Ricoh Aficio SP 1200SF, Aficio SP 1210N Service Manual

Model BL-P1

Machine Codes: M087/M088

Field Service Manual

3 Dec, 2010

Regulation

<For Europe and Other countries>

• Radio interference (220 to 240 volt model only)

This machine follows EN55022 (CISPR Publication 22)/Class B.

•

IEC 60825-1 specification (220 to 240 volt model only)

This machine is a Class 1 laser product as defined in IEC 60825-1 specifications. The label shown

below is attached in countries where it is needed.

This machine has a Class 3B laser diode which produces invisible laser radiation in the laser unit. You

should not open the laser unit under any circumstances.

Caution

controls or adjustments or performance of procedures other than those specified in this manual

Use of

may result in hazardous radiation exposure.

For Finland and Sweden

LUOKAN 1 LASERLAITE

KLASS 1 LASER APPARAT

Varoitus!

Laitteen käyttäminen muulla kuin tässä käyttöohjeessa mainitulla tavalla saattaa altistaa käyttäjän

turvallisuusluokan 1 ylittävälle näkymättömälle lasersäteilylle.

Varning

Om apparaten används på annat sätt än i denna Bruksanvisning specificerats, kan användaren

utsättas för osynlig laserstrålning, som överskrider gränsen för laserklass 1.

• Internal laser radiation

Maximum radiation power: 10 mW

Wave length: 780 - 800 nm

Laser class: Class 3B

• EU Directive 2002/96/EC and EN50419

(European Union only)

This equipment is marked with the recycling symbol below. It means that at the end of the life of the

equipment you must dispose of it separately at an appropriate collection point and not place it in the

1

normal domestic unsorted waste stream. This will benefit the environment for all. (European Union

only)

<For USA and Canada>

• Federal Communications Commission (FCC) Declaration of Conformity

(For USA)

Responsible Party:

Ricoh Americas Corporation

5 Dedrick Place, West Caldwell, NJ 07006 USA

Telephone: 973-882-2000

declares, that the products

Product name: Laser Printer

Model number: SP 1210N

complies

device may not cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant

to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guarantee that interference will not occur

in a particular installation. If this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on, the end user is encouraged

to try to correct the interference by one or more of the following measures:

2

with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

• Consult the dealer or an experienced radio/TV technician for help.

• A shielded interface cable should be used to ensure compliance with the limits for a Class B

digital device. Changes or modifications not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

• Industry Canada Compliance Statement (For Canada)

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada.

Laser Safety (110 to 120 volt model only)

•

This machine is certified as a Class 1 laser product under the U.S. Department of Health and Human

Services (DHHS) Radiation Performance Standard according to the Radiation Control for Health and

Safety Act of 1968. This means that the machine does not produce hazardous laser radiation.

Since radiation emitted inside the machine is completely confined within protective housings and

external covers, the laser beam cannot escape from the machine during any phase of user operation.

• FDA Regulations (110 to 120 volt model only)

The U.S. Food and Drug Administration (FDA) has implemented regulations for laser products

manufactured on and after August 2, 1976. Compliance is mandatory for products marketed in the

United States. The following label on the back of the machine indicates compliance with the FDA

regulations and must be attached to laser products marketed in the United States.

MANUFACTURED:

RICOH COMPANY LTD, 3-6, Naka-magome 1-Chome Ohta-ku, Tokyo 143-8555, Japan

Complies with FDA performance standards for laser products except for deviations pursuant to

Laser Notice No. 50, dated June 24, 2007.

• Internal laser radiation

Maximum radiation power: 10 mW

Wave length: 780 - 800 nm

Laser class: Class 3B

3

Safety Information

• Caution for Laser Product (WARNHINWEIS fur Laser drucker)

CAUTION:

When

the machine during servicing is operated with the cover open, the regulations of VBG 93 and

the performance instructions for VBG 93 are valid.

CAUTION:

In case of any trouble with the laser unit, replace the laser unit itself. To prevent direct exposure to the

laser beam, do not try to open the enclosure of the laser unit.

ACHTUNG:

Im Falle von Störungen der Lasereinheit muß diese ersetzt werden. Das Gehäuse der Lasereinheit darf

nicht geöffnet werden, da sonst Laserstrahlen austreten können.

• Additional Information

When servicing the optical system of the machine, be careful not to place a screwdriver or other

reflective object in the path of the laser beam. Be sure to take off any personal accessories such as

watches and rings before working on the machine. A reflected beam, though invisible, can

permanently damage the eyes.

Since the beam is invisible, the following caution label is attached on the laser unit.

• Definitions of Warnings, Cautions, and Notes

The following conventions are used in this manual:

Warnings tell you what to do to prevent possible personal injury.

Cautions specify procedures you must follow or avoid to prevent possible damage to the machine or

other objects.

4

Notes tell you useful tips when servicing the machine and bits of knowledge to help understand the

machine

Mark Contents

Electrical Hazard icons alert you to a possible electrical shock.

Hot Surface icons warn you not to touch machine parts that are hot.

• Safety Precautions

Listed below are the various kinds of “WARNING” messages included in this manual.

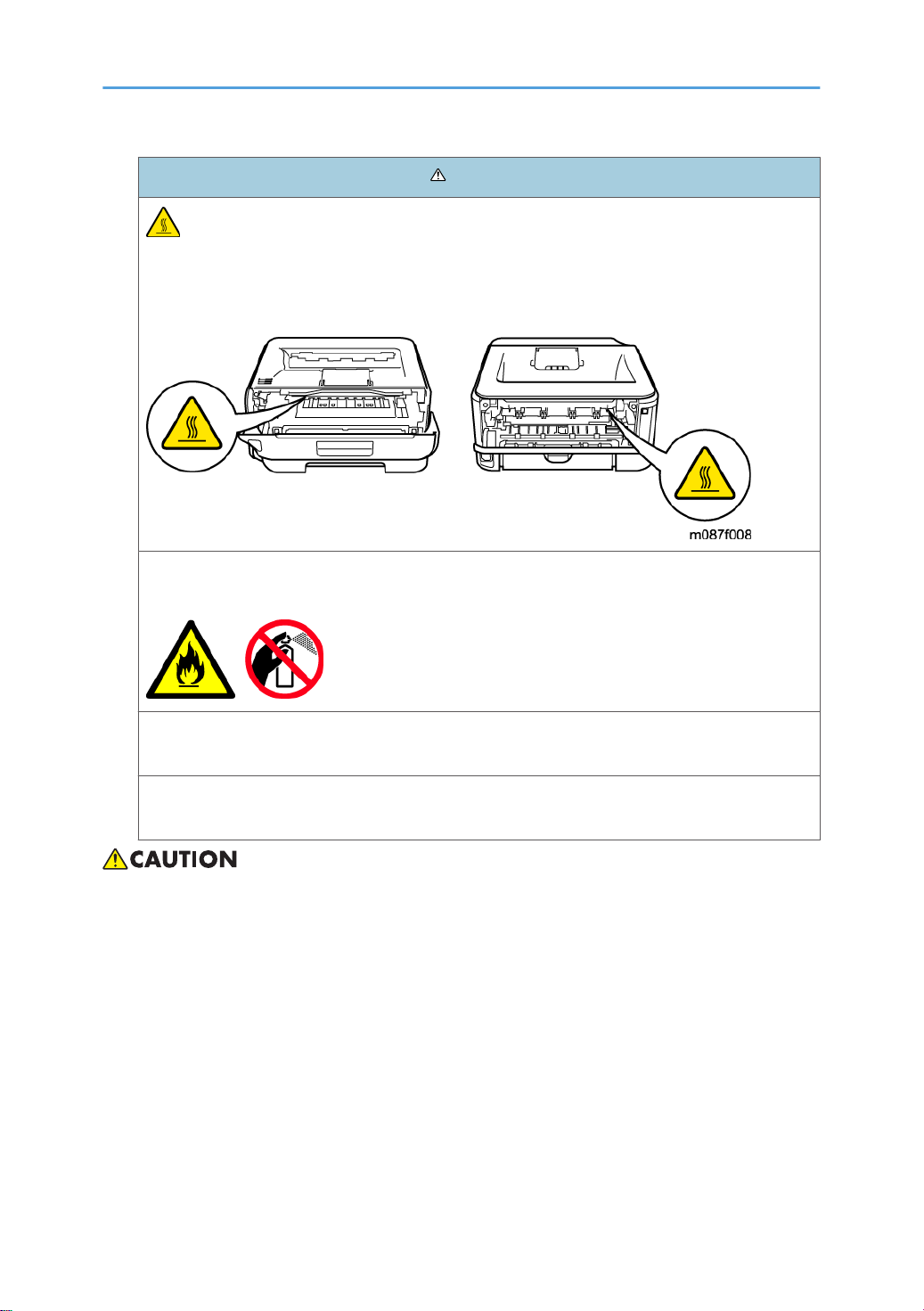

WARNING

There are high voltage electrodes inside the machine. Before you clean the inside of the machine

or replace

from the AC power outlet.

parts, make sure that you have turned off the power switch and unplugged the machine

DO NOT handle the plug with wet hands. Doing this might cause an electrical shock.

