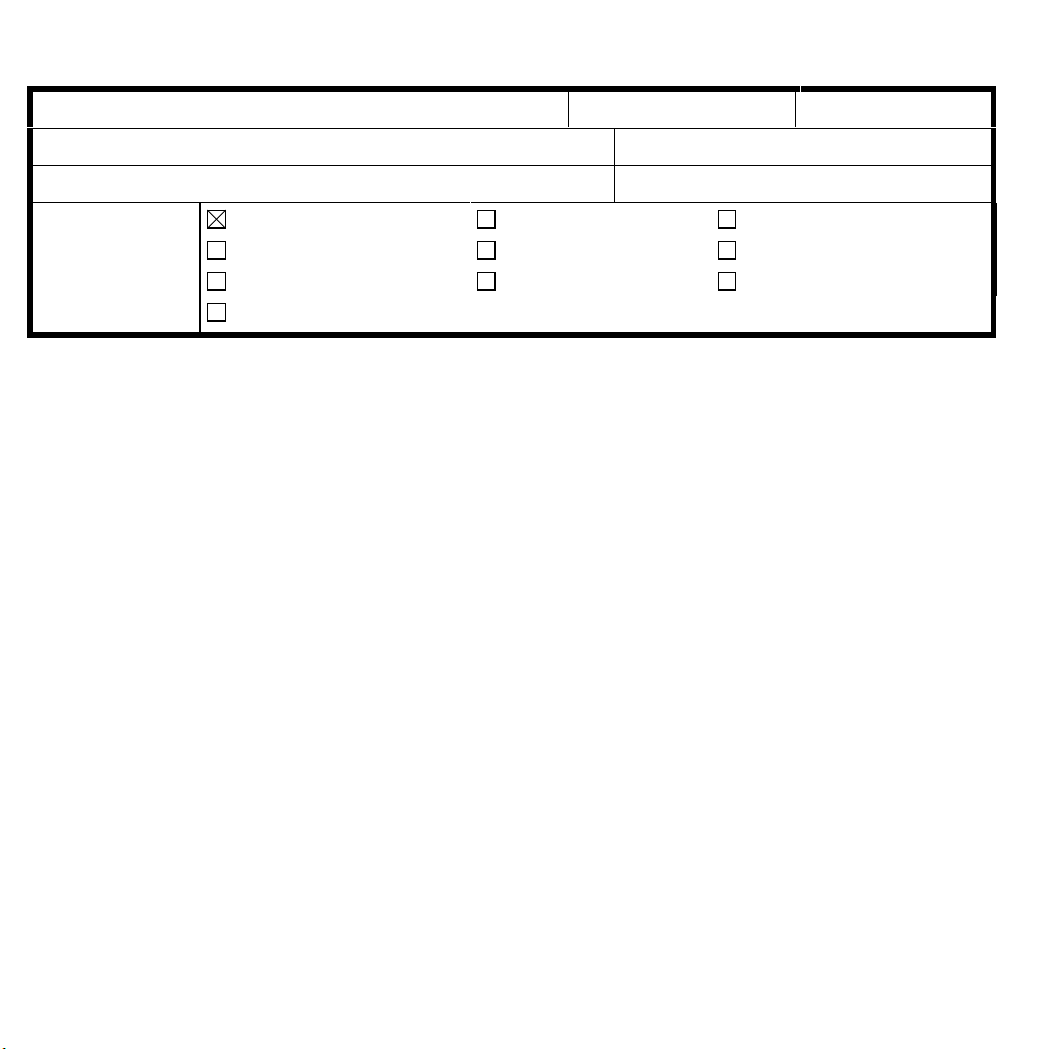

Classification:

