®

RT8166B

Dual Single-Phase PWM Controller for CPU and GPU Core

Power Supply

General Description

The RT8166B is a dual single-pha se PWM controller with

integrated MOSFET drivers, compliant with Intel IMVP7

Pulse Width Modulation Specification to support both

CPU core and GPU core power. This part a dopts G-NA VP

(Green-Native A VP), which is a Richtek proprietary topology

derived from finite DC gain compen sator in consta nt ontime control mode. G-NAVPTM makes this part an easy

setting PWM controller to meet all Intel AVP (Active

V oltage Positioning) mobile CPU/GPU requirements. The

RT8166B uses SVID interface to control a n 8-bit DAC for

output voltage programming. The built-in high accuracy

DAC converts the received VID code into a voltage value

ranging from 0V to 1.52V with 5mV step voltage. The

system accuracy of the controller can reach 0.8%. The

RT8166B operates in continuous conduction mode or

diode emulation mode, according to the SVID command.

The maximum efficiency ca n reach up to 90% in dif ferent

operating modes according to different load conditions.

The droop function (load line) can be ea sily progra mmed

by setting the DC gain of the error amplifier. With proper

compensation, the load transient response can achieve

optimized A VP performance.

The output voltage transition slew rate is set vi a the SVID

interface. The RT8166B supports both DCR and sense

resistor current sensing. The RT8166B provides

VR_READY and thermal throttling output signals for

IMVP7 CPU and GPU core. This part also features

complete fault protection functions including over voltage,

under voltage, negative voltage, over current and thermal

shutdown.

TM

Features

Dual Single-Phase PWM Controller for CPU Core

and GPU Core Power

IMVP7 Compatible Power Management States

Serial VID Interface

G-NAV P

A V P f or CPU VR Only

0.5% DAC Accuracy

0.8% System Accuracy

Differential Remote Voltage Sensing

Built-in ADC for Platform Programming

SETINI/SETINIA for CPU/GPU Core VR Initial

TM

T opology

Startup Voltage

TMPMAX to Set Platform Maximum Temperature

ICCMAX/ICCMAXA for CPU/GPU Core VR

Maximum Current

Power Good Indicator : VR_READY/VRA_READY for

CPU/GPU Core Power

Thermal Throttling Indicator : VRHOT

Diode Emulation Mode at Light Load Condition

Fast Line/Load Transient Response

Switching Frequency up to 1MHz per Phase

OVP, UVP, NVP, OTP, UVLO, OCP

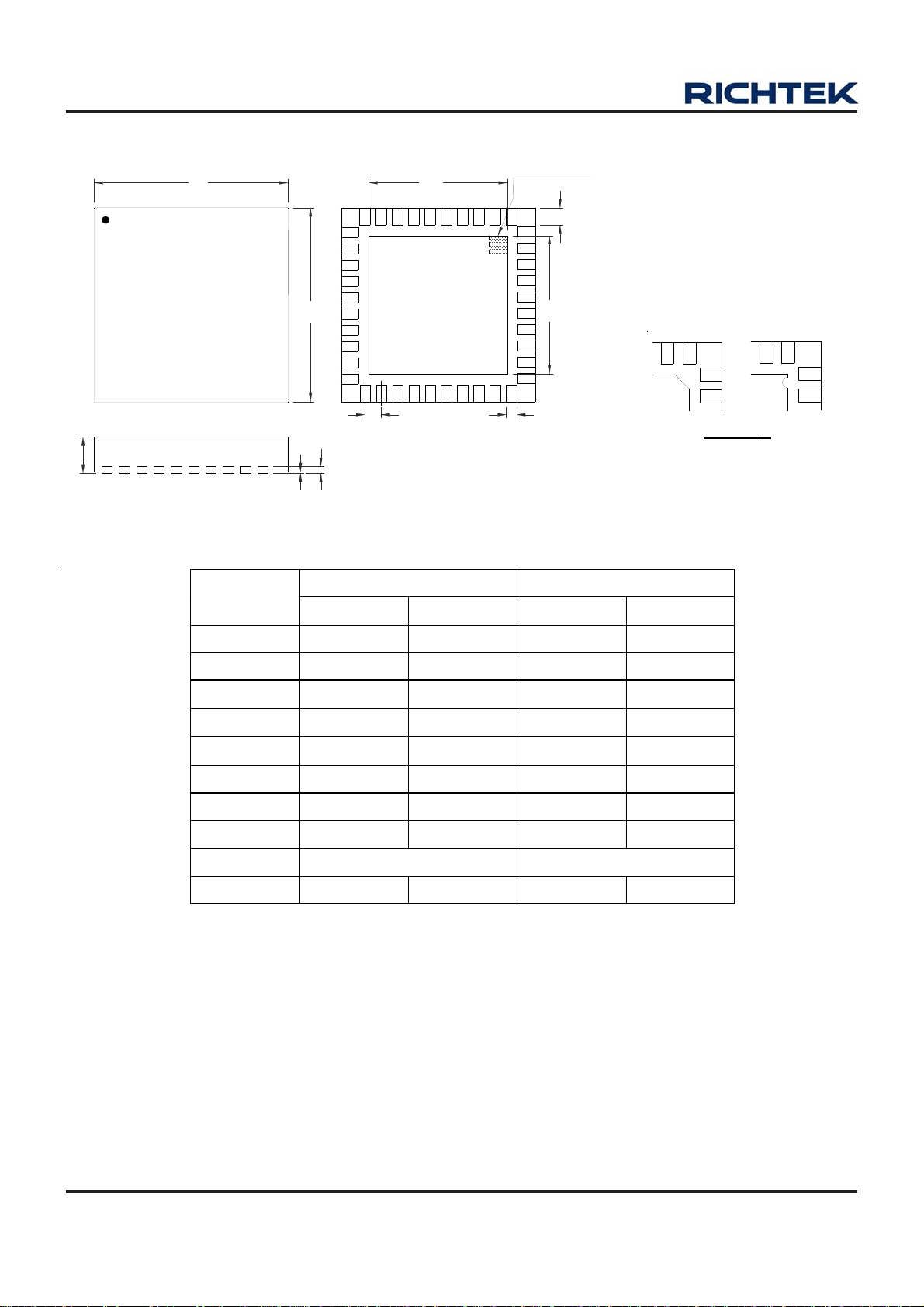

Small 40-Lead WQFN Package

RoHS Compliant and Halogen Free

Applications

IMVP7 Intel CPU/GPU Core Power Supply

Laptop Computers

A VP Step-Down Converter

The RT8166B is available in a WQFN-40L 5x5 small

footprint pack age.

Marking Information

RT8166BZQW : Product Number

RT8166B

ZQW

YMDNN

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8166B-03 November 2013 www.richtek.com

©

YMDNN : Date Code

1

RT8166B

Ordering Information

RT8166B

Package Type

QW : WQFN-40L 5x5 (W-Type)

Lead Plating System

Z : ECO (Ecological Element with

Halogen Free and Pb free)

Note :

Richtek products are :

RoHS compliant and compatible with the current require-

ments of IPC/JEDEC J-STD-020.

Suitable for use in SnPb or Pb-free soldering processes.

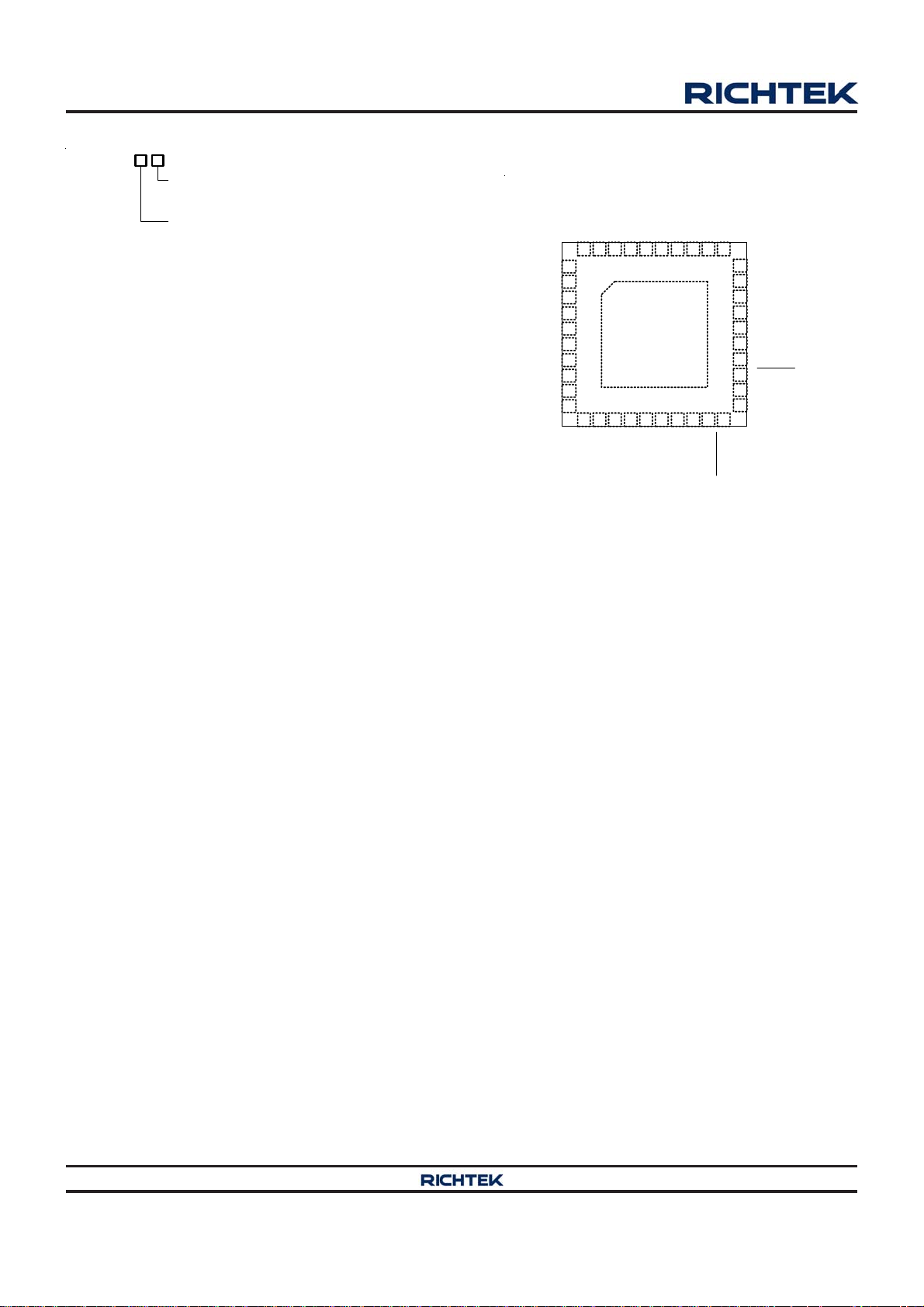

Pin Configurations

(TOP VIEW)

UGATE1

PHASE1

LGATE1

PVCC

LGATEA

PHASEA

FB

VCC

10

1

2

3

4

5

6

7

8

9

SETINI

ICCMAX

TMPMAX

ICCMAXA

WQFN-40L 5x5

GND

TSEN

OCSET

BOOT1

TONSET

ISEN1P

ISEN1N

COMP

RGND

GFXPS2

SETINIA

UGATEA

BOOTAENTONSETA

41

TSENA

OCSETA

31323334353637383940

20191817161514131211

IBIAS

VRHOT

30

ISENAP

29

ISENAN

28

COMPA

27

FBA

26

RGNDA

25

VCLK

24

VDIO

23

ALERT

22

VRA_READY

21

VR_READY

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

DS8166B-03 November 2013www.richtek.com

2

Typical Application Circuit

1

R

V

C

C

2

.

V

R

V

V

V

V

V

A

L

A

_

R

E

R

_

R

E

V

R

O

C

O

S

E

S

T

M

C

I

ICCMAXA

GFXPS2

C

C

5

V

C

C

P

C

L

K

O

D

I

E

R

T

A

D

Y

A

D

Y

H

O

T

V

C

S

E

T

C

S

E

N

T

I

I

N

I

E

T

V

C

P

M

A

X

C

M

A

X

R

4

2

1

R

R

7

6

0

3

3

1

1

0

C

R

1

7

k

7

2

A

T

A

I

R

2

4

1

k

0

C

R

2

9

k

1

5

R

3

7

k

3

3

6

N

T

C

1

T

1

0

k

k

3

=

ß

3

8

0

R

7

1

7

5

0

R

5

2

1

k

2

R

8

1

5

R

8

R

1

R

1

R

5

R

R

9

1

0

k

0

1

k

0

.

0

5

.

R

1

R

7

R

1

0

1

R

1

8

1

9

1

k

0

7

k

2

5

R

2

6

C

N

k

3

0

R

3

1

k

k

0

0

1

0

3

R

8

3

9

k

.

6

k

1

1

N

T

C

4

2

7

5

5

k

T

7

1

0

k

k

=

ß

3

3

2

0

3

R

5

4

5

3

6

.