5

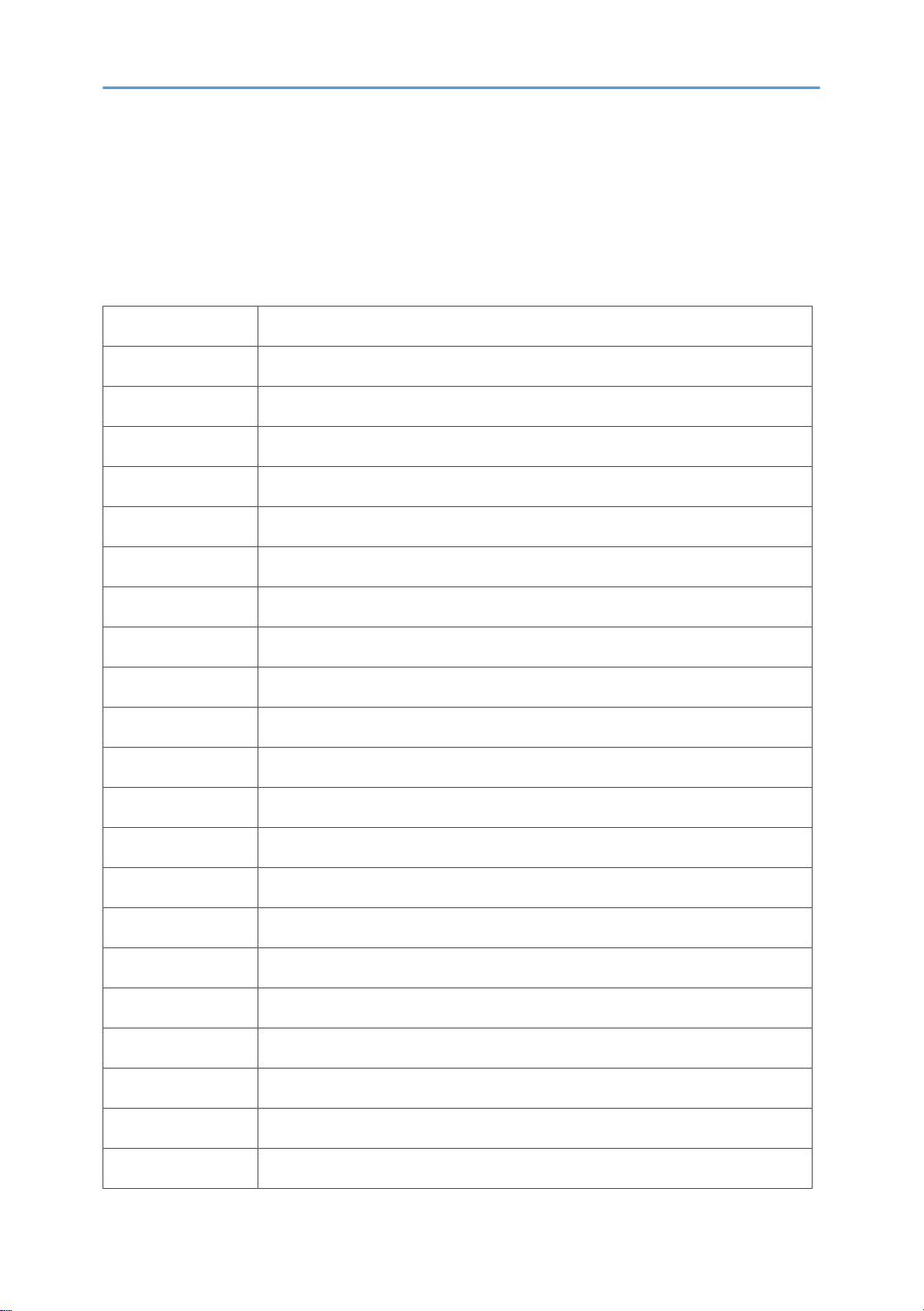

WARNING

The fuser unit becomes extremely hot during operation. Wait until it has cooled down sufficiently

before replacing

around the fuser.

DO NOT use flammable substances such as alcohol, benzine, thinner or any type of spray to clean

the inside or outside of the machine. Doing this may cause a fire or electrical shock.

consumable items. DO NOT remove or damage the caution label located on or

If the machine becomes hot, blows smoke, or generates obscure odor, immediately turn off the

power switch and unplug the machine from the AC power outlet.

If metal objects, water or other liquids get inside the machine, immediately turn off the power switch

and unplug the machine from the AC power outlet.

• Lightning and power surges can damage this product! We recommend that you use a quality surge

protection device on the AC power line, or unplug the machine during a lightning storm.

6

Acronyms and Technical Terms

In this

manual, the manual specific acronyms and technical terms are used in addition to the generally used

ones. The table below contains typical acronyms and technical terms that are used throughout these

manuals.

ASIC

CN Connector

CO Collimate

CPU Central Processing Unit

dB decibel

DEV Development

dpi dots per inch

EEPROM Electronically Erasable and Programmable Read Only Memory

HEX Hexadecimal

HVPS High Voltage Power Supply

IF Interface

IPv4 Internet Protocol Version 4

IPv6 Internet Protocol Version 6

Application Specific Integrated Circuit

LD Laser Diode

LED Light Emitting Diode

LVPS Low Voltage Power Supply

N/A Not Applicable

NC* Network Circuit

NVRAM Nonvolatile Random Access Memory

ppm pages per minute

RAM Random Access Memory

SW Switch

7

Excluding the acronym shown on the wiring diagram or circuit diagram.

*

8

TABLE OF CONTENTS

Regulation...........................................................................................................................................................1

Safety Information...............................................................................................................................................4

Acronyms and Technical Terms

.........................................................................................................................7

1. Product Information

Specifications....................................................................................................................................................13

Overview..........................................................................................................................................................14

Part names....................................................................................................................................................14

Cross-section Drawing................................................................................................................................16

2. Installation

Installation Requirements.................................................................................................................................17

Operating Environment...............................................................................................................................17

Power Supply...............................................................................................................................................17

3. Preventive Maintenance

Periodical Replacement Parts..........................................................................................................................19

4. Replacement and Adjustment

Safety Precautions............................................................................................................................................21

Screw Torque List..............................................................................................................................................23

Harness Routing

Fuser Unit......................................................................................................................................................26

...............................................................................................................................................26

FG Harness...................................................................................................................................................27

Main Frame R ASSY....................................................................................................................................28

Toner LED PCB ASSY / PS PCB Unit / Main PCB ASSY/Registration Front Sensor PCB ASSY /

Registration Rear Sensor PCB ASSY...........................................................................................................29

Panel PCB ASSY / Toner Sensor PCB Unit ASSY / New Toner Sensor Harness ASSY.......................30

High-Voltage PS PCB / Registration Solenoid / T1 Solenoid.................................................................31

Disassembly Flow.............................................................................................................................................33

Disassemble Procedure....................................................................................................................................34

Paper Tray Unit / Separation Pad Assy.....................................................................................................34

Front Cover Assy..........................................................................................................................................35

SW Key.........................................................................................................................................................37

Back Cover...................................................................................................................................................39

Outer Chute Assy.........................................................................................................................................40

Fuser Cover Assy..........................................................................................................................................41

9

Eject Actuator / Eject Actuator Spring.......................................................................................................42

Eject Roller Assy 1 / Bush C / Bush R / Bush L........................................................................................43

Inner Chute Assy..........................................................................................................................................44

Fuser Unit......................................................................................................................................................45

Side Cover R Assy........................................................................................................................................47

Corner Cover...............................................................................................................................................48

Side Cover L Assy........................................................................................................................................49

Roller Holder Assy.......................................................................................................................................50

Main Shield Cover Plate.............................................................................................................................52

Main PCB Assy.............................................................................................................................................53

Top Cover Assy............................................................................................................................................54

Paper Stack Lever........................................................................................................................................55

Support Flap 1 / Support Flap 2...............................................................................................................56

Eject Roller Assy 2 / Bush R / Bush L.........................................................................................................57

SW Supporter..............................................................................................................................................58

Panel PCB Assy............................................................................................................................................59

High-Voltage PS PCB Assy..........................................................................................................................60

New Toner Sensor Harness Assy...............................................................................................................61

Filter Assy......................................................................................................................................................62

Laser Unit......................................................................................................................................................63

Fan Motor 60 Unit.......................................................................................................................................65

Cover Sensor Harness Assy........................................................................................................................66

Toner LED PCB Assy.....................................................................................................................................67

PS PCB Unit..................................................................................................................................................69

LV Shield Plate 2..........................................................................................................................................71

Registration Front Sensor PCB Assy............................................................................................................72

Registration Rear Sensor PCB Assy............................................................................................................77

Drive Sub Assy.............................................................................................................................................81

Dev Joint / Dev Gear Joint 53R / Registration Pendulum Gear Spring.................................................83

Toner Sensor PCB Unit Assy........................................................................................................................84

Registration Solenoid...................................................................................................................................85

T1 Solenoid..................................................................................................................................................88

Main Shield Plate / Eject Sensor PCB Assy...............................................................................................89

10

Rubber Foot..................................................................................................................................................93

Main Frame L Assy.......................................................................................................................................93

Adjustments and Updating of Settings, Required After Parts Replacement..............................................100

If You Replace the Main PCB...................................................................................................................100

If You Replace The Laser Unit...................................................................................................................109

How to Select the Port Number................................................................................................................113

5. Service Maintenance

Control Panel..................................................................................................................................................117

List of Service Support Functions..............................................................................................................117

User Mode.................................................................................................................................................118

Service Mode............................................................................................................................................121

Other Service Functions................................................................................................................................134

Resetting the drum counter........................................................................................................................134

Initializing the developing bias................................................................................................................135

6. Troubleshooting

Introduction....................................................................................................................................................137

Precautions.................................................................................................................................................137

Initial Check...............................................................................................................................................138

Distinguish Error Cause.................................................................................................................................139

LED Indication............................................................................................................................................139

Message indication...................................................................................................................................142

Error Cause and Remedy..........................................................................................................................144

Paper Feeding Problems...............................................................................................................................156

No Feeding................................................................................................................................................156

Double Feeding.........................................................................................................................................157

Paper Jam...................................................................................................................................................157

Dirt on Paper..............................................................................................................................................158

Wrinkles or Creases..................................................................................................................................159

Waves in the Paper / Folds in the Paper at the Eject Roller 2...............................................................159

Curl in the Paper........................................................................................................................................159

Image Defect Troubleshooting......................................................................................................................161

Image Defect Examples............................................................................................................................161

Diameter of Rollers....................................................................................................................................162

11

Troubleshooting Image Defect.................................................................................................................162

Software Setting Problems............................................................................................................................179

Network Problems.........................................................................................................................................180

Others Problems.............................................................................................................................................181

The Machine Is Not Turned On, or the LED Indication Does Not Appear...........................................181

The fan does not work...............................................................................................................................181

Pickup Function of Paper Tray Does Not Work......................................................................................182

A New Toner Cannot Be Detected..........................................................................................................182

7. Energy Saving

Energy Save...................................................................................................................................................183

Sleep Modes.............................................................................................................................................183

Paper Save.....................................................................................................................................................185

Effectiveness of Combine Function...........................................................................................................185

INDEX...........................................................................................................................................................187