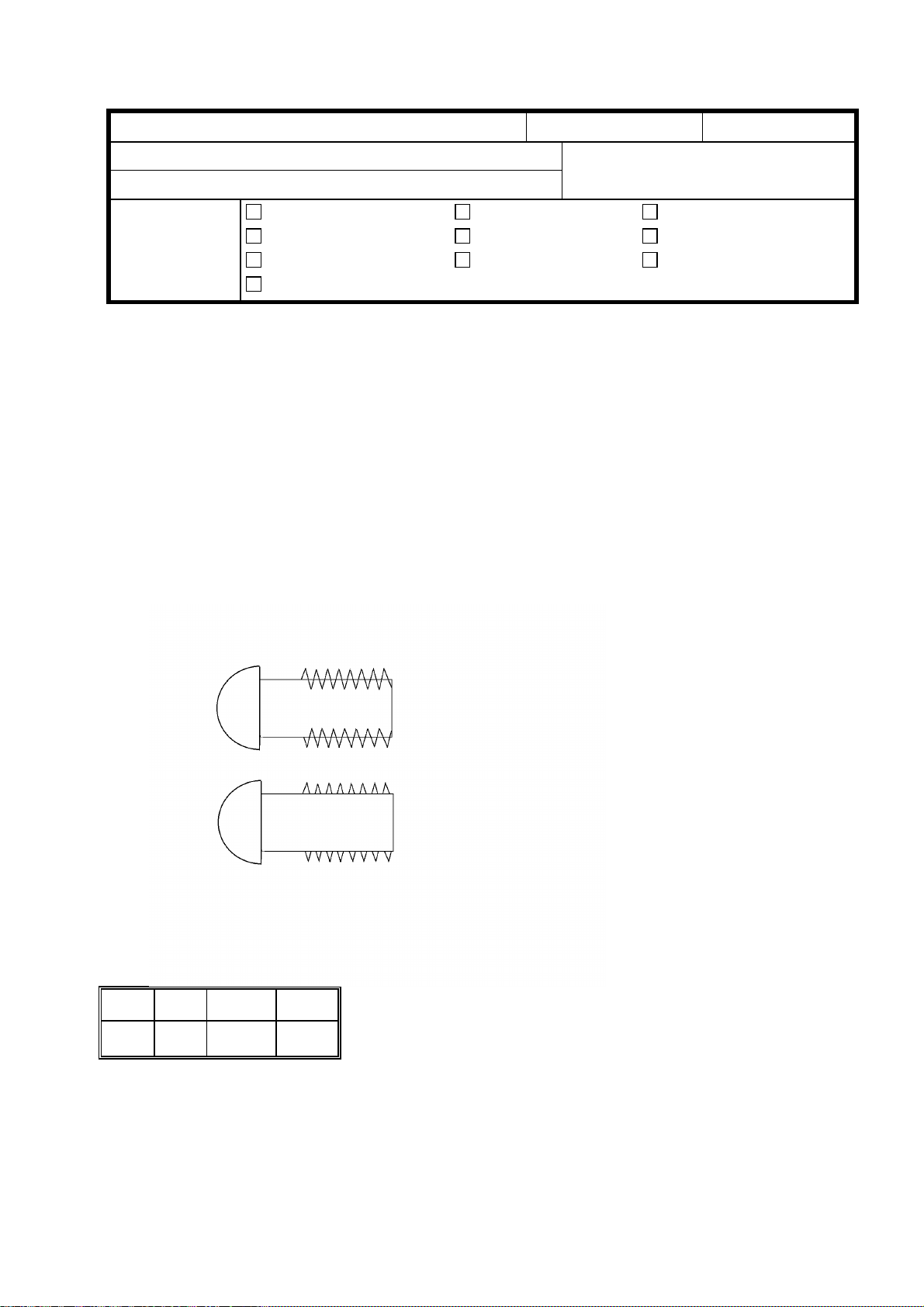

There is no tapping hole on the brackets which are service parts, because tapping screws

are used for the bracket.

The tapping screw is similar to a normal Phillips head screw. The pitch of the tapping

screw is the same as that of a normal screw; see below.

Troubleshooting

Mechanical

Paper path

Other ( )

Part information

Electrical

Transmit/receive

Action required

Service manual revision

Retrofit information

No: 012

Action required

1. Distinguish between the tapping screw and the normal screw by referring to the

following drawing.

2. Use the same tapping screw in the same place to attach the bracket.

RC RE ASIA

Normal Screw

Tapping Screw

Loading...

Loading...