9

C

1

F

µ

1

R

1

1

5

7

2

5

2

4

2

3

2

2

2

1

2

0

R

2

0

k

0

1

1

8

1

6

1

0

1

1

2

R

7

C

N

R

3

2

C

N

1

2

1

3

1

4

8

R

4

0

k

0

1

A

8

0

1

7

1

5

1

9

k

RT8166B

R

T

8

1

6

6

B

V

C

C

V

C

L

K

V

O

D

I

A

L

E

R

T

V

R

A

_

R

V

R

_

R

E

V

R

H

O

T

O

C

S

E

T

O

C

S

E

T

S

N

I

T

E

S

T

E

N

I

T

M

P

M

C

C

I

M

A

I

C

C

M

A

G

F

X

P

S

T

S

E

N

A

T

S

E

N

A

B

S

I

I

T

O

N

E

S

U

G

A

T

E

B

O

O

T

P

H

A

S

E

L

G

A

T

E

E

A

D

Y

P

V

A

D

Y

A

A

I

I

X

A

X

X

A

2

C

S

E

I

N

1

S

E

I

N

1

F

O

M

C

R

G

N

T

O

N

S

T

E

U

G

A

T

E

B

O

O

T

P

H

S

A

E

L

G

A

T

E

S

E

I

N

A

S

I

E

N

A

F

B

M

P

O

C

R

G

N

D

G

N

R

2

k

0

3

1

2

T

R

0

4

4

0

1

0

R

5

1

1

3

9

1

R

1

2

3

1

3

C

3

P

4

N

6

B

5

P

7

D

3

A

3

A

3

A

3

A

3

A

3

P

2

N

2

A

2

A

2

A

4

D

0

8

7

t

i

o

p

O

0

1

C

2

R

1

7

R

3

3

0

3

1

1

0

R

3

5

4

0

R

3

6

3

5

R

4

1

0

6

0

9

t

i

o

p

O

7

8

6

1

9

1

C

8

4

R

k

2

4

E

x

(

p

o

s

e

R

3

5

.

1

2

C

F

µ

.

1

0

Q

1

C

4

F

µ

.

1

0

Q

2

V

5

C

8

F

µ

1

l

a

n

1

k

k

l

a

n

d

P

l

a

n

i

o

t

O

p

1

1

C

2

2

R

k

0

1

R

3

4

.

1

5

2

1

C

F

µ

.

1

0

Q

3

C

1

3

F

µ

.

1

0

Q

4

l

a

n

t

O

i

o

p

0

2

C

9

4

R

k

0

1

d

)

a

C

0

1

t

n

i

o

p

a

O

R

1

3

C

7

3

2

R

0

0

1

C

0

1

a

n

t

i

p

O

o

R

4

2

C

1

5

0

5

R

0

0

1

3

F

µ

R

C

D

l

1

R

1

4

3

k

.

9

9

C

O

8

2

R

0

0

1

1

4

F

µ

R

C

D

2

l

R

4

3

k

1

1

8

1

C

1

5

R

0

0

1

V

N

I

5

o

t

V

2

5

V

7

.

m

6

=

L

1

H

µ

C

6

F

µ

0

8

6

.

0

R

R

.

2

a

i

n

o

t

p

R

O

C

V

CORE

1

1

6

4

.

7

k

4

l

E

S

V

E

C

C

CORE VSS SENSE

V

N

I

5

o

t

V

2

5

V

m

.

6

4

1

=

L

2

H

µ

C

1

6

F

µ

1

.

0

R

4

R

1

O

p

t

F

G

V

G

F

G

4

4

5

k

1

k

.

2

l

a

n

i

o

N

E

S

V

X

C

C

F

X

N

E

S

X

V

S

S

V

C

R

O

E

C

2

C

5

F

µ

0

3

3

m

/

9

N

T

C

5

k

4

.

7

k

=

3

ß

E

S

N

V

F

G

X

7

C

1

F

µ

0

3

3

m

5

/

1

N

T

C

A

k

1

5

6

3

ß

=

E

S

E

S

6

F

3

µ

0

3

m

/

9

1

0

0

5

C

2

7

F

µ

0

3

3

m

5

/

1

0

2

Chip Enable

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

3

N

E

DS8166B-03 November 2013 www.richtek.com

3

RT8166B

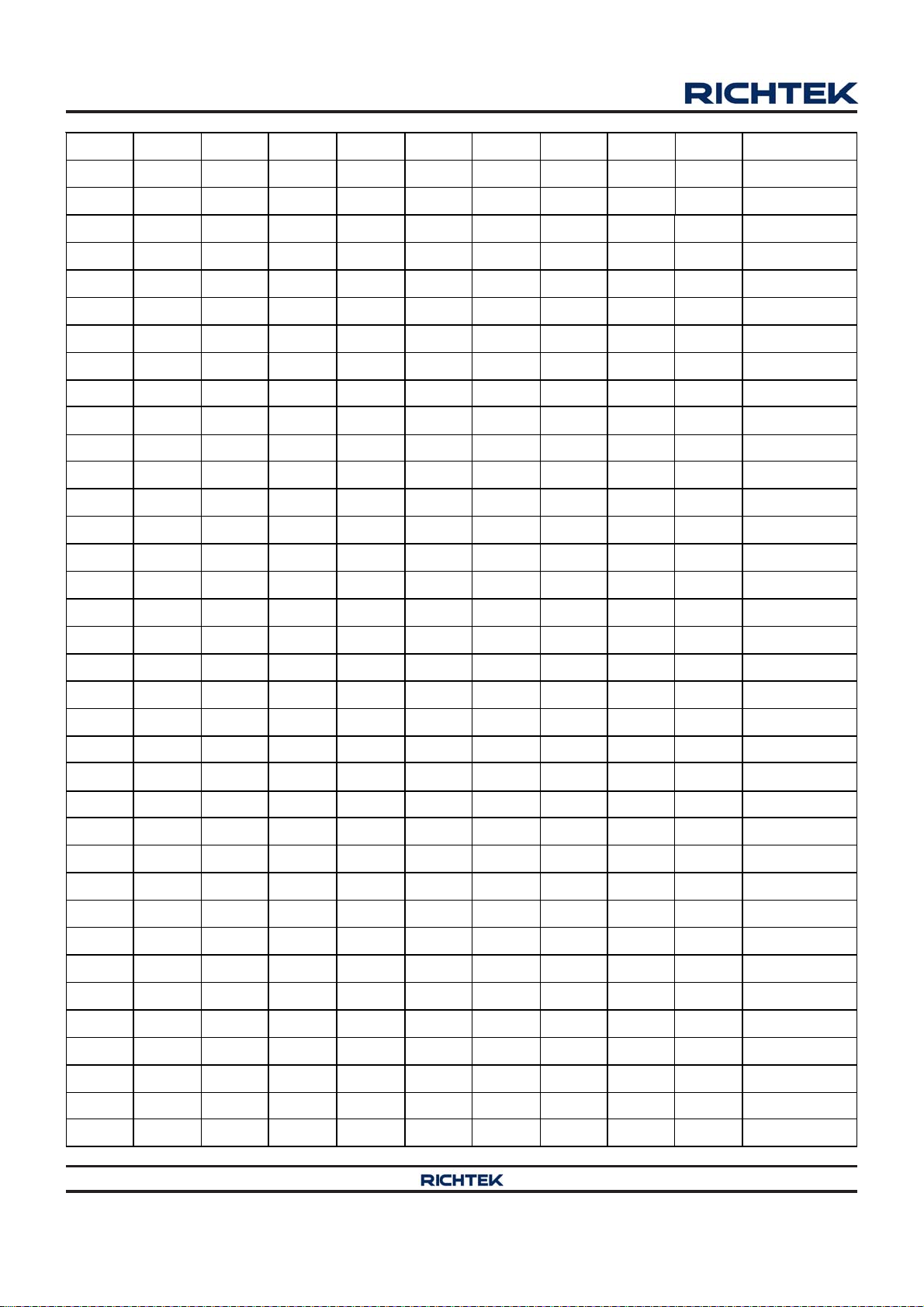

Table 1. IMVP7/VR12 Compliant VID Table

VID7 VID6 VID5 VID4 VID3 VID2 VID1 VID0 H1 H0 VDAC Voltage

0 0 0 0 0 0 0 0 0 0 0.000

0 0 0 0 0 0 0 1 0 1 0.250

0 0 0 0 0 0 1 0 0 2 0.255

0 0 0 0 0 0 1 1 0 3 0.260

0 0 0 0 0 1 0 0 0 4 0.265

0 0 0 0 0 1 0 1 0 5 0.270

0 0 0 0 0 1 1 0 0 6 0.275

0 0 0 0 0 1 1 1 0 7 0.280

0 0 0 0 1 0 0 0 0 8 0.285

0 0 0 0 1 0 0 1 0 9 0.290

0 0 0 0 1 0 1 0 0 A 0.295

0 0 0 0 1 0 1 1 0 B 0.300

0 0 0 0 1 1 0 0 0 C 0.305

0 0 0 0 1 1 0 1 0 D 0.310

0 0 0 0 1 1 1 0 0 E 0.315

0 0 0 0 1 1 1 1 0 F 0.320

0 0 0 1 0 0 0 0 1 0 0.325

0 0 0 1 0 0 0 1 1 1 0.330

0 0 0 1 0 0 1 0 1 2 0.335

0 0 0 1 0 0 1 1 1 3 0.340

0 0 0 1 0 1 0 0 1 4 0.345

0 0 0 1 0 1 0 1 1 5 0.350

0 0 0 1 0 1 1 0 1 6 0.355

0 0 0 1 0 1 1 1 1 7 0.360

0 0 0 1 1 0 0 0 1 8 0.365

0 0 0 1 1 0 0 1 1 9 0.370

0 0 0 1 1 0 1 0 1 A 0.375

0 0 0 1 1 0 1 1 1 B 0.380

0 0 0 1 1 1 0 0 1 C 0.385

0 0 0 1 1 1 0 1 1 D 0.390

0 0 0 1 1 1 1 0 1 E 0.395

0 0 0 1 1 1 1 1 1 F 0.400

0 0 1 0 0 0 0 0 2 0 0.405

0 0 1 0 0 0 0 1 2 1 0.410

0 0 1 0 0 0 1 0 2 2 0.415

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

4

©

DS8166B-03 November 2013www.richtek.com

RT8166B

VID7 VID6 VID5 VID4 VID3 VID2 VID1 VID0 H1 H0 DAC Voltage

0 0 1 0 0 0 1 1 2 3 0.420

0 0 1 0 0 1 0 0 2 4 0.425

0 0 1 0 0 1 0 1 2 5 0.430

0 0 1 0 0 1 1 0 2 6 0.435

0 0 1 0 0 1 1 1 2 7 0.440

0 0 1 0 1 0 0 0 2 8 0.445

0 0 1 0 1 0 0 1 2 9 0.450

0 0 1 0 1 0 1 0 2 A 0.455

0 0 1 0 1 0 1 1 2 B 0.460

0 0 1 0 1 1 0 0 2 C 0.465

0 0 1 0 1 1 0 1 2 D 0.470

0 0 1 0 1 1 1 0 2 E 0.475

0 0 1 0 1 1 1 1 2 F 0.480

0 0 1 1 0 0 0 0 3 0 0.485

0 0 1 1 0 0 0 1 3 1 0.490

0 0 1 1 0 0 1 0 3 2 0.495

0 0 1 1 0 0 1 1 3 3 0.500

0 0 1 1 0 1 0 0 3 4 0.505

0 0 1 1 0 1 0 1 3 5 0.510

0 0 1 1 0 1 1 0 3 6 0.515

0 0 1 1 0 1 1 1 3 7 0.520

0 0 1 1 1 0 0 0 3 8 0.525

0 0 1 1 1 0 0 1 3 9 0.530

0 0 1 1 1 0 1 0 3 A 0.535

0 0 1 1 1 0 1 1 3 B 0.540

0 0 1 1 1 1 0 0 3 C 0.545

0 0 1 1 1 1 0 1 3 D 0.550

0 0 1 1 1 1 1 0 3 E 0.555

0 0 1 1 1 1 1 1 3 F 0.560

0 1 0 0 0 0 0 0 4 0 0.565

0 1 0 0 0 0 0 1 4 1 0.570

0 1 0 0 0 0 1 0 4 2 0.575

0 1 0 0 0 0 1 1 4 3 0.580

0 1 0 0 0 1 0 0 4 4 0.585

0 1 0 0 0 1 0 1 4 5 0.590

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8166B-03 November 2013 www.richtek.com