12

1. Product Information

1

Specifications

See “Appendices” for the following information:

• Specifications List

13

1. Product Information

1

Overview

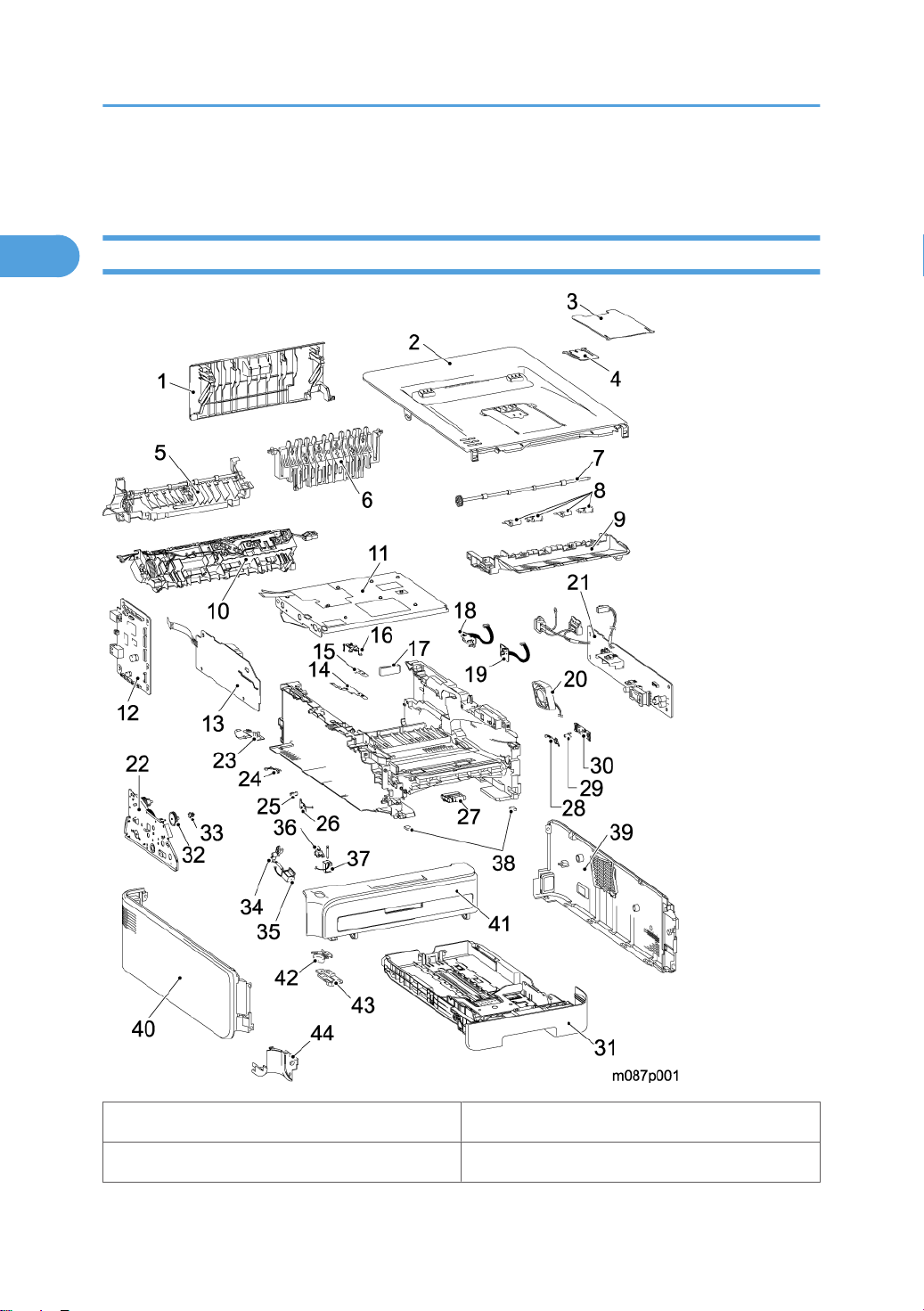

Part names

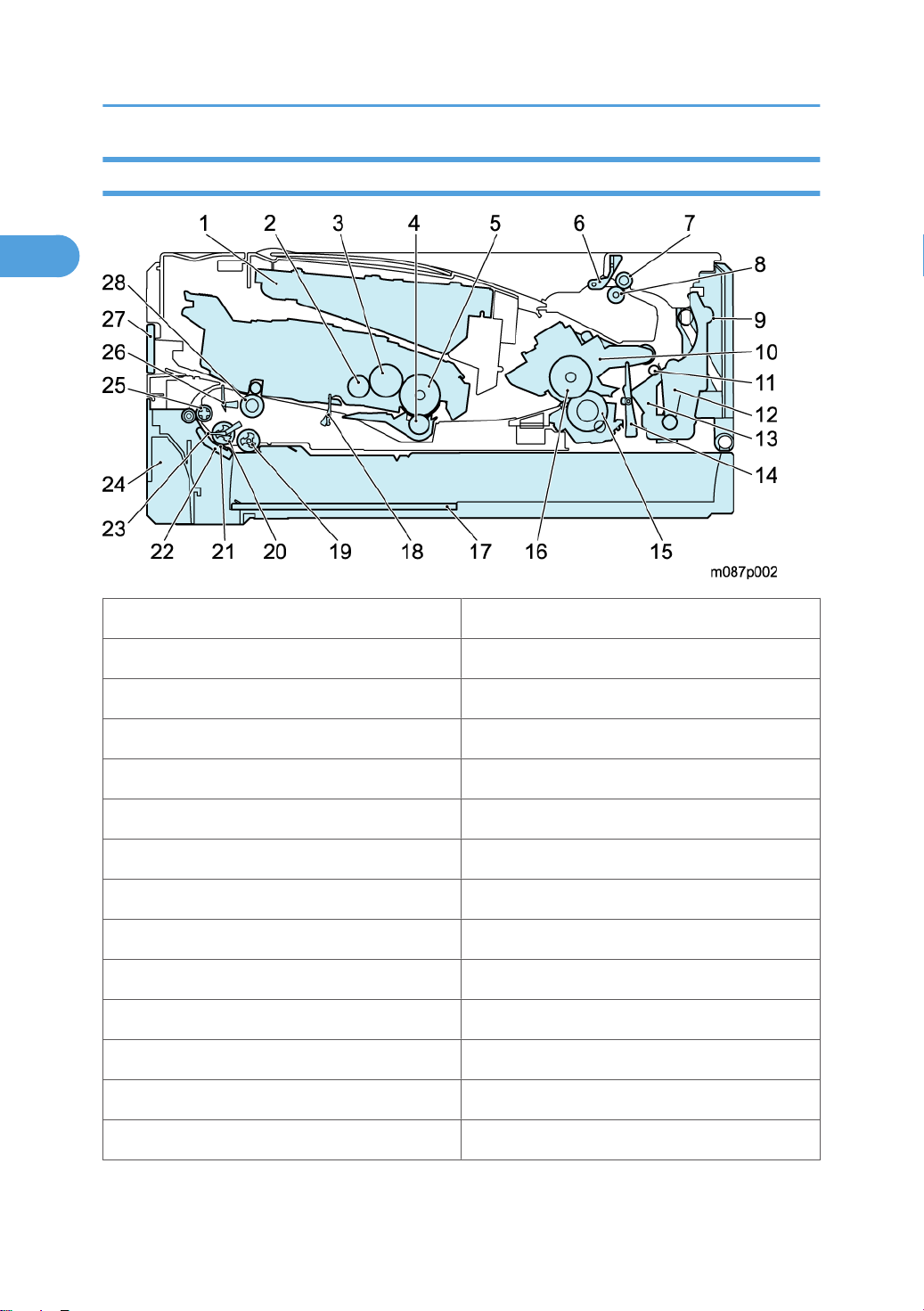

1. Back cover 23. Eject sensor PCB ASSY

2. Top cover ASSY 24. New toner sensor harness ASSY

14

3. Support flap 1 25. PT sensor holder

1

4. Support flap 2 26. Toner sensor PCB unit ASSY

5. Fuser cover ASSY 27. Roller holder ASSY

6. Outer chute ASSY 28. Cover sensor harness ASSY

7. Eject roller ASSY 2 29. LED holder

8. Inner chute ASSY 30. Toner LED PCB ASSY

9. Pinch roller ASSY 31. Paper tray unit

10. Fuser unit 32. DEV gear joint/53R

11. Laser unit 33. DEV joint

12. Main PCB ASSY 34. Registration solenoid lever

13. High-voltage PS PCB ASSY 35. Registration solenoid

Overview

14. Panel PCB ASSY 36. T1 solenoid lever

15. Panel film 37. T1 solenoid

16. Key supporter 38. Rubber foot

17. Filter ASSY 39. Side cover R ASSY

18. Registration rear sensor PCB ASSY 40. Side cover L ASSY

19. Registration front sensor PCB ASSY 41. Front cover ASSY

20. Fan motor 60 unit 42. SW key

21. PS PCB unit ASSY 43. Key stopper

22. Drive sub ASSY 44. Corner cover

15

1. Product Information

1

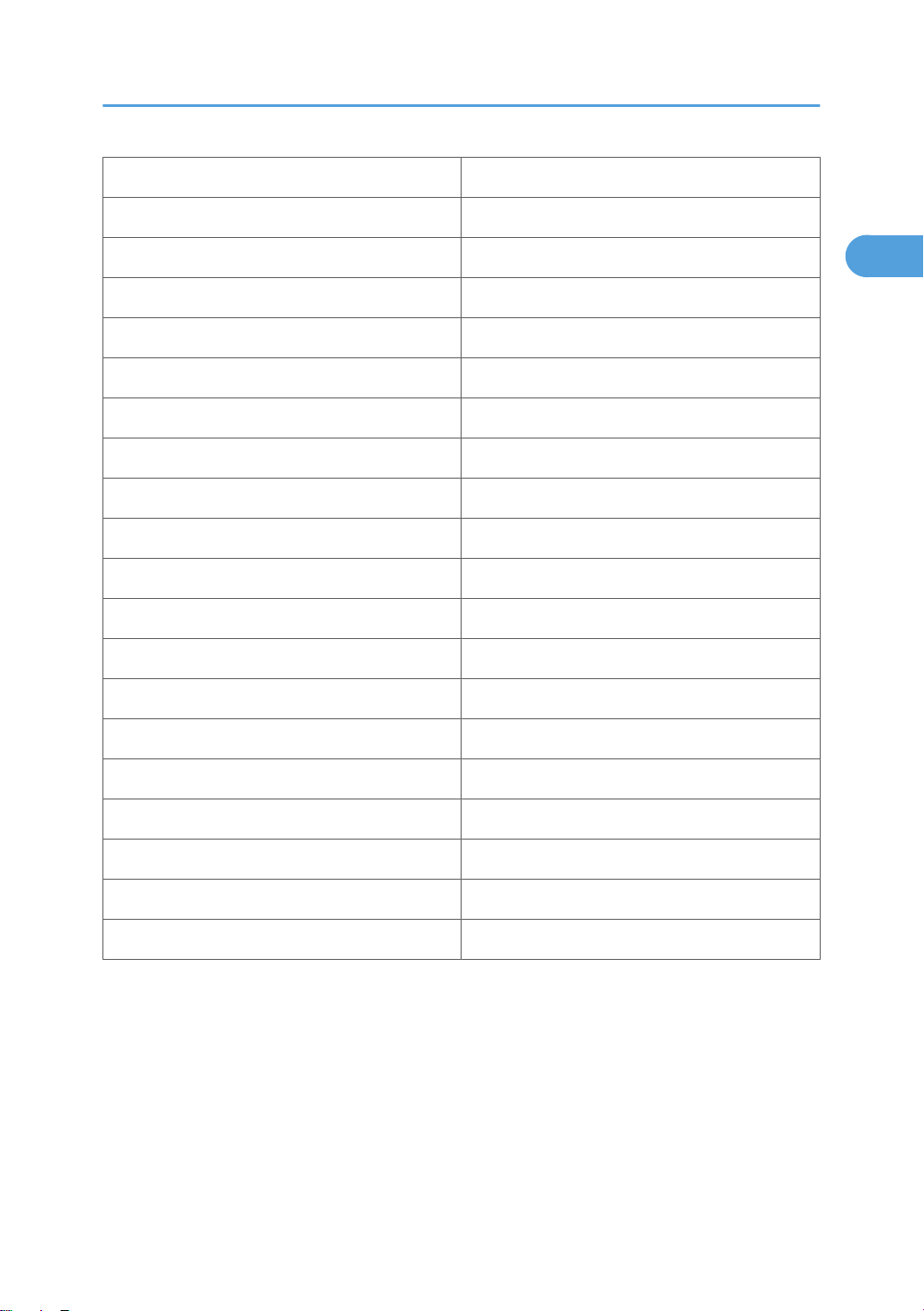

Cross-section Drawing

1. Laser unit 15. Pressure roller

2. Supply roller 16. Heat roller

3. Develop roller 17. Plate

4. Transfer roller 18. Registration rear actuator

5. Exposure drum 19. Paper feed roller

6. Paper stack lever 20. Separation roller

7. Eject roller 2 21. Separation pad

8. Pinch roller 22. Separation pad ASSY

9. Back cover 23. Edge actuator

10. Fuser unit 24. Paper tray

11. Eject roller 1 25. Front feed roller

12. Outer chute 26. Registration front actuator

13. Fuser cover 27. Manual feed slot cover

14. Eject actuator 28. Registration roller

16

2. Installation

2

Installation Requirements

Operating Environment

1. Put your machine on a flat, stable surface such as a desk that is free of vibration and shocks.

2. Use the

3. The machine is not exposed to direct sunlight, excessive heat, moisture, or dust.

4. Condensation

machine in a well-ventilated room; use the machine within the following ranges of temperature

and humidity: temperature between 10 °C and 32.5 °C (50 °F to 90.5 °F), and the relative humidity

is maintained between 20% and 80%.

When the machine is moved from a cold place into a warm room, condensation may occur inside

the machine, causing various problems as listed below.

• Condensation on the optical surfaces such as the scanner window, lenses, the reflection mirror

and the protection glass may cause the print image to be light.

• If the exposure drum is cold, the electrical resistance of the photosensitive layer is increased,

making it impossible to obtain the correct contrast when printing.

• Condensation on the charge unit may cause corona charge leakage.

• Condensation on the plate and separation pad may cause paper feed failures.

If condensation has occurred, leave the machine for at least 2 hours to allow it to reach room

temperature.

If the drum unit is unpacked soon after it is moved from a cold place to a warm room, condensation

may occur inside the unit which may cause incorrect images. Instruct the end user to allow the unit to

come to room temperature before unpacking it. This will take one or two hours.

Power Supply

1. The AC input power supply described on the rating plate of the machine should be within ±10% of

the rated voltage.

2. The AC input power supply is within the regulated value.

3.

The cables and harnesses are connected correctly.

4. The fuses are not blown.

17

3. Preventive Maintenance

3

Periodical Replacement Parts

There are no parts to be replaced periodically.

19

4. Replacement and Adjustment

4

Safety Precautions

To avoid

maintenance work.

creating secondary problems by mishandling, follow the warnings and precautions below during

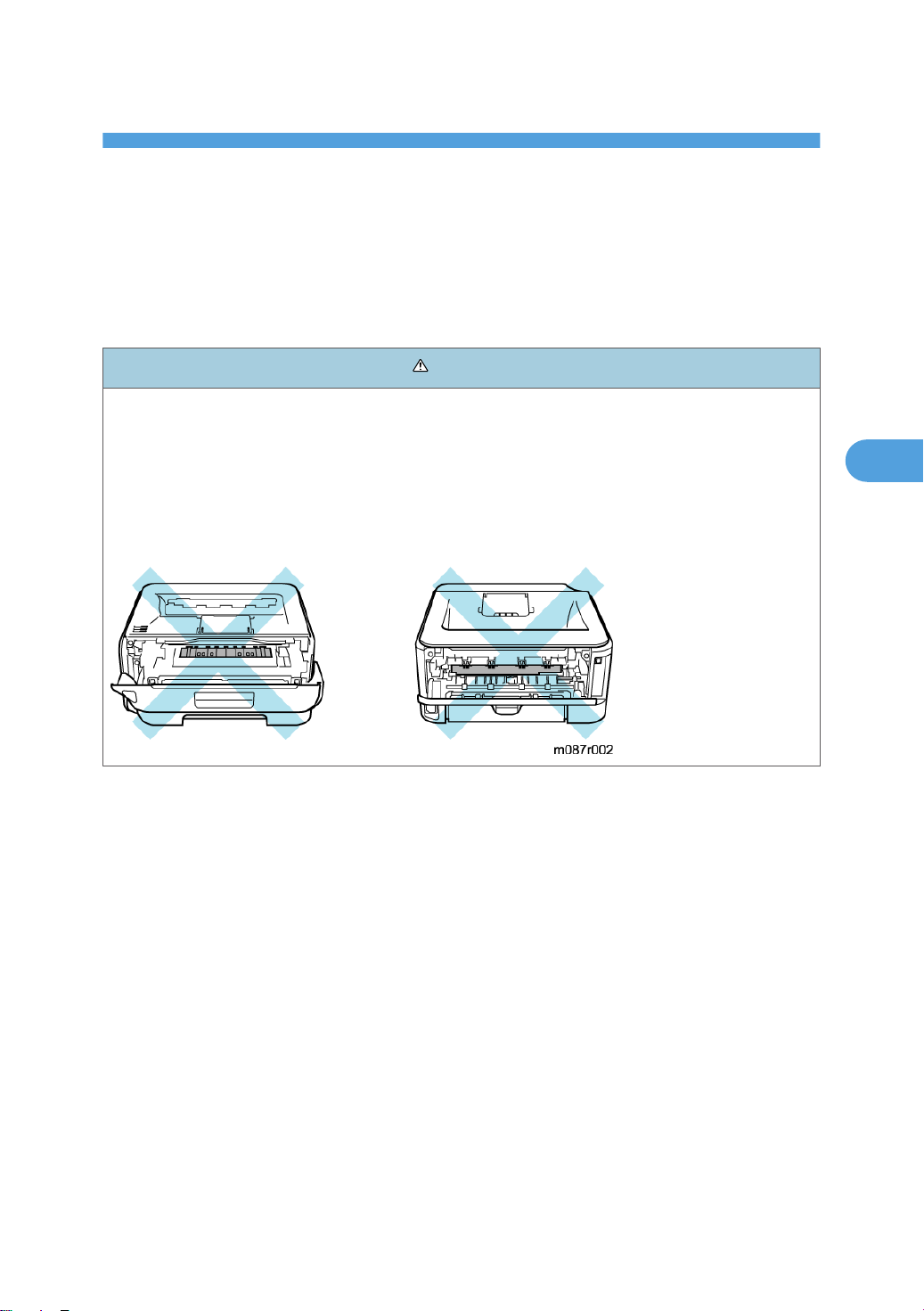

WARNING

• Always turn off the power switch and unplug the power cord from the power outlet before accessing

any parts inside the machine.

•

When opening the front cover or back cover to access any parts inside the machine, never touch

the shaded parts shown in the following figures.

• DO NOT use flammable substances such as alcohol, benzine, thinner or any type of spray to clean

the inside or outside of the machine. Doing this may cause a fire or electrical shock.

• Be careful not to lose screws, washers, or other parts removed.

• Be sure to apply grease to the gears and applicable positions specified in this chapter.

•

When using soldering irons or other heat-generating tools, take care not to accidentally damage

parts such as wires, PCBs and covers.

• Static electricity charged in your body may damage electronic parts. When transporting PCBs, be

sure to wrap them in conductive sheets.

• When replacing the PCB and all the other related parts, put on a grounding wrist band and perform

the job on a static mat. Also take care not to touch the conductor sections on the flat cables or on the

wire harness.

• When connecting or disconnecting cable connectors, hold the connector body, not the cables. If the

connector has a lock, release the connector lock first to release it.

• After a repair, check not only the repaired portion but also all connectors. Also check that other related

portions are functioning properly before operational checks.

• After disconnecting flat cables, check that each cable is not damaged at its end or short-circuited.