©

5

RT8166B

VID7 VID6 VID5 VID4 VID3 VID2 VID1 VID0 H1 H0 DAC Voltage

0 1 0 0 0 1 1 0 4 6 0.595

0 1 0 0 0 1 1 1 4 7 0.600

0 1 0 0 1 0 0 0 4 8 0.605

0 1 0 0 1 0 0 1 4 9 0.610

0 1 0 0 1 0 1 0 4 A 0.615

0 1 0 0 1 0 1 1 4 B 0.620

0 1 0 0 1 1 0 0 4 C 0.625

0 1 0 0 1 1 0 1 4 D 0.630

0 1 0 0 1 1 1 0 4 E 0.635

0 1 0 0 1 1 1 1 4 F 0.640

0 1 0 1 0 0 0 0 5 0 0.645

0 1 0 1 0 0 0 1 5 1 0.650

0 1 0 1 0 0 1 0 5 2 0.655

0 1 0 1 0 0 1 1 5 3 0.660

0 1 0 1 0 1 0 0 5 4 0.665

0 1 0 1 0 1 0 1 5 5 0.670

0 1 0 1 0 1 1 0 5 6 0.675

0 1 0 1 0 1 1 1 5 7 0.680

0 1 0 1 1 0 0 0 5 8 0.685

0 1 0 1 1 0 0 1 5 9 0.690

0 1 0 1 1 0 1 0 5 A 0.695

0 1 0 1 1 0 1 1 5 B 0.700

0 1 0 1 1 1 0 0 5 C 0.705

0 1 0 1 1 1 0 1 5 D 0.710

0 1 0 1 1 1 1 0 5 E 0.715

0 1 0 1 1 1 1 1 5 F 0.720

0 1 1 0 0 0 0 0 6 0 0.725

0 1 1 0 0 0 0 1 6 1 0.730

0 1 1 0 0 0 1 0 6 2 0.735

0 1 1 0 0 0 1 1 6 3 0.740

0 1 1 0 0 1 0 0 6 4 0.745

0 1 1 0 0 1 0 1 6 5 0.750

0 1 1 0 0 1 1 0 6 6 0.755

0 1 1 0 0 1 1 1 6 7 0.760

0 1 1 0 1 0 0 0 6 8 0.765

0 1 1 0 1 0 0 1 6 9 0.770

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

6

©

DS8166B-03 November 2013www.richtek.com

RT8166B

VID7 VID6 VID5 VID4 VID3 VID2 VID1 VID0 H1 H0 DAC Voltage

0 1 1 0 1 0 1 0 6 A 0.775

0 1 1 0 1 0 1 1 6 B 0.780

0 1 1 0 1 1 0 0 6 C 0.785

0 1 1 0 1 1 0 1 6 D 0.790

0 1 1 0 1 1 1 0 6 E 0.795

0 1 1 0 1 1 1 1 6 F 0.800

0 1 1 1 0 0 0 0 7 0 0.805

0 1 1 1 0 0 0 1 7 1 0.810

0 1 1 1 0 0 1 0 7 2 0.815

0 1 1 1 0 0 1 1 7 3 0.820

0 1 1 1 0 1 0 0 7 4 0.825

0 1 1 1 0 1 0 1 7 5 0.830

0 1 1 1 0 1 1 0 7 6 0.835

0 1 1 1 0 1 1 1 7 7 0.840

0 1 1 1 1 0 0 0 7 8 0.845

0 1 1 1 1 0 0 1 7 9 0.850

0 1 1 1 1 0 1 0 7 A 0.855

0 1 1 1 1 0 1 1 7 B 0.860

0 1 1 1 1 1 0 0 7 C 0.865

0 1 1 1 1 1 0 1 7 D 0.870

0 1 1 1 1 1 1 0 7 E 0.875

0 1 1 1 1 1 1 1 7 F 0.880

1 0 0 0 0 0 0 0 8 0 0.885

1 0 0 0 0 0 0 1 8 1 0.890

1 0 0 0 0 0 1 0 8 2 0.895

1 0 0 0 0 0 1 1 8 3 0.900

1 0 0 0 0 1 0 0 8 4 0.905

1 0 0 0 0 1 0 1 8 5 0.910

1 0 0 0 0 1 1 0 8 6 0.915

1 0 0 0 0 1 1 1 8 7 0.920

1 0 0 0 1 0 0 0 8 8 0.925

1 0 0 0 1 0 0 1 8 9 0.930

1 0 0 0 1 0 1 0 8 A 0.935

1 0 0 0 1 0 1 1 8 B 0.940

1 0 0 0 1 1 0 0 8 C 0.945

1 0 0 0 1 1 0 1 8 D 0.950

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8166B-03 November 2013 www.richtek.com

©

7

RT8166B

VID7 VID6 VID5 VID4 VID3 VID2 VID1 VID0 H1 H0 DAC Voltage

1 0 0 0 1 1 1 0 8 E 0.955

1 0 0 0 1 1 1 1 8 F 0.960

1 0 0 1 0 0 0 0 9 0 0.965

1 0 0 1 0 0 0 1 9 1 0.970

1 0 0 1 0 0 1 0 9 2 0.975

1 0 0 1 0 0 1 1 9 3 0.980

1 0 0 1 0 1 0 0 9 4 0.985

1 0 0 1 0 1 0 1 9 5 0.990

1 0 0 1 0 1 1 0 9 6 0.995

1 0 0 1 0 1 1 1 9 7 1.000

1 0 0 1 1 0 0 0 9 8 1.005

1 0 0 1 1 0 0 1 9 9 1.010

1 0 0 1 1 0 1 0 9 A 1.015

1 0 0 1 1 0 1 1 9 B 1.020

1 0 0 1 1 1 0 0 9 C 1.025

1 0 0 1 1 1 0 1 9 D 1.030

1 0 0 1 1 1 1 0 9 E 1.035

1 0 0 1 1 1 1 1 9 F 1.040

1 0 1 0 0 0 0 0 A 0 1.045

1 0 1 0 0 0 0 1 A 1 1.050

1 0 1 0 0 0 1 0 A 2 1.055

1 0 1 0 0 0 1 1 A 3 1.060

1 0 1 0 0 1 0 0 A 4 1.065

1 0 1 0 0 1 0 1 A 5 1.070

1 0 1 0 0 1 1 0 A 6 1.075

1 0 1 0 0 1 1 1 A 7 1.080

1 0 1 0 1 0 0 0 A 8 1.085

1 0 1 0 1 0 0 1 A 9 1.090

1 0 1 0 1 0 1 0 A A 1.095

1 0 1 0 1 0 1 1 A B 1.100

1 0 1 0 1 1 0 0 A C 1.105

1 0 1 0 1 1 0 1 A D 1.110

1 0 1 0 1 1 1 0 A E 1.115

1 0 1 0 1 1 1 1 A F 1.120

1 0 1 1 0 0 0 0 B 0 1.125

1 0 1 1 0 0 0 1 B 1 1.130

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

8

©

DS8166B-03 November 2013www.richtek.com

RT8166B

VID7 VID6 VID5 VID4 VID3 VID2 VID1 VID0 H1 H0 DAC Voltage

1 0 1 1 0 0 1 0 B 2 1.135

1 0 1 1 0 0 1 1 B 3 1.140

1 0 1 1 0 1 0 0 B 4 1.145

1 0 1 1 0 1 0 1 B 5 1.150

1 0 1 1 0 1 1 0 B 6 1.155

1 0 1 1 0 1 1 1 B 7 1.160

1 0 1 1 1 0 0 0 B 8 1.165

1 0 1 1 1 0 0 1 B 9 1.170

1 0 1 1 1 0 1 0 B A 1.175

1 0 1 1 1 0 1 1 B B 1.180

1 0 1 1 1 1 0 0 B C 1.185

1 0 1 1 1 1 0 1 B D 1.190

1 0 1 1 1 1 1 0 B E 1.195

1 0 1 1 1 1 1 1 B F 1.200

1 1 0 0 0 0 0 0 C 0 1.205

1 1 0 0 0 0 0 1 C 1 1.210

1 1 0 0 0 0 1 0 C 2 1.215

1 1 0 0 0 0 1 1 C 3 1.220

1 1 0 0 0 1 0 0 C 4 1.225

1 1 0 0 0 1 0 1 C 5 1.230

1 1 0 0 0 1 1 0 C 6 1.235

1 1 0 0 0 1 1 1 C 7 1.240

1 1 0 0 1 0 0 0 C 8 1.245

1 1 0 0 1 0 0 1 C 9 1.250

1 1 0 0 1 0 1 0 C A 1.255

1 1 0 0 1 0 1 1 C B 1.260

1 1 0 0 1 1 0 0 C C 1.265

1 1 0 0 1 1 0 1 C D 1.270

1 1 0 0 1 1 1 0 C E 1.275

1 1 0 0 1 1 1 1 C F 1.280

1 1 0 1 0 0 0 0 D 0 1.285

1 1 0 1 0 0 0 1 D 1 1.290

1 1 0 1 0 0 1 0 D 2 1.295

1 1 0 1 0 0 1 1 D 3 1.300

1 1 0 1 0 1 0 0 D 4 1.305

1 1 0 1 0 1 0 1 D 5 1.310

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8166B-03 November 2013 www.richtek.com

©

9

RT8166B

VID7 VID6 VID5 VID4 VID3 VID2 VID1 VID0 H1 H0 DAC Voltage

1 1 0 1 0 1 1 0 D 6 1.315

1 1 0 1 0 1 1 1 D 7 1.320

1 1 0 1 1 0 0 0 D 8 1.325

1 1 0 1 1 0 0 1 D 9 1.330

1 1 0 1 1 0 1 0 D A 1.335

1 1 0 1 1 0 1 1 D B 1.340

1 1 0 1 1 1 0 0 D C 1.345

1 1 0 1 1 1 0 1 D D 1.350

1 1 0 1 1 1 1 0 D E 1.355

1 1 0 1 1 1 1 1 D F 1.360

1 1 1 0 0 0 0 0 E 0 1.365

1 1 1 0 0 0 0 1 E 1 1.370

1 1 1 0 0 0 1 0 E 2 1.375

1 1 1 0 0 0 1 1 E 3 1.380

1 1 1 0 0 1 0 0 E 4 1.385

1 1 1 0 0 1 0 1 E 5 1.390

1 1 1 0 0 1 1 0 E 6 1.395

1 1 1 0 0 1 1 1 E 7 1.400

1 1 1 0 1 0 0 0 E 8 1.405

1 1 1 0 1 0 0 1 E 9 1.410

1 1 1 0 1 0 1 0 E A 1.415

1 1 1 0 1 0 1 1 E B 1.420

1 1 1 0 1 1 0 0 E C 1.425

1 1 1 0 1 1 0 1 E D 1.430

1 1 1 0 1 1 1 0 E E 1.435

1 1 1 0 1 1 1 1 E F 1.440

1 1 1 1 0 0 0 0 F 0 1.445

1 1 1 1 0 0 0 1 F 1 1.450

1 1 1 1 0 0 1 0 F 2 1.455

1 1 1 1 0 0 1 1 F 3 1.460

1 1 1 1 0 1 0 0

1 1 1 1 0 1 0 1 F 5 1.470

1 1 1 1 0 1 1 0 F 6 1.475

1 1 1 1 0 1 1 1 F 7 1.480

1 1 1 1 1 0 0 0

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

10

©

F 4

F 8

DS8166B-03 November 2013www.richtek.com

1.465

1.485

RT8166B

VID7 VID6 VID5 VID4 VID3 VID2 VID1 VID0 H1 H0 DAC Voltage

1 1 1 1 1 0 0 1 F 9 1.490

1 1 1 1 1 0 1 0 F A 1.495

1 1 1 1 1 0 1 1 F B 1.500

1 1 1 1 1 1 0 0 F C 1.505

1 1 1 1 1 1 0 1 F D 1.510

1 1 1 1 1 1 1 0 F E 1.515

1 1 1 1 1 1 1 1 F F 1.520

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8166B-03 November 2013 www.richtek.com

©

11

RT8166B

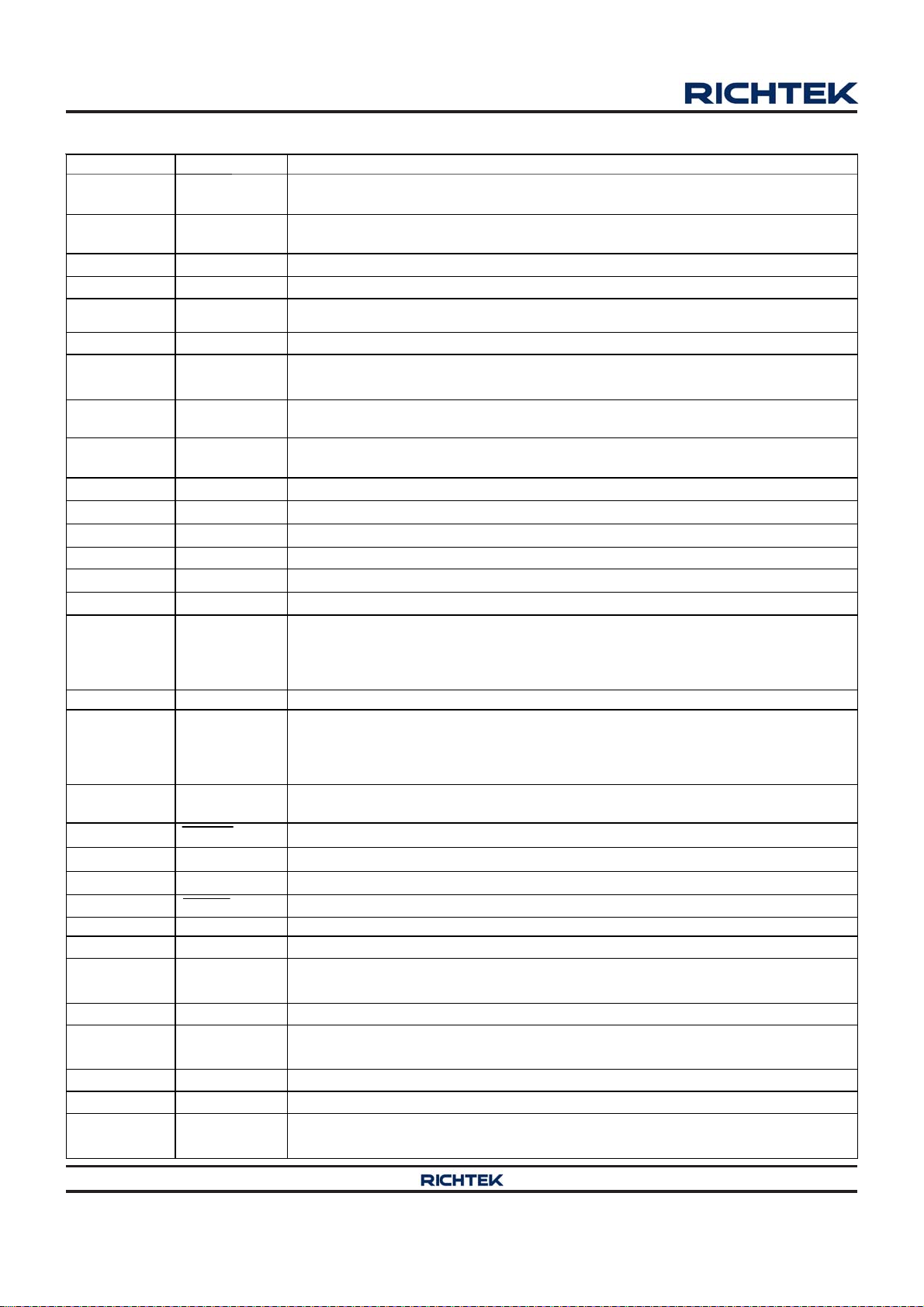

Functional Pin Description

Pin No. Pin Name Pin Function

1 BOOT1

2 TONSET

3 ISEN1P Positive Current Sense Input Pin of CPU VR.

4 ISEN1N Negative Current Sense Input Pin of CPU VR.

5 COMP CPU VR Compensation Pin. This pin is the output of the error amplifier.

6 FB CPU VR Feedback Pin. This pin is the inverting input node of the error amplifier.

7 RGND

8 GFXPS2

9 VCC

10 SETINIA ADC Input for Single-Phase GPU VR VBOOT Voltage Setting.

11 SETINI ADC Input for Single-Phase CPU VR VBOOT Voltage Setting.

12 TMPMAX ADC Input for Single-Phase CPU VR Maximum Temperature Setting.

13 ICCMAX ADC Input for Single-Phase CPU VR Maximum Current Setting.

14 ICCMAXA ADC Input for Single-Phase GPU VR Max imum Current Setting.

15 TSEN Thermal Monitor Sense Input Pin for CPU VR.

16 OCSET

17 TSENA Thermal Monitor Sense Input for GPU VR.

18 OCSETA

19 IBIAS

20

VRHOT

21 VR_READY CPU VR Voltage Ready Indicator. This pin has an open drain output.

22 VRA_READY GPU VR Voltage Ready Indicator. This pin has an open drain output.

23

ALERT

24 VDIO Data Transmission Line of SVID Interface.

25 VCLK Clock Signal Line of SVID Interface.

26 RGNDA

27 FBA GPU VR Feedback Pin. This pin is the inverting input node of the error amplifier.

28 COMPA

29 ISENAN Negative Current Sense Input Pin of Single- Phase GPU VR.

30 ISENAP Positive Current Sense Input Pin of Single-Phase GPU VR.

31 TONSETA

CPU VR Bootstrap Power Pin. Thi s pin powers the high side MOSFET drivers.

Connect this pin to the PHASE1 pin with a bootstrap capacitor.

Single-Phase CPU VR On-Time Setting Pin. Connect this pin to V

resistor to set ripple size in PWM mode.

Return Ground for CPU VR. This pin is the inverti ng input node for dif ferential

remote voltage sens ing.

Set Pin for GPU VR Operation Mode. Logic-high on this pin will force the GPU V R

to enter DCM.

Controller Power Supply Pin. Connect this pi n to GND via a ceramic capacitor

larger than 1F.

Set Pin for Single-Phase CPU VR Over Current Protection Threshold.

Connect a resistive voltage divider from VCC to ground, and connect the joint of

the voltage divider to the OCSET pin. The voltage, V

over current threshold, I

, for CPU VR.

LIMIT

, at this pin sets the

OCSET

Set Pin for Single-Phase GPU VR Over Current Protection Threshold.

Connect a resistive voltage divider from VCC to ground, and connect the joint of

the voltage divider to the OCSETA pin. The voltage, V

over current threshold, I

, for GPU VR.

LIMIT

OCSETA

, at this pin sets the

Internal Bias Current Setting. Connect a 53.6k resistor from t his pin to GND to

set the internal bias current.

Therm al Monitor Output Pin (active low).

Alert Line of SVID Interface (active low). This pin has an open drain output.

Return Ground for Single-Phase GPU VR.

This pin is the inverting input node for differential remote voltage sensing.

Single-Phase GPU VR Compensation Pin. This pin is the output of the error

amplifier.

Single-Phase GPU VR On-Time Setting Pin. Connect this pin to VIN with a

resistor to set ripple size in PWM mode.

with a

IN

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

12

©

DS8166B-03 November 2013www.richtek.com

Pin No. Pin Name Pin Function

32 E N Voltage Regulator Enable Signal Input Pin.

33 BOOTA

34 UGATEA

35 PHASEA

36 LGATEA

37 PVCC

38 LGATE1

39 PHASE1

40 UGATE1

41 (Exp osed Pad) GND

GPU VR Bootstrap Power Pi n. This pin powers the high side MOSFET drivers.

Connect thi s pin to the PHASEA pin with a bootstrap capaci tor.

Upper Gate Driver of GPU VR. Thi s pi n drives the high side MOSFET of GPU

VR.

Switc h Node of GPU VR. This pin i s the return node of the high side MOSF ET

driver for GPU VR. Connect this pin to the joint of the source of high side

MOSFET, drain of the low side MOSFET, and the output inductor.

Lowe r G ate Driv e r of GPU VR. Thi s pi n dri ves th e low s ide M OS FET of G PU

VR.

MOSFET Driver Power Supply Pin. Connect this pin to GND via a ceramic

capacitor larger than 1F.

Lower G ate Drive r of C PU VR. Th is pi n driv es th e low si de MOSF ET of CPU

VR.

Switc h Node of CPU VR. This pin is the retur n node of the high side driver f or

CPU VR. Connect this pin to the joint of the sour ce of high side MOSFET, drain

of the low side MOSFET, and the output inductor.

Upper Gate Driver of CPU VR. This pin drives the high side MOSFET of CPU

VR.

Ground of Low Side MOSFET Driver. T he exposed pad m ust be soldered to a

large PCB and connected to GND for maximum power dissipation.

RT8166B

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8166B-03 November 2013 www.richtek.com

©

13

RT8166B

Function Block Diagram

VDIO

VCLK

ICCMAX

ICCMAXA

TMPMAX

ALERT

SETINIA

TSEN

SETINI

TSENA

EN

VR_READY

VCC

VRHOT

VRA_READY

RGNDA

FBA

COMPA

IBIAS

RGND

FB

COMP

ISEN1P

ISEN1N

From Control Logic

DAC

Soft-Start & Slew

Rate Control

From Control Logic

DAC

Soft-Start & Slew

Rate Control

SVID XCVR

V

REFA

+

-

V

REF

+

-

ERROR

AMP

ERROR

AMP

MUX

ADC

Offset

Cancellation

To Protection Logic

OCPOVP/UVP/NVP

Offset

Cancellation

UVLO

Control & Protection Logic

TON Time

PWM CMP

+

-

+

10

-

PWM CMP

+

-

To Protection Logic

+

10

-

OCP OVP/UVP/NVP

Generator

Driver Logic

Control

TON Time

Generator

Driver Logic

Control

GFXPS2

TONSETA

BOOTA

UGATEA

PHASEA

PVCC

LGATEA

ISENAP

ISENAN

OCSETA

TONSET

BOOT1

UGATE1

PHASE1

LGATE1

OCSET

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

DS8166B-03 November 2013www.richtek.com

14

RT8166B

Absolute Maximum Ratings (Note 1)

PVCC, VCC to GND ------------------------------------------------------------------------------------- −0.3V to 6.5V

RGNDx to GND ------------------------------------------------------------------------------------------- −0.3V to 0.3V

TONSETx to GND ---------------------------------------------------------------------------------------- −0.3V to 28V

Others------------------------------------------------------------------------------------------------------- −0.3V to (V

BOOTx to PHASEx-------------------------------------------------------------------------------------- −0.3V to 6.5V

PHASEx to GND

DC------------------------------------------------------------------------------------------------------------ −3V to 28V

<20ns ------------------------------------------------------------------------------------------------------- −8V to 32V

UGATEx to PHASEx

DC------------------------------------------------------------------------------------------------------------ −0.3V to (BOOTx − PHASEx)

<20ns ------------------------------------------------------------------------------------------------------- −5V to 7.5V

LGA TEx to GND

DC------------------------------------------------------------------------------------------------------------ −0.3V to (PVCC + 0.3V)

<20ns ------------------------------------------------------------------------------------------------------- −2.5V to 7.5V

Power Dissipation, P

@ T

D

= 25°C

A

WQFN−40L 5x5------------------------------------------------------------------------------------------- 2.778W

Package Thermal Resistance (Note 2)

WQFN−40L 5x5, θJA------------------------------------------------------------------------------------- 36°C/W

WQFN−40L 5x5, θJC------------------------------------------------------------------------------------- 6°C/W

Junction T emperature------------------------------------------------------------------------------------ 150°C

Lead T e mperature (Soldering, 10 sec.)-------------------------------------------------------------- 26 0°C

Storage T emperature Range --------------------------------------------------------------------------- −65°C to 150°C

ESD Susceptibility (Note 3)

HBM (Human Body Mode) ----------------------------------------------------------------------------- 2kV

MM (Ma chine Mode)------------------------------------------------------------------------------------- 200V

+ 0.3V)

CC

Recommended Operating Conditions (Note 4)

Supply Voltage, V

Input V oltage, V

Junction T emperature Range--------------------------------------------------------------------------- −40°C to 125°C

Ambient T emperature Range--------------------------------------------------------------------------- −40°C to 85°C

------------------------------------------------------------------------------------- 4.5V to 5.5V

CC

----------------------------------------------------------------------------------------- 5V to 25V

IN

Electrical Characteristics

(V

= 5V, T

CC

Supply Input

Input Voltage Range

Supply Curr ent

+ PVCC)

(V

CC

Supply Curr ent

(TONSETx)

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8166B-03 November 2013 www.richtek.com

= 25°C, unless otherwise specified)

A

Parameter Symbol Test Conditions Min Typ Max Unit

VCC/V

V

Battery Input Voltage 5 -- 25 V

IN

I

+ I

VCC

I

TONSETx

©

VEN = 1.05V, Not Switching 4.5 5 5.5 V

PVCC

VEN = 1.05V, Not Switching -- 12 20 mA

PVCC

VFB =1 V, VIN = 12V, R

= 100k -- 110 -- A

TON

15

RT8166B

Parameter Symbol Test Conditions Min Typ Max Unit

Shutdown Current

(PVCC + V

CC

)

Shutdown Current

(TONSETx )

I

VCC_SHDN

+ I

PVCC_SHDN

I

TONSETx_SHDN

= 0V -- -- 5 A

V

EN

VEN = 0V -- -- 5 A

TON Setting

TONSETx Voltage V

TONSETx

On-Time tON I

TONSETx Input

Current Range

Mini mum Off-Time T

I

RTON

OFF_MIN

I

V

= 80A, V

RTON

= 80A, V

RTON

= 1.1V 2 5 -- 28 0 A

FBx

-- 350 -- ns

GFX VR Forced DEM

GFXPS2x Enable

Threshol d

G FXPS2x Disable

Threshol d

V

V

4.3 -- -- V

GFXPS

-- -- 0.7 V

GFXPS

References and System Output Voltage

DAC Accuracy

(PS0/PS1)