21

4. Replacement and Adjustment

4

• When connecting flat cables, do not insert them at an angle. After insertion, check that the cables are

not at an angle.

22

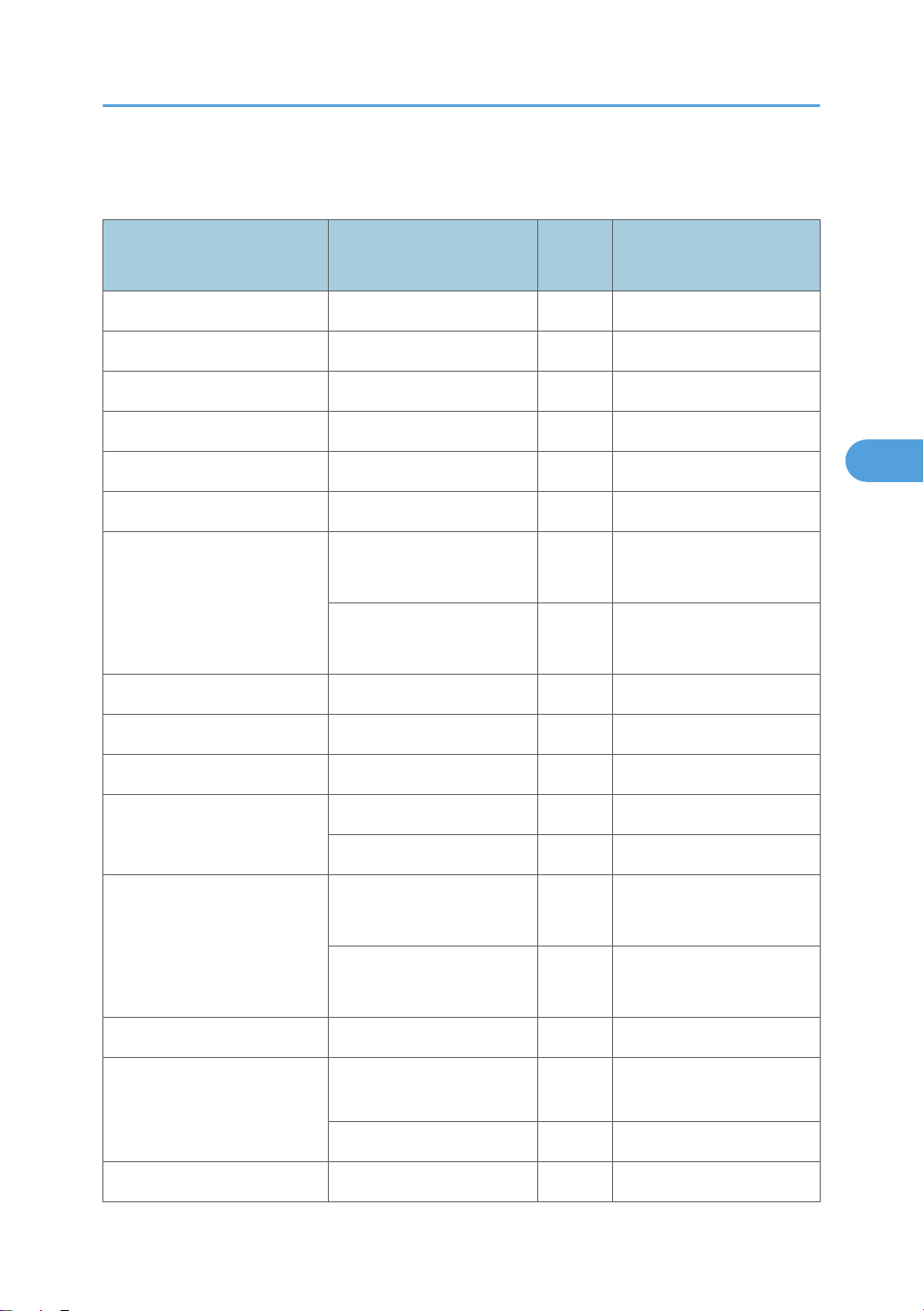

Screw Torque List

4

Screw Torque List

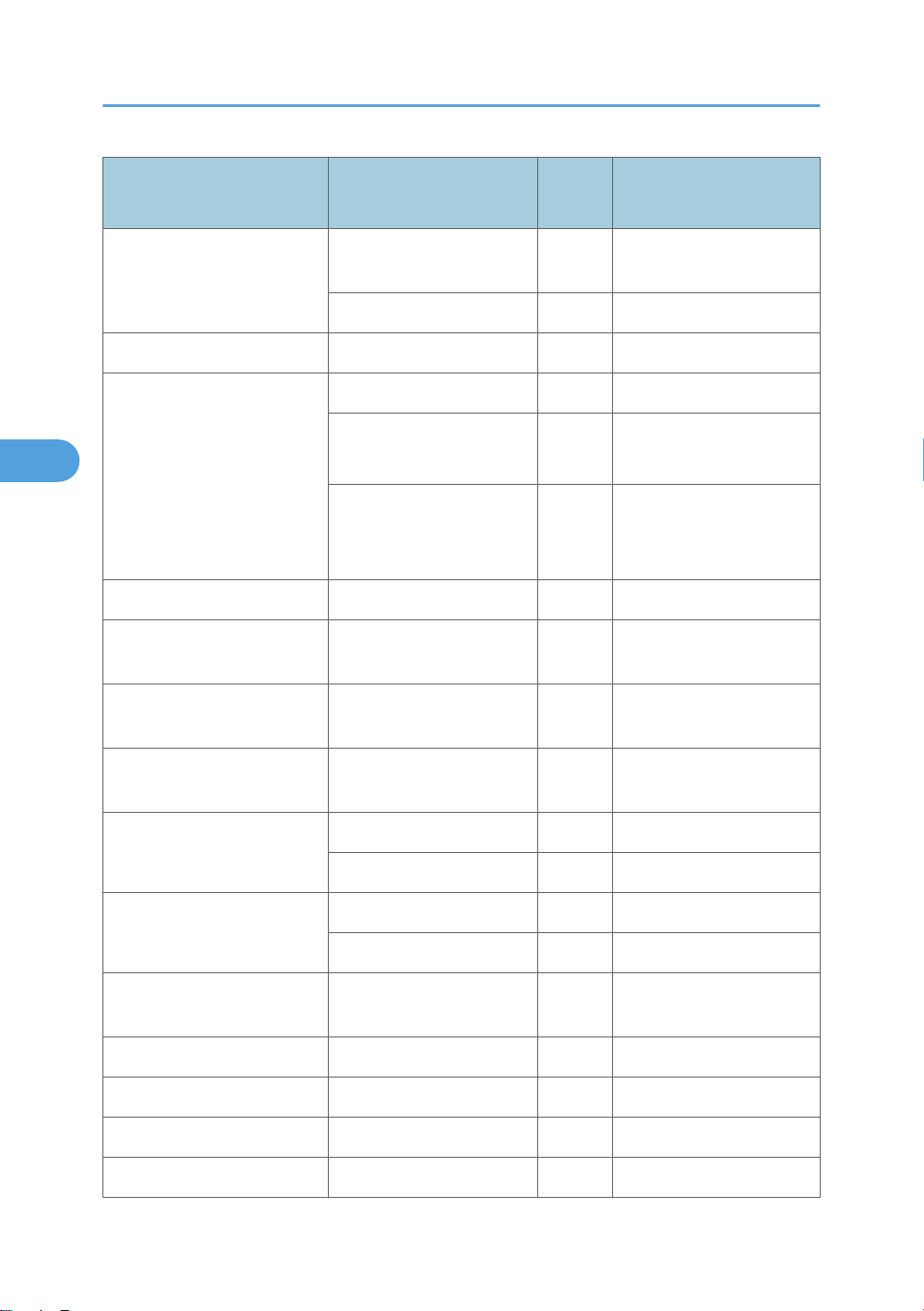

Location of screw Screw type Q’ty

KEY STOPPER Taptite cup B M3x8 2 0.4±0.05 (4±0.5)

INNER CHUTE ASSY Taptite bind B M4x12 2 0.6±0.1 (6±1)

FUSER UNIT Taptite pan B M4x14 2 0.8±0.1 (8±1)

SIDE COVER R ASSY Taptite bind B M4x12 2 0.8±0.1 (8±1)

CORNER COVER Taptite bind B M4x12 1 0.8±0.1 (8±1)

SIDE COVER L ASSY Taptite bind B M4x12 2 0.8±0.1 (8±1)

MAIN SHIELD COVER PLATE Taptite cup S M3x6 SR

2

Taptite cup S M3x6 SR

1

MAIN PCB ASSY Taptite cup S M3x6 SR 4(5)* 0.6±0.1 (6±1)

TOP COVER ASSY Taptite bind B M4x12 2 0.8±0.1 (8±1)

Tightening torque

Nm (kgf·cm)

0.55±0.05 (5.5±0.5)

Left side

0.9±0.05 (9±0.5)

Right side

PANEL PCB ASSY Taptite cup B M3x8 1 0.5±0.1 (5±1)

HIGH-VOLTAGE PS PCB

ASSY

LASER UNIT Taptite cup S M3x6 SR

AIR DUCT Taptite cup S M3x6 SR 2 0.8±0.05 (8±0.5)

LV SHIELD PLATE COVER Screw pan (S/P washer)

SW HOLDER Taptite bind B M4x12 1 0.8±0.1 (8±1)

Taptite cup S M3x6 SR 2 0.8±0.05 (8±0.5)

Taptite bind B M4x12 2 0.8±0.05 (8±0.5)

4(2)*

Taptite pan (S/P washer) S

M3x8

M3.5x6

Taptite cup S M3x6 SR 2 0.5±0.05 (5±0.5)

0(2)*

1 0.5±0.05 (5±0.5)

0.8±0.05 (8±0.5)

Left side of Main frame

0.8±0.05 (8±0.5)

Right side of Main frame

23

4. Replacement and Adjustment

4

Location of screw Screw type Q’ty

INLET HARNESS ASSY Screw pan (S/P washer)

M3.5x6

Taptite flat B M3x10 2 0.45±0.05 (4.5±0.5)

PS PCB UNIT Taptite cup S M3x6 SR 2 0.5±0.05 (5±0.5)