SETINIx Voltage V

IBIAS Pin Voltage V

Dynamic VID Slew

Rate

V

FBx

SETINIx

R

IBIAS

DVID

SR

VID

OFS

VID

OFS

VID

OFS

VID

OFS

VID

OFS

V

V

V

V

SetVID Slow 2.5 3.125 3.75

SetVID Fast 10 12.5 15

Setting = 1.000V~1.520V

SVID

Set ting = 0V

SVID

Setting = 0.800V~1.000V

SVID

Set ting = 0V

SVID

Setting = 0.500V~0.800V

SVID

Set ting = 0V

SVID

Setting = 0.250V~0.500V

SVID

Set ting = 0V

SVID

Setting = 1.100V

SVID

Set ting = 0.640V~0.635V

SVID

INI_CORE

INI_CORE

INI_CORE

INI_CORE

IBIAS

= 0V, V

= 0.9V, V

= 1V, V

= 1.1V, V

= 53.6k 2.09 2.14 2.19 V

= 1V 0.95 1.075 1.2 0V

FBx

= 1V 315 350 385 ns

FBx

0.5 0 0.5 %VID

5 0 5

8 0 8

mV

8 0 8

10 0 10

INI_GFX

INI_GFX

= 0V 0 0.3125 0.5125

= 0.9V 0.7375 0.9375 1.1375

INI_GFX

= 1V 1.3625 1.5625 1.7625

= 1.1V 2.6125 -- 5

INI_GFX

mV/s

V

Error Amplifier

DC Gain ADC R

Gain-Bandwidth

Product

Slew Rate SR

Output Voltage

Range

MAX Source/Sink

Current

Impedance of F Bx R

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

16

©

GBW C

COMP

V

I

R

COMP

V

COMP

1 -- -- M

FBx

= 47k (Note5) 70 80 -- dB

L

= 5pF (Note5) -- 10 -- MHz

LOAD

= 10pF ( Gain = 4,

C

LOAD

R

LOAD_COMP

V

COMPx

= 47k 0.5 -- 3.6 V

L

COMP

= 47k,

= 0.5V to 3V)

= 2V -- 250 -- A

-- 5 -- V/s

DS8166B-03 November 2013www.richtek.com

Current Sense Amplifier

RT8166B

Parameter Symbol Test Conditions Min Typ Max Unit

Input Offset Voltage V

Impedance of Ne g. Input R

Impedance of Pos. Input R

Current Sense

Diffe re nti al Inpu t Ra nge

Current Sense D C Gain

(Loop)

V

Linear ity V

ISEN

V

A

Gate Driver

Upper Driver Sour ce R

Upper Driver Sink R

Lower Driver Sour ce R

L o wer Dri v e r Sink R

Internal Boot Charging

Switch On - R esis ta n ce

Zero Current Det ection

Threshold

R

V

Protection

Under Vol tage Lock-out

Threshold

Under Vol tage Lock-out

Hysteresis

Over Voltage Protection

Threshold

Under Vol tage Protection

Threshold

Negat ive Voltage

Pro te cti on Threshold

Curre nt Sense Ga in for

Over Current Protection

V

V

V

V

V

A

Logic Inputs

OFS_CSA

ISENxN

ISENxP

CSDIx

V

I

ISEN_ACC

UGATEx_sr

UGATEx_sk

LGATEx_sr

LGATEx_sk

BOOTx

ZCD_TH

UVLO

UVLO

OVP

UVP

NVP

OC

1 -- 1 mV

1 -- -- M

1 -- -- M

V

= 1.1V,

FBx

V

CSDIx

FBx

V

DAC

V

BOOTx

V

BOOTx

V

UGATEx

= V

ISENxP

= 1.1V, 30mV < V

= 1.1V 30mV < V

V

PHASEx

V

UGATEx

= 0.1V -- 1 --

PVCC = 5V, PVCC V

V

LGATEx

= 0.1V -- 0.5 --

V

= 5V

= 0.1V

ISENxN

CSDIx

ISEN_IN

LGATEx

< 50mV -- 10 -- V/ V

< 50mV 1 -- 1 %

= 0.1V - - 1 --

50 -- 100 mV

-- 1 --

PVCC to BOOTx -- 30 --

V

ZCD_TH

= GN D V

PHASEx

-- 10 -- mV

VCC Falling edge 4.04 4.24 -- V

-- 100 -- mV

V

Respect to VOUT_MAX

filte r time

V

= V

UVP

<1. 52V, with 3s filter time

= V

NVP

V

OCSET

V

ISENxP

ISENxN

ISENxN

= 2.4V

V

ISENxN

V

REFx

GND 100 50 -- mV

= 50mV

, with 1s

SVID

, 0.8V < V

100 150 200 mV

REFx

350 300 250 mV

-- 48 -- V/V

EN Input

Threshold

Voltage

Logic-High VIH With respe c t to 1V, 70% 0.7 -- --

Logic-Low V

With respe c t to 1V, 30% -- -- 0.3

IL

V

Leakage Current of EN 1 -- 1 A

VCLK,VDIO Input

Threshold Vol tage

Leakage Current of

VC L K, VDI O

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8166B-03 November 2013 www.richtek.com

©

VIH With respect to Intel Spec. 0.65 -- --

With respect to Intel Spec. -- -- 0.45

V

IL

I

LEAK_IN

1 -- 1 A

V

17

RT8166B

Parameter Symbol Test Conditions Min Typ Max Unit

ALERT

A LERT Low Vo ltage

VR Ready

VRx_READY Low Voltage V

VRx_READY D elay t

Ther ma l Throttling

VRHOT Output Voltage V

High Impedance Output

V

ALERT

VRx_READY IVRx_READY_ SINK

VRx_READY

VRHOT

I

ALERT_ SINK

V

ISENxN

I

VRHOT_SINK

= V

= 4mA

BOOT

= 40mA

-- -- 0.4 V

= 4mA -- -- 0.4 V

to V

VRx_RE ADY

high 70 100 160 s

-- 0.4 -- V

ALERT, VRx_READY,

VRHOT

Temperature Zone

TSEN Threshold for

Tmp_Zone [7] transition

TSEN Threshold for

Tmp_Zone [6] transition

TSEN Threshold for

Tmp_Zone [5] transition

TSEN Threshold for

Tmp_Zone [4] transition

TSEN Threshold for

Tmp_Zone [3] transition

TSEN Threshold for

Tmp_Zone [2] transition

TSEN Threshold for

Tmp_Zone [1] transition

TSEN Threshold for

Tmp_Zone [0] transition

Update Period t

ADC

I

LEAK_OUT

1 -- 1 A

100°C -- 1.8725 -- V

97°C -- 1.8175 -- V

V

TSENx

94°C -- 1.7625 -- V

91°C -- 1.7075 -- V

88°C -- 1.6525 -- V

85°C -- 1.5975 -- V

V

TSENx

82°C -- 1.5425 -- V

75°C -- 1.4875 -- V

-- 1600 -- s

TSEN

Latency t

Digital Code of ICCMAX

Digital Code of ICCMAXA

Digital Code of TMPMAX

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

18

©

-- -- 400 s

LAT

C

ICCMAX1

C

ICCMAX2

C

ICCMAX3

C

ICCMAXA1

C

ICCMAXA2

C

ICCMAXA3

C

TMPMAX1

C

TMPMAX2

C

TMPMAX3

V

ICCMAX

V

ICCMAX

V

ICCMAX

V

ICCMAXA

V

ICCMAXA

V

ICCMAXA

V

TMPMAX

V

TMPMAX

V

TMPMAX

= 0.637V 29 32 35 decimal

= 1.2642V 61 64 67 decimal

= 2.5186V 125 128 131 decimal

= 0.1666V 5 8 11 decimal

= 0.3234V 13 16 19 decimal

= 0.637V 29 32 35 decimal

= 1.6758V 82 85 88 decimal

= 1.9698V 97 100 103 decimal

= 2.4598V 122 125 128 decimal

DS8166B-03 November 2013www.richtek.com

RT8166B

Note 1. Stresses beyond those listed “Absolute Maximum Ratings” may cause permanent damage to the device. These are

stress ratings only, and functional operation of the device at these or any other conditions beyond those indicated in

the operational sections of the specifications is not implied. Exposure to absolute maximum rating conditions may

affect device reliability.

Note 2. θ

is measured at T

JA

measured at the exposed pad of the package.

Note 3. Devices are ESD sensitive. Handling precaution is recommended.

Note 4. The device is not guaranteed to function outside its operating conditions.

Note 5. Guaranteed by design.

= 25°C on a high effective thermal conductivity four-layer test board per JEDEC 51-7. θJC is

A

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

DS8166B-03 November 2013 www.richtek.com

19

RT8166B

Typical Operating Characteristics

V

CORE

(500mV/Div)

EN

(2V/Div)

VR_READY

(2V/Div)

UGATE

(20V/Div)

V

CORE

(1V/Div)

CORE VR Power On from EN

Boot VID = 1V

Time (100μs/Div)

CORE VR OCP

V

CORE

(500mV/Div)

EN

(2V/Div)

VR_READY

(2V/Div)

UGATE

(20V/Div)

V

CORE

(1V/Div)

CORE VR Power Off from EN

Boot VID = 1V

Time (100μs/Div)

CORE VR OVP and NVP

I

LOAD

(10A/Div)

VR_READY

(1V/Div)

UGATE

(20V/Div)

V

CORE

(500mV/Div)

VCLK

(2V/Div)

VDIO

(2V/Div)

ALERT

(2V/Div)

VID = 1.1V

Time (100μs/Div)

CORE VR Dynamic VID Up

0.7V to 1.2V, Slew Rate = Slow, I

LOAD =

4A

LGATE

(10V/Div)

VR_READY

(1V/Div)

UGATE

(20V/Div)

V

CORE

(500mV/Div)

VCLK

(2V/Div)

VDIO

(2V/Div)

ALERT

(2V/Div)

VID = 1.1V

Time (40μs/Div)

CORE VR Dynamic VID Down

1.2V to 0.7V, Slew Rate = Slow, I

LOAD =

4A

Time (40μs/Div)

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

Time (40μs/Div)

DS8166B-03 November 2013www.richtek.com

20

RT8166B

V

CORE

(500mV/Div)

VCLK

(2V/Div)

VDIO

(2V/Div)

ALERT

(2V/Div)

V

CORE

(20mV/Div)

CORE VR Dynamic VID Up

0.7V to 1.2V, Slew Rate = Fast, I

Time (10μs/Div)

CORE VR Load Transient

LOAD =

4A

V

CORE

(500mV/Div)

VCLK

(2V/Div)

VDIO

(2V/Div)

ALERT

(2V/Div)

V

CORE

(20mV/Div)

CORE VR Dynamic VID Down

1.2V to 0.7V, Slew Rate = Fast, I

Time (10μs/Div)

LOAD =

CORE VR Load Transient

4A

I

LOAD

(A/Div)

V

CORE

(20mV/Div)

VCLK

(1V/Div)

LGATE

(10V/Div)

UGATE

(20V/Div)

8

1

VID = 1.1V, I

1A to 8A, Slew Time = 150ns

LOAD =

Time (100μs/Div)

CORE VR Mode Transition

VID = 1.1V , PS0 to PS2, I

Time (100μs/Div)

LOAD =

0.2A

I

LOAD

(A/Div)

V

CORE

(20mV/Div)

VCLK

(1V/Div)

LGATE

(10V/Div)

UGATE

(20V/Div)

8

1

VID = 1.1V, I

8A to 1A, Slew Time = 150ns

LOAD =

Time (100μs/Div)

CORE VR Mode Transition

VID = 1.1V , PS2 to PS0, I

Time (100μs/Div)

LOAD =

0.2A

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

DS8166B-03 November 2013 www.richtek.com

21

RT8166B

1.9

TSEN

(V/Div)

1.7

VRHOT

(500mV/Div)

V

GFX

(500mV/Div)

EN

(2V/Div)

VRA_READY

(2V/Div)

CORE VR Thermal Monitoring

TSEN Sweep from 1.7V to 1.9V

Time (10ms/Div)

GFX VR Power On from EN

1.006

1.004

1.002

1.000

(V)

0.998

REF

V

0.996

0.994

0.992

0.990

V

GFX

(500mV/Div)

EN

(2V/Div)

VRA_READY

(2V/Div)

CORE VR V

-50 -25 0 25 50 75 100 125

vs. Tem perature

REF

Temperature (°C)

GFX VR Power Off from EN

UGATEA

(20V/Div)

V

GFX

(1V/Div)

I

LOAD

(5A/Div)

VRA_READY

(1V/Div)

UGATEA

(20V/Div)

Time (100μs/Div)

GFX VR OCP

Time (100μs/Div)

Boot VID = 1V

UGATEA

(20V/Div)

V

GFX

(1V/Div)

VRA_READY

(1V/Div)

LGATEA

(10V/Div)

UGATEA

(20V/Div)

Boot VID = 1V

Time (100μs/Div)

GFX VR OVP and NVP

VID = 1.1V

Time (40μs/Div)

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

DS8166B-03 November 2013www.richtek.com

22

RT8166B

V

GFX

(500mV/Div)

VCLK

(2V/Div)

VDIO

(2V/Div)

ALERT

(2V/Div)

V

GFX

(500mV/Div)

GFX VR Dynamic VID

0.7V to 1.2V, Slew Rate = Slow, I

Time (40μs/Div)

GFX VR Dynamic VID

LOAD =

1.25A

V

GFX

(500mV/Div)

VCLK

(2V/Div)

VDIO

(2V/Div)

ALERT

(2V/Div)

V

GFX

(500mV/Div)

GFX VR Dynamic VID

1.2V to 0.7V, Slew Rate = Slow, I

Time (40μs/Div)

GFX VR Dynamic VID

LOAD =

1.25A

VCLK

(2V/Div)

VDIO

(2V/Div)

ALERT

(2V/Div)

V

GFX

(20mV/Div)

I

LOAD

(A/Div)

4

1

0.7V to 1.2V, Slew Rate = Fast, I

Time (10μs/Div)

GFX VR Load Transient

VID = 1.1V, I

1A to 4A, Slew Time = 150ns

LOAD =

LOAD =

1.25A

VCLK

(2V/Div)

VDIO

(2V/Div)

ALERT

(2V/Div)

V

GFX

(20mV/Div)

I

LOAD

(A/Div)

4

1

1.2V to 0.7V, Slew Rate = Fast, I

Time (10μs/Div)

GFX VR Load Transient

VID = 1.1V, I

4A to 1A, Slew Time = 150ns

LOAD =

LOAD =

1.25A

Time (100μs/Div)

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

Time (100μs/Div)

DS8166B-03 November 2013 www.richtek.com

23

RT8166B

V

GFX

(20mV/Div)

VCLK

(1V/Div)

LGATEA

(10V/Div)

UGATEA

(20V/Div)

1.9

TSENA

(V/Div)

1.7

GFX VR Mode Transition

VID = 1.1V , PS0 to PS2, I

Time (100μs/Div)

LOAD =

GFX VR Thermal Monitoring

0.1A

V

GFX

(20mV/Div)

VCLK

(1V/Div)

LGATEA

(10V/Div)

UGATEA

(20V/Div)

1.006

1.004

1.002

1.000

0.998

(V)

0.996

REF

V

0.994

GFX VR Mode Transition

VID = 1.1V , PS2 to PS0, I

Time (100μs/Div)

GFX VR V

vs. Temperature

REF

LOAD =

0.1A

VRHOT

(500mV/Div)

TSENA Sweep from 1.7V to 1.9V

Time (10ms/Div)

0.992

0.990

0.988

-50-250 255075100125

Temperatur e (°C)

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

DS8166B-03 November 2013www.richtek.com

24

Application Information

RT8166B

The RT8166B is a VR12/IMVP7 compliant, dual singlephase synchronous Buck PWM controller for the CPU

CORE VR a nd GFX VR. The gate drivers are embedded

to facilitate PCB design a nd reduce the total BOM cost. A

Serial VID (SVID) interface is built-in in the RT8166B to

communicate with Intel VR12/IMVP7 complia nt CPU.

The RT8166B adopts G-NAVPTM (Green Native AVP),

which is Richtek's proprietary topology derived from finite

DC gain compensator, making it an easy setting PWM

controller to meet AVP requirements. The load line can

be ea sily progra mmed by setting the DC gain of the error

amplif ier. The RT8166B has fast transient response due

to the G-NAVPTM commanding variable switching

frequency .

G-NAVPTM topology also represents a high efficiency

system with green power concept. With G-NAVP

topology , the RT8166B becomes a green power controller

with high efficiency under heavy load, light load, a nd very

light load conditions. The RT8166B supports mode

transition function between CCM a nd DEM. These dif ferent

operating states allow the overall power system to have

low power loss. By utilizing the G-NAVPTM topology , the

operating frequency of RT8166B varies with output voltage,

load and VIN to further enhance the eff iciency even in CCM.

The built-in high accuracy DAC converts the SVID code

ranging from 0.25V to 1.52V with 5mV per step. The

differential remote output voltage sense a nd high accura cy

DAC allow the system to have high output voltage accura cy.

TM

The RT8166B supports VR12/IMVP7 compatible power

management states a nd VID on-the-fly function. The power

management states include DEM in PS2/PS3 and ForcedCCM in PS1/PS0. The VID on-the-fly function has three

different slew rates : Fa st, Slow and Decay . The RT8166B

integrates a high accuracy ADC for platform setting

functions, such as no-load offset and over current level.

The controller supports both DCR and sense resistor

current sensing. The RT8166B provides VR ready output

signals of both CORE VR and GFX VR. It also features

complete fault protection functions including over voltage,

under voltage, negative voltage, over current and under

voltage lockout. The RT8166B is available in a WQFN40L 5x5 small foot print package.

Design Tool

T o help users reduce eff orts and errors caused by ma nual

calculations, a user-friendly design tool is now available

on request. This design tool calculates all necessary

design parameters by entering user's requirements.

Plea se conta ct Richtek's representatives for details.

Serial VID (SVID) Interface

SVID is a three-wire seri al synchronous interface defined

by Intel. The three wire bus includes VDIO, VCLK and

ALERT signals. The master (Intel's VR12/IMVP7 CPU)

initiates and termin ates SVID tra nsa ctions a nd drives the

V DIO, VCLK, and ALERT during a transa ction. The slave

(RT8166B) receives the SVID transactions and acts

accordingly.

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8166B-03 November 2013 www.richtek.com

©

25

RT8166B

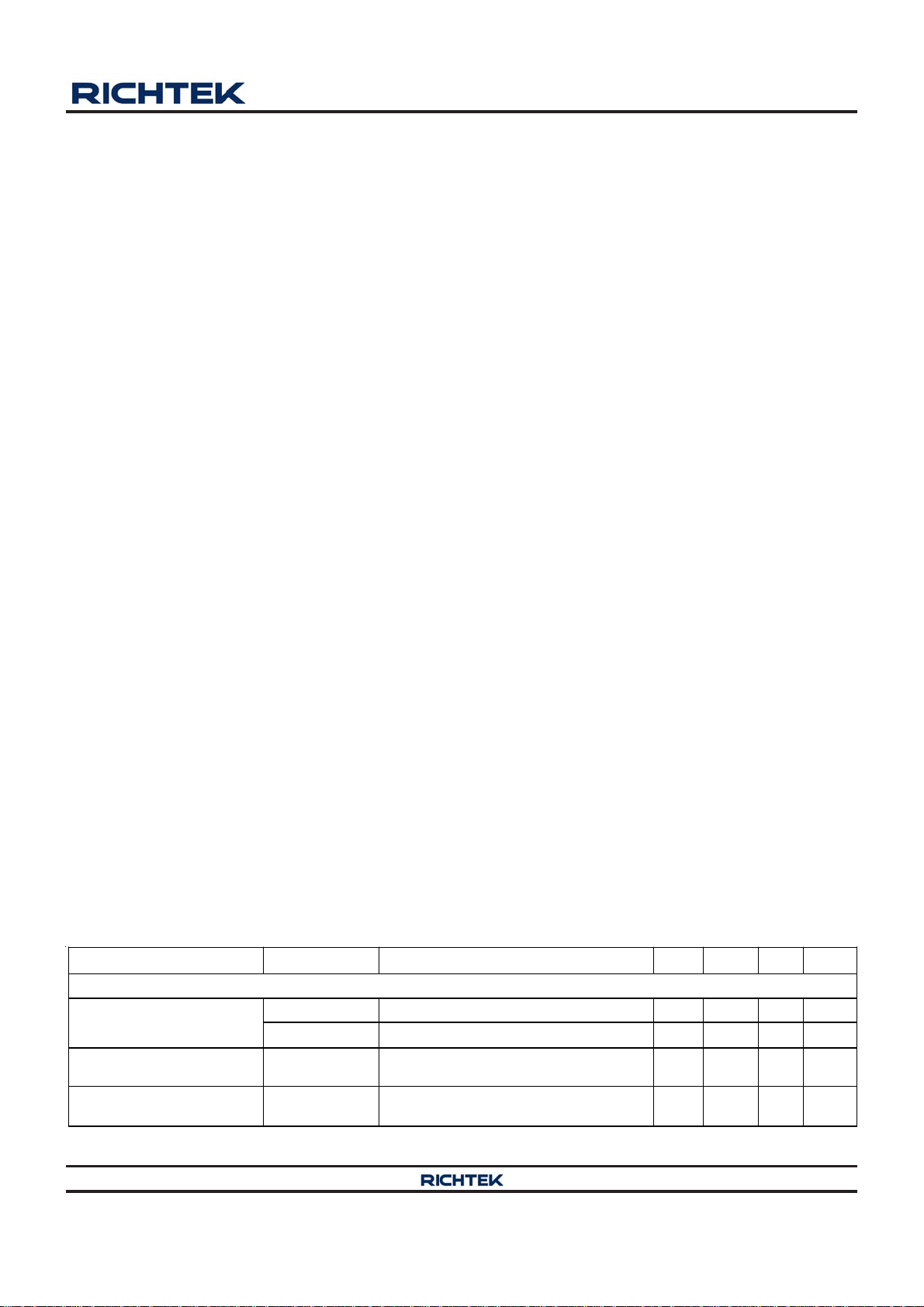

Standard Serial VID Command

Code Commands

00h not supported N/A N/A N/A

01h SetVID_Fast VID code N/A

02h SetVID_Slow VID code N/A

03h SetVID_Decay VID code N/A

04h SetPS

05h SetRegADR

06h SetReg DAT

07h GetReg

08h

-

1Fh

not supported N/A N/A N/A

Master Payload

Contents

Byte indicating

po wer st ates

Pointer of registers

in data table

New data regis ter

content

Pointer of registers

in data table

Slave Payload

Contents

Set new tar get VID code, VR jumps t o new VID

target with controlled default “fast” slew rate

12.5mV/s.

Set new tar get VID code, VR jumps t o new VID

target with controlled default “slow” slew rate

3.125m V/s.

Set new tar get VID code, VR jumps t o new VID

target, but does not control the slew rate. The

output voltage decays at a rate proportional to

the load current

N/A Set power state

N/A Set the pointer of the data register

N/A Write t he contents to the data register

Specified

Register

Contents

Slave returns the contents of the specified

register as the payload

Description

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

26

©

DS8166B-03 November 2013www.richtek.com

RT8166B

Data and Configuration Register

Index Register Name Description Access Default

00h Vendor ID Vendor ID, default 1Eh. RO, Vendor 1Eh

01h Product ID Product ID. RO, Vendor 65h

02h Product Revision Product Revision. RO, Vendor 01h

05h Protocol ID SVID Protocol ID. RO, Vendor 01h

Bit mapped register, identifies the SVID VR capabilities

06h VR_Capability

10h St a tus _1 Data regis t er co ntai nin g t he stat us of VR. R-M , W-PW M 00 h

11h Status -2 Data reg is ter co ntai ning the status of t ran smi ss ion . R- M , W-PW M 00h

12h

Temperature

Zone

15h Output_Current

1Ch Status_2_lastread The register contains a copy of the status_2. R-M, W-PWM 00h

21h ICC_Max

22h Temp_Max

24h SR-Fast

and which of the optional telemetry register are

supported.

Data reg is ter sho wi ng temp er at ure zo ne that have been

entered.

Data register showing direct ADC conversion of averaged

output current.

Data register containing the maximum ICC of platform

supports.

Binary format in Amp, IE 64h = 100A.

Data register containing the temperature max the platform

supports.

Binary format in °C, IE 64h = 100°C

Only fo r CORE VR

Data register containing the capability of fast slew rate the

platform can sustains. Binary format in mV/s, IE 0Ah =

10mV/s.

RO, Vendor 81h

R-M, W-PWM 00h

R-M, W-PWM 00h

RO, Platform --

RO, Platform --

RO 0Ah

25h SR-Slow

30h VOUT_Max

Data reg is ter co ntainin g t he capability of slow slew rat e.

Binary format in mV/s IE 02h = 2.5mV/s.

The register is programmed by the master and sets the

maximum VID.

RO 02h

RW, Master FBh

31h VID Set ti ng Data reg is ter co nt ai nin g currently prog r amm e d VID. RW, Maste r 00 h

32h Power Stat e Regis ter co ntai ni ng the cu r rent pr og ramm ed pow er state. RW, Maste r 00 h

33h Offset Set offset in VID steps. RW, Master 00h

34h Multi VR Config

35h Pointer

Notes :

RO = Read Only

RW = Read/Write

R-M = Read by Master

W -PWM = Write by PWM only

Vendor = hard coded by VR vendor

Platform = programmed by platform

Master = programmed by the master

PWM = programmed by the VR control IC

Bit mapped data register which configures multiple VRs

behavior on the same bus.

Scratch pa d registe r for temporary s torage o f the

Se tR egA DR poi nter regis ter .