LV SHIELD PLATE 2 Taptite bind B M4x12 2 0.8±0.1 (8±1)

Taptite cup S M3x6 SR

Taptite cup S M3x6 SR

ACTUATOR HOLDER ASSY Taptite bind B M3x10 2 0.5±0.1 (5±1)

REGISTRATION FRONT

SENSOR PCB ASSY

Taptite bind B M3x10

1 0.5±0.05 (5±0.5)

1

1

1 0.5±0.1 (5±1)

Tightening torque

Nm (kgf·cm)

0.6±0.1 (6±1)

Back Side

0.5±0.05 (5±0.5)

Front chute ground plate

side

REAR ACTUATOR HOLDER

ASSY

REGISTRATION REAR

SENSOR PCB ASSY

UNDER FG WIRE Taptite bind B M4x12 1 0.8±0.1 (8±1)

DRIVE SUB ASSY Taptite cup S M3x6 SR 1 0.6±0.1 (6±1)

NEW TONER SENSOR

HARNESS ASSY

REGISTRATION SOLENOID Taptite bind B M3x10 1 0.5±0.1 (5±1)

T1 SOLENOID Taptite bind B M3x10 1 0.5±0.1 (5±1)

FU FRONT PLATE GUIDE Taptite bind B M3x10 3 0.5±0.1 (5±1)

CHUTE GROUND PLATE Taptite cup S M3x6 SR 2 0.6±0.1 (6±1)

Taptite bind B M3x10

Taptite bind B M3x10

Taptite cup S M3x6 SR 1 0.8±0.05 (8±0.5)

Taptite bind B M4x12 9 0.8±0.1 (8±1)

Taptite bind B M3x10

2 0.5±0.1 (5±1)

1 0.5±0.1 (5±1)

1 0.5±0.1 (5±1)

24

Screw Torque List

4

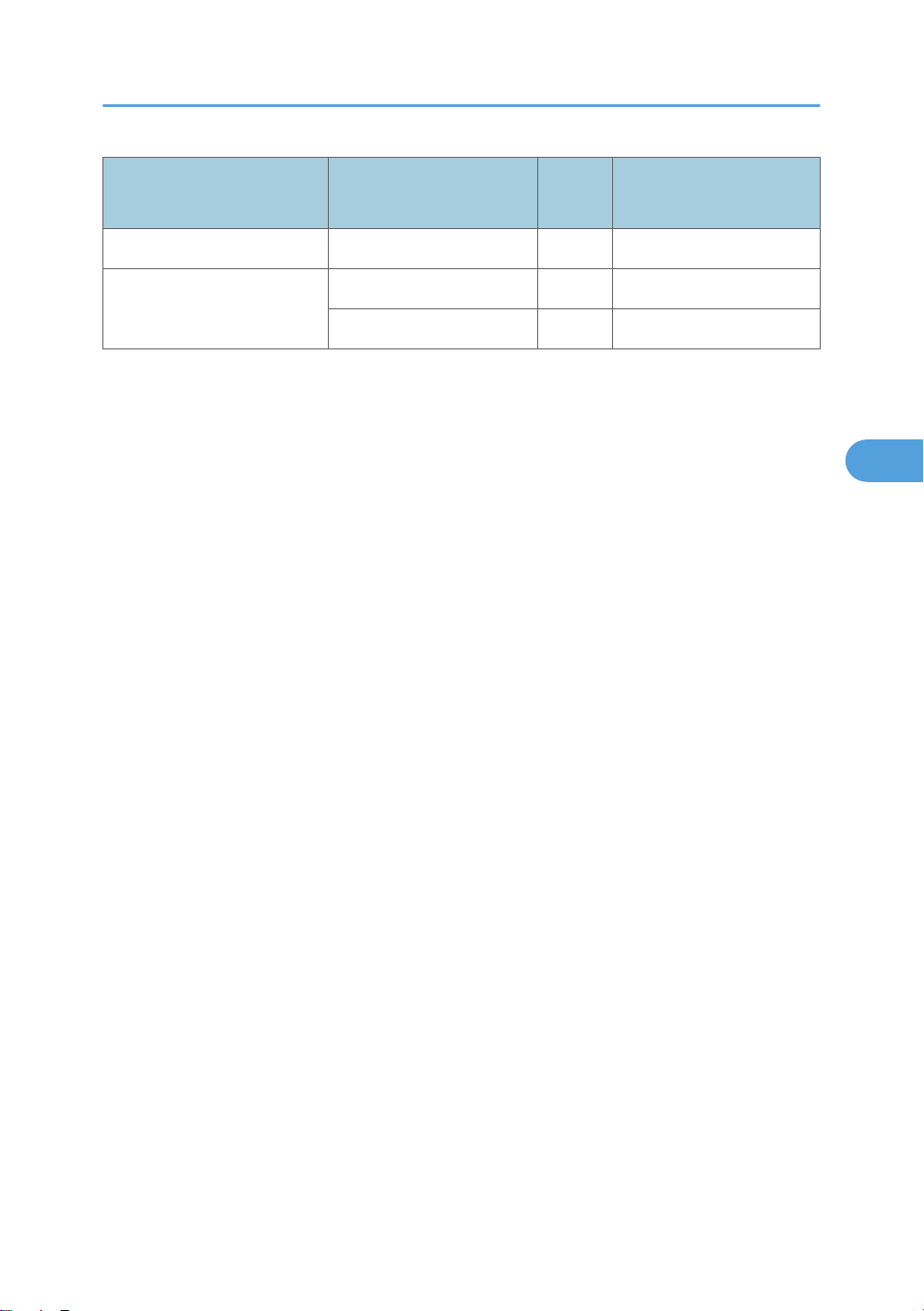

Location of screw Screw type Q’ty

MAIN SHIELD PLATE Taptite bind B M4x12 3 0.8±0.1 (8±1)

MAIN FRAME L ASSY Taptite bind B M4x12 4 0.8±0.1 (8±1)

Taptite cup S M3x6 SR 2 0.7±0.1 (7±1)

The parenthesis shows the number of screws for M087.

*

Tightening torque

Nm (kgf·cm)