RW, Master 00h

RW, Master 30h

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8166B-03 November 2013 www.richtek.com

©

27

RT8166B

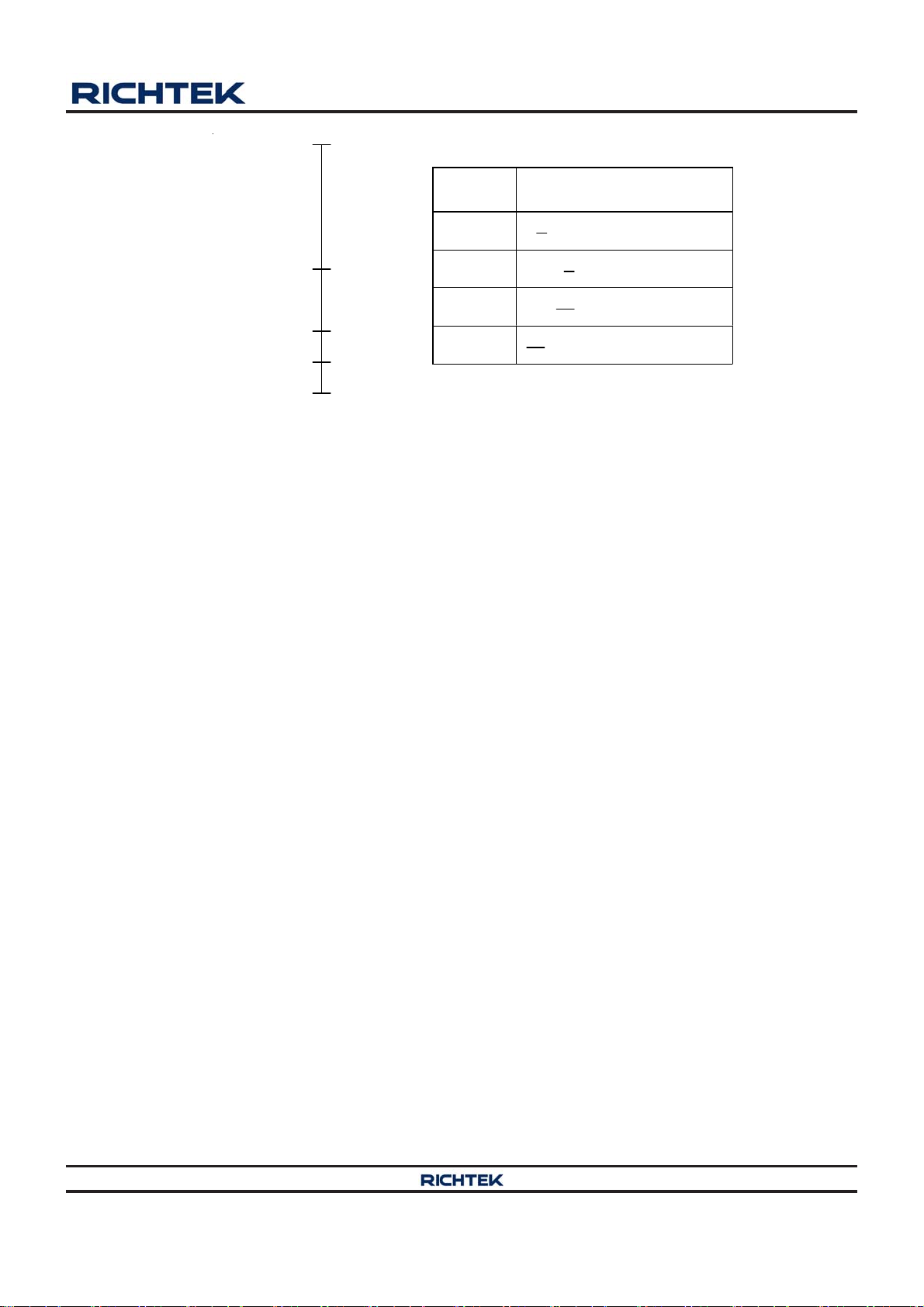

Power Ready Detection and Power On Reset (POR)

During start-up, the RT8166B detects the voltage on the

voltage input pins : VCC and EN. When VCC > V

UVLO

the RT8166B will recognize the power state of system to

be ready (POR = high) and wait for enable command at

EN pin. After POR = high and EN > V

, the RT8166B

ENTH

will enter start-up sequence for both CORE VR a nd GFX

VR. If the voltage on any voltage pin drops below POR

threshold (POR = low), the RT8166B will enter power down

sequence and all the functions will be disa bled. SVID will

be invalid within 300μs after chip becomes enabled. All

the protection latches (OVP, OCP, UVP, OTP) will be

cleared only after POR = low. EN = low will not clear

these latches.

VCC

EN

V

V

U

V

E

N

+

L

O

-

+

-

T

H

POR

Chip EN

ICCMAX, ICCMAXA and TMPMAX

The RT8166B provides ICCMAX, ICCMAXA a nd TMPMAX

pins for platform users to set the maximum level of output

,

current or VR temperature: ICCMAX for CORE VR

maximum current, ICCMAXA for GFX VR maximum

current, and TMPMAX for CORE VR maximum

temperature.

To set ICCMAX, ICCMAXA and TMPMAX, platform

designers should use resistive voltage dividers on these

three pins. The current of the divider should be several

milli-Amps to avoid noise effect. The three items share

the same algorithms : the ADC divides 5V into 255 levels.

Therefore, LSB = 5/255 = 19.6mV , which mea ns 19.6mV

applied to ICCMAX pin equals to 1A setting. For exa mple,

if a platform designer wants to set TMPMAX to 120°C, the

voltage applied to TMPMAX should be 120 x 19.6mV =

2.352V. The ADC circuit inside these three pins will

decode the voltage a pplied and store the maximum current/

temperature setting into ICC_MAX and Temp_Max

Figure 1. Power Ready Detection and Power On Reset

(POR)

Precise Reference Current Generation

The RT8166B includes extensive analog circuits inside

the controller. These analog circuits need very precise

reference voltage/current to drive these analog devices.

The RT8166B will auto-generate a 2.14V voltage source

at IBIAS pin, and a 53.6kΩ resistor is required to be

connected between IBIAS and analog ground. Through

this connection, the RT8166B generates a 40μA current

registers. The ADC monitors a nd decodes the voltage at

these three pins only after EN = high. If EN = low, the

RT8166B will not take a ny action even when the V R output

current or temperature exceeds its maximum setting at

these ADC pins. The maximum level settings at these

ADC pins are different from over current protection or over

temperature protection. That mea ns, these maximum level

setting pins are only for platform users to define their

system operating conditions and these messages will only

be utilized by the CPU.

V

CC

from IBIAS pin to analog ground a nd this 40μA current will

be mirrored inside the RT8166B for internal use. Other

types of connection or other values of resistance a pplied

at the IBIAS pin may cause failure of the RT8166B's analog

A/D

Converter

ICCMAX

ICCMAXA

TMPMAX

circuits. Thus a 53.6kΩ resistor is the only recommended

component to be connected to the IBIAS pin. The

resistance accuracy of this resistor is recommended to

be at least 1%.

Current

2.14V

-

Mirror

+

+

-

IBIAS

53.6k

V

INI_CORE

The initial start up voltage (V

RT8166B can be set by platform users through SETINI

and SETINIA pins. V oltage divider circuit is recommended

to be applied to SETINI a nd SETINIA pins. The V

V

relate to SETINI/SETINIA pin voltage setting as

INI_GFX

Figure 3. ADC Pins Setting

and V

INI_GFX

Setting

INI_CORE

, V

INI_GFX

shown in Figure 4. Recommended voltage setting at SETINI

Figure 2. IBIAS Setting

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

28

©

and SETINIA pins are also shown in Figure 4.

DS8166B-03 November 2013www.richtek.com

) of the

INI_CORE

/

RT8166B

V

(

C

C

5

V

)

V

N

I

V

V

V

N

I

V

V

=

1

.

1

I

_

C

O

I

_

I

G

N

_

I

C

N

I

V

I

N

I

_

O

I

C

I

_

I

G

N

_

I

C

N

I

V

I

N

I

V

E

R

=

1

1

.

V

F

X

2

1

/

V

C

C

1

=

V

O

E

R

1

=

V

_

G

F

X

4

1

/

V

C

=

0

.

9

V

R

E

=

0

.

9

V

F

X

0

=

V

O

E

R

=

0

V

_

G

F

X

C

8

1

/

V

C

C

D

G

N

Figure 4. SETINI and SETINIA Pin Voltage Setting

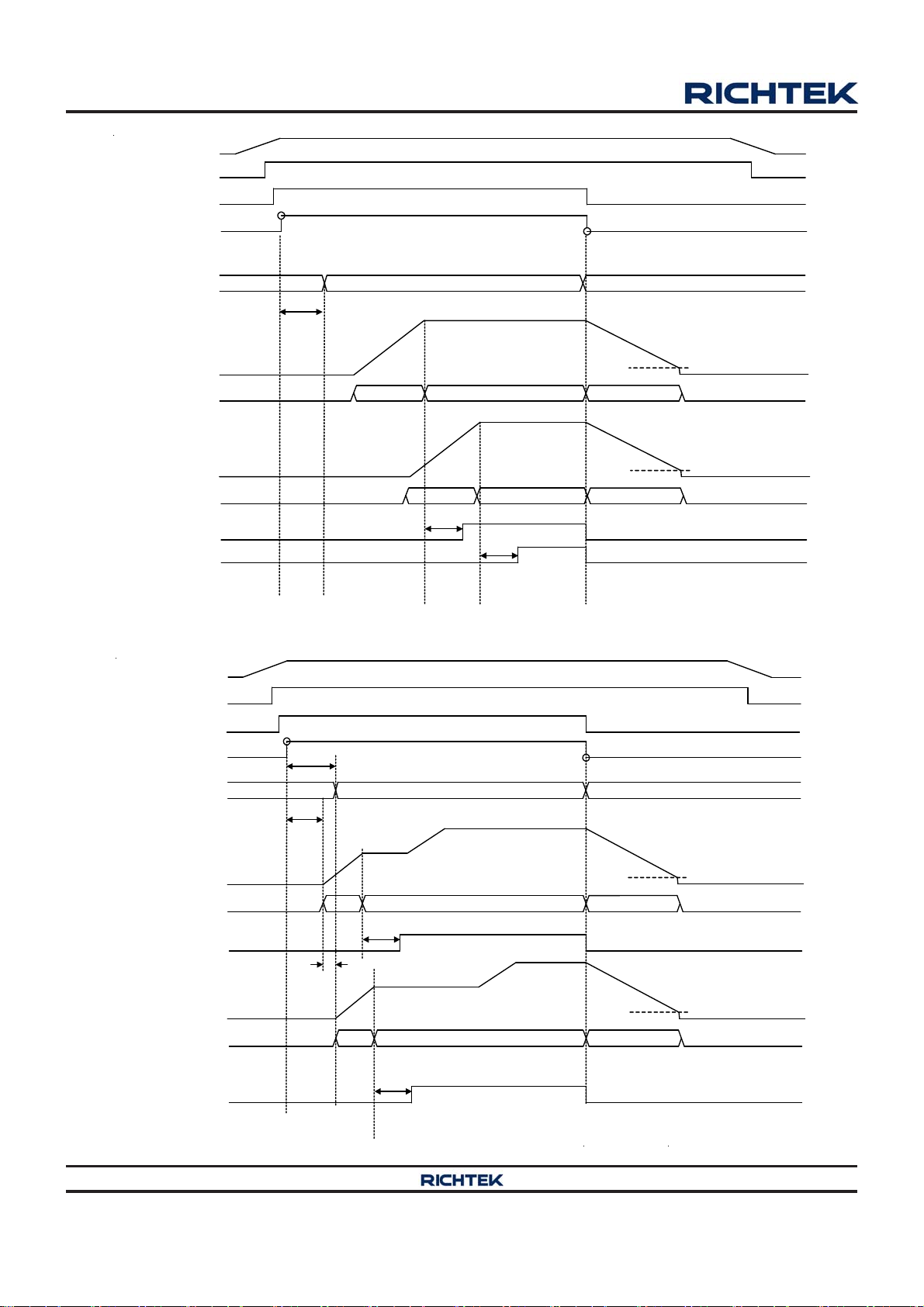

Start Up Sequence

The RT8166B utilizes internal soft-start sequence which

strictly follows Intel VR12/IMVP7 start up sequence

specifications. After POR = high a nd EN = high, a 300μs

delay is needed for the controller to determine whether all

the power inputs are ready for entering start up sequence.

If pin voltage of SETINI/SETINIA is zero, the output voltage

of CORE/GFX VR is programmed to stay at 0V. If pin

voltage of SETINI/SETINIA is not zero, VR output voltage

will ramp up to initi al boot voltage (V

INI_CORE

, V

INI_GFX

) after

both POR = high and EN = high. After the output voltage

of CORE/GFX VR rea ches target initial boot voltage, the

controller will keep the output voltage at the initial boot

voltage and wait for the next SVID commands. After the

RT8166B receives valid VID code (typically SetVID_Slow

command), the output voltage will ramp up/down to the

target voltage with specified slew rate. After the output

voltage reaches the target voltage, the RT8166B will send

out VR_READY signal to indicate the power state of the

RT8166B is ready. The VR_READY circuit is an opendrain structure so a pull-up resistor is recommended for

connecting to a voltage source.

V

INI_CORE

V

INI_GFX

1.1V

0.9V

1V

0V

SETINI/SETINIA Pin Voltage

Recommended

5

x VCC≒3.125V or VCC

8

3

x VCC≒1.875V

8

3

x VCC≒0.9375V

16

1

x VCC≒0.3125V or GND

16

Power Down Sequence

Similar to the start up sequence, the RT8166B also utilizes

a soft shutdown mechanism during turn-off. After POR =

low, the internal reference voltage (positive terminal of

compensation EA) starts ramping down with 3.125mV/μs

slew rate, and output voltage will follow the reference

voltage to 0V . After output voltage drops below 0.2V, the

RT8166B shuts down and all functions are disa bled. The

VR_READY will be pulled down immediately after POR =

low.

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

DS8166B-03 November 2013 www.richtek.com

29

RT8166B

VCC

POR

EN Chip

(Internal Signal)

EN

SVID

V

CORE

CORE VR

Operation Mode

V

GFX

GFX VR

Operation Mode

VR_READY

VRA_READY

VCC

POR

EN Chip

(Internal Signal)

XX

Off

Off

300µs

CCM CCM

CCM

100µs

Valid xx

SVID defined

Figure 5 (a). Power sequence for RT8166B (V

EN

300µs

SVID defined

100µs

INI_CORE

= V

CCM

INI_GFX

0.2V

Off

0.2V

Off

= 0V)

SVID

V

CORE

CORE VR

Operation Mode

VR_READY

V

GFX

GFX VR

Operation Mode

VRA_READY

XX

250µs

50µs

V

INI_CORE

CCM CCMOff

100µs

V

INI_GFX

CCMOff

100µs

Figure 5 (b). Power sequence for RT8166B (V

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

Valid

SVID define d

SVID define d

INI_CORE

CCM

0, V

INI_GFX

0V)

xx

0.2V

Off

0.2V

Off

DS8166B-03 November 2013www.richtek.com

30

RT8166B

Disable GFX VR : Before EN = High

GFX VR enable or disable is determined by the internal

circuitry that monitors the ISENAN voltage during start

up. Before EN = high, GFX V R detects whether the voltage

of ISENAN is higher than “VCC − 1V” to disable GFX

VR. The unused driver pins ca n be connected to GND or

left floating.

GFX VR Forced-DEM Function Enable : After

VRA_Ready = High

The GFX VR's forced-DEM function can be enabled or

disabled with GFXPS2 pin. The RT8166B detects the

voltage of GFXPS2 f or forced-DEM function. If the voltage

at GFXPS2 pin is higher tha n 4.3V , the GFX V R operates

in forced-DEM. If this voltage is lower than 0.7V, the G FX

VR follows SVID power state comma nd.

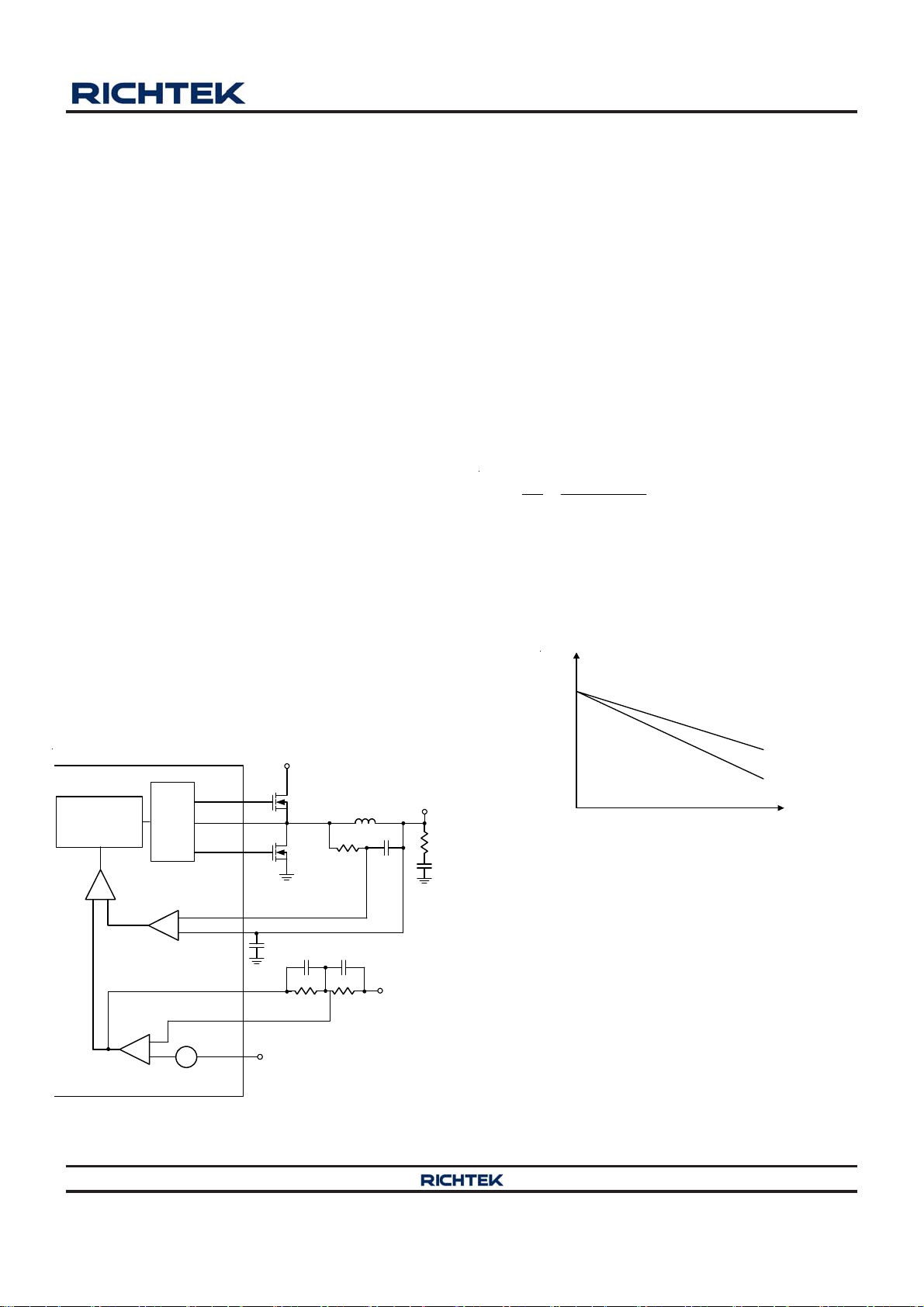

Loop Control

Both CORE and GFX VR adopt Richtek's proprietary GNAVPTM topology . G-NAVPTM is based on the f inite-gain

valley current mode with CCRCOT (Constant Current

Ripple Constant On T ime) topology. The output voltage,

V

CORE

or V

, will decrea se with incre asing output load

GFX

current. The control loop consists of PWM modulator with

power stage, current sense amplifier and error amplifier

a s shown in Figure 6.

Similar to the valley current mode control with finite

compensator gain, the high side MOSFET on-time is

determined by the CCRCOT PWM generator. When load

current increas es, VCS increa ses, the steady state COMP

voltage also increases which makes the output voltage

decrea se, thus a chieving AVP.

Droop Setting (with Temperature Compensation)

It's very easy to achieve the Active Voltage Positioning

(AVP) by properly setting the error amplifier gain due to

the native droop characteristics. The target is to have

V

= V

OUT

Then solving the switching condition V

REFx

− I

LOAD

x R

(1)

DROOP

COMPx

= V

CSx

in

Figure 6 yields the desired error amplif ier gain a s

R2

A

V

R1 R

I SENSE

DROOP

(2)

AR

where AI is the internal current sense amplifier gain and

R

is the current sense resistance. If no external sens e

SENSE

resistor is present, the DCR of the inductor will act as

R

SENSE

. R

is the resistive slope value of the converter

DROOP

output and is the desired static output impedance.

V

OUT

A

> A

V2

V1

A

V2

A

V1

OUT

GFX/CORE VR

CCRCOT

PWM Generator

CMP

+

-

V

CSx

Driver

Logic

Control

+

Ai

-

UGATEx

PHASEx

LGATEx

ISENxP

ISENxN

COMPx

FBx

C

Byp

V

IN

High Side

MOSFET

Low Side

MOSFET

C2 C1

R2

R1

R

X

(V

L

C

X

CORE/GFX VR

V

CC_SENSE

V

OUT

CORE/VGFX

R

C

C

)

0

Load Current

Figure 7. Error Amplifier Gain (AV) Influence on V

Accuracy

Since the DCR of inductor is temperature dependent, it

affects the output accura cy in high temperature conditions.

Temperature compensation is recommended for the

lossless inductor DCR current sense method. Figure 8

shows a simple but effective way of compensating the

temperature variations of the sense resistor using a n N TC

-

EA

+

VREFx

RGNDx

-

+

CORE/GFX VR

V

SS_SENSE

thermistor placed in the feedba ck path.

Figure 6. Simplified Schematic for Droop a nd Remote

Sense in CCM

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8166B-03 November 2013 www.richtek.com

©

31

RT8166B

C2 C1

EA

FBx

R2

V

SS_SENSE

COMPx

-

+

-

+

RGNDx

VREFx

R1b

R1a

NTC

V

CC_SENSE

Figure 8. Loop Setting with T emperature Compen sation

Usually, R1a is set to equal R

(25°C), while R1b is

NTC

selected to linearize the NTC's temperature chara cteristic.

For a given NTC, the design would be to obtain R1b a nd

R2 and then C1 a nd C2. According to (2), to compensate

the temperature variations of the sense resistor , the error

amplifier gain (AV) should have the same temperature

coefficient with R

AR

V, HOT SENSE, HOT

AR

V, COLD SENSE, COLD

SENSE

. Hence

(3)

From (2), we can have Av at a ny temperature (T) a s

A

V, T

R1 a / /R R1 b

R2

NTC, T

(4)

The standard formula f or the resistance of NTC thermistor

as a function of te mperature is given by :

11

T+273 298

RR e

where R

NTC, T NTC, 25

is the thermistor's nominal resistance at

NTC, 25

(5)

room temperature, β (beta) is the thermistor's material

constant in Kelvins, and T is the thermistor's actual

temperature in Celsius.

The DCR value at different te mperatures can be calculated

R1 b

R

SENSE, HOT

R

SENSE, COLD

(R1a //R ) (R1a//R )

NTC, HOT NT C, COLD

R

SENSE, HOT

1

R

SENSE, COLD

Loop Compensation

Optimized compensation of the CORE VR allows for best

possible load step response of the regulator's output. A

type-I compensator with one pole and one zero is adequate

for a proper compensation. Figure 8 shows the

compensation circuit. It wa s previously mentioned that to

determine the resistive feedback components of error

amplifier gain, C1 and C2 must be calculated for the

compensation. The target is to a chieve constant resistive

output impedance over the widest possible frequency

range.

The pole frequency of the compensator must be set to

compensate the output ca p acitor ESR zero :

f

P

1

2CR

C

where C is the cap acita nce of the output capa citor and R

is the ESR of the output cap acitor. C2 can be calculated

as follows :

CR

C2

C

R2

The zero of compensator has to be placed at half of the

switching frequency to filter the switching-related noise.

Such that,

C1

R1 b R1 a//R f

1

NTC, 25 C S W

using the equation below :

TON Setting

DCRT = DCR25 x [1+0.00393 x (T-25)] (6)

where 0.00393 is the temperature coefficient of copper.

For a given NTC thermistor , solving (4) at room temperature

(25°C) yields

R2 = A

where A

x (R1b + R1a // R

V, 25

is the error amplif ier gain at room temperature

V, 25°C

) (7)

NTC, 25

obtained from (2). R1b can be obtained by substituting

(7) to (3),

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

32

©

High frequency operation optimizes the application by

trading off efficiency due to higher switching losses with

smaller component size. This may be acceptable in ultraportable devices where the load currents are lower and

the controller is powered from a lower voltage supply . Low

frequency operation offers the best overall efficiency at

the expense of component size and board spa ce. Figure

9 shows the on-time setting circuit. Connect a resistor

(R

TONSETx

of UGA TEx :

t (V 1.2V)

ONx REFx

) between VIN and T ONSETx to set the on-time

-12

28 10 R

DS8166B-03 November 2013www.richtek.com

VV

IN REFx

TONSETx

(8)

(9)

C

(10)

(11)

(12)

RT8166B

where t

voltage of converter, and V

voltage.

When V

frequency may be over the maximum design range, ma king

it unaccepta ble. Therefore, the VR i mplements a pseudoconstant-frequency technology to avoid this disadva ntage

of CCRCOT topology. When V

the on-time equation will be modified to :

t (V 1.2V)

ONx REFx

is the UGA TEx turn on period, VIN is the input

ONx

is the internal reference

REFx

is larger than 1.2V, the equivalent switching

REFx

is larger than 1.2V,

REFx

-12

23.33 10 R V

TONSETx REFx

VV

IN REFx

(13)

Differential Remote Sense Setting

The CORE/GFX VR includes differential, remote-sense

inputs to eliminate the effects of voltage drops along the