25

4. Replacement and Adjustment

4

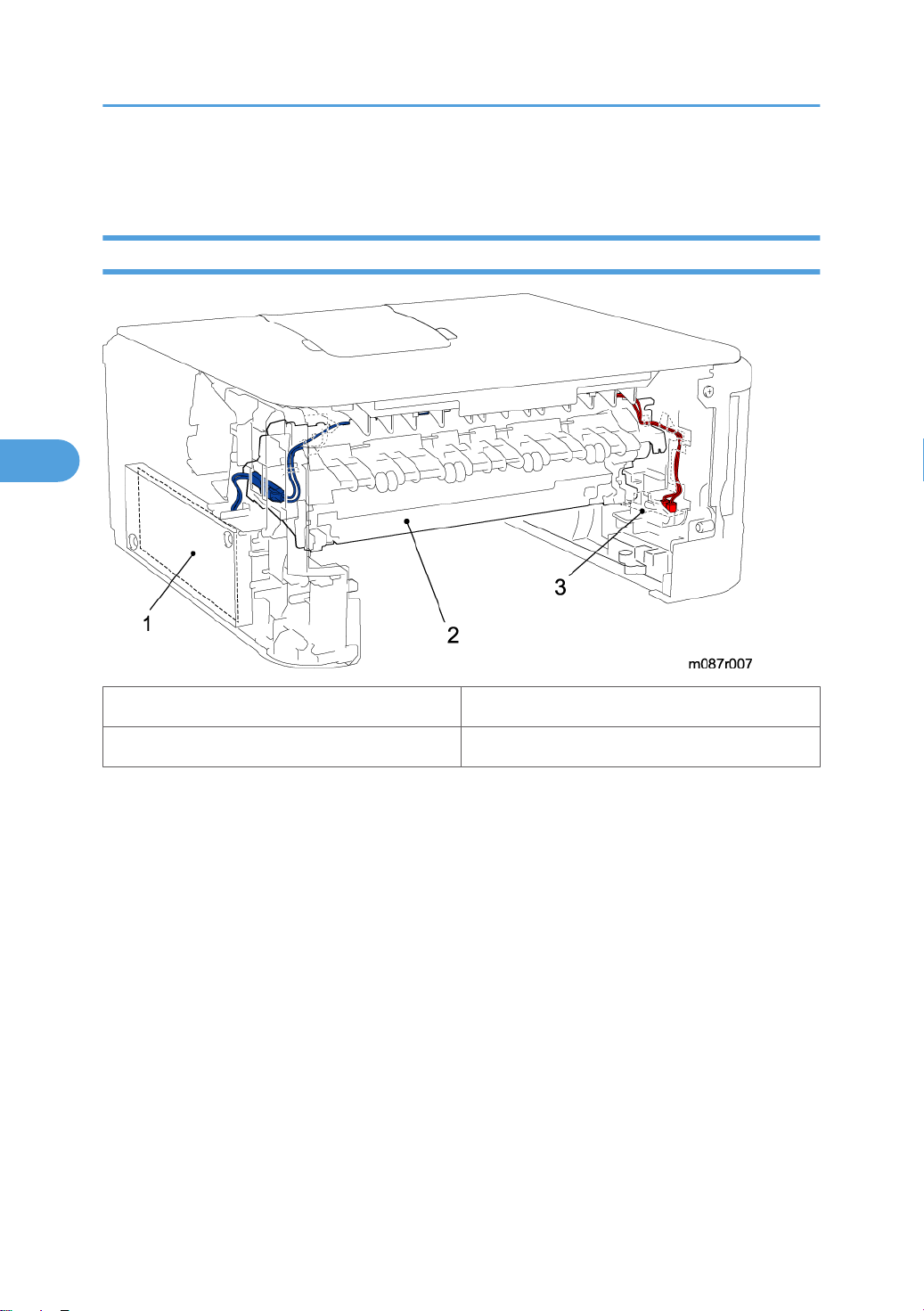

Harness Routing

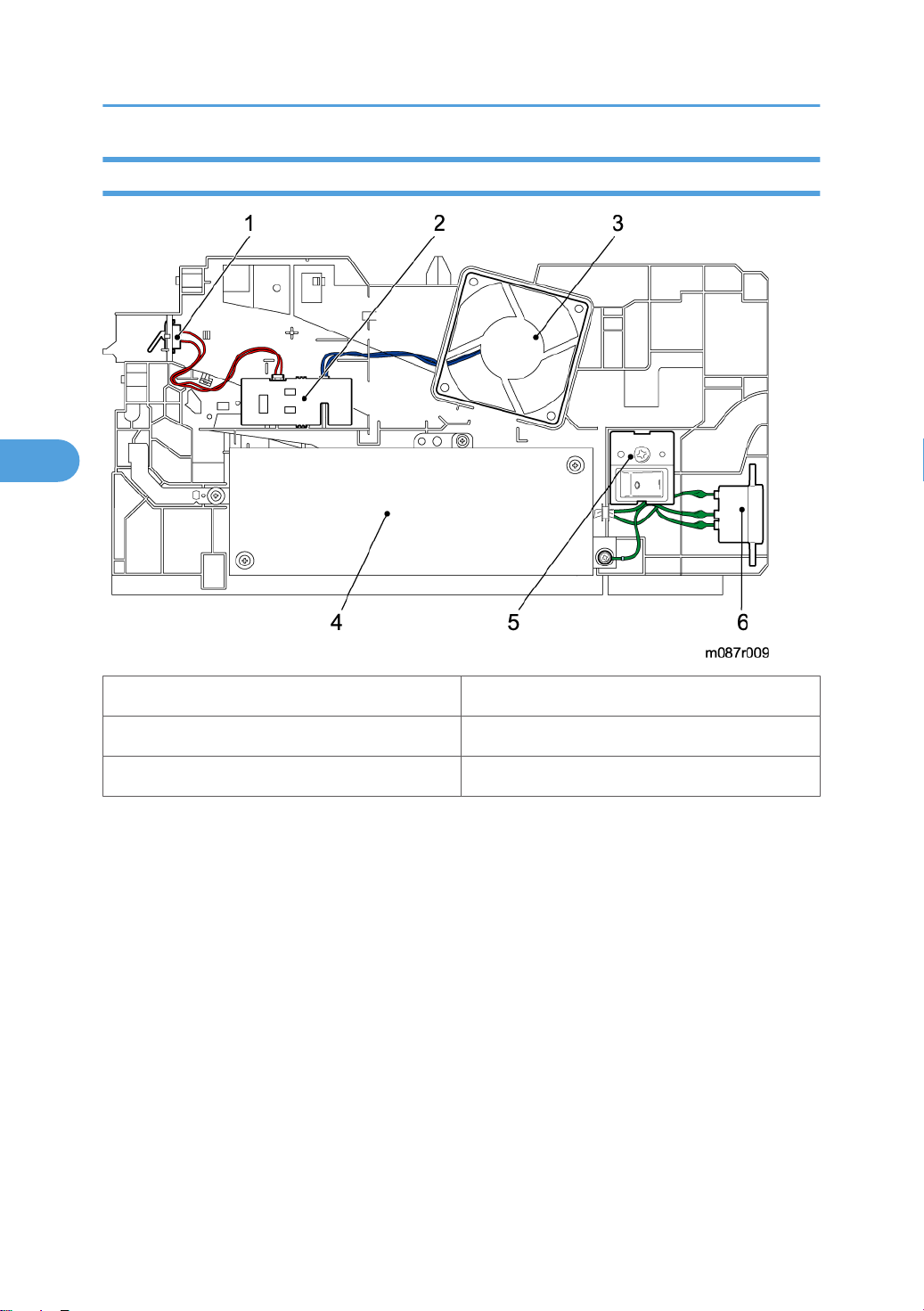

Fuser Unit

1. PS PCB unit 3. Eject sensor PCB ASSY

2. Fuser unit

26

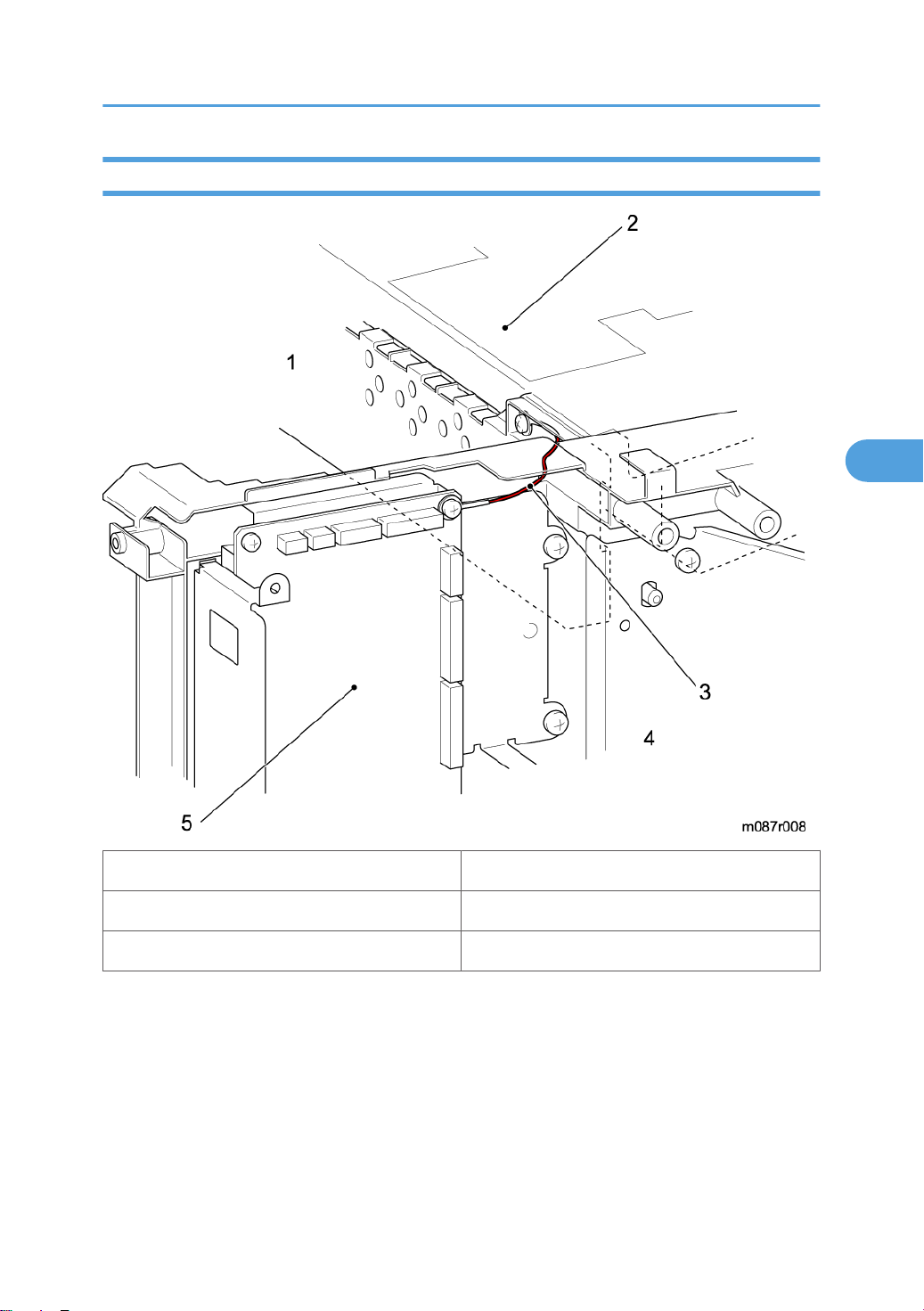

FG Harness

4

Harness Routing

1. <Back side> 4. <Left side>

2. Laser unit 5. Main PCB ASSY

3. FG harness

27

4. Replacement and Adjustment

4

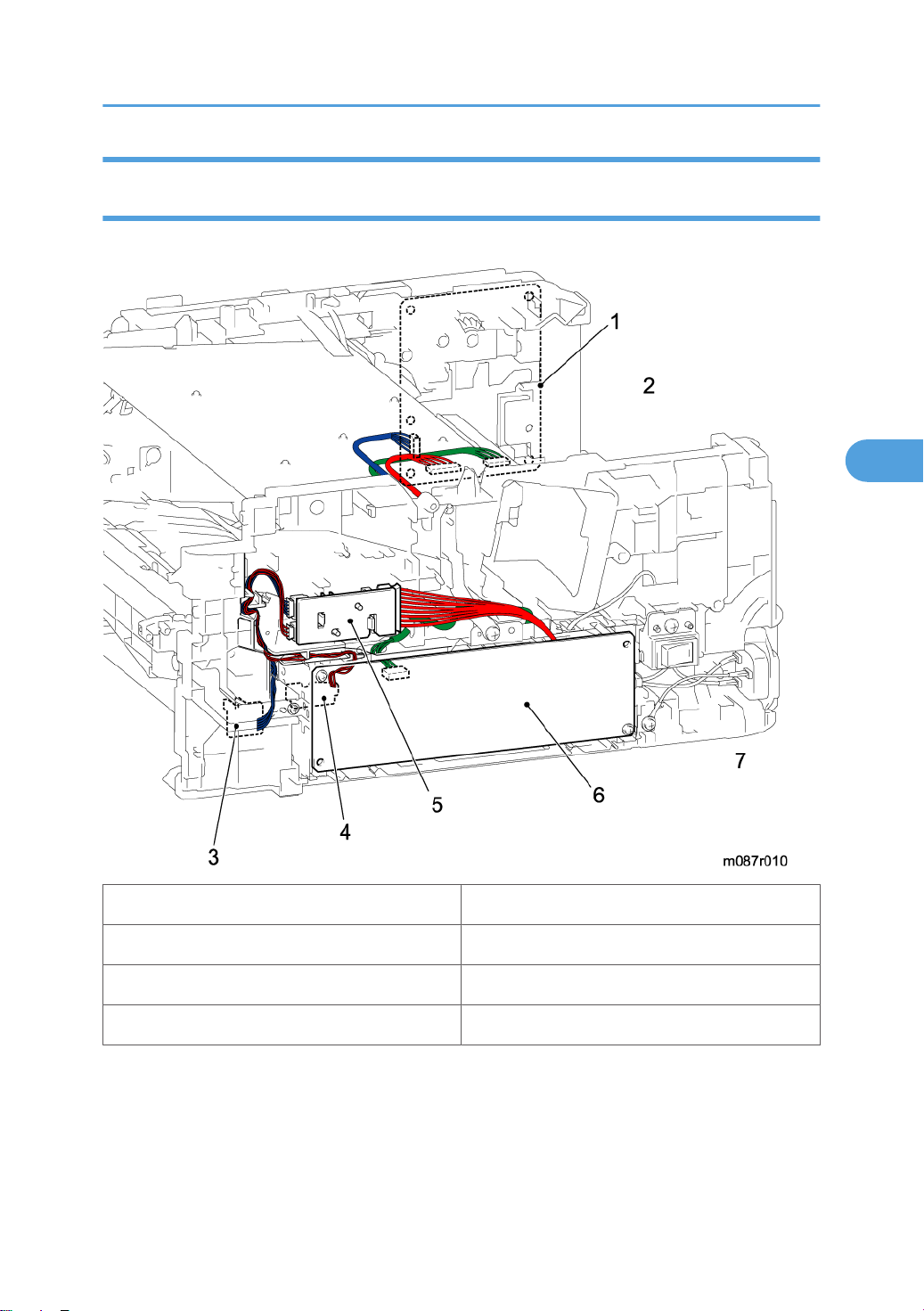

Main Frame R ASSY

1. Front cover sensor 4. PS PCB unit

2. Toner LED PCB ASSY 5. SW holder

3. Fan motor 60 unit 6. Inlet harness ASSY

28

Harness Routing

4

Toner LED PCB ASSY / PS PCB Unit / Main PCB ASSY/Registration Front Sensor PCB ASSY / Registration Rear Sensor PCB ASSY

1. Main PCB ASSY (Main Frame L ASSY) 5. Toner LED PCB ASSY

2. <Back side> 6. PS PCB unit

3. Registration front sensor PCB ASSY 7. <Right side>

4. Registration rear sensor PCB ASSY

29

4. Replacement and Adjustment

4

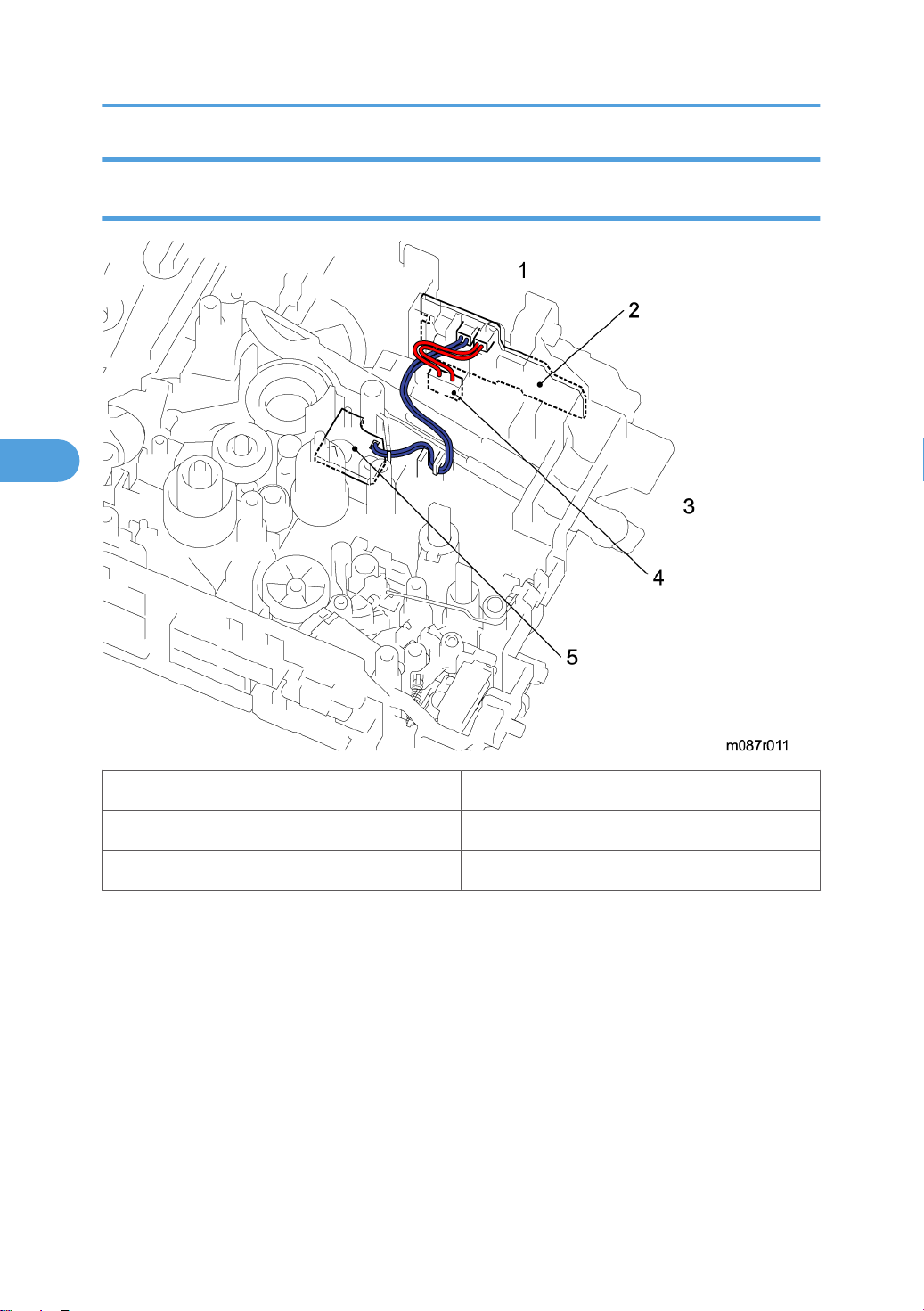

Panel PCB ASSY / Toner Sensor PCB Unit ASSY / New Toner Sensor Harness ASSY

1. <Left side> 4. New toner sensor harness ASSY

2. Panel PCB ASSY 5. Toner sensor PCB unit ASSY

3. <Front side>

30

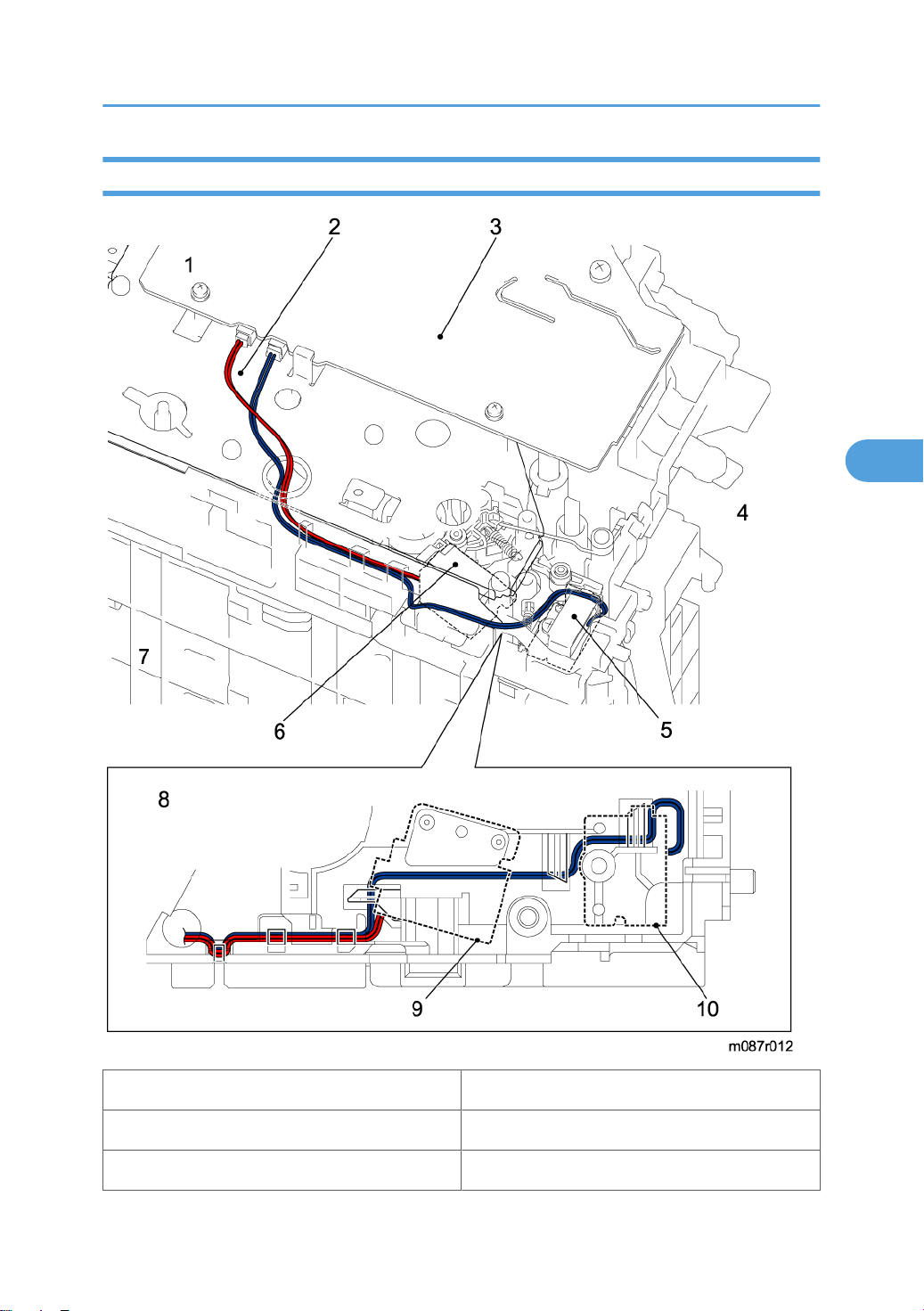

High-Voltage PS PCB / Registration Solenoid / T1 Solenoid

4

Harness Routing

1. <Left side> 6. Registration solenoid

2. Drive sub ASSY 7. <Bottom side>

3. High-voltage PS PCB ASSY 8. <Left side>

31

Loading...

Loading...